Research on Carbon Emissions Estimation in Key Industries Based on the Electricity–Energy–Carbon Model: A Case Study of Henan Province

Abstract

1. Introduction

2. Literature Review

3. Materials and Methods

3.1. Data and Variable Description

3.1.1. Industry Categorization and Correspondence

3.1.2. Electricity Consumption Data Explanation

3.2. Construction of the “Electricity–Energy–Carbon” Model

3.2.1. Electricity–Energy–Carbon Model Construction

3.2.2. Calculation Steps for the Electricity–Energy–Carbon Model in Energy Use

3.2.3. Calculation Steps for Electricity–Energy–Carbon Model of the Production Process

4. Results and Discussions

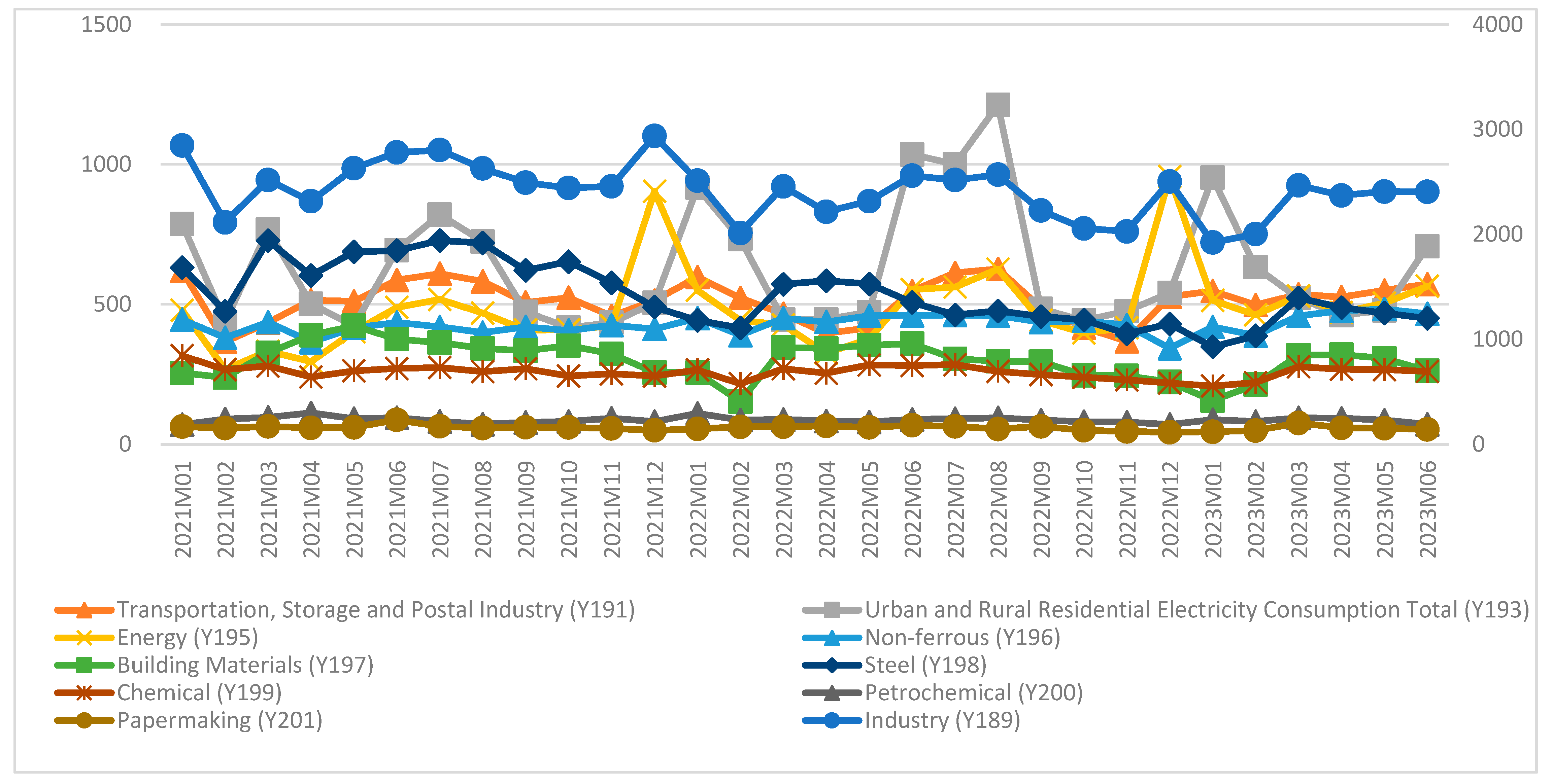

4.1. Carbon Emissions from Energy Use in Various Industries

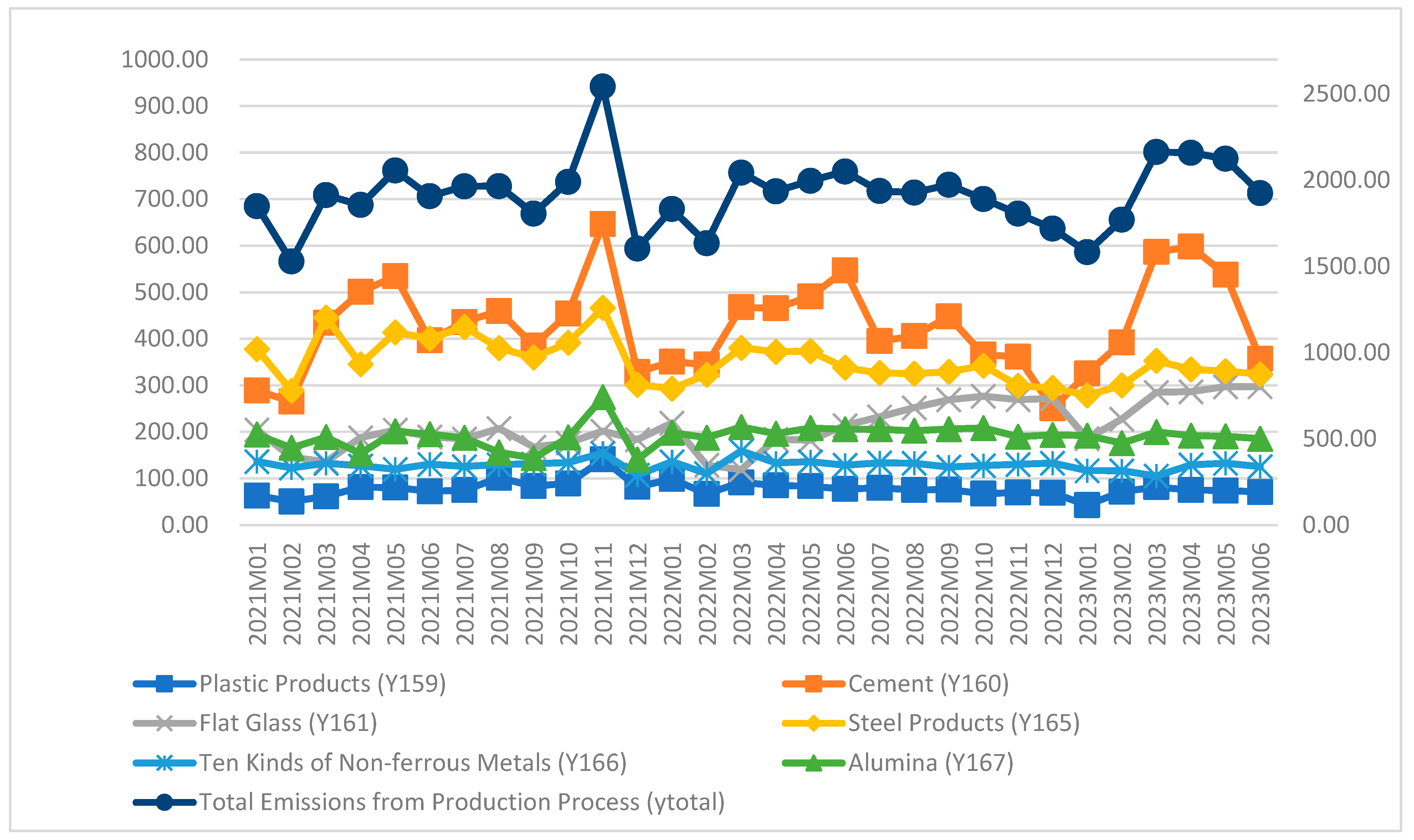

4.2. Carbon Emissions during Production Processes of Various Industries

5. Conclusions and Future Prospects

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Industry | Electricity Consumption Period |

|---|---|

| Other Subcategories Industries | January 2009–December 2022 |

| General Equipment Manufacturing Industry | January 2017–December 2022 |

| Automobile Manufacturing Industry | |

| Railway, Shipbuilding, Aerospace, and Other Transport Equipment Manufacturing Industry | |

| Electrical Machinery and Equipment Manufacturing Industry | |

| Computer, Communication, and Other Electronic Equipment Manufacturing Industry | |

| Instrument and Apparatus Manufacturing Industry | |

| Computer, Communication, and Other Electronic Equipment Manufacturing Industry | |

| Instrument and Apparatus Manufacturing Industry |

Appendix B

| Major Category | Industry Name | ID | 2022 (Monthly) | 2023 (Monthly) | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| January | February | March | April | May | June | July | August | September | October | November | December | Total | January | February | March | April | May | June | |||

| Province-wide | Total Energy Consumption of the Province | Y101 | 5937.93 | 4856.16 | 5040.74 | 4613.14 | 4885.54 | 6643.75 | 6483.63 | 7064.76 | 5077.76 | 4560.60 | 4501.61 | 5621.18 | 65,286.78 | 5475.30 | 5069.74 | 4925.13 | 4537.75 | 4655.19 | 5231.79 |

| 7 Major Industries | I. Agriculture, Forestry, Animal Husbandry, and Fishery | Y102 | 131.41 | 118.91 | 158.13 | 185.87 | 191.22 | 370.35 | 212.03 | 325.83 | 187.53 | 157.79 | 140.95 | 160.08 | 2331.38 | 169.75 | 174.40 | 217.11 | 151.13 | 166.13 | 241.98 |

| II. Industry | Y103 | 3509.75 | 2644.75 | 3199.90 | 2972.53 | 3144.99 | 3532.18 | 3518.85 | 3632.84 | 3140.24 | 2921.84 | 2884.02 | 3135.37 | 38,288.31 | 2794.28 | 2870.90 | 3055.45 | 2878.36 | 2887.25 | 2924.37 | |

| III. Construction | Y104 | 138.35 | 100.29 | 63.47 | 90.25 | 94.59 | 134.95 | 135.18 | 145.30 | 99.11 | 86.65 | 96.32 | 138.65 | 1322.48 | 97.91 | 102.86 | 95.09 | 84.06 | 85.66 | 102.65 | |

| IV. Transportation, Warehousing, and Postal Services | Y105 | 533.68 | 561.09 | 286.56 | 360.47 | 380.57 | 508.69 | 576.75 | 600.29 | 468.21 | 405.29 | 360.75 | 528.61 | 5574.20 | 557.79 | 505.51 | 475.68 | 463.68 | 484.85 | 517.36 | |

| V. Wholesale and Retail Trade, Accommodation and Catering | Y106 | 364.76 | 324.11 | 232.98 | 245.87 | 271.55 | 463.78 | 477.83 | 512.44 | 354.98 | 267.47 | 245.14 | 369.86 | 4122.78 | 411.02 | 370.05 | 312.82 | 291.43 | 321.34 | 413.79 | |

| Urban and Rural Resident Life | Y107 | 914.65 | 776.01 | 986.57 | 559.32 | 588.49 | 1289.48 | 1243.25 | 1506.23 | 591.81 | 538.17 | 575.53 | 1012.31 | 10,543.00 | 1164.14 | 762.61 | 544.32 | 473.04 | 486.55 | 734.41 | |

| Other | Y108 | 345.32 | 331.00 | 113.13 | 198.83 | 214.12 | 344.32 | 319.74 | 341.83 | 235.87 | 183.39 | 198.91 | 276.29 | 3104.63 | 280.42 | 283.40 | 224.65 | 196.06 | 223.41 | 297.22 | |

| 20 Selected Subcategories in Industry | 3. Mining of Ferrous Metals (Iron and Steel 1) | Y109 | 1.88 | 2.32 | 2.28 | 1.93 | 2.05 | 1.94 | 1.94 | 1.83 | 1.82 | 1.75 | 1.87 | 2.02 | 23.62 | 1.45 | 1.54 | 1.76 | 1.76 | 1.87 | 1.80 |

| 4. Mining of Non-ferrous Metals (Non-ferrous 1) | Y110 | 5.91 | 3.86 | 5.83 | 5.31 | 5.64 | 5.38 | 5.50 | 5.71 | 5.40 | 5.66 | 5.79 | 6.29 | 66.28 | 5.47 | 5.36 | 5.95 | 5.65 | 5.81 | 5.55 | |

| 5. Mining of Non-metallic Minerals (Building Materials) | Y111 | 1.30 | 1.30 | 1.37 | 1.09 | 1.16 | 1.13 | 1.14 | 1.13 | 1.17 | 0.96 | 1.17 | 1.35 | 14.28 | 0.63 | 0.96 | 1.31 | 1.35 | 1.28 | 1.22 | |

| 5. Textile Industry | Y112 | 18.39 | 14.11 | 18.61 | 15.57 | 15.75 | 15.47 | 14.75 | 14.89 | 16.12 | 14.97 | 14.72 | 13.44 | 186.79 | 11.49 | 16.28 | 18.51 | 17.97 | 18.70 | 17.70 | |

| 6. Textile and Apparel Industry | Y113 | 2.35 | 2.20 | 2.71 | 1.98 | 2.12 | 2.55 | 2.63 | 2.68 | 2.31 | 2.10 | 1.96 | 2.15 | 27.74 | 1.39 | 2.28 | 2.52 | 2.38 | 2.44 | 2.58 | |

| 13. Petroleum, Coal, and Other Fuel Processing Industries | Y114 | 90.56 | 77.11 | 103.76 | 84.47 | 82.74 | 89.60 | 92.30 | 94.21 | 89.99 | 86.30 | 86.46 | 108.35 | 1085.86 | 99.47 | 95.59 | 99.58 | 97.75 | 90.35 | 74.95 | |

| 14. Manufacture of Chemical Raw Materials and Chemical Products | Y115 | 468.81 | 485.57 | 598.31 | 479.13 | 548.62 | 532.20 | 541.35 | 488.95 | 486.85 | 482.16 | 449.31 | 476.24 | 6037.50 | 431.59 | 429.65 | 487.10 | 476.82 | 477.05 | 468.21 | |

| 16. Manufacture of Chemical Fibers (Chemical Industry 2) | Y116 | 11.41 | 11.40 | 15.18 | 13.54 | 12.41 | 13.48 | 12.79 | 10.82 | 13.22 | 10.40 | 9.45 | 9.13 | 143.23 | 9.02 | 10.03 | 13.84 | 11.08 | 11.35 | 11.17 | |

| 17. Rubber and Plastic Products Industry (Chemical Industry 3) | Y117 | 9.87 | 6.91 | 9.89 | 9.20 | 9.45 | 9.10 | 9.76 | 9.51 | 9.63 | 8.61 | 8.97 | 8.87 | 109.77 | 5.73 | 9.35 | 10.47 | 9.61 | 9.39 | 8.89 | |

| 18. Non-metallic Mineral Products Industry (Building Materials) | Y118 | 228.28 | 187.73 | 262.43 | 310.04 | 326.87 | 329.62 | 287.50 | 285.06 | 301.38 | 259.90 | 257.28 | 211.02 | 3247.11 | 169.74 | 239.26 | 325.50 | 331.23 | 321.73 | 277.04 | |

| 19. Smelting and Rolling Processing Industry of Ferrous Metals | Y119 | 311.88 | 329.61 | 411.18 | 422.01 | 419.41 | 365.33 | 341.34 | 357.79 | 362.50 | 360.53 | 318.42 | 318.47 | 4318.48 | 284.39 | 327.27 | 400.87 | 375.12 | 360.66 | 346.80 | |

| 20. Smelting and Rolling Processing Industry of Non-ferrous Metals | Y120 | 332.51 | 299.94 | 366.45 | 329.86 | 346.85 | 339.08 | 344.85 | 342.62 | 341.54 | 348.75 | 332.25 | 341.33 | 4066.03 | 327.02 | 310.50 | 329.28 | 345.75 | 349.89 | 338.97 | |

| 22. General Equipment Manufacturing Industry | Y121 | 7.59 | 5.47 | 8.13 | 7.11 | 6.03 | 6.26 | 6.53 | 6.31 | 5.89 | 5.22 | 5.11 | 5.09 | 74.75 | 3.81 | 5.21 | 5.65 | 5.28 | 4.97 | 4.79 | |

| 24. Automobile Manufacturing Industry | Y122 | 12.00 | 10.07 | 10.30 | 8.53 | 8.94 | 10.49 | 11.59 | 11.53 | 10.55 | 9.80 | 9.92 | 9.89 | 123.61 | 7.24 | 9.91 | 11.06 | 10.18 | 10.82 | 11.84 | |

| 25. Railway, Shipbuilding, Aerospace, and Other Transport Equipment Manufacturing Industry | Y123 | 1.56 | 1.48 | 1.92 | 1.45 | 1.35 | 1.48 | 1.54 | 1.40 | 1.14 | 0.91 | 0.81 | 0.64 | 15.69 | 0.36 | 0.34 | 0.29 | 0.18 | 0.16 | 0.15 | |

| 26. Electrical Machinery and Equipment Manufacturing Industry | Y124 | 12.82 | 9.14 | 13.96 | 12.03 | 11.25 | 12.59 | 15.64 | 17.04 | 18.30 | 20.71 | 24.94 | 31.02 | 199.46 | 30.14 | 51.44 | 81.40 | 108.43 | 156.55 | 289.86 | |

| 27. Computer, Communication, and Other Electronic Equipment Manufacturing Industry | Y125 | 9.39 | 8.64 | 12.96 | 9.81 | 10.52 | 11.35 | 12.67 | 13.37 | 12.14 | 11.27 | 9.51 | 10.37 | 132.00 | 9.04 | 8.33 | 8.27 | 6.96 | 7.36 | 7.64 | |

| 28. Instrument and Apparatus Manufacturing Industry | Y126 | 1.00 | 0.81 | 0.72 | 0.82 | 0.87 | 0.98 | 1.03 | 0.99 | 0.85 | 0.70 | 0.74 | 0.80 | 10.31 | 0.54 | 0.73 | 0.82 | 0.76 | 0.80 | 0.91 | |

| 1. Production and Supply of Electricity and Heat | Y127 | 1105.87 | 990.53 | 1007.68 | 821.57 | 909.78 | 1241.23 | 1265.63 | 1363.79 | 1052.57 | 953.13 | 976.61 | 1176.21 | 12,864.61 | 1897.70 | 1712.92 | 1735.39 | 1500.97 | 1602.55 | 1805.13 | |

| 3. Production and Supply of Water | Y128 | 4.04 | 3.87 | 4.70 | 4.04 | 4.35 | 4.30 | 4.30 | 4.33 | 4.02 | 3.92 | 3.83 | 4.06 | 49.76 | 4.17 | 4.01 | 4.48 | 4.61 | 4.85 | 4.73 | |

| Total of 20 Subcategories | 2637.41 | 2452.06 | 2858.39 | 2539.49 | 2726.19 | 2993.56 | 2974.80 | 3033.96 | 2737.40 | 2587.76 | 2519.12 | 2736.74 | 32,796.88 | 3300.40 | 3240.96 | 3544.05 | 3313.84 | 3438.60 | 3679.93 | ||

| 6 Major Sector Industries | Petroleum Petrochemical | Y129 | 99.47 | 90.80 | 120.74 | 96.40 | 99.40 | 102.54 | 105.78 | 106.75 | 100.06 | 96.53 | 93.80 | 112.40 | 1224.68 | 104.36 | 98.46 | 102.44 | 103.30 | 99.74 | 87.03 |

| Non-ferrous | Y130 | 339.93 | 300.78 | 372.15 | 335.42 | 353.14 | 344.96 | 351.23 | 350.32 | 348.36 | 356.71 | 341.89 | 353.04 | 4147.93 | 336.36 | 320.43 | 341.34 | 356.34 | 361.43 | 350.21 | |

| Building Materials | Y131 | 229.53 | 190.71 | 262.65 | 305.72 | 322.25 | 324.33 | 283.83 | 281.05 | 296.49 | 254.84 | 253.48 | 210.39 | 3215.28 | 165.58 | 233.53 | 317.18 | 322.31 | 312.39 | 269.44 | |

| Chemical | Y132 | 490.74 | 475.26 | 601.90 | 497.92 | 553.71 | 540.16 | 553.12 | 505.55 | 510.83 | 491.67 | 467.49 | 487.88 | 6176.24 | 421.34 | 458.52 | 524.63 | 502.02 | 500.91 | 488.67 | |

| Electricity | Y133 | 1105.87 | 990.53 | 1007.68 | 821.57 | 909.78 | 1241.23 | 1265.63 | 1363.79 | 1052.57 | 953.13 | 976.61 | 1176.21 | 12,864.61 | 1897.70 | 1712.92 | 1735.39 | 1500.97 | 1602.55 | 1805.13 | |

| Steel | Y134 | 315.50 | 335.39 | 414.70 | 423.01 | 421.06 | 367.53 | 343.96 | 359.05 | 363.26 | 360.53 | 320.12 | 320.70 | 4344.82 | 283.79 | 325.24 | 396.95 | 371.62 | 357.86 | 343.63 | |

| Total of Six Major Sectors | 2581.04 | 2383.47 | 2779.83 | 2480.04 | 2659.33 | 2920.75 | 2903.56 | 2966.51 | 2671.58 | 2513.41 | 2453.39 | 2660.62 | 31,973.54 | 3209.13 | 3149.10 | 3417.94 | 3156.56 | 3234.87 | 3344.11 | ||

Appendix C

| Subcategory Industry Names | Production Categories | ID | 2022 (Monthly) | 2023 (Monthly) | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| January | February | March | April | May | June | July | August | September | October | November | December | Total | January | February | March | April | May | June | |||

| Raw Coal Production | Raw Coal Production | Y135 | 44.60 | 37.55 | 64.38 | 41.78 | 43.80 | 46.50 | 43.93 | 43.67 | 39.11 | 37.20 | 37.09 | 38.94 | 518.55 | 38.10 | 38.24 | 40.76 | 39.37 | 38.59 | 39.09 |

| Oil and Natural Gas Extraction | Crude Oil Production | Y136 | 0.95 | 1.15 | 1.51 | 1.15 | 1.43 | 1.30 | 1.39 | 1.40 | 1.28 | 1.30 | 1.19 | 1.26 | 15.31 | 1.26 | 1.15 | 1.23 | 1.40 | 1.57 | 1.58 |

| Natural Gas Production | Y137 | 0.09 | 0.10 | 0.14 | 0.10 | 0.13 | 0.12 | 0.12 | 0.12 | 0.11 | 0.11 | 0.10 | 0.11 | 1.34 | 0.10 | 0.09 | 0.10 | 0.11 | 0.12 | 0.12 | |

| Ferrous Metal Mining and Dressing Industry | Iron Ore Raw Ore Production | Y138 | 3.03 | 3.79 | 3.79 | 3.25 | 3.53 | 3.42 | 3.51 | 3.40 | 3.48 | 3.43 | 3.78 | 4.19 | 42.61 | 3.09 | 3.35 | 3.91 | 4.00 | 4.33 | 4.24 |

| Non-metallic Mineral Mining and Dressing Industry | Phosphate Rock (Equivalent to 30% P2O5) Production | Y139 | 4.34 | 4.35 | 4.57 | 3.65 | 3.94 | 3.85 | 3.93 | 4.01 | 4.26 | 3.61 | 4.57 | 5.49 | 50.57 | 2.67 | 4.29 | 6.13 | 6.48 | 6.36 | 6.23 |

| Raw Salt Production | Y140 | 0.15 | 0.22 | 0.22 | 0.29 | 0.34 | 0.33 | 0.30 | 0.57 | 0.56 | 0.62 | 0.69 | 0.84 | 5.12 | 0.75 | 1.26 | 1.45 | 2.17 | 2.69 | 2.71 | |

| Textile Industry | Yarn Production | Y141 | 16.31 | 12.51 | 16.47 | 13.76 | 13.91 | 13.65 | 13.02 | 13.15 | 14.25 | 13.26 | 13.06 | 11.96 | 165.29 | 10.25 | 14.57 | 16.62 | 16.19 | 16.93 | 16.10 |

| Cloth Production | Y142 | 4.95 | 3.78 | 4.95 | 4.11 | 4.11 | 3.99 | 3.75 | 3.73 | 3.99 | 3.65 | 3.54 | 3.19 | 47.73 | 2.70 | 3.79 | 4.28 | 4.12 | 4.27 | 4.02 | |

| Textile and Apparel Industry | Apparel Production | Y143 | 4.11 | 3.84 | 4.76 | 3.51 | 3.84 | 4.72 | 5.02 | 5.34 | 4.86 | 4.72 | 4.77 | 5.77 | 55.25 | 4.16 | 7.59 | 9.31 | 9.75 | 11.11 | 12.94 |

| Petroleum Processing, Coking, and Nuclear Fuel Processing Industry | Crude Oil Processing Capacity | Y144 | 4.79 | 3.20 | 6.89 | 4.98 | 4.84 | 4.94 | 4.89 | 4.94 | 5.09 | 4.70 | 4.38 | 4.57 | 58.20 | 4.59 | 4.58 | 4.66 | 4.92 | 3.93 | 2.04 |

| Gasoline Production | Y145 | 1.17 | 0.78 | 1.68 | 1.20 | 1.15 | 1.13 | 1.07 | 1.02 | 0.97 | 0.81 | 0.66 | 0.59 | 12.24 | 0.49 | 0.40 | 0.31 | 0.26 | 0.16 | 0.06 | |

| Kerosene Production | Y146 | 0.29 | 0.20 | 0.42 | 0.31 | 0.30 | 0.30 | 0.30 | 0.31 | 0.31 | 0.29 | 0.27 | 0.28 | 3.59 | 0.28 | 0.28 | 0.29 | 0.30 | 0.24 | 0.13 | |

| Diesel Production | Y147 | 1.20 | 0.82 | 1.80 | 1.34 | 1.35 | 1.43 | 1.48 | 1.56 | 1.69 | 1.65 | 1.63 | 1.81 | 17.76 | 1.94 | 2.07 | 2.25 | 2.54 | 2.16 | 1.20 | |

| Coke Production | Y148 | 7.71 | 7.36 | 7.34 | 6.48 | 6.27 | 6.95 | 7.19 | 7.24 | 6.42 | 6.20 | 6.41 | 8.77 | 84.34 | 7.55 | 7.00 | 7.33 | 6.81 | 6.89 | 6.92 | |

| Chemical Raw Materials and Chemical Products Manufacturing Industry | Sulfuric Acid (100% Basis) Production | Y149 | 35.95 | 38.99 | 40.49 | 37.26 | 43.18 | 42.56 | 42.86 | 38.65 | 37.93 | 36.75 | 34.58 | 35.06 | 464.27 | 29.12 | 30.11 | 34.12 | 33.85 | 35.98 | 33.10 |

| Caustic Soda (100% Basis) Production | Y150 | 13.90 | 9.11 | 17.95 | 12.86 | 14.16 | 13.51 | 14.97 | 13.19 | 12.27 | 11.77 | 10.62 | 10.93 | 155.22 | 11.42 | 10.85 | 11.32 | 10.96 | 9.79 | 9.78 | |

| Soda Ash (Sodium Carbonate) Production | Y151 | 33.52 | 22.00 | 43.50 | 31.30 | 34.65 | 33.28 | 37.12 | 32.98 | 30.91 | 29.90 | 27.20 | 28.21 | 384.57 | 29.74 | 28.46 | 29.93 | 29.17 | 26.19 | 26.30 | |

| Ethylene Production | Y152 | 10.03 | 8.44 | 9.30 | 7.50 | 8.73 | 9.35 | 8.46 | 7.10 | 7.09 | 6.15 | 5.74 | 5.10 | 92.98 | 5.14 | 3.96 | 4.15 | 3.26 | 3.79 | 4.15 | |

| Synthetic Ammonia Production | Y153 | 40.38 | 44.23 | 46.82 | 44.32 | 53.28 | 54.89 | 58.21 | 55.60 | 58.10 | 60.16 | 60.63 | 65.91 | 642.53 | 58.66 | 64.87 | 78.37 | 82.53 | 92.69 | 89.62 | |

| Agricultural Nitrogen, Phosphorus, and Potassium Fertilizer (Pure Basis) Production | Y154 | 24.61 | 32.49 | 36.93 | 26.27 | 30.01 | 28.17 | 26.40 | 23.81 | 25.09 | 25.65 | 23.35 | 26.32 | 329.11 | 23.66 | 22.42 | 26.27 | 24.69 | 23.49 | 24.75 | |

| Chemical Pesticide Production | Y155 | 4.35 | 4.75 | 5.00 | 4.70 | 5.58 | 5.68 | 5.95 | 5.62 | 5.82 | 5.96 | 5.95 | 6.41 | 65.79 | 5.66 | 6.20 | 7.42 | 7.75 | 8.66 | 8.37 | |

| Primary Form Plastic Production | Y156 | 43.84 | 47.49 | 49.20 | 45.13 | 52.05 | 50.98 | 50.93 | 45.49 | 44.18 | 42.35 | 39.47 | 39.72 | 550.84 | 32.85 | 33.97 | 38.69 | 38.76 | 41.81 | 39.18 | |

| Synthetic Detergent Production | Y157 | 4.64 | 5.10 | 5.41 | 5.14 | 6.20 | 6.40 | 6.79 | 6.48 | 6.76 | 6.95 | 6.93 | 7.41 | 74.21 | 6.45 | 6.92 | 8.06 | 8.12 | 8.68 | 7.97 | |

| Chemical Fiber Manufacturing Industry | Chemical Fiber Production | Y158 | 9.34 | 9.32 | 12.40 | 11.05 | 10.10 | 10.94 | 10.34 | 8.70 | 10.57 | 8.26 | 7.44 | 7.14 | 115.59 | 7.00 | 7.73 | 10.61 | 8.46 | 8.63 | 8.47 |

| Rubber and Plastic Products Industry | Plastic Products Production | Y159 | 98.86 | 66.71 | 91.64 | 84.98 | 83.33 | 77.34 | 79.74 | 75.39 | 76.17 | 67.36 | 69.86 | 68.84 | 940.22 | 42.87 | 71.75 | 81.46 | 75.32 | 74.01 | 71.06 |

| Non-metallic Mineral Products Industry | Cement Production | Y160 | 350.82 | 344.52 | 467.82 | 465.46 | 490.93 | 547.04 | 395.15 | 405.69 | 447.77 | 365.90 | 361.27 | 250.80 | 4893.18 | 325.57 | 392.58 | 586.49 | 598.02 | 537.73 | 357.28 |

| Flat Glass Production | Y161 | 219.11 | 128.60 | 119.25 | 184.30 | 181.91 | 213.81 | 232.24 | 251.96 | 269.16 | 276.82 | 269.44 | 271.69 | 2618.30 | 185.71 | 227.60 | 284.92 | 286.59 | 297.19 | 297.66 | |

| Ferrous Metals Smelting and Rolling Processing Industry | Pig Iron Production | Y162 | 234.88 | 258.77 | 305.37 | 298.48 | 300.00 | 271.56 | 262.25 | 261.21 | 264.35 | 274.71 | 240.10 | 235.72 | 3207.39 | 223.17 | 239.94 | 281.94 | 267.17 | 264.03 | 258.65 |

| Crude Steel Production | Y163 | 219.31 | 243.51 | 290.58 | 288.16 | 294.67 | 272.40 | 269.56 | 274.90 | 285.98 | 305.43 | 273.98 | 276.45 | 3294.91 | 267.75 | 294.47 | 352.33 | 339.17 | 338.64 | 334.44 | |

| Finished Steel Products Production | Y164 | 293.39 | 323.43 | 381.68 | 373.19 | 375.21 | 339.88 | 328.46 | 327.16 | 331.42 | 344.55 | 301.26 | 296.07 | 4015.70 | 280.39 | 301.82 | 354.79 | 336.66 | 333.02 | 326.72 | |

| Steel Products Production | Y165 | 293.00 | 322.72 | 380.63 | 371.78 | 373.39 | 337.94 | 326.50 | 325.07 | 329.22 | 342.35 | 299.38 | 294.33 | 3996.31 | 278.80 | 299.96 | 352.56 | 334.36 | 330.48 | 323.95 | |

| Non-ferrous Metals Smelting and Rolling Processing Industry | Ten Kinds of Non-ferrous Metals Production | Y166 | 136.10 | 110.51 | 159.42 | 133.35 | 136.02 | 128.62 | 133.63 | 132.85 | 124.82 | 127.64 | 130.25 | 133.01 | 1586.23 | 116.87 | 116.57 | 105.39 | 129.33 | 132.82 | 125.58 |

| Alumina Production | Y167 | 198.32 | 187.76 | 210.27 | 196.09 | 208.27 | 205.66 | 205.54 | 202.52 | 206.07 | 208.40 | 189.74 | 193.49 | 2412.12 | 191.92 | 175.79 | 199.54 | 192.01 | 190.62 | 185.40 | |

| Primary Aluminum (Electrolytic Aluminum) Production | Y168 | 24.37 | 23.15 | 26.06 | 24.47 | 26.20 | 26.10 | 26.34 | 26.22 | 26.95 | 27.54 | 25.32 | 26.06 | 308.79 | 26.08 | 24.06 | 27.49 | 26.58 | 26.47 | 25.80 | |

| Copper Products Production | Y169 | 13.98 | 11.37 | 16.46 | 13.85 | 14.23 | 13.59 | 14.28 | 14.38 | 13.72 | 14.26 | 14.81 | 15.41 | 170.32 | 13.81 | 14.06 | 12.99 | 16.29 | 17.11 | 16.55 | |

| Aluminum Products Production | Y170 | 144.76 | 137.47 | 154.70 | 145.28 | 155.62 | 155.17 | 156.69 | 156.04 | 160.43 | 163.83 | 150.48 | 154.61 | 1835.08 | 154.29 | 141.97 | 161.65 | 155.82 | 154.75 | 150.40 | |

| General Equipment Manufacturing Industry | Industrial Boilers Production | Y171 | 1.66 | 1.20 | 1.82 | 1.59 | 1.36 | 1.42 | 1.49 | 1.44 | 1.34 | 1.19 | 1.17 | 1.17 | 16.85 | 0.86 | 1.16 | 1.23 | 1.14 | 1.07 | 1.03 |

| Engine Production | Y172 | 5.02 | 3.64 | 5.58 | 4.91 | 4.30 | 4.52 | 4.94 | 4.81 | 4.78 | 4.25 | 4.57 | 4.44 | 55.78 | 3.76 | 4.74 | 6.18 | 4.86 | 6.13 | 4.24 | |

| Metal Cutting Machine Tool Production | Y173 | 0.02 | 0.02 | 0.03 | 0.03 | 0.02 | 0.03 | 0.03 | 0.04 | 0.04 | 0.04 | 0.05 | 0.05 | 0.40 | 0.04 | 0.07 | 0.08 | 0.08 | 0.07 | 0.07 | |

| Crane Production | Y174 | 3.86 | 2.82 | 4.32 | 3.88 | 3.43 | 3.74 | 4.16 | 4.33 | 4.41 | 4.36 | 4.85 | 5.55 | 49.71 | 4.82 | 7.77 | 10.03 | 11.31 | 12.89 | 15.04 | |

| Packaging Equipment Production | Y175 | 0.06 | 0.04 | 0.06 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.60 | 0.04 | 0.05 | 0.06 | 0.06 | 0.06 | 0.06 | |

| Automobile Manufacturing Industry | Automobile Production | Y176 | 37.22 | 31.39 | 32.36 | 27.12 | 28.85 | 34.50 | 39.02 | 39.85 | 37.53 | 35.93 | 37.61 | 38.83 | 420.20 | 29.48 | 41.87 | 48.47 | 46.33 | 51.02 | 57.65 |

| Railway, Shipbuilding, Aerospace, and Other Transport Equipment Manufacturing Industry | Civil Steel Ship Production | Y177 | 2.14 | 2.19 | 2.91 | 2.26 | 2.11 | 2.41 | 2.74 | 2.94 | 2.74 | 2.51 | 2.77 | 2.63 | 30.36 | 1.90 | 2.60 | 3.07 | 2.48 | 2.63 | 2.63 |

| Electrical Machinery and Equipment Manufacturing Industry | Generator Set (Power Generation Equipment) Production | Y178 | 10.59 | 7.57 | 11.64 | 9.88 | 9.01 | 9.70 | 11.39 | 11.47 | 11.14 | 11.03 | 11.29 | 11.41 | 126.12 | 8.68 | 11.32 | 13.17 | 12.25 | 11.38 | 12.47 |

| AC Motor Production | Y179 | 29.08 | 20.92 | 32.05 | 27.28 | 24.83 | 26.59 | 30.93 | 30.75 | 29.34 | 28.53 | 28.54 | 28.20 | 337.06 | 20.98 | 26.59 | 30.19 | 27.27 | 24.85 | 26.73 | |

| Lithium Ion Battery Production | Y180 | 6.34 | 4.51 | 6.78 | 5.72 | 5.19 | 5.55 | 6.50 | 6.56 | 6.40 | 6.43 | 6.69 | 6.98 | 73.66 | 5.57 | 7.62 | 9.37 | 9.15 | 9.02 | 10.48 | |

| Domestic Refrigerator Production | Y181 | 4.70 | 3.32 | 4.95 | 4.07 | 3.55 | 3.65 | 4.07 | 3.89 | 3.61 | 3.43 | 3.39 | 3.33 | 45.96 | 2.49 | 3.21 | 3.68 | 3.40 | 3.16 | 3.46 | |

| Domestic Freezer (Home Freezer) Production | Y182 | 1.38 | 0.97 | 1.44 | 1.18 | 1.03 | 1.06 | 1.18 | 1.13 | 1.03 | 0.97 | 0.93 | 0.89 | 13.17 | 0.65 | 0.81 | 0.91 | 0.81 | 0.74 | 0.80 | |

| Room Air Conditioner Production | Y183 | 14.66 | 10.49 | 16.04 | 13.62 | 12.41 | 13.35 | 15.66 | 15.75 | 15.25 | 15.07 | 15.34 | 15.49 | 173.14 | 11.77 | 15.32 | 17.85 | 16.58 | 15.53 | 17.14 | |

| Domestic Washing Machine Production | Y184 | 0.84 | 0.60 | 0.91 | 0.78 | 0.72 | 0.78 | 0.92 | 0.93 | 0.90 | 0.89 | 0.90 | 0.90 | 10.07 | 0.69 | 0.89 | 1.03 | 0.95 | 0.88 | 0.96 | |

| Computer, Communication, and Other Electronic Equipment Manufacturing Industry | Mobile Communication Handset (Mobile Phone) Production | Y185 | 64.19 | 46.65 | 63.91 | 45.15 | 36.34 | 42.12 | 46.04 | 39.89 | 33.55 | 28.81 | 21.52 | 24.11 | 492.27 | 20.64 | 18.12 | 18.04 | 16.09 | 17.54 | 17.35 |

| Color TV Production | Y186 | 0.89 | 0.83 | 1.25 | 0.95 | 1.04 | 1.12 | 1.26 | 1.35 | 1.24 | 1.17 | 1.00 | 1.11 | 13.21 | 0.98 | 0.93 | 0.96 | 0.83 | 0.90 | 0.98 | |

| Instrument and Apparatus Manufacturing Industry | Electrical Instrument Production | Y187 | 0.82 | 0.67 | 0.60 | 0.69 | 0.73 | 0.83 | 0.89 | 0.86 | 0.75 | 0.63 | 0.67 | 0.73 | 8.89 | 0.50 | 0.69 | 0.78 | 0.73 | 0.78 | 0.90 |

References

- Li, J.; Guo, J.; Gao, S.; Gu, A. Current Status, Problems, and Challenges of National Carbon Emission Accounting Work. Dev. Res. 2020, 9–14. (In Chinese) [Google Scholar]

- Zhang, D.; Zhang, L. Research Progress on Estimation Methods of Carbon Source Emissions. Inn. Mong. For. Sci. Technol. 2005, 20–23. (In Chinese) [Google Scholar]

- Shi, J.; Tang, H.; Zhou, Q.; Han, L.; Hao, R. High frequency measurement of carbon emissions based on power big data: A case study of Chinese Qinghai province. Sci. Total Environ. 2023, 902, 166075. [Google Scholar] [CrossRef]

- Shi, J.; Zhou, N.; Lian, Z. Evaluation of the “Energy Saving and Emission Reduction” Effect in China—A Comparative Study Based on Different Types of Data. Macroecon. Res. 2017, 80–87+121. (In Chinese) [Google Scholar] [CrossRef]

- Li, Q.; Su, Y.; Shang, L.; Wei, W.; Wang, M. Comparative Analysis of International Typical Carbon Databases on China’s Carbon Emission Accounting. Adv. Clim. Change Res. 2018, 14, 275–280. [Google Scholar]

- Dong, H.; Geng, Y.; Xue, B.; Xi, F. Differences in Energy Consumption and Carbon Emission Patterns Between Central Urban and Suburban Areas of Shenyang. Res. Environ. Sci. 2011, 24, 354–362. [Google Scholar] [CrossRef]

- Zhao, H.; Geng, Y.; Xi, F.; Liu, Z.; Dong, H. Carbon Emissions from Industrial Energy Consumption in Liaoning Province Based on Production and Consumption Perspectives. Res. Environ. Sci. 2012, 25, 1290–1296. [Google Scholar] [CrossRef]

- Shan, Y.; Liu, Z.; Guan, D. CO2 emissions from China’s lime industry. Appl. Energy 2016, 166, 245–252. [Google Scholar] [CrossRef]

- Park, J.; Hong, T. Analysis of South Korea’s economic growth, carbon dioxide emission, and energy consumption using the Markov switching model. Renew. Sustain. Energy Rev. 2013, 18, 543–551. [Google Scholar] [CrossRef]

- Chao, Q. Theoretical Basis for Global Climate Governance and the Challenges and Opportunities China Faces. Yuejiang Acad. J. 2020, 12, 33–43+120–121. [Google Scholar] [CrossRef]

- Peng, J. Global Green Low-Carbon Development and China’s Transformation of Development Mode. Environ. Sci. Technol. 2012, 35, 1–12. [Google Scholar]

- Shimada, K.; Tanaka, Y.; Gomi, K.; Matsuoka, Y. Developing a long-term local society design methodology towards a low-carbon economy: An application to Shiga Prefecture in Japan. Energy Policy 2007, 35, 4688–4703. [Google Scholar] [CrossRef]

- Wan, Z.; Xiao, Y. A Review of Regional Differences in China’s Carbon Emissions. Econ. Res. Guide 2013, 218–219. [Google Scholar]

- Fang, K. Depth and Breadth of Ecological Footprint: Constructing a New Index of a Three-Dimensional Model. Acta Ecol. Sin. 2013, 33, 267–274. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, Z.; Pang, L.; Wang, L.; Zou, X. Predictions of China’s Energy Consumption and Carbon Emission Peaks Based on Economic Simulation. Acta Geogr. Sin. 2009, 64, 935–944. [Google Scholar]

- Dagoumas, A.S.; Barker, T.S. Pathways to a low-carbon economy for the UK with the macro-econometric E3MG model. Energy Policy 2010, 38, 3067–3077. [Google Scholar] [CrossRef]

- Liu, H.; Liu, W.; Tang, Z.; Fan, X. Analysis of CO2 Emission Reduction Effects from Regional Industrial Structure Adjustment in China—Based on Inter-Regional Input-Output Tables. Reg. Res. Dev. 2010, 29, 129–135. [Google Scholar]

- Xie, S.; Wang, L.; Shao, Z. Review of Domestic and International Carbon Emission Studies. Arid Land Geogr. 2014, 37, 720–730. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Ji, H.; Wang, S.; Wang, H.; Shi, J. Research on Carbon Emissions Estimation in Key Industries Based on the Electricity–Energy–Carbon Model: A Case Study of Henan Province. Energies 2024, 17, 2933. https://doi.org/10.3390/en17122933

Wang Y, Ji H, Wang S, Wang H, Shi J. Research on Carbon Emissions Estimation in Key Industries Based on the Electricity–Energy–Carbon Model: A Case Study of Henan Province. Energies. 2024; 17(12):2933. https://doi.org/10.3390/en17122933

Chicago/Turabian StyleWang, Yuanyuan, Haoyang Ji, Shiqian Wang, Han Wang, and Junyi Shi. 2024. "Research on Carbon Emissions Estimation in Key Industries Based on the Electricity–Energy–Carbon Model: A Case Study of Henan Province" Energies 17, no. 12: 2933. https://doi.org/10.3390/en17122933

APA StyleWang, Y., Ji, H., Wang, S., Wang, H., & Shi, J. (2024). Research on Carbon Emissions Estimation in Key Industries Based on the Electricity–Energy–Carbon Model: A Case Study of Henan Province. Energies, 17(12), 2933. https://doi.org/10.3390/en17122933