Deformation Analysis of Different Lithium Battery Designs Using the DIC Technique

Abstract

:1. Introduction

1.1. The Most Common Li-Ion Battery Geometries

1.2. Cell Deformation Processes and Investigation Possibilities

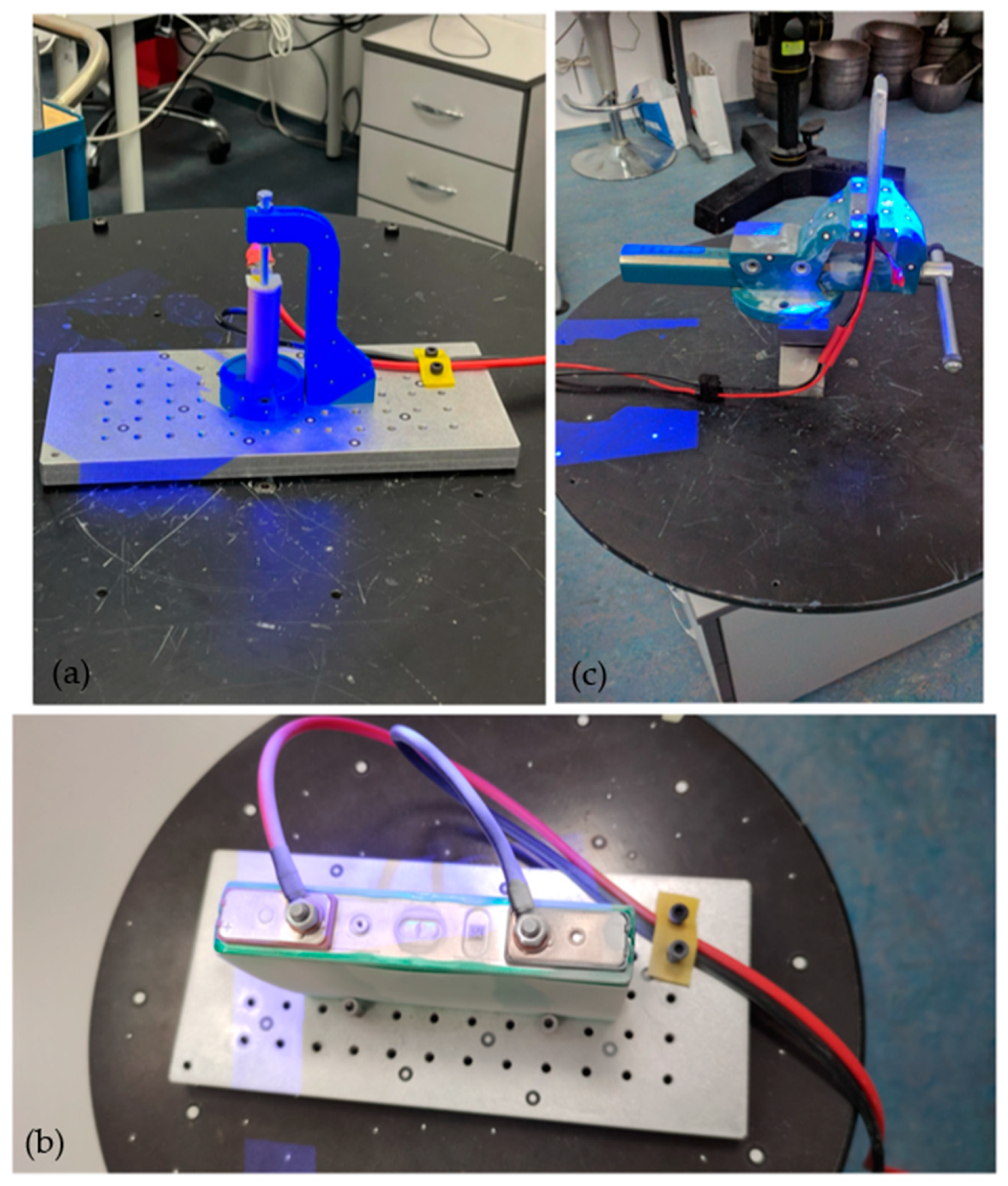

2. Materials and Methods

- Fully charge the battery to achieve a 100% SOC.

- Surface digitalization of the fully charged state. Create the initial CAD model.

- Start loading and digitizing after each interruption.

- Determination of the deviation of the deformation from the initial state. By default, a discharge during a contraction is the expected presence, which subsequently appears in the data—as a sign.

- Calculate the energy extracted during the interruption using the coulomb counting method. Generation of the SoC for the deformation data.

- Achieving a fully discharged state.

- Mapping separate interrupt data and SoC values into a matrix.

- One hour of rest.

- Surface digitalization of the fully discharged state again. Create a starting CAD model.

- Determination of the deviation of the substitution from the initial state. By default, the swelling during charging is the expected presence, which then appears as a positive value in the data.

- Calculate the energy input in the interrupt snapshot using the coulomb counting method. Generation of the SoC for the deformation data.

- Reaching a fully charged state.

- Mapping the separate interrupt data and SoC values into a matrix.

- Evaluation of the results.

3. Results

3.1. Cylindrical-Shaped Battery Analysis

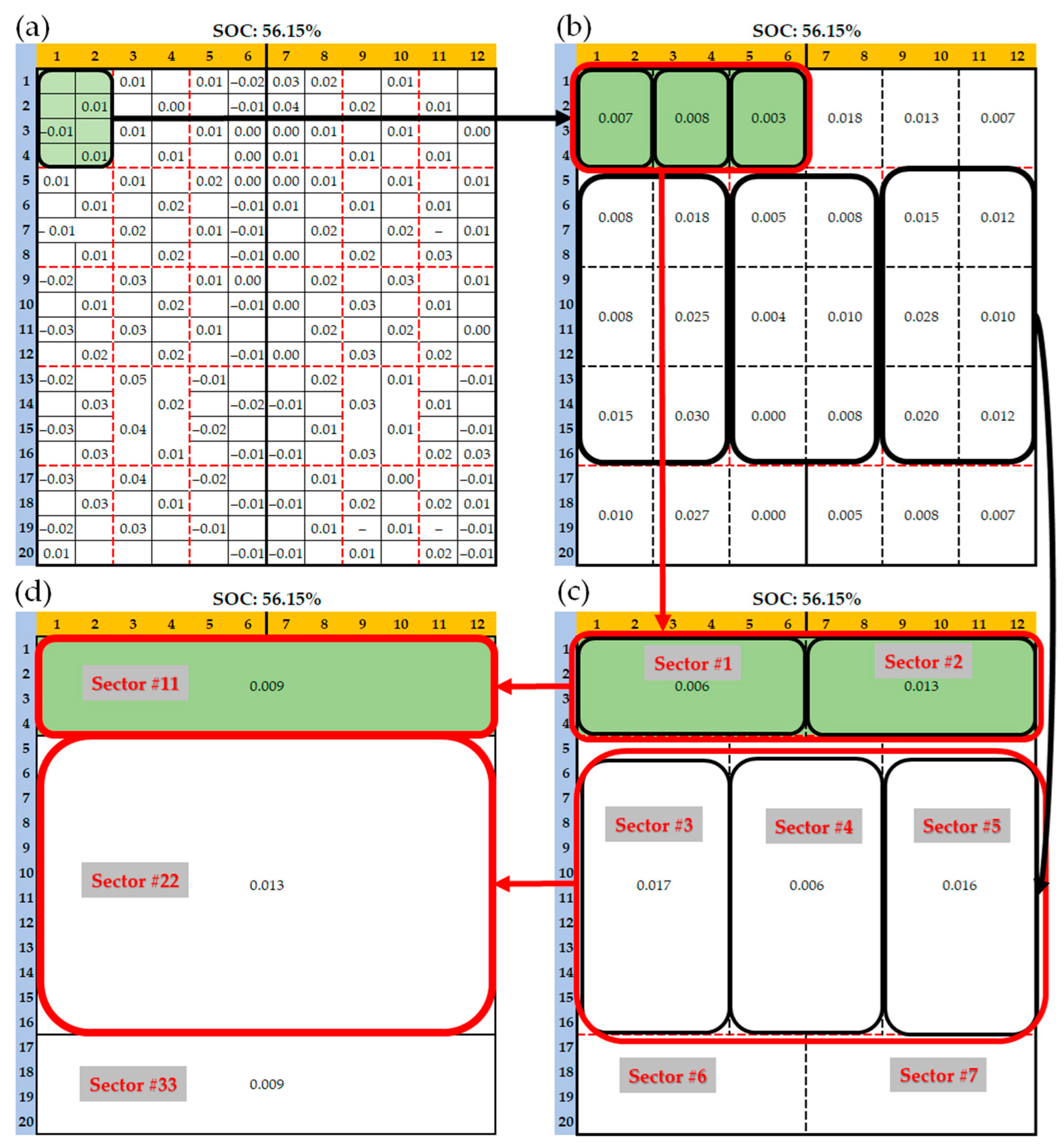

3.2. Prismatic-Shaped Battery Analysis

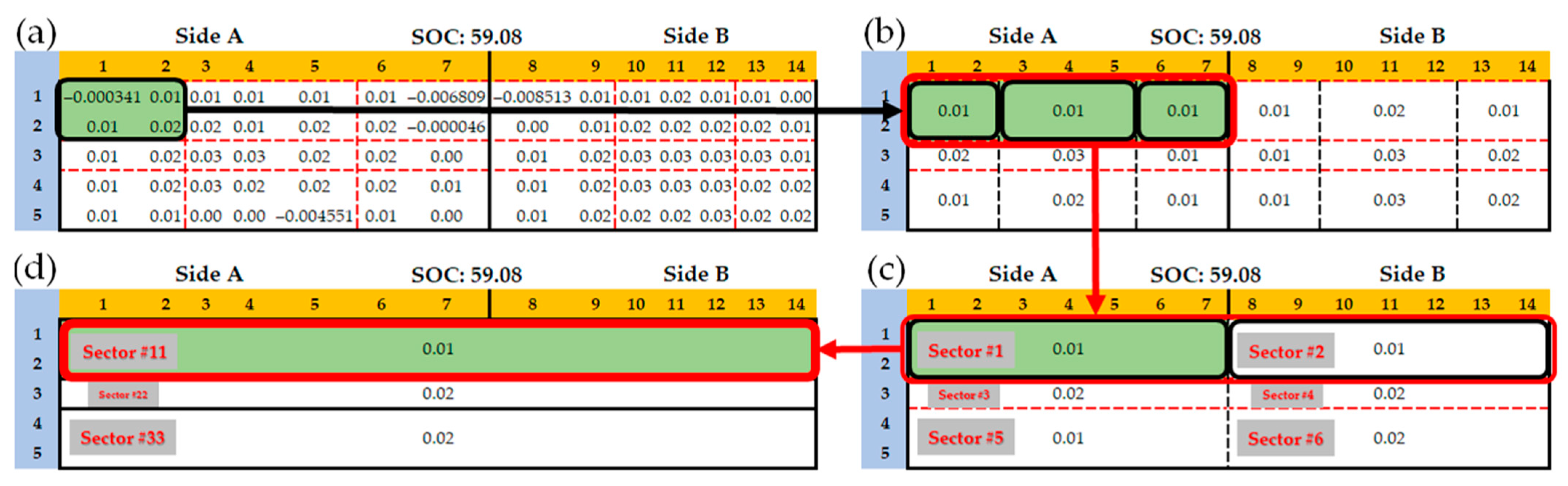

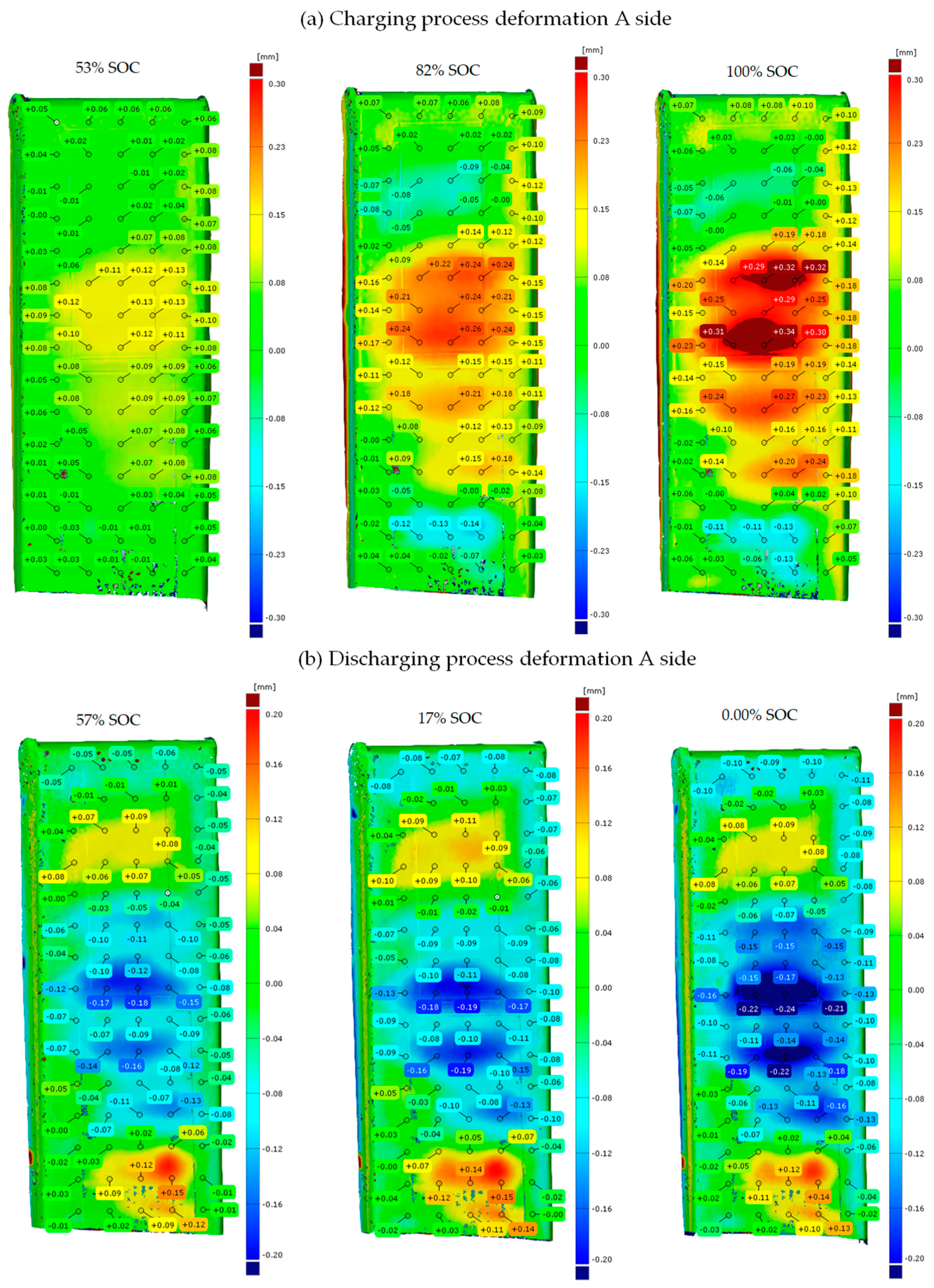

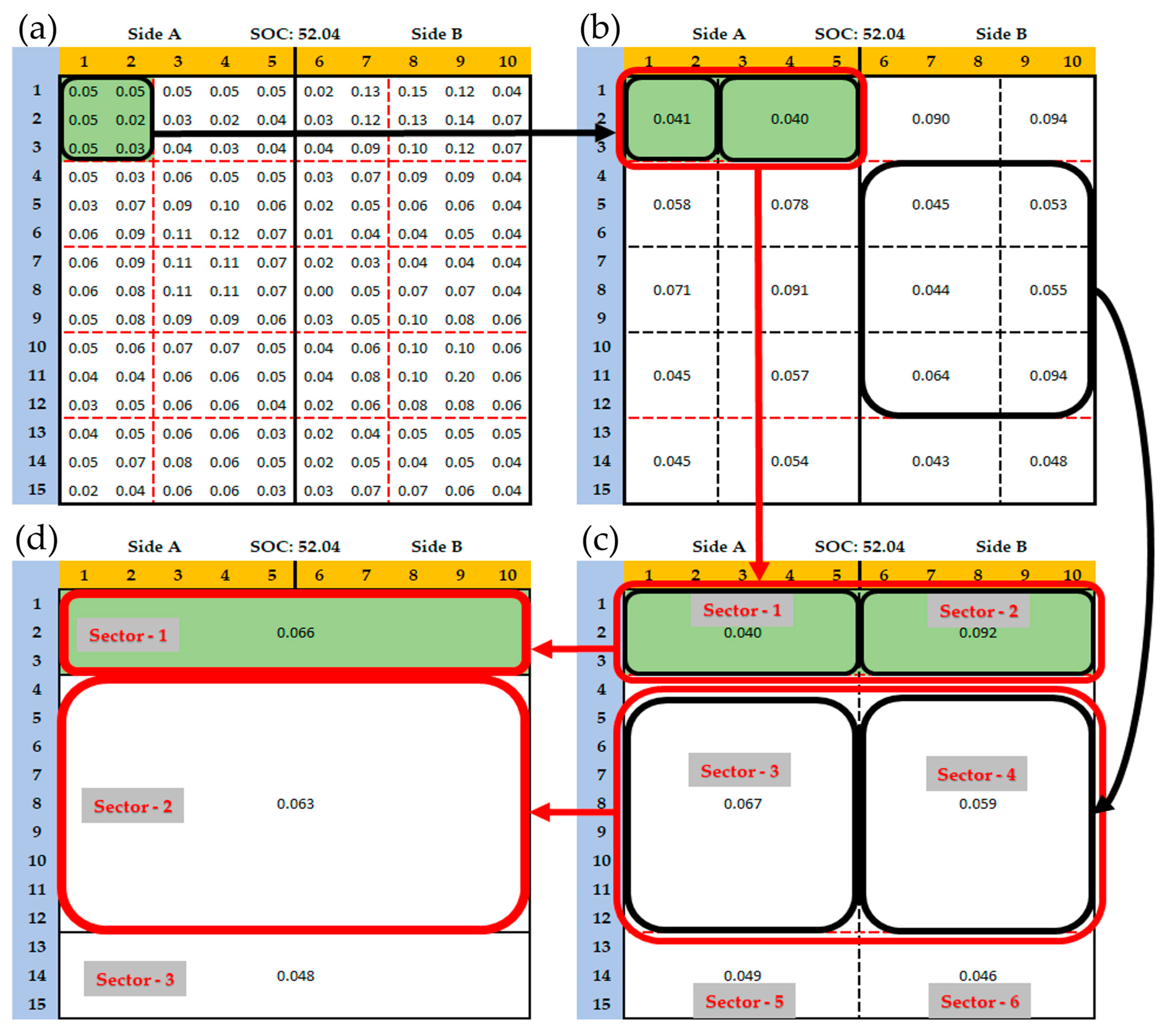

3.3. Pouch-Shaped Battery Analysis

4. Discussion

- Detection and localization of faulty cells during in-vehicle use [54].

- Removal of identified defective battery packs.

- Dismantling of battery packs, and acceptance of worn cells.

- Initiate inspection procedures, carrying out basic safety measurements (short circuit, damage tests).

- Optical inspection by surface digitization and classification of cells that can be clearly identified. The more measurement data entered into the system, the more accurate it will be. This is the fastest way of testing, as no physical connection to the cell is required. Easy to automate.

- Optical testing with battery testing. In this case, the cells are already loaded and charged with special test signals. This procedure is also more likely to be able to provide a status qualification at the beginning.

- ○

- Initially, using complete surface digitization, testing at different SOC levels. The evaluation is compared to the initial state.

- ○

- Subsequently, up to a few images and at a few SOC levels. This requires more information on the cell state.

- Displacement (tactile) sensors and battery testing. In the next phase, the cells would be tested in individual measuring frames or by robots. Here, after loading, the deformation of the cells would be tested with special load/charge signals using distance sensors (if possible).

- The last case is the implementation of distance sensors and the full-capacity test. A full-capacity test is required if the first three quick measurements do not give satisfactory results. This is a long run but gives a high-accuracy result.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

List of Abbreviations

| AE | Acoustic Emission |

| ANN | Artificial Neural Networks |

| BMS | Battery Management Systems |

| BTM | Battery Thermal Management |

| CH | Battery Charging Process |

| CNN | Convolutional Neural Networks |

| CT | Computer Tomography |

| DCH | Battery Discharging process |

| DIC | Digital Image Correlation |

| DoD | Depth of Discharge |

| EIS | Electrochemical Impedance Spectroscopy |

| LDs | Lithium Dendrites |

| Li-ion | Lithium-ion Battery |

| LiPo | Lithium Polymer Battery |

| LSTM | Long Short-Term Memory |

| LFP | Lithium Ferrophosphate |

| ML | Machine Learning |

| NMC | Lithium Nickel Manganese Cobalt Oxide |

| SEI | Solid Electrolyte Interphase |

| SEM | Scanning Electron Microscope |

| SoC | State of Charge |

| SoH | State of Health |

| TR | Thermal Runaway |

References

- Umar, M.; Ji, X.; Kirikkaleli, D.; Alola, A.A. The imperativeness of environmental quality in the United States transportation sector amidst biomass-fossil energy consumption and growth. J. Clean. Prod. 2021, 285, 124863. [Google Scholar] [CrossRef]

- Ramazan, B.; Mussaliyeva, R.; Bitileuova, Z.; Naumov, V.; Taran, I. Choosing the logistics chain structure for deliveries of bulk loads: Case study of the Republic Kazakhstan. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2021, 3, 142–147. [Google Scholar] [CrossRef]

- Nugymanova, G.; Nurgaliyeva, M.; Zhanbirov, Z.; Naumov, V.; Taran, I. Choosing a servicing company’s strategy while interacting with freight owners at the road transport market. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2021, 1, 204–210. [Google Scholar] [CrossRef]

- Olabi, A.G.; Obaideen, K.; Elsaid, K.; Wilberforce, T.; Sayed, E.T.; Maghrabie, H.M.; Abdelkareem, M.A. Assessment of the pre-combustion carbon capture contribution into sustainable development goals SDGs using novel indicators. Renew. Sustain. Energy Rev. 2022, 153, 111710. [Google Scholar] [CrossRef]

- Halttunen, K.; Slade, R.; Staffell, I. What if we never run out of oil? From certainty of “peak oil” to “peak demand”. Energy Res. Soc. Sci. 2022, 85, 102407. [Google Scholar] [CrossRef] [PubMed]

- Fischer, S.; Kocsis Szürke, S. Detection process of energy loss in electric railway vehicles. Facta Univ. Ser. Mech. Eng. 2023, 21, 81–99. [Google Scholar] [CrossRef]

- Fischer, S.; Harangozó, D.; Németh, D.; Kocsis, B.; Sysyn, M.; Kurhan, D.; Brautigam, A. Investigation of heat-affected zones of thermite rail weldings. Facta Univ. Ser. Mech. Eng. 2023. [CrossRef]

- Brautigam, A.; Szalai, S.; Fischer, S. Investigation of the application of austenitic filler metals in paved tracks for the repair of the running surface defects of rails considering field tests. Facta Univ. Ser. Mech. Eng. 2023. [CrossRef]

- Fischer, S. Evaluation of inner shear resistance of layers from mineral granular materials. Facta Univ. Ser. Mech. Eng. 2023. [CrossRef]

- Yang, Y.; Chen, S.; Chen, T.; Huang, L. State of Health Assessment of Lithium-ion Batteries Based on Deep Gaussian Process Regression Considering Heterogeneous Features. J. Energy Storage 2023, 61, 106797. [Google Scholar] [CrossRef]

- Kocsis Szürke, S.; Kovács, G.; Sysyn, M.; Liu, J.; Fischer, S. Numerical Optimization of Battery Heat Management of Electric Vehicles. J. Appl. Comput. Mech. 2023, 9, 1076–1092. [Google Scholar] [CrossRef]

- LaBelle, M.C.; Tóth, G.; Szép, T. Not fit for 55: Prioritizing human well-being in residential energy consumption in the European Union. Energies 2022, 15, 6687. [Google Scholar] [CrossRef]

- Kwade, A.; Haselrieder, W.; Leithoff, R.; Modlinger, A.; Dietrich, F.; Droeder, K. Current status and challenges for automotive battery production technologies. Nat. Energy 2018, 3, 290–300. [Google Scholar] [CrossRef]

- Hemmerling, J.; Schäfer, J.; Jung, T.; Kreher, T.; Ströbel, M.; Gassmann, C.; Günther, J.; Fill, A.; Birke, K.P. Investigation of internal gas pressure and internal temperature of cylindrical Li-ion cells to study thermodynamical and mechanical properties of hard case battery cells. J. Energy Storage 2023, 59, 106444. [Google Scholar] [CrossRef]

- Chavan, S.; Venkateswarlu, B.; Prabakaran, R.; Salman, M.; Joo, S.W.; Choi, G.S.; Kim, S.C. Thermal Runaway and Mitigation Strategies for Electric Vehicle Lithium-Ion Batteries Using Battery Cooling Approach: A Review of the Current Status and Challenges. J. Energy Storage 2023, 72, 108569. [Google Scholar] [CrossRef]

- Tang, H.; Wu, Y.; Cai, Y.; Wang, F.; Lin, Z.; Pei, Y. Design of power lithium battery management system based on digital twin. J. Energy Storage 2022, 47, 103679. [Google Scholar] [CrossRef]

- Karkuzhali, V.; Rangarajan, P.; Tamilselvi, V.; Kavitha, P. Analysis of battery management system issues in electric vehicles. IOP Conf. Ser. Mater. Sci. Eng. 2020, 994, 012013. [Google Scholar] [CrossRef]

- Lin, K.; Chen, Y.; Liu, Y.; Zhang, B. Reliability prediction of battery management system for electric vehicles based on accelerated degradation test: A semi-parametric approach. IEEE Trans. Veh. Technol. 2020, 69, 12694–12704. [Google Scholar] [CrossRef]

- Shu, X.; Yang, W.; Guo, Y.; Wei, K.; Qin, B.; Zhu, G. A reliability study of electric vehicle battery from the perspective of power supply system. J. Power Sources 2020, 451, 227805. [Google Scholar] [CrossRef]

- Waldmann, T.; Scurtu, R.G.; Richter, K.; Wohlfahrt-Mehrens, M. 18650 vs. 21700 Li-ion cells–A direct comparison of electrochemical, thermal, and geometrical properties. J. Power Sources 2020, 472, 228614. [Google Scholar] [CrossRef]

- Yin, L.; Geng, Z.; Chien, Y.C.; Thiringer, T.; Lacey, M.J.; Andersson, A.M.; Brandell, D. Implementing intermittent current interruption into Li-ion cell modelling for improved battery diagnostics. Electrochim. Acta 2022, 427, 140888. [Google Scholar] [CrossRef]

- Montanari, P.M.; Hummes, D.N.; Hunt, J.D.; Hunt, B.B.D.; Schneider, P.S. A Comparative Study of Different Battery Geometries Used in Electric Vehicles. SSRN Electron. J. 2022. [CrossRef]

- Luo, J.; Dai, C.Y.; Wang, Z.; Liu, K.; Mao, W.G.; Fang, D.N.; Chen, X. In-situ measurements of mechanical and volume change of LiCoO2 lithium-ion batteries during repeated charge-discharge cycling by using digital image correlation. Measurement 2016, 94, 759–770. [Google Scholar] [CrossRef]

- Xu, J.; Deshpande, R.D.; Pan, J.; Cheng, Y.T.; Battaglia, V.S. Electrode side reactions, capacity loss and mechanical degradation in lithium-ion batteries. J. Electrochem. Soc. 2015, 162, A2026–A2035. [Google Scholar] [CrossRef]

- Zhao, K.; Pharr, M.; Cai, S.; Vlassak, J.J.; Suo, Z. Large plastic deformation in high-capacity lithium-ion batteries caused by charge and discharge. J. Am. Ceram. Soc. 2011, 94, 226–235. [Google Scholar] [CrossRef]

- Zhao, X.; Tian, Y.; Lun, Z.; Cai, Z.; Chen, T.; Ouyang, B.; Ceder, G. Design Principles for Zero-Strain Li-Ion Cathodes. Joule 2022, 6, 1654–1671. [Google Scholar] [CrossRef]

- Jindal, P.; Bhattacharya, J. Review–understanding the thermal runaway behavior of Li-ion batteries through experimental techniques. J. Electrochem. Soc. 2019, 166, A2165–A2193. [Google Scholar] [CrossRef]

- Yao, X.Y.; Kong, L.; Pecht, M.G. Reliability of cylindrical li-ion battery safety vents. IEEE Access 2020, 8, 101859–101866. [Google Scholar] [CrossRef]

- Sahraei, E.; Campbell, J.; Wierzbicki, T. Modeling and short circuit detection of 18650 Li-ion cells under mechanical abuse conditions. J. Power Sources 2012, 220, 360–372. [Google Scholar] [CrossRef]

- Maleki, H.; Howard, J.N. Effects of overdischarge on performance and thermal stability of a Li-ion cell. J. Power Sources 2006, 160, 1395–1402. [Google Scholar] [CrossRef]

- Gao, Z.; Zhang, X.; Xiao, Y.; Wang, H.; Li, N. Influence of coupling of overcharge state and short-term cycle on the mechanical integrity behavior of 18650 Li-ion batteries subject to lateral compression. Int. J. Hydrogen Energy 2018, 43, 5261–5271. [Google Scholar] [CrossRef]

- Juarez-Robles, D.; Vyas, A.A.; Fear, C.; Jeevarajan, J.A.; Mukherjee, P.P. Overcharge and aging analytics of Li-ion cells. J. Electrochem. Soc. 2020, 167, 090547. [Google Scholar] [CrossRef]

- Kocsis Szürke, S.; Dineva, A.; Szalai, S.; Lakatos, I. Determination of critical deformation regions of a lithium polymer battery by dic measurement and wowa filter. Acta Polytech. Hung. 2022, 19, 113–134. [Google Scholar] [CrossRef]

- Szalai, S.; Kocsis Szürke, S.; Harangozó, D.; Fischer, S. Investigation of deformations of a lithium polymer cell using the Digital Image Correlation Method (DICM). Rep. Mech. Eng. 2022, 3, 116–134. [Google Scholar] [CrossRef]

- Li, A.; Weng, J.; Yuen, A.C.Y.; Wang, W.; Liu, H.; Lee, E.W.M.; Wang, J.; Kook, S.; Yeoh, G.H. Machine Learning Assisted Advanced Battery Thermal Management System: A State-of-the-Art Review. J. Energy Storage 2023, 60, 106688. [Google Scholar] [CrossRef]

- Kim, S.W.; Kwak, E.; Kim, J.H.; Oh, K.Y.; Lee, S. Modeling and Prediction of Lithium-Ion Battery Thermal Runway via Multiphysics-Informed Neural Network. J. Energy Storage 2023, 60, 106654. [Google Scholar] [CrossRef]

- Hao, W.; Yuan, Z.; Li, D.; Zhu, Z.; Jiang, S. Study on mechanical properties and failure mechanism of 18650 Lithium-ion battery using digital image correlation and acoustic emission. J. Energy Storage 2021, 41, 102894. [Google Scholar] [CrossRef]

- Bitzer, B.; Gruhle, A. A new method for detecting lithium plating by measuring the cell thickness. J. Power Sources 2014, 262, 297–302. [Google Scholar] [CrossRef]

- Rieger, B.; Erhard, S.V.; Rumpf, K.; Jossen, A. A new method to model the thickness change of a commercial pouch cell during discharge. J. Electrochem. Soc. 2016, 163, A1566–A1575. [Google Scholar] [CrossRef]

- Xu, J.; Liu, B.; Hu, D. State of charge dependent mechanical integrity behavior of 18650 lithium-ion batteries. Sci. Rep. 2016, 6, 21829. [Google Scholar] [CrossRef]

- Szabo, I.; Sirca, A.A.; Scurtu, L.; Kocsis, L.; Hanches, I.N.; Mariaşiu, F. Comparative study of Li-ion 18650 cylindrical cell under pinch indentation. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1256, 012022. [Google Scholar] [CrossRef]

- Spielbauer, M.; Bohlen, O.; Jossen, A. Safety behavior of mechanically damaged 18650 lithium-ion battery cells. In Proceedings of the Conference: Advanced Battery Power, Muenster, Germany, 29–30 March 2022. [Google Scholar] [CrossRef]

- Wu, Y.; Zhu, S.; Wang, Z.; Zhou, P.; Xie, F.; Zhou, J.; Chen, H.-S.; Song, W.-I.; Fang, D. In-situ investigations of the inhomogeneous strain on the steel case of 18650 silicon/graphite lithium-ion cells. Electrochim. Acta 2021, 367, 137516. [Google Scholar] [CrossRef]

- Pfrang, A.; Kersys, A.; Kriston, A.; Sauer, D.U.; Rahe, C.; Käbitz, S.; Figgemeier, E. Geometrical inhomogeneities as cause of mechanical failure in commercial 18650 lithium ion cells. J. Electrochem. Soc. 2019, 166, A3745–A3752. [Google Scholar] [CrossRef]

- Kong, L.; Hu, X.; Gui, G.; Su, Y.; Pecht, M. Computed tomography analysis of li-ion battery case ruptures. Fire Technol. 2020, 56, 2565–2578. [Google Scholar] [CrossRef]

- Sanad, M.M.S.; Meselhy, M.K.; El-Boraey, H.A. Surface protection of NMC811 cathode material via ZnSnO3 perovskite film for enhanced electrochemical performance in rechargeable Li-ion batteries. Colloids Surf. A Physicochem. Eng. Asp. 2023, 672, 131748. [Google Scholar] [CrossRef]

- Tao, R.; Zhu, J.; Zhang, Y.; Song, W.L.; Chen, H.; Fang, D. Quantifying the 2D anisotropic displacement and strain fields in graphite-based electrode via in situ scanning electron microscopy and digital image correlation. Extrem. Mech. Lett. 2020, 35, 100635. [Google Scholar] [CrossRef]

- Diao, W.; Xu, B.; Pecht, M. Charging induced electrode layer fracturing of 18650 lithium-ion batteries. J. Power Sources 2021, 484, 229260. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Li, D.; Wang, K. State-of-Health Estimation of Lithium-Ion Batteries Based on Electrochemical Impedance Spectroscopy: A Review. Prot. Control Mod. Power Syst. 2023, 8, 1–17. [Google Scholar] [CrossRef]

- Cheng, X.; Pecht, M. In situ stress measurement techniques on li-ion battery electrodes: A review. Energies 2017, 10, 591. [Google Scholar] [CrossRef]

- Al-Alawi, M.K.; Cugley, J.; Hassanin, H. Techno-economic feasibility of retired electric-vehicle batteries repurpose/reuse in second-life applications: A systematic review. Energy Clim. Chang. 2022, 3, 100086. [Google Scholar] [CrossRef]

- Malesa, M.; Malowany, K.; Tomczak, U.; Siwek, B.; Kujawińska, M.; Siemińska-Lewandowska, A. Application of 3D digital image correlation in maintenance and process control in industry. Comput. Ind. 2013, 64, 1301–1315. [Google Scholar] [CrossRef]

- Reddy, M.V.; Mauger, A.; Julien, C.M.; Paolella, A.; Zaghib, K. Brief history of early lithium-battery development. Materials 2020, 13, 1884. [Google Scholar] [CrossRef] [PubMed]

- Kocsis Szürke, S.; Sütheö, G.; Apagyi, A.; Lakatos, I.; Fischer, S. Cell Fault Identification and Localization Procedure for Lithium-Ion Battery System of Electric Vehicles Based on Real Measurement Data. Algorithms 2022, 15, 467. [Google Scholar] [CrossRef]

- Ma, C.; Zeng, Z.; Zhang, H.; Rui, X. A Correction Method for Heat Wave Distortion in Digital Image Correlation Measurements Based on Background-Oriented Schlieren. Appl. Sci. 2019, 9, 3851. [Google Scholar] [CrossRef]

- Hao, W.; Zhu, J.; Zhu, Q.; Chen, L.; Li, L. Displacement field denoising for high-temperature digital image correlation using principal component analysis. Mech. Adv. Mater. Struct. 2016, 24, 830–839. [Google Scholar] [CrossRef]

- Grant, B.; Stone, H.; Withers, P.; Preuss, M. High-temperature strain field measurement using digital image correlation. J. Strain Anal. Eng. Des. 2009, 44, 263–271. [Google Scholar] [CrossRef]

- Blenkinsopp, R.; Roberts, J.; Harland, A.; Sherratt, P.; Smith, P.; Lucas, T. A method for calibrating a digital image correlation system for full-field strain measurements during large deformations. Appl. Sci. 2019, 9, 2828. [Google Scholar] [CrossRef]

- Sebastian, C.; Patterson, E. Calibration of a digital image correlation system. Exp. Tech. 2012, 39, 21–29. [Google Scholar] [CrossRef]

- Kocsis Szürke, S.; Lakatos, I. The lithium polymer battery swelling test with high-precision displacement sensors. In Proceedings of the 20th International Symposium on Electrical Apparatus and Technologies (SIELA 2018), Bourgas, Bulgaria, 3–6 June 2018; p. 8447119. [Google Scholar] [CrossRef]

| Battery Type | Advantages | Disadvantages |

|---|---|---|

| Cylindrical cell | Cells and battery modules can be easily manufactured automatically. | Using cylindrical cells in a stack or module leads to lower energy density (the cell’s circular cross-section does not allow maximum use of the available space). |

| The cylindrical shape creates more space between the cells, allowing optimal heat management. | The large number of cylindrical cells requires many contact arrangements, which increases the complexity of battery–battery assembly. | |

| The circular shape of the battery provides high mechanical stability, as the internal pressure from lateral reactions is evenly distributed. | ||

| Prismatic cell | Optimal use of space in the battery pack. | The electrode and separator sheets at the container edges have a higher resistance against stress. |

| The deformation of prismatic cells is not significant. | ||

| Higher nominal capacity (Ah) and energy density can generally be achieved. | Prismatic cells can typically be more expensive to manufacture than other cell types. | |

| Pouch cell | It has the lowest weight of all these shapes. | Most pouch-type cells need to be individually customized, which increases manufacturing costs. |

| Flexible design (complex shapes can be created). | Extra protection against external influences must be provided. |

| SOC [%] | CH/DCH | Deformation [mm] | Variance Range [mm] | Deviation [mm] | |

|---|---|---|---|---|---|

| 0–25 | CH | 0.017 | 0.000 | 0.080 | 0.010 |

| DCH | −0.052 | −0.060 | 0.060 | 0.020 | |

| 25–50 | CH | 0.033 | 0.000 | 0.080 | 0.017 |

| DCH | −0.033 | −0.044 | 0.050 | 0.005 | |

| 50–75 | CH | 0.050 | 0.000 | 0.080 | 0.010 |

| DCH | −0.025 | −0.030 | 0.050 | 0.004 | |

| 75–100 | CH | 0.060 | 0.000 | 0.050 | 0.010 |

| DCH | −0.014 | −0.060 | 0.060 | 0.000 | |

| SOC [%] | CH/ DCH | Sec_1 | Sec_2 | Sec_3 | Sec_4 | Sec_5 | Sec_6 | Sec_7 | Variance Range [mm] | Deviation [mm] | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0–25 | CH | 0.012 | 0.008 | 0.008 | 0.006 | 0.012 | 0.010 | 0.007 | 0.006 | 0.012 | 0.002 |

| DCH | 0.008 | 0.026 | 0.021 | −0.011 | 0.021 | −0.003 | −0.008 | −0.011 | 0.026 | 0.015 | |

| 25–50 | CH | 0.012 | 0.009 | 0.012 | 0.006 | 0.015 | 0.013 | 0.011 | 0.006 | 0.015 | 0.003 |

| DCH | 0.007 | 0.025 | 0.016 | −0.009 | 0.011 | −0.002 | –0.006 | −0.009 | 0.025 | 0.012 | |

| 50–75 | CH | 0.021 | 0.011 | 0.030 | 0.012 | 0.018 | 0.028 | 0.012 | 0.011 | 0.030 | 0.008 |

| DCH | 0.006 | 0.021 | 0.015 | −0.007 | 0.008 | −0.002 | −0.004 | −0.007 | 0.021 | 0.010 | |

| 75–100 | CH | 0.030 | 0.016 | 0.036 | 0.016 | 0.015 | 0.033 | 0.016 | 0.015 | 0.036 | 0.010 |

| DCH | 0.003 | 0.012 | 0.012 | 0.001 | 0.015 | 0.004 | 0.004 | 0.001 | 0.015 | 0.006 | |

| SOC [%] | CH/DCH | Sec_1 | Sec_2 | Sec_3 | Variance Range [mm] | Deviation [mm] | |

|---|---|---|---|---|---|---|---|

| 0–25 | CH | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.000 |

| DCH | 0.004 | 0.003 | 0.000 | 0.000 | 0.004 | 0.002 | |

| 25–50 | CH | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 | 0.000 |

| DCH | 0.002 | 0.001 | 0.000 | 0.000 | 0.002 | 0.001 | |

| 50–75 | CH | 0.004 | 0.005 | 0.005 | 0.004 | 0.005 | 0.001 |

| DCH | 0.001 | 0.001 | 0.000 | 0.000 | 0.001 | 0.001 | |

| 75–100 | CH | 0.005 | 0.010 | 0.010 | 0.005 | 0.010 | 0.003 |

| DCH | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | |

| SOC [%] | CH/DCH | Deformation [mm] | Variance Range [mm] | Deviation [mm] | |

|---|---|---|---|---|---|

| 0–25 | CH | 0.022 | 0.000 | 0.038 | 0.016 |

| DCH | −0.020 | −0.037 | 0.002 | 0.005 | |

| 25–50 | CH | 0.032 | 0.013 | 0.038 | 0.004 |

| DCH | −0.019 | −0.029 | 0.007 | 0.003 | |

| 50–75 | CH | 0.043 | 0.017 | 0.050 | 0.002 |

| DCH | −0.018 | −0.027 | 0.008 | 0.004 | |

| 75–100 | CH | 0.049 | 0.016 | 0.055 | 0.003 |

| DCH | −0.016 | −0.030 | 0.008 | 0.011 | |

| SOC [%] | CH/ DCH | Sec_1 | Sec_2 | Sec_3 | Sec_4 | Sec_5 | Sec_6 | Variance Range [mm] | Deviation [mm] | |

|---|---|---|---|---|---|---|---|---|---|---|

| 0–25 | CH | 0.006 | 0.005 | 0.010 | 0.009 | 0.006 | 0.010 | 0.005 | 0.010 | 0.002 |

| DCH | −0.011 | −0.008 | 0.010 | 0.001 | 0.006 | 0.007 | −0.011 | 0.010 | 0.009 | |

| 25–50 | CH | 0.010 | 0.010 | 0.018 | 0.018 | 0.011 | 0.019 | 0.010 | 0.019 | 0.004 |

| DCH | −0.009 | −0.007 | 0.007 | 0.003 | 0.006 | 0.007 | −0.009 | 0.007 | 0.007 | |

| 50–75 | CH | 0.025 | 0.022 | 0.020 | 0.023 | 0.012 | 0.020 | 0.012 | 0.025 | 0.005 |

| DCH | −0.008 | −0.007 | 0.004 | 0.003 | 0.005 | 0.006 | −0.008 | 0.006 | 0.006 | |

| 75–100 | CH | 0.045 | 0.033 | 0.026 | 0.033 | 0.013 | 0.030 | 0.013 | 0.045 | 0.010 |

| DCH | −0.006 | −0.006 | 0.001 | 0.000 | 0.002 | 0.002 | −0.006 | 0.002 | 0.004 | |

| SOC [%] | CH/DCH | Sec_1 | Sec_2 | Sec_3 | Variance Range [mm] | Deviation [mm] | |

|---|---|---|---|---|---|---|---|

| 0–25 | CH | 0.006 | 0.009 | 0.008 | 0.006 | 0.009 | 0.002 |

| DCH | −0.007 | 0.004 | 0.008 | −0.007 | 0.008 | 0.008 | |

| 25–50 | CH | 0.010 | 0.018 | 0.015 | 0.010 | 0.018 | 0.004 |

| DCH | −0.005 | 0.003 | 0.007 | −0.005 | 0.007 | 0.006 | |

| 50–75 | CH | 0.018 | 0.020 | 0.016 | 0.016 | 0.020 | 0.002 |

| DCH | −0.005 | 0.003 | 0.005 | −0.005 | 0.005 | 0.005 | |

| 75–100 | CH | 0.022 | 0.026 | 0.020 | 0.020 | 0.026 | 0.003 |

| DCH | −0.004 | 0.001 | 0.002 | −0.004 | 0.002 | 0.003 | |

| SOC [%] | CH/DCH | Deformation [mm] | Variance Range [mm] | Deviation [mm] | |

|---|---|---|---|---|---|

| 0–25 | CH | 0.089 | 0.036 | 0.127 | 0.047 |

| DCH | −0.19 | −0.17 | −0.2 | 0.013 | |

| 25–50 | CH | 0.143 | 0.104 | 0.171 | 0.035 |

| DCH | −0.17 | −0.16 | −0.17 | 0.008 | |

| 50–75 | CH | 0.192 | 0.139 | 0.23 | 0.047 |

| DCH | −0.13 | –0.11 | −0.15 | 0.023 | |

| 75–100 | CH | 0.235 | 0.225 | 0.25 | 0.013 |

| DCH | −0.08 | –0.04 | −0.11 | 0.035 | |

| SOC [%] | CH/DCH | Sec_1 | Sec_2 | Sec_3 | Sec_4 | Sec_5 | Sec_6 | Variance Range [mm] | Deviation [mm] | |

|---|---|---|---|---|---|---|---|---|---|---|

| 0–25 | CH | 0.013 | 0.021 | 0.031 | 0.032 | 0.013 | 0.017 | 0.013 | 0.032 | 0.008 |

| DCH | −0.069 | −0.058 | −0.064 | −0.060 | 0.011 | 0.024 | −0.069 | 0.024 | 0.042 | |

| 25–50 | CH | 0.036 | 0.043 | 0.061 | 0.061 | 0.027 | 0.030 | 0.027 | 0.061 | 0.015 |

| DCH | −0.043 | −0.035 | −0.049 | −0.023 | –0.016 | 0.017 | −0.049 | 0.017 | 0.024 | |

| 50–75 | CH | 0.057 | 0.077 | 0.089 | 0.080 | 0.056 | 0.040 | 0.040 | 0.089 | 0.018 |

| DCH | −0.043 | −0.025 | −0.039 | −0.045 | −0.014 | 0.015 | −0.045 | 0.015 | 0.023 | |

| 75–100 | CH | 0.081 | 0.076 | 0.104 | 0.099 | 0.071 | 0.024 | 0.024 | 0.104 | 0.029 |

| DCH | −0.019 | −0.009 | −0.020 | −0.028 | –0.004 | 0.017 | −0.028 | 0.017 | 0.016 | |

| SOC [%] | CH/DCH | Sec_1 | Sec_2 | Sec_3 | Variance Range [mm] | Deviation [mm] | |

|---|---|---|---|---|---|---|---|

| 0–25 | CH | 0.024 | 0.031 | 0.016 | 0.005 | 0.048 | 0.015 |

| DCH | −0.063 | −0.061 | −0.006 | −0.075 | −0.003 | 0.029 | |

| 25–50 | CH | 0.048 | 0.059 | 0.031 | 0.022 | 0.071 | 0.018 |

| DCH | −0.052 | −0.055 | 0.000 | −0.061 | 0.003 | 0.027 | |

| 50–75 | CH | 0.072 | 0.085 | 0.048 | 0.042 | 0.100 | 0.019 |

| DCH | −0.034 | −0.042 | 0.000 | −0.050 | 0.011 | 0.021 | |

| 75–100 | CH | 0.082 | 0.105 | 0.046 | 0.042 | 0.110 | 0.026 |

| DCH | −0.014 | −0.024 | 0.007 | −0.033 | 0.011 | 0.015 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kocsis Szürke, S.; Szabó, M.; Szalai, S.; Fischer, S. Deformation Analysis of Different Lithium Battery Designs Using the DIC Technique. Energies 2024, 17, 323. https://doi.org/10.3390/en17020323

Kocsis Szürke S, Szabó M, Szalai S, Fischer S. Deformation Analysis of Different Lithium Battery Designs Using the DIC Technique. Energies. 2024; 17(2):323. https://doi.org/10.3390/en17020323

Chicago/Turabian StyleKocsis Szürke, Szabolcs, Mátyás Szabó, Szabolcs Szalai, and Szabolcs Fischer. 2024. "Deformation Analysis of Different Lithium Battery Designs Using the DIC Technique" Energies 17, no. 2: 323. https://doi.org/10.3390/en17020323

APA StyleKocsis Szürke, S., Szabó, M., Szalai, S., & Fischer, S. (2024). Deformation Analysis of Different Lithium Battery Designs Using the DIC Technique. Energies, 17(2), 323. https://doi.org/10.3390/en17020323