Technological Prospects of Biochar Derived from Viticulture Waste: Characterization and Application Perspectives

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals

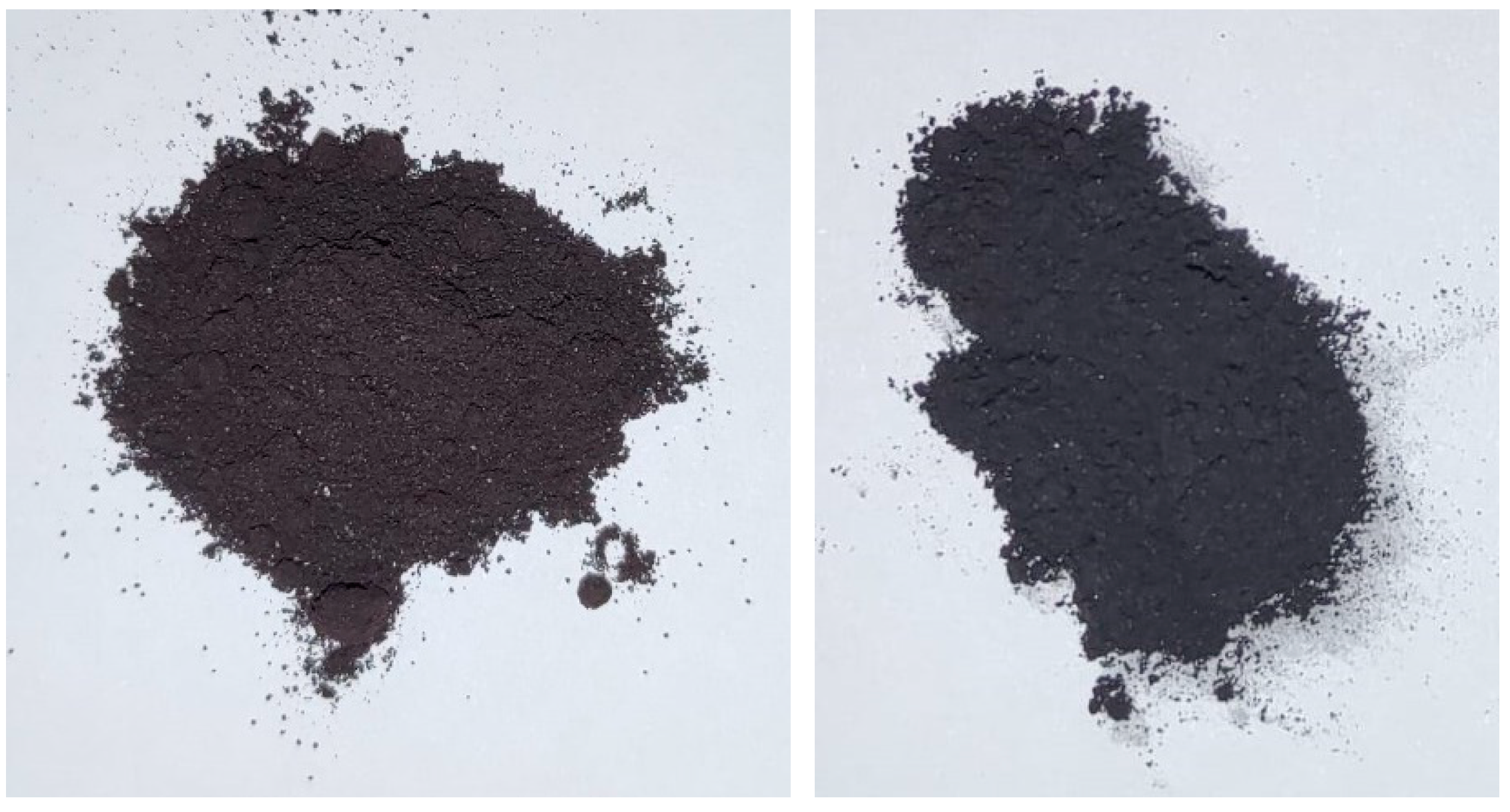

2.2. Sample Preparation

2.3. Proximate Composition

2.4. TGA

2.5. Powder Preparation

2.6. Molding

2.7. In-Plane Conductivity (IPC) Measurements

2.8. Density Measurements

2.9. Statistical Analysis

3. Results

3.1. Proximate Composition

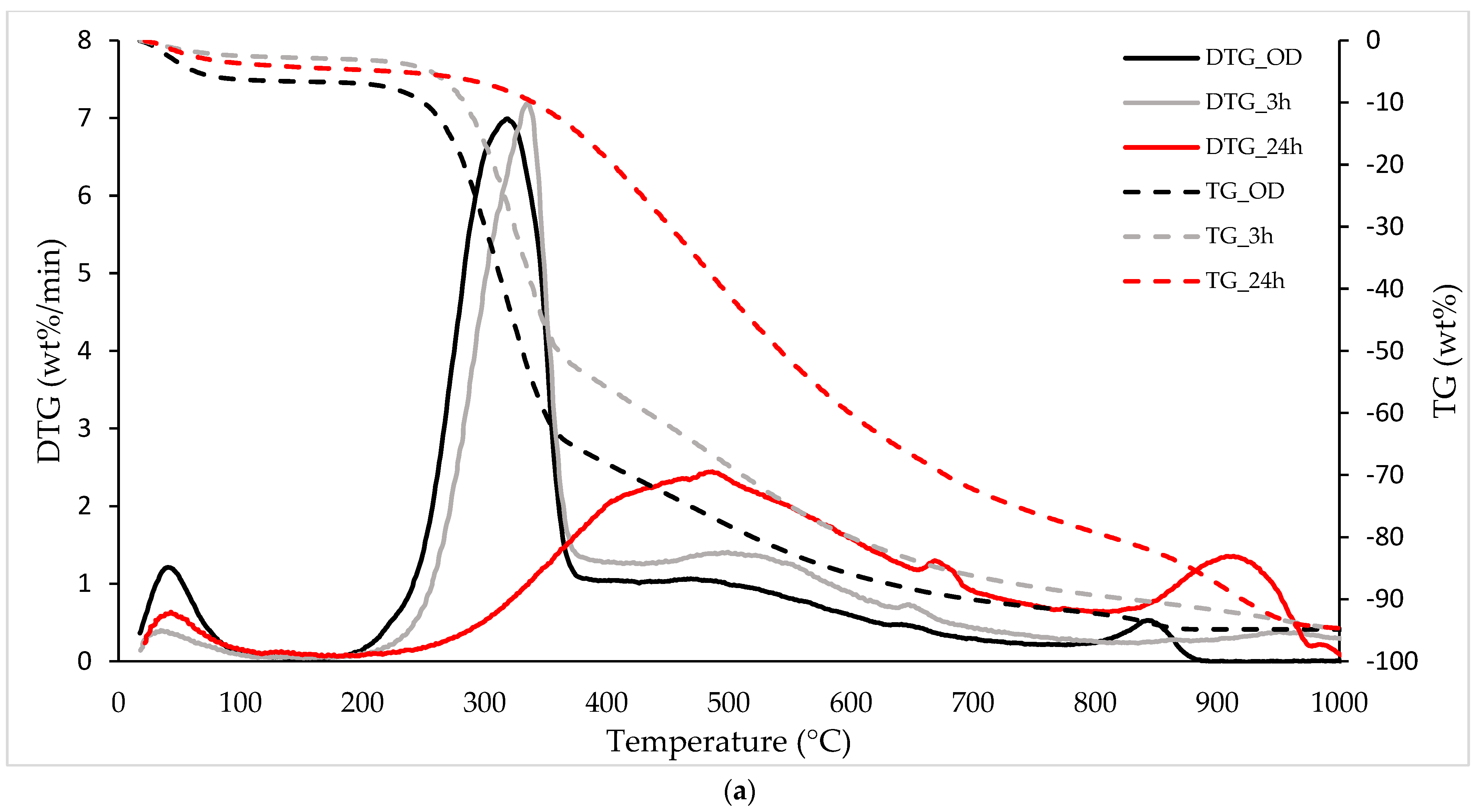

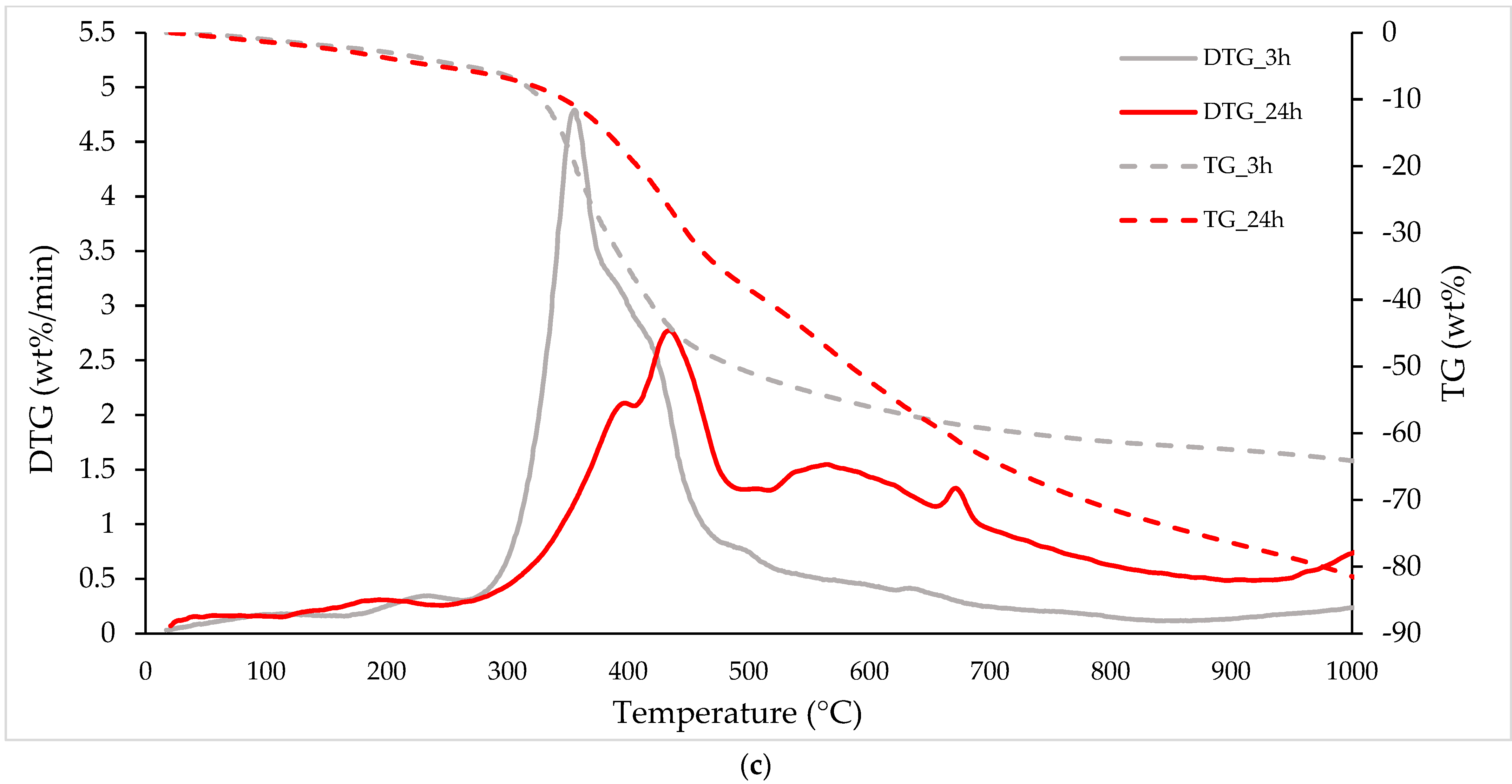

3.2. TGA

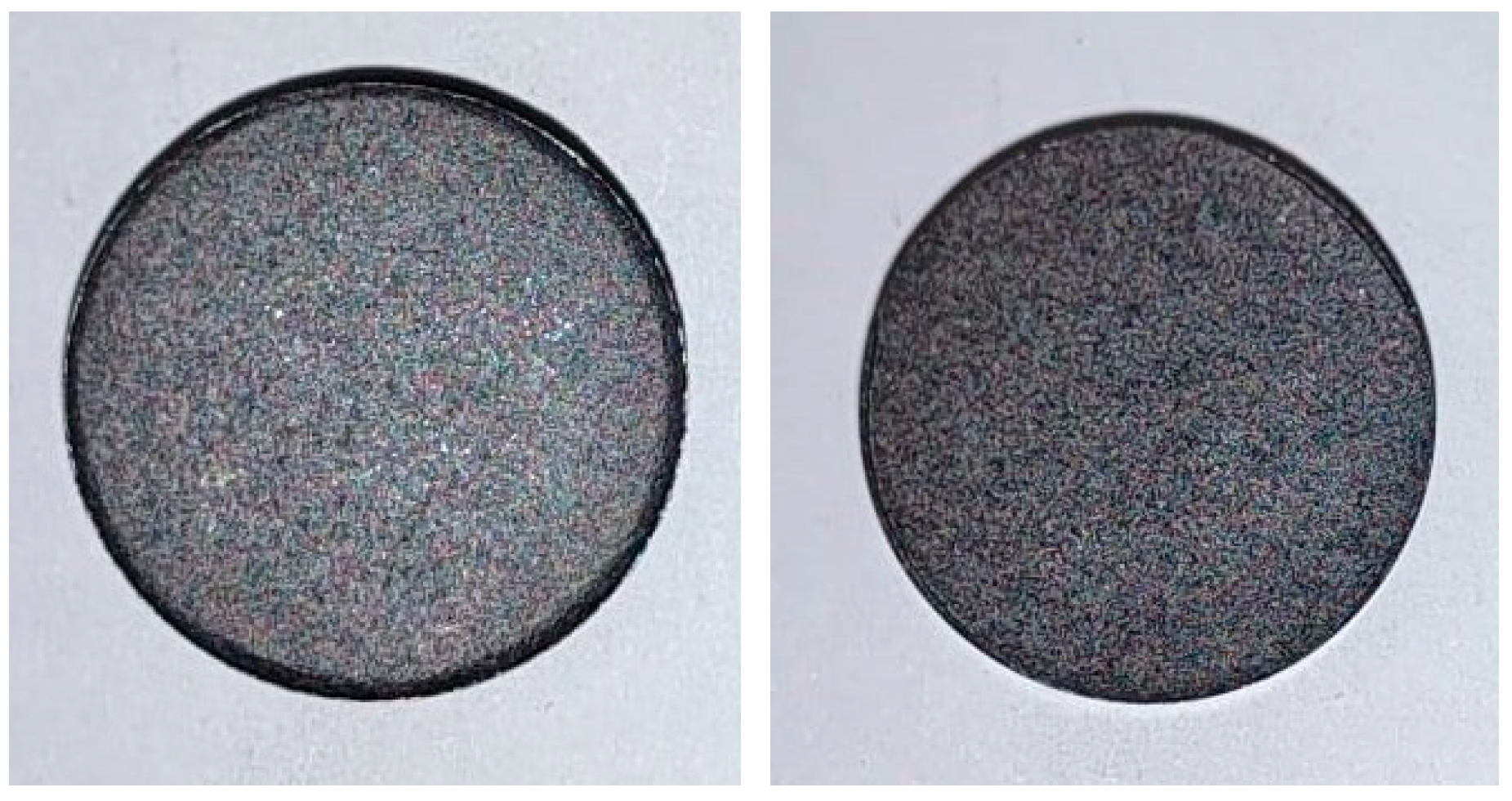

3.3. Bipolar Plates

- Prolonged pyrolysis: Extending the pyrolysis duration from 3 h to 24 h provided only a small improvement in the intrinsic conductivity of the biochar. This indicates that the additional energy and time investment for longer pyrolysis may not yield substantial benefits in terms of electrical performance.

- Fat removal: The removal of fats from the grape seeds had a significant positive impact on the performance of the biochar. Defatted biochar (DGS3 and DGS24), compared to GS biochar, produced excellent composite materials, maintaining good performance even at higher biochar loadings. Specifically, composites with 25 wt% of DGS biochar (30 wt% of substituted G45 graphite) demonstrated superior results.

- Carbon content (C %): Biochars featuring higher carbon content (lower O/C ratio) such as DGS and GS (see Table 2) led to samples with higher IPC values, suggesting a higher intrinsic conductivity occurring in biochars with higher carbon content.

- Thermal stability: GS and DGS biochars exhibited higher thermal stability compared to WS samples, as shown by the relative TGA/DTG curves (Figure 3). Therefore, a higher degree of carbonization corresponds to a more stable structure.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAOSTAT. Available online: https://www.fao.org/faostat/en/#data (accessed on 17 October 2022).

- Jin, Q.; Wang, Z.; Feng, Y.; Kim, Y.-T.; Stewart, A.C.; O’Keefe, S.F.; Neilson, A.P.; He, Z.; Huang, H. Grape Pomace and Its Secondary Waste Management: Biochar Production for a Broad Range of Lead (Pb) Removal from Water. Environ. Res. 2020, 186, 109442. [Google Scholar] [CrossRef]

- Beres, C.; Costa, G.N.S.; Cabezudo, I.; Da Silva-James, N.K.; Teles, A.S.C.; Cruz, A.P.G.; Mellinger-Silva, C.; Tonon, R.V.; Cabral, L.M.C.; Freitas, S.P. Towards Integral Utilization of Grape Pomace from Winemaking Process: A Review. Waste Manag. 2017, 68, 581–594. [Google Scholar] [CrossRef]

- Devesa-Rey, R.; Vecino, X.; Varela-Alende, J.L.; Barral, M.T.; Cruz, J.M.; Moldes, A.B. Valorization of Winery Waste vs. the Costs of Not Recycling. Waste Manag. 2011, 31, 2327–2335. [Google Scholar] [CrossRef] [PubMed]

- Gaunt, J.L.; Lehmann, J. Energy Balance and Emissions Associated with Biochar Sequestration and Pyrolysis Bioenergy Production. Environ. Sci. Technol. 2008, 42, 4152–4158. [Google Scholar] [CrossRef]

- Li, Y.; Xing, B.; Ding, Y.; Han, X.; Wang, S. A Critical Review of the Production and Advanced Utilization of Biochar via Selective Pyrolysis of Lignocellulosic Biomass. Bioresour. Technol. 2020, 312, 123614. [Google Scholar] [CrossRef] [PubMed]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar Physicochemical Properties: Pyrolysis Temperature and Feedstock Kind Effects. Rev. Environ. Sci. Biotechnol. 2020, 19, 191–215. [Google Scholar] [CrossRef]

- Vaiškūnaitė, R.; Mažeikienė, A.; Mohammadi, K. Effects of Pyrolysis Temperature on Biochar Physicochemical and Microbial Properties for H2S Removal from Biogas. Sustainability 2024, 16, 5424. [Google Scholar] [CrossRef]

- Li, Y.; Gupta, R.; Zhang, Q.; You, S. Review of Biochar Production via Crop Residue Pyrolysis: Development and Perspectives. Bioresour. Technol. 2023, 369, 128423. [Google Scholar] [CrossRef] [PubMed]

- Patzek, T.W.; Pimentel, D. Thermodynamics of Energy Production from Biomass. Crit. Rev. Plant Sci. 2005, 24, 327–364. [Google Scholar] [CrossRef]

- Metzger, J.O. Production of Liquid Hydrocarbons from Biomass. Angew. Chem. Int. Ed. 2006, 45, 696–698. [Google Scholar] [CrossRef]

- Kung, C.-C.; McCarl, B.A.; Cao, X. Economics of Pyrolysis-Based Energy Production and Biochar Utilization: A Case Study in Taiwan. Energy Policy 2013, 60, 317–323. [Google Scholar] [CrossRef]

- Chan, K.Y.; Van Zwieten, L.; Meszaros, I.; Downie, A.; Joseph, S. Agronomic Values of Greenwaste Biochar as a Soil Amendment. Soil Res. 2007, 45, 629. [Google Scholar] [CrossRef]

- Ding, W.; Dong, X.; Ime, I.M.; Gao, B.; Ma, L.Q. Pyrolytic Temperatures Impact Lead Sorption Mechanisms by Bagasse Biochars. Chemosphere 2014, 105, 68–74. [Google Scholar] [CrossRef] [PubMed]

- Shen, Z.; Hou, D.; Jin, F.; Shi, J.; Fan, X.; Tsang, D.C.W.; Alessi, D.S. Effect of Production Temperature on Lead Removal Mechanisms by Rice Straw Biochars. Sci. Total Environ. 2019, 655, 751–758. [Google Scholar] [CrossRef] [PubMed]

- Jia, M.; Wang, F.; Bian, Y.; Jin, X.; Song, Y.; Kengara, F.O.; Xu, R.; Jiang, X. Effects of pH and Metal Ions on Oxytetracycline Sorption to Maize-Straw-Derived Biochar. Bioresour. Technol. 2013, 136, 87–93. [Google Scholar] [CrossRef] [PubMed]

- Venkitasamy, C.; Zhao, L.; Zhang, R.; Pan, Z. Grapes. In Integrated Processing Technologies for Food and Agricultural By-Products; Elsevier: Amsterdam, The Netherlands, 2019; pp. 133–163. ISBN 978-0-12-814138-0. [Google Scholar]

- Deng, Q.; Penner, M.H.; Zhao, Y. Chemical Composition of Dietary Fiber and Polyphenols of Five Different Varieties of Wine Grape Pomace Skins. Food Res. Int. 2011, 44, 2712–2720. [Google Scholar] [CrossRef]

- Barros, A.; Gironés-Vilaplana, A.; Texeira, A.; Baenas, N.; Domínguez-Perles, R. Grape Stems as a Source of Bioactive Compounds: Application towards Added-Value Commodities and Significance for Human Health. Phytochem. Rev. 2015, 14, 921–931. [Google Scholar] [CrossRef]

- Kane, S.; Ulrich, R.; Harrington, A.; Stadie, N.P.; Ryan, C. Physical and Chemical Mechanisms That Influence the Electrical Conductivity of Lignin-Derived Biochar. Carbon Trends 2021, 5, 100088. [Google Scholar] [CrossRef]

- Weber, K.; Quicker, P. Properties of Biochar. Fuel 2018, 217, 240–261. [Google Scholar] [CrossRef]

- Plenča, K.; Cvetnić, S.; Prskalo, H.; Kovačić, M.; Cvetnić, M.; Kušić, H.; Matusinović, Z.; Kraljić Roković, M.; Genorio, B.; Lavrenčič Štangar, U.; et al. Biomass Pyrolysis-Derived Biochar: A Versatile Precursor for Graphene Synthesis. Materials 2023, 16, 7658. [Google Scholar] [CrossRef]

- Jeong, K.I.; Oh, J.; Song, S.A.; Lee, D.; Lee, D.G.; Kim, S.S. A Review of Composite Bipolar Plates in Proton Exchange Membrane Fuel Cells: Electrical Properties and Gas Permeability. Compos. Struct. 2021, 262, 113617. [Google Scholar] [CrossRef]

- Roncaglia, F.; Romagnoli, M.; Incudini, S.; Santini, E.; Imperato, M.; Spinelli, L.; Di Bona, A.; Biagi, R.; Mucci, A. Graphite-Epoxy Composites for Fuel-Cell Bipolar Plates: Wet vs Dry Mixing and Role of the Design of Experiment in the Optimization of Molding Parameters. Int. J. Hydrogen Energy 2021, 46, 4407–4416. [Google Scholar] [CrossRef]

- Spokas, K.A. Review of the Stability of Biochar in Soils: Predictability of O:C Molar Ratios. Carbon Manag. 2010, 1, 289–303. [Google Scholar] [CrossRef]

- Bordiga, M.; Travaglia, F.; Locatelli, M. Valorisation of Grape Pomace: An Approach That Is Increasingly Reaching Its Maturity—A Review. Int. J. Food Sci. Technol. 2019, 54, 933–942. [Google Scholar] [CrossRef]

- Shinagawa, F.B.; Santana, F.C.D.; Torres, L.R.O.; Mancini-Filho, J. Grape Seed Oil: A Potential Functional Food? Food Sci. Technol. 2015, 35, 399–406. [Google Scholar] [CrossRef]

- D’Eusanio, V.; Malferrari, D.; Marchetti, A.; Roncaglia, F.; Tassi, L. Waste By-Product of Grape Seed Oil Production: Chemical Characterization for Use as a Food and Feed Supplement. Life 2023, 13, 326. [Google Scholar] [CrossRef] [PubMed]

- Associataion of Official Analytical Chemist. AOAC Official Methods of Analysis of the Association of Official’s Analytical Chemists, 14th ed.; Associataion of Official Analytical Chemist: Washington, DC, USA, 1990; pp. 223–225+992–995. [Google Scholar]

- Smits, F.M. Measurement of Sheet Resistivities with the Four-Point Probe. Bell Syst. Tech. J. 1958, 37, 711–718. [Google Scholar] [CrossRef]

- D’Eusanio, V.; Genua, F.; Marchetti, A.; Morelli, L.; Tassi, L. Characterization of Some Stilbenoids Extracted from Two Cultivars of Lambrusco—Vitis Vinifera Species: An Opportunity to Valorize Pruning Canes for a More Sustainable Viticulture. Molecules 2023, 28, 4074. [Google Scholar] [CrossRef] [PubMed]

- D’Eusanio, V.; Genua, F.; Marchetti, A.; Morelli, L.; Tassi, L. Exploring the Mineral Composition of Grapevine Canes for Wood Chip Applications in Alcoholic Beverage Production to Enhance Viticulture Sustainability. Beverages 2023, 9, 60. [Google Scholar] [CrossRef]

- Chen, D.; Mei, J.; Li, H.; Li, Y.; Lu, M.; Ma, T.; Ma, Z. Combined Pretreatment with Torrefaction and Washing Using Torrefaction Liquid Products to Yield Upgraded Biomass and Pyrolysis Products. Bioresour. Technol. 2017, 228, 62–68. [Google Scholar] [CrossRef]

- Leng, L.; Yang, L.; Chen, J.; Leng, S.; Li, H.; Li, H.; Yuan, X.; Zhou, W.; Huang, H. A Review on Pyrolysis of Protein-Rich Biomass: Nitrogen Transformation. Bioresour. Technol. 2020, 315, 123801. [Google Scholar] [CrossRef] [PubMed]

- Neves, D.; Thunman, H.; Matos, A.; Tarelho, L.; Gómez-Barea, A. Characterization and Prediction of Biomass Pyrolysis Products. Prog. Energy Combust. Sci. 2011, 37, 611–630. [Google Scholar] [CrossRef]

- Klasson, K.T. Biochar Characterization and a Method for Estimating Biochar Quality from Proximate Analysis Results. Biomass Bioenergy 2017, 96, 50–58. [Google Scholar] [CrossRef]

- Ahmad, M.; Rajapaksha, A.U.; Lim, J.E.; Zhang, M.; Bolan, N.; Mohan, D.; Vithanage, M.; Lee, S.S.; Ok, Y.S. Biochar as a Sorbent for Contaminant Management in Soil and Water: A Review. Chemosphere 2014, 99, 19–33. [Google Scholar] [CrossRef] [PubMed]

- Leng, L.; Huang, H.; Li, H.; Li, J.; Zhou, W. Biochar Stability Assessment Methods: A Review. Sci. Total Environ. 2019, 647, 210–222. [Google Scholar] [CrossRef] [PubMed]

- Spinei, M.; Oroian, M. The Potential of Grape Pomace Varieties as a Dietary Source of Pectic Substances. Foods 2021, 10, 867. [Google Scholar] [CrossRef] [PubMed]

- Sagdic, O.; Ozturk, I.; Yetim, H.; Kayacier, A.; Dogan, M. Mineral Contents and Nutritive Values of the Pomaces of Commercial Turkish Grape (Vitis vinifera L.) Varieties. Qual. Assur. Saf. Crops Foods 2014, 6, 89–93. [Google Scholar] [CrossRef]

- Rombaut, N.; Savoire, R.; Thomasset, B.; Castello, J.; Van Hecke, E.; Lanoisellé, J.-L. Optimization of Oil Yield and Oil Total Phenolic Content during Grape Seed Cold Screw Pressing. Ind. Crops Prod. 2015, 63, 26–33. [Google Scholar] [CrossRef]

- Beveridge, T.H.J.; Girard, B.; Kopp, T.; Drover, J.C.G. Yield and Composition of Grape Seed Oils Extracted by Supercritical Carbon Dioxide and Petroleum Ether: Varietal Effects. J. Agric. Food Chem. 2005, 53, 1799–1804. [Google Scholar] [CrossRef]

- Kozioł, A.; Środa-Pomianek, K.; Górniak, A.; Wikiera, A.; Cyprych, K.; Malik, M. Structural Determination of Pectins by Spectroscopy Methods. Coatings 2022, 12, 546. [Google Scholar] [CrossRef]

- Einhorn-Stoll, U.; Kastner, H.; Fatouros, A.; Krähmer, A.; Kroh, L.W.; Drusch, S. Thermal Degradation of Citrus Pectin in Low-Moisture Environment—Investigation of Backbone Depolymerisation. Food Hydrocoll. 2020, 107, 105937. [Google Scholar] [CrossRef]

- Zhou, S.; Xu, Y.; Wang, C.; Tian, Z. Pyrolysis Behavior of Pectin under the Conditions That Simulate Cigarette Smoking. J. Anal. Appl. Pyrolysis 2011, 91, 232–240. [Google Scholar] [CrossRef]

- Díez, D.; Urueña, A.; Piñero, R.; Barrio, A.; Tamminen, T. Determination of Hemicellulose, Cellulose, and Lignin Content in Different Types of Biomasses by Thermogravimetric Analysis and Pseudocomponent Kinetic Model (TGA-PKM Method). Processes 2020, 8, 1048. [Google Scholar] [CrossRef]

- Pardo, R.; Taboada-Ruiz, L.; Fuente, E.; Ruiz, B.; Díaz-Somoano, M.; Calvo, L.F.; Paniagua, S. Exploring the Potential of Conventional and Flash Pyrolysis Methods for the Valorisation of Grape Seed and Chestnut Shell Biomass from Agri-Food Industry Waste. Biomass Bioenergy 2023, 177, 106942. [Google Scholar] [CrossRef]

- Khiari, B.; Jeguirim, M. Pyrolysis of Grape Marc from Tunisian Wine Industry: Feedstock Characterization, Thermal Degradation and Kinetic Analysis. Energies 2018, 11, 730. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of Hemicellulose, Cellulose and Lignin Pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Jeguirim, M.; Bikai, J.; Elmay, Y.; Limousy, L.; Njeugna, E. Thermal Characterization and Pyrolysis Kinetics of Tropical Biomass Feedstocks for Energy Recovery. Energy Sustain. Dev. 2014, 23, 188–193. [Google Scholar] [CrossRef]

- Khalil, I.K.; Mustafa, A.S.; Mustafa, A.M. Study of Fatty Acid Composition, Physiochemical Properties and Thermal Stability of Broad Beans (Vicia Faba) Seed Oil. Agric. Biol. J. N. Am. 2017, 8, 141–146. [Google Scholar] [CrossRef]

- Tangolar, S.G.; Özoğul, Y.; Tangolar, S.; Torun, A. Evaluation of Fatty Acid Profiles and Mineral Content of Grape Seed Oil of Some Grape Genotypes. Int. J. Food Sci. Nutr. 2009, 60, 32–39. [Google Scholar] [CrossRef]

- Valente, M.; Brillard, A.; Schönnenbeck, C.; Brilhac, J.-F. Investigation of Grape Marc Combustion Using Thermogravimetric Analysis. Kinetic Modeling Using an Extended Independent Parallel Reaction (EIPR). Fuel Process. Technol. 2015, 131, 297–303. [Google Scholar] [CrossRef]

- Shen, D.K.; Gu, S.; Bridgwater, A.V. The Thermal Performance of the Polysaccharides Extracted from Hardwood: Cellulose and Hemicellulose. Carbohydr. Polym. 2010, 82, 39–45. [Google Scholar] [CrossRef]

- Prozil, S.O.; Evtuguin, D.V.; Lopes, L.P.C. Chemical Composition of Grape Stalks of Vitis vinifera L. from Red Grape Pomaces. Ind. Crops Prod. 2012, 35, 178–184. [Google Scholar] [CrossRef]

- Mendes, J.A.S.; Xavier, A.M.R.B.; Evtuguin, D.V.; Lopes, L.P.C. Integrated Utilization of Grape Skins from White Grape Pomaces. Ind. Crops Prod. 2013, 49, 286–291. [Google Scholar] [CrossRef]

- D’Eusanio, V.; Morelli, L.; Marchetti, A.; Tassi, L. Aroma Profile of Grapevine Chips after Roasting: A Comparative Study of Sorbara and Spergola Cultivars for More Sustainable Oenological Production. Separations 2023, 10, 532. [Google Scholar] [CrossRef]

| Biochar Loading (wt%) | Biochar (g) | G45 (g) | G23 (g) | CB (g) | DGEBA (g) | IPDA (g) |

|---|---|---|---|---|---|---|

| 10 | 0.46 | 2.65 | 0.57 | 0.19 | 0.56 | 0.12 |

| 15 | 0.68 | 2.47 | 0.54 | 0.18 | 0.56 | 0.12 |

| 20 | 0.91 | 2.29 | 0.50 | 0.17 | 0.56 | 0.12 |

| 25 | 1.14 | 2.12 | 0.46 | 0.16 | 0.56 | 0.12 |

| 30 | 1.37 | 1.94 | 0.42 | 0.14 | 0.56 | 0.12 |

| 35 | 1.59 | 1.77 | 0.38 | 0.13 | 0.56 | 0.12 |

| Pyrolysis Conditions | WSs | GSs | WGSs | DGSs | |

|---|---|---|---|---|---|

| Moisture | - | 6.97 ± 0.04 ab | 6.89 ± 0.07 a | 6.12 ± 0.03 c | 7.06 ± 0.09 b |

| 300 °C, 3 h | 2.47 ± 0.02 a | 2.56 ± 0.05 a | 1.01 ± 0.06 b | 0.97 ± 0.04 b | |

| 300 °C, 24 h | 2.44 ± 0.02 a | 2.60 ± 0.02 b | 1.03 ± 0.04 c | 1.04 ± 0.03 c | |

| Ash | - | 3.07 ± 0.02 a | 5.71 ± 0.04 b | 3.13 ± 0.03 a | 2.07 ± 0.02 c |

| 300 °C, 3 h | 3.68 ± 0.02 a | 6.65 ± 0.04 b | 3.55 ± 0.02 c | 2.94 ± 0.03 d | |

| 300 °C, 24 h | 4.23 ± 0.04 a | 7.61 ± 0.03 b | 3.71 ± 0.01 c | 3.44 ± 0.04 d | |

| C | - | 45.0 ± 0.3 a | 47.2 ± 0.6 b | 51.5 ± 0.4 c | 51.2 ± 0.5 c |

| 300 °C, 3 h | 51.0 ± 0.1 a | 57.8 ± 0.4 b | 63.9 ± 0.4 c | 58.9 ± 0.1 d | |

| 300 °C, 24 h | 61.7 ± 0.1 a | 63.1 ± 0.2 b | 68.8 ± 0.2 c | 64.9 ± 0.1 d | |

| H | - | 6.99 ± 0.21 a | 6.72 ± 0.53 ab | 6.01 ± 0.31 b | 6.08 ± 0.11 b |

| 300 °C, 3 h | 5.57 ± 0.14 a | 5.08 ± 0.01 b | 5.98 ± 0.15 c | 5.28 ± 0.02 b | |

| 300 °C, 24 h | 3.10 ± 0.04 a | 3.62 ± 0.03 b | 5.62 ± 0.02 c | 3.72 ± 0.07 b | |

| N | - | 0.50 ± 0.05 a | 1.46 ± 0.08 b | 1.22 ± 0.02 c | 1.43 ± 0.07 b |

| 300 °C, 3 h | 0.58 *a | 1.67 ± 0.05 b | 1.90 ± 0.36 b | 2.26 ± 0.39 b | |

| 300 °C, 24 h | 1.19 ± 0.03 a | 2.31 ± 0.01 b | 2.38 ± 0.03 b | 2.89 ± 0.15 c | |

| S | - | <0.1 | <0.1 | <0.1 | <0.1 |

| 300 °C, 3 h | <0.1 | <0.1 | <0.1 | <0.1 | |

| 300 °C, 24 h | <0.1 | <0.1 | <0.1 | <0.1 | |

| O (by difference) | - | 44.4 ± 0.3 a | 38.9 ± 0.6 b | 38.1 ± 0.3 b | 39.2 ± 0.5 b |

| 300 °C, 3 h | 39.2 ± 0.2 a | 28.8 ± 0.4 b | 24.7 ± 0.9 c | 30.6 ± 0.5 d | |

| 300 °C, 24 h | 29.8 ± 0.1 a | 23.4 ± 0.2 b | 19.5 ± 0.2 c | 25.0 ± 0.4 d | |

| O/C | - | 0.99 | 0.82 | 0.74 | 0.77 |

| 300 °C, 3 h | 0.77 | 0.50 | 0.39 | 0.52 | |

| 300 °C, 24 h | 0.48 | 0.37 | 0.28 | 0.39 | |

| H/C | - | 0.16 | 0.14 | 0.12 | 0.12 |

| 300 °C, 3 h | 0.11 | 0.09 | 0.09 | 0.09 | |

| 300 °C, 24 h | 0.05 | 0.06 | 0.08 | 0.06 |

| Region | Thermally Activated Process |

|---|---|

| 20–120 °C | Removal of moisture and VOCs. |

| 120–250 °C | Removal of bound water, low-boiling VOCs, and caramelization of sugars. Degradation of pectin and proteins. |

| 250–400 °C | Degradation of hemicellulose, cellulose, and lipids. |

| 400–800 °C | Slow volatilization of lignin and volatilization of intermediate compounds formed after pyrolysis. |

| 800–1000 °C | Volatilization of carbon residues (C20–C40 fragments). |

| wt% | 10 | 15 | 20 | 25 | 30 | 35 | |

|---|---|---|---|---|---|---|---|

| Sample | |||||||

| GS3 | 1.78 ± 0.04 a | 1.72 ± 0.02 ac | 1.69 ± 0.04 ac | 1.62 *ac | |||

| WGS3 | 1.59 ± 0.04 b | 1.56 ± 0.02 b | 1.53 ± 0.05 b | 1.49 ± 0.02 b | |||

| DGS3 | 1.72 ± 0.07 a | 1.67 ± 0.02 a | 1.64 ± 0.03 bc | 1.57 ± 0.01 bc | 1.52 ± 0.07 a | 1.50 ± 0.01 a | |

| WD3 | 1.74 ± 0.04 a | 1.73 ± 0.03 cd | 1.70 ± 0.02 cd | 1.68 ± 0.02 ad | |||

| GS24 | 1.77 ± 0.04 a | 1.74 ± 0.01 cd | 1.70 ± 0.03 cd | 1.64 ± 0.01 ac | |||

| WGS24 | 1.74 ± 0.03 a | 1.71 ± 0.03 ad | 1.70 ± 0.01 cd | 1.66 ± 0.01 ac | 1.60 ± 0.01 ab | ||

| DGS24 | 1.84 ± 0.04 a | 1.77 ± 0.02 c | 1.75 ± 0.03 ad | 1.68 ± 0.01 ad | 1.64 ± 0.02 b | 1.57 ± 0.04 b | |

| WD24 | 1.82 ± 0.06 a | 1.76 ± 0.02 cd | 1.72 ± 0.06 cd | 1.64 ± 0.08 ac | |||

| wt% | 10 | 15 | 20 | 25 | 30 | 35 | |

|---|---|---|---|---|---|---|---|

| Sample | |||||||

| GS3 | 127.6 ± 9.6 ab | 113.1 ± 10.2 a | 96.7 ± 7.1 abc | 87.5 ± 8.8 ab | |||

| WGS3 | 102.6 ± 11.4 a | 96.4 ± 7.2 a | 89.7 ± 8.7 ac | 73.5 ± 9.1 a | |||

| DGS3 | 132.5 ± 10.1 b | 120.7 ± 9.9 a | 114.2 ± 8.1 bc | 95.4 ± 11.8 ab | 81.7 ± 10.6 ab | 74.4 ± 10.6 a | |

| WD3 | 120.5 ± 8.6 ab | 110.9 ± 11.7 a | 99.8 ± 6.2 abc | 89.4 ± 5.9 ab | |||

| GS24 | 127.8 ± 9.6 ab | 114.2 ± 10.5 a | 94.1 ± 7.7 abc | 82.3 ± 11.5 ab | |||

| WGS24 | 103.4 ± 9.9 a | 95.0 ± 10.3 a | 86.1 ± 7.2 a | 75.0 ± 8.9 ab | 66.6 ± 5.9 a | ||

| DGS24 | 128.7 ± 10.2 ab | 117.1 ± 10.6 a | 109.4 ± 8.7 c | 100.0 ± 10.0 b | 88.8 ± 8.5 b | 74.6 ± 9.9 a | |

| WD24 | 113.5 ± 9.6 ab | 104.2 ± 10.2 a | 96.2 ± 8.8 abc | 79.6 ± 6.9 ab | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

D’Eusanio, V.; Lezza, A.; Anderlini, B.; Malferrari, D.; Romagnoli, M.; Roncaglia, F. Technological Prospects of Biochar Derived from Viticulture Waste: Characterization and Application Perspectives. Energies 2024, 17, 3421. https://doi.org/10.3390/en17143421

D’Eusanio V, Lezza A, Anderlini B, Malferrari D, Romagnoli M, Roncaglia F. Technological Prospects of Biochar Derived from Viticulture Waste: Characterization and Application Perspectives. Energies. 2024; 17(14):3421. https://doi.org/10.3390/en17143421

Chicago/Turabian StyleD’Eusanio, Veronica, Antonio Lezza, Biagio Anderlini, Daniele Malferrari, Marcello Romagnoli, and Fabrizio Roncaglia. 2024. "Technological Prospects of Biochar Derived from Viticulture Waste: Characterization and Application Perspectives" Energies 17, no. 14: 3421. https://doi.org/10.3390/en17143421

APA StyleD’Eusanio, V., Lezza, A., Anderlini, B., Malferrari, D., Romagnoli, M., & Roncaglia, F. (2024). Technological Prospects of Biochar Derived from Viticulture Waste: Characterization and Application Perspectives. Energies, 17(14), 3421. https://doi.org/10.3390/en17143421