Nano-Water-Alternating-Gas Simulation Study Considering Rock–Fluid Interaction in Heterogeneous Carbonate Reservoirs †

Abstract

:1. Introduction

2. Simulation Model

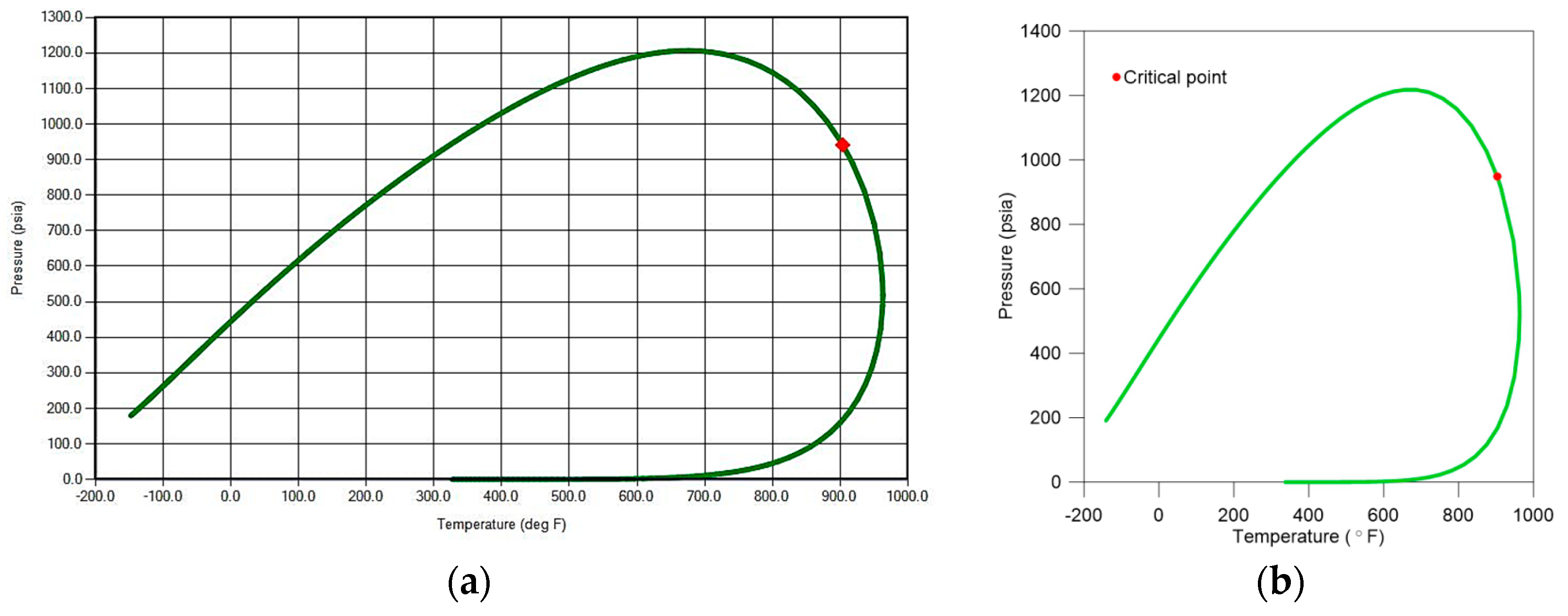

2.1. Fluid Modeling

2.2. Description of a 1D Core Model

2.3. Description of a 3D Core Model

3. Results and Discussion

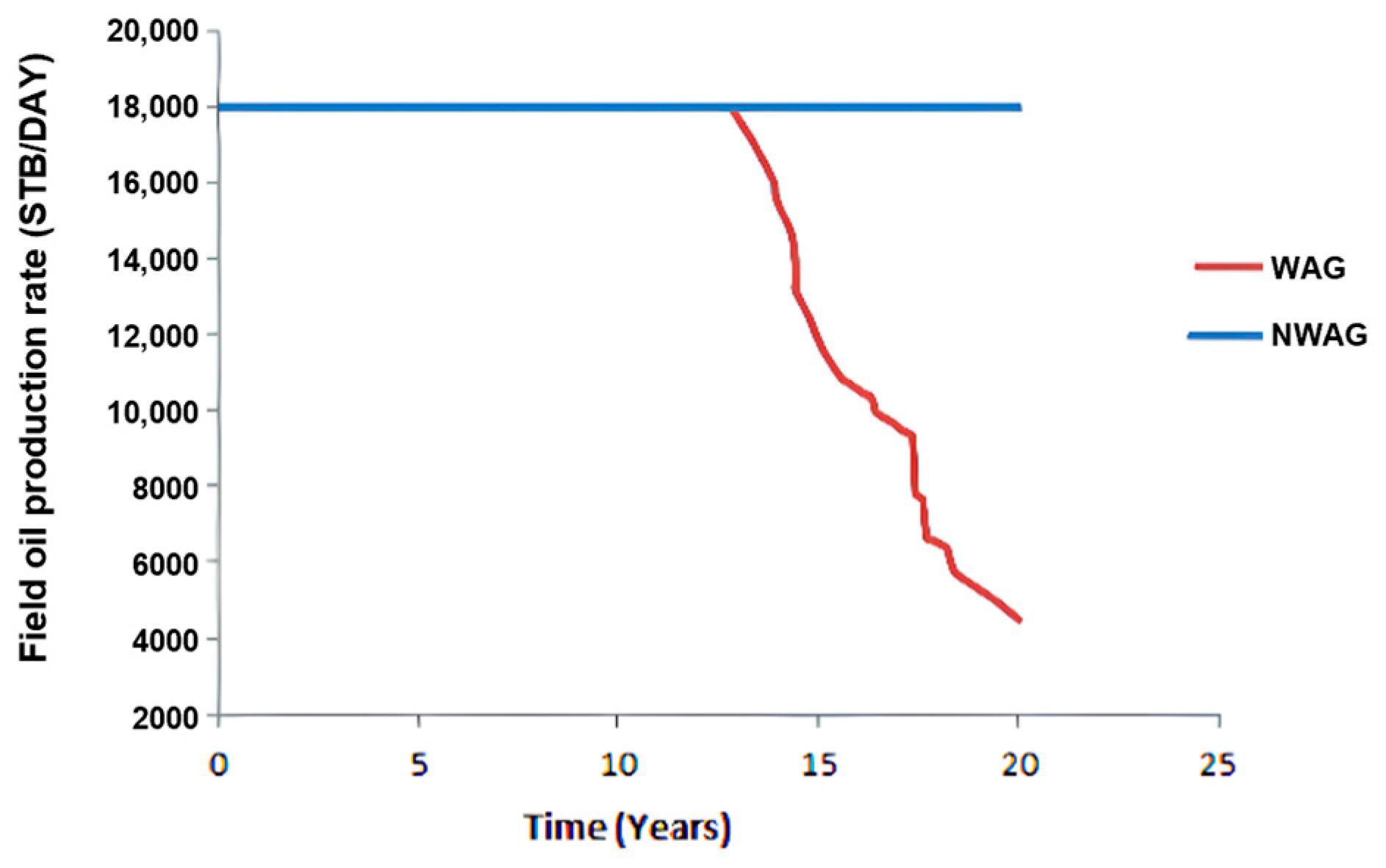

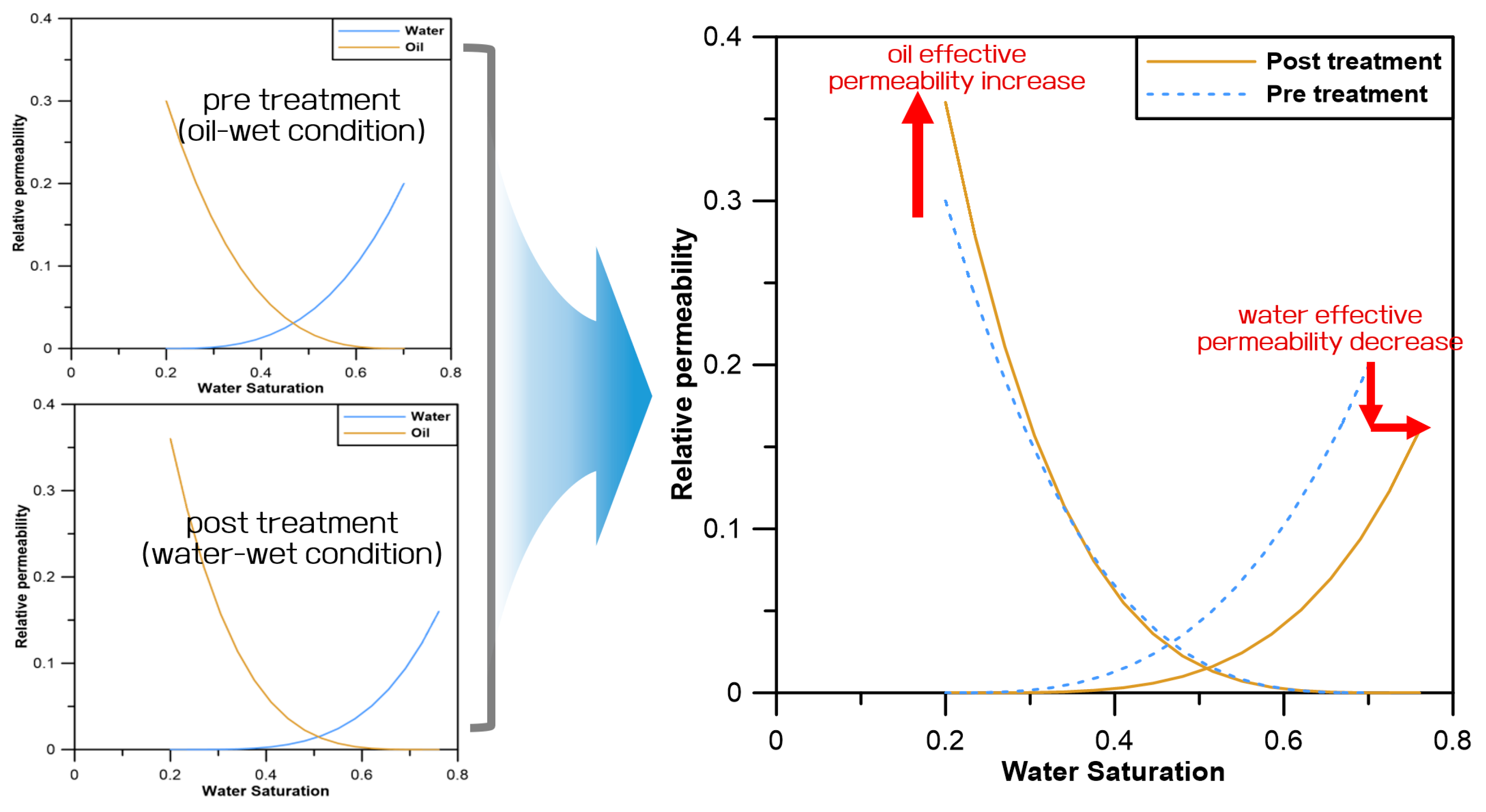

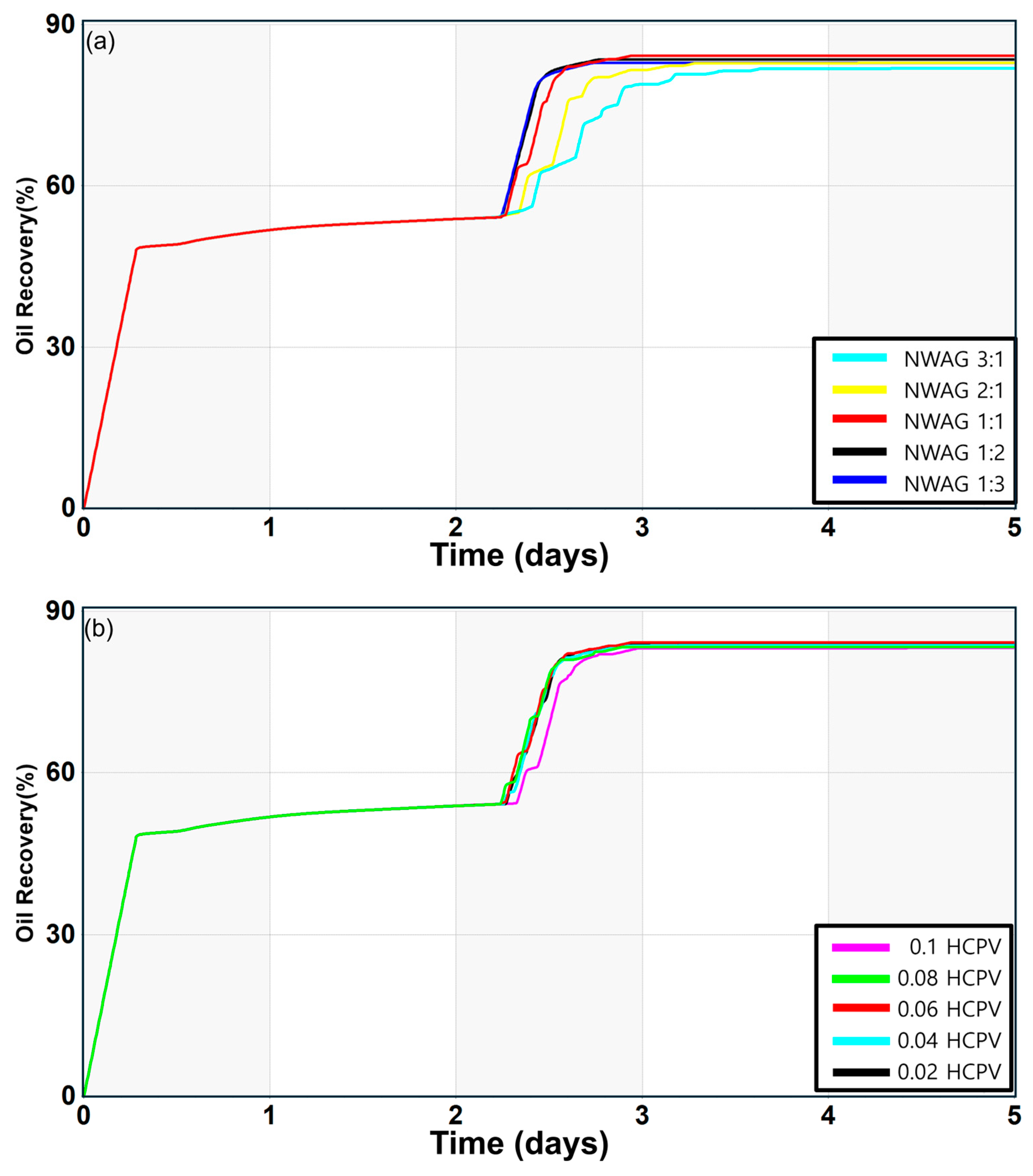

3.1. Results of 1D Simulations

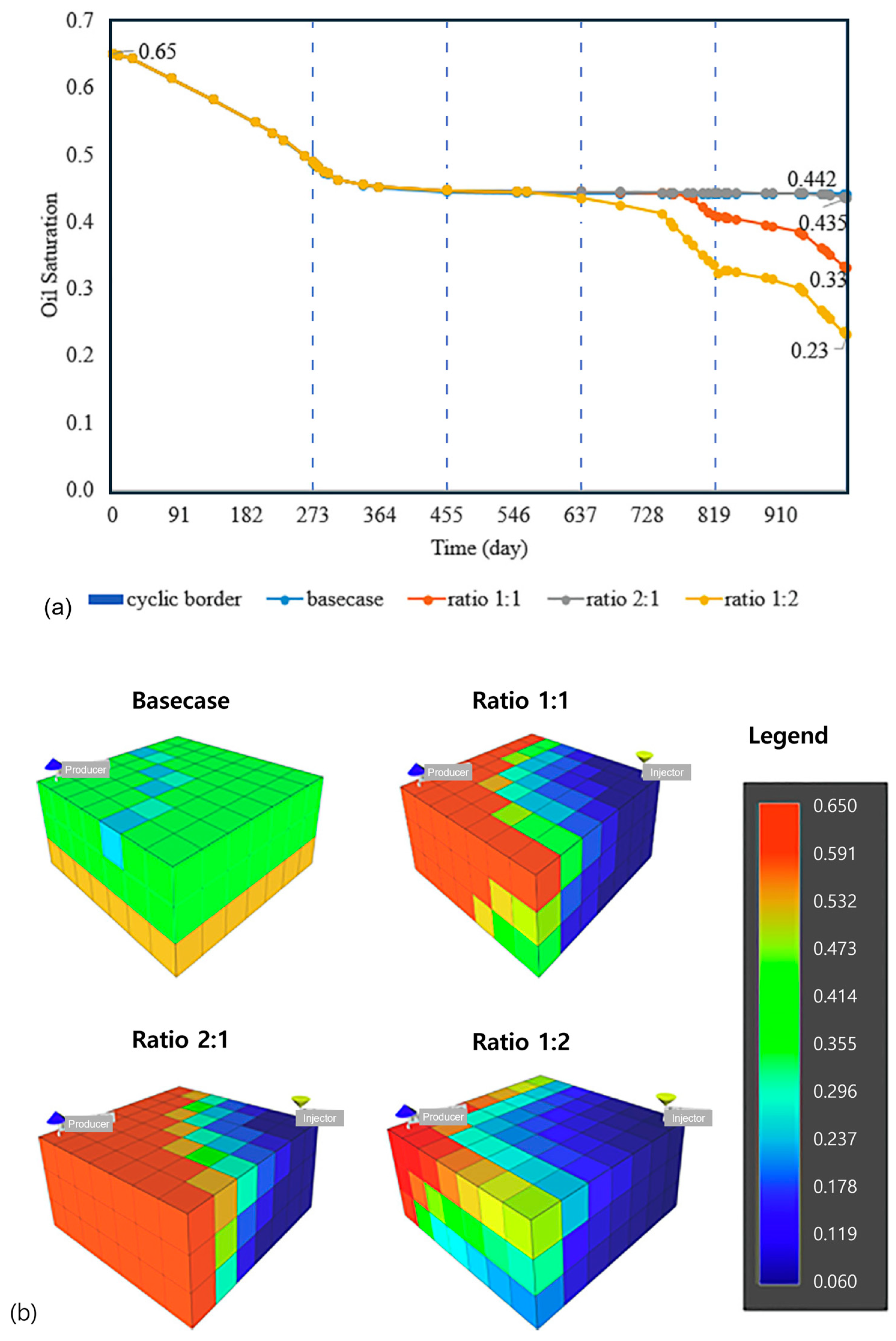

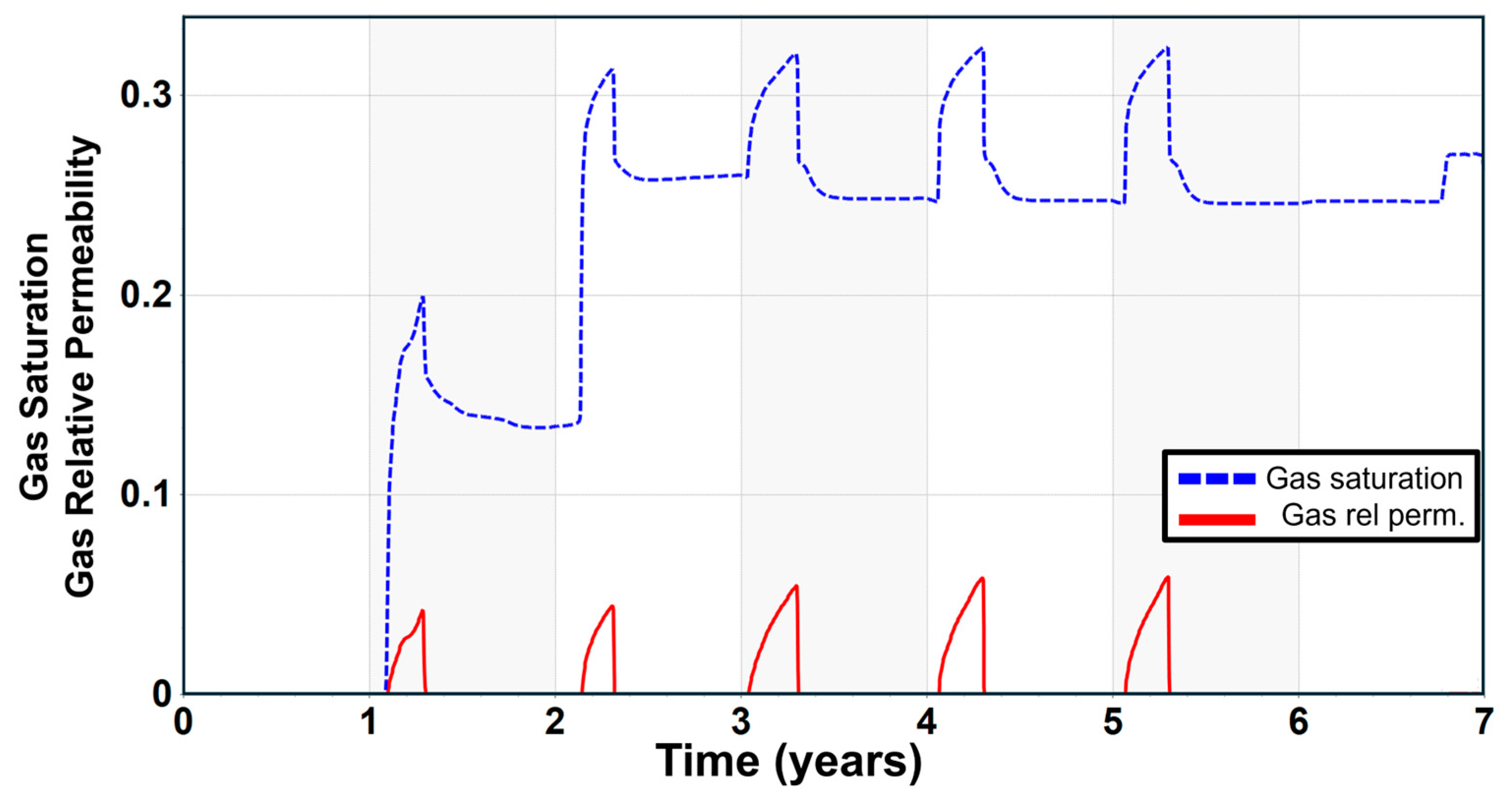

3.2. Results of 3D Simulations

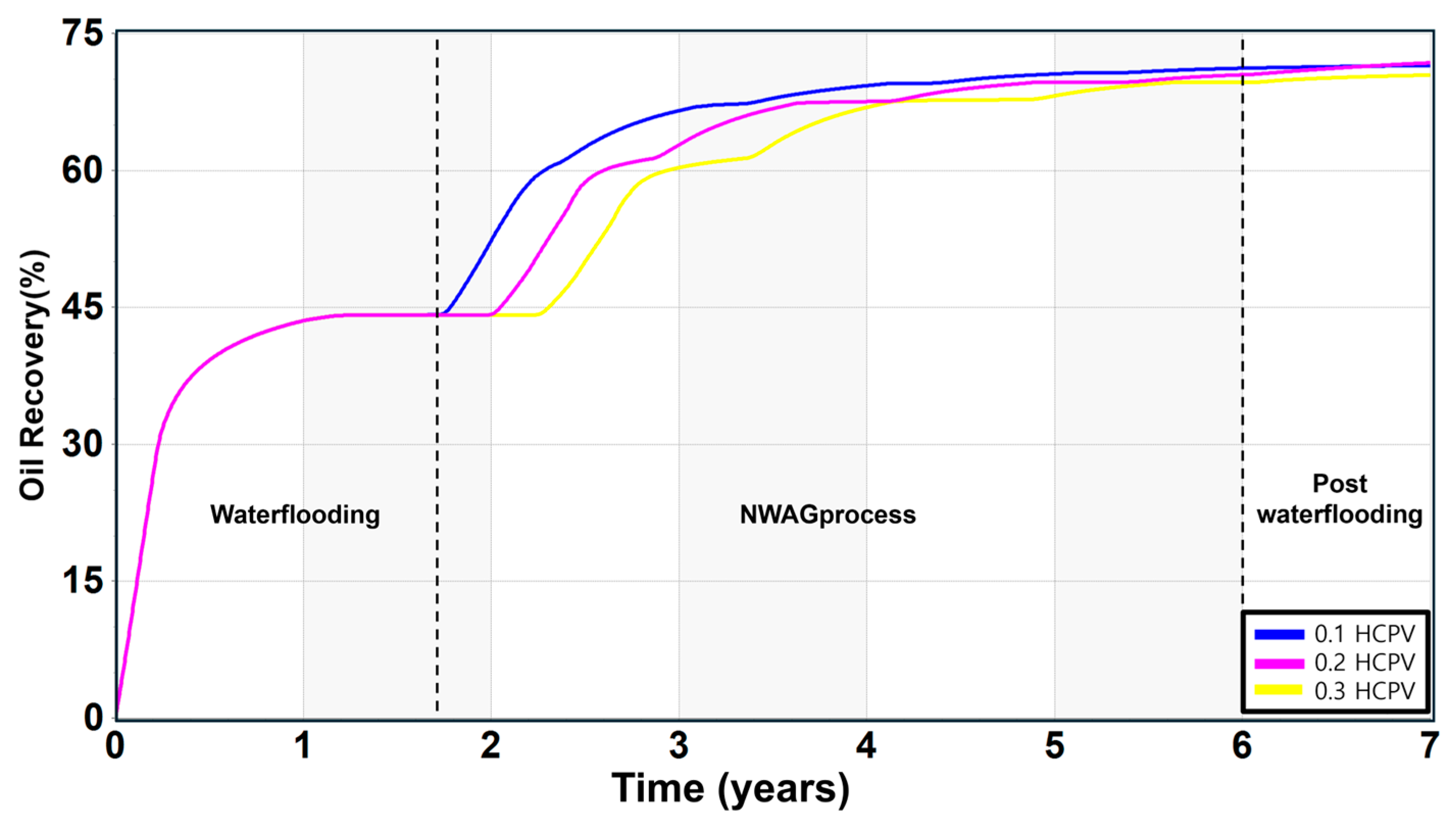

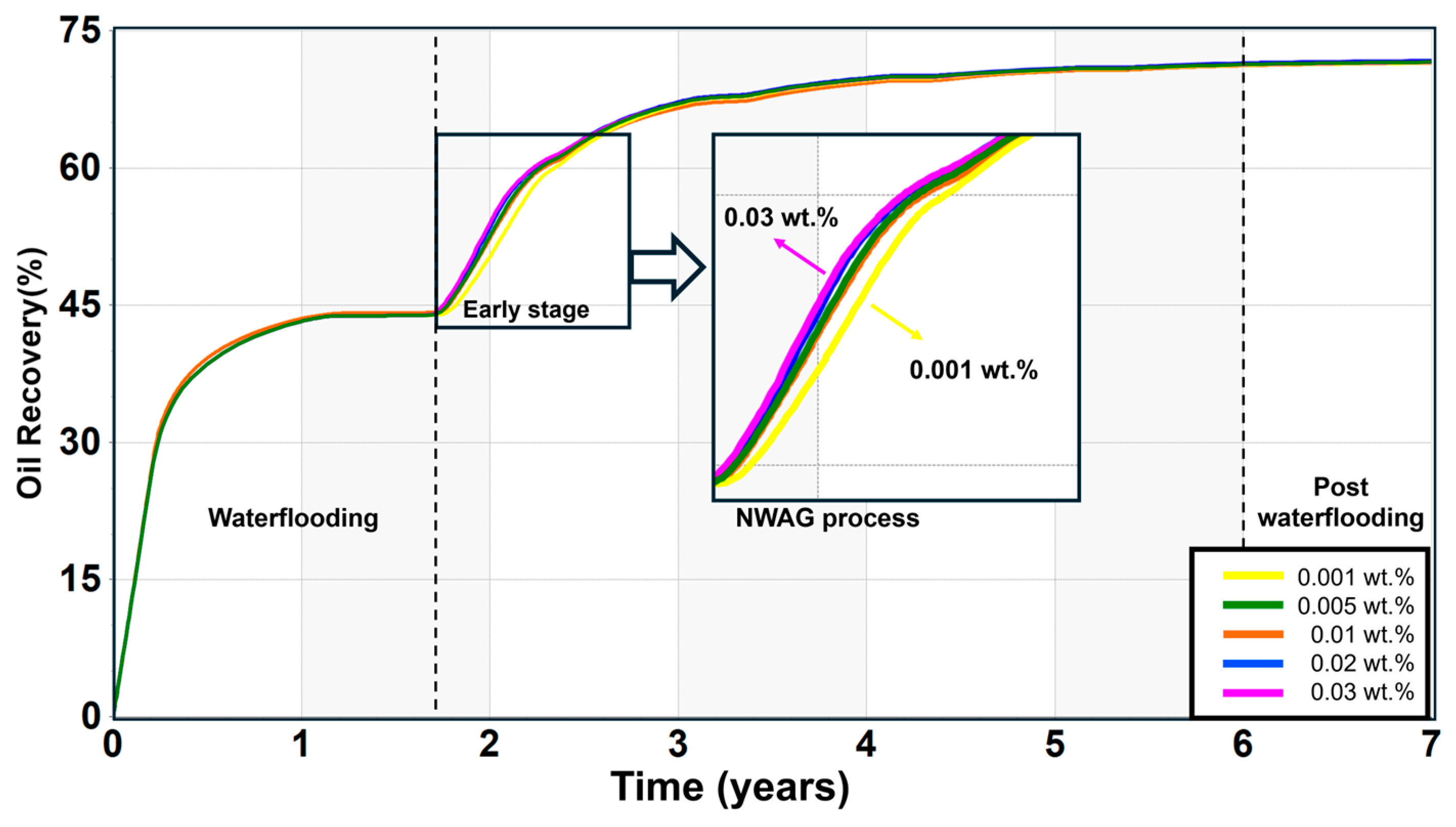

3.2.1. Results of Oil Recovery by NWAG

3.2.2. Results of CO2 Storage by NWAG

4. Conclusions

- The 1D core models based in CMG-GEM were simulated to evaluate the applicability of the NWAG method, and 1D core models based on CMG-GEM were simulated. Sensitivity analyses were conducted on the factors influencing WAG, followed by the incorporation of the effects of nanoparticles on wettability improvement and absolute permeability reduction using CMOST. The results confirmed that applying the NWAG method enhanced both oil recovery and CO2 storage efficiency.

- To construct a 3D reservoir model, a Dykstra–Parsons coefficient of 0.4 was set for heterogeneity, and Carlson’s relative permeability curve with a gas saturation threshold of 0.3 was applied to incorporate history matching. Applying the NWAG method to the 3D model considering heterogeneity and history matching yielded results for oil recovery and CO2 storage capacity based on each influencing factor.

- The optimal conditions for oil recovery were determined to be an NWAG ratio of 3:1, slug size of 0.1 HCPV, and SiO2 mole fraction of 0.001, achieving approximately 71.8% oil recovery. Optimal CO2 storage conditions were found with an NWAG ratio of 1:2, slug size of 0.1 HCPV, and SiO2 mole fraction of 0.03, resulting in 11,397 tons of CO2 storage.

- Increasing the SiO2 concentration rapidly increased oil recovery in the initial stages. Therefore, using a higher concentration of nanofluids can initially lead to quick oil recovery, whereas a lower concentration of nanofluids expands the adsorption area, resulting in long-term effectiveness. CO2 storage tended to plateau after reaching a certain range. Additionally, higher nanoparticle concentrations were found to increase the reservoir pressure and alter the wettability, thereby enhancing the CO2 storage effectiveness.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| API | American Petroleum Institute |

| CMG | Computer modeling group |

| EOR | Enhanced oil recovery |

| HCPV | Hydrocarbon pore volume |

| NWAG | Nano-water-alternating gas |

| OOIP | Original oil in place |

| PR-EOS | Peng–Robinson equation of state |

| WAG | Water-alternating gas |

| WOC | Water oil contact |

| SNP | Silica nanoparticle |

References

- Shokufe, A.; Nima, R.; Sohrab, Z. A comprehensive review on Enhanced Oil Recovery by Water Alternating. Fuel 2018, 227, 216–246. [Google Scholar] [CrossRef]

- Jang, H.C.; Ko, S.M.; Park, H.R. Novel WAG Method with Nanotechnology in a Heterogeneous Carbonate Reservoir. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 22–24 April 2024. [Google Scholar]

- Stern, D. Mechanisms of Miscible Oil Recovery: Effects of Pore-Level Fluid Distribution. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 5–9 October 1991. [Google Scholar] [CrossRef]

- Vladimir, V.; Baghir, S.; Ahmad, S.; Eldar, Z. Primer on Enhanced oil Recovery; Gulf Professional Publishing: Houston, TX, USA, 2020; pp. 53–63. [Google Scholar] [CrossRef]

- Jia, B.; Tsau, J.; Barati, R. A review of the current progress of CO2 injection EOR and carbon storage in shale oil reservoirs. Fuel 2019, 236, 404–427. [Google Scholar] [CrossRef]

- Jang, H.; Lee, W.S.; Lee, J. Performance evaluation of surface-modified silica nanoparticles for enhanced oil recovery in carbonate reservoirs. Colloids Surf. A Physicochem. Eng. Asp. 2024, 681, 132784. [Google Scholar] [CrossRef]

- Xiao, H.; Amir, Z.; Mohd Junaidi, M.U. Development of Microbial Consortium and Its Influencing Factors for Enhanced Oil Recovery after Polymer Flooding: A Review. Processes 2023, 11, 2853. [Google Scholar] [CrossRef]

- Kapanichuk, I.V.; Vanin, A.A.; Brodskaya, V.N. Disjoining pressure and structure of a fluid confined between nanoscale surface. Colloids Surf. A Physicochem. Eng. Asp. 2017, 527, 42–48. [Google Scholar] [CrossRef]

- Han, B.; Lee, J. Investigation on the Technical Characteristics and Field Cases of CO2 Enhanced Oil recovery. J. Korean Soc. Miner. Energy Resour. Eng. 2014, 51, 597–609. [Google Scholar] [CrossRef]

- Pancholi, S.; Negi, G.S.; Agarwal, J.R.; Bera, A.; Shah, M. Experimental and simulation studies for optimization of water-alternation-gas (CO2) flooding for enhanced oil recovery. Pet. Res. 2020, 5, 227–234. [Google Scholar] [CrossRef]

- Abdurrahman, M.; Hidayat, F.; Husna, U.Z.; Arsad, A. Determination of optimum CO2 water alternating gas (CO2-WAG) ratio in Sumatera Light Oilfield. Mater. Today Proc. 2021, 39, 970–974. [Google Scholar] [CrossRef]

- Al Matroushi, M.; Pourafshary, P.; Al Wahaibi, Y. Possibility of Nanofluid/Gas Alternating Injection as an EOR Method in an Oil Field. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 9–12 November 2015. [Google Scholar] [CrossRef]

- Øyvind, E.; Tore, F.; Eldri, S.; Arthur, R.; Martin, F. Nanoparticle Stabilized Foam in Harsh Conditions for CO2 EOR. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 12–15 November 2018. [Google Scholar] [CrossRef]

- Cao, C.; Song, Z.; Su, S.; Tang, Z.; Xie, Z.; Chang, X.; Shen, P. Water-Based Nanofluid-Alternating-CO2 Injection for Enhancing Heavy Oil Recovery: Considering oil-nanofluid emulsification. J. Pet. Sci. Eng. 2021, 205, 108934. [Google Scholar] [CrossRef]

- Sribastaba, R.K.; Huang, S.S.; Dong, D. Laboratory Investigation of Weyburn CO2 Miscible Flooding. J. Can. Pet. Technol. 2000, 39, PETSOC-00-02-04. [Google Scholar] [CrossRef]

- Lee, H.-S.; Cho, J.; Lee, Y.-W.; Lee, K.-S. Compositional Modeling of Impure CO2 Injection for Enhanced Oil Recovery and CO2 Storage. Appl. Sci. 2021, 11, 7907. [Google Scholar] [CrossRef]

- Choi, Y. Economic Analysis of Enhanced Oil Recovery and Carbon Storage for DME-Impure CO2 Injection to Heterogeneous Reservoir. Master’s Thesis, Hanyang University, Seoul, Republic of Korea, February 2024. [Google Scholar]

- Afzli, S.; Ghamartale, A.; Rezaei, N.; Zendeboudi, S. Mathematical modeling and simulation of water-alternating-gas(WAG) process by incorporating capillary pressure and hysteresis effect. Fuel 2020, 263, 116362. [Google Scholar] [CrossRef]

- Carlson, F.M. Simulation of Relative Permeability Hysteresis to the Nonwetting Phase. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 4–7 October 1981. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, S.; Zhou, D.; Chawathe, A. Impact of Relative Permeability Hysteresis on Water-Alternating-GAS WAG Injectivity: Modeling and Experimental Study. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 9–11 October 2017. [Google Scholar]

- Al-Anssari, S.; Wang, S.; Barifcani, A.; Lebedev, M.; Iglauer, S. Effect of temperature and SiO2 nanoparticle size on wettability alteration of oil-wet calcite. Fuel 2017, 206, 34–42. [Google Scholar] [CrossRef]

- Rahman, T.; Lebedev, M.; Barifcani, A.; Iglauer, S. Residual trapping of supercritical CO2 in oil-wet sandstone. J. Colloid Interface Sci. 2016, 469, 63–68. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Liu, T.; Liu, S.; Jia, S.; Yao, J.; Sun, H.; Yang, Y.; Zhang, L.; Delshad, M.; Sepehrnoori, K.; et al. Adsorption effects on CO2-oil minimum miscibility pressure in tight reservoirs. Energy 2024, 288, 129815. [Google Scholar] [CrossRef]

- Rahmatmand, B.; Keshavars, P.; Ayatollahi, S. Study of Absorption Enhancement of CO2 by SiO2, Al2O3, CNT, and Fe3O4 Nanoparticles in Water and Amine Solutions. J. Chem. Eng. Data 2016, 61, 1378–1387. [Google Scholar] [CrossRef]

| Component | Mole Fraction | Molecular Weight | Critical Pressure (Atm) | Critical Temperature (K) | Parachor | Acentric Factor |

|---|---|---|---|---|---|---|

| N2 | 2.07 | 28.01 | 33.5 | 126.2 | 41 | 0.040 |

| CO2 | 0.74 | 44.01 | 72.8 | 304.2 | 78 | 0.225 |

| H2S | 0.12 | 34.08 | 88.2 | 373.2 | 80 | 0.100 |

| CH4 | 7.49 | 16.04 | 45.4 | 190.6 | 77 | 0.008 |

| C2H6 | 4.22 | 30.07 | 48.2 | 305.4 | 108 | 0.098 |

| C3H8 | 7.85 | 44.10 | 41.9 | 369.8 | 150 | 0.152 |

| NC4 | 6.55 | 58.12 | 37.5 | 425.2 | 186 | 0.193 |

| NC5 | 4.59 | 72.15 | 33.3 | 469.6 | 228 | 0.251 |

| C6–9 | 21.55 | 102.50 | 29.8 | 556.4 | 297 | 0.331 |

| C10–17 | 22.02 | 184.00 | 19.9 | 692.3 | 508 | 0.584 |

| Parameters | W3 | Fluid Model in This Study |

|---|---|---|

| API (°) | 31 | 29.3 |

| Saturation pressure (psi) | 714 | 700 |

| Oil density at Pc (kg/m3) | 806.4 | 816 |

| Parameters | Values |

|---|---|

| Number of grid blocks | 1(K) |

| Length | 10 cm |

| Diameter | 3.14 cm |

| Porosity | 0.18 |

| Permeability | 50.0 md |

| Rock compressibility | 5.8 × 10−7 1/kPa |

| Pressure | 17,340 kPa |

| Temperature | 85.6 °C |

| Bulk volume | 77.3 cm3 |

| Pore volume | 13.9 cm3 |

| Initial oil saturation | 0.7 |

| Original oil in place (OOIP) | 6.13 × 10−5 bbl |

| Parameters | Values |

|---|---|

| Number of grids | 5(K) |

| Thickness | 50 m |

| WOC depth | 1050 m |

| Reference pressure | 15,000 kPa |

| Grid top | 1000 m |

| Porosity | 21.9–28% |

| Permeability | 31–75 md |

| Pressure | 15 MPa |

| Temperature | 37 °C |

| Initial oil saturation | 0.8 |

| NWAG Ratio | Slug Size | Nanoparticle Conc. (wt.%) |

|---|---|---|

| 1:3 | 0.001 | |

| 0.1 HCPV | ||

| 1:2 | 0.005 | |

| 1:1 | 0.01 | |

| 0.2 HCPV | ||

| 2:1 | 0.02 | |

| 3:1 | 0.3 HCPV | 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ko, S.; Park, H.; Jang, H. Nano-Water-Alternating-Gas Simulation Study Considering Rock–Fluid Interaction in Heterogeneous Carbonate Reservoirs. Energies 2024, 17, 4846. https://doi.org/10.3390/en17194846

Ko S, Park H, Jang H. Nano-Water-Alternating-Gas Simulation Study Considering Rock–Fluid Interaction in Heterogeneous Carbonate Reservoirs. Energies. 2024; 17(19):4846. https://doi.org/10.3390/en17194846

Chicago/Turabian StyleKo, Seungmo, Hyeri Park, and Hochang Jang. 2024. "Nano-Water-Alternating-Gas Simulation Study Considering Rock–Fluid Interaction in Heterogeneous Carbonate Reservoirs" Energies 17, no. 19: 4846. https://doi.org/10.3390/en17194846