Abstract

The paper presents a review of End-of-Life scenarios (EoL) (disposal, incineration, chemical, thermal and mechanical recycling) compared to the production stage of Fibre-Reinforced Polymers (FRPs) of composites regarding global warming potential. Innovative FRP manufacturing technologies (vacuum infusion, ultraviolet curved pultrusion, hot stamping, three-dimensional printing and automatic tape placement) commonly used in the shipbuilding industry were environmentally assessed. The materials, energy flows and waste discharged to the environment over the whole life cycle were collected, identified and quantified based on Life Cycle Assessment (LCA) analysis in the frame of the Fibre4Yards project. The results of LCA calculations show that waste management (the EoL scenario) contributes 5 to 39% of the total carbon footprint for FRP technologies. The highest contribution of the EoL scenario was found for technologies where polypropylene was applied, i.e., 33 and 38% of the total CO2 emissions. Our analysis of the literature and information from industrial partners confirm that the standard and most common waste scenario for FRP materials and compounds is still incineration and landfilling.

1. Introduction

Nowadays, environmental awareness plays a crucial role in the development of new technologies and products. Already at a design stage, companies are obliged to identify a product’s environmental load. The assessment should consider the impact across its entire life cycle, from raw materials acquisition, via manufacturing, usage and maintenance to the final End-of-Life destination. The Life Cycle Assessment (LCA) is an acknowledged tool to evaluate the environmental load on a product, service, process or organizational level. LCA analysis has been extensively used to support decision making in development, marketing, the identification of hotspots or comparative assessments of products and processes [1]. It can operate at different system boundaries (cradle-to-grave, cradle-to-cradle, cradle-to-gate and gate-to-gate) that define the scope of the assessment and specify which processes are included in the analysis. Full LCA analysis is performed from “cradle-to-grave” or “cradle-to-cradle” [2]. “Cradle-to-cradle” is a specific type of “cradle-to-grave” system boundary, where the recycling process is a fundamental part of End-of-Life (EoL) management [3].

The EoL stage is crucial for determining the overall environmental impact of products and materials. The implementation of EoL strategies for post-consumption materials or products is necessary to reduce waste, mitigate the environmental impact, conserve resources, comply with regulations and finally, achieve environmental sustainability. The EoL is not without significance at the early design stage for the configuration of final products to have closed-loop scenarios, which allow high-quality material recovery and their reintroduction into the same or similar products [4]. In general, EoL scenarios may include landfilling, incineration or recycling. Landfilling is still a predominant strategy to process solid waste in the EoL phase [5] due to economic advantages, costs and low technical requirements [6]. However, considering the environmental impact and human health [7,8,9], landfilling is the least preferable option across the European Union Waste Hierarchy [10] and should be limited to the necessary minimum. Landfilling poses significant environmental risks, including ground and surface water contamination, often despite the implementation of technical measures, e.g., bottom sealing. However, even though the total amount of waste generated is constantly increasing, a decline in the landfilling rate (from 23% to 16%) was observed between 2010 and 2020 in the EU-27 (27 member countries in the European Union). Incineration is another open-loop EoL scenario that involves burning waste materials to reduce their volume by more than 90% and recover energy [11]. Unfortunately, both landfilling and incineration are considered the least favourable EoL options and can result in resource loss [12]. Therefore, the EU’s long-term goal is to move towards a circular economy. This avoids waste generation and uses unavoidable waste as resources wherever possible. Closed-loop EoL strategies aim to maximize reuse by keeping materials and products within the economic system through continuous reuse, recycling and remanufacturing [4].

Nowadays, LCA analysis is widely used in the early design stage of products [13] and helps make decisions regarding the redesign or replacement of materials to minimize the environmental load of a product’s life and future EoL stage [14]. The International Maritime Organization (IMO) has established several regulations and initiatives aimed at reducing greenhouse gas (GHG) emissions from shipping through energy-saving and cost-effective material technology. IMO regulations represent a comprehensive approach to providing safety and mitigating the environmental impact of the marine sector through the influence of the design, architecture, operation and disposal of ships. Possible ways to reduce the costs and environmental load of marine technologies are process automation and the use of lightweight materials. Therefore, in the maritime industry, there is a need for lightweight materials that ensure durability and high efficiency, which explains the demand for technologies using composite materials [15].

Fibre-Reinforced Polymers (FRPs) are composite materials made up of strong fibres embedded in a resin matrix. Carbon fibres (CF) and glass fibres (GF) have been attracting continuously growing attention in the marine field due to their unique properties like lightweight, high mechanical properties and elevated durability in salt and corrosive marine environments [16]. The contemporary marine industry is moving toward the use of FRP materials. Their frequent use raises concerns about the environment and waste disposal.

Both CF and GF are very energy-expensive. According to data published by Song et al. [17], the amount of energy required for the production of CF is 183–286 MJ/kg, while embodied energy for GF is almost 13–32 MJ/kg. The researchers suggested that the energy demand for the production of recycled FRP is considerably less than for virgin resources [18]. In addition, legislation on disposal to landfills such as the European Union directive 2008/98/EC has highlighted the need to develop and incorporate recycling technologies for composite materials [10]. Unfortunately, the most popular management of EoL composites is still landfilling and incineration [19,20]. This approach leads to significant losses of high-value materials, which does not aid in the scarcity of natural resources. Regrettably, the resulting pattern in composite materials requires the incorporation of circular economy principles, i.e., recycle, reuse, reduce, etc.

1.1. FRP Technologies in Fibre4Yards Project

From the framework of the Fibre4Yards project (Horizon 2020 founding programme) [21], we considered various progressive and highly automated FRP production technologies for the shipyard industry (adaptive moulds, Automatic Tape (Fibre) Placement (ATP/AFP), three-dimensional (3D) printing, curved pultrusion profiles, hot stamping, innovative composite connection). The environmental loads of particular technologies were evaluated and published by Ziemińska-Stolarska et al. [3]. The results of LCA calculations proved that the largest environmental impact was caused by the materials used in technological processes (cradle-to-gate approach), with values of 80 to 95%. The typical materials used in FRP technologies were sorted from highest to lowest global warming potential (GWP) impacts as follows: carbon fibre, polyurethane foam, epoxy resin, fibreglass and polypropylene.

Our previous research shows that the carbon footprint of the system can be reduced with the recycling and recovery of materials, which can improve sustainable development [22]. The aim of this study was to determine EoL scenarios for the materials and compounds used in Fibre4Yards technologies based on a literature survey (primary data) and in cooperation with industrial partners (secondary data). The technologies targeted by the Fibre4Yards project focused on the following:

- -

- Hot stamping, employed by INEGI (Institute of Science and Innovation in Mechanical and Industrial Engineering, Porto, Portugal); thermoplastic composite sheets are hot stamped into a mould to give them the appropriate shape; the first step is prepreg uncoiling via the automatic taper lay-up (ATL) process and spot welding; next, the blank is moved the die to be 2D shape formed via the application of heat and pressure in a flat plate hot-press; after this, the previously melted component is heated by IR and pressed into a 3D shape.

- -

- The UV curved pultrusion process (Robtrusion®), proposed by the IRURENA Group (Azpeitia, Spain); UV curing of pultruded profiles enables the production of profiles with a curved longitudinal axis using a robotic pulling system; initially, the fibres are strengthened by bathing in resin; the impregnated reinforcements are pulled into the mould, which is only used to shape the profile cross-section; the profile is hardened with UV radiation and shaped using a robot arm that grabs the profile and pulls it in accordance with the specific geometry required for the profile; the last step is to manually cut the profile.

- -

- 3D printing(IRURENA Group (Azpeitia, Spain)), reported by 10XL (Rivierdijk, The Netherlands), specializes in proprietary large-scale hybrid printers; this is a process of creating three-dimensional objects from a digital file by building objects layer by layer of material.

- -

- Adaptive mould used by Curve Works (Alphen aan den Rijn, The Netherlands); in this process, the moulds for composite manufacturing are adjusted to any given geometry; at first, the structure is divided into panels within a 3D Computer-Aided Design (CAD) program; the adaptive mould shapes itself automatically to the design according to the geometry saved in the CAD file.

- -

- Vacuum infusion applied by the NAVAL Group (Nantes, France), whereby a vacuum is used to draw resin into a dry fibre reinforcement, resulting in a void-free composite structure; the first step involves fixing the fibres and core material to the mould; next, the resin feeding line is installed, which includes a vacuum line, valves and a vacuum bag, which must be properly sealed [3].

The materials, energy flows and waste discharged into the environment during the whole life cycle were identified and quantified. For LCA calculations, mass/energy were determined in relation to the functional unit, which was defined as 1 kg of the final product for each technology. SimaPro version 9.00.49 and Ecoinvent 3.8 databases were used.

It is expected that the incorporation of progressive and automated manufacturing of processes and materials for the construction of ships will bring many benefits to the marine sector, e.g., an increase in production and quality indicators, minimization of spare parts and materials and the capacity to adapt new geometry and solutions to improve the ship’s performance while reducing its weight [23].

1.2. Recycling Methods of FRP

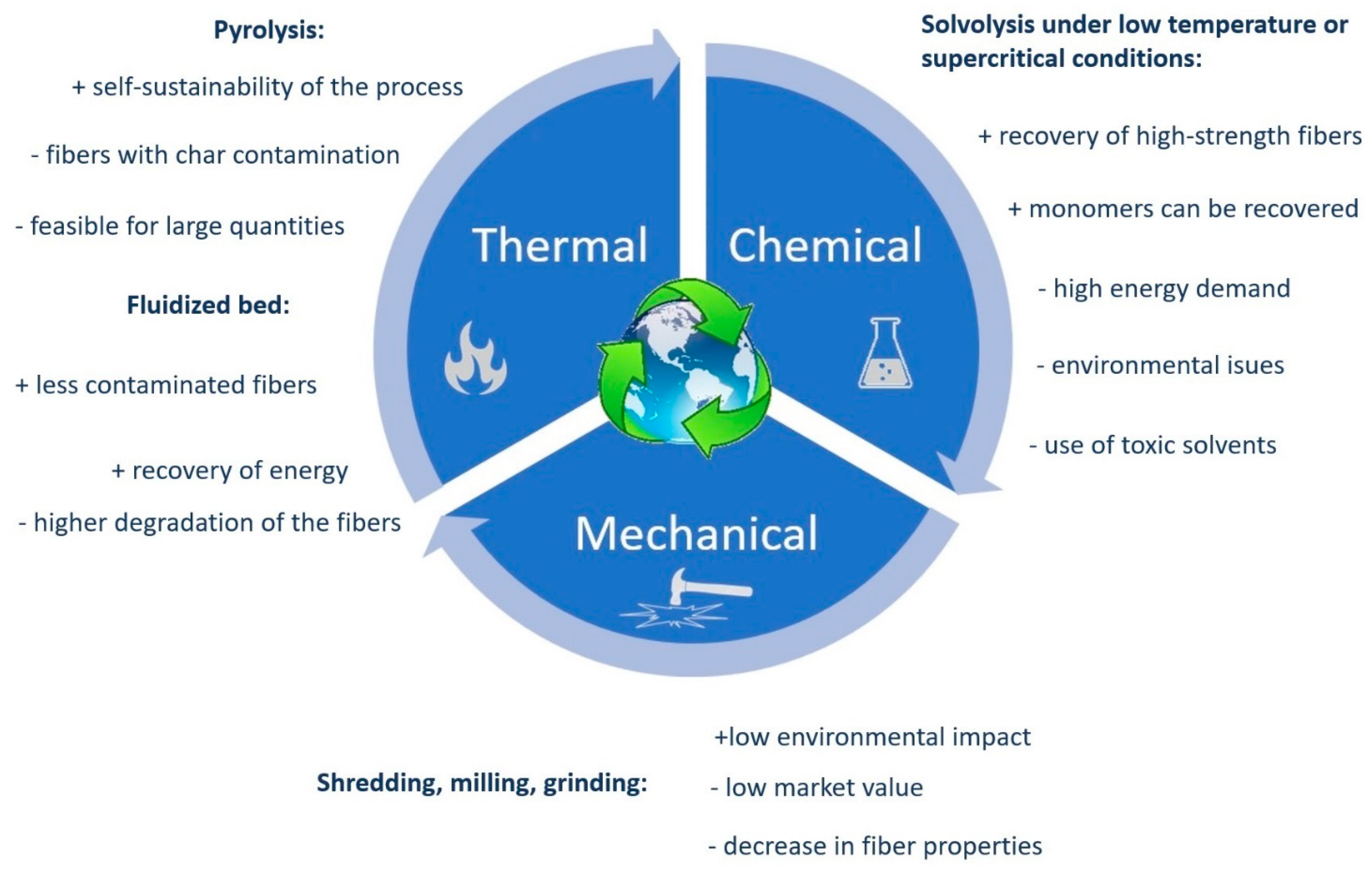

The matrix topology of FRP materials, like high chemical and thermal stability, makes them hard to recycle. The majority of the FRP market volume is based on thermoset matrices, typically epoxy resin. Despite their structural advantages, epoxy resin is considered non-recyclable or extremely difficult to recycle, requiring an aggressive chemical environment [24]. It is known that incineration with energy recovery is not the best alternative to recycling composite materials. It does not reintroduce stock into new products and inevitably leads to emissions of hazardous substances. The combustion of GF is not complete and forms a slag that requires further treatment [25]. The recycling strategies include three standard methods: chemical, thermal and mechanical as presented in Figure 1.

Figure 1.

Advantages (+) and disadvantages (−) of thermal, chemical and mechanical recycling approaches for FRP composites.

1.2.1. Chemical Recycling

Solvolysis is a chemical process used for matrix depolymerization with fibre separation. The use of solvents, like alcohols, ketones and acids, leads to depolymerization of the matrix into the basis of monomers, oils and gases. These products can be used to produce new polymers or as fuel for industrial processes [19]. Chemical recycling requires high temperatures and pressure with an energy demand of 20–90 MJ/kg. Within chemical recycling, it is possible to distinguish several kinds based on the type of solvents and process parameters. In low-temperature solvolysis (below 200 °C, at the atmospheric pressure), the chemical bonds of the polymer matrix break down under the influence of an acidic environment or solvents such as water, alcohol, ammonia, nitric acid, sulfuric acid or acetic acid [26]. Given the low temperature of the process, catalysts and additives are necessary. On the other hand, supercritical solvolysis takes place at temperatures in the range of 350–450 °C and pressure of 4–27 MPa. In these conditions, the effective diffusion of fluids occurs on the impregnated fibres, followed by the efficient dissolution of the matrix and monomer asportation. In this approach, apart from water, different solvents are used (e.g., methanol, propanol, glycols and acetone). Compared to the low-temperature methods, solvolysis in a supercritical fluid is more effective and also eliminates toxic solvents [26].

Feraboli et al. [27] used sulfuric acid to recycle carbon fibre-reinforced polymers. The composite materials were digested at 110 °C with the assistance of hydrogen peroxide, which accelerated the reaction and oxidized the matrix. The recycled fibres were reutilized to manufacture laminates. The tests showed that both the physical and mechanical properties of the recycled composite were similar to those of advanced carbon fibre sheet moulding compounds. A chemical recycling system with nitric acid solutions and a circulating flow reactor has been proposed by Lee et al. [28]. The optimum environments for the decomposition of the epoxy matrix were defined as 90 °C and a 12 M HNO3 concentration with a linear circulating flow rate of 1.0 cm/s for 6 h. This system provided the effective decomposition of the matrix with a 2.91% tensile strength loss of the recycled single carbon fibre at optimized conditions.

Shetty et al. [29] proposed recycling method of carbon FRP in a subcritical acetic acid solution. The experiments were carried out in a high-pressure batch reactor where samples of CFRP were heated to 300 °C for 30 min. The authors proved that the process yields 100% fibre recovery efficiency, and the observed mechanism is a two-step process. The first one included composite swelling under the solvent treatment, while in the second step, depolymerization and chemical decomposition of the CFRP took place. In addition, aromatic and aliphatic compounds were determined in the liquid products of the process, which could potentially be recovered for reuse. Subcritical water was used by Knight [30] for the recycling of a carbon fibre composite. The experiment was conducted in a high-pressure reactor system and KOH was used as the catalyst. The process achieved 99.2% resin elimination efficiency at a 120 min reaction time. The regenerated fibres retained the original strength, as demonstrated by a single-filament tensile test. Kim et al. [31] investigated the supercritical water without any catalyst or oxidant for the recycling of carbon FRP. The samples were heated in a reactor at 405 °C with an internal pressure of 280 bar. In this way, up to 99.5% of the epoxy resin was removed. Implementing a mixture of water and acetone at supercritical conditions was proposed by [32]. The authors proved that mixtures of solvents exposed to 320 °C for 2 h allowed the degradation of up to 98% resin of carbon FRP. The recycling methods of FRP with supercritical alcohol were also studied [33,34,35].

1.2.2. Thermal Recycling

Thermal recycling uses heat to separate the fibres from the resin matrix. It can be achieved by industrially developed techniques, pyrolysis and fluidized beds. These methods provide temperatures in the range of 450 °C to 700 °C, which allows CF and GF recovery from their composites. The selection of the optimal temperature depends on the type of resin utilized in the composite. High temperatures allow the composite to degrade but can also damage the fibre phase, which is particularly the case with glass FRP [36].

The pyrolysis process is based on thermal degradation in the absence of oxygen, where composite materials are heated to high temperatures in a special reactor. Under these conditions, the bond between the matrix and the fibre is broken down. The matrix degradation produced oily and gaseous products, like CO, CO2, CH4, H2 and other hydrocarbons [26]. Gas products are predominantly reused as heating fuels in the recycling process. The solid products (fibres and fillers) are covered by the char on the surface and a further post-pyrolysis procedure is needed to obtain clean fibres. The properties of recycled fibres depend on the process conditions, e.g., heating rate, cap temperature, rate of nitrogen flow and isothermal dwell time. The optimization of process variables could obtain carbon fibre with strengths of up to 90% of its virgin counterpart [37]. The main limitations of pyrolysis are the uncontrolled char formation, emission of toxic gas and high energy demand, estimated to be 20–30 MJ/kg [19]. To avoid these drawbacks, different modifications of the process were developed, changing atmospheric conditions inside the reactor. The most commonly used are a vacuum and nitrogen atmosphere or superheated steam [38].

Torres et al. [39] investigated the pyrolysis of fibre glass composites at different temperatures (300–700 °C). All experiments were performed in a nitrogen atmosphere for 30 min. The results showed no meaningful impact of temperatures above 400 °C on the process yields and compositions of products. Solid residues of 72–82 wt.% were obtained, while liquid products were a mixture of organic compounds with high calorific values. Nahil and Williams [40] used pyrolysis for CF recovery from composite waste. The samples were pyrolyzed at temperatures of 350–700 °C to obtain solid residues between 70 and 83.6 wt.%. The carbon fibres recovered from the sample were activated in a steam generator. The mechanical strength of recycled CF was 90% of that of the original virgin carbon fibres. Considering the mechanical properties of the recovered fibre, the pyrolysis process is more suitable for CFRP [38].

In the fluidised bed process, materials are fed into a fluidised or silica sand bed and heated by a flow of air stream for matrix thermal degradation. The operating temperature is in the range of 450–550 °C. The oxygen atmosphere provides very low char surface contaminations, resulting in clean fibre. The solid products are separated from the gas stream by a cyclone, while the volatilised polymer passes into a secondary combustion chamber for heat recovery. Unfortunately, the recovered fibres show a significant reduction in mechanical properties, mainly due to the oxidation process and sand abrasion [41]. According to Pickering et al. [42], a fluidised bed process was only able to achieve a 67% fibre yield with strength reductions of 50%. However, efforts are still being made to minimize the drawbacks of this process [43].

1.2.3. Mechanical Recycling

The mechanical recycling method is the most common process used for EoL thermoset polymers. This technique involves cutting the FRP composite into smaller fractions by a mechanical process like milling or grinding. Normally, recyclites have sizes of 50–100 mm, but in the case of homogeneous composites, it is possible to reduce the size to 10 mm and even 50 µm [38]. The main disadvantage of this process is the significant decrease in the fibre’s mechanical properties and market value. The recovered fibres contain matrix residues on the surface, and only short fibres and fillers can be recuperated. However, the mechanical process is sometimes used as a pre-recycling operation for different methods. The recyclites are generally used in other products like fillers or reinforcements, but these applications are not commercially viable due to the presence of cheaper virgin fillers. However, Mou et al. [44] emphasized the advantages of GF recyclites in the strengthening of concrete. Industrial applications of this method mainly concern manufacturers of FRP fibreglass composites [45].

Based on the energy consumption required for composite recycling, the most promising recycling method is mechanical recycling, which consumes around 0.1–4.8 MJ/kg. The next on the list is microwave pyrolysis with an energy consumption of 5–10 MJ/kg. The most energy-consuming methods are pyrolysis (24–30 MJ/kg) and chemical recycling (21–91 MJ/kg) [46].

1.3. End-of-Life for FRP Materials

The production of virgin carbon fibre is a process that requires a great deal of energy, consuming 183 to 286 MJ per kg of energy, which is approximately 10 times more energy than that consumed for glass fibre production and approximately 14 times more energy required for conventional steel production. As a result, the manufacturing of virgin carbon fibre involves high costs of production (20–40 £/kg in the UK [47] and high levels of greenhouse gas emissions (approximately 31 kg CO2 eq. per kg) [48]. Therefore, recovering carbon fibre from FRP waste could be encouraging to reduce the environmental load and cost of production [49].

As was discussed in the previous section, diverse techniques such as pyrolysis, solvolysis, mechanical grinding and chemical treatment are feasible for composite recycling; however, commercial applications of recycled carbon fibres are not popular due to their lower value compared to virgin fibres. During the recycling process, it is difficult to control the fibre length and length distribution, and additional problems arise related to the diminished surface quality and mixture of fibres coming from different sources, which altogether affect the mechanical properties of the recycled fibres [50].

Since the existing carbon fibre recycling methods are technically immature and the quality of recycled carbon fibre is significantly lower compared to virgin carbon fibre, a large part of carbon fibre waste is either landfilled or incinerated. As reported by a carbon fibre recycling company (Gen 2 Carbon, West Midlands, UK), out of 56,000 tons of carbon fibre-reinforced plastic waste generated, only 1000 tons are recycled, which accounts for only 1.7% [51].

Moreover, legislation in some countries like The Netherlands and The United Kingdom, allows landfilling in the case that the cost of alternative waste disposal routes exceeds 200 Euro per ton. For example, according to Wind Europe, estimations of the cost of mechanical recycling of wind turbine blades produced from glass fibre are between 500 and 1000 EUR. Thus, the high cost of FRP recycling is another reason why glass- and carbon-reinforced plastic ends up being landfilled or incinerated rather than recycled [41].

A literature review of disposal methods, which could be applied to carbon and glass fibre waste, is presented in Table 1.

Table 1.

Literature review on disposal method applied for carbon and glass fibre.

2. Survey of LCA Methodologies

2.1. Life Cycle Assessment Methodology

Life Cycle Assessment (LCA) is a science-based method used to evaluate the environmental impacts of a product or service throughout its entire life cycle. The methodology involves assessing the consumption of natural resources and raw materials, energy consumption and emissions into the environment (emissions into the air, water and land) for each stage of the life cycle of the system under study (either a material good or a service). Life Cycle Assessment (LCA) analysis is guided by a series of ISO (International Organization for Standardization) standards. The key standards are ISO 14040 (Environmental Management—Life cycle assessment—Principles and Framework) and ISO 14044 (Environmental Management—Life cycle assessment—Requirements and guidelines) [61]. According to ISO 14040, a complete LCA is composed of four interconnected phases:

- Goal Definition and Scoping describe the analysed product, process or activity; the purpose, scope and functional unit are defined, which establish a reference to which the inputs and outputs are related; and system boundaries are determined (which processes are included in the analysis).

- The Inventory Analysis. This step helps with identifying and quantifying inputs (e.g., row materials, energy and water usage) and outputs (e.g., emissions, solid waste disposal and wastewater discharges). This is a technical process of inventory of all relevant data for each process within the defined system boundaries.

- The Impact Assessment assesses the potential effects of energy, water and material usage and the emissions identified in the inventory analysis based on selected environmental impact categories (e.g., global warming, human health). This step includes obligatory and optional sub-phases: classification, characterization, normalization and weighting consistent with ISO standards.

- The Interpretation step analyses the results from which to draw conclusions and identify significant environmental impacts.

2.2. End-of-Life for Fibre4Yards Technologies

In the frame of this work, the End-of-Life (EoL) scenarios were determined for the materials and compounds used in FRP technologies. On the basis of the literature survey and in cooperation with industrial partners, we found that the standard and most common waste scenario for the materials and compounds used in the Fibre4Yards project was incineration or landfilling (Table 2).

Table 2.

EoL scenarios for materials and compounds of FRP technologies.

There are single companies that offer the recycling/recovery of selected materials used in the Fibre4Yards project. We decided, however, to apply the current most common standard of waste treatment of the materials and compounds used in the Fibre4Yards project as the most realistic waste scenario. The results of LCA calculations show that waste management (EoL scenario) contributes 5 to 39% of the total carbon footprint for the Fibre4Yards technologies. The results of the literature search and information obtained from industrial partners for EoL scenarios in the Fibre4Yards project are shown in Table 2.

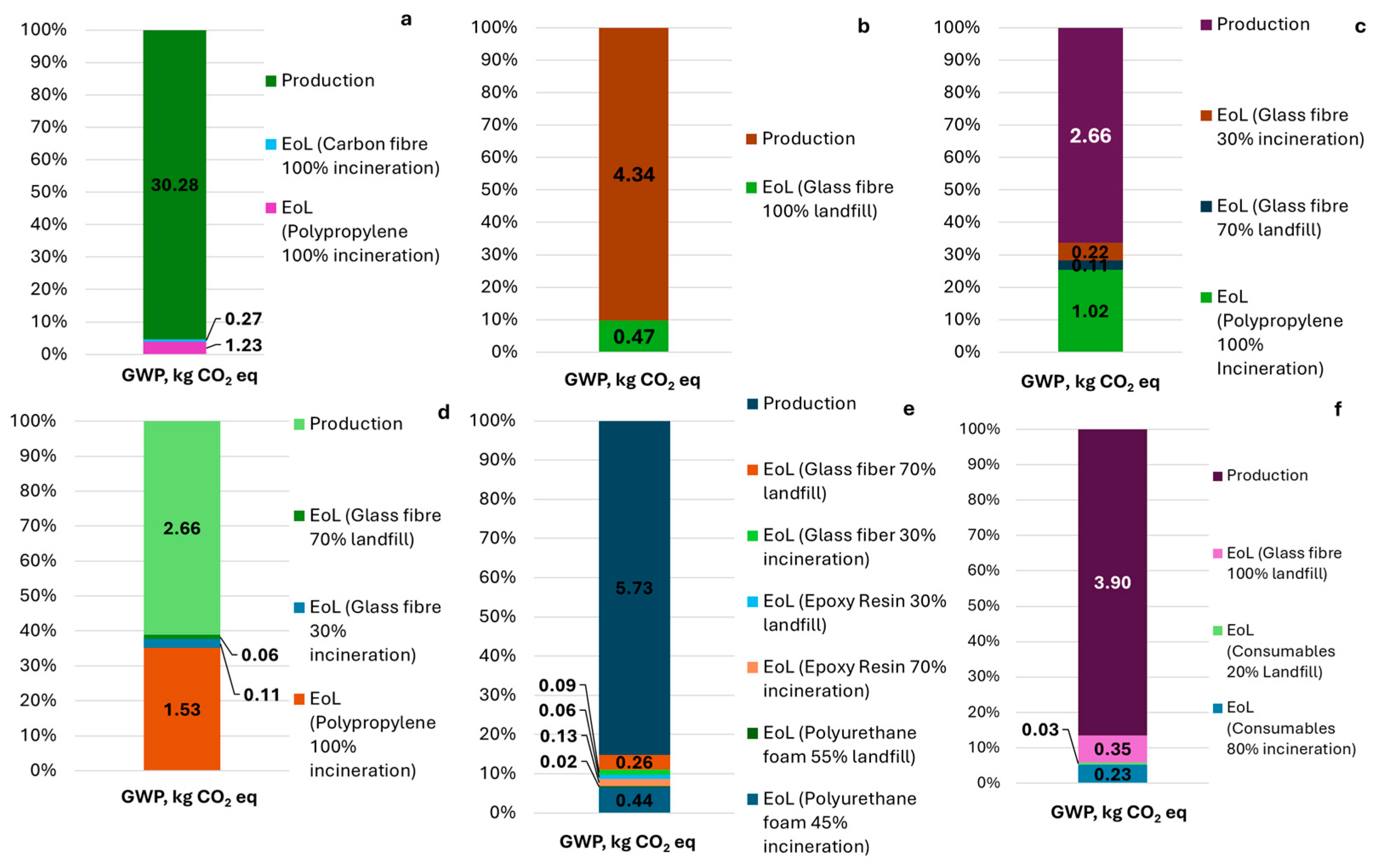

3. LCA Analysis of FRP Technologies

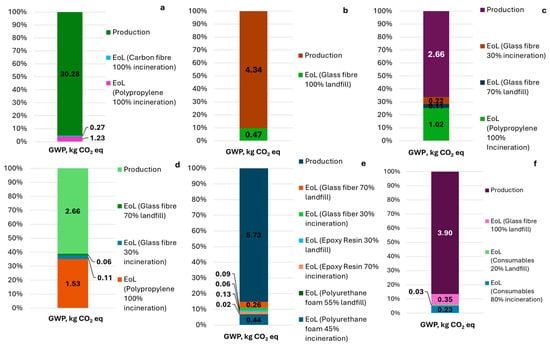

Figure 2 represents the results of the LCA analysis of six different FRP technologies in terms of the GWP impact from the manufacturing and waste treatment of materials used in production. The functional unit used in the analysis was 1 kg of the particular element produced by applying different manufacturing technologies. In this study, a Life Cycle Impact Assessment was performed based on a single-issue IPCC (International Panel on Climate Change) 2021 methodology, which analyses the GWP factor from the perspective of 100 years. Figure 2 and Figure 3 show the results of calculations performed based on data obtained from the literature and FRP technology providers [3]. The overall carbon footprint generated during manufacturing and End-of-Life stages of 1 kg of parts manufactured by hot stamping technology was 31.78 GWP, kg CO2 eq. Based on the EoL scenario covering 100% incineration of polypropylene and carbon fibre, the carbon footprint of waste disposal for hot stamping technology accounts for 1.50 kg CO2 eq. (ca. 4.7% of total emissions generated). The high total carbon footprint of hot stamping technology is a result of the application of carbon fibre for the production of the profiles.

Figure 2.

Results for Global Warming Potential (100 years) impact category for different FRP technologies: (a) hot-stamping technology, (b) UV curved pultrusion process, (c) ATP/AFP process, (d) 3D printing, (e) adaptive mould technology and (f) vacuum infusion.

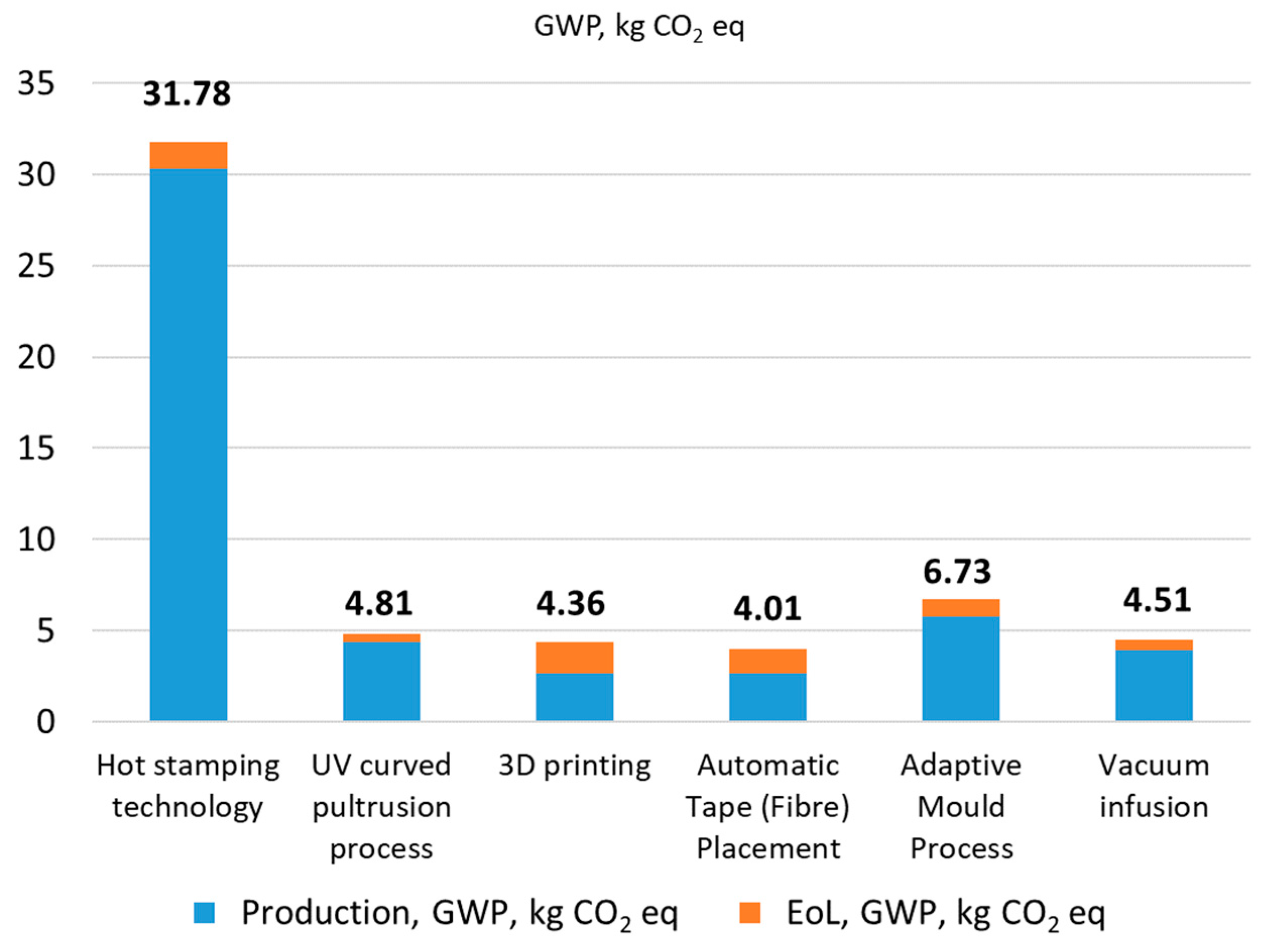

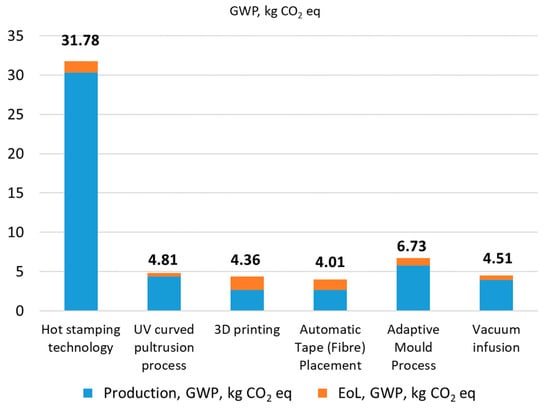

Figure 3.

Comparison of Global Warming Potential impact category of analysed fibre reinforced polymers (FRP) technologies per kg of produced part (including production and End-of-Life stage).

As shown in Figure 2b, UV curved pultrusion technology has a total carbon footprint estimated at 4.81 kg CO2 eq., where the biggest contribution belongs to the production stage with 4.34 kg CO2 eq. and waste disposal is responsible for only 0.47 kg CO2 eq. The End-of-Life scenario, where glass fibre is 100% landfilled (data provided by producer), gives 0.47 kg CO2 eq., which is below 10% of the total CO2 emissions.

Figure 2c shows the results of LCA analysis for ATP/AFP technology, where the highest impact of total carbon dioxide emissions generated belongs to the production stage (2.66 kg CO2 eq.). Waste disposal, i.e., the incineration of polypropylene and incineration of glass fibre, where only 30% is burned and the remaining 70%, representing the glass fibre, is landfilled, generated 1.34 kg CO2 eq., which accounts for approximately 33% of total CO2 emissions.

Three-dimensional printing technology was evaluated to have a GWP impact of approximately 4.36 kg CO2 eq. (Figure 2d). As was previously shown during the discussion, the highest GWP impact was caused by the production stage (61.1%). Waste disposal also had a substantial impact on the total amount of CO2 generated (38.9%), mainly due to the polypropylene incineration process, which had a high carbon footprint.

As shown in Figure 2e, AMP technology is responsible for 6.73 kg CO2 eq. emissions per 1 kg of composite element produced and disposed of. The EoL scenario contribution is evaluated as 14.9% of total emissions, and within the processes involved in waste disposal, polyurethane foam incineration and glass fibre landfill have the highest impacts in terms of the GWP factor (0.44 and 0.26 kg CO2 eq., respectively).

Figure 2f shows the GWP values for Vacuum Infusion Technology, where the production stage generates 3.9 kg CO2 eq. of emissions and the End-of-Life stage is responsible for 0.61 kg CO2 eq., which is less than 14% of the total contribution.

Figure 3 shows the comparison of the total GWP impacts of the different FRP technologies that we evaluated within cradle-to-grave LCA boundaries. The average environmental load of Fibre4Yards technologies is less than 7 kg CO2 eq. in relation to 1 kg of the final product, except hot stamping. The higher total carbon footprint of hot stamping technology is a result of the application of carbon fibre for the production of the elements and the use of the lab-scale hot stamping cell technique. Waste management (the EoL scenario) contributes 5 to 39% of the total carbon footprint for the technologies developed in the Fibre4Yards project. The highest contribution of EoL scenarios was found for technologies where polypropylene was applied (3D printing, ATP/AFP), as the further incineration of polypropylene during the disposal phase of the product life cycle generates high amounts of CO2 emissions.

4. Conclusions

The consumption and production rate of fibre-reinforced polymer (FRP) composite materials are constantly increasing, and the waste management of composites is emerging as a problem since the recycling rate of FRP materials is still low. The recycling process of FRP presents several challenges and opportunities for future studies:

- Meeting environmental regulations and sustainability targets (Environmental limits).

- Adapting to evolving laws and policies related to waste management and recycling (Governmental legislation).

- Implementing a C2C strategy (cradle-to-cradle) to transform FRP waste into a valuable product (Circular Economy approach).

- Addressing limitations in fibre properties, e.g., strength and durability (Interior fibre properties).

- Developing efficient methods for handling FRP waste during recycling (composite Processing Techniques).

In this paper, the effects of EoL stages compared to production stages of FRP materials for the shipyard industry on the Global Warming Potential impact category were analysed. The Life Cycle Assessment methodology applied for FRP manufacturing technologies (vacuum infusion, ultraviolet curved pultrusion, hot stamping, three-dimensional printing and automatic tape placement) showed that the total carbon footprint of both manufacturing and EoL stages was in the range of 4.01 kg CO2 eq. for automatic tape placement technology to 31.78 kg CO2 eq. for hot stamping technology. The EoL stage has an impact of 0.47 kg CO2 eq. for the UV curved pultrusion process to 1.7 kg CO2 eq. for 3D printing, which accounts for 5–39% of the total carbon footprint. The highest carbon footprint for the manufacturing process was generated for technology where carbon fibre was applied as a raw material, whereas in terms of the EoL scenario, the incineration of polypropylene generates the highest environmental load. As the manufacturing of FRPs such as carbon fibre and glass fibre produces high costs, energy consumption and environmental impacts, the application of recycling as a waste treatment method might become an attractive alternative. However, the wide application of FRP material recycling is still hindered by the low technology-readiness level, high cost of operation and degraded quality of recycled composites. The standard and the most common waste scenario (EoL) for FRP materials and compounds is incineration or landfilling, which must be considered in LCA analysis to obtain a realistic environmental load.

Author Contributions

Conceptualization, A.Z.-S. and I.Z.; methodology, A.Z.-S.; software, A.Z.-S.; validation, M.S.; formal analysis, M.P. and M.S.; investigation, A.Z.-S. and M.S.; resources, I.Z.; data curation, A.Z.-S. and M.S.; writing—original draft preparation, A.Z.-S., M.S. and M.P.; writing—review and editing, A.Z.-S. and M.S.; visualization, M.S.; supervision, I.Z.; project administration, A.Z.-S.; funding acquisition, A.Z.-S. and I.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 101006860.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sevigné-Itoiz, E.; Mwabonje, O.; Panoutsou, C.; Woods, J. Life cycle assessment (LCA): Informing the development of a sustainable circular bioeconomy? Phil. Trans. R. Soc. A 2021, 379, 20200352. [Google Scholar] [CrossRef] [PubMed]

- Pajula, T.; Behm, K.; Vatanen, S.; Saarivuori, E. Managing the Life Cycle to Reduce Environmental Impacts. In Dynamics of Long-Life Assets: From Technology Adaptation to Upgrading the Business Model; Grösser, S.N., Reyes-Lecuona, A., Granholm, G., Eds.; Springer International Publishing: Cham, Switherland, 2017; pp. 93–113. [Google Scholar] [CrossRef]

- Ziemińska-Stolarska, A.; Sobulska, M.; Pietrzak, M.; Zbiciński, I. Application of Life Cycle Assessment to Analysis of Fibre Composite Manufacturing Technologies in Shipyards Industry. Processes 2024, 12, 461. [Google Scholar] [CrossRef]

- Favi, C.; Germani, M.; Luzi, A.; Mandolini, M. A design for EoL approach and metrics to favour closed-loop scenarios for products A design for EoL approach and metrics to favour closed-loop scenarios for products. Int. J. Sustain. Eng. 2017, 10, 136–146. [Google Scholar] [CrossRef]

- Rosenboom, J.G.; Langer, R.; Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef]

- Vaverková, M.D. Landfill Impacts on the Environment—Review. Geosciences 2019, 9, 431. [Google Scholar] [CrossRef]

- Siddiqua, A.; Hahladakis, J.N.; Al-Attiya, W.A.K.A. An overview of the environmental pollution and health effects associated with waste landfilling and open dumping. Environ. Sci. Pollut. Res. 2022, 29, 58514–58536. [Google Scholar] [CrossRef] [PubMed]

- Iravanian, A.; Ravari, S.O. Types of Contamination in Landfills and Effects on The Environment: A Review Study. IOP Conf. Ser. Earth Environ. Sci. 2020, 614, 012083. [Google Scholar] [CrossRef]

- Njoku, P.O.; Edokpayi, J.N.; Odiyo, J.O. Health and Environmental Risks of Residents Living Close to a Landfill: A Case Study of Thohoyandou Landfill, Limpopo Province, South Africa. Int. J. Environ. Res. Public Health 2019, 16, 2125. [Google Scholar] [CrossRef]

- EC. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. 2008. Available online: https://eur-lex.europa.eu/eli/dir/2008/98/oj (accessed on 20 March 2024).

- Arvanitoyannis, I.S. Waste Management for Polymers in Food Packaging Industries. In Plastic Films in Food Packaging; Ebnesajjad, S., Ed.; William Andrew Publishing: Oxford, UK, 2012; pp. 249–310. [Google Scholar] [CrossRef]

- Mathur, N.; Last, N.; Morris, K.C. A process model representation of the end-of-life phase of a product in a circular economy to identify standards needs. Front. Manuf. Technol. 2023, 3, 988073. [Google Scholar] [CrossRef]

- Agudelo, L.M.; Mejía-Gutiérrez, R.; Nadeau, J.P.; Pailhès, J. Life cycle analysis in preliminary design stages. In Proceedings of the Joint Conference on Mechanical, Design Engineering & Advanced Manufacturing, Toulouse, France, 28 January–17 March 2014. [Google Scholar]

- Suhariyanto, T.T.; Wahab, D.A.; Rahman, M.N.A. Product Design Evaluation Using Life Cycle Assessment and Design for Assembly: A Case Study of a Water Leakage Alarm. Sustainability 2018, 10, 2821. [Google Scholar] [CrossRef]

- Dolz, M.; Martinez, X.; Sá, D.; Silva, J.; Jurado, A. Composite materials, technologies and manufacturing: Current scenario of European union shipyards. Ships Offshore Struct. 2023, 1–16. [Google Scholar] [CrossRef]

- Rubino, F.; Nisticò, A.; Tucci, F.; Carlone, P. Marine Application of Fiber Reinforced Composites: A Review. J. Mar. Sci. Eng. 2020, 8, 26. [Google Scholar] [CrossRef]

- Song, Y.S.; Youn, J.R.; Gutowski, T.G. Life cycle energy analysis of fiber-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1257–1265. [Google Scholar] [CrossRef]

- Meng, F.; McKechnie, J.; Turner, T.A.; Pickering, S.J. Energy and environmental assessment and reuse of fluidised bed recycled carbon fibres. Compos. Part A Appl. Sci. Manuf. 2017, 100, 206–214. [Google Scholar] [CrossRef]

- De Fazio, D.; Boccarusso, L.; Formisano, A.; Viscusi, A.; Durante, M. A Review on the Recycling Technologies of Fibre-Reinforced Plastic (FRP) Materials Used in Industrial Fields. J. Mar. Sci. Eng. 2023, 11, 851. [Google Scholar] [CrossRef]

- Chatziparaskeva, G.; Papamichael, I.; Voukkali, I.; Loizia, P.; Sourkouni, G.; Argirusis, C.; Zorpas, A.A. End-of-Life of Composite Materials in the Framework of the Circular Economy. Microplastics 2022, 1, 377–392. [Google Scholar] [CrossRef]

- Fibre4Yards Project. Available online: https://www.fibre4yards.eu (accessed on 20 June 2024).

- Ziemińska-Stolarska, A.; Pietrzak, M.; Zbiciński, I. Effect of Recycling on the Environmental Impact of a High-Efficiency Photovoltaic Module Combining Space-Grade Solar Cells and Optical Micro-Tracking. Energies 2023, 16, 3302. [Google Scholar] [CrossRef]

- Martinez, X.; Sá, D.; Silva, J.; Alvarez-Buylla, S. FIBRE4YARDS: Fibre Composite Manufacturing Technologies for the Automation and Modular Construction in Shipyards. Mater. Compuestos 2022, 6, 185. [Google Scholar] [CrossRef]

- Memon, H.; Wei, Y.; Zhu, C. Recyclable and reformable epoxy resins based on dynamic covalent bonds—Present, past, and future. Polym. Test. 2022, 105, 107420. [Google Scholar] [CrossRef]

- Bensadoun, F.; Vanderfeesten, B.; Verpoest, I.; Van Vuure, A.W.; Van Acker, K. Environmental impact assessment of end of life options for flax-MAPP composites. Ind. Crops Prod. 2016, 94, 327–341. [Google Scholar] [CrossRef]

- Gharde, S.; Kandasubramanian, B. Mechanothermal and chemical recycling methodologies for the Fibre Reinforced Plastic (FRP). Environ. Technol. Innov. 2019, 14, 100311. [Google Scholar] [CrossRef]

- Feraboli, P.; Kawakami, H.; Wade, B.; Gasco, F.; DeOto, L.; Masini, A. Recyclability and reutilization of carbon fiber fabric/epoxy composites. J. Compos. Mater. 2012, 46, 1459–1473. [Google Scholar] [CrossRef]

- Lee, S.H.; Choi, H.O.; Kim, J.S.; Lee, C.K.; Kim, Y.K.; Ju, C.S. Circulating flow reactor for recycling of carbon fiber from carbon fiber reinforced epoxy composite. Korean J. Chem. Eng. 2011, 28, 449–454. [Google Scholar] [CrossRef]

- Shetty, S.; Pinkard, B.R.; Novosselov, I.V. Recycling of carbon fiber reinforced polymers in a subcritical acetic acid solution. Heliyon 2022, 8, e12242. [Google Scholar] [CrossRef] [PubMed]

- Knight, C.C.; Zeng, C.; Zhang, C.; Wang, B. Recycling of woven carbon-fibre-reinforced polymer composites using supercritical water. Environ. Technol. 2012, 33, 639–644. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.N.; Kim, Y.O.; Kim, S.Y.; Park, M.; Yang, B.; Kim, J.; Jung, Y.C. Application of supercritical water for green recycling of epoxy-based carbon fiber reinforced plastic. Compos. Sci. Technol. 2019, 173, 66–72. [Google Scholar] [CrossRef]

- Keith, M.J.; Oliveux, G.; Leeke, G.A. Optimisation of solvolysis for recycling carbon fibre reinforced composites, In Proceedings of the ECCM 2016—Proceeding of the 17th European Conference on Composite Materials, Munich, Germany, 26–30 June 2016.

- Yan, H.; Lu, C.X.; Jing, D.Q.; Chang, C.B.; Liu, N.X.; Hou, X.L. Recycling of carbon fibers in epoxy resin composites using supercritical 1-propanol. New Carbon Mater. 2016, 31, 46–54. [Google Scholar] [CrossRef]

- Okajima, I.; Hiramatsu, M.; Shimamura, Y.; Awaya, T.; Sako, T. Chemical recycling of carbon fiber reinforced plastic using supercritical methanol. J. Supercrit. Fluids 2014, 91, 68–76. [Google Scholar] [CrossRef]

- Jiang, G.; Pickering, S.J.; Lester, E.H.; Warrior, N.A. Decomposition of epoxy resin in supercritical isopropanol. Ind. Eng. Chem. Res. 2010, 49, 4535–4541. [Google Scholar] [CrossRef]

- Scaffaro, R.; Di Bartolo, A.; Dintcheva, N.T. Matrix and Filler Recycling of Carbon and Glass Fiber-Reinforced Polymer Composites: A Review. Polymers 2021, 13, 3817. [Google Scholar] [CrossRef]

- Tao, Y.; Hadigheh, S.A.; Wei, Y. Recycling of glass fibre reinforced polymer (GFRP) composite wastes in concrete: A critical review and cost benefit analysis. Structures 2023, 53, 1540–1556. [Google Scholar] [CrossRef]

- Karuppannan Gopalraj, S.; Kärki, T. A review on the recycling of waste carbon fibre/glass fibre-reinforced composites: Fibre recovery, properties and life-cycle analysis. SN Appl. Sci. 2020, 2, 433. [Google Scholar] [CrossRef]

- Torres, A.; De Marco, I.; Caballero, B.M.; Laresgoiti, M.F.; Legarreta, J.A.; Cabrero, M.A.; González, A.; Chomón, M.J.; Gondra, K. Recycling by pyrolysis of thermoset composites: Characteristics of the liquid and gaseous fuels obtained. Fuel 2000, 79, 897–902. [Google Scholar] [CrossRef]

- Nahil, M.A.; Williams, P.T. Recycling of carbon fibre reinforced polymeric waste for the production of activated carbon fibres. J. Anal. Appl. Pyrolysis 2011, 91, 67–75. [Google Scholar] [CrossRef]

- Gonçalves, R.M.; Martinho, A.; Oliveira, J.P. Recycling of Reinforced Glass Fibers Waste: Current Status. Materials 2022, 15, 1596. [Google Scholar] [CrossRef] [PubMed]

- Pickering, S.J.; Kelly, R.M.; Kennerley, J.R.; Rudd, C.D.; Fenwick, N.J. A fluidised-bed process for the recovery of glass fibres from scrap thermoset composites. Compos. Sci. Technol. 2000, 60, 509–523. [Google Scholar] [CrossRef]

- Pickering, S.J.; Turner, T.A.; Meng, F.; Morris, C.N.; Heil, J.P.; Wong, K.H.; Melendi, S. Developments in the fluidised bed process for fibre recovery from thermoset composites. In Proceedings of the CAMX 2015—Composites and Advanced Materials Expo, Dallas, TX, USA, 26–29 October 2015. [Google Scholar]

- Mou, P.; Wa, L.; Xiang, D.; Gao, J.; Duan, G. A physical process for recycling and reusing waste printed circuit boards, In Proceedings of the IEEE International Symposium on Electronics and the Environment, Scottsdale, AZ, USA, 10–13 May 2004. [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Karl, C.W.; Gagani, A.I.; Jørgensen, J.K. Composite material recycling technology—State-of-the-art and sustainable development for the 2020s. J. Compos. Sci. 2021, 5, 28. [Google Scholar] [CrossRef]

- Pimenta, S.; Pinho, S.T. Recycling carbon fibre reinforced polymers for structural applications: Technology review and market outlook. Waste Manag. 2011, 31, 378–392. [Google Scholar] [CrossRef]

- Das, S. Life cycle assessment of carbon fiber-reinforced polymer composites. Int. J. Life Cycle Assess. 2011, 16, 268–282. [Google Scholar] [CrossRef]

- Li, X.; Bai, R.; McKechnie, J. Environmental and financial performance of mechanical recycling of carbon fibre reinforced polymers and comparison with conventional disposal routes. J. Clean. Prod. 2016, 127, 451–460. [Google Scholar] [CrossRef]

- Khanna, R. Introductory Chapter: Recycling and Reuse of End-of-Life Carbon Fibre Reinforced Polymers. In Recent Developments in the Field of Carbon Fibers; Khanna, R., Cayumil, R., Eds.; IntechOpen: London, UK, 2018; pp. 1–8. [Google Scholar] [CrossRef]

- Gen2Carbon Website. Available online: https://www.gen2carbon.com (accessed on 21 June 2024).

- Hermansson, F.; Janssen, M.; Svanström, M. Prospective study of lignin-based and recycled carbon fibers in composites through meta-analysis of life cycle assessments. J. Clean. Prod. 2019, 223, 946–956. [Google Scholar] [CrossRef]

- Witik, R.A.; Payet, J.; Michaud, V.; Ludwig, C.; Månson, J.A.E. Assessing the life cycle costs and environmental performance of lightweight materials in automobile applications. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1694–1709. [Google Scholar] [CrossRef]

- Overly, J.G.; Dhingra, R.; Davis, G.A.; Das, S. Environmental evaluation of lightweight exterior body panels in new generation vehicles. SAE Trans. 2002, 111, 760–772. [Google Scholar] [CrossRef]

- Witik, R.A.; Teuscher, R.; Michaud, V.; Ludwig, C.; Månson, J.A.E. Carbon fibre reinforced composite waste: An environmental assessment of recycling, energy recovery and landfilling. Compos. Part A Appl. Sci. Manuf. 2013, 49, 89–99. [Google Scholar] [CrossRef]

- Naqvi, S.R.; Prabhakara, H.M.; Bramer, E.A.; Dierkes, W.; Akkerman, R.; Brem, G. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef]

- López, F.A.; Rodríguez, O.; Alguacil, F.J.; García-Díaz, I.; Centeno, T.A.; García-Fierro, J.L.; González, C. Recovery of carbon fibres by the thermolysis and gasification of waste prepreg. J. Anal. Appl. Pyrolysis 2013, 104, 675–683. [Google Scholar] [CrossRef]

- Giorgini, L.; Benelli, T.; Mazzocchetti, L.; Leonardi, C.; Zattini, G.; Minak, G.; Dolcini, E.; Cavazzoni, M.; Montanari, I.; Tosi, C. Recovery of carbon fibers from cured and uncured carbon fiber reinforced composites wastes and their use as feedstock for a new composite production. Polym. Compos. 2015, 36, 1084–1095. [Google Scholar] [CrossRef]

- PwC Sustainable Performance and Strategy, 2016. Life Cycle Assessment of CFGF—Continuous Filament Glass Fibre Products, Report Prepared for GlassFibreEurope. Available online: https://glassfibreeurope.eu/wp-content/uploads/2023/02/GFE_LCA-report-2023-February-2023.pdf (accessed on 10 February 2024).

- Cunliffe, A.M.; Jones, N.; Williams, P.T. Recycling of fibre-reinforced polymeric waste by pyrolysis: Thermo-gravimetric and bench-scale investigations. J. Anal. Appl. Pyrolysis 2003, 70, 315–338. [Google Scholar] [CrossRef]

- Mudersbach, M.; Jürgens, M.; Pohler, M.; Spierling, S.; Venkatachalam, V.; Endres, H.J.; Barner, L. Life Cycle Assessment in a Nutshell—Best Practices and Status Quo for the Plastic Sector. Macromol. Rapid Commun. 2023, 2300466. [Google Scholar] [CrossRef]

- Karuppannan Gopalraj, S.; Deviatkin, I.; Horttanainen, M.; Kärki, T. Life Cycle Assessment of a Thermal Recycling Process as an Alternative to Existing CFRP and GFRP Composite Wastes Management Options. Polymers 2021, 13, 4430. [Google Scholar] [CrossRef] [PubMed]

- Kočí, V.; Picková, E. Life cycle perspective of liquid epoxy resin use in the automotive industry. Pol. J. Environ. Stud. 2020, 29, 653–667. [Google Scholar] [CrossRef] [PubMed]

- Marson, A.; Masiero, M.; Modesti, M.; Scipioni, A.; Manzardo, A. Life Cycle Assessment of Polyurethane Foams from Polyols Obtained through Chemical Recycling. ACS Omega 2021, 6, 1718–1724. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).