Suppression of Metal Particles by Coating for a ±550 kV DC GIS

Abstract

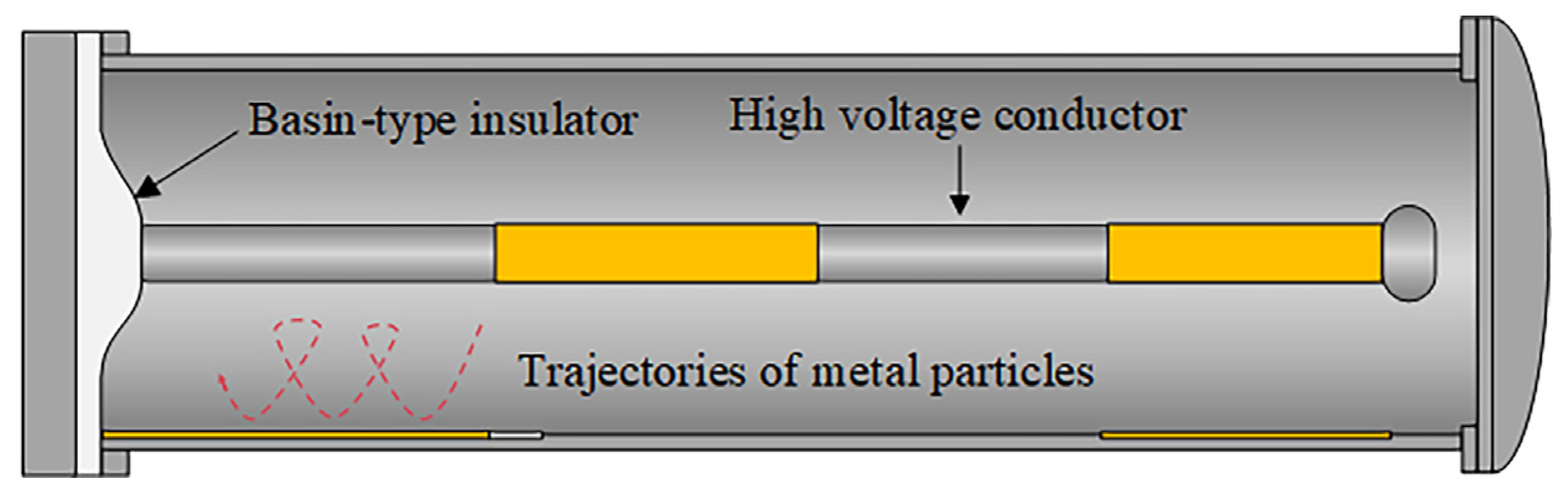

1. Introduction

2. Literature Review on Metal Particle Suppression Using Coating Technique

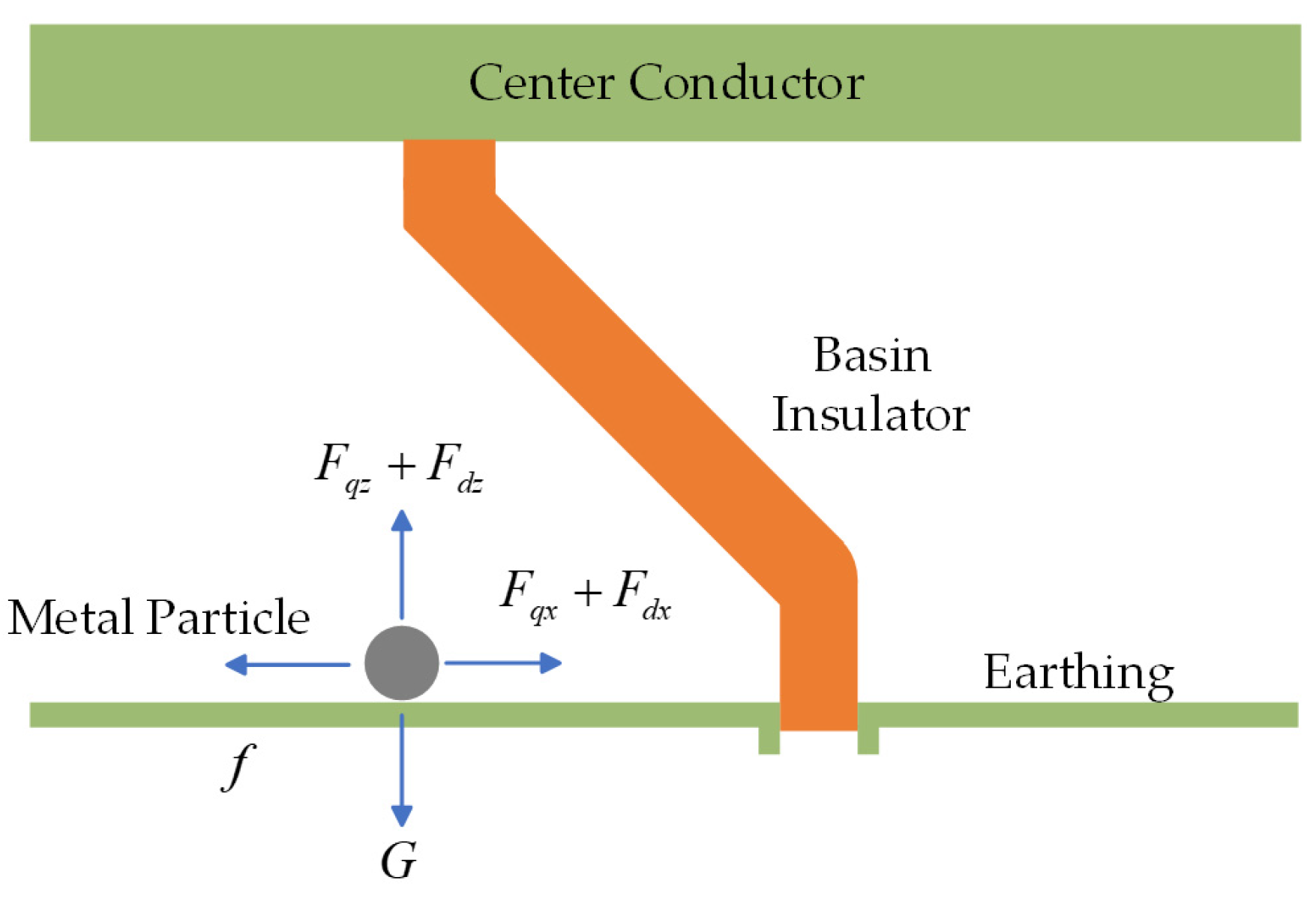

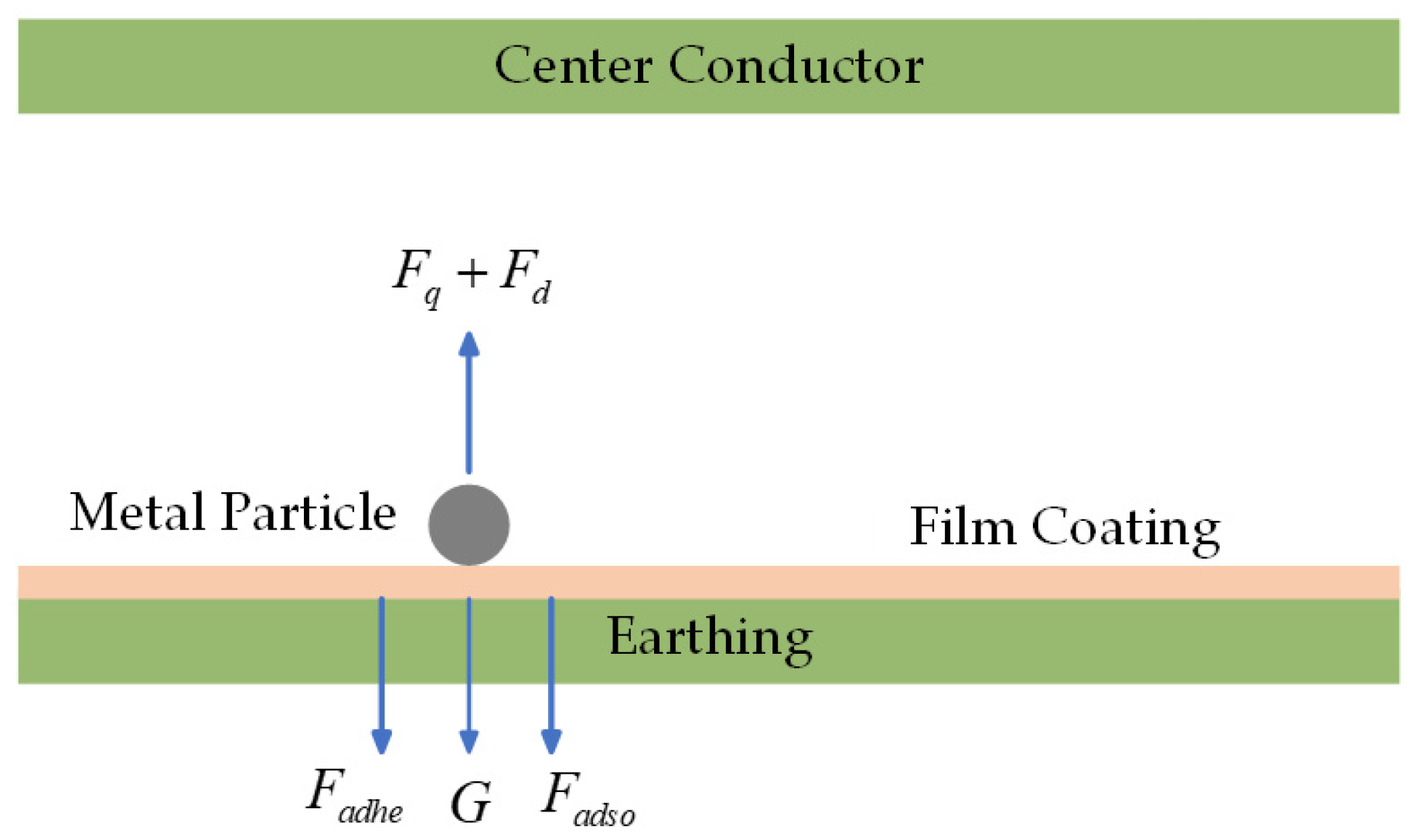

2.1. Basic Theory

2.2. Cases and Scenarios

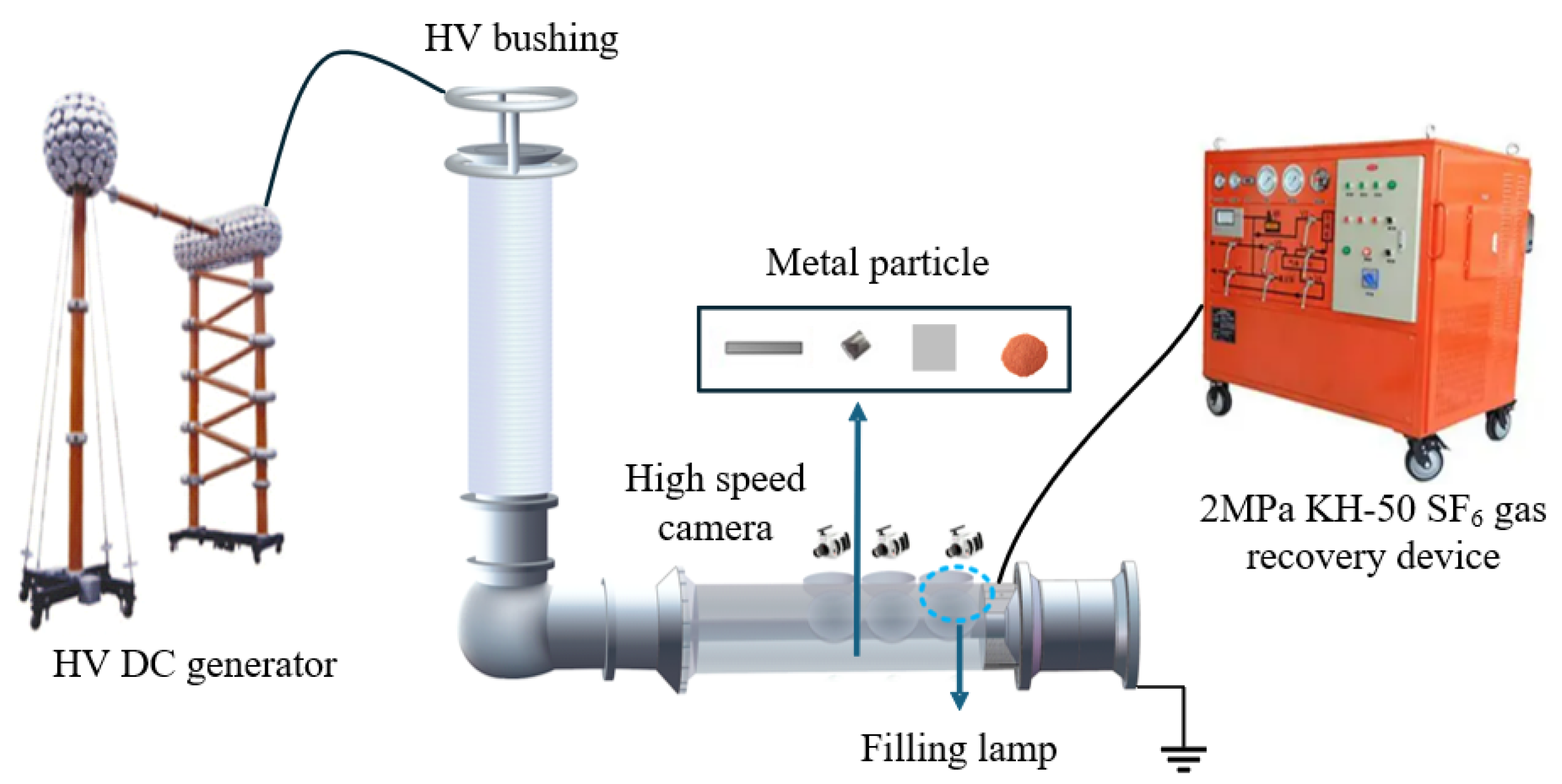

3. Experimental Setup

4. Impact Coating Test Results Based on a ±550 kV GIS Busbar

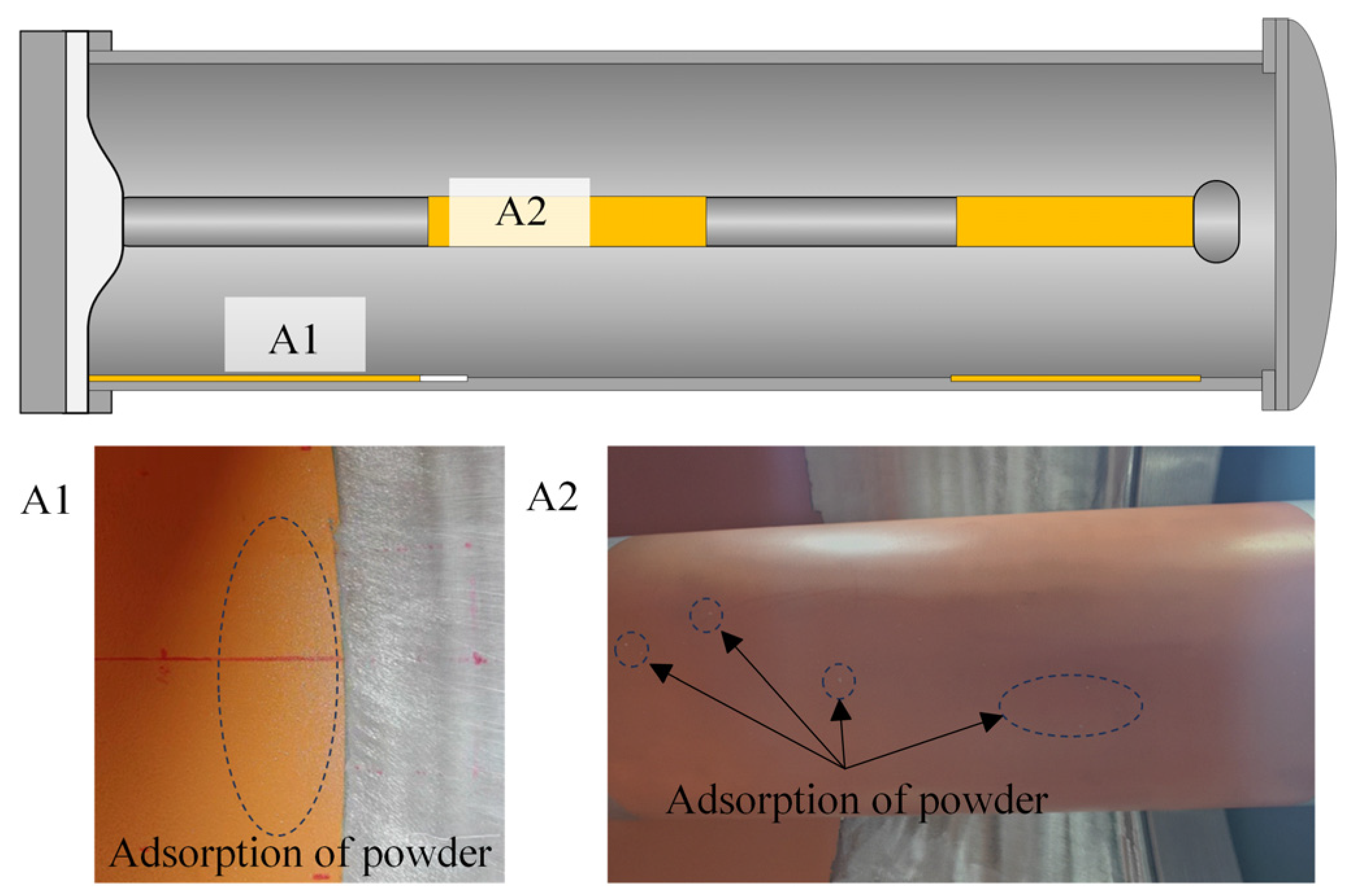

4.1. Powdery Particles

4.2. Block Particles

- (a)

- Particles that land in the lower region of the membrane (defined as the area on the circle centered on the conductor and bounded by the shell inner wall, with the vertically downward direction as the symmetry line of the sector, within an included angle of 80° and below), and do not collide with other particles, quickly cease bouncing, rolling only a short distance before coming to rest on the surface of the membrane.

- (b)

- Particles that land in the lower region of the membrane and collide with other particles, which easily causes the other particles to lift off.

- (c)

- Particles that land in the upper region of the membrane (above 80°) tend to slide down along the inner wall of the shell while moving vertically downward toward the conductor. When moving close to directly below the conductor, they move toward the direction of the conductor, almost without direct contact with the membrane surface, until colliding with the conductor. After bouncing downward, if they do not collide with other particles, they come to rest on the surface of the membrane.

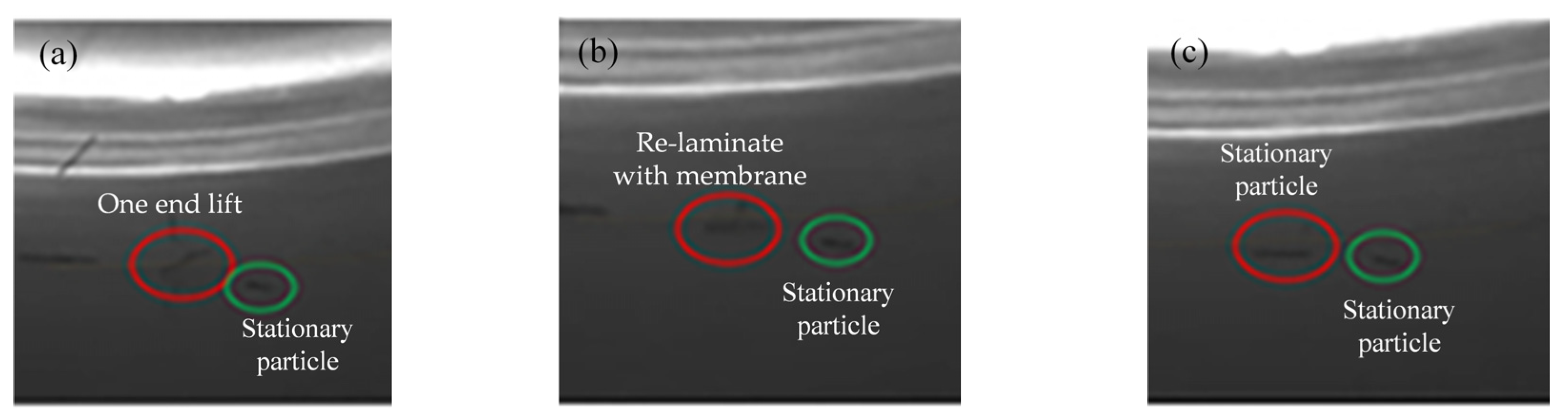

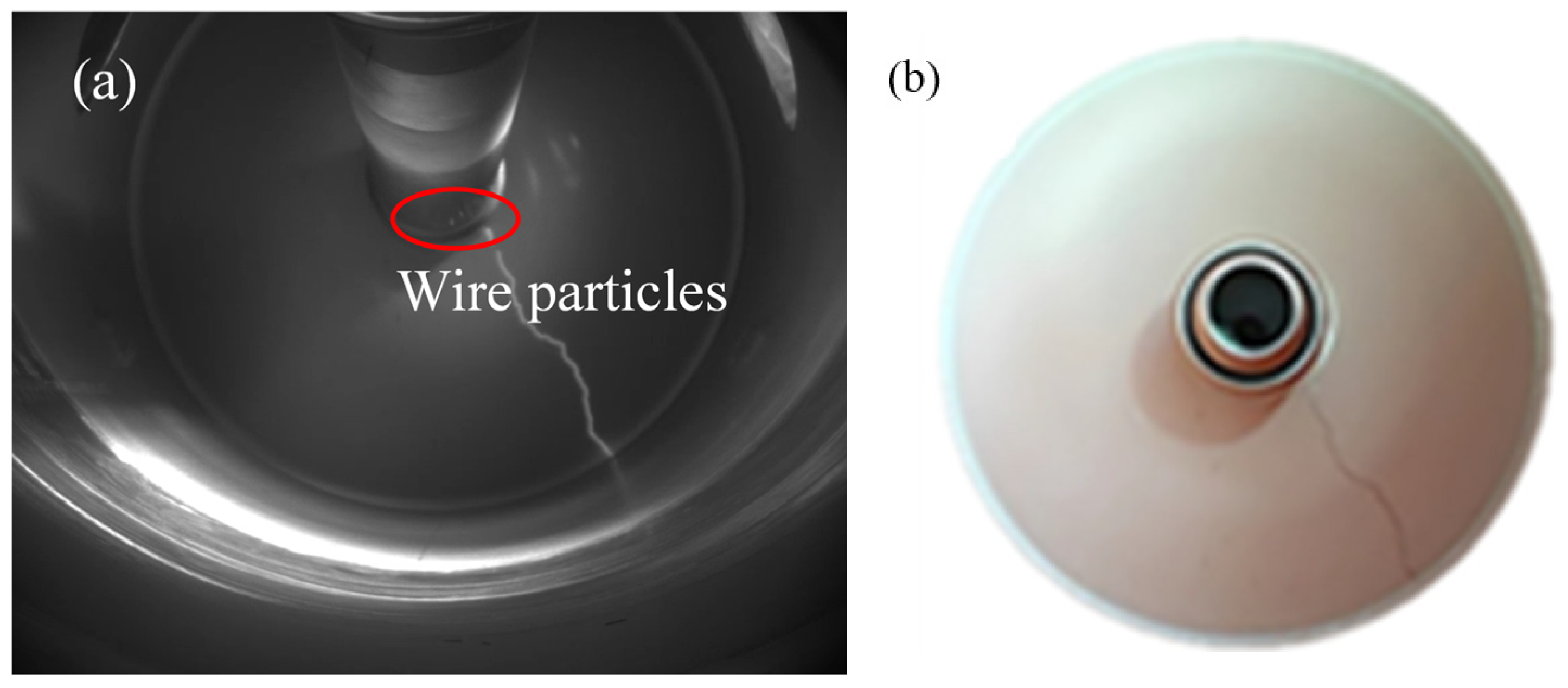

4.3. Wire Particles

- (a)

- Stationary particles on the coated surface: Wire particles initially located on the film do not exhibit motion during the pressurization process and remain stationary until the end of pressurization. This behavior is shown in Figure 11, where the green markers indicate the particle positions.

- (b)

- Tangential movement and immobilization: In some cases, wire particles that initially move during pressurization subsequently travel onto the coated surface in a direction nearly tangential to the shell’s inner wall. Once these particles make contact with the coating, they quickly cease motion and remain immobilized for the remainder of the pressurization process. This behavior is represented in Figure 11 with red markers, demonstrating the coating’s ability to inhibit particle movement upon contact.

- (c)

- Perpendicular movement and reactivation: Wire particles that move upon touching the film in a direction nearly perpendicular to the tangent of the shell inner wall either stand on the film or move near it. As pressurization continued, they re-enter motion toward the conductor and then lift off, a process that could occur at any stage of pressurization without a specific voltage value associated.

- (d)

- Axial movement along the conductor: After most wire particles lift off, they move back and forth along the axial direction of the conductor. When reaching the boundary between the coated and uncoated sections of the conductor, their motion state hardly changes, as indicated by the red markers in Figure 12. At the tips of some particles, tiny discharges with the conductor are observable by the naked eye.

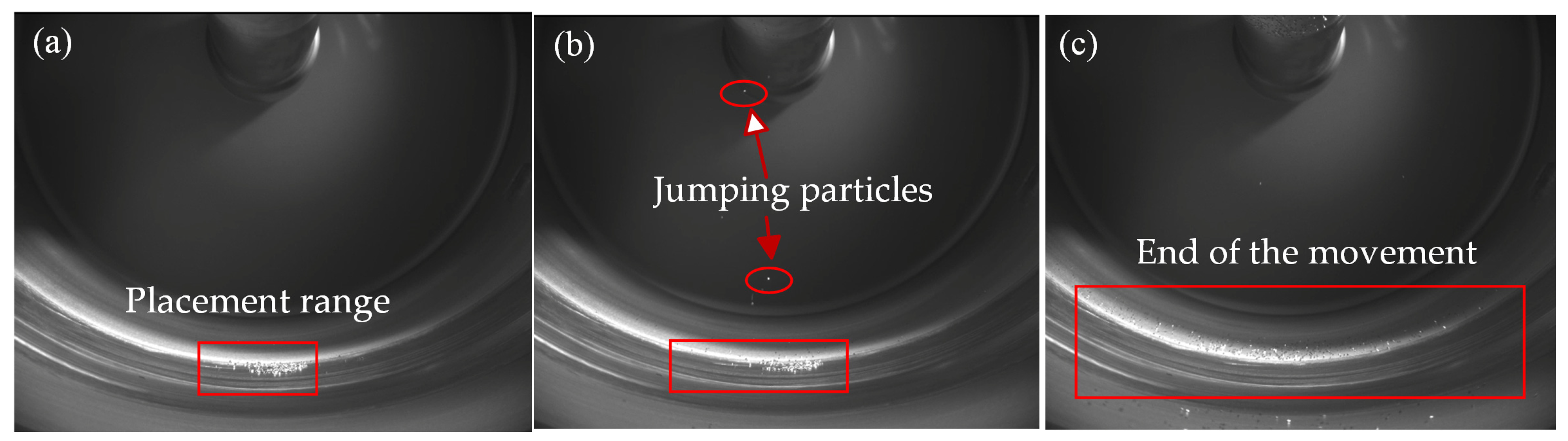

4.4. Flaky Particles

- (a)

- Stationary particles on the coated surface: The particles do not move from the beginning to the end of pressurization. This behavior is represented in Figure 14 with red markers.

- (b)

- Still after movement: After the particles jump, flaky particles move to the film and no longer jump.

- (c)

- Axial movement along the conductor: The flaky particles outside the coating position and on the membrane jump and move along the conductor in a firefly motion. The conductor coating has no effect on the firefly motion of flake particles. Green indicates jumping particles, as shown in Figure 14.

5. Conclusions

- (1)

- EMOP demonstrates a significant inhibitory effect on block and powder metal particles in real GIS systems. Under rated voltage, the occurrence of particle lift off or re-jumping is rare.

- (2)

- For wire and flake metal particles, the coating’s effectiveness depends on the particle’s contact with the grounding electrode upon settling. Overall, the thin-film coating can inhibit 30% of wire and flake metal particles.

- (3)

- The inhibitory effect of the coating tends to diminish as particle volume increases. A comparative analysis ranks the coating’s effectiveness on various particles as follows: powder > block > wire > flake.

- (4)

- For metal particles in full contact with the coated surface, the coating exhibits a more pronounced inhibitory effect.These conclusions provide an important reference for the application of EMOP in actual GIS equipment and help to improve the safety and reliability of GIS operation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- He, J. Ideas on building underground energy complex passage. South. Power Syst. Technol. 2016, 10, 66–70. [Google Scholar]

- Hu, Z.; Wei, L.; Geng, Q.; Wang, J.; Li, Q.; Chang, Y. Firefly movement phenomenon of wire particle swarm and risk assessment in DC GIS/GIL. Proc. CSEE 2024, 44, 6219–6229. [Google Scholar]

- Chang, Y. Physical Mechanism and Synergistic Suppress Method of Metal Particle Firefly in GIL. Ph.D. Thesis, North China Electric Power University, Beijing, China, 2023. [Google Scholar]

- Zhuang, W.; Liang, Z.; Liang, F.; Fan, X.; Luo, H.; Hu, J.; Li, C.; Zhang, B.; He, J. Particle behavior and trap design for ±320 kV gas-insulated power transmission line (GIL). J. Phys. D Appl. Phys. 2023, 56, 325501. [Google Scholar] [CrossRef]

- Li, C.; Lin, C.; Chen, G.; Tu, Y.; Zhou, Y.; Li, Q.; Zhang, B.; He, J. Field-dependent charging phenomenon of HVDC spacers based on dominant charge behaviors. Appl. Phys. Lett. 2019, 114, 202904. [Google Scholar] [CrossRef]

- Li, C.; Zhu, Y.; Hu, J.; Li, Q.; Zhang, B.; He, J. Charge cluster triggers unpredictable insulation surface flashover in pressurized SF6. J. Phys. D Appl. Phys. 2020, 54, 015308. [Google Scholar] [CrossRef]

- Wang, W. Research on Insulation Failure of Metal Particles in DC GIL. Master’s Thesis, Shenyang University of Technology, Shenyang, China, 2020. [Google Scholar]

- Ping, A.; Wang, J.; Xiao, R.; Liu, R.; Chang, Y.; Li, Q. Trap parameters optimization based on metal article dynamic simulation method. Symmetry 2022, 14, 1187. [Google Scholar] [CrossRef]

- Chang, Y.; Liu, C.; He, J.; Wang, J.; Wang, J.; Li, Q. Design and optimization of particle traps in DC GIL based on the capture effect analysis. Proc. CSEE 2020, 40, 5050–5061. [Google Scholar]

- Jia, J.; Zha, W.; Zhang, Q. Influence of metal inserted polytetrafluorethylene spacer on the motion of conducting particle under AC voltage. Proc. CSEE 2008, 28, 136–141. [Google Scholar]

- Di, Q.; Hu, Z.; Li, Q.; Zhuang, T.; Liu, Y. Optimal design and synergism arrangement methodology of convex-shaped traps for ultra high voltage AC GIS/GIL applications. Trans. China Electrotech. Soc. 2023, 38, 6539–6552. [Google Scholar]

- Fan, J.; Li, P.; Li, J.; Tang, H.; Zhang, Q.; Wu, G. Study on Key Technology of ±800 kV UHVDC GIL. Proc. CSEE 2008, 28, 1–7. [Google Scholar]

- Tang, H.; Wu, G.; Fan, J.; Li, P.; Li, J.; Wang, N. Insulation design of gas insulated HVDC transmission line. Power Syst. Technol. 2008, 32, 65–70. [Google Scholar]

- Guo, H.; Li, S.; He, J.; Zhang, C.; Li, Z.; Geng, Q. Assessment for particles inhibition effect and insulation life of polyimide electrode-coating in AC GIS. High Volt. Appar. 2023, 59, 223–231. [Google Scholar]

- Zhang, B.; Zhang, G.; Wang, Q.; Li, C.; He, J.; An, Z. Suppression of surface charge accumulation on Al2O3-filled epoxy resin insulator under DC voltage by direct fluorination. AI Adv. 2015, 5, 127207. [Google Scholar] [CrossRef]

- Lebedev, N.N. Force acting on conducting sphere in the field of a parallel plate condenser. Sov. Phys. Tech. Phys 1962, 7, 268. [Google Scholar]

- Khan, Y.; Sakai, K.; Lee, E.K.; Suehiro, J.; Hara, M. Motion behavior and deactivation method of free-conducting particle around spacer between diverging conducting plates under DC voltage in atmospheric air. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 444–457. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Lv, Y.; Sun, H.; Gao, G.; Zhang, Q. Study on the charging characteristics and motion law of free metal particles under power frequency voltage. Proc. CSEE 2021, 41, 1166–1176. [Google Scholar]

- Liang, R. Study on Kinetic Adsorption Behavior and Its Induced Discharge Phenomena of μm-Level Metal Dust Within DC GIL. Master’s Thesis, North China Electric Power University, Beijing, China, 2021. [Google Scholar]

- Chen, L.; Gonze, E.; Ondarts, M.; Outin, J.; Gonthier, Y. Electrostatic precipitator for fine and ultrafine particle removal form indoor air environment. Sep. Purif. Technol. 2020, 247, 116964. [Google Scholar] [CrossRef]

- Ji, H.; Li, C.; Pang, Z.; Ma, G.; Cui, X.; Zhou, H. Partial discharge characteristics of sheet free-movement particle in GIS. Proc. CSEE 2017, 37, 7367–7376. [Google Scholar]

- Anis, H.; Srivastava, K.D. Breakdown characteristics of dielectric contamination. In Proceedings of the IEEE 6th International Symposium on High Voltage Engineering, New Orleans, LA, USA, 28 August–1 September 1989; pp. 32–36. [Google Scholar]

- Wang, J.; Li, Q.; Li, B.; Chen, C. Motion analysis of spherical conducting particle in DC GIL considering the influence of inelastic random collisions and SF6/N2 gaseous mixture. Proc. CSEE 2015, 35, 3971–3978. [Google Scholar]

- Jia, J.; Tao, F.; Yang, L.; Zhang, Q. Motion analysis of spherical free conducting particle in non-uniform electric field of GIS under DC voltage. Proc. CSEE 2006, 26, 106–111. [Google Scholar]

- Wang, S. Research on Motion Characteristics and Simulation of Metal Particles in DC GIL. Master’s Thesis, Shenyang University of Technology, Shenyang, China, 2023. [Google Scholar]

- Shu, T.; Yang, Y.; Guo, R.; Wu, J.; Zhang, X.; Li, J. Partial discharge excitation characteristics of free metal particles in SF6 gas under AC and negative lightning impulse superposition voltage. High Volt. Eng. 2022, 48, 3305–3315. [Google Scholar]

- Wang, J.; Ping, A.; Chang, Y.; Hu, Z.; Li, Q. Research on dynamic coordination of active particles suppression methods under DC stress. Trans. China Electrotech. Soc. 2023, 38, 2794–2805+2831. [Google Scholar]

- Sun, X. Phenomenon and Inhibition of Chaege Accumulation Induced by Metal Particles in DC GIS/GIL. Master’s Thesis, Hebei University of Technology, Tianjin, China, 2023. [Google Scholar]

- Sun, J.; Chen, W.; Li, Z.; Yan, X.; Yang, P.; Liu, H. Charge estimation and impact analysis of moving metal particle under DC electric field. High Volt. Eng. 2018, 44, 779–786. [Google Scholar]

- Lu, F.; Liu, H.; Yin, K.; Li, Z.; Dong, M.; Cao, D.; Xie, Q. Numerical simulation and discharge characteristic analysis of metal particle motion in non-uniform electric field of DC GIL. Proc. CSEE 2017, 37, 2798–2806. [Google Scholar]

- Wang, F.; Yang, L.; Cao, D.; Wang, X.; Cheng, R. Motion and trap suppression of spherical free conducting particles in DC GIL. High Volt. Eng. 2018, 44, 3141–3149. [Google Scholar]

- Jia, J.; Ma, Z.; Cha, W.; Yang, L.; Zhang, Q. Electrostatic force on particle near spacer in inhomogeneous electric field between diverging electrodes. Proc. CSEE 2006, 26, 141–145. [Google Scholar]

- Jia, J.; Cha, W.; Yang, L.; Yang, L.; Zhang, Q. Threshold voltage of spherical conducting particle motion near spacer in inhomogeneous electric field. J. Xi’an Jiaotong Univ. 2006, 40, 699–703. [Google Scholar]

- Morcos, M.M.; Ward, S.A.; Anis, H.; Srivastava, K.D.; Gubanski, S.M. Insulation integrity of GIS/GITL systems and management of particle contamination. IEEE Electr. Insul. Mag. 2000, 16, 25–37. [Google Scholar] [CrossRef]

- Asan, K.; Hishinuma, R.; Yatsuzuka, Y. Bipolar DC corona discharge from a floating filamentary metal particle. IEEE Trans. Ind. Appl. 2002, 38, 57–63. [Google Scholar] [CrossRef]

- Wei, W. Study on the Comprehensive Inhibition Mechanism of Nano-Composite Film on the Surface of DC GIL Electrode to Particle Activity and Air Gap Discharge. Master’s Thesis, Shandong University, Jinan, China, 2020. [Google Scholar]

- Chang, Y.; Di, Q.; Hu, Z.; Li, Q. Physical Mechanism and Critical Starting Criterion of Wire Particle Firefly Movement under DC Electric Stress. Trans. China Electrotech. Soc. 2023, 38, 648–658. [Google Scholar]

- Zhang, Q.; You, H.; Ma, J.; Qin, Y.; Wen, T.; Guo, C. Motion behavior of free conducting wire-type particles in SF6 gas under DC voltage. High Volt. Eng. 2018, 44, 696–703. [Google Scholar]

- Hu, Z.; Wei, L.; Geng, Q.; Wang, J.; Li, Q.; Chang, Y. Firefly motion phenomenon and hazard assessment of linear metal particles in DC GIS/GIL. Proc. CSEE 2024, 44, 6219–6229. [Google Scholar]

- Chang, Y. Physical Mechanism of GIL Metal Microparticle Firefly Motion and Synergistic Inhibition Method. Ph.D. Thesis, North China Electric Power University, Beijing, China, 2023. [Google Scholar]

- Iwabuchi, H.; Shingo, M.; Kumada, A.; Hidaka, K.; Hoshina, Y.; Yasuoka, T.; Takei, M. Influence of tiny metal particles on charge accumulation phenomena of GIS model spacer in high-pressure SF6 gas. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1895–1901. [Google Scholar]

- Ji, H. Study on Movement Behavior and Discharge Characteristic of Metal Particle in GIS Under AC Operating Voltage. Ph.D. Thesis, North China Electric Power University, Beijing, China, 2017. [Google Scholar]

- Ma, K. Study on the Dynamic Characteristics and Suppressing Methods of Methods Metal Particle Dust in DC GIS/GIL. Ph.D. Thesis, North China Electric Power University, Beijing, China, 2023. [Google Scholar]

- Srivastava, K.D.; Heeswijk, R. Dielectric coatings-effect on breakdown and particle movement in GITL systems. IEEE Trans. Power Appar. Syst. 1985, 104, 22–31. [Google Scholar] [CrossRef]

- Huang, X.; Ni, X.; Wang, J.; Li, Q.; Lin, J.; Wang, Z. Synthesis of phenyl-thioether polyimide as the electrode coating film and its suppression effect on motion behavior of the metal particles under DC stresses. Trans. China Electrotech. Soc. 2018, 33, 4712–4721. [Google Scholar]

- Lu, F.; Liu, H.; Yan, X.; Dong, M.; Li, Z.; Zhan, Z. Calculation and analysis of lifting field of metal particle on dielectric coated electrode in SF6 under DC voltage. High Volt. Eng. 2018, 44, 1187–1195. [Google Scholar]

- Zhang, Q.; Jiang, J.; Yang, L.; Yuan, Y. Charging mechanism of metal conducting particle on a dielectrically coated electrode in gas insulated system. J. Xi’an Jiaotong Univ. 2024, 38, 1287–1291. [Google Scholar]

- Gao, Y.; Zhang, L.; Zhang, Z.; Zhuang, W.; Liu, Y.; Liu, B.; Zhang, C.; Li, T.; Wang, X.; Yi, Y.; et al. Metal particle behaviors between dielectric-coated electrodes under DC voltage. IEEE Trans. Dielectr. Electr. Insul. 2024, 31, 2045–2054. [Google Scholar] [CrossRef]

- Wang, J.; Hu, Q.; Chang, Y.; Wang, J.; Liang, R.; Tu, Y.; Li, C.; Li, Q. Metal particle contamination in gas-insulated switchgears/gas-insulated transmission lines. CSEE J. Power Energy Syst. 2019, 7, 1011–1025. [Google Scholar]

- Ni, X.; Wang, J.; Wang, J.; Wang, Z.; Li, Q. Polarity effect of DC GIL electrode coating on particle inhibition. High Volt. Eng. 2018, 44, 9. [Google Scholar]

- Wang, R.; Cui, C.; Zhang, C.; Ren, C.; Chen, G.; Shao, T. Deposition of SiOx film on electrode surface by DBD to improve the lift-off voltage of metal particles. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1285–1292. [Google Scholar] [CrossRef]

- Li, C.; Hu, J.; Lin, C.; Zhang, B.; Zhang, G.; He, J. Surface charge migration and dc surface flashover of surface-modified epoxy-based insulators. J. Phys. D Appl. Phys. 2017, 50, 065301. [Google Scholar] [CrossRef]

- Li, C.; Hu, J.; Lin, C.; He, J. The control mechanism of surface traps on surface charge behavior in alumina-filled epoxy composites. J. Phys. D Appl. Phys. 2016, 49, 445304. [Google Scholar] [CrossRef]

| Force Type | Force Direction | Force Magnitude |

|---|---|---|

| Coulomb Force | z | |

| −x | ||

| Gravity | −z | |

| Electric Field Gradient Force | z | |

| −x | ||

| Gas Resistance | −v | |

| −v |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, H.; Gong, D.; Li, S.; Zhan, Z.; Di, N.; Dolkun, D.; Fan, X.; Liu, X. Suppression of Metal Particles by Coating for a ±550 kV DC GIS. Energies 2024, 17, 5627. https://doi.org/10.3390/en17225627

Luo H, Gong D, Li S, Zhan Z, Di N, Dolkun D, Fan X, Liu X. Suppression of Metal Particles by Coating for a ±550 kV DC GIS. Energies. 2024; 17(22):5627. https://doi.org/10.3390/en17225627

Chicago/Turabian StyleLuo, Hanhua, Duohu Gong, Shan Li, Zhongqiang Zhan, Niyaer Di, Dilyar Dolkun, Xianhao Fan, and Xiangdong Liu. 2024. "Suppression of Metal Particles by Coating for a ±550 kV DC GIS" Energies 17, no. 22: 5627. https://doi.org/10.3390/en17225627

APA StyleLuo, H., Gong, D., Li, S., Zhan, Z., Di, N., Dolkun, D., Fan, X., & Liu, X. (2024). Suppression of Metal Particles by Coating for a ±550 kV DC GIS. Energies, 17(22), 5627. https://doi.org/10.3390/en17225627