Abstract

The energy supply for isolated systems remains a current challenge in Brazil and worldwide, particularly when known solutions are compared regarding their cost, ability to supply energy on demand, and sustainability. In this context, green hydrogen, which has been considered one of the main paths for the decarbonization of the energy chain, is also seen as a potential energy supply solution in isolated systems. Based on a literature review of articles addressing the topics of green hydrogen and isolated systems, an analysis is conducted on the application of green hydrogen as an energy supply solution for isolated systems. The review identified and collected data on important parameters for comparing solutions, such as CAPEX, OPEX, energy cost, and the price per kilogram of hydrogen. Using these data, analyses were performed to provide an overview of the application of green hydrogen in isolated systems. One of the objectives of this work is to present a comprehensive analysis of the green hydrogen chain and its application in the context of electricity generation, particularly for isolated systems in Brazil.

1. Introduction

The transition to a low-carbon energy matrix is an urgent global challenge. In this context, green hydrogen has been widely recognized as an essential element for the decarbonization of the energy chain [1], emerging as a promising alternative to replace fossil fuels in various sectors such as energy, transportation, and agribusiness [2,3,4].

However, the economic feasibility of green hydrogen as an energy carrier is still a goal to be achieved for most applications. Technological advances, production scale, and government policies play a fundamental role in cost reduction. Not surprisingly, new investments in large-scale green hydrogen production projects are frequently announced, with Germany striving to lead in the production and use of this resource [5].

In Brazil, the promotion of green hydrogen production is partly driven by the country’s significant potential for renewable power production, primarily wind and solar, which can significantly reduce production costs, given that the final price of the molecule largely depends on the price of energy. Additionally, Brazil’s vast territorial extent allows for the implementation of large-scale projects for hydrogen production and utilization. Nevertheless, to follow the hydrogen path towards transitioning to a low-carbon economy, solutions are needed, primarily for reducing the costs of production, storage, distribution, and utilization of green hydrogen [5].

In contemporary society, access to electricity is essential, as it relates to meeting basic needs, economic development, and improving education, health, and security, among other fundamental aspects of life. However, in geographically remote regions, energy supply remains both a technical and economic challenge [6].

Though they are exceptions, isolated systems are present worldwide in places such as remote Pacific islands like Vanuatu and Fiji, isolated systems in northern Canada in the regions of Nunavut and Yukon, parts of Africa like rural areas of Mali and Niger, and even some European islands such as the Faroe Islands and the Greek islands in the Aegean Sea. In Brazil, they are found in places like the Amazon, the Pantanal, and the northeastern region.

Given the characteristics of application for isolated systems, it is evident that green hydrogen, produced from water electrolysis using renewable energy and with the necessary infrastructure, can be stored and used for electricity generation on demand, acting as a clean and reliable energy source. Thus, green hydrogen has the potential to play an important role in supplying energy to isolated systems, which can greatly benefit from the local production of green hydrogen and possibly eliminate dependence on fossil fuels.

2. A Review on Hydrogen Uses in the Context of Isolated Power Systems

The methodology used in this work is based on the review of scientific articles, technical documents, and ongoing projects worldwide, as well as data and studies from governmental bodies.

To obtain relevant information, data related to energy generation in isolated systems in Brazil and the main aspects of green hydrogen generation and use as an energy carrier were gathered and analyzed. The primary development initiatives and projects underway in recent years were identified, focusing on making the use of hydrogen feasible as a clean and sustainable energy source.

In addition to analyzing the feasibility and technical requirements necessary for decentralized hydrogen generation, the research identified relevant parameters for the implementation of hydrogen generation systems. The methods used allowed for a comprehensive approach to the topic, enabling the linkage of relevant information for the development of the work.

In the following sections, the main results of this article will be presented. As a form of contextualization, an overview of isolated systems in Brazil will be provided, along with an analysis of the cost and socio-environmental impact of energy generation in isolated systems and aspects of green hydrogen production and use, with a focus on isolated systems.

3. Isolated Power Systems in Brazil—A Brief Overview

In Brazil, isolated systems are defined as public electricity distribution systems that, for technical or economic reasons, are not connected to the National Interconnected System (SIN). These systems are autonomous and independent in supplying the electricity/energy demand for a specific geographical area. Given Brazil’s vast territorial extent and the difficulty of accessing certain regions such as indigenous communities, rural areas, and islands, isolated systems play a fundamental role in universalizing access to electricity.

Energy supply to isolated systems has historically been a focus of public policies. According to [7], the development of these systems has been marked by cycles of development and socioeconomic transformations. The first isolated systems emerged in small towns and villages in the interior of Pará and Amazonas during the first rubber boom in the 19th century. Initially, energy was generated by small steam engines using wood as fuel, which were later replaced by diesel engines. Throughout the 20th century, several state-owned energy generation and distribution companies were created. However, the cost of energy generated in isolated systems has always been high due to technical and logistical constraints. To make this energy affordable, in 1973, the Fuel Consumption Account (CCC) was created in Brazil as a subsidy mechanism for thermal generation from fossil fuels, which remains the primary financial viability instrument for these systems.

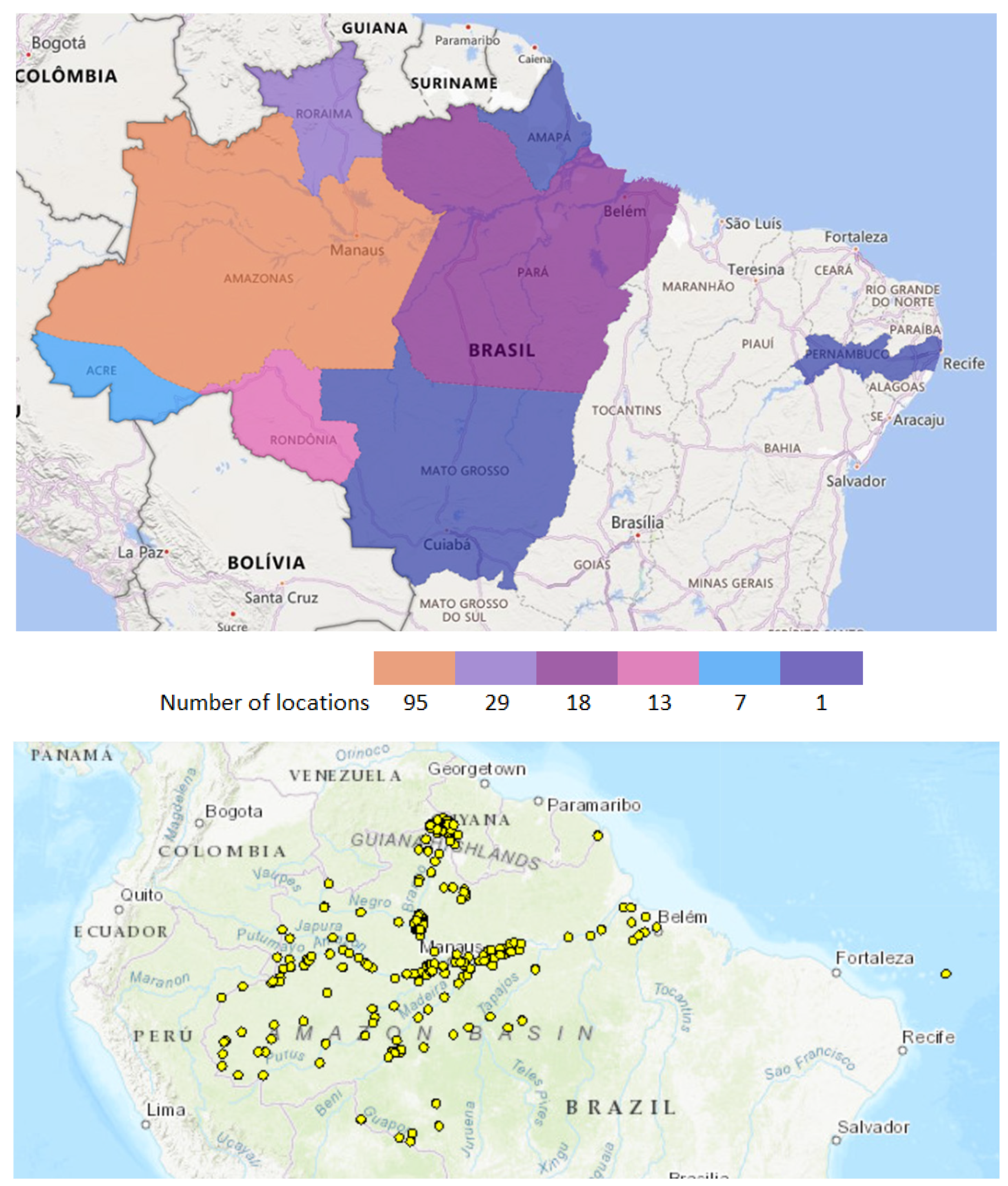

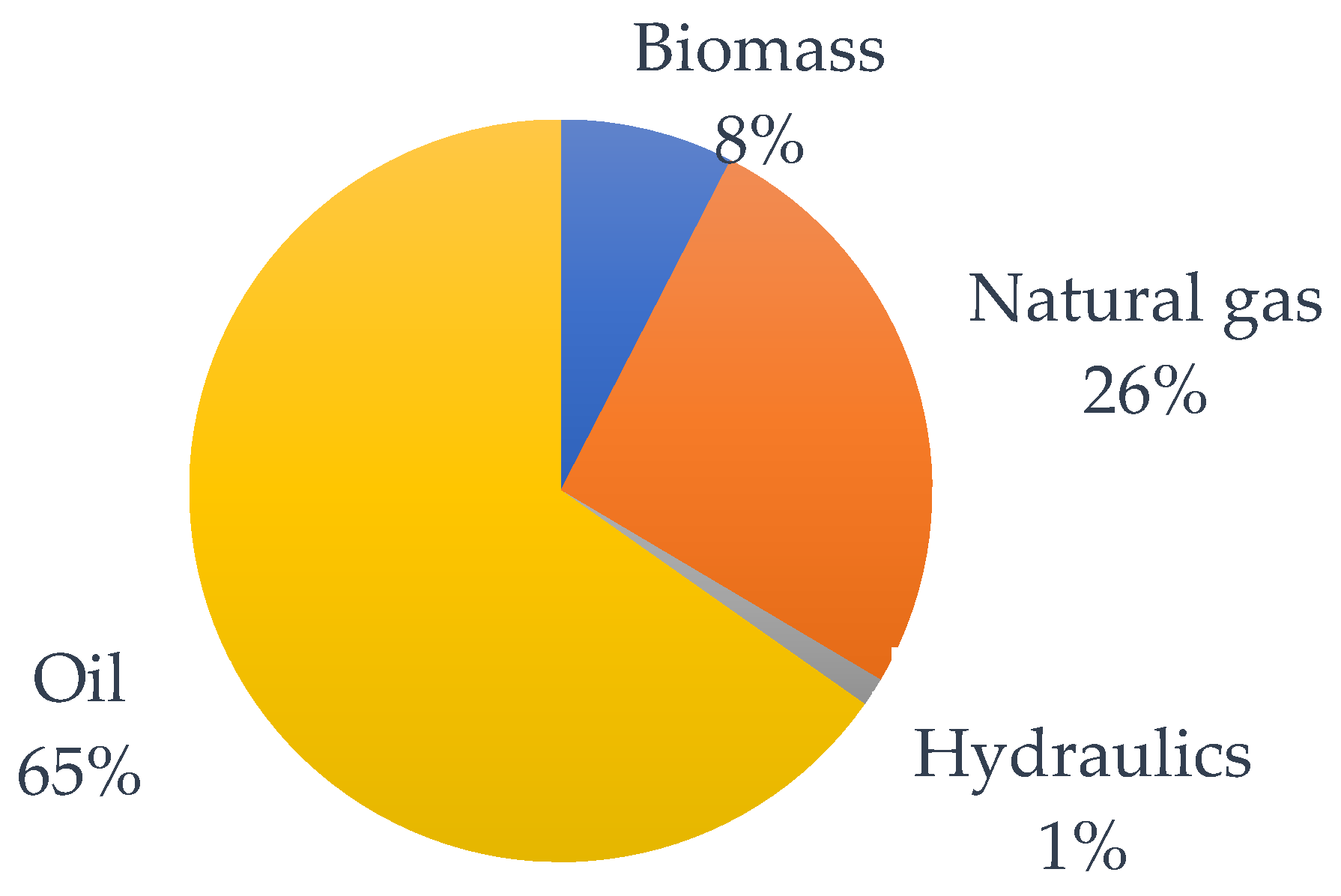

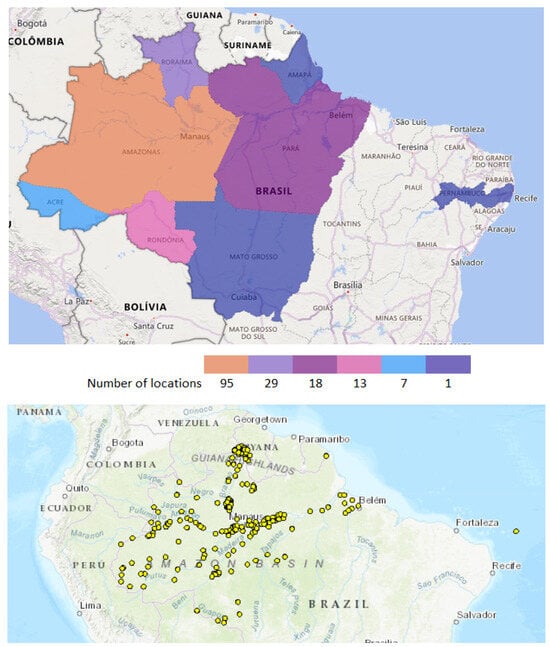

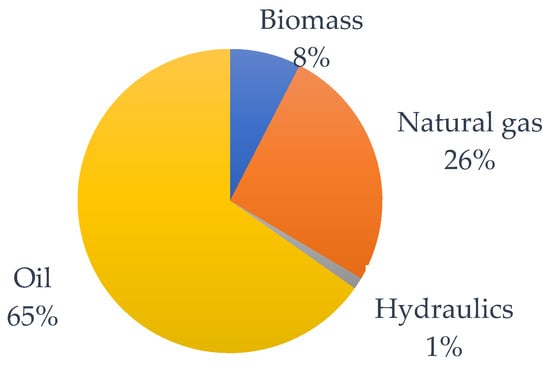

According to [8], in 2022, there were 165 isolated systems operating in the Northern, Northeastern, and Central–Western regions of Brazil. The distribution of these systems by state is shown in Figure 1. However, the percentage share of isolated systems in the total energy load for the Brazilian Electric System is slightly over 0.5%. Additionally, 2022 data report that the primary energy source for isolated systems was diesel oil, although there are also records of the use of natural gas and biomass, as illustrated in Figure 2.

Figure 1.

Geographical distribution of isolated systems in Brazil [8,9].

Figure 2.

Types of fuels used in isolated systems. Source: [8].

According to the Ministry of Mines and Energy (MME), energy supply to isolated systems is mainly provided by small thermal plants that primarily use diesel oil as fuel. In this context, since there are no alternative electricity support systems, power generation in isolated systems must be capable of meeting the total load at any given time, requiring a power reserve for potential failures or significant load variations.

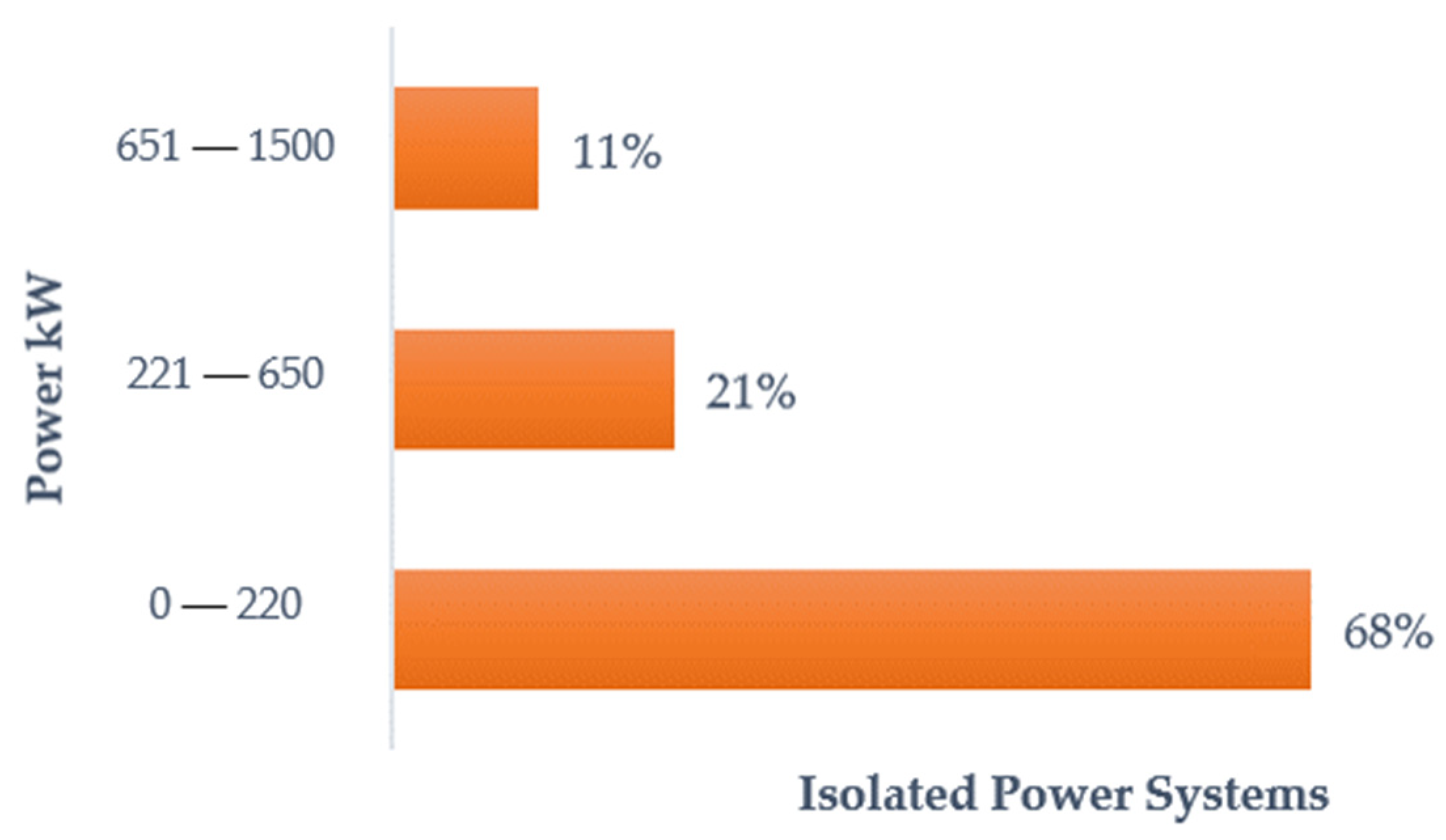

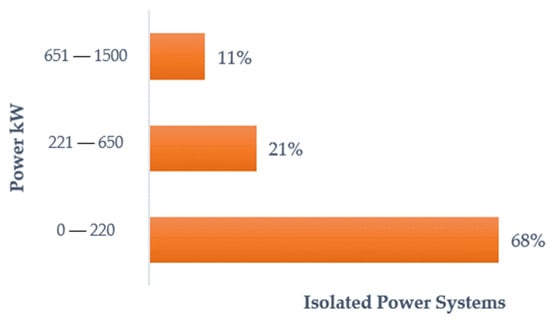

An analysis of data from isolated generation systems shows that 55% of these systems have a nominal capacity of less than 1500 kW, with 68% of these having capacities below 220 kW. Figure 3 presents a distribution of isolated systems below 1500 kW by power range.

Figure 3.

Distribution of isolated power systems by nominal/installed power range in kW. Source: Adapted from [6].

3.1. Energy Cost in Isolated Power Systems

Specifically in Brazil, a large portion of isolated systems are located near rivers, which are the main transportation routes in regions such as the Amazon [10]. Given the predominance of diesel oil for energy generation, the energy supply also depends on a complex logistics chain for fuel delivery, contributing to the high cost of generated energy and the risk of supply interruptions.

Considering logistics, the main difficulty occurs during dry periods when the draft of ships is limited, complicating transportation [10]. Another factor contributing to the high cost of electricity in independent systems is the low efficiency of diesel generators. Plants have an average efficiency of about 30%, meaning that approximately 70% of the fuel’s energy is lost during the generation process. Despite this, due to ease of construction, reliability, the ability to operate on-demand regardless of time, and maintenance, diesel generation remains the main option for Brazilian isolated systems [11].

To reduce these costs, it was established by law that concessionaires, permit holders, and authorized entities for electricity distribution services in these isolated locations must conduct procurements through public tenders or auctions [12]. The aim of these auctions is to stimulate competition among interested parties in supplying energy, encourage the implementation of alternative renewable energy sources that can replace diesel, and reduce the cost of electricity supply in these systems.

Based on data from an isolated systems auction conducted by the Energy Research Company (EPE) in 2020, the energy supply costs for a group of 23 locations across five states (Acre, Amazonas, Pará, Rondônia, and Roraima) [13] were obtained, as presented in Table 1. The average energy price obtained in this auction for isolated systems was BRL 1079/MWh or USD 197.98/MWh (considering an exchange rate of BRL 5.45 to USD 1.00), which is approximately 70% higher than the average regulated energy price in Brazil in 2020, according to Brazilian Federal Regulatory Electricity Agency (ANEEL) data [14].

Table 1.

Energy auction price results for 23 locations with isolated systems—adapted from [13].

3.2. Socio-Environmental Impact of Energy Generation in Isolated Systems

Considering that most isolated systems use diesel oil as fuel, in addition to the high cost of energy generation and the emission of greenhouse gases, another concern is the occurrence of environmental accidents. Accidents can occur both at the plant’s operation site and during transportation, where oil is commonly handled in large quantities.

Additionally, due to the location of isolated systems in Brazil, oil needs to be regularly transported through conservation areas. For instance, according to [15], in 2020, there were 112 environmental accidents in Brazil involving oil spills, with large quantities of oil frequently spilled [16,17].

However, there is another side to the coin. According to [7], in small, isolated communities, especially in the northern region, energy generation projects are important for the local economy, serving as one of the few sources of employment and income for these communities.

4. Production and Use of Hydrogen

On the path to a low-carbon economy, hydrogen has emerged as a promising solution for the decarbonization of the energy matrix and green power production. However, considering the energy supply in isolated power systems, is hydrogen a viable option? In what scenarios is the use of hydrogen in small-scale systems more likely to be feasible? To answer these questions, this section provides a brief overview of hydrogen and, connecting with isolated systems, presents research on the main projects involving green hydrogen and isolated systems.

4.1. Role of Hydrogen in the Low-Carbon Economy

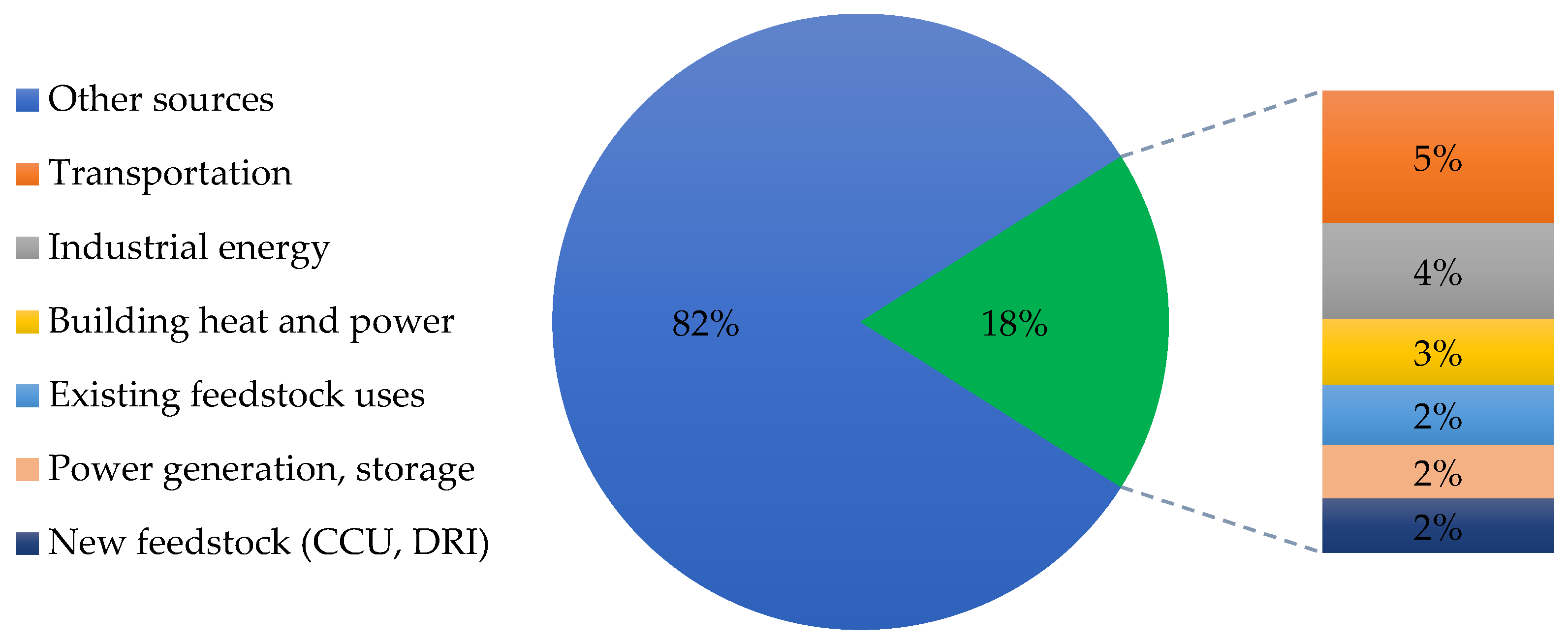

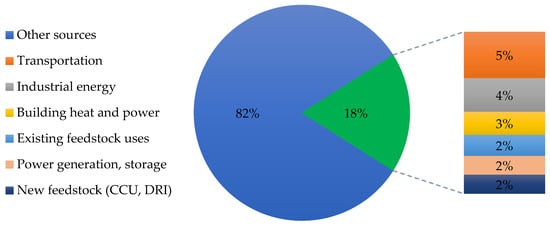

Hydrogen as a resource has had an established supply chain for decades, with various sectors using it as a raw material. However, projecting its use as an energy vector, according to the study presented in [18], it is estimated that by 2050 hydrogen could supply 18% of the world’s final energy demand. In this scenario, besides its current uses, hydrogen could additionally supply energy for the transportation sector (5%), industry (4%), heating and power generation in buildings (3%), energy generation and storage (2%), and new applications such as CCU (carbon capture and utilization) and DRI (direct reduced iron), as illustrated in Figure 4.

Figure 4.

Global energy demand supplied by hydrogen and other sources.

The consequences of global warming and climate change have heightened the sense of urgency to reduce the carbon footprint. The Paris Agreement, the first global agreement with political obligations for all countries to combat climate change, set the goal of limiting the global temperature increase to less than 2 °C above pre-industrial levels and striving to limit the increase to 1.5 °C. This established a benchmark that, among other things, implied the challenge of executing a profound transformation in the energy system, promoting a shift from a fossil-fuel-dependent energy matrix to a low-carbon energy economy [19].

These changes, set as short-, medium-, and long-term goals, heavily depend on the integration of renewable energies, which can result in the reduction in direct CO2 emissions by 41% and an additional 13% reduction through the electrification of processes that currently use fossil fuels, provided they use renewable energy [20]. However, to meet these targets, the share of renewable energy in the global energy matrix needs to grow from the current 18% to 65% by 2050 [20]. This growth raises concerns since a significant share of renewables in the energy matrix, especially in the cases of solar and wind energy, imposes a greater need for flexibility and resilience in the electrical system due to the intermittent nature of these sources.

In this context, hydrogen can play a fundamental role in enhancing the flexibility of renewable energy use. For example, hydrogen can be generated and stored during periods of high availability of solar or wind energy and converted back into energy when there is little or no renewable energy available to meet the demand.

4.2. Overview of the Hydrogen Chain

Similar to electricity, hydrogen is an energy carrier that can be produced in various ways. Each production method can be assigned a color to represent the hydrogen produced [9]. Green hydrogen is considered the cleanest, produced from water and does not release CO2. For example, black, gray, brown, and white hydrogen are produced from fossil or natural fuels and release more CO2 in the process. Pink hydrogen is produced from nuclear energy and does not release CO2.

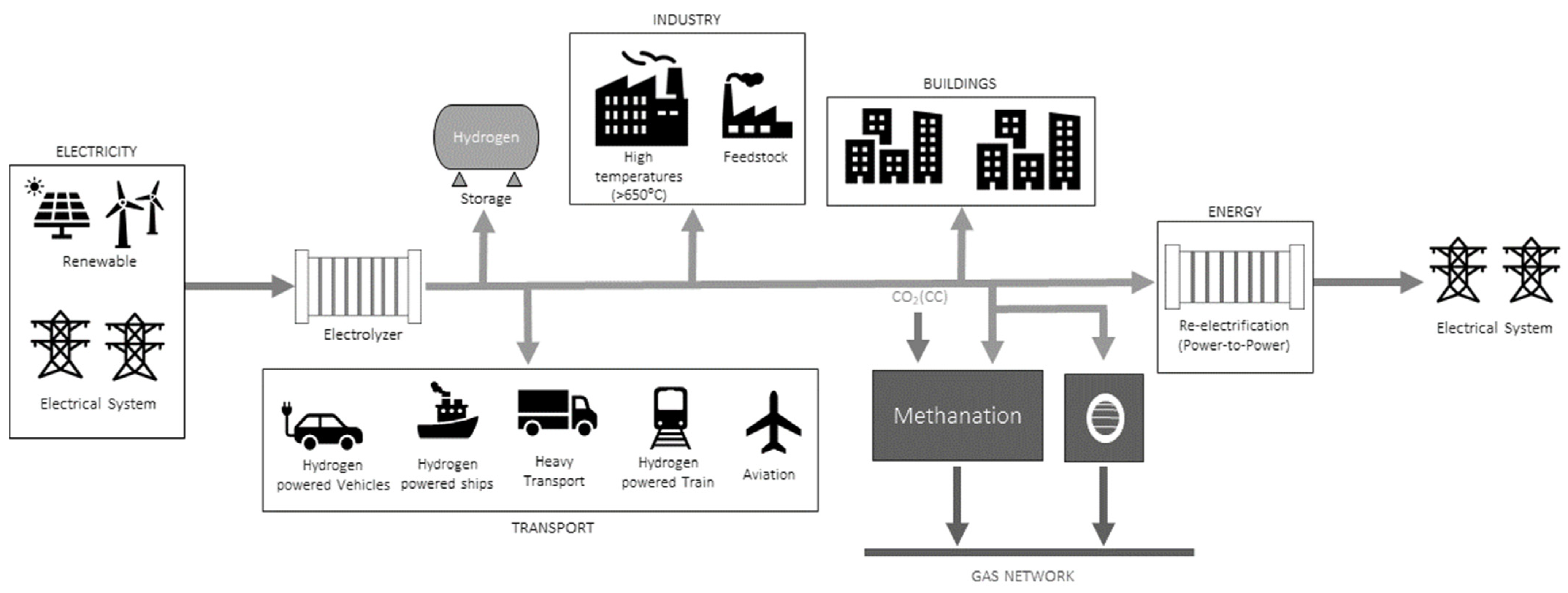

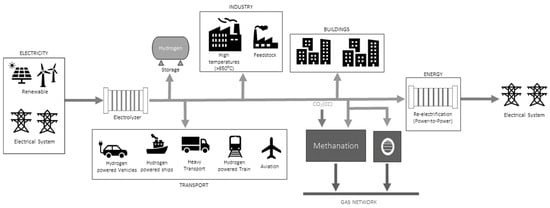

More specifically, green hydrogen (GH2) is obtained through the electrolysis of a water molecule, composed of two hydrogen atoms and one oxygen atom. Electrolysis separates hydrogen from oxygen in an energy-intensive process. In this alternative energy chain, one possible scenario is illustrated in Figure 5. Hydrogen has multiple potential functions, and one considered important, in the context of decarbonization, is enabling the use of renewable energy in sectors currently powered exclusively by fossil fuels [2].

Figure 5.

Hydrogen chain.

In industry, theoretically, hydrogen produced from fossil fuels could already be replaced by green hydrogen, which has not yet happened due to the high cost of green hydrogen, which is currently about five to ten times more expensive than gray hydrogen, and the low scale of production. In the long run, other inputs derived from fossil fuels could also be replaced by equivalents originating from green hydrogen, significantly impacting CO2 emissions [21].

In the commercial and residential gas sector, hydrogen injected into the gas network could reduce the consumption of liquefied petroleum gas (LPG) and eventually natural gas. The integration of this component into the gas network, which has been an important research topic in recent years [22,23,24,25], has the potential to create new business models and expand the market potential for green hydrogen, considering its use in industries, commerce, residences, and both light and heavy transportation.

In the transportation sector, fuel cell vehicles powered by green hydrogen will enable the sector to migrate to a low-carbon economy, a process already initiated with the introduction of battery vehicles but without some of the disadvantages associated with battery use. For example, hydrogen can be used in commercial transportation (cargo transport, public transport, etc.), where high vehicle usage rates and long-distance travel make battery use impractical due to recharge time and limited range [26].

In the energy chain, the strategy of producing and storing hydrogen can be an alternative for enhancing the flexibility of the electrical system, opportunistically absorbing excess renewable energy [27]. However, technical and economic issues remain. Green hydrogen widespread adoption faces several technical challenges mainly in the storage, transportation, distribution, production, certification and application aspects.

Storage remains a hurdle, requiring, in most cases, specialized infrastructure and materials capable of handling its high energy density and potential for leakage [28,29]. Transportation poses challenges due to the need for dedicated pipelines or the development of technologies for transporting hydrogen in liquid or gaseous states. Additionally, distribution necessitates adapting existing gas networks or building new infrastructure, as well as addressing safety concerns [30,31].

Certification of green hydrogen to ensure its renewable origin and traceability is also key for building consumer and investor confidence, but this requires the establishment of international standards and protocols [32,33,34].

The production of green hydrogen also faces several significant challenges that hinder its economic viability and market adoption. Key issues include the high costs associated with green hydrogen production, which currently makes it less competitive compared to gray hydrogen derived from fossil fuels. Current water electrolysis technologies rely on ultrapure freshwater, which is a precious and scarce source. Also, the lack of an established value chain and limited pilot projects further complicate the situation, as fossil fuels dominate the existing hydrogen market. Additionally, the need for technological advancements in electrolyzer efficiency, regulatory inconsistencies, and the absence of global standards also create challenges for market expansion, while energy losses throughout the hydrogen value chain exacerbate economic concerns. Overcoming these challenges may require substantial investment in research and development, supportive public policies, and collaboration across the entire value chain. In this way, some initiatives to increase hydrogen production can already be seen. Some examples of these initiatives are the advances in alkaline process efficiency [35,36], development in solid oxide technology [37,38], and new approaches such as the evaluation of magnetic field configuration in the increase in electrolysis production efficiency [39,40], the evaluation of the optimal electrode configuration in electrolysis process of actual industrial conditions [41]. Addressing these interconnected challenges is crucial for advancing the green hydrogen sector and achieving a sustainable energy future.

4.3. Hydrogen Applications in Isolated Systems

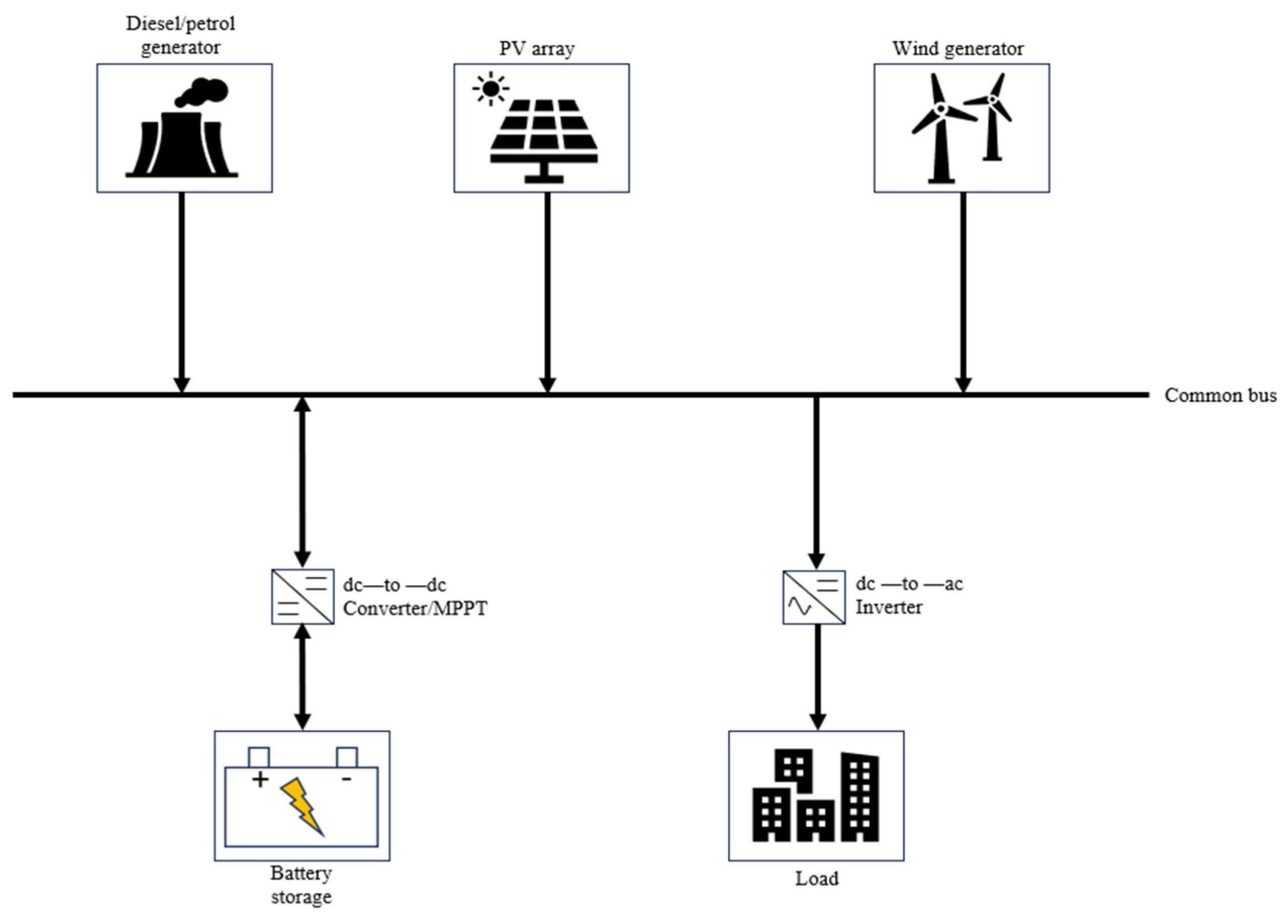

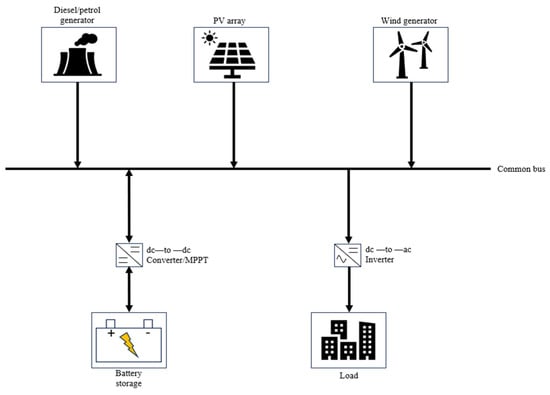

Globally and in Brazil, isolated systems are usually primarily supplied by diesel generation. However, depending on the geographical location, availability of natural resources, and energy source availability, other combinations can be made, such as energy storage, photovoltaic generation, or even wind generation, as illustrated in Figure 6.

Figure 6.

Illustration of possible topologies for energy supply in remote systems.

Based on a literature review, which will be presented in the Section 4.4, it was found that for most cases studied, the commonly used energy storage solution is battery energy storage systems, used to level the load and ensure the continuity of supply, especially given the intermittent nature of solar or wind energy supply. In this context, hydrogen emerges as a long-term energy storage alternative in isolated systems. When stored hydrogen is used in conjunction with a fuel cell, electricity can be generated to meet energy demand during periods when solar and wind energy are not being produced, conceptually creating an autonomous, reliable, and emission-free solution for applications in isolated systems.

4.4. Green Hydrogen Applications in Isolated Systems—An Overview of Economic Analysis

To understand the current scenario correlating the application of hydrogen in isolated systems, a bibliographic review was conducted. The search and selection procedure were conducted using specific combinations of key terms, such as Isolated System, Autonomous System, Remote Area, Energy Cost, and Green Hydrogen. The search focused on accessing scientific journal databases as well as databases featuring publications specific to the energy field, such as IEEE, Energies, Nature, and Elsevier. It is important to note that only peer-reviewed articles were considered for analysis. Furthermore, the review prioritized the selection of highly relevant and reliable scientific articles, thereby ensuring robustness and quality of the study.

The systematic analysis of these works aimed to identify patterns based on elements such as the proposed approach of the article, the results obtained, and the analyses presented. This classification approach allowed for a more structured understanding of the current state of research on green hydrogen in the spectrum of isolated systems. Based on the content of the literature review, the articles were classified into eight main topics: general technical-economic analysis, cost–benefit analysis for serving isolated systems, hydrogen production in weak grids, energy management of renewable generation with hydrogen, production cost analysis of hydrogen, review of social, technological, and economic aspects of hydrogen, environmental impact analysis of green hydrogen production by solar energy, and modeling and simulation of hybrid energy systems with hydrogen. Table 2 presents a summary of the classification of works related to each research theme.

Table 2.

Green hydrogen article/works for isolated systems.

Technical–economic analysis (TEA) is a widely employed approach to evaluate the technical and economic feasibility of a process technology, product, or project. TEA considers factors such as capital expenditures, payback period, internal rate of return, and net present value to calculate essential economic indicators of a project. It also takes into account environmental factors like hydrogen emissions and technical factors such as the impact on the electrical grid. In summary, TEA plays a significant role in high-level strategic decisions, assisting in determining project feasibility, selecting the option that best meets business objectives, and identifying priority areas for risk and cost reduction. A total of 35 articles directed towards this segment of analysis have been presented, subdivided into the following subtopics.

Refs. [42,43,44,45,46] present comparisons of technologies associated with the application of hydrogen systems, performing technical and economic comparisons between options for hydrogen production equipment, such as electrolyzers, PEM (proton exchange membrane) technology, and alkaline technology. They also compare different types of fuel cells, addressing PEM cells, which are commonly used in the market, and other variants. Additionally, comparisons are made in hydrogen storage systems, considering both gaseous and liquid forms.

The works described in [27,47,48,49,50,51,52,53,54,55,56,57,58,59,60] cover a subcategory of hydrogen production in isolated systems, where the hydrogen produced in these systems is used in a multipurpose approach. For example, reference. Ref. [48] uses hydrogen both as an energy storage system and for the commercialization of hydrogen produced for another location. Another usage option can be found in [50], which uses hydrogen produced in an isolated system to supply hydrogen-powered vehicles (such as cars and even boats).

The use of hydrogen systems as energy storage from renewable sources is explored in [60,61,62,63]. These articles provide a detailed assessment of the costs associated with the implementation and operation of this specific system. By offering a detailed approach to the implementation of hydrogen systems as energy storage, these articles aim to contribute to the evolution of this storage model and present the main adjustments that should be developed to make this storage model commercially viable in isolated systems compared to other renewable and even non-renewable options.

In [66,67,68,69], the use of produced hydrogen for storage is also explored. However, with an emphasis on the utilization of by-products generated in the production process and the reuse of hydrogen, as described in [66], which uses the heat generated by the fuel cell and electrolyzer to develop a cooling system for the locality. Another by-product usage option is presented in [68], which proposes the use of water released by the fuel cell to meet the demand of an isolated region.

References [70,71,72] aim to optimize the system to make green hydrogen production in isolated regions viable at the lowest cost and with the highest efficiency. This approach involves strategic adjustments, considering variations in parameters such as equipment power, operational efficiency, and costs associated with each situation. In this way, it is possible to identify the most effective configuration in terms of economic viability, maximizing the gains associated with hydrogen utilization.

Investigations into the factors influencing hydrogen production costs are described in [73,74,75,76,77,78,79], providing a comprehensive understanding of the costs associated with various technologies and production methods, from electrolysis to natural gas reforming processes. This detailed analysis not only allows the identification of areas for optimization and cost reduction but also contributes to more informed decision-making in the planning and implementation of hydrogen production infrastructure. By offering insights into the economic competitiveness of hydrogen compared to conventional energy sources, such studies play a fundamental role in driving sustainable development and influencing future energy policies.

The studies described in [80,81,82,83] conduct cost–benefit analyses focused on energy generation and storage options, especially aimed at servicing isolated systems. By examining the available alternatives, such as renewable sources combined with storage technologies, these studies provide a holistic assessment of initial, operational, and maintenance costs relative to the benefits provided. The cost–benefit analysis not only quantifies the investments needed to implement sustainable energy solutions in remote regions but also highlights the long-term economic and social returns, considering factors like the reduction in fossil fuel dependency.

Efficient and coordinated management of energy production from renewable sources, such as solar or wind, combined with hydrogen production and storage, is explored in [85,86,87], focusing on the energy management of renewable electricity generation with hydrogen. Integrated management contributes to the stability and sustainability of the energy supply.

Regarding energy management, two basic approaches have been observed. In the first, as in [88,89,90,91,92,93], emphasis is placed on developing management control systems with the aim of continuously monitoring the availability of and variability in renewable sources, dynamically adjusting hydrogen production and use in response to fluctuations in energy generation and load demand. In the second subcategory, as presented in [94,95,96,97], the studies perform energy management using an optimized techno-economic analysis. This second approach differs from the first by using data provided by techno-economic analysis, rather than real-time data (as in the first approach, which focuses on developing control systems).

Another option found in the mapping of studies involves the modeling and simulation of hybrid renewable energy systems with hydrogen, which consists of developing the process of creating mathematical representations and computer simulations that capture the dynamic behavior and interactions between different components of an energy system. In this context, the system is typically characterized by combining renewable energy sources, such as solar or wind, with hydrogen production, storage, and utilization. Modeling involves formulating equations and algorithms that describe the characteristics of each system component, such as solar panels, wind turbines, electrolyzers for hydrogen production, storage systems, and devices for electricity conversion. Simulation, in turn, uses these models to predict system behavior under different operational conditions and scenarios, enabling mathematical optimization of performance. The articles presenting this focus are categorized into two types: studies that use the developed simulation and modeling to optimize resources available in an isolated system [103,104,105,106,107,108,109,110,111,112] and studies using simulation to verify the behavior of fuel cells operating in an isolated system [98,99,100,101].

In [21,113,114,115], reviews and analyses of the social, technological, and economic aspects of hydrogen are presented through the evaluation of three fundamental dimensions related to the use and implementation of hydrogen as an energy source (social, technological, and economic). Social aspects include considerations on the impact of hydrogen use on society, local communities, and individuals, addressing issues such as public acceptance, employment impact, equity in technology access, and social effects. Technological aspects encompass an evaluation of the technologies associated with hydrogen production, storage, distribution, and utilization. This can involve technological innovations, process efficiency, technical challenges, and ongoing developments. Economic aspects pertain to the financial and economic implications associated with the hydrogen economy, addressing production costs, competitiveness relative to other energy sources, impact on existing economic sectors, job creation, and investment opportunities. The review of these aspects aims to provide a more comprehensive and contextualized understanding of hydrogen’s role in social, technological, and economic spheres.

Finally, some studies present specific topics and unconventional approaches regarding green hydrogen chain in isolated power systems. For example, references [64,65] present a TEA on the use of hydrogen in isolated systems. However, the generation sources are not limited to renewable energy sources alone but include a mix of renewable and non-renewable energy production. Reference [84] conducts an analysis of hydrogen production in so-called weak electrical grids, a term referring to grids where short-circuit power values are low (electrical grids more susceptible to occasional weather conditions, such as in isolated systems). Reference [116] evaluates aspects associated with the environmental impact analysis of hydrogen use in isolated systems, focusing on carbon emission levels.

4.5. Main Findings on Hydrogen in Isolated Systems

To understand the current scenario related to the application of hydrogen in isolated systems, a literature review was conducted, resulting in a comprehensive mapping that identified themes and approaches on the subject and gathered a survey of deployment strategies. Data (power and efficiency) from hydrogen production systems and fuel cells were collected from studies that considered these components. Another aspect observed was the inclusion (or lack thereof) of hydrogen compression and storage systems as part of the chain.

Hydrogen compression systems, when employed, account for significant energy consumption, which depends on the hydrogen pressure level at the compression stage’s entry and exit points. These parameters can significantly influence the amount of energy required for hydrogen transformation along the chain, consequently affecting its efficiency. A similar analysis was conducted on the sizing of hydrogen storage systems and the use of backup systems with batteries. In the context of isolated systems, due to the absence of a robust and extensive electrical grid, it is highly recommended that dispatchable generation systems, such as diesel or natural gas systems, have redundancies. In the case of supply by renewable energy, energy storage solutions are indispensable. For these reasons, the energy supplied to isolated systems is at a considerably higher cost level than energy supplied to the interconnected system, as observed in a previous section of this study.

The consolidated data resulting from the analysis of implemented/simulated hydrogen systems are organized in Table 3 and Table 4. Table 3 presents the main information about the equipment used in the implementations or simulations of isolated systems employing hydrogen, as identified in the study. Notable information includes the nominal power of the energy sources used, including wind, solar, and other sources. In this regard, it was found that, although most studies indicate the predominant use of renewable energies such as solar and wind, some works explore alternatives such as small hydroelectric plants (SHPs), geothermal energy, and biomass, which, for the purposes of this study, were grouped into the “Others” category.

Table 3.

Equipment parameters—according to the literature review and consulted works.

Table 4.

Economic parameters from the literature review.

Table 4 presents the main economic parameters identified in the survey. The first parameter presented is the Levelized Cost of Energy (LCOE), which is the unit cost of energy (BRL/kWh) determined by the ratio between the financial amount spent on the implementation and operation of the system over a certain time window, which is usually the solution’s useful life. The second parameter, the Levelized Cost of Hydrogen (LCOH), is calculated similarly to the LCOE, but substituting the amount of energy produced over the useful life with the amount of hydrogen produced in the same period. Observing the data reveals a variation that can be attributed to the different case study approaches, which consider, to varying degrees of detail, the costs of equipment acquisition, maintenance, and useful life. Other economic parameters considered are related to the electrolyzer, including the CAPEX, which is the cost of acquiring and installing the equipment, and the OPEX, representing maintenance and operation costs. These economic data provide an overview of the financial aspects involved in the implementation and operation of systems that use hydrogen as an energy source.

| Ref. | USD/kWh (LCOE) | USD/kg H2 (LCOH) | CAPEX Electrolyzer (USD/kW) | OPEX Electrolyzer (USD/kW/Year) |

|---|---|---|---|---|

| [60] | 1.35 | - | 17,000 | 20 |

| [57] | - | 6.64 | 856.60 | 53.54 |

| [42] | - | 7.60 | 340 | 14.88 |

| [42] | - | 8.55 | 420 | 15.86 |

| [42] | - | 10.16 | 520 | 18.78 |

| [42] | - | 7.16 | 520 | 18.69 |

| [70] | 0.55 | - | 6666.67 | 10 |

| [73] | 0.19 | - | - | - |

| [47] | 0.83 | - | 5000 | - |

| [21] | 0.41 | 5.84 | 1347 | 28 |

| [21] | 0.41 | 7.43 | 3496 | 75 |

| [27] | - | 2.33 | 600 | 12 |

| [51] | 0.66 | 22.70 | 2000 | - |

| [51] | 0.61 | 20 | 2000 | - |

| [51] | 0.50 | 17.60 | 2000 | - |

| [51] | 0.63 | 20.10 | 2000 | - |

| [51] | 0.53 | 16.70 | 2000 | - |

| [52] | 0.24 | - | 1500 | 43 |

| [58] | - | 3.75 | 784 | 17 |

| [99] | - | - | - | - |

| [61] | 0.34 | - | - | - |

| [100] | - | - | - | - |

| [113] | 0.55 | 16.01 | 200 | - |

| [114] | - | 3.48 | 1070.75 | 42.83 |

| [74] | - | 6.83 | 700 | 14 |

| [77] | 1.02 | 14.46 | - | - |

| [78] | - | 11.70 | - | - |

| [56] | 0.42 | - | 1400 | 28 |

| [93] | - | - | - | - |

| [59] | - | 3.30 | 1163 | 23.26 |

| [59] | - | 3.20 | 1163 | 23.26 |

| [59] | - | 4 | 1163 | 23.26 |

| [96] | 0.07 | - | 151 | 8 |

| [48] | - | - | - | - |

| [80] | 0.81 | 3.21 | 10,701.50 | - |

| [84] | - | - | - | - |

| [49] | - | - | - | - |

| [79] | - | 30 | 300 | 39 |

| [82] | 0.19 | - | 4280 | 89.18 |

| [85] | - | - | 13,376.90 | 30 |

| [97] | 2.80 | 21.51 | 8561.18 | 171.20 |

| [104] | - | - | - | - |

| [66] | 2.80 | 21.51 | 8561.18 | 171.20 |

| [86] | - | - | - | - |

| [105] | - | - | 1500 | - |

| [111] | - | - | - | - |

| [89] | - | - | 8000 | 230.10 |

| [112] | 0.29 | - | 600 | 15 |

| [95] | - | - | - | - |

| [90] | - | - | - | - |

| [68] | 0.11 | 9.75 | 1093.43 | 13.98 |

| [91] | 0.70 | - | 250 | - |

| [75] | 1.97 | 17.37 | - | 167.48 |

| [62] | 1.93 | - | 2140 | 64.2 |

| [62] | 3.00 | - | 2140 | 64.2 |

| [62] | 0.83 | - | 2140 | 64.2 |

| [62] | 1.28 | - | 4922 | 147.66 |

| [87] | 0.13 | - | 729.57 | 14.59 |

| [64] | 0.30 | - | 8778.13 | 526.75 |

| [107] | - | - | - | - |

| [43] | - | - | - | - |

| [108] | - | - | 303.65 | - |

| [53] | 0.49 | 6.69 | 2717.32 | 0.42 |

| [109] | 0.51 | - | 1070 | - |

| [71] | 0.44 | - | 800 | 16 |

| [101] | 0.79 | - | - | - |

| [65] | 0.20 | - | 434 | 14.10 |

| [54] | - | - | - | - |

| [116] | - | - | - | - |

| [67] | 2.5 | 83 | 1300 | 26 |

| [83] | 0.002 | - | - | - |

| [45] | 0.66 | - | 100 | 8 |

| [72] | 0.18 | - | - | - |

| [46] | - | - | 1498 | 44.94 |

| [76] | - | - | - | - |

| [115] | 0.36 | - | 1500 | - |

| [55] | 0.68 | 12.88 | 2668.89 | 0.41 |

| [55] | 0.49 | 6.88 | 2668.89 | 0.41 |

| [55] | 0.37 | 7.26 | 2668.89 | 0.41 |

| [110] | - | - | - | - |

| [98] | 1.10 | - | - | - |

| [94] | - | - | 3000 | - |

| [103] | - | - | - | - |

| [81] | 0.22 | - | - | - |

| [106] | 0.33 | - | 1960 | 4 |

| [69] | 0.16 | 4.18 | 599.50 | 11.99 |

| [50] | 4.82 | - | 5350 | 160.50 |

| [44] | - | - | 267.50 | - |

| [63] | - | 5.70 | - | - |

| [92] | - | - | - | - |

| [88] | - | - | - | - |

5. Main Results and General Discussions

Energy generation in isolated systems in Brazil is predominantly carried out by small-scale thermal plants that use diesel oil as their primary fuel. However, despite indications of the application of renewable generation in isolated systems, as reported in [117], the decarbonization of the energy matrix for these systems remains limited compared to the rest of the electrical matrix connected to the National Interconnected System (SIN). This can be attributed, in part, to the difficulty in managing the generation of solar and wind energy, which are commonly considered sources for isolated systems. In this context, the introduction of green hydrogen as an energy vector in isolated systems emerges as an alternative, enabling the use of energy on demand from renewable sources without a carbon footprint.

Flexibility in energy generation is crucial for adequately meeting demand variations in isolated systems. In this regard, hydrogen energy generation can increase system flexibility, allowing, for example, the excess solar energy produced at specific times to be stored and used on demand. Alternatively, considering a transitional scenario, the use of hydrogen in conjunction with other fuels, such as diesel engines, can provide significant cost savings and emission reductions [118].

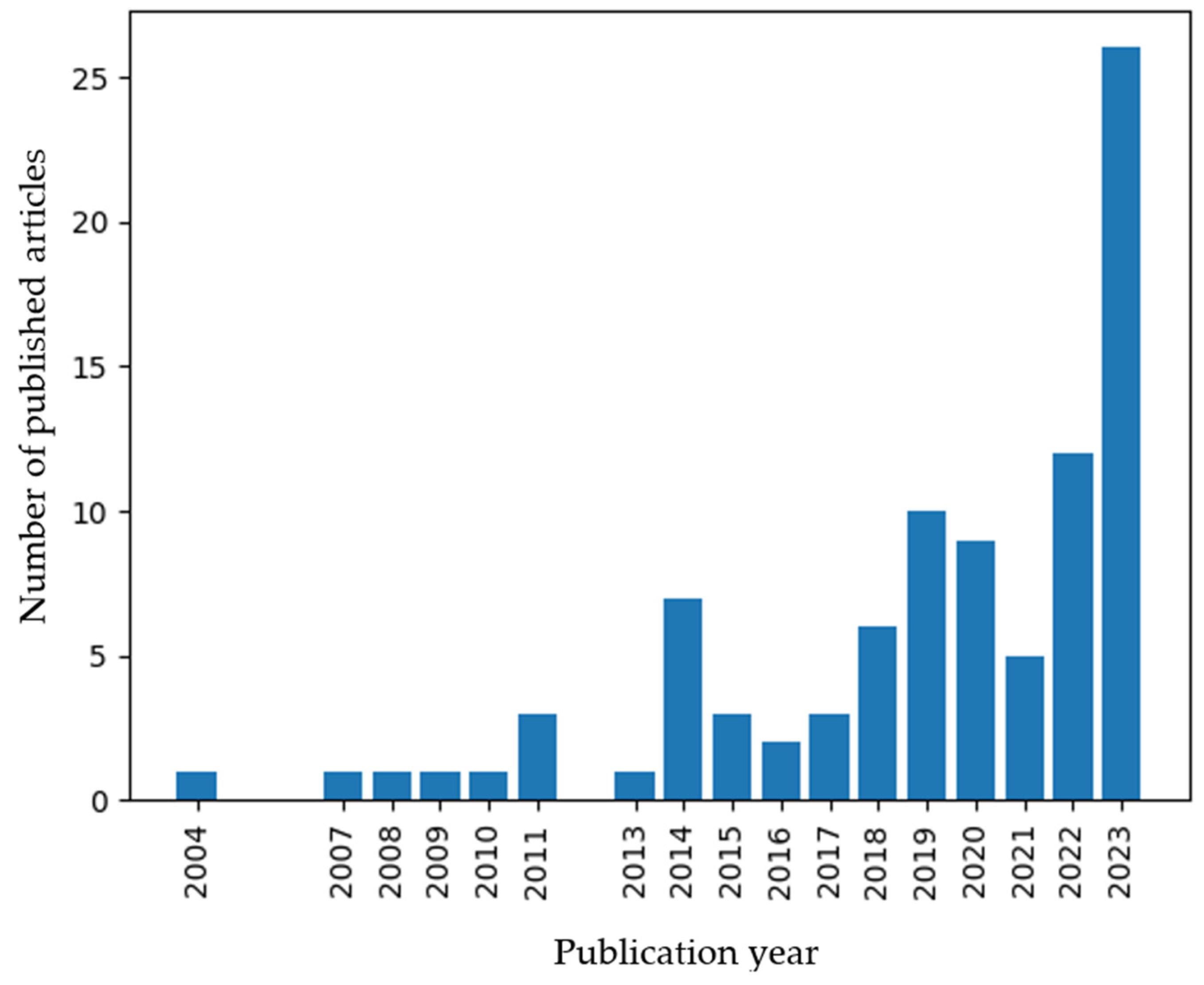

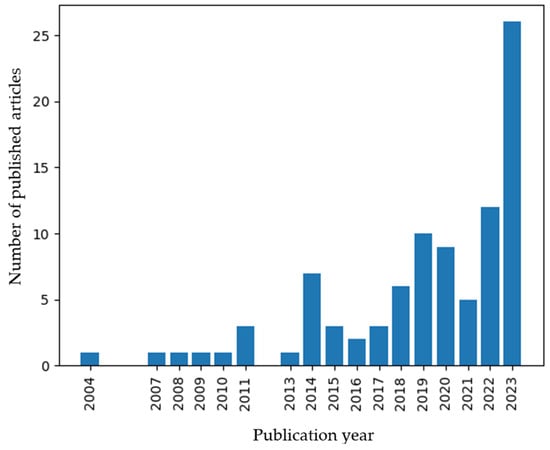

Through the analysis of the literature review, there was a significant increase in interest in hydrogen generation in the context of isolated systems. This is evidenced by the growing number of publications on this topic over the years, as illustrated in Figure 7, which shows the annual number of publications on this topic since 2004.

Figure 7.

Number of publications per year related to hydrogen generation and isolated systems.

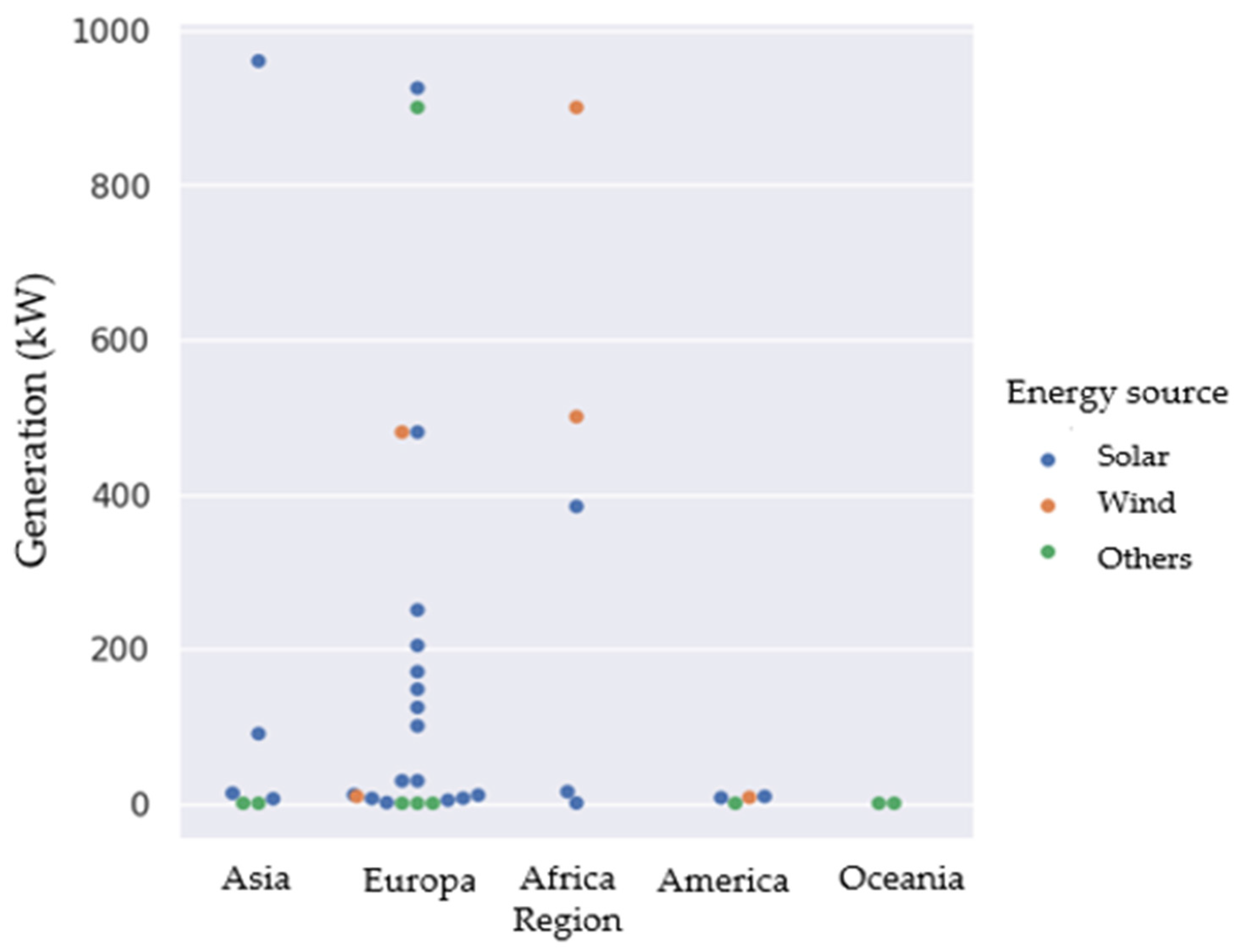

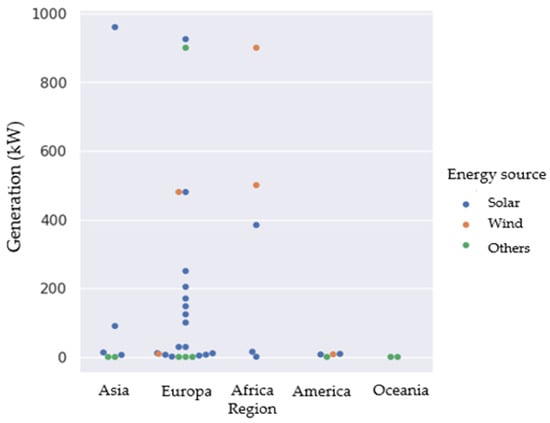

Analyzing the systems presented in these studies concerning energy generation, the most common energy generation sources are solar, wind, and others (small hydroelectric plants (SHPs), geothermal energy, and biomass), with nominal generation capacities ranging from 3 kW to 66 MW, as described in Table 3.

Regarding the locations of the projects or where the implementations were simulated, most are in Europe, followed by Asia, the Americas, and Oceania. As shown in Figure 8, the systems with a nominal generation capacity of 1 MW are classified by location and type of source.

Figure 8.

Nominal generation capacity of systems classified by location and type of source.

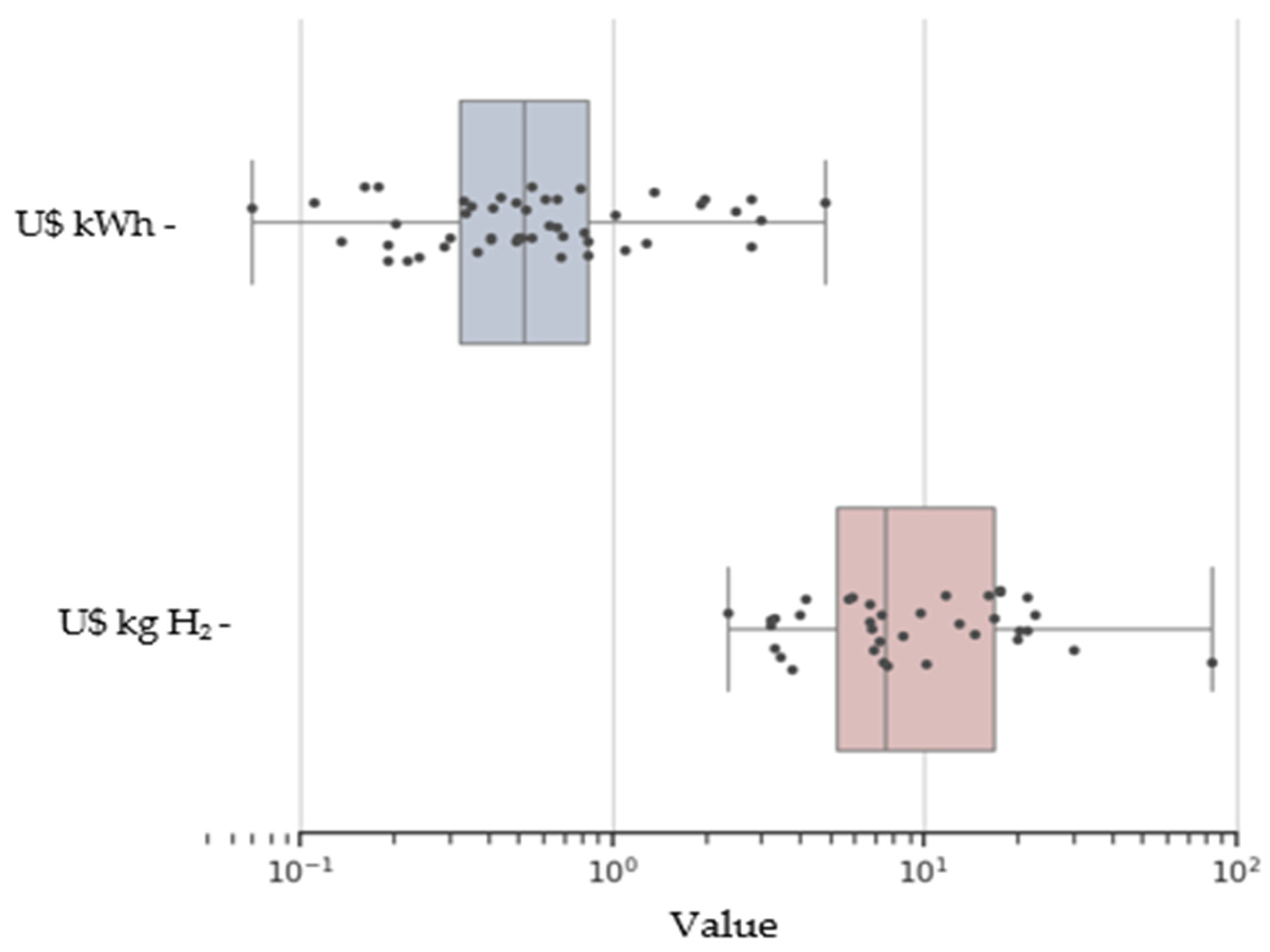

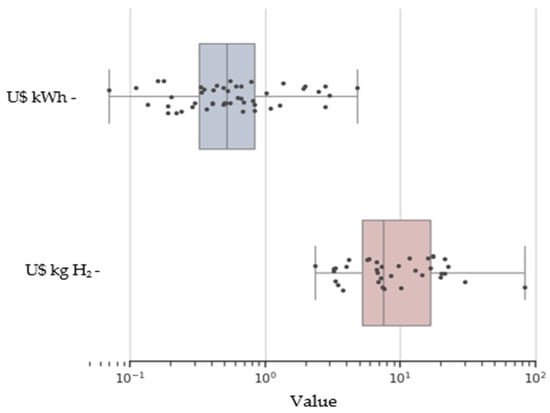

Considering that the cost values of energy and hydrogen per kilogram are fundamental parameters for the feasibility analysis of any application with green hydrogen, these parameters were also analyzed in the study. The analyzed studies presented values in different currencies, but mostly in US dollars. Thus, to simplify the analysis, all values were converted to US dollars, resulting in energy values in USD/kWh and hydrogen values in USD/kg H2. Figure 9 graphically presents the distributions of energy and hydrogen per kilogram values. Regarding energy, an average value of USD 0.81/kWh was observed, with a minimum value of USD 0.07/kWh [96] and a maximum reported value of USD 4.81/kWh [51]. For hydrogen, an average value of USD 12.58/kg H2 was observed, with a minimum value of USD 2.33/kg H2 [27] and a maximum value of USD 83/kg H2 [67].

Figure 9.

Distribution of energy values and kg of H2 reported in the analyzed works.

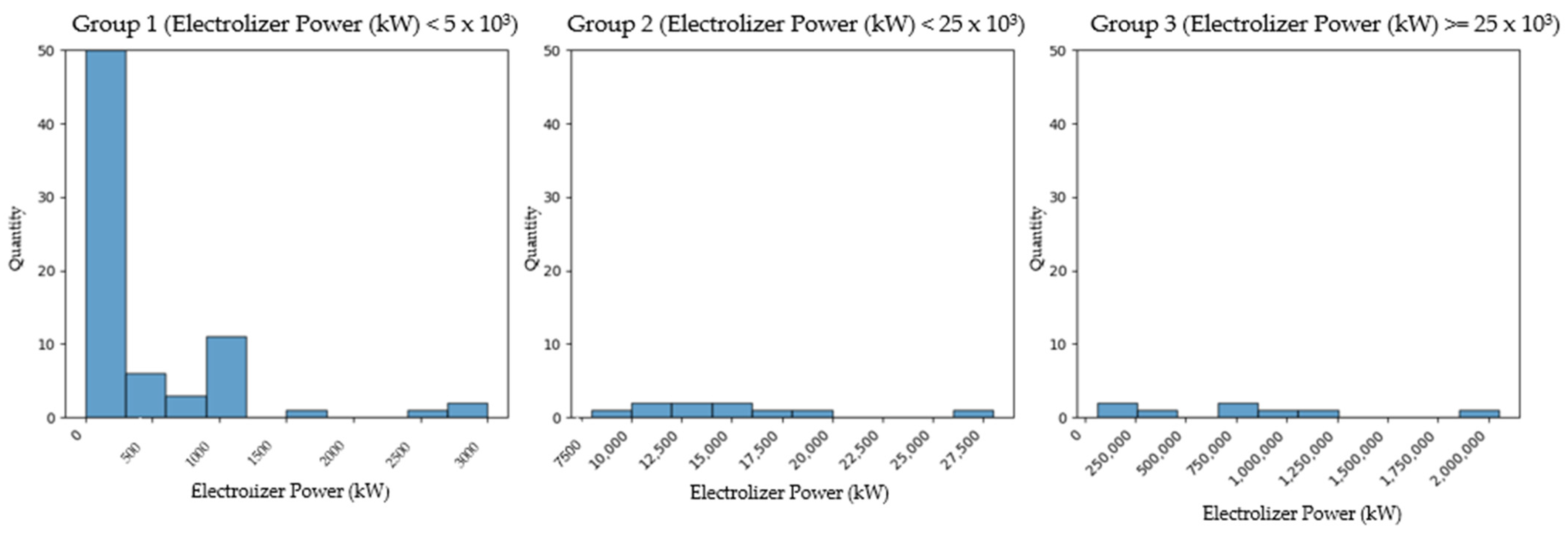

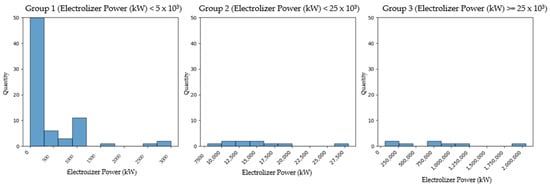

Another important aspect analyzed in the studies were the electrolyzers’ general characteristics. In the conducted study, four parameters of the electrolyzers were analyzed: nominal power, efficiency, CAPEX (capital expenditure), and OPEX (operational expenditure). Regarding nominal power, a wide range of 1 kW to 2053 MW was observed. However, most were concentrated in the range below 5 MW, with a significant percentage below 500 kW. To illustrate this distribution, the nominal powers of the electrolyzers were divided into three groups: Group 1, with a nominal power below 5 MW; Group 2, between 5 MW and 25 MW; and Group 3, with electrolyzers above 25 MW. A bar graph illustrating the number of elements in each group is presented in Figure 10. Although the studies considered different water electrolysis technologies, the efficiency reported in the studies remained within a relatively moderate range. The average efficiency was 48.25 kWh/kg H2, with a minimum reported value of 33.3 kWh/kg H2 [100] and a maximum reported value of 75 kWh/kg H2 [44].

Figure 10.

Number of electrolyzers divided into three groups according to nominal power.

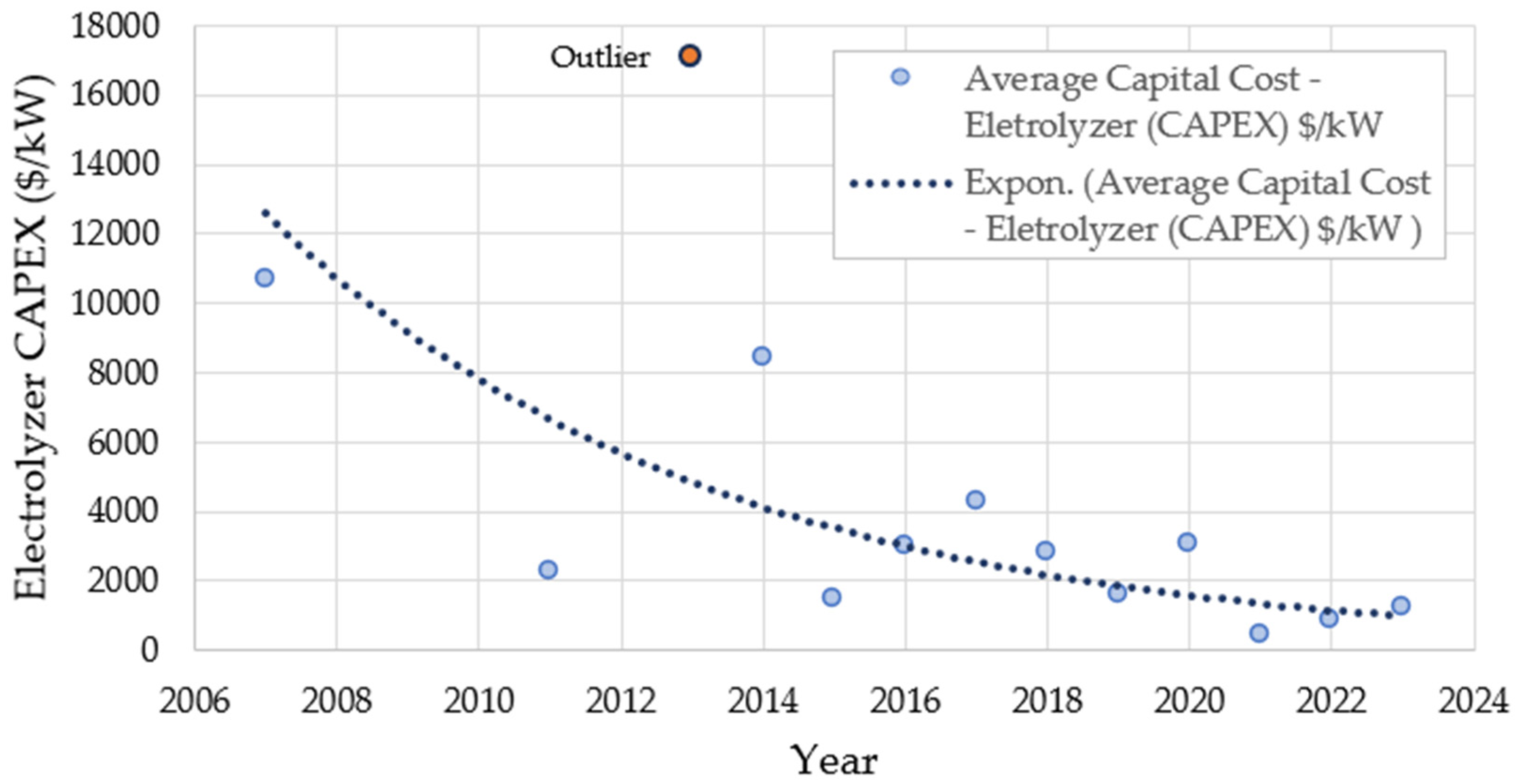

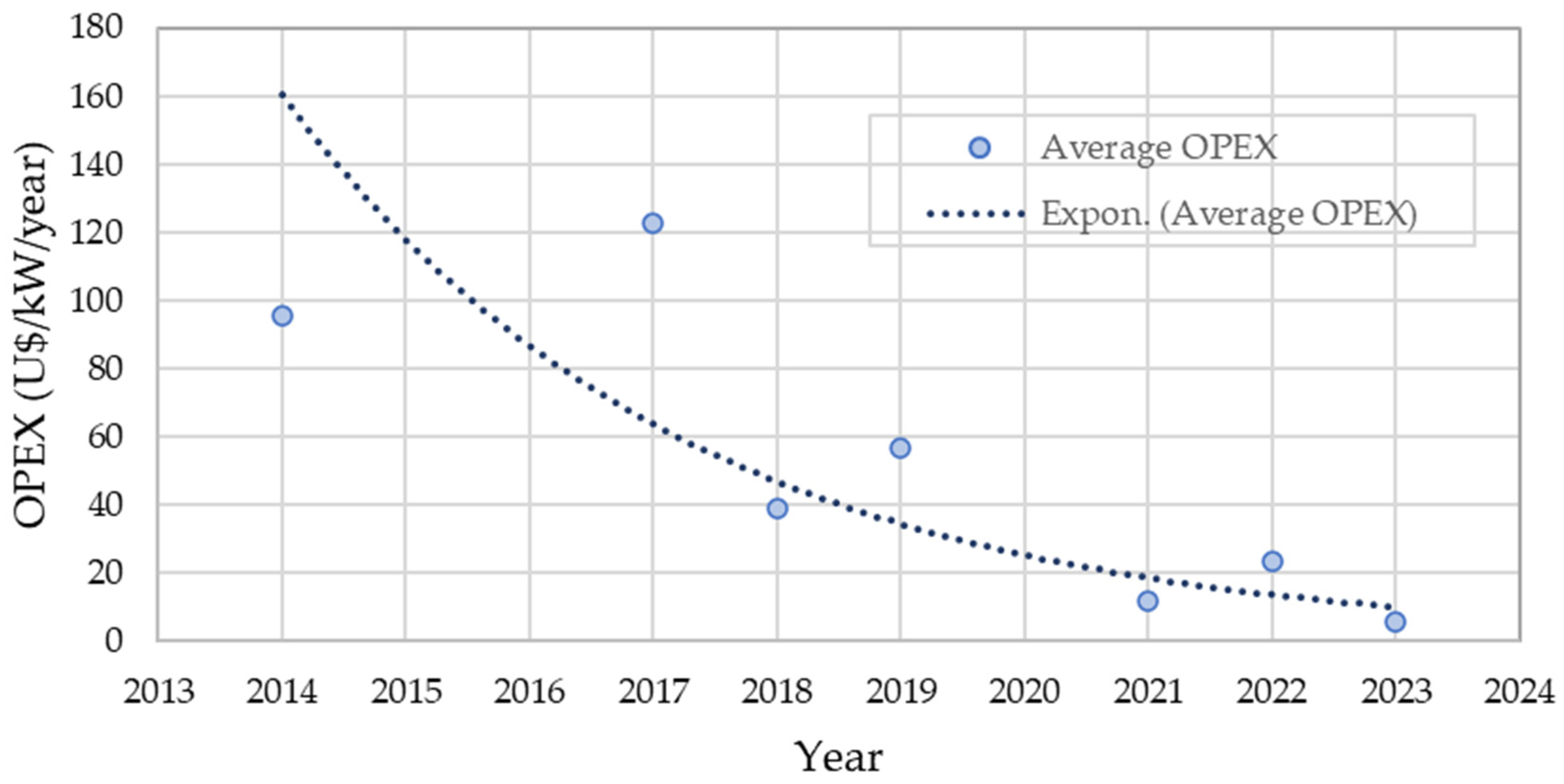

5.1. Historical Hydrogen Costs

The capital expenditure (CAPEX) for the installation of the electrolyzer and the annual operating expenditure (OPEX) of the electrolyzer are very important parameters as they relate to the number of resources that must be mobilized for the implementation and operation of the main component of a hydrogen production system, the electrolyzer. CAPEX and OPEX values are not commonly found, with few studies presenting values for these parameters. In general, the CAPEX had an average value of USD 2673.93/kW of hydrogen generated by the installed electrolyzer, a minimum value of USD 100/kW, and a maximum reported value of USD 17,000/kW. The OPEX, in turn, had an average value of USD 60.41/year, a minimum value of USD 0.41/year, and a maximum value of USD 526.75/year. Both the CAPEX and OPEX showed a wide range of variation, which can be understood as an indication that there is still no standard for the application of green hydrogen in the generation of isolated systems. Furthermore, electrolysis technologies are relatively young and will require considerable development to reach stages of technological maturity that enable large-scale adoption.

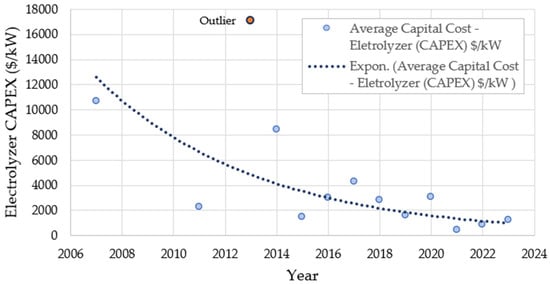

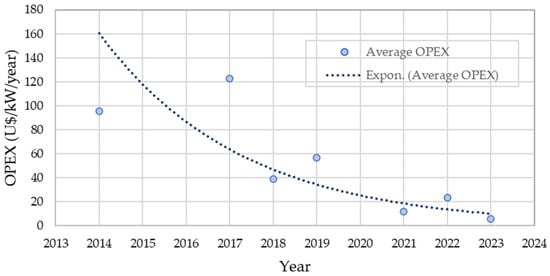

To illustrate the behavior of the CAPEX and OPEX over time, the average annual values for these variables were calculated using the data from Table 4. The average CAPEX over the years is shown in Figure 11, while the OPEX trends (from 2011 to 2024) are presented in Figure 12. A general decrease in average CAPEX values has been observed over the years. This line trend (dotted line is based on an exponential curve fitting) aligns with expectations for the adoption of new technologies, where early adopters tend to incur higher costs. As technology matures, demand increases, and more participants enter the market, leading to a typical decline in prices.

Figure 11.

Average CAPEX over the years (historical data).

Figure 12.

Average OPEX over the years (historical data).

Regarding the OPEX, although lower values have been observed in recent years (2021–2024) compared to 2011, relatively high OPEX levels are still being reported. The presented operating costs behavior can be attributed to two main factors. First, the studies primarily focused on isolated hydrogen generation systems, which typically incur higher operational costs that vary considerably depending on geographic location. Second, both OPEX and CAPEX data were sourced from articles that may not have specifically prioritized cost analysis, leading to potential imprecision in the reported figures compared to studies dedicated to cost evaluation.

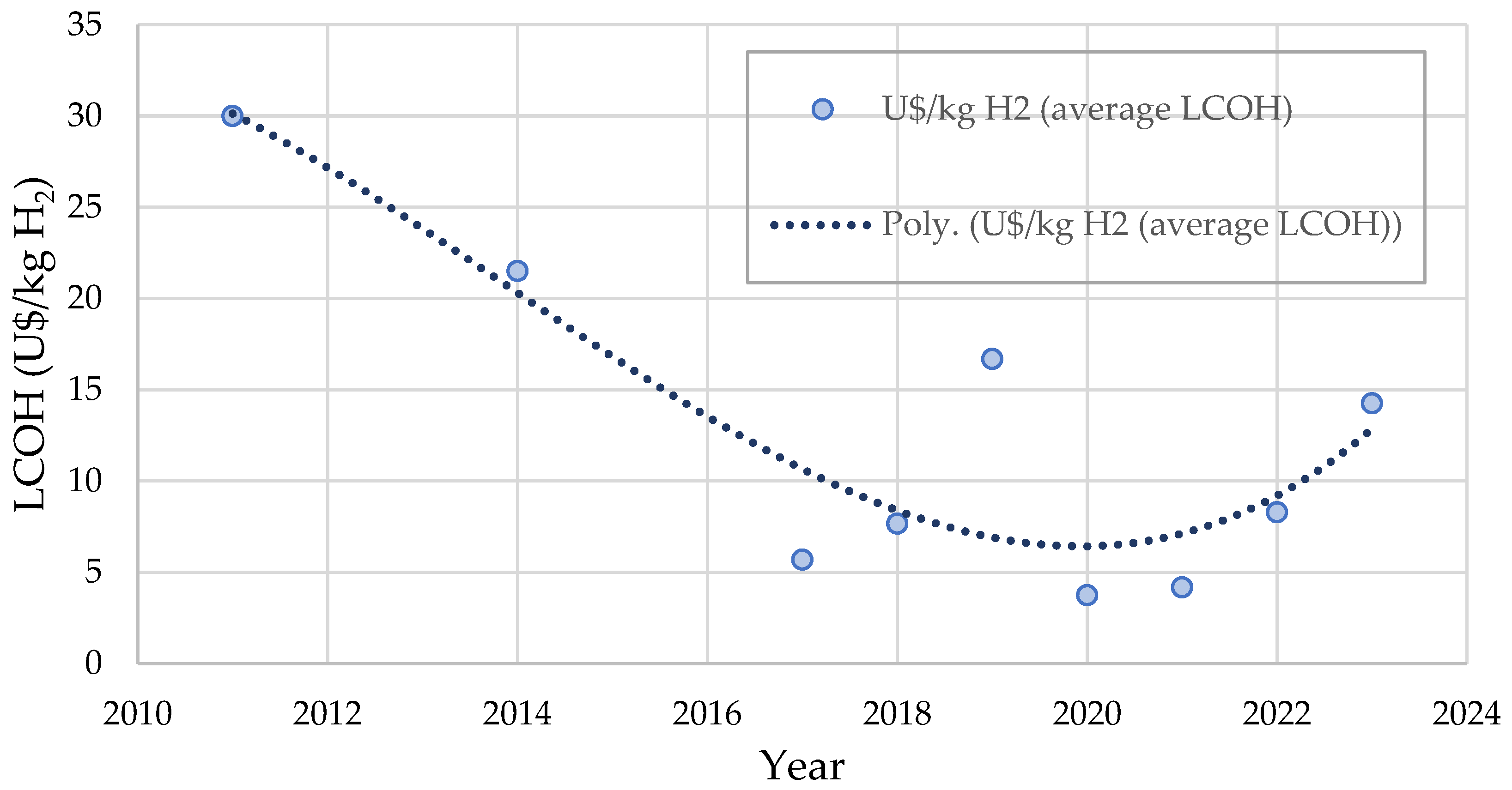

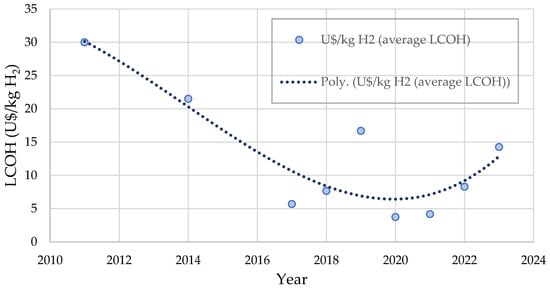

Figure 13 illustrates the average yearly LCOH over time, based on data from the references listed in Table 4. While a general downward trend is evident from 2011 to 2022, there are notable exceptions in 2019 and 2023, deviations which the articles do not provide clear explanations for. Excluding these years as outliers, the overall trend, based on a polynomial curve fitting (dotted line), shows a significant decrease in the average LCOH, dropping from USD 30/kg H2 in 2011 to below USD 10/kg H2 by 2022. However, due to the limited availability of LCOH data, it is difficult to draw definitive conclusions from this metric alone. Further research is recommended to gain a more comprehensive understanding of the trends and the factors affecting hydrogen production costs.

Figure 13.

Average LCOH over the years based on historical data.

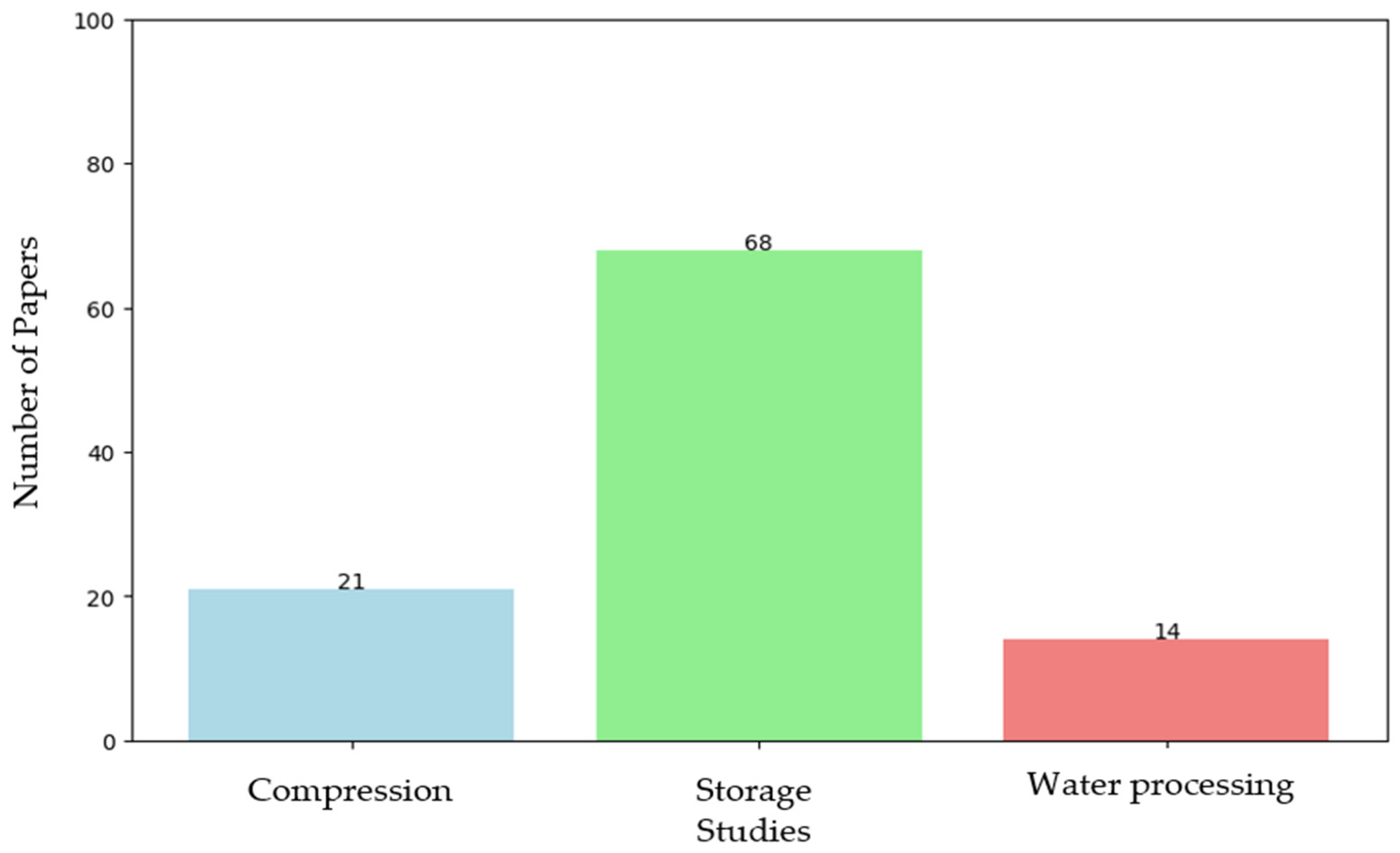

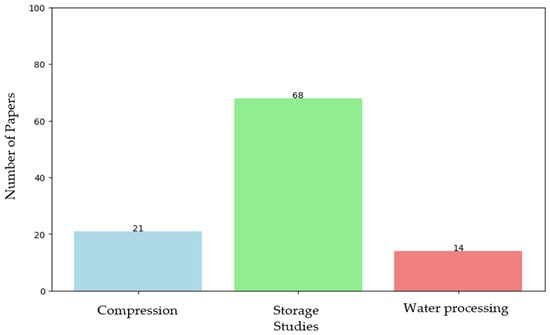

Another aspect analyzed in the studies was the scope of the hydrogen chain. Green hydrogen, as an energy vector, has attracted attention, which is evidenced by the growing number of published works, as illustrated earlier in Figure 7. However, the analysis and results of these studies depend heavily on how the scope of the hydrogen chain is defined. Specifically, they are influenced by whether key stages such as (1) hydrogen compression, (2) storage, and (3) water processing are included. The present study found that only a portion of the reviewed works considered all three of these stages, as illustrated in Figure 14. The first factor, hydrogen compression, is often overlooked in chain analysis but is crucial, particularly when considering efficiency and energy consumption. Secondly, as an energy carrier, green hydrogen produced from renewable sources will need to be stored for on-demand electricity generation in a scenario of large-scale deployment. Therefore, hydrogen storage systems will play a critical role in the widespread implementation of green hydrogen-based power systems. The third important factor is water processing for electrolysis, which requires careful analysis. Section 5.2, Section 5.3 and Section 5.4 address key aspects related to these processes.

Figure 14.

Number of studies/articles that considered the stages of compression, storage, and water processing within their scope.

5.2. Hydrogen Compression

As previously mentioned, the processes of hydrogen compression and storage are crucial for the viability of the hydrogen usage chain. Although often underestimated, these stages have a significant impact on energy efficiency, economic feasibility, and system safety.

Hydrogen produced by electrolyzers typically exits at a relatively low pressure, around 20 to 30 bar. However, for commercial, industrial, and transportation applications, much higher pressures are required, often exceeding 350 bar and, in some cases, reaching up to 700 bar. This pressure differential requires a significant amount of energy for compression, consuming up to 10% of the total energy available in the produced hydrogen, directly affecting the overall system efficiency [119].

The losses associated with compression occur primarily because this step precedes both storage and transport, as well as local use in fuel cells. The energy consumption in compression stages can vary depending on the pressure and temperature levels, as described in [21]. At low-pressure compression (30–35 bar and 25 °C), energy consumption is estimated at 2.77 kWh/kg of H2. For medium-pressure compression (50–150 bar and 25 °C), consumption ranges from 3.95 to 10.9 kWh/kg of H2. In high-pressure applications (350 bar and 25 °C), consumption increases to 23 kWh/kg of H2. In the case of compression for hydrogen liquefaction, at extremely low temperatures (−253 °C and 1 bar), energy consumption reaches 70.8 kWh/kg of H2. Lastly, for the compression of hydrogen in the form of liquid ammonia (−33 °C and 1 bar), energy consumption is estimated at 121 kWh/kg of H2, with an additional 8 kWh/kg of H2 needed to recover hydrogen from the ammonia [21].

It is important to note that inadequate compression can result in significant inefficiencies in hydrogen transport and storage. Despite the importance of the compression step, there is still a lack of studies that focus specifically on hydrogen compression and its energy impacts. In the literature review described in Table 3 and Table 4, only 21 studies considered hydrogen compression in their evaluations to estimate the economic feasibility of the hydrogen usage chain. Overlooking the energy consumption associated with compression can lead to underestimating the required energy and, consequently, the overall process efficiency.

5.3. Hydrogen Storage

Like compression, hydrogen storage is equally crucial and presents significant technical challenges. Due to its low energy and volumetric density under normal pressure and temperature conditions, hydrogen requires efficient storage methods to be viable as a fuel. Among the main storage methods, as described in [120], are the following: (1) High-pressure storage: although it is a mature technology, this requires robust tanks and safety systems to handle high pressures, which increases costs and the complexity of the necessary infrastructure; (2) Cryogenic storage (liquid hydrogen): this involves maintaining hydrogen at extremely low temperatures (−253 °C), and while energy-dense, it is an extremely costly and energy-intensive option due to the continuous cooling requirements; (3) Storage in materials, such as metal hydrides: this offers a promising alternative but still faces challenges related to cost and energy efficiency.

In scenarios where hydrogen is used for electricity generation in fuel cells, such as in backup power systems or hydrogen vehicles, the ability to store large quantities of hydrogen efficiently and safely is essential to ensure the economic viability and reliability of the system. The cost of hydrogen storage can represent up to 30% of the total cost in some applications, highlighting the need for more efficient and cost-competitive storage technologies [121].

There is evidence that the costs and energy losses associated with hydrogen storage may have been overlooked in some studies. Of the studies analyzed and described in Table 3 and Table 4, only 68 included hydrogen storage within the scope of their evaluations, as illustrated in Figure 14. Considering that storage is essential to ensuring a continuous hydrogen supply, especially in applications that require on-demand delivery, excluding the impacts of this process may compromise a precise understanding of the hydrogen value chain and the overall feasibility of its applications.

5.4. Hydrogen Water Processing

Water plays a fundamental role in the production of green hydrogen, serving as an indispensable resource for the technical and economic viability of the electroenergy supply chain. Electrolysis, the primary method for green hydrogen production, involves the decomposition of water into hydrogen and oxygen using electricity from renewable sources. However, the quality of the water used in this process is crucial, and the use of purified water instead of raw water ensures efficient operation and prolongs the lifespan of the electrolyzers [122].

Purified water is a basic input, and its purity directly influences process efficiency and equipment durability. Impurities in the water, such as metal ions and organic compounds, can cause electrode corrosion, reduce system efficiency, and increase operational costs. The purity level required for the electrolysis process must be below 1 µS/cm for standard alkaline electrolyzers and below 0.1 µS/cm for PEM electrolyzers or advanced alkaline electrolysis systems. These purity levels are essential to prevent electrode damage and maintain optimal system efficiency [122].

The consumption of purified water is directly related to hydrogen production. For each kilogram of hydrogen produced, approximately 9 L of purified water is required [122]. This means that an electrolysis plant with a production capacity of 100,000 tons of green hydrogen per year will require around 900,000 cubic meters of purified water. These figures illustrate the magnitude of water demand in large-scale processes, making the efficient use of purified water sources a critical aspect for the viability of large-scale hydrogen production.

However, the production of purified water requires a complex treatment process, involving pre-treatment and polishing stages. These steps vary depending on the source of raw water, which can include groundwater, treated wastewater, or seawater. Pre-treatment includes processes such as membrane filtration, removal of particles and ions, and desalination in the case of seawater. Water treatment consumes between 2 and 7 kWh per cubic meter, with the 7 kWh figure being associated with seawater, where desalination is required [122]. Water treatment can add between USD 0.02 and USD 0.05 per kilogram to the cost of the produced hydrogen and may impact in the technical viability of large-scale projects [123].

In addition to the purified water used directly in the electrolysis process, large volumes of water are needed for cooling, especially in larger plants. The heat generated during electrolysis must be dissipated to ensure system efficiency and prevent equipment damage. Smaller projects can use dry-cooling systems, while large-scale plants often rely on water sources for cooling, which can include groundwater, treated wastewater, or seawater, depending on the facility’s location. On average, it is estimated that about 400 L of cooling water is required per megawatt of installed capacity in electrolysis systems, further increasing the total water demand [122].

As described in [123], a 35% increase in green and blue hydrogen production capacity is expected in areas experiencing high water stress. The growing global demand for hydrogen places additional pressure on water resources, especially in regions already facing water scarcity. In this context, it is crucial to integrate water considerations into the planning of hydrogen projects to ensure that production expansion does not exacerbate water shortage issues.

Despite the importance of water processing and usage in hydrogen production, of the studies analyzed and described in Table 3 and Table 4, only 14 included hydrogen storage within the scope of their evaluations, as illustrated in Figure 14. This demonstrates that there are still considerable challenges to be explored in research to mature green hydrogen supply chains. In the context of isolated systems in the Amazon region, there is a relative abundance of water resources, widely available in rivers and reservoirs. However, the challenge remains to process the water to obtain a liquid suitable for supplying the electrolyzers.

6. Conclusions

Isolated systems remain a significant technical and economic challenge in Brazil and globally. In this context, the reality of energy prices is distorted by the scarcity or infeasibility of technical solutions and the logistical complexity involved in accessing these locations. Additionally, the commonly applied solution, diesel generation, is one of the highest greenhouse gas-emitting sources compared to the rest of the electrical grid. It also requires a supply chain whose characteristics elevate operational costs and environmental accident risks.

Given this reality, the application of green hydrogen as an energy vector for providing power to isolated systems offers promising solutions. These include the ability to produce green hydrogen using solar energy and local water supply, store it, and use it on demand for heat or electricity generation. Although this type of green hydrogen application still faces technological challenges, it increasingly shows signs of viability as solutions across different stages of the supply chain mature.

This article aims to present a perspective correlating energy supply in isolated systems with the implementation of hydrogen production systems. Through a review of key articles and technical documents related to hydrogen generation and use in isolated systems, data were collected. This data collection enabled the analysis of parameters such as the types of renewable sources, the nominal power of these sources, and the nominal power of electrolyzers; electrolyzer CAPEX, electrolyzer OPEX, and electrolyzer efficiency; the locations of implemented or simulated systems; the leveled cost of energy (LCOE) and leveled cost of hydrogen (LCOH); and the scope of analyses regarding the stages of the hydrogen production and application chain. As observed in the survey of hydrogen production projects developed in recent years, described in the literature review, cost indicators (e.g., CAPEX) are on a downward trend.

It is known that, although it is not the only parameter under consideration, the cost of energy is crucial for providing power to isolated systems. Although this cost is subsidized by the state, ultimately, someone has to pay, so it is necessary to control expenses. In this regard, the cost of applying hydrogen as an energy supply strategy for isolated systems is not far from the reality of isolated systems in Brazil. According to the study, the energy provided by hydrogen showed values ranging from USD 0.07/kWh to USD 4.81/kWh. In contrast, the energy supplied in isolated systems in Brazil has an average cost of USD 0.198/kWh.

Another noteworthy aspect is the growing relevance of the topic, evidenced by the increasing number of articles involving the keywords “green hydrogen” and “isolated systems”. However, implementing energy supply systems that use green hydrogen as a vector still incurs high installation and operation costs, particularly considering the complexity of installing in isolated systems. There is still a long way to go, both in scaling up the production systems to reduce costs and in advancing the technology’s maturity.

Overall, as a topic attracting much attention, there is a wide diversity of studies performing various analyses. The importance of considering topics of compression, energy storage systems, and water treatment for electrolysis stands out. These topics are crucial for the implementation of green hydrogen production systems but were not addressed in most of the analyzed studies. On the other hand, it is essential to emphasize the need for thoughtful analyses and critiques regarding the application of green hydrogen as a solution capable of enabling the use of renewable energy in sectors historically responsible for greenhouse gas emissions. Especially in the context of isolated systems, green hydrogen emerges as a promising alternative to facilitate the storage of renewable energy and its on-demand use, without the known losses of battery storage systems or the emissions and logistical complexities of diesel generation. Finally, considering that the main challenge lies in the high costs when compared to equivalent energy alternatives, this article proposes a different application perspective for hydrogen chains, focusing on isolated systems and microgrids to supply remote communities.

Author Contributions

Conceptualization, L.T.B. and P.A.C.R.; writing—original draft preparation, L.T.B. and S.D.V.; writing—review and editing, L.T.B., S.D.V., P.A.C.R., D.C.P.B. and J.F.C.C.; visualization, P.A.C.R., D.C.P.B., S.D.V., J.F.C.C. and D.C.P.B.; supervision, L.T.B., J.F.C.C. and P.A.C.R.; project administration, L.T.B.; funding acquisition, L.T.B. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the Research and Development Program regulated by ANEEL the Brazilian National Electric Energy Agency and the EDP Company under the project code PD-07267-0022/2021.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

The authors are grateful to the Research and Development Program regulated by ANEEL, the EDP Company, the Federal University of Pernambuco, and the Advanced Institute of Technology and Innovation (IATI), Brazil.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Gunawardane, K. Evolution of hydrogen energy and its potential opportunities around the globe. In Hydrogen Energy Conversion and Management; Khan, M.M.K., Azad, A.K., Oo, A.M.T., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; Chapter 1; pp. 3–33. [Google Scholar] [CrossRef]

- International Renewable Energy Agency. Hydrogen Overview. Available online: https://www.irena.org/Energy-Transition/Technology/Hydrogen#:~:text=As at the end of,around 4%25 comes from electrolysis (accessed on 24 February 2023).

- Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH. Mapeamento do Setor de Hidrogênio Brasileiro Panorama Atual e Potenciais para o Hidrogênio Verde; GIZ: Bonn, Germany, 2021; pp. 1–114. [Google Scholar]

- de Oliveira, R.C. TD 2787—Panorama do Hidrogênio no Brasil; Texto para Discussão; Instituto de Pesquisa Econômica Aplicada: Brasília, Brazil, 2022; pp. 1–59. [CrossRef]

- International Energy Agency. Global Hydrogen Review 2022; Organisation for Economic Co-Operation and Development (OECD): Paris, France, 2022.

- Brazilian National System Operator—ONS. Annual Plan for Energy Operation of Isolated Systems for 2021—In Portuguese: Plano Anual da Operação Energética dos Sistemas Isolados para 2021 PEN SISOL 2021; Brazilian National System Operator (ONS): Florianópolis, Brazil, 2020. [Google Scholar]

- Calili, R.F. Electric Power Generation in Isolated Systems: Challenges and Proposals for Increasing the Participation of Renewable Sources Based on a Multicriteria Analysis—Inportuguese: Geração de Energia Elétrica em Sistemas Isolados: Desafios e Propostas para Aumento da Participação de Fontes Renováveis com Base em Uma Análise Multicritérios; PUC-Rio: Rio de Janeiro, Brazil, 2019. [Google Scholar]

- Brazilian National System Operator ONS. Revista–PEN SISOL 2022; Brazilian National System Operator (ONS): Florianópolis, Brazil, 2022. [Google Scholar]

- Arcos, J.M.M.; Santos, D.M.F. The Hydrogen Color Spectrum: Techno-Economic Analysis of the Available Technologies for Hydrogen Production. Gases 2023, 3, 25–46. [Google Scholar] [CrossRef]

- Brazilian Energy Research Company—EPE. Planning for Services to Isolated Systems—Cycle 2022. Workshop with Distribution Agents—In portuguese: Planejamento do Atendimento aos Sistemas Isolados—Ciclo 2022. Workshop com os Agentes de Distribuição. 2022. Available online: https://www.epe.gov.br./ (accessed on 20 April 2024).

- da Ponte, G.P.; Calili, R.F.; Souza, R.C. Energy generation in Brazilian isolated systems: Challenges and proposals for increasing the share of renewables based on a multicriteria analysis. Energy Sustain. Dev. 2021, 61, 74–88. [Google Scholar] [CrossRef]

- Presidency of the Republic of Brazil. Electricity Service of Isolated Systems, the Transmission Facilities of International Interconnections in the National Interconnected System—SIN—Decreto N°7.246 de 28 de Julho de 2010; Presidency of the Republic of Brazil: Brasilia, Brazil, 2010. [Google Scholar]

- Brazilian Energy Research Company—EPE. Report of Winners for Supply to Isolated Systems 2021—In Portuguese: Informe de Vencendores para Suprimento aos Sitemas Isolados 2021; Brazilian Energy Research Company (EPE): Brasília, Brazil, 2021. [Google Scholar]

- Brazilian Federal Regulatory Electricity Agency—ANEEL. Despacho No2.904 Processo n°48500.007/2022-49 (Sets the average cost of energy and power sold by distribution agents in the Regulated Contracting Environment); Brazilian Federal Regulatory Electricity Agency (ANEEL): Brasília, Brazil, 2022. [Google Scholar]

- Paiva, F.A.D.L.; Coelho, J.H.M.; Barbeiro, P.P. Environmental Accident Report 2020 (Relatório de Acidentes Ambientais 2020); Instituto Brasileiro do Meio Ambiente e dos Recursos Naturais Renováveis (Brazilian Institute of Environment and Renewable Natural Resources): Brasília, Brazil, 2021; pp. 1–28. [Google Scholar]

- Palva, B. Oil Spill Threatens Rivers in the Amazon (Derramamento de Óleo Ameaça Rios na Amazônia). Available online: https://agenciabrasil.ebc.com.br/geral/noticia/2016-03/derramamento-de-oleo-ameaca-rios-na-amazonia (accessed on 20 January 2024).

- Globo. Truck Overturns on Trans-Amazonian Highway, Spilling 15,000 Liters of Diesel Oil on the Riverbank in the Amazon. Available online: https://g1.globo.com/am/amazonas/noticia/2023/07/16/carreta-tomba-na-transamazonica-e-derrama-15-mil-litros-de-oleo-diesel-as-margens-de-rio-no-am.ghtml (accessed on 1 June 2024).

- Hydrogen Council. Hydrogen Scaling up: A Sustainable Pathway for the Global Energy Transition; Hydrogen Council: Brussels, Belgium, 2017. [Google Scholar]

- Dimitrov, R.S. The Paris Agreement on Climate Change: Behind Closed Doors. Glob. Environ. Politics 2016, 16, 1–11. [Google Scholar] [CrossRef]

- Power, H.F.R. Technology Outlook for the Energy Transition; International Renewable Energy Agency (IRENA): Masdar City, United Arab Emirates, 2018.

- Bruce, S.; Temminghoff, M.; Hayward, J.; Schmidt, E.; Munnings, C.; Palfreyman, D.; Hartley, P. National Hydrogen Roadmap; CSIRO: Canberra, Australia, 2018.

- Quintino, F.M.; Nascimento, N.; Fernandes, E.C. Aspects of hydrogen and biomethane introduction in natural gas infrastructure and equipment. Hydrogen 2021, 2, 301–318. [Google Scholar] [CrossRef]

- Mejia, A.H.; Brouwer, J.; Kinnon, M.M. Hydrogen leaks at the same rate as natural gas in typical low-pressure gas infrastructure. Int. J. Hydrogen Energy 2020, 45, 8810–8826. [Google Scholar] [CrossRef]

- Mukherjee, U.; Elsholkami, M.; Walker, S.; Fowler, M.; Elkamel, A.; Hajimiragha, A. Optimal sizing of an electrolytic hydrogen production system using an existing natural gas infrastructure. Int. J. Hydrogen Energy 2015, 40, 9760–9772. [Google Scholar] [CrossRef]

- Lipiäinen, S.; Lipiäinen, K.; Ahola, A.; Vakkilainen, E. Use of existing gas infrastructure in Euro-pean hydrogen economy. Int. J. Hydrogen Energy 2023, 48, 31317–31329. [Google Scholar] [CrossRef]

- Mongkoldee, K.; Sukjit, E.; Kulworawanichpong, T. Optimal on-board energy buffer design for fuel-cell hybrid intercity vehicles. J. Energy Storage 2021, 46, 103820. [Google Scholar] [CrossRef]

- Armijo, J.; Philibert, C. Flexible production of green hydrogen and ammonia from variable solar and wind energy: Case study of Chile and Argentina. Int. J. Hydrogen Energy 2019, 45, 1541–1558. [Google Scholar] [CrossRef]

- Ma, N.; Zhao, W.; Wang, W.; Li, X.; Zhou, H. Large scale of green hydrogen storage: Opportunities and challenges. Int. J. Hydrogen Energy 2024, 50, 379–396. [Google Scholar] [CrossRef]

- Muhammed, N.S.; Gbadamosi, A.O.; Epelle, E.I.; Abdulrasheed, A.A.; Haq, B.; Patil, S.; Al-Shehri, D.; Kamal, M.S. Hydrogen production, transportation, utilization, and storage: Recent advances towards sustainable energy. J. Energy Storage 2023, 73, 109207. [Google Scholar] [CrossRef]

- Bhagavathy, S.; Thakur, J. Green Hydrogen: Challenges for Commercialization; IEEE Smart Grid: Piscataway, NJ, USA, 2021; Volume 201. [Google Scholar]

- Peschel, A. Industrial perspective on hydrogen purification, compression, storage, and distribution. Fuel Cells 2020, 20, 385–393. [Google Scholar] [CrossRef]

- Ishaq, H.; Dincer, I.; Crawford, C. A review on hydrogen production and utilization: Challenges and opportunities. Int. J. Hydrogen Energy 2021, 47, 26238–26264. [Google Scholar] [CrossRef]

- Abad, A.V.; Dodds, P.E. Green hydrogen characterisation initiatives: Definitions, standards, guarantees of origin, and challenges. Energy Policy 2020, 138, 111300. [Google Scholar] [CrossRef]

- Notteboom, T.; Haralambides, H. Seaports as green hydrogen hubs: Advances, opportunities and challenges in Europe. Marit. Econ. Logist. 2023, 25, 1–27. [Google Scholar] [CrossRef]

- Sharshir, S.W.; Joseph, A.; Elsayad, M.M.; Tareemi, A.A.; Kandeal, A.; Elkadeem, M.R. A review of recent advances in alkaline electrolyzer for green hydrogen production: Performance improvement and applications. Int. J. Hydrogen Energy 2024, 49, 458–488. [Google Scholar] [CrossRef]

- Li, Y.; Deng, X.; Zhang, T.; Liu, S.; Song, L.; Yang, F.; Ouyang, M.; Shen, X. Exploration of the configuration and operation rule of the multi-electrolyzers hybrid system of large-scale alkaline water hydrogen production system. Appl. Energy 2023, 331, 120413. [Google Scholar] [CrossRef]

- Tang, C.; Yao, Y.; Wang, N.; Zhang, X.; Zheng, F.; Du, L.; Luo, D.; Aoki, Y.; Ye, S. Green hydrogen production by intermediate-temperature protonic solid oxide electrolysis cells: Advances, challenges, and perspectives. InfoMat 2024, 6, e12515. [Google Scholar] [CrossRef]

- Vostakola, M.F.; Ozcan, H.; El-Emam, R.S.; Horri, B.A. Recent Advances in High-Temperature Steam Electrolysis with Solid Oxide Electrolysers for Green Hydrogen Production. Energies 2023, 16, 3327. [Google Scholar] [CrossRef]

- Zhao, P.; Wang, J.; He, W.; Xia, H.; Cao, X.; Li, Y.; Sun, L. Magnetic field Pre-polarization enhances the efficiency of alkaline water electrolysis for hydrogen production. Energy Convers. Manag. 2023, 283, 116906. [Google Scholar] [CrossRef]

- Zhao, P.; Zhao, P.; Wang, J.; Wang, J.; Xia, H.; Xia, H.; He, W.; He, W. A novel industrial magnetically enhanced hydrogen production electrolyzer and effect of magnetic field configuration. Appl. Energy 2024, 367, 123402. [Google Scholar] [CrossRef]

- Zhao, P.; Wang, J.; Sun, L.; Li, Y.; Xia, H.; He, W. Optimal electrode configuration and system design of compactly-assembled industrial alkaline water electrolyzer. Energy Convers. Manag. 2024, 299, 117875. [Google Scholar] [CrossRef]

- Jang, D.; Kim, J.; Kim, D.; Han, W.-B.; Kang, S. Techno-economic analysis and Monte Carlo simulation of green hydrogen production technology through various water electrolysis technologies. Energy Convers. Manag. 2022, 258, 115499. [Google Scholar] [CrossRef]

- Ammari, C.; Belatrache, D.; Makhloufi, S.; Saifi, N. Techno-economic analysis of a stand-alone photovoltaic system with three different storage systems for feeding isolated houses in south Algeria. Energy Storage 2021, 3, e211. [Google Scholar] [CrossRef]

- Gomez-Villarreal, H.; Canas-Carreton, M.; Zarate-Minano, R.; Carrion, M. Generation Capacity Expansion Considering Hydrogen Power Plants and Energy Storage Systems. IEEE Access 2023, 11, 15525–15539. [Google Scholar] [CrossRef]

- Das, S.; Pradhan, S.; De, S. Multi criteria decision making for the most suitable combination of energy resources for a decentralized hybrid energy solution with green hydrogen as the storage option. Energy Convers. Manag. 2023, 285, 117028. [Google Scholar] [CrossRef]

- Alonso, A.M.; Matute, G.; Yusta, J.; Coosemans, T. Multi-state optimal power dispatch model for power-to-power systems in off-grid hybrid energy systems: A case study in Spain. Int. J. Hydrogen Energy 2023, 52, 1045–1061. [Google Scholar] [CrossRef]

- Kalinci, Y.; Hepbasli, A.; Dincer, I. Techno-economic analysis of a stand-alone hybrid renewable energy system with hydrogen production and storage options. Int. J. Hydrogen Energy 2015, 40, 7652–7664. [Google Scholar] [CrossRef]

- Duić, N.; Carvalho, M.D.G. Increasing renewable energy sources in island energy supply: Case study Porto Santo. Renew. Sustain. Energy Rev. 2004, 8, 383–399. [Google Scholar] [CrossRef]

- Khan, M.; Iqbal, M. Analysis of a small wind-hydrogen stand-alone hybrid energy system. Appl. Energy 2009, 86, 2429–2442. [Google Scholar] [CrossRef]

- Gracia, L.; Casero, P.; Bourasseau, C.; Chabert, A. Use of hydrogen in off-grid locations, a tech-no-economic assessment. Energies 2018, 11, 3141. [Google Scholar] [CrossRef]

- Abdin, Z.; Mérida, W. Hybrid energy systems for off-grid power supply and hydrogen production based on renewable energy: A techno-economic analysis. Energy Convers. Manag. 2019, 196, 1068–1079. [Google Scholar] [CrossRef]

- Rad, M.A.V.; Ghasempour, R.; Rahdan, P.; Mousavi, S.; Arastounia, M. Techno-economic analysis of a hybrid power system based on the cost-effective hydrogen production method for rural electrification, a case study in Iran. Energy 2020, 190, 116421. [Google Scholar] [CrossRef]

- Hasan, T.; Emami, K.; Shah, R.; Hassan, N.; Anderson, J.; Thomas, D.; Louis, A. A study on green hydrogen-based isolated microgrid. Energy Rep. 2022, 8, 259–267. [Google Scholar] [CrossRef]

- Vilbergsson, K.V.; Dillman, K.; Emami, N.; Ásbjörnsson, E.J.; Heinonen, J.; Finger, D.C. Can remote green hydrogen production play a key role in decarbonizing Europe in the future? A cradle-to-gate LCA of hydrogen production in Austria, Belgium, and Iceland. Int. J. Hydrogen Energy 2023, 48, 17711–17728. [Google Scholar] [CrossRef]

- Hasan, T.; Emami, K.; Shah, R.; Hassan, N.; Belokoskov, V.; Ly, M. Techno-economic Assessment of a Hydrogen-based Islanded Microgrid in North-east. Energy Rep. 2023, 9, 3380–3396. [Google Scholar] [CrossRef]

- Ceylan, C.; Devrim, Y. Green hydrogen based off-grid and on-grid hybrid energy systems. Int. J. Hydrogen Energy 2023, 48, 39084–39096. [Google Scholar] [CrossRef]

- Zghaibeh, M.; Barhoumi, E.M.; Okonkwo, P.C.; Ben Belgacem, I.; Beitelmal, W.H.; Mansir, I.B. Analytical model for a techno-economic assessment of green hydrogen production in photovoltaic power station case study Salalah city-Oman. Int. J. Hydrogen Energy 2022, 47, 14171–14179. [Google Scholar] [CrossRef]

- Yates, J.; Daiyan, R.; Patterson, R.; Egan, R.; Amal, R.; Ho-Baille, A.; Chang, N.L. Techno-economic Analysis of Hydrogen Electrolysis from Off-Grid Stand-Alone Photovoltaics Incorporating Uncertainty Analysis. Cell Rep. Phys. Sci. 2020, 1, 100209. [Google Scholar] [CrossRef]

- Ibagon, N.; Muñoz, P.; Díaz, V.; Teliz, E.; Correa, G. Techno-economic analysis for off-grid green hydrogen production in Uruguay. J. Energy Storage 2023, 67, 107604. [Google Scholar] [CrossRef]

- Silva, S.B.; Severino, M.M.; De Oliveira, M.A.G. A stand-alone hybrid photovoltaic, fuel cell and battery system: A case study of Tocantins, Brazil. Renew. Energy 2013, 57, 384–389. [Google Scholar] [CrossRef]

- Salameh, T.; Alkasrawi, M.; Juaidi, A.; Abdallah, R.; Monna, S. Hybrid renewable energy system for a remote area in UAE. In Proceedings of the 12th International Renewable Engineering Conference (IREC), Amman, Jordan, 14–15 April 2021; pp. 1–6. [Google Scholar]

- Marocco, P.; Ferrero, D.; Gandiglio, M.; Ortiz, M.; Sundseth, K.; Lanzini, A.; Santarelli, M. A study of the techno-economic feasibility of H2-based energy storage systems in remote areas. Energy Convers. Manag. 2020, 211, 112768. [Google Scholar] [CrossRef]

- Al Rafea, K.; Elsholkami, M.; Elkamel, A.; Fowler, M. Integration of Decentralized Energy Systems with Utility-Scale Energy Storage through Underground Hydrogen–Natural Gas Co-Storage Using the Energy Hub Approach. Ind. Eng. Chem. Res. 2017, 56, 2310–2330. [Google Scholar] [CrossRef]

- Gutiérrez-Martín, F.; Calcerrada, A.; de Lucas-Consuegra, A.; Dorado, F. Hydrogen storage for off-grid power supply based on solar PV and electrochemical reforming of ethanol-water solutions. Renew. Energy 2020, 147, 639–649. [Google Scholar] [CrossRef]

- Viole, I.; Valenzuela-Venegas, G.; Zeyringer, M.; Sartori, S. A renewable power system for an off-grid sustainable telescope fueled by solar power, batteries and green hydrogen. Energy 2023, 282, 128570. [Google Scholar] [CrossRef]

- Lacko, R.; Drobnič, B.; Mori, M.; Sekavčnik, M.; Vidmar, M. Stand-alone renewable combined heat and power system with hydrogen technologies for household application. Energy 2014, 77, 164–170. [Google Scholar] [CrossRef]

- Madi, H.; Lytvynenko, D.; Schildhauer, T.; Jansohn, P. Decarbonisation of Geographical Islands and the Feasibility of Green Hydrogen Production Using Excess Electricity. Energies 2023, 16, 4094. [Google Scholar] [CrossRef]

- Prieto-Prado, I.; Del Río-Gamero, B.; Gómez-Gotor, A.; Pérez-Báez, S. Water and energy self-supply in isolated areas through renewable energies using hydrogen and water as a double storage system. Desalination 2017, 430, 1–14. [Google Scholar] [CrossRef]