The Evolutionary Path and Emerging Trends of Circulating Fluidized Bed Technology: An Integrated Analysis through Bibliometric Assessment and Data Visualization

Abstract

1. Introduction

2. Data Resources and Research Methodology

2.1. Data Resources

2.2. Research Methods

3. Overall Development Trend of CFB Technology

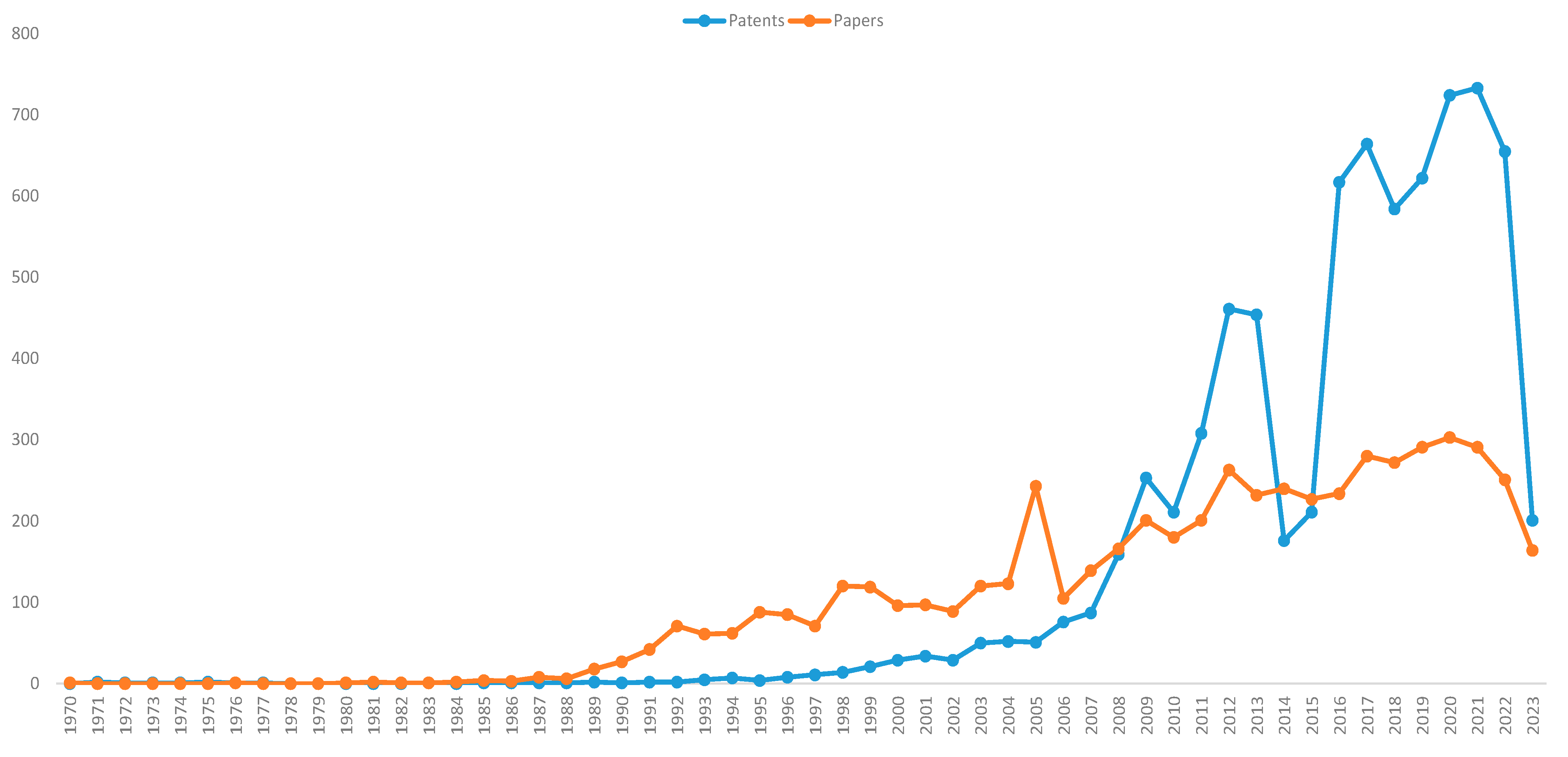

3.1. Analysis of Time Trend

3.2. Technology Research and Diffusion Study

3.2.1. Layout of Research Areas

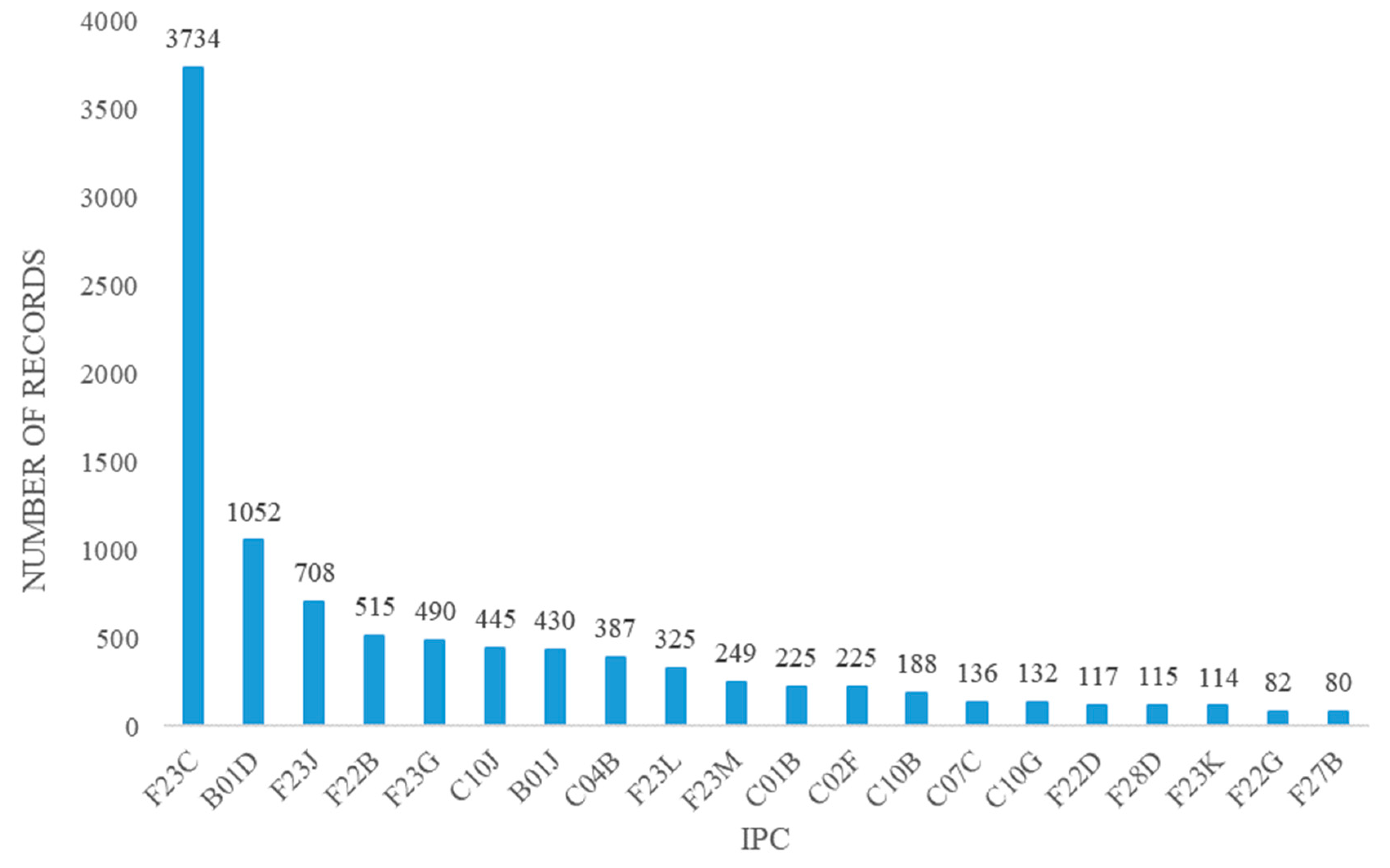

3.2.2. Layout of Technology

3.2.3. Highly Cited Papers Analysis

3.2.4. Highly Cited Patents Analysis

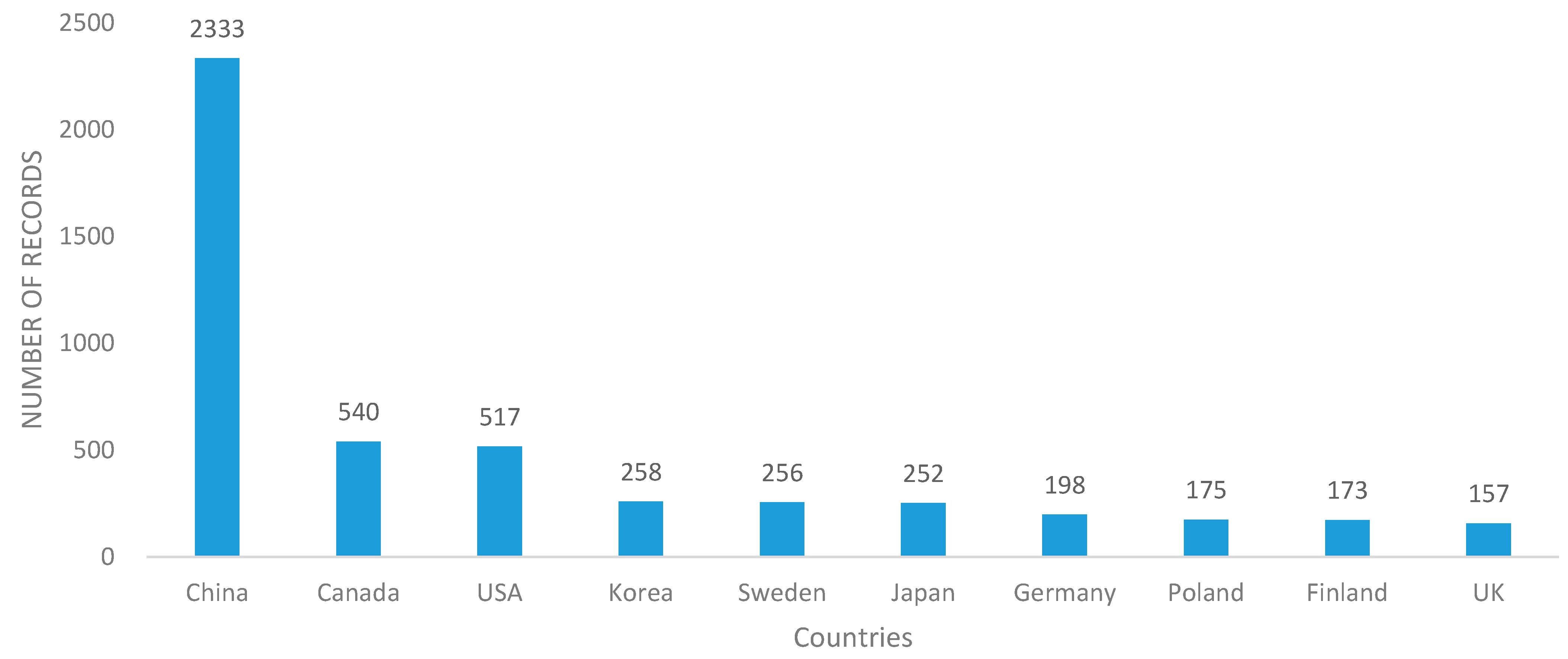

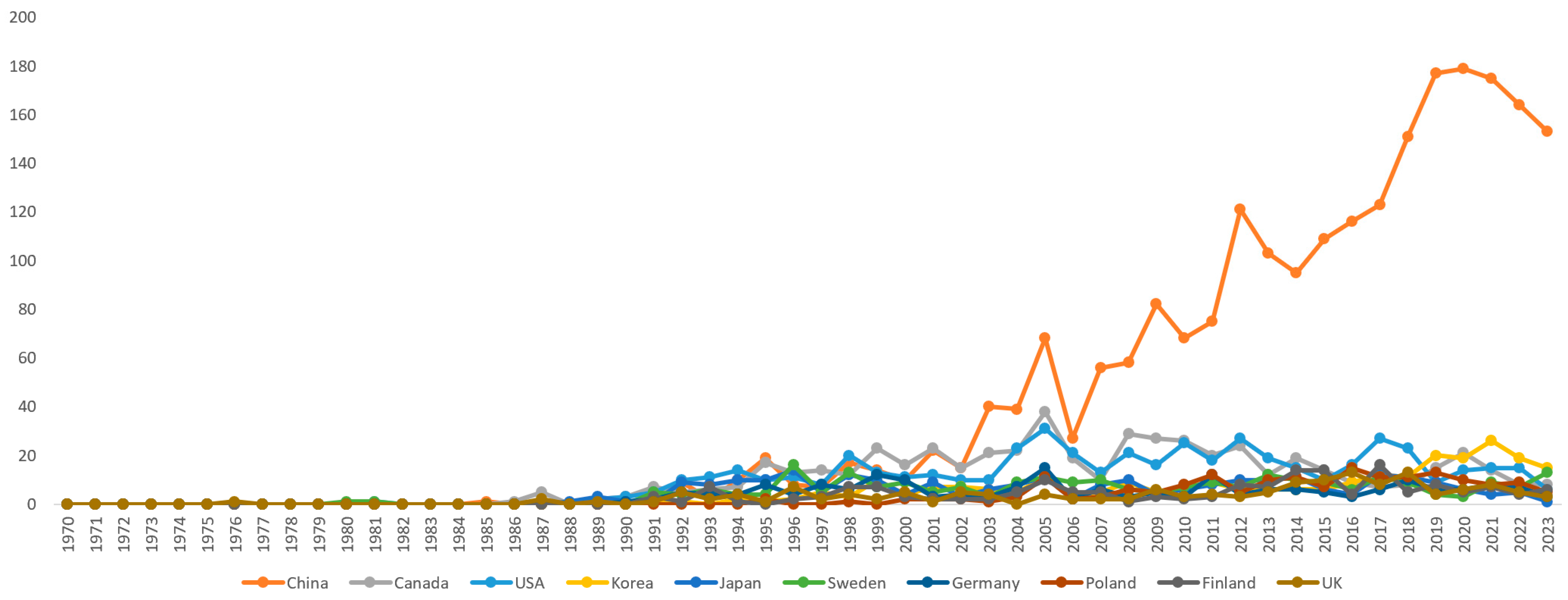

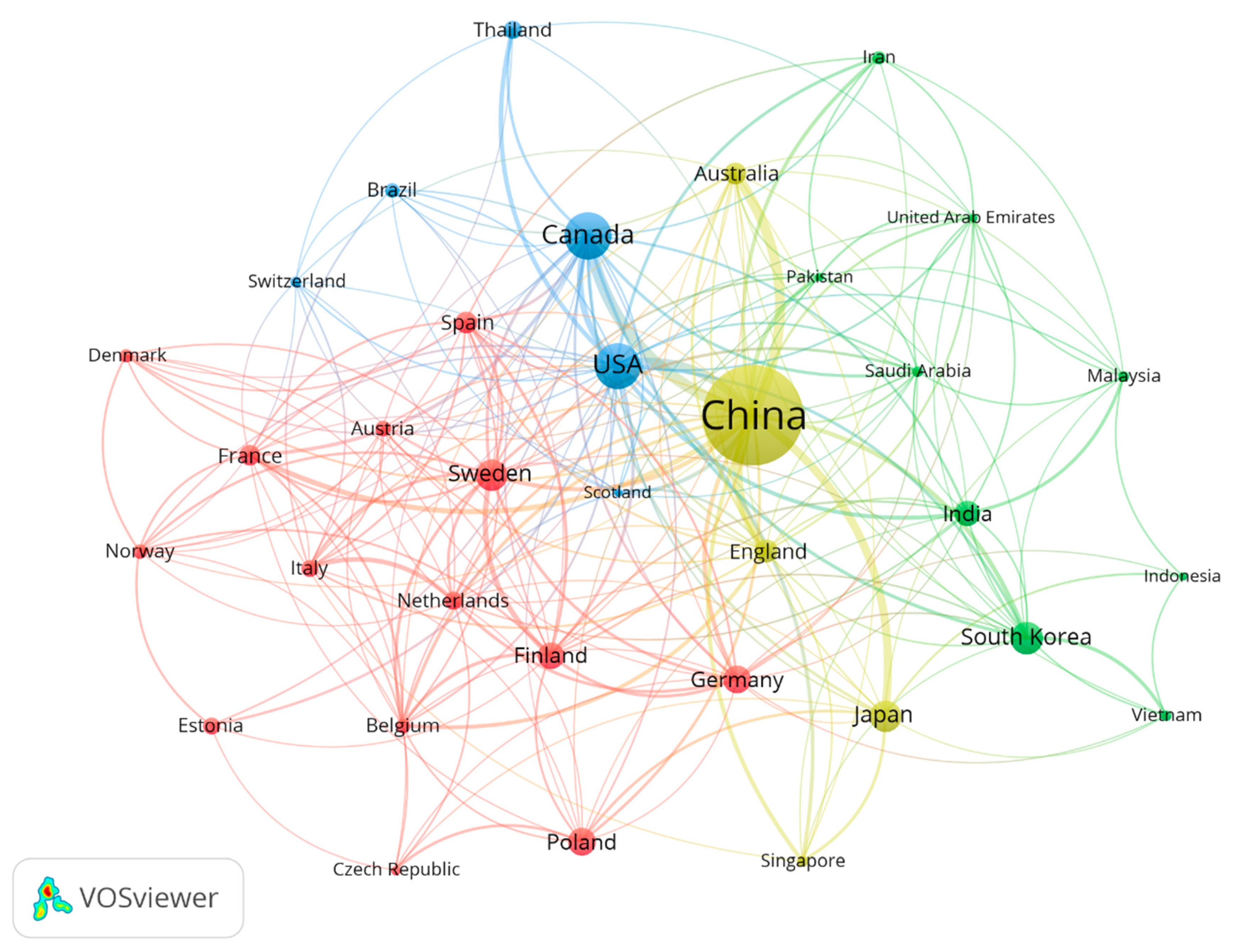

3.3. Country and Regional Analysis

3.3.1. Main Countries of SCI Paper Publication

3.3.2. Main Countries and Regions of Patents

3.4. Analysis of Organizations

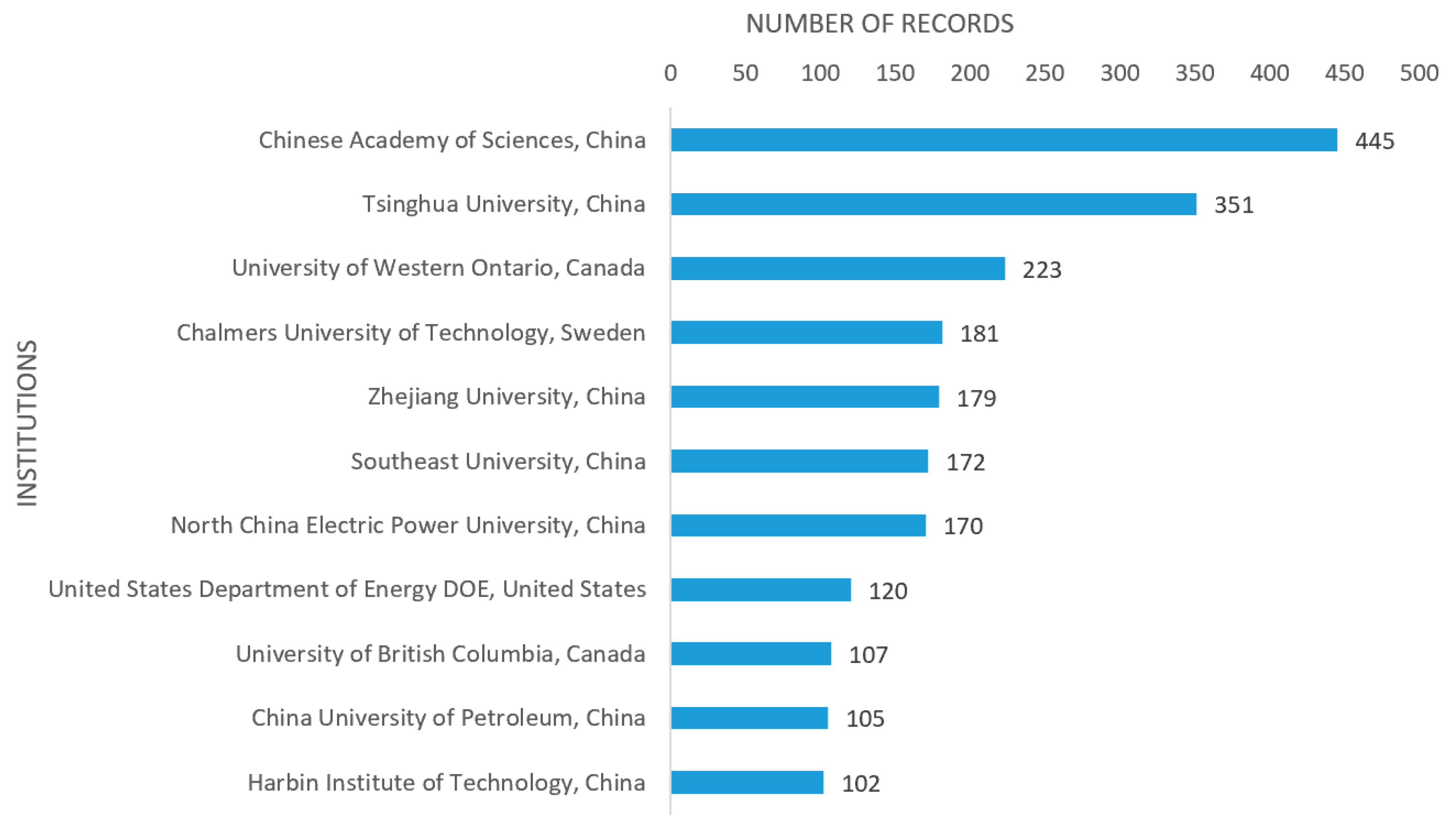

3.4.1. Main Organizations Producing CFB Papers

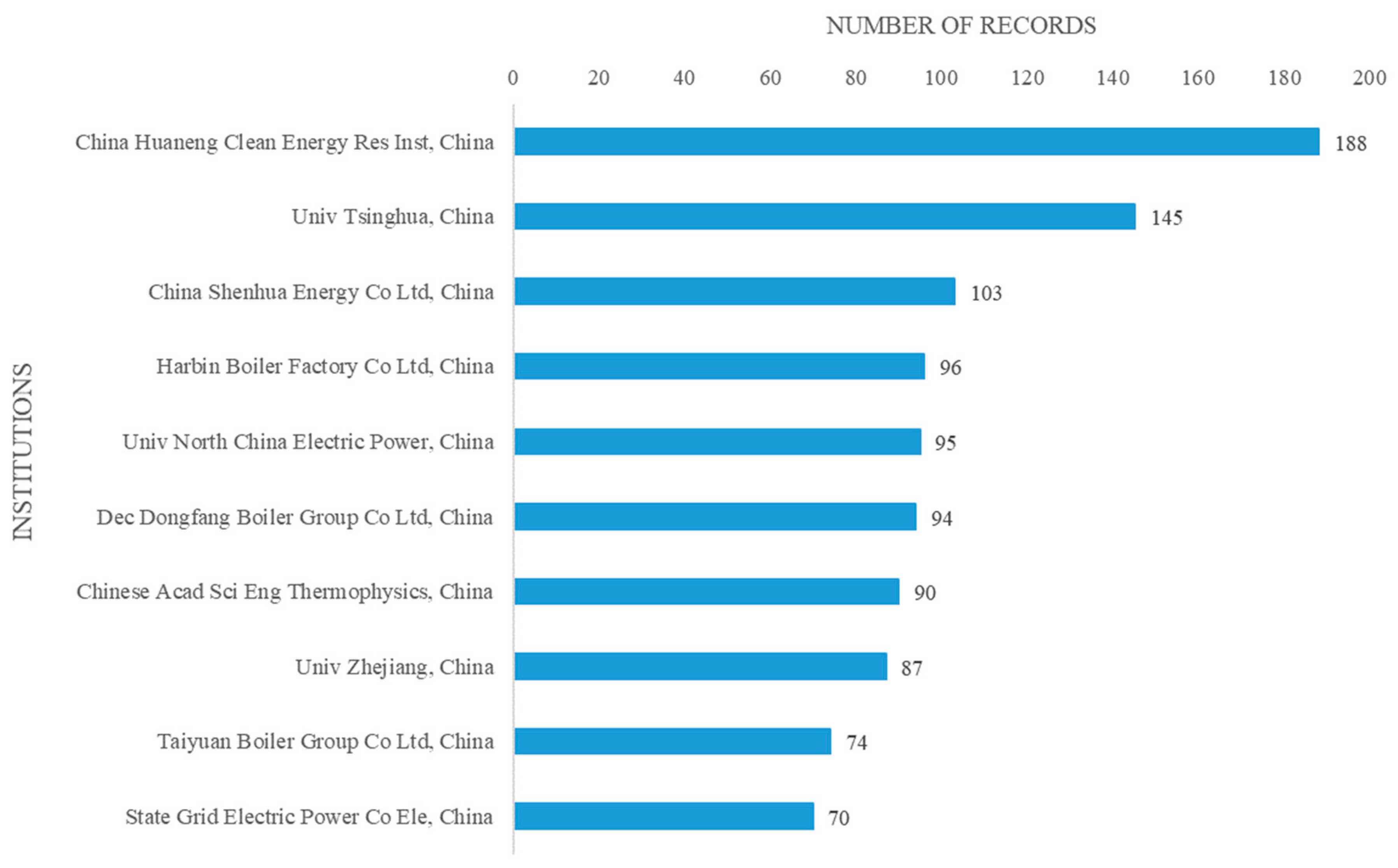

3.4.2. Main Organizations Applying for CFB Patents

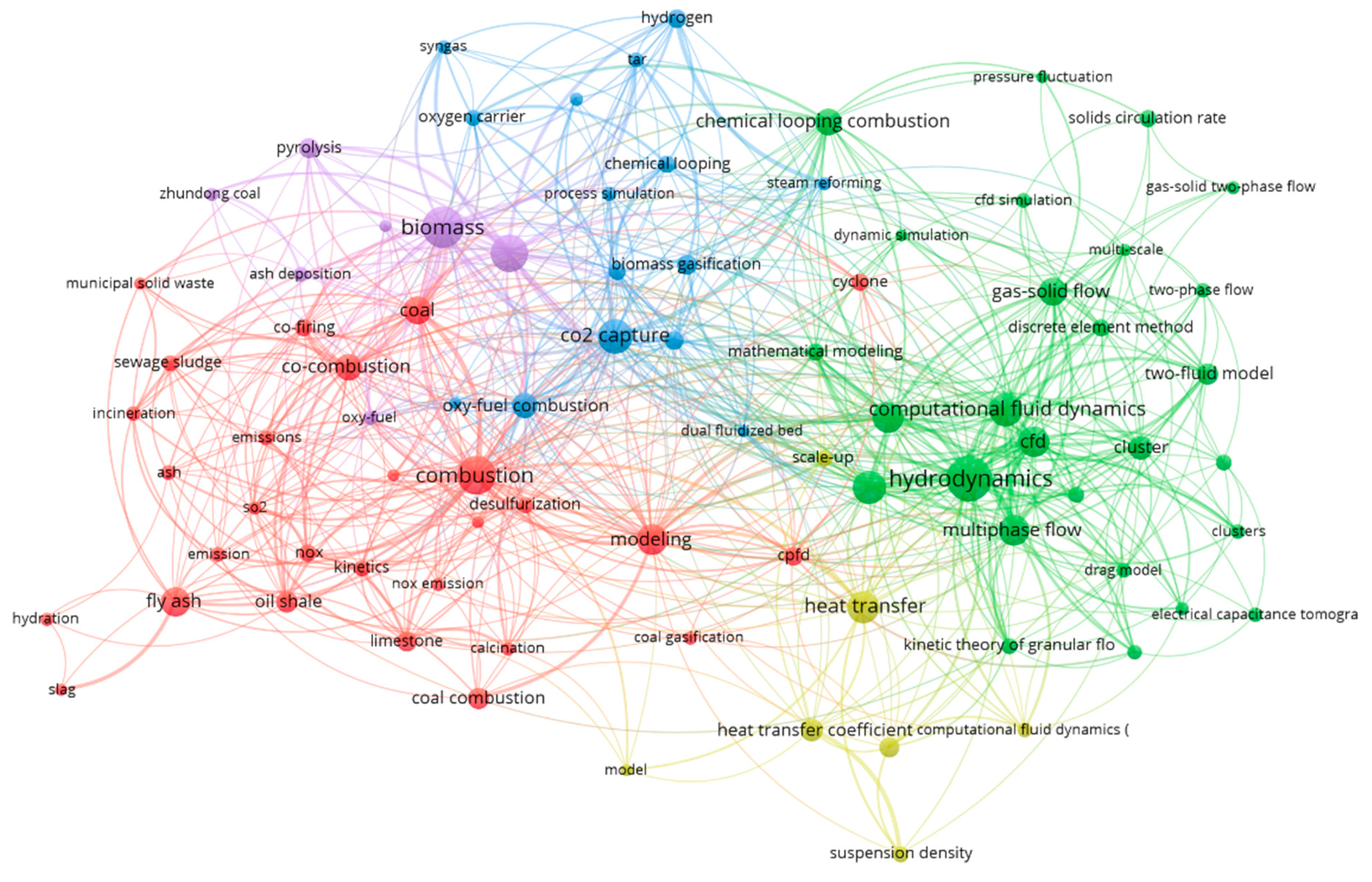

3.5. Technology Trend Analysis

4. Conclusions and Prospects

- (1)

- From the perspective of annual production trends, the CFB field has reached a mature stage, with a decrease in fundamental research and a greater emphasis on application development. Consequently, the number of related research papers has declined over the past three years, while the patent output remains consistently high.

- (2)

- From the distribution of subjects, the CFB field encompasses a wide range of disciplines and exhibits significant interdisciplinarity, with a focus on engineering applications.

- (3)

- From the perspective of major contributors to the literature, China has emerged as a major and core publishing country in this field, while developed countries such as Canada, the United States, and South Korea, and economically advanced developing countries also play significant roles in the field of CFB.

- (1)

- The core of CFB technology lies in its unique fluid dynamic characteristics, which enable fuel particles to exist in a fluidized state within the bed, facilitating efficient energy conversion and mass transfer. In recent years, with increasing demands for environmental protection, CFB technology has gained attention due to its lower pollutant emissions and good fuel adaptability. By optimizing operational parameters and improving designs, such as enhancing material circulation systems, increasing fuel adaptability, and improving heat exchange efficiency, efforts have been made to further enhance the combustion efficiency of CFB boilers and reduce harmful gas emissions.

- (2)

- In the field of materials science, researchers are developing new high-temperature and corrosion-resistant materials and manufacturing technologies to improve the durability and reliability of CFB systems. The development of these materials not only contributes to extending the equipment’s service life and reducing wear and maintenance costs but also helps maintain a stable performance under more extreme operating conditions.

- (3)

- Computational fluid dynamics (CFD) simulation has become an important tool in CFB technology research. Through CFD simulation, researchers can predict and analyze the flow characteristics and chemical reaction processes within the fluidized bed without conducting actual experiments. This is of great significance for optimizing design and operation.

- (4)

- In terms of energy utilization, CFB technology is advancing towards diversification and high efficiency. For example, by integrating gasification and combustion processes, the effective utilization of biomass and other renewable energy sources can be achieved, reducing the reliance on fossil fuels and lowering greenhouse gas emissions. With the growing global demand for sustainable development and clean energy, the application of CFB technology in waste treatment and resource recovery is also expanding.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ke, X.W.; Jiang, L.; Lv, J.F.; Yue, G.X. Prospects for Research on Low Pollution Emission Technology in Circulating Fluidized Bed Combustion. Chin. J. Eng. Sci. 2021, 23, 120–128. [Google Scholar] [CrossRef]

- Cui, Y.; Zou, Y.; Jiang, S.; Zhong, W. Scale-up prediction of supercritical CO2 circulating fluidized bed boiler based on adaptive PSO-SVM. Powder Technol. 2023, 419, 118328. [Google Scholar] [CrossRef]

- Tang, Z.; Song, G.; Yang, X.; Ji, Z. Research on combustion and emission characteristics of circulating fluidized bed during load changes. J. Energy Inst. 2022, 105, 334–341. [Google Scholar] [CrossRef]

- Hong, F.; Long, D.; Chen, J.; Gao, M. Modeling for the bed temperature 2D-interval prediction of CFB boilers based on long-short term memory network. Energy 2020, 194, 116733. [Google Scholar] [CrossRef]

- Ryabov, G.A. A Review of the Research Results into the Technologies of Solid-Fuel Combustion in a Circulating Fluidized Bed Conducted Abroad and in Russia. Therm. Eng. 2021, 68, 117–135. [Google Scholar] [CrossRef]

- Zhang, H.; Lyu, J.; Yue, G. A review on research and development of CFB combustion technology in China. Powder Technol. 2023, 414, 118090. [Google Scholar] [CrossRef]

- Kosaka, F.; Sasayama, T.; Liu, Y.; Chen, S.-Y.; Mochizuki, T.; Matsuoka, K.; Urakawa, A.; Kuramoto, K. Direct and continuous conversion of flue gas CO2 into green fuels using dual function materials in a circulating fluidized bed system. Chem. Eng. J. 2022, 450, 138055. [Google Scholar] [CrossRef]

- Choi, S.; Yun, M.; Kim, K.; Park, Y.-K.; Cho, H.H. Energy-efficient design of dual circulating fluidized bed system for CCUS by multi-tube configuration with junctions. Energy 2022, 245, 123258. [Google Scholar] [CrossRef]

- Osman, M.; Zaabout, A.; Cloete, S.; Amini, S. Mapping the operating performance of a novel internally circulating fluidized bed reactor applied to chemical looping combustion. Fuel Process. Technol. 2020, 197, 106183. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, L.; Zhang, M.; Han, Z.; Jia, X.; Bai, D.; Duo, W.; Bi, X.; Abudula, A.; Guan, G.; et al. A two-stage circulated fluidized bed process to minimize tar generation of biomass gasification for fuel gas production. Appl. Energy 2022, 323, 119639. [Google Scholar] [CrossRef]

- Reh, L. Development potentials and research needs in circulating fluidized bed combustion. Part. Sci. Technol. Engl. Ed. 2003, 1, 16. [Google Scholar] [CrossRef]

- Yang, H.R.; Yue, G.X.; Wang, Y.; Lv, J.F. Material Balance Analysis of Circulating Fluidized Bed Boiler. J. Therm. Power Eng. 2005, 3, 291–295+333. [Google Scholar]

- Lv, J.F.; Jiang, L.; Ke, X.W.; Zhang, H.; Liu, Q.; Huang, Z.; Zhou, T.; Zhang, M.; Wang, J.F.; Xiao, F.; et al. Prospects for the Development of Circulating Fluidized Bed Combustion Technology in China under the Background of Carbon Neutrality. Coal Sci. Technol. 2023, 51, 514–522. [Google Scholar] [CrossRef]

- Chen, T.; Deng, L.; Li, Y.; Li, J.; Zhao, X.; Fu, L. Removal of multiple pollutants in air pollution control devices of a coal-fired boiler installed with a flue gas condensation scrubber. J. Clean. Prod. 2024, 434, 139971. [Google Scholar] [CrossRef]

- Zhu, Y.; Wei, L.X.; Huang, M.; Deng, Q.G.; Su, H.; Lu, J.Y. Multi-stage Steam Coupling Circulating Fluidized Bed Boiler Design Scheme. Energy Conserv. 2023, 42, 71–73. [Google Scholar]

- Li, J.Y.; Ke, X.W.; Jiang, L.; Huang, Z.; Zhang, M. Lignite Circulating Fluidized Bed Boiler Combustion Performance Model. Clean Coal Technol. 2022, 28, 143–149. [Google Scholar] [CrossRef]

- Kong, D.; Wang, S.; Yu, J.; Li, D.; Luo, K.; Fan, J. Investigation of non-uniform characteristics in a 300 MWth circulating fluidized bed with different coal feeding modes. Adv. Powder Technol. 2023, 34, 104036. [Google Scholar] [CrossRef]

- Liu, Z.; Deng, B.; Zhou, T.; Huang, Z.; Sun, G.; Yang, H.; Zhang, M.; Jin, Y. Research on the measurement method of fuel feeding temperature during circulating fluidized bed boiler’s start-up. Asia-Pac. J. Chem. Eng. 2022, 17, e2810. [Google Scholar] [CrossRef]

- Man, C.; Zhu, J.; Ouyang, Z.; Liu, J.; Lyu, Q. Experimental study on combustion characteristics of pulverized coal preheated in a circulating fluidized bed. Fuel Process. Technol. 2018, 172, 72–78. [Google Scholar] [CrossRef]

- Jiang, F.W.; Luo, H.B.; Shen, G.; Hu, X.T. Numerical Simulation of the Effect of Combustion Air Modification on Reducing CO Emissions in a Circulating Fluidized Bed Waste Incineration Furnace. Environ. Pollut. Control 2020, 42, 293–298+304. [Google Scholar] [CrossRef]

- Wang, Y.F.; Chen, J. Circulating Fluidized Bed Boiler Air Distribution Device. Shanxi Electric Power 2010, 5, 43–45+55. [Google Scholar]

- Seddighi, S. Design of large scale oxy-fuel fluidized bed boilers: Constant thermal power and constant furnace size scenarios. Energy 2017, 118, 1286–1294. [Google Scholar] [CrossRef]

- Shi, B.; Cheng, W.F.; Yu, W.G.; Zhou, X.G.; Xiao, J.M.; Liu, A.P.; Dan, Z.Y. Practical Application of Fire Extinguishing Protection in Circulating Fluidized Bed Boilers. Energy Res. Manag. 2019, 4, 82–85. [Google Scholar] [CrossRef]

- Xiao, G.; Xi, Y. Analysis on cold state test of 300 MW circulating fluidized bed boiler. Energy Rep. 2020, 6, 1184–1191. [Google Scholar] [CrossRef]

- Reinking, Z.; Whitty, K.J.; Lighty, J.S. Design of a gas-solid-solid separator to remove ash from circulating fluidized bed reactors. Powder Technol. 2022, 404, 117467. [Google Scholar] [CrossRef]

- Zheng, X.; Lu, X.; Li, J.; Wang, Q.; Kang, Y.; Dong, Z.; Fan, X.; Liu, Z.; Zhang, Y.; Yang, Z.; et al. A novel thin-layer ash reciprocation heat recovery system for bottom ash from circulating fluidized bed boilers: Experimental study. Appl. Therm. Eng. 2021, 183, 116147. [Google Scholar] [CrossRef]

- Zan, H.; Chen, X.; Zhong, W.; Ma, J.; Liu, D.; Lian, G.; Geng, P.; Liang, C. Coal combustion emissions and ash formation characteristics during oxy-fuel combustion in a 100 kWth pressurized circulating fluidized bed. Fuel Process. Technol. 2022, 228, 107140. [Google Scholar] [CrossRef]

- Chen, S.; Hu, J.; Lu, J.; Xiang, W. Experimental investigation of a triplet ash valve for circulating fluidized bed. Powder Technol. 2018, 328, 397–405. [Google Scholar] [CrossRef]

- Zhang, N.; Bao, W.W.; Zhang, Q.; Yuan, J.L.; Jian, Z.Q. Study on the Characteristics of SNCR DeNOx in Supercritical Circulating Fluidized Bed Boilers. Energy Conserv. 2023, 42, 43–46. [Google Scholar]

- Zhang, Y.Y.; Qu, J.Y.; Su, X.X.; Yang, J.; Zhang, K. Gas-Liquid Mass Transfer and Reaction Characteristics during the SNCR DeNOx Process in Circulating Fluidized Bed Coal-Fired Units. CIESC J. 2023, 74, 2404–2415. [Google Scholar]

- Lu, G.F.; Liu, X.Y. Research and Practice on Full-Load DeNOx with Coupling Coordination in 350 MW Supercritical Circulating Fluidized Bed Boilers. Coal Sci. Technol. Mag. 2024, 45, 6–10. [Google Scholar] [CrossRef]

- Yoon, S.H.; Kim, S.-J.; Baek, G.-U.; Moon, J.H.; Jo, S.H.; Park, S.J.; Kim, J.-Y.; Yoon, S.-J.; Ra, H.W.; Yoon, S.-M.; et al. Operational optimization of air staging and flue gas recirculation for NOx reduction in biomass circulating fluidized bed combustion. J. Clean. Prod. 2023, 387, 135878. [Google Scholar] [CrossRef]

- Chang, J.; Ma, X.; Wang, X.; Li, X. Computational particle fluid dynamics modeling and design of in-situ catalytic deNOx in an industrial CFB boiler. Chem. Eng. Sci. 2023, 270, 118502. [Google Scholar] [CrossRef]

- Zhang, M.Z. Numerical Simulation on Structural Optimization Design of Metal Anti-Abrasion Blocks for Water-Cooled Walls in Circulating Fluidized Bed Boilers. Spec. Equip. Saf. Technol. 2023, 3, 9–11. [Google Scholar]

- Madejski, P.; Taler, D.; Taler, J. Thermal and flow calculations of platen superheater in large scale CFB boiler. Energy 2022, 258, 124841. [Google Scholar] [CrossRef]

- Jiang, L.; Li, Y.; Yao, Y.; Zhang, M.; Lu, J.; Huang, Z.; Zhou, T.; Yue, G. Heat transfer and protection of high-temperature reheater of a 660 MW circulating fluidized bed boiler after black out. Appl. Therm. Eng. 2022, 213, 118654. [Google Scholar] [CrossRef]

- Xia, Y.; Cheng, L.; Yu, C.; Xu, L.; Wang, Q.; Fang, M. Anti-wear beam effects on gas-solid hydrodynamics in a circulating fluidized bed. Particuology 2015, 19, 173–184. [Google Scholar] [CrossRef]

- Han, L.; Wang, L.; Yang, H.; Jia, C.; Meng, E.; Liu, Y.; Yin, S. Optimization of Circulating Fluidized Bed Boiler Combustion Key Control Parameters Based on Machine Learning. Energies 2023, 16, 5674. [Google Scholar] [CrossRef]

- Kim, D.; Won, Y.; Hwang, B.W.; Kim, J.Y.; Kim, H.; Choi, Y.; Lee, Y.-R.; Lee, S.-Y.; Jo, S.-H.; Park, Y.C.; et al. Loop-seal flow characteristics of a circulating fluidized bed for 3 MWth scale chemical looping combustion system. Energy 2023, 274, 127271. [Google Scholar] [CrossRef]

- Chen, Q.; Zheng, C.; Li, H. Analysis on international development trend of energy storage technology based on bibliometrics. Energy Storage Sci. Technol. 2020, 9, 296–305. [Google Scholar]

- Culp, G.L.; Stricker, V.J.; Nelson, J.R.; Bhasin, M.M.; Nielsen, K.A. Production of Olefins (e.g., Ethylene and/or Propylene) from Lower Alkane (e.g., Ethane) Involves Converting Lower Alkane by Oxidative Dehydrogenation, and Recovering Olefin Product by Complexation Separation. WO200224614-A1, 14 September 2001. [Google Scholar]

- Anderson, D.K.; Liljedahl, G.N.; Marion, J.L. Operating Method for Circulating Fluidized Bed Steam Generator Involves Separating Flue Gas into End Product and Recycling Portion to Be Directed to Steam Generator for Combustion Process. U.S. Patent US6505567-B1, 26 November 2001. [Google Scholar]

- Huber, G.W.; Cheng, Y.-T.; Carlson, T.; Vispute, T.; Jae, J.; Tompsett, G. Producing Fluid Hydrocarbon Products Comprises Providing Solid Catalyst in a Reactor and Feeding Solid Hydrocarbonaceous Material, Pyrolyzing the Reactor, and Catalytically Reacting Obtained Pyrolysis Products with the Catalyst. U.S. Patent US2009227823-A1, 3 March 2009. [Google Scholar]

- Dubois, J.-L.; Duquenne, C.; Hölderlich, W. Manufacturing Acrolein, Useful as Intermediate for Synthesis of Methionine and Acrylic Acid, by Dehydration of Glycerol in the Presence of Molecular Oxygen at Outside the Flammability Range. WO2006087083-A2, 6 January 2006. [Google Scholar]

- Sellakumar, K.; Sellakumar, K.M. Removal of Mercury from Flue Gas Containing Mercury and Particulate Solids, Comprises Contacting Mercury in Flue Gas with Solution Containing Chloride-Containing Salt. WO2003076051-A1, 26 February 2003. [Google Scholar]

- Chiu, J.H., Jr.; Andrus, H.E.; Liljedahl, G.N.; Thibeault, P.R. System for Hot Solids Combustion and Gasification, Has Chemical Looping System, Including Endothermic Reducer Reactor and Oxidizer Reactor, Which Is in Fluid Communication with at Least Portion of Existing Power Generation System. WO2010014938-A2, 31 July 2009. [Google Scholar]

- Beal, C.; Morin, J.-X.; Vandycke, M. Simultaneous Reduction of Carbon Dioxide and Sulfur Dioxide Emissions by Injecting Calcium-Based Agent into Hearth, Subjecting Flue Gases to Intermediate Cooling, Carbonizing, and Extracting Solids Contained in the Flue Gases. U.S. Patent US2002037246-A1, 14 September 2001. [Google Scholar]

- Kang, S.-K.; Shin, H.-D. Apparatus for Catalytic Gasification of Refined Biomass Fuel Comprises Catalytic Circulating Fluidized-Bed Gasifier; Dust Collector to Collect Fly Ash; Catalytic Reformer; Heat Exchanger; and Tar Scrubber. WO2006031011-A1, 14 June 2005. [Google Scholar]

- Fan, Z.; Zhen, F. Power Generation System Has Pipe to Conduct Portion of Compressed Exhaust Gas of Gas Turbine, to Gasifier, to Control Gasifier Temperature, Provide Carbon Dioxide, Steam for Gasification, and Reduce Oxygen Demand of Gasifier. WO2004027220-A1, 17 September 2003. [Google Scholar]

- Dubois, J.-L.; Duquenne, C.; Hölderich, W.; Kervennal, J. Production of Acrolein by Gas-Phase Dehydration of Glycerol in the Presence of Strongly Acidic Solid Catalyst with Specified Hammett Acidity. WO2006087084-A2, 6 January 2006. [Google Scholar]

- Tsinghua University Social Practice. Tsinghua Dialogue 100+10 | Yue Guangxi: Harnessing Heat as Energy, Unceasing Combustion. Available online: https://mp.weixin.qq.com/s?__biz=MjM5OTY0NTgyMg==&mid=2650809220&idx=2&sn=4235aa89552da15c4503b6fa7881eeae&chksm=bcccc4958bbb4d83670c3c8827baf28a180577f67517ee7b10513e915660a30bc61d760ce7b4&scene=27 (accessed on 13 June 2021).

- Yang, H.; Zhang, H.; Yang, S.; Yue, G.; Su, J.; Fu, Z. Effect of Bed Pressure Drop on Performance of a CFB Boiler. Energy Fuels 2009, 23, 2886–2890. [Google Scholar] [CrossRef]

- Cai, R.; Ke, X.; Lyu, J.; Yang, H.; Zhang, M.; Yue, G.; Ling, W. Progress of circulating fluidized bed combustion technology in China: A review. Clean Energy 2017, 1, 36–49. [Google Scholar] [CrossRef]

- Institute of Coal Chemistry, Chinese Academy of Sciences. [Pilot Scale-Up] Multi-Linked Supply Technology of Coal Combustion and Pyrolysis in Circulating Fluidized Bed. Available online: http://www.sxicc.ac.cn/result/cg/mtly/202111/t20211101_6239923.html (accessed on 29 August 2016).

| Rank | Subject | Number of Papers | Proportion of Total Papers/% |

|---|---|---|---|

| 1 | Engineering Chemical | 3281 | 57.59 |

| 2 | Energy Fuels | 1988 | 34.83 |

| 3 | Thermodynamics | 594 | 10.41 |

| 4 | Engineering Mechanical | 563 | 9.87 |

| 5 | Engineering Environmental | 461 | 8.08 |

| 6 | Materials Science Multidisciplinary | 393 | 6.89 |

| 7 | Environmental Sciences | 374 | 6.55 |

| 8 | Mechanics | 341 | 5.98 |

| 9 | Chemistry Applied | 157 | 2.75 |

| 10 | Engineering Electrical Electronic | 156 | 2.73 |

| IPC | Number of Patents | Ratio over the Past Three Years |

|---|---|---|

| F23C (Methods or Apparatus for Combustion Using Fluid Fuel or Solid Fuel Suspended in Air) | 3734 | 16% |

| B01D (Separation) | 1052 | 14% |

| F23J (Removal or Treatment of Combustion Products or Combustion Residues; Flues) | 708 | 21% |

| F22B (Methods of Steam Generation; Steam Boilers) | 515 | 11% |

| F23G (Cremation Furnaces; Consuming Waste or Low-Grade Fuels by Combustion) | 490 | 14% |

| C10J (Production of Gases Containing Carbon Monoxide and Hydrogen from Solid Carbonaceous Materials by Partial Oxidation Processes Involving Oxygen or Steam) | 445 | 11% |

| B01J (Chemical or Physical Processes, E.G. Catalysis or Colloid Chemistry; Their Relevant Apparatus) | 430 | 14% |

| C04B (Lime; Magnesia; Slag; Cements; Compositions Thereof, e.g., Mortars, Concrete or Similar Building Materials; Artificial Stone; Ceramics; Refractories; Treatment of Natural Stone) | 387 | 18% |

| F23L (Supplying Air or Non-Combustible Liquids or Gases to Combustion Apparatus in General; Valves or Dampers Specially Adapted for Controlling Air Supply or Draught in Combustion Apparatus; Inducing Draught in Combustion Apparatus; Tops for Chimneys or Ventilating Shafts; Terminals for Flues) | 325 | 17% |

| F23M (Casings, Linings, Walls or Doors Specially Adapted for Combustion Chambers, e.g., Firebridges; Devices for Deflecting Air, Flames or Combustion Products in Combustion Chambers; Safety Arrangements Specially Adapted for Combustion Apparatus; Details of Combustion Chambers, Not Otherwise Provided for) | 249 | 14% |

| Title | Year | Cited |

|---|---|---|

| Modeling of biomass gasification in fluidized bed | 2010 | 645 |

| Biomass gasification in a circulating fluidized bed | 2004 | 584 |

| More efficient biomass gasification via torrefaction | 2006 | 497 |

| CFD simulation of concurrent-up gas–solid flow in circulating fluidized beds with structure-dependent drag coefficient | 2003 | 474 |

| Eulerian two-phase flow theory applied to fluidization | 1996 | 457 |

| Chemical looping combustion of solid fuels | 2018 | 418 |

| A review on bio-oil production from biomass by using pyrolysis method | 2012 | 404 |

| Characterization of fluidization regimes by time-series analysis of pressure fluctuations | 2000 | 368 |

| Filtered two-fluid models for fluidized gas–particle suspensions | 2008 | 365 |

| State of the art of applied fast pyrolysis of lignocellulosic materials—a review | 1999 | 317 |

| Patent Number | Title | Priority Application Date | Cited |

|---|---|---|---|

| WO200224614-A1 | Production of olefins (e.g., ethylene and/or propylene) from lower alkane (e.g., ethane) involves converting lower alkane by oxidative dehydrogenation, and recovering olefin product by complexation separation | 18 September 2000 | 131 |

| US6505567-B1 | Operating method for circulating fluidized bed steam generator involves separating flue gas into end product and recycling portion to be directed to steam generator for combustion process | 26 November 2001 | 120 |

| US2009227823-A1 | Producing fluid hydrocarbon products comprises providing solid catalyst in a reactor and feeding solid hydrocarbonaceous material, pyrolyzing the reactor, and catalytically reacting obtained pyrolysis products with the catalyst | 3 March 2009 | 101 |

| WO2006087083-A2 [44] | Manufacturing acrolein, useful as intermediate for synthesis of methionine and acrylic acid, by dehydration of glycerol in the presence of molecular oxygen at outside the flammability range | 10 June 2005 | 89 |

| WO2003076051-A1 [45] | Removal of mercury from flue gas containing mercury and particulate solids, comprises contacting mercury in flue gas with solution containing chloride-containing salt | 12 March 2002 | 86 |

| WO2010014938-A2 [46] | System for hot solids combustion and gasification, has chemical looping system, including endothermic reducer reactor and oxidizer reactor, which is in fluid communication with at least portion of existing power generation system | 19 September 2008 | 82 |

| US2002037246-A1 [47] | Simultaneous reduction in carbon dioxide and sulfur dioxide emissions by injecting calcium-based agent into hearth, subjecting flue gases to intermediate cooling, carbonizing, and extracting solids contained in the flue gases | 27 September 2000 | 70 |

| WO2006031011-A1 [48] | Apparatus for catalytic gasification of refined biomass fuel comprises catalytic circulating fluidized bed gasifier; dust collector to collect fly ash; catalytic reformer; heat exchanger; and tar scrubber | 5 August 2004 | 67 |

| WO2004027220-A1 [49] | Power generation system has pipe to conduct portion of compressed exhaust gas of gas turbine to gasifier, to control gasifier temperature, provide carbon dioxide, and steam for gasification, and reduce oxygen demand of gasifier | 17 September 2002 | 67 |

| WO2006087084-A2 [50] | Production of acrolein by gas-phase dehydration of glycerol in the presence of strongly acidic solid catalyst with specified Hammett acidity | 10 Jun 2005 | 66 |

| Countries/Regions | Number of Patents Issued | Ratio over the Past Three Years |

|---|---|---|

| China | 6215 | 24% |

| South Korea | 290 | 13% |

| United States | 237 | 4% |

| Japan | 209 | 9% |

| Canada | 75 | 7% |

| European | 71 | 6% |

| Finland | 71 | 8% |

| Germany | 40 | 5% |

| France | 37 | 3% |

| India | 36 | 0% |

| Organizations | Number of Patents | Ratio over the Past Three Years |

|---|---|---|

| China Huaneng Clean Energy Research Institute, Beijing, China | 188 | 23% |

| Tsinghua University, Beijing, China | 145 | 20% |

| China Shenhua Energy Company Limited, Shanghai, China | 103 | 1% |

| Harbin Boiler Factory Company Limited, Harbin, China | 96 | 20% |

| North China Electric Power University, Beijing, China | 95 | 17% |

| Dongfang Boiler Group Company Limited, Zigong, China | 94 | 9% |

| Institute of Engineering Thermophysics, Chinese Academy of Sciences, Beijing, China | 90 | 11% |

| Zhejiang University, Hangzhou, China | 87 | 13% |

| Taiyuan Boiler Group Company Limited, Taiyuan, China | 74 | 9% |

| The State Grid Corporation of China, Beijing, China | 70 | 19% |

| Clustering Number | Research Topic | Keywords |

|---|---|---|

| #1 | Combustion and Pollutant Emissions | ash, calcination, co-combustion, co-firing, CO2, coal, coal combustion, coal gasification, combustion, CPFD, cyclone, desulfurization, emission, fly ash, hydration, incineration, kinetics, limestone, modeling, municipal solid waste, NOx, NOx emission, oil shale, oxy-combustion, sewage sludge, slag, SO2 |

| #2 | Pyrolysis | heat transfer, heat transfer coefficient, scale-up, solid circulation rate, suspension density, computational fluid dynamics (CFD), model |

| #3 | Gasification | ash deposition, biomass, gasification, lignite, oxy-fuel, pyrolysis, zhundong coal |

| #4 | Dynamics simulation/Numerical simulation | CFD simulation, chemical looping combustion, cluster, computational fluid dynamics, discrete element method, drag model, dynamic simulation, electrical capacitance tomography, fast fluidization, gas–solid flow, gas–solid two-phase flow, gas–solids flow, hydrodynamics, kinetic theory, kinetic theory of granular flow, mass transfer, mathematical modeling, multi-scale, multiphase flow, numerical simulation, pressure fluctuation, simulation, solids circulation rate, two-fluid model, two-phase flow |

| #5 | Low-Carbon/Zero-Carbon | biomass combustion, biomass gasification, carbon capture, chemical looping, chemical looping combustion, CO2 capture, dual fluidized bed, hydrogen, modelling, oxy-fuel combustion, oxygen carrier, process simulation, steam reforming, syngas, tar |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Q.; Gou, Y.; Wang, T.; Liu, P.; Zhu, J. The Evolutionary Path and Emerging Trends of Circulating Fluidized Bed Technology: An Integrated Analysis through Bibliometric Assessment and Data Visualization. Energies 2024, 17, 3514. https://doi.org/10.3390/en17143514

Chen Q, Gou Y, Wang T, Liu P, Zhu J. The Evolutionary Path and Emerging Trends of Circulating Fluidized Bed Technology: An Integrated Analysis through Bibliometric Assessment and Data Visualization. Energies. 2024; 17(14):3514. https://doi.org/10.3390/en17143514

Chicago/Turabian StyleChen, Qimei, Yurong Gou, Tangrong Wang, Pengbo Liu, and Jianguo Zhu. 2024. "The Evolutionary Path and Emerging Trends of Circulating Fluidized Bed Technology: An Integrated Analysis through Bibliometric Assessment and Data Visualization" Energies 17, no. 14: 3514. https://doi.org/10.3390/en17143514

APA StyleChen, Q., Gou, Y., Wang, T., Liu, P., & Zhu, J. (2024). The Evolutionary Path and Emerging Trends of Circulating Fluidized Bed Technology: An Integrated Analysis through Bibliometric Assessment and Data Visualization. Energies, 17(14), 3514. https://doi.org/10.3390/en17143514