Investigation of the Arc Characteristics in a Nozzle with C4F7N/CO2 Mixtures

Abstract

1. Introduction

2. Mathematical Modelling of Electric Arc

2.1. Fundamental Equation Governing the System

2.2. Turbulence Model

2.3. Radiation Model

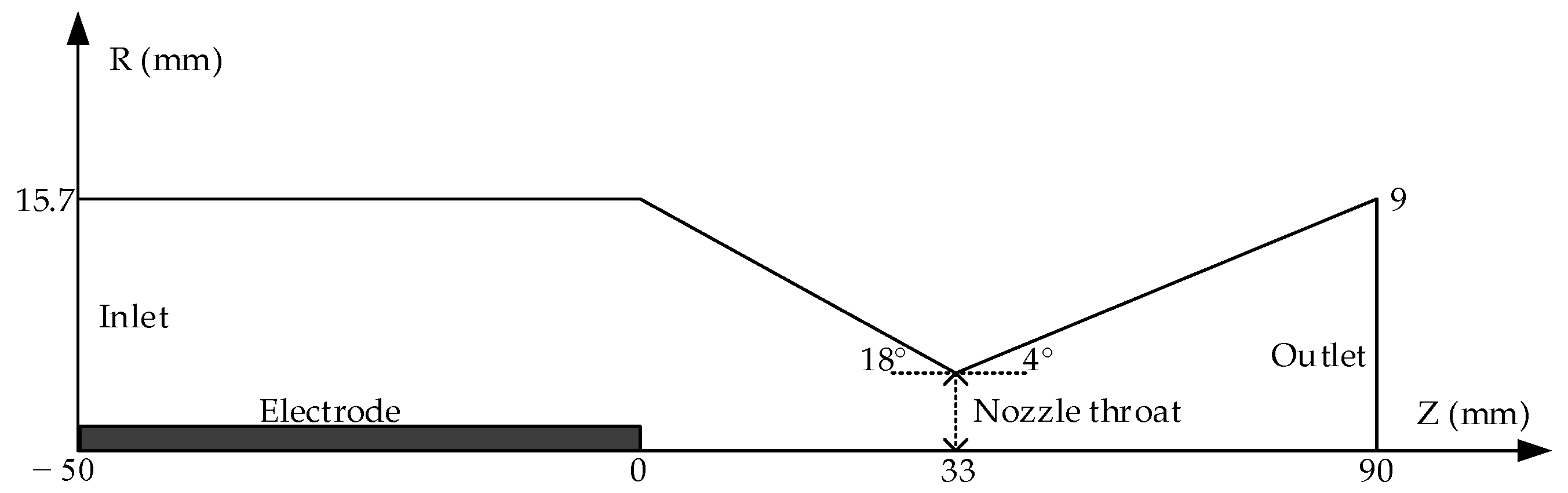

2.4. Geometric Model and Boundary Conditions

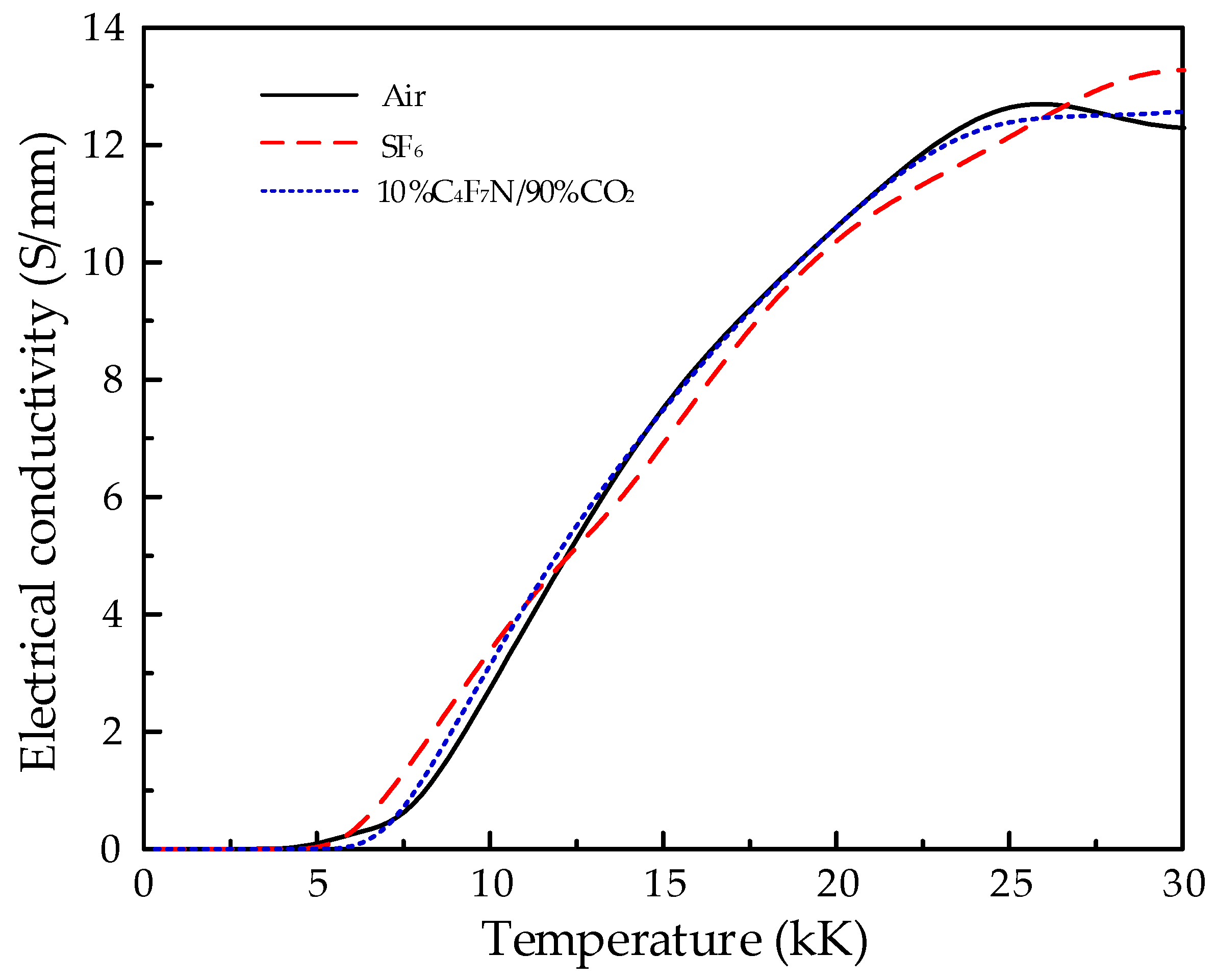

2.5. Parameters of Gas Conductivity

3. Comparative Study of Arc Characteristics between Environmentally Friendly Gases and SF6

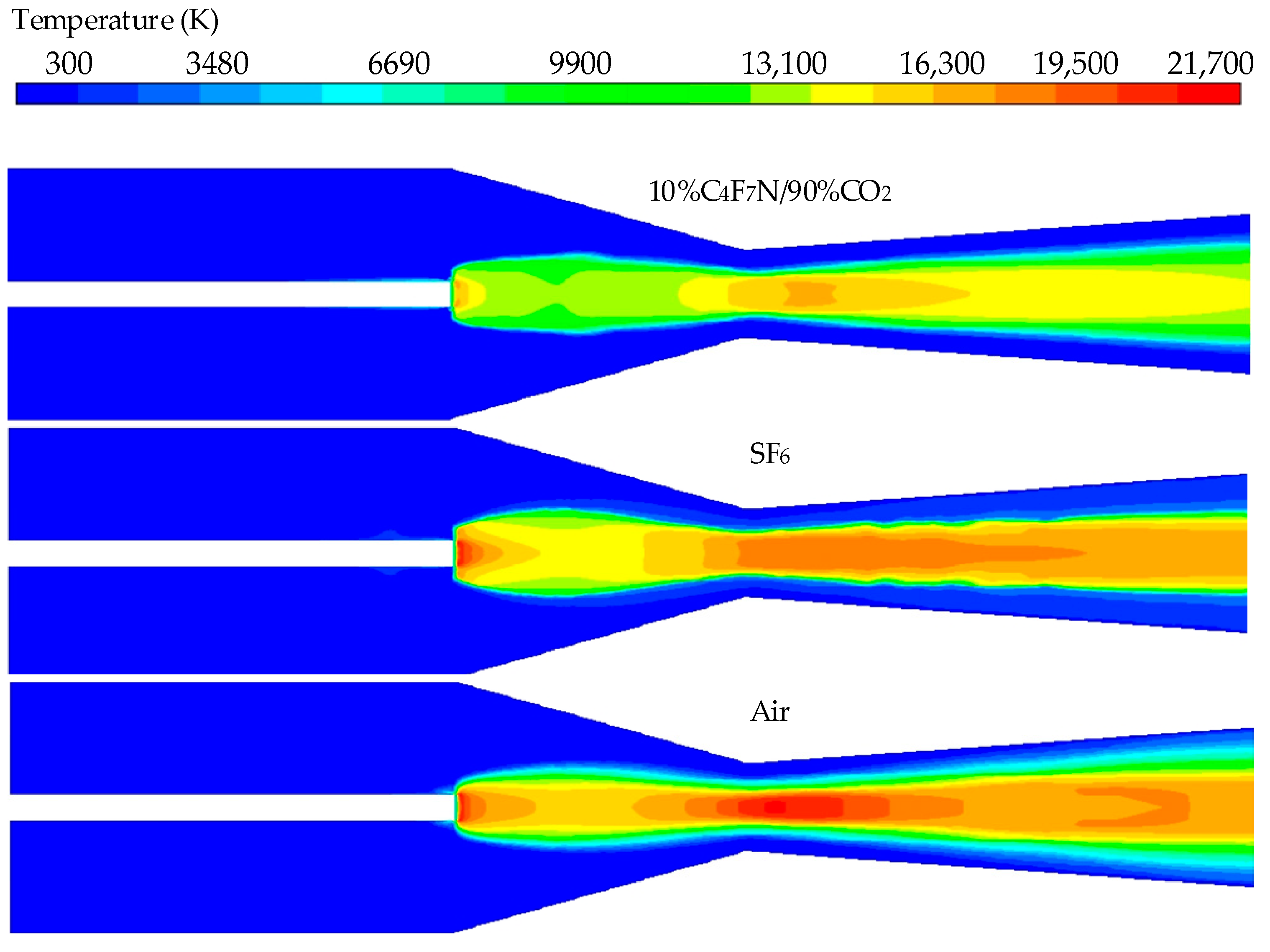

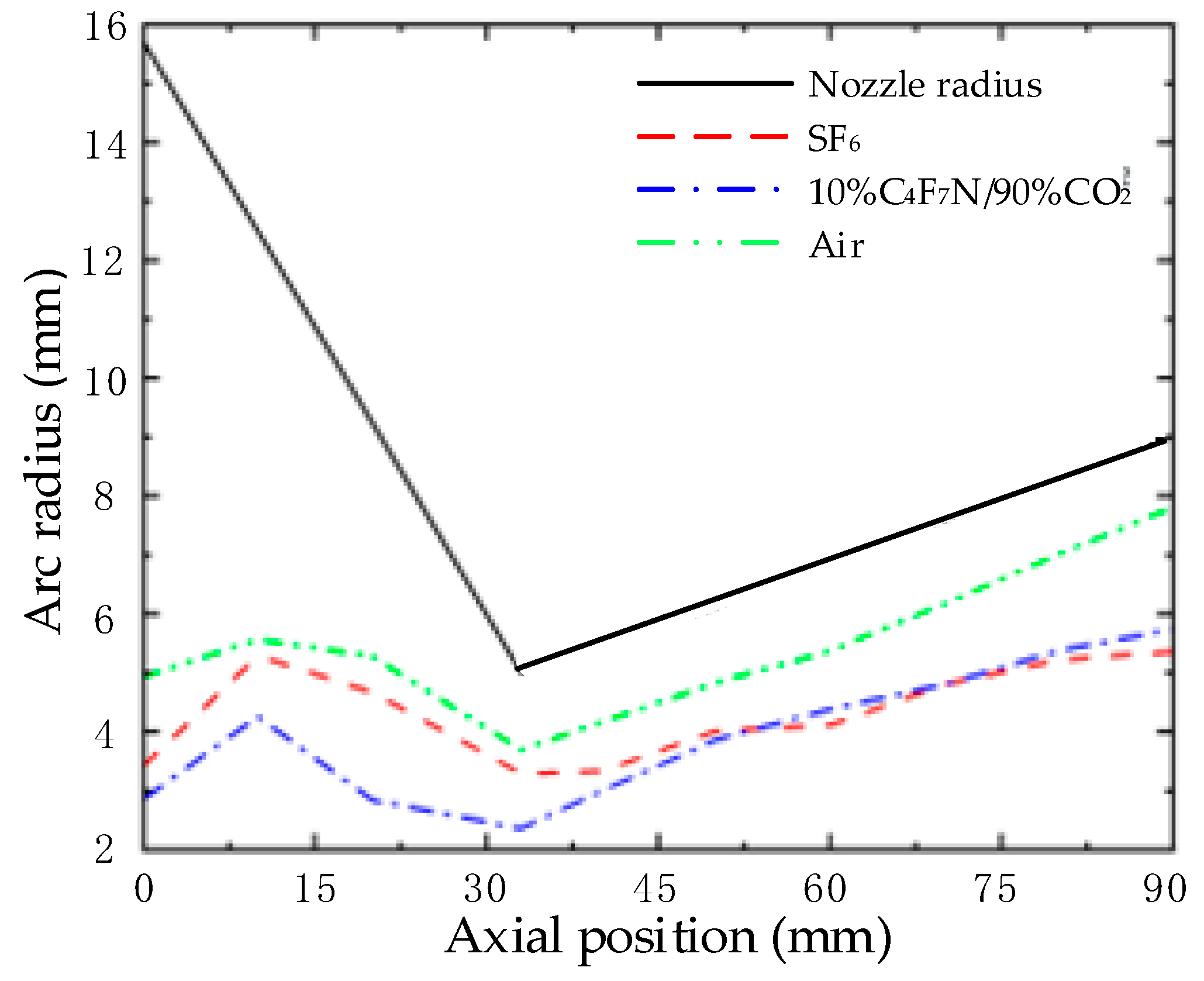

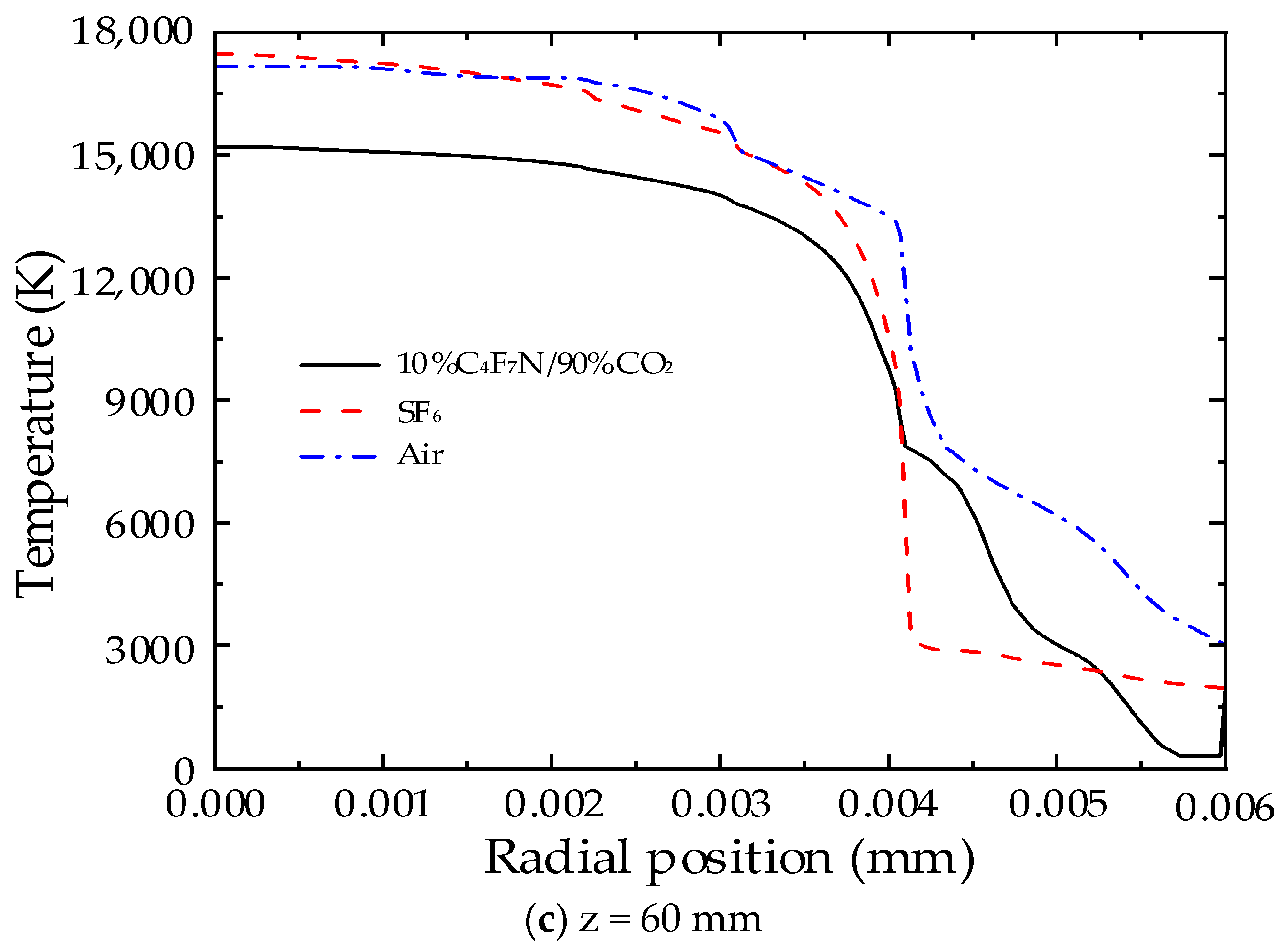

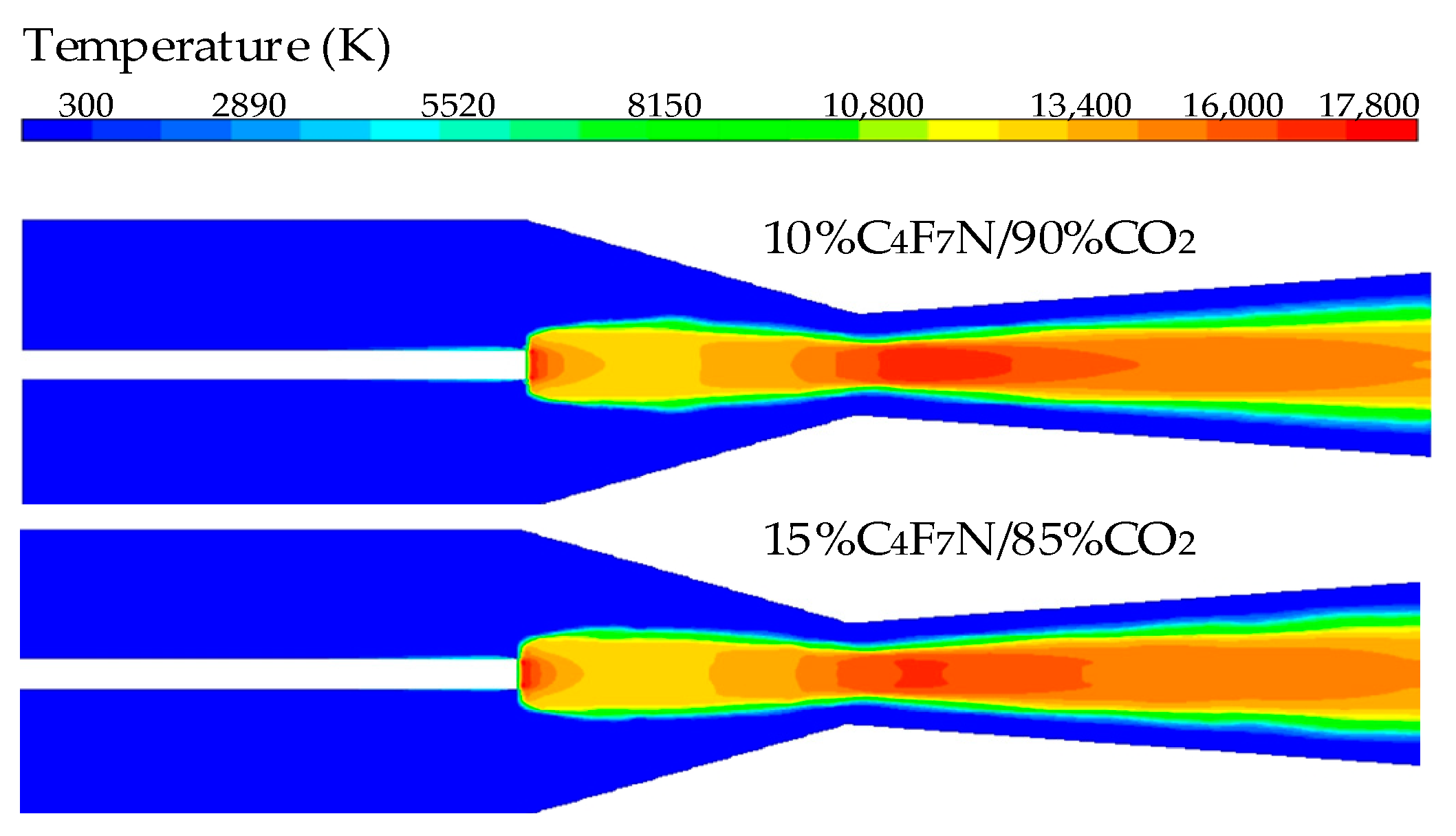

3.1. Temperature Distribution

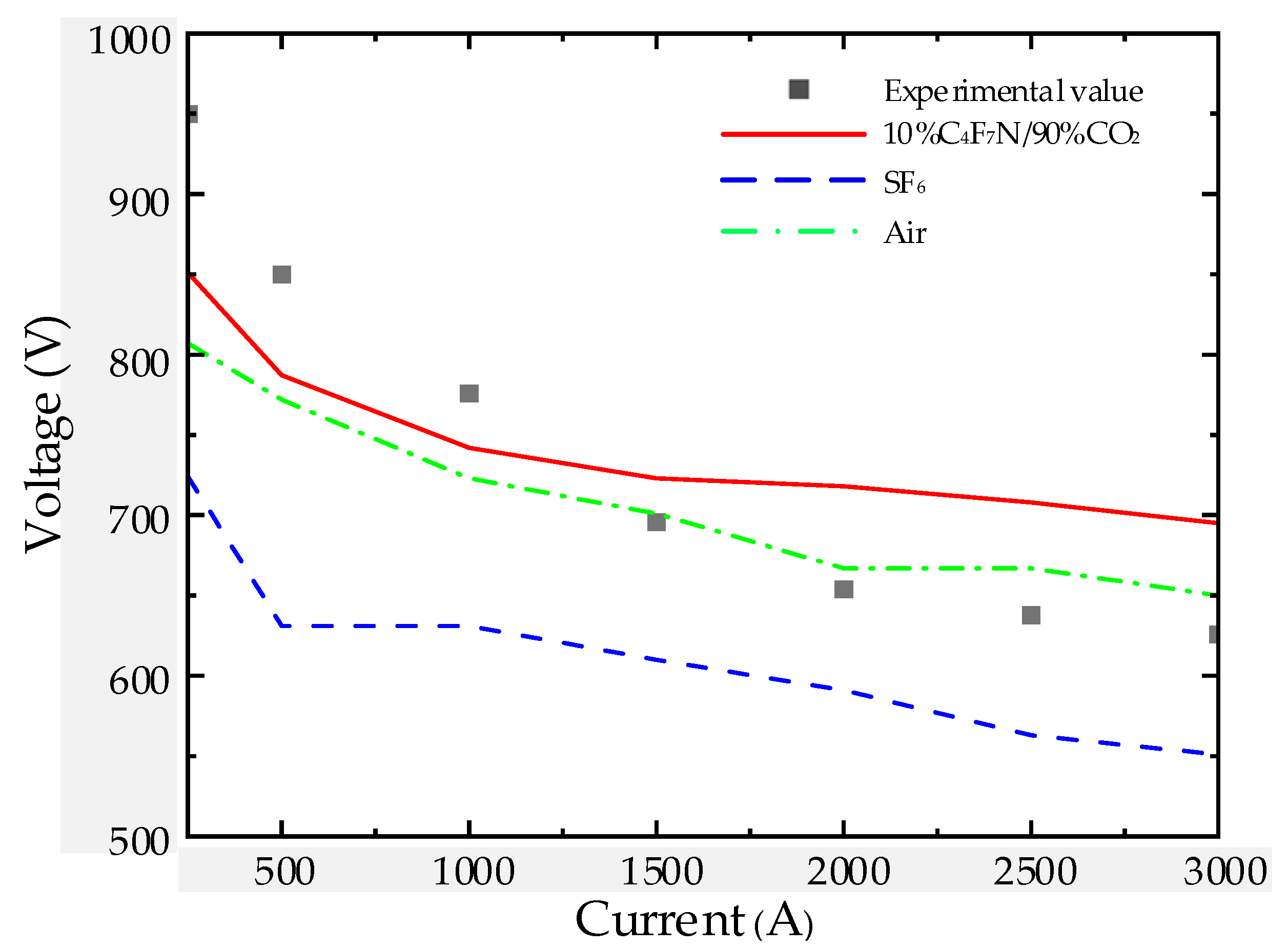

3.2. Arc Voltage

3.3. Energy Balance

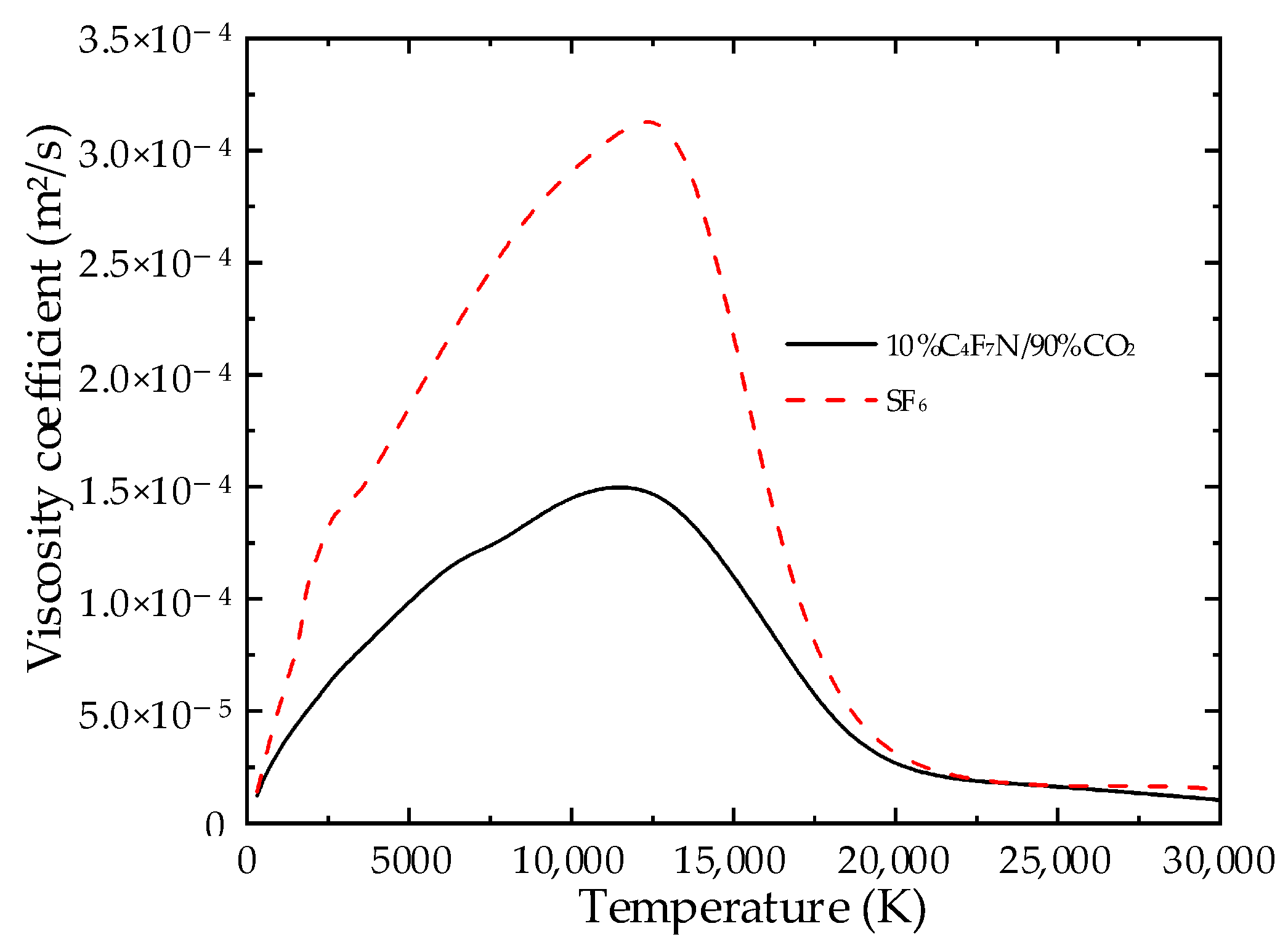

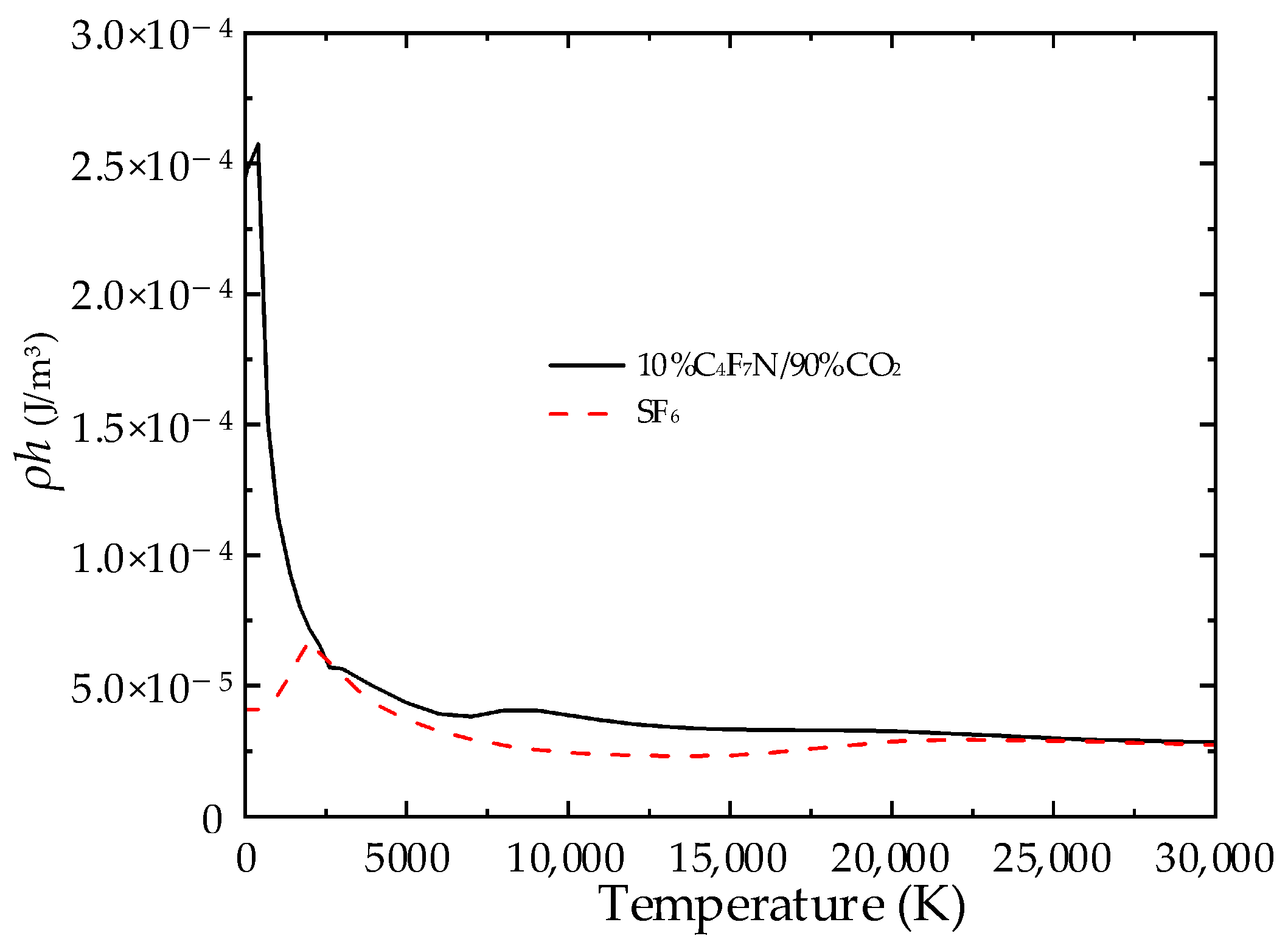

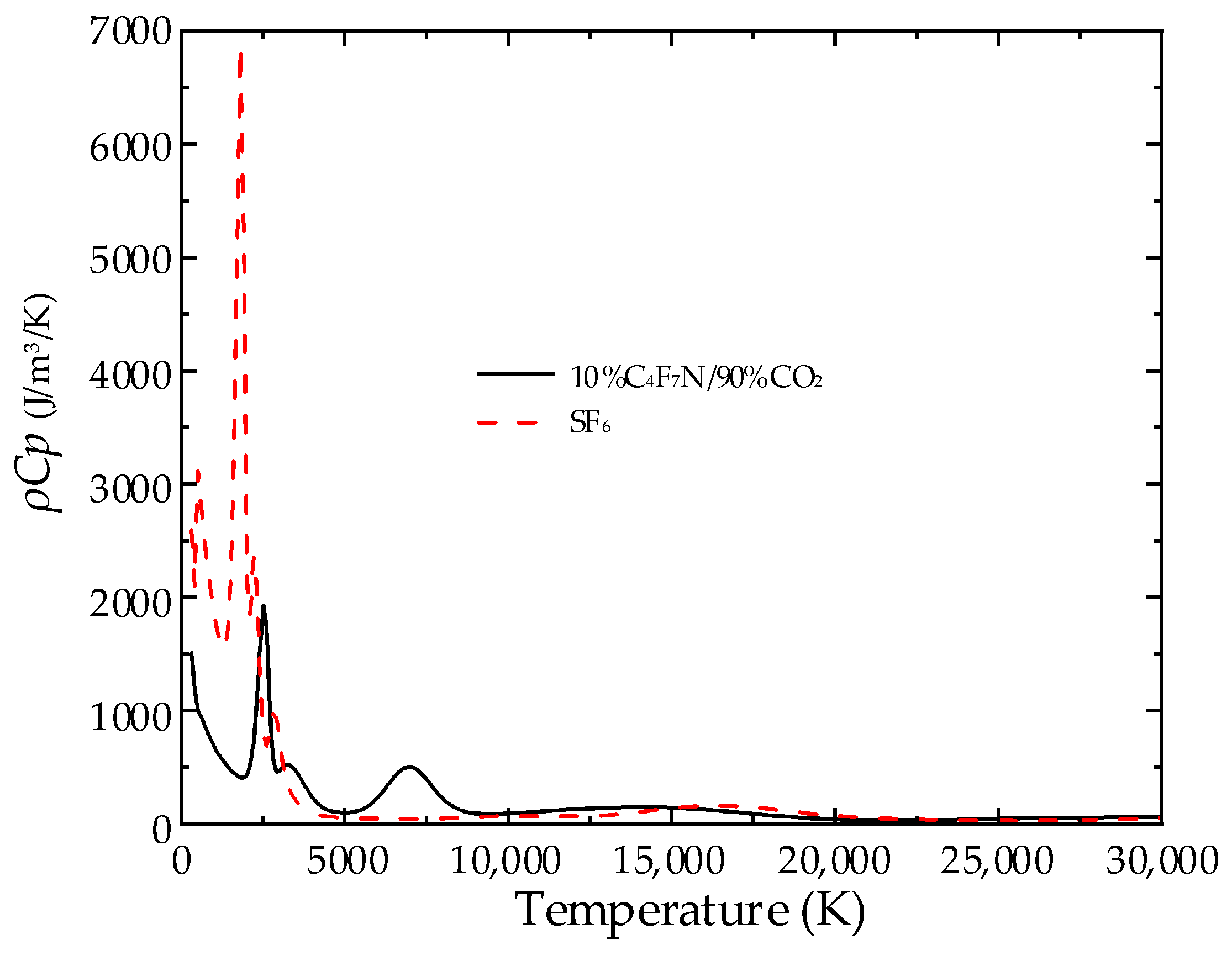

3.4. Analysis of Gas Physical Properties

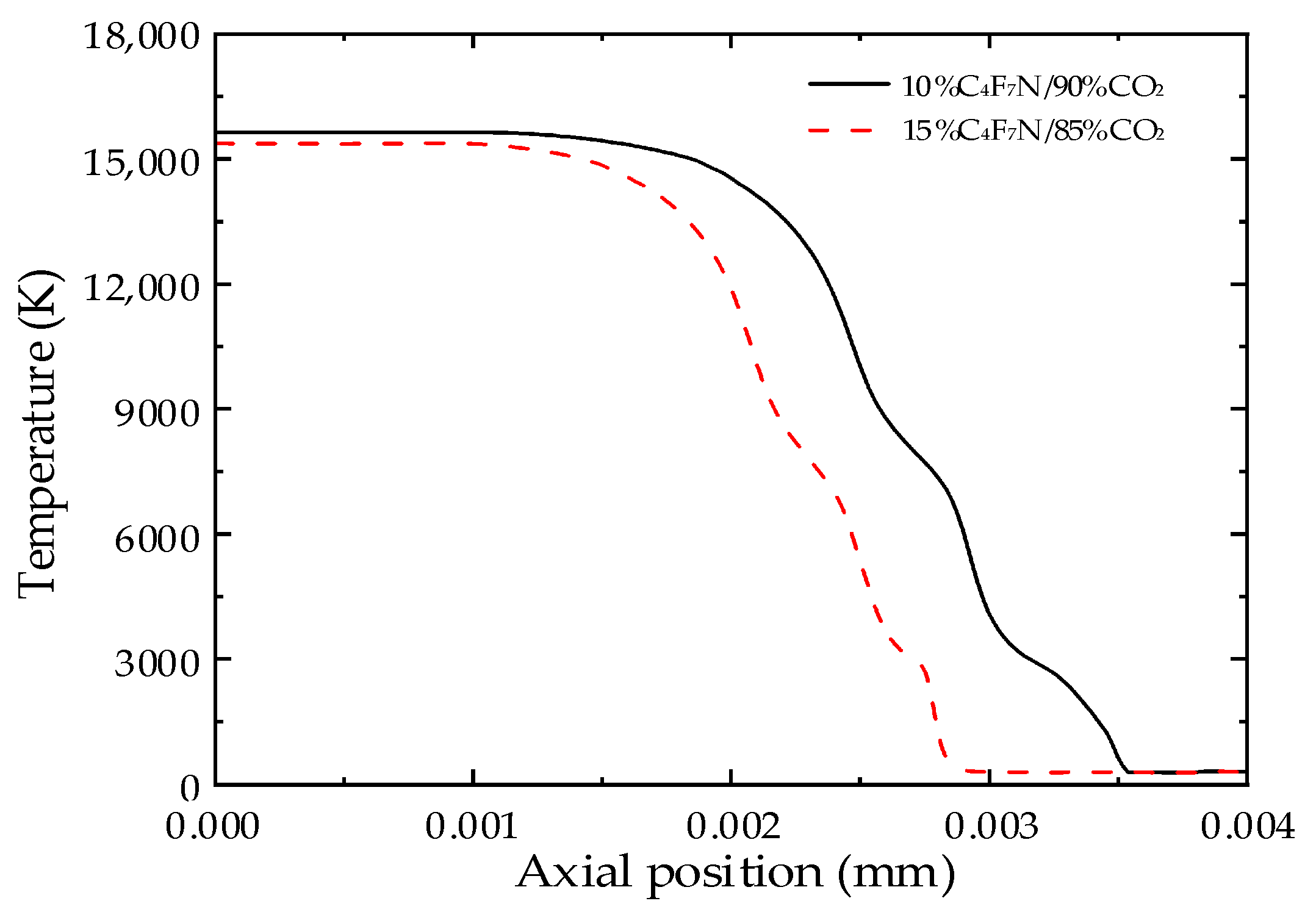

3.5. The Impact of C4F7N Content on Arc Characteristics

4. Conclusions

- Under the influence of gas blowing, the primary energy dissipation process of the arc is axial convection, where the axial temperature gradient of the 10%C4F7N/90%CO2 mixtures’ arc is significantly higher than that of the SF6 gas under the same blowing intensity. This indicates that the energy loss in the C4F7N mixture arc occurs more rapidly under gas blowing, making it more favourable for arc extinguishing.

- Through the comparison of physical parameters, it is concluded that the lower viscosity coefficient of the mixed gas results in a weaker turbulence effect compared to pure SF6 gas. The larger value of the mixed gas below 4000 K enhances the heat dissipation process at the electrical boundary, while the larger value above 4000 K increases the arc radius, which is unfavourable for arc extinguishing.

- The 15%C4F7N/85%CO2 mixtures exhibit stronger radial heat conduction, resulting in a lower arc temperature. Therefore, increasing the C4F7N content is beneficial for arc extinguishing.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Simmonds, P.G.; Rigby, M.; Manning, A.J.; Park, S.; Stanley, K.M.; McCulloch, A.; Henne, S.; Graziosi, F.; Maione, M.; Arduini, J.; et al. The increasing atmospheric burden of the greenhouse gas sulfur hexafluoride (SF6). Atmos. Chem. Phys. 2020, 20, 7271–7290. [Google Scholar] [CrossRef]

- Xiao, A.; Owens, J.G.; Bonk, J.; Zhang, A.; Wang, C.; Tu, Y. Environmentally friendly insulating gases as SF6 alternatives for power utilities. In Proceedings of the 2019 2nd International Conference on Electrical Materials and Power Equipment (ICEMPE), Guangzhou, China, 7–10 April 2019. [Google Scholar]

- Owens, J.G. Greenhouse gas emission reductions through use of a sustainable alternative to SF6. In Proceedings of the 2016 IEEE Electrical Insulation Conference (EIC), Montreal, QC, Canada, 19–22 June 2016. [Google Scholar]

- Kovács, T.; Feng, W.; Totterdill, A.; Plane, J.; Dhomse, S.; Gómez-Martín, J.C.; Stiller, G.P.; Haenel, F.J.; Smith, C.; Forster, P.M.; et al. Determination of the atmospheric lifetime and global warming potential of sulfur hexafluoride using a three-dimensional model. Atmos. Chem. Phys. 2017, 17, 883–898. [Google Scholar] [CrossRef]

- Li, X.; Liu, L.; Wang, W.; Geng, Z. Analysis of breaking characteristics of C4F7N/CO2 mixture gas in circuit breaker. Energies 2024, 17, 2638. [Google Scholar] [CrossRef]

- Nechmi, H.E.; Michelarakis, M.; Haddad, A.; Wilson, G. Clarifications on the behavior of alternative gases to SF6 in divergent electric field distributions under AC voltage. Energies 2021, 14, 1065. [Google Scholar] [CrossRef]

- Kieffel, Y. Characteristics of g³—An alternative to SF6. In Proceedings of the 2016 IEEE International Conference on Dielectrics (ICD), Montpellier, France, 3–7 July 2016. [Google Scholar]

- Chen, L.; Zhang, B.; Li, X.; Yang, T. Decomposition pathway of C4F7N gas considering the participation of ions. J. Appl. Phys. 2018, 51, 153001. [Google Scholar] [CrossRef]

- Gao, W.; Posada, L.; Shiravand, V.; Shubhashish, S.; Price, C.; Zhang, B.; Potyrailo, R.; Younsi, K.; Shan, S.; Ndiaye, I.; et al. Decomposition characteristics of C4F7N-based SF6-alternative gas. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1340–1350. [Google Scholar] [CrossRef]

- Andersen, M.; Kyte, M.; Andersen, S.; Steffensen, A.L.; Sørensen, S.R.; Nielsen, C.J. Environmental and insulation characteristics of C4F7N as an alternative to SF6. Environ. Sci. Technol. 2017, 51, 1321–1329. [Google Scholar]

- Chen, J.; Smith, A.; Johnson, P. Decomposition mechanism of C4F7N/CO2 gas mixture based on molecular dynamics. AIP Adv. 2023, 13, 024401. [Google Scholar]

- Miller, B.; Thompson, D.; Evans, R. Detection of decomposition products of C4F7N/CO2 gas mixture. Sci. Direct. 2022, 18, 104567. [Google Scholar]

- Williams, M.; Roberts, T.; Brown, H. Calculation of thermodynamic physical properties of C4F7N/CO2 mixed gas. IEEE Trans. Dielectr. Electr. Insul. 2021, 26, 1949–1955. [Google Scholar]

- Preve, C.; Maladen, R.; Piccoz, D. Method for validation of new eco-friendly insulating gases for medium voltage equipment. In Proceedings of the 2016 IEEE International Conference on Dielectrics (ICD), Montpellier, France, 3–7 July 2016. [Google Scholar]

- Nechmi, H.E.; Beroual, A.; Girodet, A.; Vinson, P. Fluoronitriles/CO2 gas mixture as promising substitute to SF6 for insulation in high voltage applications. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2587–2593. [Google Scholar] [CrossRef]

- Hopf, A.; Britton, J.A.; Rossner, M.; Berger, F. Dielectric strength of SF6 substitutes, alternative insulation gases and PFC-gas-mixtures. In Proceedings of the IEEE Electrical Insulation Conference (EIC), Montreal, QC, Canada, 18–22 June 2017. [Google Scholar]

- Yi, C.; Yuan, Z.; Tu, Y.; Zhang, Y.; Wang, C. Measurements of discharge parameters in C3F7CN/CO2 and C3F7CN/N2 gas mixtures by SST. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 1015–1021. [Google Scholar] [CrossRef]

- Tu, Y.; Ai, X.; Cheng, Y.; Jin, H.; Wang, C. DC breakdown characteristics of C3F7CN/N2 gas mixtures. Trans. China Electrotech. Soc. 2018, 33, 5189–5195. [Google Scholar]

- Sun, H.; Zhang, C.; Shen, M.; Liu, Y.; Wang, X.; Li, J. Study on the operating impulse insulation characteristics of environmentally friendly C4F7N/CO2 gas mixtures. High Volt. Appar. 2021, 57, 90–95. [Google Scholar]

- Liu, J. Modelling and Simulation of Air and SF6 Switching Arcs in High Voltage Circuit Breakers. Ph.D. Thesis, University of Liverpool, Liverpool, UK, 2016. [Google Scholar]

- Zhang, Q. Modelling of Turbulent SF6 Switching Arcs. Ph.D. Thesis, University of Liverpool, Liverpool, UK, 2014. [Google Scholar]

- Yan, J.; Nuttall, K.; Fang, M. A comparative study of turbulence models for SF6 arcs in a supersonic nozzle. J. Phys. Appl. Phys. 1999, 32, 14–19. [Google Scholar] [CrossRef]

- Plasma Data Exchange Project. Available online: http://plasma-data.net/index (accessed on 3 August 2024).

- Fang, M.T.C.; Ramakrishnan, S.; Meserle, H.K. Scaling laws for gas-blast circuit-breaker arcs during the high current phase. IEEE Trans. Plasma Sci. 1980, 8, 357–362. [Google Scholar] [CrossRef]

- Bian, C.; He, B.; Lin, X.; Liu, Y.; Lou, H.; Kong, L.; Dai, X.; Wu, S.; Meng, F.; Liu, Y. Research on Interruption Performance of Environmentally Friendly C4F7N Mixed-Gas-Insulated Switchgear. Energies 2022, 15, 6500. [Google Scholar] [CrossRef]

| Symbol | Interpretation and Unit |

|---|---|

| B | Magnetic induction intensity (T) |

| E | Electric field intensity (V/m) |

| J | Current density (A/m2) |

| Temperature (K) | |

| Velocity vector (m/s) | |

| k | Heat conductivity (w/(m·K)) |

| p | Pressure (Pa) |

| Net radiation loss per unit volume and time (w/m3) | |

| t | Time (seconds) |

| μm | Magnetic conductivity (H/m) |

| ρ | Density (kg/m3) |

| σ | Conductivity (S/m) |

| τ | Pressure tensor (Pa) |

| φ | Electric potential (V) |

| Constant Parameter | Value |

|---|---|

| σk | 1 |

| σε | 1.3 |

| C | 0.09 |

| C1ε | 1.44 |

| C2e | 1.92 |

| Gas Type | Maximum Temperature (kK) | Voltage (V) | Arc Radius-z = 15 mm (mm) | Arc Radius-z = 33 mm (mm) | Arc Radius-z = 60 mm (mm) |

|---|---|---|---|---|---|

| SF6 | 21.1 | 600 | 5 | 3.25 | 4.1 |

| 10%C4F7N/90%CO2 | 17.8 | 725 | 3.6 | 2.4 | 4.4 |

| Gas Type | Energy Input (106 W) | Radiation Loss (%) | Radial Heat Conduction (%) | Axial Convection Heat Transfer (%) | Radial Convection Heat Transfer (%) |

|---|---|---|---|---|---|

| Air | 1.34 | −11.7 | −25.5 | −74.2 | 14.5 |

| SF6 | 1.14 | −12.2 | −29.9 | −73.1 | 8.5 |

| C4F7N/CO2 | 1.44 | −9.72 | −34.9 | −81.2 | 18.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Yan, X.; Li, X.; Guo, D.; Geng, Z. Investigation of the Arc Characteristics in a Nozzle with C4F7N/CO2 Mixtures. Energies 2024, 17, 4593. https://doi.org/10.3390/en17184593

Wang W, Yan X, Li X, Guo D, Geng Z. Investigation of the Arc Characteristics in a Nozzle with C4F7N/CO2 Mixtures. Energies. 2024; 17(18):4593. https://doi.org/10.3390/en17184593

Chicago/Turabian StyleWang, Wen, Xianglian Yan, Xiaolong Li, Dongyu Guo, and Zhenxin Geng. 2024. "Investigation of the Arc Characteristics in a Nozzle with C4F7N/CO2 Mixtures" Energies 17, no. 18: 4593. https://doi.org/10.3390/en17184593

APA StyleWang, W., Yan, X., Li, X., Guo, D., & Geng, Z. (2024). Investigation of the Arc Characteristics in a Nozzle with C4F7N/CO2 Mixtures. Energies, 17(18), 4593. https://doi.org/10.3390/en17184593