The Contribution of Biogas to the Electricity Supply Chain: An Italian Life Cycle Assessment Database

Abstract

1. Introduction

1.1. Renewable Energy Sources: Biogas as Energy Carrier

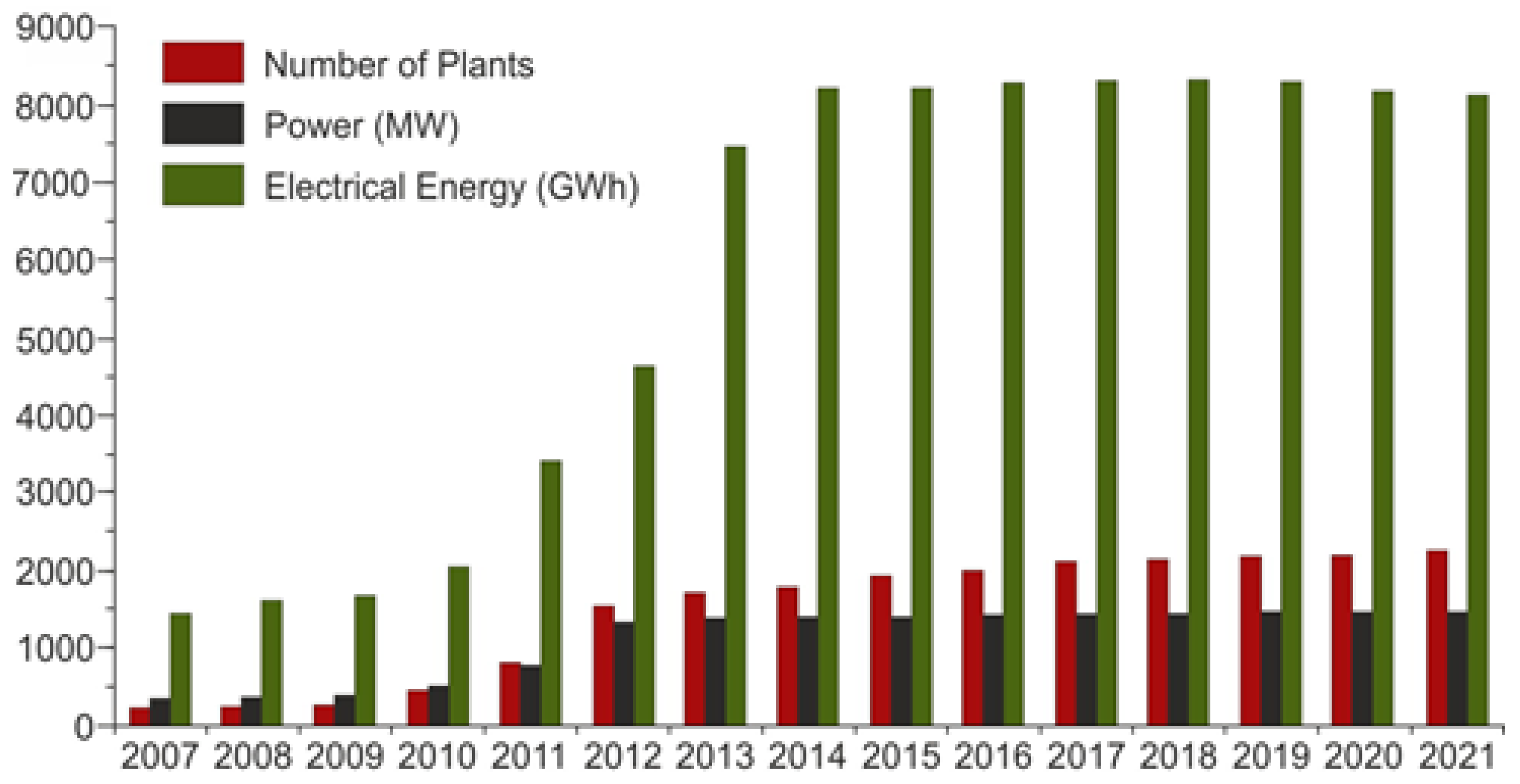

1.2. The Contribution of Biogas to the Italian Electricity Mix

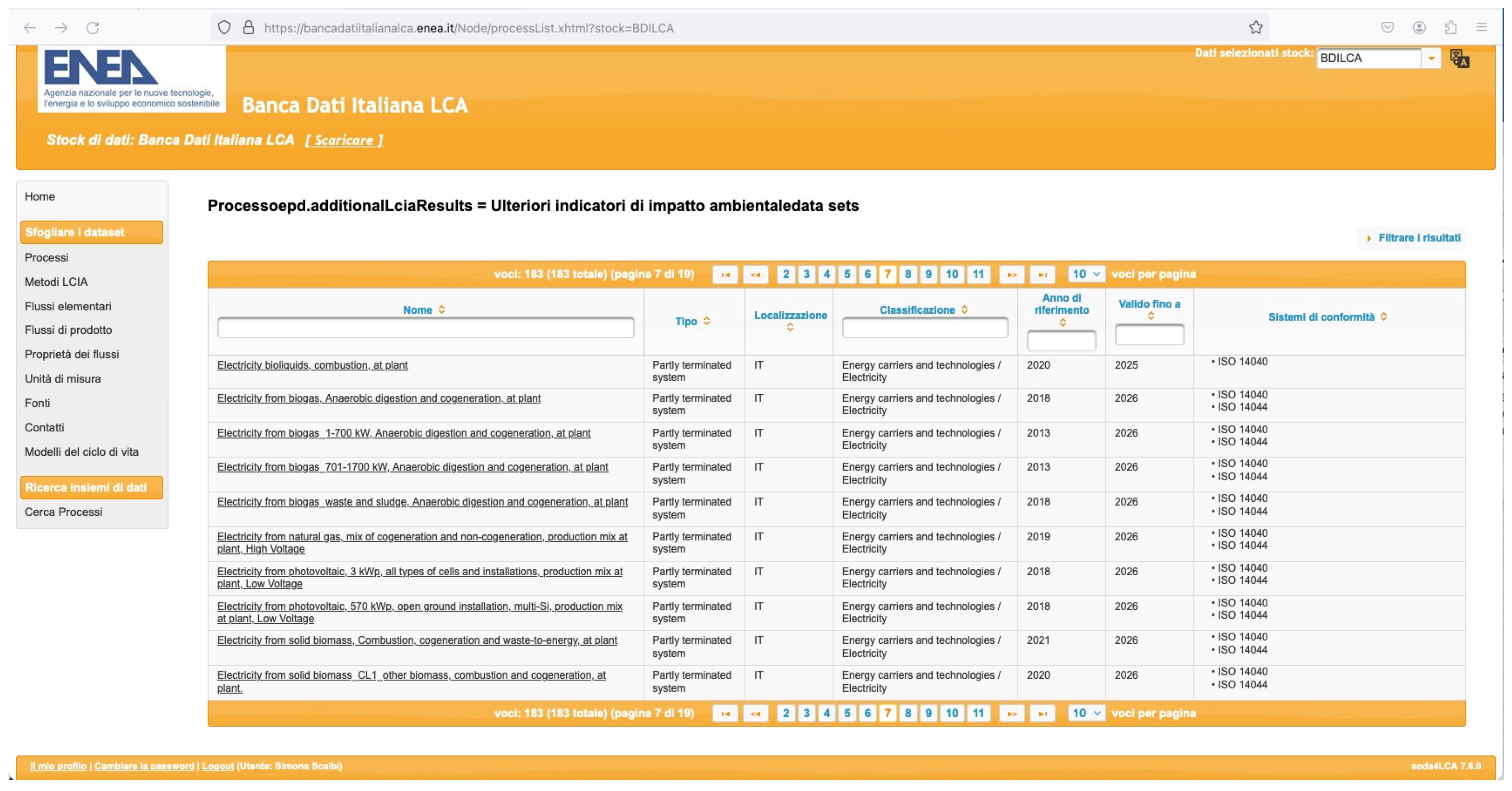

1.3. The Arcadia Project and the Italian LCA Database

2. Data and Method

2.1. The Investigated Case Study

- -

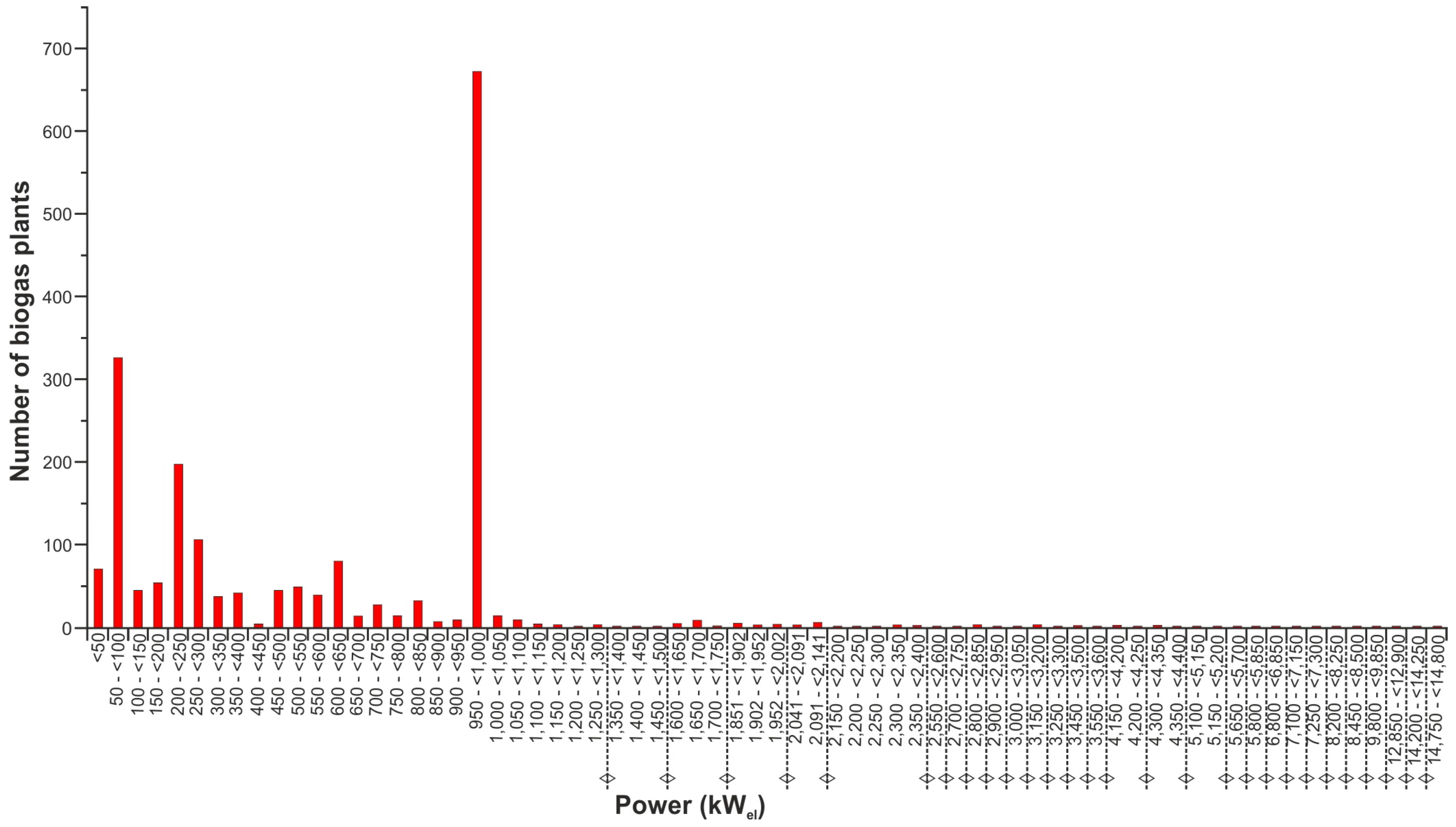

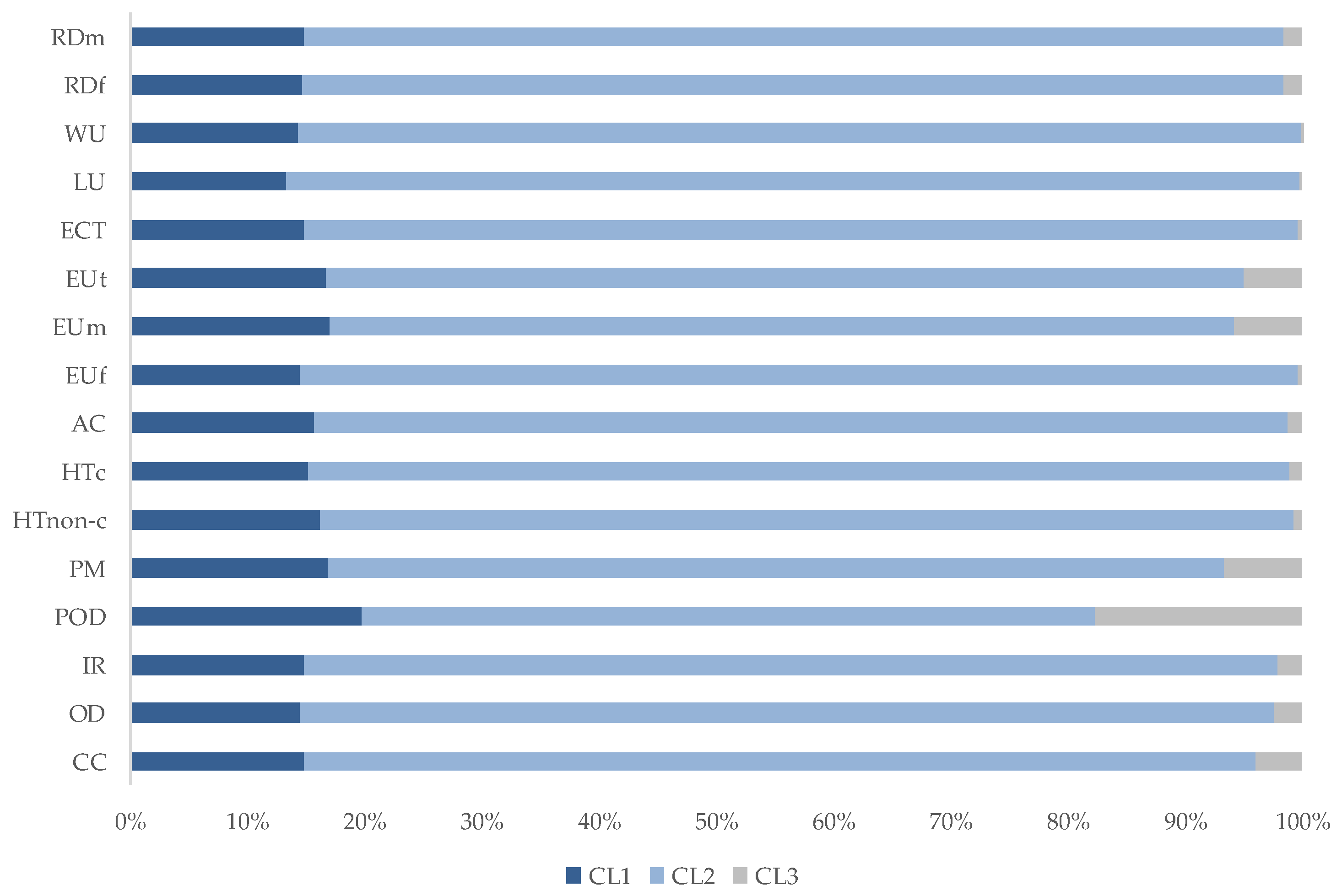

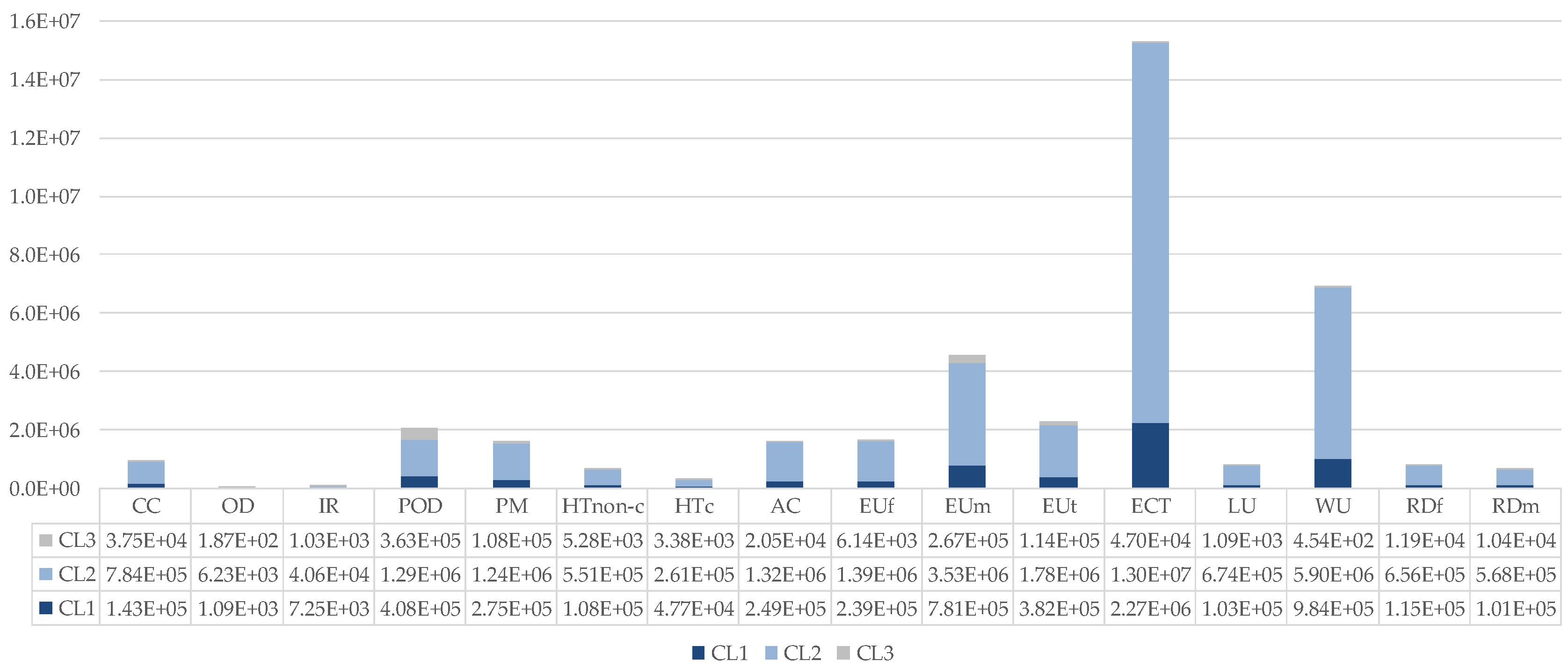

- Class 1 (CL1): Energy production from biogas derived from biomass of agricultural and forestry origin and animal manure in plants with a nominal power in the range of 1–700 kW (this class contributes to electricity production from biogas, in Italy, for 22%);

- -

- Class 2 (CL2): Energy production from biogas derived from biomass of agricultural and forestry origin and animal manure in plants with a nominal power in the range 701–1700 kW (this class contributes to electricity production from biogas, in Italy, for 60%);

- -

- Class 3 (CL3): Energy production from biogas derived from waste and sludge (this class contributes to electricity production from biogas in Italy, for 18%).

2.1.1. Modeling of Unit Processes CL1 and CL2

- CL1: 1 ≤ PNel ≤ 700 kWel, including 1109 plants, with an overall nominal power of 287,067 kWel and an estimated value of electricity production (1803 GWh), equal to approximately 22% of total electricity production from biogas plants in Italy (8379 GWh, data estimated for the year 2020);

- CL2: 701 ≤ PNel ≤ 1700 kWel, including 810 plants, with an overall nominal power of 803,042 kWel and an estimated value of electricity production (5044 GWh), equal to approximately 60% of total electricity production from biogas plants in Italy (8379 GWh, data estimated for the year 2020).

2.2. The LCA Methodology

2.2.1. Goal and Scope Definition

- Biomass production, including collection and transportation to the treatment site;

- Anaerobic digestion process, which converts biomass into biogas and digestate;

- Generation of heat and electricity through a CHP plant. The development of the Combined Heat and Power (CHP) units emerged as a need to increase the economic viability of biogas plants through the use of heat.

2.2.2. LCI

2.2.3. LCIA

3. Results and Interpretation

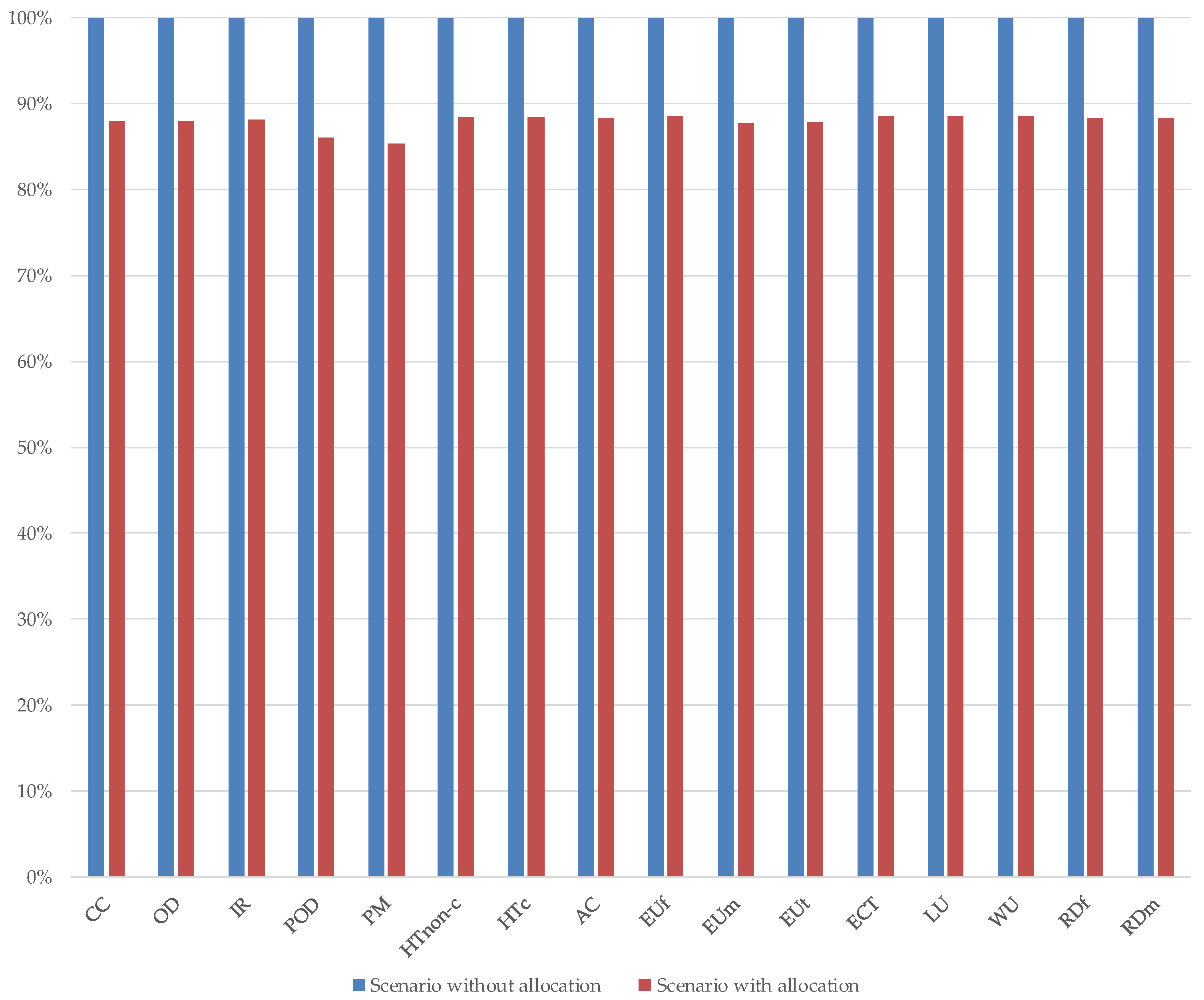

The Sensitivity Analysis

4. Discussion

4.1. Added Value of Environmental Assessments Based on Site-Specific Database

4.2. Future Perspective on Upgrading Biogas to Biomethane

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. ‘Fit for 55’: Delivering the EU’s 2030 Climate Target on the Way to Climate Neutrality. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52021DC0550 (accessed on 3 April 2024).

- Pavičić, J.; Novak Mavar, K.; Brkić, V.; Simon, K. Biogas and Biomethane Production and Usage: Technology Development, Advantages and Challenges in Europe. Energies 2022, 15, 2940. [Google Scholar] [CrossRef]

- IEA—International Energy Agency. Global Energy Review: CO2 Emissions in 2021. Global Emissions Rebound Sharply to Highest ever Level. 2022. Available online: https://www.iea.org/reports/global-energy-review-co2-emissions-in-2021-2 (accessed on 21 March 2023).

- Directive (EU) 2023/2413 of the European Parliament and of the Council of 18 October 2023 Amending Directive (EU) 2018/2001, Regulation (EU) 2018/1999 and Directive 98/70/EC as Regards the Promotion of Energy from Renewable Sources, and Repealing Council Directive (EU) 2015/652. Available online: https://eur-lex.europa.eu/eli/dir/2023/2413/oj (accessed on 24 February 2024).

- Zucaro, A.; Fiorentino, G.; Ulgiati, S. Constraints, impacts and benefits of lignocellulose conversion pathways to liquid biofuels and biochemicals. In Lignocellulosic Biomass to Liquid Biofuels; Yousuf, A., Pirozzi, D., Sannino, F., Eds.; Academic Press: London, UK, 2019; pp. 249–282. ISBN 9780128159361. [Google Scholar]

- Bedoić, R.; Jurić, F.; Ćosić, B.; Pukšec, T.; Čuček, L.; Duić, N. Beyond energy crops and subsidised electricity—A study on sustainable biogas production and utilisation in advanced energy markets. Energy 2020, 201, 117651. [Google Scholar] [CrossRef]

- Commission Regulation (EU) No 147/2013 of 13 February 2013 Amending Regulation (EC) No 1099/2008 of the European Parliament and of the Council on Energy Statistics, as Regards the Implementation of Updates for the Monthly and Annual Energy Statistics. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32013R0147 (accessed on 3 April 2024).

- Szyba, M.; Mikulik, J. Energy Production from Biodegradable Waste as an Example of the Circular Economy. Energies 2022, 15, 1269. [Google Scholar] [CrossRef]

- Battini, F.; Agostini, A.; Boulamanti, K.; Giuntoli, J.; Amaducci, S. Mitigating the environmental impacts of milk production via anaerobic digestion of manure: Case study of a dairy farm in the Po Valley. Sci. Total Environ. 2014, 481, 196–208. [Google Scholar] [CrossRef] [PubMed]

- EurObserv’ER. Employment & Turnover 2020–2022. Available online: https://www.eurobserv-er.org/online-database/ (accessed on 25 June 2023).

- Eurostat. Share of Renewable Energy in Gross Final Energy Consumption. Available online: https://ec.europa.eu/eurostat/web/products-eurostat-news/w/DDN-20230119-1 (accessed on 24 May 2024).

- GSE—Gestore dei Servizi Energetici, S.p.A. Martino dal Verme, Duilio Lipari, Gabriele Lucido, Vincenzo Maio, Vincenzo Surace e Paolo Liberatore. Rapporto Statistico 2021 Energia da Fonti Rinnovabili in Italia. 2023. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/Rapporto%20Statistico%20GSE%20-%20FER%202021.pdf (accessed on 22 June 2023).

- Ministerial Decree of 18 December 2008. Recent Regulatory Developments in Italian Gas and Electricity Sectors. Available online: https://www.gop.it/doc_pubblicazioni/13_4doy3q1fg4_eng.pdf (accessed on 1 April 2024).

- Carlini, M.; Mosconi, E.M.; Castellucci, S.; Villarini, M.; Colantoni, A. An Economical Evaluation of Anaerobic Digestion Plants Fed with Organic Agro-Industrial Waste. Energies 2017, 10, 1165. [Google Scholar] [CrossRef]

- Decreto Ministeriale 6 Luglio 2012—Incentivi per Energia da Fonti Rinnovabili Elettriche non Fotovoltaiche. Available online: https://www.mimit.gov.it/images/stories/normativa/DM_6_luglio_2012_sf.pdf (accessed on 29 November 2021).

- EBA—European Biogas Association. Statistical Report 2023. Available online: https://www.europeanbiogas.eu/eba-statistical-report-2023/ (accessed on 26 March 2023).

- Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions. REPowerEU Plan. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2022%3A230%3AFIN (accessed on 19 December 2023).

- Arcadia. Available online: www.arcadia.enea.it (accessed on 25 February 2023).

- Banca Dati Italiana LCA. Available online: https://bancadatiitalianalca.enea.it/Node/ (accessed on 27 February 2023).

- ILCD International Life Cycle Data System. Available online: https://eplca.jrc.ec.europa.eu/ilcd.html (accessed on 30 March 2022).

- Insola, F.; Bonoli, A.; Buttol, P.; Scalbi, S. Banca dati Italiana LCA: Creazione di dataset sul mix elettrico nazionale. In Proceedings of the Atti del XIV Convegno Della Rete Italiana LCA-IX Convegno Dell’associazione Rete Italiana LCA, Cortina d’Ampezzo, Italy, 9–11 December 2020; ISBN 978-88-8286-416-3. [Google Scholar]

- Ripa, M.; Fiorentino, G.; Vacca, V.; Ulgiati, S. The relevance of site-specific data in Life Cycle Assessment (LCA). The case of the municipal solid waste management in the metropolitan city of Naples (Italy). J. Clean. Prod. 2017, 142, 445–460. [Google Scholar] [CrossRef]

- Ning, S.-K.; Chang, N.-B.; Hung, M.-C. Comparative streamlined life cycle assessment for two types of municipal solid waste incinerator. J. Clean. Prod. 2013, 53, 56–66. [Google Scholar] [CrossRef]

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A.; Di Capua, R.; Saija, G.; Salomone, R.; Primerano, P.; Petti, L.; Raggi, A.; Casolani, N.; et al. Life cycle inventory data for the Italian agri-food sector: Background, sources and methodological aspects. Int. J. Life Cycle Assess. 2022. [Google Scholar] [CrossRef]

- Scalbi, S.; Buttol, P.; Rinaldi, C. La banca dati italiana LCA BDI-LCA. In Proceedings of the Atti del XV Convegno della rete Italiana LCA- IX Convegno Dell’associazione Rete Italiana LCA, Università Mediterranea di Reggio Calabria, Reggio Calabria, Italy, 22–24 September 2021; ISBN 979122004564. [Google Scholar]

- Flagship 2a. Available online: https://www.lifecycleinitiative.org/activities/phase-iii/data-and-database-management/ (accessed on 8 May 2024).

- Technical Helpdesk for National LCA Databases. Available online: https://www.oneplanetnetwork.org/knowledge-centre/projects/technical-helpdesk-national-lca-databases (accessed on 8 May 2024).

- Global LCA Data Access Network. Available online: https://www.globallcadataaccess.org/ (accessed on 8 May 2024).

- Florio, C.; Fiorentino, G.; Corcelli, F.; Ulgiati, S. A Life Cycle Assessment of Biomethane Production from Waste Feedstock Through Different Upgrading Technologies. Energies 2019, 12, 718. [Google Scholar] [CrossRef]

- Ncube, A.; Cocker, J.; Ellis, D.; Fiorentino, G. Biogas from source separated organic waste within a circular and life cycle perspective. A case study in Ontario, Canada. Environ. Sustain. Indic. 2021, 11, 100134. [Google Scholar] [CrossRef]

- Pirelli, T.; Chiumenti, A.; Morese, M.M.; Bonati, G.; Fabiani, S.; Pulighe, G. Environmental sustainability of the biogas pathway in Italy through the methodology of the Global Bioenergy Partnership. J. Clean. Prod. 2021, 318, 128483. [Google Scholar] [CrossRef]

- Sica, D.; Esposito, B.; Supino, S.; Malandrino, O.; Sessa, M.R. Biogas-based systems: An opportunity towards a post-fossil and circular economy perspective in Italy. Energy Policy 2023, 182, 113719. [Google Scholar] [CrossRef]

- GSE—Gestore dei Servizi Energetici, S.p.A. Alessio Agrillo, Martino dal Verme, Paolo Liberatore, Duilio Lipari, Gabriele Lucido, Vincenzo Maio, Vincenzo Surace. Rapporto Statistico 2019 Fonti Rinnovabili. 2021. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/Rapporto%20Statistico%20GSE%20-%20FER%202019.pdf (accessed on 25 March 2023).

- Gestore Servizi Energetici (GSE)—Atlaimpianti 2020. Available online: https://www.gse.it/dati-e-scenarios/atlaimpianti) (accessed on 25 November 2023).

- ILCD Handbook, European Commission, Joint Research Centre and Institute for Environment and Sustainability, “International Reference Life Cycle Data System (ILCD) Handbook—General Guide for Life Cycle Assessment—Detailed Guidance”, First Edition March 2010. Available online: https://eplca.jrc.ec.europa.eu/uploads/ILCD-Handbook-General-guide-for-LCA-DETAILED-GUIDANCE-12March2010-ISBN-fin-v1.0-EN.pdf (accessed on 2 July 2024).

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO (International Organization for Standardization): Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 20 December 2023).

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO (International Organization for Standardization): Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 20 December 2023).

- Roos, A.; Ahlgren, S. Consequential life cycle assessment of bioenergy systems—A literature review. J. Clean. Prod. 2018, 189, 358–373. [Google Scholar] [CrossRef]

- Alcaraz, M.L.; Noshadravan, A.; Zgola, M.; Kirchain, R.E.; Olivetti, E.A. Streamlined life cycle assessment: A case study on tablets and integrated circuits. J. Clean. Prod. 2018, 200, 819–826. [Google Scholar] [CrossRef]

- Ekvall, T.; Assefa, G.; Björklund, A.; Eriksson, O.; Finnveden, G. What life-cycle assessment does and does not do in assessments of waste management. Waste Manag. 2007, 27, 989–996. [Google Scholar] [CrossRef] [PubMed]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in life cycle assessment. J. Environ Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Aziz, N.I.H.A.; Hanafiah, M.M.; Gheewala, S.H.; Ismail, H. Bioenergy for a Cleaner Future: A Case Study of Sustainable Biogas Supply Chain in the Malaysian Energy Sector. Sustainability 2020, 12, 3213. [Google Scholar] [CrossRef]

- Reichhalter, H.; Bozzo, A.; Dal Savio, S.; Guerra, T. Analisi Energetica, Ambientale ed Economica di Impianti a Biogas in Provincia di Bolzano–Relazione Conclusiva. 2011. Available online: http://www.provincia.bz.it/agricoltura/download/Bilancio_ecologico_di_impianti_a_biogas.pdf (accessed on 20 December 2021).

- Herambiente, T. Dichiarazione Ambientale 2020 Relativa al Complesso Impiantistico Via Traversagno 30, Località Voltana, Lugo (RA). 2020. Available online: https://ha.gruppohera.it/binary/hera_herambiente_r15/dichiarazioni_ambientali/Dichiarazione_Ambientale_Via_Traversagno_Voltana.1597749927.pdf (accessed on 20 December 2021).

- Busato, J. Analisi LCA del Biogas Prodotto da un Mix Agrozootecnico in un’azienda del Settore Agricolo Considerando Diversi Utilizzi Finali. Master’s Thesis, University of Padova, Padua, Italy, 2020. [Google Scholar]

- Lijó, L.; González-García, S.; Bacenetti, J.; Fiala, M.; Feijoo, G.; Lema, J.M.; Moreira, M.T. Life Cycle Assessment of electricity production in Italy from anaerobic co-digestion of pig slurry and energy crops. Renew. Energy 2014, 68, 625–635. [Google Scholar] [CrossRef]

- ISPRA (Istituto Superiore per la Protezione e la Ricerca Ambientale, Rome, Italy). Personal communication, 2019.

- National Inventory Report (NIR) 2021. Available online: https://unfccc.int/documents/271491. (accessed on 6 July 2022).

- Informative Inventory Report (IIR) 2021. Available online: https://www.isprambiente.gov.it/files2021/pubblicazioni/rapporti/rapp-342-2021.pdf (accessed on 8 July 2022).

- Decreto Ministeriale 2 Marzo 2010—Attuazione Della Legge 27 Dicembre 2006, n. 296, Sulla Tracciabilità Delle Biomasse per la Produzione di Energia Elettrica. Available online: https://www.politicheagricole.it/flex/cm/pages/ServeBLOB.php/L/IT/IDPagina/13563 (accessed on 23 October 2022).

- Progetto Biomasse. ENAMA (Ente Nazionale per la Meccanizzazione Agricola). Available online: https://www.progettobiomasse.it (accessed on 4 September 2021).

- Jungbluth, N.; Chudacoff, M.; Dauriat, A.; Dinkel, F.; Doka, G.; Faist Emmenegger, M.; Gnansounou, E.; Kljun, N.; Schleiss, K.; Spielmann, M.; et al. Life Cycle Inventories of Bioenergy; coinvent report No.17; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar]

- Bejan, A. Exergy analysis of thermal, chemical and metallurgical processes. Int J Heat Fluid Flow 1989, 10, 87–88. [Google Scholar] [CrossRef]

- Zampori, L.; Pant, R. Suggestions for Updating the Product Environmental Footprint (PEF) Method; EUR 29682 EN; Publications Office of the European Union: Luxembourg, 2019; ISBN 978-92-76-00654-1. JRC115959. [Google Scholar] [CrossRef]

- Claus, S.; Taube, F.; Wienforth, B.; Svoboda, N.; Sieling, K.; Kage, H.; Senbayram, M.; Dittert, K.; Gericke, D.; Pacholski, A.; et al. Life-cycle assessment of biogas production under the environmental conditions of northern Germany: Greenhouse gas balance. J. Agric. Sci. 2014, 152 (Suppl. S1), 172–181. [Google Scholar] [CrossRef]

- Björnsson, L.; Prade, T. Introduction of grass-clover crops as biogas feedstock in cereal-dominated crop rotations. Part II: Effects on greenhouse gas emissions. In Proceedings of the 9th International Conference on Life Cycle Assessment in the Agri-Food Sector (LCA Food 2014), San Francisco, CA, USA, 8–10 October 2014; pp. 8–10, ISBN 978-0-9882145-7-6. [Google Scholar]

- Forte, A.; Zucaro, A.; Faugno, S.; Basosi, R.; Fierro, A. Carbon footprint and fossil energy consumption of bio-ethanol fuel production from Arundo donax L. crops on marginal lands of Southern Italy. Energy 2018, 150, 222–235. [Google Scholar] [CrossRef]

- Meisterl, K.; Sastre, S.; Puig-Ventosa, I.; Chifari, R.; Martínez Sánchez, L.; Chochois, L.; Fiorentino, G.; Zucaro, A. Circular Bioeconomy in the Metropolitan Area of Barcelona: Policy Recommendations to Optimize Biowaste Management. Sustainability 2024, 16, 1208. [Google Scholar] [CrossRef]

- Duval-Dachary, S.; Beauchet, S.; Lorne, D.; Salou, T.; Helias, A.; Pastor, A. Life cycle assessment of bioenergy with carbon capture and storage systems: Critical review of life cycle inventories. Renew. Sustain. Energy Rev. 2023, 183, 113415. [Google Scholar] [CrossRef]

- Kozuch, A.; Cywicka, D.; Adamowicz, K.; Wieruszewski, M.; Wysocka-Fijorek, E.; Kiełbasa, P. The Use of Forest Biomass for Energy Purposes in Selected European Countries. Energies 2023, 16, 5776. [Google Scholar] [CrossRef]

- Forfora, N.; Azuaje, I.; Vivas, K.A.; Vera, R.E.; Brito, A.; Venditti, R.; Kelley, S.; Tu, Q.; Woodley, A.; Gonzale, R. Evaluating biomass sustainability: Why below-ground carbon sequestration matters. J. Clean Prod. 2024, 439, 140677. [Google Scholar] [CrossRef]

- Gradin, K.T.; Björklund, A. The common understanding of simplification approaches in published LCA studies—A review and mapping. Int. J. Life Cycle Assess 2021, 26, 50–63. [Google Scholar] [CrossRef]

- Net-Zero Industry Act. Available online: https://european-union.europa.eu/index_en (accessed on 24 April 2023).

- REPowerEU: Affordable, Secure and Sustainable Energy for Europe. Available online: https://www.europeanbiogas.eu/the-repowereu-puts-forward-a-biomethane-action-plan-to-scale-up-the-sector-by-2030/ (accessed on 7 April 2024).

- Biomethane Industrial Partnership. Available online: https://bip-europe.eu/ (accessed on 8 April 2024).

- European Biogas Association (EBA). EBA Statistical Report 2021. Available online: https://www.europeanbiogas.eu/eba-statistical-report-2021/ (accessed on 8 April 2024).

- Alberici, S.; Grimme, W.; Toop, G. Biomethane Production Potentials in the EU—Feasibility of REPowerEU 2030 Targets, Production Potentials in the Member Biomethane Production Potentials in the EU. A Gas for Climate Report 2022. Available online: https://www.europeanbiogas.eu/wp-content/uploads/2022/07/GfC_national-biomethane-potentials_070722.pdf (accessed on 21 September 2023).

- Motola, V.; Scarlat, N.; Hurtig, O.; Buffi, M.; Georgakaki, A.; Letout, S.; Mountraki, A.; Joanny Ordonez, G. Clean Energy Technology Observatory: Bioenergy in the European Union—2022 Status Report on Technology Development, Trends, Value Chains and Markets. Publications Office of the European Union: Luxembourg, 2022. [CrossRef]

- European Biogas Association (EBA). Statistical Report 2022 Tracking Biogas and Biomethane 2022. Available online: https://www.europeanbiogas.eu/__trashed-3/ (accessed on 9 May 2024).

- Ardolino, F.; Cardamone, G.F.; Parrillo, F.; Arena, U. Biogas-to-biomethane upgrading: A comparative review and assessment in a life cycle perspective. Renew. Sustain. Energy Rev. 2021, 139, 110588. [Google Scholar] [CrossRef]

- Ministry of Environment and Energy Security. Directorial Decree n 23, 13 January 2023 “Approval of the Application Regulations of Ministerial Decree no 340 of 15 September 2022 Containing Provisions to Encourage the Introduction of Biomethane into the Natural Gas Network”. Available online: https://www.mase.gov.it/bandi/decreto-direttoriale-n-23-del-13-gennaio-2023-di-approvazione-delle-regole-applicative-del (accessed on 14 May 2021).

| Continent | Country | Name | Website |

|---|---|---|---|

| Europe | France | Base-Cabone | http://www.bilans-ges.ademe.fr/en (accessed on 1 April 2024) |

| Germany | OKOBAUDAT-Sustainable Construction Information Portal | https://www.oekobaudat.de/en.html (accessed on 1 April 2024) | |

| Asia | China | CLCD-Chinese Life Cycle Database | http://www.ike-global.com/products-2/chinese-lca-database-clcd (accessed on 1 April 2024) |

| Thailand | Thai National LCI | https://www.nstda-tiis.or.th/en/lci-database/ (accessed on 1 April 2024) | |

| Japan | IDEA v.2 | http://idea-lca.com/features/?lang=en/#japanese-database (accessed on 1 April 2024) | |

| India | LCA data collection for textiles and agriculture (2017–2018) | Included in EcoInvent DB | |

| America | U.S.A. | U.S. Life Cycle Inventory (LCI) | https://www.nrel.gov/lci/ (accessed on 1 April 2024) |

| Canada | Canadian Raw Material Database | https://uwaterloo.ca/canadian-raw-materials-database/ (accessed on 1 April 2024) | |

| Brasil | SICV-Banco Nacional de Inventários do Ciclo de Vida | https://www.gov.br/ibict/pt-br/central-de-conteudos/noticias/2023/maio/sicv-brasil-amplia-sua-base-de-inventarios-do-ciclo-de-vida (accessed on 1 April 2024) | |

| Peru | Peru LCA database | http://perulca.com/registro/ (accessed on 1 April 2024) | |

| Oceania | Australia | AusLCI–Australian National LCI Database | http://www.auslci.com.au/ (accessed on 1 April 2024) |

| Input/Output Flows | Unit | CL1 | CL2 | CL3 |

|---|---|---|---|---|

| Inputs | ||||

| Biomass a | ||||

| Maize (grain + silage) | ton | 1.46 × 10−3 | 2.31 × 10−3 | |

| Rye grain | ton | 1.87 × 10−4 | 3.40 × 10−4 | |

| Sweet sorghum (grain + stem) | ton | 9.13 × 10−5 | 4.62 × 10−4 | |

| Wheat grain | ton | - | 8.90 × 10−5 | |

| Barley grain | ton | - | 7.97 × 10−6 | |

| Sugar beet | ton | - | 7.86 × 10−6 | |

| Grass silage, organic | ton | - | 1.28 × 10−4 | |

| Straw, stand-alone | ton | - | 9.60 × 10−7 | |

| Livestock manure | ton | 3.62 × 10−3 | 1.34 × 10−3 | - |

| Agro-industrial waste | ton | 6.74 × 10−4 | 3.12 × 10−3 | - |

| Water (vegetable, industrial, washing) | ton | 2.13 × 10−4 | 4.14 × 10−4 | - |

| Biomass from waste and sludge | ton | - | - | 5.08 × 10−3 |

| Anaerobic digestion plant b | p | 2.29 × 10−8 | 3.22 × 10−8 | 6.70 × 10−8 |

| Cogeneration plant c | ||||

| CHP, electricity production unit | kWh | 1.11 | 1.11 | 1.33 |

| CHP, heat production unit | MJ | 4.01 | 3.22 | 6.99 |

| Lubricant oil d | kg | 4.02 × 10−4 | 9.33 × 10−4 | 8.40 × 10−3 |

| Transport e | ||||

| Transport, freight, lorry > 32 metric ton, euro6 | tkm | 4.24 × 10−2 | 9.99 × 10−2 | 3.56 × 10−1 |

| Outputs | ||||

| Energy production | ||||

| Electricity | kWh | 1 | 1 | 1 |

| Heat | MJ | 3.41 | 2.73 | 6.31 |

| Emissions to air f | ||||

| Carbon dioxide, biogenic | kg | 4.31 × 10−1 | 3.89 × 10−1 | 5.95 × 10−1 |

| Methane, biogenic | kg | 2.17 × 10−3 | 1.10 × 10−3 | 1.80 × 10−3 |

| Dinitrogen monoxide | kg | 2.39 × 10−5 | 2.16 × 10−5 | 3.53 × 10−5 |

| Nitrogen oxides | kg | 7.98 × 10−3 | 7.21 × 10−3 | 1.18 × 10−2 |

| Carbon monoxide, biogenic | kg | 2.39 × 10−3 | 2.16 × 10−3 | 3.53 × 10−3 |

| NMVOC, non-methane volatile organic compounds | kg | 7.09 × 10−4 | 6.41 × 10−4 | 1.05 × 10−3 |

| Particulates < 10 um | kg | 7.98 × 10−5 | 7.21 × 10−5 | 1.18 × 10−4 |

| Particulate < 2.5 um | kg | 7.98 × 10−5 | 7.21 × 10−5 | 1.18 × 10−4 |

| Carbon black | kg | 3.20 × 10−6 | 2.89 × 10−6 | 4.71 × 10−6 |

| Methane, biogenic g | kg | 1.22 × 10−3 | 5.02 × 10−3 | 4.53 × 10−4 |

| Outputs | CL1 | CL2 | CL3 |

|---|---|---|---|

| Electricity | 86% | 89% | 77% |

| Heat | 14% | 11% | 23% |

| Impact Category | Unit | Abbreviation |

|---|---|---|

| Climate change | kg CO2 eq | CC |

| Ozone depletion | kg CFC11 eq | OD |

| Ionizing radiation | kBq U-235 eq | IR |

| Photochemical ozone formation | kg NMVOC eq | POD |

| Particulate matter | disease inc. | PM |

| Human toxicity, non-cancer | CTUh | HTnon-c |

| Human toxicity, cancer | CTUh | HTc |

| Acidification | mol H+ eq | AC |

| Eutrophication, freshwater | kg P eq | EUf |

| Eutrophication, marine | kg N eq | EUm |

| Eutrophication, terrestrial | mol N eq | EUt |

| Ecotoxicity, freshwater | CTUe | ECT |

| Land use | Pt | LU |

| Water use | m3 depriv. | WU |

| Resource use, fossils | MJ | RDf |

| Resource use, minerals and metals | kg Sb eq | RDm |

| Impact Category | Unit | Total | CL1 | CL2 | CL3 |

|---|---|---|---|---|---|

| CC | kg CO2 eq | 7.81 × 109 | 1.16 × 109 | 6.35 × 109 | 3.03 × 108 |

| OD | kg CFC11 eq | 4.03 × 102 | 5.86 × 101 | 3.34 × 102 | 1.00 × 101 |

| IR | kBq U-235 eq | 2.06 × 108 | 3.06 × 107 | 1.71 × 108 | 4.34 × 106 |

| POD | kg NMVOC eq | 8.35 × 107 | 1.66 × 107 | 5.22 × 107 | 1.47 × 107 |

| PM | disease inc. | 9.67 × 102 | 1.64 × 102 | 7.39 × 102 | 6.44 × 101 |

| HTnon-c | CTUh | 1.53 × 102 | 2.48 × 101 | 1.27 × 102 | 1.21 |

| HTc | CTUh | 5.28 | 8.05 × 10−1 | 4.42 | 5.71 × 10−2 |

| AC | mol H+ eq | 8.84 × 107 | 1.38 × 107 | 7.34 × 107 | 1.14 × 106 |

| EUf | kg P eq | 2.63 × 106 | 3.84 × 105 | 2.23 × 106 | 9.87 × 103 |

| EUm | kg N eq | 8.95 × 107 | 1.53 × 107 | 6.90 × 107 | 5.21 × 106 |

| EUt | mol N eq | 4.03 × 108 | 6.75 × 107 | 3.15 × 108 | 2.02 × 107 |

| ECT | CTUe | 6.53 × 1011 | 9.69 × 1010 | 5.54 × 1011 | 2.01 × 109 |

| LU | Pt | 6.38 × 1011 | 8.48 × 1010 | 5.52 × 1011 | 8.92 × 108 |

| WU | m3 depriv. | 7.89 × 1010 | 1.13 × 1010 | 6.76 × 1010 | 5.21 × 106 |

| RDf | MJ | 5.09 × 1010 | 7.47 × 109 | 4.26 × 1010 | 7.71 × 108 |

| RDm | kg Sb eq | 4.33 × 104 | 6.46 × 103 | 3.61 × 104 | 6.63 × 102 |

| Impact Category | Unit | CL2 Original Scenario | CL2 Sensitivity Scenario | % Variation |

|---|---|---|---|---|

| CC | kg CO2 eq | 6.34 × 109 | 6.34 × 109 | 0.08% |

| OD | kg CFC11 eq | 3.34 × 102 | 3.34 × 102 | 0.12% |

| IR | kBq U-235 eq | 1.71 × 108 | 1.71 × 108 | −0.07% |

| POD | kg NMVOC eq | 5.22 × 107 | 5.22 × 107 | 0.04% |

| PM | disease inc. | 7.38 × 102 | 7.38 × 102 | 0.00% |

| HTnon-c | CTUh | 1.27 × 102 | 1.25 × 102 | 1.27% |

| HTc | CTUh | 4.41 | 4.34 | 1.72% |

| AC | mol H+ eq | 7.33 × 107 | 7.31 × 107 | 0.29% |

| EUf | kg P eq | 2.23 × 106 | 2.18 × 106 | 2.14% |

| EUm | kg N eq | 6.90 × 107 | 6.93 × 107 | −0.45% |

| EUt | mol N eq | 3.15 × 108 | 3.14 × 108 | 0.45% |

| ECT | CTUe | 5.54 × 1011 | 5.53 × 1011 | 0.22% |

| LU | Pt | 5.52 × 1011 | 5.43 × 1011 | 1.58% |

| WU | m3 depriv. | 6.75 × 1010 | 6.76 × 1010 | −0.08% |

| RDf | MJ | 4.26 × 1010 | 4.27 × 1010 | −0.26% |

| RDm | kg Sb eq | 3.61 × 104 | 3.59 × 104 | 0.48% |

| Impact Category | Unit | Electricity from Biogas-Original Scenario | Electricity from Biogas-Sensitivity Scenario | % Variation |

|---|---|---|---|---|

| CC | kg CO2 eq | 5.02 × 10−1 | 9.61 × 10−1 | −47.80% |

| OD | kg CFC11 eq | 2.37 × 10−8 | 4.96 × 10−8 | −52.26% |

| IR | kBq U-235 eq | 1.19 × 10−2 | 2.54 × 10−2 | −53.23% |

| POD | kg NMVOC eq | 1.00 × 10−2 | 1.03 × 10−2 | −2.69% |

| PM | disease inc. | 7.38 × 10−8 | 1.19 × 10−7 | −37.96% |

| HTnon-c | CTUh | 8.22 × 10−9 | 1.88 × 10−8 | −56.21% |

| HTc | CTUh | 2.85 × 10−10 | 6.49 × 10−10 | −56.02% |

| AC | mol H+ eq | 4.88 × 10−3 | 1.09 × 10−2 | −55.11% |

| EUf | kg P eq | 1.34 × 10−4 | 3.23 × 10−4 | −58.61% |

| EUm | kg N eq | 6.56 × 10−3 | 1.10 × 10−2 | −40.42% |

| EUt | mol N eq | 2.82 × 10−2 | 4.96 × 10−2 | −43.09% |

| ECT | CTUe | 3.32 × 101 | 8.03 × 101 | −58.67% |

| LU | Pt | 3.12 × 101 | 7.85 × 101 | −60.26% |

| WU | m3 depriv. | 3.89 | 9.70 | −59.95% |

| RDf | MJ | 2.81 | 6.26 | −55.11% |

| RDm | kg Sb eq | 2.40 × 10−6 | 5.32 × 10−6 | −54.89% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fiorentino, G.; Zucaro, A.; Cerbone, A.; Giocoli, A.; Motola, V.; Rinaldi, C.; Scalbi, S.; Ansanelli, G. The Contribution of Biogas to the Electricity Supply Chain: An Italian Life Cycle Assessment Database. Energies 2024, 17, 3264. https://doi.org/10.3390/en17133264

Fiorentino G, Zucaro A, Cerbone A, Giocoli A, Motola V, Rinaldi C, Scalbi S, Ansanelli G. The Contribution of Biogas to the Electricity Supply Chain: An Italian Life Cycle Assessment Database. Energies. 2024; 17(13):3264. https://doi.org/10.3390/en17133264

Chicago/Turabian StyleFiorentino, Gabriella, Amalia Zucaro, Antonietta Cerbone, Alessandro Giocoli, Vincenzo Motola, Caterina Rinaldi, Simona Scalbi, and Giuliana Ansanelli. 2024. "The Contribution of Biogas to the Electricity Supply Chain: An Italian Life Cycle Assessment Database" Energies 17, no. 13: 3264. https://doi.org/10.3390/en17133264

APA StyleFiorentino, G., Zucaro, A., Cerbone, A., Giocoli, A., Motola, V., Rinaldi, C., Scalbi, S., & Ansanelli, G. (2024). The Contribution of Biogas to the Electricity Supply Chain: An Italian Life Cycle Assessment Database. Energies, 17(13), 3264. https://doi.org/10.3390/en17133264