The Impact of Wide Discharge C-Rates on the Voltage Plateau Performance of Cylindrical Ternary Lithium-Ion Batteries

Abstract

:1. Introduction

2. Experiments and Methods

2.1. Test Samples and Equipment

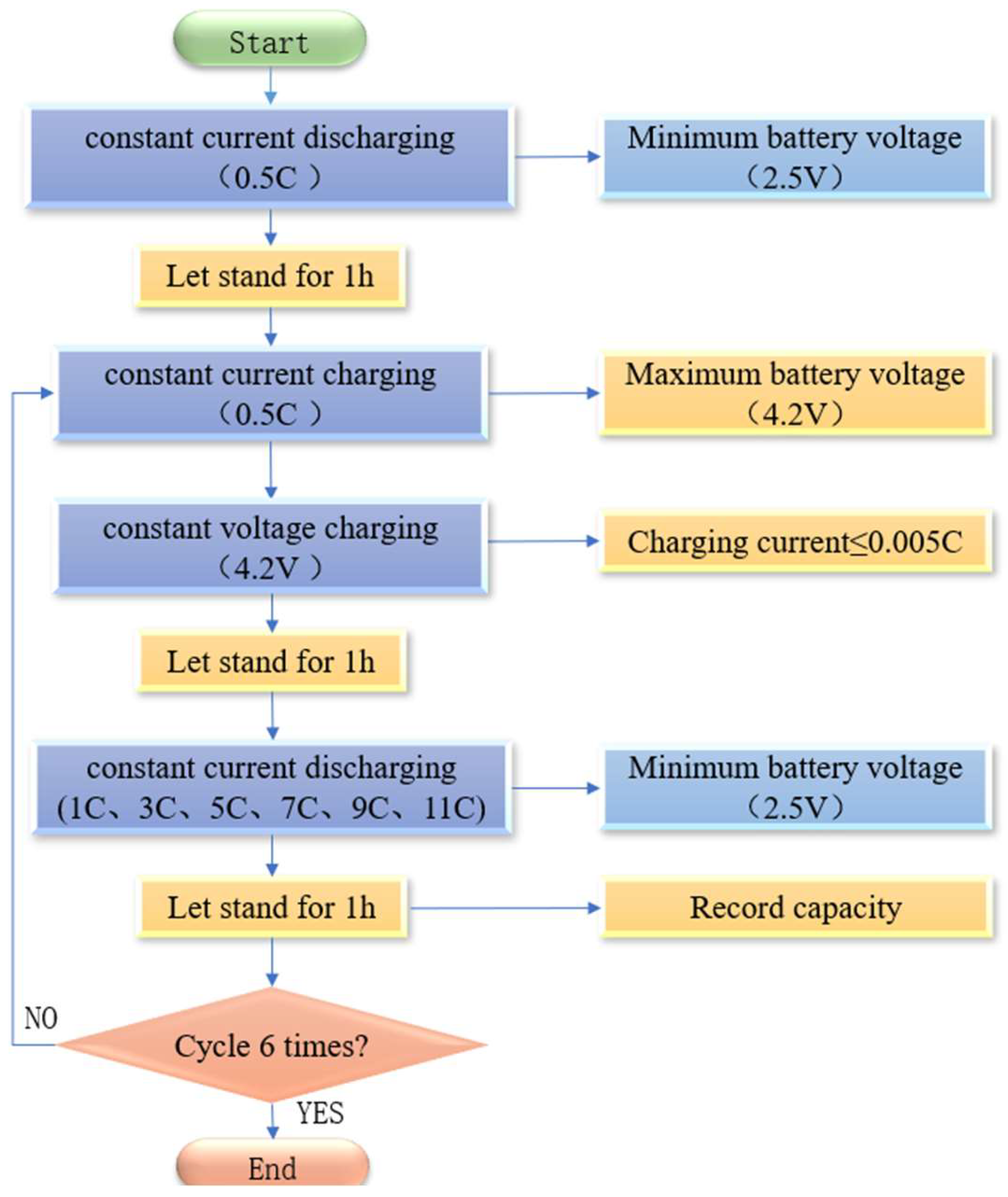

2.2. Methods

3. Experimental Results

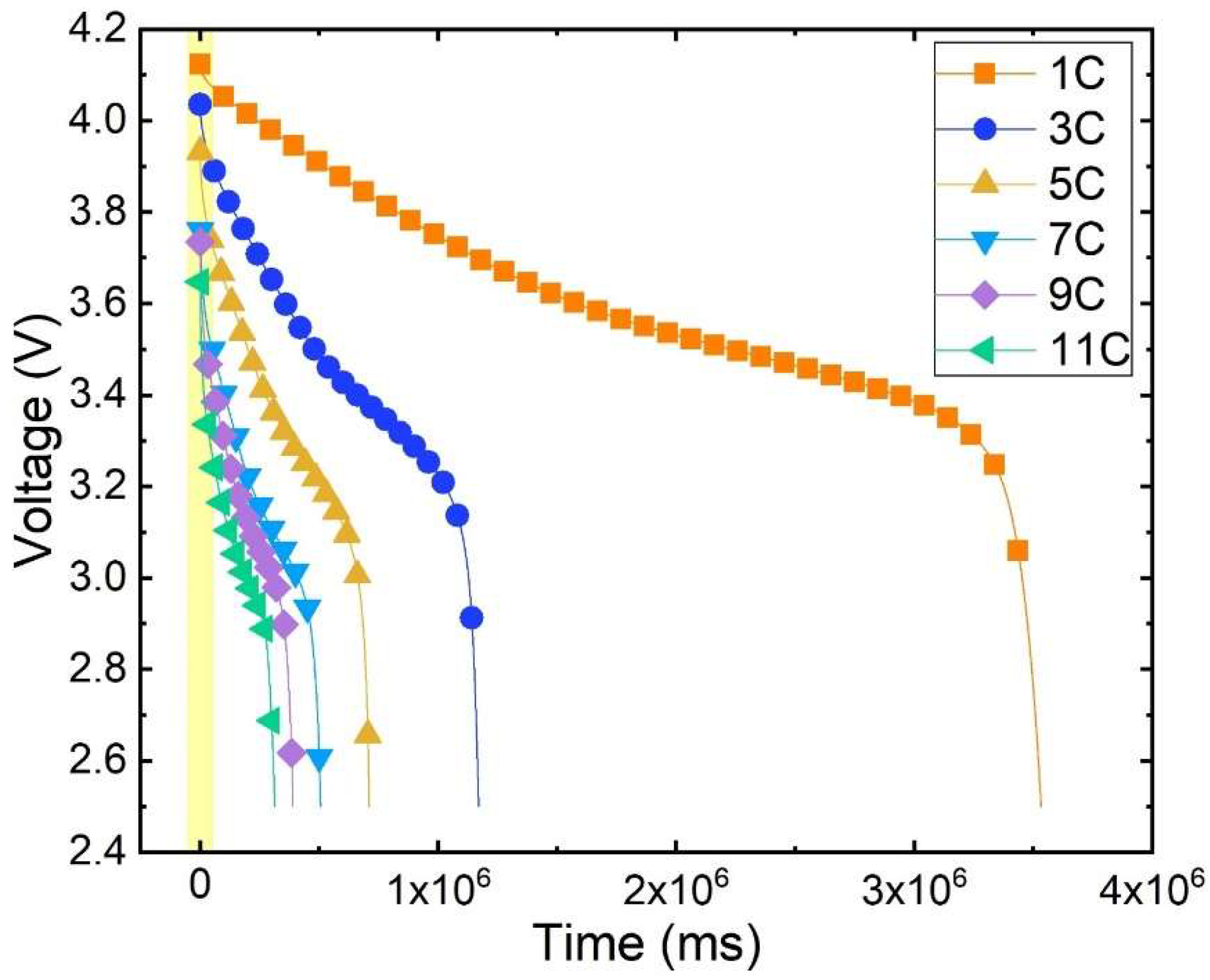

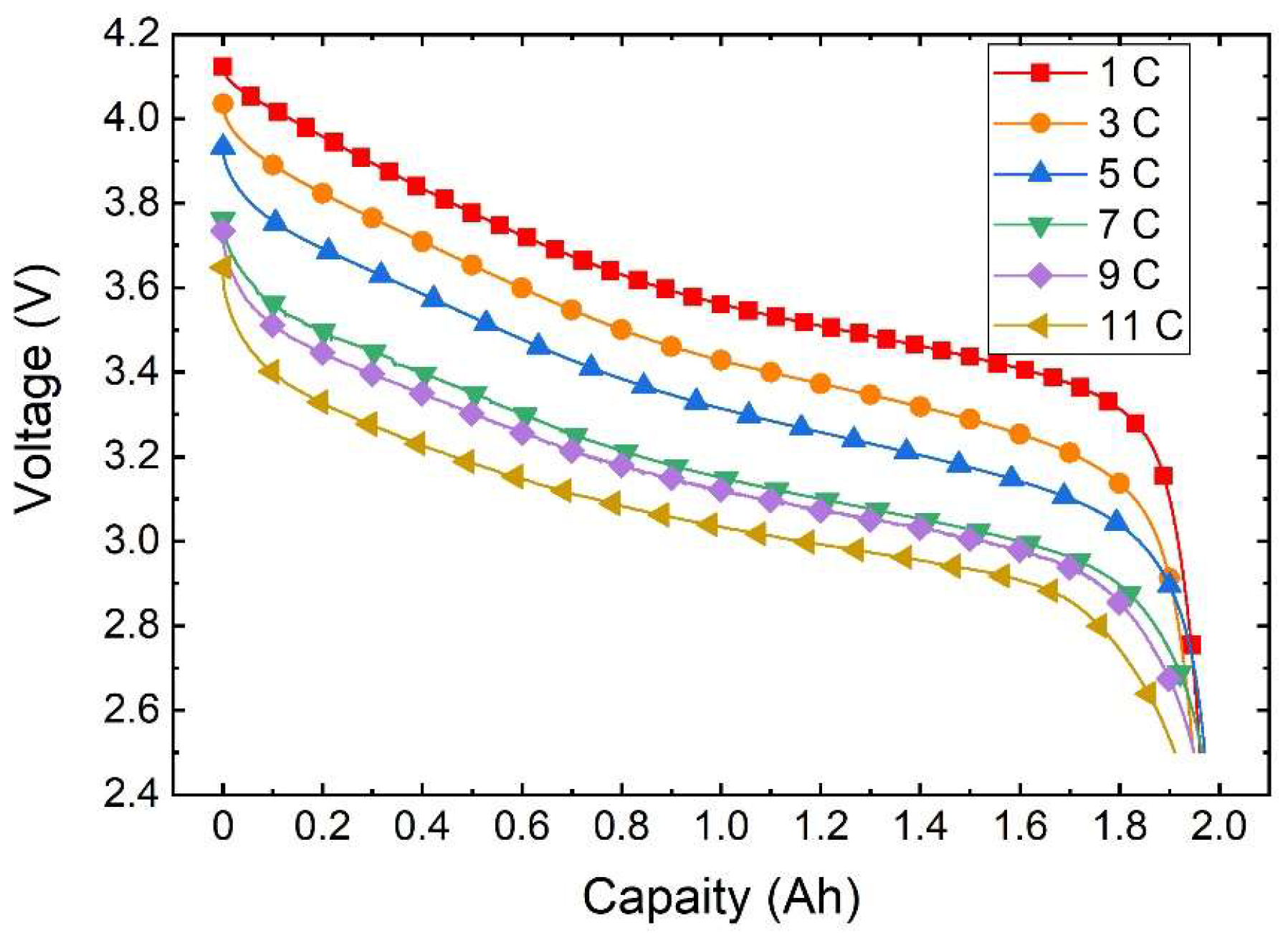

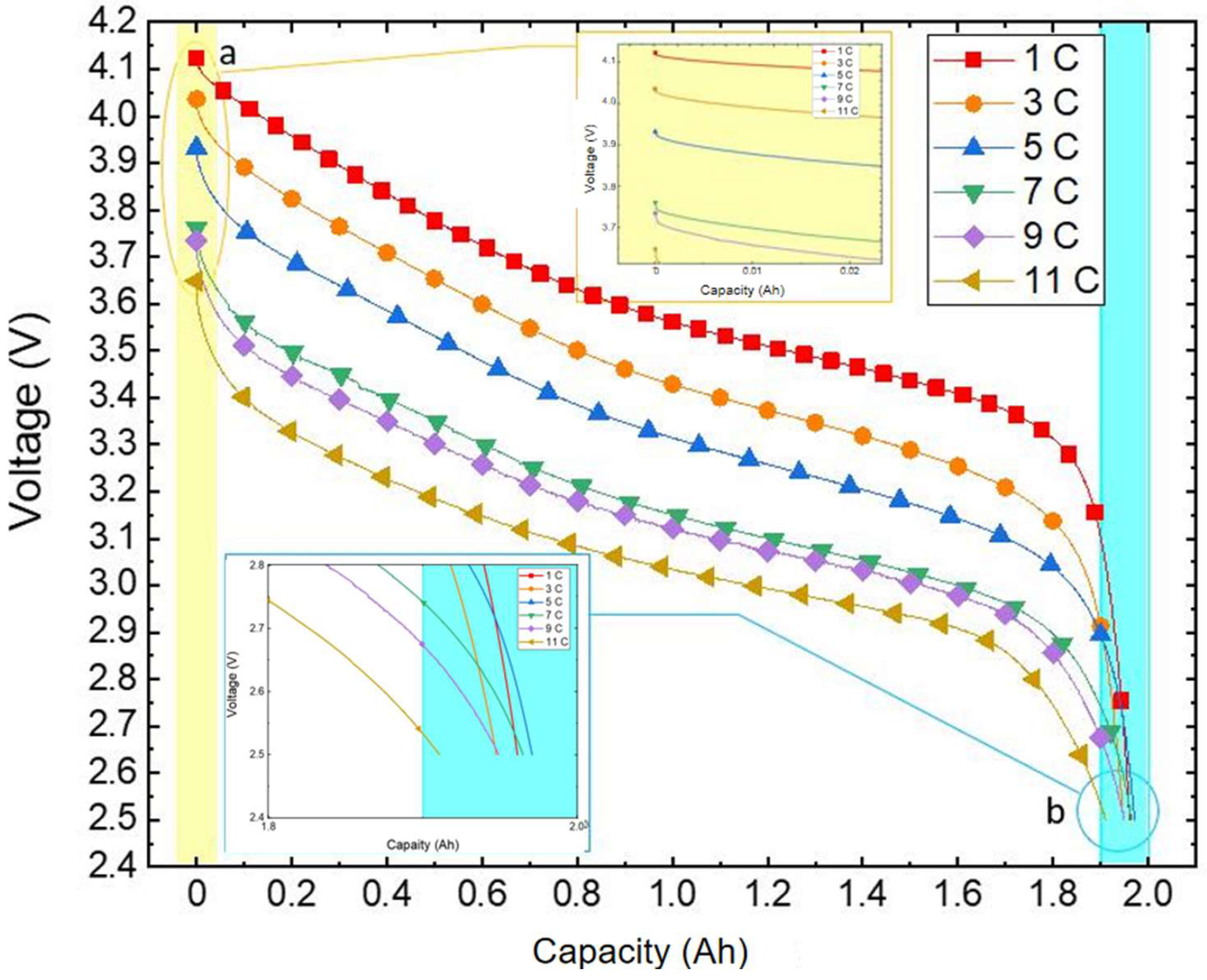

3.1. Effect of Different Discharge Rates on Battery Discharge Voltage

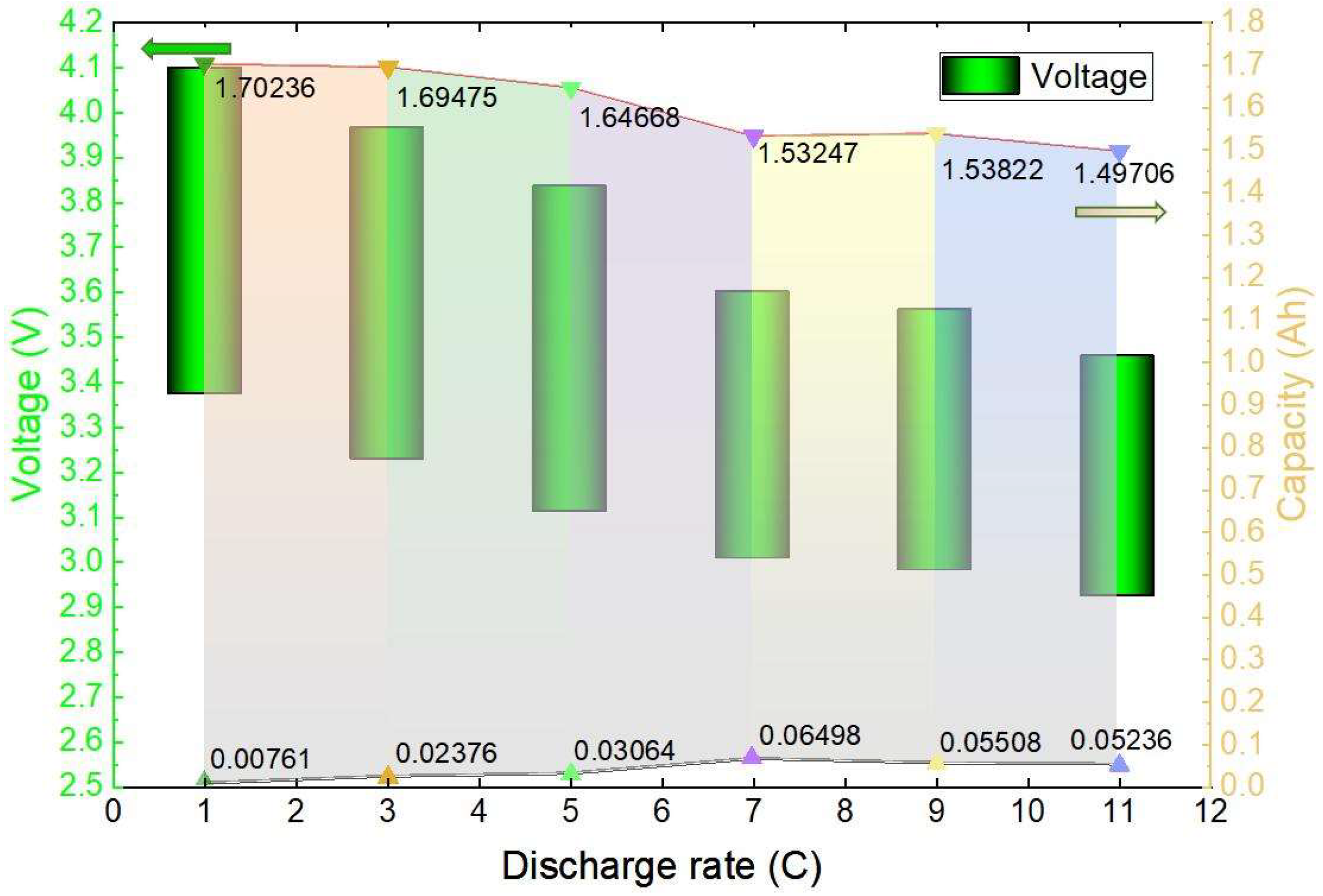

3.2. Effect of Different Discharge Rates on Battery Capacity

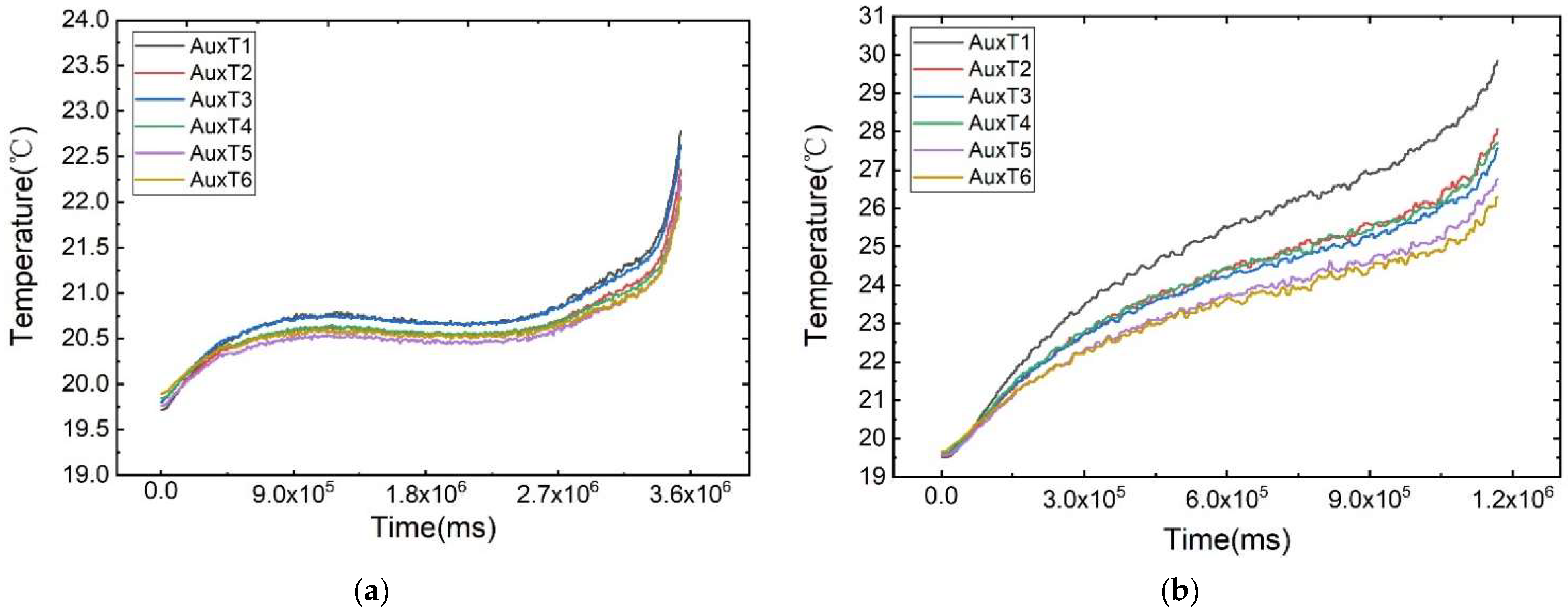

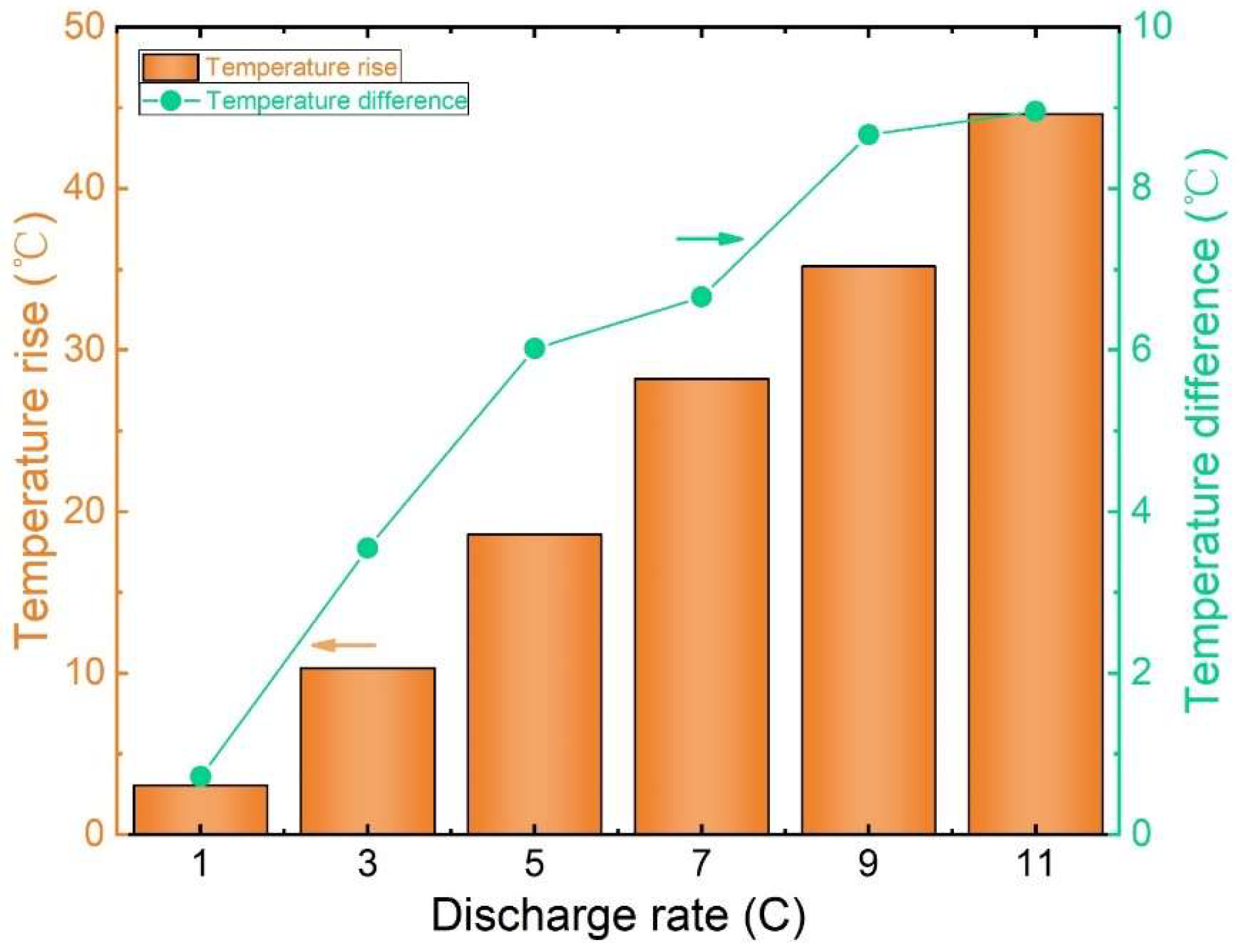

3.3. Effect of Different Discharge Rates on Battery Temperature

4. Analysis of the Experimental Results

4.1. Analysis of the Internal Resistance and Polarisation Phenomenon

4.2. Voltage Plateau Period Fitting Curve Analysis

4.3. Analysis of Changes in Voltage and Capacity during the Voltage Plateau Period

4.4. Comparative Analysis of Discharge Energy during the Voltage Plateau Period

5. Conclusions

- (1)

- The overall discharge curve exhibits a consistent trend; however, the discharge rate significantly influences the maximum discharge capacity, energy output, discharge time, terminal voltage, and internal resistance of lithium batteries. Higher discharge rates result in shorter discharge times, lower battery voltage at the corresponding remaining capacity, and higher battery surface temperatures. At low ambient temperatures, limited heat dissipation leads to significant accumulation of Joule heat within the battery, which in turn reduces internal resistance and delays the time required to reach the discharge cut-off voltage. Consequently, within a certain range of discharge rates, the battery’s capacity does not decrease with an increase in the discharge rate.

- (2)

- During the voltage plateau period, the battery temperature increases gradually. Beyond the plateau period, there is a notable change in temperature, with more pronounced increases at higher discharge rates. The impact on battery lifespan is greater after discharging beyond the plateau period.

- (3)

- During the plateau phase, the time, capacity, and voltage used for discharging decrease as the discharge rate increases. At 1 C, 3 C, 5 C, 7 C, 9 C, and 11 C discharge rates, the battery voltage decreases from 4.098 V to 3.372 V, 3.966 V to 3.228 V, 3.835 V to 3.112 V, 3.600 V to 3.007 V, 3.561 V to 2.980 V, and 3.457 V to 2.923 V, respectively, with the discharged-capacity-to-total-capacity ratio decreasing from 86.45% to 78.42%. The variations in voltage and temperature during the plateau period are significantly reduced compared to the pre-discharge and post-discharge periods.

- (4)

- Polynomial and linear fittings were performed for the plateau period at different discharge rates, achieving fitting accuracies above 93%. Although polynomial fitting demonstrated higher accuracy, it is more susceptible to noise, whereas the linear model maintains accuracy while being computationally efficient.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liao, H.; Peng, S.; Li, L.; Zhu, Y. The role of governmental policy in game between traditional fuel and new energy vehicles. Comput. Ind. Eng. 2022, 169, 108292. [Google Scholar] [CrossRef]

- Wang, X.; Liu, S.; Zhang, Y.; Lv, S.; Ni, H.; Deng, Y.; Yuan, Y. A review of the power battery thermal management system with different cooling, heating and coupling system. Energies 2022, 15, 1963. [Google Scholar] [CrossRef]

- Zhou, P.; Zhu, L.; Fu, D.; Du, J.; Zhao, X.; Sun, B. Research on the Performance Improvement Method for Lithium-Ion Battery in High-Power Application Scenarios. Energies 2024, 17, 1746. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y.; Deng, Y.; Yuan, Y.; Zhang, F.; Lv, S.; Zhu, Y.; Ni, H. Effects of Different Charging Currents and Temperatures on the Voltage Plateau Behavior of Li-Ion Batteries. Batteries 2023, 9, 42. [Google Scholar] [CrossRef]

- Sang, B.; Wu, Z.; Yang, B.; Wei, J.; Wan, Y. Joint Estimation of SOC and SOH for Lithium-Ion Batteries Based on Dual Adaptive Central Difference H-Infinity Filter. Energies 2024, 17, 1640. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Lu, J.Y.; Li, X.P.; Song, J.L. Aging life characteristics of high-rate pulse discharged lithium battery. J. Nav. Univ. Eng. 2023, 35, 1–7. [Google Scholar]

- Wei, T.D. Research on Transmission System Parameters Matching and Optimization of Pure Electric Vehicle. Ph.D. Thesis, Jilin University, Changchun, China, 2023. (In Chinese). [Google Scholar]

- Li, K.; He, C.; Xie, L.; Liu, B.; Deng, S.S. Thermal management of 48_V soft-pack battery pack under high rate discharge condition. Energy Storage Sci. Technol. 2021, 10, 679–688. (In Chinese) [Google Scholar]

- Kim, Y.; Jacquet, Q.; Griffith, K.; Lee, J.; Dey, S.; Rinkel, B.L.; Grey, C.P. High rate lithium ion battery with niobium tungsten oxide anode. J. Electrochem. Soc. 2021, 168, 010525. [Google Scholar] [CrossRef]

- Yang, A.; Wang, Y.; Yang, F.; Wang, D.; Zi, Y.; Tsui, K.L.; Zhang, B. A comprehensive investigation of lithium-ion battery degradation performance at different discharge rates. J. Power Sources 2019, 443, 227108. [Google Scholar] [CrossRef]

- Naik, A.; Zhou, J.; Gao, C.; Liu, G.; Wang, L. Rapid and facile synthesis of Mn doped porous LiFePO4/C from iron carbonyl complex. J. Energy Inst. 2016, 89, 21–29. [Google Scholar] [CrossRef]

- Taleghani, S.T.; Marcos, B.; Zaghib, K.; Lantagne, G. A study on the effect of porosity and particles size distribution on Li-ion battery performance. J. Electrochem. Soc. 2017, 164, E3179. [Google Scholar] [CrossRef]

- Li, D.Q.; Zhang, Q.S.; Zheng, S.S. Influence of high rate charge and discharge cycle on the electronic performance and thermal safety of lithium ion battery. Lanzhou Univ. Technol. J. 2023, 49, 30–35. [Google Scholar]

- Yang, B.; Fan, L.P.; Gao, Y.H.; Chen, H.T.; Chen, S.K.; Yan, P. Study on the effect of discharge rate on capacity of high power lithium-ion battery. Machinery 2023, 61, 1–4. (In Chinese) [Google Scholar]

- Huang, Y.X.; Lai, H.X. Effects of discharge rate on electrochemical and thermal characteristics of LiFePO4/graphite battery. Appl. Therm. Eng. 2019, 157, 113744. [Google Scholar] [CrossRef]

- Daud, Z.H.C.; Chrenko, D.; Aglzim, E.H.; Keromnes, A.; LeMoyne, L. Experimental study of lithium-ion battery thermal behaviour for electric and hybrid electric vehicles. In Proceedings of the 2014 IEEE Vehicle Power and Propulsion Conference, Coimbra, Portugal, 27–30 October 2014; pp. 1–6. [Google Scholar]

- Ye, Y.; Shi, Y.; Cai, N.; Lee, J.; He, X. Electro-thermal modeling and experimental validation for lithium-ion battery. J. Power Sources 2012, 199, 227–238. [Google Scholar] [CrossRef]

- Wu, T.; Wang, C.; Hu, Y.; Liang, Z.; Fan, C. Research on electrochemical characteristics and heat generating properties of power battery based on multi-time scales. Energy 2023, 265, 126416. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Y.; Bai, J.; Zhou, L.; Wang, Z. Influence of lithium plating on lithium-ion battery aging at high temperature. Electrochimica 2023, 454, 142362. [Google Scholar] [CrossRef]

- Li, Y.; Hu, Y.; Liu, Q.G. Influence of discharge rate on cycling performance of lithium-ion battery. J. Power Sources 2006, 30, 488–491. [Google Scholar] [CrossRef]

- Jiang, C.N.; Li, H.; Luo, Y.T.; Xie, B.; He, X.C. Experimental study on the effect of temperature and discharge rate on battery performance. Sci. Technol. Eng. 2013, 13, 2496–2502. (In Chinese) [Google Scholar]

- Gang, N.; Bala, H.; Branko, N.P. Capacity fade study of lithium-ion batteries cycled at high discharge rates. J. Power Sources 2003, 117, 160–169. [Google Scholar]

- Wang, X.; Zhang, Y.; Ni, H.; Lv, S.; Zhang, F.; Zhu, Y.; Yuan, Y.; Deng, Y. Influence of Different Ambient Temperatures on the Discharge Performance of Square Ternary Lithium-Ion Batteries. Energies 2022, 15, 5348. [Google Scholar] [CrossRef]

- Mei, W.; Li, H.; Zhao, C.; Sun, J.; Wang, Q. Numerical study on thermal characteristics comparison between charge and discharge process for lithium ion battery. Heat Mass Transf. 2020, 162, 120319. [Google Scholar] [CrossRef]

- Wang, X.Y.; Wei, X.Z.; Zhu, J.G.; Dai, H.F.; Zheng, Y.J.; Xu, X.M.; Chen, Q.J. A review of modeling, acquisition, and application of lithium-ion battery impedance for onboard battery management. eTransportation 2021, 7, 100093. [Google Scholar] [CrossRef]

- Remmlinger, J.; Buchholz, M.; Meiler, M.; Bernreuter, P.; Dietmayer, K. State-of-health monitoring of lithium-ion batteries in electric vehicles by on-board internal resistance estimation. J. Power Sources 2011, 196, 5357–5363. [Google Scholar] [CrossRef]

- Chen, L.; Lv, Z.; Lin, W.; Li, J.; Pan, H. A new state-of-health estimation method for lithium-ion batteries through the intrinsic relationship between ohmic internal resistance and capacity. Measurement 2018, 116, 586–595. [Google Scholar] [CrossRef]

- Qiu, C.; He, G.; Shi, W.; Zou, M.; Liu, C. The polarization characteristics of lithium-ion batteries under cyclic charge and discharge. J. Solid State Electrochem. 2019, 23, 1887–1902. [Google Scholar] [CrossRef]

- Lou, T.T.; Zhang, W.G.; Guo, H.Y.; Wang, J.S. The internal resistance characteristics of lithium-ion battery based on HPPC method. In Advanced Materials Research; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2012; Volume 455, pp. 246–251. [Google Scholar]

- Wei, X.; Zhu, B.; Xu, W. Internal resistance identification in vehicle power lithium-ion battery and application in lifetime evaluation. In Proceedings of the 2009 International Conference on Measuring Technology and Mechatronics Automation, Changchun, China, 9–12 August 2009; Volume 3, pp. 388–392. [Google Scholar]

- Huria, T.; Ceraolo, M.; Gazzarri, J.; Jackey, R. High fidelity electrical model with thermal dependence for characterization and simulation of high power lithium battery cells. In Proceedings of the 2012 IEEE International Electric Vehicle Conference, Greenville, NC, USA, 4–8 March 2012; pp. 1–8. [Google Scholar]

- Liang, X.M. Modeling and Output Performance of Aluminum Air Battery Based on DC Internal Resistance and AC Impedance. Ph.D. Thesis, Jiliang University, Hangzhou, China, 2021. (In Chinese). [Google Scholar]

- Zouhri, K.; Lee, S. Evaluation and optimization of the alkaline water electrolysis ohmic polarization: Exergy study. Int. J. Hydrogen Energy 2016, 41, 7253–7263. [Google Scholar] [CrossRef]

- Stolz, L.; Hochstadt, S.; Roser, S.; Hansen, M.R.; Winter, M.; Kasnatscheew, J. Single-ion versus dual-ion conducting electrolytes: The relevance of concentration polarization in solid-state batteries. ACS Appl. Mater. Interfaces 2022, 14, 11559–11566. [Google Scholar] [CrossRef]

- Eom, K.S.; Joshi, T.; Bordes, A.; Do, I.; Fuller, T.F. The design of a Li-ion full cell battery using a nano silicon and nano multi-layer graphene composite anode. J. Power Sources 2014, 249, 118–124. [Google Scholar] [CrossRef]

- Zhao, D.; Wei, C. Analysis of polarization and thermal characteristics in lithium-ion battery with various electrode thicknesses. J. Energy Storage 2023, 71, 108159. [Google Scholar] [CrossRef]

- Li, T.; Yuan, X.Z.; Zhang, L.; Song, D.; Shi, K.; Bock, C. Degradation Mechanisms and Mitigation Strategies of Nickel-Rich NMC-Based Lithium-Ion Batteries. Electrochem. Energy Rev. 2020, 3, 43–80. [Google Scholar] [CrossRef]

- Aurbach, D.; Markovsky, B.; Salitra, G.; Markevich, E.; Talyossef, Y.; Koltypin, M.; Nazar, L.; Ellis, B.; Kovacheva, D. Review on electrode–electrolyte solution interactions, related to cathode materials for Li-ion batteries. J. Power Sources 2007, 165, 491–499. [Google Scholar] [CrossRef]

- Barcellona, S.; Colnago, S.; Dotelli, G.; Latorrata, S.; Piegari, L. Aging effect on the variation of Li-ion battery resistance as function of temperature and state of charge. J. Energy Storage 2022, 50, 104658. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, M.; Ding, Y.; Wu, S.; Li, Y.; Liang, G.; Li, H.; Pan, H. Estimation the internal resistance of lithium-ion-battery using a multi-factor dynamic internal resistance model with an error compensation strategy. Energy Rep. 2021, 7, 3050–3059. [Google Scholar] [CrossRef]

- Panchal, S.; Dincer, I.; Agelin-Chaab, M.; Fraser, R.; Fowler, M. Experimental and theoretical investigation of temperature distributions in a prismatic lithium-ion battery. Int. J. Therm. Sci. 2016, 99, 204–212. [Google Scholar] [CrossRef]

| Researchers | Research Content | Result |

|---|---|---|

| Li et al. [8] | The performance of a lithium battery pack under different temperatures and discharge rate (1 C to 12.5 C) conditions. | Under the same discharge rate, as the ambient temperature rises the battery’s temperature rise gradually slows down, reflected in the decreasing slope of the temperature rise curve. |

| Kim et al. [9] | The performance of Li-ion batteries with niobium tungsten anodes at various temperatures and discharge rates (0.2 C to 20 C). | A high-rate lithium-ion battery with niobium tungsten oxide anode performance at high magnification suffered a specific capacity loss but still showed good cycle stability. |

| Yang et al. [10] | The effects of different discharge rates and cycles on battery performance were studied. | The capacity diversity caused by the discharge rate can be summarised by Peukert’s law. |

| Naik et al. [11] | The discharge rate and the impact of environmental temperature on the battery performance. | At a 1 C discharge rate, the battery’s heating rate decreases by 20% as the temperature increases. At an ambient temperature of 0 °C, increasing the discharge rate from 1 C to 1.5 C boosts the battery’s capacity by 6% and doubles the temperature rise rate. |

| Taleghani et al. [12] | The effects of discharge rate and particle size distribution on battery performance were studied. | The effect of particle size distribution on voltage, capacity, and specific power is more obvious at a higher discharge rate. |

| Li et al. [13] | The effect of high-rate charge and discharge on the performance and thermal safety of a Li-ion battery was studied. | The true potential of the battery diminishes during rapid charging and discharging cycles, with the extent of this decline directly linked to the speed of such charging and discharging. |

| Yang et al. [14] | The effect of battery discharge rate on capacity was studied. | The capacity of the battery decreases rapidly in the process of high-rate discharge. |

| Huang et al. [15] | The effect of discharge rate on electrochemical and thermal characteristics of a lithium iron phosphate battery was studied. | The electrochemical reaction rate and heat generated are not uniform, and the non-uniformity increases with the increase in discharge rate. |

| Daud et al. [16] | The thermal performance of lithium-ion electric and hybrid electric vehicle batteries was studied. | Higher discharge rates contribute to higher temperature increases and larger maximum and minimum temperature differences. |

| Ye et al. [17] | The influence of thermal management on the efficiency of charge and discharge and the cycle life of lithium-ion batteries was studied. | The optical fibre sensor was used to measure the battery’s temperature variation under different discharge rates. The higher the discharge rate, the greater the battery’s in-plane temperature difference. |

| Wu et al. [18] | The basic performance of lithium-ion batteries at different temperatures was studied. | A large discharge rate at low temperatures will raise the reaction temperature inside the battery. When the capacity increase caused by temperature increase is greater than the capacity decrease caused by high-rate discharge, the actual discharge capacity shows an overall increase trend. |

| Liu et al. [19] | The ageing of batteries at high temperatures after a prolonged cryogenic cycle and cryogenic cycle was studied. | When charging at high currents and discharging at high and low currents, the factors affecting battery ageing, in order of importance, are charging current > lithium plating content > high temperature > discharge current. |

| Li et al. [20]. | The cyclic performance of 18,650 lithium-ion batteries with different discharge rates at room temperature was studied. | High-rate cycle LiCoO2/graphite lithium-ion battery capacity attenuation is serious. |

| Jiang et al. [21] | The effects of temperature and discharge rate on battery performance were studied. | The increasing battery’s maximum temperature is related to the discharge rate. The temperature at the positive electrode is the highest, and the temperature difference between the negative electrode and the positive electrode increases with the discharge rate. |

| Gang et al. [22] | The capacity attenuation of SONY US18650 lithium-ion batteries with different discharge rate cycles at ambient temperature was studied. | After 300 cycles at 2 C and 3 C discharge rates, the estimated capacity loss is 13.2% and 16.9% of the initial capacity, respectively. A mechanism is proposed to explain the capacity attenuation at high discharge rates. |

| Discharge Rate (C) | Intercept | Slope | R2 | ∆t (ms) |

|---|---|---|---|---|

| 1 | 4.01705 | −2.32224 × 10−7 | 0.96168 | 3,056,290 |

| 3 | 3.88669 | −7.08299 × 10−7 | 0.97244 | 982,940 |

| 5 | 3.75442 | −1.13906 × 10−6 | 0.97392 | 592,760 |

| 7 | 3.54764 | −1.45139 × 10−6 | 0.97131 | 388,390 |

| 9 | 3.52609 | −1.96799 × 10−6 | 0.96304 | 305,950 |

| 11 | 3.38386 | −2.05107 × 10−6 | 0.94994 | 245,000 |

| Discharge Rate (C) | Intercept | B1 | B2 | R2 | ∆t (ms) |

|---|---|---|---|---|---|

| 1 | 4.09117 | −3.95763 × 10−7 | 5.59244 × 10−14 | 0.99876 | 3,056,290 |

| 3 | 3.95873 | −1.15559 × 10−6 | 4.5258 × 10−13 | 0.99866 | 982,940 |

| 5 | 3.82384 | −1.83768 × 10−6 | 1.1655 × 10−12 | 0.9985 | 592,760 |

| 7 | 3.62185 | −2.44127 × 10−6 | 2.36879 × 10−12 | 0.99913 | 388,390 |

| 9 | 3.5708 | −3.12007 × 10−6 | 4.18403 × 10−12 | 0.99769 | 305,950 |

| 11 | 3.44902 | −3.7342 × 10−6 | 6.92712 × 10−12 | 0.99559 | 245,000 |

| Discharge Rate (C) | (Wh) | (Wh) | (Wh) | (Wh) | (Wh) | (%) | (%) |

|---|---|---|---|---|---|---|---|

| 1 | 6.69 | 7.12 | 6.98 | 0.3041 | 0.2051 | 93.57 | 95.67 |

| 3 | 6.22 | 6.48 | 6.36 | 0.1838 | 0.0990 | 95.82 | 97.75 |

| 5 | 5.99 | 6.30 | 6.18 | 0.2192 | 0.1344 | 94.82 | 96.83 |

| 7 | 5.23 | 5.48 | 5.42 | 0.1768 | 0.1344 | 95.22 | 96.37 |

| 9 | 5.17 | 5.46 | 5.42 | 0.2051 | 0.1768 | 94.39 | 95.16 |

| 11 | 4.89 | 5.16 | 5.06 | 0.1902 | 0.1202 | 94.49 | 96.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Chen, Y.; Chen, L.; Liu, S.; Zhu, Y.; Deng, Y. The Impact of Wide Discharge C-Rates on the Voltage Plateau Performance of Cylindrical Ternary Lithium-Ion Batteries. Energies 2024, 17, 3488. https://doi.org/10.3390/en17143488

Wang X, Chen Y, Chen L, Liu S, Zhu Y, Deng Y. The Impact of Wide Discharge C-Rates on the Voltage Plateau Performance of Cylindrical Ternary Lithium-Ion Batteries. Energies. 2024; 17(14):3488. https://doi.org/10.3390/en17143488

Chicago/Turabian StyleWang, Xingxing, Yuhang Chen, Linfei Chen, Shengren Liu, Yu Zhu, and Yelin Deng. 2024. "The Impact of Wide Discharge C-Rates on the Voltage Plateau Performance of Cylindrical Ternary Lithium-Ion Batteries" Energies 17, no. 14: 3488. https://doi.org/10.3390/en17143488

APA StyleWang, X., Chen, Y., Chen, L., Liu, S., Zhu, Y., & Deng, Y. (2024). The Impact of Wide Discharge C-Rates on the Voltage Plateau Performance of Cylindrical Ternary Lithium-Ion Batteries. Energies, 17(14), 3488. https://doi.org/10.3390/en17143488