Phase Behavior and Rational Development Mode of a Fractured Gas Condensate Reservoir with High Pressure and Temperature: A Case Study of the Bozi 3 Block

Abstract

:1. Introduction

2. Experimental Section

2.1. PVT Experiment

2.2. Experimental Results

- a.

- Flash test

- b.

- Constant composition expansion

- c.

- Constant volume depletion

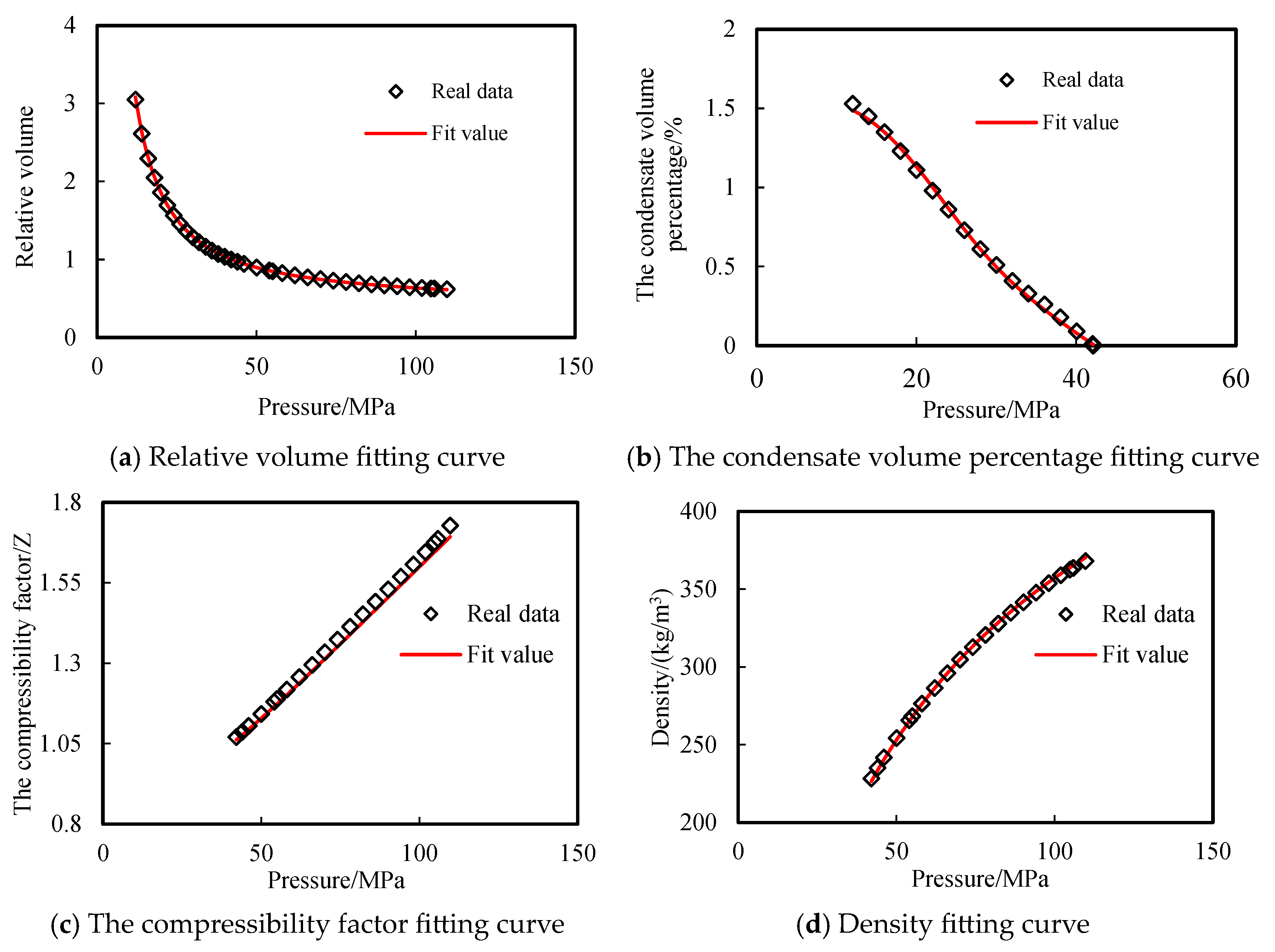

3. EOS Tuning

3.1. Phase Behavior Modeling

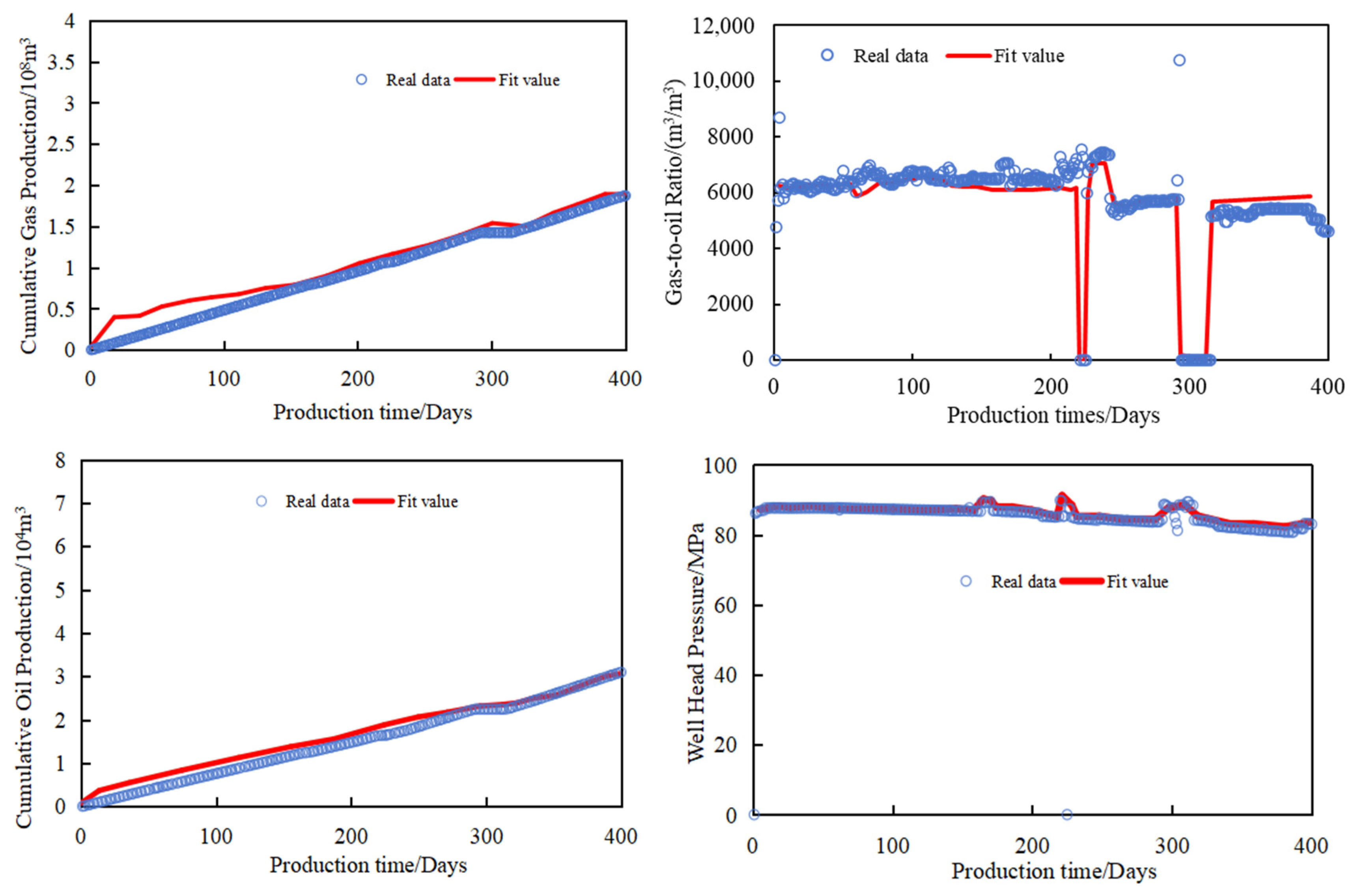

3.2. Reservoir Modeling

4. Injection Gas Selection

5. Sensitivity Analysis

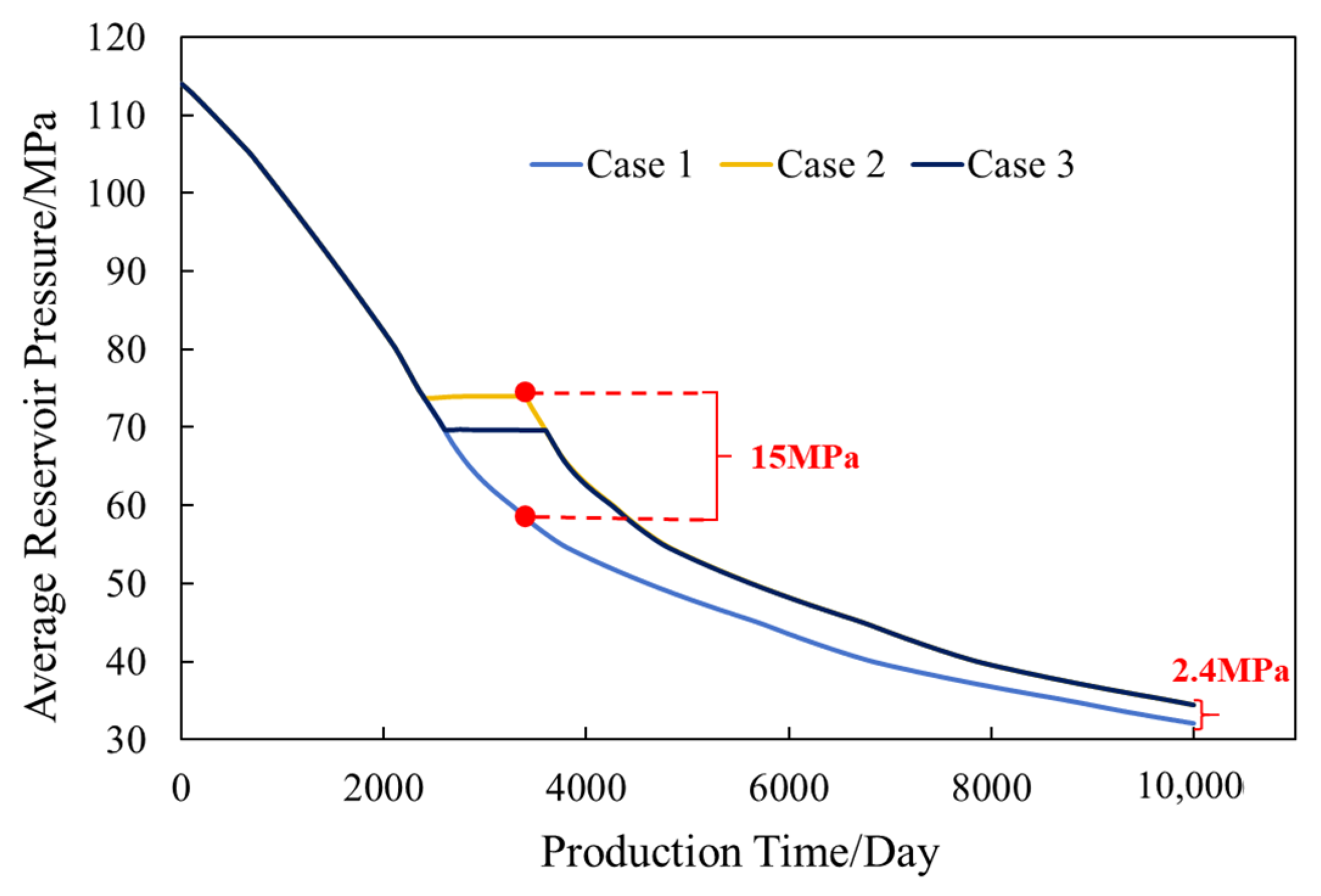

5.1. Gas Injection Timing

5.2. Gas Injection Volume

5.3. Injection and Extraction Position

6. Conclusions and Recommendation

- (1)

- Bozi 3 Block is a super deep condensate reservoir with a high temperature (138.24 °C) and high pressure (104.78 MPa). PVT experiments showed the composition of the fluid sample were: C1+N2: 89.16 mol.%, CO2+C2-C6: 9.04 mol.%, and C7+: 1.8 mol.%.

- (2)

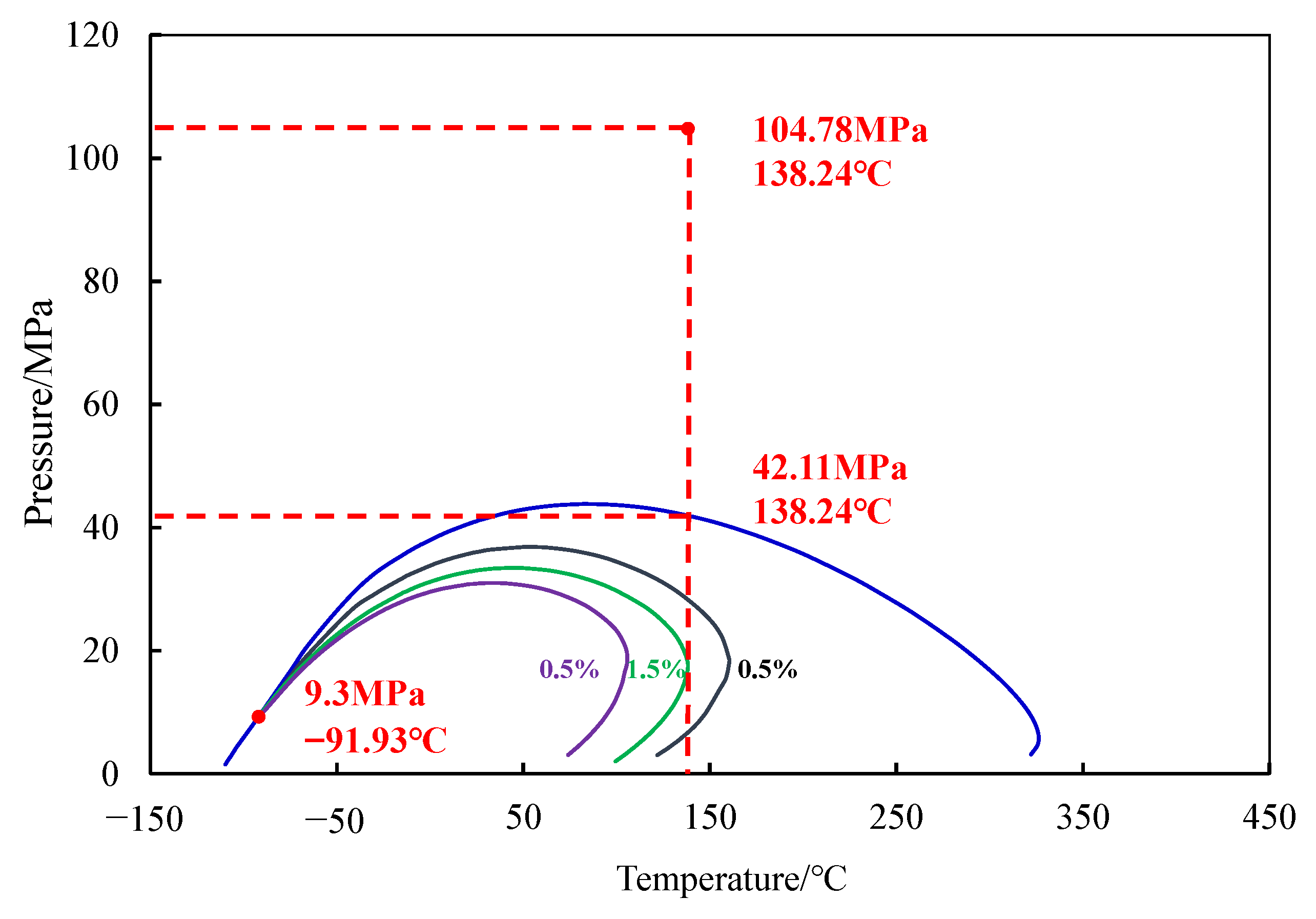

- The phase diagram indicated that the critical temperature and pressure of the fluid were −91.93 °C and 9.30 MPa, respectively; the critical condensate temperature and pressure were 326.24 °C and 43.83 MPa, respectively.

- (3)

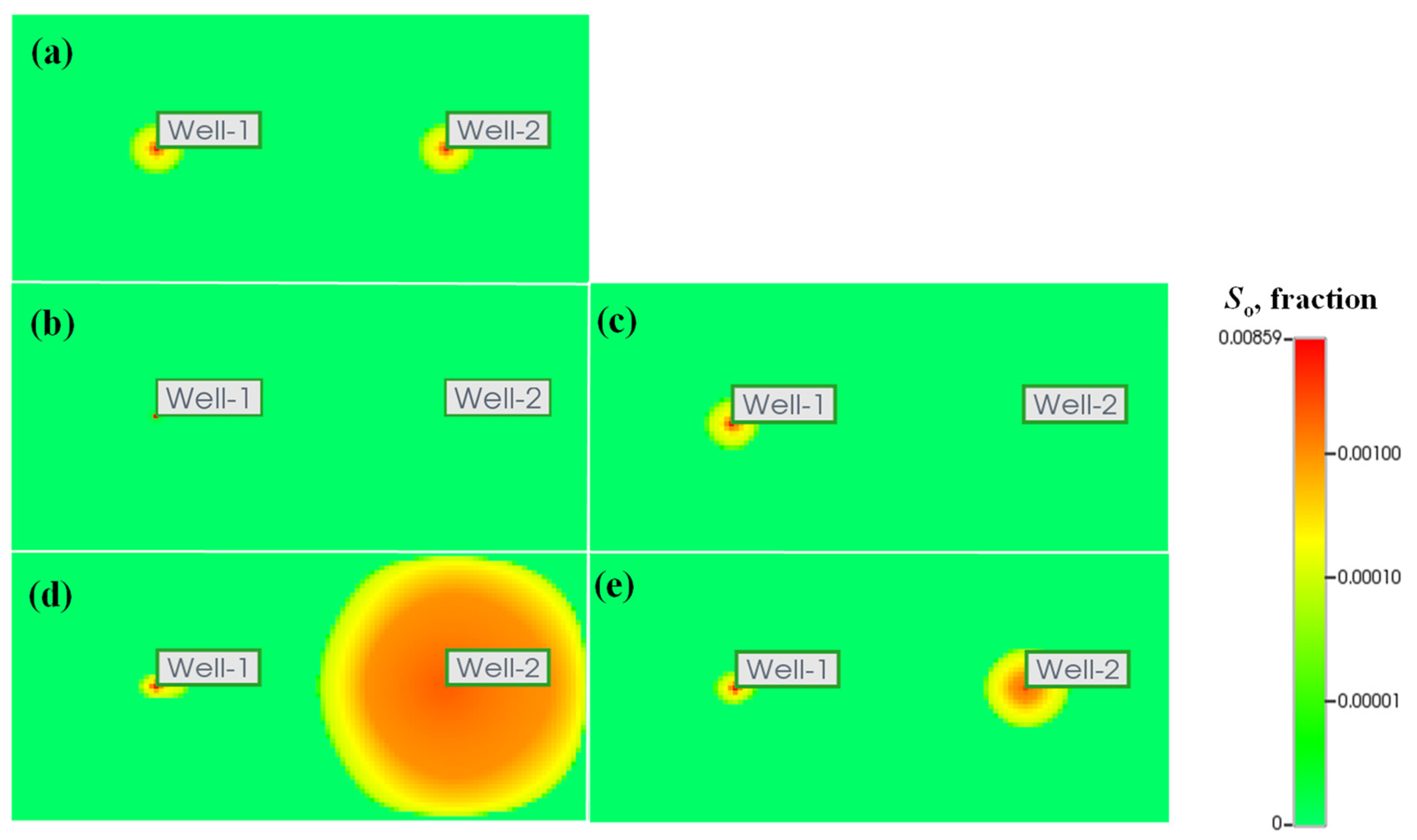

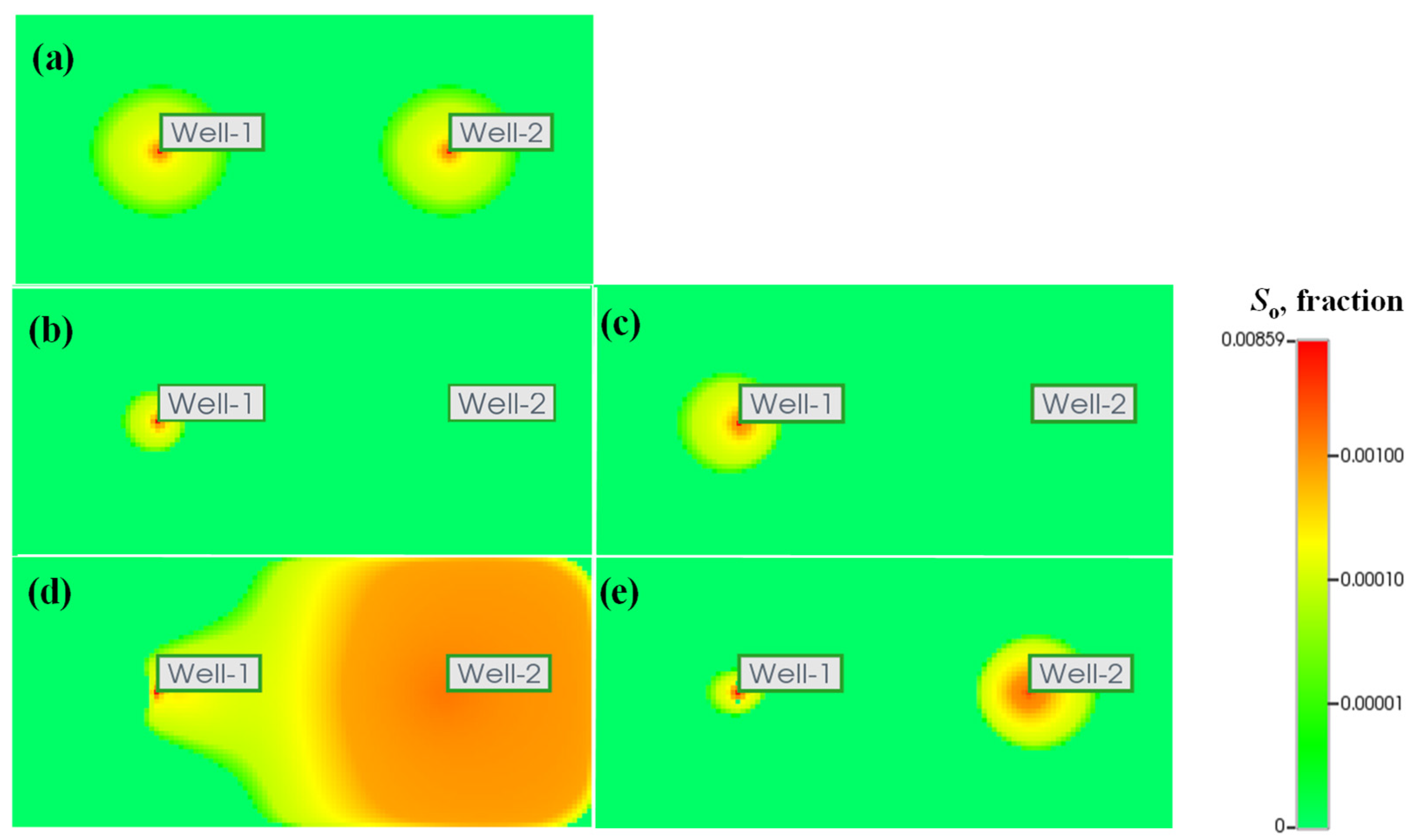

- Compositional reservoir simulation showed that the recovery mechanisms of methane and recycled gas injection were similar, maintaining the formation pressure and reducing the condensate oil saturation, which effectively mitigated the condensate blocking around the injection well. There was nearly no retrograde condensate between wells during gas injection. Injecting nitrogen aggravated the retrograde condensation. Carbon dioxide injection created an extraction zone near the borehole, which inhibited retrograde condensation between wells. Overall, methane was identified as the optimal injection gas.

- (4)

- Gas injection started when the production began to fall, achieving higher recovery than gas injection starting when the pressure fell below the dew-point pressure. When the production rate starts to fall, simultaneous injection of methane at both the upper and lower parts of the reservoir, at a rate of 50 × 104 m3/d for 1000 days, can effectively produce condensate oil over the entire block. This scheme achieved 8690.43 m3 more oil production and 2.75% higher recovery factor in comparison with depletion production.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kamari, E.; Shadizadeh, S.R. An experimental phase diagram of a gas condensate reservoir. Pet. Sci. Technol. 2012, 30, 2114–2121. [Google Scholar] [CrossRef]

- Shi, J.; Huang, L.; Li, X.; Sepehrnoori, K. Production forecasting of gas condensate well considering fluid phase behavior in the reservoir and wellbore. J. Nat. Gas Sci. Eng. 2015, 24, 279–290. [Google Scholar] [CrossRef]

- Pan, Y.; Sun, L.; Luo, L.; Du, J.; Liu, J.; Tang, Y.; Shi, D. Experiment and analysis of oil/gas/water multi-phase behavior of condensate gas reservoir. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2006, 28, 48–51. [Google Scholar]

- Allahyari, M.; Aminshahidy, B.; Sanati, A.; Taghikhani, V. Analysis of near well-bore behavior of gas condensate reservoir in production stage. Pet. Sci. Technol. 2012, 30, 2594–2603. [Google Scholar] [CrossRef]

- Li, S.; Pan, Y.; Sun, L. A new idea on enhancing the recovery rate of condensate gas reservoirs. Nat. Gas Ind. 2008, 28, 1–5. [Google Scholar]

- Li, S.; Sun, L.; Du, J.; Tang, Y.; Zhou, S.; Guo, P.; Li, J. Difficulties and measures for development of low permeability tight gas reservoirs and condensate gas reservoirs. Xinjiang Pet. Geol. 2004, 25, 225–230. [Google Scholar]

- Li, M. Study on Condensate Saturation in Porous Media During Depletion and Gas Injection. Master’s thesis, Southwest Petroleum University, Chengdu, China, 2006. [Google Scholar]

- Zhu, H.; Shen, Y.; Fan, C.; Hu, J.; Yu, J. Gas injection to enhance oil recovery in condensate gas reservoirs. Inn. Mong. Petrochem. Ind. 2013, 18, 137–139. [Google Scholar]

- Wu, Y.; Yao, K.; Liu, Y.; Li, X.; Wu, M.; Cheng, R.; Wang, B. Experimental study on enhanced condensate recovery by gas injection in Yaha condensate gas reservoir. Geofluids 2021, 1, 7698970. [Google Scholar] [CrossRef]

- Jiang, T.; Sun, L.; Xie, W.; Xiao, X.; Wang, Y.; Xia, J. Three-element development mechanism of cyclic gas injection in condensate gas reservoirs and a new technique of enhancing condensate oil recovery. Acta Pet. Sin. 2021, 42, 137–139. [Google Scholar]

- Shi, J.; Li, X.; Zhou, J.; Li, Q.; Wu, K. How to evaluate and predict the deliverability change of gas condensate wells. Pet. Sci. Technol. 2014, 32, 442–449. [Google Scholar] [CrossRef]

- Chen, L.; Luo, J.; Rao, H.; Feng, X.; Kang, A.; Le, X. Gas injection EOR at mid-late development stage in condensate gas reservoirs. Xinjiang Pet. Geol. 2019, 40, 98–102. [Google Scholar]

- Li, S.; Guo, P.; Du, J.; Wang, Y. New way to improve gas well production and condensate gas field′ s recovery factor. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2007, 29, 1–6. [Google Scholar]

- Feng, Q.; Deng, B.; Yang, Y. Evaluations and removing methods of the retrograde condensate damage for the gas condensate reservoirs in the tight sandstone. Pet. Geol. Oilfield Dev. Daqing 2020, 39, 139–146. [Google Scholar]

- Li, G.; Guo, X.; Zi, Q.; Wu, S. Effect analysis of cyclic gas injection in fractured condensate gas reservoir. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2003, 25, 44–46. [Google Scholar]

- Zhu, W.; Zhang, F.; Tang, M.; Wang, H. Methods of cyclic gas injection to retard gas channeling in the Yaha condensate gas field. Nat. Gas Ind. 2008, 28, 76–77. [Google Scholar]

- Wan, T.; Sheng, J. Evaluation of the EOR potential in hydraulically fractured shale oil reservoirs by cyclic gas injection. Pet. Sci. Technol. 2015, 33, 812–818. [Google Scholar] [CrossRef]

- Jiao, Y.; Xie, W.; Di, B.; Liang, T.; Liu, L. Gas condensate phase behavior in process of cyclic gas injection. Xinjiang Pet. Geol. 2012, 33, 704–707. [Google Scholar]

- Kang, H.; Zhang, J.; Fan, X.; Huang, Z. Cyclic injection to enhance hydraulic fracturing efficiency: Insights from laboratory experiments. Geofluids 2020, 2020, 8844293. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Zhou, Y.; Kang, X.; Tong, M. New method of cyclic gas injection for condensate reservoirs. Nat. Gas Ind. 2004, 24, 76–79. [Google Scholar]

- Poordad, S.; Forutan, M.K. A review of the potential for CO2 sequestration and enhanced gas recovery in an Iranian gas condensate reservoir from a fluid properties point of view. Pet. Sci. Technol. 2013, 31, 2157–2165. [Google Scholar] [CrossRef]

- Fath, A.H.; Dashtaki, N.B. Evaluation of effective parameters on CO2 injection process in a gas condensate reservoir: A case study. Energy Sources Part A Recovery Util. Environ. Eff. 2016, 38, 3680–3686. [Google Scholar]

- Meng, X.; Meng, Z.; Ma, J.; Wang, T. Performance evaluation of CO2 huff-n-puff gas injection in shale gas condensate reservoirs. Energies 2018, 12, 42. [Google Scholar] [CrossRef]

- Wu, Z.; Sun, Z.; Shu, K.; Jiang, S.; Gou, Q.; Chen, Z. Mechanism of shale oil displacement by CO2 in nanopores: A molecular dynamics simulation study. Adv. Geo-Energy Res. 2024, 11, 141–151. [Google Scholar] [CrossRef]

- Wan, T.; Mu, Z. The use of numerical simulation to investigate the enhanced Eagle Ford shale gas condensate well recovery using cyclic CO2 injection method with nano-pore effect. Fuel 2018, 233, 123–132. [Google Scholar] [CrossRef]

- Narinesingh, J.; Alexander, D. CO2 enhanced gas recovery and geologic sequestration in condensate reservoir: A simulation study of the effects of injection pressure on condensate recovery from reservoir and CO2 storage efficiency. Energy Procedia 2014, 63, 3107–3115. [Google Scholar] [CrossRef]

- Nasriani, H.R.; Borazjani, A.A.; Sinaei, M.; Hashemi, A. The effect of gas injection on the enhancement of condensate recovery in gas condensate reservoirs: A comparison between a synthetic model and PVT cell results. Pet. Sci. Technol. 2014, 32, 593–601. [Google Scholar] [CrossRef]

- Barrufet, M.A.; Bacquet, A.; Falcone, G. Analysis of the storage capacity for CO2 sequestration of a depleted gas condensate reservoir and a saline aquifer. J. Can. Pet. Technol. 2010, 49, 23–31. [Google Scholar] [CrossRef]

- Song, Y.; Song, Z.; Chen, Z.; Zhang, L.; Zhang, Y.; Feng, D.; Wu, Z.; Wu, J. Fluid phase behavior in multi-scale shale reservoirs with nano-confinement effect. Energy 2024, 289, 130027. [Google Scholar] [CrossRef]

- Zhang, A.; Fan, Z.; Zhao, L. An investigation on phase behaviors and displacement mechanisms of gas injection in gas condensate reservoir. Fuel 2020, 268, 117–373. [Google Scholar] [CrossRef]

- Gu, Q.; Tang, Z.; Xian, B.; Huang, B.; Wang, Y.; Zhang, D. Application of gas-drive characteristic curve in condensate gas reservoir by methane injection development process. Xinjiang Pet. Geol. 2014, 35, 724–727. [Google Scholar]

- Bonyadi, M.; Esmaeilzadeh, F.; Mowla, D. Methane flooding in lean gas condensate reservoir. Energy Sources Part A Recovery Util. Environ. Eff. 2015, 37, 2240–2246. [Google Scholar] [CrossRef]

- Masoumi, S.; Helalizadeh, A.; Bahrami, M. The performance of various injecting gases into fractured retrograde gas reservoirs for revaporization of liquid drop–out. Pet. Sci. Technol. 2011, 29, 2536–2544. [Google Scholar] [CrossRef]

- Ghiri, M.N.; Nasrian, H.R.; Sinaei, M.; Najibi, S.H.; Nasrian, E.; Parchami, H. Gas injection for enhancement of condensate recovery in a gas condensate reservoir. Energy Sources Part A Recovery Util. Environ. Eff. 2015, 37, 799–806. [Google Scholar] [CrossRef]

- Syzdykov, M. Evaluating Gas Injection Performance in Very Low Permeability, Thick Carbonate Gas–Condensate Reservoirs to Improve Ultimate Liquid Yield. Master’s Thesis, Colorado School of Mines, Golden, CO, USA, 2014. [Google Scholar]

- Sadooni, M.; Zonnouri, A. The effect of nitrogen injection on production improvement in an Iranian rich gas condensate reservoir. Pet. Sci. Technol. 2015, 33, 422–429. [Google Scholar] [CrossRef]

- Davarpanah, A.; Mazarei, M.; Mirshekari, B. A simulation study to enhance the gas production rate by nitrogen replacement in the underground gas storage performance. Energy Rep. 2019, 5, 431–435. [Google Scholar] [CrossRef]

- Du, J.; Xiao, C.; Wang, Z. Laboratory study on the evaluation and removal of retrograde condensate damage in the Baka Gas Reservoir, Tuha Basin. Nat. Gas Ind. 2015, 35, 52–56. [Google Scholar]

- Pang, Z.; Liu, H.; Zhu, L. A laboratory study of enhancing heavy oil recovery with steam flooding by adding nitrogen foams. J. Pet. Sci. Eng. 2015, 128, 184–193. [Google Scholar] [CrossRef]

- Eid, M.E.G. Simulation Study to Determine the Feasibility of Injecting Hydrogen Sulfide, Carbon Dioxide and Nitrogen Gas Injection to Improve Gas and Oil Recovery Oil–Rim Reservoir. Master’s Thesis, The Petroleum Institute (United Arab Emirates), Abu Dhabi, United Arab Emirates, 2012. [Google Scholar]

- Zheng, X.; Shi, J.; Cao, G.; Yang, N.; Cui, M.; Jia, D.; Liu, H. Progress and prospects of oil and gas production engineering technology in China. Pet. Explor. Dev. 2022, 49, 644–659. [Google Scholar] [CrossRef]

- Mou, W.; Che, C.; Wang, X.; Deng, X.; Chen, S.; Cui, T.; Zong, W. Numerical simulation of exploration methods for Kekeya condensate oil–gas reservoir. Xinjiang Pet. Geol. 2007, 28, 94–96. [Google Scholar]

- GB/T 26981-2020; Analysis Method for Reservoir Fluid Physical Properties. National Standardization Administration of China: Beijing, China, 2020.

| Sampling Depth/m | Vial Volume/mL | Sampler Numbering | Temperature/20 °C | Sample Type | |

|---|---|---|---|---|---|

| External Pressure/MPa | Turn on the Pressure/MPa | ||||

| 7200 | 700 | 818,796 | 96 | 81.9 | Condensate |

| Component | Flash Oil | Flash | Well Flow | |

|---|---|---|---|---|

| % (Molar Score) | % (Molar Score) | % (Molar Score) | g/m3 | |

| H2S | 0.00 | 0.00 | 0.00 | |

| N2 | 0.00 | 0.80 | 0.78 | |

| CO2 | 0.00 | 0.38 | 0.38 | |

| C1 | 0.00 | 90.16 | 88.38 | |

| C2 | 0.00 | 6.99 | 6.85 | 85.62 |

| C3 | 0.00 | 0.81 | 0.79 | 14.48 |

| iC4 | 0.34 | 0.31 | 0.31 | 7.49 |

| nC4 | 0.72 | 0.32 | 0.33 | 7.97 |

| iC5 | 1.22 | 0.13 | 0.16 | 4.80 |

| nC5 | 1.29 | 0.09 | 0.11 | 3.30 |

| C6 | 5.43 | 0.00 | 0.11 | 3.84 |

| C7 | 16.51 | 0.00 | 0.33 | 13.17 |

| C8 | 23.38 | 0.00 | 0.46 | 20.46 |

| C9 | 12.45 | 0.00 | 0.25 | 12.57 |

| C10 | 8.96 | 0.00 | 0.18 | 10.03 |

| C11+ | 29.71 | 0.00 | 0.58 | 49.91 |

| total | 100.00 | 100.00 | 100.00 | 233.64 |

| C11+Relative molecular weight | 203.5 | |||

| C11+Relative density | 0.8279 | |||

| Pressure, MPa | 42.11 * | 36.00 | 30.00 | 24.00 | 18.00 | 12.00 | 6.00 | |

| The compressibility factor Z | 1.0704 | 1.0066 | 0.9566 | 0.9119 | 0.8966 | 0.9030 | 0.9435 | |

| Two-phase compressibility factor | 1.0704 | 0.9295 | 0.9060 | 0.8747 | 0.8572 | 0.8514 | 0.8583 | |

| Cumulative percentage of extraction | 10.76 | 21.24 | 34.89 | 49.50 | 66.46 | 83.33 | ||

| Viscosity/mPa·s | 0.0278 | 0.0254 | 0.0231 | 0.0208 | 0.0188 | 0.0171 | 0.0158 | |

| Composition/mol % | ||||||||

| N2 | Nitrogen | 0.78 | 0.86 | 0.75 | 0.71 | 0.72 | 0.74 | 0.73 |

| CO2 | Carbon dioxide | 0.38 | 0.36 | 0.38 | 0.39 | 0.38 | 0.38 | 0.39 |

| C1 | Methane | 88.38 | 88.67 | 88.83 | 88.79 | 89.03 | 89.20 | 89.06 |

| C2 | Ethane | 6.85 | 6.62 | 6.88 | 6.99 | 6.88 | 6.87 | 7.00 |

| C3 | Propane | 0.79 | 0.82 | 0.82 | 0.84 | 0.83 | 0.82 | 0.85 |

| iC4 | Isobutane | 0.31 | 0.33 | 0.33 | 0.35 | 0.34 | 0.33 | 0.35 |

| nC4 | n-butane | 0.33 | 0.34 | 0.36 | 0.38 | 0.38 | 0.36 | 0.38 |

| iC5 | Isopentane | 0.16 | 0.20 | 0.18 | 0.20 | 0.19 | 0.18 | 0.19 |

| nC5 | n-pentane | 0.11 | 0.15 | 0.13 | 0.14 | 0.14 | 0.13 | 0.14 |

| C6 | Hexane | 0.11 | 0.09 | 0.08 | 0.07 | 0.06 | 0.06 | 0.05 |

| C7 | Heptane | 0.33 | 0.28 | 0.23 | 0.21 | 0.19 | 0.17 | 0.16 |

| C8 | Octane | 0.46 | 0.40 | 0.33 | 0.29 | 0.26 | 0.24 | 0.22 |

| C9 | Nonane | 0.25 | 0.21 | 0.17 | 0.16 | 0.14 | 0.13 | 0.12 |

| C10 | Decane | 0.18 | 0.15 | 0.13 | 0.11 | 0.10 | 0.09 | 0.08 |

| C11+ | Undecane or more | 0.58 | 0.52 | 0.40 | 0.37 | 0.36 | 0.30 | 0.28 |

| Total | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | |

| C11+ molecular weight | 203.5 | 199.7 | 195.9 | 192.2 | 188.4 | 184.6 | 184.9 | |

| C11+ relative density | 0.8279 | 0.8241 | 0.8203 | 0.8166 | 0.8128 | 0.8090 | 0.8098 | |

| Parameter | Values | Unit | Source |

|---|---|---|---|

| Reservoir pressure | 104.78 | MPa | Geological data |

| Reservoir temperature | 138.24 | °C | PVT data |

| Matrix permeability | 0.024 | mD | Geological data + historical fitting adjustment |

| Matrix porosity | 6 | % | Geological data + historical fitting adjustment |

| Water saturation | 36 | % | Geological data |

| Net gross ratio | 0.32 | / | Geological data + historical fitting adjustment |

| Crack permeability | 10 | mD | Geological data + historical fitting adjustment |

| Crack porosity | 0.1 | % | Geological data + historical fitting adjustment |

| Crack density | 5 | strip/m | Geological data + historical fitting adjustment |

| Option | Case 1 | Case 2 | Case 3 |

|---|---|---|---|

| Development Approach | Depletion development | Inject at the Dew-point pressure | Inject when production is reduced |

| Timing of injection/Day | / | 2400 | 2600 |

| Injection duration/Days | / | 1000 | 1000 |

| Final oil production/m3 | 571,901 | 573,871 | 574,755 |

| Oil production before injection/m3 | / | 403,089 | 434,261 |

| Increase oil production/m3 | / | 1970 | 2854 |

| Proportion of condensate production increase | / | 1.17% | 2.07% |

| Cumulative gas production/m3 | 3.56 × 109 | 4.03 × 109 | 4.03 × 109 |

| Injection volume/m3 | / | 5.00 × 108 | 5.00 × 108 |

| Gas boost/m3 | / | 4.63 × 108 | 4.65 × 108 |

| Total loss of gas volume/m3 | / | 3.67 × 107 | 3.54 × 107 |

| Option | Case 1 | Case 4 | Case 5 |

|---|---|---|---|

| Development approach | Depletion development | Inject at the Dew-point pressure | Inject when production is reduced |

| Timing of injection/Days | / | 2400 | 2600 |

| Injection duration/Days | / | 2000 | 2000 |

| Final oil production/m3 | 571,901 | 569,967.25 | 571,098 |

| Oil production before injection/m3 | / | 403,089 | 434,261 |

| Increase oil production/m3 | / | −1933.98 | −802.281 |

| Proportion of condensate production increase | / | −1.15% | −0.58% |

| Cumulative gas production/m3 | 3.56 × 109 | 3.48 × 109 | 3.48 × 109 |

| Injection volume/m3 | / | 1.00 × 109 | 1.00 × 109 |

| Gas boost/m3 | / | 9.17 × 108 | 9.17 × 108 |

| Total loss of gas volume/m3 | / | 8.29 × 107 | 8.28 × 107 |

| Option | Injection Method | Gas Injection Concept | Increase Oil Production | Percentage of Increase in Production |

|---|---|---|---|---|

| Case 6 | BZ3 inject (K1bs) | Injection at the upper part and production at the lower part | 6193.91 | 1.96% |

| Case 7 | BZ3-3X inject (K1bx) | Injection at the lower part and production at the upper part | 6731.13 | 2.13% |

| Case 8 | BZ3 and BZ3-3X inject | Simultaneous injection at both the upper and lower parts | 8690.43 | 2.75% |

| Case 1 | No Injection (Depletion development) | / | / | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Tang, Y.; Shi, J.; Dai, H.; Jia, X.; Feng, G.; Yang, B.; Li, W. Phase Behavior and Rational Development Mode of a Fractured Gas Condensate Reservoir with High Pressure and Temperature: A Case Study of the Bozi 3 Block. Energies 2024, 17, 5367. https://doi.org/10.3390/en17215367

Zhang Y, Tang Y, Shi J, Dai H, Jia X, Feng G, Yang B, Li W. Phase Behavior and Rational Development Mode of a Fractured Gas Condensate Reservoir with High Pressure and Temperature: A Case Study of the Bozi 3 Block. Energies. 2024; 17(21):5367. https://doi.org/10.3390/en17215367

Chicago/Turabian StyleZhang, Yongling, Yangang Tang, Juntai Shi, Haoxiang Dai, Xinfeng Jia, Ge Feng, Bo Yang, and Wenbin Li. 2024. "Phase Behavior and Rational Development Mode of a Fractured Gas Condensate Reservoir with High Pressure and Temperature: A Case Study of the Bozi 3 Block" Energies 17, no. 21: 5367. https://doi.org/10.3390/en17215367

APA StyleZhang, Y., Tang, Y., Shi, J., Dai, H., Jia, X., Feng, G., Yang, B., & Li, W. (2024). Phase Behavior and Rational Development Mode of a Fractured Gas Condensate Reservoir with High Pressure and Temperature: A Case Study of the Bozi 3 Block. Energies, 17(21), 5367. https://doi.org/10.3390/en17215367