Processing Orchard Grass into Carbon Bio Pellets via Hydrothermal Carbonisation—A Case Study Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Analytical Methods

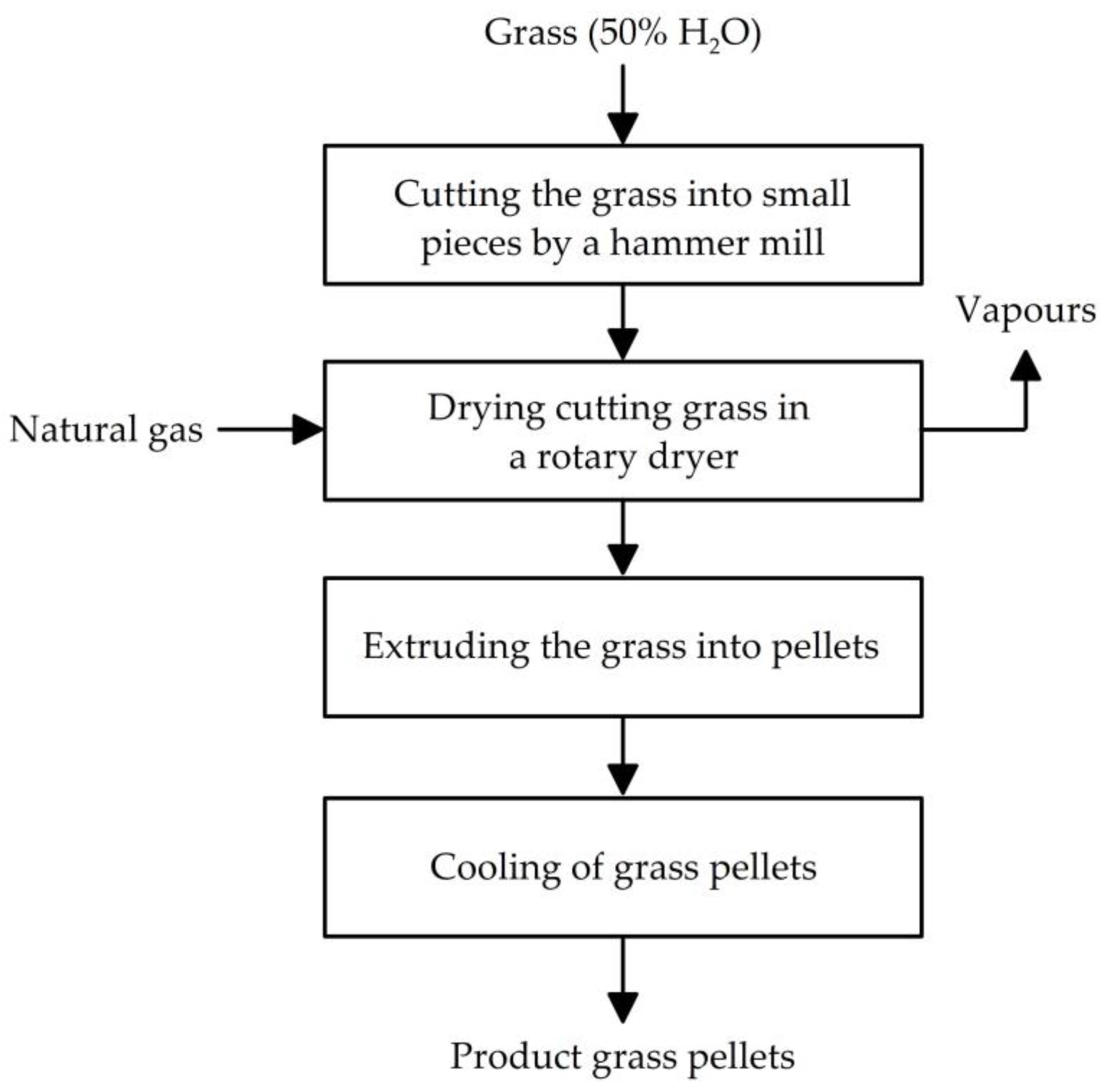

2.2. Grass Production Pellets from Orchard Grass

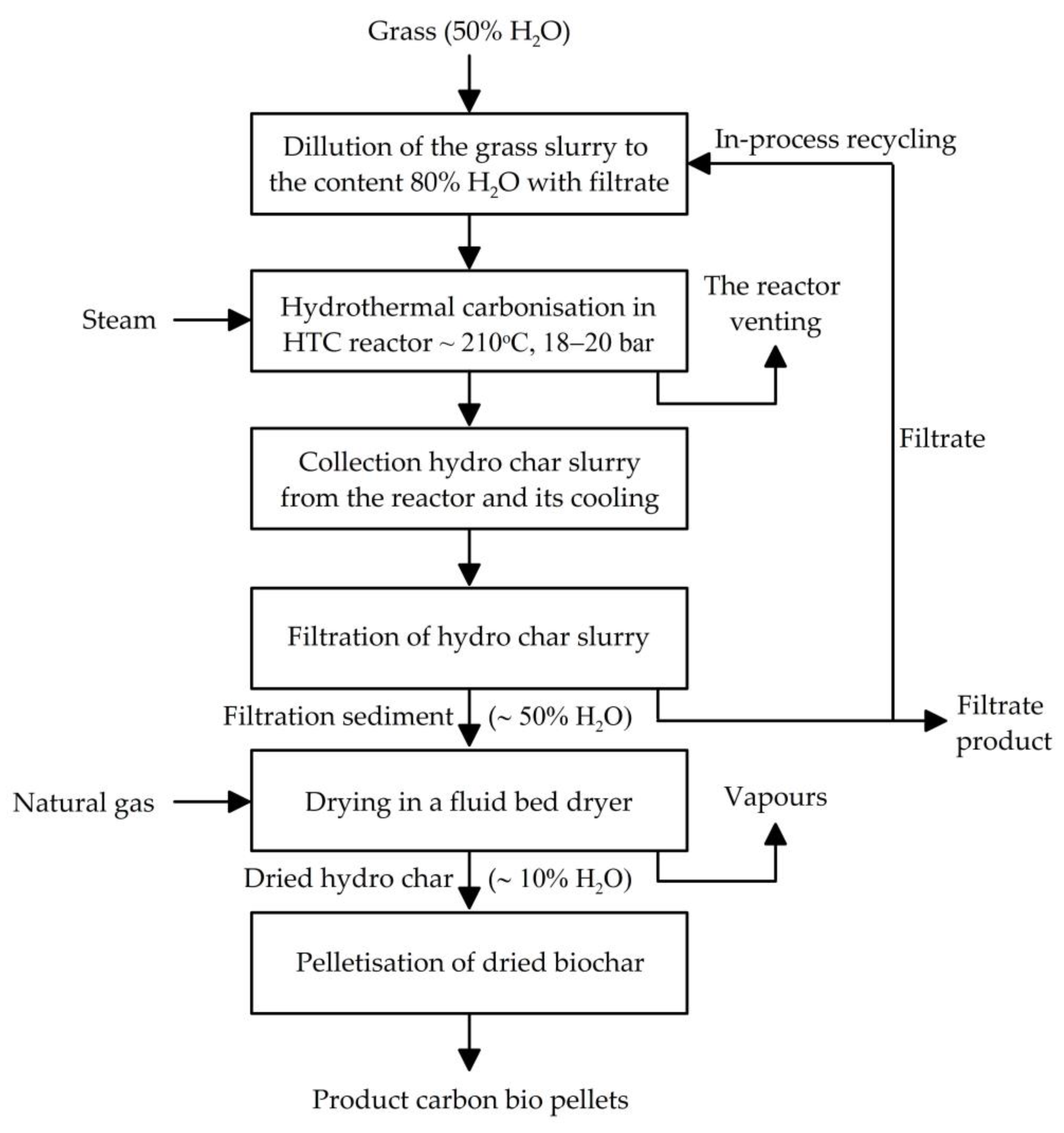

2.3. Processing of Hydrated Biomass by the HTC Hydrothermal Carbonisation Method

3. Results and Discussion

Processing of Orchard Grass into Carbon Bio Pellets by HTC Method

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sertolli, A.; Gabnai, Z.; Lengyel, P.; Bai, A. Biomass Potential and Utilization in Worldwide Research Trends—A Bibliometric Analysis. Sustainability 2022, 14, 5515. [Google Scholar] [CrossRef]

- Energy Technology Perspectives: Scenarios and Strategies to 2050. International Energy Agency. Available online: https://iea.blob.core.windows.net/assets/0e190efb-daec-4116-9ff7-ea097f649a77/etp2008.pdf (accessed on 8 November 2023).

- FAO, FAOSTAT Statistics Database. Food and Agriculture Organization of the United Nations. Available online: http://www.fao.org/faostat/en/#home (accessed on 25 January 2024).

- World Bioenergy Association (WBA), Global Bioenergy Statistics 2019. Available online: https://www.worldbioenergy.org/uploads/191129%20WBA%20GBS%202019_LQ.pdf (accessed on 10 January 2024).

- U.S. Energy Information Administration. Biomass Explained. Available online: https://www.eia.gov/energyexplained/biomass/ (accessed on 4 April 2024).

- Górnicki, K.; Kaleta, A.; Winiczenko, R. Estimating the higher heating value of forest and agricultural biomass. In Proceedings of the E3S Web of Conferences, 2020, 6th International Conference–Renewable Energy Sources (ICoRES 2019), Krynica, Poland, 12–14 June 2020; Volume 154, p. 01002. [Google Scholar] [CrossRef]

- Vaithyanathan, V.K.; Cabana, H. Integrated Biotechnology Management of Biosolids: Sustainable Ways to Produce Value—Added Products. Front. Water. 2021, 3, 729679. [Google Scholar] [CrossRef]

- Van den Born, G.J.; Van Minnen, J.G.; Olivier, J.G.J.; Ros, J.P.M. PBL-Report, Integrated Analysis of Global Biomass Flows in Search of the Sustainable Potential for Bioenergy Production; PBL Netherlands Environmental Assessment Agency: Hague, The Netherlands, 2014; PBL Publication Number: 1509. [Google Scholar]

- Speight, J.G.; Singh, K. Environmental Management of Energy from Biofuels and Biofeedstocks; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014. [Google Scholar]

- Moomaw, W.; Yamba, F.; Kamimoto, M.; Maurice, L.; Nyboer, J.; Urama, K.; Weir, T. Introduction. In IPCC Special Report on Renewable Energy Sources and Climate Change Mitigation; Edenhofer, O., Pichs-Madruga, R., Sokona, Y., Seyboth, K., Matschoss, P., Kadner, S., Zwickel, T., Eickemeier, P., Hansen, G., Schlömer, S., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2011. [Google Scholar]

- International Renewable Energy Agency (IRENA). Global Bioenergy Supply and Demand Projections—A Working Paper for REmap 2030, 2014. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2014/IRENA_REmap_2030_Biomass_paper_2014.pdf?rev=346f632ace3b43ab8d5 (accessed on 10 January 2024).

- Working Party on Agricultural Policies and Markets. Available online: https://one.oecd.org/document/TAD/CA/APM/WP(20 09)11/FINAL/en/pdf (accessed on 15 November 2023).

- Brown, A.E.; Hammerton, J.M.; Camargo-Valero, M.A.; Ross, A.B. Integration of Hydrothermal Carbonisation and Anaerobic Digestion for the Energy Valorisation of Grass. Energies 2022, 15, 3495. [Google Scholar] [CrossRef]

- Prochnow, A.; Heiermann, M.; Plöchl, M.; Linke, B.; Idler, C.; Amon, T.; Hobbs, P.J. Bioenergy from permanent grassland—A review: 1. Biogas. Bioresour. Technol. 2009, 100, 4931–4944. [Google Scholar] [CrossRef] [PubMed]

- Watson, L. The grass family, Poaceae. In Reproductive Versatility in the Grasses; Chapman, G.P., Ed.; Cambridge University Press: Cambridge, UK, 1990. [Google Scholar]

- Xu, J.; Wang, Z.; Cheng, J.J. Bermuda grass as feedstock for biofuel production: A review. Bioresour. Technol. 2011, 102, 7613–7620. [Google Scholar] [CrossRef]

- Smith, A.M.; Whittaker, C.; Shield, I.; Ross, A.B. The potential for production of high quality bio-coal from early harvested Miscanthus by hydrothermal carbonisation. Fuel 2018, 220, 546–557. [Google Scholar] [CrossRef]

- European Commission, Environment Action Programme to 2030. Available online: https://environment.ec.europa.eu/strategy/environment-action-programme-2030_en (accessed on 16 November 2023).

- United Nations 2030 Agenda for Sustainable Development. Available online: https://www.un.org/sustainabledevelopment/development-agenda/ (accessed on 16 November 2023).

- Ellen MacArthur Foundation. Towards the Circular Economy, Vol. 3: Accelerating the Scale-Up across Global Supply Chains. 2014. Available online: https://www.ellenmacarthurfoundation.org/towards-the-circular-economy-vol-3-accelerating-the-scaleup-across-global (accessed on 12 November 2023).

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- IEA International Energy Agency. Tracking Clean Energy Progress 2023. Available online: https://www.iea.org/reports/tracking-clean-energy-progress-2023 (accessed on 17 November 2023).

- Ellen MacArthur Foundation. SUN, McKinsey Centre for Business and Environment. Growth Within: A Circular Economy Vision for a Competitive Europe. 2015. Available online: https://www.ellenmacarthurfoundation.org/growth-within-a-circulareconomy-vision-for-a-competitive-europe (accessed on 12 November 2023).

- Kowalski, Z.; Makara, A. The circular economy model used in the Polish agro-food consortium: A case study. J. Clean. Prod. 2021, 284, 124751. [Google Scholar] [CrossRef]

- Kowalski, Z.; Makara, A.; Kulczycka, J.; Generowicz, A.; Kwaśnicki, P.; Ciuła, J.; Gronba-Chyła, A. Conversion of Sewage Sludge into Biofuels via Different Pathways and Their Use in Agriculture: A comprehensive Review. Energies 2024, 17, 1383. [Google Scholar] [CrossRef]

- Goyal, H.B.; Seal, D.; Saxena, R.C. Bio-fuels from thermochemical conversion of renewable resources: A review. Renew. Sustain. Energy Rev. 2008, 12, 504–517. [Google Scholar] [CrossRef]

- Baruah, J.; Nath, B.K.; Sharma, R.; Kumar, S.; Deka, R.C.; Baruah, D.C.; Kalita, E. Recent Trends in the Pretreatment of Lignocellulosic Biomass for Value-Added Products. Front. Energy Res. 2018, 6, 141. [Google Scholar] [CrossRef]

- Kruse, A.; Funke, A.; Titirici, M.M. Hydrothermal conversion of biomass to fuels and energetic materials. Curr. Opin. Chem. Biol. 2013, 17, 515–521. [Google Scholar] [CrossRef] [PubMed]

- Gil, M.V.; Oulego, P.; Casal, M.D.; Pevida, C.; Pis, J.J.; Rubiera, F. Mechanical durability and combustion characteristics of pellets from biomass blends. Bioresour. Technol. 2010, 101, 8859–8867. [Google Scholar] [CrossRef] [PubMed]

- Shantz, H.L. The Place of Grasslands in the Earth’s Cover. Ecology 1954, 35, 143–145. [Google Scholar] [CrossRef]

- Sutherland, D.M. Genera Graminum. Grasses of the World. Brittonia 1987, 39, 508. [Google Scholar] [CrossRef]

- Watson, L.; Dallwitz, M.J. The Families of Flowering Plants. Interactive Identification and Information Retrieval on CD-ROM version 1.0 1993, and colour illustrated manual. Nord. J. Bot. 1994, 14, 486. [Google Scholar] [CrossRef]

- Tenikecier, H.S.; Ates, E. Chemical Composition of Six Grass Species (Poaceae sp.) from Protected Forest Range in Northern Bulgaria. Asian J. Appl. Sci. 2018, 11, 71–75. [Google Scholar] [CrossRef]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Production and utilization of fuel pellets from biomass: A review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar] [CrossRef]

- Heil, N.; Ciolkosz, D. On-Farm Production of Biomass Grass Pellets. A Case Study of Wood Crest Farm in Wapwallopen, Pennsylvania. The Pennsylvania State University 2014. Code EE0130 12/14pod. Available online: https://www.sare.org/wp-content/uploads/ONE13-178CiolkoczPelletCaseStudy.pdf (accessed on 21 March 2024).

- Manouchehrinejad, M.; Sahoo, K.; Kaliyan, N.; Singh, H.; Mani, S. Economic and environmental impact assessments of a stand-alone napier grass-fired combined heat and power generation system in the south eastern US. Int. J. Life Cycle Assess. 2020, 25, 89–104. [Google Scholar] [CrossRef]

- Cherney, J.H.; Verma, V.K. Grass pellet Quality Index: A tool to evaluate suitability of grass pellets for small scale combustion systems. Appl. Energy 2013, 103, 679–684. [Google Scholar] [CrossRef]

- Kubík, Ľ.; Kažimírová, V. Mechanical properties of pellets in compression. Res. Agric. Eng. 2015, 61, S1–S8. [Google Scholar] [CrossRef]

- PN-EN ISO 17225-8:2023-10; Solid Biofuels—Fuel Specifications and Classes—Part 8: Fuel Classes from Thermally Processed and Compressed Biomass for Non-Industrial and Industrial Use. Polish Committee for Standardization: Warsaw, Poland, 2023.

- Hardy, T.; Kordylewski, W.; Mościcki, K. Zagrożenie korozją chlorkową w wyniku spalania i współspalania biomasy w kotłach. Arch. Spalania 2009, 9, 3–4, 181–195. [Google Scholar]

- Marinovic, A.; Pileidis, F.D.; Titirici, M.M. Chapter—5: Hydrothermal Carbonisation (HTC): History, State-of-the-Art and Chemistry. In Porous Carbon Materials from Sustainable Precursors; White, R.J., Ed.; Royal Society of Chemistry: London, UK, 2015; pp. 129–155. [Google Scholar]

- Dos Santos Dalbelo, T.; Rutkowski, E.W. Industrial Ecology: Ultimate of the Industrial Revolution Toward Sustainability. In Industry, Innovation and Infrastructure; Leal Filho, W., Azul, A.M., Brandli, L., Lange Salvia, A., Wall, T., Eds.; Springer: Cham, Switzerland, 2021; pp. 553–563. [Google Scholar]

- Funke, A.; Ziegler, F. Hydrothermal carbonization of biomass: A summary and discussion of chemical mechanisms for process engineering. Biofuels Bioprod. Biorefin. 2010, 4, 160–177. [Google Scholar] [CrossRef]

- Nicolae, S.A.; Au, H.; Modugno, P.; Luo, H.; Szego, A.E.; Qiao, M.; Li, L.; Yin, W.; Heeres, H.J.; Berge, N.; et al. Recent advances in hydrothermal carbonisation: From tailored carbon materials and biochemicals to applications and bioenergy. Green Chem. 2020, 22, 4747–4800. [Google Scholar] [CrossRef]

- González-Arias, J.; Sánchez, M.E.; Cara-Jiménez, J.; Baena-Moreno, F.M.; Zhang, Z. Hydrothermal carbonization of biomass and waste: A review. Environ. Chem. Lett. 2022, 20, 211–221. [Google Scholar] [CrossRef]

- Liu, X.; Zhai, Y.; Li, S.; Wang, B.; Wang, T.; Liu, Y.; Qiu, Z.; Li, C. Hydrothermal carbonization of sewage sludge: Effect of feed-water pH on hydrochar’s physicochemical properties, organic component and thermal behavior. J. Hazard. Mater. 2020, 388, 122084. [Google Scholar] [CrossRef] [PubMed]

- Zhai, Y.; Peng, C.; Xu, B.; Wang, T.; Li, C.; Zeng, G.; Zhu, Y. Hydrothermal carbonization of sewage sludge for char production with different waste biomass: Effects of reaction temperature and energy recycling. Energy 2017, 127, 167–174. [Google Scholar] [CrossRef]

- Wang, W.; Chen, W.-H.; Jang, M.-F. Characterization of Hydrochar Produced by Hydrothermal Carbonization of Organic Sludge. Future Cities Environ. 2020, 6, 13. [Google Scholar] [CrossRef]

- Titirici, M.M. Chapter 12—Hydrothermal Carbons: Synthesis, Characterization, and Applications. In Novel Carbon Adsorbents; Tascón, J.M.D., Ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2012; pp. 351–399. [Google Scholar]

- Bergius, F. Die Anwendung Hoher Drucke bei Chemischen Vorgängen und Eine Nachbildung des Entstehungsprozesses der Steinkohle; Publisher Knapp: Halle, Germany, 1913. [Google Scholar]

- Owsianiak, M.; Ryberg, M.W.; Renz, M.; Hitzl, M.; Hauschild, M.Z. Environmental performance of hydrothermal carbonization of four wet biomass waste streams at industry-relevant scales. ACS Sustain. Chem. Eng. 2016, 4, 6783–6791. [Google Scholar] [CrossRef]

- Burguete, P.; Corma, A.; Hitzl, M.; Modrego, R.; Ponce, E.; Renz, M. Fuel and chemicals from wet lignocellulosic biomass waste streams by hydrothermal carbonization. Green Chem. 2016, 18, 1051–1060. [Google Scholar] [CrossRef]

- Hitzl, M.; Corma, A.; Pomares, F.; Renz, M. The hydrothermal carbonization (HTC) plant as a decentral biorefinery for wet biomass. Catal. Today 2015, 257, 154–159. [Google Scholar] [CrossRef]

- Kowalski, Z.; Kulczycka, J.; Verhé, R.; Desender, L.; De Clercq, G.; Makara, A.; Generowicz, N.; Harazin, P. Second-generation biofuel production from the organic fraction of municipal solid waste. Front. Energy Res. 2022, 10, 919415. [Google Scholar] [CrossRef]

- Kowalski, Z.; Banach, M.; Makara, A. Optimisation of the co-combustion of meat–bone meal and sewage sludge in terms of the quality produced ashes used as substitute of phosphorites. Environ. Sci. Pollut. Res. 2021, 28, 8205–8214. [Google Scholar] [CrossRef]

- Kladisios, P.; Sagia, A. Hydrothermal carbonization: Production of energy through the thermochemical treatment of biomass. J. Sustain. Energy 2018, 9, 77–86. [Google Scholar]

- Ingelia. Ingelia Biorefinery—From Organic Waste to High Value Bioproducts. Available online: https://ingelia.com/index.php/quienes-somos/english-ingelias-hystory/?lang=en (accessed on 10 November 2023).

- Ingelia Sustainable Business Model. Available online: https://ingelia.com/index.php/que-hacemos/?lang=en (accessed on 21 March 2024).

- Oliver-Tomas, B.; Hitzl, M.; Owsianiak, M.; Renz, M. Evaluation of hydrothermal carbonization in urban mining for the recovery of phosphorus from the organic fraction of municipal solid waste. Resour. Conserv. Recycl. 2019, 147, 111–118. [Google Scholar] [CrossRef]

- Sharma, R.; Jasrotia, K.; Singh, N.; Ghosh, P.; Srivastava, S.; Sharma, N.R.; Singh, J.; Kanwar, R.; Kumar, A. A Comprehensive Review on Hydrothermal Carbonization of Biomass and its Applications. Chem. Afr. 2020, 3, 1–19. [Google Scholar] [CrossRef]

- Renz, M.; Corma, A.; Hitzl, M. Biocoal Water Fuel (BWF) obtained by Hydro Thermal Carbonization (HTC). In Proceedings of the 21st European Biomass Conference and Exhibition, Copenhagen, Denmark, 3–7 June 2013. [Google Scholar]

- Tasca, A.L.; Puccini, M.; Gori, R.; Corsi, I.; Raspolli Galletti, A.M.; Vitolo, S. Hydrothermal carbonization of sewage sludge: A critical analysis of process severity, hydrochar properties and environmental implications. Waste Manag. 2019, 93, 1–13. [Google Scholar] [CrossRef] [PubMed]

- ISO 5074:2015; Hard Coal—Determination of Hardgrove Grindability Index. ISO: Geneva, Switzerland, 2015.

- Kowalski, Z.; Makara, A. Sustainable Systems for the Production of District Heating Using Meat-Bone Meal as Biofuel: A Polish Case Study. Energies 2022, 15, 3615. [Google Scholar] [CrossRef]

- Kowalski, Z.; Kulczycka, J.; Makara, A.; Harazin, P. Quantification of material recovery from meat waste incineration—An approach to an updated food waste hierarchy. J. Hazard. Mater. 2021, 416, 126021. [Google Scholar] [CrossRef]

- Actual Prices of Natural Gas in Poland. Available online: https://www.bing.com/search?q=ceny+gazu+ziemnego+polska&form=ANSPH1&refig=CFB0FA694A6447D08500DCD290FAF90B&pc=U531 (accessed on 21 March 2024).

| Parameters | Unit | Value * |

|---|---|---|

| Calorific value | MJ/kg | >23 |

| Bulk density | kg/m3 | 700 |

| Ash content (SiO2, CaO) | % | 4–6 |

| Water | <10 | |

| C | >58 | |

| C solid | 25 | |

| H | 5.8–6.4 | |

| N | 0.6 | |

| S | <0.2 | |

| Cl | <0.2 | |

| Volatile substances | 65 | |

| Durability | 95–98 | |

| The melting point of ashes in an oxidising atmosphere | °C | >1200 |

| Grindability (Hardgrove index ISO 5074:2015 [63]) | - | 44–52 |

| Parameters | Unit | Result |

|---|---|---|

| Water content | % | 96.5 |

| Dry mass at 105 °C | 3.50 | |

| Total organic matter | 2.40 | |

| C organic total | 1.39 | |

| Humid extract | 1.49 | |

| pH | - | 5.80 |

| C/N | - | 10.6 |

| N total | g/kg | 1.307 |

| N ammonium (N-NH4+) | 0.277 | |

| N nitrate (N-NO3−) | 0.007 | |

| P2O5 | 0.043 | |

| K2O | 2.4 | |

| CaO | 1.8 | |

| MgO | 0.827 | |

| Na2O | 1.109 | |

| B | mg/kg | 3.20 |

| Fe | 24.5 | |

| Cu | 0.070 | |

| Mn | 2.79 | |

| Zn | 1.54 | |

| Ni | 0.26 | |

| Pb | 0.045 | |

| Cd | 0.0040 | |

| Cr | 0.086 | |

| Cl | 1.523 | |

| Electrical conductivity | dS/m in 25 °C | 15.5 |

| Specification | Capacity Variants (t) | |||

|---|---|---|---|---|

| 1000 | 40,000 * | 50,000 ** | 60,000 *** | |

| I. Preparation of feedstock (grass slurry) | ||||

| Input: | ||||

| 1. Feedstock (grass 50% H2O) | 1000 | 40,000 | 50,000 | 60,000 |

| 2. Recycled filtrate from III | 1500 | 60,000 | 75,000 | 90,000 |

| Total | 2500 | 100,000 | 125,000 | 150,000 |

| Output: | ||||

| 1. Feedstock (grass slurry 20% H2O) | 2500 | 100,000 | 125,000 | 150,000 |

| II. Hydrothermal reaction | ||||

| Input: | ||||

| 1. Feedstock (grass slurry 20% H2O) | 2500 | 100,000 | 125,000 | 150,000 |

| Output: | ||||

| 1. Hydro char slurry | 2500 | 100,000 | 125,000 | 150,000 |

| III. Filtration of hydro char slurry | ||||

| Input: | ||||

| 1. Hydro char slurry from II | 2500 | 100,000 | 125,000 | 150,000 |

| Output: | ||||

| 1. Filtration sediment hydro char (50% H2O) | 447 | 17,880 | 22,350 | 26,820 |

| 2. Filtrate (fertiliser solution AHL)—recycled to I | 1500 | 60,000 | 75,000 | 90,000 |

| 3. Filtrate (fertiliser solution AHL)–product | 503 | 20,120 | 25,150 | 30,180 |

| Total: | 2500 | 100,000 | 125,000 | 150,000 |

| IV. Drying of filtration sediment (50% H2O) | ||||

| Input: | ||||

| 1. Filtration sediment hydro char (50% H2O) | 447 | 17,880 | 22,350 | 26,820 |

| Output: | ||||

| 1. Dried hydro char (10% H2O) | 331 | 13,240 | 16,550 | 19,860 |

| 2. Vapours | 116 | 4640 | 5800 | 6960 |

| Total: | 447 | 17,880 | 22,350 | 26,820 |

| V. Production of carbon bio pellets | ||||

| Input: | ||||

| 1. Dried hydro char (10% H2O) | 331 | 13,240 | 16,550 | 19,860 |

| Output: | ||||

| 1. Carbon bio pellets (10% H2O) product | 331 | 13,240 | 16,550 | 19,860 |

| Items | Unit | Variant of Capacity | ||

|---|---|---|---|---|

| 1 | 2 | 3 | ||

| Amount of orchard grass (50% DM) | t/y | 40,000 | 50,000 | 60,000 |

| Amount of feedstock grass sludge (20% DM) | 100,000 | 125,000 | 150,000 | |

| Carbon bio pellets production | 13,240 | 16,550 | 19,860 | |

| Bio pellets price | EUR/t | 465 | 465 | 465 |

| Carbon bio pellets production value | EUR million/y | 6.2 | 7.7 | 9.2 |

| Estimated operation cost | 2.0 | 2.4 | 3.0 | |

| Gross profit | 4.2 | 5.3 | 6.2 | |

| Quantity of Ingelia reactors | pieces | 8 | 10 | 12 |

| Investment expenditures | EUR million | 19.5 | 24.4 | 29.3 |

| Revenue | year | 4.6 | 4.6 | 4.6 |

| Amount of heat after combustion of carbon bio pellets (LHV = 23 GJ/t) | GJ | 304,520 | 380,650 | 456,780 |

| Decreasing fee for CO2 emission (60 €/t of CO2) | EUR million/y | 2.9 | 3.9 | 4.4 |

| Items | Unit | Capacity | ||

|---|---|---|---|---|

| Amount of orchard grass (50% DM) | t/y | 40,000 | 50,000 | 60,000 |

| Production of fertiliser solution AHL | t/y | 16,000 | 20,000 | 24,000 |

| (N + K) ** | 66.4 | 83.0 | 99.6 | |

| AHL price * | €/t | 7.7 | 7.7 | 7.7 |

| AHL production value | €/y | 122,791 | 153,488 | 184,186 |

| Area of lands fertilised | ha/y | 332 | 415 | 498 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kowalski, Z.; Makara, A. Processing Orchard Grass into Carbon Bio Pellets via Hydrothermal Carbonisation—A Case Study Analysis. Energies 2024, 17, 2956. https://doi.org/10.3390/en17122956

Kowalski Z, Makara A. Processing Orchard Grass into Carbon Bio Pellets via Hydrothermal Carbonisation—A Case Study Analysis. Energies. 2024; 17(12):2956. https://doi.org/10.3390/en17122956

Chicago/Turabian StyleKowalski, Zygmunt, and Agnieszka Makara. 2024. "Processing Orchard Grass into Carbon Bio Pellets via Hydrothermal Carbonisation—A Case Study Analysis" Energies 17, no. 12: 2956. https://doi.org/10.3390/en17122956

APA StyleKowalski, Z., & Makara, A. (2024). Processing Orchard Grass into Carbon Bio Pellets via Hydrothermal Carbonisation—A Case Study Analysis. Energies, 17(12), 2956. https://doi.org/10.3390/en17122956