Effect of Using Moisture-Buffering Finishing Materials and DCV Systems on Environmental Comfort and Energy Consumption in Buildings

Abstract

1. Introduction

2. Methods

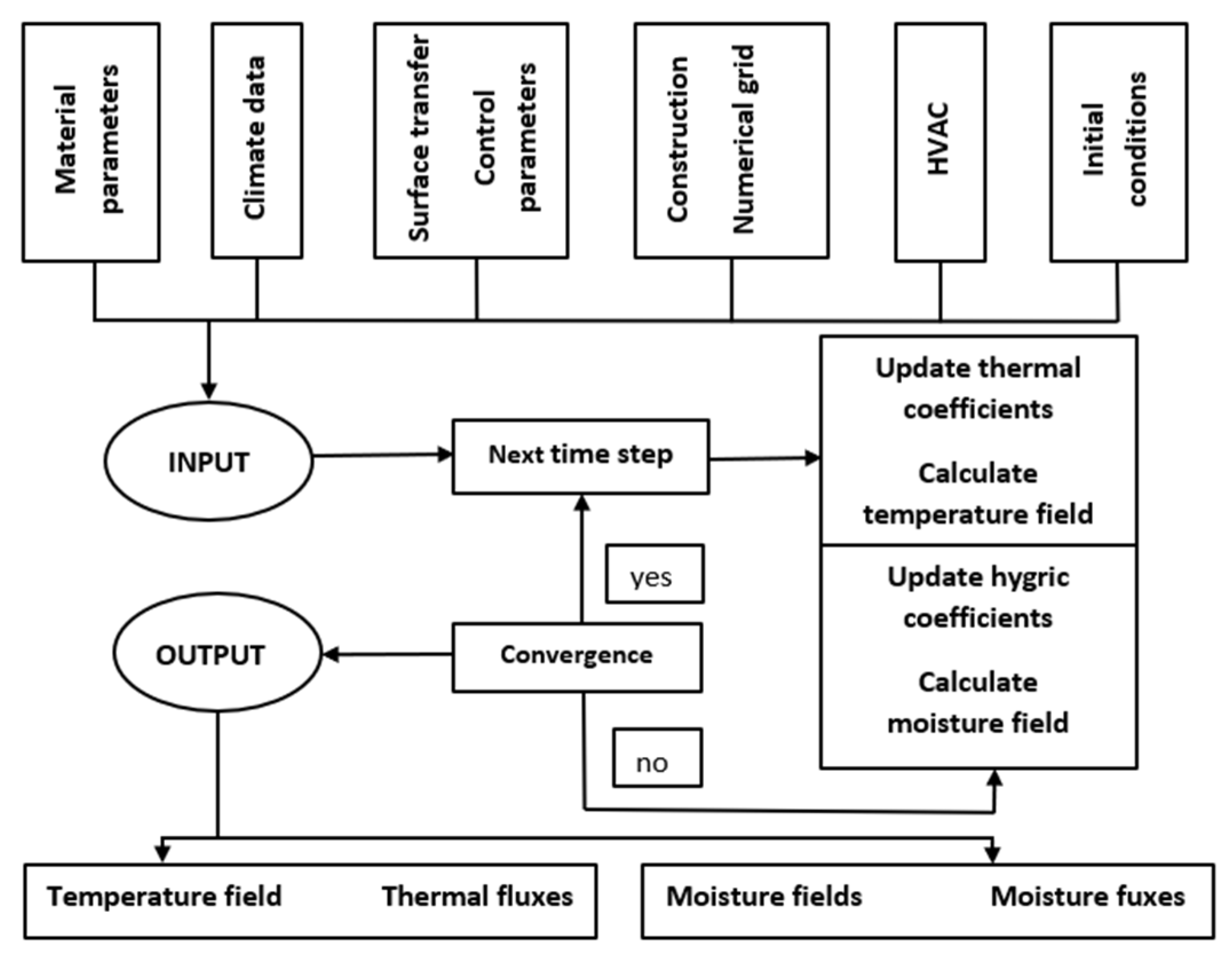

2.1. Model of Heat and Moisture Transfer

2.1.1. Validation

2.1.2. Assumptions

2.2. Building Description

2.3. Material Scenarios

2.4. Room Occupancy Scenarios

2.5. Ventilation Control Scenarios

- DCV serves all rooms with a heat recovery ventilation (HRV) efficiency level of 0.80;

- The indoor temperature in winter is no lower than 20 °C, while in summer, it does not exceed 26 °C;

- For the air stream supplied to the zone, determined based on the maximum loads resulting from gas pollution concentration reduction, the system provides a stream of fresh air according to the following relationship (3):

- C1 scenario—temperature control, with the supply air stream determined based on pollution emissions for the nursery (B1) at 359 m3/h and for the office (B2) at 129 m3/h (30 m3/(h·person) per adult and 15 m3/(h·person) per child [45]);

- C3 scenario—RH as the priority combined with temperature control, with relative humidity in the 40–60% range and with the supply air stream determined based on the same pollution emission levels as in the C1 scenario;

- C4 scenario—CO2 as the priority combined with temperature control, with the CO2 concentration no higher than 1500 ppm (in accordance with the acceptable levels defined in references [46,47]) and with the supply air stream determined based on air stream units per capita according to the room’s occupancy profile: 285 m3/h for the nursery (B1) and 150 m3/h for the office (B2).

2.6. Analysed Options—Symbols

2.7. Evaluation Methods

- The number of hours for which, during the room occupancy hours (from 6:00 a.m. to 5:00 p.m. from Monday to Friday), the air quality parameters were within the acceptable range, assumed as follows:

- -

- Temperature 20–26 °C;

- -

- Relative humidity 40–60%;

- -

- Carbon dioxide concentrations up to 1500 ppm.

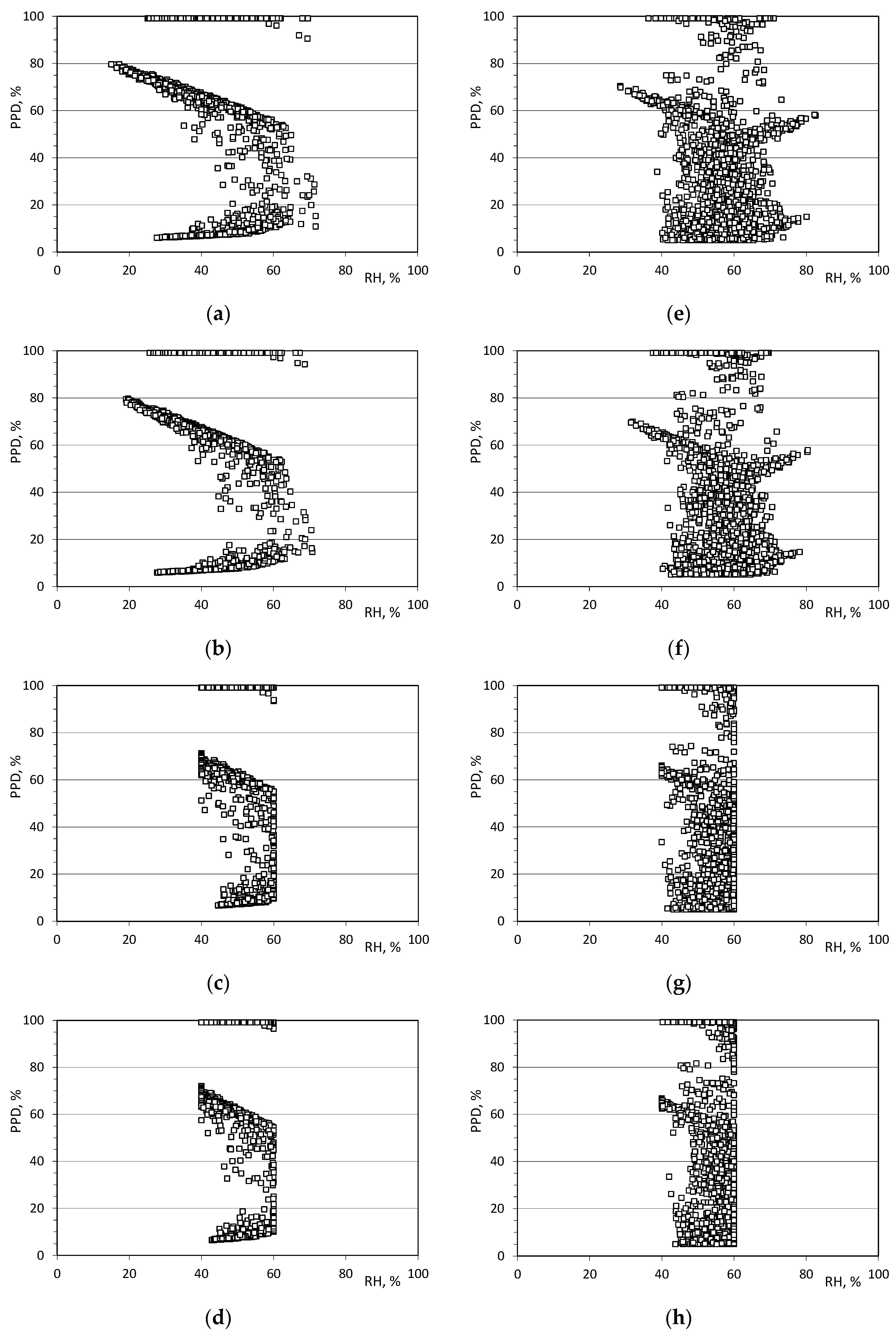

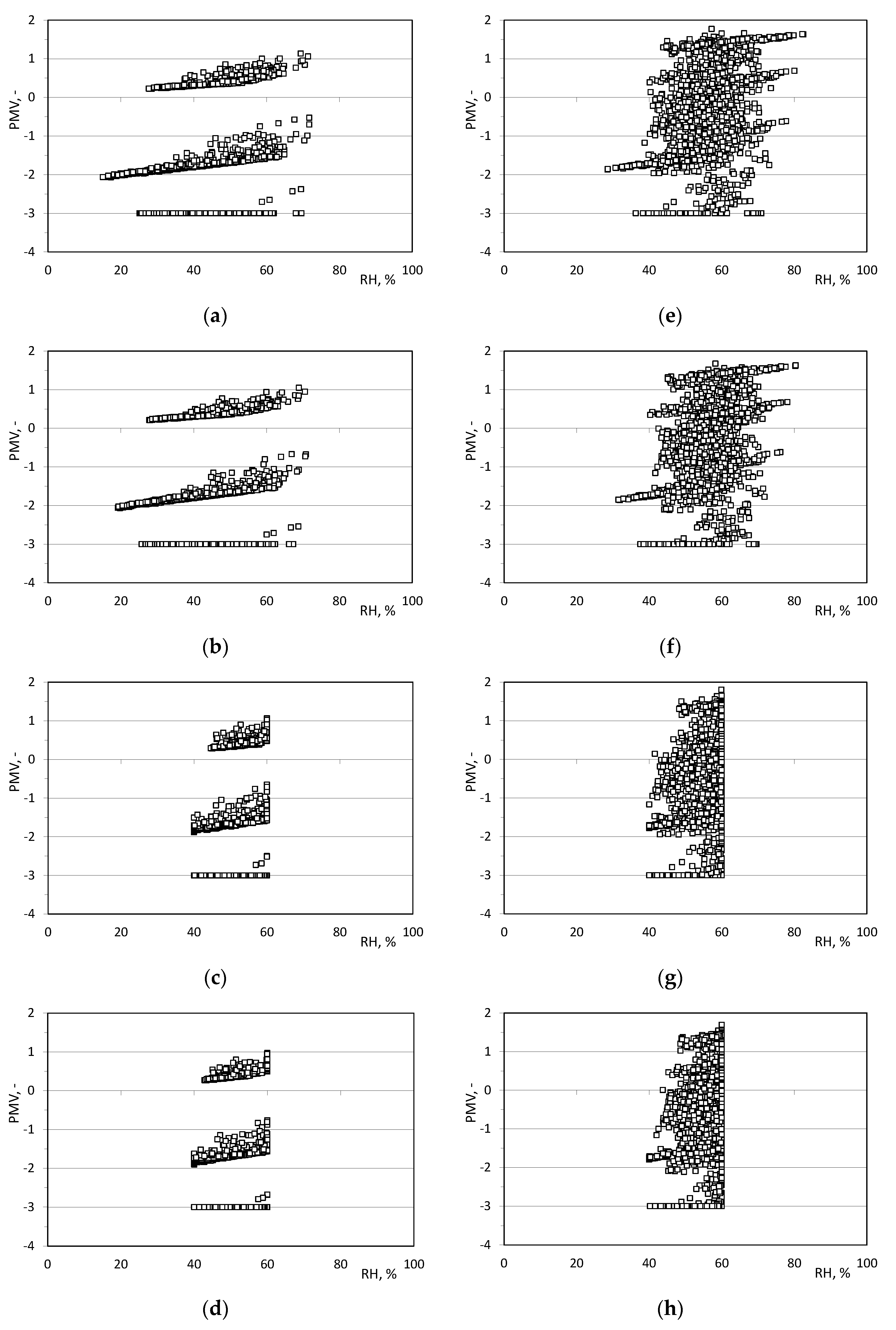

- Values of thermal comfort parameters PMV and PPD [8]:

- -

- Category A—PMV in the range <−0.2, +0.2> and PPD < 6%;

- -

- Category B—PMV in the range <−0.5, +0.5> and PPD < 10%;

- -

- Category C—PMV in the range <−0.7, +0.7> and PPD < 15%.

3. Results and Discussion

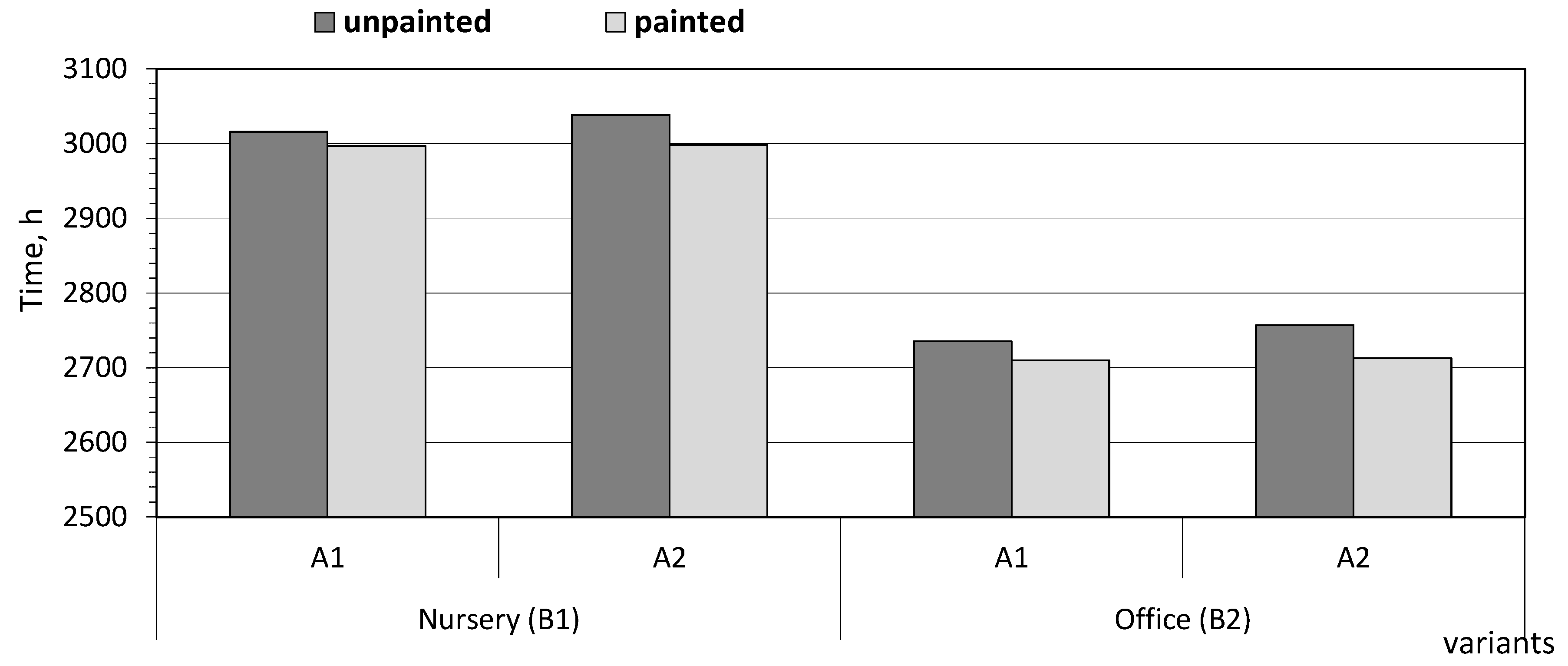

3.1. Number of Comfort Hours

3.2. Evaluation of Occupancy Comfort

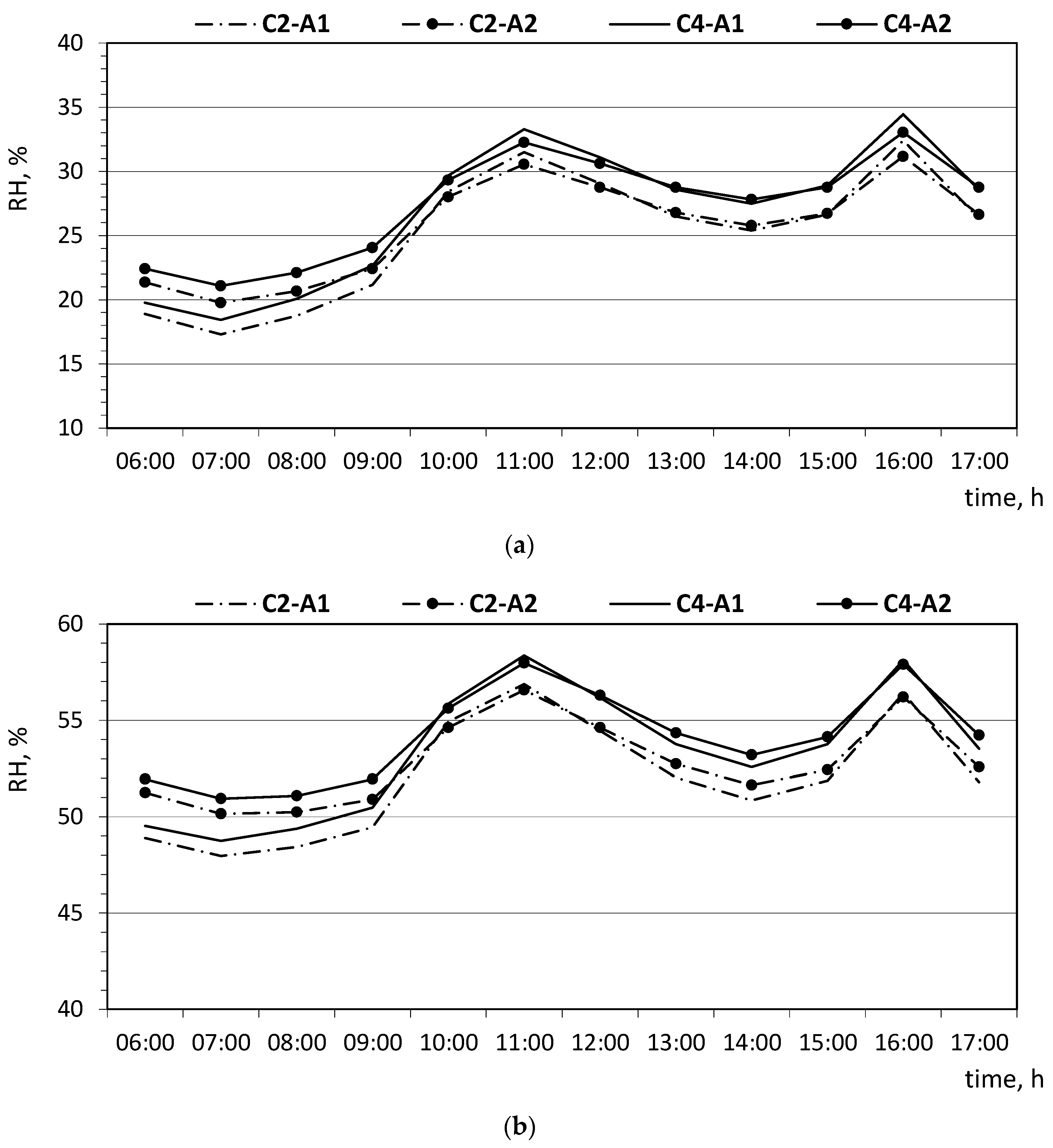

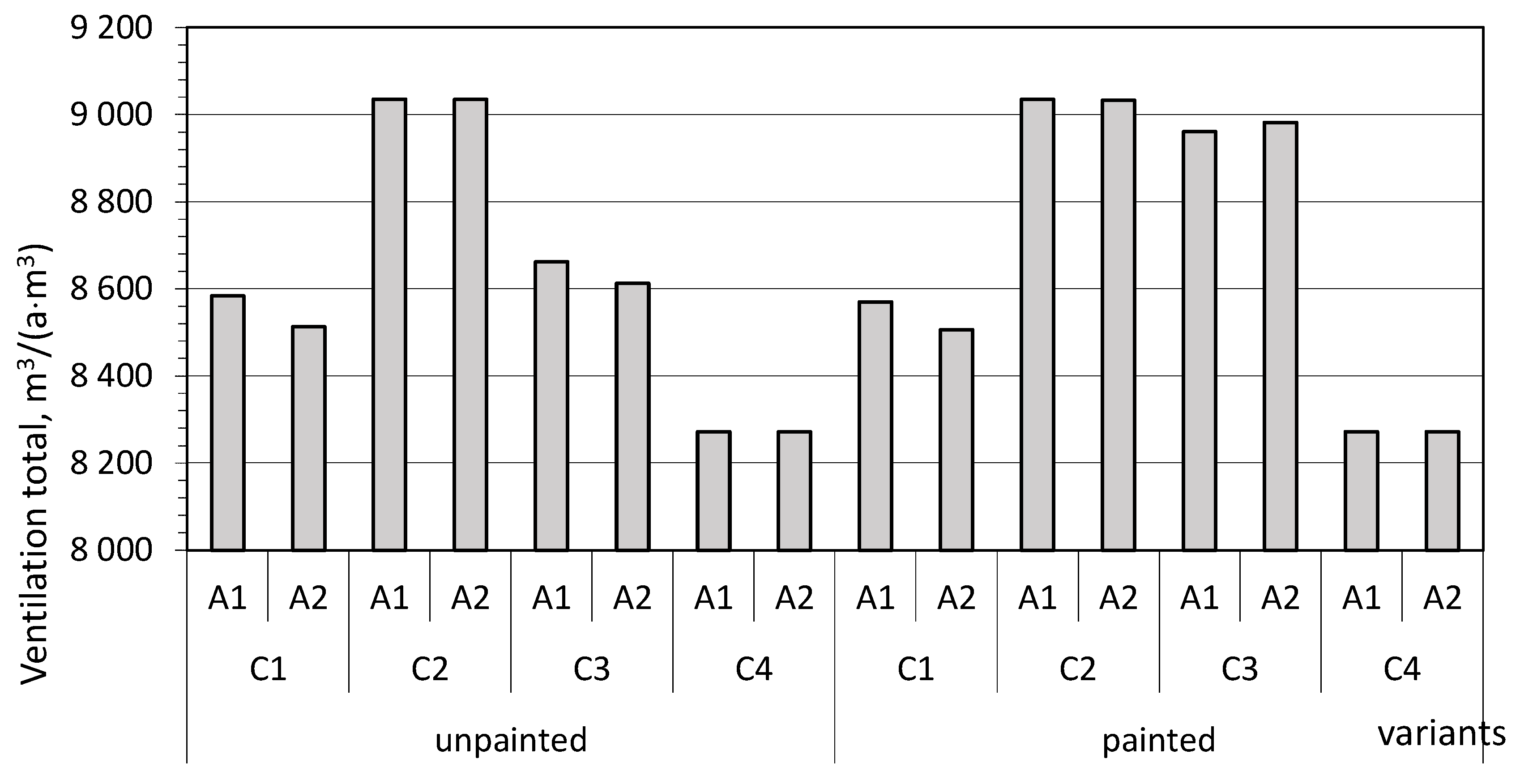

3.3. Moisture-Buffering Effect and Ventilation Air Stream

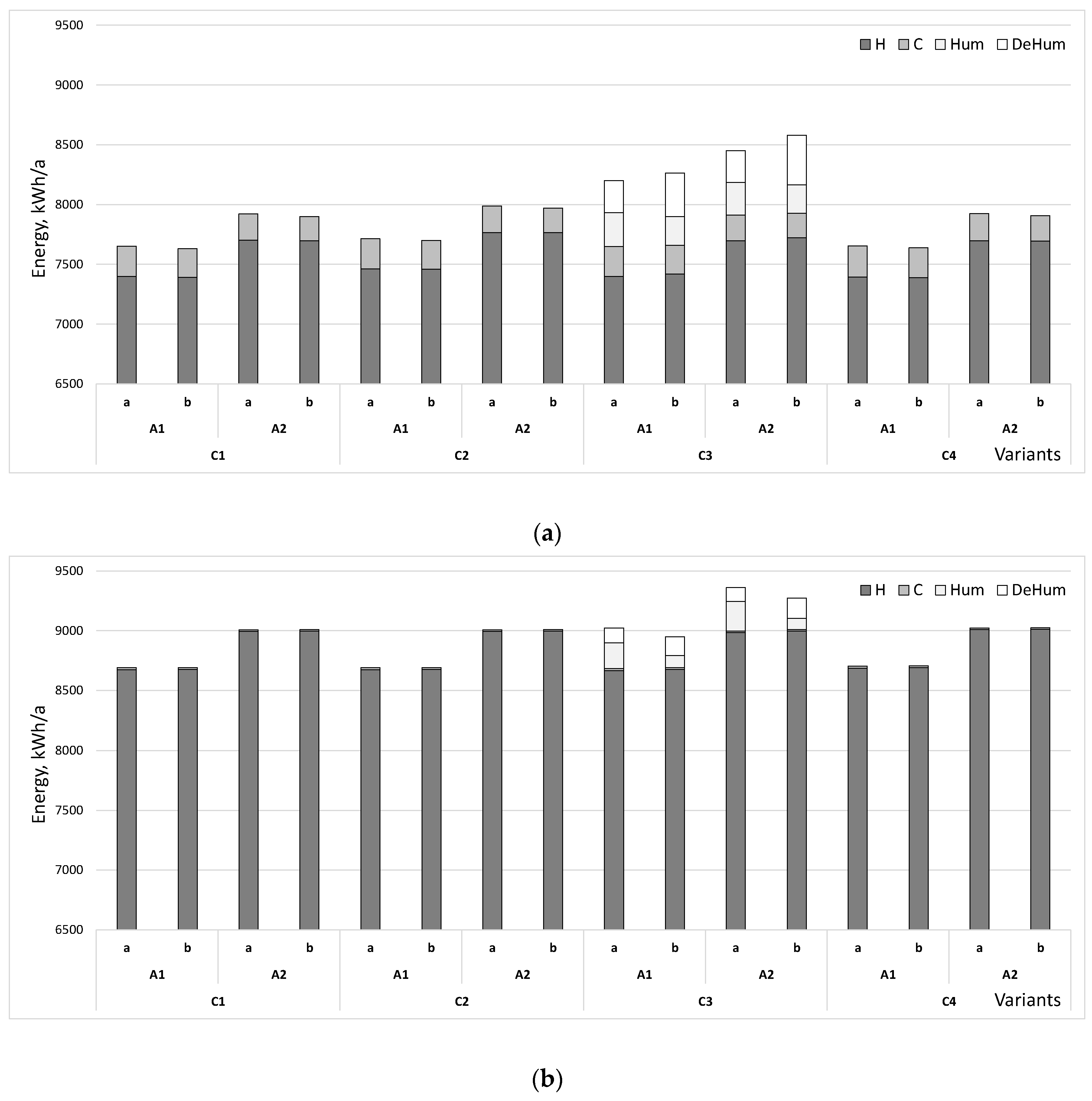

3.4. Energy Consumption for Each Purpose

4. Conclusions

- Combining moisture-buffering materials with DCV systems can be used to balance occupant comfort and building energy efficiency, provided that the materials are selected appropriately;

- The higher the requirements regarding environmental comfort (class A), the more important the method of controlling the DCV system;

- Taking environment comfort as the evaluation criterion, the scenario characterised by the highest number of comfort hours, both for the nursery (B1) and the office (B2), was the C3 scenario involving relative humidity control in all analysed material solutions;

- The solutions based on humidity-level control turned out to be more effective for energy consumption when only heating and cooling purposes were compared, whereas when taking into account humidification and dehumidification, these solutions become energy-inefficient;

- The moisture-buffering effect in rooms with CO2-controlled mechanical systems is more limited compared to the rooms with RH-controlled systems;

- Higher energy consumption for heating was observed for cement–lime plaster (A2), which has better moisture-buffering characteristics than gypsum board (A1), demonstrating poorer moisture-buffering performance;

- Moisture-buffering materials become active as the humidity load in the rooms increases;

- The moisture-buffering potential effectively regulates indoor humidity peaks and maintains relative humidity levels within acceptable thresholds when coupled with adequate ventilation;

- Because measures to reduce a building’s energy consumption do not always improve occupant comfort, solutions that compromise air quality and energy consumption must be sought.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tham, K.W.; Willem, H.C. Room air temperature affects occupants’ physiology, perceptions and mental alertness. Build. Environ. 2010, 45, 40–44. [Google Scholar] [CrossRef]

- Tham, J.S.; Thompson, R.; Landeg, O.; Murray, K.A.; Waite, T. Indoor temperature and health: A global systematic review. Public Health 2020, 179, 9–17. [Google Scholar] [CrossRef] [PubMed]

- Tang, H.; Ding, Y.; Singer, B. Interactions and comprehensive effect of indoor environmental quality factors on occupant satisfaction. Build. Environ. 2020, 167, 106462. [Google Scholar] [CrossRef]

- Zalejska-Jonsson, A.; Wilhelmsson, M. Impact of perceived indoor environment quality on overall satisfaction in Swedish dwellings. Build. Environ. 2013, 63, 134–144. [Google Scholar] [CrossRef]

- Halawa, E.; Van Hoof, J. The adaptive approach to thermal comfort: A critical overview. Energy Build. 2012, 51, 101–110. [Google Scholar] [CrossRef]

- Gauthier, S. The role of environmental and personal variables in influencing thermal comfort indices used in building, Building Simulation. In Proceedings of the 13th Conference of the International Building Performance Simulation Association, Chambéry, France, 26–28 August 2013; pp. 2320–2325. [Google Scholar] [CrossRef]

- The European Parliament and the Council of the European Union. Directive (EU) 2018/844, Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 amending Directive 2010/31/EU on the energy performance of buildings and Directive 2012/27/EU on energy efficiency. Off. J. Eur. Union 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32018L0844&from=EN (accessed on 20 January 2024).

- PN-EN ISO 7730; Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. Polish Organization for Standardization: Warsaw, Poland, 2006.

- PN-EN 16798-1; Energy Performance of Buildings. Ventilation for Buildings. Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics. Polish Organization for Standardization: Warsaw, Poland, 2019.

- Song, W.; Zhang, Z.; Chen, Z.; Wang, F.; Yang, B. Thermal comfort and energy performance of personal comfort systems (PCS): A systematic review and meta-analysis. Energy, Build. 2022, 256, 111747. [Google Scholar] [CrossRef]

- Martínez-Molina, A.; Tort-Ausina, I.; Cho, S.; Vivancos, J.L. Energy efficiency and thermal comfort in historic buildings: A review. Renew. Sustain. Energy Rev. 2016, 61, 70–85. [Google Scholar] [CrossRef]

- Halhoul Merabet, G.; Essaaidi, M.; Ben Haddou, M.; Qolomany, B.; Qadir, J.; Anan, M.; Al-Fuqaha, A.; Abid, M.R.; Benhaddou, D. Intelligent building control systems for thermal comfort and energy-efficiency: A systematic review of artificial intelligence-assisted techniques. Renew. Sustain. Energy Rev. 2021, 144, 111116. [Google Scholar] [CrossRef]

- Zhuang, C.; Shan, K.; Wang, S. Coordinated demand-controlled ventilation strategy for energy-efficient operation in multi-zone cleanroom air-conditioning systems. Build. Environ. 2021, 191, 107588. [Google Scholar] [CrossRef]

- Guyot, G.; Sherman, M.H.; Walker, I.S. Smart ventilation energy and indoor air quality performance in residential buildings: A review. Energy Build. 2018, 165, 416–430. [Google Scholar] [CrossRef]

- Afroz, Z.; Higgins, G.; Shafiullah, G.M.; Urmee, T. Evaluation of real-life demand-controlled ventilation from the perception of indoor air quality with probable implications. Energy Build. 2020, 219, 110018. [Google Scholar] [CrossRef]

- Lu, X.; O’Neill, Z.; Li, Y.; Niu, F. A novel simulation-based framework for sensor error impact analysis in smart building systems: A case study for a demand-controlled ventilation system. Appl. Energy 2020, 263, 114638. [Google Scholar] [CrossRef]

- Merema, B.; Delwati, M.; Sourbron, M.; Breesch, H. Demand controlled ventilation (DCV) in school and office buildings: Lessons learnt from case studies. Energy Build. 2018, 172, 349–360. [Google Scholar] [CrossRef]

- Simonson, C.J.; Salonvaara, M.; Ojanen, T. The effect of structures on indoor humidity—Possibility to improve comfort and perceived air quality. Indoor Air 2002, 12, 243–251. [Google Scholar] [CrossRef] [PubMed]

- Teodosiu, C.; Hohota, R.; Rusaouen, G.; Woloszyn, M. Numerical prediction of indoor air humidity and its effect on indoor environment. Build. Environ. 2003, 38, 655–664. [Google Scholar] [CrossRef]

- Isetti, C.; Laurenti, L.; Ponticiello, A. Predicting vapour content of the indoor air and latent loads for air-conditioned environments: Effect of moisture storage capacity of the walls. Energy Build. 1988, 12, 141–148. [Google Scholar] [CrossRef]

- Kurnitski, J.; Kalamees, T.; Palonen, J.; Eskola, L.; Seppanen, O. Potential effects of permeable and hygroscopic lightweight structures on thermal comfort and perceived IAQ in a cold climate. Indoor Air 2007, 17, 37–49. [Google Scholar] [CrossRef] [PubMed]

- Kunzel, H.M.; Holm, A.; Zirkelbach, D.; Karagiozis, A.N. Simulation of indoor temperature and humidity conditions including hygrothermal interactions with the building envelope. Sol. Energy 2005, 78, 554–556. [Google Scholar] [CrossRef]

- Mendes, N.; Winkelmann, F.C.; Lamberts, R.; Philippi, P.C. Moisture effects on conduction loads. Energy Build. 2003, 35, 631–644. [Google Scholar] [CrossRef]

- Hameury, S. Moisture buffering capacity of heavy timber structures directly exposed to an indoor climate: A numerical study. Build. Environ. 2005, 40, 1400–1412. [Google Scholar] [CrossRef]

- Diasty, R.E.; Fazio, P.; Budaiwi, I. Modelling of indoor air humidity: The dynamic behaviour within an enclosure. Energy Build. 1992, 19, 61–73. [Google Scholar] [CrossRef]

- El Diasty, R.; Fazio, P.; Budaiwi, I. The dynamic modelling of air humidity behaviour in a multi-zone space. Build. Environ. 1993, 28, 33–51. [Google Scholar] [CrossRef]

- Derluyn, H.; Janssen, H.; Diepens, J.; Derome, D.; Carmeliet, J. Hygroscopic behaviour of paper and books. J. Build. Phys. 2007, 31, 9–34. [Google Scholar] [CrossRef]

- Osanyintola, O.F.; Simonson, C.J. Moisture buffering capacity of hygroscopic building materials: Experimental facilities and energy impact. Energy Build. 2006, 38, 1270–1282. [Google Scholar] [CrossRef]

- Holm, A.; Künzel, H.M. Experimental investigation of the hygric buffering capacity of wood based interior panelling. In Research in building physics and building engineering. In Proceedings of the Third International Building Physics Conference, Montreal, QC, Canada, 27–31 August 2006. [Google Scholar]

- Plathner, P.; Woloszyn, M. Interzonal air and moisture transport in a test house: Experiment and modelling. Build. Environ. 2002, 37, 189–199. [Google Scholar] [CrossRef]

- Kalamees, T.; Korpi, M.; Vinha, J.; Kurnitski, J. The effects of ventilation systems and building fabric on the stability of indoor temperature and humidity in Finnish detached houses. Build. Environ. 2009, 44, 1643–1650. [Google Scholar] [CrossRef]

- Woloszyn, M.; Kalamees, T.; Abadie, M.O.; Steeman, M.; Kalagasidis, A.S. The effect of combining a relative-humidity-sensitive ventilation system with the moisture-buffering capacity of materials on indoor climate and energy efficiency of buildings. Build. Environ. 2009, 44, 515–524. [Google Scholar] [CrossRef]

- Pedram, S.; Tariku, F. Moisture buffering and ventilation strategies to control indoor humidity in a marine environment: A field experimental study. In Proceedings of the 15th Canadian Conference on Building Science and Technology, Vancouver, BC, Canada, 6–8 November 2017. [Google Scholar]

- Abuimara, T.; O’Brien, W.; Gunay, B. Quantifying the impact of occupants’ spatial distributions on office buildings energy and comfort performance. Energy Build. 2021, 233, 110695. [Google Scholar] [CrossRef]

- WUFI Plus, v.3.1.0.3 DB; Version 24/79: Fraunhofer Institute for Building Physics. License Building Research Institute (ITB): Stuttgart, Germany, 2017.

- Künzel, H.M. Simultaneous Heat and Moisture Transport in Building Components—One- and Two-Dimensional Calculation Using Simple Parameters. Ph.D. Thesis, Fraunhofer Institute of Building Physics, Stuggart, Germany, 1995. [Google Scholar]

- Coelho, G.B.A.; Entradas Silva, H.; Henriques, F.M.A. Calibrated hygrothermal simulation models for historical buildings. Build. Environ. 2018, 142, 439–450. [Google Scholar] [CrossRef]

- Kaczorek, D.; Basińska, M.; Koczyk, H. Hygrothermal behaviour of a room with different occupancy scenarios. J. Build. Eng. 2023, 66, 105928. [Google Scholar] [CrossRef]

- Ruiz, G.; Bandera, C. Validation of calibrated energy models: Common errors. Energies 2017, 10, 1587. [Google Scholar] [CrossRef]

- ASHRAE Guideline 14-2014, Measurement of Energy, Demand, and Water Savings, ASHRAE, Atlanta. 2014. Available online: https://webstore.ansi.org/preview-pages/ASHRAE/preview_ASHRAE+Guideline+14-2014.pdf (accessed on 15 December 2023).

- Kaczorek, D.; Basińska, M. Hygrothermal The impact of ventilation combining with moisture-buffering materials on selected parameters of environmental comfort in a nursery. Mater. Bud. 2024, 620, 15–19. (In Polish) [Google Scholar] [CrossRef]

- ASHRAE. ANSI/ASHRAE Standard 55-2004; Thermal Environmental Conditions for Human Occupancy. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.: Atlanta, GA, USA, 2004.

- IEA Annex 41. Whole Building Heat, Air, Moisture Response. Available online: https://research.tuni.fi/buildingphysics/international-collaboration/annex-41/ (accessed on 17 December 2023).

- ASHRAE. ANSI/ASHRAE Standard 62.1-2004; Ventilation for Acceptable Indoor Air Quality. Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.: Atlanta, GA, USA, 2004.

- Regulation of Minister of Infrastructure of 12 April 2002 on the Technical Condition That Should Be Met by Buildings and Their Location; Journal of Laws of the Republic of Poland No 75, Item 690, (with Recast); Polish Ministry of Infrastructure: Warsaw, Poland, 2002. (In Polish)

- Deutsches Institut für Normung. DIN 1946-2 Ventilation and Air Conditioning. Technical Health Requirements (VDI Ventilation rules). Germany. Available online: https://standards.globalspec.com/std/1331773/DIN%201946-2 (accessed on 5 April 2023).

- Education and Skills Funding Agency. Building Bulletin 101 Ventilation and School Buildings (BB101). UK. Available online: https://ves.co.uk/hvac-solutions/school-ventilation/insights/building-bulletin-101/ (accessed on 5 April 2023).

- D’Ambrosio Alfano, F.R.; Pepe, D.; Riccio, G.; Vio, M.; Palella, B.I. On the effects of the mean radiant temperature evaluation in the assessment of thermal comfort by dynamic energy simulation tools. Build. Environ. 2023, 236, 110254. [Google Scholar] [CrossRef]

- Zhang, M.; Qin, M.; Rode, C.; Chen, Z. Moisture buffering phenomenon and its impact on building energy consumption. Appl. Therm. Eng. 2017, 124, 337–345. [Google Scholar] [CrossRef]

- Ranesi, A.; Faria, P.; Freire, M.T.; Gonçalves, M.; Veiga, M.R. Eco-efficient plastering mortars for improved indoor comfort. The influence of A. dealbata bark addition. Constr. Build. Mater. 2024, 421, 135572. [Google Scholar] [CrossRef]

- Fang, J.; Zhang, H.; Ren, P.; He, B.-J.; Tang, M.; Feng, C. Influence of climates and materials on the moisture buffering in office buildings: A comprehensive numerical study in China. Environ. Sci. Pollut. Res. 2022, 29, 14158–14175. [Google Scholar] [CrossRef] [PubMed]

- Latif, E.; Lawrence, M.; Shea, A.; Walker, P. Moisture buffer potential of experimental wall assemblies incorporating formulated hemp-lime. Build. Environ. 2015, 93, 199–209. [Google Scholar] [CrossRef]

- Shang, Y.; Tariku, F. Hempcrete building performance in mild and cold climates: Integrated analysis of carbon footprint, energy, and indoor thermal and moisture buffering. Build. Environ. 2021, 206, 108377. [Google Scholar] [CrossRef]

- Singh, M.K.; Ooka, R.; Rijal, H.B.; Kumar, S.; Kumar, A.; Mahapatra, S. Progress in thermal comfort studies in classrooms over last 50 years and way forward. Energy Build. 2019, 188–189, 149–174. [Google Scholar] [CrossRef]

- Fan, M.; Fu, Z.; Wang, J.; Wang, Z.; Suo, H.; Kong, X.; Li, H. A review of different ventilation modes on thermal comfort, air quality and virus spread control. Build. Environ. 2022, 212, 108831. [Google Scholar] [CrossRef]

- Yang, X.; Fazio, P.; Ge, H.; Rao, J. Evaluation of moisture buffering capacity of interior surface materials and furniture in a full-scale experimental investigation. Build. Environ. 2012, 47, 188–196. [Google Scholar] [CrossRef]

- Yoshino, H.; Mitamura, T.; Hasegawa, K. Moisture buffering and effect of ventilation rate and volume rate of hygrothermal materials in a single room under steady state exterior conditions. Build. Environ. 2009, 44, 1418–1425. [Google Scholar] [CrossRef]

- Lu, T.; Lü, X.; Viljanen, M. A novel and dynamic demand-controlled ventilation strategy for CO2 control and energy savings in buildings. Energy Build. 2011, 43, 2499–2508. [Google Scholar] [CrossRef]

- Jia, J.L.; Han, R.; Chen, X.; Li, Q.Y.; Lee, C.; Fung, Y.H. Interaction between thermal comfort, indoor air quality and ventilation energy consumption of educational buildings: A comprehensive review. Buildings 2021, 11, 591. [Google Scholar] [CrossRef]

- Tran Le, A.D.; Maalouf, C.; Mai, T.H.; Wurtz, E.; Collet, F. Transient hygrothermal behaviour of a hemp concrete building envelope. Energy Build. 2010, 42, 1797–1806. [Google Scholar] [CrossRef]

| I | II | III | IV | V | VI | VII | VIII | IX | X | XI | XII | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T, °C | −3.6 | −1.8 | 3.9 | 7.8 | 14.1 | 17.1 | 17.9 | 16.6 | 13.7 | 8.7 | 2.3 | −0.7 |

| RH, % | 84 | 83 | 80 | 80 | 73 | 71 | 75 | 80 | 79 | 84 | 87 | 89 |

| Building Component | Design (Outwards) | Thermal Transmittance U, W/(m2·K) |

|---|---|---|

| Exterior wall (south and west) |

| 1.04 |

| ||

| ||

| ||

| Roof (horizontal) |

| 0.42 |

| ||

| ||

| ||

| ||

| Interior wall |

| 2.06 |

| ||

| Ceiling |

| 0.89 |

| ||

| ||

| ||

| ||

| ||

| Windows | 2.53 |

| Properties | Finishing Material | |

|---|---|---|

| (A1) Gypsum Board | (A2) Cement–Lime Plaster | |

| Thermal conductivity λ, W/(m·K) | 0.20 | 0.80 |

| Water vapour diffusion resistance μ, - | 6.1 | 19.0 |

| Symbol | Description |

|---|---|

| B1 | nursery |

| B2 | office |

| A1 | gypsum board |

| A2 | cement–lime plaster |

| C1 | DCV system (temperature control) |

| C2, C4 | DCV system (CO2 as priority and temperature control) |

| C3 | DCV system (RH as priority and temperature control) |

| Nursery (B1) | |||||||

| Material A1 | Material A2 | ||||||

| T | CO2 | RH | T | CO2 | RH | ||

| The unpainted finishing material | C1 | 98.2 | 73.3 | 53.3 | 98.8 | 71.5 | 54.4 |

| C2 | 98.3 | 100.0 | 56.7 | 98.8 | 100.0 | 57.5 | |

| C3 | 98.0 | 77.1 | 96.3 | 98.7 | 75.8 | 97.0 | |

| C4 | 98.3 | 86.1 | 56.1 | 98.8 | 86.3 | 56.5 | |

| The painted finishing material | C1 | 98.5 | 72.7 | 44.2 | 98.9 | 71.0 | 43.5 |

| C2 | 98.5 | 100.0 | 51.3 | 98.9 | 100.0 | 50.2 | |

| C3 | 98.4 | 86.6 | 95.7 | 98.8 | 97.2 | 95.7 | |

| C4 | 98.4 | 86.3 | 50.3 | 98.8 | 86.6 | 49.2 | |

| Office (B2) | |||||||

| Material A1 | Material A2 | ||||||

| T | CO2 | RH | T | CO2 | RH | ||

| The unpainted finishing material | C1 | 98.2 | 73.3 | 53.3 | 98.8 | 71.5 | 54.4 |

| C2 | 98.3 | 100.0 | 56.7 | 98.8 | 100.0 | 57.5 | |

| C3 | 98.0 | 77.1 | 96.3 | 98.7 | 75.8 | 97.0 | |

| C4 | 98.3 | 86.1 | 56.1 | 98.8 | 86.3 | 56.5 | |

| The painted finishing material | C1 | 98.5 | 72.7 | 44.2 | 98.9 | 71.0 | 43.5 |

| C2 | 98.5 | 100.0 | 51.3 | 98.9 | 100.0 | 50.2 | |

| C3 | 98.4 | 86.6 | 95.7 | 98.8 | 97.2 | 95.7 | |

| C4 | 98.4 | 86.3 | 50.3 | 98.8 | 86.6 | 49.2 | |

| Nursery (B1) | |||||||

| Material A1 | Material A2 | ||||||

| A | B | C | A | B | C | ||

| The unpainted finishing material | C1 | C1 | 151 | 602 | 859 | 144 | 630 |

| C2 | C2 | 148 | 624 | 875 | 143 | 659 | |

| C3 | C3 | 153 | 633 | 860 | 154 | 659 | |

| C4 | C4 | 153 | 630 | 881 | 147 | 654 | |

| The painted finishing material | C1 | C1 | 151 | 588 | 848 | 143 | 611 |

| C2 | C2 | 149 | 628 | 872 | 143 | 651 | |

| C3 | C3 | 155 | 667 | 870 | 156 | 689 | |

| C4 | C4 | 151 | 627 | 880 | 144 | 644 | |

| Office (B2) | |||||||

| Material A1 | Material A2 | ||||||

| A | B | C | A | B | C | ||

| The unpainted finishing material | C1 | 193 | 566 | 918 | 182 | 540 | 895 |

| C2 | 193 | 566 | 918 | 182 | 540 | 895 | |

| C3 | 188 | 576 | 929 | 186 | 555 | 903 | |

| C4 | 190 | 566 | 915 | 182 | 539 | 893 | |

| The painted finishing material | C1 | 187 | 594 | 925 | 187 | 582 | 902 |

| C2 | 187 | 594 | 925 | 187 | 582 | 902 | |

| C3 | 183 | 598 | 924 | 180 | 578 | 905 | |

| C4 | 184 | 590 | 922 | 182 | 575 | 900 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaczorek, D.; Basińska, M. Effect of Using Moisture-Buffering Finishing Materials and DCV Systems on Environmental Comfort and Energy Consumption in Buildings. Energies 2024, 17, 3937. https://doi.org/10.3390/en17163937

Kaczorek D, Basińska M. Effect of Using Moisture-Buffering Finishing Materials and DCV Systems on Environmental Comfort and Energy Consumption in Buildings. Energies. 2024; 17(16):3937. https://doi.org/10.3390/en17163937

Chicago/Turabian StyleKaczorek, Dobrosława, and Małgorzata Basińska. 2024. "Effect of Using Moisture-Buffering Finishing Materials and DCV Systems on Environmental Comfort and Energy Consumption in Buildings" Energies 17, no. 16: 3937. https://doi.org/10.3390/en17163937

APA StyleKaczorek, D., & Basińska, M. (2024). Effect of Using Moisture-Buffering Finishing Materials and DCV Systems on Environmental Comfort and Energy Consumption in Buildings. Energies, 17(16), 3937. https://doi.org/10.3390/en17163937