Numerical Investigation on the Flame Characteristics of Lean Premixed Methane Flame Piloted with Rich Premixed Flame

Abstract

1. Introduction

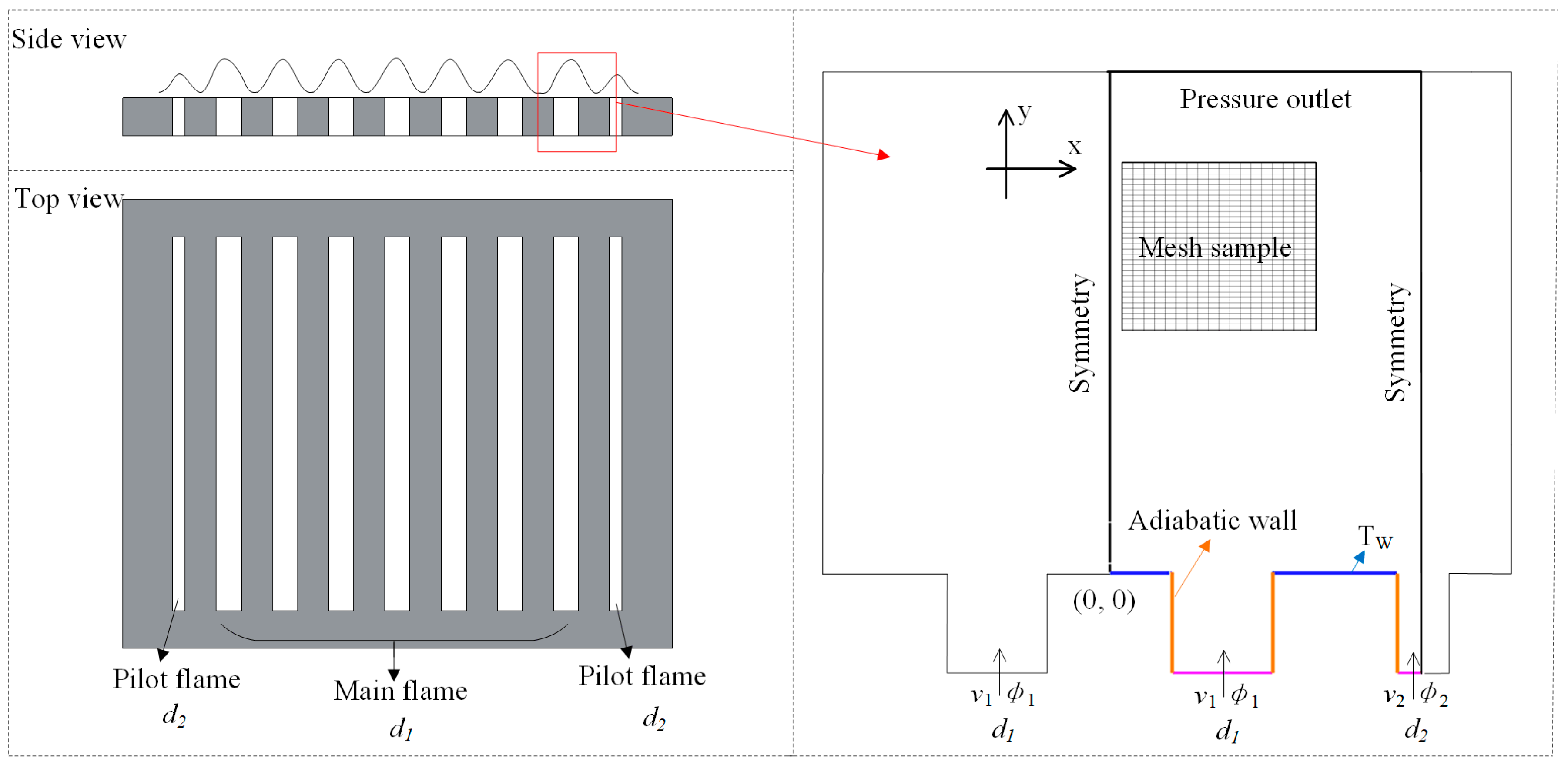

2. Model and Numerical Methodology

2.1. Computational Method

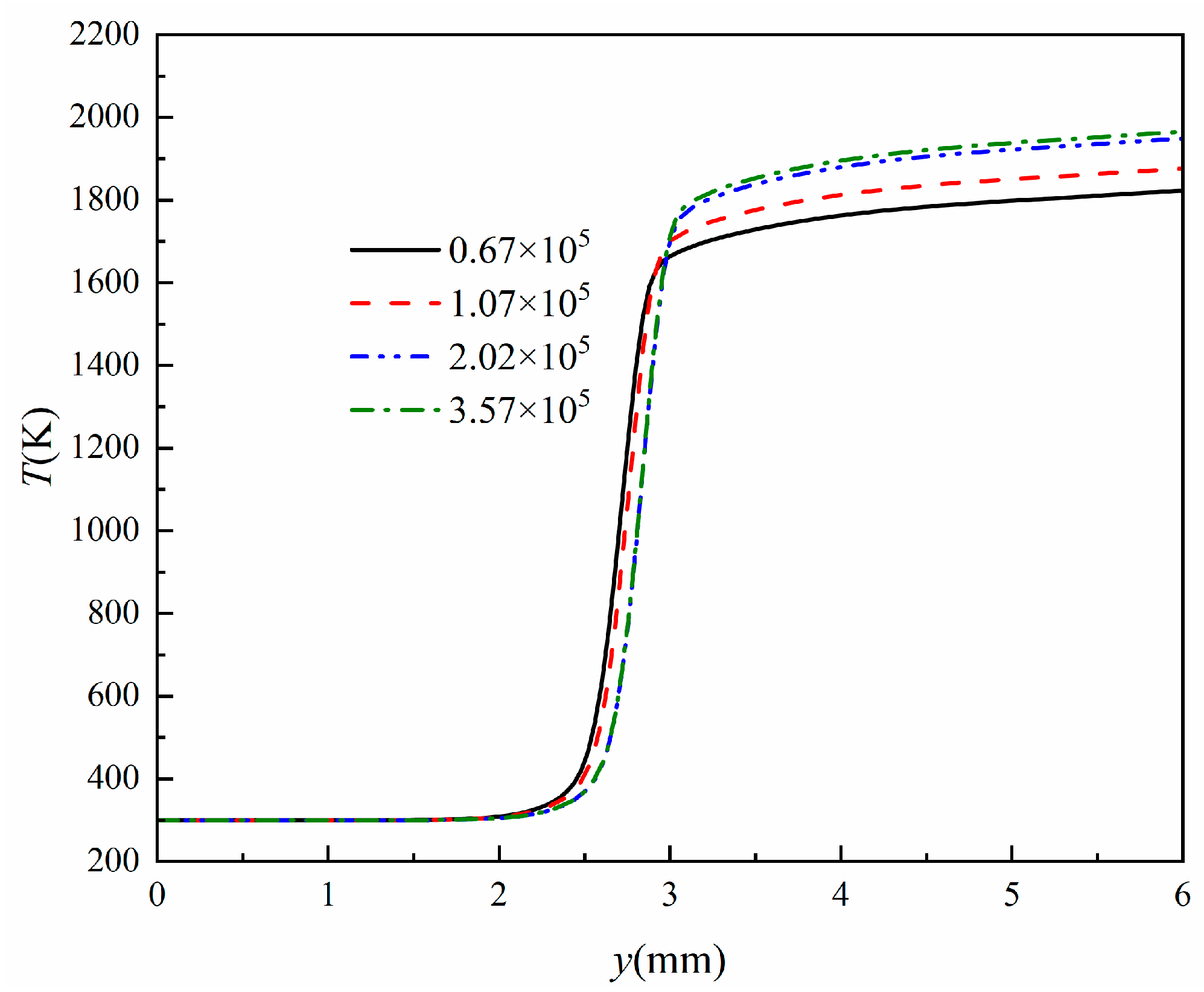

2.2. Computational Domain and Mesh Independence

2.3. Numerical Setup

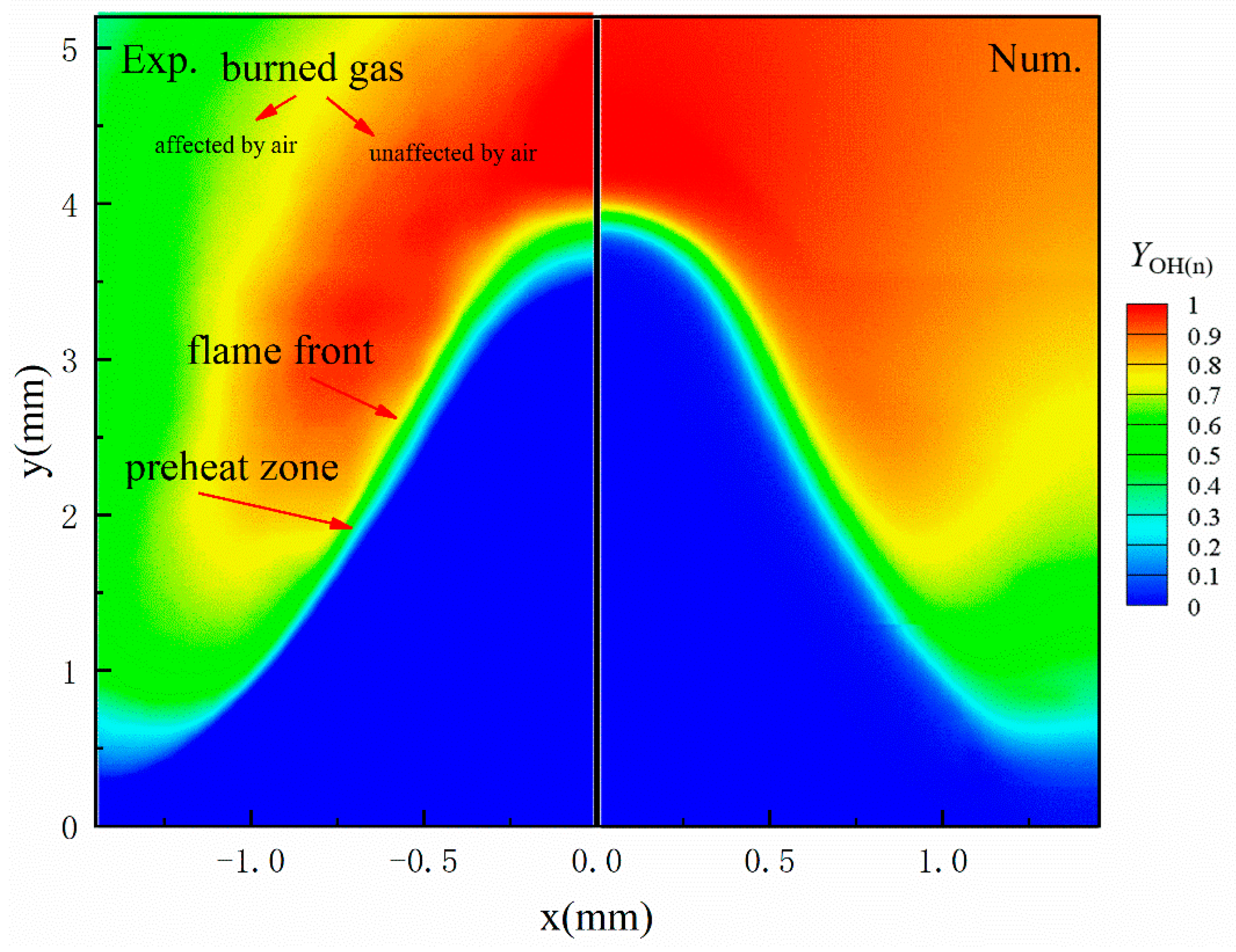

3. Validation of the Numerical Model

4. Result and Discussion

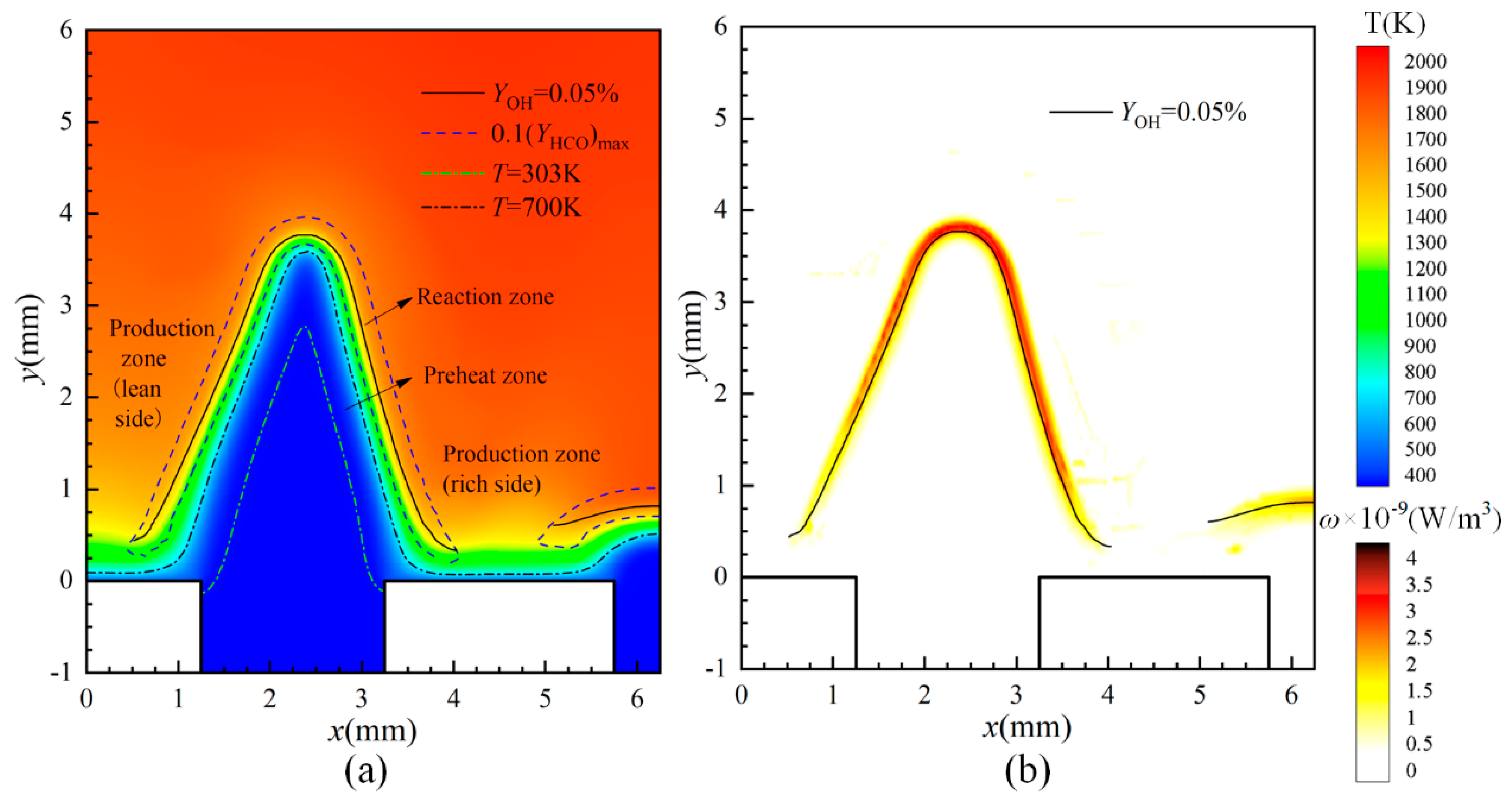

4.1. Flame Characteristic

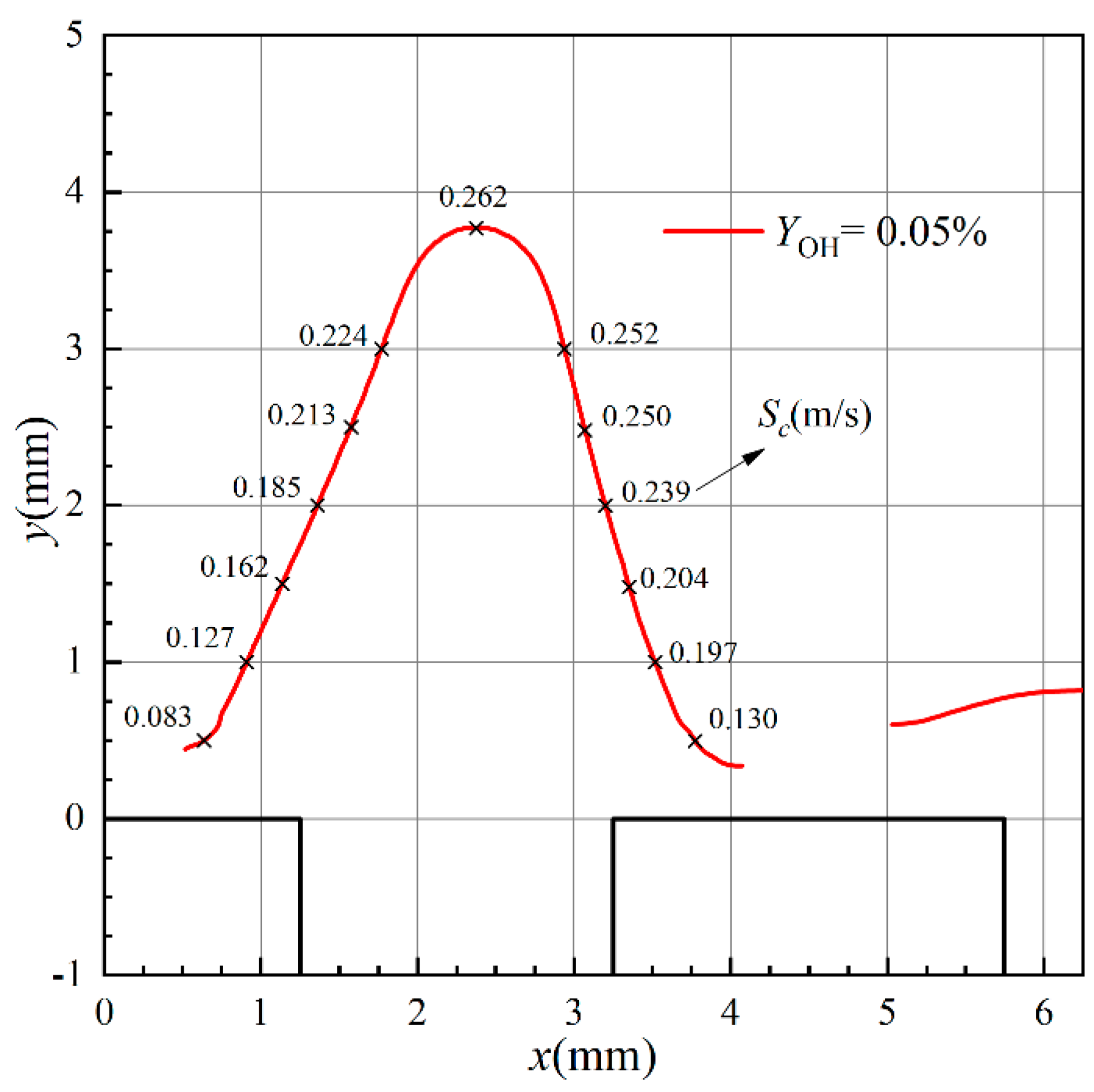

4.2. Consumption Speed

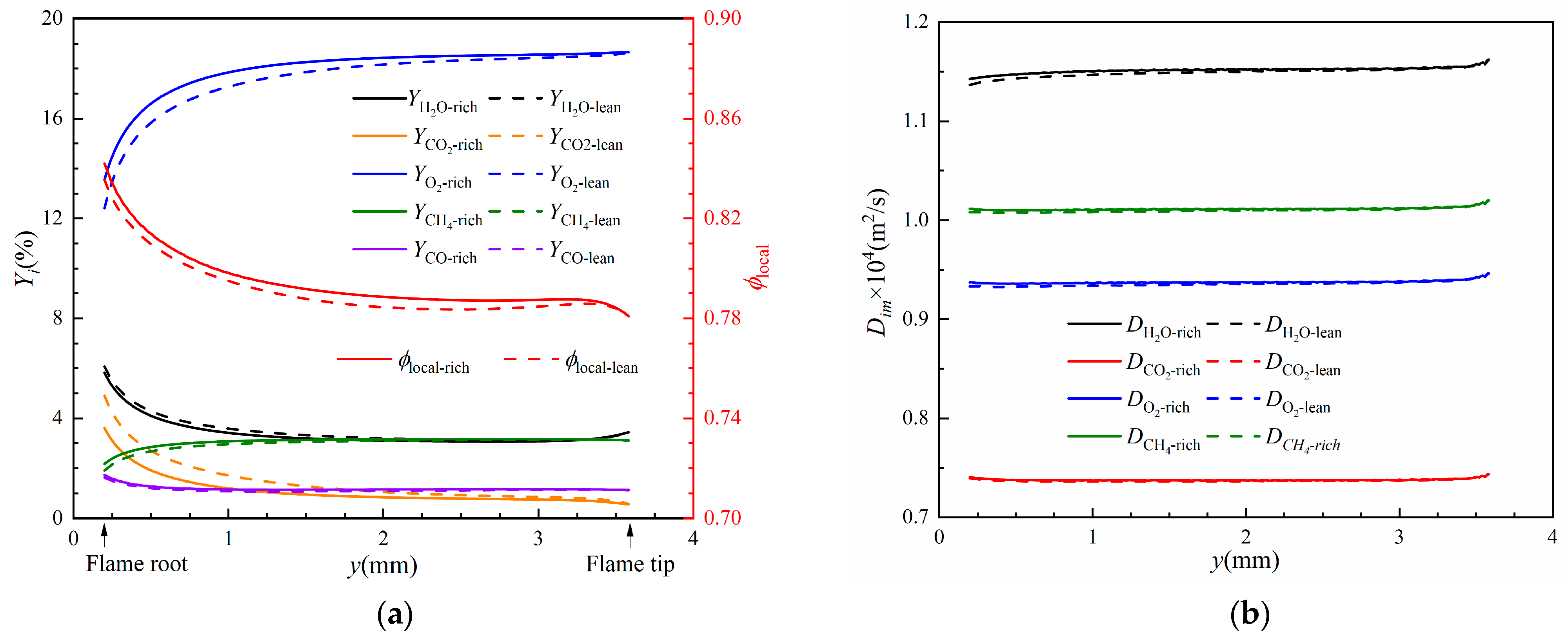

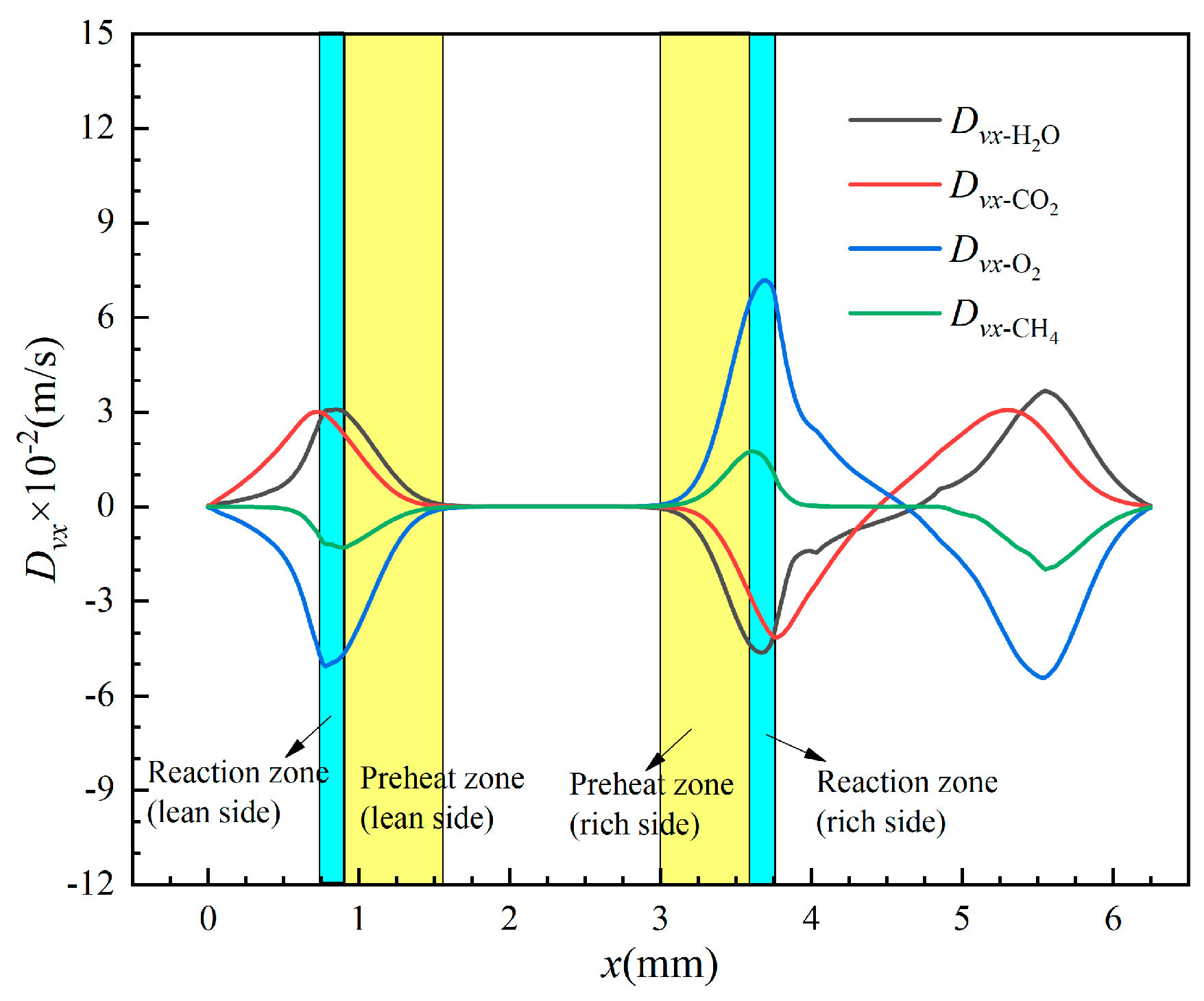

4.2.1. Effect of Preferential Diffusion

4.2.2. Effect of Heat Transfer

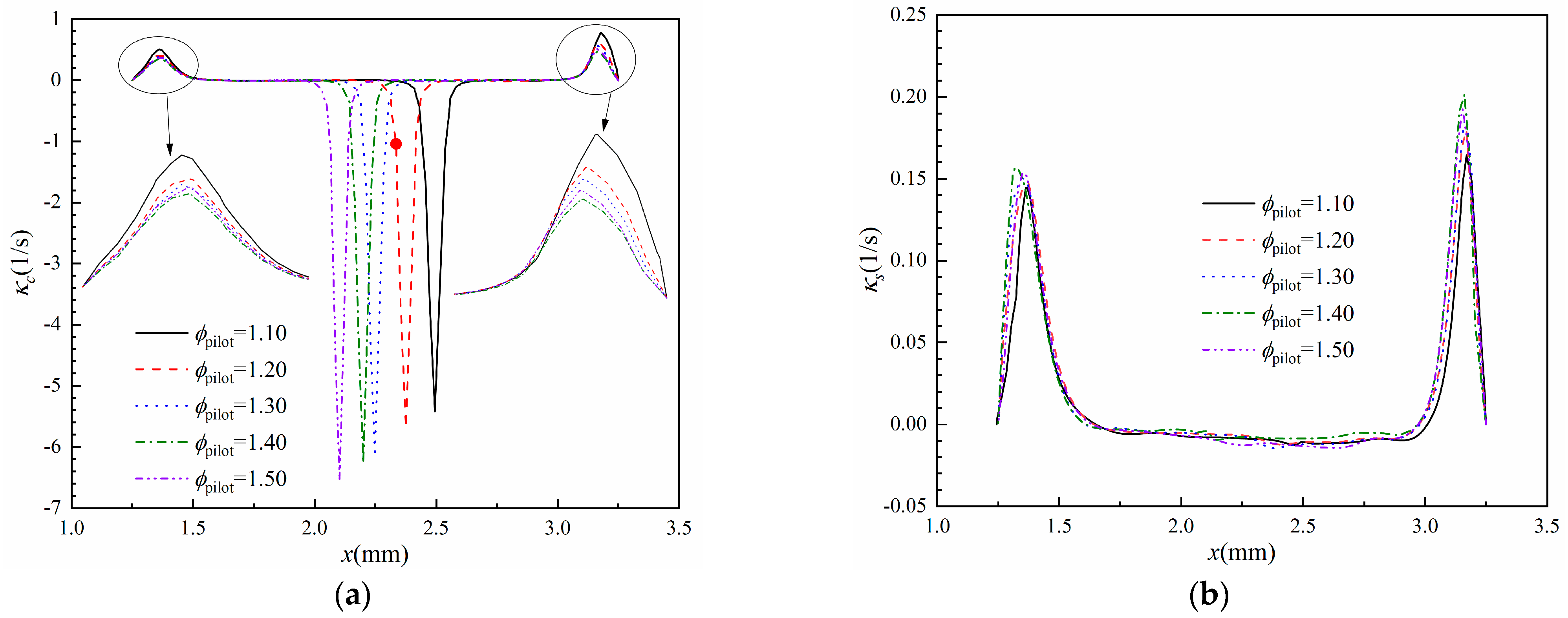

4.3. Flame Stretch

5. Conclusions

- (1)

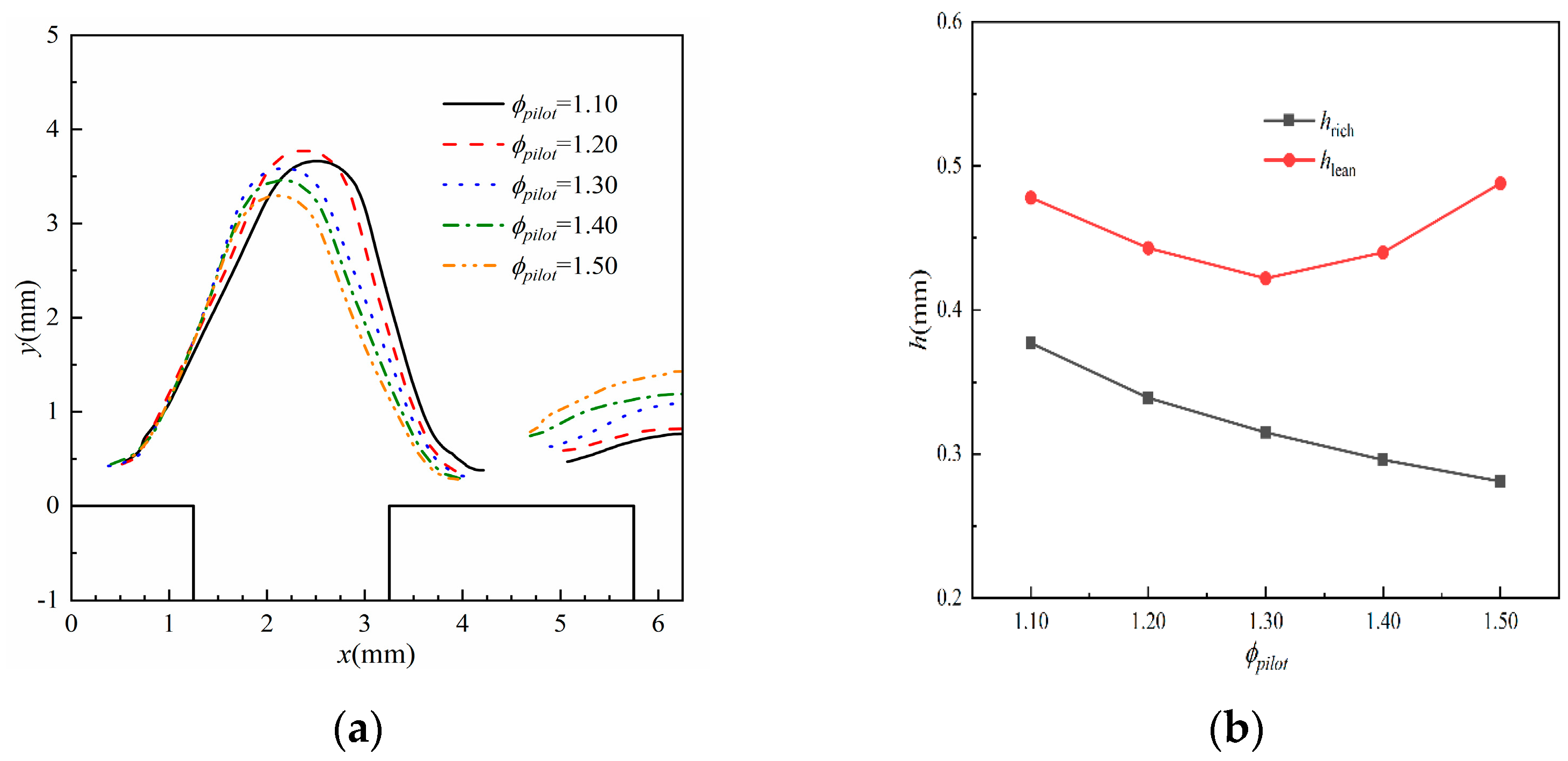

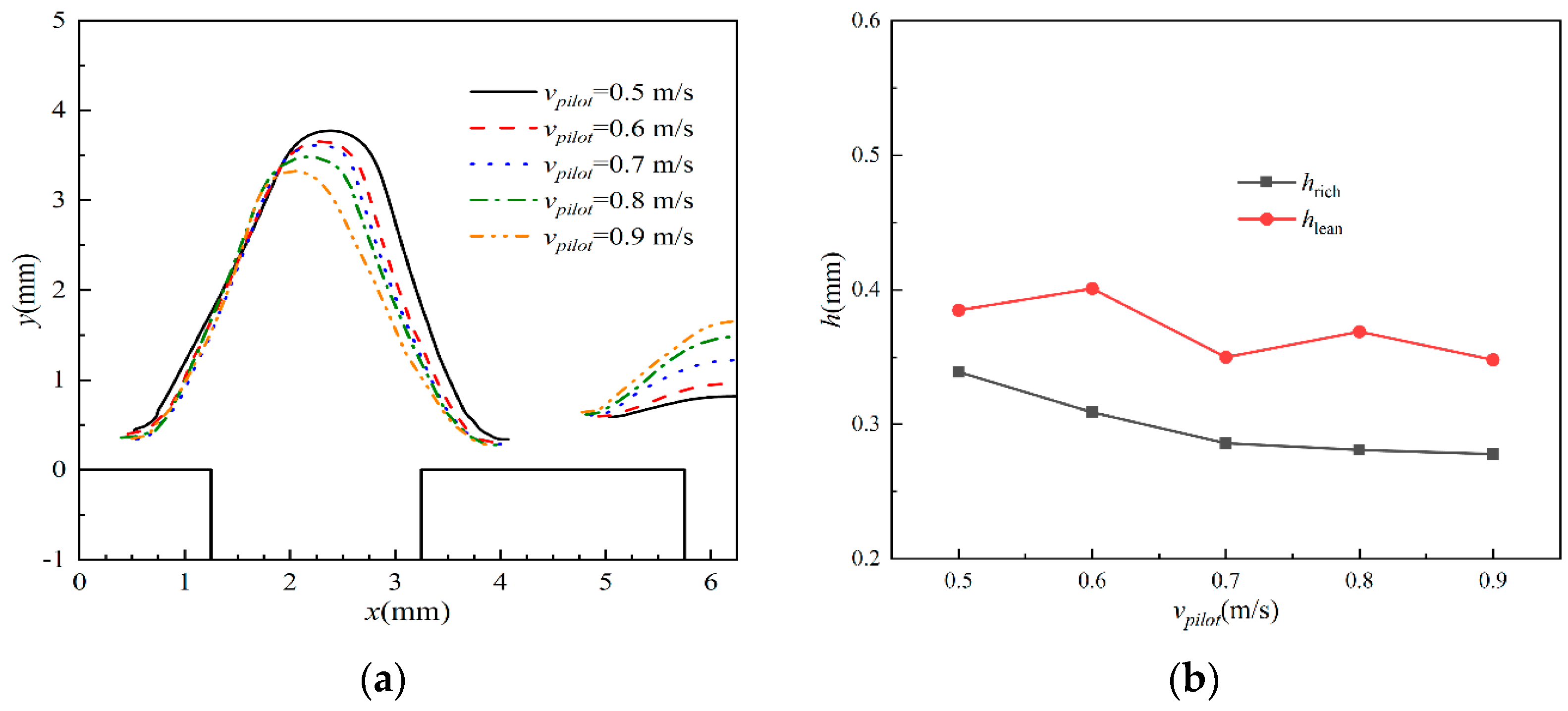

- The main flame is asymmetrical, with the flame tip inclining toward the pilot flame. Meanwhile, the main flame stand-off distances of the lean side are larger than those of the rich side. The pilot flame could help the main flame anchor closer to the flame wall, and this influence is more remarkable as the ϕpilot and vpilot increase.

- (2)

- Affected by the pilot flame, the combustion speeds on the rich side are generally greater than those on the lean side. The increasing ϕpilot and vpilot promote the combustion on the rich side of the main flame root, and this effect becomes weaker gradually as ϕpilot increases from 1.1 to 1.5 and vpilot increases from 0.5 m/s to 0.9 m/s.

- (3)

- The local equivalence ratio on the main flame preheat zone of the rich side is generally greater than that of the lean side. Meanwhile, the conductive heat flux on the preheat and reaction zones of the rich side is greater than that of the lean side. The distribution of the local equivalence ratio and heat transfer contribute to the increase in combustion speeds on the rich side of the main flame.

- (4)

- The flame stretch rate near the flame tip is negative and dominated by the curvature rate, while it is positive and related to both the curvature rate and strain rate near the flame root. Both the curvature and strain rate show more significant effects on the rich side of the main flame root, which contributes to the main flame bending towards the pilot flame.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Cp | Specific heat capacity (J/(kg·K)) |

| d | Width of flame port (mm) |

| D | Diffusion coefficient (m2/s) |

| Dv | Diffusion velocity (m/s) |

| H | Flame height (mm) |

| h | Stand-off distance (mm) |

| p | Pressure (Pa) |

| ri | Enthalpy of species i |

| Sc | Consumption speed (m/s) |

| T | Temperature (K) |

| u | Velocity in x-direction (m/s) |

| v | Velocity in y-direction (m/s) |

| W | Molar mass (g/mol) |

| x | x-coordinate (m) |

| y | y-coordinate (m) |

| Xi | Molar fraction of the ith species |

| Yi | Mass fraction of the ith species |

| Greek symbols | |

| ρ | Density (kg/m3) |

| ϕ | Equivalence ratio |

| Molar production rate of species i | |

| ω | Volumetric heat release rate (W/m3) |

| λ | Thermal conductivity (W/(m·K)) |

| κ | Flame stretch rate (1/s) |

| Subscripts | |

| main | Main flame |

| pilot | Pilot flame |

| lean | Lean side of main flame |

| rich | Rich side of main flame |

| b | Burned mixture |

| u | Unburned mixture |

References

- Altay, H.M.; Kedia, K.S.; Speth, R.L.; Ghoniem, A.F. Two-dimensional simulations of steady perforated-plate stabilized premixed flames. Combust. Theory Model. 2010, 14, 125–154. [Google Scholar] [CrossRef]

- Kedia, K.S.; Ghoniem, A.F. Mechanisms of stabilization and blowoff of a premixed flame downstream of a heat-conducting perforated plate. Combust. Flame 2012, 159, 1055–1069. [Google Scholar] [CrossRef]

- Qin, F.; Shah, A.; Huang, Z.W.; Peng, L.N.; Tunestal, P.; Bai, X.S. Detailed numerical simulation of transient mixing and combustion of premixed methane/air mixtures in a pre-chamber/main-chamber system relevant to internal combustion engines. Combust. Flame 2018, 188, 357–366. [Google Scholar] [CrossRef]

- Yasuda, H.; Asato, K.; Miyasaka, T.; Miyashita, T.; Sakakibara, D.; Kurachi, S.; Hagi, S.; Umeda, Y. Characteristics of Combustion of Rich-Lean Burner Controlled Boundary Region between Rich and Lean Flames. Trans. Jpn. Soc. Mech. Eng. B 2006, 73, 3143–3150. [Google Scholar]

- Aoki, S.; Yamazaki, H. Combustion Mechanism of Rich-Lean Flame Burner Controlled Boundary Zone. In Proceedings of the ASME/JSME Thermal Engineering Heat Transfer Summer Conference collocated with the ASME 2007 InterPACK Conference, Vancouver, BC, Canada, 8–12 July 2007. [Google Scholar]

- Vance, F.H.; Shoshin, Y.; Goey, L.; Oijen, J. An investigation into flashback and blow-off for premixed flames stabilized without a recirculation vortex. Combust. Flame 2021, 235, 111690. [Google Scholar] [CrossRef]

- Yu, S.; Bai, X.S.; Zhou, B.; Wang, Z.; Aldén, M. Numerical Studies of the Pilot Flame Effect on a Piloted Jet Flame. Combust. Sci. Technol. 2019, 194, 351–364. [Google Scholar] [CrossRef]

- Zhou, B.; Brackmann, C.; Li, Z.; Aldén, M.; Bai, X.S. Simultaneous multi-species and temperature visualization of premixed flames in the distributed reaction zone regime. Proc. Combust. Inst. 2015, 35, 1409–1416. [Google Scholar] [CrossRef]

- Pires, J.M.; Fernandes, E.C. Combined effect of equivalence ratio and velocity gradients on flame stability and emission formation. Fuel 2018, 222, 800–809. [Google Scholar] [CrossRef]

- Li, Z.S.; Li, B.; Sun, Z.W.; Bai, X.S.; Aldén, M. Turbulence and combustion interaction: High resolution local flame front structure visualization using simultaneous single-shot PLIF imaging of CH, OH, and CH2O in a piloted premixed jet flame. Combust. Flame 2010, 157, 1087–1096. [Google Scholar] [CrossRef]

- Zhou, B.; Costa, M.; Li, Z.; Aldén, M.; Bai, X.S. Characterization of the reaction zone structures in a laboratory combustor using optical diagnostics: From flame to flameless combustion. Proc. Combust. Inst. 2016, 36, 4305–4312. [Google Scholar] [CrossRef]

- Zhou, B.; Brackmann, C.; Wang, Z.; Li, Z.; Richter, M.; Alden, M.; Bai, X.S. Thin reaction zone and distributed reaction zone regimes in turbulent premixed methane/air flames: Scalar distributions and correlations. Combust. Flame 2017, 175, 220–236. [Google Scholar] [CrossRef]

- Lúcio, T.; Fernandes, E. Rich–Lean Flame Interaction in a Lamella-Type Burner. Combust. Sci. Technol. 2015, 188, 416–438. [Google Scholar] [CrossRef]

- Guo, H.; Liu, F.; Smallwood, G.J. A numerical study of laminar methane/air triple flames in two-dimensional mixing layers. Int. J. Therm. Sci. 2006, 45, 586–594. [Google Scholar] [CrossRef]

- Azzoni, R.; Ratti, S.; Puri, I.K.; Aggarwal, S.K. The structure of triple flames stabilized on slot burner. Combust. Flame 1999, 119, 23–40. [Google Scholar] [CrossRef]

- Barlow, R.S.; Dunn, M.J.; Sweeney, M.S.; Hochgreb, S. Effects of preferential transport in turbulent bluff-body-stabilized lean premixed CH4/air flames. Combust. Flame 2012, 159, 2563–2575. [Google Scholar] [CrossRef]

- Wan, J.; Zhao, H.; Akkerman, V.Y. Anchoring mechanisms of a holder-stabilized premixed flame in a preheated mesoscale combustor. Phys. Fluids 2020, 32, 97103. [Google Scholar] [CrossRef]

- Vance, F.H.; Shoshin, Y.; de Goey, L.P.H.; van Oijen, J.A. Quantifying the impact of heat loss, stretch and preferential diffusion effects to the anchoring of bluff body stabilized premixed flames. Combust. Flame 2022, 237, 111729. [Google Scholar] [CrossRef]

- Choi, C.W.; Puri, I.K. Flame stretch effects on partially premixed flames. Combust. Flame 2000, 123, 119–139. [Google Scholar] [CrossRef]

- Choi, C.W.; Puri, I.K. Contribution of curvature to flame-stretch effects on premixed flames. Combust. Flame 2001, 126, 1640–1654. [Google Scholar] [CrossRef]

- Michaels, D.; Ghoniem, A.F. Impact of the bluff-body material on the flame leading edge structure and flame–flow interaction of premixed CH4/air flames. Combust. Flame 2016, 172, 62–78. [Google Scholar] [CrossRef]

- Bennett, B.A.V.; Fielding, J.; Mauro, R.J.; Long, M.B.; Smooke, M.D. A comparison of the structures of lean and rich axisymmetric laminar Bunsen flames: Application of local rectangular refinement solution-adaptive gridding. Combust. Theory Model. 1999, 3, 657–687. [Google Scholar] [CrossRef]

- Smooke, M.D.; Puri, I.K.; Seshadri, K. A comparison between numerical calculations and experimental measurements of the structure of a counterflow diffusion flame burning diluted methane in diluted air. Symp. (Int.) Combust. 1988, 21, 1783–1792. [Google Scholar] [CrossRef]

- Kedia, K.S. Development of a Multi-Scale Projection Method with Immersed Boundaries for Chemically Reactive Flows and Its Application to Examine Flame Stabilization and Blow-Off Mechanisms. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2013. [Google Scholar]

- Hu, S.; Gao, J.; Gong, C.; Zhou, Y.; Bai, X.S.; Li, Z.S.; Alden, M. Assessment of uncertainties of laminar flame speed of premixed flames as determined using a Bunsen burner at varying pressures. Appl. Energy 2017, 227, 149–158. [Google Scholar] [CrossRef]

- Bechtold, J.K.; Matalon, M. The dependence of the Markstein length on stoichiometry. Combust. Flame 2001, 127, 1906–1913. [Google Scholar] [CrossRef]

- Kedia, K.S.; Ghoniem, A.F. The blow-off mechanism of a bluff-body stabilized laminar premixed flame. Combust. Flame 2015, 162, 1304–1315. [Google Scholar] [CrossRef]

- Chen, T.; Yu, S.; Liu, Y.C. Effects of pressure on propagation characteristics of methane-air edge flames within two-dimensional mixing layers: A numerical study. Fuel 2021, 301, 120857. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Cui, Y.; Yin, P.; Mao, W.; Zhang, P. Numerical Investigation on the Flame Characteristics of Lean Premixed Methane Flame Piloted with Rich Premixed Flame. Energies 2024, 17, 3430. https://doi.org/10.3390/en17143430

Zhang L, Cui Y, Yin P, Mao W, Zhang P. Numerical Investigation on the Flame Characteristics of Lean Premixed Methane Flame Piloted with Rich Premixed Flame. Energies. 2024; 17(14):3430. https://doi.org/10.3390/en17143430

Chicago/Turabian StyleZhang, Lili, Yongzhang Cui, Pengfei Yin, Wenlong Mao, and Pengzhao Zhang. 2024. "Numerical Investigation on the Flame Characteristics of Lean Premixed Methane Flame Piloted with Rich Premixed Flame" Energies 17, no. 14: 3430. https://doi.org/10.3390/en17143430

APA StyleZhang, L., Cui, Y., Yin, P., Mao, W., & Zhang, P. (2024). Numerical Investigation on the Flame Characteristics of Lean Premixed Methane Flame Piloted with Rich Premixed Flame. Energies, 17(14), 3430. https://doi.org/10.3390/en17143430