Reforming Natural Gas for CO2 Pre-Combustion Capture in Trinary Cycle Power Plant

Abstract

:1. Introduction

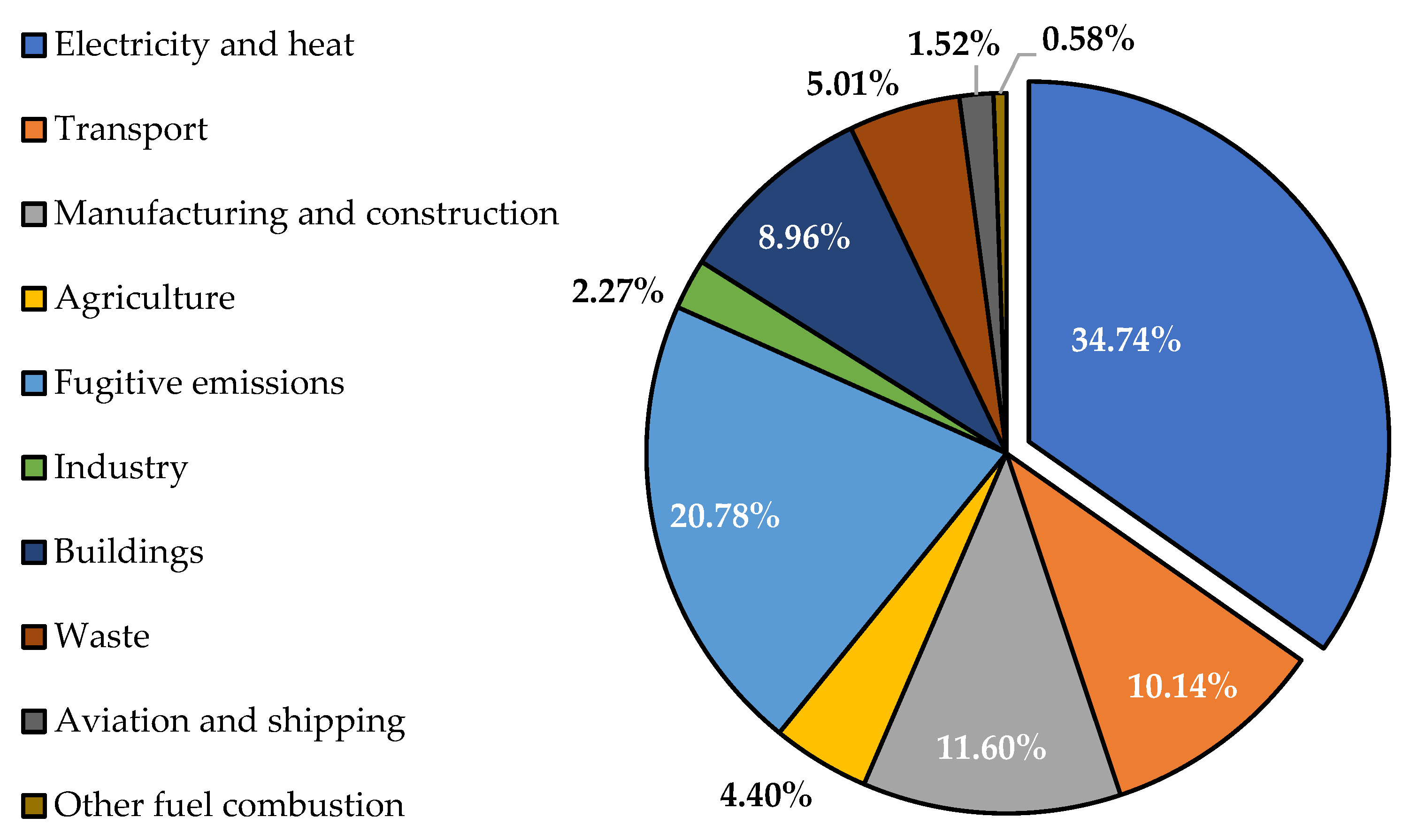

1.1. The Problem of Increasing Energy Efficiency and Environmental Safety of Electricity Production at Combined-Cycle Plants

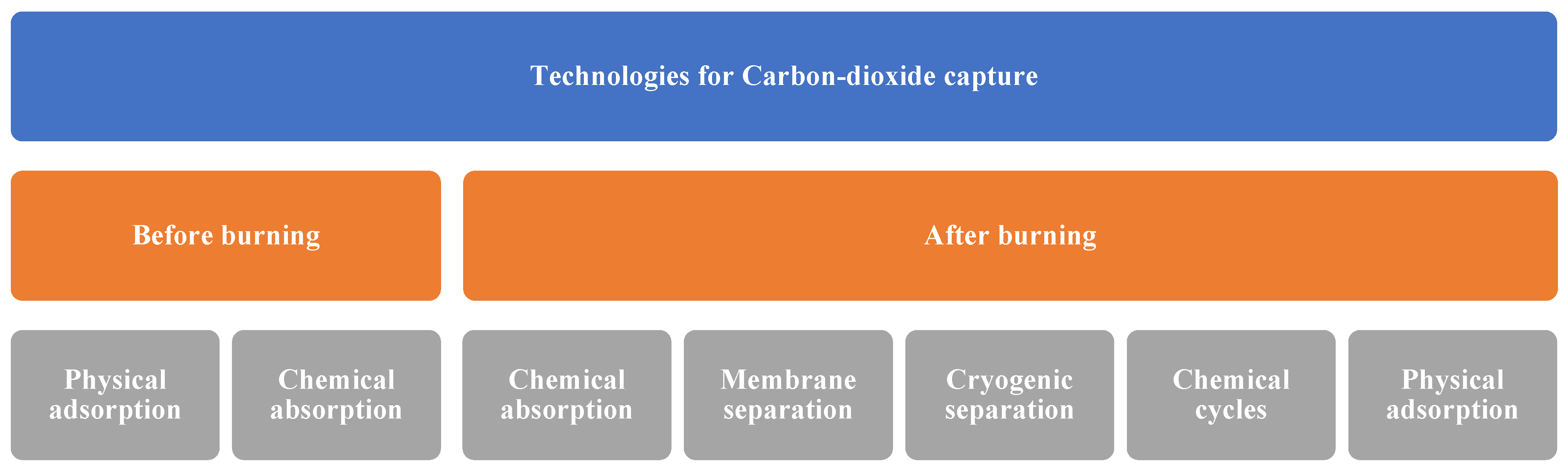

1.2. Methods of Capturing Carbon Dioxide at Thermal Power Plants

1.3. Current State of Combined-Cycle Power Systems with Integrated Steam Methane Reforming Units

2. Study Object

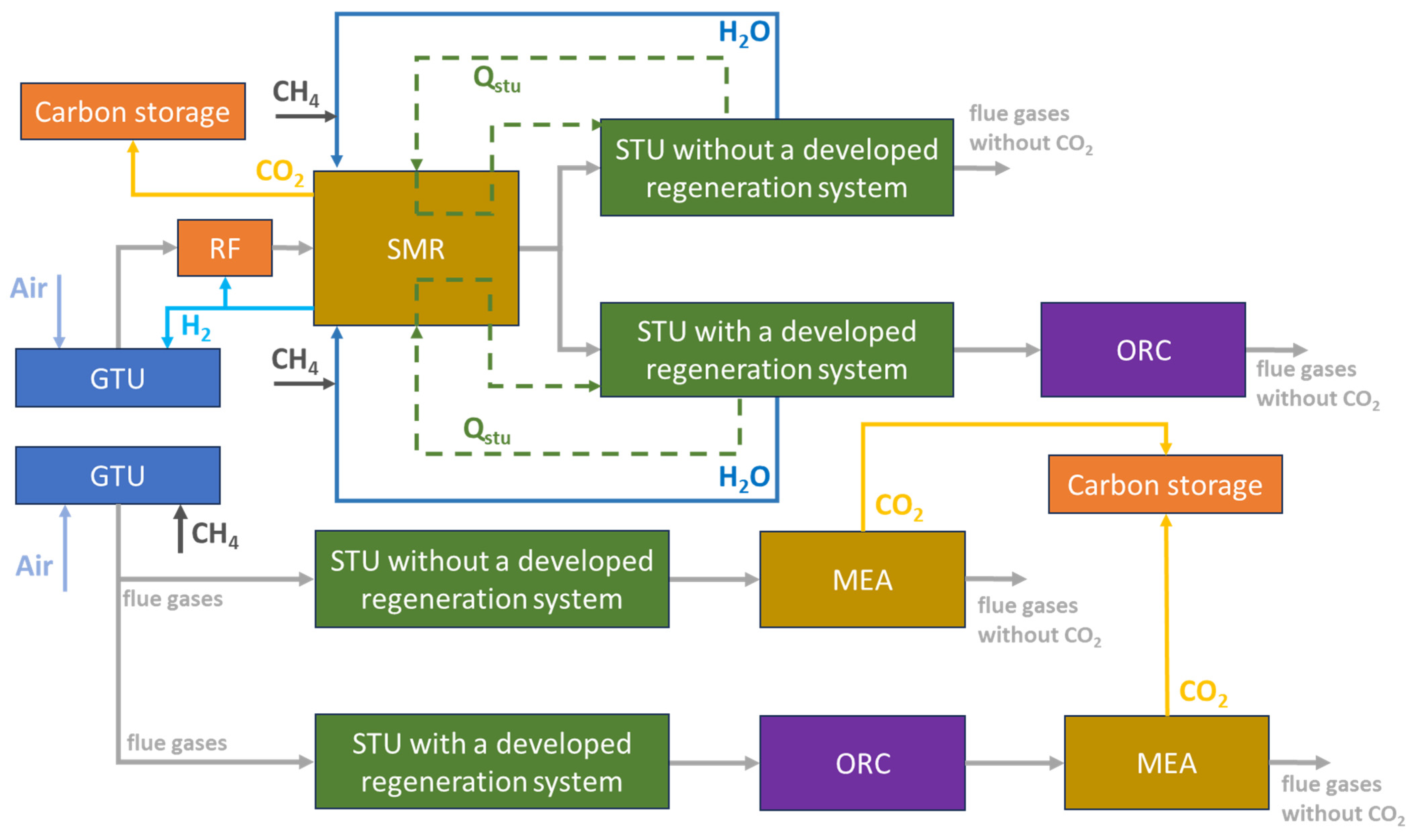

- (1)

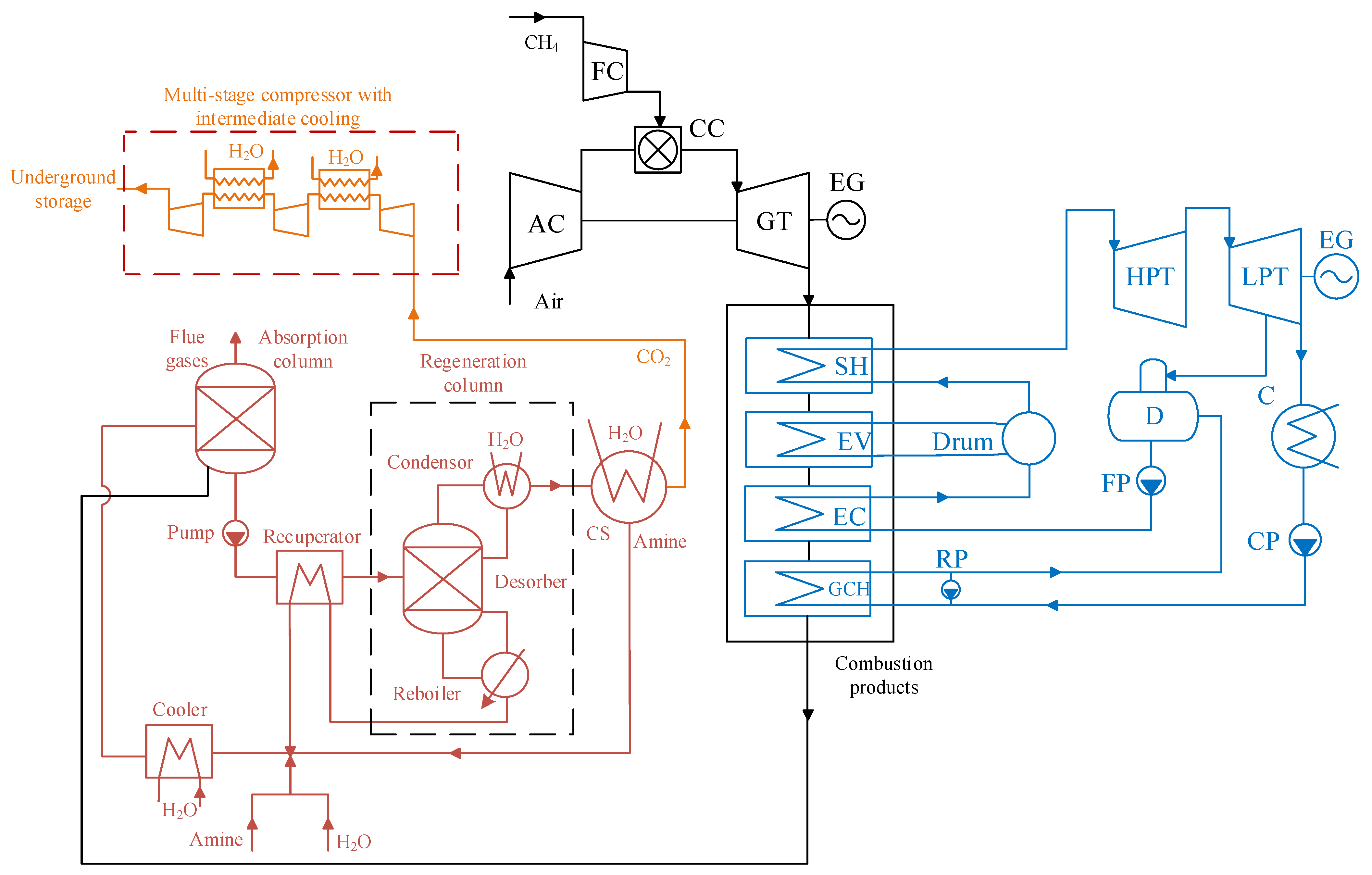

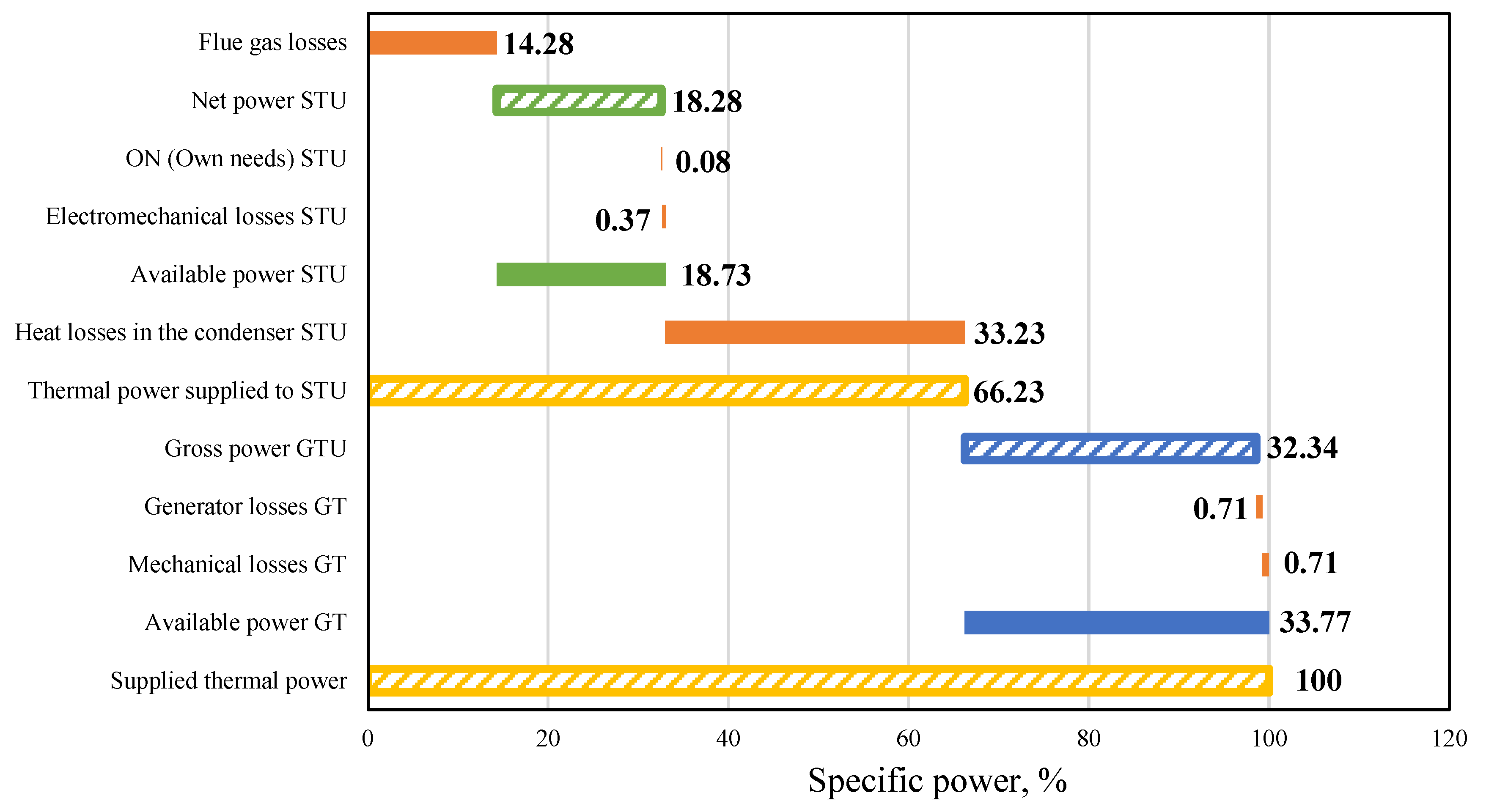

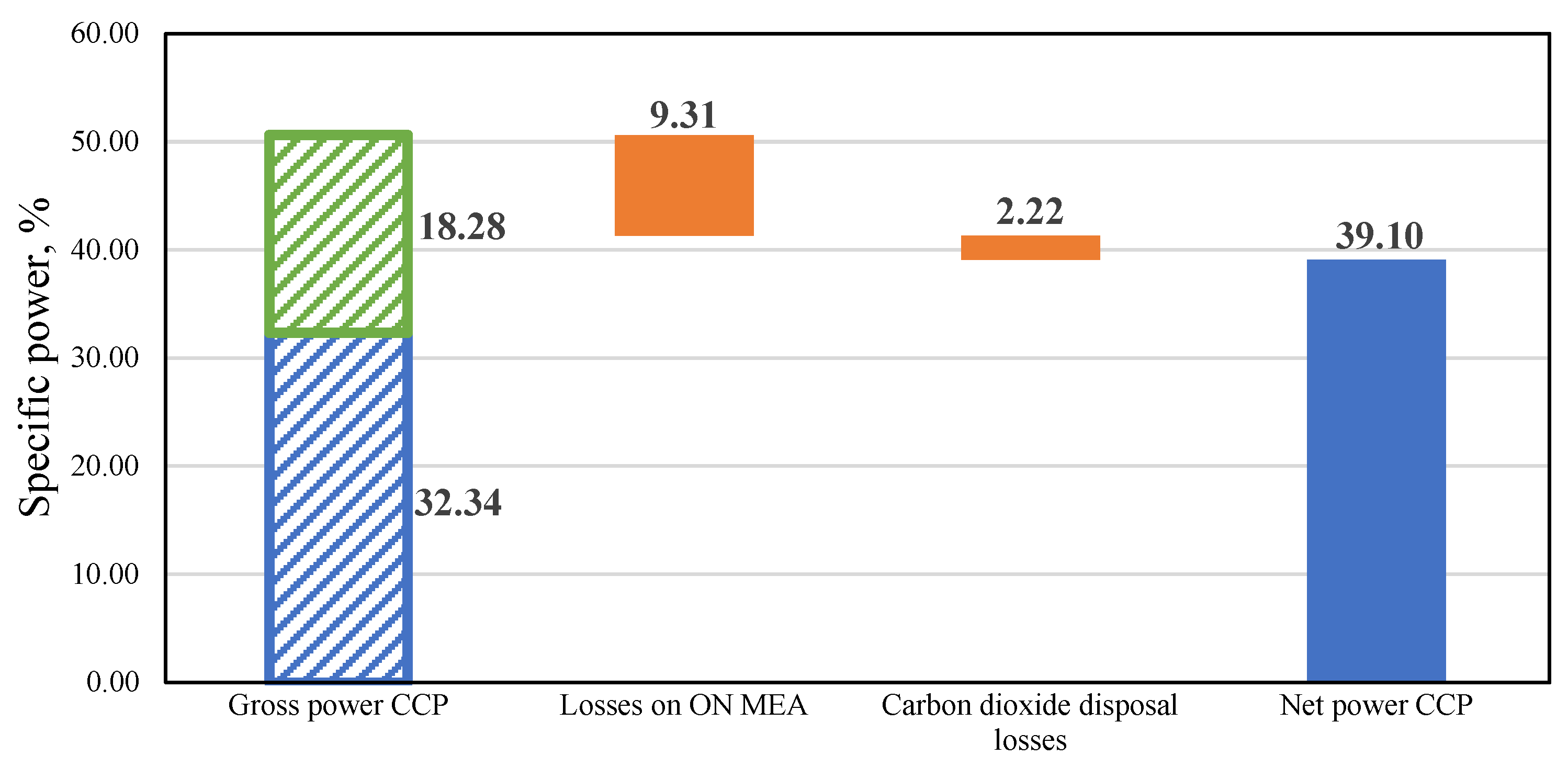

- Binary combined-cycle gas turbine with monoethanolamine cleaning of exhaust gases (Figure 6);

- (2)

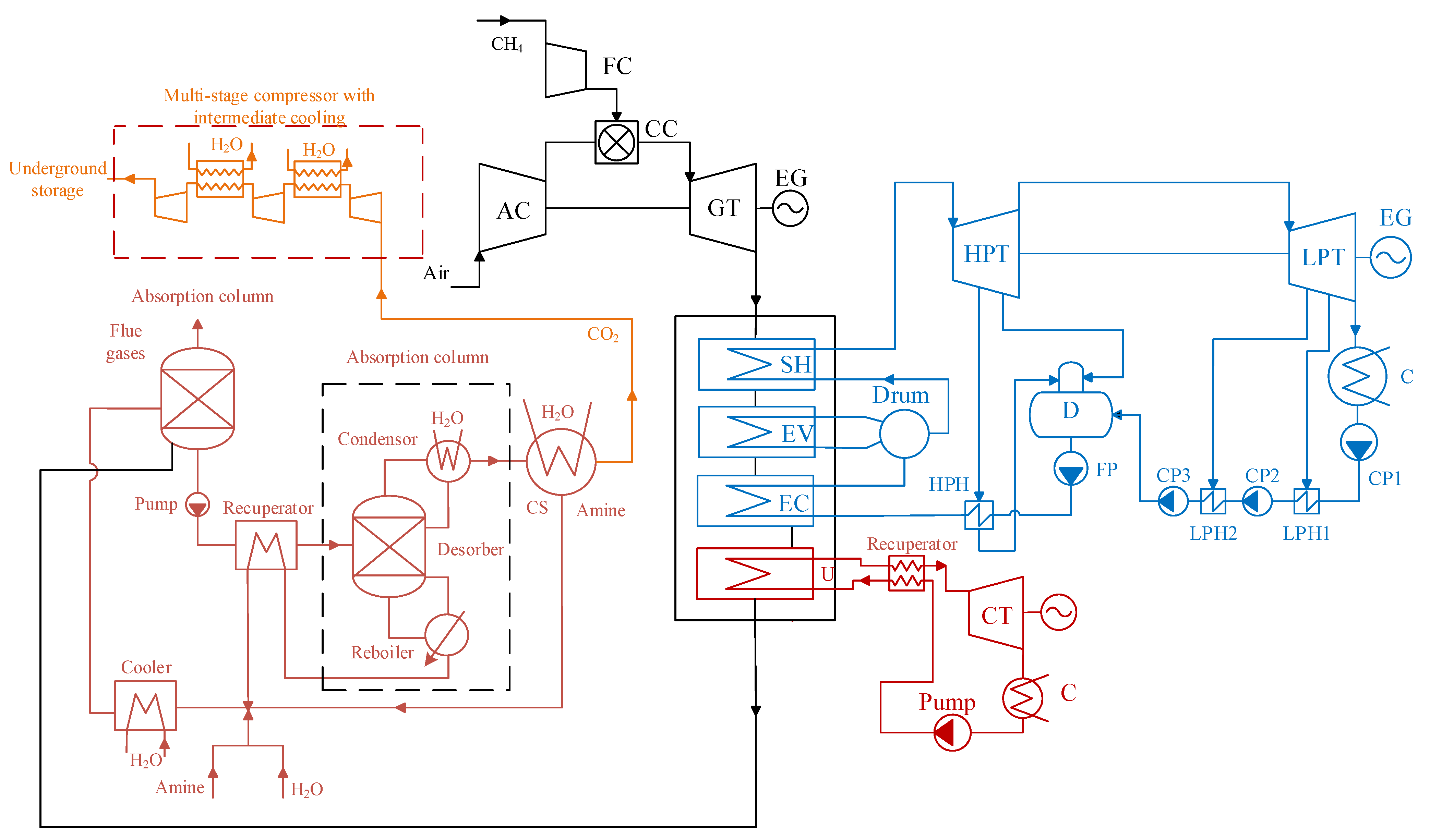

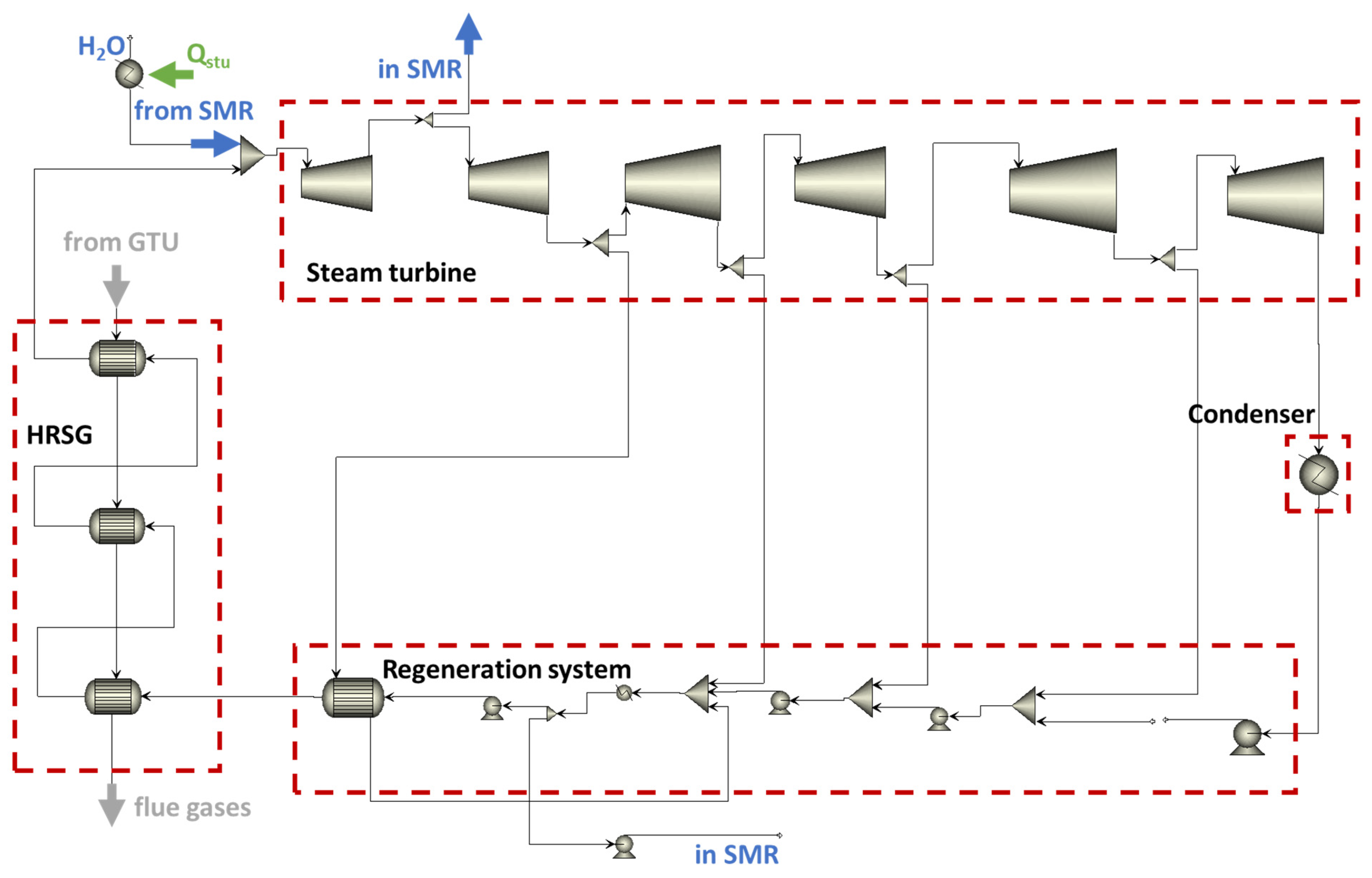

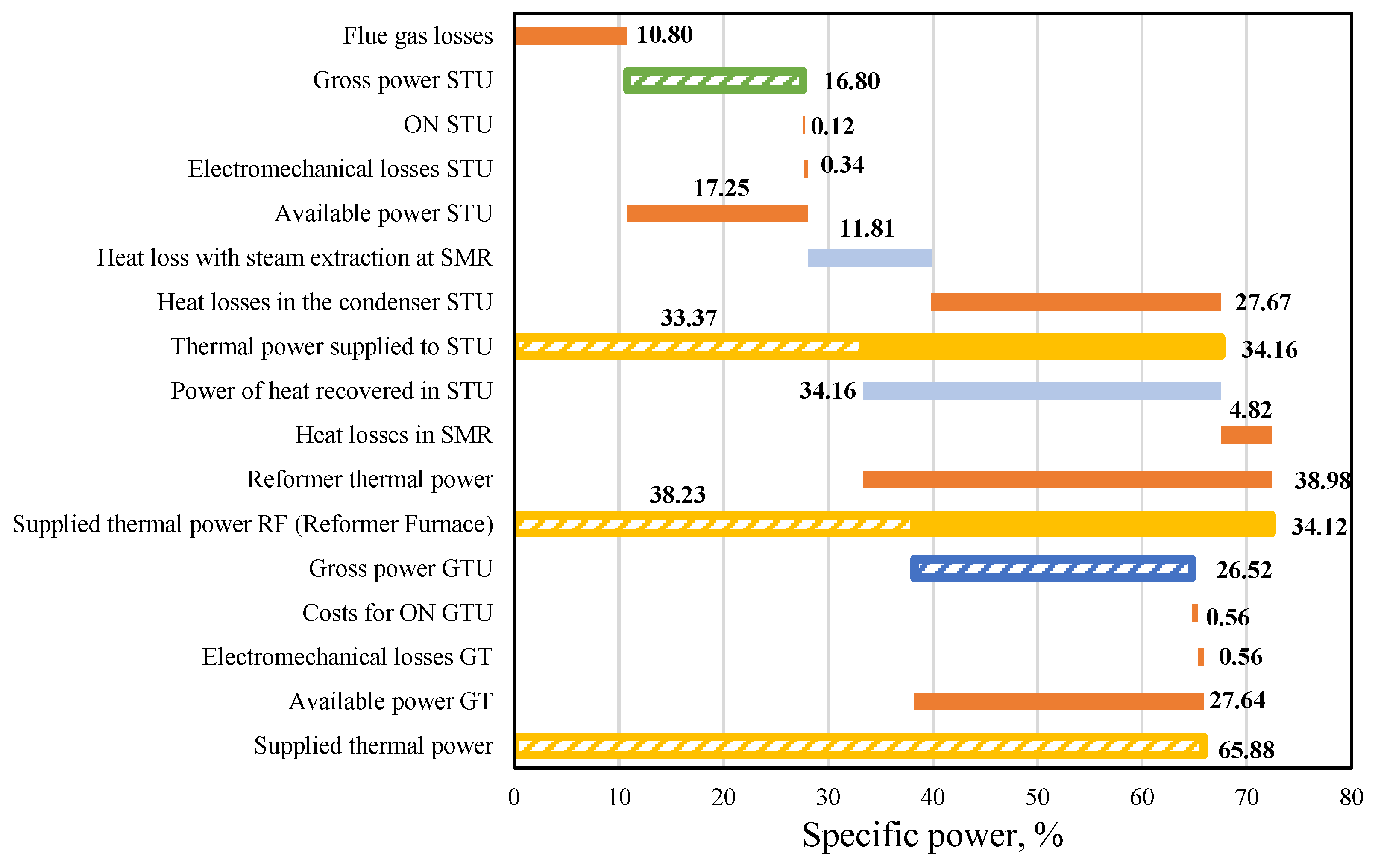

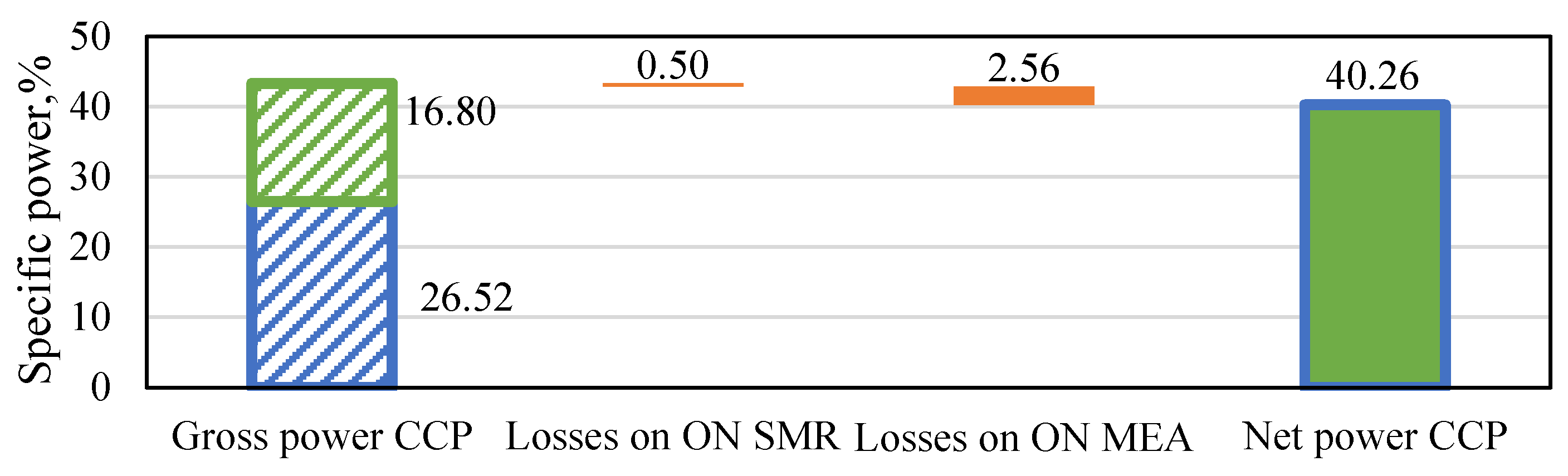

- Trinary combined-cycle gas turbine with monoethanolamine cleaning of exhaust gases (Figure 7);

- (3)

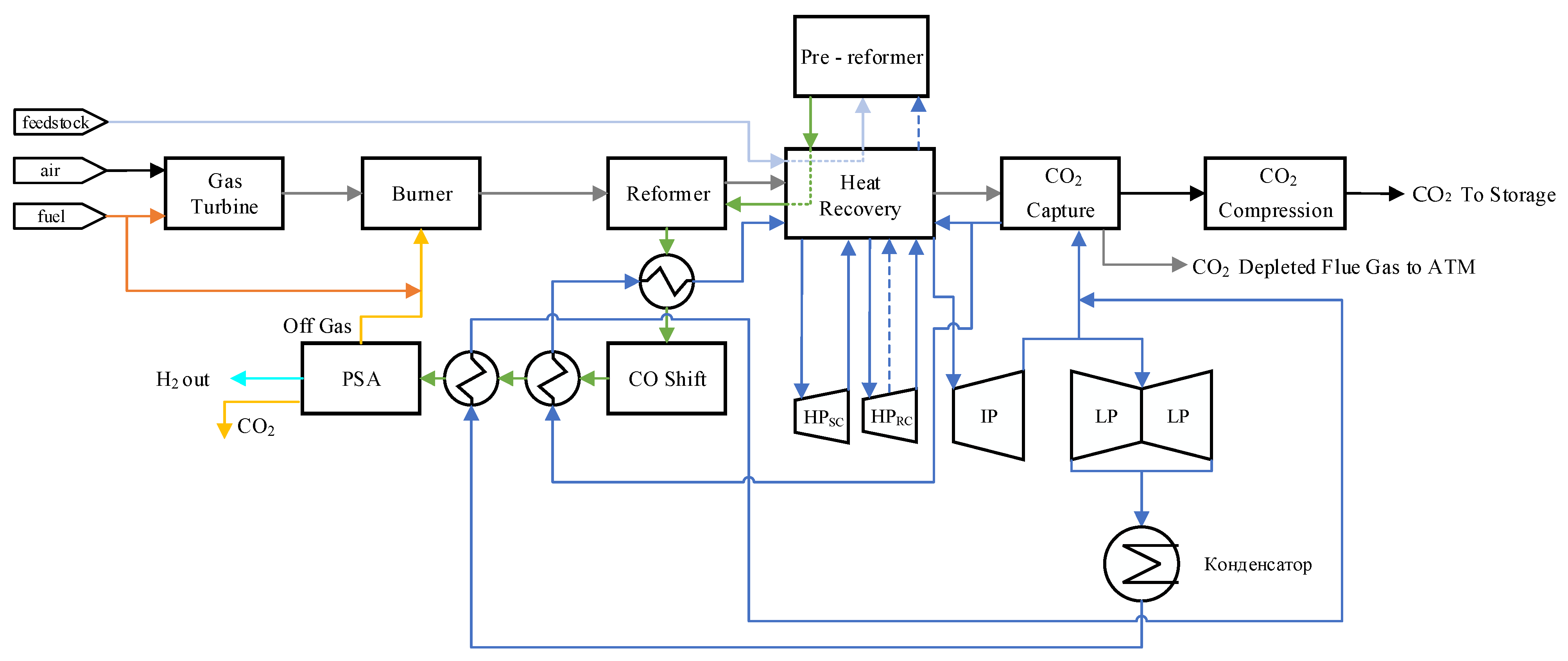

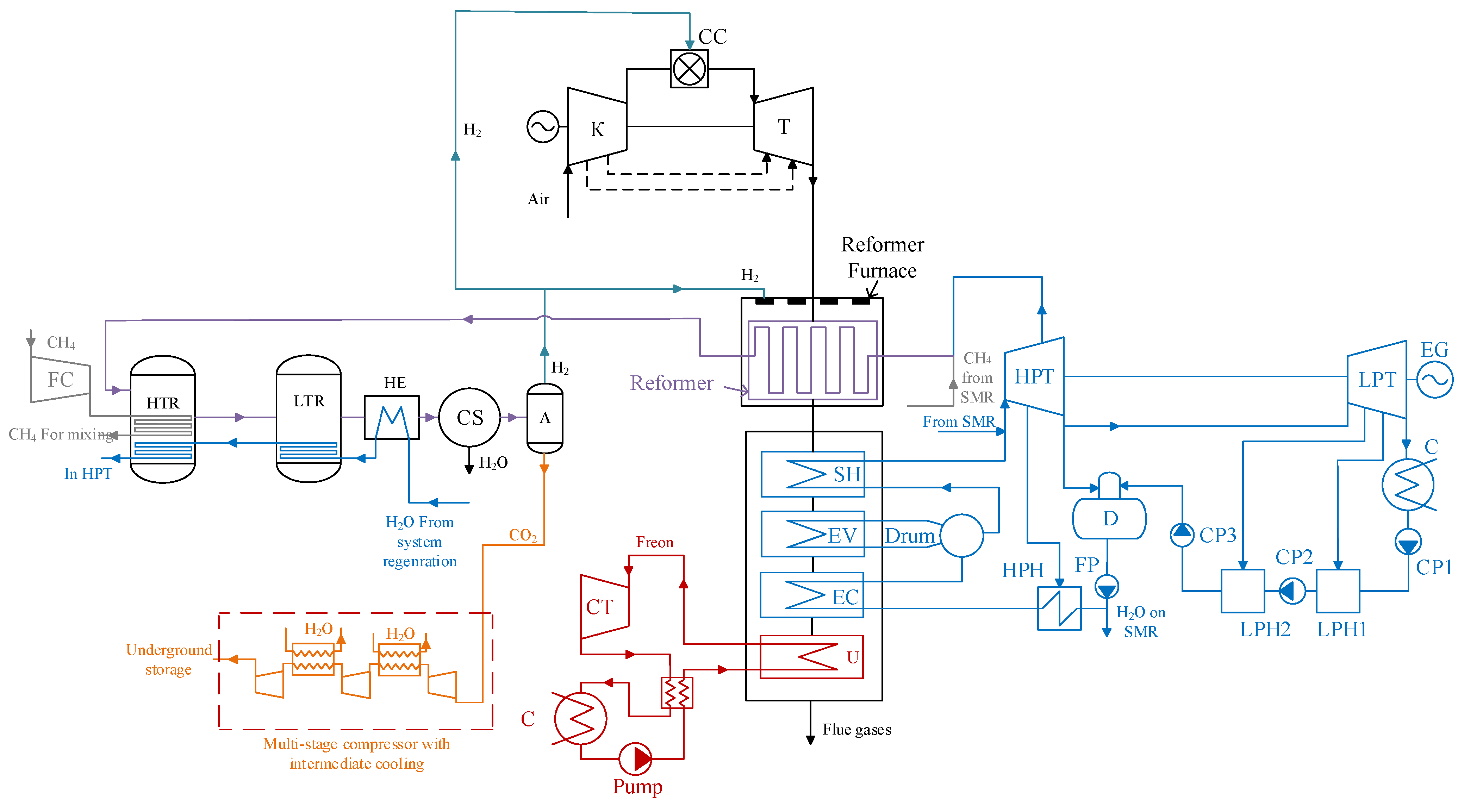

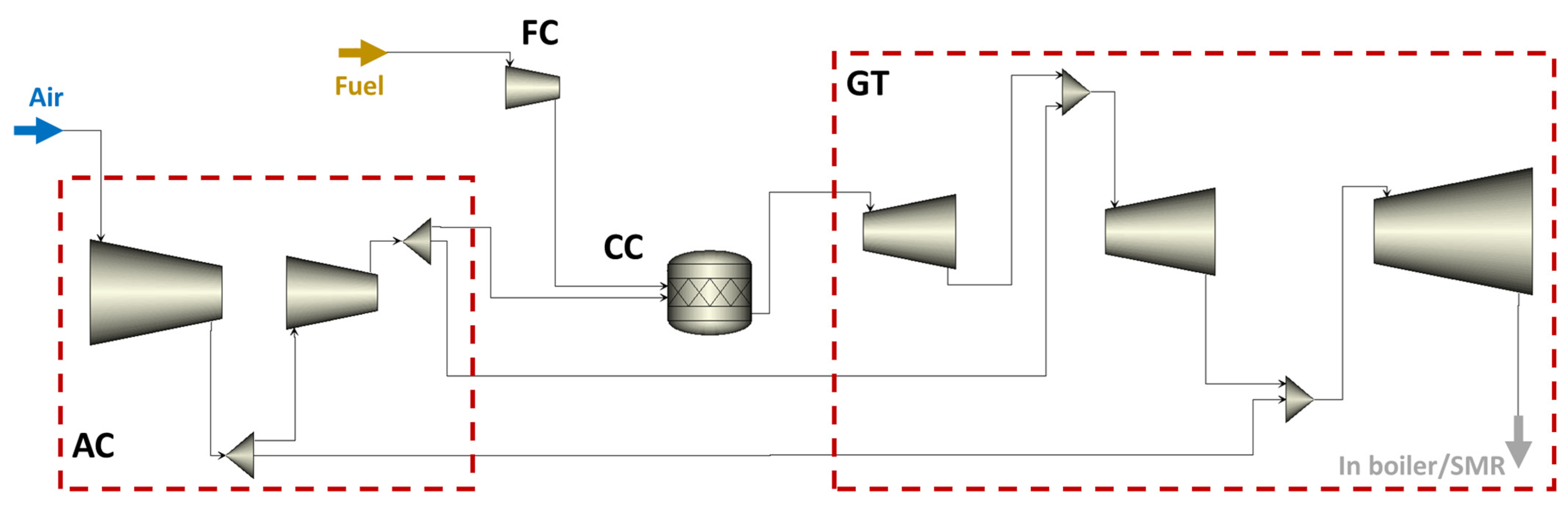

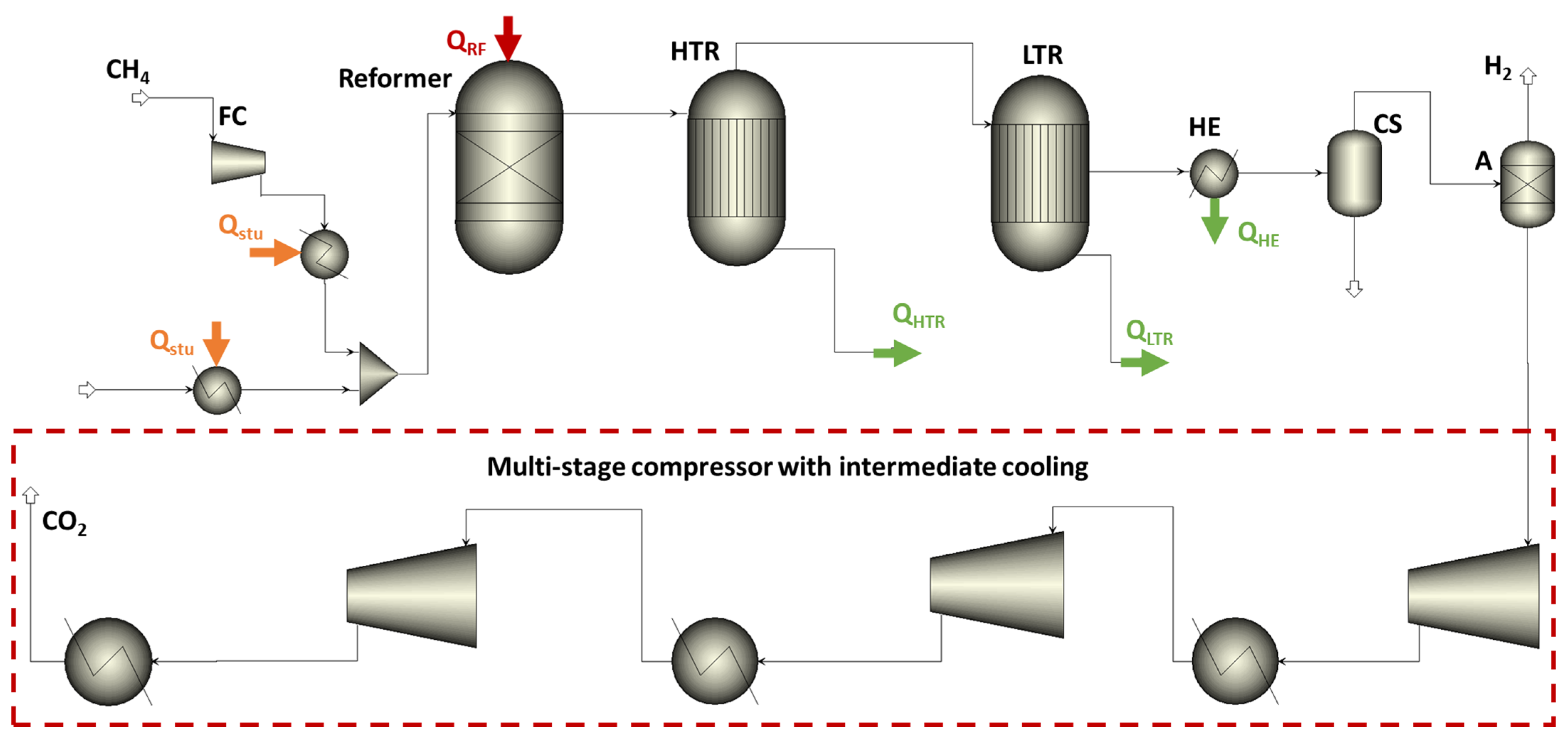

- Binary combined-cycle gas turbine with integrated steam methane reforming unit (Figure 8);

- (4)

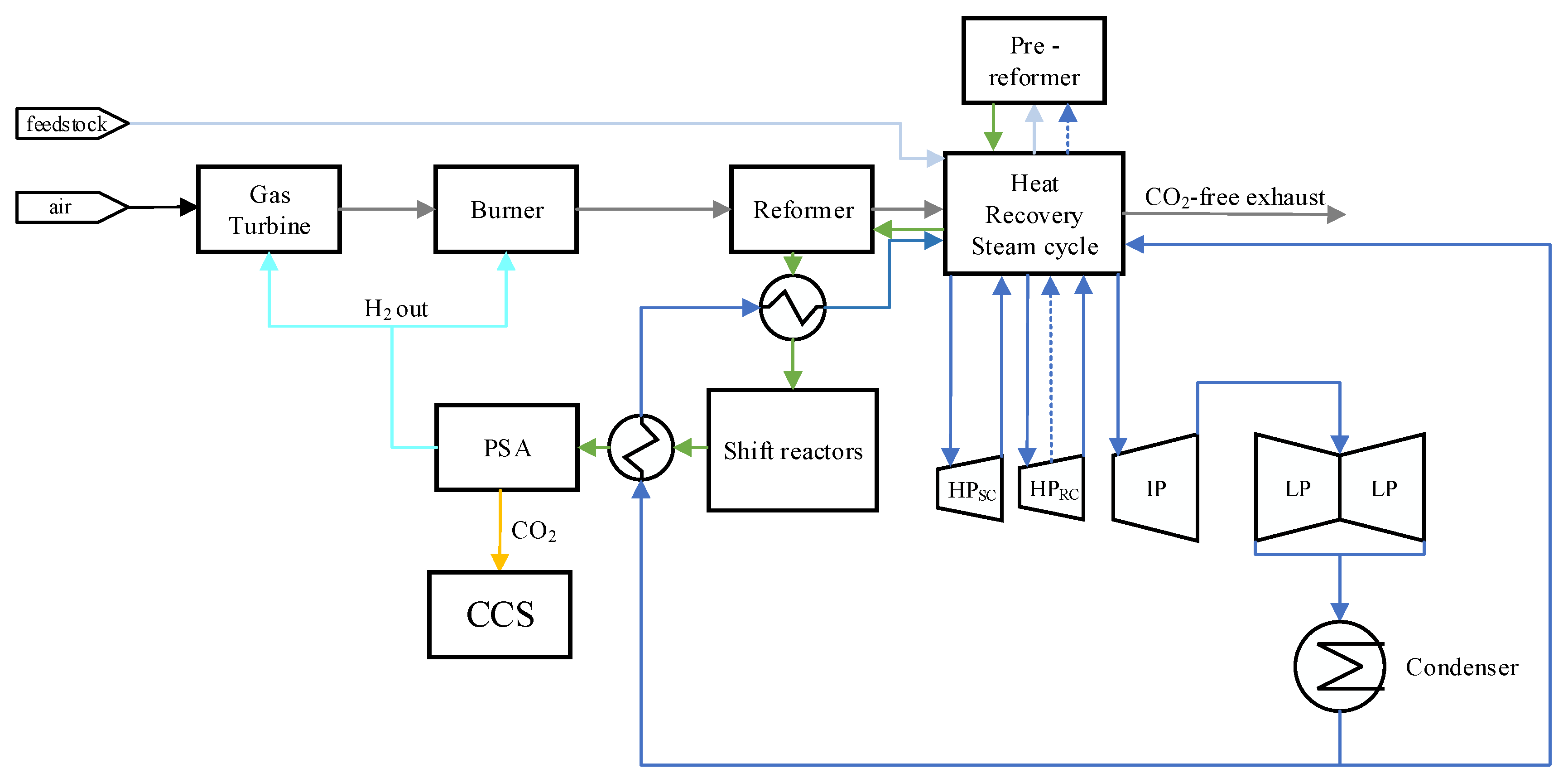

- Trinary combined-cycle gas turbine with integrated steam methane reforming unit (Figure 9).

2.1. Trinary and Binary Power Plants with Carbon Dioxide Capture Technologies for Post-Combustion Capture

2.2. Trinary and Binary Power Plants with Carbon Dioxide Capture Technologies for Pre-Combustion Capture

3. Methodology

- -

- Absence of chemicals under burning during the fuel combustion process;

- -

- No pressure loss in pipelines;

- -

- When fuel is distilled, no nitrogen oxides are formed.

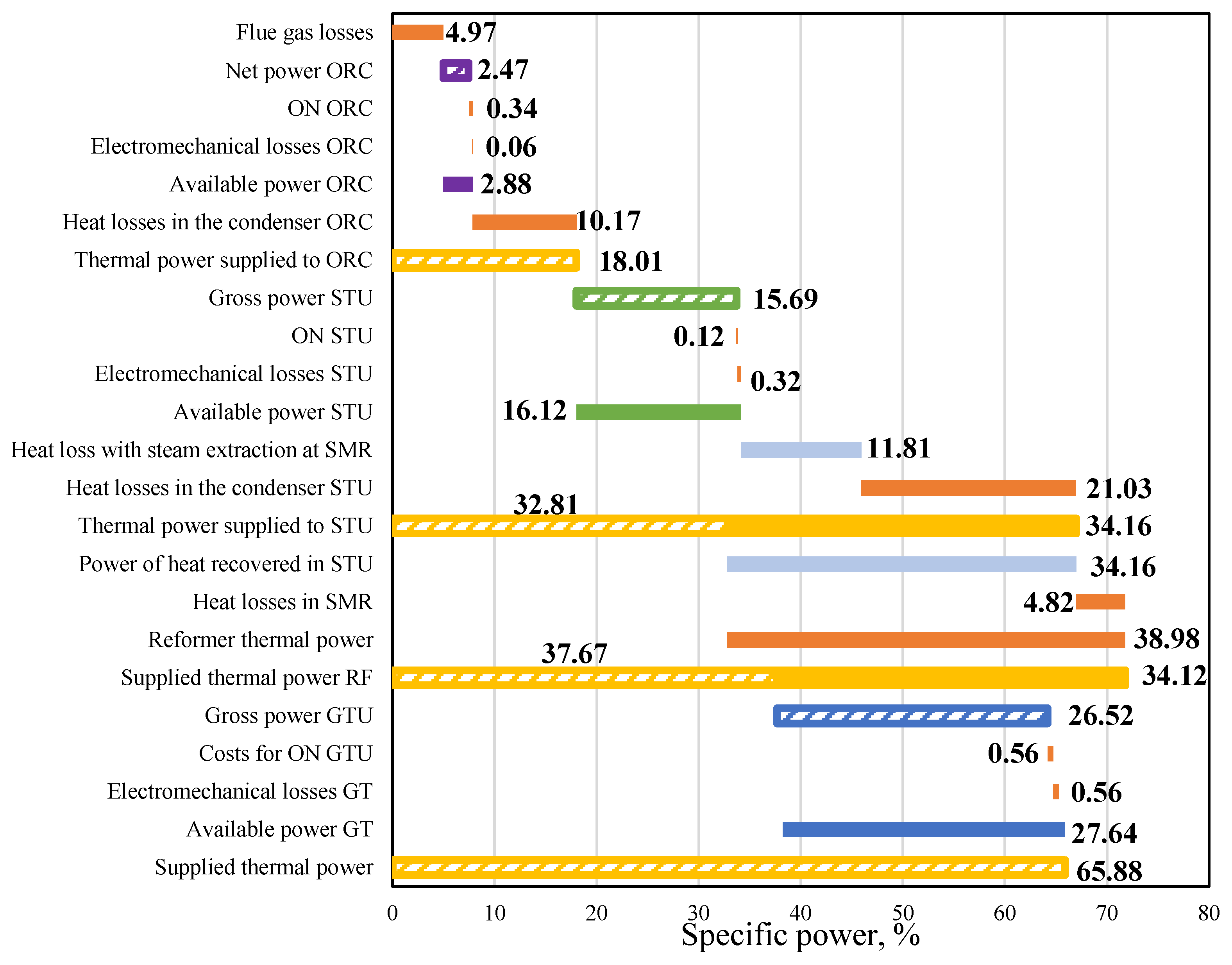

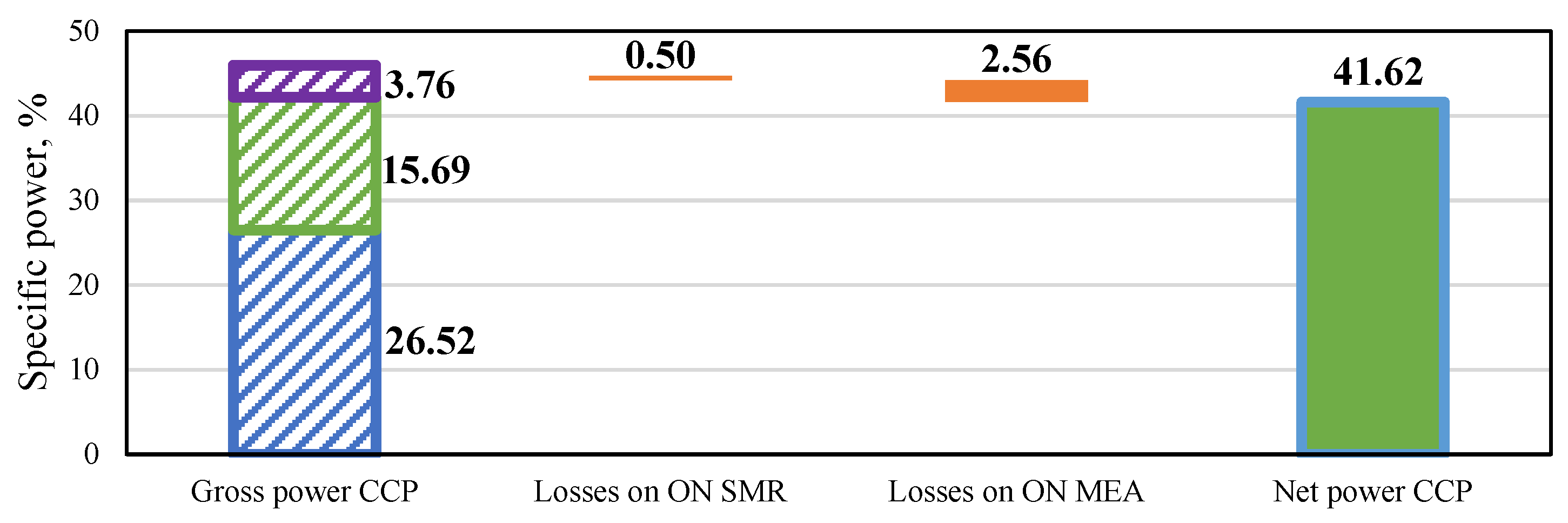

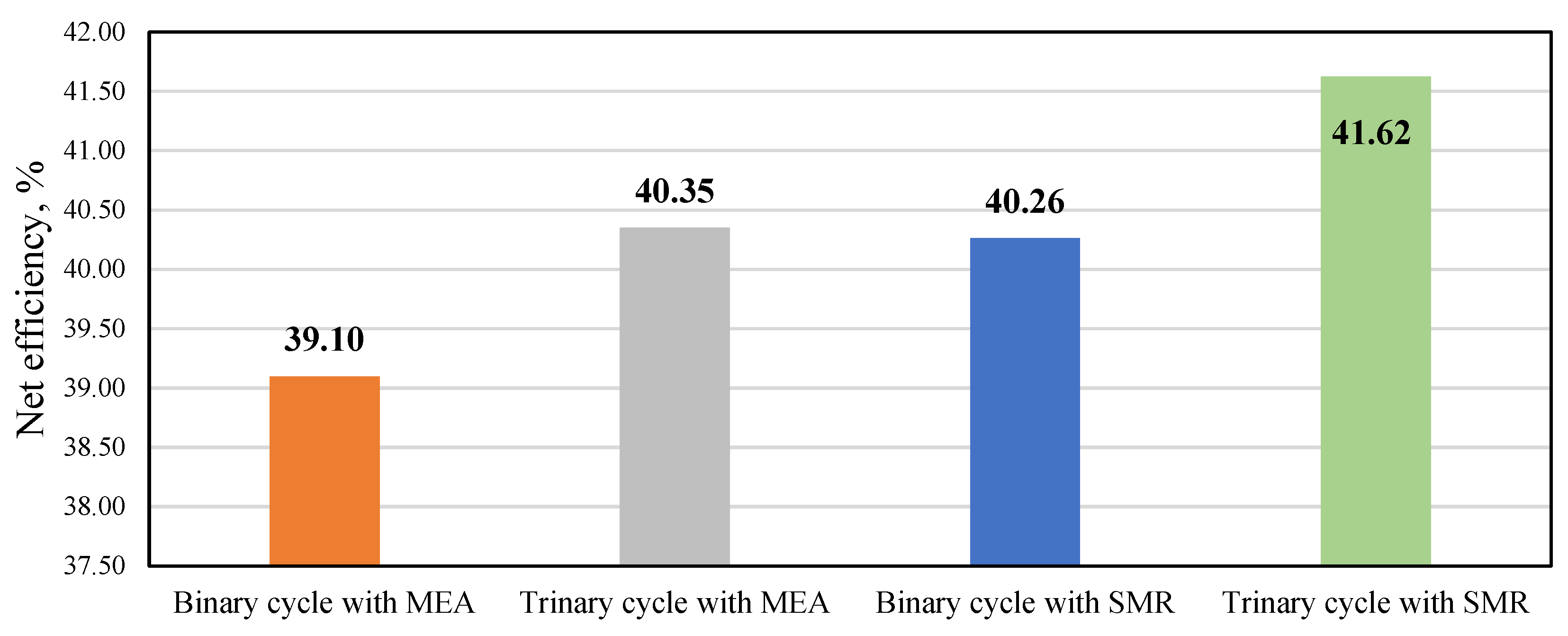

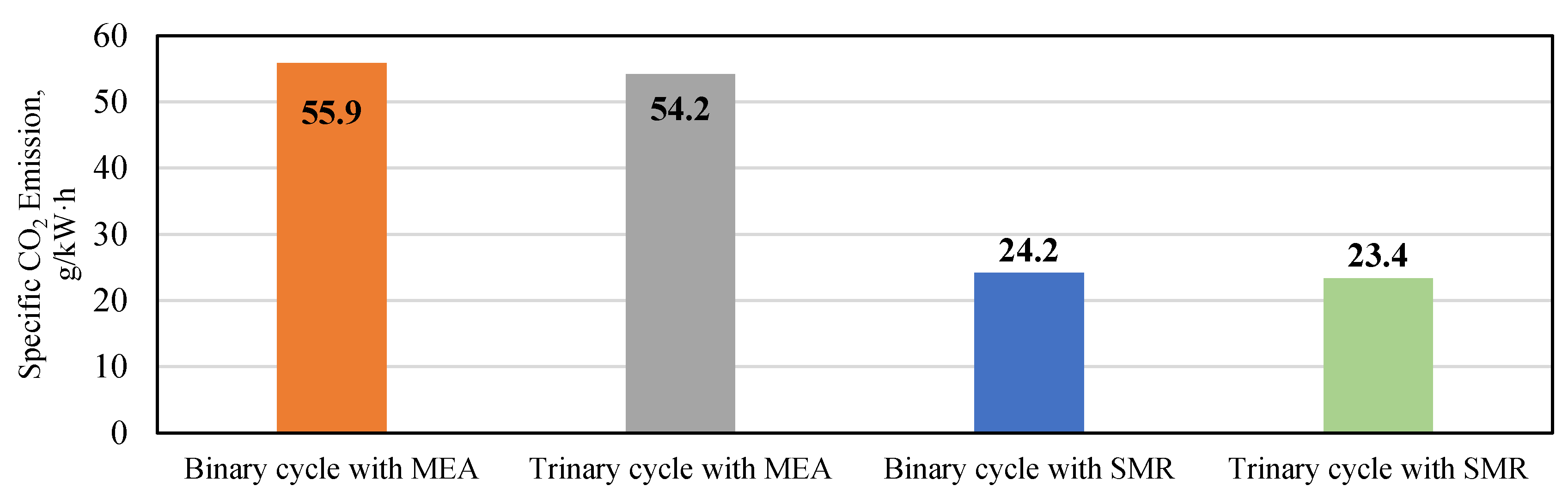

4. Results

5. Conclusions

- (1)

- Binary combined-cycle plant with monoethanolamine cleaning of exhaust gases;

- (2)

- Three-stage combined-cycle gas turbine with monoethanolamine cleaning of exhaust gases;

- (3)

- Binary combined-cycle gas turbine with integrated steam methane reforming unit;

- (4)

- Trinary combined-cycle gas turbine with integrated steam methane reforming unit.

- (1)

- During the cooling of synthesis gas in a steam methane reforming unit, 27.1 MW of thermal energy is lost in the cooler–separator but during monoethanolamine cleaning of exhaust gases, 40 MW of electrical energy must be spent on heating the amine in the reboiler;

- (2)

- When switching from a binary combined-cycle plant with MEA to a binary combined-cycle plant with an integrated SMR unit, energy losses for carbon dioxide disposal increase by 4.7 MW, which is associated with an increase in carbon dioxide emissions by 33% due to an increase in fuel consumption by 3.19 kg/s;

- (3)

- For the steam reforming reaction to take place, 52 kg/s is removed from the steam turbine, however, due to the fact that when utilizing 191.7 MW of thermal energy, 61 kg/s of steam is generated—which is sent to the steam turbine unit—the net capacity of the steam turbine unit increases by 16.2 MW.

- -

- An increase in total losses in the condensers of the steam turbine and the central heating system by 24.2 MW;

- -

- An increase in the total own needs of the steam-turbine unit and the central heating system by 1.4 MW;

- -

- A reduction in losses with exhaust gases at the outlet of the gas–air circuit of the combined-cycle power plant by 31.7 MW;

- -

- An increase in the net capacity of the combined-cycle power plant by 5.4 MW.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ivanova, S.; Vesnina, A.; Fotina, N.; Prosekov, A. An Overview of Carbon Footprint of Coal Mining to Curtail Greenhouse Gas Emissions. Sustainability 2022, 14, 15135. [Google Scholar] [CrossRef]

- Rashid, M.I.; Benhelal, E.; Rafiq, S. Reduction of Greenhouse Gas Emissions from Gas, Oil, and Coal Power Plants in Pakistan by Carbon Capture and Storage (CCS): A Review. Chem. Eng. Technol. 2020, 43, 2140–2148. [Google Scholar] [CrossRef]

- Kindra, V.; Rogalev, A.; Lisin, E.; Osipov, S.; Zlyvko, O. Techno-economic analysis of the oxy-fuel combustion power cycles with near-zero emissions. Energies 2021, 14, 5358. [Google Scholar] [CrossRef]

- Mohamed, U.; Zhao, Y.-J.; Yi, Q.; Shi, L.-J.; Wei, G.-Q.; Nimmo, W. Evaluation of life cycle energy, economy and CO2 emissions for biomass chemical looping gasification to power generation. Renew. Energy 2021, 176, 366–387. [Google Scholar]

- Ritchie, H.; Rosado, P.; Roser, M. Breakdown of Carbon Dioxide, Methane, and Nitrous Oxide Emissions by Sector. 2024. Available online: https://ourworldindata.org/emissions-by-sector (accessed on 10 June 2024).

- Novak, A. Fuel and Energy Complex of Russia Today and Tomorrow: Results and Tasks. Energy Policy 2024, 1, 6–13. [Google Scholar]

- Inderjeet, M. Fuel Transition from Non-Renewable to Renewable for Gas Turbines in a Changing Europe. Ph.D. Thesis, Technische Hochschule Ingolstadt, Ingolstadt, Germany, 2023. [Google Scholar]

- Sultan, H.; Muhammad, H.A.; Bhatti, U.H.; Min, G.H.; Baek, I.H.; Baik, Y.J.; Nam, S.C. Reducing the efficiency penalty of carbon dioxide capture and compression process in a natural gas combined cycle power plant by process modification and liquefied natural gas cold energy integration. Energy Convers. Manag. 2021, 244, 114495. [Google Scholar] [CrossRef]

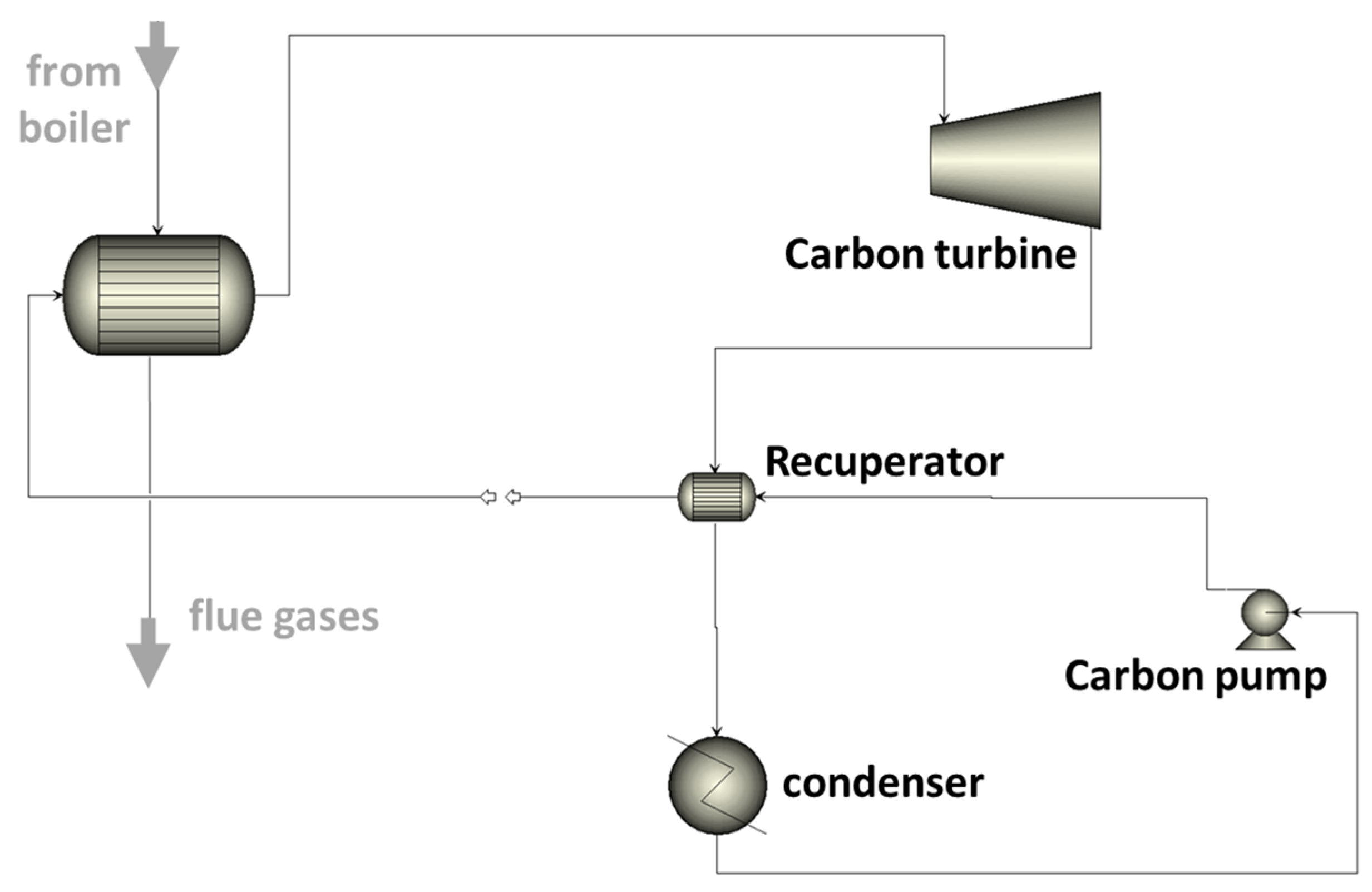

- Kindra, V.; Maksimov, I.; Komarov, I.; Xu, C.; Xin, T. Feasibility Study of Scheme and Regenerator Parameters for Trinary Power Cycles. Energies 2023, 16, 3886. [Google Scholar] [CrossRef]

- Ancona, M.A.; Bianchi, M.; Branchini, L.; de Pascale, A.; Melino, F.; Peretto, A.; Torricelli, N. Systematic Comparison of ORC and S-CO2 Combined Heat and Power Plants for Energy Harvesting in Industrial Gas Turbines. Energies 2021, 14, 3402. [Google Scholar] [CrossRef]

- Kindra, V.; Rogalev, N.; Osipov, S.; Zlyvko, O.; Naumov, V. Research and Development of Trinary Power Cycles. Inventions 2022, 7, 56. [Google Scholar] [CrossRef]

- Kindra, V.O.; Komarov, I.I.; Zlyvko, O.V.; Maksimov, I.A.; Ostrovsky, M.A. Thermodynamic Analysis of a Trinary Power Plant. Energetika 2024, 1, 70–81. [Google Scholar] [CrossRef]

- Ibigbami, O.A.; Onilearo, O.D.; Akinyeye, R.O. Post-combustion capture and other Carbon Capture and Sequestration (CCS) technologies: A review. Environ. Qual. Manag. 2024, 34, e22180. [Google Scholar] [CrossRef]

- Song, C.; Liu, Q.; Deng, S.; Li, H.; Kitamura, Y. Cryogenic-based CO2 capture technologies: State-of-the-art developments and current challenges. Renew. Sustain. Energy Rev. 2019, 101, 265–278. [Google Scholar] [CrossRef]

- Rath, G.K.; Pandey, G.; Singh, S.; Molokitina, N.; Kumar, A.; Joshi, S.; Chauhan, G. Carbon Dioxide Separation Technologies: Applicable to Net Zero. Energies 2023, 16, 4100. [Google Scholar] [CrossRef]

- Maniarasu, R.; Rathore, S.K.; Murugan, S. A review on materials and processes for carbon dioxide separation and capture. Energy Environ. 2023, 34, 3–57. [Google Scholar] [CrossRef]

- Kamio, E.; Yoshioka, T.; Matsuyama, H. Recent Advances in Carbon Dioxide Separation Membranes: A Review. J. Chem. Eng. Jpn. 2023, 56, 2222000. [Google Scholar] [CrossRef]

- Jiang, W.; Luo, X.; Gao, H.; Liang, Z.; Liu, B.; Tontiwachwuthikul, P.; Hu, X. A comparative kinetics study of CO2 absorption into aqueous DEEA/MEA and DMEA/MEA blended solutions. AIChE J. 2017, 64, 1350–1358. [Google Scholar] [CrossRef]

- Jasim, D.J.; Mohammed, T.J.; Harharah, H.N.; Harharah, R.H.; Amari, A.; Abid, M.F. Modeling and Optimal Operating Conditions of Hollow Fiber Membrane for CO2/CH4 Separation. Membranes 2023, 13, 557. [Google Scholar] [CrossRef]

- Mondal, M.K.; Balsora, H.K.; Varshney, P. Progress and trends in CO2 capture/separation technologies: A review. Energy 2012, 46, 431–441. [Google Scholar] [CrossRef]

- Kim, I.; Svendsen, H.F. Comparative study of the heats of absorption of post-combustion CO2 absorbents. Int. J. Greenh. Gas Control 2011, 5, 390–395. [Google Scholar] [CrossRef]

- Chai, S.Y.W.; Ngu, L.H.; How, B.S. Review of carbon capture absorbents for CO2 utilization. Greenh. Gases Sci. Technol. 2022, 12, 394–427. [Google Scholar] [CrossRef]

- Kindra, V.; Maksimov, I.; Oparin, M.; Zlyvko, O.; Rogalev, A. Hydrogen Technologies: A Critical Review and Feasibility Study. Energies 2023, 16, 5482. [Google Scholar] [CrossRef]

- Ma, L.-C.; Dominguez, B.C.; Kazantzis, N.K.; Ma, Y.H. Integration of membrane technology into hydrogen production plants with CO2 capture: An economic performance assessment study. Int. J. Greenh. Gas Control 2015, 42, 424–438. [Google Scholar] [CrossRef]

- Fernandez, J.R.; Abanades, J.C.; Grasa, G. Modeling of sorption enhanced steam methane reforming-Part II: Simulation within a novel Ca/Cu chemical loop process for hydrogen production. Chem. Eng. Sci. 2012, 84, 12–20. [Google Scholar] [CrossRef]

- Komarov, I.; Osipov, S.; Zlyvko, O.; Vegera, A.; Naumov, V. Combined Cycle Gas Turbine for Combined Heat and Power Production with Energy Storage by Steam Methane Reforming. J. Energy Syst. 2021, 5, 231–243. [Google Scholar] [CrossRef]

- Pashchenko, D. Performance Evaluation of a Combined Power Generation System Integrated with Thermochemical Exhaust Heat Recuperation Based on Steam Methane Reforming. Int. J. Hydrogen Energy 2023, 48, 5823–5835. [Google Scholar] [CrossRef]

- Mullen, D.; Herraiz, L.; Lucquiaud, M. Advanced Thermodynamic Integration in Combined Fuel and Power (CFP) Plants Producing Low Carbon Hydrogen & Power with CCUS. In Proceedings of the 15th Greenhouse Gas Control Technologies Conference, Abu Dhabi, United Arab Emirates, 5–18 March 2021; pp. 15–18. [Google Scholar]

- Lozza, G.; Chiesa, P. Natural gas decarbonization to reduce CO2 emission from combined cycles—Part I: Partial oxidation. J. Eng. Gas Turbines Power 2000, 124, 82–88. [Google Scholar] [CrossRef]

- Vorokhta, M.; Kusdhany, M.I.M.; Vöröš, D.; Nishihara, M.; Sasaki, K.; Lyth, S.M. Microporous carbon foams: The effect of nitrogen-doping on CO2 capture and separation via pressure swing adsorption. Chem. Eng. J. 2023, 471, 144524. [Google Scholar] [CrossRef]

- Aspen Technology, Inc. AspenPlus. Available online: https://www.aspentech.com/en/products/engineering/aspen-plus (accessed on 19 July 2021).

- Lemmon, E.W.; Bell, I.H.; Huber, M.L.; McLinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 10.0; National Institute of Standards and Technology: Gaithersburg, MA, USA; Standard Reference Data Program: Gaithersburg, MA, USA, 2018.

- Quirino, P.; Amaral, A.; Pontes, K.; Rossi, F.; Manenti, F. Impact of kinetic models in the prediction accuracy of an industrial steam methane reforming unit. Comput. Chem. Eng. 2021, 152, 107379. [Google Scholar] [CrossRef]

- Stray, J.D. Control of Corrosion and Fouling in Amine Sweetening Systems. Presented at the NACE Canada Region Western Conference, Calgary, AB, USA, 21 February 1990; pp. 20–22. [Google Scholar]

| Unit | Efficiency, % | Direct CO2 Emissions, g CO2/kWhel |

|---|---|---|

| Gas turbine unit | 35.5 | 566 |

| Steam turbine unit | 38.4 | 524 |

| Combined-cycle gas turbine | 51.3 | 392 |

| Parameter | Method CO2 Capture | ||

|---|---|---|---|

| Absorption | Membranes | Cryogenic Separation | |

| Cost energy, MJ/kg CO2 | 4–6 | 0.5–6 | 6–10 |

| Degree CO2 capture, % | 88–98 | 80–90 | >95 |

| Unit | SMR | ATR | CLR |

|---|---|---|---|

| Levelized cost of production LCOH, USD/kgH2 | 1.07–2.26 | 1.70–2.31 | 3.31 |

| Efficiency, % | 85 | 87 | 75 |

| Specific direct emission, kg CO2eq/kgH2 | 1 | 1.27 | 1.01 |

| Air separation unit required | No | Yes | Yes |

| Parameter | Meaning | |

|---|---|---|

| Method of Capturing Carbon Dioxide | MEA | SMR |

| Outside air temperature, °C | 15 | |

| Outside air pressure, kPa | 101.3 | |

| Pressure of combustion products at the outlet of the combustion chamber, kPa | 1060 | |

| Temperature of combustion products at the outlet of the CC, °C | 1060 | |

| Mass flow compressor air, kg/s | 500 | |

| Fuel supplied to the CC | CH4 | H2 |

| Temperature of synthesis gas at the reformer outlet, °C | - | 850 |

| Synthesis gas pressure at the reformer outlet, kPa | - | 1060 |

| Reboiler share | 0.7 | - |

| Outlet saturated amine pump pressure, kPa | 110 | - |

| Reflux fraction in the condenser | 0.5 | - |

| Underheating at the hot end of the superheater, °C | 20 | |

| Steam temperature at the outlet of the waste heat boiler, °C | 515 | |

| Underheating at the cold end of the evaporator, °C | 10 | |

| Underheating at the economizer inlet, °C | 10 | |

| Underheating at the deaerator inlet, °C | 10 | |

| Temperature in the condenser, °C | 30 | |

| Deaerator pressure, kPa | 120 | |

| Hydraulic losses in heaters, % | 5 | |

| Internal efficiency of feed, condensate, circulation pumps, % | 85 | |

| Dryness level at the outlet of the steam turbine, % | 90 | |

| Heat losses in heat exchangers, % | 1 | |

| Underheating in high-pressure heater, °C | 1.5 | |

| Underheating in low-pressure heater, °C | 5 | |

| Cooling water temperature before feed pump, °C | 15 | |

| Relative internal efficiency of gas turbine, % | 89 | |

| Hydraulic pressure loss in the combustion chamber, % | 3 | |

| Distribution of cooling flow in the first two stages, %/% | 70/30 | |

| Mechanical efficiency, % | 99 | |

| Efficiency of electric generator, % | 99 | |

| Working environment of the organic Rankine cycle | R245fa | |

| Temperature in the ORC cycle condenser, °C | 30 | |

| Minimum temperature pressure in the waste heat recovery unit, °C | 5 | |

| Internal relative efficiency of pump/compressor, % | 85 | |

| Internal relative efficiency of turbine, % | 85 | |

| Efficiency of electric generators and electric motors, % | 99 | |

| Mechanical efficiency, % | 99 | |

| Steam dryness level at turbine outlet, % | 90 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rogalev, N.; Rogalev, A.; Kindra, V.; Zlyvko, O.; Kovalev, D. Reforming Natural Gas for CO2 Pre-Combustion Capture in Trinary Cycle Power Plant. Energies 2024, 17, 5544. https://doi.org/10.3390/en17225544

Rogalev N, Rogalev A, Kindra V, Zlyvko O, Kovalev D. Reforming Natural Gas for CO2 Pre-Combustion Capture in Trinary Cycle Power Plant. Energies. 2024; 17(22):5544. https://doi.org/10.3390/en17225544

Chicago/Turabian StyleRogalev, Nikolay, Andrey Rogalev, Vladimir Kindra, Olga Zlyvko, and Dmitriy Kovalev. 2024. "Reforming Natural Gas for CO2 Pre-Combustion Capture in Trinary Cycle Power Plant" Energies 17, no. 22: 5544. https://doi.org/10.3390/en17225544

APA StyleRogalev, N., Rogalev, A., Kindra, V., Zlyvko, O., & Kovalev, D. (2024). Reforming Natural Gas for CO2 Pre-Combustion Capture in Trinary Cycle Power Plant. Energies, 17(22), 5544. https://doi.org/10.3390/en17225544