Comprehensive Review of Carbon Capture and Storage Integration in Hydrogen Production: Opportunities, Challenges, and Future Perspectives

Abstract

1. Introduction

1.1. Significance of Hydrogen Production in Decarbonization and Clean Energy Transitions

- Reducing Greenhouse Gas Emissions: Green hydrogen, produced from sustainable sources, offers an eco-friendly alternative to traditional fuels due to its minimal greenhouse gas emissions during production [8]. By utilizing sustainable electricity to power electrolysis machines that separate water into hydrogen and oxygen, we can significantly reduce carbon emissions across various industries, including transportation, manufacturing, and heating, thereby contributing to the fight against climate change [9].

- Energy Storage and Grid Balancing: Hydrogen can function as an energy storage solution, enabling the integration of intermittent renewable energy sources like solar and wind power into the power grid [10]. Excess electricity generated during peak renewable energy production periods can be used to create hydrogen through electrolysis. This stored hydrogen can then be converted back into electricity via fuel cells as needed, helping to balance energy supply and demand on the power grid [11].

- Sector Coupling and Electrification: Hydrogen has the potential to promote sector integration by connecting traditionally separate energy sectors such as transportation, industry, and power generation. By employing hydrogen fuel cells in electric vehicles, for heating purposes, and in high-temperature industrial processes, hydrogen can enable the electrification of sectors that are challenging to decarbonize solely through direct electricity [12]. Several studies have investigated the potential of hydrogen to facilitate sector integration. For example, a recent paper published in Angewandte Chemie International Edition [13] highlighted the role of hydrogen in decarbonizing the transportation sector through the use of fuel cell electric vehicles (FCEVs). The authors emphasized the advantages of FCEVs in terms of their longer driving range and faster refueling times compared to battery electric vehicles (BEVs).Beyond transportation, hydrogen can also play a crucial role in decarbonizing the heating sector. A study published in Rare Metals [14] explored the potential of hydrogen fuel cells for residential and commercial heating applications. The authors found that hydrogen fuel cells can provide efficient and clean heating solutions, with the added benefit of generating electricity as a byproduct. Additionally, hydrogen can be utilized in high-temperature industrial processes such as steelmaking and chemical production. A paper published in Exploration [15] discussed the potential of hydrogen as a reducing agent in steelmaking, which could significantly reduce carbon emissions from this energy-intensive industry.

- Industrial Decarbonization: The industrial sector, which is heavily reliant on fossil fuels for heat and power generation, can benefit substantially from clean hydrogen as a substitute for natural gas or coal [16]. By substituting hydrogen for fossil fuels in activities like steelmaking, ammonia production, and chemical manufacturing, industries can decrease their carbon footprint and transition towards more sustainable and cleaner production practices [17].

- International Energy Trade: Hydrogen has the potential to become a globally traded commodity, facilitating the exchange of clean energy between regions with abundant renewable resources and those in need of energy imports [18]. By establishing hydrogen supply chains and infrastructure for international trade, countries can diversify their energy sources, enhance energy security, and promote international cooperation in achieving climate goals [19].

- Innovation and Technological Advancements: The increasing interest in hydrogen production has driven innovation in electrolysis technologies, storage methods, and fuel cell applications [20]. Research and development initiatives are reducing costs, enhancing efficiency, and expanding the potential uses of hydrogen in various sectors, accelerating the transition towards a cleaner and more sustainable energy infrastructure [21].

1.2. The Role of Carbon Capture and Storage in Reducing Greenhouse Gas Emissions

- Capture: The initial phase of CCS involves the capture of CO2 emissions from various sources such as power plants, cement factories, or industrial facilities to prevent their release into the atmosphere [24]. Diverse capture technologies, including post-combustion capture, pre-combustion capture, and oxy-fuel combustion, are used to separate and capture CO2 from the flue gas or exhaust streams of these facilities [25].

- Transport: Once CO2 is captured, it must be transported to suitable storage locations for long-term sequestration. CO2 can be conveyed through pipelines, trucks, ships, or other methods to designated injection sites, where it will be securely stored beneath the ground [26].

- Storage: In the storage phase, the captured CO2 is commonly injected deep beneath the Earth’s surface into geological formations like depleted oil and gas reservoirs, saline aquifers, or coal seams [24]. These locations provide safe and long-term storage for CO2, where it is contained in either gaseous or liquid form, confined by impermeable rock formations to prevent any release back into the atmosphere [27].

- Enhanced Oil Recovery (EOR): In certain cases, carbon dioxide captured through CCS may be utilized for enhanced oil recovery. This process involves injecting CO2 into oil reservoirs to boost the production of oil [23]. This method not only stores CO2 underground but also offers a financial incentive for implementing CCS technologies [26].

- Role in Greenhouse Gas Emissions Reduction: CCS is instrumental in decreasing greenhouse gas emissions by trapping and storing CO2 that would otherwise escape into the atmosphere [28]. It is considered a critical technology for achieving net-zero emissions targets and combating climate change by assisting industries and power plants in reducing their carbon footprints [28].

- Technological Advancements: Research and development efforts are currently focused on enhancing CCS technologies to make them more affordable, environmentally friendly, and scalable [29]. Innovations in capture methods, storage techniques, and monitoring technologies aim to improve the overall performance and viability of CCS projects [30].

- Policy Support and Incentives: Governments, international organizations, and industry stakeholders recognize the importance of CCS in achieving climate goals and reducing emissions [31]. Government support, financial incentives, carbon pricing systems, and regulations are crucial in stimulating the implementation of CCS projects and accelerating the transition towards a sustainable, low-carbon economy [32].

1.3. The Purpose of This Article

2. Hydrogen Production Methods

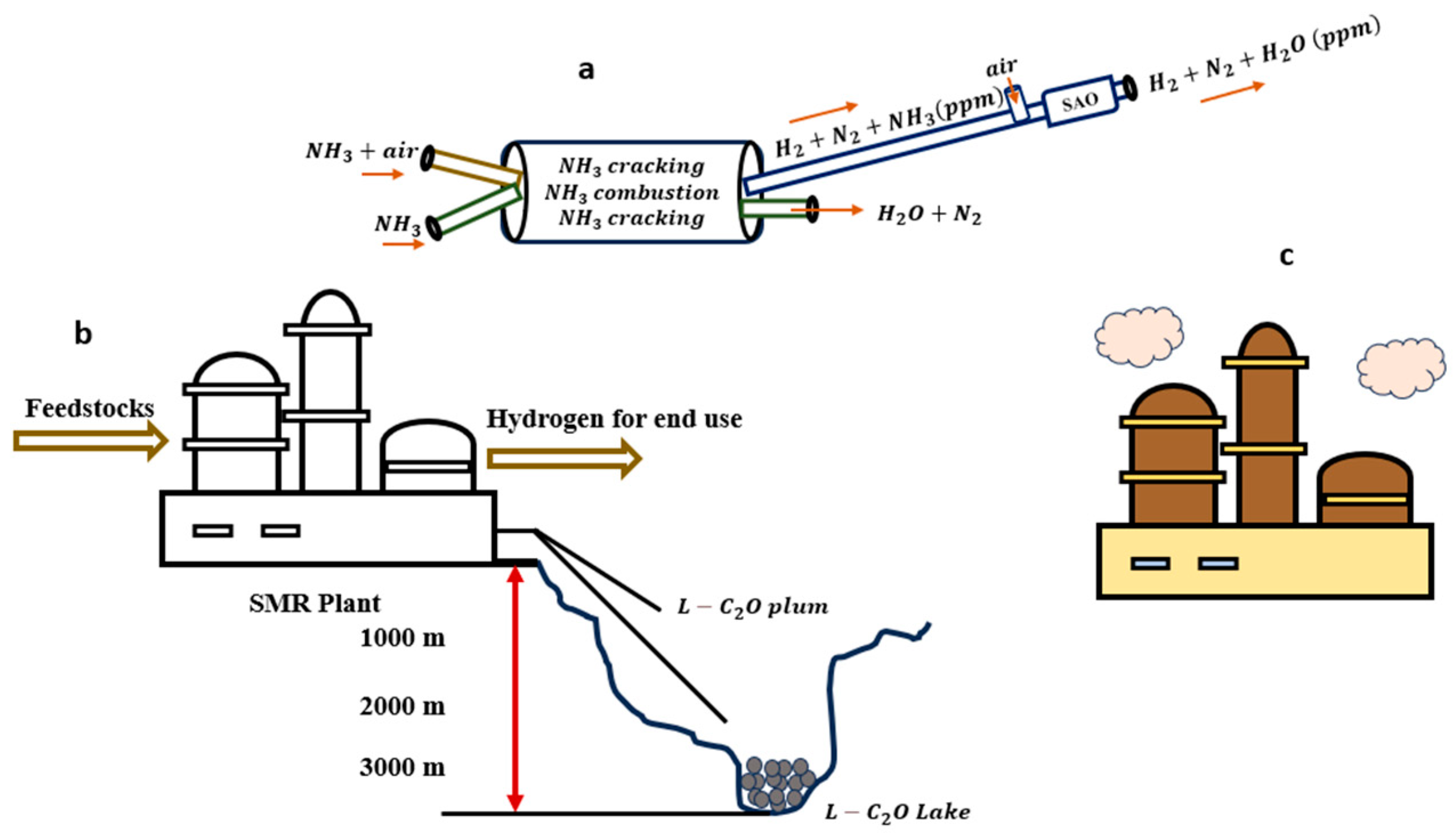

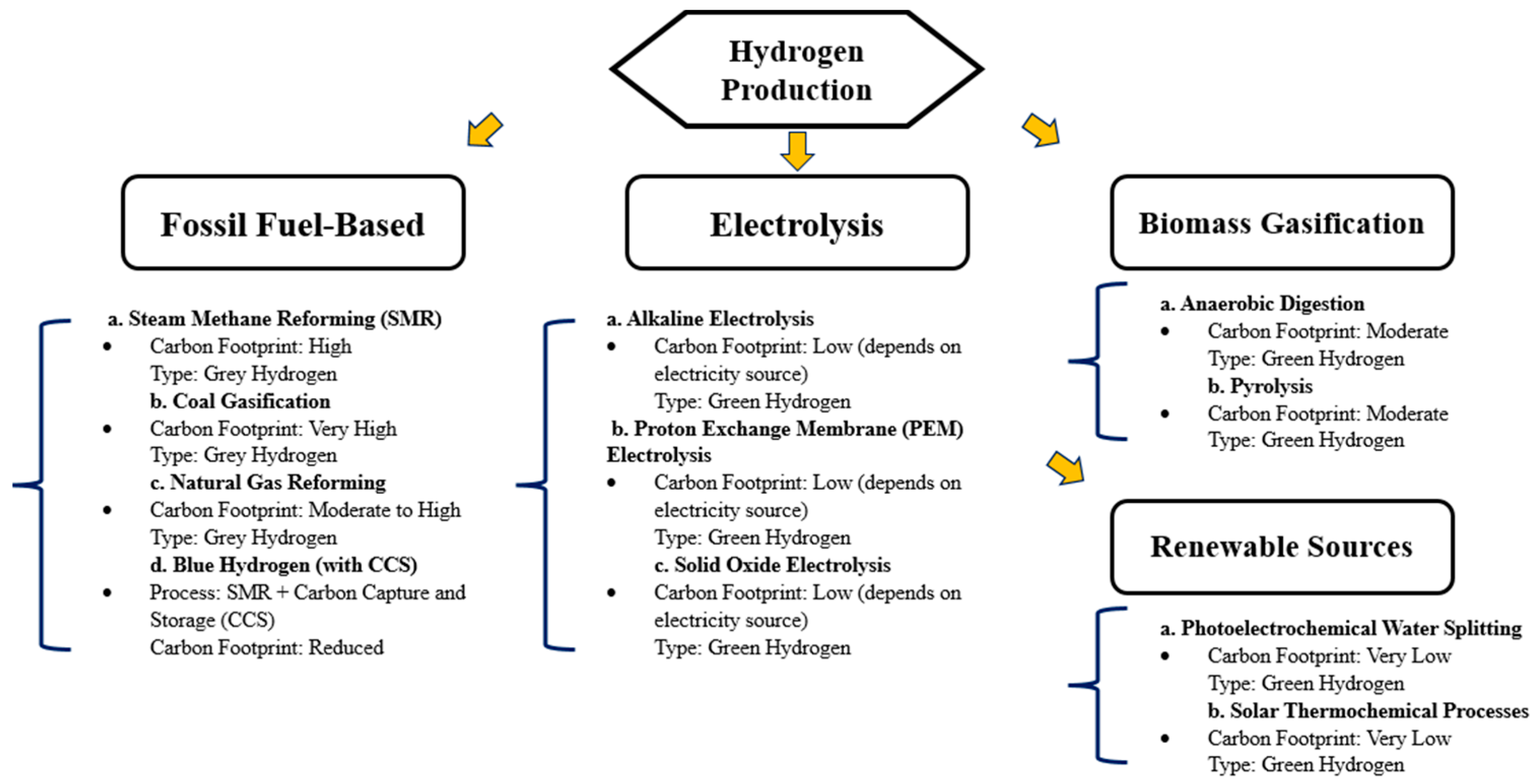

2.1. Exploration of Different Methods of Hydrogen Production

- SMR: High carbon footprint; produces grey hydrogen.

- Coal Gasification: Very high carbon footprint; also produces grey hydrogen.

- Natural Gas Reforming: Moderate to high carbon footprint; yields grey hydrogen.

- Blue Hydrogen: Incorporates carbon capture and storage, reducing the carbon footprint.

- Alkaline Electrolysis: Low carbon footprint; green hydrogen when powered by renewables.

- PEM Electrolysis: Similar benefits to alkaline electrolysis.

- Solid Oxide Electrolysis: Also, low carbon footprint when reliant on renewable energy.

- Anaerobic Digestion: Moderate carbon footprint; produces green hydrogen from organic waste.

- Pyrolysis: Moderate carbon footprint; converts biomass to hydrogen.

- Photoelectrochemical Water Splitting: Very low carbon footprint; utilizes sunlight directly for hydrogen.

- Solar Thermochemical Processes: Another very low carbon footprint method using solar energy.

2.2. Discussion of the Environmental Impact

Environmental Impacts of Large-Scale Hydrogen Production with CCS

- 1.

- Energy Intensity of Hydrogen and CCS Processes:

- 2.

- Risks of CO2 Leakage:

- 3.

- Infrastructure and Ecological Impact:

- 4.

- Long-Term Storage Uncertainty:

- 5.

- Public Perception and Opposition:

- 6.

- Land and Water Use Concerns:

| Method | Environmental Impact | Carbon Footprint |

|---|---|---|

| Steam methane reforming | SMR is the most commonly utilized approach for generating hydrogen, yet it poses environmental difficulties [45]. It produces CO2 emissions as a byproduct since it relies on natural gas as a feedstock. For every kilogram of hydrogen produced through SMR, about 9–12 kg of CO2 are emitted [53]. | The carbon footprint of SMR is significant due to greenhouse gas emissions from methane reforming. It contributes to carbon emissions if not coupled with CCS technologies to capture and store the CO2 byproduct [48]. |

| Electrolysis | Using renewable energy sources to power electrolysis can make hydrogen production a more environmentally friendly process [46]. Green hydrogen produced through electrolysis with renewable electricity has minimal environmental impact, as the only byproduct is oxygen. However, if electrolysis is powered by fossil fuels, it can still have a carbon footprint [49]. | The carbon footprint of electrolysis depends on the source of electricity used. When powered by renewable energy, electrolysis can be a carbon-neutral or low-carbon method of hydrogen production. However, utilizing electricity from fossil fuels increases the carbon footprint associated with the process [51]. |

| Biomass gasification | Biomass gasification offers a renewable alternative for hydrogen production. While biomass gasification produces carbon dioxide as a byproduct, the carbon released during the gasification process is considered part of the natural carbon cycle when sustainably sourced biomass feedstocks are used [47]. | The sustainability of biomass acquisition and the effectiveness of the gasification process are significant factors influencing the carbon footprint of biomass gasification. Biomass gasification has the potential to achieve carbon neutrality or even carbon negativity when the biomass input is sourced sustainably and any carbon emissions are counterbalanced through carbon capture or storage [50,52]. |

2.3. Risks and Mitigation Strategies for Large-Scale CCS Deployment

- CO2 Leakage: One of the primary concerns with large-scale CCS deployment is the risk of CO2 leakage from storage sites, which could undermine the environmental benefits of CCS. CO2 leakage can occur through geological faults or improperly sealed wells. To mitigate this risk, rigorous site selection criteria are crucial. Storage sites should be chosen based on their geological stability and the presence of impermeable cap rocks to prevent CO2 escape. Additionally, advanced monitoring technologies such as seismic imaging, pressure sensors, and soil gas sampling can detect early signs of leakage, enabling timely intervention.

- Induced Seismicity: The injection of large volumes of CO2 into deep geological formations can potentially trigger small seismic events due to increased subsurface pressure. This risk is particularly relevant in regions with existing fault lines or high tectonic activity. Risk assessments should be conducted prior to injection to evaluate the seismic stability of storage sites. Furthermore, pressure management techniques, such as regulating the rate of CO2 injection, can reduce the risk of induced seismicity. In some cases, water extraction from the formation can help balance the pressure and minimize the likelihood of seismic activity.

- Public Perception and Acceptance: Public opposition to CCS projects, often due to concerns about safety and environmental impact, can hinder large-scale deployment. Transparent communication about safety measures and environmental benefits is essential for gaining public trust. Engaging with local communities and stakeholders early in the project development process can address concerns and provide accurate information on risks and mitigation strategies. Additionally, government regulations and certification programs can ensure CCS projects comply with the highest safety standards, further building public confidence.

- Long-Term Liability: The long-term responsibility for stored CO2 is a significant issue, particularly if leakage occurs decades after injection. To mitigate this risk, long-term monitoring plans should be established for CCS projects, even after injection operations have ceased. Governments should implement clear legal frameworks that define liability for stored CO2, including who is responsible for monitoring and remediation in the event of leakage. Insurance mechanisms or carbon storage funds can also be established to cover potential costs associated with future leakage incidents.

- Ecosystem Disruption: Although the direct environmental footprint of CCS is relatively small, large-scale deployment could disrupt local ecosystems, particularly during the construction of storage sites and pipelines. Environmental impact assessments (EIAs) should be conducted to evaluate and minimize the potential impact on biodiversity and local ecosystems. These assessments should include strategies such as revegetation, habitat restoration, and the use of biodiversity corridors to ensure minimal disruption to wildlife. By incorporating these mitigation strategies into the design and implementation of large-scale CCS projects, we can significantly reduce the potential risks and make CCS a more viable and environmentally sustainable solution for carbon mitigation.

3. Carbon Capture and Storage Techniques

3.1. Explanation of Various CCS Technologies

3.2. Importance of CCS in Reducing CO2 Emissions

- Emissions Reduction: Industrial operations contribute significantly to global CO2 emissions, particularly in sectors such as cement manufacturing, steel production, and chemical processing. By deploying CCS technologies in industrial plants, CO2 emissions can be captured and securely stored underground, leading to a substantial reduction in the carbon footprint of these industries [66].

- Process Decarbonization: Many industrial processes rely on fossil fuels for heat and power generation, leading to significant CO2 emissions. CCS provides a means to decarbonize these operations by capturing CO2 emissions directly from the source and preventing their release into the atmosphere, assisting industries in transitioning to greener and more sustainable production practices [67].

- Decarbonization of Energy-Intensive Industries: Industries that rely heavily on energy and have limited low-carbon alternatives, such as cement and steel manufacturing, can greatly benefit from CCS. By capturing and storing CO2 emissions, these industries can continue their operations while minimizing their environmental impact and meeting emissions reduction targets [68].

- Technological Innovation: The deployment of CCS technologies in industrial processes drives innovation and research in carbon capture, utilization, and storage. Advancements in capture technologies, storage methods, and process optimization contribute to the development of more efficient and cost-effective solutions for reducing CO2 emissions across industries [69].

- Sectoral Collaboration: CCS encourages collaboration between industry stakeholders, policymakers, and researchers to develop tailored solutions for industrial decarbonization. Partnerships between governments, research institutions, and industry players drive knowledge sharing, investment opportunities, and regulatory support for the effective implementation of CCS in industrial processes [70].

- Economic Viability: By capturing and monetizing CO2 emissions through processes like enhanced oil recovery or industrial reuse, CCS can offer economic benefits for industrial facilities. In addition to reducing emissions, CCS can create new revenue streams and support the transition to a low-carbon economy without compromising industrial competitiveness [71].

- Climate Goals and Sustainability: Meeting climate targets and achieving sustainability objectives requires significant reductions in industrial emissions. CCS provides a proven technology for capturing and storing CO2 emissions from industrial processes, playing a critical role in achieving net-zero emissions and advancing sustainable industrial practices [72]. Overall, CCS is a vital tool for reducing CO2 emissions from industrial processes, offering industries a pathway to achieve decarbonization goals, enhance competitiveness, and contribute to global efforts to address climate change. By integrating CCS technologies into industrial operations, industries can lower their carbon footprint, enhance environmental performance, and drive sustainable growth in a carbon-constrained world [73].

4. Integration of CCS into Hydrogen Production

4.1. How CCS Can Be Integrated into Hydrogen Production Processes

- SMR with CCS:

- ⚬

- Integration: In SMR, CO2 is a byproduct of hydrogen production. Implementing CCS in SMR facilities enables the capture, compression, and underground storage of CO2 emissions [75].

- ⚬

- Process: Captured CO2 from the SMR process undergoes purification and compression before being transported to suitable storage sites for sequestration [76].

- ⚬

- Environmental Benefits: Combining CCS with SMR significantly reduces CO2 emissions linked to hydrogen production, promoting environmental sustainability [77].

- Electrolysis with CCS:

- ⚬

- Integration: When electrolysis is powered by fossil fuels, it can result in carbon emissions. Integrating CCS with electrolysis facilities allows for the capture and storage of CO2 emitted during the process [78].

- ⚬

- Process: CO2 generated as a byproduct during electrolysis can be captured using CCS technologies and stored underground, effectively reducing the carbon footprint of hydrogen production [79].

- ⚬

- Advantages: Coupling electrolysis with CCS further lowers emissions and promotes climate-friendly hydrogen generation [80].

- Biomass Gasification with CCS:

- ⚬

- Integration: Biomass gasification for hydrogen production can benefit from CCS. CO2 produced during biomass gasification can be captured and stored, enabling carbon-neutral or even carbon-negative hydrogen production [81].

- ⚬

- Process: Captured CO2 from the gasification process undergoes purification and compression before injection into suitable geological storage formations [82].

- ⚬

- Environmental Benefits: Integrating biomass gasification with CCS enhances the environmental sustainability of hydrogen production, offering a renewable and low-carbon pathway for hydrogen generation [83].

- Synergy with Renewables:

- ⚬

- Renewable Energy Integration: CCS can complement renewable hydrogen production methods, such as electrolysis powered by renewable energy sources. Excess renewable energy can be used to capture and store CO2 emissions from other energy-intensive processes, promoting a circular and sustainable energy system [84].

4.2. Synergies, Benefits, and Challenges of Combining CCS with Hydrogen Production

- Emissions Reduction: Integrating CCS with hydrogen production processes enables industries to significantly reduce their carbon footprints by capturing and storing CO2 emissions, contributing to climate change mitigation efforts [87].

- Sustainability: The combination of CCS and hydrogen production promotes sustainable energy practices, enhances environmental performance, and supports the transition to low-carbon energy systems [88].

- Circular Economy: The synergy between CCS and hydrogen production creates a circular energy system where CO2 emissions are captured and utilized or stored, fostering resource efficiency and environmental stewardship [89].

- Climate Mitigation: CCS integration into hydrogen production helps industries meet emissions reduction targets, comply with regulations, and support global efforts to combat climate change by reducing CO2 emissions [90].

- Cleaner Hydrogen: Incorporating CCS ensures that the hydrogen produced is cleaner and more environmentally friendly, enhancing its marketability and sustainability as a low-carbon energy carrier [91].

- Decarbonization: The coupling of CCS with hydrogen production accelerates the decarbonization of industrial processes, power generation, and transportation by mitigating emissions and promoting sustainable energy practices [92].

- Cost: The upfront capital costs of implementing CCS technologies can be substantial, posing a financial barrier to the adoption of CCS in hydrogen production facilities [93].

- Energy Intensity: CCS integration may increase the energy requirements of hydrogen production processes, affecting overall efficiency and operational costs [94].

- Infrastructure Requirements: Establishing the infrastructure for CO2 capture, transport, and storage can be complex and require coordination among stakeholders, regulatory compliance, and investment in storage sites [95].

- Technological Advancements: The advancement and implementation of CCS technologies for hydrogen production may encounter obstacles concerning technology readiness, scalability, and economic feasibility, necessitating ongoing research and innovation [96].

Technological Challenges in Integrating CCS with Hydrogen Production

- SMR with CCS: SMR is the most widely used method for large-scale hydrogen production, but it generates significant CO2 emissions. Integrating CCS into SMR facilities involves capturing CO2 from flue gases, compressing it, and transporting it to storage sites. The main technological challenges include the efficiency of CO2 capture, the high energy penalty of the capture process (typically 10–15% of the plant’s total energy consumption), and ensuring the scalability of capture systems to reduce costs over time. There are also challenges in retrofitting existing SMR plants with CCS technologies.

- Electrolysis with CCS: When electrolysis is powered by fossil fuels, carbon emissions are still a concern. Integrating CCS with these systems involves capturing the CO2 generated during electricity production. The challenges here include improving the efficiency of the electrolysis process, particularly with high-temperature electrolysis techniques such as solid oxide electrolysis, which can achieve efficiencies above 85%. However, capturing CO2 from power plants that use fossil fuels to supply electricity to electrolysis adds complexity, particularly in terms of optimizing both the hydrogen production and carbon capture processes.

- Biomass Gasification with CCS: Biomass gasification with CCS offers the potential for carbon-neutral or even carbon-negative hydrogen production, but integrating CCS with this method introduces complexities. The CO2 captured from biomass gasification must be purified and compressed for storage, similar to SMR, but the process of capturing CO2 from biomass requires advanced purification technologies to handle impurities in the gas stream. Additionally, optimizing the capture process while maintaining the efficiency of hydrogen production is a significant challenge.

- Infrastructure and Integration Challenges: Regardless of the hydrogen production method, one of the biggest challenges in integrating CCS is developing the necessary infrastructure for CO2 transport and storage. Pipelines and storage sites must be developed and maintained, which requires substantial investment and coordination between different sectors. The monitoring of long-term CO2 storage sites to prevent leakage is another significant technological and regulatory hurdle.

5. Opportunities and Advantages

5.1. Opportunities Presented by Integrating CCS into Hydrogen Production

- Green Hydrogen Production: Coupling CCS with hydrogen production methods powered by renewable energy sources enables the production of green hydrogen with minimal to no carbon emissions, contributing to carbon neutrality goals [99].

- Industrial Decarbonization: The integration of CCS into hydrogen production allows industries to decarbonize their operations, reduce greenhouse gas emissions, and transition towards cleaner and more sustainable production methods, aligning with carbon neutrality objectives [100].

- Sectoral Decarbonization: Integrating CCS into hydrogen production offers a means to decarbonize sectors that are difficult to electrify directly, such as heavy industry, transportation, and power generation, facilitating the transition to low-carbon energy systems [101].

- Sector Coupling: The synergy between CCS and hydrogen production enables sector coupling, integrating renewable energy sources with carbon capture technologies to produce clean hydrogen for various applications and fostering a holistic approach to achieving carbon neutrality [102].

- Carbon Offsetting: Capturing and storing CO2 emissions from hydrogen production processes through CCS provides industries with a carbon offsetting mechanism, helping to balance emissions and achieve net-zero carbon emissions targets [103].

- Emissions Reduction: Integrating CCS into hydrogen production supports emissions reduction strategies by capturing CO2 emissions, minimizing the environmental impact of hydrogen production, and contributing to a more sustainable and environmentally conscious energy sector [104].

- Technological Innovation: Continued advancements in CCS technologies, hydrogen production methods, and energy storage solutions drive innovation towards carbon-neutral hydrogen production, offering efficient and scalable pathways to reach carbon neutrality [105].

- Policy Support: Policy frameworks that incentivize CCS integration into hydrogen production, establish carbon pricing mechanisms, and promote renewable energy adoption create an enabling environment for industries to transition towards carbon neutrality [106].

- Collaborative Partnerships: Collaborations among governments, industry stakeholders, research institutions, and technology developers foster knowledge sharing, investment opportunities, and regulatory support for implementing CCS in hydrogen production to achieve carbon neutrality [107].

- Market Transformation: The incorporation of CCS in hydrogen production can disrupt conventional energy systems, accelerate the uptake of low-carbon technologies, and drive market evolution towards a carbon-neutral economy, promoting sustainability and resilience in the energy industry [108].

5.2. Possible Advantages in the Areas of Economy, Environment, and Society

- Market Growth and Job Creation: CCS integration into hydrogen production can drive the expansion of the clean energy technology market, leading to increased innovation, investment, and job opportunities in the renewable energy and carbon capture industries [111].

- Revenue Generation: CCS can create new revenue streams through carbon offsetting, emissions trading, and value-added products derived from captured CO2, boosting economic opportunities for industries [112].

- Cost Reduction: The scalability and efficiency of CCS technologies in hydrogen production can drive down costs over time, making carbon-neutral hydrogen more competitive and economically viable compared to conventional high-emissions processes [113].

- Emissions Reduction: CCS integration into hydrogen production leads to substantial reductions in greenhouse gas emissions, contributing to climate change mitigation efforts by capturing and storing CO2 emissions [114].

- Air Quality Improvement: By reducing CO2 emissions and other pollutants from industrial processes, CCS integration enhances air quality, diminishes health risks associated with pollution, and promotes cleaner environments for communities near industrial facilities [115].

- Resource Conservation: Shifting towards carbon-neutral hydrogen production through CCS helps conserve natural resources, reduce fossil fuel dependency, and promote sustainable practices that safeguard ecosystems and biodiversity [116].

- Health and Wellbeing: The deployment of CCS technologies in hydrogen production enhances public health by lowering emissions of pollutants and greenhouse gases and creating cleaner and healthier living conditions for communities in industrial areas [117].

- Community Engagement: Engaging local communities in CCS projects fosters transparency, trust, and social acceptance of sustainable energy initiatives, promoting collaboration and mutual understanding [118].

- Energy Access and Equity: CCS integration into hydrogen production supports the transition to low-carbon energy systems, promoting equitable access to clean energy, addressing energy poverty, and ensuring energy security for all segments of society [119].

6. Challenges and Limitations

6.1. Technical, Economic, and Regulatory Challenges

- Efficiency and Energy Consumption: CCS integration can increase energy requirements and affect overall process efficiency. Innovations in capture technologies, process optimization, and energy management are essential to address these challenges [124].

- Storage and Transportation: Secure storage of captured CO2 and efficient transportation to storage sites are crucial technical challenges. Developing safe and cost-effective storage solutions, enhancing transportation systems, and optimizing capture technologies are key focus areas [125].

- CO2 Capture Costs: The cost of CO2 capture technologies can be high, impacting the overall economics of CCS in hydrogen production. Research and development efforts to reduce capture costs, improve efficiency, and scale up technologies are essential [126].

- Capital Investment: Implementing CCS technologies requires significant upfront capital investment, which can be a barrier to adoption. Financial incentives, supportive policies, and public–private partnerships can help offset initial costs and encourage investment [127].

- Operating Costs: Operating and maintenance costs associated with CCS integration, including storage, monitoring, and verification, add to the economic challenges. Innovations in operational efficiency, cost-effective solutions, and optimized workflows can help manage ongoing expenses [128].

- Carbon Pricing and Market Mechanisms: The absence of formal carbon pricing mechanisms or supportive market frameworks can hinder the economic viability of CCS in hydrogen production. Establishing carbon pricing, emissions trading systems, or carbon offset markets can incentivize investment in carbon-neutral technologies [129].

- Regulatory Frameworks: The complexity of regulatory requirements, permits, and approvals for CCS projects presents a regulatory challenge. Streamlining regulatory processes, providing clear guidelines, and promoting regulatory certainty can facilitate the deployment of CCS technologies [130].

- Liability and Risk Management: Legal aspects related to liability, long-term liability for stored CO2, and risk management in CCS projects need to be addressed. Establishing liability frameworks, risk mitigation strategies, and insurance mechanisms can provide clarity and confidence for stakeholders [131].

- Public Acceptance: Social acceptance and stakeholder engagement are vital for the success of CCS projects. Building public awareness, fostering community involvement, and ensuring transparent communication can address concerns and enhance public support for CCS integration in hydrogen production [132].

- Research and Development: Continued research and innovation in CCS technologies, storage solutions, and process optimization can drive technical advancements and improve the efficiency and cost-effectiveness of CCS in hydrogen production [133].

- Collaboration and Partnerships: Collaboration among industry stakeholders, governments, research institutions, and communities is essential to address technical, economic, and regulatory obstacles. Leveraging specialized skills, resources, and information exchange can facilitate the implementation of CCS [134].

- Policy Support: Implementing supportive policies, incentives, and regulatory frameworks that promote CCS integration into hydrogen production is crucial. Policy alignment with climate goals, carbon pricing mechanisms, and carbon-neutral strategies can create an enabling environment for CCS implementation [135].

6.2. Potential Barriers to Widespread Adoption and Implementation

- Technology Maturity: CCS technologies are still in the early stages of development or testing, with limited full-scale implementation. Advancements in technology readiness, scalability, and performance are crucial to overcome these technical barriers [137].

- Energy Intensity: Integrating CCS into hydrogen production processes may increase energy demands and operational complexity, impacting overall efficiency and productivity. Developing solutions to minimize energy requirements and enhance system integration is essential [138].

- Carbon Capture Efficiency: Achieving high capture rates and optimal CO2 separation efficiency remains a technical challenge. Enhancing the efficiency, reliability, and affordability of capture technologies is essential for their widespread adoption [139].

- Capital Investment: The high capital costs associated with CCS deployment, including infrastructure, equipment, maintenance, and operational expenses, can be a significant barrier to adoption. Developing cost-effective solutions, incentivizing investment, and reducing overall lifecycle costs are critical [140].

- Economic Viability: Industries may face uncertainties regarding the economic viability and return on investment of CCS projects. Clear business cases, financial incentives, and economic assessments are needed to demonstrate the long-term benefits of CCS integration [141].

- Carbon Pricing: The lack of strong carbon pricing mechanisms or market incentives for CO2 reduction can hinder the economic viability of CCS projects. Establishing carbon pricing frameworks, emissions trading systems, or carbon offset markets is crucial for overcoming economic barriers [142].

- Regulatory Complexity: Compliance with evolving regulatory requirements, permitting processes, and environmental standards for CCS projects can be complex and time-consuming. Streamlining regulatory processes, providing clear guidelines, and promoting regulatory certainty can facilitate the deployment of CCS technologies [143].

- Liability and Risk Management: Legal aspects related to liability, long-term liability for stored CO2, and risk management in CCS projects need to be addressed. Establishing liability frameworks, risk mitigation strategies, and insurance mechanisms can provide clarity and confidence for stakeholders [144].

- Policy Alignment: Inconsistencies in national policies, international agreements, and regulatory frameworks related to carbon reduction and CCS deployment can create barriers to widespread adoption. Aligning policies with climate goals, sustainability objectives, and clean energy strategies is essential for promoting CCS implementation [145].

- Public Perception: Limited awareness, misconceptions, and concerns about CCS technologies and their environmental impacts can hinder public acceptance. Education, outreach, and stakeholder engagement efforts are necessary to build trust, address misconceptions, and promote social acceptance [146].

- Community Engagement: Lack of community involvement, consultation, and participation in decision-making processes for CCS projects can lead to resistance and opposition. Establishing transparent communication channels, fostering engagement, and addressing community concerns are key to overcoming social barriers [147].

- Information Exchange: Limited knowledge sharing, collaboration, and technology transfer among nations, industries, and stakeholders may impede the global deployment of CCS technologies. Promoting international cooperation, fostering best practices, and facilitating technology exchange can enhance adoption and implementation [148].

- Capacity Building: Insufficient expertise, resources, and institutional capacity for CCS project development and deployment in certain regions can be a barrier to implementation. Building technical capacity, skill development, and knowledge exchange initiatives can support widespread adoption of CCS technologies [149].

7. Current Trends and Case Studies

7.1. Review of Recent Developments, Pilot Projects, and Commercial Initiatives

- H21 North of England Project: This project aims to transition the UK’s gas infrastructure to hydrogen with CCS, reducing carbon emissions from industrial areas and residential heating systems [151].

- H2H Saltend Project: This UK-based project focuses on generating low-carbon hydrogen by capturing and sequestering CO2 emissions from SMR operations [152].

- Oxyfuel Project at Longannet: This Scottish project is researching oxy-fuel combustion combined with CCS for hydrogen production, aiming to create a concentrated CO2 stream for storage [153].

- H-Vision Project: This Dutch project seeks to manufacture blue hydrogen by capturing CO2 from steam methane reforming processes and storing it underground [154].

- Hybrit Initiative: This Swedish pilot project focuses on green hydrogen production and CCS integration, using renewable energy sources to power electrolysis for hydrogen production [155].

- Drax Bioenergy CCS Project: Drax Group in the UK is exploring bioenergy with CCS to produce hydrogen, capturing CO2 emissions from bioenergy production and extracting hydrogen for various applications [156].

- Port of Rotterdam H-vision Project: This project aims to implement large-scale hydrogen production with carbon capture infrastructure at the Port of Rotterdam in The Netherlands [157].

- Northern Lights Project (2023): This Norwegian project is one of the largest CCS projects in Europe, designed to capture CO2 from industrial sources and store it in offshore geological formations [159].

- Solid Oxide Electrolysis (2023): Research into SOECs has demonstrated record efficiency levels for green hydrogen production, exceeding 90% when integrated with waste heat from industrial processes. Pilot projects have successfully scaled up SOEC technology for industrial applications [160].

- Allam Cycle Hydrogen Plant (2022): This plant produces clean hydrogen while capturing CO2 as part of the production process, utilizing supercritical CO2 as a working fluid in a closed-loop system. It has successfully demonstrated its capacity to generate 50 MW of clean hydrogen [161].

- Direct Air Capture Integration (2023): Several hydrogen production facilities have begun integrating DAC technology to achieve carbon-negative hydrogen. The Climeworks project in Iceland is a prime example, combining DAC with hydrogen production powered by geothermal energy [162].

7.2. Analysis of Successful Case Studies and Lessons Learned

- Early Planning and Risk Assessment: Conducting thorough risk assessments, comprehensive feasibility studies, and scenario planning early in the project lifecycle helps identify potential challenges, mitigate risks, and enhance project preparedness [166].

- Technology Selection and Scalability: Careful selection of appropriate CCS technologies, evaluation of scalability requirements, and consideration of integration with hydrogen production processes are critical factors for successful deployment and long-term viability [167].

- Stakeholder Engagement and Communication: Engaging with stakeholders, fostering open communication, and addressing community concerns are essential for gaining support, building trust, and ensuring the social license to operate CCS projects [168].

- Regulatory Compliance and Permitting: Navigating regulatory landscapes, securing necessary permits, and complying with environmental standards in CCS integration require strategic planning, regulatory expertise, and proactive engagement with regulatory bodies [169].

- Monitoring and Verification: Implementing robust monitoring, reporting, and verification protocols is vital for ensuring the efficiency, safety, and environmental performance of CCS projects, including in hydrogen production applications [170].

- Knowledge Sharing and Collaboration: Encouraging knowledge sharing, fostering industry collaboration, and disseminating best practices from successful case studies can drive innovation, accelerate technology deployment, and facilitate the wider adoption of CCS in hydrogen production [171].

8. Future Perspectives

8.1. Insights into the Future

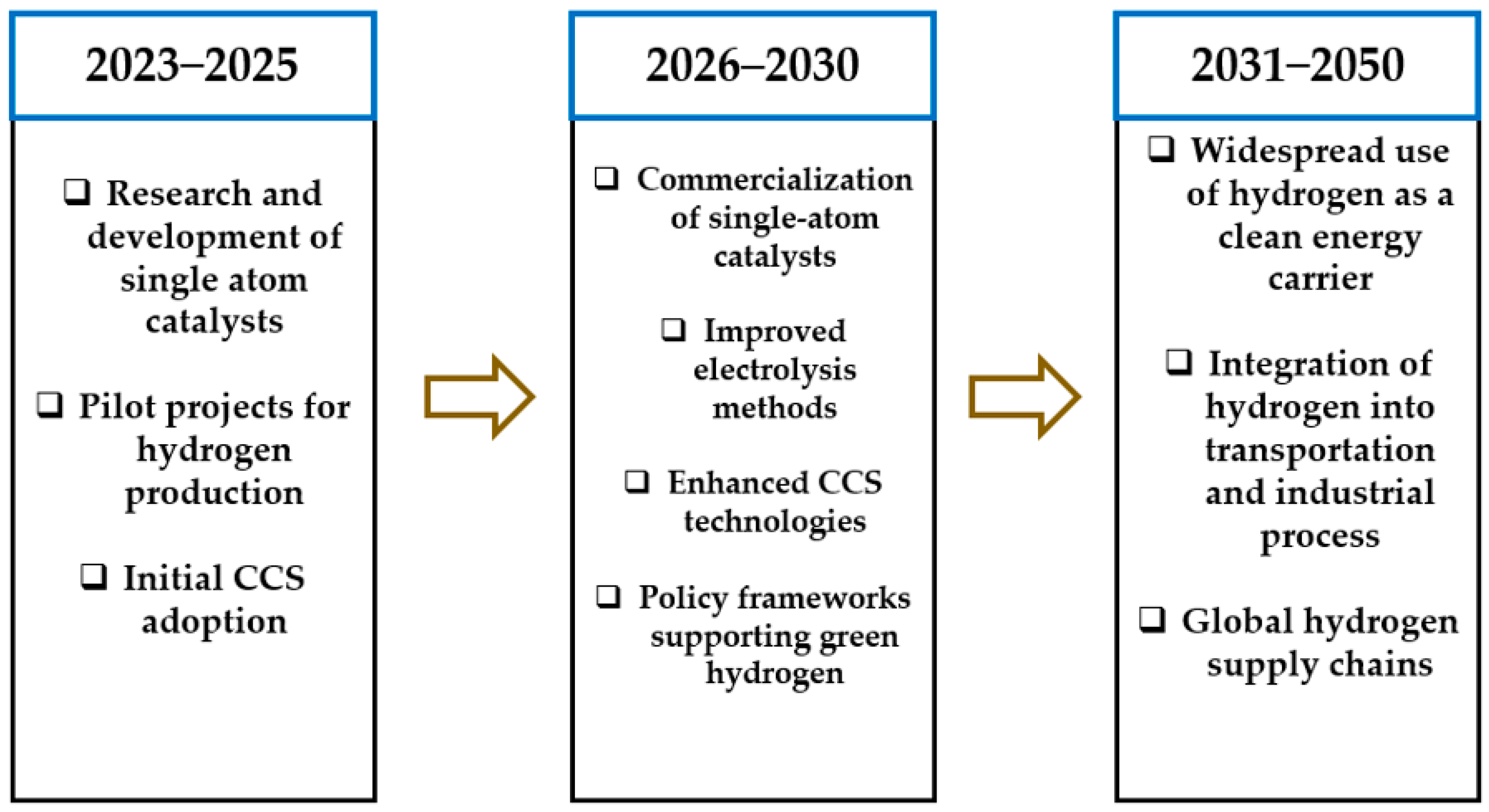

- Rapid Expansion: The adoption of CCS technologies in hydrogen production is expected to expand rapidly, driven by emissions reduction targets, climate initiatives, and the growing demand for low-carbon hydrogen [174].

- Technological Advancements: Continued innovations in CCS technologies, efficiency improvements, cost reductions, and scalability enhancements will drive the development of more effective and commercially viable solutions for CCS integration into hydrogen production [175].

- Renewable Energy Integration: The integration of CCS with electrolysis powered by renewable energy sources is anticipated to grow, leading to increased production of green hydrogen and further decarbonization of industrial processes [176].

- Industrial Transformation: CCS integration into hydrogen production is crucial for reshaping energy-intensive sectors towards carbon-neutral processes, promoting sustainable industrial practices and improved environmental sustainability [177].

- Infrastructure Expansion: Investments in CCS infrastructure, storage facilities, transportation networks, and hydrogen production plants will expand to support the scaling up of CCS integration into hydrogen production [178].

- Policy Support: Strong policy frameworks, carbon pricing mechanisms, regulatory incentives, and government support will be instrumental in driving the deployment of CCS technologies and accelerating the adoption of carbon-neutral hydrogen production [179].

- International Cooperation: Global collaboration, information exchange, partnerships, and technology transfer programs will be vital for driving worldwide efforts towards combining CCS with hydrogen production and meeting carbon-neutrality objectives [180].

- Innovation and Research: Research and development initiatives, pilot projects, demonstration facilities, and collaborative partnerships will focus on advancing CCS technologies, exploring new applications, and addressing technical challenges to further enhance the feasibility and efficiency of CCS integration into hydrogen production processes [181].

- Emissions Reduction: Widespread adoption of CCS integration into hydrogen production will significantly reduce CO2 emissions, contributing to climate change mitigation, improved air quality, and sustainable development [182].

- Biodiversity Preservation: CCS integration into hydrogen production can help preserve biodiversity and natural ecosystems by promoting sustainable industrial practices, reducing environmental impacts, and fostering responsible resource management [183].

- Job Creation: The growth of CCS integration into hydrogen production will create employment opportunities, promote skill development, and stimulate economic growth in clean energy sectors, contributing to a more resilient and diverse workforce [184].

- Community Engagement: Strengthening community engagement, fostering social acceptance, and ensuring transparent communication with local residents will be essential for building trust, addressing concerns, and promoting the benefits of CCS integration into hydrogen production at the grassroots level [185].

- Catalyst Technologies: Breakthroughs in single-atom catalysts and other novel materials have the potential to significantly reduce the energy consumption of hydrogen production through electrolysis. Future research should focus on improving the efficiency and scalability of these materials to make green hydrogen production more cost-competitive.

- Renewable Energy Integration: A key future perspective is the integration of hydrogen production with intermittent renewable energy sources like wind and solar. Research should aim to develop flexible, efficient systems that can store excess energy as hydrogen, enhancing grid stability and energy storage solutions.

- Policy and Economic Incentives: Supportive policy frameworks that incentivize investment in green hydrogen and carbon capture, as well as international collaborations to standardize regulations, are crucial for shaping the future of these technologies.

- Scalability and Infrastructure: While pilot projects have demonstrated feasibility, large-scale deployment of hydrogen production and CCS infrastructure remains a challenge. Future work should explore solutions for scaling up these technologies, particularly in regions with abundant renewable resources and industrial demand.

8.2. Discussion of Emerging Technologies, Research Directions, and Policy Considerations

- Emerging Technologies:

- Advanced Capture Methods: Continued research focuses on enhancing capture technologies to improve efficiency, reduce energy requirements, and lower costs. Innovations in solvent-based capture, membrane technologies, and solid sorbents aim to optimize CO2 capture in hydrogen production processes [187].

- Direct air capture technologies are increasingly recognized for extracting CO2 directly from the air. By incorporating DAC with hydrogen production, carbon-negative hydrogen pathways can be realized, providing a flexible strategy to achieve net-negative emissions [188].

- Novel Electrolysis Techniques: Studies are investigating improvements in electrolysis techniques, including high-temperature electrolysis, solid oxide electrolysis cells, and membrane electrolysis, to enhance efficacy, lower energy usage, and facilitate extensive green hydrogen manufacturing [189].

- Storage Optimization: Innovations in CO2 storage methods, including geological sequestration, mineralization, and utilization, aim to enhance CO2 storage capacities, improve containment effectiveness, and ensure long-term stability for carbon sequestration in hydrogen production applications [190].

- Direct air capture is a groundbreaking technology that directly removes CO2 from the atmosphere, offering the potential for large-scale carbon removal. DAC systems typically rely on chemical processes using solid sorbents or liquid solvents to capture CO2 from ambient air, which is then either sequestered underground or utilized in synthetic fuel production. Recent advancements have led to improved efficiency and cost reductions, though the current cost is estimated to be between USD 100 and USD 300 per metric ton of CO2 captured. However, with ongoing research and increased deployment, costs are expected to decrease significantly. DAC offers a unique opportunity for producing carbon-neutral or carbon-negative hydrogen when integrated with hydrogen production systems. Captured CO2 can be combined with green hydrogen to create synthetic fuels, or it can be stored permanently, offsetting emissions from other sectors.

- Recent advancements in water electrolysis have focused on improving efficiency and reducing costs. High-temperature electrolysis (HTE), using solid oxide electrolysis cells (SOECs), has emerged as a promising method for producing green hydrogen. SOECs operate at temperatures between 600 °C and 800 °C, utilizing heat energy to lower the electrical energy required for splitting water into hydrogen and oxygen. This results in overall system efficiencies of above 85%, which is significantly higher than conventional PEM or alkaline electrolyzers, which typically operate at 60–70% efficiency.

- Research Directions:

- Carbon Recycling: Research is looking into carbon recycling approaches where captured CO2 is transformed into valuable products like synthetic fuels, chemicals, or construction materials, establishing a circular carbon economy and boosting the economic feasibility of hydrogen production with CCS [191].

- Hybrid Energy Systems: Combining renewable energy sources with CCS-integrated hydrogen production can lead to the development of hybrid energy systems that leverage intermittent renewables alongside carbon capture technologies for sustainable and resilient energy generation [192].

- Material Innovation: Research on advanced materials, catalysts, and membranes for CO2 capture, electrolysis, and storage aims to enhance the performance, durability, and efficiency of hydrogen production processes, driving technological breakthroughs in clean hydrogen production pathways [193].

- System Integration: Comprehensive studies on system integration of CCS technologies with hydrogen production facilities focus on optimizing process flows, improving energy utilization, and minimizing environmental impacts to create integrated, efficient, and sustainable hydrogen production systems [194].

- 1.

- Capital Costs:

- 2.

- Operational Costs and Energy Penalty:

- 3.

- Potential Revenue and Cost Savings:

- 4.

- Levelized Cost of Hydrogen (LCOH):

- 5.

- Cost–Benefit Analysis (CBA):

- Policy Considerations:

- Carbon Pricing Mechanisms: The implementation of robust carbon pricing mechanisms, emissions trading systems, and carbon markets can incentivize investments in CCS-integrated hydrogen production, drive decarbonization efforts, and align economic incentives with climate goals [200,201,202,203,204,205].

- Future Landscape:

Policy Recommendations for Promoting CCS-Integrated Hydrogen Production

- 1.

- Carbon Pricing Mechanisms:

- 2.

- Regulatory Frameworks and Standards:

- 3.

- Financial Incentives and Subsidies:

- 4.

- Research and Innovation Funding:

- 5.

- International Cooperation:

- 6.

- Public Awareness and Engagement:

8.3. Techno-Economic Analysis of Hydrogen Production with CCS

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nagarajan, D.; Dong, C.D.; Chen, C.Y.; Lee, D.J.; Chang, J.S. Biohydrogen production from microalgae—Major bottlenecks and future research perspectives. Biotechnol. J. 2021, 16, 2000124. [Google Scholar] [CrossRef] [PubMed]

- Navas-Anguita, Z.; García-Gusano, D.; Dufour, J.; Iribarren, D. Revisiting the role of steam methane reforming with CO2 capture and storage for long-term hydrogen production. Sci. Total Environ. 2021, 771, 145432. [Google Scholar] [CrossRef] [PubMed]

- Sazali, N. Emerging technologies by hydrogen: A review. Int. J. Hydrogen Energy 2020, 45, 18753–18771. [Google Scholar] [CrossRef]

- Rastler, D. Challenges for fuel cells as stationary power resource in the evolving energy enterprise. J. Power Sources 2000, 86, 34–39. [Google Scholar] [CrossRef]

- Züttel, A.; Remhof, A.; Borgschulte, A.; Friedrichs, O. Hydrogen: The future energy carrier. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2010, 368, 3329–3342. [Google Scholar] [CrossRef]

- Noussan, M.; Raimondi, P.P.; Scita, R.; Hafner, M. The role of green and blue hydrogen in the energy transition—A technological and geopolitical perspective. Sustainability 2020, 13, 298. [Google Scholar] [CrossRef]

- Bertagni, M.B.; Pacala, S.W.; Paulot, F.; Porporato, A. Risk of the hydrogen economy for atmospheric methane. Nat. Commun. 2022, 13, 7706. [Google Scholar] [CrossRef]

- Islam, M.H.; Burheim, O.S.; Pollet, B.G. Sonochemical and sonoelectrochemical production of hydrogen. Ultrason. Sonochemistry 2019, 51, 533–555. [Google Scholar] [CrossRef]

- Sherwin, E.D. Electrofuel synthesis from variable renewable electricity: An optimization-based techno-economic analysis. Environ. Sci. Technol. 2021, 55, 7583–7594. [Google Scholar] [CrossRef]

- Dupas, M.C.; Parison, S.; Noel, V.; Chatzimpiros, P.; Herbert, É. Variable renewable energy penetration impact on productivity: A case study of poultry farming. PLoS ONE 2023, 18, e0286242. [Google Scholar] [CrossRef]

- Mulla, R.; Dunnill, C.W. Powering the hydrogen economy from waste heat: A review of heat-to-hydrogen concepts. ChemSusChem 2019, 12, 3882–3895. [Google Scholar] [CrossRef]

- Jiang, B.; Xia, D. Toward carbon neutrality in China: A national wide carbon flow tracing and the CO2 emission control strategies for CO2-intensive industries. Sci. Total Environ. 2023, 879, 163009. [Google Scholar] [CrossRef]

- Wu, L.M.; Chen, B.Y.; Ou, L.C.; Bai, Y.J.; Liu, K.X.; Wang, W.W.; Peng, B.; Wang, X.M. Impact of Accelerated Electrification Under the Low Carbon Path in Dongguan City on the Coordinated Emission Reduction of CO2 and Pollutants. Huanjing Kexue 2023, 44, 6653–6663. [Google Scholar]

- Wan, C.; Li, R.; Wang, J.; Cheng, D.G.; Chen, F.; Xu, L.; Gao, M.; Kang, Y.; Eguchi, M.; Yamauchi, Y. Silica Confinement for Stable and Magnetic Co− Cu Alloy Nanoparticles in Nitrogen-Doped Carbon for Enhanced Hydrogen Evolution. Angew. Chem. 2024, 63, e202404505. [Google Scholar] [CrossRef]

- Wu, C.; Li, X.; Liu, X.; Wei, S.; Tang, J.; Cheng, Y.; Zhao, Z.; Wang, A.; Jiang, J. Ce-doping-induced defect effects boosting H2 generation. J. Mater. Sci. Technol. 2024, in press. [CrossRef]

- Tang, J.; Su, C.; Shao, Z. Advanced membrane-based electrode engineering toward efficient and durable water electrolysis and cost-effective seawater electrolysis in membrane electrolyzers. Exploration 2024, 4, 20220112. [Google Scholar] [CrossRef]

- Zang, G.; Sun, P.; Yoo, E.; Elgowainy, A.; Bafana, A.; Lee, U.; Wang, M.; Supekar, S. Synthetic methanol/Fischer–Tropsch fuel production capacity, cost, and carbon intensity utilizing CO2 from industrial and power plants in the United States. Environ. Sci. Technol. 2021, 55, 7595–7604. [Google Scholar] [CrossRef]

- Artz, J.; Müller, T.E.; Thenert, K.; Kleinekorte, J.; Meys, R.; Sternberg, A.; Bardow, A.; Leitner, W. Sustainable conversion of carbon dioxide: An integrated review of catalysis and life cycle assessment. Chem. Rev. 2018, 118, 434–504. [Google Scholar] [CrossRef]

- Shah SA, A.; Solangi, Y.A. A sustainable solution for electricity crisis in Pakistan: Opportunities, barriers, and policy implications for 100% renewable energy. Environ. Sci. Pollut. Res. 2019, 26, 29687–29703. [Google Scholar] [CrossRef]

- Cooper, J.; Dubey, L.; Bakkaloglu, S.; Hawkes, A. Hydrogen emissions from the hydrogen value chain-emissions profile and impact to global warming. Sci. Total Environ. 2022, 830, 154624. [Google Scholar] [CrossRef]

- Singla, S.; Shetti, N.P.; Basu, S.; Mondal, K.; Aminabhavi, T.M. Hydrogen production technologies-membrane based separation, storage and challenges. J. Environ. Manag. 2022, 302, 113963. [Google Scholar] [CrossRef] [PubMed]

- Saini, P.; Singh, S.; Kajal, P.; Dhar, A.; Khot, N.; Mohamed, M.E.; Powar, S. A review of the techno-economic potential and environmental impact analysis through life cycle assessment of parabolic trough collector towards the contribution of sustainable energy. Heliyon 2023, 9, e17626. [Google Scholar] [CrossRef] [PubMed]

- Wilberforce, T.; Baroutaji, A.; Soudan, B.; Al-Alami, A.H.; Olabi, A.G. Outlook of carbon capture technology and challenges. Sci. Total Environ. 2019, 657, 56–72. [Google Scholar] [CrossRef]

- Yasemi, S.; Khalili, Y.; Sanati, A.; Bagheri, M. Carbon capture and storage: Application in the oil and gas industry. Sustainability 2023, 15, 14486. [Google Scholar] [CrossRef]

- Subraveti, S.G.; Rodríguez Angel, E.; Ramírez, A.; Roussanaly, S. Is Carbon Capture and Storage (CCS) really so expensive? An analysis of cascading costs and CO2 emissions reduction of industrial CCS implementation on the construction of a bridge. Environ. Sci. Technol. 2023, 57, 2595–2601. [Google Scholar] [CrossRef]

- Mukherjee, A.; Okolie, J.A.; Abdelrasoul, A.; Niu, C.; Dalai, A.K. Review of post-combustion carbon dioxide capture technologies using activated carbon. J. Environ. Sci. 2019, 83, 46–63. [Google Scholar] [CrossRef]

- Gluyas, J.; Thompson, L.; Allen, D.; Benton, C.; Chadwick, P.; Clark, S.; Klinger, J.; Kudryavtsev, V.; Lincoln, D.; Maunder, B.; et al. Passive, continuous monitoring of carbon dioxide geostorage using muon tomography. Philos. Trans. R. Soc. A 2019, 377, 20180059. [Google Scholar] [CrossRef]

- Salone, R.; De Paola, C.; Carbonari, R.; Rufino, F.; Avino, R.; Caliro, S.; Cuoco, E.; Santi, A.; Di Maio, R. High-resolution geoelectrical characterization and monitoring of natural fluids emission systems to understand possible gas leakages from geological carbon storage reservoirs. Sci. Rep. 2023, 13, 18585. [Google Scholar] [CrossRef]

- Cheah, W.Y.; Ling, T.C.; Juan, J.C.; Lee, D.J.; Chang, J.S.; Show, P.L. Biorefineries of carbon dioxide: From carbon capture and storage (CCS) to bioenergies production. Bioresour. Technol. 2016, 215, 346–356. [Google Scholar] [CrossRef]

- Zhang, Y.; Shi, L.; Ye, Z.; Chen, L.; Yuan, N.; Chen, Y.; Yang, H. Experimental Investigation of Supercritical CO2–Rock–Water Interactions in a Tight Formation with the Pore Scale during CO2–EOR and Sequestration. ACS Omega 2022, 7, 27291–27299. [Google Scholar] [CrossRef]

- Xu, M.; Zhang, X.; Shen, S.; Wei, S.; Fan, J.L. Assessment of potential, cost, and environmental benefits of CCS-EWR technology for coal-fired power plants in Yellow River Basin of China. J. Environ. Manag. 2021, 292, 112717. [Google Scholar] [CrossRef] [PubMed]

- Braun, C. Not in my backyard: CCS sites and public perception of CCS. Risk Anal. 2017, 37, 2264–2275. [Google Scholar] [CrossRef] [PubMed]

- Pratama, Y.W.; Patrizio, P.; Mac Dowell, N. National priorities in the power system transition to net-zero: No one size fits all. Iscience 2022, 25, 105260. [Google Scholar] [CrossRef]

- Pu, Z.; Amiinu, I.S.; Cheng, R.; Wang, P.; Zhang, C.; Mu, S.; Zhao, W.; Su, F.; Zhang, G.; Liao, S.; et al. Single-atom catalysts for electrochemical hydrogen evolution reaction: Recent advances and future perspectives. Nano-Micro Lett. 2020, 12, 1–29. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Song, Y.; Zheng, S.; Zhen, G.; Lu, X.; Kobayashi, T.; Xu, K.; Bakonyi, P. Electro-conversion of carbon dioxide (CO2) to low-carbon methane by bioelectromethanogenesis process in microbial electrolysis cells: The current status and future perspective. Bioresour. Technol. 2019, 279, 339–349. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, Z.; Liu, L.; Wang, Y.; Kawi, S. Catalytic CO2 Conversion to C1 Chemicals over Single-Atom Catalysts. Adv. Energy Mater. 2023, 13, 2301852. [Google Scholar] [CrossRef]

- Ahmad Kamaroddin, M.F.; Sabli, N.; Tuan Abdullah, T.A.; Siajam, S.I.; Abdullah, L.C.; Abdul Jalil, A.; Ahmad, A. Membrane-based electrolysis for hydrogen production: A review. Membranes 2021, 11, 810. [Google Scholar] [CrossRef]

- Agaton, C.B. Application of real options in carbon capture and storage literature: Valuation techniques and research hotspots. Sci. Total Environ. 2021, 795, 148683. [Google Scholar] [CrossRef]

- Liang, S.; Lin, X.; Liu, X.; Pan, H. The pathway to China’s carbon neutrality based on an endogenous technology CGE model. Int. J. Environ. Res. Public Health 2022, 19, 6251. [Google Scholar] [CrossRef]

- Dindi, A.; Coddington, K.; Garofalo, J.F.; Wu, W.; Zhai, H. Policy-driven potential for deploying carbon capture and sequestration in a fossil-rich power sector. Environ. Sci. Technol. 2022, 56, 9872–9881. [Google Scholar] [CrossRef]

- Siegelman, R.L.; Kim, E.J.; Long, J.R. Porous materials for carbon dioxide separations. Nat. Mater. 2021, 20, 1060–1072. [Google Scholar] [CrossRef] [PubMed]

- Yusuf, B.O.; Umar, M.; Kotob, E.; Abdulhakam, A.; Taialla, O.A.; Awad, M.M.; Hussain, I.; Alhooshani, K.R.; Ganiyu, S.A. Recent Advances in Bimetallic Catalysts for Methane Steam Reforming in Hydrogen Production: Current Trends, Challenges, and Future Prospects. Chem. Asian J. 2023, 19, e202300641. [Google Scholar] [CrossRef] [PubMed]

- Al-Fatesh, A.S.; Kumar, R.; Fakeeha, A.H.; Kasim, S.O.; Khatri, J.; Ibrahim, A.A.; Arasheed, R.; Alabdulsalam, M.; Lanre, M.S.; Osman, A.I.; et al. Promotional effect of magnesium oxide for a stable nickel-based catalyst in dry reforming of methane. Sci. Rep. 2020, 10, 13861. [Google Scholar] [CrossRef]

- Devasahayam, S. Decarbonising the Portland and other cements—Via simultaneous feedstock recycling and carbon conversions sans external catalysts. Polymers 2021, 13, 2462. [Google Scholar] [CrossRef] [PubMed]

- Sun, P.; Young, B.; Elgowainy, A.; Lu, Z.; Wang, M.; Morelli, B.; Hawkins, T. Criteria air pollutants and greenhouse gas emissions from hydrogen production in US steam methane reforming facilities. Environ. Sci. Technol. 2019, 53, 7103–7113. [Google Scholar] [CrossRef]

- Rego de Vasconcelos, B.; Lavoie, J.M. Recent advances in power-to-X technology for the production of fuels and chemicals. Front. Chem. 2019, 7, 454241. [Google Scholar] [CrossRef]

- Vecten, S.; Wilkinson, M.; Bimbo, N.; Dawson, R.; Herbert, B.M. Hydrogen-rich syngas production from biomass in a steam microwave-induced plasma gasification reactor. Bioresour. Technol. 2021, 337, 125324. [Google Scholar] [CrossRef]

- Le Formal, F.; Bourée, W.S.; Prévot, M.S.; Sivula, K. Challenges towards economic fuel generation from renewable electricity: The need for efficient electro-catalysis. Chimia 2015, 69, 789. [Google Scholar] [CrossRef]

- Tursunov, O.; Śpiewak, K.; Abduganiev, N.; Yang, Y.; Kustov, A.; Karimov, I. Thermogravimetric and thermovolumetric study of municipal solid waste (MSW) and wood biomass for hydrogen-rich gas production: A case study of Tashkent region. Environ. Sci. Pollut. Res. 2023, 30, 112631–112643. [Google Scholar] [CrossRef]

- Gatto, A.; Sadik-Zada, E.R. People have the power. Electricity production, renewable energy transition, and communities empowerment across 11 Nordic-Baltic countries. Environ. Sci. Pollut. Res. 2023, 30, 125464–125477. [Google Scholar] [CrossRef]

- Werle, S. Impact of feedstock properties and operating conditions on sewage sludge gasification in a fixed bed gasifier. Waste Manag. Res. 2014, 32, 954–960. [Google Scholar] [CrossRef] [PubMed]

- Shaker, L.M.; Al-Amiery, A.A.; Al-Azzawi, W.K. Nanomaterials: Paving the way for the hydrogen energy frontier. Discov. Nano 2024, 19, 3. [Google Scholar] [CrossRef] [PubMed]

- Sangtam, B.T.; Park, H. Review on Bubble Dynamics in Proton Exchange Membrane Water Electrolysis: Towards Optimal Green Hydrogen Yield. Micromachines 2023, 14, 2234. [Google Scholar] [CrossRef]

- Bose, S.; Sengupta, D.; Malliakas, C.D.; Idrees, K.B.; Xie, H.; Wang, X.; Barsoum, M.L.; Barker, N.M.; Dravid, V.P.; Islamoglu, T.; et al. Suitability of a diamine functionalized metal–organic framework for direct air capture. Chem. Sci. 2023, 14, 9380–9388. [Google Scholar] [CrossRef]

- Kaur, R.; Kaur, N.; Kumar, S.; Dass, A.; Singh, T. Carbon capture and sequestration for sustainable land use–A review. Indian J. Agric. Sci. 2023, 93, 11–18. [Google Scholar] [CrossRef]

- Cooley, S.R.; Klinsky, S.; Morrow, D.R.; Satterfield, T. Sociotechnical considerations about ocean carbon dioxide removal. Annu. Rev. Mar. Sci. 2023, 15, 41–66. [Google Scholar] [CrossRef]

- Zore, U.K.; Yedire, S.G.; Pandi, N.; Manickam, S.; Sonawane, S.H. A review on recent advances in hydrogen energy, fuel cell, biofuel and fuel refining via ultrasound process intensification. Ultrason. Sonochemistry 2021, 73, 105536. [Google Scholar] [CrossRef]

- Zang, G.; Sun, P.; Elgowainy, A.; Wang, M. Technoeconomic and life cycle analysis of synthetic methanol production from hydrogen and industrial byproduct CO2. Environ. Sci. Technol. 2021, 55, 5248–5257. [Google Scholar] [CrossRef] [PubMed]

- Law, Z.X.; Tsai, D.H. Exploring the Challenges of Calcium Looping Integrated with Methane Bireforming for Enhanced Carbon Capture and Utilization. Langmuir 2023, 39, 14782–14790. [Google Scholar] [CrossRef]

- Peng, L.; Min, J.; Bendavid, A.; Chu, D.; Lu, X.; Amal, R.; Han, Z. Stabilizing the unstable: Chromium coating on NiMo electrode for enhanced stability in intermittent water electrolysis. ACS Appl. Mater. Interfaces 2022, 14, 40822–40833. [Google Scholar] [CrossRef]

- Slobodkin, I.; Davydova, E.; Sananis, M.; Breytus, A.; Rothschild, A. Electrochemical and chemical cycle for high-efficiency decoupled water splitting in a near-neutral electrolyte. Nat. Mater. 2024, 23, 398–405. [Google Scholar] [CrossRef] [PubMed]

- Valente, A.; Iribarren, D.; Dufour, J. Prospective carbon footprint comparison of hydrogen options. Sci. Total Environ. 2020, 728, 138212. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; Greiner, M.; Schlögl, R.; Heumann, S. A Metal-Free Electrode: From Biomass-Derived Carbon to Hydrogen. ChemSusChem 2020, 13, 4064–4068. [Google Scholar] [CrossRef]

- Leitner, W.; Klankermayer, J.; Pischinger, S.; Pitsch, H.; Kohse-Höinghaus, K. Advanced biofuels and beyond: Chemistry solutions for propulsion and production. Angew. Chem. Int. Ed. 2017, 56, 5412–5452. [Google Scholar] [CrossRef]

- Kwon, E.E.; Cho, S.H.; Kim, S. Synergetic sustainability enhancement via utilization of carbon dioxide as carbon neutral chemical feedstock in the thermo-chemical processing of biomass. Environ. Sci. Technol. 2015, 49, 5028–5034. [Google Scholar] [CrossRef]

- Karekar, S.C.; Seiple, T.; Ahring, B.K.; Fuller, C. Assessing feasible H2–CO2 sources in the US as Feedstocks for Sustainable Aviation Fuel Precursors: Acetic Acid and Ethanol Production via Hydrogenotrophic Pathways. J. Environ. Manag. 2023, 345, 118641. [Google Scholar] [CrossRef]

- Ming, T.; De_richter, R.; Shen, S.; Caillol, S. Fighting global warming by greenhouse gas removal: Destroying atmospheric nitrous oxide thanks to synergies between two breakthrough technologies. Environ. Sci. Pollut. Res. 2016, 23, 6119–6138. [Google Scholar] [CrossRef]

- Dutcher, B.; Fan, M.; Russell, A.G. Amine-based CO2 capture technology development from the beginning of 2013—A Review. ACS Appl. Mater. Interfaces 2015, 7, 2137–2148. [Google Scholar] [CrossRef]

- Fisher, J.C.; Gray, M. Cyclic Stability Testing of Aminated-Silica Solid Sorbent for Post-Combustion CO2 Capture. ChemSusChem 2015, 8, 452–455. [Google Scholar] [CrossRef]

- Liu, M.; Nothling, M.D.; Webley, P.A.; Fu, Q.; Qiao, G.G. Postcombustion carbon capture using thin-film composite membranes. Acc. Chem. Res. 2019, 52, 1905–1914. [Google Scholar] [CrossRef]

- Hiremath, V.; Shavi, R.; Seo, J.G. Mesoporous magnesium oxide nanoparticles derived via complexation-combustion for enhanced performance in carbon dioxide capture. J. Colloid Interface Sci. 2017, 498, 55–63. [Google Scholar] [CrossRef] [PubMed]

- Fan, G.; Zheng, Z.; Zhu, Z. Combustion and Emission Characteristics of Gasoline Engine Blended Combustion Syngas. ACS Omega 2022, 7, 26375–26395. [Google Scholar] [CrossRef]

- Pang, S. Advances in thermochemical conversion of woody biomass to energy, fuels and chemicals. Biotechnol. Adv. 2019, 37, 589–597. [Google Scholar] [CrossRef] [PubMed]

- Ochoa-González, R.; Díaz-Somoano, M.; Martínez-Tarazona, M.R. A comprehensive evaluation of the influence of air combustion and oxy-fuel combustion flue gas constituents on Hg0 re-emission in WFGD systems. J. Hazard. Mater. 2014, 276, 157–163. [Google Scholar] [CrossRef]

- Moroń, W.; Ferens, W.; Wach, J. Emission of typical pollutants (NOX, SO2) in the oxygen combustion process with air in-leakages. Environ. Sci. Pollut. Res. 2021, 28, 50683–50695. [Google Scholar] [CrossRef]

- Akeeb, O.; Wang, L.; Xie, W.; Davis, R.; Alkasrawi, M.; Toan, S. Post-combustion CO2 capture via a variety of temperature ranges and material adsorption process: A review. J. Environ. Manag. 2022, 313, 115026. [Google Scholar] [CrossRef]

- Kamolov, A.; Turakulov, Z.; Rejabov, S.; Díaz-Sainz, G.; Gómez-Coma, L.; Norkobilov, A.; Fallanza, M.; Irabien, A. Decarbonization of Power and Industrial Sectors: The Role of Membrane Processes. Membranes 2023, 13, 130. [Google Scholar] [CrossRef]

- Ju, Y.; Hargreaves, C.A. The impact of shipping CO2 emissions from marine traffic in Western Singapore Straits during COVID-19. Sci. Total Environ. 2021, 789, 148063. [Google Scholar] [CrossRef]

- Tomatis, M.; Jeswani, H.K.; Stamford, L.; Azapagic, A. Assessing the environmental sustainability of an emerging energy technology: Solar thermal calcination for cement production. Sci. Total Environ. 2020, 742, 140510. [Google Scholar] [CrossRef]

- Sreejyothi, P.; Mandal, S.K. From CO2 activation to catalytic reduction: A metal-free approach. Chem. Sci. 2020, 11, 10571–10593. [Google Scholar]

- Ostovari, H.; Müller, L.; Skocek, J.; Bardow, A. From unavoidable CO2 source to CO2 sink? A cement industry based on CO2 mineralization. Environ. Sci. Technol. 2021, 55, 5212–5223. [Google Scholar] [CrossRef] [PubMed]

- Maitland, G.C. Carbon capture and storage: Concluding remarks. Faraday Discuss. 2016, 192, 581–599. [Google Scholar] [CrossRef] [PubMed]

- Shi, X.; Wang, G.; Wang, X.; Chen, B. A Study on the Promoting Role of Renewable Hydrogen in the Transformation of Petroleum Refining Pathways. Processes 2024, 12, 1317. [Google Scholar] [CrossRef]

- Abuov, Y.; Serik, G.; Lee, W. Techno-economic assessment and life cycle assessment of C-EOR. Environ. Sci. Technol. 2022, 56, 8571–8580. [Google Scholar] [CrossRef]

- Ringrose, P.S.; Furre, A.K.; Gilfillan, S.M.; Krevor, S.; Landrø, M.; Leslie, R.; Meckel, T.; Nazarian, B.; Zahid, A. Storage of carbon dioxide in saline aquifers: Physicochemical processes, key constraints, and scale-up potential. Annu. Rev. Chem. Biomol. Eng. 2021, 12, 471–494. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, Y.; Pan, S.Y.; Snyder, S.W. Catalytic processes to accelerate decarbonization in a net-zero carbon world. ChemSusChem 2022, 15, e202201290. [Google Scholar] [CrossRef]

- Schuler, E.; Demetriou, M.; Shiju, N.R.; Gruter GJ, M. Towards sustainable oxalic acid from CO2 and biomass. ChemSusChem 2021, 14, 3636–3664. [Google Scholar] [CrossRef]

- Leonhardt, B.E.; Tyson, R.J.; Taw, E.; Went, M.S.; Sanchez, D.L. Policy Analysis of CO2 Capture and Sequestration with Anaerobic Digestion for Transportation Fuel Production. Environ. Sci. Technol. 2023, 57, 11401–11409. [Google Scholar] [CrossRef]

- Dai, Z.; Viswanathan, H.; Middleton, R.; Pan, F.; Ampomah, W.; Yang, C.; Jia, W.; Xiao, T.; Lee, S.Y.; McPherson, B.; et al. CO2 accounting and risk analysis for CO2 sequestration at enhanced oil recovery sites. Environ. Sci. Technol. 2016, 50, 7546–7554. [Google Scholar] [CrossRef]

- Charalambous, M.A.; Tulus, V.; Ryberg, M.W.; Pérez-Ramírez, J.; Guillén-Gosálbez, G. Absolute environmental sustainability assessment of renewable dimethyl ether fuelled heavy-duty trucks. Sustain. Energy Fuels 2023, 7, 1930–1941. [Google Scholar] [CrossRef]

- Liu, L.; Miranda, M.M.; Bielicki, J.M.; Ellis, B.R.; Johnson, J.X. Life Cycle Greenhouse Gas Emissions of CO2-Enabled Sedimentary Basin Geothermal. Environ. Sci. Technol. 2024, 58, 1882–1893. [Google Scholar] [CrossRef] [PubMed]

- Anwar, M.N.; Fayyaz, A.; Sohail, N.F.; Khokhar, M.F.; Baqar, M.; Khan, W.D.; Rasool, K.; Rehan, M.; Nizami, A.S. CO2 capture and storage: A way forward for sustainable environment. J. Environ. Manag. 2018, 226, 131–144. [Google Scholar] [CrossRef] [PubMed]

- Nyangon, J.; Darekar, A. Advancements in hydrogen energy systems: A review of levelized costs, financial incentives and technological innovations. Innov. Green Dev. 2024, 3, 100149. [Google Scholar] [CrossRef]

- Chun, Y.N.; Jeong, B.R. Characteristics of the microwave pyrolysis and microwave CO2-assisted gasification of dewatered sewage sludge. Environ. Technol. 2018, 39, 2484–2494. [Google Scholar] [CrossRef]

- Zhang, S.; DePaolo, D.J. Rates of CO2 mineralization in geological carbon storage. Acc. Chem. Res. 2017, 50, 2075–2084. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Dufour, J. Comparative life cycle sustainability assessment of renewable and conventional hydrogen. Sci. Total Environ. 2021, 756, 144132. [Google Scholar] [CrossRef]

- Zoback, M.; Smit, D. Meeting the challenges of large-scale carbon storage and hydrogen production. Proc. Natl. Acad. Sci. USA 2023, 120, e2202397120. [Google Scholar] [CrossRef]

- O’Rourke, P.; Mignone, B.K.; Kyle, P.; Chapman, B.R.; Fuhrman, J.; Wolfram, P.; McJeon, H. Supply and Demand Drivers of Global Hydrogen Deployment in the Transition toward a Decarbonized Energy System. Environ. Sci. Technol. 2023, 57, 19508–19518. [Google Scholar] [CrossRef]

- Brandon, N.P.; Kurban, Z. Clean energy and the hydrogen economy. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2017, 375, 20160400. [Google Scholar] [CrossRef]

- Bahman, N.; Alalaiwat, D.; Abdulmohsen, Z.; Al Khalifa, M.; Al Baharna, S.; Al-Mannai, M.A.; Younis, A. A critical review on global CO2 emission: Where do industries stand? Rev. Environ. Health 2023, 38, 681–696. [Google Scholar] [CrossRef]

- Chu, X.; Sathish, C.I.; Yang, J.H.; Guan, X.; Zhang, X.; Qiao, L.; Domen, K.; Wang, S.; Vinu, A.; Yi, J. Strategies for Improving the Photocatalytic Hydrogen Evolution Reaction of Carbon Nitride-Based Catalysts. Small 2023, 19, 2302875. [Google Scholar] [CrossRef] [PubMed]

- Jia, W.; Li, L.; Zhu, L.; Lei, Y.; Wu, S.; Dong, Z. The synergistic effects of PM2. and CO2 from China’s energy consumption. Sci. Total Environ. 2024, 908, 168121. [Google Scholar] [CrossRef] [PubMed]

- Cui, C.; Guan, D.; Wang, D.; Meng, J.; Chemutai, V.; Brenton, P.; Zhang, S.; Shan, Y.; Zhang, Q.; Davis, S.J. Global mitigation efforts cannot neglect emerging emitters. Natl. Sci. Rev. 2022, 9, nwac223. [Google Scholar] [CrossRef]

- Gogoi, S.; Karak, N. Solar-driven hydrogen peroxide production using polymer-supported carbon dots as heterogeneous catalyst. Nano-Micro Lett. 2017, 9, 40. [Google Scholar] [CrossRef]

- Xue, N.; Lu, J.; Gu, D.; Lou, Y.; Yuan, Y.; Li, G.; Kumagai, S.; Saito, Y.; Yoshioka, T.; Zhang, N. Carbon footprint analysis and carbon neutrality potential of desalination by electrodialysis for different applications. Water Res. 2023, 232, 119716. [Google Scholar] [CrossRef]

- Aleluia, J.; Ferrão, P. Assessing the costs of municipal solid waste treatment technologies in developing Asian countries. Waste Manag. 2017, 69, 592–608. [Google Scholar] [CrossRef]

- Sweeney, D.M.; Alves, V.; Sakhai, S.; Dinh, S.; Lima, F.V. Techno-economic Analysis and Optimization of Intensified, Large-Scale Hydrogen Production with Membrane Reactors. Ind. Eng. Chem. Res. 2023, 62, 19740–19751. [Google Scholar] [CrossRef]

- Lopez, M.; Broderick, L.; Carey, J.J.; Vines, F.; Nolan, M.; Illas, F. Tuning transition metal carbide activity by surface metal alloying: A case study on CO 2 capture and activation. Phys. Chem. Chem. Phys. 2018, 20, 22179–22186. [Google Scholar] [CrossRef]

- Sovacool, B.K.; Del Rio, D.F.; Herman, K.; Iskandarova, M.; Uratani, J.M.; Griffiths, S. Reconfiguring European industry for net-zero: A qualitative review of hydrogen and carbon capture utilization and storage benefits and implementation challenges. Energy Environ. Sci. 2024, 17, 3523–3569. [Google Scholar] [CrossRef]

- Sofian AD AB, A.; Lim, H.R.; Chew, K.W.; Khoo, K.S.; Tan, I.S.; Ma, Z.; Show, P.L. Hydrogen production and pollution mitigation: Enhanced gasification of plastic waste and biomass with machine learning & storage for a sustainable future. Environ. Pollut. 2023, 342, 123024. [Google Scholar]

- Raza, S.; Ghasali, E.; Raza, M.; Chen, C.; Li, B.; Orooji, Y.; Lin, H.; Karaman, C.; Maleh, H.K.; Erk, N. Advances in technology and utilization of natural resources for achieving carbon neutrality and a sustainable solution to neutral environment. Environ. Res. 2023, 220, 115135. [Google Scholar] [CrossRef] [PubMed]

- Maganza, A.; Gabetti, A.; Pastorino, P.; Zanoli, A.; Sicuro, B.; Barcelò, D.; Cesarani, A.; Dondo, A.; Prearo, M.; Esposito, G. Toward Sustainability: An Overview of the Use of Green Hydrogen in the Agriculture and Livestock Sector. Animals 2023, 13, 2561. [Google Scholar] [CrossRef] [PubMed]

- Llamas-Orozco, J.A.; Meng, F.; Walker, G.S.; Abdul-Manan, A.F.; MacLean, H.L.; Posen, I.D.; McKechnie, J. Estimating the environmental impacts of global lithium-ion battery supply chain: A temporal, geographical, and technological perspective. PNAS Nexus 2023, 2, pgad361. [Google Scholar] [CrossRef] [PubMed]

- Lamers, P.; Ghosh, T.; Upasani, S.; Sacchi, R.; Daioglou, V. Linking life cycle and integrated assessment modeling to evaluate technologies in an evolving system context: A power-to-hydrogen case study for the United States. Environ. Sci. Technol. 2023, 57, 2464–2473. [Google Scholar] [CrossRef]

- Sahrin, N.T.; Khoo, K.S.; Lim, J.W.; Shamsuddin, R.; Ardo, F.M.; Rawindran, H.; Hassan, M.; Kiatkittipong, W.; Abdelfattah, E.A.; Da Oh, W.; et al. Current perspectives, future challenges and key technologies of biohydrogen production for building a carbon–neutral future: A review. Bioresour. Technol. 2022, 364, 128088. [Google Scholar]

- Madokoro, H.; Sato, K.; Nix, S.; Chiyonobu, S.; Nagayoshi, T.; Sato, K. OutcropHyBNet: Hybrid Backbone Networks with Data Augmentation for Accurate Stratum Semantic Segmentation of Monocular Outcrop Images in Carbon Capture and Storage Applications. Sensors 2023, 23, 8809. [Google Scholar] [CrossRef]

- Yuhuan, Z.; Rasheed, M.Q.; Saud, S. Environmental deterioration in the age of industrialization and production: Do industrial competition and renewable energy reduce the ecological burden? Environ. Sci. Pollut. Res. 2024, 31, 2258–2278. [Google Scholar] [CrossRef]

- Nielsen, J.A.E.; Stavrianakis, K.; Morrison, Z. Community acceptance and social impacts of carbon capture, utilization and storage projects: A systematic meta-narrative literature review. PLoS ONE 2022, 17, e0272409. [Google Scholar] [CrossRef]