Design of Underwater Compressed Air Flexible Airbag Energy Storage Device and Experimental Study of Physical Model in Pool

Abstract

:1. Introduction

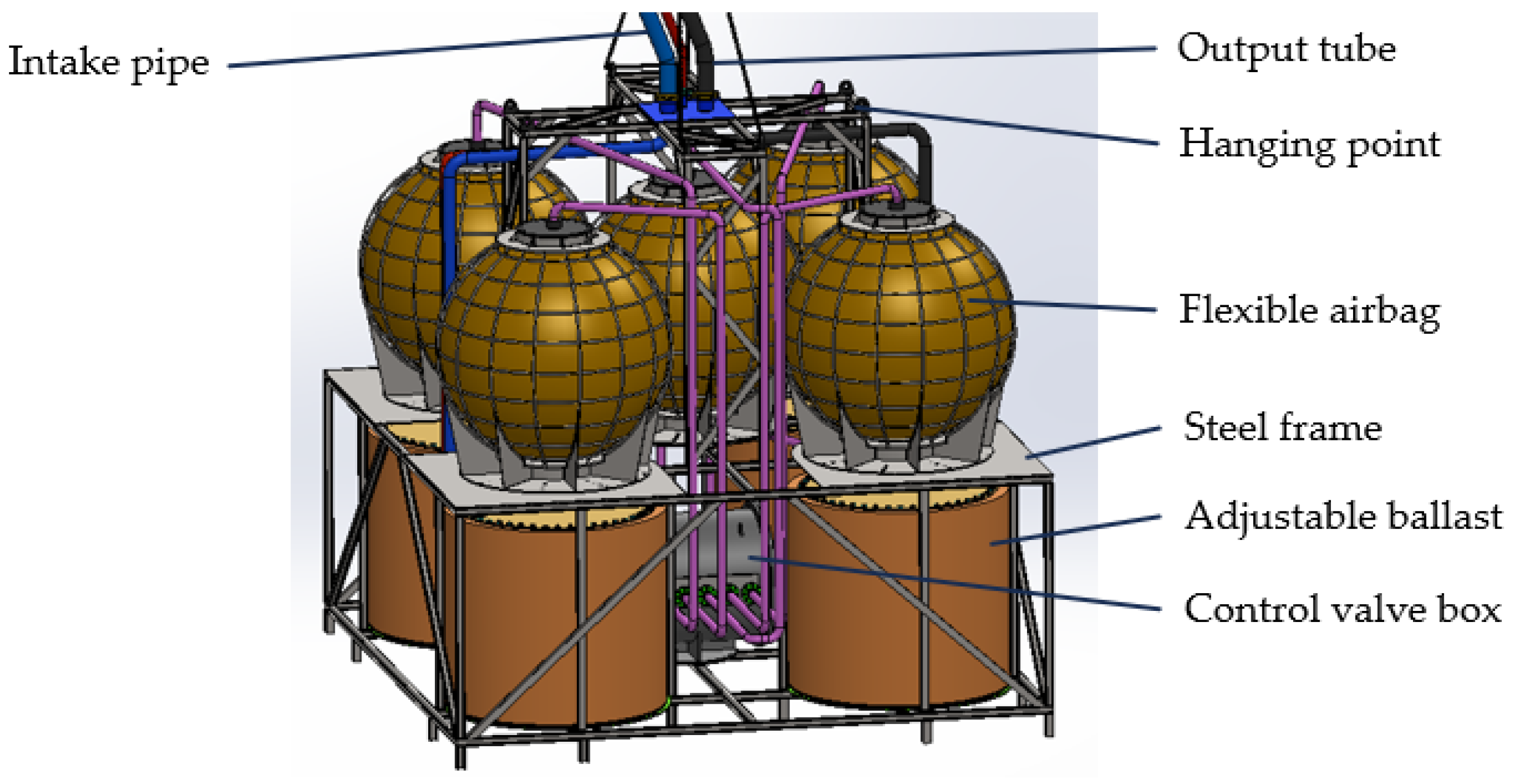

2. Design of Flexible Air Bag Storage Device for Underwater Compressed Gas

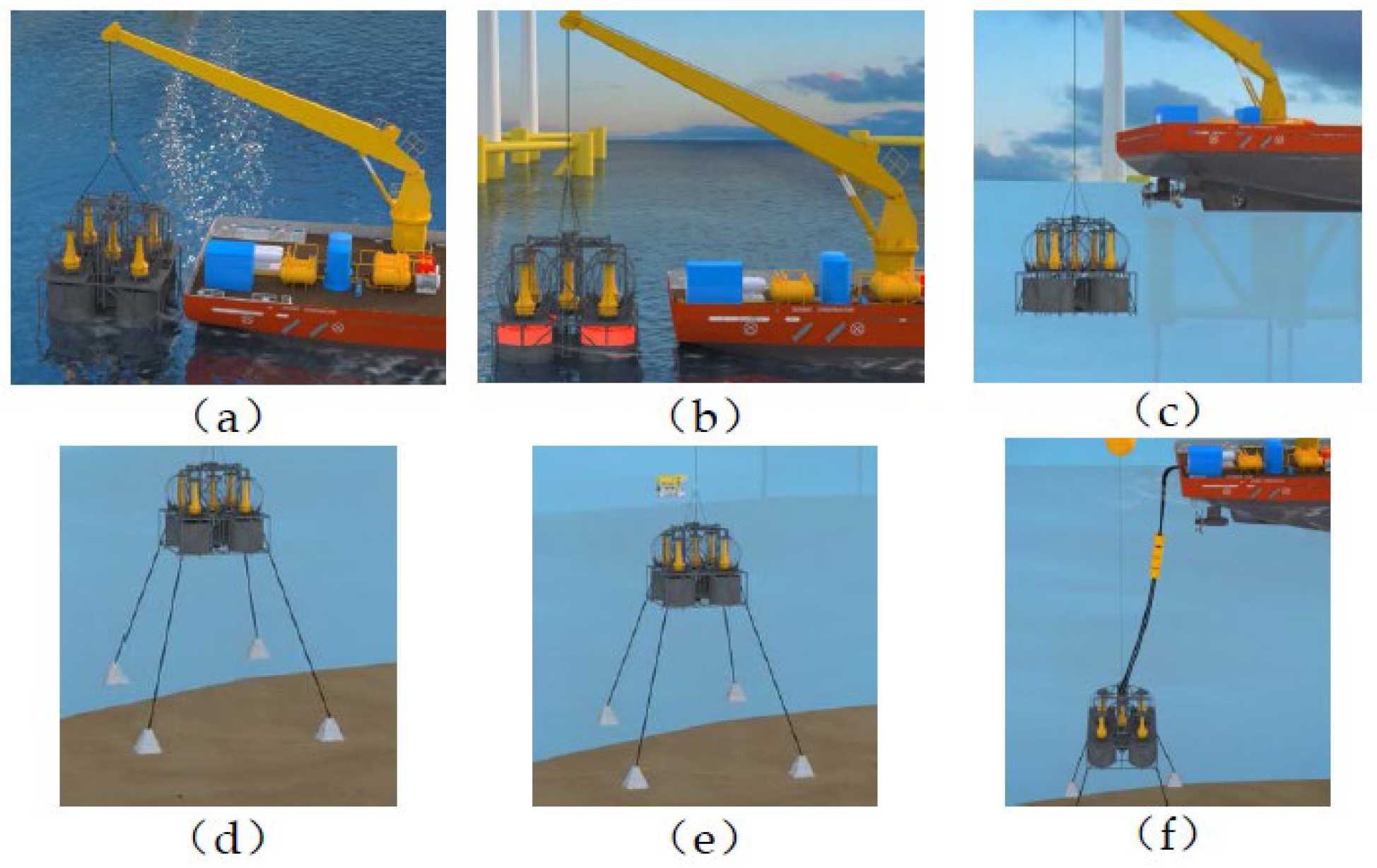

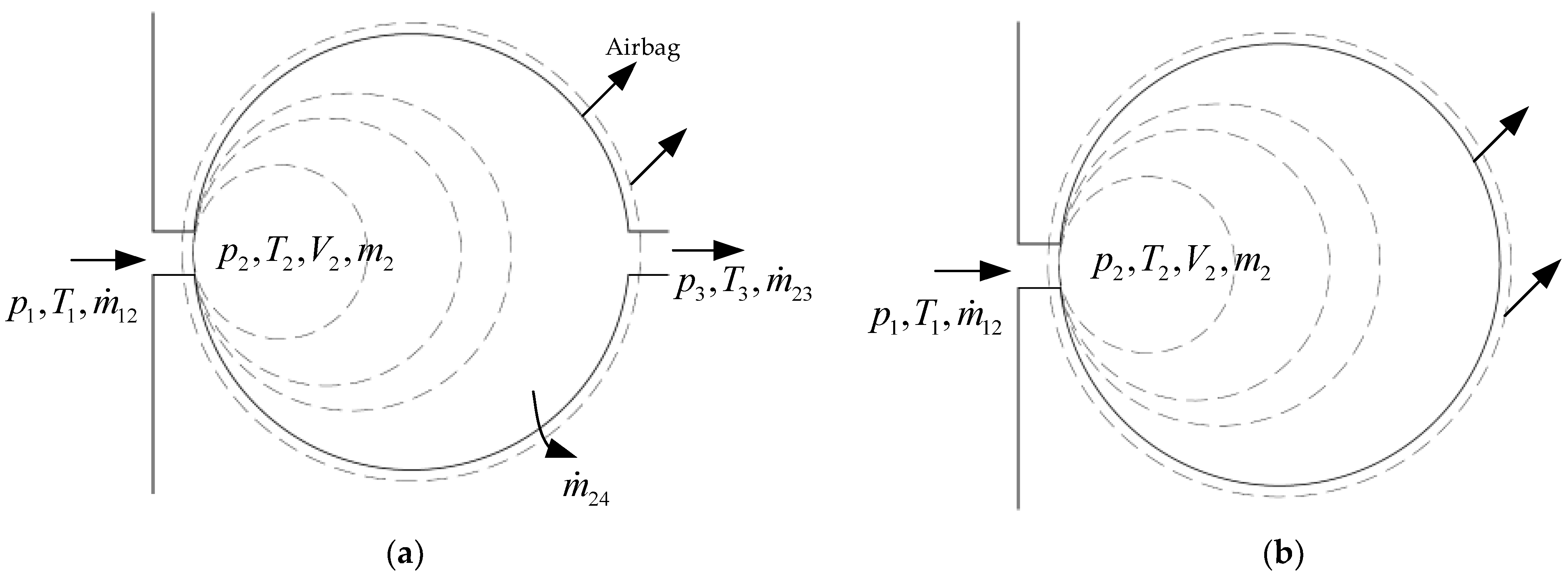

2.1. The Working System of Underwater Compressed Gas Flexible Air Bag Energy Storage Device

2.2. Design and Calculation of Flexible Air Bag Storage Device for Underwater Compressed Air

3. Airbag Inflation Simulation Test and Physical Model Test

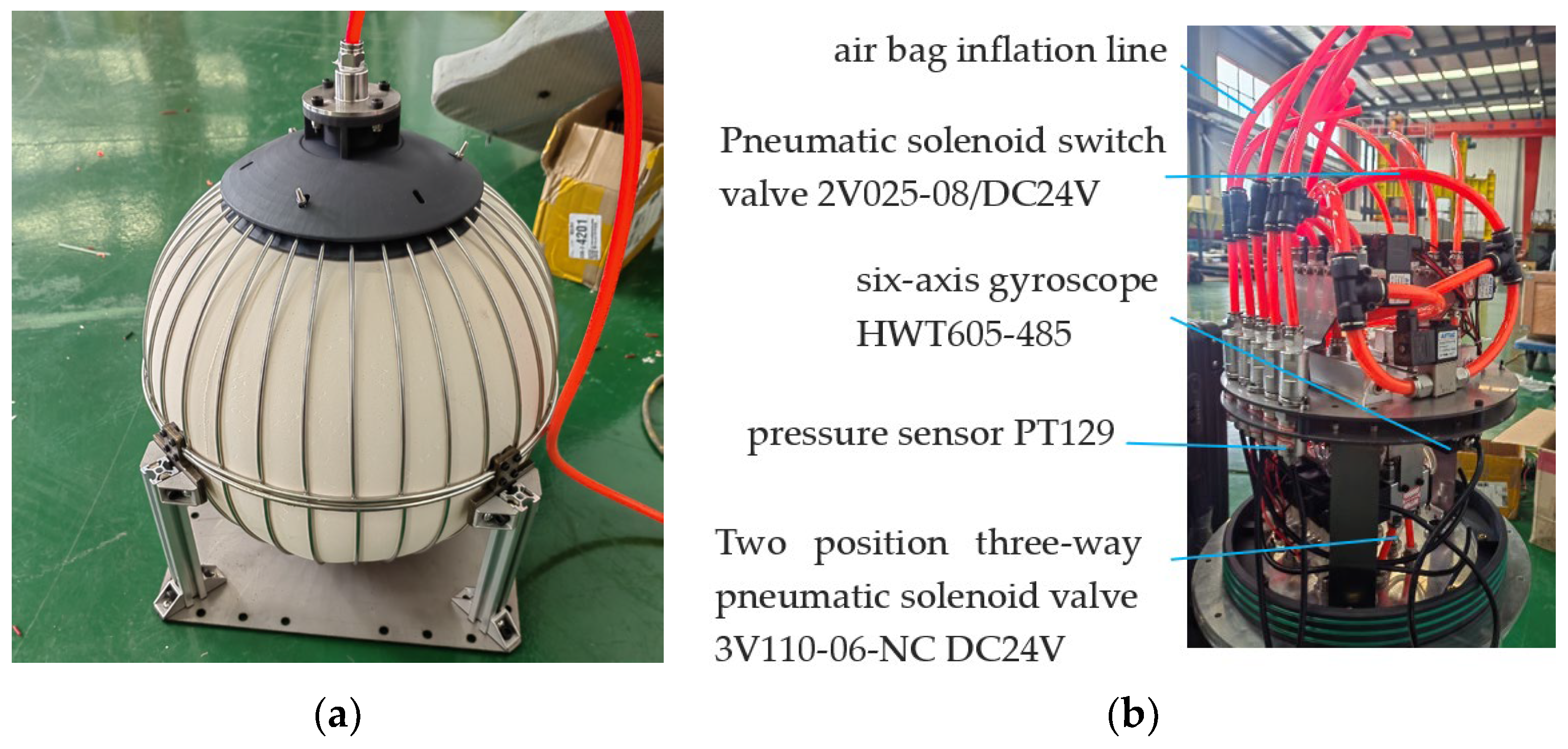

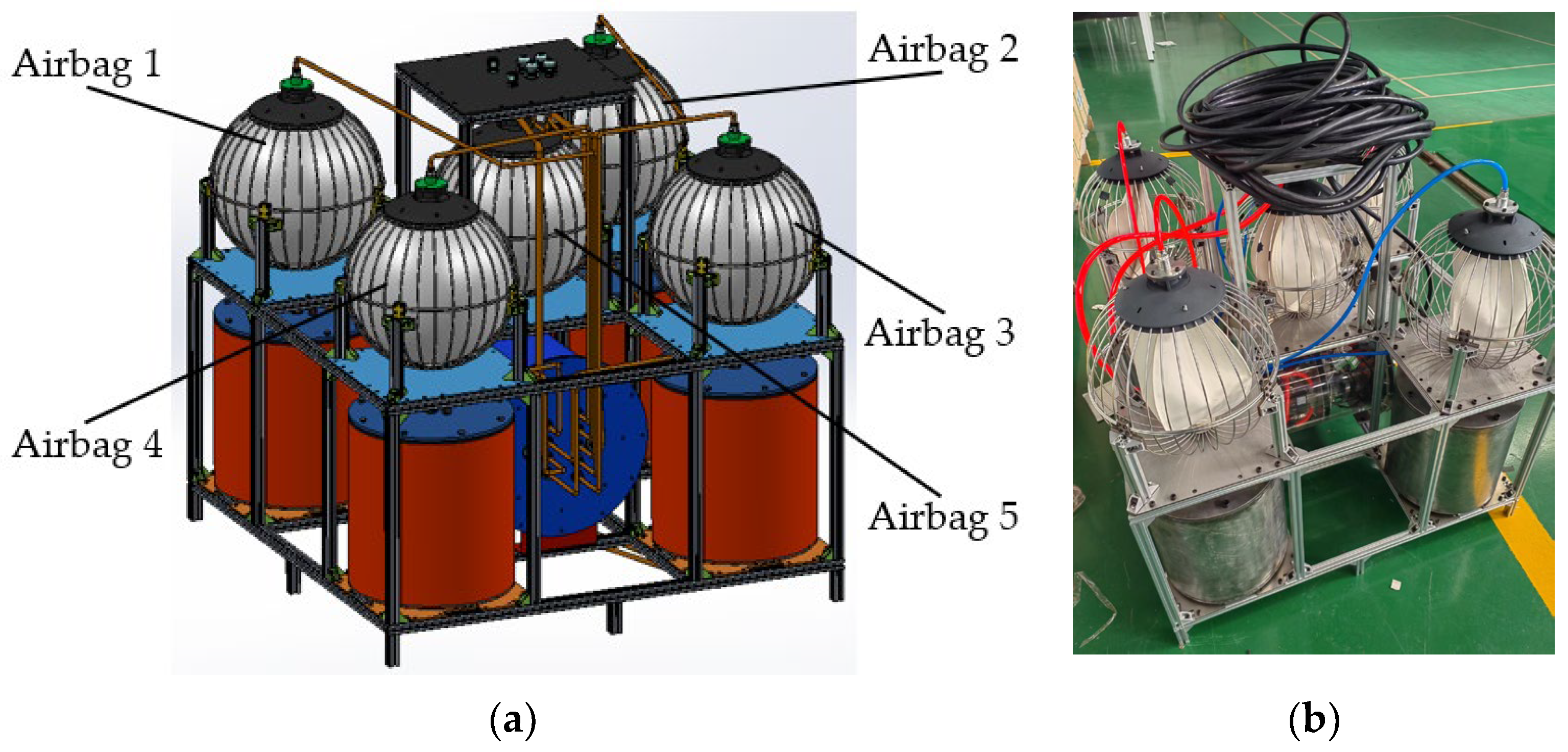

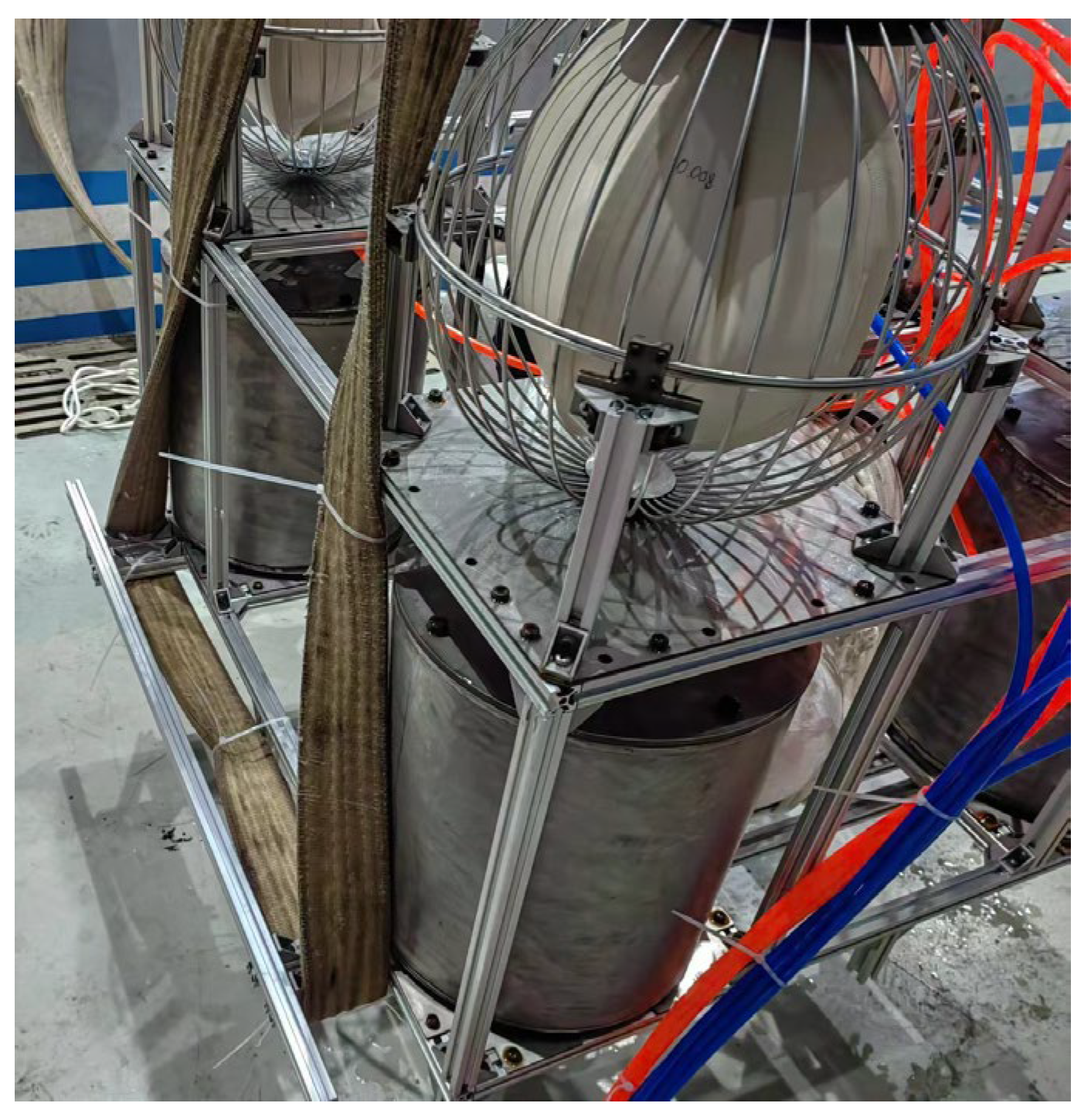

3.1. Test Models and Objects

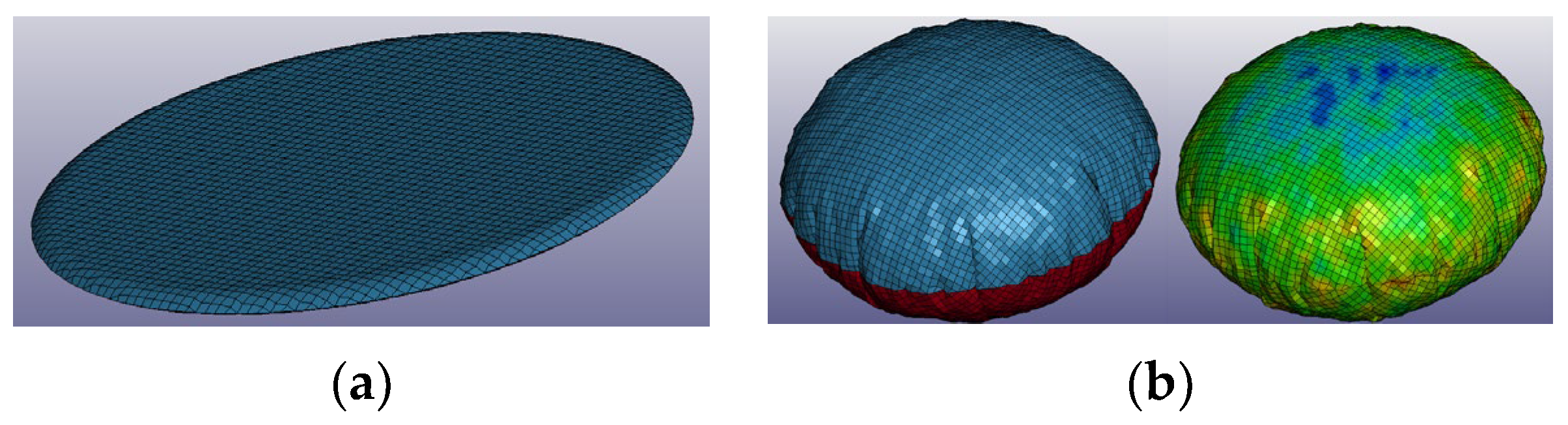

3.2. Airbag Inflation Simulation Test

3.3. Experimental Scheme

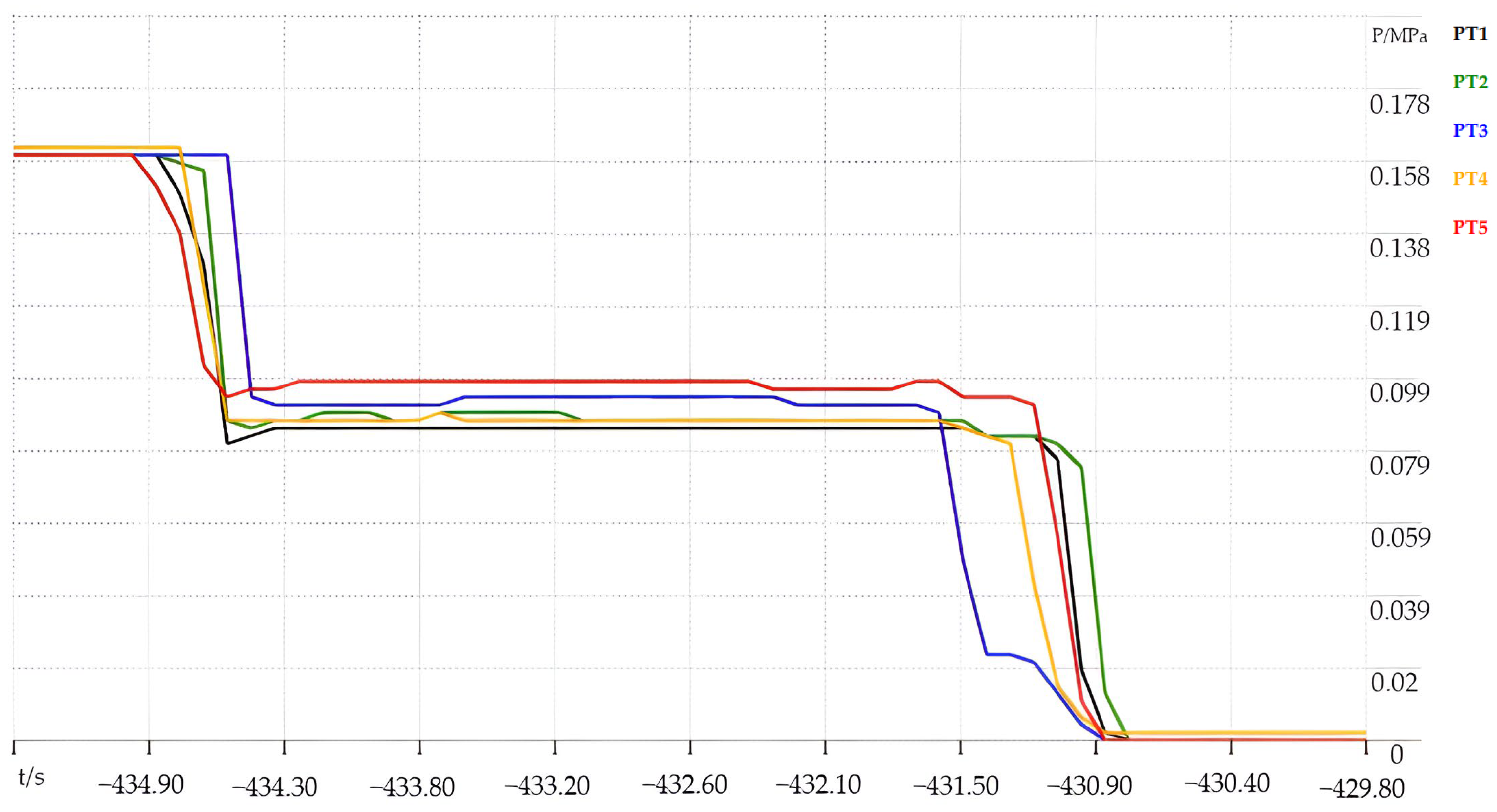

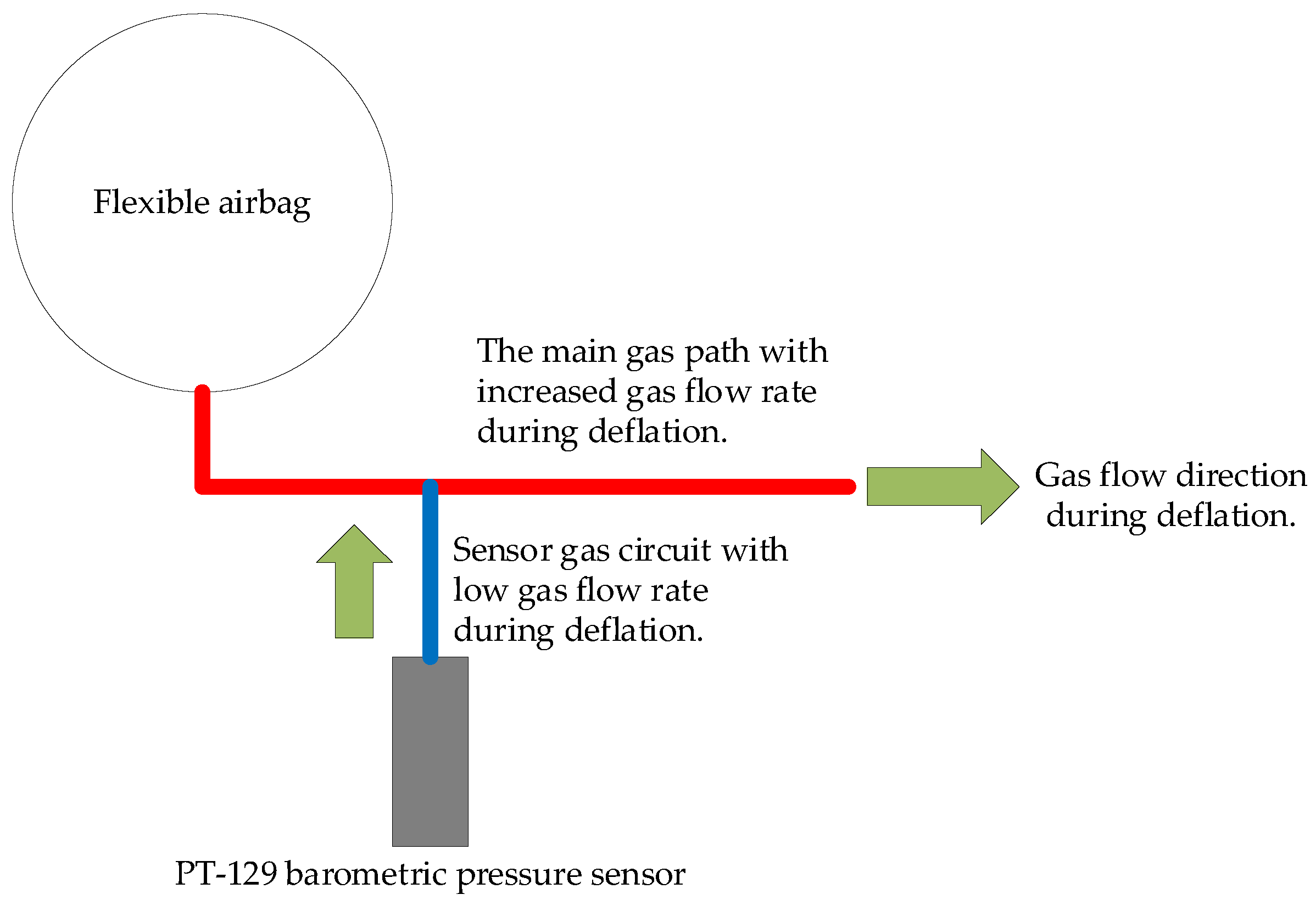

3.4. Ashore Charging and Deflating Test

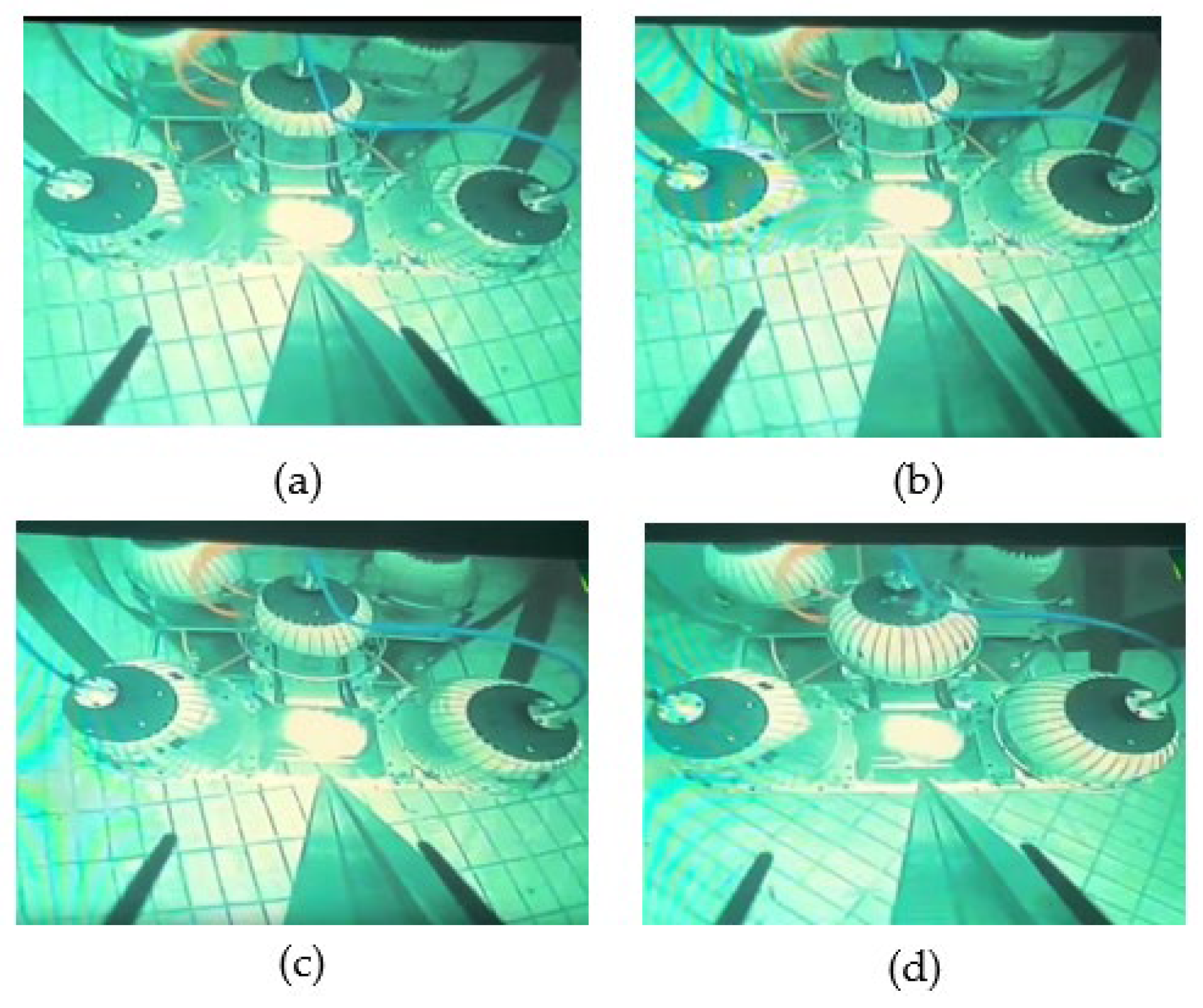

3.5. Device Posture Adjustment and Layout Test

3.6. Underwater Inflation and Deflation Test

4. Conclusions

- A physical model designed with the same functionality as the engineering model can function properly. Adjustable ballast can adjust the posture of the UWCA-FABESD and its buoyancy and gravity ratio. The designed steel mesh cover of the airbag can protect the airbag while limiting its displacement and expanded shape. The device can store compressed air and release compressed air normally;

- The static pressure of water can increase the pressure of gas storage, improve the efficiency of UWCAES systems, assist airbag contraction, improve the consistency of external deflation of the five airbags, and reduce the manufacturing requirements of airbags, and lower costs;

- The designed UWCA-FABESD should output to the outside during the stable deflation stage of the airbag. It is not recommended to generate electricity at the beginning of deflation. When truly deflating to the outside, the gas in the airbag should not be completely discharged, and a portion of the gas should be retained inside the airbag to ensure that the gas flow rate and pressure in the tube remain unchanged when deflation is about to end;

- When inflating the device, in order to ensure that the airbags are fully charged at the same time, it is necessary to ensure that the length of the intake pipeline of each airbag is consistent, minimize the bending part of the gas pipeline, and allow each airbag to be inflated separately. When some airbags are not fully charged, they should be inflated separately to improve the utilization rate of the airbags.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, Y.M. Novel Concepts of Compressed Air Energy Storage and Thermo-Electric Energy Storage; Ecole Polytechnique Fédérale de Lausanne: Lausanne, Switzerland, 2012. [Google Scholar]

- Edward, B. An Investigation into the Potential of Energy Storage to Tackle Intermittency in Renewable Energy Generation; The University of Edinburgh: Edinburgh, UK, 2013. [Google Scholar]

- Kim, Y.M.; Shin, D.G.; Favrat, D. Operating characteristics of constant-pressure compressed air energy storage (CAES) system combined with pumped hydro storage based on energy and exergy analysis. Energy 2011, 36, 6220–6233. [Google Scholar] [CrossRef]

- Johnson, P.; Johnson, P.; Kazemersky, P.; Kazemersky, P. Assessment of Compressed Air Energy Storage System (CAES); The University of Tennessee: Chattanooga, TN, USA, 2014. [Google Scholar]

- He, W.; Luo, X.; Evans, D.; Busby, J.; Garvey, S.; Parkes, D.; Wanga, J. Exergy storage of compressed air in cavern and cavern volume estimation of the large-scale compressed air energy storage system. Appl. Energy 2017, 208, 745–757. [Google Scholar] [CrossRef]

- United Nations Economic Commission for Europe. Working Party on Gas. In Study on Underground Gas Storage in Europe and Central Asia; UNECE: Geneva, Switzerland, 1999. [Google Scholar]

- Pimm, A.J.; Garvey, S.D.; de Jong, M. Design and testing of Energy Bags for underwater compressed air energy storage. Energy 2014, 66, 496–508. [Google Scholar] [CrossRef]

- Tiano, F.A.; Rizzo, G. Use of an Under-Water Compressed Air Energy Storage (UWCAES) to Fully Power the Sicily Region (Italy) With Renewable Energy: A Case Study. Front. Mech. Eng. 2021, 7, 641995. [Google Scholar] [CrossRef]

- Burian, O.; Dancova, P. Compressed Air Energy Storage (CAES) and Liquid Air Energy Storage (LAES) Technologies—A Comparison Review of Technology Possibilities. Processes 2023, 11, 3061. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Z.; Liang, C.; Carriveau, R.; Ting, D.S.-K.; Li, P.; Cen, H.; Xiong, W. Underwater Compressed Gas Energy Storage (UWCGES): Current Status, Challenges, and Future Perspectives. Appl. Sci. 2022, 12, 9361. [Google Scholar] [CrossRef]

- Pimm, A.; Garvey, S. Analysis of flexible fabric structures for large-scale subsea compressed air energy storage. J. Phys. Conf. Ser. 2009, 181, 012049. [Google Scholar] [CrossRef]

- Pimm, A.; Garvey, S.D.; Drew, R.J. Shape and cost analysis of pressurized fabric structures for subsea compressed air energy storage. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2011, 225, 1027–1043. [Google Scholar] [CrossRef]

- Pimm, A.J. Analysis of Flexible Fabric Structures; The University of Nottingham: Nottingham, UK, 2011. [Google Scholar]

- Vasel-Be-Hagh, A.R.; Carriveau, R.; Ting, D.K. Numerical simulation of flow past an underwater energy storage balloon. Comput. Fluids 2013, 88, 272–286. [Google Scholar] [CrossRef]

- Liu, M.; Sun, K.; Wang, X.; Lu, C.; Ma, G.; Long, K. Experiment and Simulation of the Shape and Stored Gas Characteristics of the Flexible Spherical Airbag for Underwater Compressed Air Energy Storage. J. Mar. Sci. Eng. 2023, 11, 774. [Google Scholar] [CrossRef]

- Du, H. Static analysis and verification of flexible riser for underwater compressed air energy storage system with different boundary conditions. Ships Offshore Struct. 2022, 17, 1427–1436. [Google Scholar] [CrossRef]

- Alfosail, F.K.; Nayfeh, A.H.; Younis, M.I. An analytic solution of the static problem of inclined risers conveying fluid. Meccanica 2017, 52, 1175–1187. [Google Scholar] [CrossRef]

- Vasel-Be-Hagh, A.R.; Ting, D.S.K.; Carriveau, R. Structural analysis of an underwater energy storage accumulator. Sustain. Energy Technol. Assess. 2015, 11, 165–172. [Google Scholar] [CrossRef]

- Vasel-Be-Hagh, A.; Carriveau, R.; Ting, D.S. Flow past an accumulator unit of an underwater energy storage system: Three touching balloons in a floral configuration. J. Mar. Sci. Appl. 2014, 13, 467–476. [Google Scholar] [CrossRef]

- Vasel-Be-Hagh, A.; Carriveau, R.; Ting, D.S.K. Flow over submerged energy storage balloons in closely and widely spaced floral conflgurations. Ocean Eng. 2015, 95, 59–77. [Google Scholar] [CrossRef]

- Dittakavi, R.S.S. Exergy Analysis of a Small-Scale Trigenerative Compressed Air Energy Storage System. Master’s Thesis, University of Windsor, Windsor, ON, Canada, 2021; p. 180. [Google Scholar]

- Wolf, D.; Budt, M. LTA-CAES—A low-temperature approach to Adiabatic Compressed Air Energy Storage. Appl. Energy 2014, 125, 158–164. [Google Scholar] [CrossRef]

- Dooner, M.; Wang, J. Potential Exergy Storage Capacity of Salt Caverns in the Cheshire Basin Using Adiabatic Compressed Air Energy Storage. Entropy 2019, 21, 1065. [Google Scholar] [CrossRef]

- Zhao, W. Technical Terminology of Maritime Telemetry and Telecontrol; National Defense Industry Press: Beijing, China, 2013; p. 359. [Google Scholar]

- Klaycham, K.; Athisakul, C.; Chucheepsakul, S. Nonlinear vibration of marine riser with large displacement. Mar. Sci. Technol. 2017, 22, 361–375. [Google Scholar] [CrossRef]

- Hu, B. Static Analysis and Verification of Flexible Risers in Underwater Compressed Air Energy Storage Systems; Dalian Maritime University: Dalian, China, 2019; pp. 2–5. [Google Scholar]

- Yang, Z. Practical Steel Rolling Technology Manual; Metallurgical Industry Press: Beijing, China, 1995; p. 20. [Google Scholar]

- Dai, X.; Zong, Z.; Wang, X.; Nie, C. A comparative study on the CV and ALE methods for simulating folded airbag deployment. Automot. Eng. 2008, 30, 676–680. [Google Scholar]

- Dai, X. Numerical Simulation of Airbag Deployment Based on Fluid-Structure Interaction Methodology; Dalian University of Technology: Dalian, China, 2007. [Google Scholar]

- Dindorf, R. Measurement of Pneumatic Valve Flow Parameters on the Test Bench with Interchangeable Venturi Tubes and Their Practical Use. Sensors 2023, 23, 6042. [Google Scholar] [CrossRef]

- Xu, Y.; Jia, S.J.; Yuan, C.; Zhang, Y.M.; Zuo, R.J.; Xue, D.D.; Zheng, C.F. A Study of Downhole Gas Injection Flow Measurement Method. In Proceedings of the IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Kuala Lumpur, Malaysia, 22–25 May 2023; pp. 1–6. [Google Scholar]

| Name | Parameter Data |

|---|---|

| Gas storage depth | 700 m |

| Gas storage pressure | 7 MPa |

| Installation sea conditions | Level 3 |

| Name | Parameter Data |

|---|---|

| Overall dimensions | 8 m × 8 m × 8 m |

| Total weight | 94.2 t |

| Inner diameter of flexible air bag | 3 m |

| Adjustable ballast external dimensions | Diameter: 2.916 m, Height: 2.64 m |

| Adjustable ballast internal dimensions | Diameter: 2.6 m, Height: 2.62 m |

| External dimensions of control valve box | Diameter: 1.7 m, Height: 1.92 m |

| Inner diameter of intake pipe | 160 mm |

| Inner diameter of output pipe | 160 mm |

| Part of the Device | Number | Volume |

|---|---|---|

| Flexible airbag | 5 | 14.14 |

| Adjustable ballast | 4 | 17.63 |

| Control valve box | 1 | 4.34 |

| Adjustable ballast cavity | 4 | 13.91 |

| Name | Parameter Data |

|---|---|

| Overall dimensions | 0.9 m × 0.9 m × 0.9 m |

| Total weight | 105 |

| Inner diameter of flexible air bag | 0.3 m |

| Adjustable ballast external dimensions | Diameter: 0.3 m, Height: 0.327 m |

| Adjustable ballast internal dimensions | Diameter: 0.29 m, Height: 0.317 m |

| External dimensions of control valve box | Diameter: 0.3 m, Height: 0.41 m |

| Inner diameter of intake pipe | 12 mm |

| Inner diameter of output pipe | 12 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, X.; Peng, W.; Wang, Z.; Ma, H. Design of Underwater Compressed Air Flexible Airbag Energy Storage Device and Experimental Study of Physical Model in Pool. Energies 2024, 17, 3478. https://doi.org/10.3390/en17143478

Ren X, Peng W, Wang Z, Ma H. Design of Underwater Compressed Air Flexible Airbag Energy Storage Device and Experimental Study of Physical Model in Pool. Energies. 2024; 17(14):3478. https://doi.org/10.3390/en17143478

Chicago/Turabian StyleRen, Xiangang, Wanlang Peng, Zhuo Wang, and Hongwen Ma. 2024. "Design of Underwater Compressed Air Flexible Airbag Energy Storage Device and Experimental Study of Physical Model in Pool" Energies 17, no. 14: 3478. https://doi.org/10.3390/en17143478

APA StyleRen, X., Peng, W., Wang, Z., & Ma, H. (2024). Design of Underwater Compressed Air Flexible Airbag Energy Storage Device and Experimental Study of Physical Model in Pool. Energies, 17(14), 3478. https://doi.org/10.3390/en17143478