Effect of Environmental and Operating Conditions on Partial Discharge Activity in Electrical Machine Insulation: A Comprehensive Review

Abstract

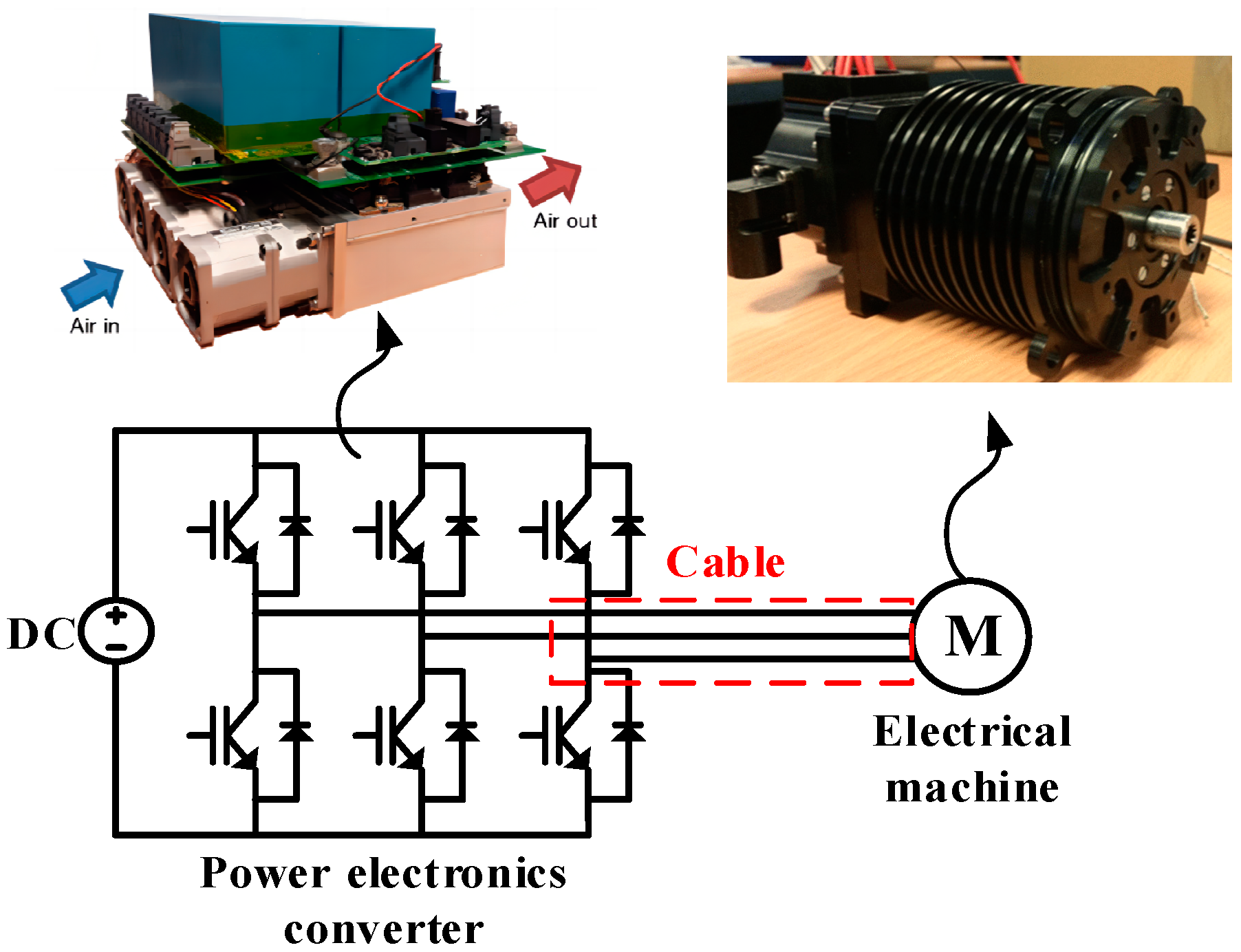

:1. Introduction

2. Effect of Temperature on PD Activity

| Ref. | Temperature Range (°C) | Influencing Factors | Measured Quantity | Test Sample (Insulation Material) | Test Voltage (Impulse Voltage Parameters) |

|---|---|---|---|---|---|

| [17] | 0 to 200 | PDIV, PDEV | Twisted pairs (Grade II Polyesterimide (PEI) + Polyamide-imide (PAI)) | Bipolar impulse (rise time (tr): 80 ns, frequency (f): 60 kHz) | |

| [43] | 25 to 240 | PDIV | Form-winding with Litz wire (Duralco resin, glass fiber, polyimide (PI)) | Sinusoidal | |

| [44] | 20 to 230 | PDIV | Twisted pairs (Grade II PAI) | Unipolar impulse (tr: 150 ns, f: 2.5 kHz) | |

| [45] | 25 to 175 | PDIV, PD-frequency | Twisted pairs | PWM (tr: 225 ns, f: 16 kHz (pulse) and 0.4 kHz (fundamental)) | |

| [46] | 60 to 155 | PD magnitude, PDIV, PD delay | Twisted pairs | Bipolar impulse (tr: 40 ns, duty cycle (dc): 50%, f: 0.05 and 10 kHz) | |

| [47] | 25 to 220 | PDIV | Twisted pairs | Unipolar impulse (tr: 40 ns, dc: 20%, f: 1 kHz) | |

| [48] | 20 to 120 | PRPD patterns | Film (25 μm PI with nano-Al2O3) | Unipolar impulse (tr: 120 ns, dc: 50%, f: 1 kHz) | |

| [49] | 10 to 60 | Different phase | RPDEV | Motor | Impulse |

| [50] | 25 to 155 | RPDIV, capacitance | Motorette | Unipolar impulse (dv/dt: 50 V/s, pulse width (pw): 50 μs, f: 1 kHz) | |

| [51] | 23 to 180 | Insulation material (100 μm PAI, 100 and 130 μm Polyetheretherketone (PEEK)) | PDIV | Twisted pairs | Bipolar impulse (tr: 80 ns, f: 60 kHz) |

| [52] | 25 to 230 | Insulation material (30 μm PAI and PEEK) | PDIV | Twisted pairs | Sinusoidal |

| [53] | 25 to 250 | Insulation material (PI, PI with microcellular coating) | PDIV | Parallel wire | Sinusoidal |

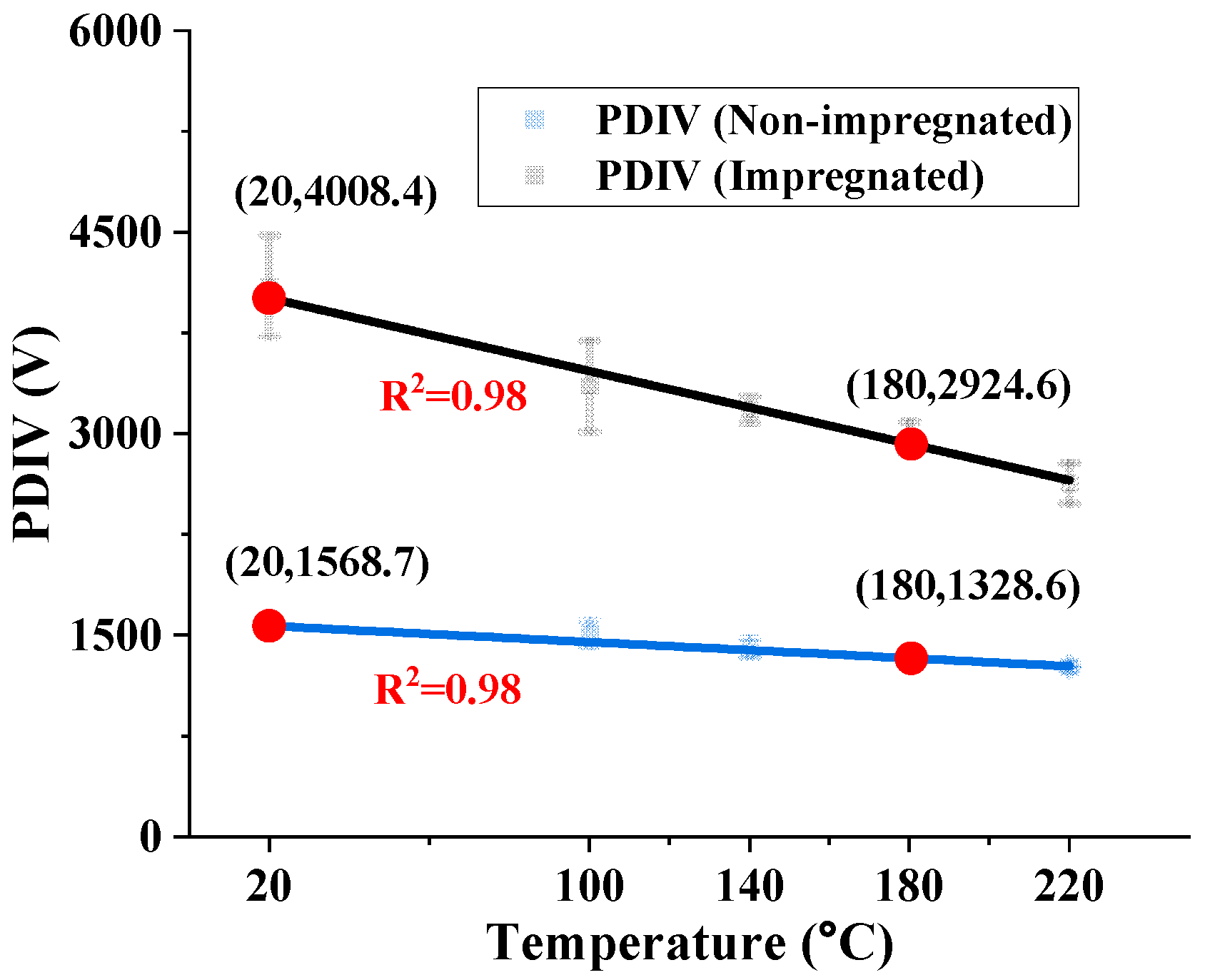

| [54] | 25 to 200 | Impregnation status | PDIV, dielectric spectroscopy | Twisted pairs (35 μm PEI and epoxy-based resin) | Sinusoidal |

| [55] | 20 to 220 | Impregnation status | PDIV, PDEV | Twisted pairs (0.03 mm PEI + PAI and silicon resin) | Unipolar impulse (pw: 0.2 ms) |

| [56] | 24 to 120 | Impregnation status (polyester, epoxy resin) | PDIV, RPDIV | Stator winding | Sinusoidal, unipolar impulse (f: 25 Hz) |

| [57] | Room temperature (RT) and 155 | Impregnation status (PEI, three other non-specified resin) | PDIV, PDEV | Twisted pairs | Sinusoidal |

| [58] | 25 to 180 | Different wire (thermal-bonded, impregnated) | PDIV | Adjacent wire in the slot entrance | Sinusoidal |

| [59] | 25 to 180 | Different wire (thermal-bonded, impregnated) | PDIV | Adjacent wire in the slot entrance | Sinusoidal |

| [60] | 20 to 500 | Wire diameter | PDIV | Two wires with a single contact point (28 μm PEI + PAI, 10 μm ceramic) | Sinusoidal |

| [61] | 20 to 500 | Insulation material (10 μm ceramic, 0.1 mm mica phlogopite, 3–6 μm Al2O3) | PDIV, resistance, tanδ, capacitance | Wire wrapped on a stainless steel | Sinusoidal |

| [62] | 20 to 500 | Sample configuration, impregnation material (air, silicon, cement) | PDIV, resistance, capacitance | Crossed wires, wrapped samples on metallic cylinders, coils | Sinusoidal |

| [63] | 25 to 160 | Rise time (50, 250, 700 ns) | PDIV, RPDIV | Twisted pairs (39 μm PEI + PAI) | Impulse |

| [64] | 25 to 125 | Rise time (250 to 1700 ns), voltage waveform | RPDIV, PDIV | Twisted pairs (0.025 mm PAI) | Sinusoidal, bipolar impulse (f: 2.4 kHz (pulse) and 0.3 kHz (fundamental), dc: 50%) |

| [65] | 20 and 180 | Voltage waveform, different wire | PDIV, PDEV | Twisted pairs | Sinusoidal, bipolar impulse |

| [66] | 24 to 180 | Impregnation status, sample configuration | PDIV | Coil sample, specified designed sample (Grade II PAI with PEI impregnation resin) | Sinusoidal, bipolar impulse (tr: 1 μs, f: 800 Hz) |

| [67] | 25 to 150 | Wire specifications | PDIV | Twisted pairs | Sinusoidal |

| [68] | 20 to 180 | Impregnation status (epoxy and PEI resin) | PDIV | Motorette | Sinusoidal |

| [69] | RT to 230 | PDIV | Twisted pairs | Sinusoidal | |

| [70] | RT and 180 | Insulation material (Kapton film, Nomex paper, Nomex-Mylar-Nomex (NMN) paper), insulation thickness (190 and 240 μm NMN paper, 125 and 175 μm PI-FEP) | PDIV | Motorette, parallel wire | Sinusoidal |

| [71] | 25 and 150 | Wire size | PDIV | Twisted pairs (16 to 43 μm PAI) | Sinusoidal |

| [72] | 25 and 100 | Wire size | PDIV | Twisted pairs | Sinusoidal |

| [73] | 32 to 160 | PDIV, average discharge current, quadratic rate, accumulative apparent current, discharge power | Motor | Sinusoidal | |

| [74] | 20 to 180 | Thermal aging | PDIV, PDEV | Parallel wire (Grade II PEI) | Unipolar impulse (tr: 49 ns, pw: 200μs) |

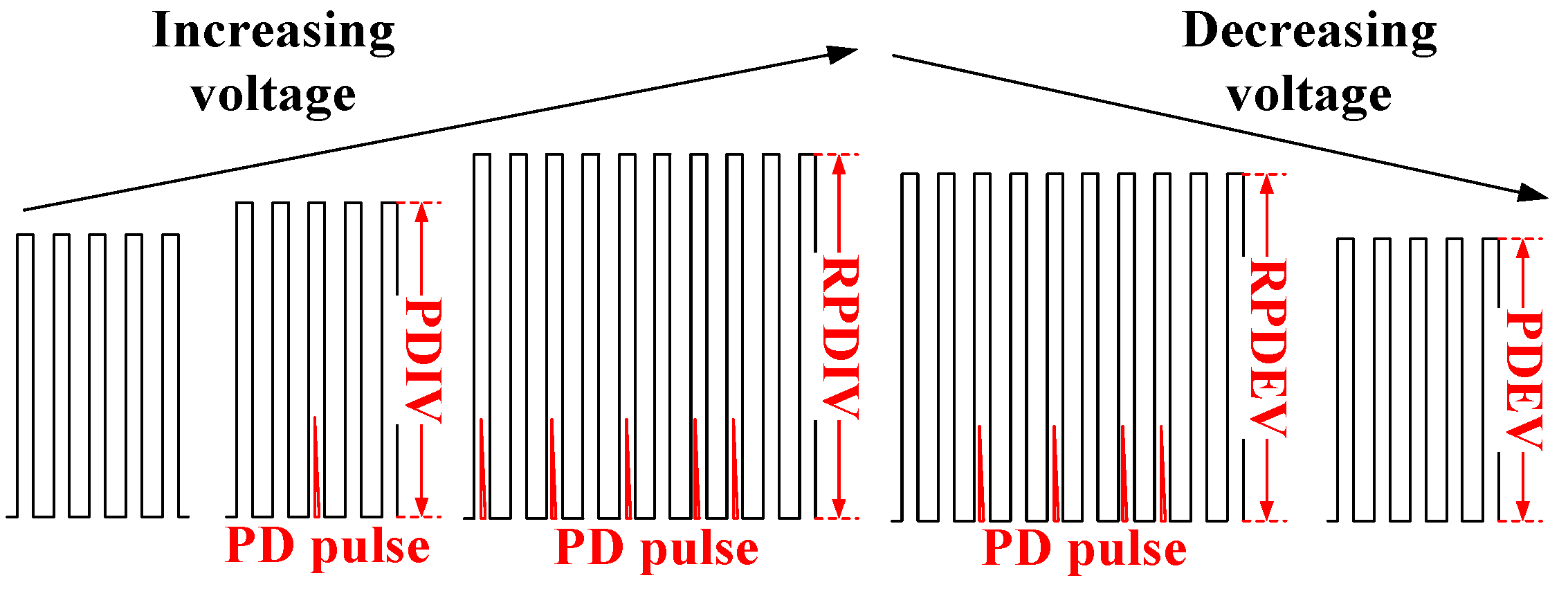

2.1. Influence of Temperature on PD Activity

2.2. Influence of Temperature on PD Activity Considering Different EIS

2.3. Combined Effect of Temperature and Voltage Characteristics on PD Activity

2.4. PD Modeling Approach Considering Temperature Conditions

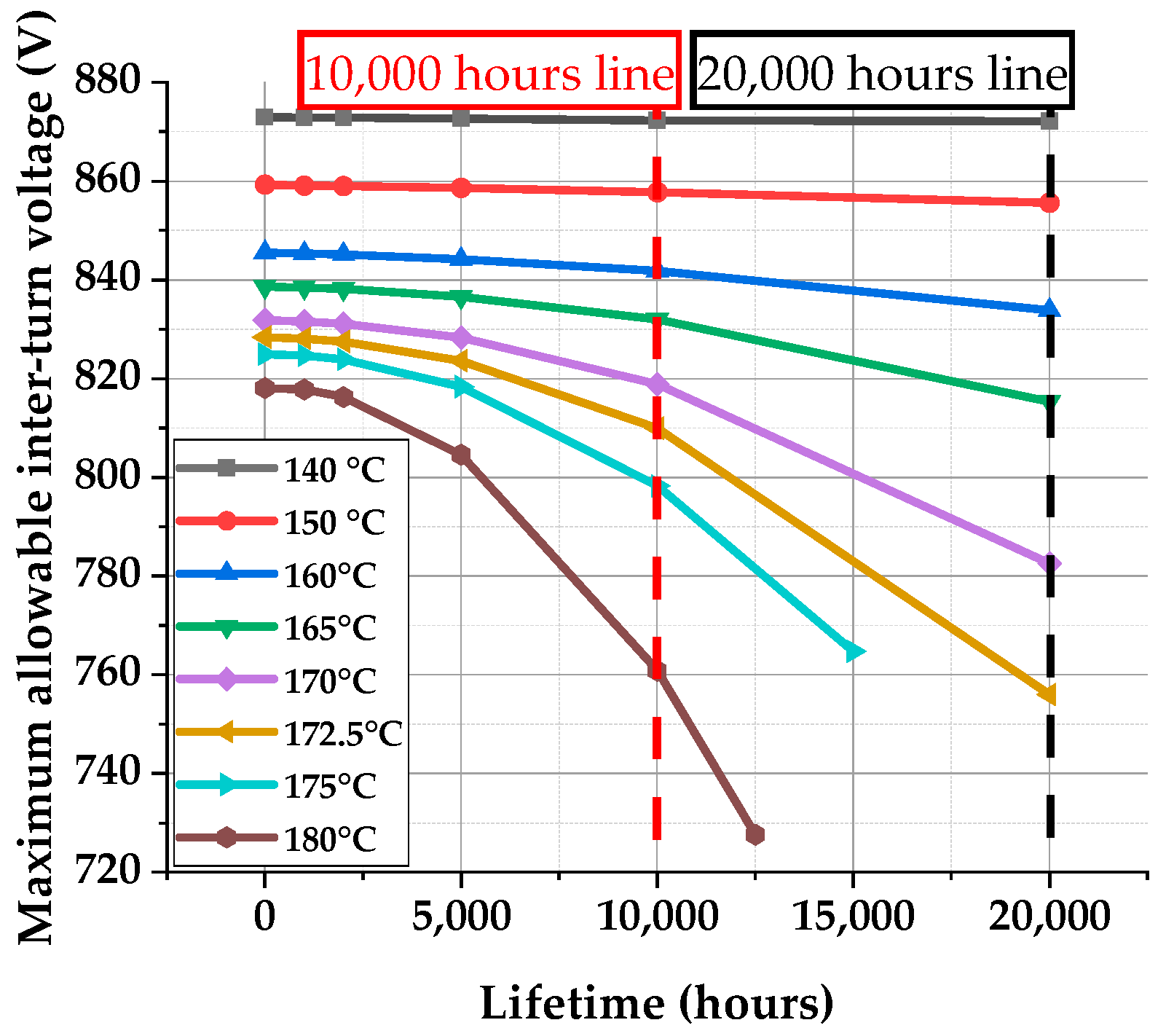

2.5. Application of PD Test Results under Different Temperature Levels

3. Effect of Pressure on PD Activity

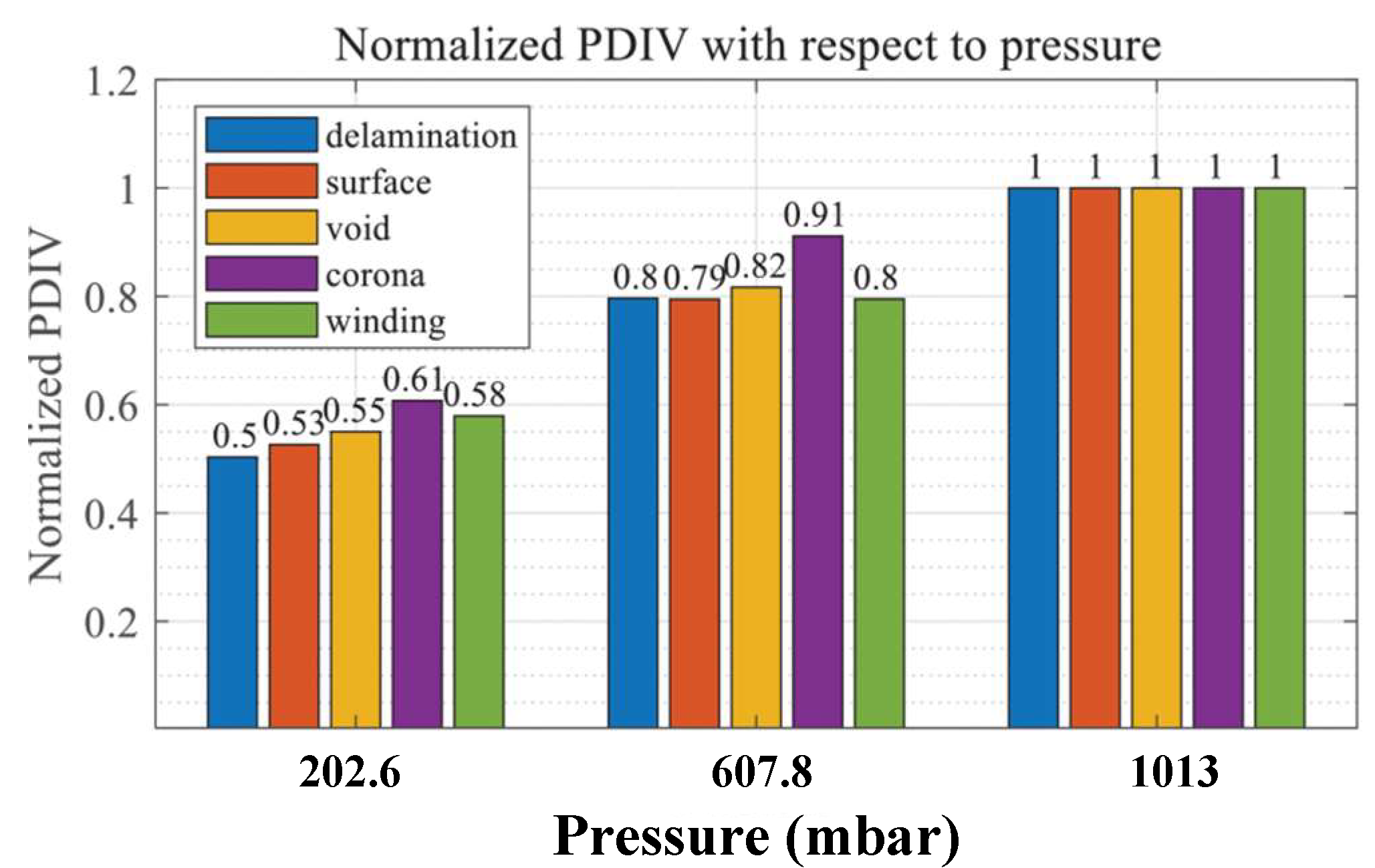

3.1. Influence of Pressure on PD Activity Considering Different EIS

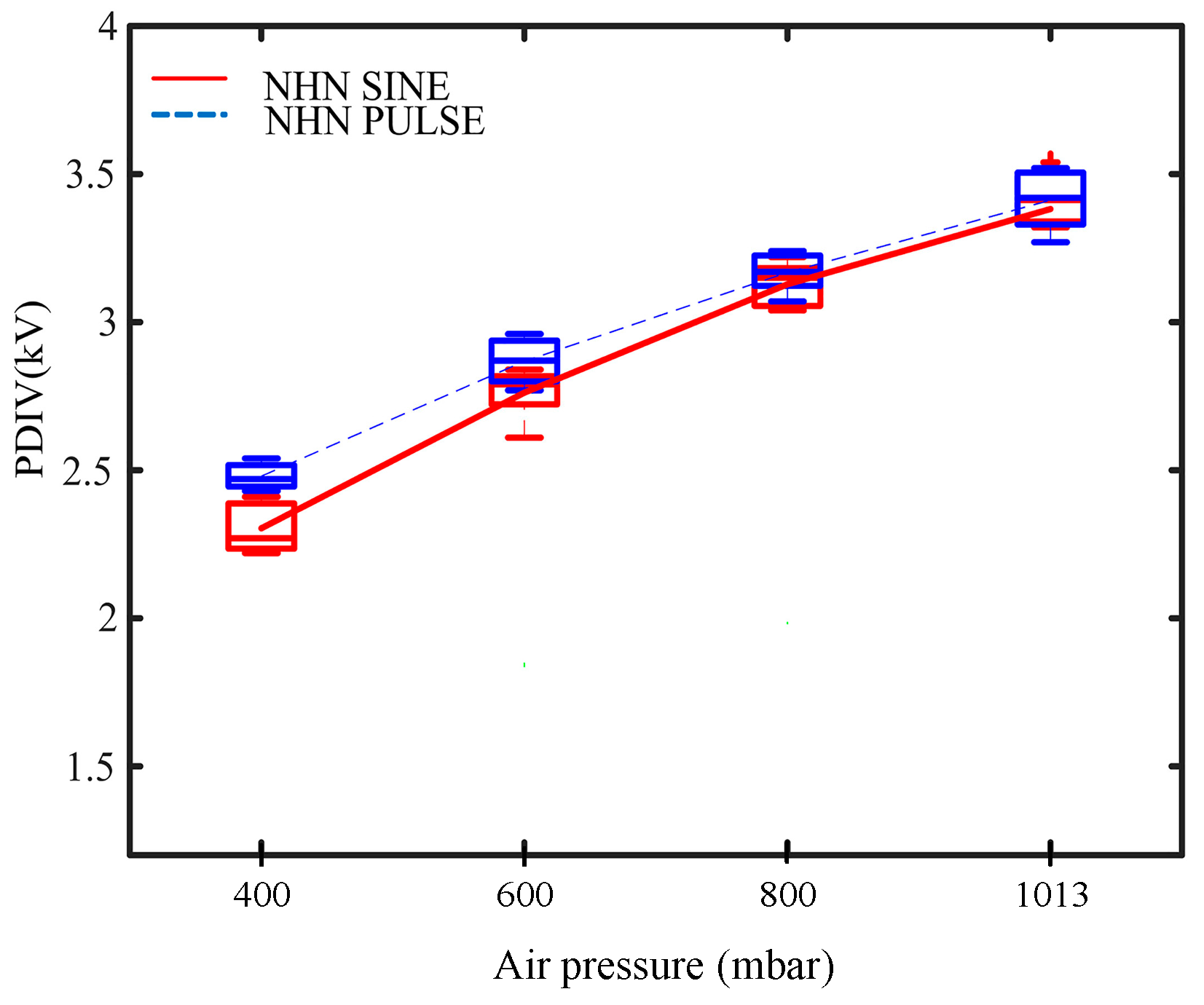

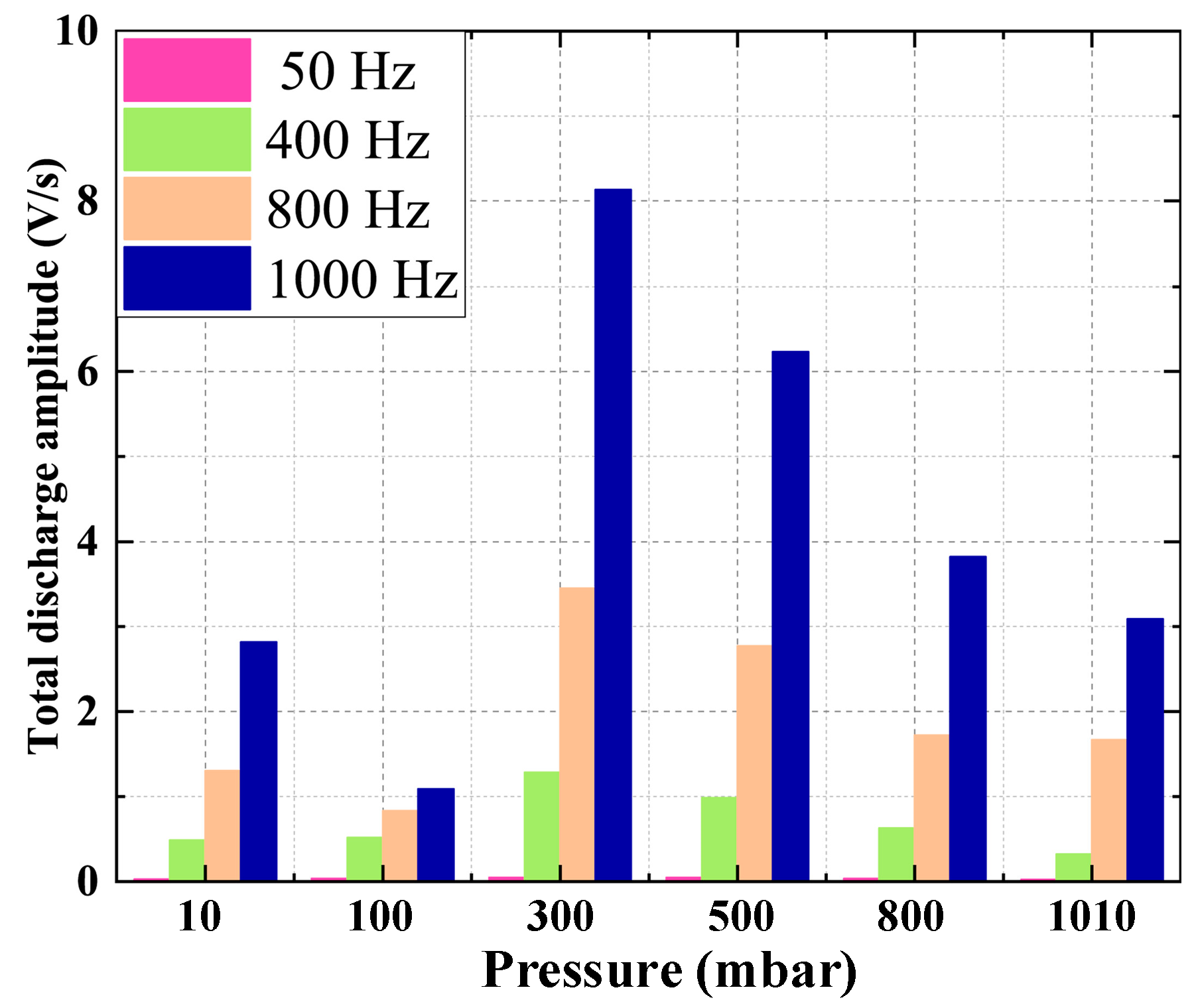

3.2. Combined Effect of Pressure and Voltage Characteristics on PD Activity

3.3. PD Modeling Approach Considering Pressure Conditions

3.4. Application of PD Test Results under Different Pressure Levels

3.5. Influence of Pressure on PD Activity under Variable Temperature Level

4. Effect of Humidity on PD Activity

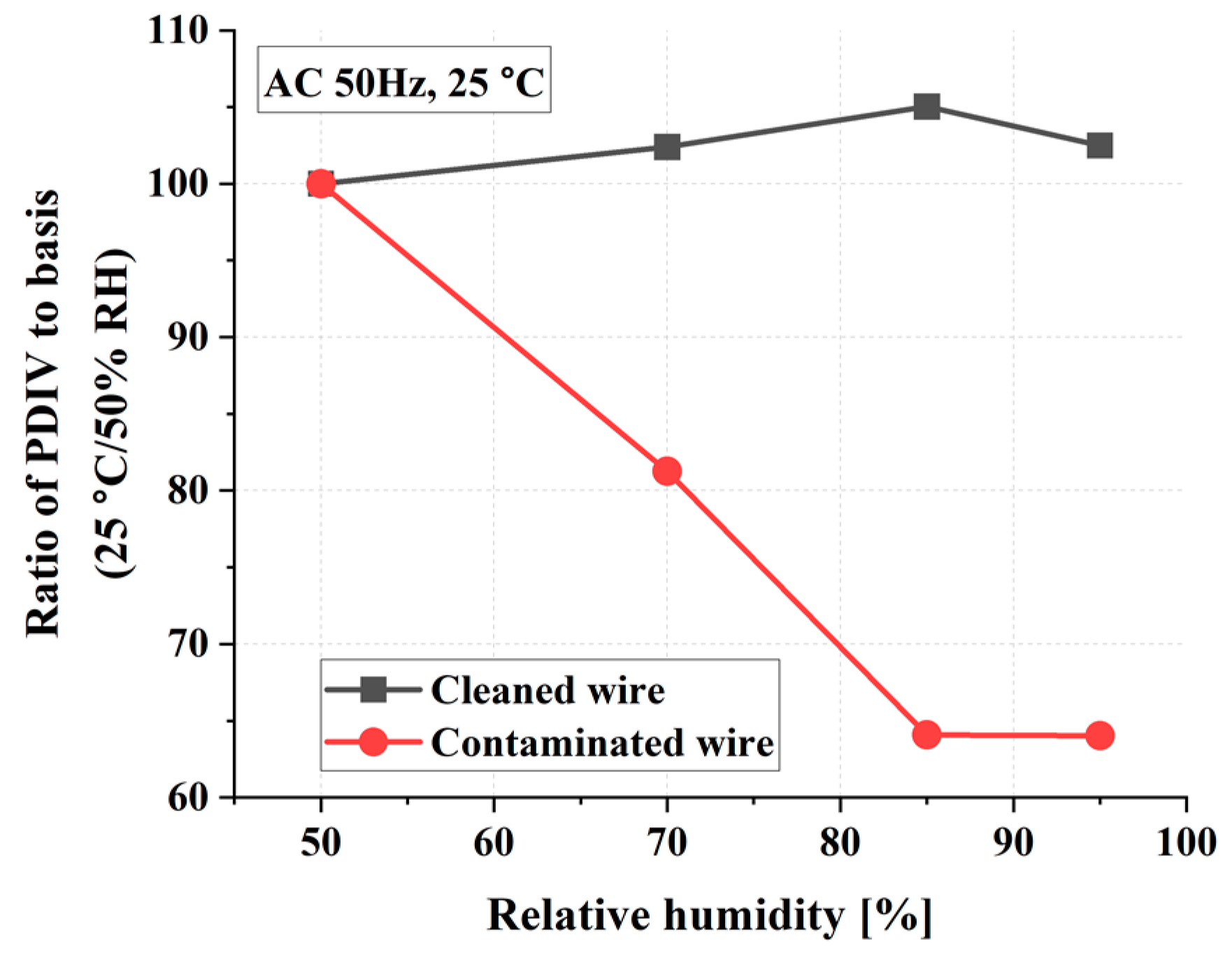

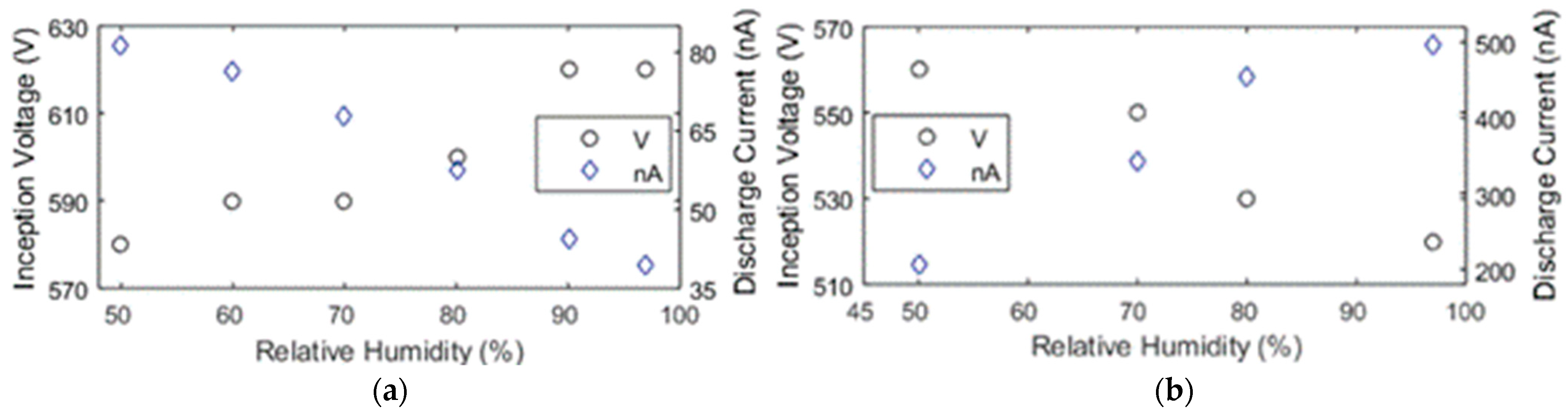

4.1. Influence of Humidity on PD Activity under a Fixed Temperature

| Ref. | RH Range % | Influencing Factors | Measured Quantity | Test Sample (Insulation Material) | Test Voltage (Impulse Voltage Parameters) |

|---|---|---|---|---|---|

| [25] | 40 to 95 | PDIV | Bar-plate electrode (0.1 mm PI film) | Sinusoidal | |

| [45] | 5 to 70 | PDIV, PD-frequency | Twisted pairs | PWM (tr: 225 ns, f: 16 kHz (pulse) and 0.4 kHz (fundamental)) | |

| [47] | 30 to 90 | PDIV | Twisted pairs | Unipolar impulse (tr: 40 ns, dc: 20%, f: 1 kHz) | |

| [49] | 10 to 90 | Different phase | RPDEV | Motor | Impulse |

| [51] | 55 to 100 | Insulation material (100 μm PAI, 100 and 130 μm PEEK) | PDIV | Twisted pairs | Bipolar impulse (tr: 80 ns, f: 60 kHz) |

| [52] | 50 to 95 | Insulation material (40 μm PAI and Polyphenylene-sulfide) | PDIV | Rectangular wire | Sinusoidal |

| [55] | 30 to 90 | Impregnation | PDIV, PDEV | Twisted pairs (0.03 mm PEI + PAI and silicon resin) | Unipolar impulse (pw: 0.2 ms) |

| [103] | 18 to 70 | RPDIV | Stator coil winding | Bipolar impulse (pw: 2.6 ms, tr: 0.14 μs) | |

| [104] | 30 to 90 | RPDIV | Stator coil winding | Bipolar impulse (pw: 7.6 μs, tr: 0.14 μs) | |

| [105] | 33 to 98 | PDIV, surface resistivity, average PD magnitude, number of PD pulses, time lag | CIGRE method II type (1 mm polymethylmethacrylate (PMMA)) | Sinusoidal | |

| [106] | 30 to 90 | Discharge time, PD magnitude | Twisted pairs (PI) | Unipolar impulse (tr: 10 ns, voltage duration: 200 ns) | |

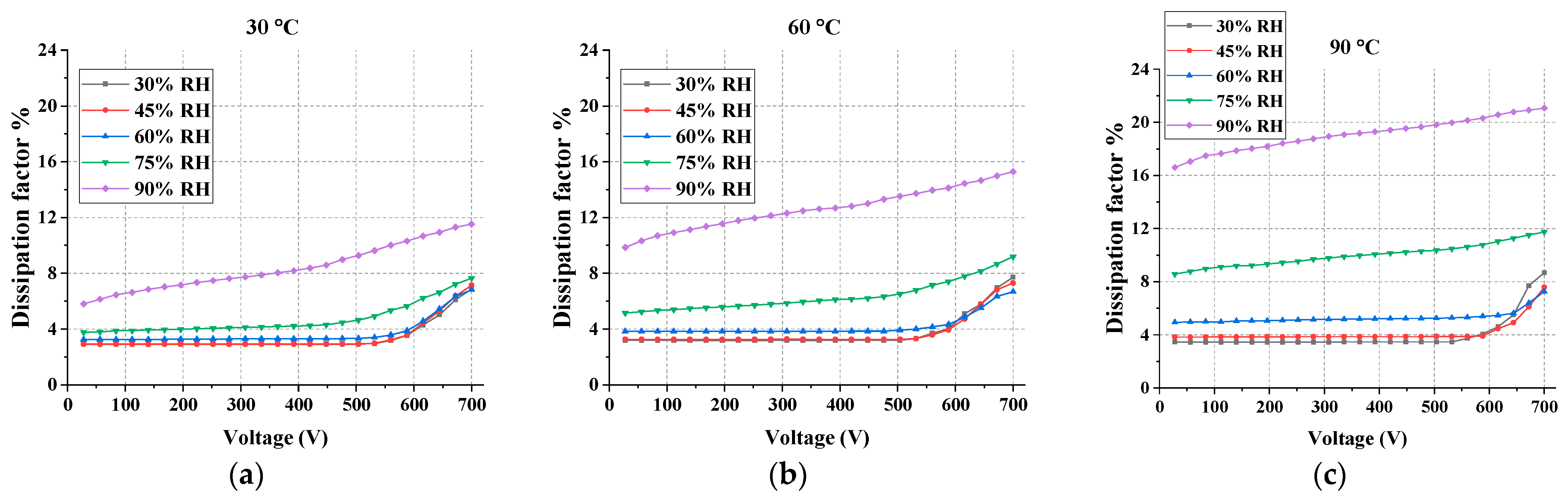

| [107] | 30 to 90 | PDIV, dissipation factor, capacitance | Twisted pairs (Grade II PEI) | Sinusoidal | |

| [108] | 20 and 90 | Pre-discharge time, insulation thickness (40 and 160 μm PAI) | PDIV | Rectangular wire | Sinusoidal |

| [109] | 30 to 90 | Pulse repetition frequency (60 to 106 pulse per second (pps)) | PDIV, RPDIV | Twisted pairs (0.036 mm PAI) | Unipolar impulse |

| [110] | 39 to 89 | Rise time (514, 967 ns) | PDIV | Twisted pairs | Impulse |

| [111] | 30 to 60 | Thermal aging | PDIV, capacitance | Twisted pairs (Grade II PEI) | Sinusoidal |

| Reference Number | RH Range % | Temperature Range (°C) | Influencing Factors | Measured Quantity | Test Sample (Insulation Material) | Test Voltage (Impulse Voltage Parameters) |

|---|---|---|---|---|---|---|

| [17] | 30 to 85 | 20 to 80 | PDIV, PDEV | Twisted pairs (Grade II PEI + PAI) | Bipolar impulse (tr: 80 ns, f: 60 kHz) | |

| [112] | 40 to 95 | 30 to 80 | PDIV, light intensity | Twisted pairs (PEI) | Sinusoidal | |

| [113] | 20 to 95 | 25 to 90 | PDIV, surface conductivity | Twisted pairs (Grade II PEI + PAI) | Sinusoidal | |

| [114] | 50 to 97 | 30 and 90 | PDIV, discharge current, accumulated charge, cumulative energy | Motor | Sinusoidal | |

| [115] | 30 to 80 | 30 to 80 | Insulation material (PEI + with/without nano-sized inorganic material of layered silicate) | PDIV, PD charge, relative permittivity, dielectric loss | Twisted pairs | Sinusoidal |

| [116] | 30 to 90 | 30 to 90 | PDIV, dissipation factor, capacitance | Twisted pairs (0.035 mm PEI) | Sinusoidal | |

| [117] | 20 to 90 | 25 to 90 | PDIV | Twisted pairs (28.5 µm PEI + PAI) | Sinusoidal |

4.2. Combined Effects of Humidity and Other Factors on PD Activity under a Fixed Temperature

4.3. Influence of Humidity on PD Activity under Variable Temperature

5. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bilgin, B.; Magne, P.; Malysz, P.; Yang, Y.; Pantelic, V.; Preindl, M.; Korobkine, A.; Jiang, W.; Lawford, M.; Emadi, A. Making the Case for Electrified Transportation. IEEE Trans. Transp. Electrif. 2015, 1, 4–17. [Google Scholar] [CrossRef]

- Sarlioglu, B.; Morris, C.T. More electric aircraft: Review, challenges, and opportunities for commercial transport aircraft. IEEE Trans. Transp. Electrif. 2015, 1, 54–64. [Google Scholar] [CrossRef]

- Madonna, V.; Giangrande, P.; Galea, M. Electrical Power Generation in Aircraft: Review, Challenges, and Opportunities. IEEE Trans. Transp. Electrif. 2018, 4, 646–659. [Google Scholar] [CrossRef]

- European Environment Agency. Greenhouse Gas Emissions from Transport in Europe. 2020. Available online: https://www.eea.europa.eu/data-and-maps/indicators/transport-emissions-of-greenhouse-gases/transport-emissions-of-greenhouse-gases-12 (accessed on 15 March 2023).

- European Environment Agency. Air Pollution Still Too High across Europe. 2018. Available online: https://www.eea.europa.eu/highlights/air-pollution-still-too-high (accessed on 15 March 2023).

- European Commission JRC Technical Reports. Identifying Key Priorities in Support to the EU Macro-Regional Strategies Implementation; An Ex-Ante Assessment for the Adriatic-Ionian and Alpine Regions Focusing on Clean Growth in Transport and Bioenergy. 2019. Available online: https://www.researchgate.net/publication/331864691_Identifying_key_priorities_in_support_to_the_EU_Macro-regional_Strategies_implementation_An_ex-ante_assessment_for_the_Adriatic-Ionian_and_Alpine_regions_focusing_on_clean_growth_in_transport_and_bioe/references (accessed on 15 March 2023).

- Samaras, Z.; Vouitsis, I. 3.13—Transportation and Energy. In Climate Vulnerability; Pielke, R.A., Ed.; Academic Press: Oxford, UK, 2013; pp. 183–205. [Google Scholar]

- NASA. Global Climate Change; Vital Signs of the Planet; Understanding Our Planet to Benefit Humankind. Available online: https://climate.nasa.gov (accessed on 15 March 2023).

- Giangrande, P.; Galassini, A.; Papadopoulos, S.; Al-Timimy, A.; Calzo, G.L.; Degano, M.; Galea, M.; Gerada, C. Considerations on the development of an electric drive for a secondary flight control electromechanical actuator. IEEE Trans. Ind. Appl. 2019, 55, 3544–3554. [Google Scholar] [CrossRef]

- Aghabali, I.; Bauman, J.; Kollmeyer, P.J.; Wang, Y.; Bilgin, B.; Emadi, A. 800-V Electric Vehicle Powertrains: Review and Analysis of Benefits, Challenges, and Future Trends. IEEE Trans. Transp. Electrif. 2021, 7, 927–948. [Google Scholar] [CrossRef]

- Jiang, J.; Li, Z.; Li, W.; Ranjan, P.; Wei, X.; Zhang, X.; Zhang, C. A review on insulation challenges towards electrification of aircraft. High Volt. 2023, 8, 209–230. [Google Scholar] [CrossRef]

- Seri, P.; Montanari, G.C. A Voltage Threshold in Operating Condition of PWM Inverters and its Impact on Reliability of Insulation Systems in Electrified Transport Applications. IEEE Trans. Transp. Electrif. 2021, 7, 69–77. [Google Scholar] [CrossRef]

- Morya, A.K.; Gardner, M.C.; Anvari, B.; Liu, L.; Yepes, A.G.; Doval-Gandoy, J.; Toliyat, H.A. Wide Bandgap Devices in AC Electric Drives: Opportunities and Challenges. IEEE Trans. Transp. Electrif. 2019, 5, 3–20. [Google Scholar] [CrossRef]

- Ju, X.; Cheng, Y.; Yang, M.; Cui, S.; Sun, A.; Liu, X.; He, M. Voltage Stress Calculation and Measurement for Hairpin Winding of EV Traction Machines Driven by SiC MOSFET. IEEE Trans. Ind. Electron. 2021, 69, 8803–8814. [Google Scholar] [CrossRef]

- Shamsi, P.; McDonough, M.; Fahimi, B. Wide-Bandgap Semiconductor Technology: Its impact on the electrification of the transportation industry. IEEE Electrif. Mag. 2013, 1, 59–63. [Google Scholar] [CrossRef]

- IEC 60034-18-41; Rotating Electrical Machines—Part 18–41: Partial Discharge Free Electrical Insulation Systems (Type I) Used in Rotating Electrical Machines Fed from Voltage Converters—Qualification and Quality Control Tests. IEC Standard: Geneva, Switzerland, 2014.

- Driendl, N.; Pauli, F.; Hameyer, K. Influence of Ambient Conditions on the Qualification Tests of the Interturn Insulation in Low-Voltage Electrical Machines. EEE Trans. Ind. Electron. 2021, 69, 7807–7816. [Google Scholar] [CrossRef]

- Ji, Y.; Giangrande, P.; Zhao, W.; Madonna, V.; Zhang, H.; Galea, M. Determination of electrical aging test voltage level under a low-pressure environment for accurate lifetime prediction. In Proceedings of the 2023 26th International Conference on Electrical Machines and Systems (ICEMS), Zhuhai, China, 5–8 November 2023; pp. 550–554. [Google Scholar] [CrossRef]

- Ji, Y.; Giangrande, P.; Zhao, W.; Madonna, V.; Zhang, H.; Galea, M. Lifetime estimation of corona-resistance wire for electrical machines operating under the partial discharge regime. In Proceedings of the 2023 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Newcastle upon Tyne, UK, 13–14 April 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Rumi, A.; Marinelli, J.G.; Seri, P.; Kohler, M.; Cavallini, A. Performance of Corona Resistant Insulation for Aerospace. In Proceedings of the 2021 IEEE Electrical Insulation Conference (EIC), Denver, CO, USA, 7–28 June 2021; pp. 22–25. [Google Scholar] [CrossRef]

- Zheng, C.; Wang, Q.; Shen, Z.; Bak, C.L.; Da Silva, F.F.; Wang, H. Influence of pressure on the PD and induced aging behavior of polyimide insulation under repetitive pulse voltage. IEEE Trans. Dielectr. Electr. Insul. 2023, 30, 1283–1293. [Google Scholar] [CrossRef]

- Wang, P.; Yu, C.; Akram, S.; Fan, Z.; Zhao, W. Impact of air pressure variations on electrical vehicle motor insulation. High Volt. 2023, 8, 1011–1019. [Google Scholar] [CrossRef]

- Gavrilenko, V.; Leonov, A.; Bukharkin, A.; Hlioui, S.; Lefebvre, S. A Method for Endurance Testing of Enameled Round and Rectangular Wires for Motors Controlled by SiC-based Inverters. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 2091–2098. [Google Scholar] [CrossRef]

- Alkhalid, K.; Wang, J.; Fu, P.; Schweickart, D.; Grosjean, D. Temperature Impact on Partial Discharge Induced Aging of Aviation Wires Under High DV/DT Voltage Excitations. In Proceedings of the 2023 IEEE Workshop on Power Electronics for Aerospace Applications (PEASA), Nottingham, UK, 18–19 July 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Wang, P.; Gu, Y.; Wu, Q.; Cavallini, A.; Zhang, Q.; Zhang, J.; Li, P.; Li, Y. Influence of ambient humidity on PDIV and endurance of inverter-fed motor insulation. In Proceedings of the 2019 IEEE Electrical Insulation Conference (EIC), Calgary, AB, Canada, 16–19 June 2019; IEEE: Piscataway, NJ, USA, 2020; pp. 201–204. [Google Scholar]

- Sili, E.; Cambronne, J.; Naude, N.; Khazaka, R. Polyimide lifetime under partial discharge aging: Effects of temperature, pressure and humidity. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 435–442. [Google Scholar] [CrossRef]

- Lusuardi, L.; Rumi, A.; Cavallini, A.; Barater, D.; Nuzzo, S. Partial Discharge Phenomena in Electrical Machines for the More Electrical Aircraft. Part II: Impact of Reduced Pressures and Wide Bandgap Devices. IEEE Access 2021, 9, 27485–27495. [Google Scholar] [CrossRef]

- Wei, Z.; You, H.; Fu, P.; Hu, B.; Wang, J. Partial Discharge Inception Characteristics of Twisted Pairs under Single Voltage Pulses Generated by Silicon-Carbide Devices. IEEE Trans. Transp. Electrif. 2021, 8, 1674–1683. [Google Scholar] [CrossRef]

- Kaufhold, M.; Borner, G.; Eberhardt, M.; Speck, J. Failure mechanism of the interturn insulation of low voltage electric machines fed by pulse-controlled inverters. IEEE Electr. Insul. Mag. 1996, 12, 9–16. [Google Scholar] [CrossRef]

- Driendl, N.; Pauli, F.; Hameyer, K. Modeling of Partial Discharge Processes in Winding Insulation of Low-Voltage Electrical Machines Supplied by High du/dt Inverters. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; Volume 1, pp. 7102–7107. [Google Scholar] [CrossRef]

- Lusuardi, L.; Rumi, A.; Neretti, G.; Seri, P.; Cavallini, A. Assessing the severity of partial discharges in aerospace applications. In Proceedings of the 2019 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Richland, WA, USA, 20–23 October 2019; pp. 267–270. [Google Scholar] [CrossRef]

- Cavallini, A.; Lusuardi, L.; Meyer, D.R.; Machipeddy, S. Modelling Partial Discharge Inception in magnet wires at different altitudes. In Proceedings of the 2016 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Toronto, ON, Canada, 16–19 October 2016; pp. 449–452. [Google Scholar] [CrossRef]

- Fuerst, M.; Bakran, M. Influence of the PWM Voltage Waveform on Partial Discharge Occurrence in Motor Windings. In Proceedings of the PCIM Europe Digital Days 2020, International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Toronto, ON, Canada, 7–8 July 2020; pp. 1–8. [Google Scholar]

- Kaufhold, M.; Aninger, H.; Berth, M.; Speck, J.; Eberhardt, M. Electrical stress and failure mechanism of the winding insulation in PWM-inverter-fed low-voltage induction motors. IEEE Trans. Ind. Electron. 2000, 47, 396–402. [Google Scholar] [CrossRef]

- Fabiani, D.; Montanari, G.; Cavallini, A.; Mazzanti, G. Relation between space charge accumulation and partial discharge activity in enameled wires under PWM-like voltage waveforms. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 193–205. [Google Scholar] [CrossRef]

- Hayakawa, N.; Morikawa, M.; Okubo, H. Partial discharge inception and propagation characteristics of magnet wire for inverter-fed motor under surge voltage application. IEEE Trans. Dielectr. Electr. Insul. 2007, 14, 39–45. [Google Scholar] [CrossRef]

- Kaji, T.; Asai, H.; Kojima, H.; Hayakawa, N. Combined Effect of Temperature and Humidity of Magnet-Wires on Partial Discharge Inception Voltage under Inverter-Surge Voltage. In Proceedings of the 2018 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Cancun, Mexico, 21–24 October 2018; pp. 554–557. [Google Scholar] [CrossRef]

- Montanari, G.C.; Seri, P.; Hebner, R. Type Of Supply Waveform, Partial Discharge Behavior And Life Of Rotating Machine Insulation Systems. In Proceedings of the 2018 IEEE International Power Modulator and High Voltage Conference (IPMHVC), Jackson, WY, USA, 3–7 June 2018; pp. 176–179. [Google Scholar] [CrossRef]

- Montanari, G.C.; Seri, P. About the Definition of PDIV and RPDIV in Designing Insulation Systems for Rotating Machines Controlled by Inverters. In Proceedings of the 2018 IEEE Electrical Insulation Conference (EIC), San Antonio, TX, USA, 17–20 June 2018; pp. 554–557. [Google Scholar] [CrossRef]

- Hayakawa, N.; Okubo, H. Partial discharge characteristics of inverter-fed motor coil samples under ac and surge voltage conditions. IEEE Electr. Insul. Mag. 2005, 21, 5–10. [Google Scholar] [CrossRef]

- IEC TS 61934:2011; Electrical Insulating Materials and Systems. Electrical Measurement of Partial Discharges (PD) under Short Rise Time and Repetitive Voltage Impulses. IEC Standard: Geneva, Switzerland, 2011.

- Greg, C.S.; Andrea, C.; Glenn, B.; Angelo, S.C. PD Measurement System Instrumentation and Software. In Practical Partial Discharge Measurement on Electrical Equipment; IEEE: Piscataway, NJ, USA, 2023; pp. 159–191. [Google Scholar]

- Balachandran, T.; Sirimmana, S.; Jin, A.; Haran, K.S. Partial Discharge Testing of Form-Wound Air-Core Armature Windings for a High-Frequency PMSM for Electric Aircraft Applications. In Proceedings of the 2018 IEEE International Conference on Information and Automation for Sustainability (ICIAfS), Colombo, Sri Lanka, 21–22 December 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Madonna, V.; Giangrande, P.; Zhao, W.; Zhang, H.; Gerada, C.; Galea, M. Electrical Machines for the More Electric Aircraft: Partial Discharges Investigation. IEEE Trans. Ind. Appl. 2020, 57, 1389–1398. [Google Scholar] [CrossRef]

- Busch, R.; Pohlmann, F.; Muller, K. The influence of several environmental conditions on the partial discharge characteristics and on the lifetime of magnet wires under inverter pulse operation. In Proceedings of the 2001 International Symposium on Electrical Insulating Materials (ISEIM 2001). 2001 Asian Conference on Electrical Insulating Diagnosis (ACEID 2001). 33rd Symposium on Electrical and Ele, Himeji, Japan, 22 November 2001; pp. 645–648. [Google Scholar] [CrossRef]

- Wang, P.; Xu, H.; Wang, J.; Cavallini, A.; Montanari, G.C. Temperature effects on PD statistics and endurance of inverter-fed motor insulation under repetitive square wave voltages. In Proceedings of the 2016 IEEE Electrical Insulation Conference (EIC), Montreal, QC, Canada, 19–22 June 2016; pp. 202–205. [Google Scholar] [CrossRef]

- Ji, Y.; Giangrande, P.; Zhao, W.; Madonna, V.; Zhang, H.; Galea, M. Determination of Dominant Influencing Factors on Partial Discharge Inception Voltage. In Proceedings of the 2023 IEEE 14th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Chania, Greece, 28–31 August 2023; pp. 324–329. [Google Scholar] [CrossRef]

- Luo, Y.; Wu, G.N.; Jia, P.; Liu, J.W.; Wang, P.; Cao, K.J.; Cui, Y. Partial discharge characteristics of polyimide films used in inverter-fed traction motor under different temperatures. In Proceedings of the 2013 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Chenzhen, China, 20–23 October 2013; pp. 809–812. [Google Scholar] [CrossRef]

- Weisenseel, L.; Sieling, D.; Gudelhofer, J. Increasing the Reproducibility of Impulse PD Measurements and Development of an Online Interturn Fault Monitoring Routine for External Rotor Motors. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020; Volume 1, pp. 1356–1362. [Google Scholar] [CrossRef]

- Nishigaki, Y.; Matsuzoe, T.; Kubo, T.; Nakano, Y.; Kozako, M.; Hikita, M.; Nakamura, T.; Sun, J.; Izumi, A.; Sakurai, T.; et al. Temperature Dependence of RPDIV of Motorette Sample with Varnish Treatment. In Proceedings of the 2019 IEEE Electrical Insulation Conference (EIC), Calgary, AB, Canada, 16–19 June 2019; IEEE: Piscataway, NJ, USA, 2020; pp. 18–21. [Google Scholar]

- He, C.; Beltle, M.; Tenbohlen, S.; Hubert, T.; Schmidt, S.; Schneider, J. Partial Discharge Characteristic of Hairpin Windings for Inverter-Fed Motors. In Proceedings of the 2022 IEEE 4th International Conference on Dielectrics (ICD), Palermo, Italy, 3–7 July 2022; pp. 49–52. [Google Scholar] [CrossRef]

- Muto, D.; Oya, M.; Aoi, T.; Ueno, T. A study on partial discharge phenomena of winding wires. Furukawa Rev. 2014, 45, 13–21. [Google Scholar]

- Ota, S.; Yamauchi, M.; Mizoguchi, A.; Yoshida, K. Rectangular Magnet Wire for Electric and Hybrid Electric Inverter-Drive Motors. SEI Tech. Rev. 2019, 88, 44–48. [Google Scholar]

- Rumi, A.; Seri, P.; Cavallini, A. Electric Field Distribution at High Temperatures in Impregnated Enameled Conductors Used in Electrical Machines. In Proceedings of the 2023 International Symposium on Electrical Insulating Materials (ISEIM), Shimane, Japan, 24–28 September 2023; pp. 1–4. [Google Scholar] [CrossRef]

- Ji, Y.; Giangrande, P.; Zhao, W.; Madonna, V.; Zhang, H.; Galea, M. Derivation of Ambient Enhancement Factors of Impregnated Twisted pairs for Partial Discharge Risk Evaluation. IEEE Trans. Transp. Electrif. 2023, 10, 485–495. [Google Scholar] [CrossRef]

- Guastavino, F.; Rossi, F.; Gianoglio, C.; Torello, E.; Cordano, D. PDIV and RPDIV on different temperatures on different kind of type I insulating system. In Proceedings of the 2017 IEEE Conference on Electrical Insulation and Dielectric Phenomenon (CEIDP), Fort Worth, TX, USA, 22–25 October 2017; pp. 369–372. [Google Scholar] [CrossRef]

- Rumi, A.; Cavallini, A.; Marinelli, J. The Impact of Impregnating Resins in Ensuring the Reliability of Inverter-Fed Machines. In Proceedings of the 2020 International Symposium on Electrical Insulating Materials (ISEIM), Tokyo, Japan, 13–17 September 2020; pp. 253–256. [Google Scholar]

- Duchesne, S.; Moeneclaey, J.; Velu, G.; Roger, D. Is thermo-bonded coils a good solution for electric machines fed by fast PWM inverters? In Proceedings of the 2014 IEEE Electrical Insulation Conference (EIC), Philadelphia, PA, USA, 8–11 June 2014; pp. 425–429. [Google Scholar] [CrossRef]

- Boughamni, W.; Manata, J.-P.; Ait-Amar, S.; Roger, D. Electrical machines insulation: Towards low environmental impact solutions. In Proceedings of the 2013 IEEE International Conference on Solid Dielectrics (ICSD), Bologna, Italy, 30 June–4 July 2013; pp. 557–560. [Google Scholar] [CrossRef]

- Iosif, V.; Roger, D.; Duchesne, S.; Malec, D. Assessment and improvements of inorganic insulation for high temperature low voltage motors. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2534–2542. [Google Scholar] [CrossRef]

- Cozonac, D.; Mihaila, V.; Velu, G.; Duchesne, S.; Lecointe, J.-P.; Roger, D. Performance comparision of winding wires for high-temperature rotating machines. In Proceedings of the 2013 IEEE International Conference on Solid Dielectrics (ICSD), Bologna, Italy, 30 June–4 July 2013; pp. 318–321. [Google Scholar] [CrossRef]

- Cozonac, D.; Babicz, S.; Ait-Amar-Djennad, S.; Velu, G.; Cavalini, A.; Wang, P. Study on ceramic insulation wires for motor windings at high-temperature. In Proceedings of the 2014 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Des Moines, IA, USA, 19–22 October 2014; pp. 172–175. [Google Scholar] [CrossRef]

- Zenda, Y.; Takenouchi, S.; Kozako, M.; Hikita, M.; Okamoto, T.; Jintong, S.; Izumi, A.; Karasawa, K. Effect of Temperature on RPDIV of Enamel Twisted Pair under Repetitive Impulse Voltage Application with Different Rise Time. In Proceedings of the 2021 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Vancouver, BC, Canada, 12–15 December 2021; pp. 603–606. [Google Scholar] [CrossRef]

- Guastavino, F.; Cotella, G.; Dardano, A.; Massa, G.F.; Ratto, A.; Squarcia, S.; Torello, E. Influence of the rise time and of the temperature on the PD inception voltage of enameled wires. In Proceedings of the 2010 Annual Report Conference on Electrical Insulation and Dielectic Phenomena, West Lafayette, IN, USA, 17–20 October 2010; pp. 1–4. [Google Scholar] [CrossRef]

- Hammarstroem, T.J. Evaluation of Different Waveforms to Study the Insulation Performance on Electrical Vehicle Motors. In Proceedings of the 2022 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Denver, CO, USA, 30 October–2 November 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Sahlén, F.; Takala, M. Factors influencing the partial discharge inception voltage in Type I insulation systems. In Proceedings of the 2023 IEEE Electrical Insulation Conference (EIC), Quebec City, QC, Canada, 18–21 June 2023; pp. 1–4. [Google Scholar] [CrossRef]

- La De Calle, M.G.; Martinez-Tarifa, J.M.; Solanilla, A.M.G.; Robles, G. Uncertainty Sources in the Estimation of the Partial Discharge Inception Voltage in Turn-to-Turn Insulation Systems. IEEE Access 2020, 8, 157510–157519. [Google Scholar] [CrossRef]

- Rain, P.; Loubeau, F.; Durieux, A.; Le Strat, F.; Fresnet, F. Using motorettes for the experimental and numerical determinations of the PDIV in an electric motor. In Proceedings of the 2016 IEEE International Conference on Dielectrics (ICD), Montpellier, France, 3–7 July 2016; Volume 2, pp. 967–970. [Google Scholar] [CrossRef]

- Kaji, T.; Amano, Y.; Asai, H. Analysis of Influence Factors for Partial Discharge Inception Voltage between Magnet-Wires on Rotating Machines. In Proceedings of the SAE 2016 World Congress and Exhibition, Detroit, MI, USA, 12–14 April 2016. [Google Scholar] [CrossRef]

- Gao, J.; Rumi, A.; He, Y.; Cavallini, A. Towards a Holistic Approach to Inverter-Fed Machine Design: FEM-Based PDIV Prediction of Complete Windings. IEEE Trans. Dielectr. Electr. Insul. 2023, 30, 2870–2877. [Google Scholar] [CrossRef]

- Lusuardi, L.; Cavallini, A.; de la Calle, M.G.; Martinez-Tarifa, J.M.; Robles, G. Insulation design of low voltage electrical motors fed by PWM inverters. IEEE Electr. Insul. Mag. 2019, 35, 7–15. [Google Scholar] [CrossRef]

- Li, P.; Zhang, X.; Wang, P.; Wang, J.; Shang, Z. A data-driven approach for exploring partial discharge inception voltage of turn-to-turn insulation in inverter-fed motors. Electr. Eng. 2023, 105, 2861–2870. [Google Scholar] [CrossRef]

- Hassan, W.; Hussain, G.A.; Mahmood, F.; Shafiq, M.; Montanari, G.C. Effects of Temperature and Pressure on Failure Risk of Electric Motors based on Partial Discharge Measurements. IEEE Trans. Aerosp. Electron. Syst. 2023, 59, 5624–5633. [Google Scholar] [CrossRef]

- Ji, Y.; Giangrande, P.; Zhao, W.; Madonna, V.; Zhang, H.; Galea, M. Determination of Hotspot Temperature Margin for Rectangular Wire Windings Considering Insulation Thermal Degradation and Partial Discharge. IEEE Trans. Transp. Electrif. 2023, 10, 2057–2069. [Google Scholar] [CrossRef]

- Madonna, V.; Migliazza, G.; Giangrande, P.; Lorenzani, E.; Buticchi, G.; Galea, M. The rebirth of the current source inverter: Advantages for aerospace motor design. IEEE Ind. Electron. Mag. 2019, 13, 65–76. [Google Scholar] [CrossRef]

- Kuffel, J.; Kuffel, P.; Kuffel, J. High Voltage Engineering Fundamentals; Elsevier Science & Technology: Oxford, UK, 2000. [Google Scholar]

- Haghighi, H.; Cotton, I.; Gardner, R.; Sauvage, B. Definitions of Test Conditions for High Voltage Aerospace Systems Using the IAGOS Atmospheric Dataset. In Proceedings of the Aerospace Systems and Technology Conference, Warrendale, PA, USA, 6–8 November 2018. [Google Scholar] [CrossRef]

- Han, Q.; Chen, L.; Cotton, I.; Khan, J. Insulating Gases for Partial Discharge Management of Electrical Machines in Aerospace Applications. IEEE Trans. Transp. Electrif. 2023, 9, 3590–3600. [Google Scholar] [CrossRef]

- Billard, T.; Abadie, C.; Taghia, B. Non-intrusive partial discharges investigations on aeronautic motors. In Proceedings of the SAE 2016 (Aerospace and Technology Conference-ASTC), Tampa, FL, USA, 20–25 September 2016; pp. 1–18. [Google Scholar]

- Billard, T.; Abadie, C.; Lebey, T. Partial discharge testing in aeronautic environment on magnet wire and feeder cables. In Proceedings of the 2016 IEEE Electrical Insulation Conference (EIC), Montreal, QC, Canada, 19–22 June 2016; pp. 101–104. [Google Scholar] [CrossRef]

- Rui, R.; Cotton, I. Impact of low pressure aerospace environment on machine winding insulation. In Proceedings of the 2010 IEEE International Symposium on Electrical Insulation, San Diego, CA, USA, 6–9 June 2010; pp. 1–5. [Google Scholar] [CrossRef]

- Rumi, A.; Marinelli, J.G.; Barater, D.; Cavallini, A.; Seri, P. The challenges of reliable dielectrics in modern aerospace applications: The hazard of Corona Resistant materials. IEEE Trans. Transp. Electrif. 2022, 8, 4646–4653. [Google Scholar] [CrossRef]

- Wang, Y.; Balachandran, T.; Hoole, Y.; Yin, Y.; Haran, K.S. Partial Discharge Investigation of Form-Wound Electric Machine Winding for Electric Aircraft Propulsion. IEEE Trans. Transp. Electrif. 2020, 6, 1638–1647. [Google Scholar] [CrossRef]

- Wei, Z.; Kasten, D.G.; Hu, B.; Abdullah, Y.; Wang, J.; Grosjean, D.; Schweickart, D. Study of Partial Discharge Behavior at Flight-Altitude Pressures under 60 Hz and Impulse Voltages for Samples Related to Aircraft Motors. In Proceedings of the 2018 IEEE International Power Modulator and High Voltage Conference (IPMHVC), Jackson, WY, USA, 3–7 June 2018; IEEE: Piscataway, NJ, USA, 2019; pp. 180–185. [Google Scholar]

- Gardner, R.; Cotton, I.; Kohler, M. Comparison of power frequency and impulse based Partial Discharge measurements on a variety of aerospace components at 1000 and 116 mbar. In Proceedings of the 2015 IEEE Electrical Insulation Conference (EIC), Seattle, WA, USA, 7–10 June 2015; pp. 430–433. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, B.; Li, Z.; Zhang, C.; Ranjan, P.; Zhang, X. Partial Discharge Investigation under Low Air Pressure and Variable Frequency for More-electric-aircraft. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 1793–1801. [Google Scholar] [CrossRef]

- Wei, Z.; Alkhalid, K.; Alsaif, F.; Wang, J.; Grosjean, D.; Schweickart, D. Study of Partial Discharge Inception Characteristics of Aviation Wire Stressed by PWM Voltages Under Various Air Pressures. In Proceedings of the 2022 IEEE International Power Modulator and High Voltage Conference (IPMHVC), Knoxville, TN, USA, 19–23 June 2022; pp. 133–136. [Google Scholar] [CrossRef]

- Meyer, D.R.; Cavallini, A.; Lusuardi, L.; Barater, D.; Pietrini, G.; Soldati, A. Influence of impulse voltage repetition frequency on RPDIV in partial vacuum. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 873–882. [Google Scholar] [CrossRef]

- Pietrini, G.; Barater, D.; Franceschini, G.; Mancinelli, P.; Cavallini, A. An open problem for More Electrical Aircraft (MEA): How insulation systems of actuators can be qualified? In Proceedings of the 2016 IEEE Energy Conversion Congress and Exposition (ECCE), Milwaukee, WI, USA, 18–22 September 2016; pp. 1–8. [Google Scholar] [CrossRef]

- Emersic, C.; Cotton, I. Experimental comparison of partial discharge between fast-switching pulse waves and square waves. J. Phys. D Appl. Phys. 2022, 55, 385502. [Google Scholar] [CrossRef]

- Abadie, C.; Billard, T.; Lebey, T. Partial Discharges in Motor Fed by Inverter: From Detection to Winding Configuration. IEEE Trans. Ind. Appl. 2019, 55, 1332–1341. [Google Scholar] [CrossRef]

- Naderiallaf, H.; Ji, Y.; Giangrande, P.; Galea, M. Air Pressure Impact on the Avalanche Size for Turn-to-Turn Insulation of Inverter-Fed Motors. IEEE Trans. Dielectr. Electr. Insul. 2024, 31, 85–94. [Google Scholar] [CrossRef]

- Taghia, B.; Billard, T.; Carayon, J.-P.; Malec, D.; Piquet, H.; Belinger, A. Investigations on Partial Discharges Risk in Aeronautical Rotating Machine Fed by HVDC 540VDC Network. In Proceedings of the 2018 IEEE Electrical Insulation Conference (EIC), San Antonio, TX, USA, 17–20 June 2018; pp. 491–494. [Google Scholar] [CrossRef]

- Niemeyer, L. A generalized approach to partial discharge modeling. IEEE Trans. Dielectr. Electr. Insul. 1995, 2, 510–528. [Google Scholar] [CrossRef]

- Fulnecek, J.; Kabot, O.; Kedron, P. Partial discharges analysis of electrical machine winding in low pressure enviroment. In Proceedings of the 2022 International Conference on Diagnostics in Electrical Engineering (Diagnostika), Pilsen, Czech Republic, 6–8 September 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Sun, H.; Wang, Y.; Ding, Y.; Rui, Y.; Fan, L.; Yin, Y. Partial Discharge Detection of Electrical Machine Insulation Under PWM Voltage with High dv/dt for More Electric Aircraft. In Proceedings of the 2022 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 9–13 October 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Ji, Y.; Giangrande, P.; Zhao, W.; Wang, H.; Madonna, V.; Zhang, H.; Galea, M. Moving Towards Partial Discharge-Free Design of Electrical Machines for More Electric Aircraft Applications. IEEE Trans. Transp. Electrif. 2023, 9, 4668–4679. [Google Scholar] [CrossRef]

- Naderiallaf, H.; Ji, Y.; Giangrande, P.; Galea, M. Temperature Impact on PDIV for Turn-to-Turn Insulation of Inverter-Fed Motors: From Ground Level to Cruising Altitude. IEEE Trans. Dielectr. Electr. Insul. 2023, 31, 1044–1053. [Google Scholar] [CrossRef]

- Wang, Y.; Yi, X.; Wang, Y.; Zhang, X.; Yin, Y.; Han, T.; Haran, K.S. Partial-Discharge-Free Insulation Design of Air-Core Permanent Magnet Synchronous Machine for Aircraft Propulsion. IEEE Trans. Transp. Electrif. 2020, 7, 78–90. [Google Scholar] [CrossRef]

- Ji, Y.; Giangrande, P.; Wang, H.; Zhao, W.; Madonna, V.; Zhang, H.; Galea, M. Time-to-failure analysis of short-duty cycle, inverter-fed electrical machines exposed to prevailing electrical stress. IEEE Trans. Aerosp. Electron. Syst. 2023, 59, 9368–9378. [Google Scholar] [CrossRef]

- Hoffmann, J.; Linde, T.; Schlegel, S.; Schulz, F.; Machetti, D. PDIV Measurements on Aviation Electric Motor Insulation Systems—Influence of Operating Temperature and Low Air Pressure. In Proceedings of the Elektromechanische Antriebssysteme 2023, 9. Fachtagung (VDE OVE), Wien, Österreich, 8–9 November 2023; pp. 112–117. [Google Scholar]

- Ji, Y.; Giangrande, P.; Zhao, H.; Zhao, W.; Madonna, V.; Zhang, H.; Galea, M. Electrical Machine Design Considering Corona-Resistant Wire for More Electric Aircraft Applications. IEEE Trans. Transp. Electrif. 2022, 9, 3192–3202. [Google Scholar] [CrossRef]

- Kikuchi, Y.; Ishida, T.; Ueno, T.; Kanazawa, S.; Nagao, M.; Hikita, M.; Murakami, Y.; Nagata, M. Recent progress in round-robin test of repetitive partial discharge inception voltage measurements on complete winding of 4 Kw random-wound motor. In Proceedings of the 2017 International Symposium on Electrical Insulating Materials (ISEIM), Toyohashi, Japan, 11–15 September 2017; Volume 1, pp. 159–162. [Google Scholar] [CrossRef]

- Kikuchi, Y.; Nagata, M.; Kanazawa, S.; Ishida, T.; Nagao, M.; Murakami, Y.; Ueno, T.; Hikita, M. Round-robin test of repetitive partial discharge inception voltage measurements on complete winding of 4 kW random-wound motor. In Proceedings of the 2016 IEEE Electrical Insulation Conference (EIC), Montreal, QC, Canada, 19–22 June 2016; pp. 248–251. [Google Scholar] [CrossRef]

- Nawawi, Z.; Murakami, Y.; Hozumi, N.; Nagao, M. Effect of Humidity on Time Lag of Partial Discharge in Insulation-Gap-Insulation System. In Proceedings of the 2006 IEEE 8th International Conference on Properties & applications of Dielectric Materials, Bali, Indonesia, 26–30 June 2006; pp. 199–203. [Google Scholar] [CrossRef]

- Wang, P.; Li, Y.; Cavallini, A.; Zhang, J.; Xiang, E.; Wang, K. The Influence of Relative Humidity on Partial Discharge and Endurance Features under Short Repetitive Impulsive Voltages. In Proceedings of the 2018 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Cancun, Mexico, 21–24 October 2018; pp. 506–509. [Google Scholar] [CrossRef]

- Ji, Y.; Giangrande, P.; Zhao, W.; Madonna, V.; Zhang, X.; Zhang, H.; Galea, M. Partial discharge investigation under humidity conditions via dissipation factor and insulation capacitance tip-up test. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 1483–1490. [Google Scholar] [CrossRef]

- Wakimoto, T.; Kojima, H.; Hayakawa, N. Measurement and evaluation of partial discharge inception voltage for enameled rectangular wires under AC voltage. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 3566–3574. [Google Scholar] [CrossRef]

- Kikuchi, Y.; Matsusue, J.; Yamada, F.; Okuda, T.; Nishimura, Y.; Nakamura, T. Partial Discharge Characteristics in Twisted Enameled Wires Under High Repetition Voltage Pulses Generated by a SiC-MOSFET Inverter Power Supply. In Proceedings of the 2023 International Symposium on Electrical Insulating Materials (ISEIM), Shimane, Japan, 24–28 September 2023; pp. 80–83. [Google Scholar] [CrossRef]

- Fenger, M.; Stone, G.; Lloyd, B. The impact of humidity on PD inception voltage as a function of rise-time in random wound motors of different designs. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Cancun, Mexico, 20–24 October 2002; pp. 501–505. [Google Scholar] [CrossRef]

- Ji, Y.; Giangrande, P.; Madonna, V.; Zhao, W.; Galea, M.; Li, J.; Zhang, H. Investigation on Humidity Effect on Partial Discharge Considering Thermal Aging. In Proceedings of the 2022 International Conference on Electrical Machines (ICEM), Valencia, Spain, 5–8 September 2022; pp. 2325–2330. [Google Scholar] [CrossRef]

- Kikuchi, Y.; Murata, T.; Fukumoto, N.; Nagata, M.; Wakimoto, Y.; Yoshimitsu, T. Investigation of partial discharge with twisted enameled wires in atmospheric humid air by optical emission spectroscopy. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 839–845. [Google Scholar] [CrossRef]

- Rumi, A.; Cavallini, A.; Lusuardi, L. Combined Effects of Temperature and Humidity on the PDIV of Twisted Pairs. In Proceedings of the 2020 IEEE 3rd International Conference on Dielectrics (ICD), Valencia, Spain, 5–31 July 2020; pp. 906–909. [Google Scholar] [CrossRef]

- Hassan, W.; Hussain, G.A.; Mahmood, F.; Amin, S.; Lehtonen, M. Effects of Environmental Factors on Partial Discharge Activity and Estimation of Insulation Lifetime in Electrical Machines. IEEE Access 2020, 8, 108491–108502. [Google Scholar] [CrossRef]

- Kikuchi, Y.; Murata, T.; Uozumi, Y.; Fukumoto, N.; Nagata, M.; Wakimoto, Y.; Yoshimitsu, T. Effects of ambient humidity and temperature on partial discharge characteristics of conventional and nanocomposite enameled magnet wires. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 1617–1625. [Google Scholar] [CrossRef]

- Ji, Y.; Giangrande, P.; Zhao, W.; Madonna, V.; Zhang, H.; Li, J.; Galea, M. Investigation on combined effect of humidity–temperature on partial discharge through dielectric performance evaluation. IET Sci. Meas. Technol. 2022, 17, 37–46. [Google Scholar] [CrossRef]

- Naderiallaf, H.; Ji, Y.; Giangrande, P.; Galea, M. Modeling Humidity Impact on PDIV for Turn-to-Turn Insulation of Inverter-Fed Motors at Different Temperatures. IEEE Trans. Dielectr. Electr. Insul. 2023, 31, 1573–1582. [Google Scholar] [CrossRef]

| Ref. | Pressure Range (mbar) | Influencing Factors | Measured Quantity | Test Sample (Insulation Material) | Test Voltage (Impulse Voltage Parameters) |

|---|---|---|---|---|---|

| [17] | 200 to 1000 | PDIV, PDEV | Twisted pairs (Grade II PEI + PAI) | Bipolar impulse (tr: 80 ns, f: 60 kHz) | |

| [22] | 400 to 1013 | PDIV, PRPD | Insulation paper (0.3 mm Nomex-polyimide-Nomex) | Sinusoidal, bipolar impulse (tr: 100 ns, f: 50 Hz) | |

| [27] | 5 to 1013 | Rise time (7, 15, 150 ns), frequency (10, 50, 100 kHz) | PDIV | Twisted pairs (Grade II PEI + PAI) | Sinusoidal, bipolar impulse |

| [32] | 200 to 1000 | Frequency | PDIV | Twisted pairs | Sinusoidal |

| [43] | 51 to 1013 | PDIV, PDEV | Form-winding with Litz wire (Duralco resin, glass fiber, PI) | Sinusoidal | |

| [44] | 50 to 1000 | PDIV, PDEV, RPDIV | Twisted pairs (PAI, Grade II) | Unipolar impulse (tr: 150 ns, f: 2.5 kHz) | |

| [51] | 590 to 1000 | Insulation material (100 μm PAI, 100 and 130 μm PEEK) | PDIV | Twisted pairs | Bipolar impulse (tr: 80 ns, f: 60 kHz) |

| [53] | 470 to1013 | Insulation material (PI, PI with microcellular coating) | PDIV | Parallel wire | Sinusoidal |

| [55] | 200 to 1000 | Impregnation status | PDIV, PDEV | Twisted pairs (0.03 mm PEI + PAI and silicon resin) | Unipolar impulse (pw: 0.2 ms) |

| [69] | 200 to 1013 | PDIV | Twisted pairs | Sinusoidal | |

| [73] | 100 to 1750 | PDIV, average discharge current, quadratic rate, accumulative apparent current, discharge power | Motor | Sinusoidal | |

| [78] | 200 to 1000 | Insulating gases (air, CO2, SF6, CF3I, C3H2F4, C3F7CN) | PRDIV, PDIV, discharge magnitude | Twisted pairs | Sinusoidal, unipolar impulse (tr: 10 ns, pw: 15 ms) |

| [79] | 100 and 1013 | PDIV, PDEV | Twisted pairs, stator, motorette (0.15 mm Nomex-410, 0.5 mm ISOVALFR4, 0.065 mm Intertape, 0.2 mm Siligaine) | Sinusoidal, bipolar impulse (f: 1 kHz, dc: 50%) | |

| [80] | 100 and 1013 | Insulation thickness | PDIV, PRPD patterns | Twisted pairs (28, 53, 80 μm PEI + PAI) | Sinusoidal |

| [81] | 100 to 1000 | PDIV, discharge magnitude, PRPD patterns | Twisted pairs, insulated wire wound with a plain metallic conductor (0.04 mm Kapton®FCR PI film) | Sinusoidal | |

| [82] | 100 and 1000 | Rise time (12, 237 ns), insulation material (Grade II PEI + PAI + with/without an inorganic nano-filler) | PDIV | Twisted pairs | Bipolar impulse |

| [83] | 203 to 1013 | Insulation defects | PDIV, PRPD patterns | Form-wound winding (Duralco 128 resin, glass fiber, PI) | Sinusoidal |

| [84] | 67 to 1013 | PDIV, PDEV, RPDIV | Twisted pairs, shielded wire samples (Polytetrafluoroethylene (PTFE)), motorette (200 μm Nomex-polyimide-Nomex, Nomex phase separator, impregnation resin and PEI), PCB board | Sinusoidal, bipolar impulse (tr: 150 ns, pw: 180 ms) | |

| [85] | 116 and 1000 | PDIV, PDEV | Twisted pairs, stator, motorette | Sinusoidal, impulse (dv/dt: 2500 V/μs) | |

| [86] | 10 to 1000 | Frequency | PDIV, average discharge amplitude, total discharge amplitude, discharge repetition rate, PRPD | Twisted pairs (0.025 mm PI) | Sinusoidal |

| [87] | 116 to 1013 | Rise time (55, 130, 200 ns), pulse number | PDIV, PRDIV, PDEV, RPDEV | Wire wrapped on a stainless-steel mandrel | Unipolar impulse |

| [88] | 200 to 1000 | Frequency (5 to 200 kHz) | RPDIV | Twisted pairs | Unipolar impulse |

| [89] | 12 to 750 | EIS | PDIV | Motorette (Dophon 1105/LV) | Impulse (f: 5 kHz) |

| [90] | 116 and 1000 | Voltage type, pulse width (50 ns to 50 ms) | PDIV, PD time delay | Twisted pairs (75 µm PI) | Impulse |

| [91] | 100 to 1013 | Sensor type | PDIV, PD spectrum | Twisted pairs | Sinusoidal, PWM |

| [92] | 100 to 1000 | PDIV | Twisted pairs (28.5 µm, PEI + PAI) | Sinusoidal | |

| [93] | 100 to 1013 | PDIV | Insulating paper set-up (125 µm, PI) | Sinusoidal |

| Ref. | Pressure Range (mbar) | Temperature Range (°C) | Influencing Factors | Measured Quantity | Test Sample (Insulation Material) | Test Voltage (Impulse Voltage Parameters) |

|---|---|---|---|---|---|---|

| [95] | 200 to 1000 | 20 to 80 | PDIV, number of PD | Stator | Sinusoidal | |

| [96] | 200 to 1000 | 20 to 180 | RPDIV | Twisted pairs (50 μm PI) | Unipolar impulse (tr: 100 ns, f: 5 kHz, dc: 50%) | |

| [97] | 200 to 1000 | 20 to 220 | Rise time (20 to 200 ns) | PDIV | Twisted pairs (Grade II PEI + PAI) | Unipolar impulse (tr: 50 ns, f: 1 kHz, dc: 20%) |

| [98] | 200 and 1000 | 20 to 120 | PDIV | Twisted pairs (28.5 μm PEI + PAI) | Sinusoidal | |

| [99] | 203 to 1013 | 30 to 210 | PDIV | Form-wound winding (0.013 mm PI, 0.127 mm Nomex, 0.178 mm Glass fiber, Duralco 128 resin) | Sinusoidal | |

| [100] | 200 to 1000 | 20 to 200 | PDIV | Twisted pairs (PEI + PAI + inorganic layer) | Bipolar impulse | |

| [101] | 200 to 1000 | 20 to 140 | PDIV | Litz wire | Sinusoidal | |

| [102] | 200 to 1000 | 20 and 180 | Rise time (30 to 200 ns), insulation material (PEI + PAI + with/without inorganic layer) | PDIV, PDEV | Twisted pairs | Unipolar impulse |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, Y.; Giangrande, P.; Zhao, W. Effect of Environmental and Operating Conditions on Partial Discharge Activity in Electrical Machine Insulation: A Comprehensive Review. Energies 2024, 17, 3980. https://doi.org/10.3390/en17163980

Ji Y, Giangrande P, Zhao W. Effect of Environmental and Operating Conditions on Partial Discharge Activity in Electrical Machine Insulation: A Comprehensive Review. Energies. 2024; 17(16):3980. https://doi.org/10.3390/en17163980

Chicago/Turabian StyleJi, Yatai, Paolo Giangrande, and Weiduo Zhao. 2024. "Effect of Environmental and Operating Conditions on Partial Discharge Activity in Electrical Machine Insulation: A Comprehensive Review" Energies 17, no. 16: 3980. https://doi.org/10.3390/en17163980

APA StyleJi, Y., Giangrande, P., & Zhao, W. (2024). Effect of Environmental and Operating Conditions on Partial Discharge Activity in Electrical Machine Insulation: A Comprehensive Review. Energies, 17(16), 3980. https://doi.org/10.3390/en17163980