Abstract

The increasing focus on sustainability and the circular economy has brought waste-to-energy technologies to the forefront of renewable energy research. However, the environmental impacts and management of contaminants associated with these technologies remain critical issues. This article comprehensively reviews the environmental impacts of converting sewage sludge into energy and fertilizers, focusing on managing potential contaminants and assessing the implications and ecological risks. It also highlights the latest trends in waste-to-energy technologies, waste-to-soil amendment, and their integration into circular economy frameworks. The discussion encompasses challenges and opportunities in optimizing these processes in wastewater treatment plants to minimize pollutants and enhance sustainability. Addressing these challenges is essential for ensuring the long-term viability and acceptance of waste-to-energy solutions, making this topic highly relevant and timely.

1. Introduction to Sewage Sludge

Sewage sludge is an integral part of the operation of wastewater treatment plants, and the amount of sludge is increasing every year as a result of the development of municipal infrastructure, the sewerage network, and the increase in the capacity of the treatment plants themselves [1]. Sludge is generated by treating domestic and industrial wastewater delivered to the wastewater treatment plant by the sewerage system. Its composition varies significantly, depending on factors such as the degree of industrialization of the city, the number of residents, average water consumption, and seasonal cycles, among others. Thus, the final composition of rural and urban sewage sludge can differ significantly [2]. Being organic–mineral and solid, sludge is a rich source of many biogenic elements and is a good raw material for further management [3]. Most wastewater treatment plants are described as producing raw, untreated sludge with a characteristic strong odor, primary sludge resulting from the sedimentation of suspended solids (in primary settling tanks), secondary sludge formed after biological treatment of wastewater (usually in activated sludge flow devices), and mixed sludge resulting from a combination of primary and secondary sludge.

Considering the high water content, and possible micropollution by heavy metals, microplastics, parasite eggs, or pesticides, it is necessary to properly process the sludge further to ensure that it becomes environmentally safe [4]. Directions for the management of finished sludge are strictly standardized by law, whether for use in agriculture, soil remediation, thermal treatment, or temporary storage [5,6].

The introduction of regulations in Europe for the sustainable management of non-renewable resources and waste management aims to ensure their efficient processing in an environmentally safe manner. Achieving climate neutrality regarding greenhouse gas emissions and efficient use of secondary resources is also a major goal of the European Green Deal. One of the proposed solutions is using sewage sludge in agriculture, due to its high content of elements such as nitrogen, phosphorus, potassium, and calcium, while maintaining low levels of heavy metals and pathogens. The use of sludge can enhance soil fertility, porosity, aggregate stability, microbial biomass, and biological properties of the soil [5]. Thus, sludge treatment has therefore become crucial for its reuse. An ecological approach begins at the sludge drying stage, where standard procedures like thermal or mechanical drying are energy-intensive and contribute to fossil fuel consumption and greenhouse gas emissions. Therefore, solar drying is proposed as a solution, despite the longer processing time [7,8]. For many authors, the main obstacle to the use of sludge in agriculture is the content of heavy metals such as cadmium or copper, and, as they point out, the degree of toxicity is determined by their speciation rather than the concentration itself [9]. Heavy metals are not biodegradable, so repeated fertilization of cultivated soil with sludge leads to accumulation and increased ecotoxicity, negatively impacting soil fertility. Heavy metals can eventually contaminate surface and groundwater, entering the human body [10,11]. In recent years, many effective methods have been proposed for removing heavy metals from sewage sludge, such as ion exchange extraction, thermal conversion, chemical treatment, and electrokinetic techniques, with conversion considered an effective method for reducing the bioavailability of heavy metals in plants [12].

Despite the diversity of wastewater treatment plant designs, the regulatory-based process sequence looks similar in most cases. Typically, wastewater flows into the treatment plant via interceptors from different parts of the region and combines in a connection chamber to enter the treatment plant via a collection pipeline. The first stage involves using rare earth grids to remove larger contaminants such as tampons, stones, and bottle caps, and from there, the wastewater is directed to a pool equipped with pumps that take it to a higher level so that further treatment processes can occur by gravity flow. Some treatment plants have two such basins that can be directly accessed by pumps to retention tanks in case of heavy rains or wastewater accumulation. The next stage of filtration is dense sieves with a mesh diameter of 0.5 cm where smaller contaminants are retained; these, in turn, are transported by feeder to the operation, which recovers excess water and reduces their volume significantly. The pre-treated wastewater is directed to a sand pit, where the flow rate is about 0.3 m/s to retain fines and grease effectively. Thus, prepared wastewater goes to settling tanks, where the organic fraction is separated, from which sludge will be formed [13].

Biological treatment is associated with removing phosphorus and nitrogen compounds from wastewater, which can lead to environmental eutrophication. An effective method is using a Bardenpho bioreactor, where the levels of these elements are reduced in the anaerobic, hypoxic, and aerobic zones [14]. The first anaerobic stage occurs in a chamber equipped with an agitator to maintain the activated sludge in suspension. Under anaerobic conditions, phosphorus bacteria get rid of phosphorus accumulated in their cells, and the energy gained allows them to take up and store acetic acid as a spare substance. In the aerobic chamber, the bacteria again take up phosphorus, however, in a much larger amount than in the anaerobic process, and by removing the final biomass from the wastewater, the phosphorus level in the treated wastewater is significantly reduced. The nitrogen removal process is similar and uses the processes of nitrification and denitrification to make the bacteria that take oxygen from nitrates release pure nitrogen into the atmosphere. After leaving the bioreactor, the wastewater flows to a settling chamber, where activated sludge is separated, and the treated wastewater can be discharged into a river or a retention basin. Activated sludge is often reused in the bioreactor for nitrogen and phosphorus removal processes [14].

In the chemical treatment of wastewater, iron sulfate is most often used, which, reacting with phosphates contained in sewage, leads to the formation of chemical sludge, reducing the amount of phosphorus. This process supports biological filtration, increasing the amount of final sludge. The resulting sludge can have many avenues of application, depending on its chemical composition; after appropriate mechanical and thermal treatment, it is thickened and dehydrated. Quicklime can assist in dewatering, which further reduces the amount of sludge. After leaving the dewatering centrifuges, the sludge can be stored or used in this form for biofuel production. Application in agriculture requires additional qualitative and quantitative analyses [15,16].

European Trends in Sewage Sludge Generation

The scale of sludge production is upward, but estimating exact quantities seems difficult. Water consumption from 2015 to 2030 will increase by 24%, and by 2025 by 51%, sewage networks in Europe have an estimated length of 3.3 million kilometers, an increase of 10% in recent years. In addition, the increase in the urban population and the decrease in the rural population should be taken into account; this together translates into the amount of sludge produced [17]. It is also important to mention the rapidly growing market of Asia, and China, which has built more than 39,000 treatment plants since 2020 and plans to renovate 80,000 km of sewer pipes, which is expected to translate into an increase in treatment capacity by 7.3 cubic kilometers of wastewater by 2025 [3,18]. In total, production is probably led by 12–18 million tons per year, India 10–15 million tons, Russia 5–10 million tons, the European Union 12–14 million tons, Japan 2–3 million tons, and the UK 1.6–1.8 million tons [4]. In China, 29.3% of municipal sewage sludge was treated by agricultural route, 26.7% by incineration, and 20.1% by sanitary landfill. The dominant technologies were incineration, composting, thermal hydrolysis, and anaerobic digestion, with the capacity of 27,122 t/d, 11,250 t/d, 8342 t/d, and 6944 t/d, respectively [3]. In the USA. nearly 43% of these biosolids were applied to land, while the rest were either disposed of in landfills, incinerated, or handled through other means such as storage or deep well injection [19]. In the European Union, the vast majority of sludge is incinerated (25%), used in agriculture depending on the law (27%), composted (21%), or stored periodically or permanently (9%). As studies indicate, sludge incineration leads to the formation of ash, which often contains metals, and the cost of disposal is high [20].

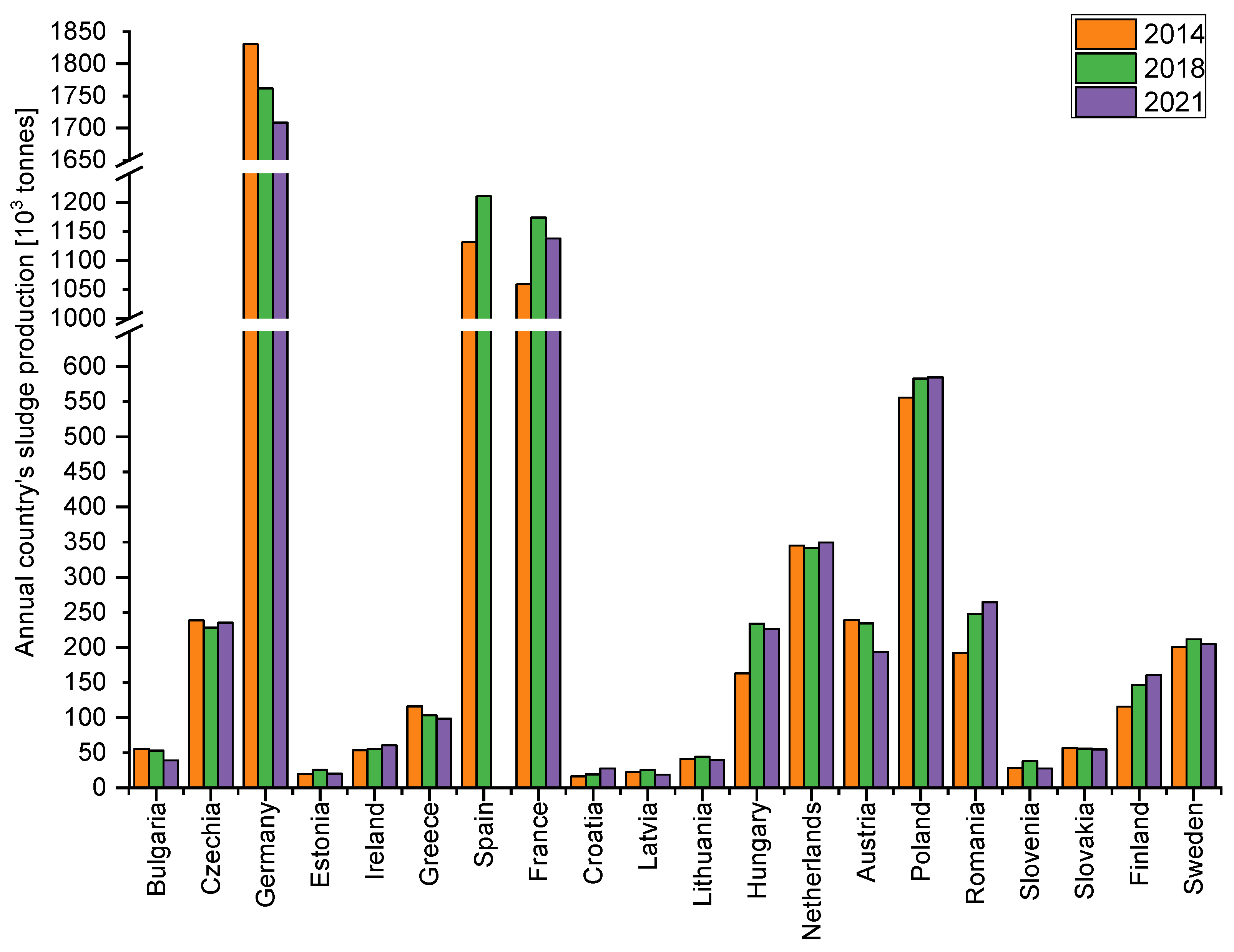

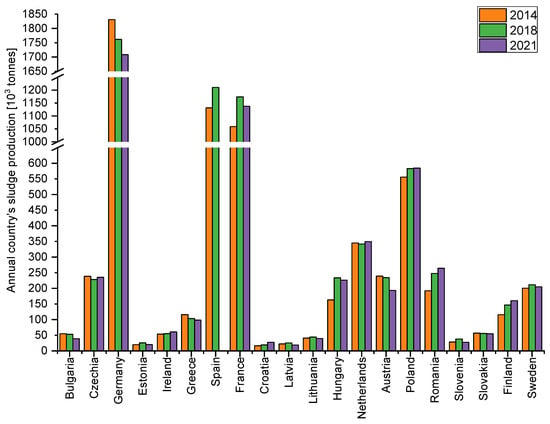

In Europe, the total reported amount of sludge generated in 20 selected EU countries was 6464.37 thousand tons in 2014, which then increased to 6792.94 thousand tons in 2018. The year 2021 already shows a total decline, which is difficult to interpret, but this result is significantly influenced by the lack of reporting data for Spain. In 2021, we had a declared decrease in EUROSTAT data to 5451.98 thousand tons. The decline in sewage sludge production may also reflect the impact of improved environmental policies and technological advances in wastewater treatment, which focus on waste reduction and improved plant efficiency and recovery of possible nutrients (Figure 1).

Figure 1.

EU selected countries’ sludge production in thousand tons from urban wastewater treatment plants in 2014, 2018 (2017 for France, no data for 2018), 2021 (2022 for the Netherlands, no data for 2021) (Based on Eurostat data); total reported amount (2014) 6464.37, 2018 (6792.94), 2021 (5451.98) thousand tons from 20 EU countries [21].

In addition, there is a global trend in sewage sludge management towards a circular economy, such as resource recovery from sludge and production of energy and fertilizers, which can contribute to reducing the overall volume of sludge. Differences in trends between countries underline the variability of policy implementation, population and demographic changes, adaptation of technologies to new climate and energy challenges, and investments in wastewater infrastructure across Europe.

2. Sewage Sludge Treatment and Reuse Technologies—Need for Development in the Context of Circular Economy, Sustainable Development, Human Health, and Energy and Fertilizer Saving

Sewage sludge treatment and reuse technologies are essential to modern waste management systems. Currently, these technologies stabilize sludge, reduce its volume, and remove harmful contaminants, making it safe for reuse or disposal. Commonly used methods include anaerobic digestion, thermal hydrolysis, composting, landfilling, and advanced oxidation processes [22,23]. These techniques enable the extraction of valuable resources such as biogas, fertilizers, and water, which can be repurposed for various applications [24,25]. However, developing these technologies is necessary to enhance efficiency, increase resource recovery rates, and address emerging environmental and health challenges. By advancing sludge treatment and reuse technologies, we can better support sustainable development goals, protect public health, and promote energy and resource conservation.

Walter’s definition of a circular economy (CE) states that “A ‘circular economy’ would turn goods that are at the end of their service life into resources for others, closing loops in industrial ecosystems and minimizing waste” [26]. It is crucial to fully integrate the CE with sustainable development, ensuring that they share common goals. This integration necessitates a comprehensive rethinking and broadening of CE’s focus beyond mere recycling and short-term economic benefits. To contribute to sustainability, CE must evolve into a holistic economic model that enhances social well-being and environmental quality [27]. In this context, sewage sludge treatment and reuse technologies are indispensable, requiring a focus on environmental sustainability and social well-being.

One of the primary benefits of these technologies is the recovery of valuable materials from sludge, such as phosphorus (P), nitrogen (N), and organic matter. Phosphorus, for example, is a critical component of agricultural fertilizers and is essential for food production. However, natural phosphate rock reserves are finite and depleting. Technologies such as struvite precipitation allow for phosphorus recovery from sludge, which can then be used as a fertilizer. In addition to struvite precipitation, thermal treatment technologies, such as incineration, pyrolysis, and thermal hydrolysis, are employed to recover phosphorus and reduce the volume and toxicity of sewage sludge. These methods enhance resource recovery while minimizing environmental impact [28,29,30]. Thanks to the development of technology and process optimization, it is possible to recover phosphorus much more effectively and, consequently, to use it further. For example, struvite precipitation, which is a commonly used method for phosphorus recovery, can be improved in terms of efficiency. Further development of low-energy recovery systems and scaling these technologies will be key to making phosphorus recovery more viable and cost-effective. This provides a sustainable source of phosphorus and reduces the environmental impact of mining activities.

Moreover, the treatment and reuse of sewage sludge can contribute significantly to reducing greenhouse gas emissions. For instance, anaerobic digestion of sludge produces biogas, a renewable energy source [25,31,32]. The use of biogas can replace fossil fuels, leading to a reduction in carbon dioxide emissions. The development of biogas technology and improvement of this process is necessary to meet the growing demand for energy and mitigate climate change [33,34]. Additionally, the application of treated sludge in agriculture can enhance soil carbon sequestration, further mitigating climate change [35]. Examples from various regions highlight the potential of these technologies. In Denmark, for instance, nearly all sewage sludge is treated and reused, primarily as fertilizer in agriculture. This not only closes the nutrient loop but also supports sustainable farming practices [36]. Lessons learned from these examples emphasize the importance of regulatory frameworks and public acceptance. Robust regulations ensure the safe and sustainable application of treated sludge, while public awareness campaigns can foster acceptance and support for these practices. Collaboration between stakeholders, including governments, industry, and communities, is crucial for successfully implementing sludge treatment and reuse technologies.

Sewage sludge, if not properly treated, can pose serious health risks due to the presence of pathogens, heavy metals, organic pollutants such as pharmaceuticals, parabens, and microplastic [24,37]. Therefore, it is necessary to constantly develop and improve sewage sludge treatment technologies to minimize the release of these pollutants into the natural environment and to minimize exposure to the toxic effects of these pollutants for humans. The modern treatment processes aim to reduce or eliminate these contaminants, making the sludge safe for reuse.

Pathogens in untreated sludge, such as bacteria, viruses, and parasites, can cause diseases if they enter the food chain or water supplies [38]. Treatment technologies like thermal hydrolysis, composting, and advanced digestion processes significantly reduce pathogen levels, ensuring the safe reuse of sludge [39]. For example, composting stabilizes organic matter and generates heat, which destroys pathogens, resulting in a safe and nutrient-rich soil conditioner.

Heavy metals, including cadmium, lead, and mercury, can accumulate in the food chain and pose long-term health risks. Advanced treatment methods, such as chemical precipitation and adsorption, can effectively remove heavy metals from sludge [40,41]. Ensuring that these metals are below permissible levels before applying sludge to land is crucial for protecting human health.

Pharmaceuticals and microplastics in sewage sludge also present significant concerns for human health. Residues of pharmaceuticals, including antibiotics, hormones, and other drugs, often persist through wastewater treatment processes and can accumulate in sewage sludge [24,42]. When this sludge is used in agriculture or disposed of improperly, these substances may enter the food chain or water sources, potentially leading to adverse health effects such as antibiotic resistance and hormonal disruptions. Similarly, microplastics—tiny plastic particles that result from the breakdown of larger plastic debris or are introduced through personal care products and industrial processes—are increasingly found in sewage sludge. These particles can carry harmful chemicals and pathogens, and their environmental persistence risks human health. Microplastics in the soil can enter the food chain through crops, and their potential effects on human health are a growing area of concern [43,44]. Addressing these issues requires advanced treatment technologies and regulatory measures to effectively remove or mitigate the presence of this micropollutant in sewage sludge. Enhanced treatment processes, such as advanced oxidation, activated carbon adsorption, and membrane filtration, are essential to reducing these contaminants. Developing and implementing robust guidelines for sludge management and disposal can also help minimize their impact on human health.

In addition, emerging contaminants, such as PFAS (per- and polyfluoroalkyl substances), present a growing challenge, requiring adaptation of existing treatment technologies or the development of new approaches. PFAS are highly persistent in the environment and resistant to conventional treatment processes, making their removal difficult [18]. To address this, the development of targeted treatment methods is essential. Innovative solutions such as PFAS-specific adsorption techniques, using advanced materials like engineered activated carbons or biochar, as well as destruction technologies like plasma treatment, AOPs, and electrochemical degradation, will be critical. These methods can effectively break down or capture PFAS compounds, preventing their accumulation in agricultural soils and mitigating potential risks to the environment and human health. Additionally, integrating these solutions into existing sewage sludge treatment systems will be vital to ensure comprehensive contaminant removal while maintaining the efficiency of resource recovery processes [18].

Sewage sludge contains significant organic matter, making it an excellent feedstock for energy production through various technologies. Anaerobic digestion is one of the most widely used methods, stabilizing the sludge and producing biogas—a renewable energy source. Biogas can be used to generate electricity and heat or upgraded to biomethane as vehicle fuel [45]. Optimizing anaerobic digestion processes to improve biogas yields while reducing emissions is crucial. Incorporating combined heat and power (CHP) systems can help maximize energy recovery from sludge. Furthermore, integrating renewable energy sources with these technologies could reduce reliance on fossil fuels, lowering the overall carbon footprint. Other technologies for energy recovery include thermal treatment methods like incineration, pyrolysis, and gasification. These processes convert organic material into heat, electricity, and syngas. Incineration reduces sludge volume and produces ash that can be further utilized, while pyrolysis and gasification offer the potential to produce cleaner energy forms with fewer emissions. Improving these technologies is crucial for maximizing energy recovery and efficiency. Emission control remains a priority for technologies like pyrolysis, gasification, and incineration. Innovations such as advanced flue gas cleaning systems can significantly reduce air pollutants like nitrogen oxides (NOx) and sulfur oxides (SOx), volatile organic acids, CH4, and others. Additionally, optimizing these processes, to reduce the production of ash and other byproducts, can lessen their environmental impact. The use of sewage sludge for energy purposes reduces the need for its storage and, at the same time, reduces the burden on the environment by reducing greenhouse gas emissions and other pollutants. Enhancements could include optimizing anaerobic digestion conditions, integrating combined heat and power (CHP) systems, and developing more efficient thermal processes. Advancements are necessary to increase the economic viability and environmental sustainability of energy recovery from sewage sludge, meet rising energy demands, and contribute to climate change mitigation efforts. Also, extracting nutrients from sewage sludge for use as fertilizers presents significant energy savings and environmental benefits [39]. The production of synthetic fertilizers is energy-intensive, involving mining raw materials and chemical processes. Recovering nutrients like nitrogen and phosphorus from sludge reduces the need for artificial fertilizers and their associated energy consumption. Technologies such as struvite precipitation and advanced nutrient recovery systems extract these valuable nutrients. Using treated sludge as a soil amendment also improves soil health, enhancing its ability to retain water and nutrients. This can lead to better crop yields and reduced need for additional fertilizers. The holistic approach of using treated sludge in agriculture supports sustainable farming practices and conserves energy. Advancing fertilizer recovery technologies involves refining processes to increase nutrient recovery rates and ensure the safety of the end products. Research and development efforts should focus on improving the efficiency and scalability of these technologies. Additionally, policies and incentives encouraging the use of recovered nutrients in agriculture can drive wider adoption and reduce reliance on synthetic fertilizers [46].

Developing and implementing sewage sludge treatment and reuse technologies are critical for advancing the circular economy (CE), protecting human health, and achieving energy and fertilizer savings. These efforts promote resource efficiency, reduce environmental impacts, and support resilient agricultural systems, contributing significantly to sustainable development goals. To fully understand and optimize the environmental and health impacts of sewage sludge-to-energy and fertilizer technologies, life cycle assessments (LCAs) should be incorporated into the design and operation of these systems. This can help identify key stages in the process, where improvements can be made to reduce energy consumption, emissions, and contaminant levels.

3. Anaerobic Digestion and Biogas Production

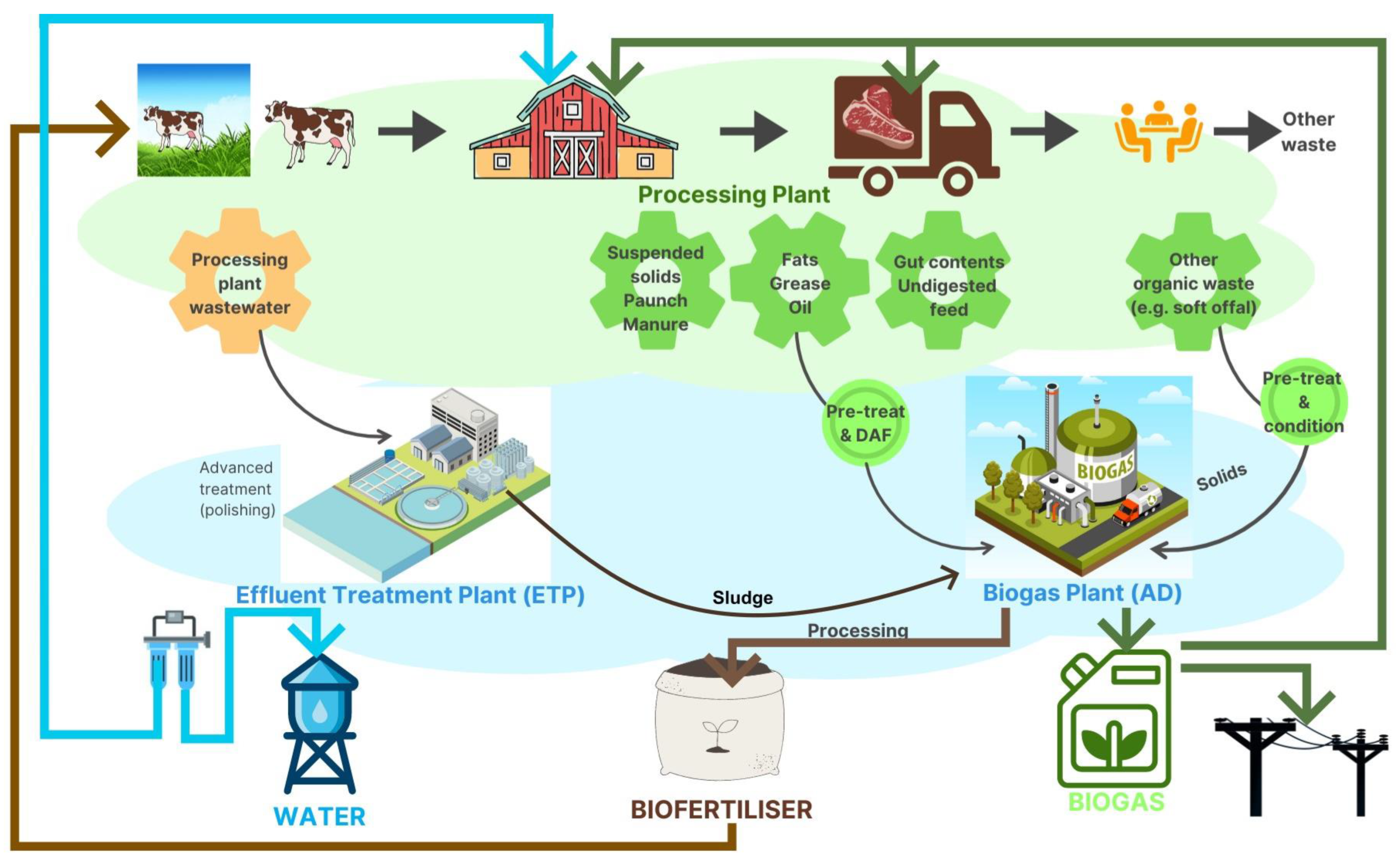

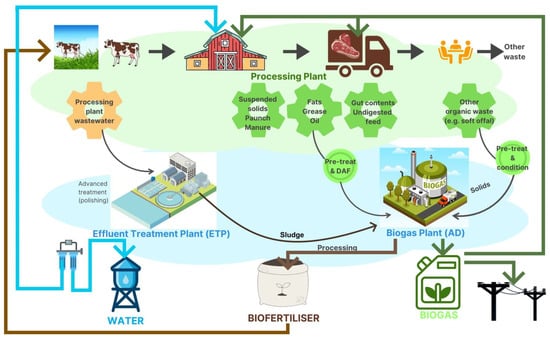

Anaerobic digestion is considered an effective and environmentally friendly technology that allows for the utilization of sewage sludge and the production of significant amounts of biogas which contains up to 75% methane [47]. Therefore, improving this technology contributes to implementing the assumptions of the closed-loop economy and, consequently, reducing the amount of waste generated. This process stabilizes sewage sludge, reduces pathogens, and produces biofuel with high potential for use as a renewable energy source. To improve the process, pre-treatment of sludge is increasingly used, which allows for enhanced methane production and efficiency of substrate decomposition in biodegradation processes (Figure 2). Moreover, this results in a reduction in solid mass [48].

Figure 2.

Stages of biogas production in organic waste-to-energy concept.

Improving wastewater treatment processes has often led to expanded biogas production from sewage sludge. One of the flagship treatment plants using organic substrates, such as food waste in fermentation, is the East Bay Municipal Utility District (EBMUD) in Oakland, California. The amount of renewable energy produced by this treatment plant is higher than the demand for this source (Home: East Bay Municipal Utility District, n.d.). The United States Environmental Protection Agency and EBMUD pilot project confirmed that implementation of food industry waste increased the methane potential and generated enough energy to power 1400 houses from biogas obtained from processing 100 tons of food waste [49].

Another technologically advanced wastewater treatment plant is the Blue Plains Advanced Wastewater Treatment Plant in Washington DC with an average treatment capacity of 1.45 million m3 per day [50]. It uses hydrothermal carbonization (HTC) technology which leads to the formation of hydrochar. This effectively increases the amount of energy produced by improving the quality of substrates. Additionally, a reduction in fermentation inhibitors is observed. HTC is a treatment that transforms organic waste in process water into biogas with the optimal temperature being in the range of 180–200 °C [51]. Analyses conducted by Aragón-Briceño et al. [52] showed that the use of hydrothermal carbonization in sewage sludge processing leads to obtaining 10 times more energy than in conventional fermentation. In Sweden, anaerobic digestion of sewage sludge contributes to over 0.7 TWh of biogas annually. The pasteurization process is often used in sewage treatment plants due to the effective increase in dissolved organic carbon (DOC) concentrations and generally increasing methane potential [53].

Research conducted by Ahn (2021) confirms the effectiveness of mechanical pre-treatment of sewage sludge with subsequent low-temperature treatment in increasing biogas production. The high potential of using this method also results from the acceleration of the biodegradation rate [54].

Microplastics, according to modern terminology, are defined as plastic particles with a diameter of less than 5 mm, which enter the environment in an uncontrolled manner, and their amount is closely related to the number of inhabitants, population density, and environmental awareness [55]. Modern measuring equipment can detect and characterize plastic particles below 10 µm. Still, the constant modernization of the plastic production process and the enrichment of plastics with dyes, resins, or stabilizers make it difficult to determine the origin of each particle tested [15]. Based on current publications, it can be concluded that the efficiency of wastewater treatment plants in removing microplastic ranges from 16.5% to 98.4% for primary treatment and 78.1% to 100% for secondary treatment [56]. Current wastewater treatment technologies partially remove contaminants such as microplastics (MPs) but are not 100% effective. Microplastics are mainly removed during primary and secondary treatment stages, where physical processes such as sedimentation and filtration allow for the retention of about 80–90% of MPs in sewage sludge. Primary treatment removes 78–98% of MPs, while secondary treatment reduces MPs by only 7–20%, and tertiary treatment has little effect on microplastic removal. However, these treatments are not specifically designed to remove microplastics, but mainly to retain them in sewage sludge, leading to their accumulation in sewage sludge, which is often used as fertilizer in agriculture, posing a risk to the environment. The efficiency of microplastic removal is influenced by various factors, such as sewage flow, temperature, and type of treatment. Studies have shown that anaerobic digestion and other sludge treatment methods may not effectively break down MPs. Almost 100% efficiency of microplastic removal in anaerobic digestion process is achieved only for microplastics derived from natural, biodegradable polymers such as PLA. The article emphasizes that although sewage treatment plants are the last barrier against MP particles entering the environment, there is an urgent need to develop standard protocols and conduct further research to optimize MP particle removal and reduce their impact on the environment [57].

Most microplastic removed by conventional means is ultimately trapped in sewage sludge. In many countries, there are no standards for the amount of plastic in the volume of sludge to be allowed for soil fertilization [54]. Thus, the study showed that in the studied glen, which was regularly fertilized with sludge, the number of detectable particles increased from an average of 4 pcs/kg to 542 pcs/kg (North America, New York area) and in other samples detected 71,000 pcs/kg in Denmark, 10,200 pcs/kg in Chile, 1900 pcs/kg in Mexico, and 38 pcs/kg in Iran, among others. A comprehensive analysis of more than 150 sites worldwide further proved that microplastic concentrations in industrial areas were four times higher than others, in the case of sewage sludge by up to 70 times. The highest documented concentration of microplastic in sludge-fertilized soil was described in China, in the Wuhan area, and was 690,000 pcs/kg, with more than 82% of the particles being less than 250 µm in size and including film fines and synthetic fibers [58].

Sewage sludge processing technologies differ in their efficiency in removing specific microplastics. Composting of sewage sludge leads to the removal of polyethylene (PE) at a level of 13%. In the case of hyperthermophilic composting of sewage sludge, the results are more diverse depending on the type of microplastics—for PHA (polyhydroxyalkanoates) degradation is 29%, for PVC (polyvinyl chloride) only 3%, while for PS (polystyrene) it is 43.7%, which leads to a significant reduction in these microplastics. Traditional composting of sludge with green waste shows lower efficiency, especially for polystyrene, the degradation of which is only 4.5%. On the other hand, composting with the addition of biochar from animal manure results in a reduction in PHA at a level of 50%. Aerobic processes used for sewage sludge lead to low degradation of PE (4.1%) and PLA (polylactide) (3.7%), but are more effective for PCL (polycaprolactone), which is degraded by 34.8%. Vermicomposting is particularly effective in removing PP (polypropylene) and HDPE (high-density polyethylene), with degradation rates of 22–78% and 31–56%, respectively. However, the highest efficiency is demonstrated by anaerobic digestion at 55 °C, with degradation rates of 90%, 80%, and 75%, respectively, for biodegradable microplastics such as PHB (polyhydroxybutyrate), PCL, and PLA [5,18,55].

Screening studies of sewage sludge show that sewage sludge contains significant amounts of microplastics, among which fibers and fragments dominate (Table 1). In terms of polymer types, polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET) are predominant, originating mainly from consumer products. We know more and more about the potential use of sewage sludge as fertilizer for agricultural soils. Unfortunately, microplastics remain in these soils, infiltrating plants and soil organisms. It turns out that microplastics migrate horizontally to adjacent fields and penetrate deep into the soil profile [59]. Agricultural application of microplastic-rich sewage sludge leads to further unchecked contamination. It should also be noted that the sewage sludge currently produced has significantly different parameters than those used 20 or 30 years ago. Currently, consumers have different preferences, and the market offers many synthetic products. As a result, the consumption of synthetic plastic products compared to natural products in cosmetics and everyday items is dominant compared to previous decades. The majority of microplastics from wastewater are captured in sewage sludge; therefore, the concentration of microplastics in sewage sludge is expected to increase in the coming years.

Table 1.

Microplastics in sewage sludge from municipal WWTPs in selected countries.

Due to the composition of sewage sludge, effective technologies should be used to reduce pollutants in the digestate. The presence of compounds such as naphthalene, polycyclic aromatic hydrocarbons (PAHs), toluene, nitrobenzene, or the presence of pathogens, filamentous bacteria, and heavy metals, affects the quality and possibilities of using the digestate and poses a threat to human health and environment. Therefore, selecting the appropriate method for these pollutants increases the process’s effectiveness and minimizes the pollutants’ content in the digestate. Co-fermentation technology is used more often, leading to the stabilization of feedstock, optimization of biogas production, and improvement of the C/N ratio [47]. However, it is associated with determining the optimal proportion of co-substrates and adjusting the process conditions.

Generally, the methods for reducing the content of contaminants in digestate include mechanical, chemical, and biological techniques. One of the effective methods for eliminating pathogenic microorganisms is the preliminary treatment of sludge using microwave reduction. As a consequence of this process, it is possible to remove such species as Escherichia coli bacteria effectively. A similar effect can be achieved by alkaline treatment, which allows the destruction of E. coli and Salmonella species. Another chemical method of reducing pollution is the oxidation process, which contributes to the removal of pathogens and converts complex compounds into substances with higher biodegradation abilities [47]. Other commonly used chemical methods for digestate treatment are flocculation, ion exchange, and precipitation [63]. In turn, biological methods include bioaugmentation, which involves the application of microorganisms to stimulate the anaerobic decomposition of sewage sludge. This technology is effective in reducing the content of heavy metals in digestate. Research conducted by Montusiewicz A. et al. [64] proved that microorganism vaccination increases fermentation efficiency and reduces metal content in digestate. However, no significant differences were observed in the amount of biogas produced with and without the addition of microorganisms [64]. Among biological methods, the use of enzymes to reduce contaminants also deserves attention. Typically, proteases and lipases are used to degrade polymeric substances [47].

4. Thermochemical Conversion: Pyrolysis and Gasification and Combustion

Thermochemical conversion, including pyrolysis and gasification, is a process that can be used to convert sewage sludge into energy and chemical products. These are modern technologies that allow for effective waste management and limiting their impact on the environment. Both processes have advantages in the context of sewage sludge management. Pyrolysis and gasification reduce the volume of waste, limit the emission of pollutants into the environment, and enable the recovery of valuable energy and chemical products. Additionally, with proper management, they can be part of a sustainable municipal and industrial waste management system.

In the thermochemical conversion of sewage sludge, such as pyrolysis and gasification, many technological innovations have been introduced to improve process efficiency, reduce costs, and minimize environmental impact. Recent years have shown increased interest in sewage sludge treatment thermochemical methods. Team Rijo et al. [65] reviewed various thermochemical conversion processes of sewage sludge aimed at generating products with positive value such as biochar, biofuels, and renewable gases. Research indicates the effectiveness of using catalysts such as Ni, Cu, Mg, and Al in pyrolysis and gasification processes, which leads to increased hydrogen production efficiency and reduction of undesirable pollutants. The authors also characterize other processes: hydrothermal carbonization (HTC), hydrothermal liquefaction (HTL), and hydrothermal gasification (HTG). The operation of HTC is conducted at temperatures in the range of 180–250 °C with the pressure at 2–25 MPa allowing it to reach the product of biochar, hydrochar, or char. In turn, the performing conditions of HTL are as follows: temperature 250–374 °C, and pressure at 2–25 MPa allowing to achieve biooil, or aqueous phase oil. The HTG is performed at a temperature above 375 °C, and pressure of 18–25 MPa with gaseous products (such as CH4, H2, CO2, C2H4, etc.) as final products [66]. Pyrolysis and gasification have high energy recovery but involve significant capital and operating costs. In contrast, HTC, HTL, and HTG have lower energy requirements, but product quality control and process optimization pose problems.

A fascinating comparison of the two technologies was presented in the research by Giwa et al. [67]. By combining plasma pyrolysis with anaerobic fermentation, the efficiency of the process increases. Sewage sludge is pre-processed in the plasma pyrolysis process. This makes the substrate available to bacteria. These two processes rely on high temperatures, which can cause problems with energy demand. According to the authors, these challenges are offset by the energy generated, which can power the treatment plant or be sold to the grid. Plasma pyrolysis waste can be converted into biochar, organic fertilizer, or soil conditioner.

There are also several publications on optimizing the sewage sludge gasification process. One of them is [68]. The publication’s authors assessed the impact of the operating parameters of the gasification agent heating temperature and the equivalence coefficient on converting sewage sludge into synthesis gas through gasification and combined heat and power generation. This approach allows reducing CO2/kg of sewage sludge emissions.

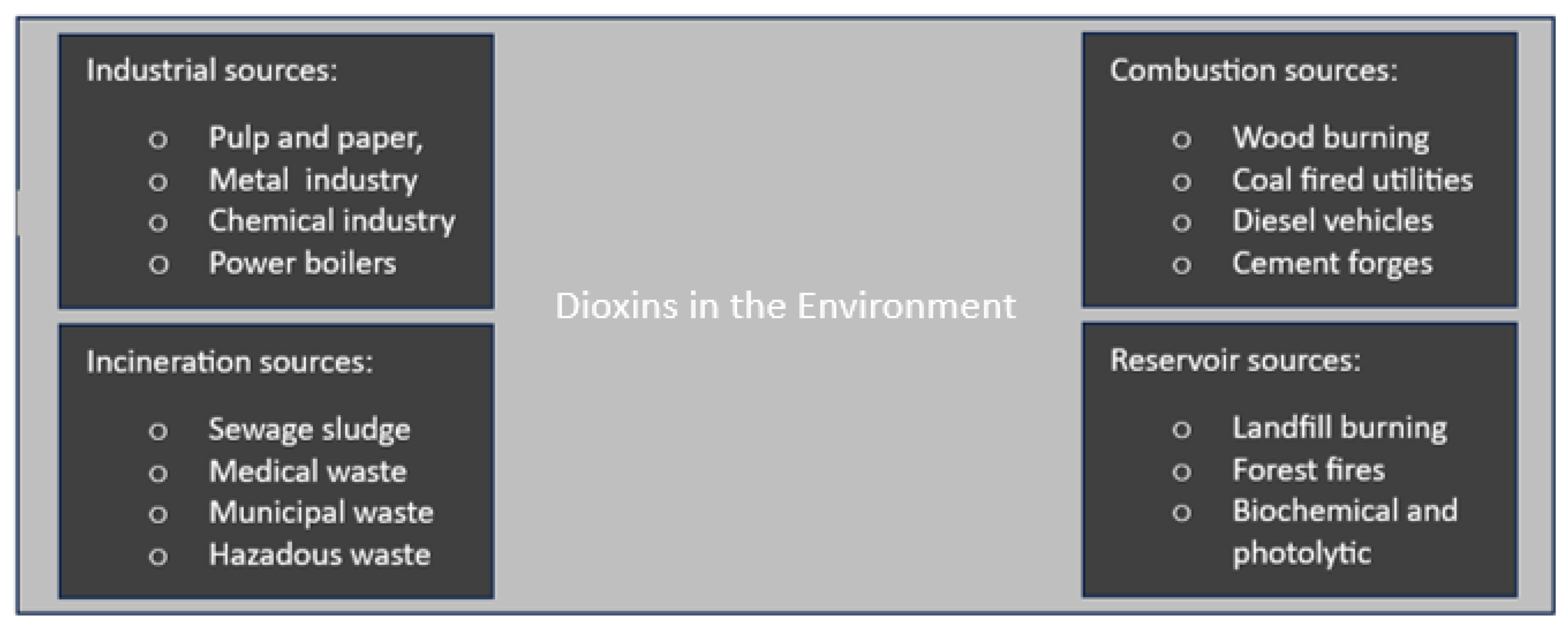

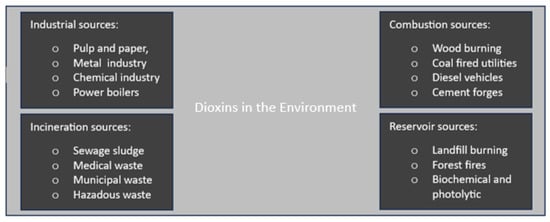

Thermochemical processing of sewage sludge, such as pyrolysis and gasification, may produce pollutants, including dioxins, furans, and solid particles. Dioxins and furans are toxic and can be emitted during high-temperature processes if improperly controlled. Particulate matter, which contains heavy metals and other harmful substances, can also be emitted, affecting air quality. Emission controls, including filters and catalytic converters, are key to minimizing these pollutants [69]. Dioxins and furans are recognized as highly toxic organochlorine pollutants with significant detrimental effects on public health and major economic repercussions. These compounds include polychlorinated dibenzo-p-dioxins, dibenzofurans, and dioxin-like substances such as polychlorinated biphenyls and carbazoles. Classified as persistent organic pollutants, they are featured in the Stockholm Convention’s “Dirty Dozen” list. They are also identified by the International Agency for Research on Cancer as Group 1 carcinogens, indicating that they are known to cause cancer in humans [70]. Figure 3 below shows the main sources of dioxins in the environment. Therefore, many studies focus on the formation and control of dioxin and furan emissions during the pyrolysis of sewage sludge. One of them is research conducted by Cones’s team [71]. The author aimed to estimate the emission of dioxins and furans under various decomposition conditions. This made obtaining an approximation of waste distribution in real conditions possible. A group of researchers from Iceland [72] analyzed the formation of dioxins in the gasification process and the operational parameters that can be controlled during the process to minimize the formation of dioxins. The authors note that using a high-temperature reactor at temperatures above 800 °C, combined with rapid gas cooling and the absence of oxygen, significantly reduces the formation of dioxins. This method is effective even for fuels with high chlorine content, demonstrating that high-temperature gasification can mitigate dioxin production under challenging conditions.

Figure 3.

Sources of dioxins in the environment, based on [69,70].

Several studies and simulations have been conducted to reduce the emission of hazardous compounds such as dioxins, furans, or solid particles. This is evidenced by publication [73], in which the authors try to optimize the sewage sludge processing processes most efficiently. An interesting solution was proposed in the research presented in the publication by Pacheco’s team [74]. The study aimed to contribute to developing sustainable waste-to-energy technologies, namely plasma gasification, by using sewage sludge as a valuable resource for syngas production.

Dioxins, furans, and particulate matter emissions seriously threaten human health and the environment. Protection against these pollutants requires monitoring emission sources, implementing appropriate emission reduction technologies, and taking action to improve air quality.

Thermochemical treatment of sewage sludge is a process that can generate various hazardous pollutants. There are several strategies to control and reduce these pollutants. It is essential to properly optimize each process, either by controlling the temperature or determining the exposure time. Another important factor is implementing monitoring systems to track pollution levels in real time continuously. Monitoring pollutant emissions allows for ongoing adjustment of process parameters. The composition of sewage sludge itself is more important. Therefore, before processing the sludge, its composition should be analyzed to identify potential sources of pollution and adjust the processing. Pretreatment methods such as pre-incineration, composting, or chemical stabilization are also recommended to reduce the amount of pollutants before the main thermochemical process [75]. Pollution control and reduction strategies are of increasing interest. It is becoming increasingly important to ensure that processes comply with national and international environmental standards regarding pollutant emissions [76].

The limited availability of landfill areas has led to the increasing incineration of sewage sludge. The result of burning the organic matter contained in sewage sludge is its conversion into carbon dioxide and water vapor, while simultaneously generating energy. Incineration significantly reduces the mass and volume of sewage sludge. In recent years, research on the co-incineration of sewage sludge has progressed. Co-incineration of sewage sludge with fossil fuels is a viable way to reduce environmental pollution. One of the most extensively studied mixtures is coal and biomass. The use of such a mixture helps to reduce the amount of coal (by supplementing it with sewage sludge biomass) and contributes to the reduction of greenhouse gas emissions. It turns out that adding sewage sludge improves the ignition and combustion properties of anthracite and bituminous coal. Additionally, it has been observed that sewage sludge improves the ignition properties of coal slurries in power plants. Co-incineration of biomass with fossil fuels is considered a promising method for reducing fossil fuel consumption. Efforts are also being made to introduce sewage sludge into natural gas-powered power plants. The use of renewable energy seems economically promising, especially given high natural gas prices.

The document “Guidance on Best Available Techniques for Waste Incineration” issued by the European Commission contains the best available techniques (BAT) for waste incineration, including technologies reducing dioxin and furan emissions [77]. Similar information can also be found in the report “Sewage Sludge Management: Best Practices for Thermochemical Treatment” issued by the U.S. Environmental Protection Agency (EPA) [78]. The report presents best practices for sewage sludge management in thermochemical treatment.

Effective emission management during the thermochemical treatment of sewage sludge requires using complex strategies including process optimization, advanced treatment technologies, monitoring and control, reduction of pollution sources, and compliance with appropriate norms and standards. Implementing these strategies helps minimize negative impacts on human health and the environment.

5. Fertilizers from Sewage Sludge

Sewage sludge as a byproduct of wastewater treatment is rich in organic matter and essential nutrients such as nitrogen (N), phosphorus (F), and potassium (K) [79]. The concentration of those elements in sewage sludge organic fertilizers is comparable to traditional organic fertilizers. Additionally, fertilizer from sewage sludge is long-acting and contains micronutrients like copper, zinc, and iron, which are vital for plant health [80]. However, in inadequate concentrations, those trace elements are harmful. The sewage sludge properties depend on the wastewater type, treatment process, and often on the seasons [81]. The heterogeneous nature of sewage sludge forces its usage for fertilizer purposes and requires strict legal regulation and continuous monitoring of the content of trace elements [82]. Fertilizer from sewage sludge may contain many pollutants that pose a threat to human health and the environment, such as heavy metals [83], pathogens [84], pesticides, herbicides [85], dioxins [70], hormones [86], antibiotics [9], and microplastics [15]. Pharmaceuticals found in sewage sludge may have a negative impact on the functioning of soil microorganisms and increase the resistance of pathogens to antibiotics [9]. Moreover, sewage sludge may contain biogenic elements such as nitrogen and phosphorus that are too high, which, when flowing into water reservoirs with precipitation, may contribute to eutrophication processes. The organic matter in sewage sludge enhances soil structure, improves water retention, and promotes the growth of beneficial microorganisms [87], which play a crucial role in nutrient cycling and disease suppression. Sewage sludge as an organogenic substrate contains high amounts of humic acids and proteins. Therefore, sewage sludge is known to improve the quality of organic matter in the degraded soil, which is promising for soil carbon sequestration limiting the emission of CO2 from the soil [88].

Using sewage sludge as an organic fertilizer recycles essential nutrients back into the soil, reducing the need for synthetic fertilizers [79]. This not only conserves natural resources but also lowers the environmental footprint of agricultural practices. Due to the organic and inorganic components, sewage sludge can be used for soil remediation purposes, improving soil quality and increasing soil productivity [89].

By harnessing the nutrient-rich properties of sewage sludge, we can reduce dependency on synthetic fertilizers, improve soil health, and address environmental challenges associated with waste disposal [13]. Using sewage sludge in soil fertilization is either due to reuse or relatively low costs.

6. Emerging Trends and Future Directions

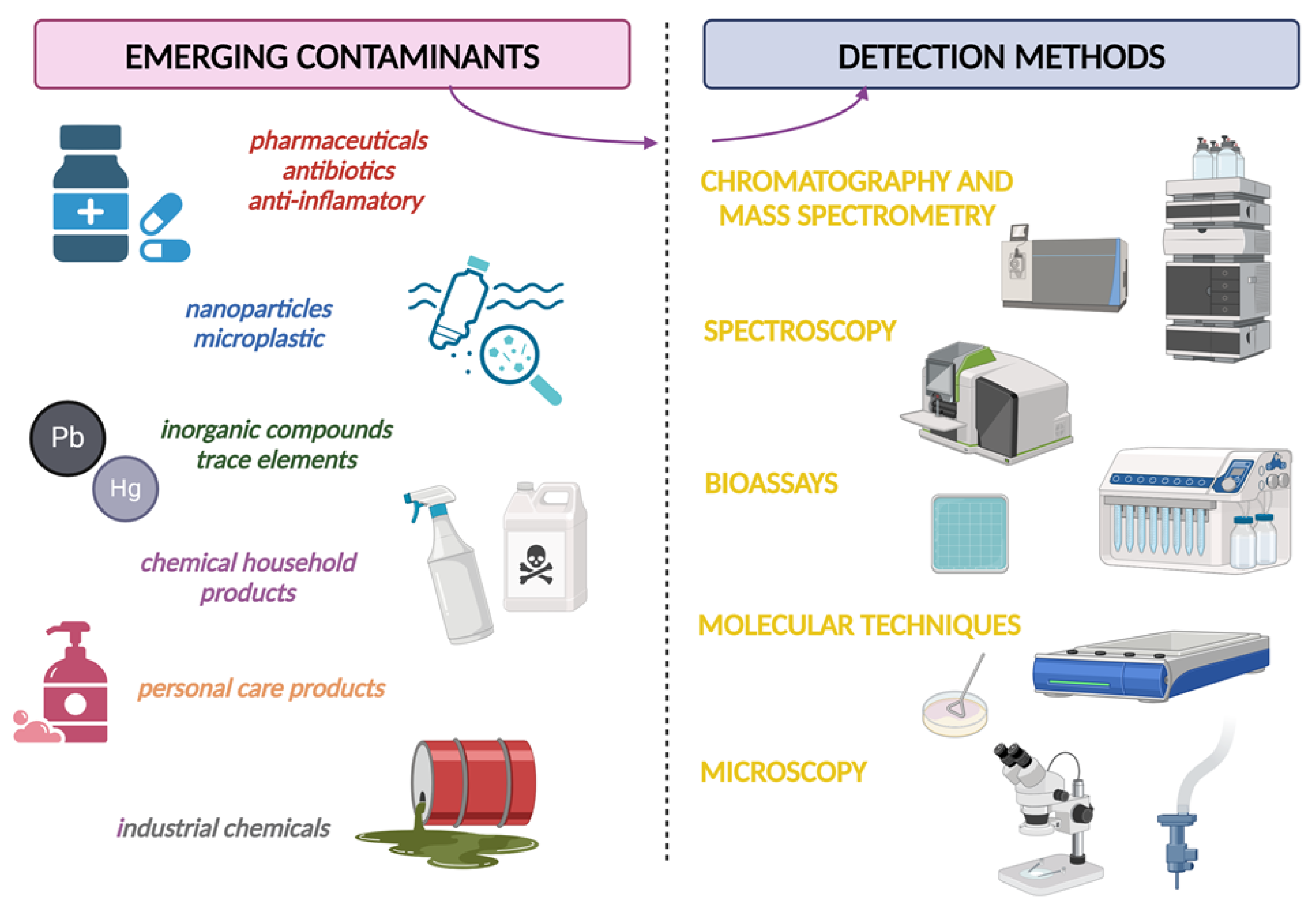

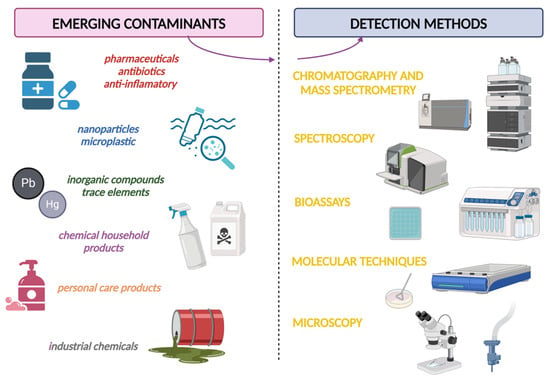

The assessment of environmental risk associated with using sewage sludge for fertilizer and energy purposes is complex and involves various analytical and modeling tools. These tools help to identify, quantify, and assess potential environmental and health risks associated with contaminants present in sewage sludge. Wastewater contaminants are mainly biodegradable during the treatment process, while the resistant ones are retained in sewage sludge to the greatest extent. Wastewater contains high levels of MPs, and most of them (≈99%) remain in sewage sludge [18]. Many are not biodegradable or only slightly biodegradable and have high water solubility. Therefore, pharmaceuticals and personal care products (PPCPs), endocrine disrupting chemicals (EDCs), such as bisphenol A (BPA) and phthalates, per- and polyfluoroalkyl substances (PFASs), known for their persistence in the environment, pose a major threat. For this reason, the presence of these contaminants in sewage sludge is associated with a potential threat, both in ecological and health terms (Figure 4). Therefore, it is important to monitor the total content of these contaminants in sewage sludge and their intermediate forms of decomposition. Emerging pollutants in sewage sludge, including pharmaceuticals, personal care products, endocrine-disrupting chemicals, and microplastics, pose increasing risks to human health and the environment [90]. Various scientific and technical analytical tools evaluate these contaminants in sewage sludge (Table 2).

Figure 4.

Emerging contaminants in sewage sludge and detection methods.

Table 2.

Tools and techniques used for emerging contaminants assessment.

The tool that facilitates the decision on whether a given sewage sludge can be used for natural purposes, especially in agriculture, is the analysis of the potential ecological risk. Such an assessment requires many procedures, tools, and models (Table 3). These models simulate the movement and transformation of contaminants in the environment, helping to predict their distribution, persistence, and potential impacts on ecosystems and human health.

Table 3.

Table summarizing the monitoring and risk assessment tools for sewage sludge usage.

By utilizing these tools and sources, researchers and practitioners can effectively assess the presence and impact of emerging contaminants in sewage sludge, facilitating informed decision-making and the development of mitigation strategies.

The integration of artificial intelligence and smart technologies for real-time monitoring and control of pollutants represents a significant advancement in environmental protection and management [115]. AI can play a pivotal role in controlling pollutants through several advanced techniques and systems [116]. Machine learning algorithms can predict contaminant levels based on historical data and operating conditions of wastewater treatment plants [117]. Additionally, AI can analyze data from sensors monitoring soil parameters such as pH, moisture, nutrients, and heavy metal levels, quickly alerting you to sudden changes [118]. Integrating AI and smart technologies enables ongoing monitoring of environmental pollution and soil condition monitoring, indicating areas requiring attention and quick response in a compatible application. Precise application of sewage sludge can be carried out using AI which, based on GPS data, determines areas requiring fertilization, thus limiting the possibility of over-fertilization and groundwater contamination. AI can assess the risks associated with using sewage sludge by analyzing data on the content of heavy metals, pathogens, and other contaminants [119]. AI can create early warning systems to inform farmers and authorities about the potential risks associated with the use of sewage sludge. Artificial intelligence can be helpful at the sewage sludge’s composition level. AI may control pollution by offering a range of prediction and forecasting models. Models available include, among others, a forecast model based on linear regression for determining the content of heavy metals in plants fertilized with sewage sludge, allowing the determination of the mobility and accumulation of heavy metals in soil fertilized with sewage sludge [120]. Another model provides for controlling and estimating sludge efficiency at the sewage treatment plant using machine learning models [121]. In turn, neural network models can be used to study plants’ uptake of toxic organic substances. Artificial intelligence also allows you to control the sewage sludge composting process before its use as fertilizer and can be helpful to decision-makers [122]. Using AI to fertilize soil with sewage sludge can significantly improve the efficiency and safety of this process. AI provides tools to monitor sudden increases in the concentration of emerging contaminants, allowing for quick response and prevention of ecological disasters. In turn, Ai et al. [123] proposed a model for rapidly identifying microplastic in soil using hyperspectral imaging technology. Such a tool may be useful for quickly controlling the enormous concentration of microplastics in soil treated by sewage sludge.

Currently, legal provisions in force in the European Union govern sewage sludge management. In the EU, sewage sludge is regulated mainly by three legal acts: the Waste Framework Directive (2008/98/EC) [124], which contains general principles applicable to all waste (e.g., treatment by the waste hierarchy); The Urban Waste Water Directive (91/271/EEC) [125], which contains detailed rules on how to deal with residues from sewage treatment; and the Sludge Directive (86/278/EEC) [126]. The latter two pieces of legislation were considered outdated by industry. The European Commission published a roadmap for evaluating the Sludge Directive (86/278/EEC) concerning the use of sludge in agriculture. The Directive requires that sludge is used in such a way as to take into account the needs of plants and not to deteriorate the quality of soil and surface and groundwater, and to take into account the aspect of new micropollutants such as pharmaceuticals and microplastics. Many countries have guidelines and standards for sludge application, including risk assessment protocols for emerging contaminants. Currently, the main goal of many WWTP operators is to reduce sludge production to maintain affordable disposal costs. Operators are also exploring innovative stabilization processes that may still allow agricultural use by eliminating pathogens and minimizing bad odors. In Europe still, overall 50% of sewage sludge is applied to the soil [21].

Work was carried out on changes to Directive 91/271/EEC. The version voted on in April 2024 is revolutionary in changing the regulations. The changes to the directive are based on the “One Health” approach aimed at permanently balancing and optimizing the health of humans, animals, and ecosystems sustainably. The directive will cover agglomerations above 1000 population equivalent. By 2045, Member States will have to ensure the use of tertiary treatment (i.e., nitrogen and phosphorus removal) in larger treatment plants. Pharmaceutical and cosmetic manufacturers and Member States will have to finance the costs of additional treatment of micropollutants. Reuse of treated municipal wastewater will be promoted. By 2035, municipal wastewater will be subject to secondary treatment (i.e., removal of biodegradable organic matter) before being discharged into the environment, in all agglomerations of 1000 population equivalent (PE) or more. By 2039, tertiary treatment (i.e., nitrogen and phosphorus removal) will be applied in all wastewater treatment plants covering 150,000 PE and more, and by 2045 in plants covering 10,000 PE and more. Additional treatment removing a broad spectrum of micropollutants (quaternary treatment) will be mandatory for all plants above 150,000 PE (and above 10,000 PE based on a risk assessment) by 2045. Various public health parameters will be closely monitored, such as pathogens, chemical pollutants, so-called “forever chemicals” (per- and poly-fluoroalkyl substances or PFAS), microplastics, and the resistance to antimicrobials. The Act introduces extended producer responsibility (EPR) for human medicines and cosmetic products. This covers the costs of quaternary treatment (removal of micropollutants from municipal wastewater). Producers will cover at least 80% of the costs, and national funding for this process will also be introduced. EU countries must promote the reuse of treated wastewater from all municipal wastewater treatment plants, especially in areas with water shortages. The directive also introduces an energy neutrality goal. This means that municipal wastewater treatment plants will have to increase the share of renewable energy used each year gradually. This is 20% by 2030; 40% by 2035; 70% by 2040; and 100% by 2045. Member States have until 2026 to adapt their regulations and submit an appropriate implementation program. Europe is preparing for a revolution in water and wastewater management: legislative resolution of the European Parliament of 10 April 2024 on the proposal for a directive of the European Parliament and of the Council on wastewater treatment.

7. Sewage Sludge-to-Energy and Fertilizer Technologies for Enhanced Sustainability

Previously seen as very burdensome and problematic, the sewage treatment plant sector has recently begun to undergo a green, sustainable transformation towards energy and material recovery. Sewage sludge treatment poses several challenges, especially in terms of managing contaminants such as heavy metals, organic pollutants, and pathogens. Although technologies such as thermal hydrolysis, incineration, and anaerobic digestion are commonly used to address these issues, their complete elimination of harmful substances is not always guaranteed. Therefore, to protect public health and the environment, effective monitoring and prevention of municipal wastewater mixing with highly polluted industrial wastewater is needed. Nowadays, rising energy prices are forcing treatment plants to optimize treatment technologies and introduce sludge technologies such as gasification, pyrolysis, and advanced anaerobic digestion. Sludge treatment plants can improve their energy efficiency while reducing their environmental impact. These methods help to recover valuable resources such as biogas and minimize the ecological footprint of sewage sludge treatment. However, integrating these technologies into existing infrastructure requires significant investments. The circular economy framework provides a key opportunity to increase sustainability by recovering essential nutrients such as nitrogen and phosphorus from sewage sludge, which can then be reused as fertilizer. Although land-based application of sewage sludge supports nutrient recycling, it carries risks such as soil contamination, making advanced nutrient recovery technologies such as struvite precipitation and composting safer alternatives that also promote agricultural productivity and environmental safety. It is essential to balance the environmental benefits of sludge-to-energy technologies, such as reducing greenhouse gas emissions, with the potential health risks associated with residual contaminants when sewage sludge is used as fertilizer. Optimizing these processes involves adopting sustainability indicators that assess energy efficiency, pollution reduction, and long-term environmental impacts. Public health and environmental impacts should be at the forefront of any technology deployed.

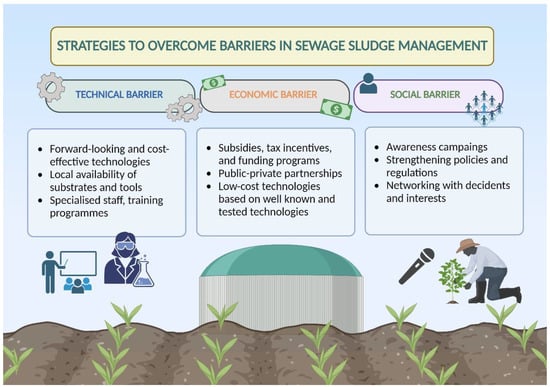

Sewage sludge management is developing significantly. The life of this waste no longer ends at the landfill. Sustainable sewage sludge management is the short-term goal of many sewage treatment plants today. We are moving towards maximizing all nutrients, carbon, energy, and other substances while minimizing the negative impact on the environment. The achievement of all sustainable goals requires new technologies development, which can lead to the possible energy and material recovery through specific processes [127]. However, we still face barriers that affect the implementation of new technologies in sewage sludge management. Overcoming the technical, economic, and social obstacles can minimize the environmental impacts of sewage sludge management [128]. Among the main technical barriers are infrastructure and technology [129]. Sewage sludge node at the sewage treatment plant is unfortunately still visible as a short, side technological line, in most treatment plants ending with the dewatering of the sludge, often with lime stabilization, and sending it to the landfill. The sludge node as an important element of the treatment plant in terms of sustainable development must stop being perceived this way. Investments and implementation of new technologies are necessary, including the transformation of sludge, at the place of its generation, into valuable products. Access to modern, efficient, and environmentally friendly treatment technologies is becoming less limited. Among currently available sewage sludge processing methods we can provide the basic ones like anaerobic digestion process, incineration, and composting, as well as the more advanced ones like anaerobic co-digestion, pyrolysis, gasification, hydrothermal treatment (hydrothermal carbonization (HTC), hydrothermal liquefaction (HTL), hydrothermal gasification (HTG), plasma gasification, and torrefaction. We can provide future methods for material recovery, hydrogen generation, and biofuel production. Implementing the selected technology for a given sewage treatment plant to process sewage sludge requires solving many technical and location issues. The selection of the appropriate technology is therefore crucial to ensure its optimization and functioning and the implementation of economic and environmental aspects (Table 4). It also requires modern pollution monitoring, ensuring the safety of the environment and users, including end users and intermediate users. Developing robust pollutant monitoring systems is essential for tracking pollutant levels in sludge, ensuring safety and compliance with environmental standards. Utilizing cost-effective and locally appropriate technologies ensures sustainability and practical application.

Table 4.

Pros and cons of various sludge treatment technologies.

Overcoming economic barriers plays a crucial role in green transformation as well. In a real wastewater treatment plant case study, different scenarios with different sludge train technologies were assessed using the DSS-WWTP simulator. It was shown that although both thermal utilization and thermal hydrolysis showed the highest economic efficiency, thermal hydrolysis brought additional benefits in improving the heat balance of the entire wastewater treatment plant, even when combined with other technologies [113]. Implementing financial incentives such as subsidies, tax incentives, and funding programs can encourage adopting best practices and technologies. Public–private partnerships are also beneficial, as they leverage private sector investment and expertise, bringing innovative solutions and enhancing the overall effectiveness of sludge management programs. Focusing on cost-effective solutions, and prioritizing the implementation of technologies that offer significant benefits without high costs, ensures broader adoption and greater overall impact. Currently, in Europe, treatment plants pay for the collection of sludge by entities that deal with its storage or disposal. Therefore, the main goal of many wastewater treatment plant operators is to reduce sludge production to keep the costs of its disposal at an affordable level. In addition, rising energy costs force treatment plants to invest in new sludge nodes to maximize profits. Additional trends in Europe are the progressive reduction of landfill availability for waste disposal, increased local opposition to agricultural use, anticipated stricter standards for metals and emerging micropollutants under the upcoming European directive, and rising disposal costs for off-site solutions [130]. They are further trends that are largely generated by social barriers. Social approaches are equally important. Engaging communities in planning and decision-making promotes ownership, ensures solutions are tailored to local needs, and increases acceptance and compliance. Awareness campaigns to educate the public about the benefits and safety of proper sludge management can lead to greater community support and participation. Strengthening policies and regulations to ensure compliance and incentivize best practices is also essential. Robust policies and regulations, with incentives for compliance and penalties for non-compliance, ensure adherence to high standards in sludge management [22].

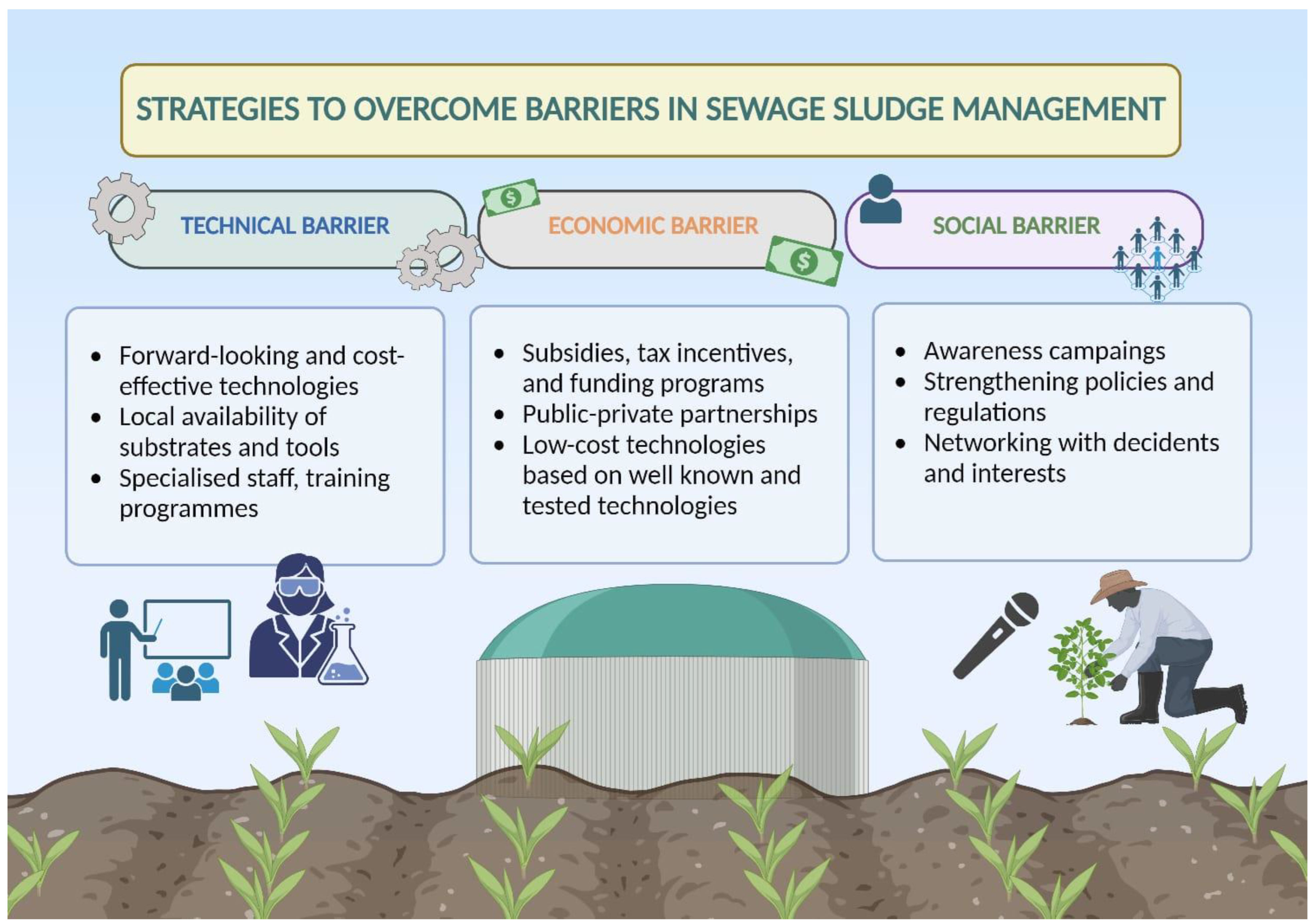

Addressing these barriers requires a multifaceted approach integrating technological innovations, economic incentives, and strong community and institutional engagement (Figure 5).

Figure 5.

Strategies to overcome barriers in sewage sludge management.

8. Conclusions

Wastewater treatment plants can meet “net zero” emission commitments in the future and have ambitions to go even beyond net zero emissions. These include solar photovoltaics, biomass, hydropower, solar thermal, wind power, anaerobic digestion, combined heat and power (CHP), and wastewater heat collection. These initiatives are also possible in partnership with local industry and the community where other sources of organic and biodegradable waste are also generated and there is a demand for next-generation waste products.

In Europe, current challenges in sludge management are driven by several significant trends, including the progressive reduction of landfill availability for biodegradable waste disposal, increased local opposition to agricultural use, anticipated stricter standards for metals and emerging micropollutants under the upcoming European directive, and rising disposal costs for off-site solutions. WWTPs can significantly reduce climate emissions, green growth, and value creation in the region.

The reluctance to use sludge directly for agriculture results from the growing knowledge of the pervasive problem of microplastic contamination and emerging contaminants in sewage sludge worldwide. Despite progress in wastewater treatment, microplastics and recalcitrant or undiscovered contaminants remain a persistent environmental challenge, with potential implications for soil health and food safety when contaminated sludge is applied to agricultural land. The results underscore the urgent need for innovative treatment technologies, improved regulatory frameworks, and public awareness to address this growing problem effectively. As research evolves, these insights will be crucial to informing policies and practices to mitigate microplastic pollution and protect ecosystems. It is therefore important to emphasize that increasing the sustainability of sewage sludge treatment requires multifaceted solutions, that include implementing next-generation advanced technologies, rigorous pollutant monitoring in the interests of health, and transforming the economy into a circular rather than linear economy. By aligning these efforts with public health and environmental safety goals, the challenges of sewage sludge treatment can be transformed into opportunities for resource recovery and energy generation.

Author Contributions

Conceptualization, A.G.; formal analysis, A.G.; investigation and data curation, A.G.; writing—original draft preparation, A.G., M.K., K.C.-M., A.W.-P., A.K., D.S. and D.A.; writing—review and editing, A.G.; visualization, E.B., A.J., D.A. and A.W.-P.; editing and review, A.G.; supervision, management, editing, and review, A.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research in part was funded by the statute subvention of Czestochowa University of Technology (Faculty of Infrastructure and Environment).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author/s.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CE | Circular economy |

| OWtE | Organic waste-to-energy |

| WtE | Waste-to-energy |

| GHGs | Greenhouse gasses |

| RRfW | Resource recovery from waste |

| OSW | Organic solid waste |

| AF | Anaerobic fermentation |

| ETP | Electron transport phosphorylation |

| AD | Anaerobic digestion |

| VFAs | Volatile fatty acids |

| MSW | Municipal solid waste |

| COD | Chemical oxygen demand |

| HTC | Hydrothermal carbonization |

| CHP | combined heat and power systems |

| HTC | Hydrothermal carbonization |

| HTL | Hydrothermal liquefaction |

| BAT | Best available techniques |

| PAHs | polycyclic aromatic hydrocarbons |

| HTV | Hydrothermal vaporization |

| HTG | Hydrothermal gasification |

| DCWG | Supercritical water gasification |

| (EPA) | Environmental Protection Agency |

| PPCPs | pharmaceuticals and personal care products |

| EDCs | endocrine-disrupting chemicals |

| BPA | bisphenol A |

| PFAS | per- and poly-fluoroalkyl substances |

| LC-MS | Liquid Chromatography-Mass Spectrometry |

| GC-MS | Gas Chromatography-Mass Spectrometry |

| UPLC | Ultra-Performance Liquid Chromatography |

| FTIR | Fourier Transform Infrared Spectroscopy |

| PCR | Polymerase Chain Reaction |

| SEM | Scanning Electron Microscopy |

| TEM | Transmission Electron Microscopy |

| QSAR | Quantitative Structure–Activity Relationship |

| RQ | Risk Quotient Method: |

| PNEC | predicted no-effect concentration |

| LCA | Life Cycle Assessment |

| RA | Risk Assessment |

| PERI | potential environmental risk indicator |

| RAC | risk assessment code |

| ERF | environmental risk factor |

| ERA | Environmental Risk Assessment |

| ER | Potential Ecological Risk Factor |

| RI | Risk Index |

| RAC | Risk Assessment Code |

| ICF | Individual Contamination Factor |

| GRI | Global Risk Index |

| IER | Individual Ecological Risk |

| GER | Global Ecological Risk |

| GIS | Geographic Information Systems |

| AI | artificial intelligence |

| PE | population equivalent |

References

- Zuloaga, O.; Navarro, P.; Bizkarguenaga, E.; Iparraguirre, A.; Vallejo, A.; Olivares, M.; Prieto, A. Overview of extraction, clean-up and detection techniques for the determination of organic pollutants in sewage sludge: A review. Anal. Chim. Acta 2012, 736, 7–29. [Google Scholar] [CrossRef]

- Qadir, M.; Drechsel, P.; Jiménez Cisneros, B.; Kim, Y.; Pramanik, A.; Mehta, P.; Olaniyan, O. Global and regional potential of wastewater as a water, nutrient and energy source. Nat. Resour. Forum 2020, 44, 40–51. [Google Scholar] [CrossRef]

- Wei, L.; Zhu, F.; Li, Q.; Xue, C.; Xia, X.; Yu, H.; Zhao, Q.; Jiang, J.; Bai, S. Development, current state and future trends of sludge management in China: Based on exploratory data and CO2-equivaient emissions analysis. Environ. Int. 2020, 144, 106093. [Google Scholar] [CrossRef]

- Han, W.; Jin, P.; Chen, D.; Liu, X.; Jin, H.; Wang, R.; Liu, Y. Resource reclamation of municipal sewage sludge based on local conditions: A case study in Xi’an, China. J. Clean. Prod. 2021, 316, 128189. [Google Scholar] [CrossRef]

- Zhou, G.; Gu, Y.; Yuan, H.; Gong, Y.; Wu, Y. Selecting sustainable technologies for disposal of municipal sewage sludge using a multi-criterion decision-making method: A case study from China. Resour. Conserv. Recycl. 2020, 161, 104881. [Google Scholar] [CrossRef]

- Medaoud, S.; Mokrani, L.; Mezhoud, S.; Ziane, S. Characterization of Stabilised Sewage Sludge for Reuse in Road Pavement. Civ. Environ. Eng. Rep. 2022, 32, 201–217. [Google Scholar] [CrossRef]

- Shanmugam, K.; Gadhamshetty, V.; Tysklind, M.; Bhattacharyya, D.; Upadhyayula, V.K.K. A sustainable performance assessment framework for circular management of municipal wastewater treatment plants. J. Clean. Prod. 2022, 339, 130657. [Google Scholar] [CrossRef]

- Masmoudi, A.; Ben Sik Ali, A.; Dhaouadi, H.; Mhiri, H. Comparison Between Two Solar Drying Techniques of Sewage Sludge: Draining Solar Drying and Drying Bed. Waste Biomass Valorization 2021, 12, 4089–4102. [Google Scholar] [CrossRef]

- Wang, J.; Xu, S.; Zhao, K.; Song, G.; Zhao, S.; Liu, R. Risk control of antibiotics, antibiotic resistance genes (ARGs) and antibiotic resistant bacteria (ARB) during sewage sludge treatment and disposal: A review. Sci. Total Environ. 2023, 877, 162772. [Google Scholar] [CrossRef]

- Sharma, P.; Sharma, A. Heavy metals in ground water affect the human health global challenge. In Computational Intelligence and Applications for Pandemics and Healthcare; IGI Global: Hershey, PA, USA, 2022; pp. 139–158. [Google Scholar]

- Li, S.; Li, R.; Tang, Y.; Chen, G. Microwave-induced heavy metal removal from dewatered biosolids for cost-effective composting. J. Clean. Prod. 2019, 241, 118342. [Google Scholar] [CrossRef]

- Kosowski, P.; Szostek, M.; Pieniazek, R.; Antos, P.; Skrobacz, K.; Piechowiak, T.; Zaczek, A.; Józefczyk, R.; Balawejder, M. New approach for sewage sludge stabilization with ozone. Sustainability 2020, 12, 886. [Google Scholar] [CrossRef]

- Kamizela, T.; Lyng, K.A.; Saxegård, S.; Švédová, B.; Grobelak, A. Bionor sewage sludge technology—Biomass to fertiliser and a soil addition. J. Clean. Prod. 2021, 319, 128655. [Google Scholar] [CrossRef]

- Jafarinejad, S. Comparison of the Full-Scale Municipal Wastewater Treatment Plant Designs Consisting of Modified Bardenpho Process with and Without Membrane Bioreactor for Nutrient Removal: Cost Analysis. In International Conference on Sustainable Development of Water and Environment; Springer International Publishing: Cham, Switzerland, 2021; pp. 47–63. [Google Scholar]

- Buta, M.; Hubeny, J.; Zieliński, W.; Harnisz, M.; Korzeniewska, E. Sewage sludge in agriculture–the effects of selected chemical pollutants and emerging genetic resistance determinants on the quality of soil and crops–a review. Ecotoxicology and Environmental Safety. 2021, 214, 112070. [Google Scholar] [CrossRef] [PubMed]

- Gupta, R.K.; Poddar, B.J.; Nakhate, S.P.; Chavan, A.R.; Singh, A.K.; Purohit, H.J.; Khardenavis, A.A. Role of heterotrophic nitrifiers and aerobic denitrifiers in simultaneous nitrification and denitrification process: A nonconventional nitrogen removal pathway in wastewater treatment. Lett. Appl. Microbiol. 2022, 74, 159–184. [Google Scholar] [CrossRef] [PubMed]

- Ehalt Macedo, H.; Lehner, B.; Nicell, J.; Grill, G.; Li, J.; Limtong, A.; Shakya, R. Distribution and characteristics of wastewater treatment plants within the global river network. Earth Syst. Sci. Data 2022, 14, 559–577. [Google Scholar] [CrossRef]

- Huang, A.; Zhi, D.; Zhou, Y. Current Progress of Microplastics in Sewage Sludge. Handb. Environ. Chem. 2023, 114, 167–187. [Google Scholar]

- Pozzebon, E.A.; Seifert, L. Emerging environmental health risks associated with the land application of biosolids: A scoping review. Environ. Health 2023, 22, 57. [Google Scholar] [CrossRef]

- Fu, X.; Hou, R.; Yang, P.; Qian, S.; Feng, Z.; Chen, Z.; Wang, F.; Yuan, R.; Chen, H.; Zhou, B. Application of external carbon source in heterotrophic denitrification of domestic sewage: A review. Sci. Total Environ. 2022, 817, 153061. [Google Scholar] [CrossRef]

- Available online: https://ec.europa.eu/eurostat/databrowser/view/env_ww_spd/default/table?lang=en&category=env.env_wat.env_nwat (accessed on 18 August 2024).

- Ding, A.; Zhang, R.; Ngo, H.H.; He, X.; Ma, J.; Nan, J.; Li, G. Life cycle assessment of sewage sludge treatment and disposal based on nutrient and energy recovery: A review. Sci. Total Environ. 2021, 769, 144451. [Google Scholar] [CrossRef]

- Hušek, M.; Moško, J.; Pohořelý, M. Sewage sludge treatment methods and P-recovery possibilities: Current state-of-the-art. J. Environ. Manag. 2022, 315, 115090. [Google Scholar] [CrossRef]

- Bolesta, W.; Głodniok, M.; Styszko, K. From Sewage Sludge to the Soil—Transfer of Pharmaceuticals: A Review. Int. J. Environ. Res. Public Health 2022, 19, 10246. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.D.; Upadhyay, A.; Shrivastava, S.; Vivekanand, V. Life-cycle assessment of sewage sludge-based large-scale biogas plant. Bioresour. Technol. 2020, 309, 123373. [Google Scholar] [CrossRef] [PubMed]

- Stahel, W.R. The circular economy. Nature 2016, 531, 435–438. [Google Scholar] [CrossRef] [PubMed]

- Velenturf, A.P.M.; Purnell, P. Principles for a sustainable circular economy. Sustain. Prod. Consum. 2021, 27, 1437–1457. [Google Scholar] [CrossRef]

- Kwapinski, W.; Kolinovic, I.; Leahy, J.J. Sewage Sludge Thermal Treatment Technologies with a Focus on Phosphorus Recovery: A Review. Waste Biomass Valorization 2021, 12, 5837–5852. [Google Scholar] [CrossRef]

- Yu, B.; Luo, J.; Xie, H.; Yang, H.; Chen, S.; Liu, J.; Zhang, R.; Li, Y.Y. Species, Fractions, and Characterization of Phosphorus in Sewage Sludge: A Critical Review from the Perspective of Recovery. Sci. Total Environ. 2021, 786, 147437. [Google Scholar] [CrossRef]

- Neczaj, E.; Grosser, A.; Grobelak, A.; Celary, P.; Singh, B.R. Conversion of Sewage Sludge and Other Biodegradable Waste into High-Value Soil Amendment within a Circular Bioeconomy Perspective. Energies 2021, 14, 6953. [Google Scholar] [CrossRef]

- Lazaroiu, G.; Valaskova, K.; Nica, E.; Durana, P.; Kral, P.; Bartoš, P.; Maroušková, A. Techno-Economic Assessment: Food Emulsion Waste Management. Energies 2020, 13, 4922. [Google Scholar] [CrossRef]

- Wu, D.; Peng, X.; Li, L.; Yang, P.; Peng, Y.; Liu, H.; Wang, X. Commercial biogas plants: Review on operational parameters and guide for performance optimization. Fuel 2021, 303, 121282. [Google Scholar] [CrossRef]

- Balasundaram, G.; Tyagi, V.K.; Lo, S.-L. Environmental Materials and Waste: Circular Economy and Pollution Abatement; Prasad, M.N.V., Ed.; Elsevier: Amsterdam, The Netherlands, 2024; Volume 2, Chapter 9; pp. 289–314. [Google Scholar] [CrossRef]

- Mitraka, G.C.; Kontogiannopoulos, K.N.; Batsioula, M.; Banias, G.F.; Zouboulis, A.I.; Kougias, P.G. A Comprehensive Review on Pretreatment Methods for Enhanced Biogas Production from Sewage Sludge. Energies 2022, 15, 6536. [Google Scholar] [CrossRef]

- Paradelo, R.; Navarro-Pedreño, J.; Glaser, B.; Grobelak, A.; Kowalska, A.; Singh, B.R. Potential and Constraints of Use of Organic Amendments from Agricultural Residues for Improvement of Soil Properties. Sustainability 2024, 16, 158. [Google Scholar] [CrossRef]

- Fernando-Foncillas, C.; Estevez, M.M.; Uellendahl, H.; Varrone, C. Co-management of sewage sludge and other organic wastes: A scandinavian case study. Energies 2021, 14, 3411. [Google Scholar] [CrossRef]