Research on the Configuration of a 100% Green Electricity Supplied Zero-Carbon Integrated Energy Station

Abstract

1. Introduction

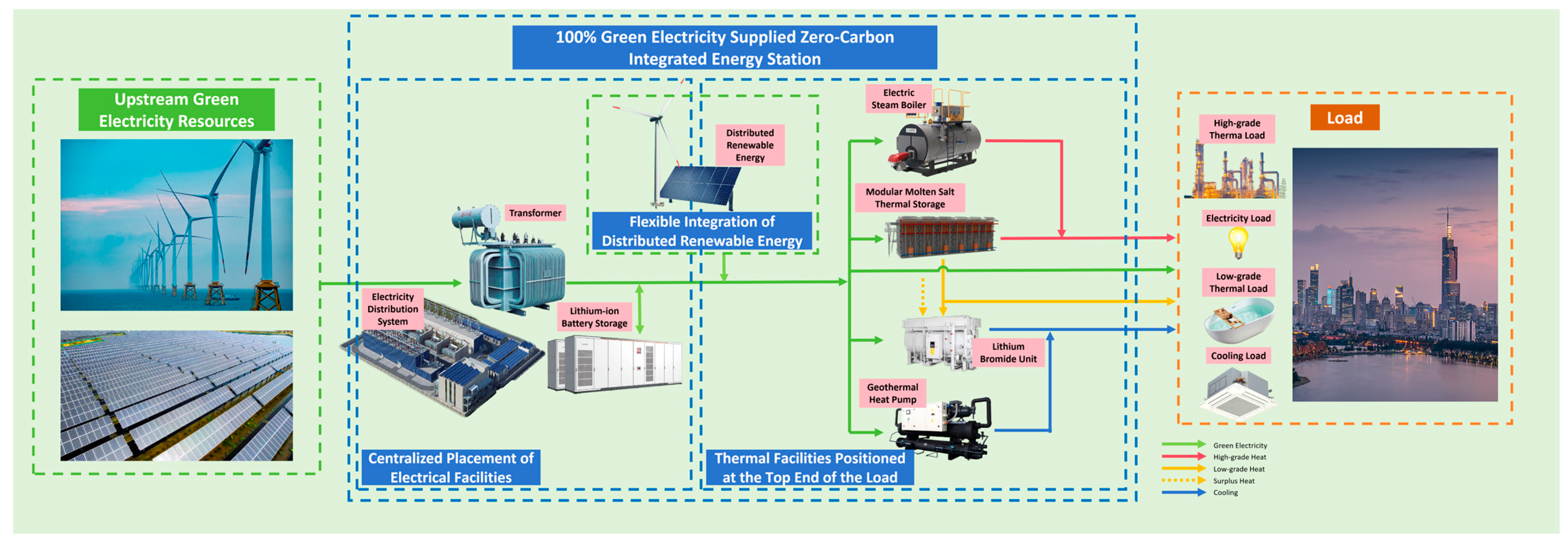

2. Core Characteristics of the Studied IES

2.1. Integrated Energy Station (IES)

2.2. Zero Carbon Emissions

2.3. 100% Green Electricity Supply

2.4. Centralized–Distributed System

3. Optimization Configuration Research

3.1. Equipment Selection

3.1.1. Substation Equipment

3.1.2. Power Generation Equipment

3.1.3. Energy Conversion Equipment

3.1.4. Energy Storage Equipment

3.2. Configuration Model

3.2.1. Upstream Green Electricity Resources Configuration Model

3.2.2. Power Generation Equipment Configuration Model

3.2.3. Energy Storage Equipment Configuration Model

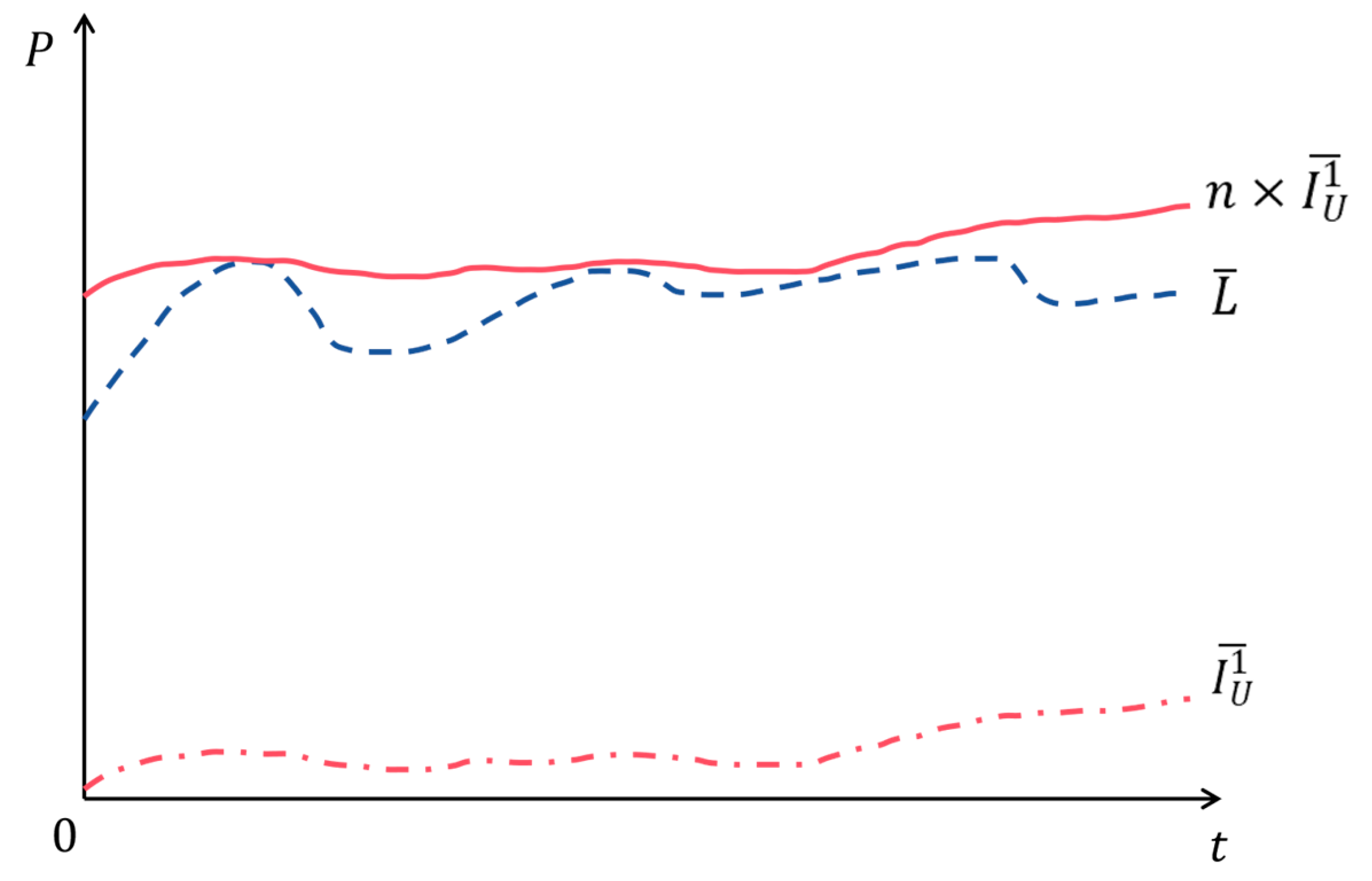

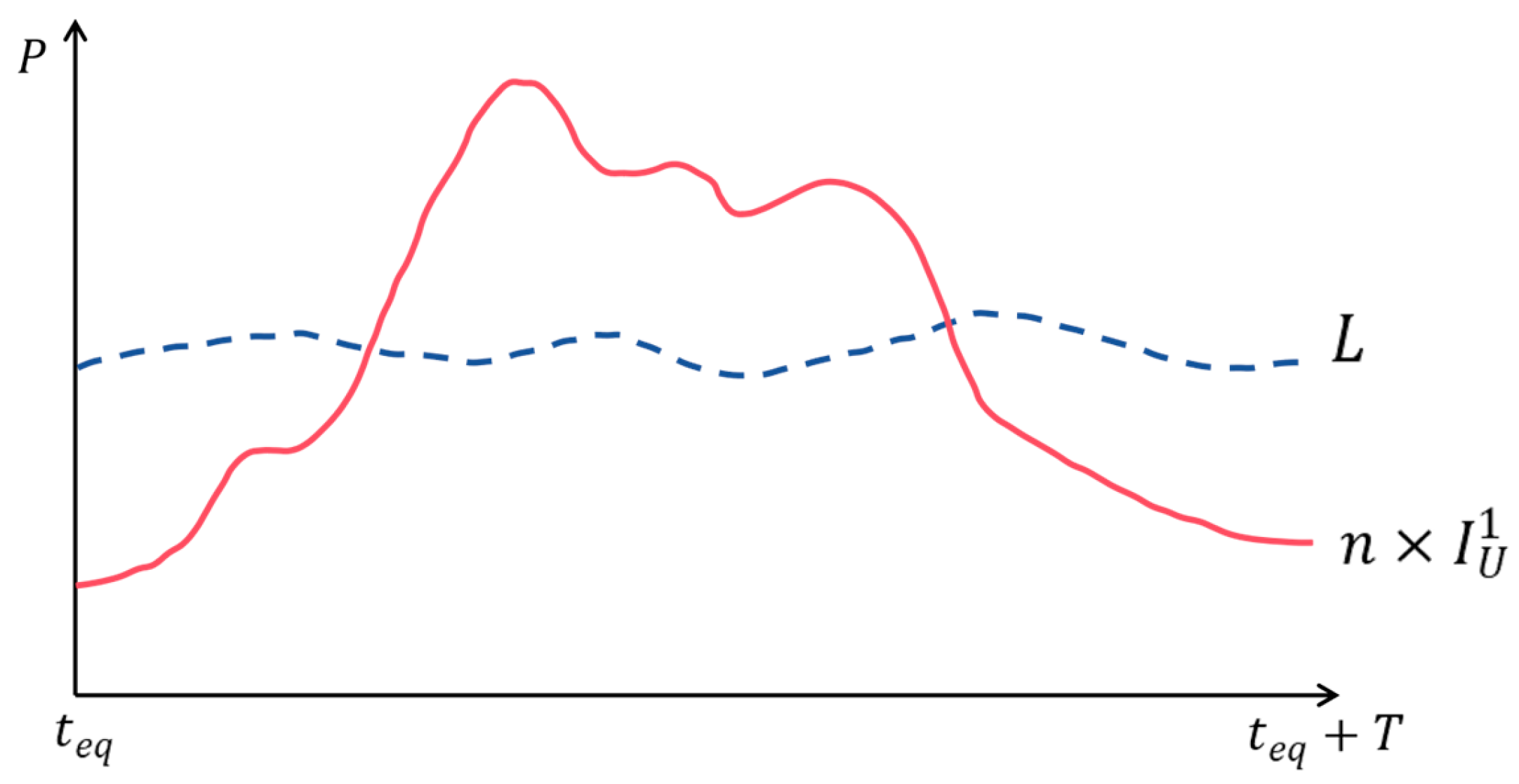

- Overall Configuration of Energy Storage Facilities

- 2.

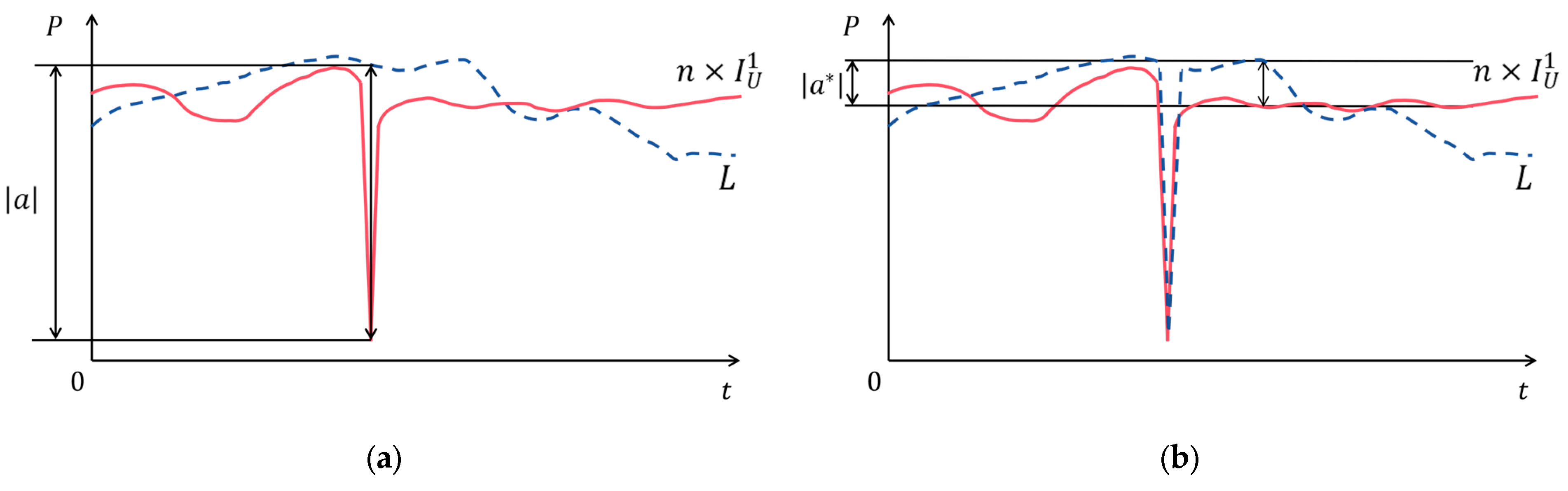

- Virtual Energy Storage Configuration Formed by Thermal Load Inertia

- 3.

- Energy Storage Configuration for the IES

- 4.

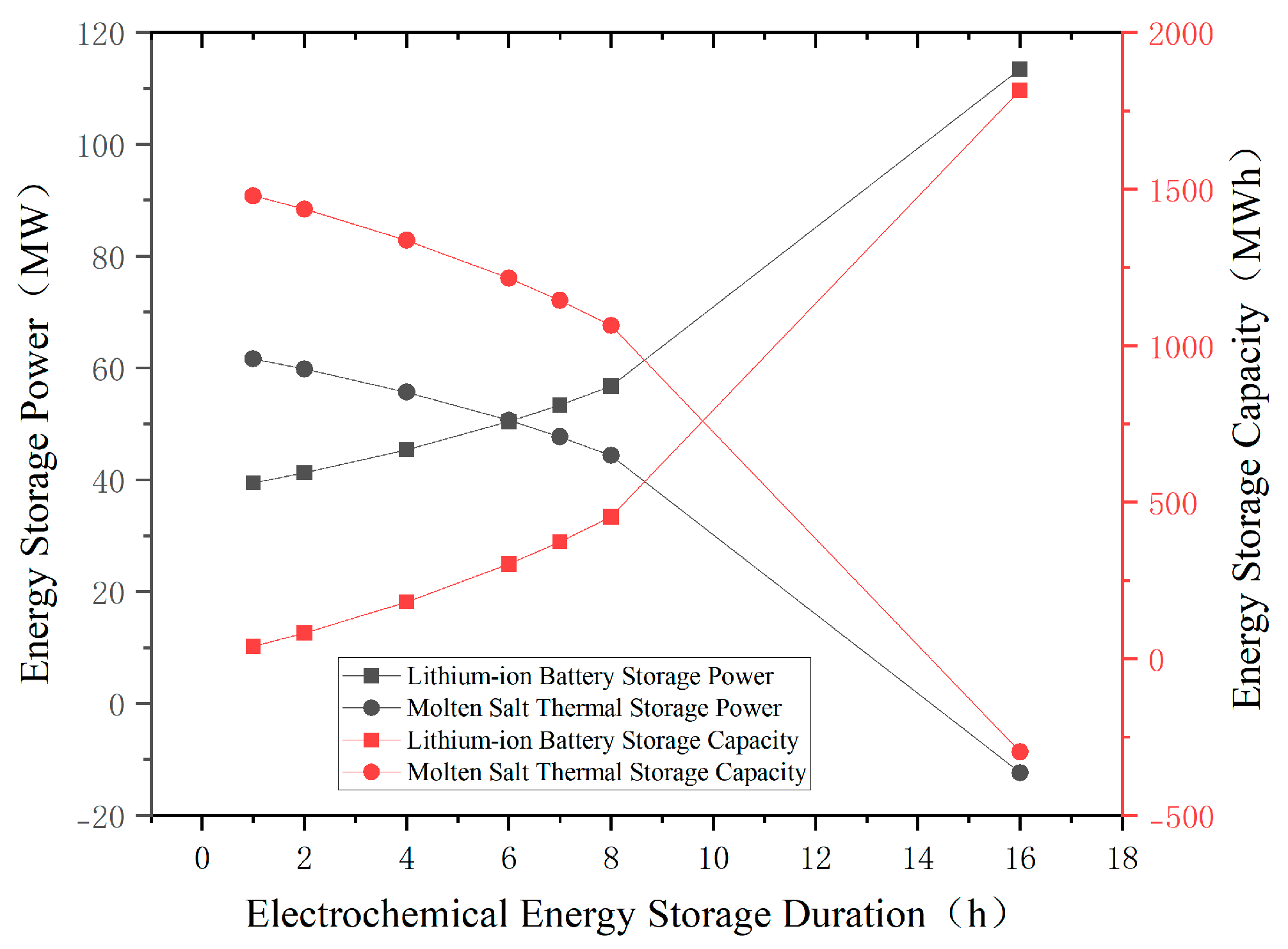

- Lithium-ion Battery Storage and Modular Molten Salt Thermal Storage Configuration for the IES

3.2.4. Substation Equipment Configuration Model

3.2.5. Energy Conversion Equipment Configuration Model

4. Case Study

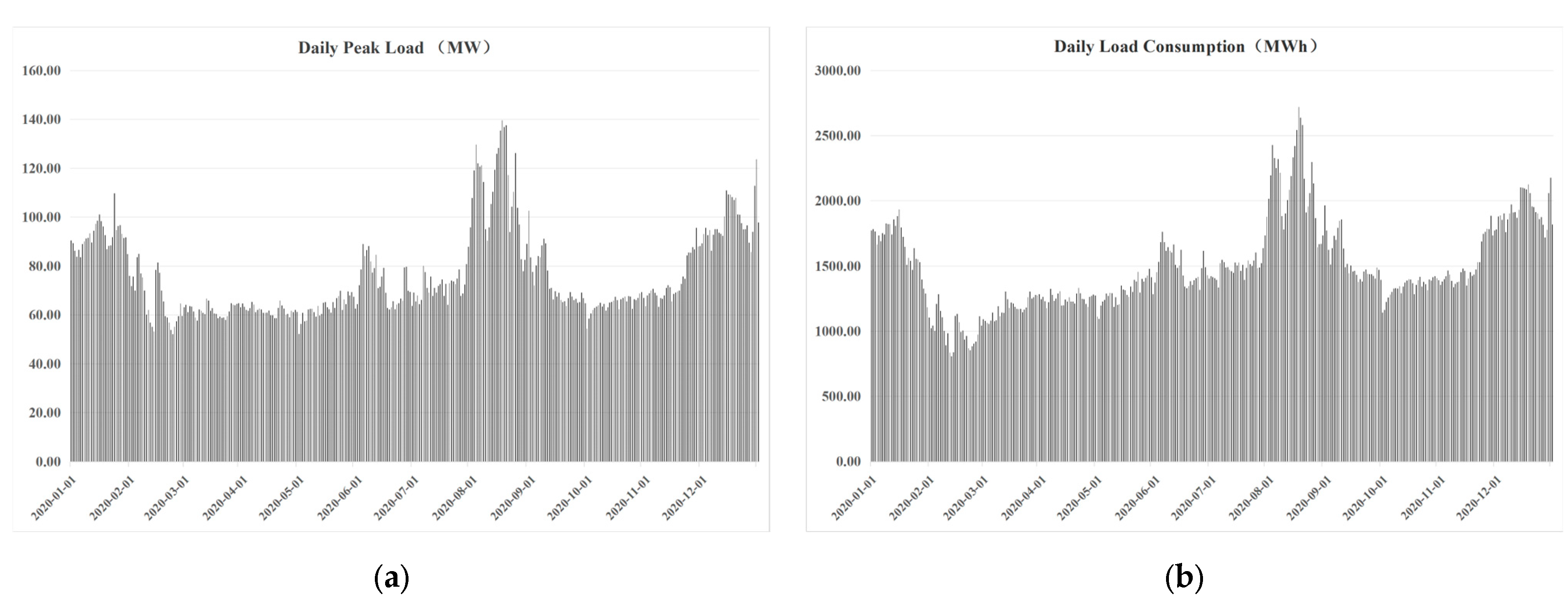

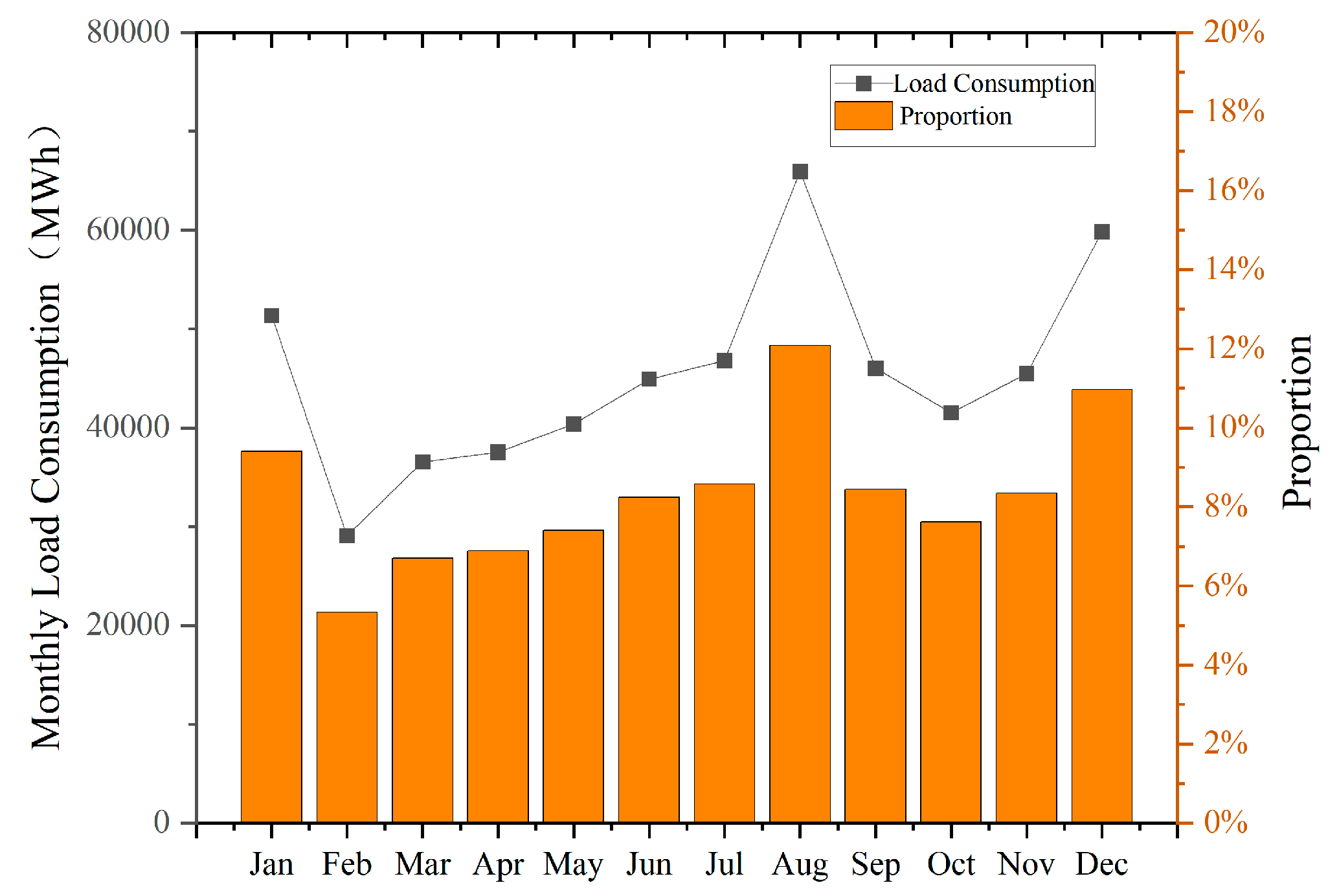

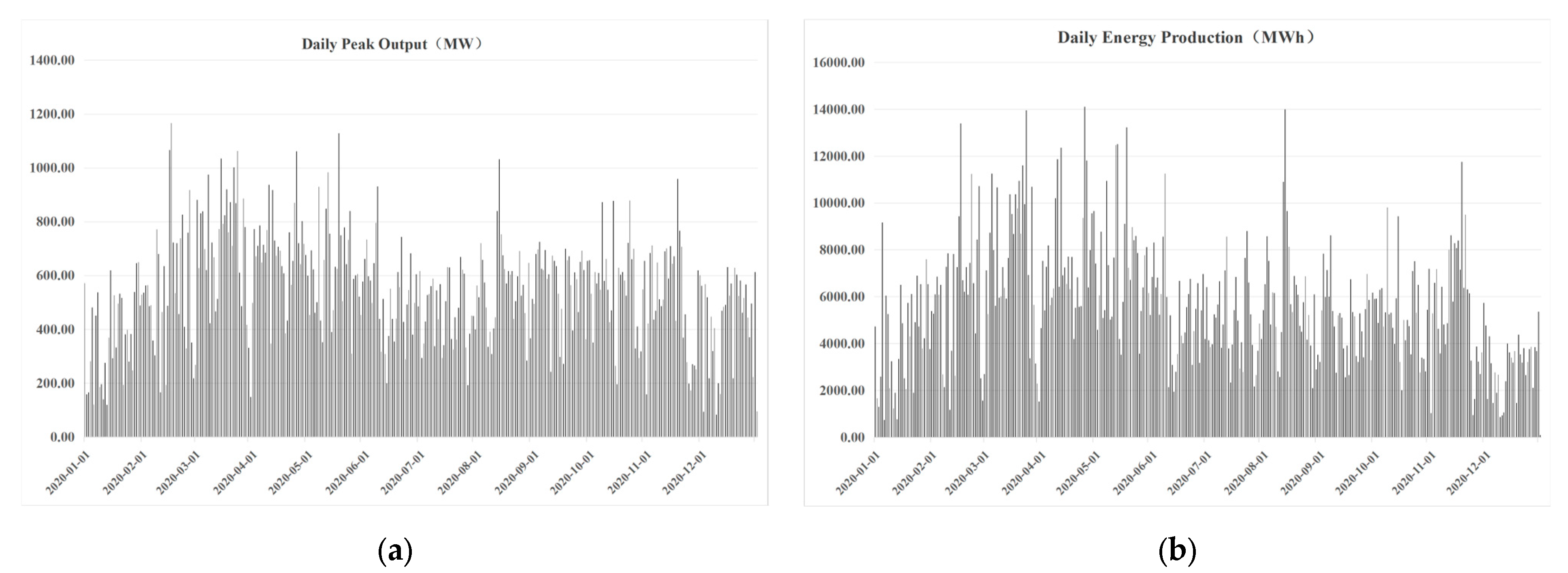

4.1. Case Background and Parameters

4.2. Results Analysis

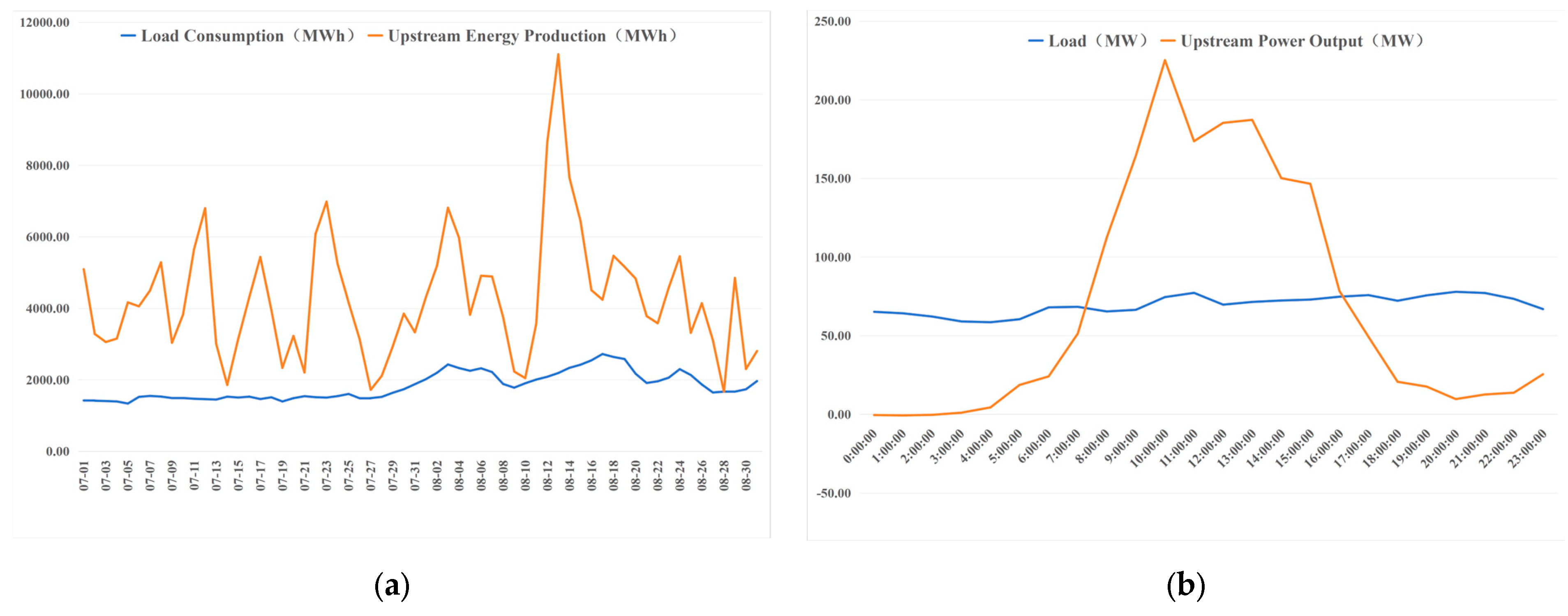

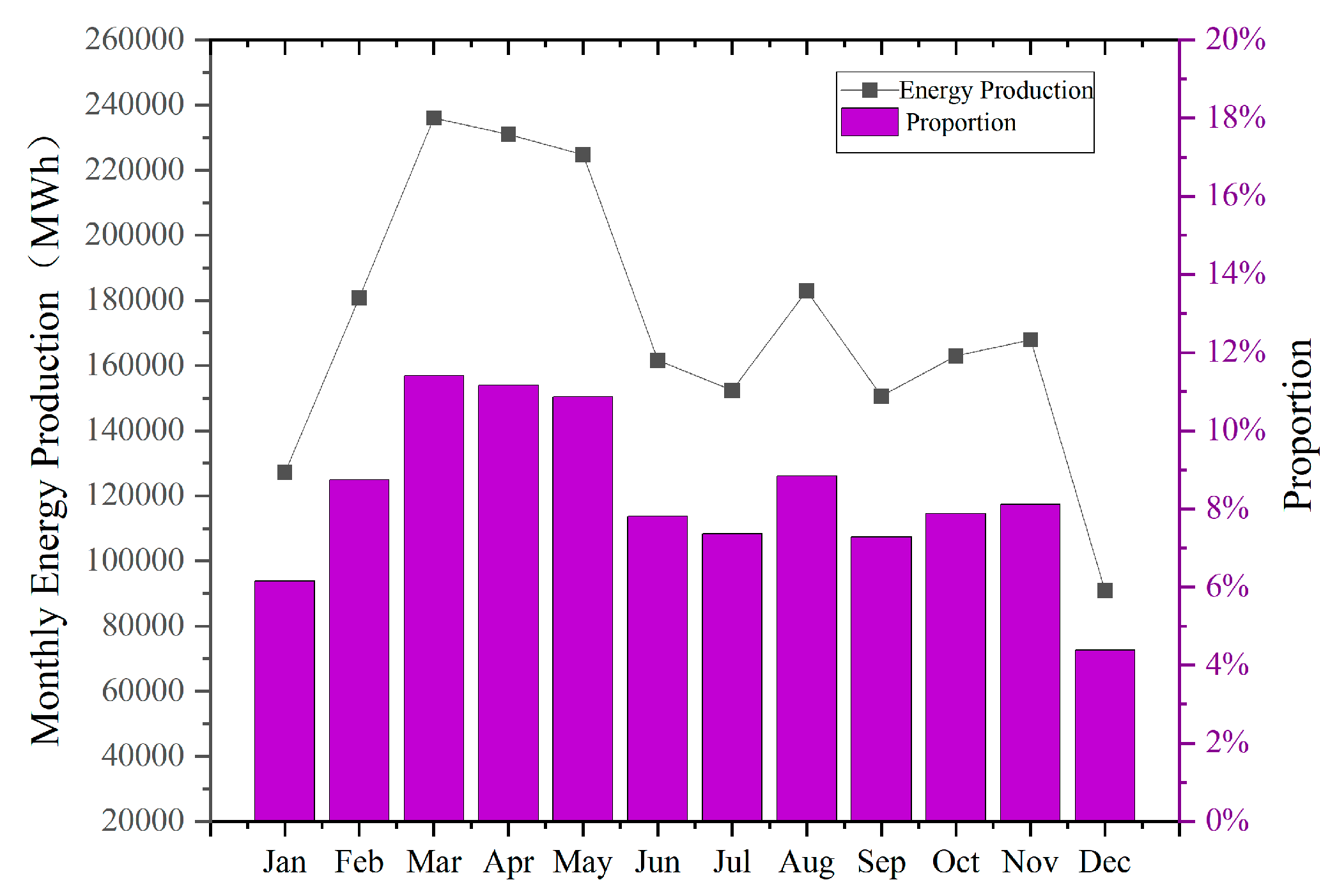

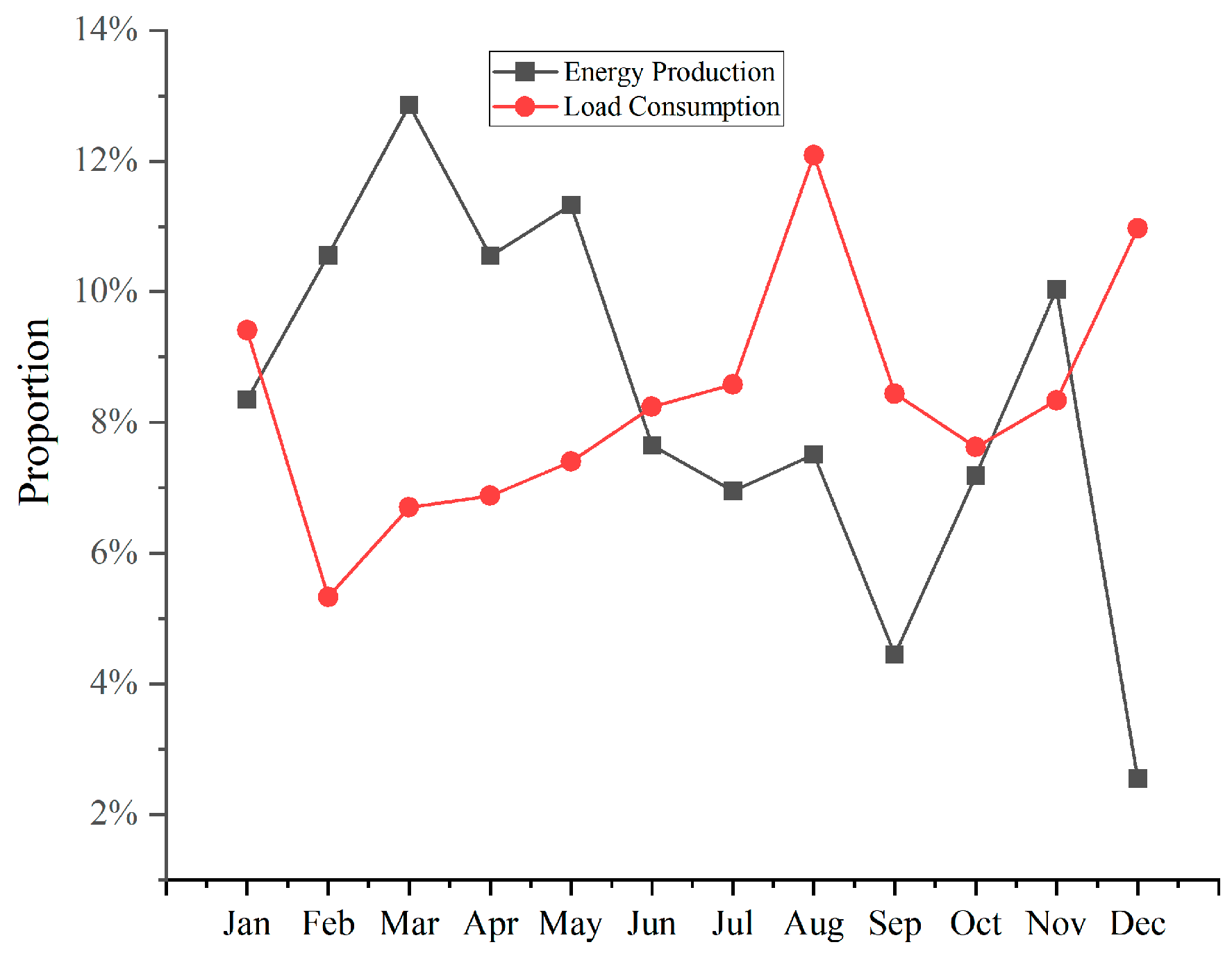

4.2.1. Upstream Green Electricity Resources Configuration

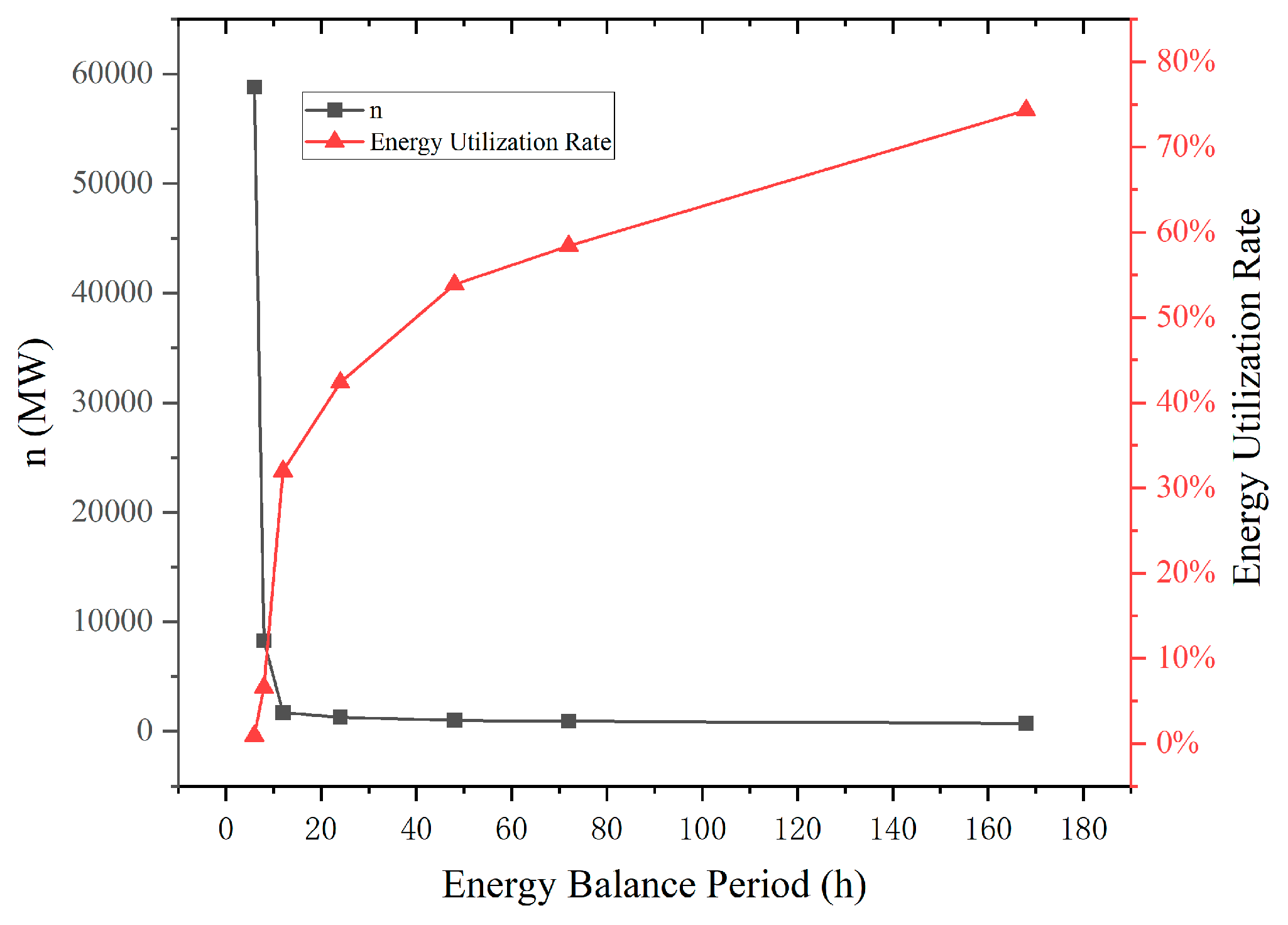

4.2.2. Energy Storage Configuration

4.2.3. Substation Equipment Configuration

4.2.4. Energy Conversion Equipment Configuration

5. Discussion

- This paper presents mathematical models for configuring upstream green electricity resources, power generation equipment, energy storage equipment, substation equipment, and energy conversion equipment for a 100% green electricity supplied zero-carbon integrated energy station, from both power and energy perspectives. The models are validated through case studies.

- Through case analysis, it was found that while fully relying on green electricity can achieve zero-carbon energy use, the lack of controllable supportive energy requires an upstream green electricity resource configuration that is exceptionally large relative to the load. In the case study of this research, the capacity of upstream green electricity resources is nearly 17 times the average load of the IES during peak demand periods (July and August). From an energy utilization perspective, the load of the IES utilized 42.37% of the upstream green electricity resources’ generation, which is a reasonable value. This not only verifies the model’s rationality but also raises new requirements for subsequent research on the rational utilization of upstream green electricity resources.

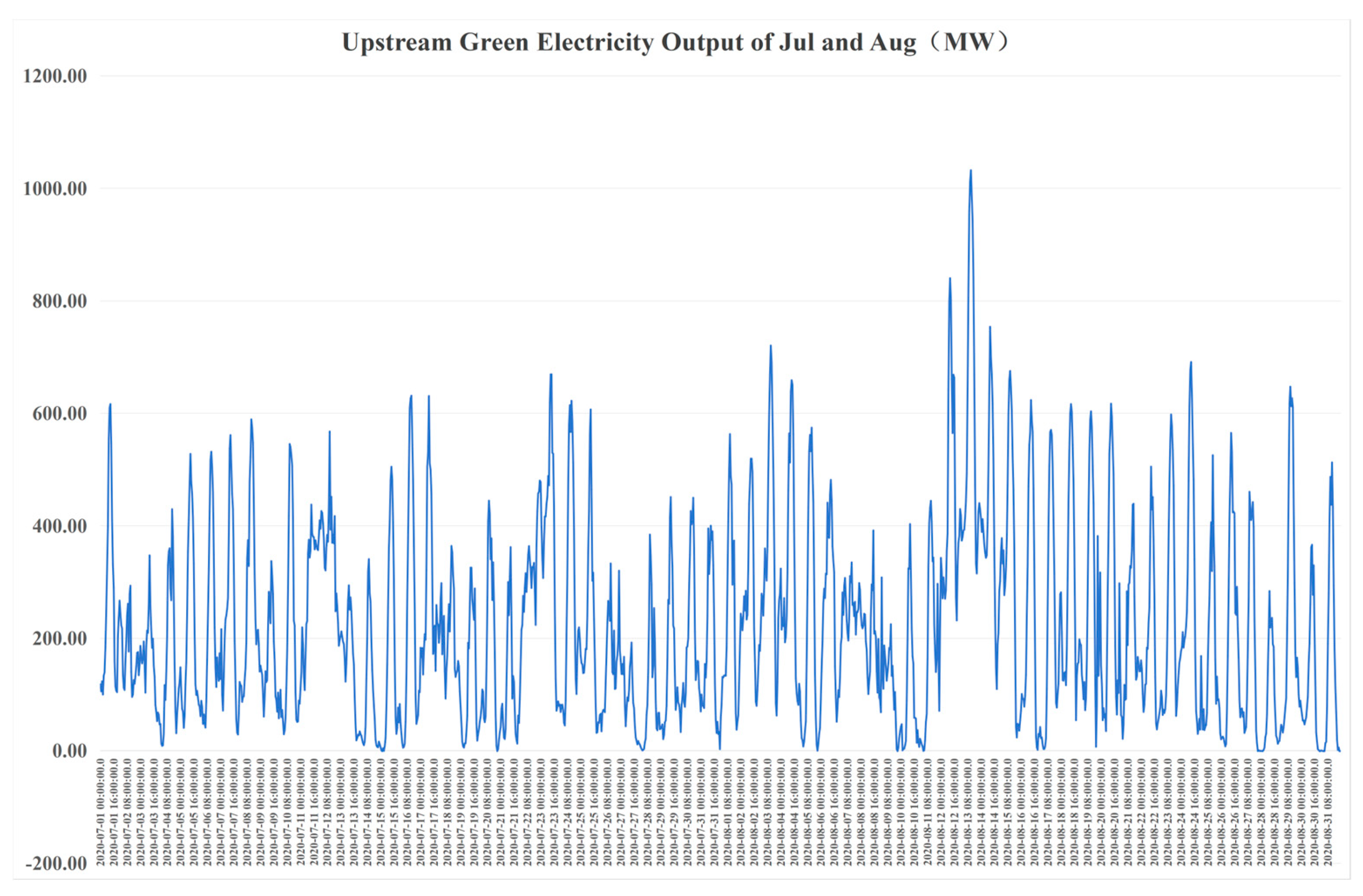

- This study quantitatively describes the significant volatility of green electricity sources such as wind and solar power. The upstream green electricity base in this study is configured with 583.3 MW of wind power and 1037 MW of solar power, covering a total area of approximately 10,000 square kilometers. With a robust grid structure, it already has the conditions for regional green electricity interconnection and complementarity. Despite these favorable conditions, the overall output of the green electricity base remains highly unstable. Specifically, during the peak load months of July and August, the output was below 10% of the installed capacity for 45.97% of the time and below 2% for 10.61% of the time. Such significant fluctuations in output are highly detrimental to meeting load demands, necessitating further in-depth research and extensive engineering practice to find reasonable solutions.

- This study demonstrates that energy storage is the key technology for mitigating the uncertainties in upstream green electricity output. The rapid power regulation capabilities of lithium-ion battery storage, along with the flexible capacity and thermal synergy features of modular molten salt thermal storage, form a supportive electro-thermal energy storage system. This system enhances the overall controllability of upstream green electricity resources, effectively supporting load energy demands. Based on the proposed configuration model, the case study system requires the installation of 53.39 MW/444.93 MWh of lithium-ion battery storage and 47.68 MW/1300.43 MWh of modular molten salt thermal storage. The relatively large power and capacity configurations in relation to the load scale indicate the need for further optimization in future research.

- This study preliminarily explores the characteristics of virtual energy storage based on thermal load inertia. It finds that the energy imbalance caused by renewable energy fluctuations exhibits characteristics of short-term peak spikes with high power and short duration, similar to the virtual energy storage properties of thermal loads. Effectively utilizing virtual energy storage of thermal loads can mitigate peak spikes in power, thereby reducing the total power configuration of energy storage systems and lowering configuration costs. Using the averaging method in this study, the total power of energy storage facilities can be reduced by 10.42%. Future research will focus on further exploring thermal load virtual energy storage.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, D.; Zhi, Y.Q.; Jia, H.J.; Hou, K.; Zhang, S.X.; Du, W.; Wang, X.D.; Fan, M.H. Optimal scheduling strategy of district integrated heat and power system with wind power and multiple energy stations considering thermal inertia of buildings under different heating regulation modes. Appl. Energy 2019, 240, 341–358. [Google Scholar] [CrossRef]

- Ma, T.; Wu, J.; Hao, L.; Lee, W.-J.; Yan, H.; Li, D. The optimal structure planning and energy management strategies of smart multi energy systems. Energy 2018, 160, 122–141. [Google Scholar] [CrossRef]

- Xie, S.; Hu, Z.; Wang, J.; Chen, Y. The optimal planning of smart multi-energy systems incorporating transportation, natural gas and active distribution networks. Appl. Energy 2020, 269, 115006. [Google Scholar] [CrossRef]

- Yuman, Z.; Xuezhi, L.; Zheng, Y.; Peichao, Z. Decomposition-coordination based optimization for PV-BESS-CHP integrated energy systems. Trans. China Electrotech. Soc. 2020, 35, 2372–2386. [Google Scholar]

- Chen, X. Green and low-carbon energy-use. Innov. Energy 2024, 1, 100003. [Google Scholar] [CrossRef]

- Wang, S.; Wang, X.; Wang, S.; Wang, D. Bi-directional long short-term memory method based on attention mechanism and rolling update for short-term load forecasting. Int. J. Electr. Power Energy Syst. 2019, 109, 470–479. [Google Scholar] [CrossRef]

- Li, L.; Yu, S.; Mu, H.; Li, H. Optimization and evaluation of CCHP systems considering incentive policies under different operation strategies. Energy 2018, 162, 825–840. [Google Scholar] [CrossRef]

- Zhang, X.; Shahidehpour, M.; Alabdulwahab, A.; Abusorrah, A. Optimal expansion planning of energy hub with multiple energy infrastructures. IEEE Trans. Smart Grid 2015, 6, 2302–2311. [Google Scholar] [CrossRef]

- Olsen, D.J.; Zhang, N.; Kang, C.; Ortega-Vazquez, M.A.; Kirschen, D.S. Planning low-carbon campus energy hubs. IEEE Trans. Power Syst. 2018, 34, 1895–1907. [Google Scholar] [CrossRef]

- Hanbin, D.; Peiqiang, L.; Xiaoxiu, L.; Xiaolong, L.; Xinran, L. Coordinated optimal allocation of energy storage in regional integrated energy system considering the diversity of multi-energy storage. Trans. China Electrotech. Soc. 2021, 36, 151–165. [Google Scholar]

- Yufeng, X.; Laijun, C.; Tianwen, Z.; Mei, S.; Shengwei, M. Optimal configuration of hydrogen energy storage in low-carbon park integrated energy system considering electricity-heat-gas coupling characteristics. Electr. Power Autom. Equip. 2021, 41, 31–38. [Google Scholar]

- Yu, X.; Xu, X.; Chen, S.; Wu, J.; Jia, H. A brief review to integrated energy system and energy internet. Diangong Jishu Xuebao Trans. China Electrotech. Soc. 2016, 31, 1–13. [Google Scholar]

- Lu, X.; Wang, J.; Liu, G.; Du, W.; Yang, D. Station-and-network–coordinated planning of integrated energy system considering integrated demand response. Glob. Energy Interconnect. 2021, 4, 39–47. [Google Scholar] [CrossRef]

- Liu, X. Energy station and distribution network collaborative planning of integrated energy system based on operation optimization and demand response. Int. J. Energy Res. 2020, 44, 4888–4909. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, N.; Lu, Z.; Kang, C. Planning multiple energy systems toward low-carbon society: A decentralized approach. IEEE Trans. Smart Grid 2018, 10, 4859–4869. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, N.; Kirschen, D.S.; Huang, W.; Kang, C. Planning multiple energy systems for low-carbon districts with high penetration of renewable energy: An empirical study in China. Appl. Energy 2020, 261, 114390. [Google Scholar] [CrossRef]

- Pursiheimo, E.; Holttinen, H.; Koljonen, T. Path toward 100% renewable energy future and feasibility of power-to-gas technology in Nordic countries. IET Renew. Power Gener. 2017, 11, 1695–1706. [Google Scholar] [CrossRef]

- Hu, J.; Wang, Y.; Dong, L. Low carbon-oriented planning of shared energy storage station for multiple integrated energy systems considering energy-carbon flow and carbon emission reduction. Energy 2024, 290, 130139. [Google Scholar] [CrossRef]

- Wang, J.; Jin, Y.; Zheng, J.; Xue, P.; Sun, C. Optimal quantity, location and capacity allocation of the additional renewable energy stations in a large-scale district heating system and comprehensive case analyses. Energy Convers. Manag. 2023, 284, 116975. [Google Scholar] [CrossRef]

- Zhong, J.; Bollen, M.; Rönnberg, S. Towards a 100% renewable energy electricity generation system in Sweden. Renew. Energy 2021, 171, 812–824. [Google Scholar] [CrossRef]

- Kroposki, B.; Johnson, B.; Zhang, Y.; Gevorgian, V.; Denholm, P.; Hodge, B.-M.; Hannegan, B. Achieving a 100% renewable grid: Operating electric power systems with extremely high levels of variable renewable energy. IEEE Power Energy Mag. 2017, 15, 61–73. [Google Scholar] [CrossRef]

- Child, M.; Kemfert, C.; Bogdanov, D.; Breyer, C. Flexible electricity generation, grid exchange and storage for the transition to a 100% renewable energy system in Europe. Renew. Energy 2019, 139, 80–101. [Google Scholar] [CrossRef]

- Ponnaganti, P.; Bak-Jensen, B.; Wæhrens, B.V.; Asmussen, J. Assessment of energy arbitrage using energy storage systems: A wind park’s perspective. Energies 2021, 14, 4718. [Google Scholar] [CrossRef]

- van der Roest, E.; Beernink, S.; Hartog, N.; van der Hoek, J.P.; Bloemendal, M. Towards sustainable heat supply with decentralized multi-energy systems by integration of subsurface seasonal heat storage. Energies 2021, 14, 7958. [Google Scholar] [CrossRef]

- Hameer, S.; van Niekerk, J.L. A review of large-scale electrical energy storage. Int. J. Energy Res. 2015, 39, 1179–1195. [Google Scholar] [CrossRef]

- Gür, T.M. Review of electrical energy storage technologies, materials and systems: Challenges and prospects for large-scale grid storage. Energy Environ. Sci. 2018, 11, 2696–2767. [Google Scholar] [CrossRef]

- Alva, G.; Lin, Y.; Fang, G. An overview of thermal energy storage systems. Energy 2018, 144, 341–378. [Google Scholar] [CrossRef]

- Sarbu, I.; Sebarchievici, C. A comprehensive review of thermal energy storage. Sustainability 2018, 10, 191. [Google Scholar] [CrossRef]

- Hoivik, N.; Greiner, C.; Barragan, J.; Iniesta, A.C.; Skeie, G.; Bergan, P.; Blanco-Rodriguez, P.; Calvet, N. Long-term performance results of concrete-based modular thermal energy storage system. J. Energy Storage 2019, 24, 100735. [Google Scholar] [CrossRef]

| Technology | Lithium-Ion Battery Storage | Modular Molten Salt Thermal Storage |

|---|---|---|

| Unit Cost (yuan/Wh) | 1.3 | 0.53 |

| Unit Volume Capacity (MWh/m3) | 0.078 | 0.183 |

| Unit Area Capacity (MWh/m2) | 0.005 | 0.339 |

| Charging Capacity | 0.5 c | 0.25 c |

| Discharging Capacity | 0.5 p | 0.25 p |

| Energy Type | Actual Load (MW) | Proportion | Conversion Factor | Converted to Electrical Load (MW) | Proportion |

|---|---|---|---|---|---|

| High-grade heat | 24.55 | 10.48% | 0.9 | 27.28 | 36.00% |

| cooling | 192.78 | 82.31% | 6.1 | 31.60 | 41.71% |

| Electricity | 16.89 | 7.21% | 1 | 16.89 | 22.29% |

| Total | 234.22 | 75.77 |

| Energy Balance Period (h) | n (MW) | Energy Utilization Rate |

|---|---|---|

| 0 | ∞ | 0 |

| 6 | 58,813 | 0.93% |

| 8 | 8269 | 6.59% |

| 12 | 1705 | 31.96% |

| 24 | 1286 | 42.37% |

| 48 | 1011 | 53.89% |

| 72 | 933 | 58.40% |

| 168 | 733 | 74.33% |

| Duration of Lithium-Ion Battery Storage (h) | Lithium-Ion Battery Storage Power (MW) | Lithium-Ion Battery Storage Capacity (MWh) | Modular Molten Salt Thermal Storage Power (MW) | Modular Molten Salt Thermal Storage Capacity (MWh) |

|---|---|---|---|---|

| 1 | 39.46 | 39.46 | 61.61 | 1478.66 |

| 2 | 41.26 | 82.51 | 59.82 | 1435.61 |

| 4 | 45.38 | 181.53 | 55.69 | 1336.59 |

| 6 | 50.43 | 302.55 | 50.65 | 1215.57 |

| 7 | 53.39 | 373.74 | 47.68 | 1144.38 |

| 8 | 56.73 | 453.83 | 44.35 | 1064.3 |

| 16 | 113.46 | 1815.32 | −12.38 | −297.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, J.; Chen, X.; Yu, K.; Gan, L.; Hua, H.; Wang, B.; Qu, Y. Research on the Configuration of a 100% Green Electricity Supplied Zero-Carbon Integrated Energy Station. Energies 2024, 17, 4111. https://doi.org/10.3390/en17164111

Xie J, Chen X, Yu K, Gan L, Hua H, Wang B, Qu Y. Research on the Configuration of a 100% Green Electricity Supplied Zero-Carbon Integrated Energy Station. Energies. 2024; 17(16):4111. https://doi.org/10.3390/en17164111

Chicago/Turabian StyleXie, Jieyu, Xingying Chen, Kun Yu, Lei Gan, Haochen Hua, Bo Wang, and Yuelong Qu. 2024. "Research on the Configuration of a 100% Green Electricity Supplied Zero-Carbon Integrated Energy Station" Energies 17, no. 16: 4111. https://doi.org/10.3390/en17164111

APA StyleXie, J., Chen, X., Yu, K., Gan, L., Hua, H., Wang, B., & Qu, Y. (2024). Research on the Configuration of a 100% Green Electricity Supplied Zero-Carbon Integrated Energy Station. Energies, 17(16), 4111. https://doi.org/10.3390/en17164111