Experimental Study on the Heat Pump Performance Combined with Dual-Purpose Solar Collector

Abstract

:1. Introduction

2. Experimental Apparatus and Methods

2.1. Experimental Apparatus

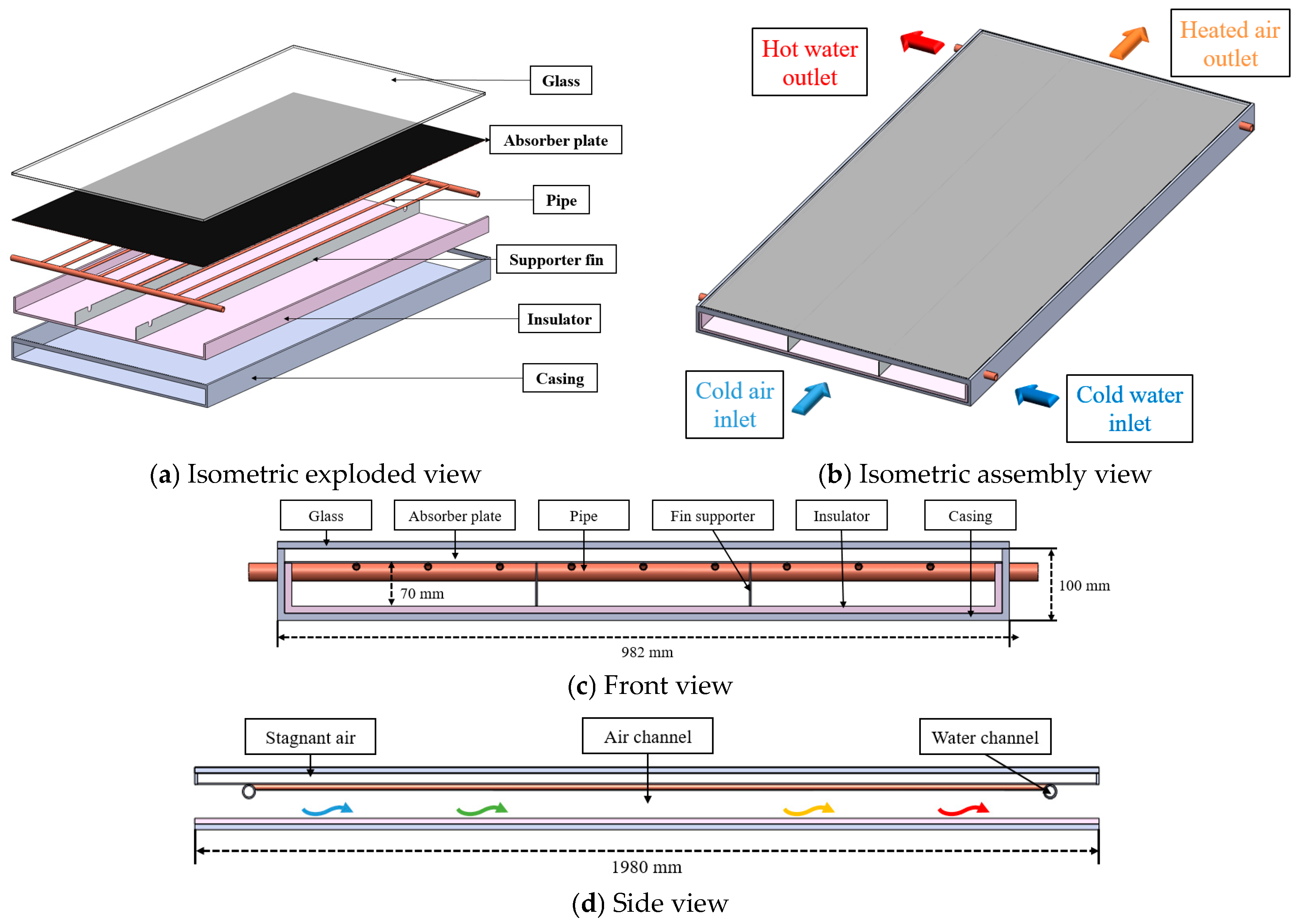

2.1.1. Dual-Purpose Solar Collector

2.1.2. Heat Pump

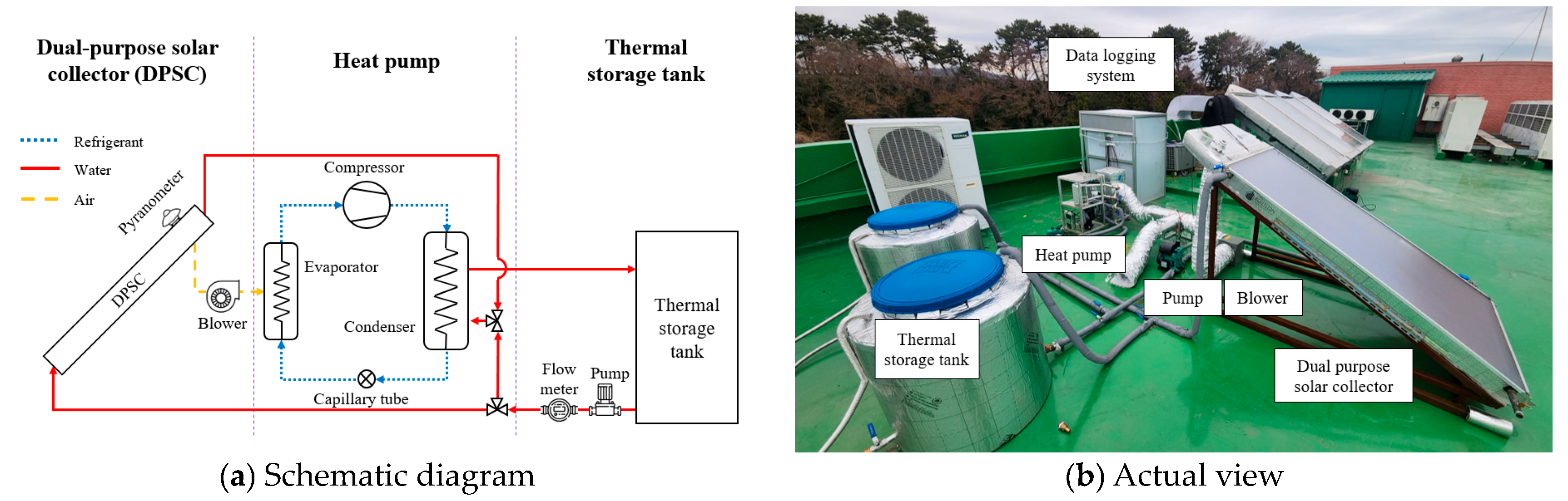

2.1.3. Solar-Assisted Heat Pump Combined with DPSC

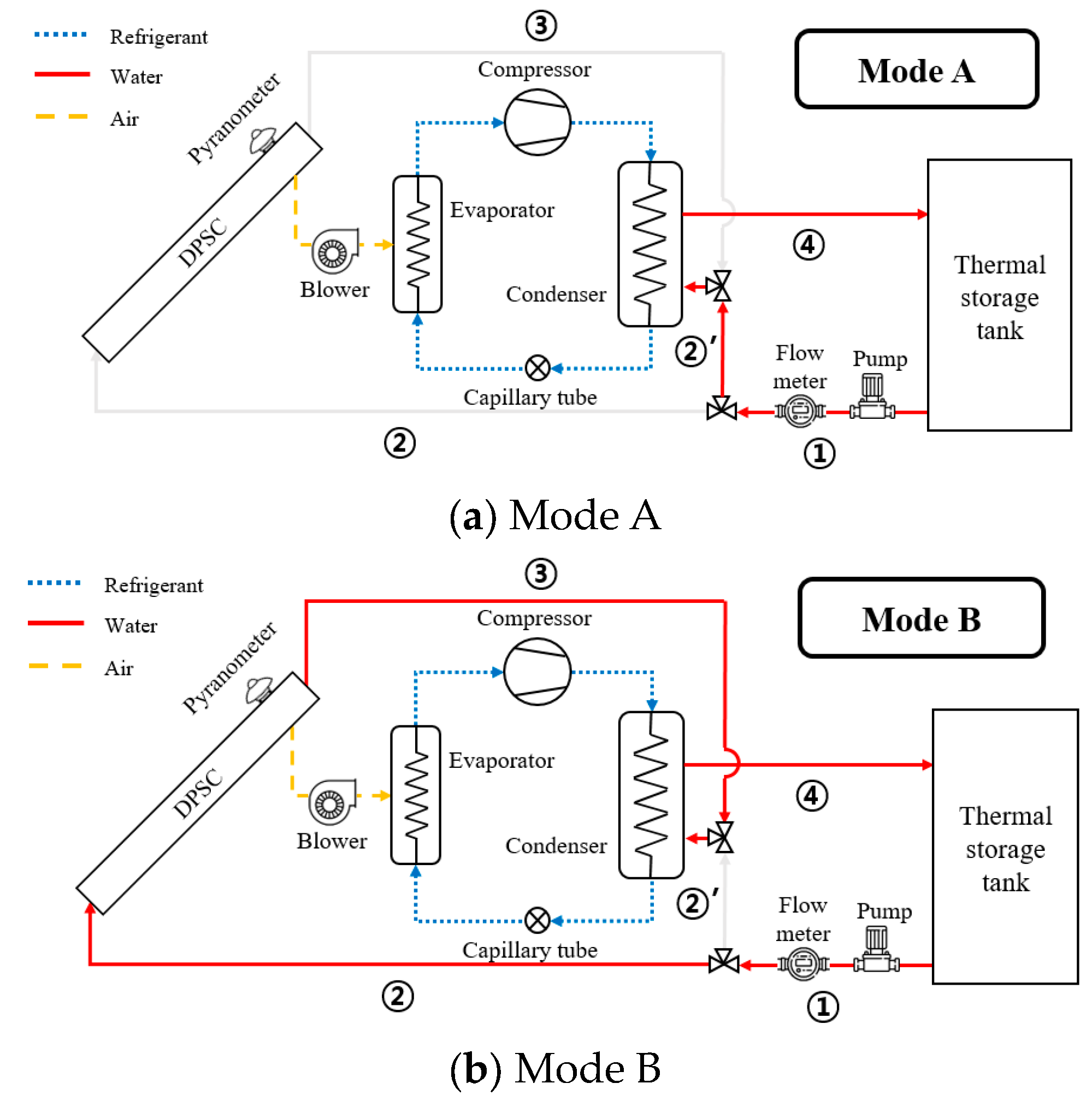

2.2. Experimental Procedure

2.3. Performance Indices

3. Results and Discussions

3.1. Weather Conditions

3.2. Performance of DPSC

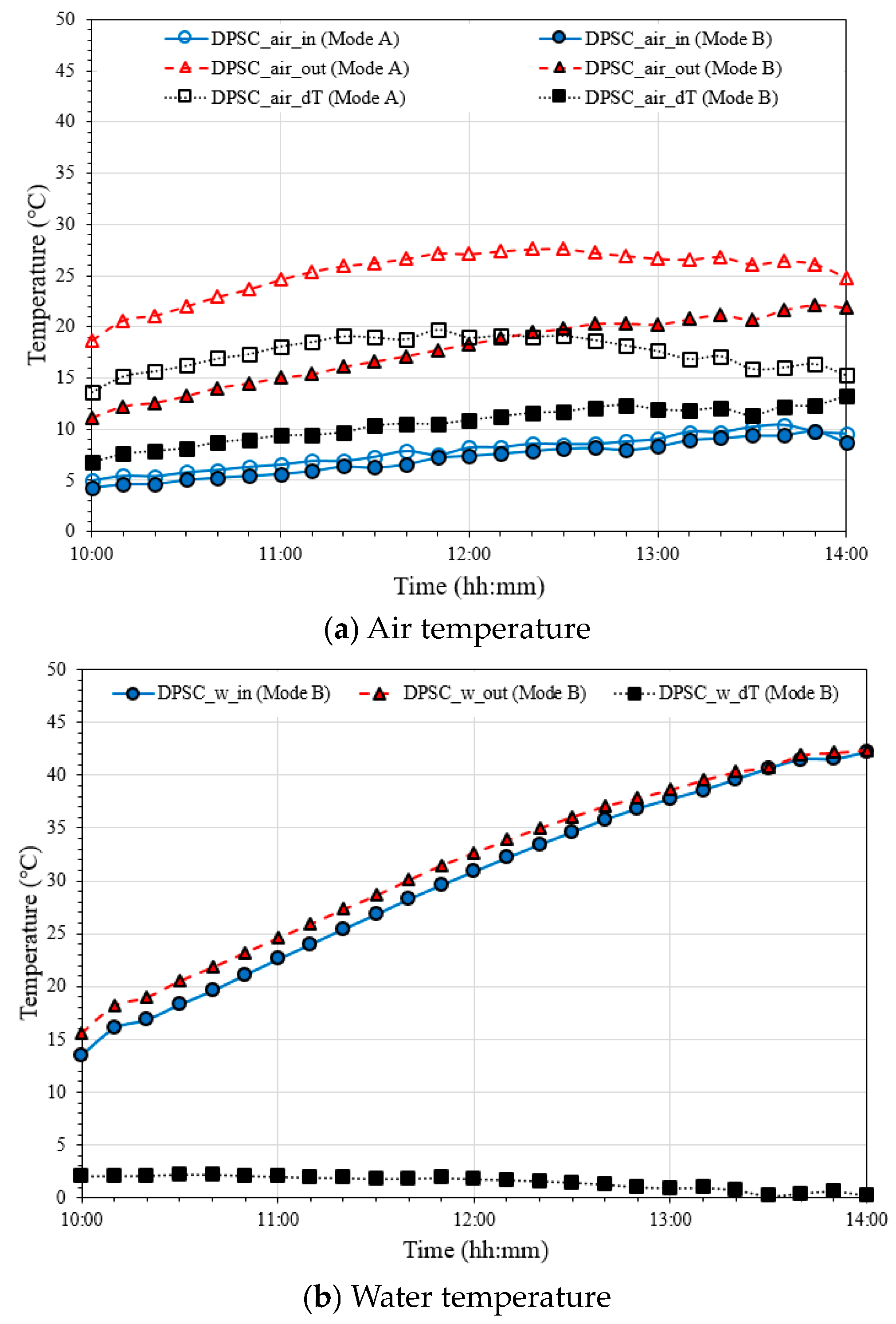

3.2.1. Working Fluid Temperature at DPSC

3.2.2. Heat Gain of Fluids

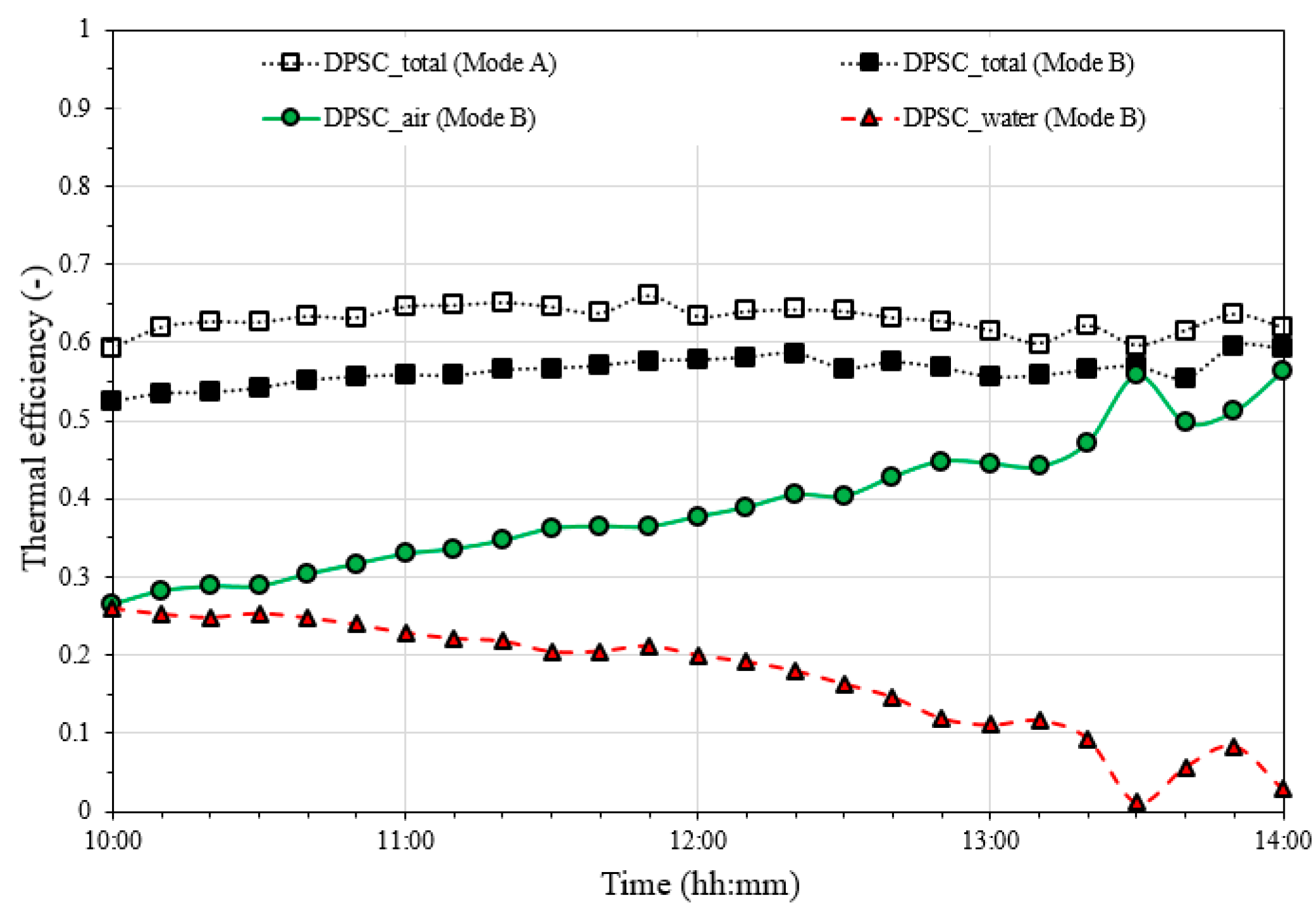

3.2.3. Thermal Efficiency

3.3. Performance of the SAHP

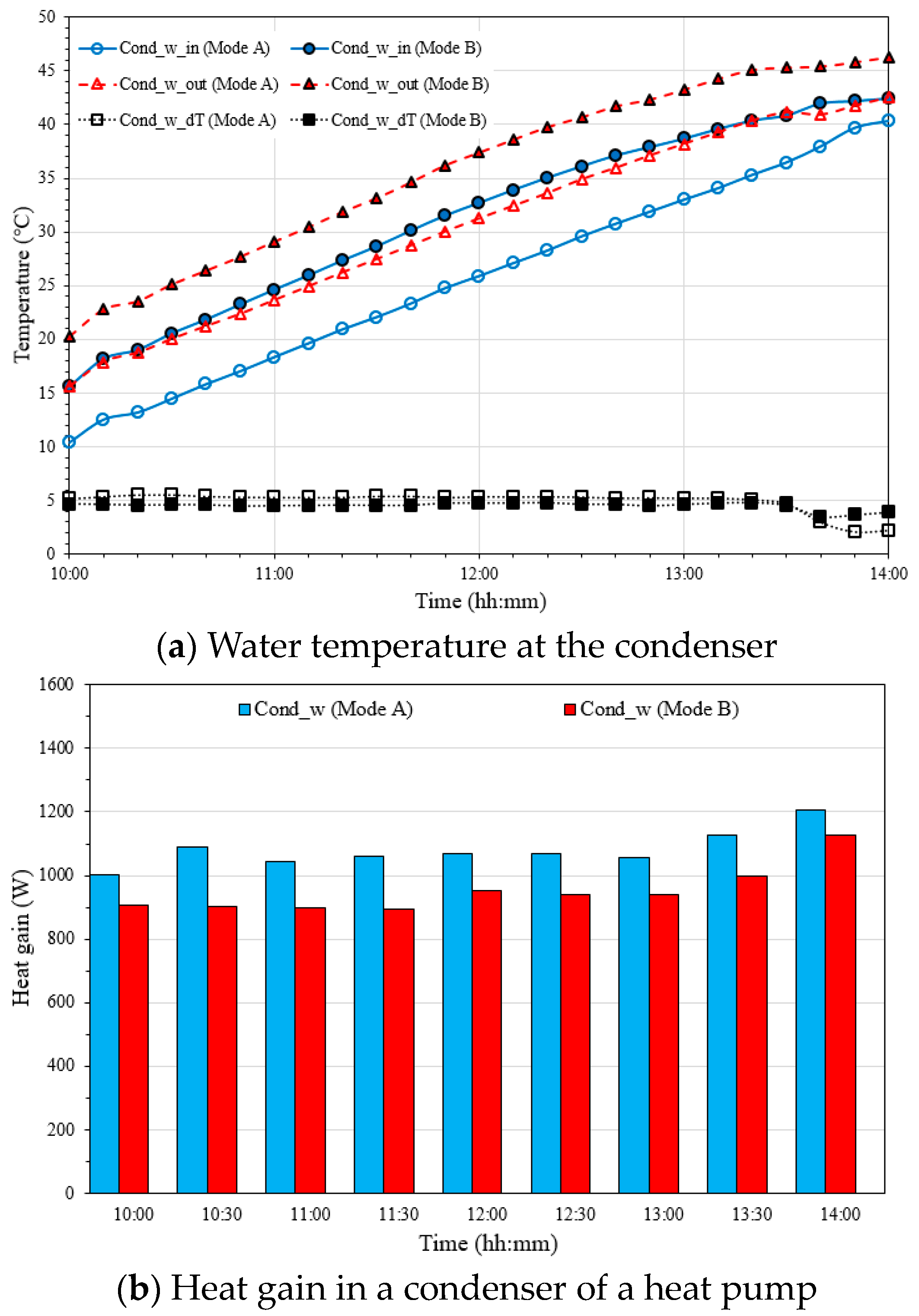

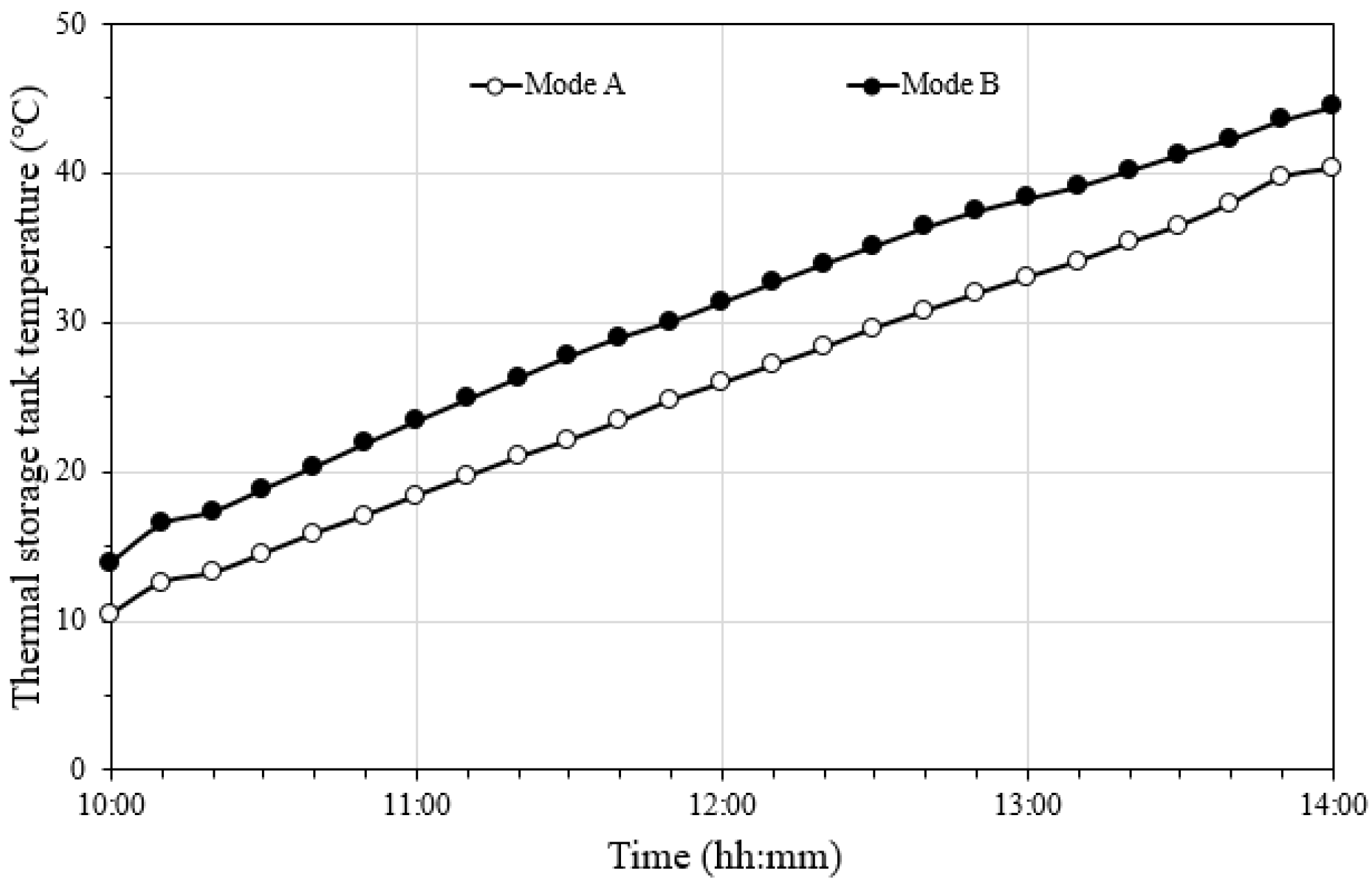

3.3.1. Heating Capacity

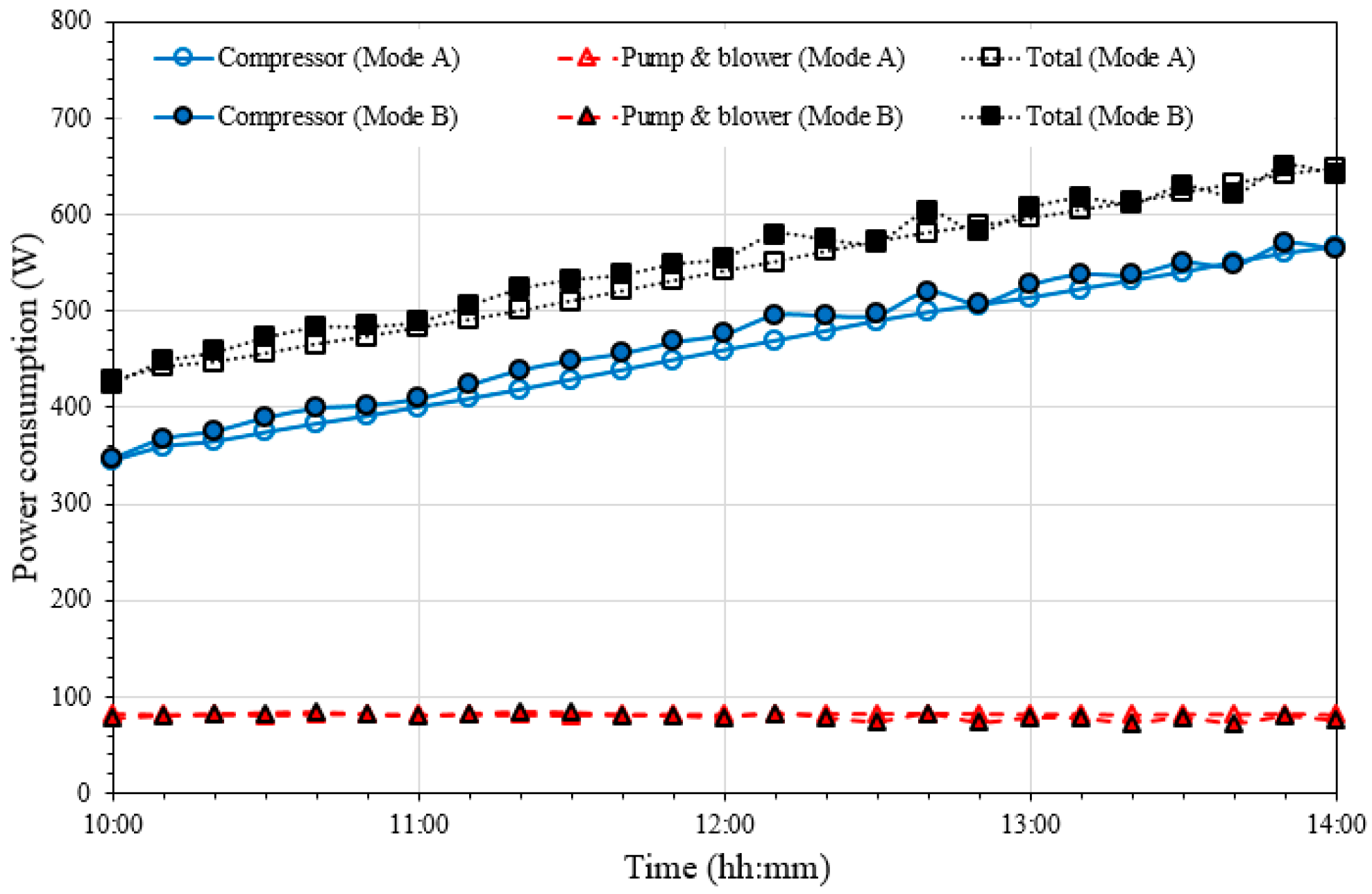

3.3.2. Power Consumption

3.3.3. Coefficient of Performance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbols | |

| A | Area (m2) |

| COP | Coefficient of performance (-) |

| Specific heat (J/kg°C) | |

| Solar irradiation (W/m2) | |

| Mass flowrate (kg/s) | |

| Q | Heat transfer rate (W) |

| T | Temperature (°C) |

| W | Power consumption (W) |

| Greek symbols | |

| η | Thermal efficiency (-) |

| Subscripts | |

| a | Air |

| c | Collector |

| cond | Condenser |

| comp | Compressor |

| DPSC | Dual-purpose solar collector |

| HP | Heat pump |

| sys | System |

| w | Water |

References

- Yoon, S.; Kim, M.; Seo, J.; Kim, S.; Lee, H.; Lee, J.; Lee, B.J. Performance Analysis of a Hybrid HVAC System Consisting of a Solar Thermal Collector and a Radiative Cooling Panel. Energy Build. 2021, 241, 110921. [Google Scholar] [CrossRef]

- Assari, M.R.; Basirat Tabrizi, H.; Jafari, I. Experimental and Theoretical Investigation of Dual Purpose Solar Collector. Sol. Energy 2011, 85, 601–608. [Google Scholar] [CrossRef]

- Mohajer, A.; Nematollahi, O.; Joybari, M.M.; Hashemi, S.A.; Assari, M.R. Experimental Investigation of a Hybrid Solar Drier and Water Heater System. Energy Convers. Manag. 2013, 76, 935–944. [Google Scholar] [CrossRef]

- Nematollahi, O.; Alamdari, P.; Assari, M.R. Experimental Investigation of a Dual Purpose Solar Heating System. Energy Convers. Manag. 2014, 78, 359–366. [Google Scholar] [CrossRef]

- Zhang, D.; Li, J.; Gao, Z.; Wang, L.; Nan, J. Thermal Performance Investigation of Modified Flat Plate Solar Collector with Dual-Function. Appl. Therm. Eng. 2016, 108, 1126–1135. [Google Scholar] [CrossRef]

- Hu, Z.; Luo, B.; He, W.; Hu, D.; Ji, J.; Ma, J. Performance Study of a Dual-Function Roof Solar Collector for Chinese Traditional Buildings Application. Appl. Therm. Eng. 2018, 128, 179–188. [Google Scholar] [CrossRef]

- Hao, W.; Lu, Y.; Lai, Y.; Yu, H.; Lyu, M. Research on Operation Strategy and Performance Prediction of Flat Plate Solar Collector with Dual-Function for Drying Agricultural Products. Renew. Energy 2018, 127, 685–696. [Google Scholar] [CrossRef]

- Ma, J.; Zhao, Q.; Su, Y.; Ji, J.; He, W.; Hu, Z.; Fang, T.; Wang, H. The Thermal Behavior of a Dual-Function Solar Collector Integrated with Building: An Experimental and Numerical Study on the Air Heating Mode. Energies 2018, 11, 2402. [Google Scholar] [CrossRef]

- Pathak, P.K.; Chandra, P.; Raj, G. Comparative Analysis of Single- and Dual-Purpose Corrugated Plate Solar Collector by Force Convection. Heat Transf.-Asian Res. 2019, 48, 2387–2401. [Google Scholar] [CrossRef]

- Pathak, P.K.; Chandra, P.; Raj, G. Comparative Analysis of Modified and Convectional Dual Purpose Solar Collector: Energy and Exergy Analysis. Energy Sources Part A Recover. Util. Environ. Eff. 2019, 1–17. [Google Scholar] [CrossRef]

- Shemelin, V.; Matuska, T. Performance Modelling of Dual Air/Water Collector in Solar Water and Space Heating Application. Int. J. Photoenergy 2019, 2019, 8560193. [Google Scholar] [CrossRef]

- Somwanshi, A.; Sarkar, N. Thermal Performance of a Dual-Purpose Collector-Cum-Storage Type Air-Water Heater. Appl. Therm. Eng. 2020, 171, 115094. [Google Scholar] [CrossRef]

- Hasan, M.M.; Hriczó, K. A Literature Review of a Dual-Purpose Solar Collector. Veh. Automot. Eng. 2022, 3, 302–321. [Google Scholar]

- Çomakli, Ŏ.; Kaygusuz, K.; Ayhan, T.; Arslan, F. Experimental Investigation and a Dynaminc Simulation of the Solar-Assisted Energy-Storaged Heat Pump System. Sol. Energy 1993, 51, 147–158. [Google Scholar] [CrossRef]

- Li, Y.W.; Wang, R.Z.; Wu, J.Y.; Xu, Y.X. Experimental Performance Analysis and Optimization of a Direct Expansion Solar-Assisted Heat Pump Water Heater. Energy 2007, 32, 1361–1374. [Google Scholar] [CrossRef]

- Dikici, A.; Akbulut, A. Performance Characteristics and Energy-Exergy Analysis of Solar-Assisted Heat Pump System. Build. Environ. 2008, 43, 1961–1972. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, Y.Q.; Liang, G.F.; Li, J.R.; Sun, S.F.; Chen, G.M. Development and Experimental Validation of a Novel Indirect-Expansion Solar-Assisted Multifunctional Heat Pump. Energy Build. 2011, 43, 300–304. [Google Scholar] [CrossRef]

- Fernández-Seara, J.; Piñeiro, C.; Alberto Dopazo, J.; Fernandes, F.; Sousa, P.X.B. Experimental Analysis of a Direct Expansion Solar Assisted Heat Pump with Integral Storage Tank for Domestic Water Heating under Zero Solar Radiation Conditions. Energy Convers. Manag. 2012, 59, 1–8. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, J.; Zhou, G.; Zhang, C.; Wan, W. Performance of a Solar Air Composite Heat Source Heat Pump System. Renew. Energy 2016, 87, 1053–1058. [Google Scholar] [CrossRef]

- Hematian, A.; Ajabshirchi, Y.; Ranjbar, S.F.; Taki, M. An Experimental Analysis of a Solar-Assisted Heat Pump (SAHP) System for Heating a Semisolar Greenhouse. Energy Sources Part A Recover. Util. Environ. Eff. 2019, 43, 1724–1744. [Google Scholar] [CrossRef]

- Singh, A.; Sarkar, J.; Sahoo, R.R. Experimental Energy, Exergy, Economic and Exergoeconomic Analyses of Batch-Type Solar-Assisted Heat Pump Dryer. Renew. Energy 2020, 156, 1107–1116. [Google Scholar] [CrossRef]

- Sharaborova, E.S.; Shepitko, T.V.; Loktionov, E.Y. Experimental Proof of a Solar-Powered Heat Pump System for Soil Thermal Stabilization. Energies 2022, 15, 2118. [Google Scholar] [CrossRef]

- Choi, H.U.; Kim, Y.B.; Son, C.H.; Yoon, J.I.; Choi, K.H. Experimental Study on the Performance of Heat Pump Water Heating System Coupled with Air Type PV/T Collector. Appl. Therm. Eng. 2020, 178, 115427. [Google Scholar] [CrossRef]

- Choi, H.U.; Choi, K.H. Numerical Study on the Performance of a Solar-Assisted Heat Pump Coupled with a Photovoltaic-Thermal Air Heater. Energy 2023, 285, 129480. [Google Scholar] [CrossRef]

- Wu, J.; Shen, M.; Feng, J. The Application of a Solar–Air-Source Heat Pump Dual-Supply Heating System in a High-Cold Area in China. Processes 2023, 11, 737. [Google Scholar] [CrossRef]

- Vengadesan, E.; Bharathwaj, D.; Kumar, B.S.; Senthil, R. Experimental Study on Heat Storage Integrated Flat Plate Solar Collector for Combined Water and Air Heating in Buildings. Appl. Therm. Eng. 2022, 216, 119105. [Google Scholar] [CrossRef]

| Parameter | Specification |

|---|---|

| Size of the DPSC (L × W × H) | 1980 mm × 982 mm × 100 mm |

| Area of an absorber plate | 1.91 m2 |

| Distance between glass and absorber plate | 20 mm |

| Absorber plate thickness | 0.7 mm (copper plate) |

| Outer diameter of water pipe | 12.7 mm |

| Inner diameter of water pipe | 10 mm |

| Number of pipes | 9 ea |

| Height of the airflow path | 70 mm |

| Width of each airflow path | 960 mm |

| Fin height | 70 mm |

| Fin thickness | 2 mm |

| Item | Specification | Value |

|---|---|---|

| Compressor | Model name | 39A172A |

| Input power | 695 W | |

| Condenser | Type | Plate heat exchanger |

| Number of the plate | 20 ea | |

| Size (W × H × L) | 77 mm × 207 mm × 55 mm | |

| Evaporator | Type | Fin-tube heat exchanger |

| Size (W × H × L) | 230 mm × 210 mm × 20 mm |

| Operating Mode | Mode A | Mode B |

|---|---|---|

| Date (Day/Month/Year) | 10/02/2024 | 11/02/2024 |

| Time (hh:mm) | 10:00~14:00 | |

| Air mass flowrate (kg/s) | 0.0635 | 0.0609 |

| water flow rate (kg/s) | 0.05 | 0.05 |

| Initial thermal storage tank temperature (°C) | 10.42 | 13.89 |

| Hot water tank capacity (L) | 150 | |

| Instrument | Model | Range | Accuracy | Uncertainty |

|---|---|---|---|---|

| Pyranometer | MS-802 (EKO instrument, MS-802, Tokyo, Japan) | 0~4000 W/m2 | ±10 W/m2 | ±2% |

| Thermocouple | T-type | −270~370 °C | ±1 °C | ±0.75% |

| Anemometer | Kanomax 6531-2G (Kanomax Japan Inc., 6531-2G, Suita, Japan) | 0.01~30 m/s | ±0.6 m/s | ±2% |

| Turbine flow sensor | GMP (Nuritech, GMP, Siheung, Republic of Korea) | 3.8~38 L/min | ±0.4 L/min | ±1% |

| Powermeter | PW3336 (Hioki, PW3336, Nagano, Japan) | 3 W~100 kW | ±0.05 W | ±0.1% |

| Data logger | Agilent 34972A (keysight, 34972A, Santa Rosa, CA, USA) | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moon, K.-A.; Kim, S.-B.; Choi, H.-U.; Choi, K.-H. Experimental Study on the Heat Pump Performance Combined with Dual-Purpose Solar Collector. Energies 2024, 17, 3038. https://doi.org/10.3390/en17123038

Moon K-A, Kim S-B, Choi H-U, Choi K-H. Experimental Study on the Heat Pump Performance Combined with Dual-Purpose Solar Collector. Energies. 2024; 17(12):3038. https://doi.org/10.3390/en17123038

Chicago/Turabian StyleMoon, Kwang-Am, Seong-Bhin Kim, Hwi-Ung Choi, and Kwang-Hwan Choi. 2024. "Experimental Study on the Heat Pump Performance Combined with Dual-Purpose Solar Collector" Energies 17, no. 12: 3038. https://doi.org/10.3390/en17123038

APA StyleMoon, K.-A., Kim, S.-B., Choi, H.-U., & Choi, K.-H. (2024). Experimental Study on the Heat Pump Performance Combined with Dual-Purpose Solar Collector. Energies, 17(12), 3038. https://doi.org/10.3390/en17123038