Estimation of Energy-Saving Potential Using Commercial SiC Power Converters †

Abstract

:1. Introduction

2. SiC Power Semiconductors

3. Methodology

- The datasheets often lack comprehensive information, typically providing only peak efficiency figures. This can obscure the true benefits of WBG converters, especially in scenarios where they operate under partial load. To enhance the precision of our estimates, further characterization and simulation that take into account different load profiles are necessary.

- The estimated energy savings are based on the total energy consumption figures for the various applications, which themselves are approximations.

- Generally, there is a lack of detailed information regarding the converters’ internal designs from the manufacturers. It remains unclear whether these converters are fully equipped with SiC MOSFET (metal-oxide semiconductor field-effect transistor) configurations or if they incorporate SiC diodes alongside Si IGBTs (insulated-gate bipolar transistors) within a hybrid setup. The latter scenario could lead to an underestimation of efficiency gains.

- The efficiency of converters is highly influenced by additional parameters such as power rating, frequency, and operational ranges. When power converter manufacturers have access to better semiconductors, such as SiC devices, they often do more than simply replace the old components to achieve lower power losses. Typically, they leverage the superior performance characteristics of these semiconductors to enhance the overall design. One common approach is to increase the switching frequency, which allows for the reduction in the size of passive components like inductors and capacitors, leading to more compact and lighter converters. However, this design choice can impact the real energy savings, as higher switching frequencies may introduce additional losses due to increased switching events. Designers often face a trade-off between maximizing efficiency and achieving higher power density. While SiC devices inherently offer higher efficiency, the ultimate savings depend on how these devices are integrated into the system. If the primary goal shifts towards improving power density, the efficiency gains might be partially sacrificed. Therefore, while SiC semiconductors present significant advantages, the actual energy savings realized in practice will depend on the specific design choices made by the engineers.

4. Silicon Carbide Applications

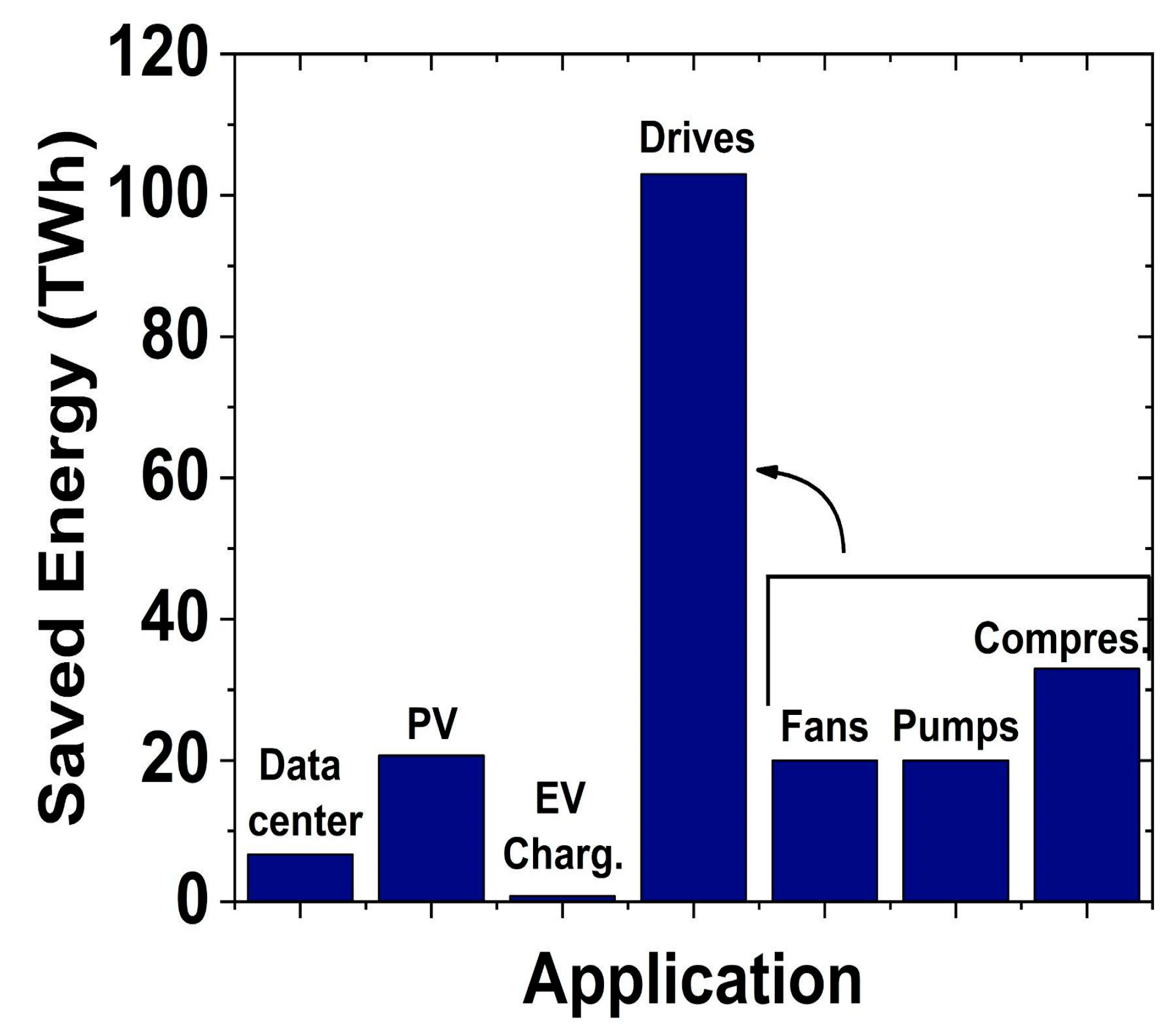

4.1. Data Centers

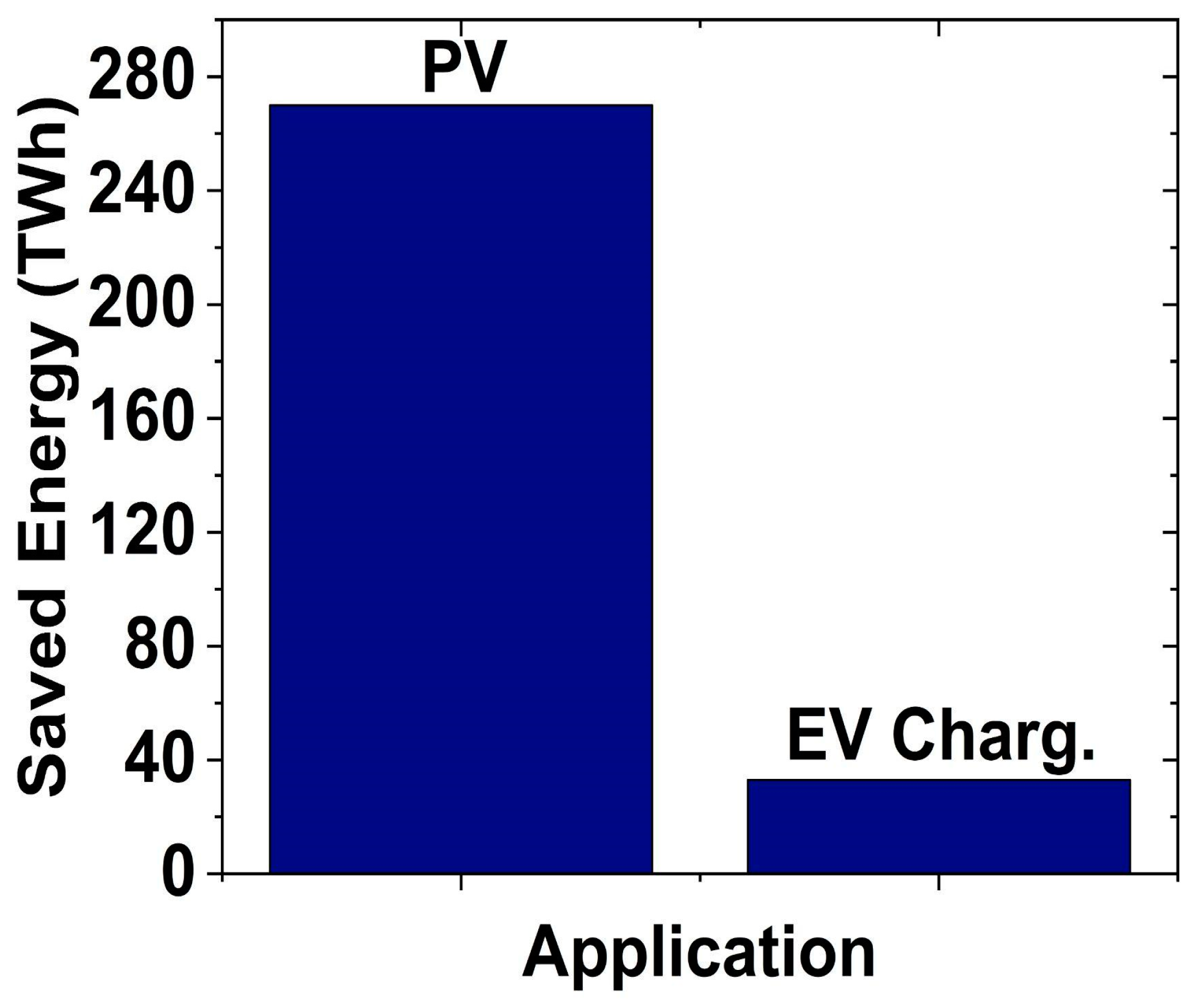

4.2. PV Power Generation

4.3. Motor Drives

4.4. HVAC

4.5. E-Vehicle DC Fast Charging Stations (Off-Board) and On-Board Chargers (OBC)

4.6. EV Traction Inverters

4.7. Battery Storage

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rahimo, M.; Nistor, I.; Lanctot, P.; Idaka, S.; Kondo, H.; Majumdar, G.; Miyoshi, A.; Trifunovich, D.; Akagi, H.; Blaabjerg, F.; et al. Power Semiconductors for an Energy-Wise Society; IEC White Paper; Austrian Institute of Technology: Seibersdorf, Austria, 2023. [Google Scholar]

- Yuan, X.; Laird, I.; Walder, S. Opportunities, Challenges, and Potential Solutions in the Application of Fast-Switching SiC Power Devices and Converters. IEEE Trans. Power Electron. 2021, 36, 3925–3945. [Google Scholar] [CrossRef]

- Iannaccone, G.; Sbrana, C.; Morelli, I.; Strangio, S. Power Electronics Based on Wide-Bandgap Semiconductors: Opportunities and Challenges. IEEE Access 2021, 9, 139446–139456. [Google Scholar] [CrossRef]

- PECTA. Power Electronic Conversion Technology Annex. Available online: https://www.iea-4e.org/pecta/ (accessed on 12 June 2023).

- Buttay, C.; Planson, D.; Allard, B.; Bergogne, D.; Bevilacqua, P.; Joubert, C.; Lazar, M.; Martin, C.; Morel, H.; Tournier, D.; et al. State of the art of high temperature power electronics. Mater. Sci. Eng. B 2011, 176, 283–288. [Google Scholar] [CrossRef]

- Marzoughi, A.; Burgos, R.; Boroyevich, D. Characterization and Performance Evaluation of the State-of-the-Art 3.3 kV 30 A Full-SiC MOSFETs. IEEE Trans. Ind. Appl. 2019, 55, 575–583. [Google Scholar] [CrossRef]

- Tamaso, H.; Sawada, K.; Fujikawa, K.; Harada, S.; Shinkai, J.; Tokuda, H.; Masuda, T.; Honaga, M.; Itoh, S.; Tsuno, T.; et al. Development of Fast-Switching SiC Transistor. SEI Tech. Rev. 2008, 43–49. Available online: https://sumitomoelectric.com/sites/default/files/2020-12/download_documents/66-05.pdf (accessed on 12 June 2023).

- She, X.; Huang, A.Q.; Lucía, Ó.; Ozpineci, B. Review of Silicon Carbide Power Devices and Their Applications. IEEE Trans. Ind. Electron. 2017, 64, 8193–8205. [Google Scholar] [CrossRef]

- Spejo, L.B.; Akor, I.; Rahimo, M.; Minamisawa, R.A. Life-cycle energy demand comparison of medium voltage silicon IGBT and silicon carbide MOSFET power semiconductor modules in railway traction applications. Power Electron. Dev. Comp. 2023, 6, 100050. [Google Scholar] [CrossRef]

- EATON. Eaton 93PR UPS Range Brochure. Available online: https://www.eaton.com/content/dam/eaton/products/backup-power-ups-surge-it-power-distribution/backup-power-ups/eaton-93pr/eaton-93pr-300-1200kw-ups-brochure-en-us-east-asia.pdf (accessed on 12 June 2023).

- Mitsubishi. Summit Series Datasheet. Available online: https://www.mitsubishicritical.com/media/6317/sa-enl0048-summit-series-data-sheet.pdf (accessed on 12 June 2023).

- Toshiba. Uninterruptible Power Systems G2020 Series. Available online: https://www.toshiba.com/tic/datafiles/brochures/G2020_Series_ESSENCE_101619_nocrop.pdf (accessed on 12 June 2023).

- TMEIC. TMUPS Next Generation UPS for Business Critical Loads. Available online: https://5.imimg.com/data5/SELLER/Doc/2021/4/DQ/BE/TJ/60336995/tmups-w250-series-ups.pdf (accessed on 12 June 2023).

- General Electric. LV5+ Solar Inverter Datasheet. Available online: https://www.google.com.hk/url?sa=t&source=web&rct=j&opi=89978449&url=https://www.gevernova.com/content/dam/gepower-new/global/en_US/documents/lvs1500-series-inverters/Flexinverter-solar-inverter-datasheet-en-x88009-202112-ltr-r002.pdf&ved=2ahUKEwjkruKe57eIAxVOslYBHS7qEygQFnoECBoQAQ&usg=AOvVaw2YMo1wY0d5QqxJdHriFC8u (accessed on 12 June 2023).

- SMA. SMA and Infineon Reduce System Costs for Inverters. Available online: https://www.sma.de/en/newsroom/news-details/sma-and-infineon-reduce-system-costs-for-inverters (accessed on 12 June 2023).

- Sungrow. SG250HX Datasheet. Available online: https://en.sungrowpower.com/upload/file/20210108/DS_20201121_SG250HX%20Datasheet_V1.5.4_EN.pdf.pdf (accessed on 12 June 2023).

- Fronius. Fronius Symo GEN24 Plus Datasheet; Fronius International: Wels, Austria, 2022. [Google Scholar]

- REFUsol. REFUsol 020K-SCI Datasheet. Available online: https://cdn.enfsolar.com/Product/pdf/Inverter/507280bfa89a8.pdf (accessed on 12 June 2023).

- Kaco. Blueplanet 150 TL3 Datasheet. Available online: https://kaco-newenergy.com/index.php?eID=dumpFile&t=f&f=2768&token=bce54fc792e4f842a145ac1f0891d739d95f95e4 (accessed on 12 June 2023).

- Infinitum. Infineon Collaborates with Infinitum for the New Aircore Electric Motor with Aircore. Available online: https://goinfinitum.com/infineon-collaborates-with-infinitum-for-the-new-air-core-electric-motor-with-air-core/ (accessed on 12 June 2023).

- Plettenberg. MST 400-160 (SiC). Available online: https://plettenbergmotors.com/product/mst-400-160-sic-silicon-carbide/ (accessed on 12 June 2023).

- APD. Aergility ATLIS UAV. Available online: https://www.unmannedsystemstechnology.com/company/advanced-power-drives-apd/silicon-carbide-sic-inverters/ (accessed on 12 June 2023).

- Ingeteam. Rapid ST 200/400. Available online: https://www.ingeteam.com/en-us/sectors/electric-mobility/p15_58_686/ingerev-rapid-station.aspx (accessed on 12 June 2023).

- Kaco. Blueplanet Gridsave 92.0-137 TL3-S. Available online: https://kaco-newenergy.com/products/blueplanet-gridsave-92-TL3-S/ (accessed on 12 June 2023).

- Yang, Y. Electrification: Is it Now? Not Really…—Automotive 2023 Review, Part I. Available online: https://www.yolegroup.com/strategy-insights/electrification-is-it-now-not-really/ (accessed on 12 June 2023).

- Mitsubishim, MSZ-L SERIES Datasheet. Available online: https://it.mitsubishielectric.com/it/ (accessed on 6 May 2024).

- Innoelectric. High Efficiency Thanks to Silicon Carbide Technology. Available online: https://innolectric.ag/high-efficiency-thanks-to-silicon-carbide-technology/?lang=en (accessed on 6 May 2024).

- IEA. Data Centres and Data Transmission Networks. Available online: https://www.iea.org/energy-system/buildings/data-centres-and-data-transmission-networks (accessed on 12 June 2023).

- Statista. Data Center Average Annual Power Usage Effectiveness (PUE) Worldwide 2007–2022. Available online: https://www.statista.com/statistics/1229367/data-center-average-annual-pue-worldwide/ (accessed on 12 June 2023).

- ABB. How Data Centers Can Minimize Their Energy Use. Available online: https://library.e.abb.com/public/ffa3a0ef7d7245b79807eeae2eaf7879/How%20data%20centers%20can%20minimize%20their%20energy%20use.pdf?x-sign=a+ZdVrPy6ESg6HKPF+tn0b08WMF+qeUck79UGJRQh1vGGTEnJ30jMRDw1lk4bmV0 (accessed on 12 June 2023).

- IEA. Solar PV. Available online: https://www.iea.org/energy-system/renewables/solar-pv (accessed on 12 June 2024).

- Statista. Solar Energy—Worldwide. Available online: https://www.statista.com/outlook/io/energy/renewable-energy/solar-energy/worldwide?currency=usd (accessed on 12 June 2023).

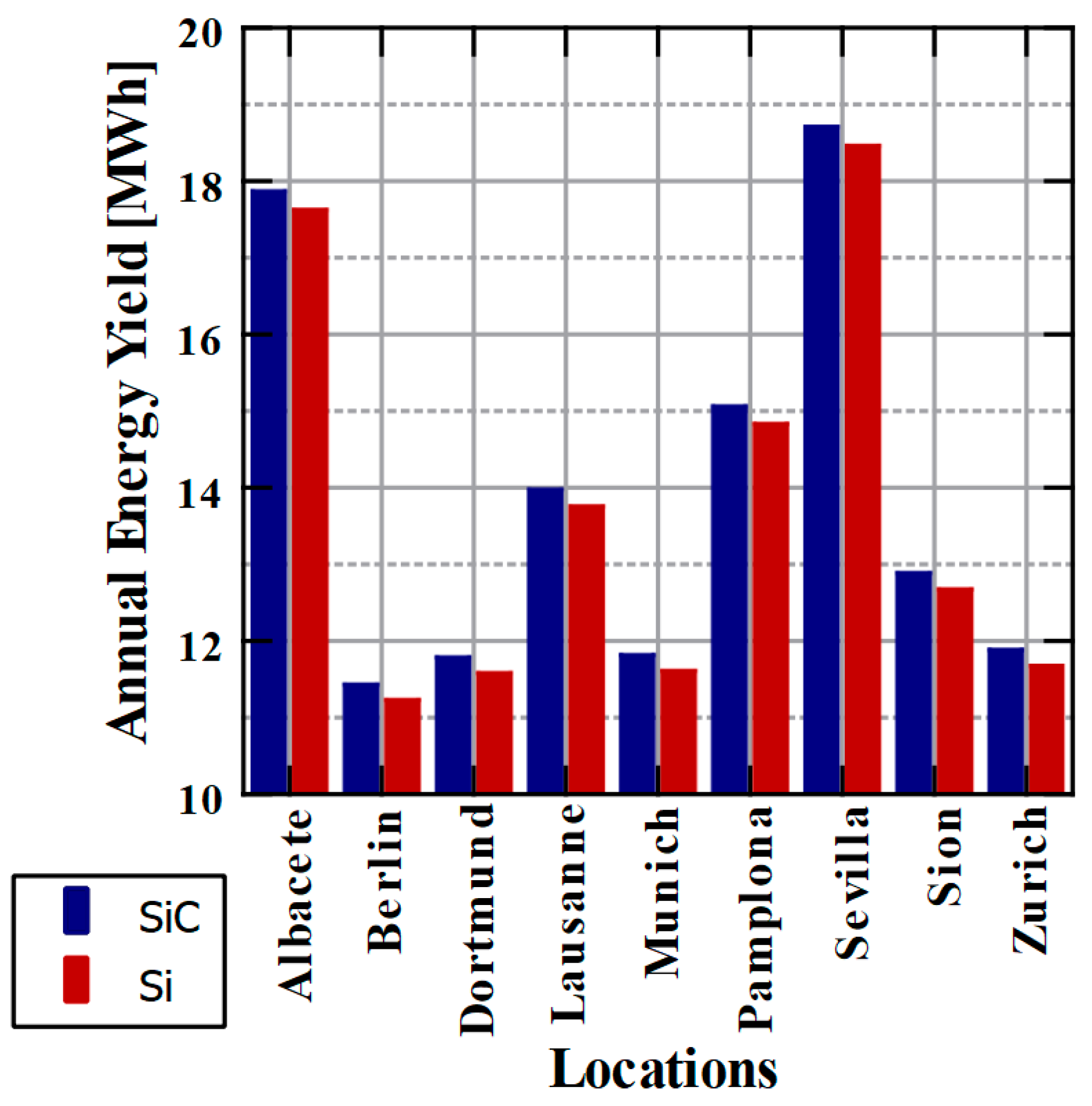

- Thekemuriyil, T.; Schneider, D.; Rohner, J.D.; Rahimo, M.T.A.; Aga, V.; Mastellone, S.; Minamisawa, R.A. Comparison of Si IGBT, SiC MOSFET and Adjustable Hybrid Switch PV Inverters for Different Geographical Locations. In Proceedings of the International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 11–13 June 2024. [Google Scholar]

- Waide, P.; Brunner, C.U. Energy-Efficiency Policy Opportunities for Electric Motor-Driven Systems—IEA. 2011. Available online: https://iea.blob.core.windows.net/assets/d69b2a76-feb9-4a74-a921-2490a8fefcdf/EE_for_ElectricSystems.pdf (accessed on 12 June 2023).

- Steimer, P.K.; Baden, Switzerland. Private communication, 2014.

- World Energy & Climate Statistics—Yearbook. 2022. Available online: https://yearbook.enerdata.net/electricity/electricity-domestic-consumption-data.html (accessed on 12 June 2023).

- ABB Whitepaper. Achieving the Paris Agreement. The Vital Role of High-Efficiency Motors and Drives in Reducing Energy Consumption. Available online: https://www.energyefficiencymovement.com/wp-content/uploads/2021/03/ABB_MotionEnergyEfficiency_WhitePaper.pdf (accessed on 12 June 2023).

- Virta Global. EV Charging—How Much Electricity Does an Electric Car Use? Available online: https://www.virta.global/blog/ev-charging-101-how-much-electricity-does-an-electric-car-use (accessed on 12 June 2023).

- Odyssee-Mure. Sectoral Profile—Transport. Available online: https://www.odyssee-mure.eu/publications/efficiency-by-sector/transport/distance-travelled-by-car.html (accessed on 12 June 2023).

- IEA. Electric Vehicles. Available online: https://www.iea.org/reports/electric-vehicles (accessed on 5 July 2023).

- Wolfspeed. Fast Charging. Available online: https://www.wolfspeed.com/applications/power/automotive/fast-charging/#:~:text=Wolfspeed%20Silicon%20Carbide%20power%20modules,frequency%20(45%2D250kHz) (accessed on 12 June 2023).

- ABB. Terra 360 Charger. Available online: https://search.abb.com/library/Download.aspx?DocumentID=9AKK107992A8963&LanguageCode=en&DocumentPartId=&Action=Launch (accessed on 12 June 2023).

- Baldwin, R. Car and Drive. 2020. Available online: https://www.caranddriver.com/news/a34046953/tesla-range-strategy-details/ (accessed on 12 June 2023).

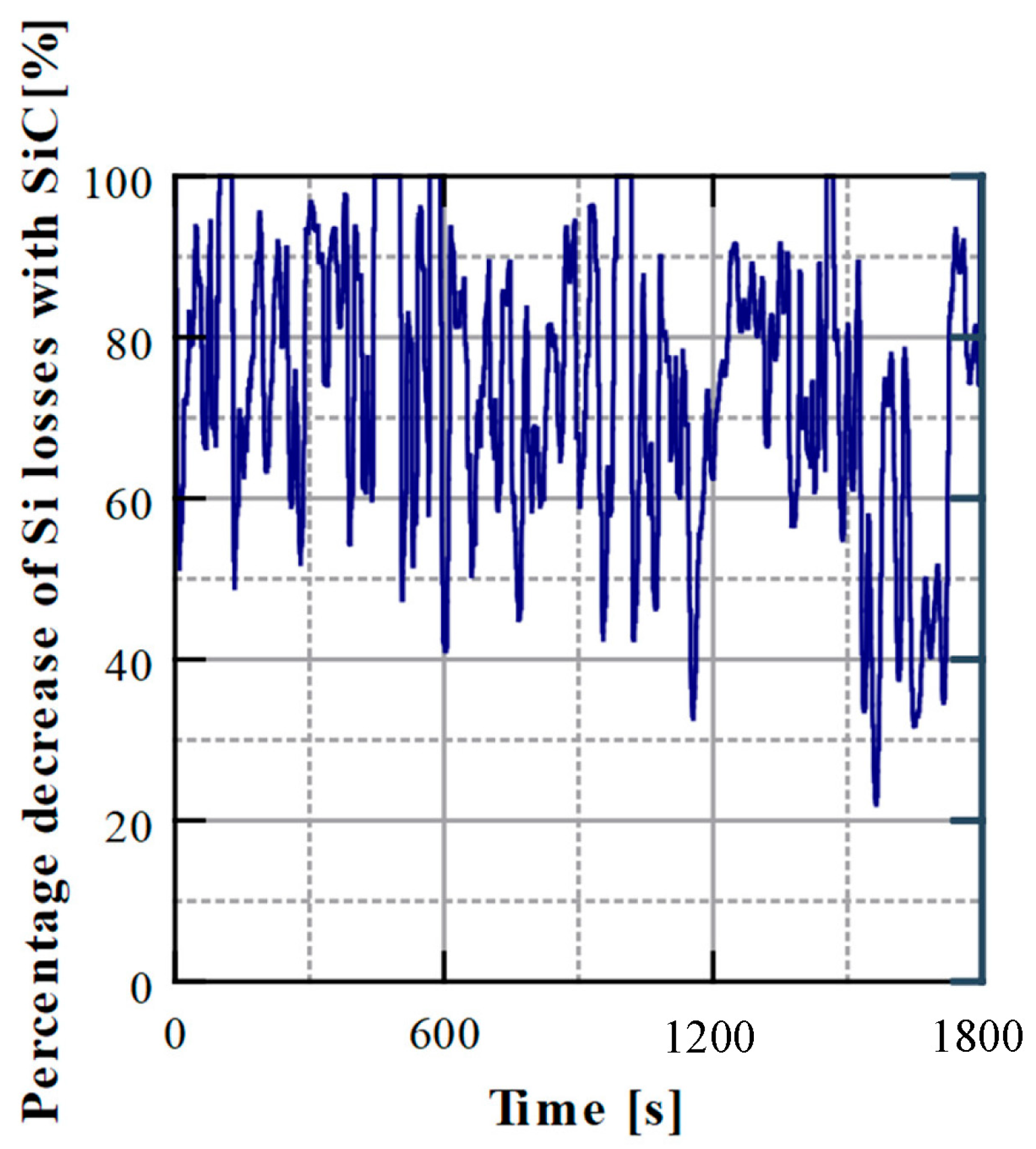

- Tan, C.; Stecca, M.; Soeiro, T.B.; Dong, J.; Bauer, P. Performance Evaluation of an Electric Vehicle Traction Drive using Si/SiC Hybrid Switches. In Proceedings of the 2021 IEEE 19th International Power Electronics and Motion Control Conference (PEMC), Gliwice, Poland, 25–29 April 2021; pp. 278–283. [Google Scholar] [CrossRef]

- Thekemuriyil, T.; Rahimo, M.T.A.; Minamisawa, R.A.; Mastellone, S. Performance Assessment of the Adjustable Hybrid Switch Converter for E-mobility Applications. In Proceedings of the 2023 25th European Conference on Power Electronics and Applications (EPE’23 ECCE Europe), Aalborg, Denmark, 4–8 September 2023; pp. 1–8. [Google Scholar] [CrossRef]

- BloombergNEF. Global Energy Storage Market to Grow 15-Fold by 2030. Available online: https://about.bnef.com/blog/global-energy-storage-market-to-grow-15-fold-by-2030/ (accessed on 14 June 2023).

- SMA. Sunny Boy Storage. Available online: https://www.sma.de/en/products/battery-inverters/sunny-boy-storage-25 (accessed on 12 June 2023).

- Irena Insights. Wind and Solar PV—What We Need by 2050. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Webinars/07012020_INSIGHTS_webinar_Wind-and-Solar.pdf?la=en&hash=BC60764A90CC2C4D80B374C1D169A47FB59C3F9D (accessed on 14 June 2023).

- Wiklund, J. Electric Vehicles Expected to Comprise 31% of the Global Fleet by 2050. Available online: https://www.globalfleetmanagement.com/10159371/electric-vehicles-expected-to-comprise-31-of-the-global-fleet-by-2050 (accessed on 14 June 2023).

| Device Model SiC MOSFET /Price | On State Voltage (25 °C) | Switching Losses | Device Model Si IGBT /Price | On State Voltage (25 °C) | Switching Losses | |

|---|---|---|---|---|---|---|

| Nominal current: 100 A (Tc at 25 C) Voltage: 650 V | TW015Z65C 42.94 CHF | 0.7 V at 50 A | Eon: 310 μJ Eoff: 232 μJ (Vdd: 400 V, I: 50 A, T: 25 °C) | FGH4L50T65MQDC50 10.24 CHF | 1.45 V at 50 A | Eon: 540 μJ Eoff: 590 μJ (Vdd: 400 V, I: 50 A, T: 25 °C) |

| Nominal current 100 A (Tc at 25 C) Voltage: 1200 V | AIMZHN120R020M1T 29.05 CHF | 2 V at 100 A | Eon: 0.55 mJ Eoff: 0.25 mJ (Vdd: 800 V, I: 100 A, T: 175 °C) | IKQ50N120CH3 9.92 CHF | 2.9 V at 100 A | Eon: 5.3 mJ Eoff: 4.1 mJ (Vdd: 600 V, I: 50 A, T: 175 °C) |

| Nominal current 300 A Voltage: 1200 V | CAS300M12BM2 808.28 CHF | 1.5 V at 300 A | Eon: 3 mJ Eoff: 3.4 mJ (Vdd: 600 V, I: 300 A, T: 125 °C) | FF300R12KS4P 194.3 CHF | 3.2 V at 300 A | Eon: 25 mJ Eoff: 15 mJ (Vdd: 600 V, I: 300 A, T: 125 °C) |

| Nominal current 300 A Voltage: 1700 V | CAS300M17BM2 942.17 CHF | 2.2 V at 300A | Eon: 13 mJ Eoff: 10 mJ (Vdd: 900 V, I: 300 A, T: 150 °C) | 5SNG 0300Q170300 188.20 CHF | 2.25 V at 300A | Eon: 95 mJ Eoff: 75 mJ (Vdd: 900 V, I: 300 A, T: 125 °C) |

| Nominal current 100 A (Tc at 25 C) Voltage: 1700 V | C3M0021120K 33.25 CHF | 1 V at 50A | Eon: 0.65 mJ Eoff: 0.2 mJ (Vdd: 600 V, I: 50 A, T: 25 °C) | IXYH30N170C 13.53 CHF | 4.4 V at 50A | Eon: 3.8 mJ Eoff: 3.4 mJ (Vdd: 850 V, I: 50 A, T: 25 °C) |

| Application | Manufacturer | Product | Power | Efficiency (%) |

|---|---|---|---|---|

| Data center | Eaton | Eaton 93 PR UPS [10] | 300–1200 kW | 99 |

| Mitsubishi | Summit series [11] | 500 kW | 98.2 | |

| Toshiba | G2020 series [12] | 500, 750 kW | 98.2 | |

| TMEIC | Next GEN UPS [13] | n/a | 98 | |

| PV inverter | GE | LV5+ [14] | 2.7–3.5 MW | 98.9 |

| SMA | Sunny High power peak 3 [15] | 150 kW | 99 | |

| Sungrow | SG250HX [16] | 250 kW | 99 | |

| Fronius | Symo GEN 24 Plus [17] | 3–5 kW | 98.2 | |

| REFUsol | 020K-SCI [18] | 20 kW | 98.7 | |

| Kaco | Blue Planet 150 TL3 [19] | 150 kW | 99.2 | |

| Motor drives | Infinitum | Aircore EC: Int. drive [20] | 3–12 kW | n/a |

| Plettenberg | MST 400-160 SiC [21] | 66 kW | n/a | |

| APD | Aergility ATLIS UAV [22] | n/a | 98 | |

| Off-board EV charger | Ingeteam | Rapid ST400 [23] | Up to 400 kW | n/a |

| Residential battery storage | Kaco | Blueplanet 92.0-137 TL3-S [24] | 92–137 kW | 98.8 |

| Electric | Tesla | Model 3 | 208 kW | n/a |

| Vehicles | Model Y | 220–286 kW | n/a | |

| Traction | Model S | 615 kW | 99 | |

| Inverter | BYD | Han EV | 363 kW | n/a |

| [25] | Tang | 151 kW | n/a | |

| Seal | 390 kW | n/a | ||

| Kia | EV6 | 125–430 kW | n/a | |

| Ford | F-150 Lightning | 337 kW | n/a | |

| Hyndai | Ioniq 5 | 239 kW | n/a | |

| Ioniq 6 | 111 kW | n/a | ||

| Genesis | GV60 | 160 kW | n/a | |

| Lucid | Air | 321 kW | n/a | |

| Volvo | EM90 | 398 kW | n/a | |

| Zeekr | 007 | 310 kW | n/a | |

| 001FR | 930 kW | n/a | ||

| 009 | 400 kW | n/a | ||

| Lotus | Electre | 675 kW | n/a | |

| Maserati | GranTurismo | 405 kW | n/a | |

| Smart | #1 EV | 200 kW | n/a | |

| Nio | ET7 | 480 kW | n/a | |

| ET5 | 360 kW | n/a | ||

| HVAC | Mitsubishi | MSZ-LN60VG (W) (V) (R) (B) | 6 kW | n/a |

| [26] | MSZ-LN50VG (W) (V) (R) (B) | 5 kW | n/a | |

| MSZ-LN35VG (W) (V) (R) (B) | 3.5 kW | n/a | ||

| MSZ-LN25VG (W) (V) (R) (B) | 2.5 kW | n/a | ||

| On-board charger [27] | Innoelectric | On-board charger (OBC) | 22 kW | 96 |

| Inverter Type | Efficiency |

|---|---|

| Si IGBT | 93.8% |

| SiC MOSFET | 98.8% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spejo, L.B.; Thekemuriyil, T.; Minamisawa, R.A. Estimation of Energy-Saving Potential Using Commercial SiC Power Converters. Energies 2024, 17, 4570. https://doi.org/10.3390/en17184570

Spejo LB, Thekemuriyil T, Minamisawa RA. Estimation of Energy-Saving Potential Using Commercial SiC Power Converters. Energies. 2024; 17(18):4570. https://doi.org/10.3390/en17184570

Chicago/Turabian StyleSpejo, Lucas Barroso, Tanya Thekemuriyil, and Renato Amaral Minamisawa. 2024. "Estimation of Energy-Saving Potential Using Commercial SiC Power Converters" Energies 17, no. 18: 4570. https://doi.org/10.3390/en17184570