Abstract

With the increasingly severe climate change situation and the trend of green energy transformation, the development and utilization of hydrogen energy has attracted extensive attention from government, industry, and academia in the past few decades. Renewable energy electrolysis stands out as one of the most promising hydrogen production routes, enabling the storage of intermittent renewable energy power generation and supplying green fuel to various sectors. This article reviews the evolution and development of green hydrogen policies in the United States, the European Union, Japan, and China, and then summarizes the key technological progress of renewable energy electrolysis while introducing the progress of hydrogen production from wind and photovoltaic power generation. Furthermore, the environmental, social, and economic benefits of different hydrogen production routes are analyzed and compared. Finally, it provides a prospective analysis of the potential impact of renewable energy electrolysis on the global energy landscape and outlines key areas for future research and development.

1. Introduction

Energy security, environmental pollution, and climate change are common challenges for all humanity. Hydrogen energy rich in sources, as a widely applied, clean, and pollution-free secondary energy with high energy density, is an important component of the future energy system and carrier for achieving green and low-carbon transformation in industries, transportation, and other sectors. It has been elevated to a national strategic height by 41 governments [1], including the United States, Germany, Japan, and China. According to the Hydrogen Council, by 2050, hydrogen energy is projected to create 30 million jobs, reduce carbon dioxide emissions by 6 billion tons, generate a production value of USD 2.5 trillion, and account for 18% of the global energy supply [2].

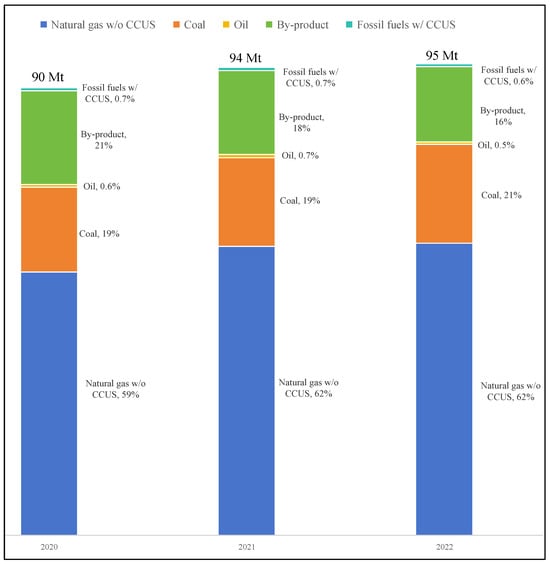

Production is the starting point of the hydrogen industrial chain, which mainly includes four technological paths [3]: (1) hydrogen production from fossil fuels, such as coal and natural gas.; (2) hydrogen production from industrial by-products, such as coke-oven gas and chlor-alkali tail gas; (3) hydrogen production from water electrolysis, such as wind power, solar photovoltaic, and nuclear high-temperature electrolysis; (4) other new technologies, including solar photolysis, thermochemical cycles, and biomass gasification. Currently, hydrogen production from fossil fuels remains the predominant method globally, with hydrogen production from natural gas comprising up to 62%, followed by coal at 21%, industrial by-products at 16%, and water electrolysis at only 0.1% [1], as is shown in Figure 1. China is the world’s largest hydrogen producer, contributing 30% to the global total. According to the China Hydrogen Alliance Research Institute, coal-based hydrogen production is the primary method in China, accounting for 56%, followed by natural gas at 21%, industrial by-products at 20%, and water electrolysis at approximately 2%.

Figure 1.

Hydrogen production by technology, 2020–2022 [1]. Citations: “w/” means “with”, “w/o” means “without”.

On the basis of carbon emission intensity, hydrogen can be broadly classified into three categories [4]: (1) grey hydrogen, referring to hydrogen production from fossil fuels, which has significant cost advantages but high carbon emissions; (2) blue hydrogen, derived from industrial by-products and fossil fuels with carbon capture, utilization, and storage (CCUS), which substantially reduces carbon emissions but entails high capture costs; (3) green hydrogen, generated from renewable energy and nuclear sources, emits almost no carbon but involves high production costs. Figure 2 illustrates the methods and classification of hydrogen production. Currently, grey hydrogen is the dominant method of production, while the shift towards using renewable energy sources to produce green hydrogen represents the emerging trend.

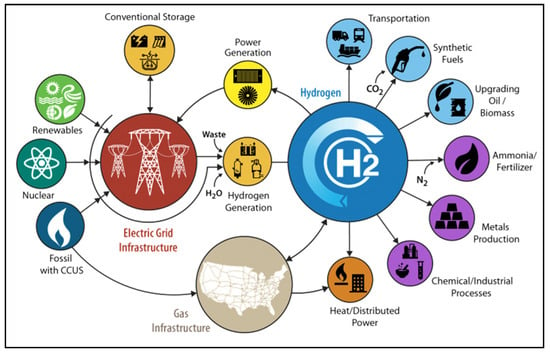

Figure 2.

US DOE’s H2@Scale initiative [5].

2. Policy Advances

From a global perspective, developed countries and regions such as the United States, the European Union, and Japan have been early adopters of hydrogen energy, with a focus on renewable energy electrolysis for hydrogen production. These countries have considered factors such as resource availability, industrial foundation, and practical requirements to guide their industrial development strategies. They have also outlined specific directions, goals, pathways, models, and policies for hydrogen energy development that align with their respective national conditions [6].

The United States has been among the pioneers in developing a comprehensive hydrogen energy strategy, aiming to achieve a leading position in key core hydrogen technologies. Since 1990, the US Department of Energy has introduced multiple policies and action plans to promote the development of hydrogen energy industry. These initiatives include the “National Hydrogen Energy Roadmap” (2002), “Hydrogen Posture Plan” (2006), “H2@Scale Initiative” (2016), and the “Hydrogen Program Plan” (2020), along the development path from policy evaluation, prospect prediction, technology research, and development to demonstration and extension. With the United States rejoining the Paris Agreement in February 2021 and setting ambitious carbon neutrality goals, its hydrogen strategy has undergone a new transformation, placing emphasis on research and promotion of green hydrogen technology [7]. In June of the same year, the US Department of Energy launched the Hydrogen Shot program, aiming to reduce the cost of clean hydrogen by 80% to 1 dollars/kg within a decade (“1 1 1” goal). Subsequently, in October, the department released “Foundational Science for Carbon-Neutral Hydrogen Technologies”, identifying efficient electrolysis of water for hydrogen production as one of the priority research and development directions. In November, President Biden signed the “Bipartisan Infrastructure Law”, which proposed allocating USD 1 billion for electrolytic hydrogen production research and development between 2022 and 2026. Additionally, in August 2022, the “Inflation Reduction Act” was signed into law, providing a tax credit of up to 3 dollars/kg for green hydrogen production. Furthermore, in March and June 2023, the US Department of Energy unveiled “Pathways to Commercial Liftoff: Clean Hydrogen” and “U.S. National Clean Hydrogen Strategy and Roadmap”, solidifying the strategic importance of clean hydrogen energy. These initiatives forecasted a growing demand for clean hydrogen in the United States, projecting figures of 10 million tons, 20 million tons, and 50 million tons per year by 2030, 2040, and 2050, respectively [5].

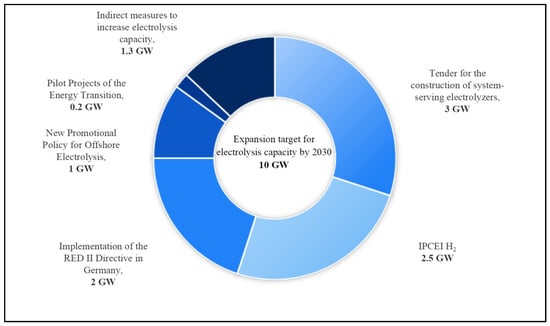

The European Union considers hydrogen energy a crucial element for energy security, energy transformation, and a key component for deep decarbonization, especially in sectors where emission reduction is challenging. As part of the European Great Deal framework, the EU released “A hydrogen strategy for a climate-neutral Europe” in July 2020, prioritizing the development of renewable energy from wind and solar for hydrogen production, and proposed to install at least 40 GW of renewable hydrogen electrolysis cells by 2030, producing 10 million tons of renewable hydrogen. By 2050, approximately a quarter of renewable energy generation is projected to be used for renewable hydrogen production [8]. After the outbreak of the Ukrainian crisis, the EU accelerated the pace towards green energy transformation. In May 2022, the European Commission released the “REPowerEU”, aiming to produce and import 10 million tons of renewable hydrogen energy by 2030, doubling the strategic goal set in the 2020 version [9]. They later introduced the European Hydrogen Bank plan and launched the first round of auctions in November, providing an EUR 800 million subsidy for renewable hydrogen energy. Germany has taken a more proactive stance in developing hydrogen energy. In June 2020, it launched the “National Hydrogen Strategy”, prioritizing the development of green hydrogen production from renewable energy sources. In July 2023, Germany updated this strategy, increasing its domestic electrolytic cell production capacity target for green hydrogen manufacturing from 5 GW to 10 GW by 2030 [10] (Figure 3).

Figure 3.

German instrument mix for expansion target for electrolysis capacity by 2030 [10].

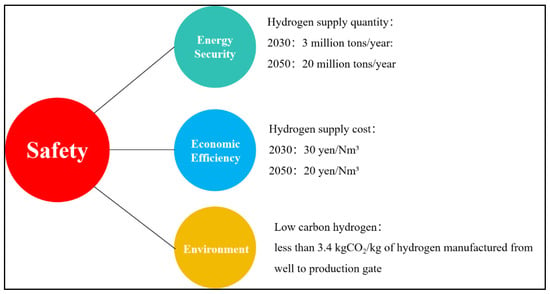

Japan’s energy policy is guided by the principle of “3E+S” (Figure 4), which prioritizes energy security and stable supply while simultaneously promoting environmental compatibility and economic efficiency to reduce costs [11]. The development of hydrogen energy in Japan is primarily aimed at reducing external energy dependence and meeting carbon dioxide reduction commitments, particularly in the wake of the Fukushima nuclear accident in 2011. In May 2013, Japan elevated the development of hydrogen energy to a national strategy through the Japan Rejuvenation Strategy. Subsequently, in April 2014, the Fourth Strategic Energy Plan designated hydrogen energy as a core secondary energy source alongside electricity and thermal energy. In December 2017, Japan released the world’s first national strategy for hydrogen energy, known as the “Basic Hydrogen Strategy”, which aimed to lead the global transition to a “hydrogen society”. In June 2023, Japan updated this strategy to establish a stable, affordable, and low-carbon hydrogen supply chain. The updated targets include reaching a hydrogen supply of 3 million tons per year at a cost of 30 yen per cubic meters by 2030 and expanding it to 20 million tons per year at a cost of 20 yen per cubic meters by 2050. Additionally, Japan set the carbon emissions of low-carbon hydrogen (“well to gate”) to be less than 3.4 kgCO2/kgH2 [12].

Figure 4.

The basic principle of Japan’s energy policy “3E+S” [12].

China regards hydrogen energy as a crucial driver for green energy transition and achieving carbon peak and carbon neutrality goals. In March 2019, hydrogen energy was prominently featured in the government work report for the first time. Subsequently, in September 2020, China introduced the “dual carbon” goal of peaking carbon emissions before 2030 and achieving carbon neutrality by 2060, thereby elevating hydrogen energy to national strategic importance. In March 2022, the National Development and Reform Commission and the National Energy Administration jointly issued the “Medium and Long-Term Plan for the Development of the Hydrogen Energy Industry (2021–2035)”, officially integrating hydrogen energy in the energy strategy. The plan emphasizes the prioritization of renewable energy hydrogen production while strictly regulating fossil energy hydrogen production. It sets a target of achieving a renewable energy hydrogen production capacity of 100,000 to 200,000 tons per year by 2025 [13]. At present, China is vigorously promoting the development of wind and photovoltaic power generation, but new energy generation has strong intermittency and volatility, which has brought about problems such as wind and solar power abandonment. In 2022, the utilization rates of wind and photovoltaic power generation in China were 96.8% and 98.3%, respectively (see Table 1). Northwest regions such as Qinghai and Xinjiang were generally lower [14]. To address this issue, the integrated development of renewable energy and hydrogen presents a promising solution. According to a report from the China Hydrogen Alliance Research Institute, as of the end of 2022, China had planned over 300 renewable energy hydrogen production projects, completed and operated 36 projects, with a cumulative hydrogen production capacity of approximately 56,000 tons per year [15].

Table 1.

Western China’s photovoltaic/wind power grid connected consumption situation in 2022 [14].

3. Technological Progress

The current mainstream renewable energy for hydrogen production involves water electrolysis technology, mainly including alkaline water electrolysis (AWE), proton exchange membrane (PEM) water electrolysis, solid oxide electrolysis cell (SOEC), and anion exchange membrane water electrolysis (AEM). AWE and PEM are considered relatively mature and have already entered commercial applications [16]. AWE boasts a straightforward process and low costs, making it widely utilized. Both domestically and internationally, large-scale hydrogen production has been achieved using this method. However, its drawbacks include low electrolysis efficiency, narrow load range, and corrosive alkaline solution. On the other hand, PEM exhibits good adaptability to renewable energy volatility and does not require corrosive liquids. However, the utilization of precious metals significantly increases the device’s cost, hindering its large-scale implementation. SOEC operates at high temperatures (700–900 °C), providing thermodynamic and kinetic advantages such as high efficiency, simplicity, flexibility, and environmental friendliness. Nevertheless, the high-temperature operation places stringent requirements on material performance, stability, and compatibility [17]. Compared to AWE and PEM, the technology maturity is still relatively low and is currently in the early demonstration stage. AEM combines the cost-effectiveness of AWE with the adaptability to renewable energy fluctuations characteristic of PEM, making it an enticing technology for producing low-cost clean hydrogen [18]. Currently, AEM is undergoing laboratory research and development. The comparative analysis between four technologies is shown in Table 2.

Table 2.

Comparison of four hydrogen production technologies by water electrolysis [19,20,21,22].

According to the Hydrogen Council, the global total installed capacity for electrolytic cells in 2022 was approximately 700 MW, with AWE and PEM accounting for 60% and 30% respectively, and SOEC and AEM made up a small fraction of the total capacity [23]. In China, the total shipment volume of electrolytic cells in 2022 reached about 800 MW; AWE dominated with approximately 776 MW, representing 97% of the total; and PEM contributed about 24 MW, making up the remaining 3% [24].

3.1. Wind Power Generation for Hydrogen Production

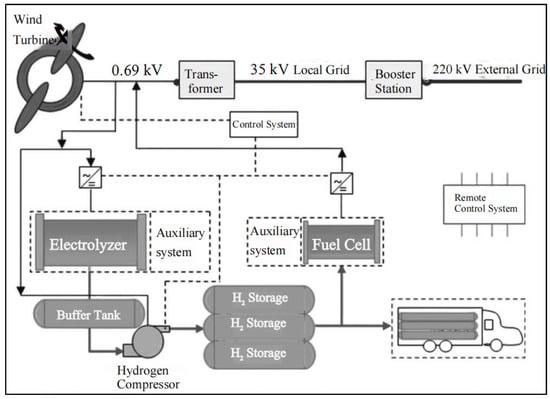

Wind power hydrogen production technology converts wind energy into electricity through wind turbines, and electricity is converted into hydrogen through water electrolyzers. By delivering hydrogen to application scenarios such as fuel-cell vehicles, the conversion from wind energy to hydrogen energy is completed, as is shown in Figure 5. Among various renewable energy hydrogen production technologies, the use of wind power as a power source for electrolysis of water is the most mature technology [25]. Wind power hydrogen production utilizes the surplus electricity generated by wind power beyond the grid’s capacity for electrolysis of water to produce hydrogen. This approach not only enhances the grid compatibility of wind power but also lowers the production costs of hydrogen [26,27,28,29]. Mirzaei [30] addressed the challenge of stochastic day-ahead security-constrained scheduling by integrating wind energy and hydrogen energy storage systems while considering hourly demand response to manage the uncertainty of wind power generation. Their findings demonstrated that simultaneous consideration of these resources substantially reduced wind power spillage and daily operation costs compared to scenarios where these resources were managed separately. Lin [31] proposed an integrated power hydrogen emission analytical framework for H2 production. By conducting hourly system simulations with real data for Western Inner Mongolia, China, they found that carbon-free H2 produced from wind power can be cost-competitive (0.5–2 dollars/kg).

Figure 5.

Schematic diagram of a wind power hydrogen production system. Adapted from [29].

During the last decade, the focus of interest in wind energy has shifted from onshore to offshore locations. This move capitalizes on the greater resource potential, higher and steadier wind speeds, and higher social acceptability [32]. Crivellari [33] assessed six alternative strategies for offshore wind power conversion, with all the pathways starting with H2 production by means of H2O electrolysis after seawater desalination. They found that a situation where conversion processes are used to limit wind power curtailments due to grid integration appeared more favorable in net present value (NPV) assessment than the sole chemical production. D’Amore-Domenech [34] employed five multicriteria decision-making methods (MCDM) to rank electrolysis technologies comprising direct electrolysis of seawater (DES), AEM, PEM, and SOE able to produce green hydrogen from seawater. They found that the AEM performed the best concerning economic-related criteria despite potential leaks of highly caustic electrolyte, while PEM excelled in social and environmental criteria, also scoring well in economic-related criteria. Tian [35] used a 300 MW offshore wind farm as an example to compare the economic feasibility of three offshore wind power hydrogen production schemes: onshore hydrogen production, offshore platform hydrogen production with pipeline hydrogen transportation, and offshore platform hydrogen production with ship hydrogen transportation. The research revealed that hydrogen production on offshore platforms and hydrogen transportation on ships were the most cost-effective options, and as the offshore distance increases, the annual cost of this plan remains basically unchanged.

3.2. Photovoltaic Hydrogen Production

Photovoltaic hydrogen production technology utilizes the volt effect generated by light to directly convert solar energy into electric energy through photovoltaic components, and then it decomposes water into hydrogen and oxygen through water electrolysis. With the continuous decrease in the cost of photovoltaic power generation, the competitiveness of photovoltaic hydrogen production is constantly increasing, which has attracted widespread attention from domestic and foreign researchers [36,37,38,39]. Mokhtara [40] proposed H2-HRES (hydrogen based hybrid renewable energy systems) that used solar PV to power a university campus building, and excess power generated by the solar PV system would be converted into hydrogen. This hydrogen would then be utilized to supply electric trams in the city of Ouargla, Algeria. Song [41] proposed a hybrid energy system that utilized the excess photovoltaic power to produce hydrogen. This system provided energy for three public buildings in Dalian City, Liaoning Province, China. Through optimization, the system configuration with the lowest unit energy cost (0.0615 dollars/kWh) was achieved.

Due to the spatiotemporal complementarity of photovoltaic and wind power generation [42,43,44], a hybrid solar–wind power generation system is presented as a viable, safe, effective, and low-cost solution to hydrogen production [45,46]. Apostolou [47] selected the Danish electricity market DK1 as a case study and evaluated three scenarios regarding the utilization of a hydrogen-based system in the electricity and/or transportation markets. They found that abandoned wind and solar power to drive electrolysis water for hydrogen production would significantly improve the utilization rate of wind and solar resources and the economic efficiency of wind and solar power generation. Zheng [48] proposed a wind solar complementary hydrogen production strategy that operated in collaboration with the alkaline and proton exchange membrane electrolyzers. Compared to single wind power generation, this strategy reduced the average fluctuation rate of complementary power generation output by 43.7% and increased energy efficiency and internal rate of return by 40% and 38.7%, respectively, thereby notably enhancing the dynamic coupling characteristics of wind–solar complementary power generation and electrolytic hydrogen production.

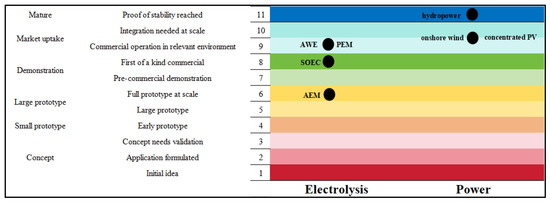

The International Energy Agency categorizes the technology readiness level (TRL) of clean energy into 11 levels (see Figure 6). Regarding electrolytic cells, the technological maturity of AWE and PEM has reached level 9 (market uptake), while SOEC and AEM have progressed from level 7 (demonstration) and level 4 (small prototype) in 2021 to level 8 (demonstration market uptake) and level 6 (large prototype) in 2023, respectively. In terms of renewable energy generation, the technological maturity of onshore wind and concentrated PV has remained at levels 9–10 in recent years, while hydropower has reached level 11 [49,50,51].

Figure 6.

Technology readiness levels of key hydrogen production technologies [51].

4. Comprehensive Assessment

Hydrogen can be produced from a variety of feedstocks including fossil resources (e.g., natural gas and coal) as well as renewable resources (e.g., biomass and water). Local availability of feedstock, the maturity of the technology, market applications and demand, policy issues, and costs all play crucial roles in determining the choice and timing of different options for hydrogen production [52]. With the deepening of global energy transformation and the accelerated development of the hydrogen economy, more and more scholars are paying attention to the economic, social, and environmental benefits of renewable energy electrolysis for hydrogen production and comparing it with other hydrogen production routes.

Acar [53] compared environmental impacts (global warming potential, GWP, and acidification potential, AP), social cost of carbon (SCC), production costs, and energy and exergy efficiencies of eight different hydrogen production methods in Turkey, concluding that wind electrolysis had the lowest AP and lower GWP and SCC than the rest of the methods except nuclear Cu-Cl and S-I cycles, while wind and solar electrolysis had the highest hydrogen production costs and lowest energetic efficiencies.

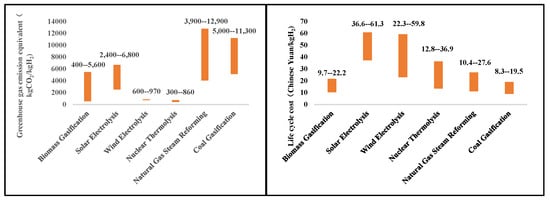

Xie [54] compared the environmental and economic benefits of traditional hydrogen production technology and new hydrogen production technology, finding that wind power hydrogen production (785 gCO2/kgH2, 10.5 MJ/kgH2) was currently the most environmentally friendly hydrogen production technology, while photovoltaic power generation (4600 gCO2/kgH2, 55 MJ/kgH2) had weak energy-saving and environmental advantages, which was closely related to the current high-energy consumption and high pollution manufacturing process of photovoltaic panels. Wind power hydrogen production (41.1 Chinese Yuan/kgH2) and photovoltaic hydrogen production (48.9 Chinese Yuan/kgH2) were high-cost hydrogen production technologies, which were related to the high investment of wind turbine equipment and photovoltaic power generation equipment. This information is illustrated in Figure 7.

Figure 7.

Carbon emission and life cycle costs of key hydrogen production technologies. Adapted from [54].

Life cycle assessment (LCA) is a commonly used method for examining the environmental and social impacts of renewable energy electrolysis for hydrogen production [55,56,57,58]. Bhandari [59] conducted a review of twenty-one studies on LCA of hydrogen production technologies and concluded that electrolysis using wind, solar, or hydropower generated electricity ranked among the most favorable hydrogen production methods, compared to those using conventional grid electricity mix or fossil fuel feedstocks. Although the nuclear-based high temperature technologies performed better in GWP and AP categories, further analysis across other impact categories was deemed necessary. Suleman [60] compared environmental impacts, namely, abiotic depletion potential, acidification potential, eutrophication potential, global warming potential, ozone depletion potential, and human toxicity, of 1 kg of hydrogen produced from different processes. Their findings indicated that renewable hydrogen production options offered the lowest environmental impacts when compared to fossil fuel-based alternatives.

Many scholars have explored and compared the economy of renewable energy electrolysis for hydrogen production [61,62,63]. Nikolaidis [64] assessed both the technical and economic aspects of 14 different hydrogen production methods. Steam methane reforming (SMR) was the most cost-effective process followed by coal gasification (CG). Both the high capital costs and low conversion efficiencies led to high production costs of solar and wind electrolysis. Milani [65] identified two main categories for competitive and commercial-scale hydrogen production routes, including electrolysis powered by renewable and fossil fuel cracking coupled with carbon capture and sequestration in Australia. They estimated the levelized cost of hydrogen via alkaline electrolysis technologies in the range of 4.78–5.84 dollars/kgH2, while for PEM technologies, it was in the range of 6.08–7.43 dollars/kgH2. Wang [66] established a Levelized Hydrogen Production Cost (LCOH) model based on the current situation and actual price level of hydrogen production in China. Research found that the cost of hydrogen production from fossil fuels and coke oven gas was the lowest, below 20 Chinese Yuan/kg, and the cost of hydrogen production from wind and photovoltaic power is the highest, reaching 44–85 Chinese Yuan/kg.

5. Prospects for Water Electrolysis Based on Renewable Energy

The interconversion of electricity and hydrogen is becoming accepted by the public as a means of efficiently using abundant renewable energy [67]. However, renewable energy for hydrogen production is not a universal solution and is influenced by various factors such as geographical location, feedstock availability, infrastructure, renewable energy options, supportive legislative frameworks, and the dynamic market for alternative fuels [65]. Therefore, scholars from various countries have evaluated the feasibility and economy of local renewable energy electrolysis for hydrogen production. For example, Sigal [68] conducted a detailed analysis of hydrogen production potential from three primary renewable resources (wind energy, solar energy, and biomass) in Argentina, marking the first such study in the country. China boasts abundant renewable resources, particularly wind and solar energy in northwest regions like Xinjiang, Ningxia, and Inner Mongolia. Additionally, it possesses hydrogen energy consumption scenarios in sectors such as oil and gas processing and coal chemical industries, which account for 63% of the country’s electrolytic water hydrogen production capacity, with approximately 80% utilizing photovoltaic hydrogen production [69]. This will effectively mitigate issues like wind and solar power curtailment in the region and facilitate the smooth operation of the power grid. In the long term, as offshore wind power technology advances and matures, the eastern coastal areas could emerge as significant hubs for China’s wind power hydrogen production, thereby stimulating the development of hydrogen-related industries such as transportation.

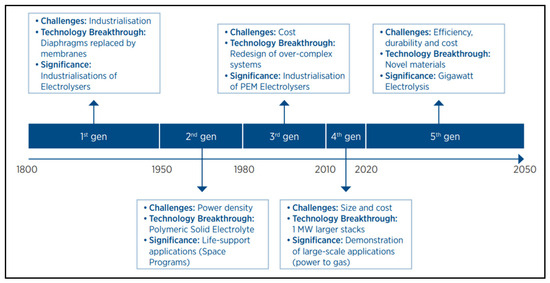

According to EnerScen [69], by the end of December 2023, the cumulative global water electrolytic capacity for hydrogen production will reach approximately 167,000 tons. The total installed capacity of global electrolyzers has begun to transition from the hundred-megawatt level to gigawatt level. Renewable energy electrolysis for hydrogen production entails high energy consumption and substantial equipment investment, yet it has not yet demonstrated economic advantages, thus hindering its widespread development and application [70]. Favorable policies play a significant role in enhancing the economic feasibility of renewable energy [71]. Worldwide, countries have introduced various renewable energy electricity support policies, including fixed electricity price systems, premium electricity price subsidy systems, differential payment contract systems, and renewable energy quota systems [72], which effectively promote the development and cost reduction of renewable energy electricity. Moreover, innovation and breakthroughs in key technologies, materials, and other aspects by researchers can significantly reduce equipment costs. The International Renewable Energy Agency report shows that cost has always been a challenge for every generation of electrolytic cell technology since 1980 [73] (Figure 8). AWE and PEM are currently the two mainstream hydrogen production technologies for electrolysis of water. AWE technology is relatively mature, but there is limited room for cost reduction. PEM technology has a good coupling with renewable energy and is currently in a period of rapid development, with huge potential for cost reduction. The grid electricity prices for wind and photovoltaic power generation in China are gradually decreasing. Compared with the grid electricity prices for coal-fired power generation, it is basically possible to achieve parity or even low-priced grid access, which can better meet the low-cost, clean, and sustainable electricity needs of users [74]. Wang [75] pointed out that if photovoltaic electricity prices could be reduced to commercial electricity prices and hydrogen production energy consumption could be reduced, the cost of standardized hydrogen production could be reduced by 47.1%. In the future, the focus of China’s renewable energy electrolysis for hydrogen production should be on the cost reduction of electrolysis cell technology. As for PEM, there is a significant gap between China and foreign countries. Developing high-performance non-precious metal catalysts and achieving the localization of key materials and components as soon as possible are effective ways to reduce its costs and achieve large-scale hydrogen production applications [3,4,76].

Figure 8.

Challenges and technological breakthroughs for each of the generation of electrolyzers [73].

6. Conclusions

This article provides a comprehensive review of the policy and technological advancements in hydrogen production from renewable energy electrolysis. It compares the environmental, social, and economic performance of this method with alternative approaches. The concluding remarks of this paper can be summarized as follows:

Hydrogen, as a clean and efficient energy source with a wide range of applications and good coupling with renewable energy, is rapidly becoming a strategic energy highland that governments around the world are vying to secure. China’s rapid development and remarkable achievements in the field of new energy have indeed attracted global attention, always facing the problem of abandoning wind and solar power. To address climate change and promote green transformation, China is positioning hydrogen energy as a national strategy and a crucial support to fulfil the goal of peaking carbon emissions and achieving carbon neutrality. Moreover, renewable-energy-based hydrogen production can help relieve the deviation between energy centers and industrial centers.

Among the four water electrolysis technologies for hydrogen production, AWE, distinguished by its low cost and high maturity, is the most widely applied at present. The core advantage of PEM lies in its adaptability to the fluctuation of renewable energy, with high cost constraining its large-scale development. SOEC and AEM are still in the research and demonstration phase and have not yet been commercialized. Renewable energy electrolysis for hydrogen production can not only enhance grid-connected stability of wind and solar power but also significantly reduce the cost of hydrogen production. The coupling of wind and solar power for hydrogen production is emerging as a new energy development paradigm that can enhance the flexibility and efficiency of the energy system.

Hydrogen production necessitates striking a balance between environmental and economic benefits. Presently, traditional energy-based hydrogen production, predominantly through methods such as natural gas reforming and coal gasification, will remain the primary approach due to their maturity, established infrastructure, and relatively low cost. However, with the global emphasis on carbon emission reduction and comprehensive green transformation intensifying, hydrogen production via renewable energy electrolysis is gaining traction, poised to serve as a robust complement to conventional methods once economic viability is attained. Compared to AWE, PEM technology holds greater potential for cost reduction through technological advancements, scale expansion, localization of key materials, and other avenues.

Author Contributions

Conceptualization, L.W. and L.H.; methodology, L.W. and L.H.; validation, W.L., H.S. and L.Y.; formal analysis, L.W. and L.H.; writing—original draft preparation, L.W., W.L. and H.S.; writing—review and editing, L.Y. and L.H.; supervision, L.H.; project administration, W.L. and H.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

L.W. and H.S. were employed by China Machinery Huanyu Certification and Inspection Co., Ltd. W.L. was employed by Guangdong Rising Oriental Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- International Energy Agency. Global Hydrogen Review 2023; International Energy Agency: Paris, France, 2023.

- Hydrogen Council. Hydrogen, Scaling Up; Hydrogen Council: Bonn, Germany, 2017. [Google Scholar]

- Cao, J.W.; Zhang, W.Q.; Li, Y.F.; Zhao, C.H.; Zheng, Y.; Yu, B. Current status of hydrogen production in China. Prog. Chem. 2021, 33, 2215–2244. [Google Scholar]

- Xu, S.; Yu, B.Y. Current development and prospect of hydrogen energy technology in China. J. Beijing Inst. Technol. 2021, 23, 1–12. [Google Scholar]

- U.S. Department of Energy. U.S. National Clean Hydrogen Strategy and Roadmap; U.S. Department of Energy: Washington, DC, USA, 2023.

- Fu, G.Y.; Xiong, H.W. Hydrogen energy development models and their implications in Japan, Germany, and United States. Macroecon. Manag. 2020, 84–90. [Google Scholar] [CrossRef]

- Wei, F.; Ren, X.B.; Gao, L.; Gao, G.Q.; Zhou, C.F. Analysis on transformation and characteristics of American hydrogen energy strategy under carbon neutralization goal. Bull. Chin. Acad. Sci. 2021, 36, 1049–1057. [Google Scholar]

- European Commission. A Hydrogen Strategy for a Climate-Neutral Europe; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- European Commission. REPowerEU: Joint European Action for More Affordable, Secure and Sustainable Energy; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- German Federal Government. National Hydrogen Strategy (Revision); German Federal Government: Berlin, Germany, 2023.

- Ministry of Economy, Trade and Industry. The Fourth Strategic Energy Plan; Ministry of Economy, Trade and Industry: Tokyo, Japan, 2014.

- Ministry of Economy, Trade and Industry. Basic Hydrogen Strategy; Ministry of Economy, Trade and Industry: Tokyo, Japan, 2023.

- National Development and Reform Commission; National Energy Administration. Medium and Long Term Plan for the Development of Hydrogen Energy Industry (2021–2035); National Development and Reform Commission: Beijing, China, 2022.

- National Energy Administration. 2022 National Renewable Energy Power Development Monitoring and Evaluation Report; National Energy Administration: Beijing, China, 2023.

- China Hydrogen Alliance Research Institute. Report on the Development of China’s Hydrogen Energy and Fuel Cell Industry in 2022; China Hydrogen Alliance Research Institute: Beijing, China, 2023. [Google Scholar]

- Asghhari, E.; Abdullah, M.I.; Foroughi, F.; Lamb, J.J. Advance, opportunities, and challenges of hydrogen and oxygen production from seawater electrolysis: An electrocatalysis perspective. Curr. Opin. Electrochem. 2022, 31, 100879. [Google Scholar] [CrossRef]

- Zhang, W.Q.; Yu, B. Development status and prospects of hydrogen production by high temperature solid oxide electrolysis. J. Electrochem. 2020, 26, 212–229. [Google Scholar]

- Shirvanian, P.; Loh, A.; Sluijter, S.; Li, X.H. Novel components in anion exchange membrane water electrolyzers (AEMWE’s): Status, challenges and future needs. A mini review. Electrochem. Commun. 2021, 132, 107140. [Google Scholar] [CrossRef]

- Yu, H.M.; Shao, Z.G.; Hou, M.; Yi, B.L.; Duan, F.W.; Yang, Y.X. Hydrogen production by water electrolysis: Progress and suggestions. Strateg. Study CAE 2021, 23, 146–152. [Google Scholar] [CrossRef]

- El-Eman, R.S.; Özcan, H. Comprehensive review on the techno-economics of sustainable large-scale clean hydrogen production. J. Clean. Prod. 2019, 220, 593–609. [Google Scholar] [CrossRef]

- Hu, S.; Guo, B.; Ding, S.L.; Yang, F.Y.; Dang, J.; Liu, B.; Gu, J.J.; Ma, J.G.; Ouyang, M.G. Acomprehensive review of alkaline water electrolysis mathematical modeling. Appl. Energy 2022, 327, 120099. [Google Scholar] [CrossRef]

- Wu, X.T.; Tan, L.; Zheng, Y.Y.; Lin, C.; Xiao, Q.; Li, X.P. Outlook on hydrogen economy and techno-economic assessment of water electrolysis-based hydrogen production. Chem. Ind. Eng. 2024, 41, 131–140. [Google Scholar]

- Hydrogen Council. Hydrogen Insights 2023; Hydrogen Council: Brussels, Belgium, 2023. [Google Scholar]

- TrendBank. Annual Blue Book of China’s Hydrogen and Fuel Cell Industry (2022); TrendBank: Ningbo, China, 2022. [Google Scholar]

- Yan, Z.Y.; Kong, X.W. Research on non-grid-connected wind power water-electrolytic hydrogen production system and its applications. Strateg. Study CAE 2015, 17, 30–34. [Google Scholar]

- Jorgensen, C.; Ropenus, S. Production price of hydrogen from grid connected electrolysis in a power market with high wind penetration. Int. J. Hydrogen Energy 2008, 33, 5335–5344. [Google Scholar] [CrossRef]

- Zhang, G.T.; Wan, X.H. A wind-hydrogen energy storage system model for massive wind energy curtailment. Int. J. Hydrogen Energy 2014, 39, 1243–1252. [Google Scholar] [CrossRef]

- Yi, W.; Xu, J.Y.; Wu, G.N.; Jiang, Y.Y.; Teng, Y.L. Improvement of wind abandoned consumption capacity in a region of northeast region China by wind power hydrogen storage energy system. Power Capacit. React. Power Compens 2018, 39, 190–197. [Google Scholar]

- Shao, Z.F.; Wu, J.L.; Zhao, Q.; Zhang, Y.J. Cost effectiveness analysis model for wind power produce hydrogen system and simulation. Technol. Econ. 2018, 37, 69–75. [Google Scholar]

- Mirzaei, M.A.; Yazdankhah, A.S.; Mohammadi-Ivatloo, B. Stochastic security-constrained operation of wind and hydrogen energy storage systems integrated with price-based demand response. Int. J. Hydrogen Energy 2019, 44, 14217–14227. [Google Scholar] [CrossRef]

- Lin, H.Y.; Wu, Q.W.; Chen, X.Y.; Yang, X.; Guo, X.Y.; Lv, J.J.; Lu, T.G.; Song, S.J.; McElroy, M. Economic and technological feasibility of using power-to-hydrogen technology under higher wind penetration in China. Renew. Energy 2021, 173, 569–580. [Google Scholar] [CrossRef]

- Kaldellis, J.K.; Apostolou, D.; Kapsali, M.; Kondili, E. Environmental and social footprint of offshore wind energy comparison with onshore counterpart. Renew. Energy 2016, 92, 543–556. [Google Scholar] [CrossRef]

- Crivellari, A.; Cozzani, V. Offshore renewable energy exploitation strategies in remote areas by power-to-gas and power-to-liquid conversion. Renew. Energy 2020, 45, 2936–2953. [Google Scholar] [CrossRef]

- D’Amore-Domenech, R.; Santiago, O.; Leo, T.J. Multicriteria analysis of seawater electrolysis technologies for green hydrogen production at sea. Renew. Sustain. Energy Rev. 2020, 133, 110166. [Google Scholar] [CrossRef]

- Tian, T.; Li, Y.X.; Huang, L.; Shu, J. Comparative analysis of the economy of hydrogen production technology for offshore wind power consumption. Electr. Power. Constr. 2021, 42, 136–144. [Google Scholar]

- Zhou, K.; Ferreira, J.A.; Haan, S. Optimal energy management strategy and system sizing method for stand-alone photovoltaic-hydrogen systems. Int. J. Hydrogen Energy 2008, 33, 477–489. [Google Scholar] [CrossRef]

- Liu, J.Y.; Zhang, H.; Lei, M.J.; Xue, Y.Z. Experimental study on solar photovoltaic electrolysis of water for hydrogen production. Renew. Energy 2014, 32, 1603–1608. [Google Scholar]

- Zini, G.; Rosa, A.D. Hydrogen systems for large-scale photovoltaic plants: Simulation with forecast and real production data. Int. J. Hydrogen Energy 2014, 39, 107–118. [Google Scholar] [CrossRef]

- Homayouni, F.; Roshandel, R.; Hamidi, A. Techno-economic and environmental analysis of an integrated standalone hybrid solar hydrogen system to supply CCHP loads of a greenhouse in Iran. Int. J. Green. Energy 2017, 14, 295–309. [Google Scholar] [CrossRef]

- Mokhtara, C.; Negrou, B.; Settou, N.; Bouferrouk, A.; Yao, Y.F. Design optimization of grid-connected PV-Hydrogen for energy prosumers considering sector-coupling paradigm: Case study of a university building in Algeria. Int. J. Hydrogen Energy 2021, 46, 37564–37582. [Google Scholar] [CrossRef]

- Song, Y.J.; Mu, H.L.; Li, N.; Shi, X.P.; Zhao, X.W.; Chen, C.N.; Wang, H.Y. Techno-economic analysis of a hybrid energy system for CCHP and hydrogen production based on solar energy. Int. J. Hydrogen Energy 2022, 47, 24533–24547. [Google Scholar] [CrossRef]

- Zhou, W.; Lou, C.Z.; Li, Z.S.; Lu, L.; Yang, H.X. Current status of research on optimum sizing of stand-alone hybrid solar-wind power generation systems. Appl. Energy 2010, 87, 380–389. [Google Scholar] [CrossRef]

- Bajpai, P.; Dash, V. Hybrid renewable energy systems for power generation in stand-alone applications: A review. Renew. Sustain. Energy Rev. 2012, 16, 2926–2939. [Google Scholar] [CrossRef]

- Fathima, A.H.; Palanisamy, K. Optimization in microgrids with hybrid energy systems—A review. Renew. Sustain. Energy Rev. 2015, 45, 431–446. [Google Scholar] [CrossRef]

- Vivas, F.J.; Heras, A.D.; Segura, F.; Andújar, J.M. A review of energy management strategies for renewable hybrid energy systems with hydrogen backup. Renew. Sust. Energy Rev. 2018, 82, 126–155. [Google Scholar] [CrossRef]

- Shi, X.F.; Qian, Y.; Yang, S.Y. Fluctuation analysis of a complementary wind-solar energy system and integration for large scale hydrogen production. ACS. Sustain. Chem. Eng. 2020, 8, 7097–7110. [Google Scholar] [CrossRef]

- Apostolou, D. Optimisation of a hydrogen production-storage-re-powering system participating in electricity and transportation markets. A case study for Denmark. Appl. Energy 2020, 265, 114800. [Google Scholar] [CrossRef]

- Zheng, B.; Bai, Z.; Yuan, Y.; Hu, W.X. Hydrogen production system and capacity optimization based on synergistic operation with multi-type electrolyzers under wind-solar power. Proc. CSEE 2022, 42, 8486–8496. [Google Scholar]

- International Energy Agency. Tracking Clean Energy Progress 2023; International Energy Agency: Paris, France, 2023.

- International Energy Agency. Global Hydrogen Review2021; International Energy Agency: Paris, France, 2021.

- International Energy Agency. ETP Clean Energy Technology Guide; International Energy Agency: Paris, France, 2023.

- International Energy Agency. Hydrogen Production and Storage; International Energy Agency: Paris, France, 2006.

- Acar, C.; Dincer, I. Comparative assessment of hydrogen production methods from renewable and non-renewable sources. Int. J. Hydrogen Energy 2014, 39, 1–12. [Google Scholar] [CrossRef]

- Xie, X.S.; Yang, W.J.; Shi, W.; Zhang, S.S.; Wang, Z.H.; Zhou, J.H. Life cycle assessment of technologies for hydrogen production—A review. Chem. Ind. Eng. Prog. 2018, 37, 2147–2158. [Google Scholar]

- Koroneos, C.J.; Dompros, A.; Roumbas, G.; Moussiopoulos, N. Life cycle assessment of hydrogen fuel production processes. Int. J. Hydrogen Energy 2004, 29, 1443–1450. [Google Scholar] [CrossRef]

- Granovskii, M.; Dincer, I.; Rosen, M.A. Exergetic life cycle assessment of hydrogen production from renewables. J. Power Sources 2007, 167, 461–471. [Google Scholar] [CrossRef]

- Cetinkaya, E.; Dincer, I.; Naterer, G.F. Life cycle assessment of various hydrogen production methods. Int. J. Hydrogen Energy 2012, 37, 2071–2080. [Google Scholar] [CrossRef]

- Ozbilen, A.; Dincer, I.; Rosen, M.A. Comparative environmental impact and efficiency assessment of selected hydrogen production methods. Environ. Impact Assess. Rev. 2013, 42, 1–9. [Google Scholar] [CrossRef]

- Bhandari, R.; Trudewind, C.A.; Zapp, P. Life cycle assessment of hydrogen production via electrolysis—A review. J. Clean. Prod. 2014, 85, 151–163. [Google Scholar] [CrossRef]

- Suleman, F.; Dincer, I.; Agelin-Chaab, M. Environmental impact assessment and comparison of some hydrogen production options. Int. J. Hydrogen Energy 2015, 40, 6976–6987. [Google Scholar] [CrossRef]

- Bartels, J.R.; Pate, M.B.; Olson, N.K. An economic survey of hydrogen production from conventional and alternative energy sources. Int. J. Hydrogen Energy 2010, 35, 8371–8384. [Google Scholar] [CrossRef]

- Li, Y.Y. Research on Evaluating the Several Methods of Hydrogen Production Technology by Life Cycle Assessment; Xi’an University of Architecture and Technology: Xi’an, China, 2010. [Google Scholar]

- Olateju, B.; Kumar, A.; Secanell, M. A techno-economic assessment of large scale wind-hydrogen production with energy storage in Western Canada. Int. J. Hydrogen Energy 2016, 41, 8755–8776. [Google Scholar] [CrossRef]

- Nikolaidis, P.; Poullikkas, A. A comparative overview of hydrogen production processes. Renew. Sustain. Energy Rev. 2017, 67, 597–611. [Google Scholar] [CrossRef]

- Milani, D.; Kiani, A.; McNaughton, R. Renewable-powered hydrogen economy from Australia’s perspective. Int. J. Hydrogen Energy 2020, 45, 24125–24145. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Zhou, S.; Zhou, X.W.; Ou, X.M. Cost analysis of different hydrogen production methods in China. Energy China 2021, 43, 29–37. [Google Scholar]

- Chi, J.; Yu, H.M. Water electrolysis based on renewable energy for hydrogen production. Chin. J. Catal. 2018, 39, 390–394. [Google Scholar] [CrossRef]

- Sigal, A.; Leiva, E.P.M.; Rodrıguez, C.R. Assessment of the potential for hydrogen production from renewable resources in Argentina. Int. J. Hydrogen Energy 2014, 39, 8204–8214. [Google Scholar] [CrossRef]

- CIECC; EnerScen. Global Hydrogen Energy Industry Outlook Report; CIECC: Beijing, China, 2024. [Google Scholar]

- Maggio, G.; Nicita, A.; Squadrito, G. How the hydrogen production from RES could change energy and fuel markets: A review of recent literature. Int. J. Hydrogen Energy 2019, 44, 11371–11384. [Google Scholar] [CrossRef]

- Pudukudy, M.; Yaakob, Z.; Mohammad, M.; Narayanan, B.; Sopian, K. Renewable hydrogen economy in Asia-Opportunities and challenges: An overview. Renew. Sustain. Energy Rev. 2014, 30, 743–757. [Google Scholar] [CrossRef]

- Ding, F.; Li, X.G.; Liang, Z.Q.; Wu, M.; Zhu, Y.H.; Feng, D.H.; Zhou, Y. Review of Foreign Experience in Promoting Renewable Energy Development and Inspiration to China. Electr. Power Constr. 2022, 43, 1–11. [Google Scholar]

- International Renewable Energy Agency. Green Hydrogen Cost Reduction: Scaling up Electrolysers to Meet the 1.5 °C Climate Goal; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2020. [Google Scholar]

- Ju, L.W.; Liu, L. Explore the Greater Potential of Wind and Solar Power; Economic Daily Press: Beijing, China, 2021. [Google Scholar]

- Wang, H.X.; Xu, W.Y.; Zhang, Z.J. Development status and suggestions for green hydrogen energy produced by water electrolysis from renewable energy. Chem. Ind. Eng. Prog. 2022, 41, 118–131. [Google Scholar]

- Guo, B.W.; Luo, D.; Zhou, H.J. Recent advances in renewable energy electrolysis hydrogen production technology and related electrocatalysts. Chem. Ind. Eng. Prog. 2021, 40, 2933–2951. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).