Abstract

Existing research on direct interspecies electron transfer (DIET) has predominantly focused on the types and concentrations of conductive materials across diverse anaerobic digestion. However, insufficient understanding of the impact of residence time, a critical economic factor, prompted this investigation. Magnetite, a conductive material, was introduced into the anaerobic digestion of food wastewater, leading to a significant increase in ultimate methane production (Bu) with 25 mM-Fe3O4 (p < 0.05). Despite a subsequent decline in methane production efficiency from 388.9% to 7.1% over the 15- to 65-day anaerobic digestion period, the initial impact of increased methane production due to magnetite addition was evident. Control’s maximum methane production rate (Rm) was 27.5 mL/day, reaching its highest point at 37.4 mL/day with 15 mM-Fe3O4, accompanied by a noteworthy 56.6% reduction in the attainment day of Rm (Rm-day), shortened to 8.2 days. Even with 100 mM-Fe3O4, while Bu showed no significant difference, Rm-day exhibited a substantial reduction of 22.8. Despite the lower overall anaerobic digestion efficiency under some magnetite input conditions, this study confirmed a substantial shortening of Rm-day, suggesting that the DIET mechanism induced by conductive materials such as magnetite could reduce the residence time in continuous-type anaerobic reactors, contributing to improved economic feasibility.

1. Introduction

The transferable energy potential of food waste in Korea for 2020 has been quantified as 419,116 TOE/year, constituting 55.2% of the total energy potential derived from organic biomass generated in urban areas [1]. The annual generation of food waste in Korea is 5,160,000 tons, and over 95% of this volume is recycled through methods such as conversion into animal feed or compost [2]. Notably, a substantial volume of food wastewater is produced during recycling processes associated with food waste. In Korea, food wastewater is directed to anaerobic digesters, where it serves as a raw material for biogas production.

In 2021, the operational count of biogas production facilities in Korea is 110 [3]. Food wastewater, distinguished by its heightened organic matter content and accelerated decomposition rate compared to livestock manure and sewage sludge, has emerged as a commendable feedstock for anaerobic digestion. The anaerobic digestion of food wastewater offers advantages in odor control over alternative physical, chemical, and biological treatment methods. Moreover, the co-digestion of food wastewater with livestock manure facilitates the utilization of the resultant digestate as a fertilizer for farmland without requiring supplementary wastewater treatment. Consequently, this integrated approach is acknowledged for its rationality and economic viability in renewable energy production and the circular utilization of resources [4].

Anaerobic digestion is a biological treatment method in which anaerobic microorganisms facilitate the conversion of organic substrates into methane. This process occurs through a sequence of hydrolysis, acidogenesis, acetogenesis, and methanogenesis reactions under anaerobic conditions devoid of oxygen [5]. The anaerobic microorganisms engaged in this intricate process operate in a syntrophic (cross-feeding) manner, wherein the product of one microbial reaction serves as a substrate for the subsequent microbial reaction. Notably, symbiotic relationships, especially in terms of nutritional interactions between acetic acid-producing and methanogenic microorganisms, play an important role in enhancing the operational stability of anaerobic digesters. This symbiosis elevates the activity of anaerobic microorganisms while simultaneously preserving the equilibrium of reaction rates among methane-producing microorganisms [6]. Within the context of acetogenesis, the electrons liberated during the generation of H2 and formate serve as crucial components of the syntrophic mechanism of methane production. Indirect interspecies electron transfer (IIET) facilitates methane production during anaerobic digestion process [7]. The effectiveness of IIET within an anaerobic digester is notably influenced by shifts in environmental conditions, including variations in the pH, temperature, organic loading rate (OLR), and volatile fatty acids (VFAs) concentrations. This sensitivity is particularly evident when utilizing food wastewater as a substrate for anaerobic digestion, given its distinctive characteristics, such as low pH, elevated organic loading, heightened VFAs concentration, and increased salt content (Na+, Ca2+, K+, Mg2+) [8]. The physicochemical properties of food wastewater can induce rapid environmental fluctuations in anaerobic digesters. These abrupt changes in the anaerobic digester environment, arising from the unique properties of food wastewater, have given rise to challenges in the IIET mechanism. An imbalance in the reaction rates among anaerobic microorganisms results in the accumulation of VFAs within the digester [9]. Additionally, the decrease in pH adversely affects the efficiency of methane conversion to organic matter.

Consequently, the intricate interplay between these physicochemical characteristics poses challenges in maintaining optimal conditions for the IIET mechanism, thereby compromising the overall methane conversion efficiency of organic matter in the anaerobic digestion process [10,11,12]. Recent studies have focused on direct interspecies electron transfer (DIET) to enhance the stability of anaerobic digesters and boost the methane production efficiency. This involves introducing conductive materials into the digester to facilitate electron transfer between acetic acid-producing (electron donor) species and methane-producing (electron accepting) species with the aim of improving the overall operational efficiency [13,14]. Magnetite, known for its high conductivity, has been reported to improve the efficiency of DIET among microorganisms engaged in syntrophic relationships when introduced into anaerobic digester. This is attributed to the promotion of syntrophic interactions between microorganisms, resulting in enhanced electron transfer efficiency.

The conductive materials that facilitate DIET include iron-based (magnetite, hematite, ferrihydrite, etc.) and carbon-based (GAC, biochar, graphite, etc.) substances. Numerous studies have indicated that their incorporation promotes electron transfer among anaerobic microorganisms, mitigates VFAs accumulation, and augments the decomposition rate of organic matter within anaerobic digesters [15,16,17,18]. Furthermore, conductive materials contribute to the stability of anaerobic digestion by providing a reaction surface for biofilm formation by anaerobic microorganisms [19]. Materials such as magnetite have been reported to enhance the anaerobic digestion environment, mitigate the inhibitory impact of salt on food wastewater through adsorption reactions, and alleviate the inhibitory effects of hydrogen sulfide [20,21].

Studies on enhancing anaerobic digestion efficiency through DIET have exhibited varied outcomes influenced by factors such as the conductive material type, input concentration, and raw materials. While some studies indicate improved efficiencies, others suggest reductions [22,23,24,25].

Thus far, DIET research has predominantly focused on assessing methane production efficiency with respect to the addition of conductive materials. However, anaerobic digesters typically require extended residence times that frequently exceed 30 days. Studies on DIET using magnetite have reported research aimed at reducing lag growth times, improving methane production rates, and increasing methane yields. These findings suggest a significant enhancement of conventional anaerobic digestion through the supplementation of conductive substances. This suggests a potential for substantial improvement in anaerobic digestion through the addition of conductive substances [26]. From an economic standpoint, assessing the efficiency of anaerobic digestion is imperative, considering not only the impact on methane production enhancement, but also the potential benefits derived from shortening residence time. In the anaerobic digestion process, residence time is an important design factor that affects the economic feasibility of the initial installation cost. Additionally, shortening the residence time has the advantage of reducing the volume of the anaerobic digester and significantly improving its operating stability of the anaerobic digester. Nevertheless, the assessment of the impact of anaerobic digestion following the inclusion of conductive materials has predominantly focused on the biochemical methane potential (Bu) and maximum methane production rate (Rm). However, research on the potential impact of reduced residence time in this context is lacking. Therefore, this study aimed to analyze the influence of shortened residence time, a critical factor affecting the economic feasibility and operational stability of anaerobic digestion digesters. Concurrently, we investigated the impact of introducing conductive materials on methane production efficiency. Specifically, an assessment index was developed, focusing on the time to attain the maximum methane production rate during batch anaerobic digestion of food wastewater with varying inputs of conductive material (magnetite, Fe3O4).

2. Materials and Methods

2.1. Materials

The food wastewater, which used as a raw material for the batch anaerobic reactor in this study, was collected from the liquid food wastewater generated during the first solid–liquid separation process at a food waste composting facility located in Icheon City, South Korea. The analysis results of the chemical properties of the collected food wastewater are shown in Table 1; the SCOD in the food wastewater accounted for 85.3% of TCOD.

Table 1.

Chemical composition of food wastewater and inoculum used in the biochemical methane potential assay.

2.2. Biochemical Methane Potential (BMP) Assay

The study utilized inoculum sourced from a 20 m3/day mesophilic (38 °C) anaerobic digester in Icheon, South Korea. The digester processed a mixture of pig slurry and food wastewater (7:3, w/w). After two weeks of anaerobic storage at 38 °C, the inoculum was used in a biochemical methane potential (BMP) assay, ensuring the removal of any residual biodegradable fraction. Table 1 presents the chemical analysis of inoculum. Employing a 160 mL serum bottle as a batch-type anaerobic reactor, the BMP assay incorporated 75 mL of inoculum. Food wastewater was utilized as the substrate in the anaerobic batch reactors, maintaining a consistent substrate to inoculum ratio of 0.5 (g-VSsubstrate/g-VSinoculum). The volume of the food wastewater used in the experiment was 9.28 mL. Magnetite (Fe3O4) powder (diameter < 5 μm) (Samchun, Seoul, Republic of Korea, CAS No. 1317-61-9) was used to facilitate the DIET. Various concentrations of magnetite (5, 15, 25, 40, 70, and 100 mM-Fe3O4) were introduced, equivalent to 1.2, 3.5, 5.8, 9.3, 16.2, and 23.2 g-Fe3O4/L concerning the reactor’s effective volume. This approach allowed for the systematic exploration of DIET efficiency in the different concentration of magnetite. The control group was prepared without magnetite addition. Additionally, a blank test was conducted in the batch anaerobic reactor with 75 mL of inoculum, excluding food wastewater, to account for the inoculum-generated biogas. Both the sample and blank anaerobic batch reactors were replicated three times to ensure robust experimental consistency. Operating under mesophilic conditions at 38 °C, the batch-type anaerobic reactor facilitated anaerobic digestion of 65 days. The reactor was sealed with a butyl rubber septum stopper and aluminum crimp seal. Daily measurements of biogas generation and gas concentration were conducted. The measurement intervals were flexibly adjusted to accommodate the varying biogas production rates.

The biogas was quantified using a water-column-type gas meter. The cumulative methane production curve was derived by converting the generated biogas to dry gas volume under standard conditions (0 °C, 1 atm), as expressed in Equation (1). In Equation (1), Vdry gas denotes gas volume at standard conditions, with T as the anaerobic reactor’s operating temperature (38 °C). Vwet gas represents the volume of wet gas at reactor temperature. P stands for atmospheric pressure during gas measurement (assumed as 760 mmHg), and PT is the saturated water vapor pressure (calculated for 38 °C in this study) [27].

2.3. Analysis of Reaction Kinetics

This investigation scrutinized the methane production kinetics concerning magnetite input using the cumulative methane production [P(t)] curve derived from the BMP assay. The methane production rate [P’(t)] curve, obtained through the initial differentiation of the cumulative methane production curve, revealed the peak value as the maximum methane production rate (Rm). To evaluate the reduction efficiency of residence time, we determined the time (Rm-day) to achieve the maximum methane production rate (Rm) from the methane production acceleration [P’(t)] curve generated by the second differentiation of the methane production rate [P’’(t)]. The point of zero methane production acceleration is defined as Rm-day and serves as a key index for residence time reduction [28].

2.4. Chemical Analysis

Chemical properties and organic composition evaluation involved analyses of pH, alkalinity, total solid (TS), volatile solid (VS), total chemical oxygen demand (TCOD), soluble chemical oxygen demand (SCOD), total Kjeldahl nitrogen (TKN), ammonium nitrogen (NH4+-N), and total volatile fatty acids (TVFAs) [29]. The gas samples were subjected to CH4 and CO2 concentration determination using a Clarus 680 gas chromatograph (PerkinElmer, Inc., Waltham, MA, USA) equipped with a thermal conductivity detector (TCD) and a HayeSepQ packed column (CRS, Inc., Louisville, KY, USA). Helium was used as the carrier gas at a flow rate of 5 mL/min. The injector, oven, and detector were set to 150, 90, and 150 °C, respectively [30].

2.5. Statistical Analysis

The results were statistically analyzed using the general linear model (GLM) procedure in SASⓇ (version 9.4; SAS Institute Inc., Cary, NC, USA). Duncan’s multiple range test revealed significant differences (p < 0.05) in the means between treatments, providing a robust assessment of the experimental outcomes [31].

3. Results and Discussion

3.1. Biochemical Methane Potential Assay

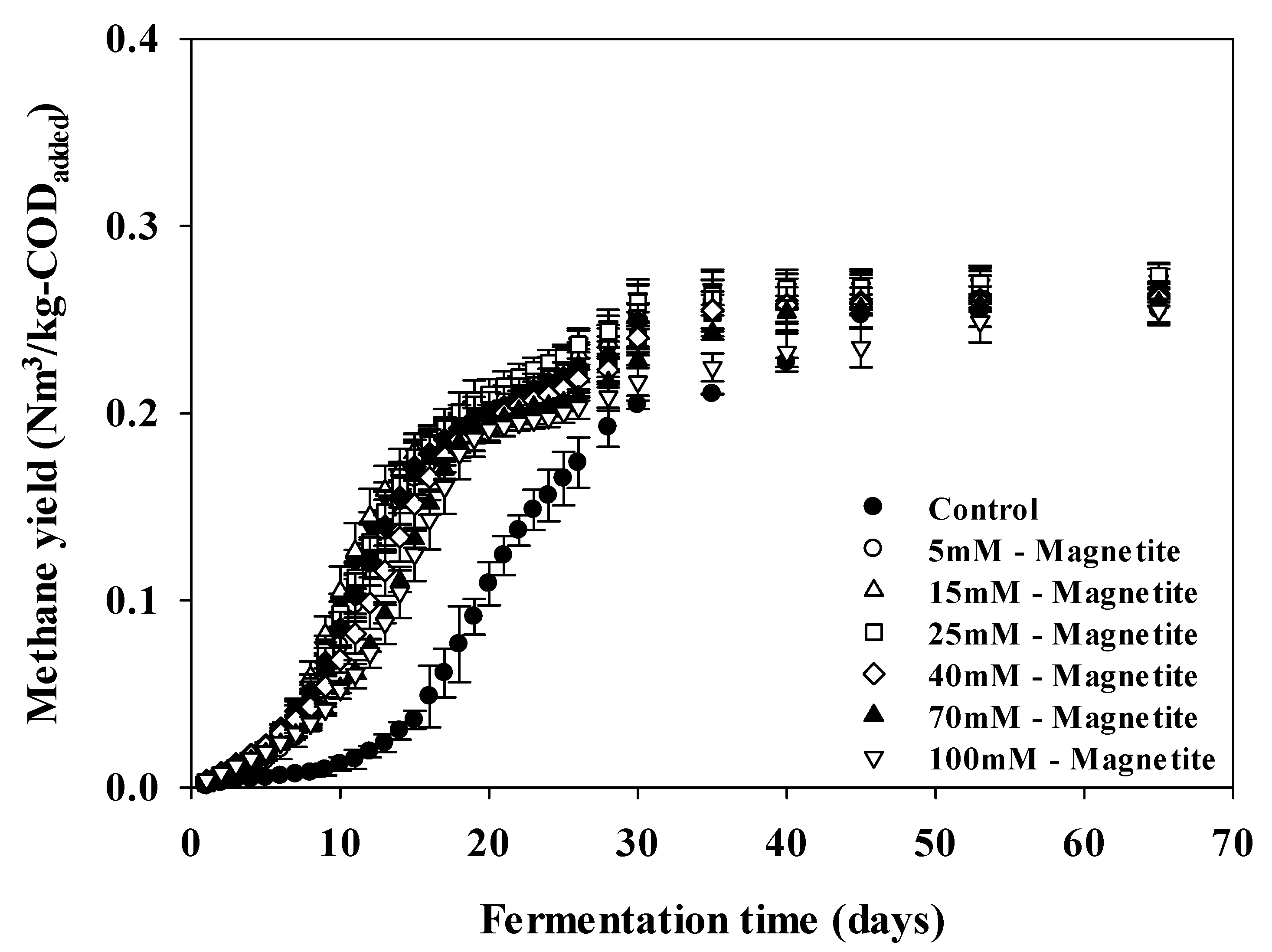

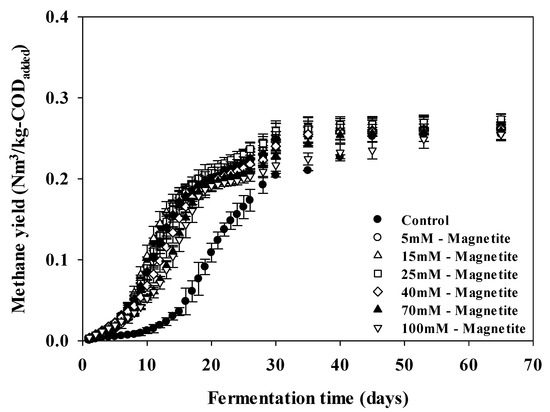

The biochemical methane potential (Bu) of food wastewater by magnetite input concentration is shown in Table 2, and the cumulative methane production curve [P(t)] during the operation period of the batch anaerobic reactor is shown in Figure 1. During the first 15 days of batch anaerobic reactor operation, the control exhibited a methane production efficiency of 0.036 Nm3/kg-CODadded. The introduction of magnetite significantly enhanced the methane production efficiency, reaching its peak at 0.180 Nm3/kg-CODadded with a magnetite input of 15 mM-Fe3O4. However, beyond this concentration, the methane production efficiency declined, reaching 0.124 Nm3/kg-CODadded with a magnetite input of 100 mM-Fe3O4. After extending the operation period to 20 days, the control yielded a methane production efficiency of 0.109 Nm3/kg-CODadded. Notably, the application of magnetite further optimized the efficiency, with a peak observed at 0.210 Nm3/kg-CODadded with a magnetite input of 25 mM-Fe3O4. However, similar to the 15-day period, the efficiency gradually decreased with increasing magnetite input, stabilizing at 0.191 Nm3/kg-CODadded to 100 mM-Fe3O4. The methane production efficiency trends observed during the 30–65-day period after batch reactor operation showed consistent patterns. This period demonstrates that the impact of magnetite input on methane production efficiency remained stable. Finally, over the 65-day batch anaerobic reactor operation period, the Bu of the control was 0.255 Nm3/kg-CODadded. As the concentration of magnetite increased, there was a significant increase in Bu, reaching 0.273 Nm3/kg-CODadded (p < 0.05) at 25 mM-Fe3O4. However, Bu subsequently decreased with higher magnetite inputs, reaching 0.255 Nm3/kg-CODadded (p < 0.05) with 100 mM-Fe3O4. For a 25 mM-Fe3O4 magnetite input yielding the highest Bu, the escalating impact on methane production diminished over time, decreasing by 388.9%, 92.7%, 26.3%, 17.6%, and 7.1% at 15, 20, 30, 40, and 65 days of anaerobic digestion, respectively. This underscores the declining efficacy of the magnetite input in enhancing methane production with prolonged residence time in the reactor.

Table 2.

Biochemical methane potential by the addition of magnetite during the anaerobic digestion of food wastewater.

Figure 1.

Methane yield curve by the addition of magnetite.

The study concluded that in the batch anaerobic digestion of food wastewater, the primary influence of magnetite lies in amplifying the initial methane production rather than sustaining elevated levels throughout the digestion period. This temporal analysis emphasizes the dynamic nature of the impact of magnetite on methane production efficiency. Lee et al. [32] conducted a batch reactor study using food wastewater and observed that magnetite additions of 0.25%, 0.50%, 1.00%, and 1.50%-Fe3O4 resulted in Bu values of 0.411, 0.412, 0.431, and 0.419 Nm3/kg-VSadded, respectively. Notably, all magnetite treatment groups exhibited a significant increase in Bu compared to the control (0.380 Nm3/kg-VSadded), with a 1.00%-Fe3O4 concentration (approximately 45 mM-Fe3O4), demonstrating the highest methane production efficiency. Although this aligns with our findings, the concentrations representing the maximum methane potential differed. The experimental substrate of Lee et al. had a TCOD of 166,333 mg/L, which is similar to the food wastewater TCOD of 179,540 mg/L in our study. This suggests that the impact of magnetite on methane production efficiency remains consistent across varying organic matter concentrations. The positive impact of magnetite on the methane production efficiency was evident across diverse substrates. In the anaerobic digestion of pig slurry, Zhang et al. [33] demonstrated an escalating Bu with increasing magnetite concentrations (5, 75, 150, and 350 mM-Fe3O4), resulting in Bu values of 0.303, 0.291, 0.318, and 0.332 Nm3/kg-VSadded. Remarkably, at 350 mM-Fe3O4, Bu exhibited a substantial 16.1% increase compared to the control (0.286 Nm3/kg-VSadded). Similarly, in the anaerobic digestion of sewage sludge, Wang et al. [34] observed augmented methane production upon the addition of magnetite (10, 50, and 100 mg-Fe3O4/g-TS) for 24 days of operation. In contrast, the influence of magnetite addition on the anaerobic digestion efficiency of food wastewater was variable. Although studies by Lee et al. [32] and Zhang et al. [33] showed increased methane production efficiency with magnetite, this phenomenon was not consistently replicated across all scenarios, underscoring the substrate-specific nature of the effects of magnetite in anaerobic processes. The efficacy of improving the anaerobic digestion of food wastewater through magnetite addition appears to be contingent on specific conditions. Akturk and Demier [35] revealed that in the control, the Bu was 0.409 Nm3/kg-VSadded. However, with the introduction of magnetite at concentrations of 2.0, 5.0, and 10.0 g-Fe3O4/L, Bu values were 0.272, 0.370, and 0.413 Nm3/kg-VSadded, respectively. Notably, in the 2.0 and 5.0 g-Fe3O4/L treatments, Bu decreased by 33.6% and 9.7%, respectively, compared to the control, indicating a reduction in methane production efficiency.

The variability in responses underscores the necessity for a tailored approach that considers specific conditions and optimal magnetite concentrations in food wastewater anaerobic digestion systems. Such nuanced insights are crucial for maximizing the benefits of magnetite while avoiding its potential drawbacks in different operational scenarios.

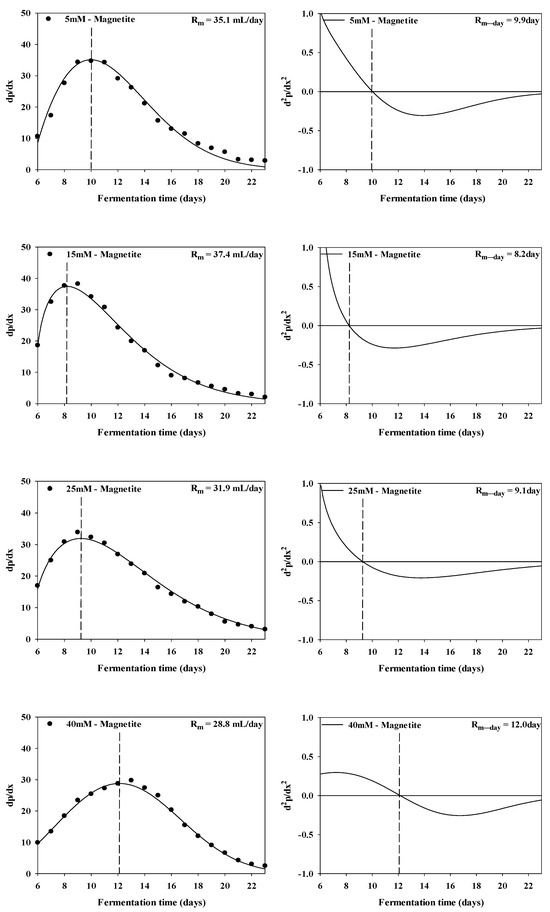

3.2. Reaction Kinetics of Methane Production

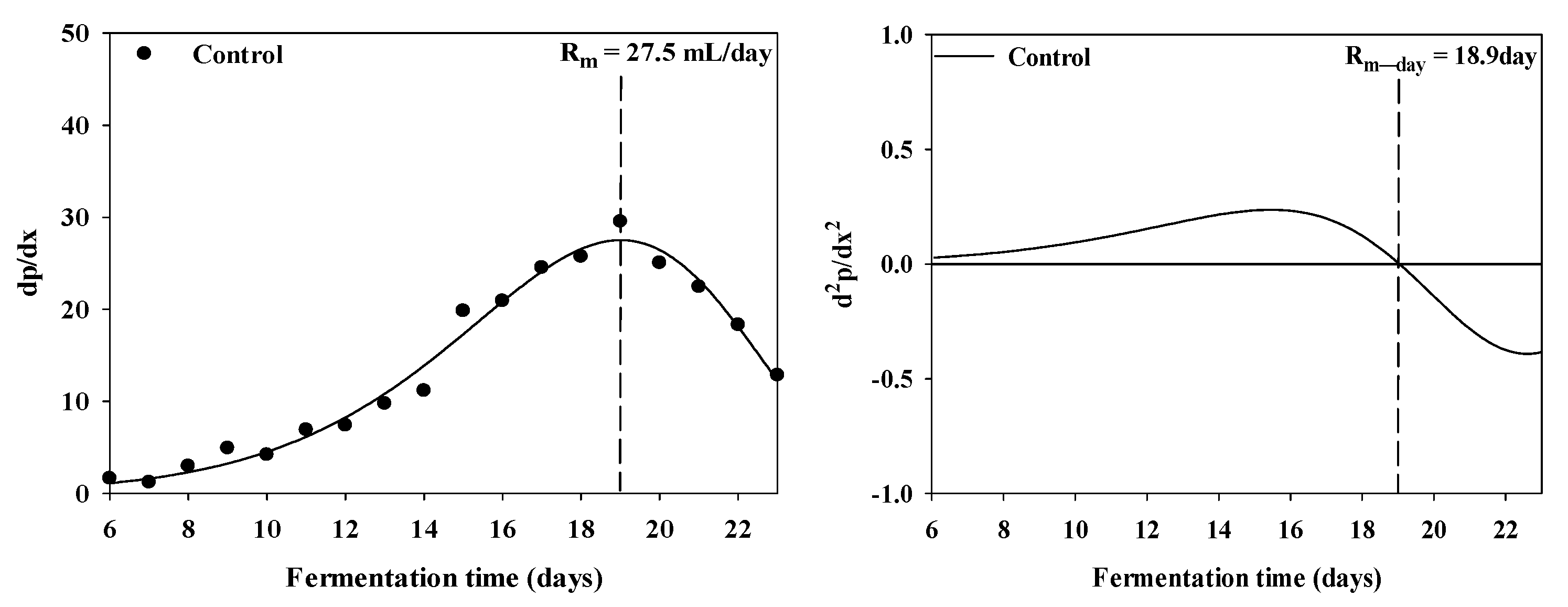

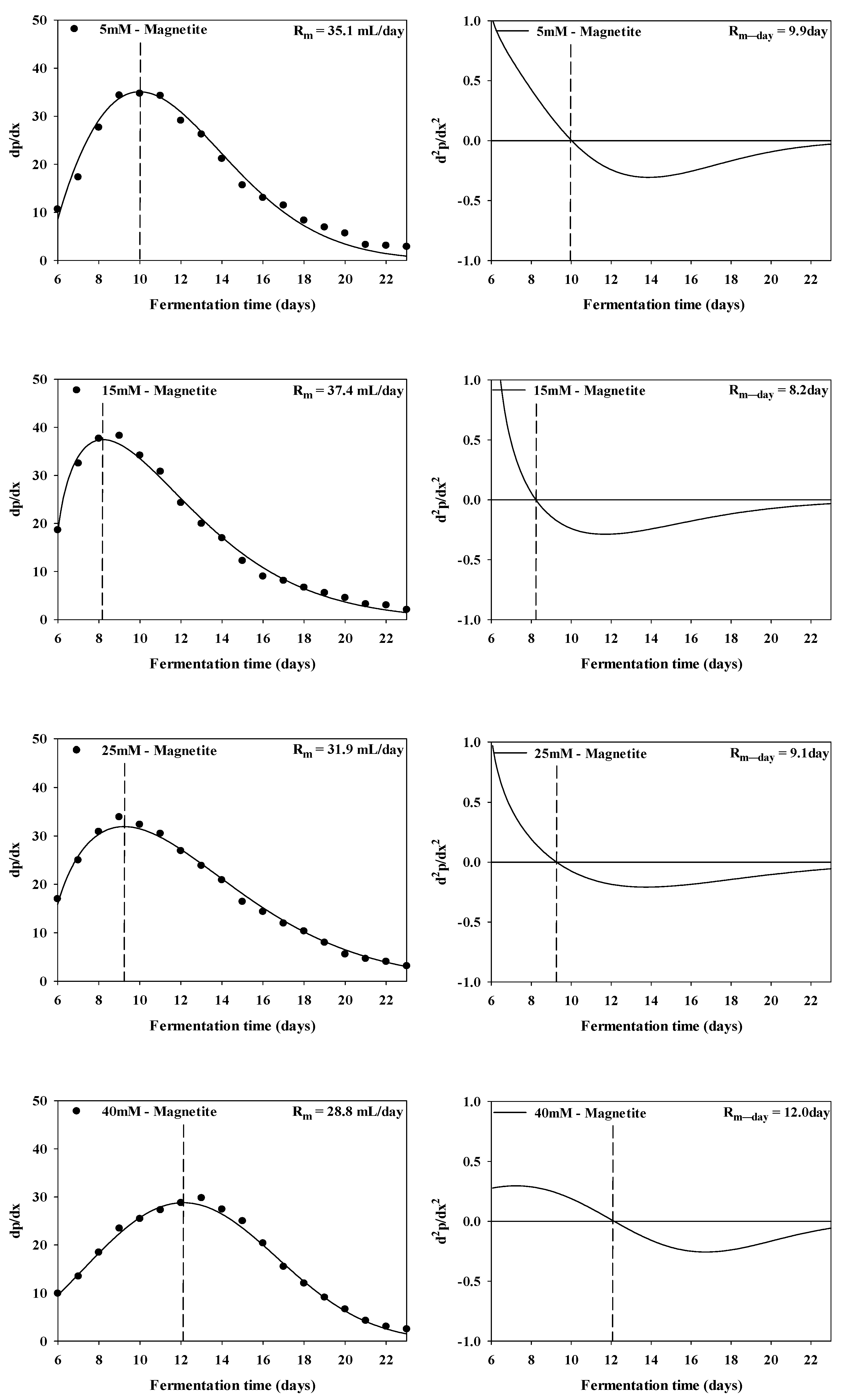

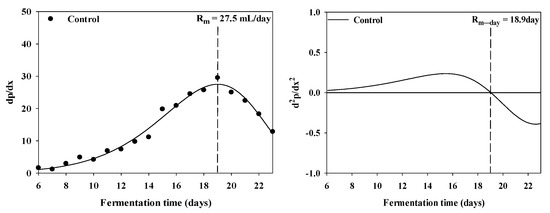

This study examined methane production kinetics in a batch anaerobic reactor for food wastewater. The cumulative methane production curves were differentially analyzed to derive the methane production rate [P’(t)] and acceleration [P’’(t)] curves. Figure 2 shows the control curves, establishing a baseline, and Figure 3 illustrates the effects of magnetite supplementation. The control group exhibited an Rm of 27.5 mL/day, with an Rm-day of 18.9 days. In the magnetite treatment group, Rm significantly increased to 35.1 mL/day at 5 mM-Fe3O4, further reaching 37.4 mL/day at 15 mM-Fe3O4, marking a substantial 36.0% increase compared to the control. However, with higher magnetite input (25–70 mM-Fe3O4), Rm gradually declined to its lowest level of 28.8 mL/day at 40 mM-Fe3O4, followed by a subsequent increase to 33.9 mL/day at 70 mM-Fe3O4. The Rm-day values showed significant variation. In the presence of 5 mM-Fe3O4, Rm-day decreased by 47.6%, reaching 9.9 days compared to the control. At 15 mM-Fe3O4, the shortest Rm-day of 8.2 days was observed, representing a 56.6% reduction compared to the control. Additionally, at higher magnetite concentrations (25–100 mM-Fe3O4), Rm-day exhibited a subsequent increase, with 14.6 days at 100 mM-Fe3O4, reflecting a 22.8% reduction compared with the control. Lee et al. conducted a study assessing the enhancement of methane production with magnetite in food wastewater, similar to our study’s chemical composition (TCOD 166,333 mg/L). Injecting 1.00%-Fe3O4 increased Rm to 18.44 mL/day, a 17.2% improvement over the control (15.73 mL/day). This aligns with our findings and reinforces the positive impact of magnetite on methane production in the anaerobic digestion of food wastewater. Lee et al. [32] further analyzed the lag growth phase time (λ) during initial anaerobic digestion, a factor influencing residence time. They reported a shortening of λ from 0.541 days in the control to 0.469 days with 0.25%-Fe3O4. The positive effect of magnetite in enhancing the Rm extends beyond food wastewater to other raw materials. Zhang et al. [36] investigated magnetite supplementation in a batch anaerobic digester for pig slurry by adding 5, 75, 150, and 350 mM-Fe3O4 with 20–30 nm particle size. Rm increased to 11.4, 13.3, 13.4, and 13.4 mL/day, respectively, showing a significant increase of 48.9% compared to the control (9.0 mL/day) above 150 mM-Fe3O4. However, Zhang et al. focused on the enhancement efficiency of Rm without reporting Rm-day values. The cumulative methane production curve in the study by Zhang et al. indicated a shortening effect on Rm-day with increasing magnetite input. However, a detailed analysis of Rm-day, specifically its values and variations, was not performed. This trend underscores the need for a more nuanced exploration of the temporal dynamics of methane production, especially considering Rm-day, to optimize magnetite supplementation for diverse anaerobic digestion scenarios.

Figure 2.

Analysis of maximum methane production rate and attainment day by the 1st and 2nd derivative from the cumulative methane production curve of control.

Figure 3.

Analysis of maximum methane production rate and attainment day by the 1st and 2nd derivative from the cumulative methane production curve of Fe3O4 addition.

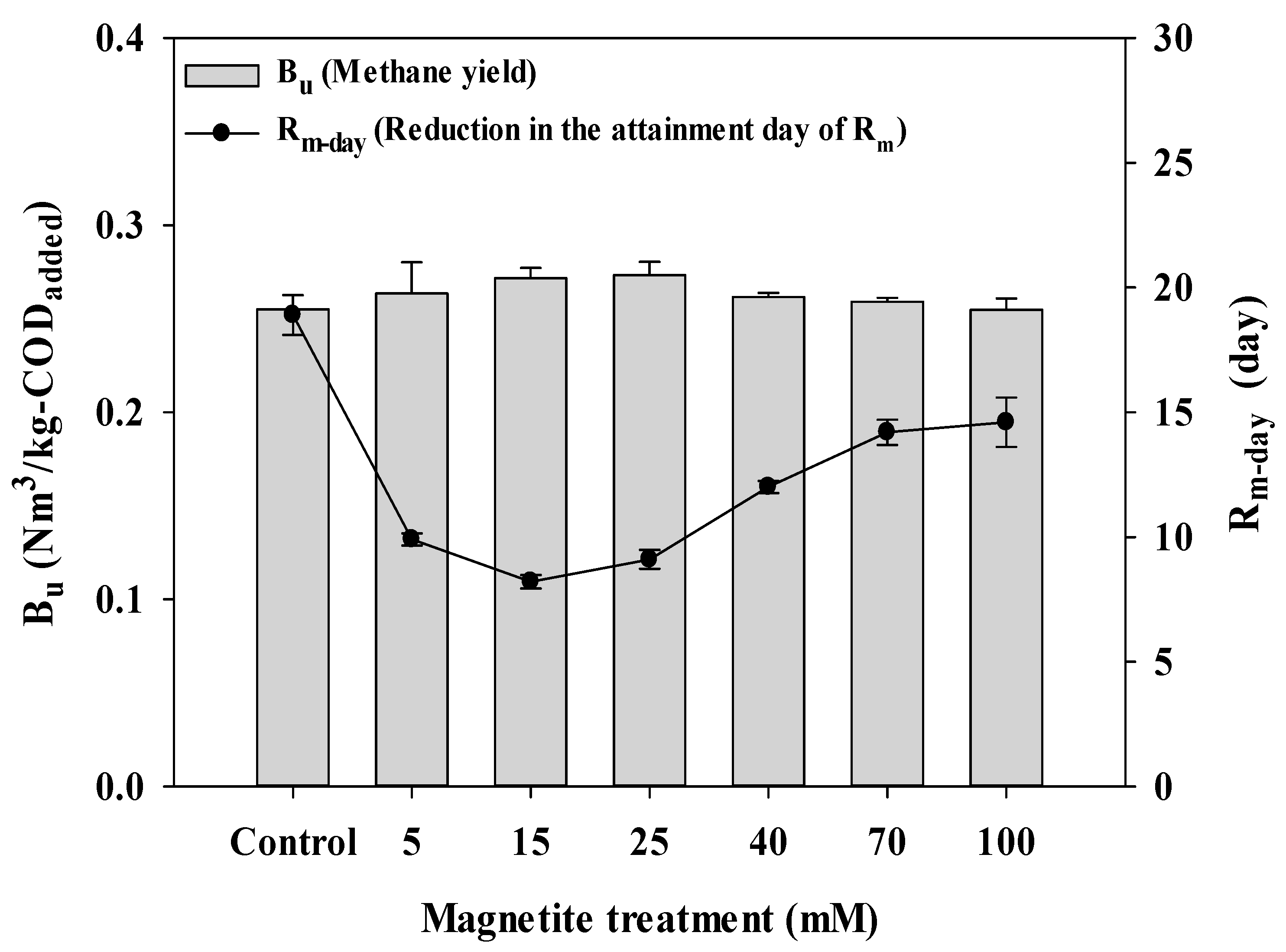

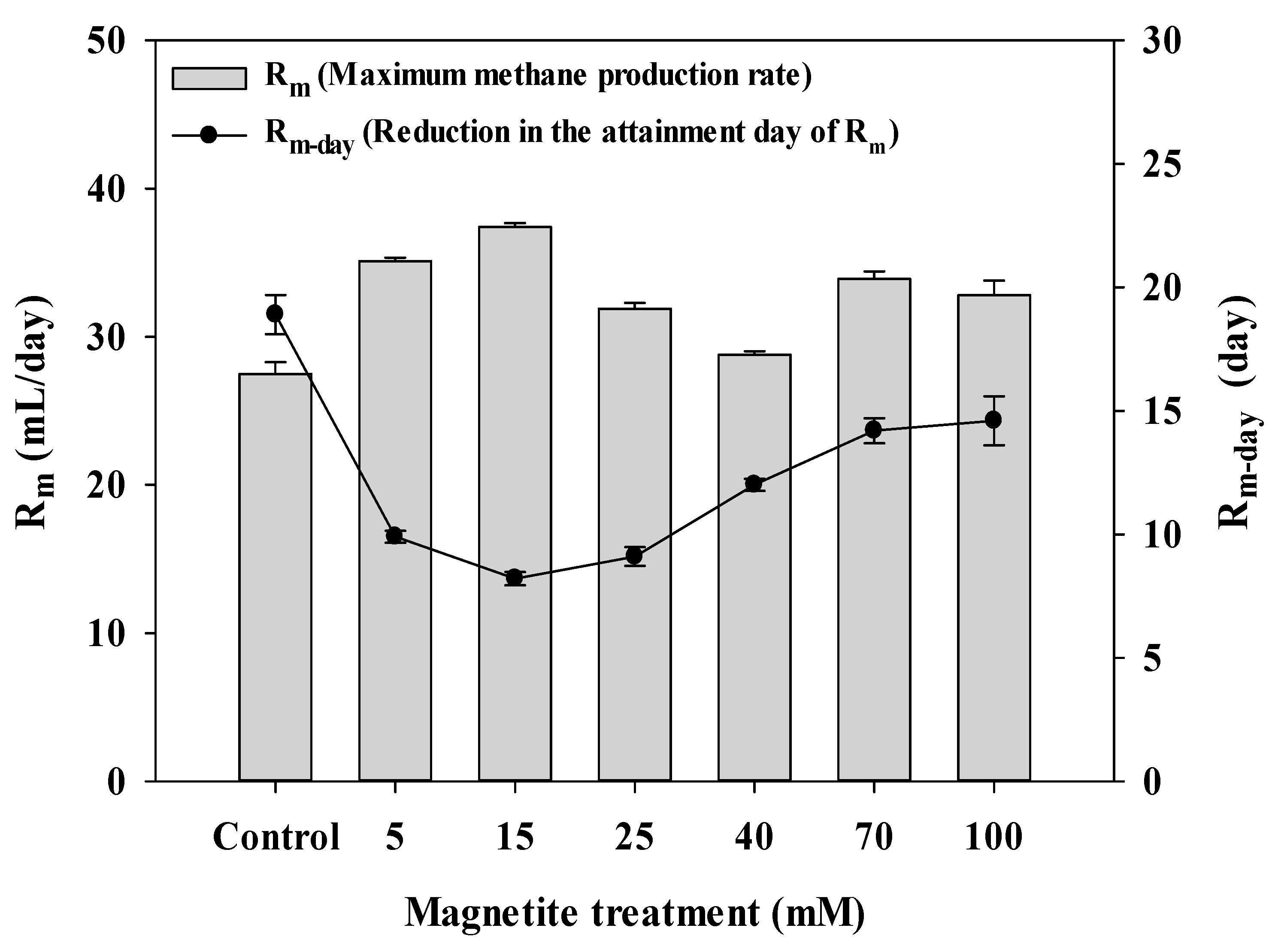

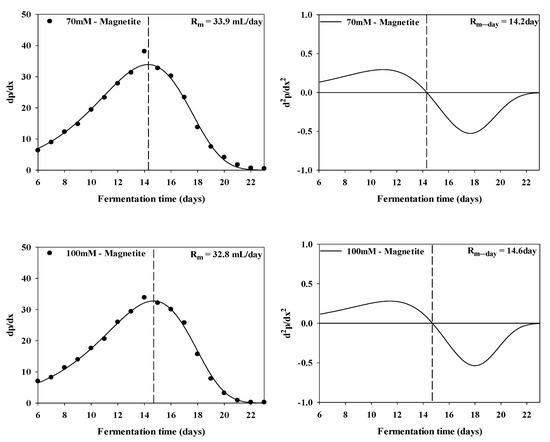

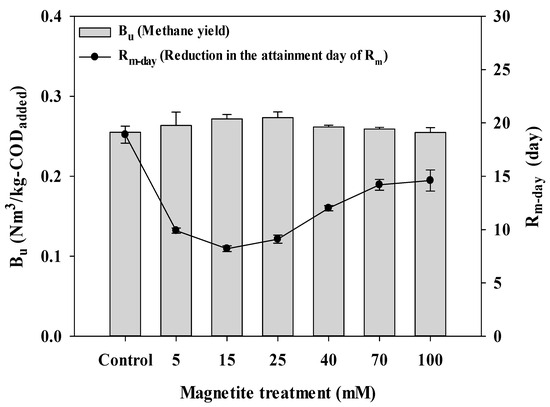

Specifically, Lee et al. [37] investigated the impact of magnetite addition in a batch anaerobic reactor using VFAs, specifically acetate, propionate, and butyrate, as substrates. In the absence of magnetite, the Rm values for acetate, propionate, and butyrate were 20.2, 8.7, and 19.6 mL/g-VSS/day, respectively. Introducing 20 mM-Fe3O4 magnetite resulted in Rm values of 19.9, 12.6, and 19.8 mL/g-VSS/day, with a notable 46% increase in propionate compared to the control. Examining these results in conjunction with the methanogenesis reaction of acetate (CH3COO− + H+ → CH4 + CO2; ΔG0 −32.5 kJ/mole), it was observed that magnetite had a marginal effect on increasing the reaction rate. This observation aligns with thermodynamic considerations, as acetate’s negative standard Gibbs free energy change (ΔG0) suggests a less substantial impact on reaction rate enhancement with magnetite. Further supporting this inference, Yamada et al. [38] demonstrated in a batch anaerobic reactor experiment that acetate was completely decomposed within 15 days with the addition of magnetite (5 and 10 mM-Fe3O4). Propionate and butyrate, which are substrates for acetogenesis, showed varied responses to the addition of magnetite, with propionate displaying a significant increase in Rm. The relatively larger ΔG0 of propionate (CH3CH2COO− + 3H2O → CH3COO− + H+ + 3H2 + HCO3−; ΔG0 + 76.1 kJ/mole) compared to butyrate (CH3CH2CH2COO− + 2H2O → 2CH3COO− + H+ + 2H2; ΔG0 + 48.1 kJ/mole) suggests that the favorable electron transfer facilitated by magnetite predominantly influences propionate’s acetogenesis reaction [39,40]. This effect is particularly crucial because propionate accumulation in anaerobic digesters, which is indicative of low methanogen activity, poses operational challenges that inhibit methane production. Thus, the introduction of magnetite is implicated not only in enhancing overall methane production rates, but also in ameliorating issues associated with propionate accumulation during the anaerobic digestion of organic matter. The validity of this inference was substantiated by Jing et al. [41], who investigated methane production efficiency through magnetite introduction into a batch anaerobic reactor employing propionate as a substrate. The control group exhibited an Rm of 3.0 mL/day, whereas magnetite injections at 10, 100, and 1000 mg-Fe3O4/L resulted in respective Rm values of 4.11, 4.33, and 4.06 mL/day. Notably, the discernible enhancement in anaerobic digestion efficiency with the addition of 10 mg-Fe3O4/L. Despite the divergence in findings across various studies on DIET, a recurring trend in the literature is the predominant focus on the augmentation of Bu and Rm following the addition of magnetite. Notably, there is a paucity of detailed analyses concerning the impact of residence time on anaerobic digestion, exemplified by the insufficient exploration of Rm-day. Figure 4 and Figure 5 depict graphical representations of Bu and Rm-day, and Rm and Rm-day, respectively, based on varying magnetite inputs. In the anaerobic digestion of food wastewater, the results of the study revealed a distinct trend in the change in anaerobic digestion efficiency (Bu and Rm) relative to magnetite input compared to Rm-day. Notably, the addition of 100 mM-Fe3O4 demonstrated no statistically significant difference in Bu compared with the control (0.255 Nm3/kg-CODadded). However, Rm-day exhibits a substantial reduction of approximately 22.8%, as illustrated in Figure 4. Furthermore, the introduction of 40 mM-Fe3O4 led to a 5.1% improvement in Rm compared to that of the control (27.5 mL/day). Intriguingly, the Rm-day experienced a more substantial reduction of approximately 36.5%, as shown in Figure 5.

Figure 4.

Bu and Rm-day by concentration according to the addition of magnetite (Bu mean of methane yield and Rm-day mean of reduction in the attainment day of Rm).

Figure 5.

Rm and Rm-day by concentration according to the addition of magnetite (Bu mean of maximum methane production rate and Rm-day mean of reduction in the attainment day of Rm).

The addition of a conductive substance can enhance the efficiency of anaerobic digestion by promoting the decomposition rate of organic materials. In this study, the reaction rates (Rm and Rm-day) of food wastewater treated with magnetite were analyzed. The results showed that the highest efficiency was observed at a magnetite concentration of 15 mM, with Rm increasing by 36.0% and Rm-day decreasing by 56.6% compared to the control. The enhanced anaerobic digestion reaction rate can shorten the HRT, providing the advantage of improving the economic feasibility of the anaerobic digestion system.

4. Conclusions

The direct interspecies electron transfer (DIET) mechanism, which facilitates electron transfer between acetic acid and methane-producing microorganisms, holds promise for enhancing anaerobic digester stability and methane production efficiency. While existing research on DIET has explored conductive materials under diverse anaerobic digestion conditions, comprehensive assessments of the residence time, which is crucial for economic feasibility, are lacking. In this study, magnetite, a conductive material, was introduced into food wastewater by anaerobic digestion, and the reduction in residence time and methane production efficiency were concurrently analyzed. Control’s Bu was 0.255 Nm3/kg-CODadded, which significantly increased to 0.273 Nm3/kg-CODadded (p < 0.05) with 25 mM-Fe3O4, showing the highest Bu. However, from 15 to 65 days, the methane production efficiency decreased, ranging from 388.9% to 7.1%. Initially, magnetite addition increased methane production, which diminished with prolonged reactor operation. Rm of control was 27.5 mL/day (Rm-day of 18.9 days), peaking at 37.4 mL/day with 15 mM-Fe3O4, accompanied by a 56.6% reduction in Rm-day (8.2 days). Even with 100 mM-Fe3O4, Bu remained comparable to the control, yet Rm-day was shortened by approximately 22.8%. At 40 mM-Fe3O4, Rm improved by 5.1%, but Rm-day decreased by approximately 36.5%. Despite the lower anaerobic digestion efficiency, Rm-day was significantly shortened, suggesting the potential benefits of residence time reduction in a continuous anaerobic reactor. Introducing conductive materials via the DIET mechanism may enhance economic feasibility by optimizing the retention time of the anaerobic digestion facility. Continuous anaerobic digester research is essential to confirm these economic implications and to provide a holistic understanding of the impact of the DIET mechanism.

Author Contributions

Conceptualization, Y.-M.Y.; methodology, T.-B.K. and Y.-M.Y.; software, T.-B.K. and J.-H.L.; validation, T.-B.K. and Y.-M.Y.; formal analysis, T.-B.K. and J.-H.L.; investigation, T.-B.K., J.-H.L., and Y.-M.Y.; resources, Y.-M.Y.; data curation, Y.-M.Y.; writing—original draft preparation, T.-B.K.; writing—review and editing, Y.-M.Y.; visualization, T.-B.K. and J.-H.L.; supervision, Y.-M.Y.; project administration, Y.-M.Y.; funding acquisition, Y.-M.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the MAFRA and IPET for industrialization technology development in response to current livestock issues (Project NO. 321091-03).

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

Tae-Bong Kim has received research grants from KEC System Co., Ltd. Other authors have no conflict of interest to declare.

References

- MOTIE [Ministry of Trade Industry and Energy]. New & Renewable Energy White Paper; MOTIE [Ministry of Trade Industry and Energy]: Sejong, Republic of Korea, 2020.

- ME [Ministry of Environment]. Status of Installation and Operation of Food Waste Treatment Facilities in 2020; ME [Ministry of Environment]: Sejong, Republic of Korea, 2021.

- ME [Ministry of Environment]. Status of Organic Waste Biogasification Facilities in 2021; ME [Ministry of Environment]: Sejong, Republic of Korea, 2021.

- KEITI [Korea Environmental Industry & Technology Institute]. Trends in Land Treatment of Food Wastewater; KEITI [Korea Environmental Industry & Technology Institute]: Seoul, Republic of Korea, 2016.

- Meegoda, J.N.; Li, B.; Patel, K.; Wang, L.B. A review of the processes, parameters, and optimization of anaerobic digestion. Int. J. Environ. Res. Public Health 2018, 15, 2224. [Google Scholar] [CrossRef]

- Yadav, M.; Joshi, C.; Paritosh, K.; Thakur, J.; Pareek, N.; Masakapalli, S.K.; Vivekanand, V. Organic waste conversion through anaerobic digestion: A critical insight into the metabolic pathways and microbial interactions. Metab. Eng. 2022, 69, 323–337. [Google Scholar] [CrossRef] [PubMed]

- Baek, G.; Kim, J.; Lee, C. A review of the effects of iron compounds on methanogenesis in anaerobic environments. Renew. Sustain. Energy Rev. 2019, 113, 109282. [Google Scholar] [CrossRef]

- Yeo, J.; Kim, C.-G.; Lee, J.-H.; Song, E.; Yoon, Y.-M. Effects of Water Potential on Anaerobic Methane Production and a Microbial Consortium. Fermentation 2023, 9, 244. [Google Scholar] [CrossRef]

- El-Qelish, M.; Elgarahy, A.M.; Ibrahim, H.S.; El-Kholly, H.K.; Gad, M.; Ali, M.E.M. Multi-functional core-shell pomegranate peel amended alginate beads for phenol decontamination and bio-hydrogen production: Synthesis, characterization, and kinetics investigation. Biochem. Eng. J. 2023, 195, 108932. [Google Scholar] [CrossRef]

- Akindele, A.A.; Sartaj, M. The toxicity effects of ammonia on anaerobic digestion of organic fraction of municipal solid waste. Waste Manag. 2018, 71, 757–766. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Xu, Y.; Dai, X.; Dai, L. Principles and advancements in improving anaerobic digestion of organic waste via direct interspecies electron transfer. Renew. Sustain. Energy Rev. 2021, 148, 111367. [Google Scholar] [CrossRef]

- Müller, N.; Worm, P.; Schink, B.; Stams, A.J.; Plugge, C.M. Syntrophic butyrate and propionate oxidation processes: From genomes to reaction mechanisms. Environ. Microbiol. Rep. 2010, 2, 489–499. [Google Scholar] [CrossRef]

- Morita, M.; Malvankar, N.S.; Franks, A.E.; Summers, Z.M.; Giloteaux, L.; Rotaru, A.E.; Rotaru, C.; Lovley, D.R. Potential for direct interspecies electron transfer in methanogenic wastewater digester aggregates. MBio 2011, 2, e00159-11. [Google Scholar] [CrossRef]

- Rotaru, A.-E.; Shrestha, P.M.; Liu, F.; Markovaite, B.; Chen, S.; Nevin, K.P.; Lovley, D.R. Direct interspecies electron transfer between Geobacter metallireducens and Methanosarcina barkeri. Appl. Environ. Microbiol. 2014, 80, 4599–4605. [Google Scholar] [CrossRef]

- Baek, G.; Kim, J.; Kim, J.; Lee, C. Role and potential of direct interspecies electron transfer in anaerobic digestion. Energies 2018, 11, 107. [Google Scholar] [CrossRef]

- Kim, S.-Y.; Bae, G.-S.; Lee, J.-H.; Yoon, Y.-M.; Kim, C.-H. Effects of Magnetite (Fe3O4) as an Electrical Conductor of Direct Interspecies Electron Transfer on Methane Production from Food Wastewater in a Plug Flow Reactor. Processes 2023, 11, 3001. [Google Scholar] [CrossRef]

- Tan, J.; Wang, J.; Xue, J.; Liu, S.-Y.; Peng, S.-C.; Ma, D.; Chen, T.-H.; Yue, Z. Methane production and microbial community analysis in the goethite facilitated anaerobic reactors using algal biomass. Fuel 2015, 145, 196–201. [Google Scholar] [CrossRef]

- Wang, G.; Li, Q.; Gao, X.; Wang, X.C. Synergetic promotion of syntrophic methane production from anaerobic digestion of complex organic wastes by biochar: Performance and associated mechanisms. Bioresour. Technol. 2018, 250, 812–820. [Google Scholar] [CrossRef]

- Chen, Q.; Liu, C.; Liu, X.; Sun, D.; Li, P.; Qiu, B.; Dang, Y.; Karpinski, N.A.; Smith, J.A.; Holmes, D.E. Magnetite enhances anaerobic digestion of high salinity organic wastewater. Environ. Res. 2020, 189, 109884. [Google Scholar] [CrossRef]

- Hwang, Y.; Kim, D.; Shin, H.-S. Inhibition of nitrate reduction by NaCl adsorption on a nano-zero-valent iron surface during a concentrate treatment for water reuse. Environ. Technol. 2015, 36, 1178–1187. [Google Scholar] [CrossRef] [PubMed]

- Sebastian, A.; Nangia, A.; Prasad, M. Cadmium and sodium adsorption properties of magnetite nanoparticles synthesized from Hevea brasiliensis Muell. Arg. bark: Relevance in amelioration of metal stress in rice. J. Hazard. Mater. 2019, 371, 261–272. [Google Scholar] [CrossRef]

- Aguilar-Moreno, G.S.; Navarro-Cerón, E.; Velázquez-Hernández, A.; Hernández-Eugenio, G.; Aguilar-Méndez, M.Á.; Espinosa-Solares, T. Enhancing methane yield of chicken litter in anaerobic digestion using magnetite nanoparticles. Renew. Energy 2020, 147, 204–213. [Google Scholar] [CrossRef]

- Altamirano-Corona, M.F.; Anaya-Reza, O.; Durán-Moreno, A. Biostimulation of food waste anaerobic digestion supplemented with granular activated carbon, biochar and magnetite: A comparative analysis. Biomass Bioenergy 2021, 149, 106105. [Google Scholar] [CrossRef]

- Li, D.; Song, L.; Fang, H.; Li, P.; Teng, Y.; Li, Y.-Y.; Liu, R.; Niu, Q. Accelerated bio-methane production rate in thermophilic digestion of cardboard with appropriate biochar: Dose-response kinetic assays, hybrid synergistic mechanism, and microbial networks analysis. Bioresour. Technol. 2019, 290, 121782. [Google Scholar] [CrossRef]

- Yan, W.; Zhang, L.; Wijaya, S.M.; Zhou, Y. Unveiling the role of activated carbon on hydrolysis process in anaerobic digestion. Bioresour. Technol. 2020, 296, 122366. [Google Scholar] [CrossRef]

- Park, J.-H.; Kang, H.-J.; Park, K.-H.; Park, H.-D. Direct interspecies electron transfer via conductive materials: A perspective for anaerobic digestion applications. Bioresour. Technol. 2018, 254, 300–311. [Google Scholar] [CrossRef]

- Oh, S.-Y.; Yoon, Y.-M. Energy recovery efficiency of poultry slaughterhouse sludge cake by hydrothermal carbonization. Energies 2017, 10, 1876. [Google Scholar] [CrossRef]

- Lee, J.-H.K.; Kim, T.-B.; Kim, C.-H.; Yoon, Y.-M. Effects of Magnetite(Fe3O4) as Electrical Conductor of Direct Interspecies Electron Transfer on Methane Yield of Food Wastewater. J. Korea Org. Resour. Recycl. Assoc. 2023, 31, 15–26. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater; Water Environment Federation: Alexandria, VA, USA, 1998; p. 324. [Google Scholar]

- Sørensen, A.H.; Winther-Nielsen, M.; Ahring, B.K. Kinetics of lactate, acetate and propionate in unadapted and lactate-adapted thermophilic, anaerobic sewage sludge: The influence of sludge adaptation for start-up of thermophilic UASB-reactors. Appl. Microbiol. Biotechnol. 1991, 34, 823–827. [Google Scholar] [CrossRef]

- Duncan, D.B. Multiple range and multiple F tests. Biometrics 1955, 11, 1–42. [Google Scholar] [CrossRef]

- Lee, J.-H.; Lee, J.-H.; Kim, S.-Y.; Yoon, Y.-M. Effect of Addition of Zero-Valent Iron (Fe) and Magnetite (Fe3O4) on Methane Yield and Microbial Consortium in Anaerobic Digestion of Food Wastewater. Processes 2023, 11, 759. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, T.; Wang, Z.; Wang, Y.; Zhong, H.; Shen, P.; Wei, Y. Effects of magnetite on anaerobic digestion of swine manure: Attention to methane production and fate of antibiotic resistance genes. Bioresour. Technol. 2019, 291, 121847. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, D.; Dai, L.; Dong, B.; Dai, X. Magnetite triggering enhanced direct interspecies electron transfer: A scavenger for the blockage of electron transfer in anaerobic digestion of high-solids sewage sludge. Environ. Sci. Technol. 2018, 52, 7160–7169. [Google Scholar] [CrossRef]

- Akturk, A.S.; Demirer, G.N. Improved food waste stabilization and valorization by anaerobic digestion through supplementation of conductive materials and trace elements. Sustainability 2020, 12, 5222. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.; Lu, T.; Liu, J.; Wang, Y.; Shen, P.; Wei, Y. Response and mechanisms of the performance and fate of antibiotic resistance genes to nano-magnetite during anaerobic digestion of swine manure. J. Hazard. Mater. 2019, 366, 192–201. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Koo, T.; Yulisa, A.; Hwang, S. Magnetite as an enhancer in methanogenic degradation of volatile fatty acids under ammonia-stressed condition. J. Environ. Manag. 2019, 241, 418–426. [Google Scholar] [CrossRef] [PubMed]

- Yamada, C.; Kato, S.; Ueno, Y.; Ishii, M.; Igarashi, Y. Conductive iron oxides accelerate thermophilic methanogenesis from acetate and propionate. J. Biosci. Bioeng. 2015, 119, 678–682. [Google Scholar] [CrossRef] [PubMed]

- Mostafa, A.; Im, S.; Song, Y.-C.; Ahn, Y.; Kim, D.-H. Enhanced anaerobic digestion by stimulating DIET reaction. Processes 2020, 8, 424. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, J.; Liu, F.; Yan, H.; Li, J.; Zhang, X. Reduction of Gibbs free energy and enhancement of Methanosaeta by bicarbonate to promote anaerobic syntrophic butyrate oxidation. Bioresour. Technol. 2018, 267, 209–217. [Google Scholar] [CrossRef]

- Jing, Y.; Wan, J.; Angelidaki, I.; Zhang, S.; Luo, G. iTRAQ quantitative proteomic analysis reveals the pathways for methanation of propionate facilitated by magnetite. Water Res. 2017, 108, 212–221. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).