Assessment of Engine Performance and Emissions with Eucalyptus Oil and Diesel Blends

Abstract

:1. Introduction

2. Materials and Methods

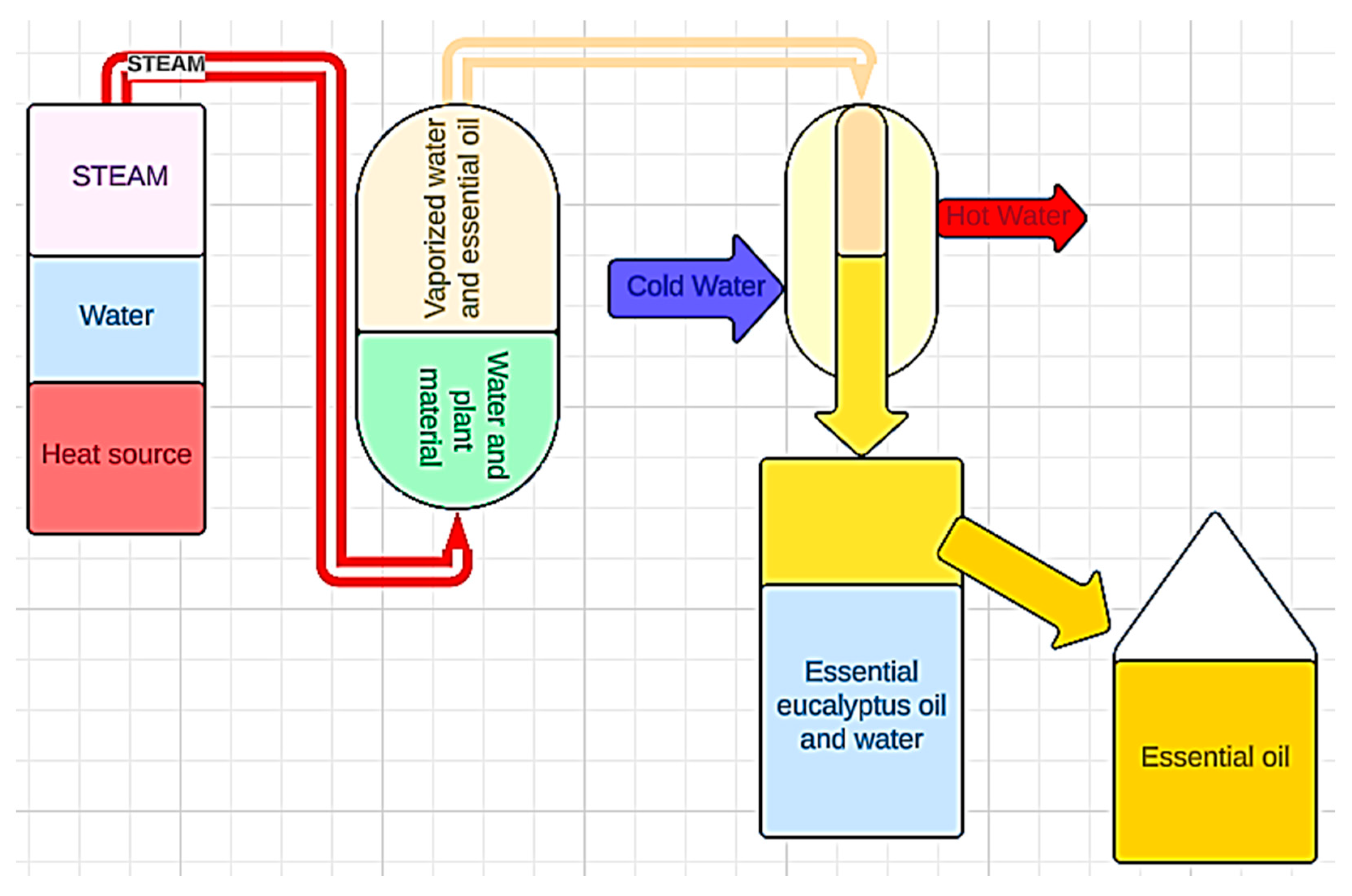

2.1. Biofuel Preparation

2.2. Biofuel Properties

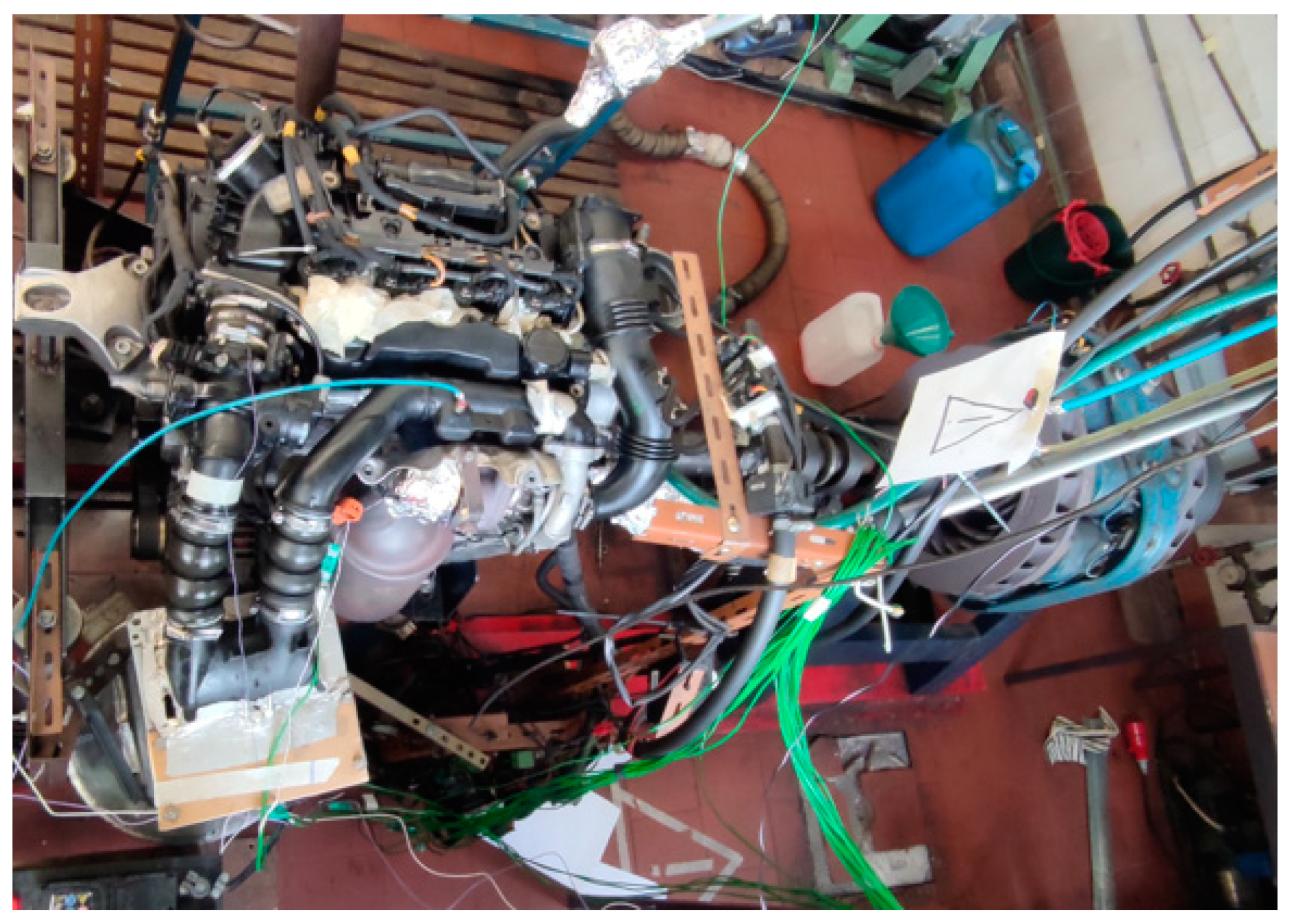

2.3. Experimental Setup

2.4. Test Parameters

3. Results and Discussions

3.1. Engine Performances Parameters

3.1.1. Engine Torque

3.1.2. Brake Specific Fuel Consumption (BSFC)

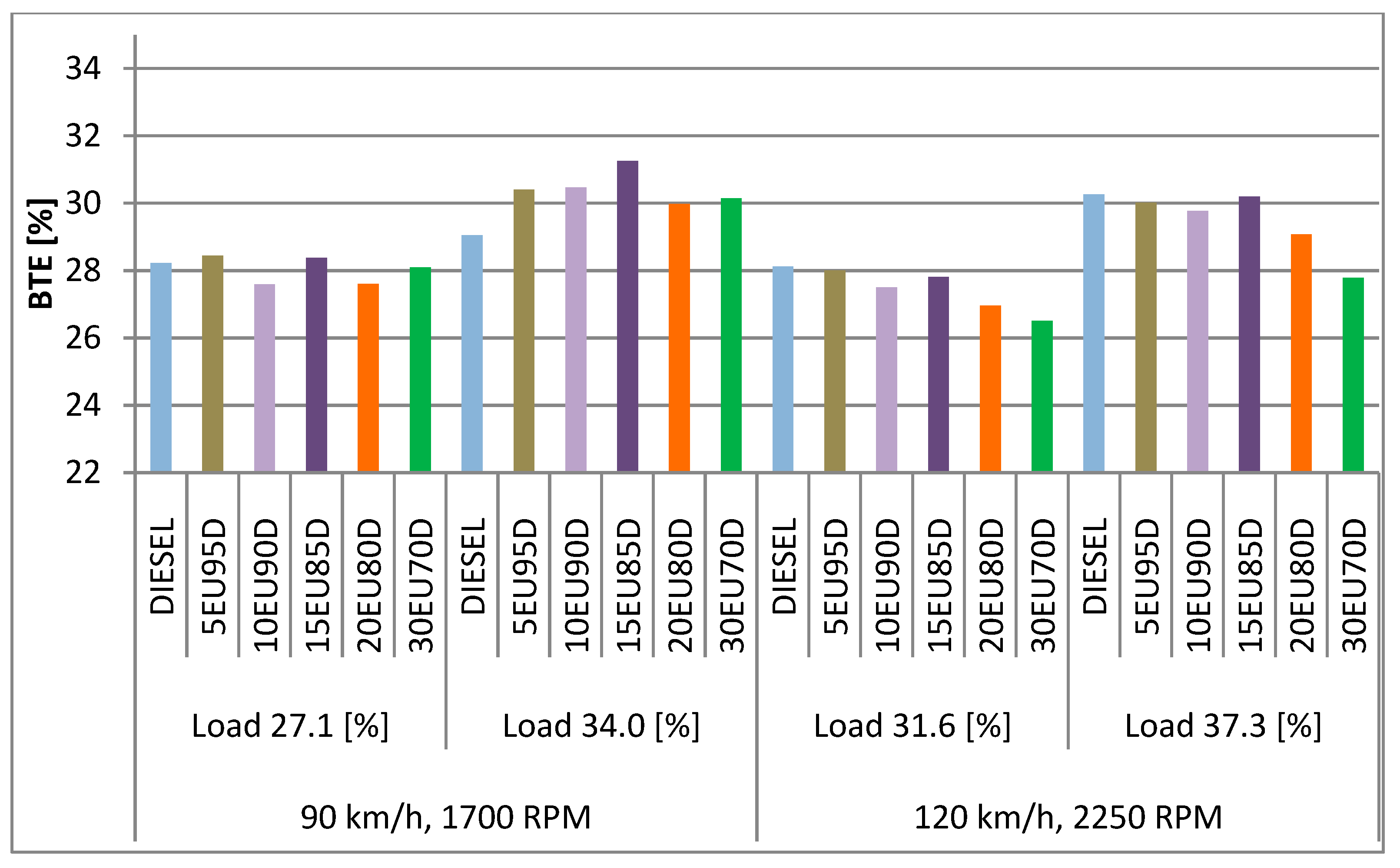

3.1.3. Brake Thermal Efficiency (BTE)

3.2. Emissions

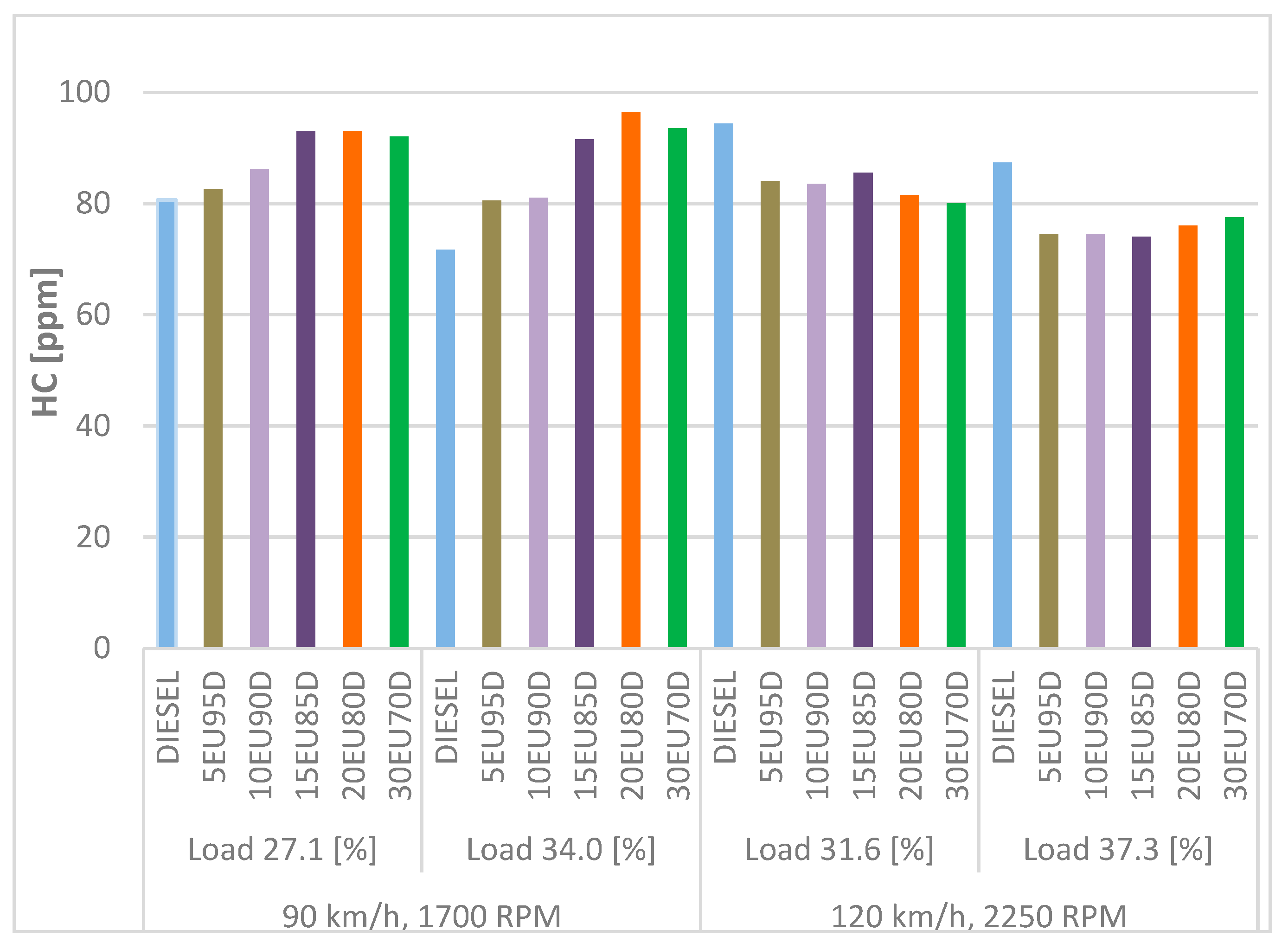

3.2.1. Unburned Hydrocarbons

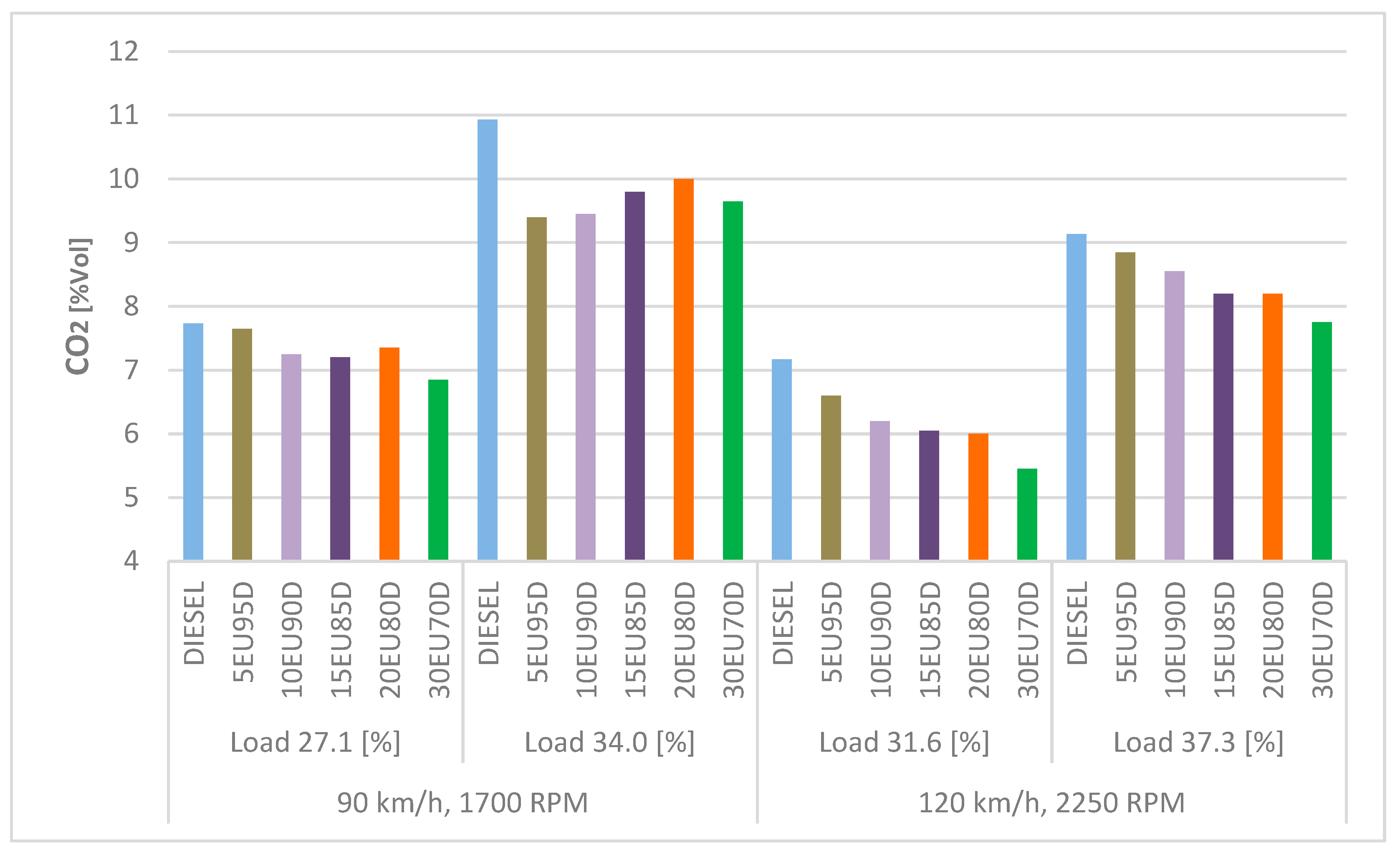

3.2.2. Carbon Dioxide

3.2.3. Nitrogen Oxides

3.2.4. Smoke (Opacity)

4. Conclusions

- The CO concentration was so low in all of the tests that it was below the threshold measured by the gas analyzer, even without exhaust after-treatment. This low carbon monoxide (CO) concentration compared with gasoline engines can be attributed to the diesel engine’s constant operation with excess air, but CO emissions could still be detected under certain conditions, such as during cold starts.

- At specific conditions such as low engine speed and high engine load, CO2 emissions showed an increase. Importantly, a significant aspect of CO2 emissions from eucalyptus oil blends is their neutrality, as eucalyptus trees absorb CO2 during their growth, effectively offsetting emissions associated with their combustion.

- Nitrogen oxide (NOx) emissions were lower for all mixtures of eucalyptus oil–diesel compared to diesel, indicating a decrease in combustion temperature, which was also indicated by the lower exhaust gas temperatures recorded when the eucalyptus oil concentration was higher in the mixture.

- The incorporation of eucalyptus oil blends into diesel fuel nearly always provided a reduction in smoke. This reduction was stronger (a peak 57% reduction in smoke opacity) for the case in which the reference fuel emitted the most smoke, at the low speed and high load setting. This behavior might be related to the higher cetane number of the eucalyptus-oil-based fuel, which improves combustion.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bergthorson, J.M.; Thomson, M.J. A Review of the Combustion and Emissions Properties of Advanced Transportation Biofuels and Their Impact on Existing and Future Engines. Renew. Sustain. Energy Rev. 2015, 42, 1393–1417. [Google Scholar] [CrossRef]

- Martins, J.; Brito, F.P. Alternative Fuels for Internal Combustion Engines. Energies 2020, 13, 4086. [Google Scholar] [CrossRef]

- Lundberg, L.; Cintas Sanchez, O.; Zetterholm, J. The Impact of Blending Mandates on Biofuel Consumption, Production, Emission Reductions and Fuel Prices. Energy Policy 2023, 183, 113835. [Google Scholar] [CrossRef]

- Puricelli, S.; Cardellini, G.; Casadei, S.; Faedo, D.; van den Oever, A.E.M.; Grosso, M. A Review on Biofuels for Light-Duty Vehicles in Europe. Renew. Sustain. Energy Rev. 2021, 137, 110398. [Google Scholar] [CrossRef]

- Prasad, S.; Yadav, K.K.; Kumar, S.; Pandita, P.; Bhutto, J.K.; Alreshidi, M.A.; Ravindran, B.; Yaseen, Z.M.; Osman, S.M.; Cabral-Pinto, M.M.S. Review on Biofuel Production: Sustainable Development Scenario, Environment, and Climate Change Perspectives—A Sustainable Approach. J. Environ. Chem. Eng. 2024, 12, 111996. [Google Scholar] [CrossRef]

- Ellappan, S.; Rajendran, S. A Comparative Review of Performance and Emission Characteristics of Diesel Engine Using Eucalyptus-Biodiesel Blend. Fuel 2021, 284, 118925. [Google Scholar] [CrossRef]

- Ferreira, S.; Monteiro, E.; Brito, P.; Vilarinho, C. Biomass Resources in Portugal: Current Status and Prospects. Renew. Sustain. Energy Rev. 2017, 78, 1221–1235. [Google Scholar] [CrossRef]

- Chahomchuen, T.; Insuan, O.; Insuan, W. Chemical Profile of Leaf Essential Oils from Four Eucalyptus Species from Thailand and Their Biological Activities. Microchem. J. 2020, 158, 105248. [Google Scholar] [CrossRef]

- Thiyagarajan, S.; Sonthalia, A.; Geo, V.E.; Viswanathan, K.; Balasubramaniyam, D. Effect of Low Carbon Biofuel on Carbon Emissions in Biodiesel Fueled CI Engine. In Bioenergy Resources and Technologies; Academic Press: Cambridge, MA, USA, 2021; pp. 291–326. [Google Scholar] [CrossRef]

- Portucel Soporcel Group Wins International Prize for Green Energy and Biofuels. Available online: https://en.thenavigatorcompany.com/var/ezdemo_site/storage/original/application/3861e0801d2bf4bd869e10dbca162996.pdf (accessed on 20 March 2024).

- The Navigator Company. Available online: https://en.thenavigatorcompany.com/ (accessed on 23 May 2024).

- Srinivas, K.; Balu Naik, B.; Kalyani Radha, K. Impact of Fuel Injection Pressure and Compression Ratio on Performance and Emission Characteristics of VCR CI Engine Fueled with Palm Kernel Oil-Eucalyptus Oil Blends. Mater. Today Proc. 2017, 4, 2222–2230. [Google Scholar] [CrossRef]

- Senthur, N.S.; Karthikeyen, R.; BalaMurugan, S.; Divakara, S.; Esakkiraja, M. Experimental Investigation of Nano Metal Oxide Blended Eucalyptus Bio Fuel on Common Rail Direct Injected Diesel Engine. Mater. Today Proc. 2020, 33, 2605–2610. [Google Scholar] [CrossRef]

- Tarabet, L.; Loubar, K.; Lounici, M.S.; Hanchi, S.; Tazerout, M. Experimental Evaluation of Performance and Emissions of DI Diesel Engine Fuelled with Eucalyptus Biodiesel. In Proceedings of the Internal Combustion Engines: Performance, Fuel Economy and Emissions, London, UK, 29–30 November 2011; pp. 167–176. [Google Scholar] [CrossRef]

- Sathish Kumar, T.; Ashok, B.; Senthilkumar, M.; Saiteja, P.; Vignesh, R.; Karthick, C.; Nithin, P.S.; Durairaj, K.; Saju, N.; Agarwal, C.; et al. Enhancement of Engine Characteristics through Zirconium Nano Particle Addition and Split Injection Parameter Optimization for the Adaptability of Eucalyptus Biofuel in Diesel Engine. Fuel 2022, 323, 124425. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, J.; Kumar, S.; Goga, G. An Experimental Analysis on Performance of CI Engine Fuelled with Eucalyptus Oil. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Kommana, S.; Banoth, B.N.; Kadavakollu, K.R. Performance and Emission of VCR-CI Engine with Palm Kernel and Eucalyptus Blends. Perspect. Sci. 2016, 8, 195–197. [Google Scholar] [CrossRef]

- Patel, A.K.; Agrawal, B.; Rawal, B.R. Assessment of Diesel Engine Performance and Emission Using Biodiesel Obtained from Eucalyptus Leaves. Eur. J. Sustain. Dev. Res. 2023, 7, em0210. [Google Scholar] [CrossRef]

- Naima, K.; Bousbaa, H.; Ahmad, H.; Al-Bahrani, M.; Tarabet, L.; Menni, Y.; Lorenzini, G. A Comparative Assessment of Combustion Behavior and Emissions Characteristics of DI Diesel Engine Fueled with Waste Plastic Oil and Eucalyptus Biofuel for Sustainable Development Applications. Int. J. Low-Carbon Technol. 2022, 17, 1399–1405. [Google Scholar] [CrossRef]

- Liazid, A.; Naima, K.; Tazerout, M.L.; Tarabet, L.; Bousbaa, H. Eucalyptus Biofuel Study as Alternative for Diesel Engine. Int. J. Renew. Energy Technol. 2019, 10, 247. [Google Scholar] [CrossRef]

- Costa, J.; Martins, J.; Arantes, T.; Gonçalves, M.; Durão, L.; Brito, F.P. Experimental Assessment of the Performance and Emissions of a Spark-Ignition Engine Using Waste-Derived Biofuels as Additives. Energies 2021, 14, 5209. [Google Scholar] [CrossRef]

- Durão, L.; Costa, J.; Arantes, T.; Brito, F.P.; Martins, J.; Gonçalves, M. Performance and Emissions of a Spark Ignition Engine Operated with Gasoline Supplemented with Pyrogasoline and Ethanol. Energies 2020, 13, 4671. [Google Scholar] [CrossRef]

- Chivu, R.M.; Martins, J.; Popescu, F.; Uzuneanu, K.; Ion, I.V.; Goncalves, M.; Codău, T.-C.; Onofrei, E.; Brito, F.P. Turpentine as an Additive for Diesel Engines: Experimental Study on Pollutant Emissions and Engine Performance. Energies 2023, 16, 5150. [Google Scholar] [CrossRef]

- Immaroh, N.Z.; Kuliahsari, D.E.; Nugraheni, S.D. Review: Eucalyptus Globulus Essential Oil Extraction Method. IOP Conf. Ser. Earth Environ. Sci. 2021, 733, 012103. [Google Scholar] [CrossRef]

- Rao, V.P.S.; Sahoo, A. Extraction of Essential Oil and Its Applications. Ph.D. Thesis, National Institute of Technology, Rourkela, India, 2007. [Google Scholar]

- Rathore, H.S. Green Pesticides for Organic Farming: Occurrence and Properties of Essential Oils for Use in Pest Control. In Green Pesticides Handbook; CRC Press: Boca Raton, FL, USA, 2017; pp. 3–26. [Google Scholar] [CrossRef]

- Tarabet, L.; Loubar, K.; Lounici, M.S.; Hanchi, S.; Tazerout, M. Eucalyptus Biodiesel as an Alternative to Diesel Fuel: Preparation and Tests on Di Diesel Engine. J. Biomed. Biotechnol. 2012, 2012, 235485. [Google Scholar] [CrossRef] [PubMed]

- Verma, P.; Sharma, M.P.; Dwivedi, G. Potential Use of Eucalyptus Biodiesel in Compressed Ignition Engine. Egypt. J. Pet. 2016, 25, 91–95. [Google Scholar] [CrossRef]

- AVL DiGas 4000 AVL DiCom 4000 AVL DiSmoke 4000 Engine Diagnostics. Available online: https://docplayer.net/20998407-Avl-digas-4000-avl-dicom-4000-avl-dismoke-4000-engine-diagnostics.html (accessed on 20 February 2024).

- Martins, J. Motores de Combustão Interna, 5th ed.; Engebook; Pubindústria: Porto, Portugal, 2016; ISBN 978-989-723-190-2. [Google Scholar]

- Martins, J.M. Mateus. In Motores de Combustão Interna; Publindústria: Porto, Portugal, 2006; ISBN 972895302X. [Google Scholar]

- Heywood, J.B. Internal Combustion Engine Fundamentals, 2nd ed.; McGraw-Hill Education: New York, NY, USA, 2018; ISBN 9781260116106. [Google Scholar]

- Tarabet, L.; Loubar, K.; Lounici, M.S.; Khiari, K.; Belmrabet, T.; Tazerout, M. Experimental Investigation of DI Diesel Engine Operating with Eucalyptus Biodiesel/Natural Gas under Dual Fuel Mode. Fuel 2014, 133, 129–138. [Google Scholar] [CrossRef]

| Properties | Diesel | Eucalyptus Oil (Sample A) | Eucalyptus Oil (Sample B) |

|---|---|---|---|

| Formula | C12H23 | C10H18O | C10H18O |

| Density (kg/m3) | 830 | 913 | 930 |

| Boiling point (°C) | 180–340 | 175 | 178 |

| Viscosity (cSt) @40 °C | 2.5 | 3.2 | 3 |

| Latent heat of vaporization (kJ/kg) | 230 | 305 | 318 |

| Lower heating value (kJ/kg) | 42,500 | 43,270 | 44,100 |

| Flash point (°C) | 74 | 93 | 98 |

| Auto ignition temperature (°C) | 254–258 | 300–330 | 300–330 |

| Cetane number | 40–55 | 52 | 55 |

| Engine | In-Line 4 Cylinder, PSA HDI |

|---|---|

| Fuel injection | diesel common rail |

| Displacement | 1560 cm3 |

| Compression ratio | 18:1 |

| Power | 75 HP/56 kW @ 4000 rpm |

| Torque | 170 N∙m @ 1700 rpm |

| Eucalyptus oil incorporations tested [%] Example: 5EU95D = 5% eucalyptus oil + 95% diesel (mixed by volume) | 5%, 10%, 15%, 20%, 30% | |||

| Engine speed [rpm] (constant speed) | 1700 | 2250 | ||

| Engine load (for all fuels) [%] | 27.1 | 34.0 | 31.6 | 37.3 |

| Equivalent driving conditions (constant) | Road 90 km/h | Highway 120 km/h | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chivu, R.M.; Martins, J.; Popescu, F.; Gonçalves, M.; Uzuneanu, K.; Frătița, M.; Brito, F.P. Assessment of Engine Performance and Emissions with Eucalyptus Oil and Diesel Blends. Energies 2024, 17, 3528. https://doi.org/10.3390/en17143528

Chivu RM, Martins J, Popescu F, Gonçalves M, Uzuneanu K, Frătița M, Brito FP. Assessment of Engine Performance and Emissions with Eucalyptus Oil and Diesel Blends. Energies. 2024; 17(14):3528. https://doi.org/10.3390/en17143528

Chicago/Turabian StyleChivu, Robert Mădălin, Jorge Martins, Florin Popescu, Margarida Gonçalves, Krisztina Uzuneanu, Michael Frătița, and Francisco P. Brito. 2024. "Assessment of Engine Performance and Emissions with Eucalyptus Oil and Diesel Blends" Energies 17, no. 14: 3528. https://doi.org/10.3390/en17143528