Increasing the Thermal Resistance of Water-Based Mud for Drilling Geothermal Wells

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

- Biopolymer (xanthan), obtained in the process of fermentation of polysaccharides with microorganisms (Xanthomonas campestris bacteria). It is used to increase the viscosity of drilling muds of various degrees of salinity and to hold the weighting agents in suspension.

- Polyanionic cellulose, referred to as highly purified carboxymethylcellulose, is used mainly to regulate the filtration and viscosity of drilling muds, whereas it can be used for the chemical treatment of all types of water-based muds. The tests were performed using two versions of this agent: low-viscosity (LV) and regular (R).

- Starch HHT—starch with improved thermal resistance.

- Carbonate blocker (CaCO3), a weighting agent obtained as a result of the mechanical processing of marble. Due to its solubility in acids, it is used primarily for weighting drilling muds and workover fluids used in opening the deposit and in workover works in boreholes

- Carbon nanotubes—an agent used to increase the thermal resistance of the polymers and improve thermal conductivity.

- PSP109—sulphonated amide polymer.

- CR480—binding retarder and an agent used to reduce the filtration of cement slurry.

- SR5—ethoxylated fatty amine.

- TEA—amine compound.

- Cocamide DEA.

- Graphite—an agent used to improve thermal conductivity.

- Ferohem—weighting material.

- PEG8000—polyethylene glycol with a molecular weight of 8000.

- HCOOK, KCl.

2.2. Preparation of Invert Emulsion Drilling Mud

2.3. Experimental Procedures

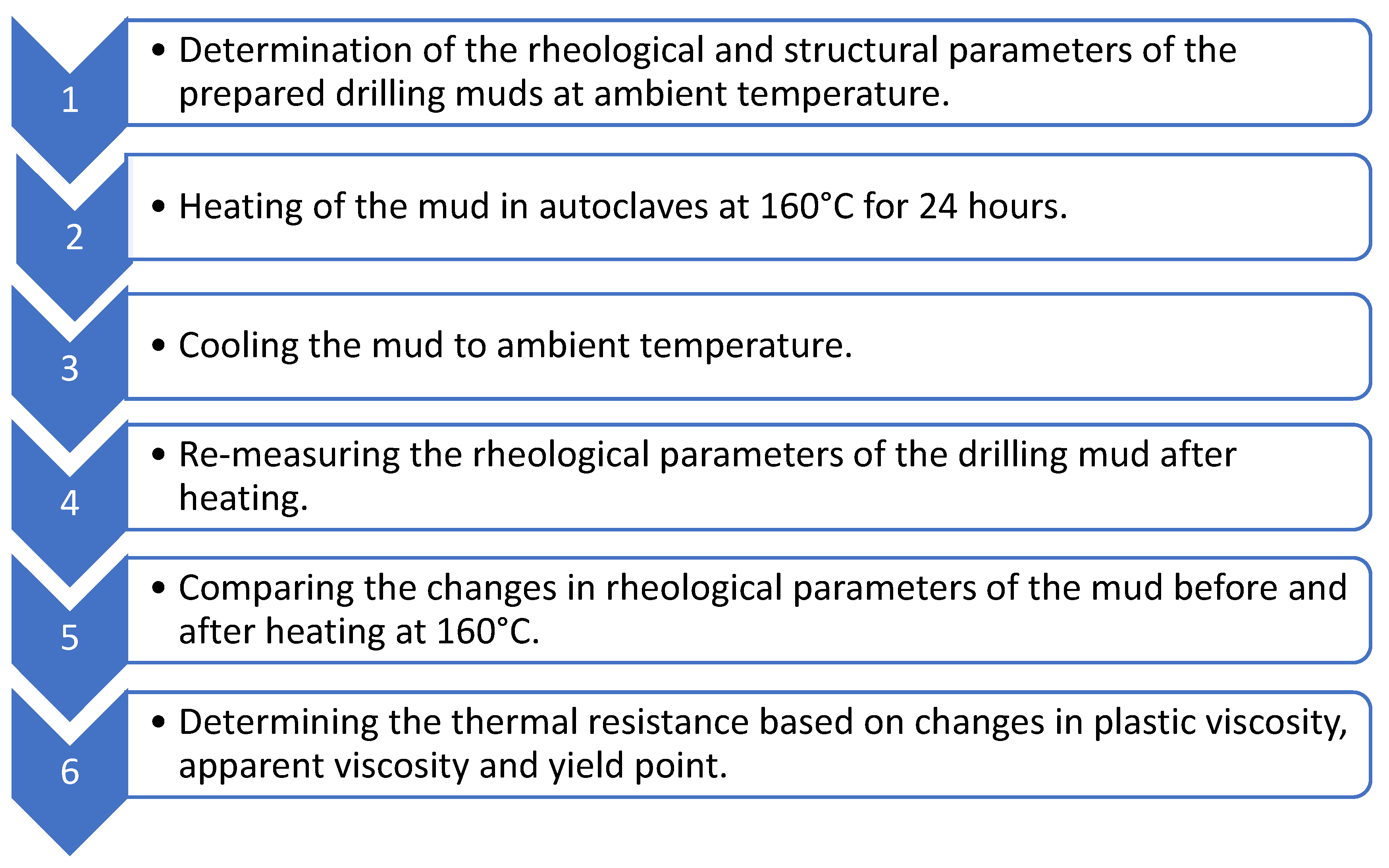

2.3.1. Testing Procedures

2.3.2. Density Measurement

2.3.3. Measurements of Rheological Parameters

2.3.4. Filtration Measurement

2.3.5. Measurements of the Thermal Conductivity of Drilling Muds

3. Results and Discussion

Tests of the Improvement of the Thermal Resistance of Water-Based Drilling Mud

4. Conclusions

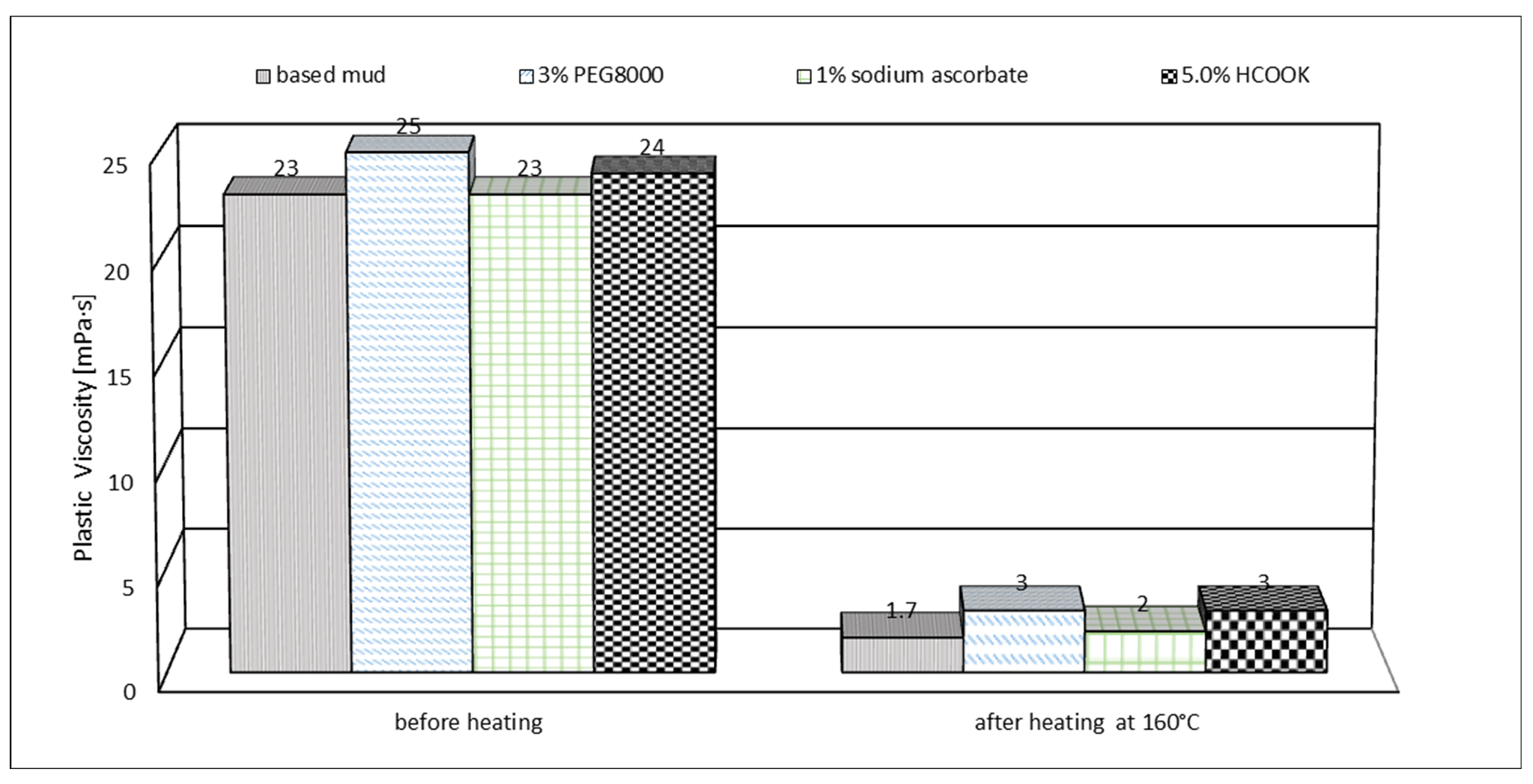

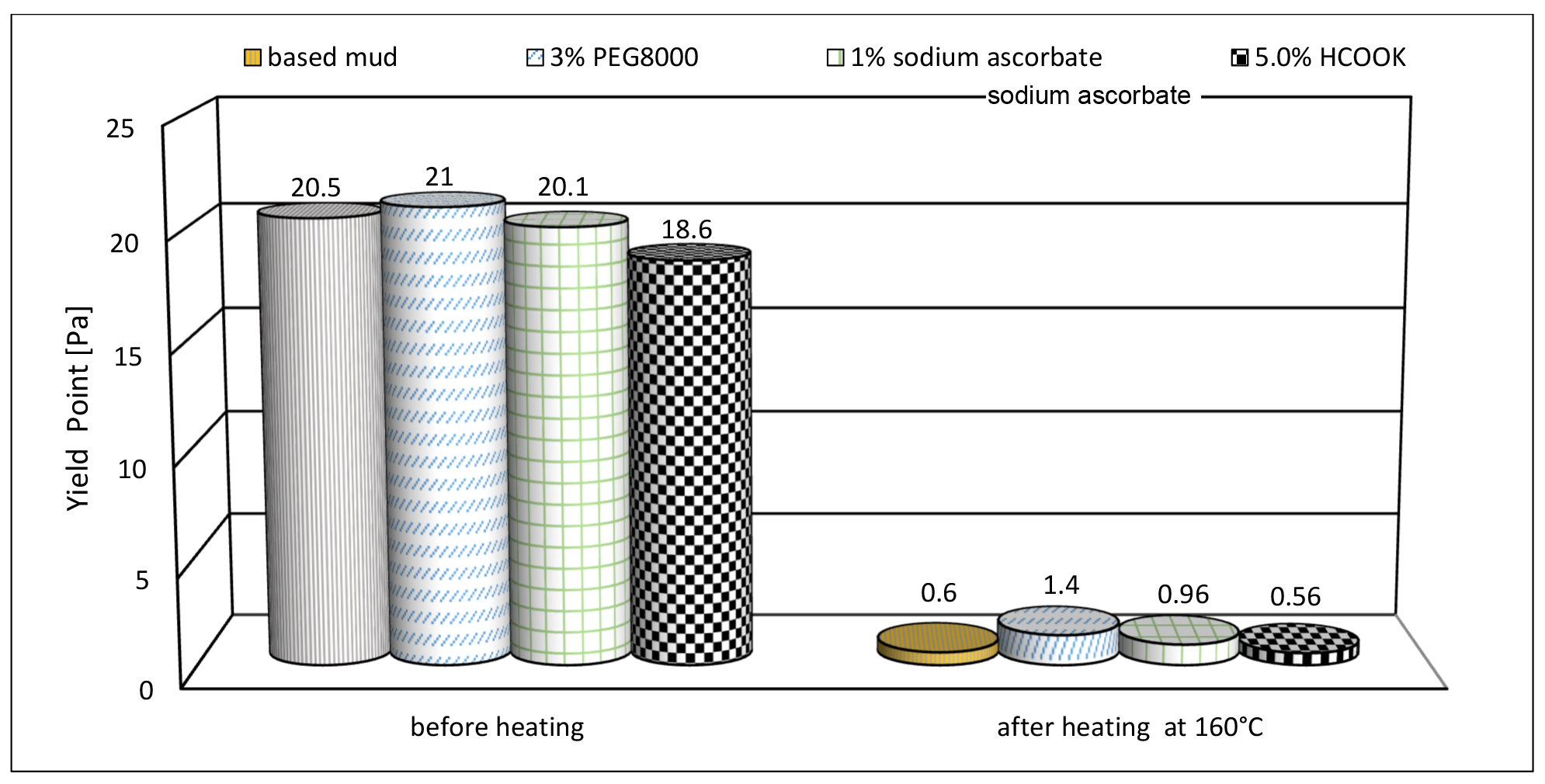

- The conducted laboratory tests indicate that adding glycol compounds with a molecular weight of 8000 and sodium ascorbate to the mud does not protect the polymers from breakdown at 160 °C.

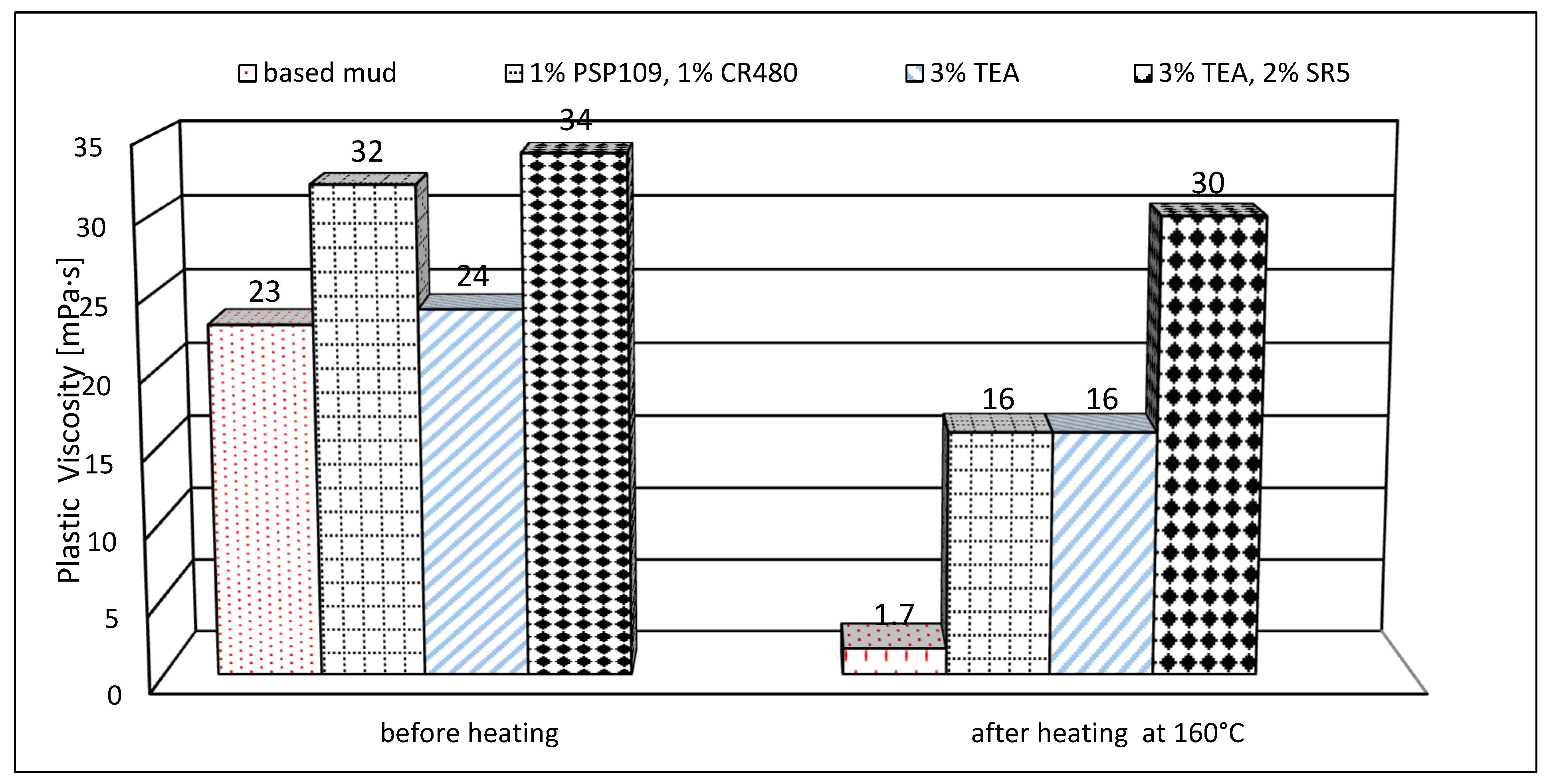

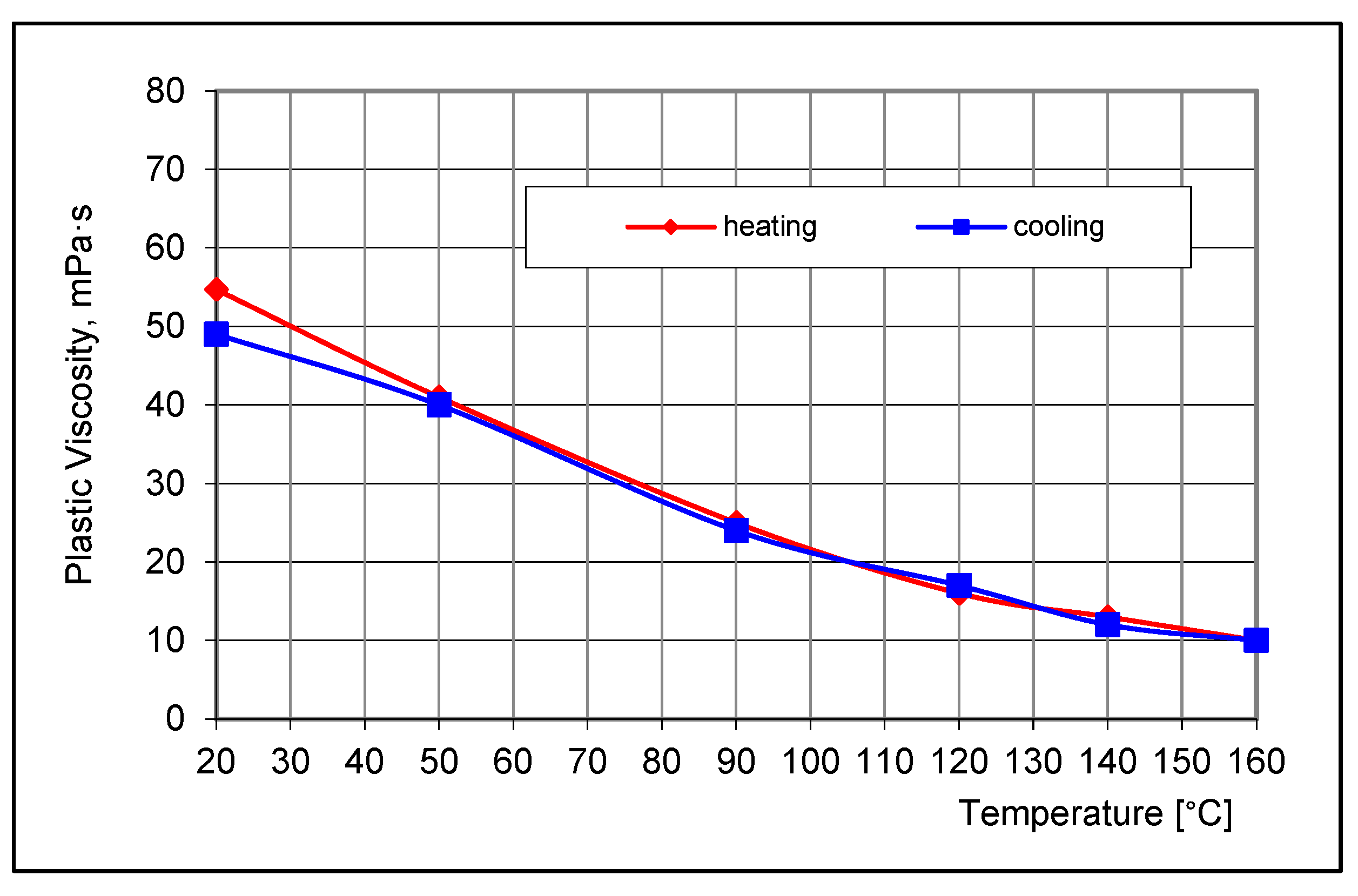

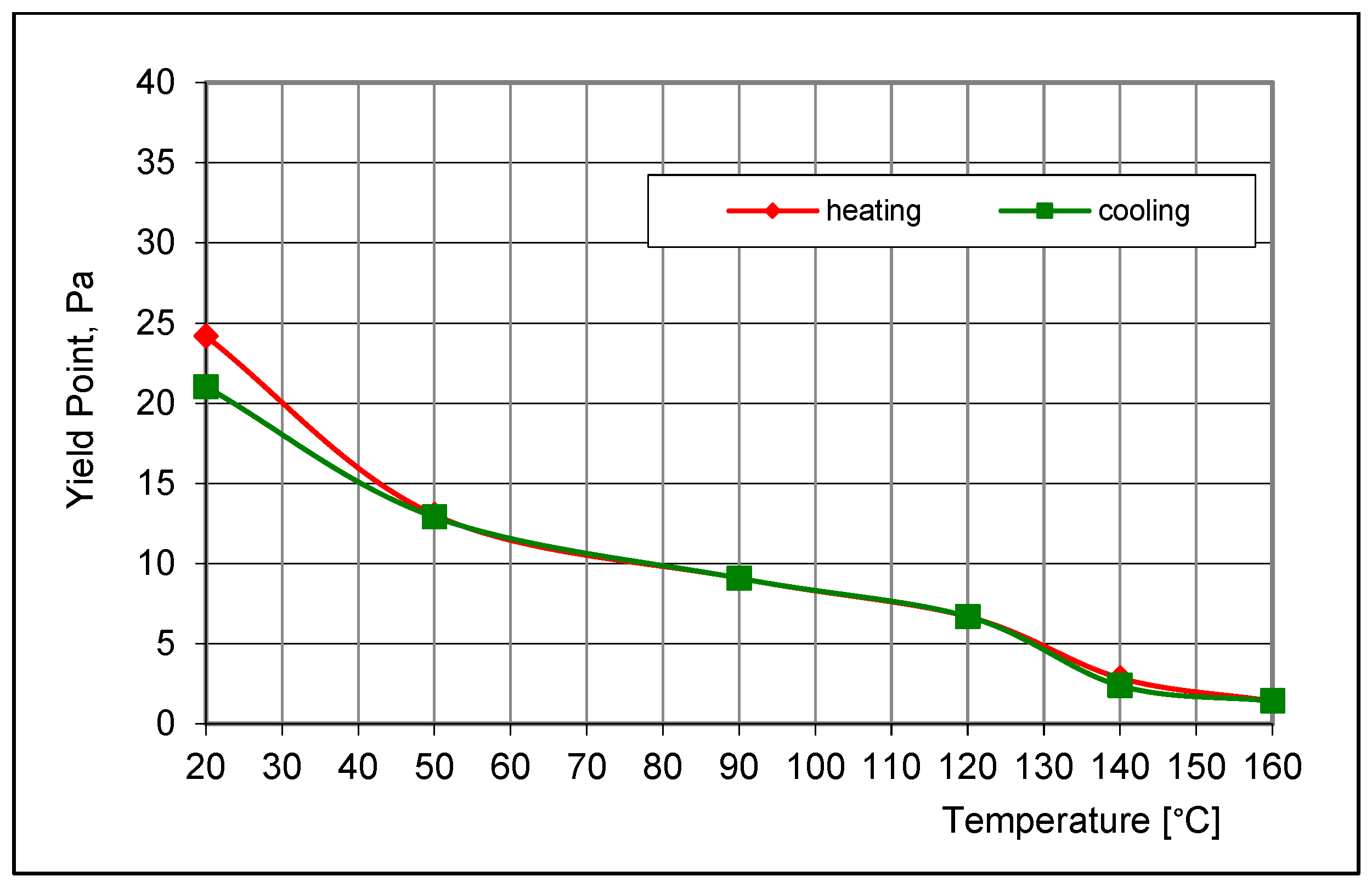

- The conducted research showed that the thermal resistance of the potassium-polymer mud was increased by the use of fatty amine compounds and the “TEA” amine compound. After being exposed to 160 °C, the mud with 3% “TEA” retained 66.7% of the plastic viscosity and 54.7% of the yield point.

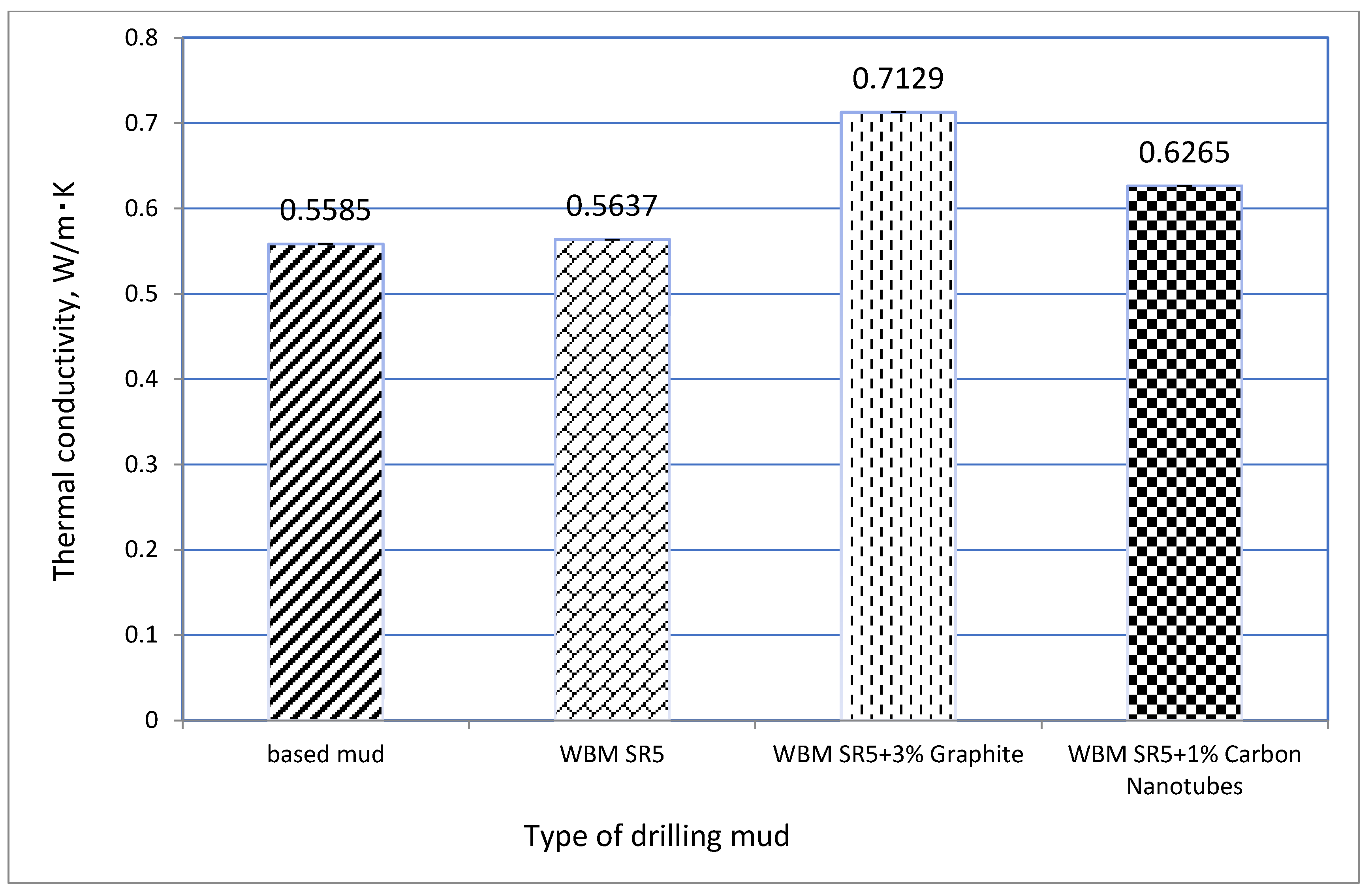

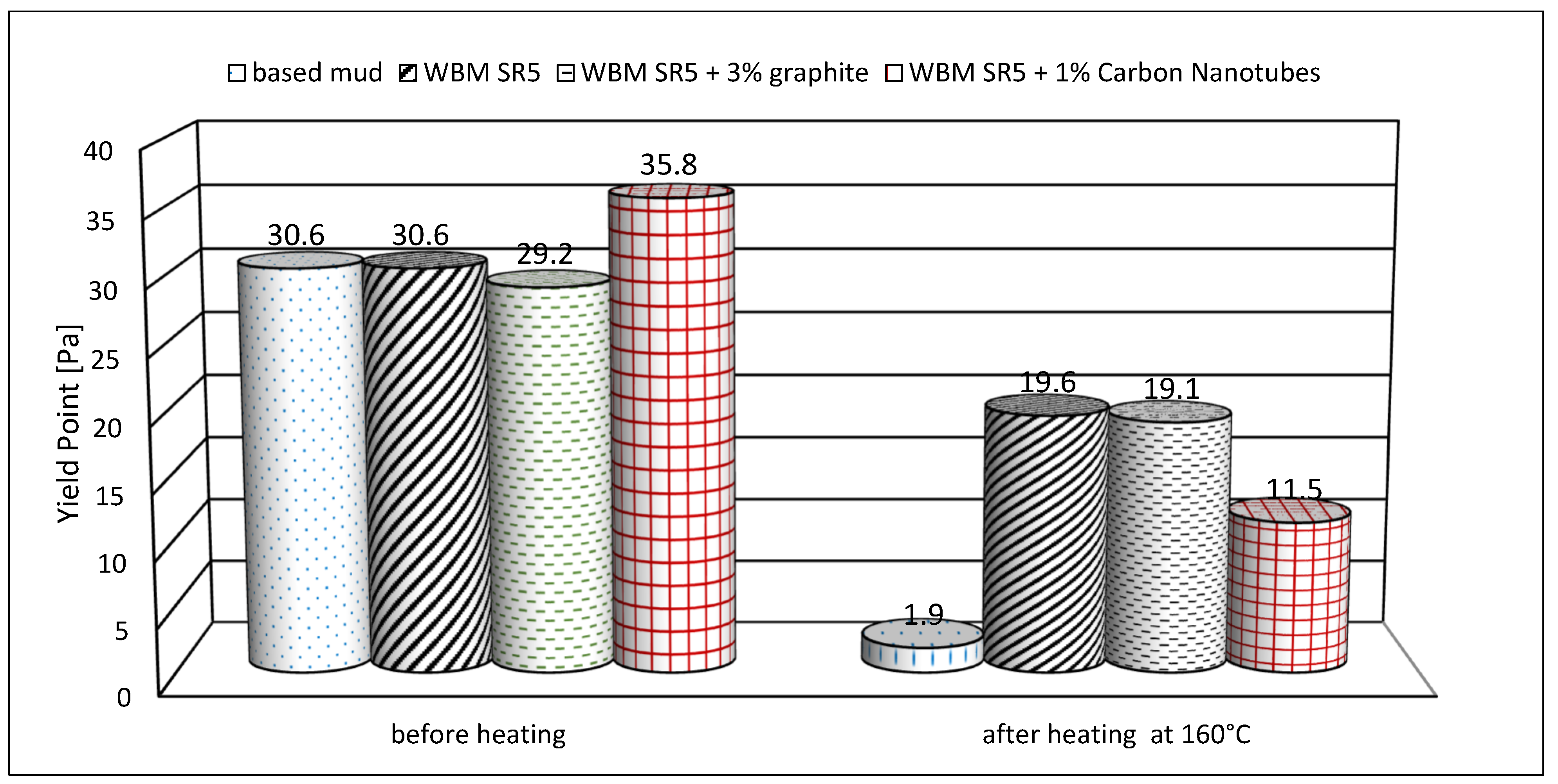

- Modifying the composition of the water-based drilling mud using 3.0% graphite and changing the type of the weighting material based on iron compounds (hematite) improved thermal conductivity by 21.6% relative to the base mud. The mud with carbon nanotubes, in turn, had a thermal conductivity of 0.6265 W/m·K.

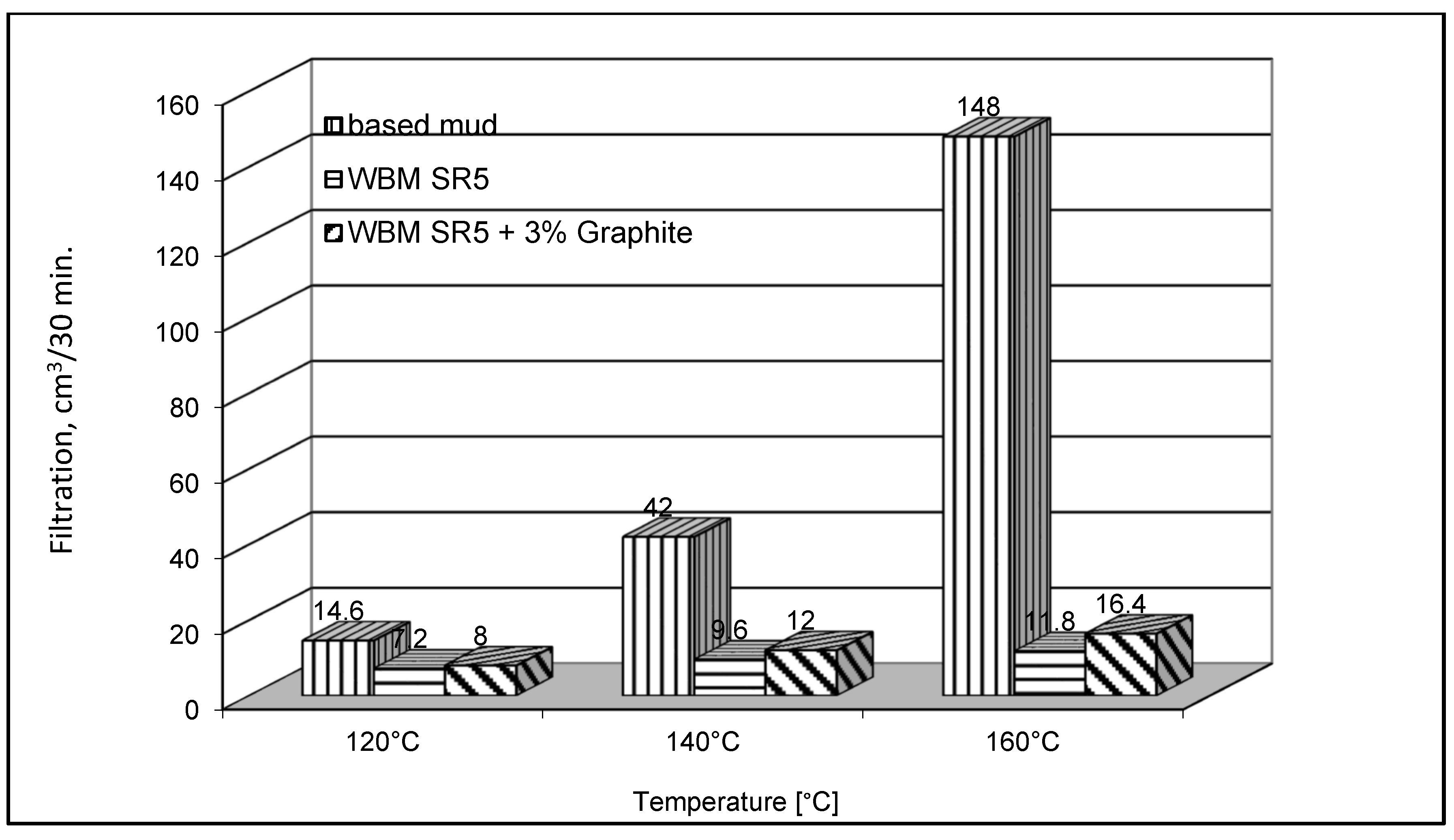

- The increase in thermal conductivity of drilling mud after adding 1% of carbon nanotubes resulted in a decrease in its thermal resistance. The plastic viscosity of the drilling mud with thermal conductivity of 0.6265 W/m·K, as a result of its heating, decreased by 34.1%, and the yield point by 67.9%. The drilling mud with lower thermal conductivity of 0.5637 W/m·K was characterized by higher thermal resistance, which retained 72.5% of the plastic viscosity and 64.1% of the yield point of the mud before heating. The improvement in the thermal properties of the mud to 0.7129 W/m·K did not reduce the filtration after exposure to temperature. The filtration of the mud with 3% graphite at 160 °C was 16.4 cm3/30 min. For comparison, the filtration of the developed mud WBM SR5 at 160 °C was 11.8 cm3/30 min. The filtration of the potassium-polymer mud, in turn, was 148 cm3/30 min.

- The extent of the conducted laboratory tests is sufficient to develop the composition of a water-based drilling mud for geothermal drilling. The developed drilling mud had a high resistance to temperatures up to 160 °C, stable rheological parameters, and low filtration (Table 3, item 3).

- Obtaining positive results from the tests conducted allows us to conclude that further work on increasing the thermal resistance of the water-based mud will be continued. In the longer term, research is planned to increase the thermal resistance of water-based drilling mud without the clay phase up to 200 °C.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| HTHP | High temperature high pressure |

| λ | Thermal conductivity |

| PV | Plastic viscosity |

| AV | Apparent viscosity |

| YP | Yield point |

| WBM | Water-based mud |

References

- Jasiński, B. Analiza możliwości podwyższenia stabilności termicznej płuczek wiertniczych poprzez dobór środków chemicznych. Nafta-Gaz 2021, 3, 152–163. [Google Scholar] [CrossRef]

- Zima, G. Nowy rodzaj płuczki wiertniczej do zastosowania w warunkach HPHT. Nafta-Gaz 2015, 8, 556–564. [Google Scholar]

- Kruszewski, M.; Wittig, V. Wiercenia geotermalne za wodami w stanie nadkrytycznym, jako szansa na zrewolucjonizowanie światowego rynku energii. Wiad. Naft. Gazow. 2017, 12, 4–8. [Google Scholar]

- Abdelmjeed, M.; Saeed, S.; Ramadan, A. Significance and complications of drilling fluid rheology in geothermal drilling, A review. Geothermics 2021, 93, 102066. [Google Scholar] [CrossRef]

- Sabori, R.; Sabbaghi, S.; Kalantariasl, A. Improvement of rheological, filtration and thermal conductivity of bentonite drilling fluid using copper oxide/polyacrylamide nanocomposite. Powder Technol. 2019, 353, 257–266. [Google Scholar] [CrossRef]

- Davoodi, S.; Al-Shargabi, M.; Wood, D.A.; Rukavishnikov, V.S.; Minaev, K.M. Thermally stable and salt-resistant synthetic polymers as drilling fluid additives for deployment in harsh sub-surface conditions: A review. J. Mol. Liq. 2023, 371, 121117. [Google Scholar] [CrossRef]

- Espinosa-Paredes, G.; Garcia-Gutierrez, A. Thermal behaviour of geothermal wells using mud and air–water mixtures as drilling fluids. Energy Convers. Manag. 2004, 45, 1513–1527. [Google Scholar] [CrossRef]

- Parizad, A.; Shahbazi, K.; Tanha, A.A. SiO2 nanoparticle and KCl salt effects on filtration and thixotropical behavior of polymeric water based drilling fluid: With zeta potential and size analysis. Results Phys. 2018, 9, 1656–1665. [Google Scholar] [CrossRef]

- Downs, J.D. Life without Barite: Ten Years of Drilling Deep HPHT Gas Wells with Cesium Formate Brine. In Proceedings of the SPE/IADC Middle East Drilling Technology Conference and Exhibition, Muscat, Oman, 24–26 October 2011. SPE-145562-MS. [Google Scholar] [CrossRef]

- Duangthongsuk, W.; Wongwises, S. Measurement of temperature-dependent thermal conductivity and viscosity of TiO2-water nanofluids. Exp. Therm. Fluid Sci. 2009, 33, 706–714. [Google Scholar] [CrossRef]

- Vryzas, Z.; Mahmoud, O.; Nasr-El-Din, H.; Zaspalis, V.; Kelessidis, V.C. Incorporation of Fe3O4 nanoparticles as drilling fluid additives for improved drilling operations. In Proceedings of the ASME 2016 35th International Conference on Ocean, Offshore and Arctic Engineering, Busan, Republic of Korea, 19–24 June 2016; American Society of Mechanical Engineers: New York, UY, USA, 2016. [Google Scholar]

- Zhong, H.; Guan, Y.; Qiu, Z.; Grady, B.P.; Su, J.; Huang, W. Application of carbon coated bentonite composite as an ultra-high temperature filtration reducer in water-based drilling fluid. J. Mol. Liq. 2023, 375, 121360. [Google Scholar] [CrossRef]

- Gautam, S.; Guria, C.; Rajak, V.K. A state of the art review on the performance of high-pressure and high-temperature drilling fluids: Towards understanding the structure-property relationship of drilling fluid additives. J. Pet. Sci. Eng. 2022, 213, 110318. [Google Scholar] [CrossRef]

- Guerrero, M.; Guerrero, X. Use of Amine/PHPA System To Drill High Reactive Shales in the Orito Field in Colombia. In Proceedings of the International Oil Conference and Exhibition in Mexico, Cancun, Mexico, 31 August–2 September 2006. SPE-104010-MS. [Google Scholar] [CrossRef]

- Mao, H.; Yang, Y.; Zhang, H.; Zheng, J.; Zhong, Y. Conceptual design and methodology for rheological control of water-based drilling fluids in ultra-high temperature and ultra-high pressure drilling applications. J. Pet. Sci. Eng. 2020, 188, 106884. [Google Scholar] [CrossRef]

- Sowiżdżał, A. Potencjał geotermalny zbiorników mezozoicznych niżu polskiego do produkcji energii elektrycznej. Tech. Poszuk. Geol. 2016, 55, 105–115. [Google Scholar]

- Agwu, O.E.; Akpabio, J.U.; Ekpenyong, M.E.; Inyang, U.G.; Asuquo, D.E.; Eyoh, I.J.; Adeoye, O.S. A comprehensive review of laboratory, field and modelling studies on drilling mud rheology in high temperature high pressure (HTHP) conditions. J. Nat. Gas Sci Eng. 2021, 94, 104046. [Google Scholar] [CrossRef]

- Akpan, E.U.; Enyi, G.C.; Nasr, G.; Yahaya, A.A.; Ahmadu, A.A.; Saidu, B. Water-based drilling fluids for high-temperature applications and water-sensitive and dispersible shale formations. J. Pet. Sci. Eng. 2019, 175, 1028–1038. [Google Scholar] [CrossRef]

- Cheraghian, G. Nanoparticles in drilling fluid: A review of the state-of-the-art. J. Mater. Res. Technol. 2021, 13, 737–753. [Google Scholar] [CrossRef]

- Davarpanah, A.; Mirshekari, B. Effect of formate fluids on the shale stabilization of shale layers. Energy Rep. 2019, 5, 987–992. [Google Scholar] [CrossRef]

- Abdo, J.; Haneef, M.D. Clay nanoparticles modified drilling fluids for drilling of deep hydrocarbon wells. Appl. Clay Sci. 2013, 86, 76–82. [Google Scholar] [CrossRef]

- Abdo, J.; Haneef, M.D. Nano-Enhanced Drilling Fluids: Pioneering Approach to Overcome Uncompromising Drilling Problems. J. Energy Resour. Technol. 2012, 134, 014501. [Google Scholar] [CrossRef]

- Echt, T.; Plank, J. An improved test protocol for high temperature carrying capacity of drilling fluids exemplified on a sepiolite mud. J. Nat. Gas Sci. Eng. 2019, 70, 102964. [Google Scholar] [CrossRef]

- Uliasz, M.; Zima, G.; Błaż, S.; Jasiński, B. Roztwory mrówczanów jako składniki płuczek wiertniczych. Przemys. Chem. 2016, 95, 297–302. [Google Scholar] [CrossRef]

- Aftab, A.; Ismail, A.R.; Ibupoto, Z.H. Enhancing the rheological properties and shale inhibition behavior of water-based mud using nanosilica, multi-walled carbon nanotube, and graphene nanoplatelet. Egypt. J. Pet. 2017, 26, 291–299. [Google Scholar] [CrossRef]

- Aftab, A.; Ismail, A.R.; Ibupoto, Z.H.; Akeiber, H.; Malghani, M.G.K. Nanoparticles based drilling muds a solution to drill elevated temperature wells: A review. Renew. Sustain. Energy Rev. 2017, 76, 1301–1313. [Google Scholar] [CrossRef]

- Cheraghian, G.; Wu, Q.; Mostofi, M.; Li, M.C.; Afrand, M.; Sangwai, J.S. Effect of a novel clay/silica nanocomposite on water-based drilling fluids: Improvements in rheological and filtration properties. Coll. Surf. A Physicochem. Eng. Asp. 2018, 555, 339–350. [Google Scholar] [CrossRef]

- Iijima, S. Carbon nanotubes: Past, present, and future. Phys. B Condens. Matter 2002, 323, 1–5. [Google Scholar] [CrossRef]

- Rafati, R.; Smith, S.R.; Haddad, A.S.; Novara, R.; Hamidi, H. Effect of nanoparticles on the modifications of drilling fluids properties: A review of recent advances. J. Pet. Sci. Eng. 2018, 161, 61–76. [Google Scholar] [CrossRef]

- Sahu, A.; Jain, A.; Gulbake, A. The role of carbon nanotubes in nanobiomedicines. Int. J. Pharm. Pharm. Sci. 2017, 9, 235–251. [Google Scholar] [CrossRef]

- Amirhossein, P.; Khalil, S.; Abbas Ayatizadeh, T. Enhancement of polymeric water-based drilling fluid properties using nanoparticles. J. Pet. Sci. Eng. 2018, 170, 813–828. [Google Scholar] [CrossRef]

- Zakaria, M.; Husein, M.M.; Harland, G. Novel Nanoparticle-based Drilling Fluid with Improved Characteristics. In Proceedings of the SPE International Oilfield Nanotechnology Conference and Exhibition, Nooedwijk, The Netherlands, 12–14 June 2012. [Google Scholar]

- Liu, L.; Sun, J.; Wang, R.; Qu, Y.; Liu, F.; Yang, J.; Cheng, R.; Gao, S.; Huang, H. Synthesis of a new high temperature and salt resistant zwitterionic filtrate reducer and its application in water-based drilling fluid. Colloids Surf. A Physicochem. Eng. Asp. 2022, 651, 129730. [Google Scholar] [CrossRef]

- Martin, C.; Nourian, A.; Babaie, M.; Nasr, G.G. Innovative drilling fluid containing sand grafted with a cationic surfactant capable of drilling high pressure and high temperature geothermal and petroleum wells. Geoenergy Sci. Eng. 2024, 237, 212767. [Google Scholar] [CrossRef]

- Błaż, S.; Zima, G.; Jasiński, B. Badania laboratoryjne nad zwiększeniem przewodności cieplnej płuczek wiertniczych przeznaczonych do wierceń geotermalnych. Nafta-Gaz 2023, 5, 338–348. [Google Scholar] [CrossRef]

- Sedaghatzadeh, M.; Khodadadi, A. An improvement in thermal and rheological properties of water-based drilling fluids using multiwall carbon nanotube (MWCNT). Iran. J. Oil Gas Sci. Technol. 2012, 1, 55–65. [Google Scholar]

- William, J.K.M.; Ponmani, S.; Samuel, R.; Nagarajan, R.; Sangwai, J.S. Effect of CuO and ZnO nanofluids in xanthan gum on thermal, electrical and high pressure rheology of water-based drilling fluids. J. Pet. Sci. Eng. 2014, 117, 15–27. [Google Scholar] [CrossRef]

- Ismail, A.R.; Aftab, A.; Ibupoto, Z.H.; Zolkifile, N. The novel approach for the enhancement of rheological properties of water-based drilling fluids by using multi-walled carbon nanotube, nanosilica and glass beads. J. Pet. Sci. Eng. 2016, 139, 264–275. [Google Scholar] [CrossRef]

- Chen, H.; Ding, Y. Heat Transfer and Rheological Behaviour of Nanofluids-A Review. Adv. Transp. Phenom. 2009, 2009, 135–177. [Google Scholar]

- Dirmye, M.R.; Martin, J.; Nolas, G.S.; Sen, A.; Badding, J.V. Thermal and Electrical Conductivity of Size-Tuned Bismuth Telluride Nanoparticles. Small 2009, 5, 933–937. [Google Scholar] [CrossRef] [PubMed]

- Sing, J.; Choudhary, N.; Nigam, K.D.P. The thermal and transport characteristics of nanofluids in a novel three-dimensional device. Can. J. Chem. Eng. 2014, 92, 2185–2201. [Google Scholar] [CrossRef]

- Numano, T.; Higuchi, H.; Alexander, D.B.; Alexander, W.T.; Abdelgied, M.; El-Gazzar, A.M.; Saleh, D.; Takase, H.; Hirose, A.; Naiki-Ito, A.; et al. MWCNT-7 administered to the lung by intratracheal instillation induces development of pleural mesothelioma in F344 rats. Cancer Sci. 2019, 110, 2485–2492. [Google Scholar] [CrossRef] [PubMed]

- Suzui, M.; Futakuchi, M.; Fukamachi, K.; Numano, T.; Abdelgied, M.; Takahashi, S.; Ohnishi, M.; Omori, T.; Tsuruoka, S.; Hirose, A.; et al. Multiwalled carbon nanotubes intratracheally instilled into the rat lung induce development of pleural malignant mesothelioma and lung tumors. Cancer Sci. 2016, 107, 924–935. [Google Scholar] [CrossRef]

- PN-EN ISO 10414-1; Petroleum and Natural Gas Industries. Field Testing of Drilling Fluids. Part 1: Water-Based Fluids. Polish Committee for Standardization: Warsaw, Poland, 2013.

- PN-EN ISO 10414-2; Petroleum and Natural Gas Industries. Field Testing of Drilling Fluids. Part 2: Oil-Based Fluids. Polish Committee for Standardization: Warsaw, Poland, 2013.

| Composition | Water-Based Mud |

|---|---|

| H2O | 1000 cm3 |

| Biocyde | 0.1% |

| XCD | 0.4% |

| PAC R | 0.3% |

| PAC L | 0.5% |

| Starch HHT | 0.5% |

| KCl | 5% |

| Carbonate blocker | 7% |

| No. | Water Based Mud WBM | Density, g/cm3 | Plastic Viscosity, mPa.s | Apparent Viscosity, mPa.s | Yield Point, Pa | Gel Strength, I/II, Pa | Filtration API [cm3] | pH |

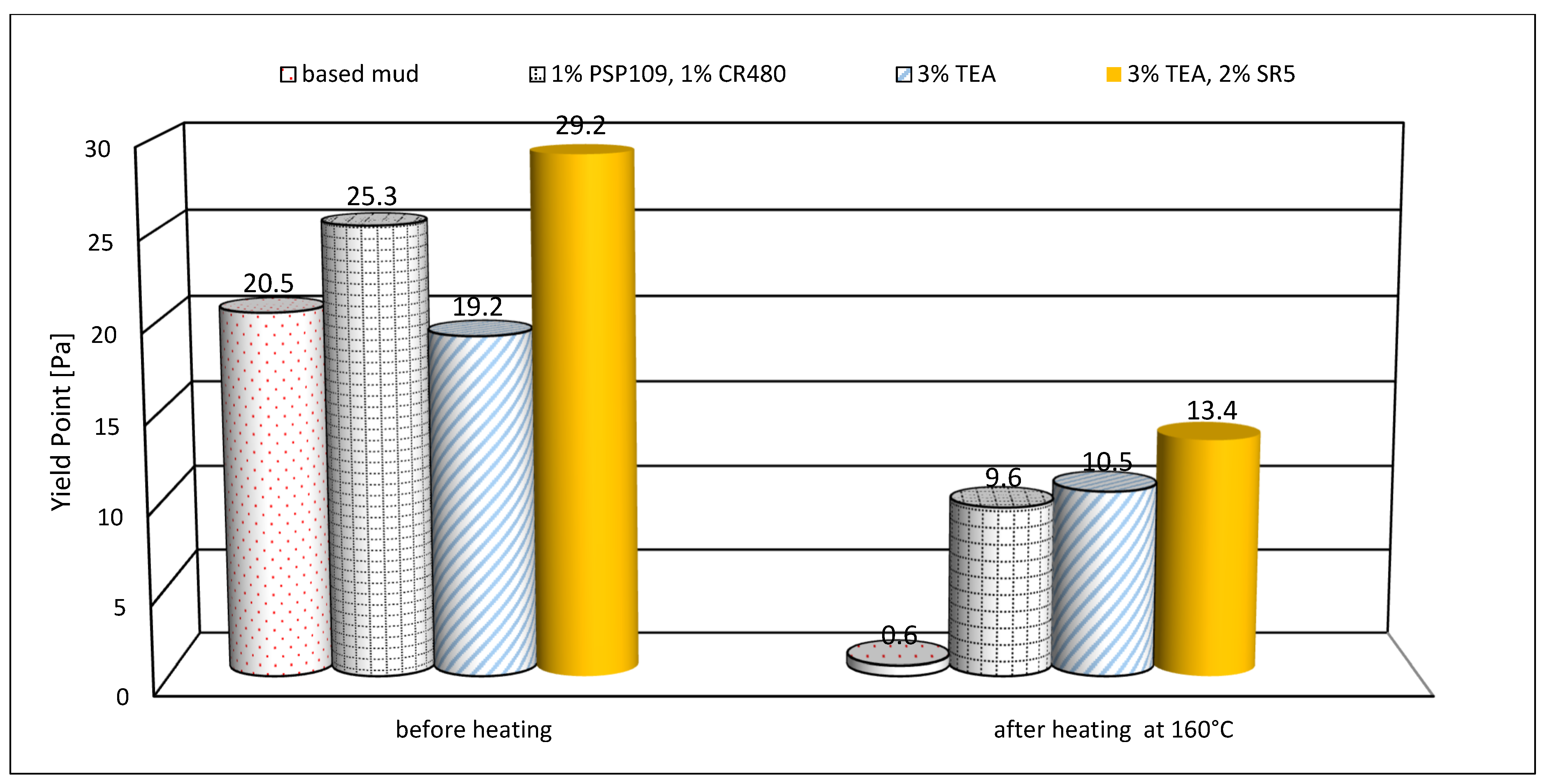

|---|---|---|---|---|---|---|---|---|

| ±0.05 | ±1 | ±1 | ±0.75 | ±0.25 | ±0.1 | ±1 | ||

| 1 | WBM before heating | 1.08 | 23 | 44.5 | 20.5 | 4.8/7.2 | 8.0 | 9.4 |

| 2 | after heating at 160 °C | 1.08 | 1.7 | 2.35 | 0.6 | 0.05/0.05 | 56.0 | 6.9 |

| 3 | WBM No.1 +1% PSP109 +1% CR480 | 1.09 | 32 | 58.5 | 25.3 | 4.8/7.2 | 6.4 | 9.4 |

| 4 | after heating at 160 °C | 1.09 | 16 | 26 | 9.6 | 0.96/1.4 | 6.8 | 8.9 |

| 5 | WBM No.1 +3% TEA before heating | 1.08 | 24 | 44 | 19.2 | 3.8/6.7 | 7.8 | 10.6 |

| 6 | after heating at 160 °C | 1.08 | 16 | 27 | 10.5 | 1.4/1.9 | 18 | 10.4 |

| 7 | WBM No.3 +3% TEA +2% KAD before heating | 1.09 | 33 | 60 | 25.8 | 5.3/7.2 | 5.2 | 10.2 |

| 8 | after heating at 160 °C | 1.09 | 27 | 38 | 10.5 | 1.4/2.4 | 6.6 | 9.7 |

| 9 | WBM No.3 +3% TEA +2% SR5 before heating | 1.09 | 34 | 64.5 | 29.2 | 4.8/7.6 | 3.6 | 10.5 |

| 10 | after heating at 160 °C | 1.09 | 30 | 44 | 13.4 | 1.4/2.9 | 4.8 | 10.3 |

| No. | Water Based Mud WBM | Density, g/cm3 | Plastic Viscosity, mPa.s | Apparent Viscosity, mPa.s | Yield Point, Pa | Thermal Conductivity, W/m·K | Filtration API cm3 | pH |

|---|---|---|---|---|---|---|---|---|

| ±0.05 | ±1 | ±1 | ±0.75 | ±0.0001 | ±0.1 | ±1 | ||

| 1 | WBM + barite before heating | 1.19 | 29 | 61 | 30.6 | 0.5585 | 5.2 | 9.5 |

| 2 | after heating at 160 °C | 1.19 | 4 | 6 | 1.9 | - | 120 | 7.7 |

| 3 | WBM No.1 +1% PSP109 +1% CR480 +3% TEA +2% SR5 | 1.21 | 40 | 72 | 30.6 | 0.5637 | 2.0 | 10.5 |

| 4 | after heating at 160 °C | 1.21 | 29 | 49.5 | 19.6 | - | 2.6 | 10.3 |

| 5 | WBM +1% PSP109 +1% CR480 +3% TEA +2% SR5 +3% graphite + hematite before heating | 1.2 | 40 | 70.5 | 29.2 | 0.7129 | 3.2 | 10.5 |

| 6 | after heating at 160 °C | 1.2 | 28 | 48 | 19.1 | - | 6.4 | 10.3 |

| 7 | WBM No.3 +3% carbon nanotubes before heating | 1.21 | 44 | 81.5 | 35.8 | 0.6265 | 2.8 | 10.5 |

| 8 | after heating at 160 °C | 1.21 | 29 | 41 | 11.5 | - | 5.2 | 10.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Błaż, S.; Zima, G.; Jasiński, B.; Kremieniewski, M. Increasing the Thermal Resistance of Water-Based Mud for Drilling Geothermal Wells. Energies 2024, 17, 4537. https://doi.org/10.3390/en17184537

Błaż S, Zima G, Jasiński B, Kremieniewski M. Increasing the Thermal Resistance of Water-Based Mud for Drilling Geothermal Wells. Energies. 2024; 17(18):4537. https://doi.org/10.3390/en17184537

Chicago/Turabian StyleBłaż, Sławomir, Grzegorz Zima, Bartłomiej Jasiński, and Marcin Kremieniewski. 2024. "Increasing the Thermal Resistance of Water-Based Mud for Drilling Geothermal Wells" Energies 17, no. 18: 4537. https://doi.org/10.3390/en17184537

APA StyleBłaż, S., Zima, G., Jasiński, B., & Kremieniewski, M. (2024). Increasing the Thermal Resistance of Water-Based Mud for Drilling Geothermal Wells. Energies, 17(18), 4537. https://doi.org/10.3390/en17184537