Simulation of the Static Sealing Performance of Rubber Packer Cylinders in a Supercritical–CO2 Environment

Abstract

1. Introduction

2. Theoretical Calculation of the Mechanical Properties of the Rubber Cylinder

3. Establishment of Finite Element Model of Rubber Packer Cylinder

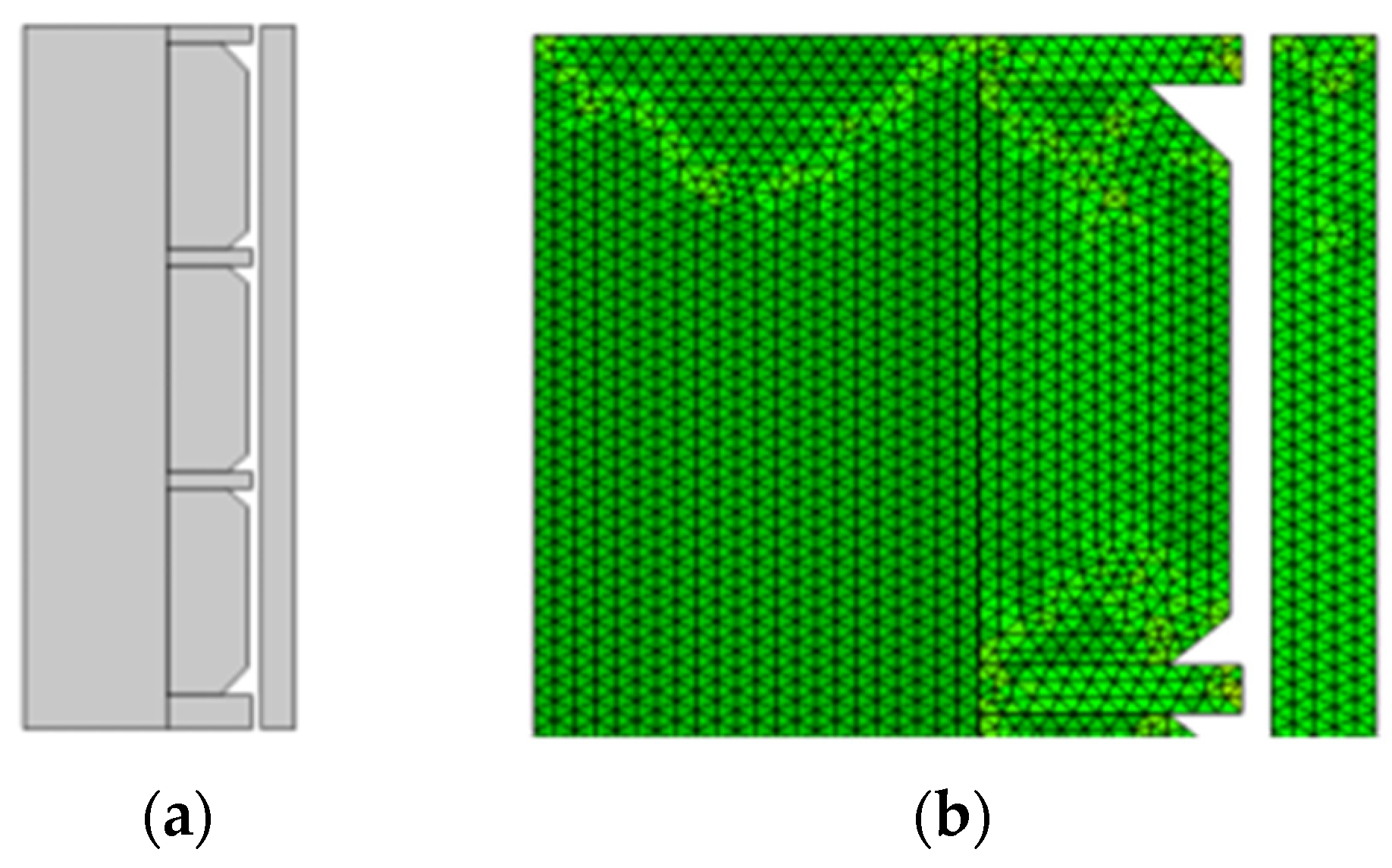

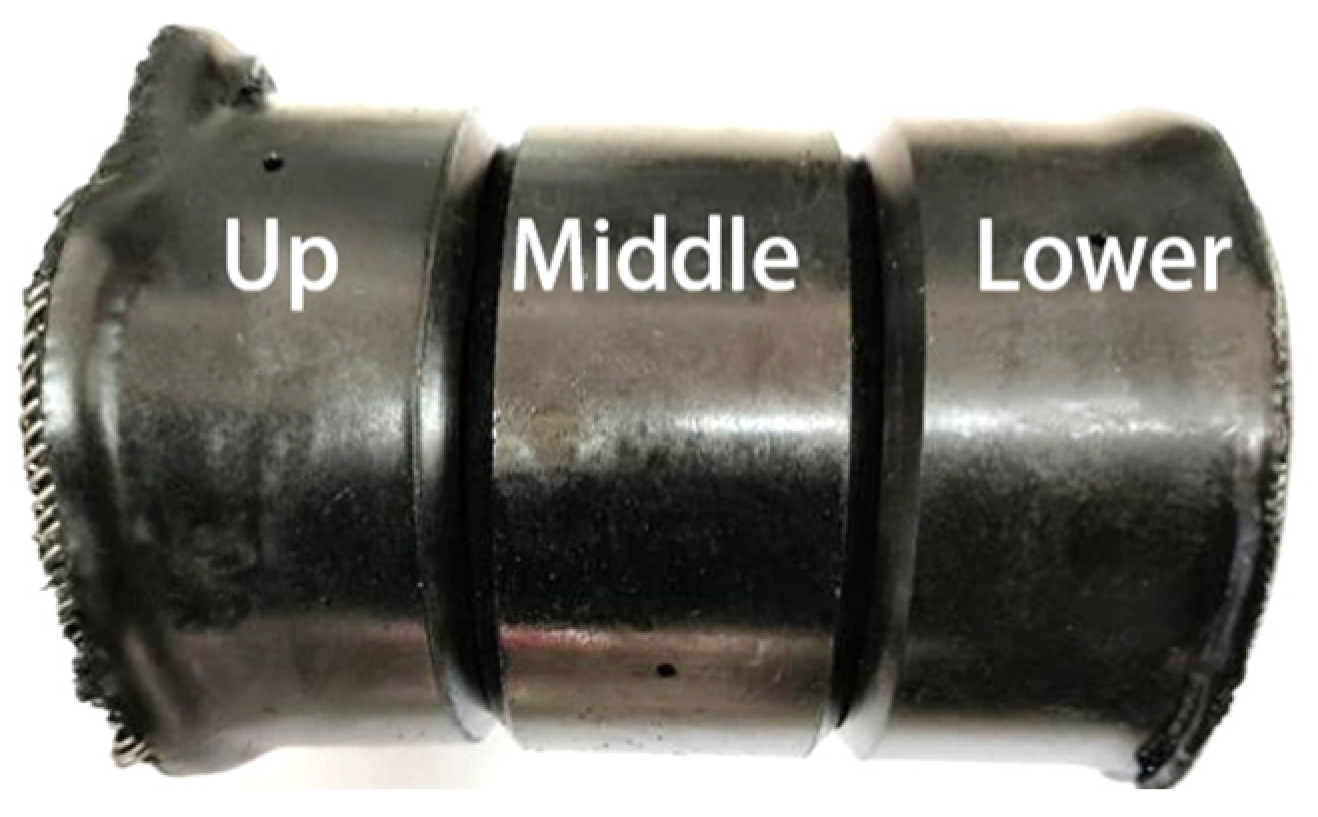

3.1. Geometric Model Establishment and Mesh Generation

3.2. Setting the Material Properties

3.3. Boundary Condition Settings

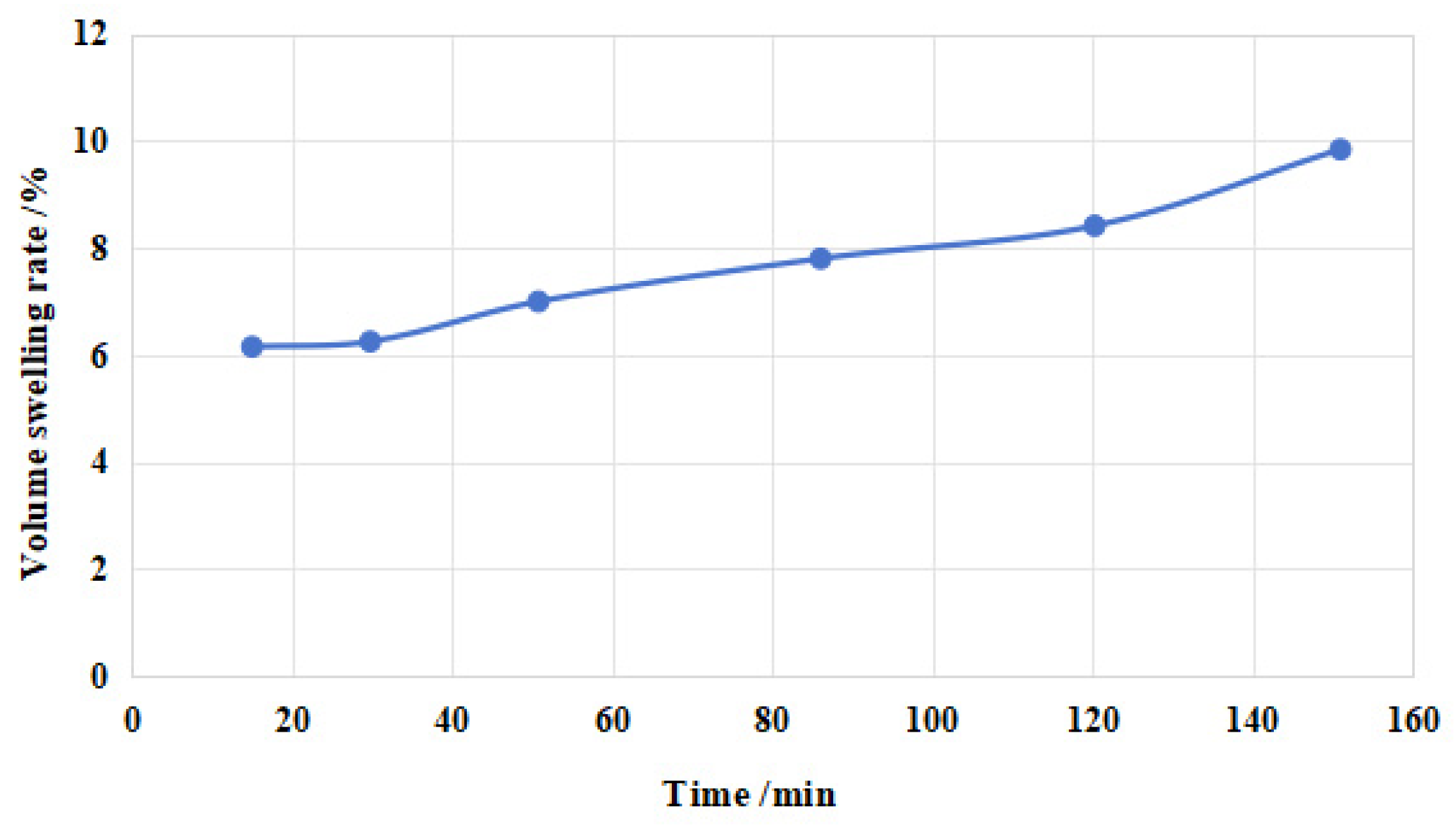

3.4. Finite Element Model Setup of Rubber Swelling Process with CO2 as Swelling Agent

4. Analysis of the Simulation Results

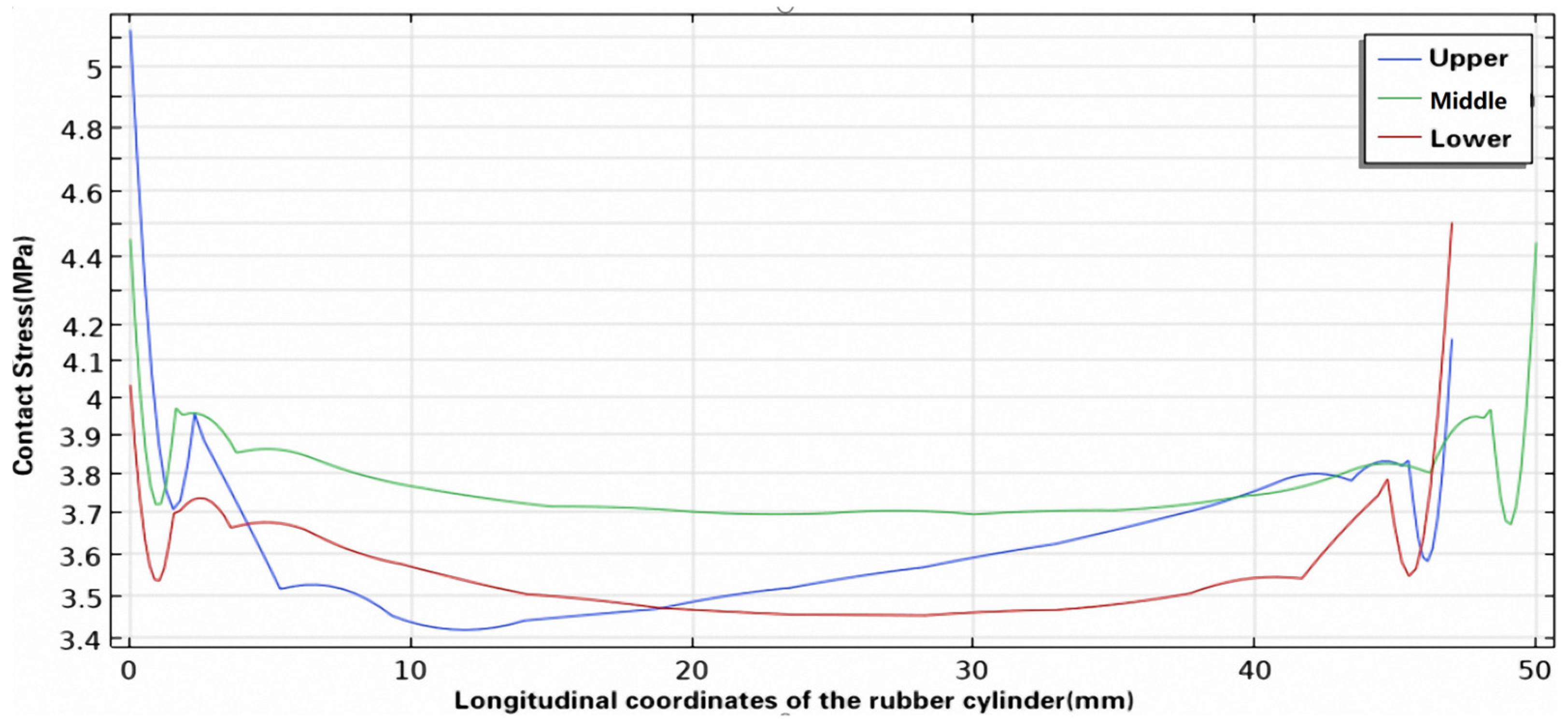

4.1. Effect of Seating Distance on Sealing Performance of Rubber Cylinder

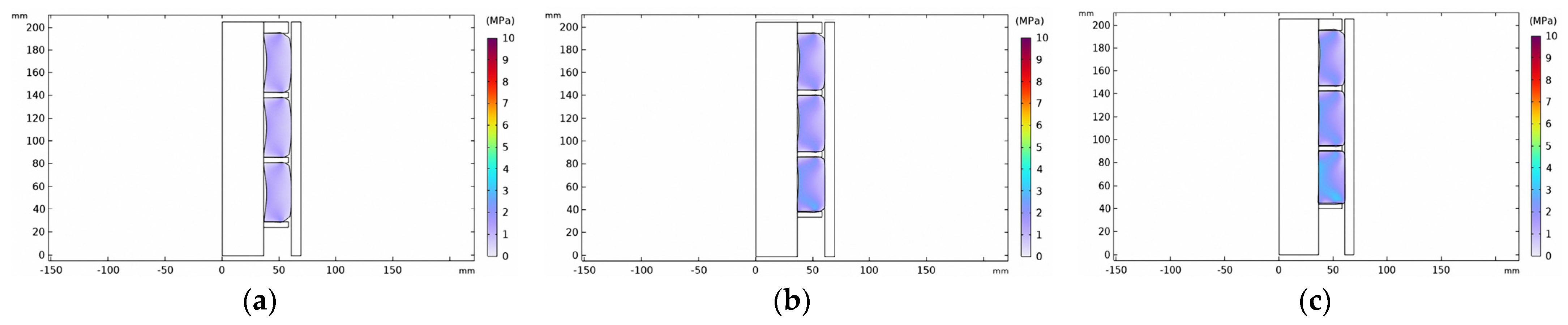

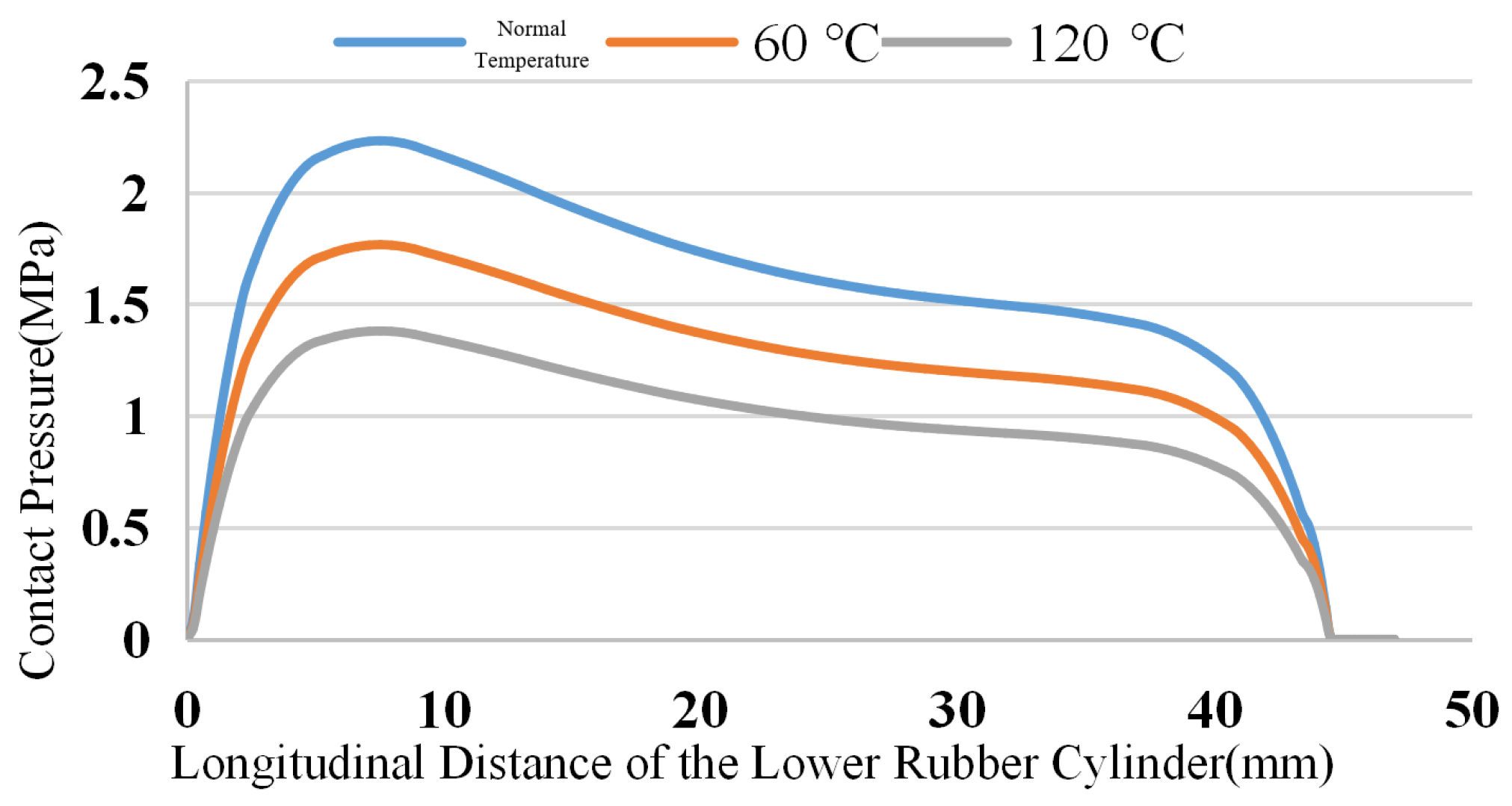

4.2. Effect of Underground Temperature on Sealing Performance of Rubber Cylinder

4.3. Effect of Working Pressure Difference on Sealing Performance of Rubber Cylinder

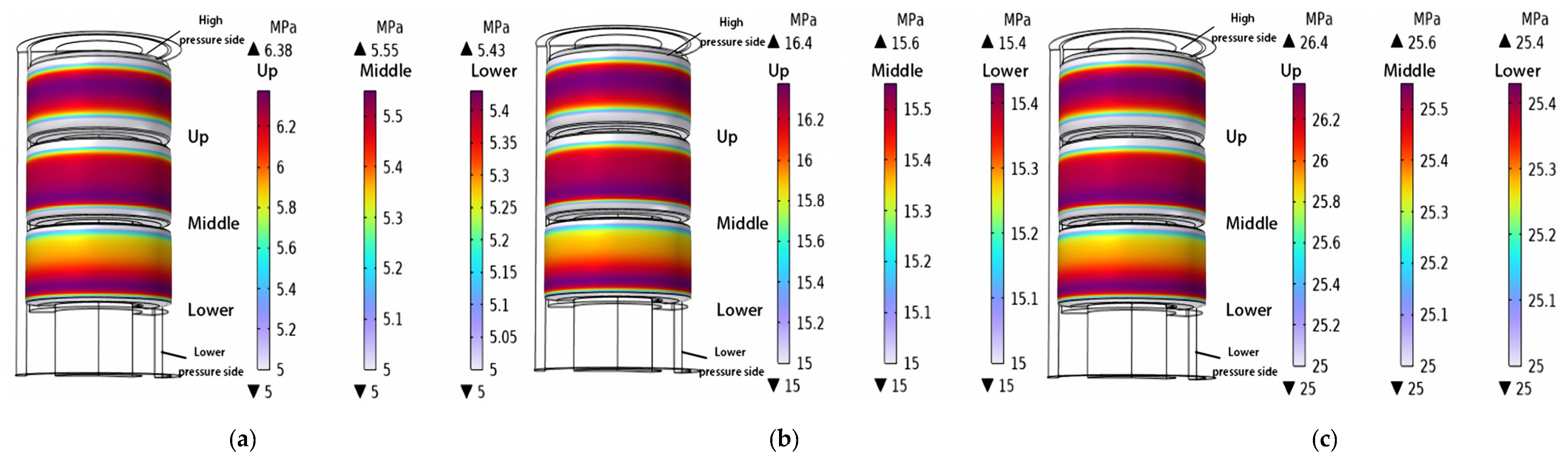

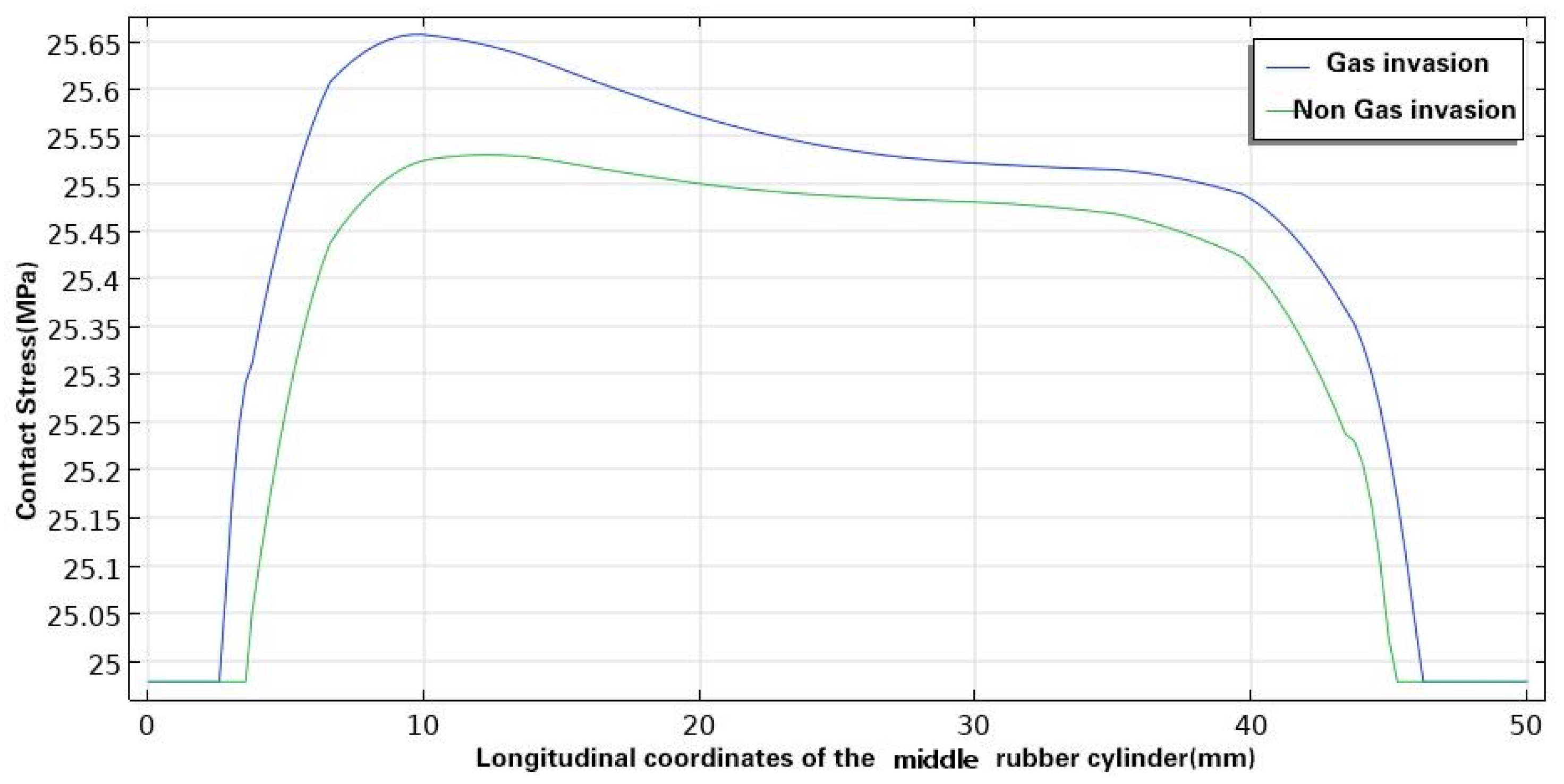

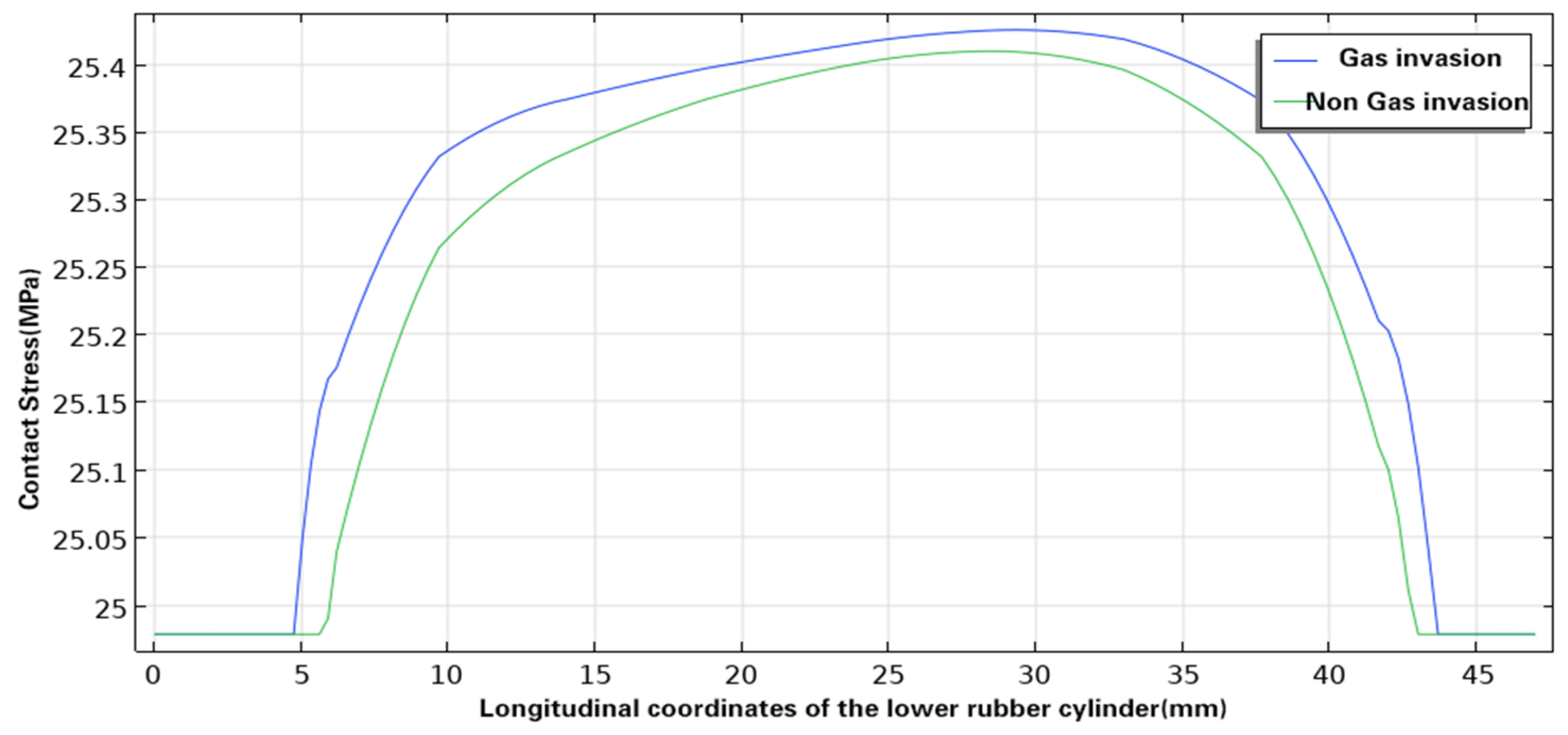

4.4. Effect of SC–CO2 on Sealing Performance of Rubber Cylinder

5. Conclusions

- (1)

- Unidirectional compression seating at the lower end is usually used for conventional packers. The simulation results show that the deformation of the three rubber cylinders was uneven, and if the seating distance is not set reasonably, this can easily lead to the tearing and damage of the rubber cylinder. Therefore, when designing the seating mechanism of a packer, a reasonable seating distance should be retained to prevent poor sealing or damage to the rubber cylinder. Further, the seating mechanism should be optimized and upgraded, such as by using a bidirectional seating mechanism, to fundamentally change the overall stress of the rubber cylinder and improve the sealing reliability.

- (2)

- The downhole temperature of CO2 injection wells usually exceeds 373 K, and the simulation results show that the contact stress between the rubber cylinder and the inner wall of the casing decreases significantly with an increase in downhole temperature. Under the steady–state condition of 393 K, the contact stress of the rubber cylinder decreases by about 40% compared with that when it is just seated. In order to ensure long–lasting sealing under high–temperature conditions, the rubber packer cylinders selected for CO2 injection wells should have the characteristics of high temperature resistance.

- (3)

- The thermal analogy method was used to simulate the effect of SC–CO2 on the sealing performance of rubber cylinders, and the results show that with the rubber swelling under SC–CO2 diffusion, the deformation of the rubber cylinder is enhanced, and the contact stress between the rubber cylinder and the inner wall of the casing is increased. However, the deformation is small, which will not result in the tearing of the cylinder.

- (4)

- The simulation results show that in the process of the packer unsealing, the swelling effect greatly increases the contact stress between the rubber cylinder and the inner wall of the casing, thus increasing the overall unsealing force of the pipe string. If more than three sets of packers were applied to a gas injection well, the unsealing force would be more than 60 t, which would disable the normal pipe string operation. Therefore, when designing or selecting packers for CO2 injection, attention should be paid to whether they have the function of step–by–step releasing, to reduce the difficulty of field operation.

- (5)

- The above conclusions were made after the digital simulation of a rubber cylinder made of hydrogenated nitrile, providing a certain reference for cylinders made of other types of rubber.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rui, Z.; Li, Y.; Xue, Z.; Liu, Y. Development Suggestions on Key Technologies of CO2 Enhanced Oil and Gas Recovery and Geological Storage. Prospect. Sci. Technol. 2023, 2, 145–160. [Google Scholar]

- Zhu, D.; Lin, Y.; Zou, D.; Li, Y. Study on Corrosion Mechanical Properties of Rubber Material for CO2 Flooding Gas Well Packer. Pet. Drill. Tech. 2014, 42, 5. [Google Scholar]

- Zhang, K.; Chen, Z.X.; Lan, H.F.; Ma, H.M.; Jiang, L.L.; Xue, Z.Q.; Zhang, Y.M.; Cheng, S.X. Status and Prospect of Carbon Capture, Utilization and Storage Technology. Spec. Oil Gas Reserv. 2023, 30, 1–9. [Google Scholar]

- Aminu, M.D.; Nabavi, S.A.; Rochelle, C.A.; Manovic, V. A Review of Developments in Carbon Dioxide Storage. Appl. Energy 2017, 208, 1389–1419. [Google Scholar] [CrossRef]

- Baklid, A.; Korbol, R.; Owren, G. Sleipner Vest CO2 Disposal, CO2 Injection into a Shallow Underground Aquifer. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 6–9 October 1996; p. SPE–36600–MS. [Google Scholar]

- Cook, P.J. CCS Research Development and Deployment in a Clean Energy Future: Lessons from Australia over the Past two Decades. Engineering 2017, 3, 477–484. [Google Scholar] [CrossRef]

- Wang, F.S.; Xu, D.K.; Li, K.L.; Li, J.Y.; Wang, L.J. Research on Sealing Mechanism of CO2 Packer Cartridge. J. Oil Prod. Eng. 2018, 3, 1–4+84. [Google Scholar]

- Liu, J.X.; Wang, S.J.; Zhang, R.X.; Wei, W. Bidirectional Compression Packer for Stratified Gas Injection in CO2 Flooding. China Pet. Mach. 2017, 45, 87–89. [Google Scholar]

- Zhang, X.; Xu, X.P.; Wang, L. Improvement and Advantage Analysis of Packer Rubber Cylinder Structure. Oil Field Mach. 2013, 1, 62–66. [Google Scholar]

- Zhang, Z.; Zhu, X.H.; Xu, J.B. Optimization of Structural Parameters of a Compression Packer Casing Based on Orthogonal Tests. Nat. Gas Ind. 2019, 39, 80–84. [Google Scholar]

- Daou, F.; de Miranda, C.R.; De Oliveira, J.L.; Engelke, B.; Borman, C.; Le Roy–Delage, S.; Lungwitz, B. Swelling of Elastomers in CO2 Environment: Testing Methodology and Experimental Data. In Proceedings of the SPE Latin America and Caribbean Petroleum Engineering Conference, Maracaibo, Venezuela, 21–23 May 2014; p. D031S023R002. [Google Scholar]

- Zhu, D.; Lin, Y.; Zhang, H.; Li, Y.; Zeng, D.; Liu, W.; Qiang, C.; Deng, K. Corrosion Evaluation of Packer Rubber Materials in CO2 Injection Wells under Supercritical Conditions. J. Pet. Sci. Eng. 2017, 151, 311–317. [Google Scholar] [CrossRef]

- Davies, O.M.; Arnold, J.C.; Sulley, S. The Mechanical Properties of Elastomers in High–pressure CO2. J. Mater. Sci. 1999, 34, 417–422. [Google Scholar] [CrossRef]

- Yamabe, J.; Nishimura, S. Failure Behavior of Rubber O–ring under Cyclic Exposure to High–pressure Hydrogen Gas. Eng. Fail. Anal. 2013, 35, 193–205. [Google Scholar] [CrossRef]

- Wang, J.L.; Gao, B.K.; Ma, C.; Chen, X.W. Effect of Casing Wear on Sealing Performance of Packer. Pet. Mach. 2021, 9, 55–60. [Google Scholar]

- Ge, Y. Research on Structure Design and Performance of Rubber Cylinder of New Gas Injection Packer. Ph.D. Thesis, China University of Petroleum, Beijing, China, 2022. [Google Scholar]

- Wang, L.; Xu, P.; Tao, J.H. Finite Element Analysis of Rubber O–ring Static Seal Structure in High–pressure Hydrogen Environment. Manuf. Autom. 2022, 46, 143–149. [Google Scholar]

- Wang, W. Coupling Simulation of Hydrogen Concentration Field and Stress Field Based on Thermal Analogy. Ph.D. Dissertation, Huazhong University of Science and Technology, Wuhan, China, 2018. [Google Scholar]

- Liu, M.T. Study on the Swelling Law of Hydrogenated Nitrile Butadiene Rubber and Fluorine Rubber in Carbon Dioxide. Ph.D. Thesis, China University of Petroleum, Beijing, China, 2021. [Google Scholar]

- Jin, L.; Li, S.; Cheng, Y.; Liu, J. A time–dependent Yeoh model to predict the corrosion effect of supercritical CO2 on the HNBR sealing rubber. J. Mech. Sci. Technol. 2022, 36, 2461–2470. [Google Scholar] [CrossRef]

- Huang, X.M.; Xiao, G.H.; Wang, L. Design and Development of Plug–in High Temperature and High Pressure Gas Injection Packer. Xinjiang Oil Gas 2023, 19, 21–25. [Google Scholar]

- Wang, Z.Y.; Liu, Y.J.; Zhu, S.; Dou, Y.H. Nonlinear Simulation and Performance Evaluation of Packer Cartridge. Inf. Technol. 2023, 52, 112–116. [Google Scholar]

- Huang, L.; Guo, Z.L.; Wang, X.L.; He, F.G.; Wu, C.H.; Li, W.B. Failure Analysis and Improvement Design of Packer Seal Casing Extrusion. Hydraul. Pneum. 2023, 47, 177–182. [Google Scholar]

- Mao, J. Development of Rubber Casing for High Temperature and High Pressure Test Packer. Oil Drill. Prod. Technol. 2023, 45, 638–643. [Google Scholar]

- Sun, Y.; Wei, A.; Chen, Z.; Cheng, W.; Cai, Y. Sealing Structure Design of Rubber Cylinder for High Temperature and High Pressure Packer. Lubr. Seal. 2023, 48, 140–145. [Google Scholar]

- Yue, Q.B.; Wang, G.; Liu, J.B.; Sun, G.H.; Wang, X.X.; Liu, Y.Q.; Cao, W.; Zhang, Q. Simulation and Calculation of Nonlinear Flow in Expansion Packer under High Temperature and Pressure. Chin. J. Comput. Mech. 2023, 40, 411–423. [Google Scholar]

- Kim, B.; Lee, S.B.; Lee, J.; Cho, S.; Park, H.; Yeom, S.; Han Park, S. A Comparison Among Neo–Hookean Model, Mooney–Rivlin Model, and Ogden Model for Chloroprene Rubber. Int. J. Precis. Eng. Manuf. 2012, 13, 759–764. [Google Scholar] [CrossRef]

- Zhong, W. Research on Sealing Performance of Packer Rubber Casing. Ph.D. Thesis, China University of Petroleum, Beijing, China, 2022. [Google Scholar]

- Koga, A.; Uchida, K.; Yamabe, J. Evaluation on High–pressure Hydrogen Decompression Failure of Rubber O–ring Using Design of Experiments. Int. J. Automot. Eng. 2011, 2, 123–129. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Shi, C.; Pan, X.; Yang, L. Influence of Supercritical Carbon Dioxide–Assisted Polyamide Acid Modification of Aramid Fibers on the Properties of Aramid Fiber–Reinforced Styrene Butadiene Rubber. J. Fibers Polym. 2024, 25, 2117–2130. [Google Scholar] [CrossRef]

- Gumerov, F.M.; Zaripov, Z.I.; Khairutdinov, V.F.; Sagdeev, D.I. Universality of Supercritical Carbon Dioxide in the Process of Tertiary Oil Production. J. Theor. Found. Chem. Eng. 2023, 57, 45–55. [Google Scholar] [CrossRef]

- Guo, H.; Wang, Y.; Tan, L.; Lu, Z.; Bai, L. Corrosion Behaviors of Iron in a Supercritical CO2 Environment: A Molecular Dynamics Study. J. Mater. Sci. 2023, 58, 14758–14772. [Google Scholar] [CrossRef]

| Temperature | C10 (MPa) | C01 (MPa) |

|---|---|---|

| Room temperature | 0.887 | 0.443 |

| 333 K | 0.747 | 0.298 |

| 393 K | 0.583 | 0.233 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Z.; Cai, M.; Cui, L.; Song, X.; Xu, X.; Cong, C.; Li, H.; Gao, Q. Simulation of the Static Sealing Performance of Rubber Packer Cylinders in a Supercritical–CO2 Environment. Energies 2024, 17, 3305. https://doi.org/10.3390/en17133305

Zhu Z, Cai M, Cui L, Song X, Xu X, Cong C, Li H, Gao Q. Simulation of the Static Sealing Performance of Rubber Packer Cylinders in a Supercritical–CO2 Environment. Energies. 2024; 17(13):3305. https://doi.org/10.3390/en17133305

Chicago/Turabian StyleZhu, Zhenkun, Meng Cai, Lining Cui, Xingliang Song, Xiaoyu Xu, Chuanbo Cong, Haicheng Li, and Qiming Gao. 2024. "Simulation of the Static Sealing Performance of Rubber Packer Cylinders in a Supercritical–CO2 Environment" Energies 17, no. 13: 3305. https://doi.org/10.3390/en17133305

APA StyleZhu, Z., Cai, M., Cui, L., Song, X., Xu, X., Cong, C., Li, H., & Gao, Q. (2024). Simulation of the Static Sealing Performance of Rubber Packer Cylinders in a Supercritical–CO2 Environment. Energies, 17(13), 3305. https://doi.org/10.3390/en17133305