Abstract

Diesel engines are extensively employed in transportation, agriculture, and industry due to their high thermal efficiency and fuel economy. However, the combustion of conventional diesel fuel is accompanied by substantial emissions of pollutants, including carbon monoxide (CO), hydrocarbons (HC), nitrogen oxides (NOx), and carbon dioxide (CO2), posing significant threats to environmental quality. Biodiesel, as a renewable and cleaner alternative fuel, can significantly reduce emissions of CO, HC, and particulate matter (PM) due to its unique molecular structure. Nonetheless, its lower calorific value and poor cold-start performance limit its application, while its high oxygen content may contribute to increased NOx emissions. To address these limitations, researchers have proposed blending biodiesel with alcohol-based fuels such as methanol, ethanol, or butanol to create synergistic combustion systems that optimize engine performance and emission characteristics. This paper systematically reviews the effects of alcohol fuels on the performance and emission characteristics of biodiesel blends in diesel engines. Studies indicate that the addition of alcohol fuels can significantly enhance engine performance by improving fuel atomization, extending ignition delay, and increasing premixed combustion efficiency. These enhancements result in higher cylinder pressure, net heat release rate (HRR), and brake thermal efficiency (BTE), while reducing brake-specific fuel consumption (BSFC) to some extent. Moreover, most studies report that alcohol fuels help reduce CO, HC, smoke, and NOx emissions but tend to increase CO2 emissions. However, some findings suggest that in certain cases, the opposite results may occur. The impact of different types of alcohol fuels on performance and emissions varies significantly, requiring a comprehensive evaluation of their properties, such as latent heat, viscosity, and oxygen content. Although the appropriate addition of alcohol fuels demonstrates substantial potential for optimizing engine performance and reducing emissions, excessive blending may lead to adverse effects, necessitating careful control of the blending ratio. Future research should consider mixing two or more alcohol fuels with biodiesel to explore synergistic effects beyond the capabilities of single alcohols. Additionally, further studies should focus on optimizing fuel compositions and emission control strategies for varying operating conditions.

1. Introduction

Diesel engines, as widely used internal combustion devices in transportation, agriculture, industry, and power generation, are valued for their high thermal efficiency, low fuel consumption, and robust power output [1,2]. Compared to gasoline engines, diesel engines feature a higher compression ratio and greater combustion efficiency, offering significant advantages in fuel economy [3]. However, the combustion of conventional diesel fuel, while providing power, also leads to significant pollutant emissions. Diesel engine combustion typically generates various harmful substances, including carbon monoxide (CO), unburned hydrocarbons (HC), nitrogen oxides (NOx), and particulate matter (PM) [4,5]. Due to the compression-ignition mechanism, diesel engines operate at high combustion temperatures, which promote NOx formation. Additionally, the long and complex carbon chains in diesel molecules increase the likelihood of PM generation during incomplete combustion, further exacerbating air pollution [6,7]. Furthermore, with population growth and the advancement of industrialization, global energy demand continues to rise, while the limited reserves of traditional fossil fuels highlight an increasing risk of depletion. To address the dual crises of energy shortages and environmental pollution, governments and research institutions worldwide are actively exploring renewable energy technologies to reduce dependence on fossil fuels and minimize pollutant formation. Among these efforts, the development and application of clean fuels have garnered significant attention [8].

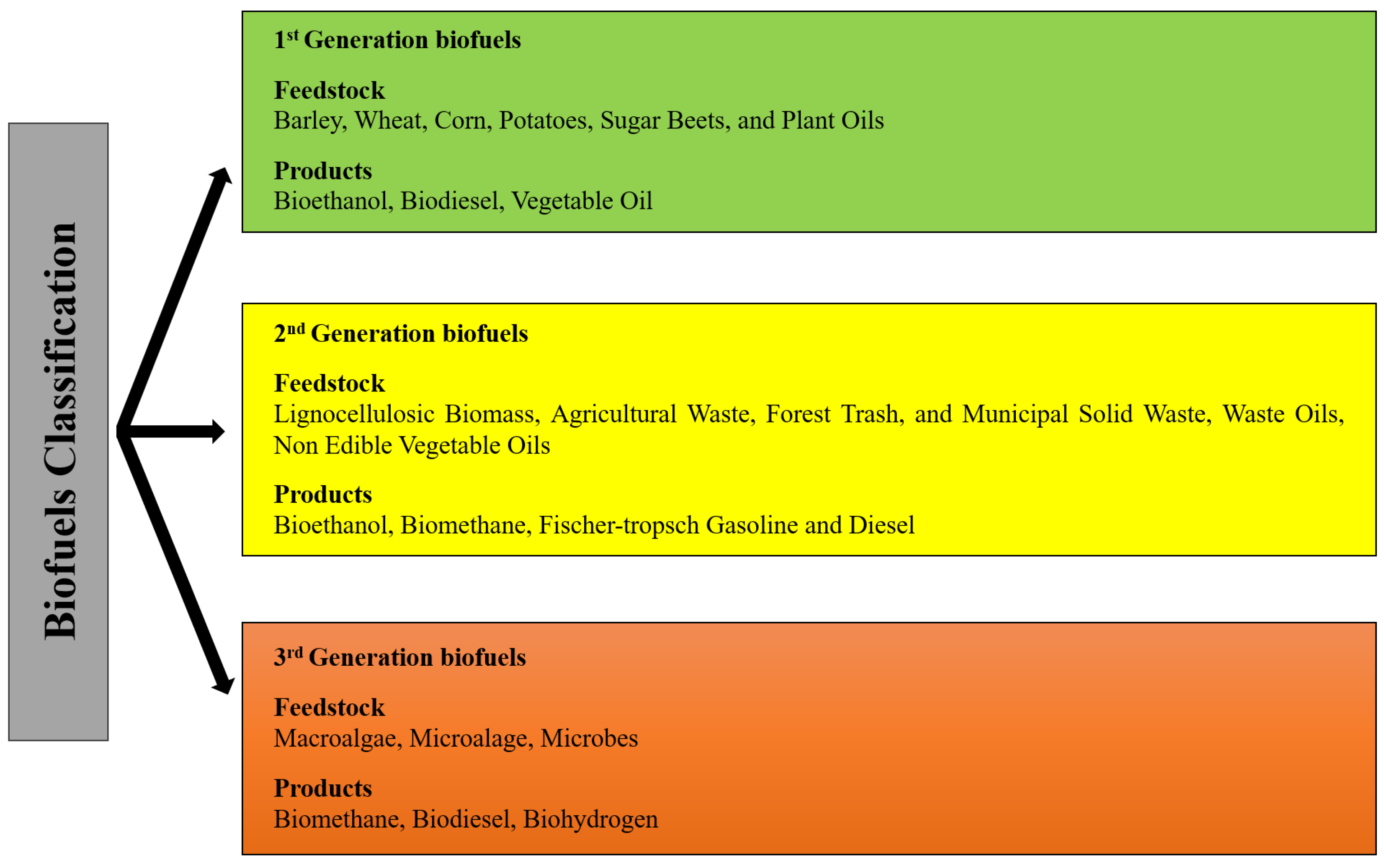

Biodiesel is a renewable and clean fuel derived from animal and vegetable fats, typically produced through a transesterification process [9,10,11]. As illustrated in Figure 1, its primary feedstocks include vegetable oils (e.g., castor oil, soybean oil, palm oil), waste cooking oils from animal and plant sources, and even certain industrial waste oils and algae.

Figure 1.

Types of raw materials for producing biofuels [12].

The biodiesel production process is characterized by low energy consumption and a favorable carbon balance. Moreover, the raw materials used for biodiesel production can absorb greenhouse gases during their growth, making biodiesel a carbon-neutral fuel. As such, it is considered a potential solution for addressing climate change [13,14,15,16]. Compared to conventional diesel, biodiesel offers several advantages. First, its molecular structure contains a higher oxygen content, which facilitates more complete combustion, thereby reducing emissions of carbon monoxide (CO) and hydrocarbons (HC) [17]. Second, biodiesel has an extremely low sulfur content, resulting in negligible sulfur dioxide (SO2) emissions during combustion, which helps mitigate acid rain formation [18]. Additionally, the simpler hydrocarbon structure of biodiesel significantly reduces soot emissions after combustion. These characteristics make biodiesel a clean fuel with substantial environmental benefits.

However, biodiesel also has inherent limitations as a diesel substitute, which hinder its widespread application in diesel engines. First, the production cost of biodiesel is higher than that of conventional diesel due to its manufacturing process and the cost of raw materials. Nonetheless, with advancements in technology and the adoption of large-scale centralized production, the cost is gradually decreasing [19]. Second, biodiesel has a lower calorific value, meaning it releases less energy per unit of volume or mass, resulting in reduced engine power output [20]. Compared to conventional diesel, the calorific value of biodiesel is approximately 10–12% lower, which can lead to increased fuel consumption under identical operating conditions, particularly at high engine loads. Additionally, biodiesel performs poorly in low-temperature environments, with cold-start issues being especially problematic [21]. Its high cold filter plugging point (CFPP) and pour point make biodiesel prone to thickening or solidifying at low temperatures, impairing fuel flow in the fuel system. This can cause blockages in fuel injection systems and poor atomization, further affecting engine performance [22]. In terms of emissions, while biodiesel significantly reduces CO, HC, PM, and sulfur oxide emissions, its high oxygen content, which promotes complete combustion, also facilitates the formation of NOx.

To address the shortcomings of biodiesel, researchers have proposed using alcohol fuels as additives, and the synergistic combustion effects of alcohol fuels and biodiesel have gained increasing attention. Alcohol fuels, such as methanol, ethanol, and butanol, exhibit unique combustion synergy due to their distinct molecular structures. These fuels contain hydroxyl groups (-OH), which contribute high oxygen content and polarity, while biodiesel, composed of long-chain fatty acid methyl esters, offers high energy density and combustion stability. During co-combustion, the hydroxyl groups in alcohol fuels release reactive oxygen species, promoting the decomposition and oxidation of biodiesel’s long-chain fatty acid methyl esters, thereby enhancing combustion efficiency [23,24]. Additionally, radicals released by alcohol fuels during combustion react with biodiesel decomposition products (e.g., hydrocarbon radicals and incomplete oxidation products), further facilitating complete oxidation. Alcohol fuels are classified into high-carbon and low-carbon alcohols based on the number of carbon atoms in their chemical structure. As the carbon chain length increases, cetane number and calorific value improve, making them more compatible for blending with biodiesel and diesel [25,26,27]. Current studies suggest that high-carbon alcohols are generally more suitable as alternative fuels than low-carbon alcohols due to their higher latent heat of vaporization and energy density [28,29].

Alcohol fuels are generally derived from biomass or renewable resources, with production methods including fermentation, distillation, and gasification processes. For example, ethanol can be obtained through the fermentation of crops such as corn and sugarcane or by converting cellulosic materials. Methanol and butanol can also be produced from biomass, with butanol gaining significant attention due to its higher energy density and good water solubility [30]. The abundant oxygen molecules in alcohol fuels ensure more uniform oxidation of hydrocarbon chains, thereby reducing the formation of CO and HC. This additional oxygen, embedded within the fuel itself, does not rely on ambient air supply, making this property particularly advantageous in scenarios with insufficient air-fuel mixing, such as high-load operations or transient engine conditions. Furthermore, the high oxygen content of alcohol fuels supports more stable combustion under lean-burn conditions. Lean-burn strategies are often employed to enhance engine efficiency but can lead to incomplete combustion due to limited oxygen availability. Alcohol fuels compensate for this limitation by providing intrinsic oxygen, enabling complete oxidation even at lower air-fuel ratios [31,32,33,34,35]. Additionally, their high volatility, low viscosity, and low freezing point improve fuel atomization, enhancing engine combustion efficiency [36,37,38,39]. Furthermore, higher alcohols such as butanol, with their higher calorific value, can increase the overall energy density of fuel blends, addressing the issue of biodiesel’s lower calorific value [40]. However, different types of alcohol fuels exhibit varying combustion characteristics and emission effects when blended with biodiesel. To achieve optimal synergistic combustion effects, it is essential to conduct in-depth research on the blending ratios and combustion conditions of different alcohol fuels with biodiesel, aiming to identify the best fuel combinations and combustion parameters.

Although numerous studies have individually explored the applications of biodiesel and alcohol fuels in diesel engines, systematic analyses and reviews of their synergistic effects remain limited, particularly in areas such as fuel ratio optimization, combustion efficiency improvement, and emission reduction. This paper aims to conduct an in-depth investigation, through literature review and data analysis, into the changes in physicochemical properties (including oxygen content, latent heat of vaporization, viscosity, density, and cetane number) when different alcohol fuels are added to diesel/biodiesel blends, as well as the impact of these changes on diesel engine combustion performance and emission characteristics. Furthermore, optimization strategies will be proposed based on these findings. By synthesizing existing research results, this study seeks to provide a scientific basis for improving clean combustion technologies in diesel engines and offer practical research directions for achieving environmentally friendly fuel substitution.

2. The Impact on the Characteristics of Biodiesel

Blending alcohol fuels with biodiesel alters the original fuel properties, and the physicochemical characteristics vary across different blends. Table 1 and Table 2 provide a summary of the physicochemical properties of common alcohol fuels and biodiesel/alcohol fuel blends, respectively.

Table 1.

Characteristics of common alcohol fuels.

Table 2.

Characteristics of different fuels.

As shown in Table 1 and Table 2, the addition of alcohol fuels significantly affects the density and kinematic viscosity of biodiesel or biodiesel/diesel blends. Alcohol fuels typically have lower densities, and when blended with biodiesel or diesel in specific proportions, the overall fuel density decreases. This reduction in density plays a crucial role in fuel injection performance and atomization quality. Specifically, lower-density fuels form finer and more uniform fuel droplets upon injection into the combustion chamber. These finely atomized droplets mix more effectively with air, enhancing the uniformity of the air-fuel mixture. A more homogeneous mixture promotes more efficient combustion, increasing combustion efficiency while reducing the formation of incomplete combustion products. Additionally, improved atomization shortens ignition delay and significantly enhances the rate and stability of heat release during combustion. From the perspective of spray dynamics, the quality of fuel atomization is critical to the combustion process. Fine fuel droplets have a larger specific surface area, which significantly accelerates evaporation under high-temperature conditions. The resulting fuel vapor readily interacts with oxygen molecules in the air, forming an ideal air-fuel mixture ratio. This process not only reduces soot formation but also suppresses emissions of incomplete combustion products, such as carbon monoxide (CO) and hydrocarbons (HC). The reduction in kinematic viscosity also positively impacts the fuel atomization and combustion processes. Lower viscosity improves the fuel’s flowability within high-pressure injection systems, reducing the system’s pressure burden. Enhanced flowability ensures that fuel passes through the nozzle at higher speeds and in a more uniform manner. This facilitates faster breakup and finer atomization of the fuel spray, further improving spray uniformity and droplet size. Moreover, lower viscosity reduces the formation of carbon deposits and residues in the injection system, minimizing the risk of nozzle clogging and ensuring long-term stability in injection performance.

The addition of alcohol fuels also lowers the fuel’s flash point, enabling the fuel to release combustible gases at lower temperatures, which facilitates ignition. This reduction in flash point is particularly advantageous in cold environments, as it significantly improves the engine’s cold-start performance. It reduces energy consumption and startup delay, allowing the engine to start more quickly and smoothly under low-temperature conditions. However, the lower flash point also increases safety risks during storage and transportation. To mitigate these potential hazards, additional protective measures, such as explosion-proof containers and adequate ventilation systems, are necessary to ensure safe handling and minimize risks.

The addition of alcohol fuels may reduce the calorific value and cetane number of biodiesel, which can negatively impact engine power performance and combustion stability to some extent. A lower calorific value means that less energy is released per unit volume of fuel, potentially leading to a slight reduction in engine output power, particularly under high-load conditions. This imposes higher requirements on engine performance, necessitating measures such as optimizing fuel injection quantity, redesigning the combustion chamber, or employing high-calorific-value fuel blends to mitigate power losses. Similarly, a reduction in the cetane number may extend the ignition delay time, slightly postponing the combustion process. This effect could adversely affect combustion stability, especially at high speeds and loads. However, under certain conditions, a lower cetane number may offer potential advantages. For instance, an extended ignition delay can provide more time for fuel-air mixing and vaporization, thereby improving mixture uniformity. In direct-injection diesel engines, this may enhance combustion uniformity and efficiency under low-load conditions. Additionally, a lower cetane number may suppress knocking tendencies in engines with high compression ratios. Notably, the high oxygen content of alcohol fuels supplies additional oxygen during the combustion process, significantly improving combustion completeness. This can enhance thermal efficiency and reduce emissions of carbon monoxide (CO) and hydrocarbons (HC). Although the reduced calorific value and cetane number present challenges, proper combustion tuning and technical improvements can leverage the advantages of alcohol fuels, resulting in cleaner and more efficient combustion.

3. Engine Performance

To date, researchers worldwide have extensively studied the application of various alcohol and biodiesel blends in diesel engine combustion performance. The findings consistently demonstrate that blending alcohol fuels with biodiesel enhances the combustion characteristics of engines. Table 3 systematically compiles and analyzes these research outcomes, comparing different types of alcohol-biodiesel blends in terms of combustion efficiency, thermal efficiency, brake-specific fuel consumption (BSFC), and cylinder pressure. This analysis provides valuable references for further research and practical applications.

Table 3.

Combustion performance of engines with different fuels.

3.1. Cylinder Pressure

Cylinder pressure refers to the pressure generated in the combustion chamber during the late compression and early expansion phases. During the intake stroke, fuel and air mix in the intake manifold before entering the combustion chamber, where compression and ignition produce high-temperature, high-pressure gases that drive the piston. As shown in Table 3, the cylinder pressure of biodiesel/diesel blends is generally lower than that of pure diesel. This is primarily because biodiesel has a lower calorific value than diesel, releasing less energy during combustion. When alcohol fuels are added to the blend, cylinder pressure tends to increase to some extent. However, most studies indicate that even with alcohol additives, cylinder pressure remains lower than that of pure diesel. Murat Kadir Yesilyurt et al. [53] investigated the variation of cylinder pressure with crank angle (CA) at engine speeds of 1400 rpm and 2600 rpm. They found that cylinder pressure at high speeds was significantly lower than at low speeds, likely due to the reduced combustion time at higher speeds, resulting in incomplete combustion. Under similar operating conditions, biodiesel/diesel/alcohol ternary blends exhibited lower cylinder pressures than diesel, but the pressure increased progressively with higher alcohol content in the blend. Notably, when 50% n-butanol was added to low-concentration biodiesel/diesel blends, the cylinder pressure slightly exceeded that of diesel, suggesting that an appropriate proportion of alcohol can enhance combustion efficiency. B. Musthafa et al. [54] studied the effects of ethanol, propanol, and n-butanol on biodiesel blends and reported that peak cylinder pressure correlated directly with the fuel’s calorific value. Diesel, having the highest calorific value, exhibited the highest cylinder pressure. Although biodiesel blends generally had lower cylinder pressure due to their lower calorific value, the addition of alcohol fuels improved combustion characteristics, leading to a moderate increase in cylinder pressure, albeit still below that of diesel. Similarly, A. Osman Emiroğlu et al. [45] prepared B20 blends (20% biodiesel and 80% diesel) and further added methanol, ethanol, and butanol at a 10% ratio to create ternary blends. They found that B20 alone exhibited the lowest cylinder pressure, while the addition of alcohol fuels increased the pressure to varying degrees. Among them, methanol-blended fuel achieved the highest cylinder pressure, reaching 83.68 bar. This indicates that despite the lower calorific value of alcohol fuels, their high oxygen content and favorable combustion properties enhance the combustion process, thereby increasing cylinder pressure. Arulkumar Selvanathan et al. [55] observed a similar trend in cylinder pressure variations and explained this phenomenon through detailed chemical reaction mechanisms. They identified that the hydroxyl groups (OH groups) in alcohol fuels play a critical role in combustion by promoting chain reactions that significantly enhance combustion speed and efficiency. During combustion, hydroxyl groups extract hydrogen atoms from hydrocarbon molecules through hydrogen abstraction reactions, generating hydroperoxyl and alkyl radicals, which serve as active species for subsequent chain reactions. These radicals further react with oxygen molecules to produce additional hydroxyl radicals, thereby accelerating the combustion process. Moreover, intermediate products generated during the decomposition of alcohol fuels, such as formaldehyde and formic acid, participate in oxidation reactions, releasing more heat and generating extra radicals. These radicals further react with oxygen to release energy and produce final combustion products. Such chain reactions substantially increase the combustion rate and efficiency, leading to higher peak cylinder pressures and shorter pressure rise times, which intensify the combustion process. Other studies also suggest that the inclusion of alcohol fuels reduces the density and viscosity of biodiesel/diesel blends and increases their oxygen content, further facilitating the combustion process [58]. However, the proportion of alcohol fuels must be carefully controlled. Excessive alcohol content can negatively affect cylinder pressure due to the high latent heat of alcohols, which may lower the in-cylinder temperature and suppress combustion efficiency [60,61]. In conclusion, the appropriate addition of alcohol fuels to biodiesel blends can effectively increase cylinder pressure by improving combustion processes and enhancing oxygen availability. However, overly high alcohol content may lead to incomplete combustion or reduced calorific value, adversely affecting engine performance.

3.2. Heat Release Rate (HRR)

The net heat release rate (HRR) represents the heat released per unit time and provides important insights into ignition delay and combustion duration. Meisam Ahmadi Ghadikolae et al. [62] observed that biodiesel blends exhibit shorter ignition delays and relatively lower HRR. This is primarily attributed to the high cetane number of biodiesel, which facilitates easier ignition. Consequently, combustion begins near the end of the compression stroke, with insufficient fuel accumulation, resulting in a lower heat release rate. In comparison, alcohol fuels exhibit higher volatility and lower viscosity, which significantly enhance the atomization and injection performance of blended fuels, thereby exerting a profound impact on the combustion process. Lower viscosity improves the flowability of the fuel in high-pressure injection systems, reducing injection resistance and facilitating the breakup of liquid streams into fine, uniform droplets. This improvement increases the specific surface area of the fuel particles, accelerating the evaporation process and enabling the fuel to rapidly transition into the gas phase. The resulting fuel vapor mixes thoroughly with air, greatly enhancing the homogeneity of the air-fuel mixture and contributing to more efficient combustion. Similar findings were reported by Ambarish Datta et al. [63], who concluded that HRR variations are primarily influenced by ignition delay and combustion duration. The high volatility of alcohol fuels ensures more uniform fuel distribution. Upon injection into the combustion chamber, the fuel evaporates rapidly, forming a more homogeneous fuel-air mixture. This leads to an increased accumulation of the mixture, and upon ignition, the intense combustion significantly enhances the heat release rate. They further noted that different alcohol fuels have varying effects on HRR. Methanol, with its higher latent heat of vaporization and oxygen content, achieves more complete combustion and exhibits higher HRR. A. Osman Emiroğlu et al. [45] conducted experimental studies using a single-cylinder diesel engine, blending 10% methanol, ethanol, or butanol into B20 biodiesel (20% biodiesel and 80% diesel) to create ternary fuel blends. Their results showed that the addition of alcohol fuels significantly increased the HRR of B20 blends. Under identical operating conditions, ethanol exhibited a higher HRR than methanol and butanol, likely due to its more balanced combustion properties. They concluded that despite the lower calorific value of alcohol fuels compared to diesel, their high oxygen content, low cetane number, and longer ignition delay concentrated combustion in the premixed phase rather than the diffusion phase, aligning with findings from other researchers [53,64]. Lei Zhu et al. [65] focused on the effects of pentanol on HRR. They reported that pentanol, with its lower viscosity compared to other alcohol fuels, enhances atomization and improves the mixing efficiency of air and fuel, resulting in better combustion performance and higher HRR. These studies collectively demonstrate that alcohol fuels significantly improve HRR by enhancing the atomization and combustion characteristics of blended fuels. However, the extent of improvement varies among different alcohol fuels due to differences in their volatility, viscosity, oxygen content, and calorific value.

3.3. Brake Thermal Efficiency (BTE)

Brake thermal efficiency (BTE) is a key metric for evaluating engine performance, with higher BTE indicating more efficient fuel utilization and reduced energy consumption. Arun Kumar Kadian et al. [57] investigated the impact of varying concentrations of heptanol in biodiesel/diesel blends on engine performance. Their findings showed that pure diesel, having the highest calorific value, achieved the highest BTE. However, as the proportion of heptanol increased in biodiesel/diesel blends, the BTE of the ternary fuel improved progressively. This was attributed to heptanol’s high oxygen content, which enhanced the combustion process by promoting more complete fuel oxidation. Additionally, heptanol’s high volatility and low viscosity improved fuel injection and atomization, further enhancing combustion efficiency. Similar conclusions were drawn by M.A. Mujtaba et al. [59], who observed that biodiesel/diesel blends had the lowest BTE among all tested fuels, while ternary blends with alcohols demonstrated significantly higher BTE. They analyzed five alcohols (ethanol, pentanol, isobutanol, 2-propanol, and 1-hexanol) and found that ethanol and pentanol produced the most notable improvements in BTE. These results were attributed to their high oxygen content and excellent volatility, which improved combustion efficiency and reduced unburned residues. Kundan Kumar et al. [58] reported that ternary blends with 1-pentanol exhibited higher BTE compared to biodiesel/diesel blends but still fell short of pure diesel. In their experiments, BTE increased as the concentration of 1-pentanol rose, but beyond a 10% ratio, BTE began to decline. They attributed this decrease to excessively low fuel viscosity caused by higher alcohol content, which affected injection pressure and atomization quality, leading to uneven combustion. Moreover, excessive alcohol concentrations were found to lower in-cylinder combustion temperatures, reducing fuel reactivity and hindering further improvements in BTE [66,67]. Murat Kadir Yesilyurt et al. [53] also investigated the impact of alcohol additives on brake thermal efficiency (BTE). Their experimental results showed that adding 5% concentrations of 1-butanol or n-pentanol to biodiesel/diesel blends significantly increased BTE, even surpassing the levels achieved with conventional diesel fuel. However, as the proportion of alcohol in the blend increased further, a decline in BTE was observed. At higher alcohol concentrations, the high latent heat of vaporization of alcohol fuels absorbs more heat, leading to a drop in combustion chamber temperature. This lowers combustion efficiency by extending the ignition delay period. Additionally, while low viscosity enhances atomization, excessively low viscosity can adversely affect spray breakup and atomization quality, reducing the uniformity of combustion. This, combined with the dilution of the overall energy density of the fuel, results in reduced energy release per unit volume of fuel and insufficient engine power output. These factors highlight the trade-offs associated with higher alcohol fuel concentrations and underscore the need for careful optimization of blending ratios to achieve optimal engine performance. Candan et al. [68] observed similar trends, indicating that the enhancement of BTE with alcohol fuels has a critical threshold; excessive alcohol addition can deteriorate combustion characteristics. In summary, the appropriate addition of alcohol fuels can significantly improve BTE by enhancing combustion efficiency, optimizing injection characteristics, and increasing oxygen availability. However, excessive alcohol content may lead to reduced calorific value, lower combustion temperatures, and compromised atomization, ultimately causing a decline in BTE [69,70].

3.4. Brake Specific Fuel Consumption (BSFC)

Brake-specific fuel consumption (BSFC) measures how efficiently fuel is utilized in an engine, with lower BSFC indicating higher fuel efficiency [71]. Arulkumar Selvanathan et al. [55] studied the effects of benzyl alcohol, diethyl ether, and hydrogen as additives under full-load conditions. They found that adding benzyl alcohol and hydrogen significantly reduced the BSFC of B20 biodiesel/diesel blends. Notably, when the benzyl alcohol concentration increased from 10% to 20%, BSFC showed a progressive decline. At 20% benzyl alcohol under full-load conditions, BSFC reached its lowest value, 28.4% lower than diesel under the same conditions. This improvement was attributed to benzyl alcohol’s high oxygen content and favorable combustion characteristics, which enhanced fuel combustion efficiency and reduced fuel consumption. Arun Kumar Kadian et al. [57] further confirmed the positive impact of alcohol fuels on BSFC. Using heptanol as an additive in biodiesel/diesel blends, they observed a continuous decrease in BSFC with increasing heptanol concentrations. This was primarily due to heptanol’s high oxygen content, which improved the oxygen supply during combustion and enhanced combustion efficiency. However, despite the reduction, the BSFC of all ternary blends remained higher than diesel fuel due to heptanol’s lower calorific value, which required more fuel to achieve the same energy output. M.A. Mujtaba et al. [59] reported that B20 fuels exhibited the highest BSFC among all tested fuels due to their lower calorific value and higher viscosity and density, which increased fuel consumption during combustion. However, adding 10% alcohol fuels (ethanol, pentanol, isobutanol, 2-propanol, and 1-hexanol) to the biodiesel/diesel blends led to a general decrease in BSFC across all ternary blends. Among the tested alcohols, 2-propanol showed the most significant reduction in BSFC. Nevertheless, the BSFC of all five alcohol-blended fuels remained higher than diesel due to the lower calorific value of alcohol fuels, requiring more fuel to compensate for energy deficits during combustion. In contrast, Kundan Kumar et al. [58] observed an increase in BSFC when 1-pentanol was used as an additive in biodiesel/diesel blends. They attributed this to 1-pentanol’s high latent heat, which absorbed heat during combustion and reduced the in-cylinder temperature, leading to decreased combustion efficiency. Additionally, 1-pentanol’s lower calorific value increased the fuel required per unit of power output. These findings align with the observations of Liangjie Wei et al. [72] and Nadir Yilmaz et al. [73]. Overall, most studies suggest that alcohol fuels can reduce BSFC by improving combustion efficiency. However, some studies highlight that the lower calorific value, high latent heat, or altered combustion characteristics of alcohol fuels can adversely affect BSFC, depending on the type and concentration of the alcohol used.

4. Exhaust Emissions

Researchers have extensively explored the application of various alcohol and biodiesel blends in reducing diesel engine exhaust emissions. Studies indicate that blending alcohol fuels with biodiesel has varying degrees of effectiveness in reducing engine emissions. Table 4 systematically summarizes these findings, focusing on key emission metrics such as CO, HC, CO2, NOx, and smoke. The comparative analysis of different alcohol-biodiesel blends’ emission characteristics provides valuable insights for the development and application of cleaner fuels.

Table 4.

Exhaust emissions of different fuel engines.

4.1. Carbon Monoxide (CO)

Carbon monoxide (CO) is a colorless, odorless, and toxic gas primarily produced when there is insufficient air supply or low combustion temperatures [78]. During combustion, unoxidized carbon forms CO, making its emissions closely linked to combustion efficiency. In recent years, extensive studies have investigated the effects of alcohol fuels on CO emissions and their mechanisms in diesel and biodiesel blends. H.K. Imdadul et al. [74] studied the impact of butanol (C4) and pentanol (C5) as alcohol additives on CO emissions. Their results showed that adding alcohols to biodiesel/diesel blends significantly reduced CO emissions, with a more pronounced decline as the proportion of alcohol increased. They attributed this to the reduced overall fuel density and improved air-fuel mixing, which enhanced atomization and injection efficiency, making the fuel more readily vaporized in the cylinder [57]. Additionally, the high oxygen content of alcohol fuels ensured sufficient oxygen supply during combustion, further reducing CO formation [58]. Murat Kadir Yesilyurt et al. [75] investigated CO emissions using various concentrations of alcohol blends in a single-cylinder, four-stroke direct-injection diesel engine at a fixed speed and varying loads. Their findings indicated that diesel had the highest CO emissions among all tested fuels, while adding alcohols to biodiesel/diesel blends significantly lowered CO emissions across all load conditions. Among the alcohols tested, pentanol exhibited the best CO reduction, achieving a 47.09% decrease compared to diesel. This improvement was attributed to the shorter carbon chain and higher oxygen content of alcohol fuels. The researchers also highlighted that the higher cetane number of alcohol fuels played a key role in reducing CO emissions. Arulkumar Selvanathan et al. [55] found that adding 10% benzyl alcohol to biodiesel/diesel blends reduced CO emissions. However, increasing the benzyl alcohol content to 20% caused CO emissions to rise, particularly under low-load conditions, even exceeding those of diesel. They suggested that this could be due to the high latent heat of vaporization of alcohol fuels, which lowered the combustion chamber temperature and led to incomplete combustion, thereby increasing CO formation. M.A. Mujtaba et al. [59] examined the effects of five different alcohol additives on CO emissions in a single-cylinder, four-stroke diesel engine. At low engine speeds, CO emissions from certain alcohol blends, such as hexanol and ethanol, were higher than those of diesel due to poor fuel mixing and lower combustion temperatures. However, as engine speed increased, the faster combustion rate led to more complete combustion, resulting in significantly lower CO emissions compared to diesel. The other three alcohols (2-propanol, isobutanol, and pentanol) consistently demonstrated lower CO emissions throughout the experiments. Murat Kadir Yesilyurt et al. [53] further analyzed the properties of alcohol fuels, emphasizing that in addition to high oxygen content, their shorter carbon chains and higher cetane numbers are crucial factors in reducing CO emissions. These unique physicochemical properties enhance combustion efficiency, thereby minimizing CO formation. Similarly, studies by Basir Maleki et al. [22], Mustafa Atakan Akar et al. [79], and Li Li et al. [80] also reported reductions in CO emissions with the addition of alcohol fuels to biodiesel/diesel blends, corroborating the emission-reducing effects of alcohol additives. In summary, the addition of alcohol fuels typically improves combustion efficiency and reduces CO emissions. However, under specific conditions, incomplete combustion may result in increased CO emissions.

4.2. Carbon Dioxide (CO2)

Carbon dioxide (CO2) is a major contributor to the greenhouse effect. During combustion, when oxygen is sufficient, hydroxyl radicals (OH) react with carbon monoxide (CO) at high temperatures, converting CO to CO2. Therefore, the oxygen concentration and fuel composition significantly influence CO2 emissions. H.K. Imdadul et al. [74] found that biodiesel emits more CO2 than conventional diesel, and the addition of alcohol fuels to biodiesel further increases CO2 emissions. This is attributed to the high oxygen content of alcohol fuels, which promotes more complete combustion and facilitates the oxidation of CO into CO2. Similarly, Basir Maleki et al. [22] examined the effects of mixing propanol and butanol with biodiesel on CO2 emissions. They reported that the lower density and higher latent heat of vaporization of alcohol fuels improved fuel atomization, enhancing combustion efficiency. However, this complete combustion also led to higher CO2 emissions, with butanol blends emitting 11.79% more CO2 than pure diesel under full-load conditions. These findings suggest that in some cases, the addition of alcohol fuels can significantly increase CO2 emissions. Contrasting these results, some studies have found that alcohol additives may reduce CO2 emissions. İlker Örs et al. [81] investigated butanol-biodiesel blends and observed that pure biodiesel produced the highest CO2 emissions among all tested fuels. Adding 5% butanol to the blend reduced CO2 emissions slightly, though levels remained higher than diesel. As the butanol proportion increased further, CO2 emissions continued to decrease, eventually falling below those of diesel. This reduction was attributed to alcohol fuels potentially suppressing the formation of certain carbon oxides during combustion, thereby lowering CO2 emissions. Similarly, Murat Kadir Yesilyurt et al. [75] prepared quaternary fuel blends by adding ethanol, isopropanol, n-butanol, and isopentanol to biodiesel/diesel/vegetable oil ternary blends. Their experiments showed that these quaternary blends reduced CO2 emissions compared to pure diesel and ternary blends. The researchers suggested that alcohols might inhibit carbon-oxygen reactions during combustion, reducing CO2 formation. Ertan Alptekin et al. [82] further validated this phenomenon, reporting a significant reduction in CO2 emissions when ethanol was used as an additive. This was attributed to ethanol’s low carbon-to-hydrogen (C/H) ratio, which reduces the number of carbon atoms available for CO2 formation during combustion. Similar findings were reported by M.H. Mat Yasin et al. [83] and Mustafa Atakan Akar et al. [79], supporting the potential of alcohol fuels to lower CO2 emissions. In summary, the impact of alcohol fuels on CO2 emissions varies significantly across studies. These differences are likely influenced by factors such as fuel blending ratios, combustion conditions, engine characteristics, and the physicochemical properties of the alcohols. Further research is warranted to better understand these effects and optimize alcohol fuel use for emission reductions.

4.3. Hydroxide (HC)

Unburned hydrocarbons (HC) are harmful gases whose emissions are closely linked to fuel-air mixing and combustion efficiency. H.K. Imdadul et al. [74] investigated the effects of butanol and pentanol as additives on HC emissions. They observed that under low-speed conditions, slow airflow in the combustion chamber and inadequate mixing resulted in higher HC emissions. Compared to B15 and B20 biodiesel blends, the addition of alcohols increased oxygen content, enhanced combustion, and improved atomization due to the lower viscosity of the fuel, which reduced regions of incomplete combustion and significantly decreased HC emissions. Murat Kadir Yesilyurt et al. [75] highlighted the importance of oxygen content, cetane number, and latent heat of vaporization in influencing HC formation. Their study showed that adding alcohols to B20 blends reduced HC emissions to varying degrees, with ethanol and pentanol exhibiting the most pronounced effects. Similarly, A.I. EL-Seesy et al. [84] found that butanol reduced the viscosity and density of biodiesel blends, improving injection and atomization efficiency, which minimized fuel pooling and further decreased HC emissions. Arun Kumar Kadian et al. [57] reported that heptanol’s high oxygen content contributed to a significant reduction in HC emissions as its proportion in the blend increased. The enhanced mixing efficiency of air and fuel due to heptanol addition inhibited incomplete combustion. Other studies, including those by Arulkumar Selvanathan et al. [55], Kundan Kumar et al. [58], and Nadir Yilmaz et al. [67], also consistently demonstrated that alcohol fuels generally reduce HC emissions significantly. However, conflicting findings have been reported. M.A. Mujtaba et al. [59] observed that while 2-propanol, isobutanol, and 1-hexanol reduced HC emissions, ethanol and pentanol led to increased HC emissions. They attributed this to uneven mixing and slower evaporation rates of the latter, which created regions of unvaporized fuel during combustion, increasing HC emissions. Additionally, Nadir Yilmaz et al. [85] noted that pentanol’s low cetane number caused combustion delays, allowing fuel to penetrate the cylinder walls before ignition. This contact with cooler cylinder walls led to quenching effects, further raising HC emissions. These findings suggest that certain physicochemical properties, such as low cetane numbers and high latent heat, can negatively impact HC emissions under specific conditions. In summary, the impact of alcohol fuels on HC emissions is highly dependent on operating conditions. In most cases, alcohol fuels reduce HC emissions by increasing oxygen content, improving atomization, and promoting uniform combustion. However, specific fuel properties (e.g., low cetane number) and certain combustion conditions can lead to increased HC emissions.

4.4. Nitrogen Oxides (NOx)

The formation of NOx is primarily influenced by combustion temperature, oxygen content, and combustion duration. The interplay among these factors determines the amount of NOx produced. As additives to biodiesel blends, alcohol fuels exhibit complex and variable effects on NOx emissions. H.K. Imdadul et al. [74] investigated the impact of pentanol and butanol on NOx emissions in B15 blends. They found that adding 15% pentanol and butanol increased NOx emissions by 13.2% and 16.8%, respectively, with pentanol producing lower NOx emissions than butanol at the same concentration. This difference was attributed to the physical properties of pentanol and butanol, including lower viscosity and density and higher volatility, which improved combustion. However, the increased ignition delay led to higher combustion pressure and temperature during the diffusion combustion phase, significantly contributing to higher NOx emissions. Arun Kumar Kadian et al. [57] further confirmed the role of oxygen content in NOx formation. They reported that the high oxygen content of heptanol accelerated combustion reactions, increasing combustion temperatures and, consequently, NOx emissions. As the proportion of heptanol increased, oxygen availability improved, leading to a corresponding rise in NOx emissions. Contrarily, some studies have demonstrated that alcohol fuels can reduce NOx emissions. For instance, Murat Kadir Yesilyurt et al. [75] evaluated the effects of ethanol, isopropanol, butanol, and isopentanol on NOx emissions. Under a 1250 W engine load, they observed that isopropanol, butanol, and isopentanol increased NOx emissions, while ethanol reduced them. This reduction was attributed to ethanol’s high latent heat of vaporization, which created a cooling effect during combustion, lowering the temperature and inhibiting NOx formation. Similarly, Kundan Kumar et al. [58] investigated the effects of 1-pentanol as an additive in B30 blends and found that NOx emissions decreased with higher 1-pentanol concentrations, even falling below diesel emissions under certain conditions. This was attributed to leaner combustion induced by 1-pentanol, which reduced combustion temperatures and slowed NOx formation. M.A. Mujtaba et al. [59] examined ethanol, 2-propanol, isobutanol, pentanol, and 1-hexanol and reported that the effects of alcohols on NOx emissions were fuel-dependent. While 2-propanol and 1-hexanol increased NOx emissions due to higher oxygen content and elevated combustion temperatures, ethanol, isobutanol, and pentanol reduced NOx emissions. This reduction was attributed to the cooling effect of these alcohols, which partially offset temperature increases during combustion. Other studies, such as those by Alpaslan Atmanli et al. [26] and Po-Ming Yang et al. [86], also highlighted that alcohol fuels with high latent heat of vaporization could significantly reduce combustion temperatures, thereby suppressing NOx formation. In summary, the effect of alcohol fuels on NOx emissions is complex and multifaceted. While the increased oxygen content and combustion temperature associated with alcohol fuels can raise NOx emissions, their cooling effect can lower combustion temperatures, reducing emissions.

4.5. Smoke

Smoke, a key pollutant in internal combustion engine emissions, consists of fine carbon particles produced by incomplete combustion. This incomplete combustion typically results from insufficient oxygen supply or poor fuel-air mixing during the combustion process. Oxygenated fuels, such as alcohols and biodiesel, inherently contain oxygen, which promotes more complete combustion and significantly reduces smoke emissions—a major advantage of using oxygenated fuels. Murat Kadir Yesilyurt et al. [75] found through experiments that biodiesel, with its high oxygen content, effectively enhances the combustion process and facilitates the complete oxidation of the fuel. Consequently, biodiesel blends exhibit lower smoke emissions compared to pure diesel. Furthermore, their research demonstrated that adding alcohol fuels to biodiesel-diesel blends further reduces smoke emissions. This reduction is attributed to the lower cetane number of alcohol fuels, which increases ignition delay during combustion. The extended ignition delay allows more time for fuel-air mixing, resulting in a more homogeneous mixture and reducing smoke formation caused by pyrolysis during combustion. Additional studies highlight the chemical composition of alcohol fuels as a critical factor influencing smoke emissions. For instance, butanol and pentanol, which contain more carbon atoms in their molecular structures, are more likely to create carbon-rich regions during combustion, leading to slightly higher smoke emissions compared to other alcohol-blended fuels. Arulkumar Selvanathan et al. [55] emphasized that the hydroxyl groups in alcohol fuels readily react with oxygen in the air during combustion, accelerating the oxidation of combustion products and contributing to lower smoke emissions. M.A. Mujtaba et al. [59] further explained the mechanism of smoke formation, noting that it primarily originates from the thermal cracking of long-chain hydrocarbons under oxygen-deficient conditions. The high oxygen content in alcohol-blended fuels is thus critical for controlling smoke emissions. Moreover, alcohol fuels possess advantageous physical properties, such as lower viscosity and density, which improve atomization and optimize injection characteristics. These properties produce finer and more uniform fuel droplets, significantly reducing the diffusion flame sheath in the combustion chamber and thereby lowering smoke emissions. Murat Kadir Yesilyurt et al. [53] highlighted that the oxygen content in fuels plays a decisive role in smoke emissions. As the proportion of alcohol fuels in the blend increases, the oxygen content rises correspondingly, leading to a continuous decline in smoke emissions. Similar findings have been corroborated by other researchers. Studies by Arun Kumar Kadian [57], Jincheng Huang [87], and Cenk Sayin [88] consistently demonstrate that increasing the proportion of oxygenated fuels significantly reduces smoke emissions in internal combustion engines, further affirming the advantages and potential of oxygenated fuels in improving combustion efficiency and reducing pollutant emissions.

5. Conclusions

Alcohol fuels, as additives to biodiesel/diesel blends, have demonstrated significant potential in optimizing engine performance and reducing emissions, providing crucial support for the sustainable development of clean energy. This paper reviews the changes in the physicochemical properties of diesel/biodiesel blends with the addition of various alcohol fuels, including oxygen content, latent heat of vaporization, viscosity, density, and cetane number. It further examines how these changes influence the combustion performance and emission characteristics of diesel engines and proposes strategies for further optimization.

Compared to pure biodiesel/diesel blends, the addition of alcohol fuels significantly improves diesel engine combustion performance, including increased cylinder pressure and HRR, as well as optimized BTE and BSFC. The high volatility and low viscosity of alcohol fuels enhance fuel atomization quality, producing fine and uniform droplets with a larger specific surface area. This accelerates the evaporation process, resulting in more uniform and complete combustion, effectively improving combustion efficiency. These characteristics play a crucial role in enhancing engine power output and fuel economy.

In terms of emissions, most studies indicate that the high oxygen content of alcohol fuels promotes combustion, significantly reducing CO, HC, and smoke emissions. However, in certain cases, uneven mixing of alcohols with the fuel or the presence of unvaporized fuel may lead to increased HC emissions. Additionally, the lower cetane number of alcohol fuels can cause quenching effects, further impacting combustion efficiency and HC emission levels.

Notably, while the high oxygen content and combustion-promoting properties of alcohol fuels can increase combustion temperatures and potentially elevate CO2 and NOx emissions, this trend is not absolute. The high latent heat of alcohol fuels generates a cooling effect during combustion, partially offsetting the temperature rise. Additionally, the lower C/H ratio of alcohol fuels helps reduce CO2 formation. Thus, the overall emission performance of alcohol fuels is significantly influenced by their intrinsic properties and blending ratios.

While the appropriate addition of alcohol fuels shows significant potential in optimizing engine performance and reducing emissions, excessive use can lead to excessively low viscosity, density, and cetane number in the blended fuel. This can adversely affect the formation of the air-fuel mixture and combustion stability, resulting in degraded engine performance and increased emissions. Low-viscosity fuels may increase spray penetration during injection but compromise atomization quality. Similarly, an excessively low cetane number extends the ignition delay, potentially causing a portion of the fuel to combust during the later stages of the expansion stroke, reducing the efficiency of converting heat into useful work. Therefore, carefully controlling the blending ratio of alcohol fuels is critical to achieving a balance between enhanced engine performance and reduced emissions.

Future research should further explore the synergistic effects of combining two or more alcohol fuels with biodiesel to achieve optimization outcomes that cannot be attained with a single alcohol fuel. Optimizing fuel blends and emission control strategies under various operating conditions will be critical for improving engine performance and reducing pollutant emissions. Additionally, the stability and economic feasibility of alcohol fuels in practical applications should be a key focus to promote their widespread use in industrial and transportation sectors. These studies hold significant theoretical and practical value for advancing the cleaner and more sustainable development of diesel engine fuels.

Author Contributions

Conceptualization, F.Z.; methodology, F.Z.; software, F.Z.; validation, F.Z. and H.M.C.; formal analysis, F.Z.; investigation, F.Z.; resources, H.M.C.; data curation, F.Z.; writing—original draft preparation, F.Z.; writing—review and editing, F.Z. and H.M.C.; visualization, F.Z.; supervision, H.M.C.; project administration, H.M.C.; funding acquisition, H.M.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Almanzalawy, M.S.; Elkady, M.F.; Sanad, A.; Yousef, M.; Elwardany, A.E. Combined effects of ferric oxide nanoparticles and C2–C4 alcohols with diesel/biodiesel blend on diesel engine operating characteristics. Alex. Eng. J. 2024, 103, 38–50. [Google Scholar] [CrossRef]

- Ai, W.; Cho, H.M. Predictive Models for Biodiesel Performance and Emission Characteristics in Diesel Engines: A Review. Energies 2024, 17, 4805. [Google Scholar] [CrossRef]

- Wamankar, A.K.; Satapathy, A.K.; Murugan, S. Experimental investigation of the effect of compression ratio, injection timing & pressure in a DI (direct injection) diesel engine running on carbon black-water-diesel emulsion. Energy 2015, 93 Pt 1, 511–520. [Google Scholar]

- Cernat, A.; Pana, C.; Negurescu, N.; Lazaroiu, G.; Nutu, C.; Fuiorescu, D. Hydrogen—An alternative fuel for automotive diesel engines used in transportation. Sustainability 2020, 12, 9321. [Google Scholar] [CrossRef]

- Das, A.K.; Sahu, S.K.; Panda, A.K. Current status and prospects of alternate liquid transportation fuels in compression ignition engines: A critical review. Renew. Sustain. Energy Rev. 2022, 161, 112358. [Google Scholar] [CrossRef]

- Vellaiyan, S. Experimental study on energy and environmental impacts of alcohol-blended water emulsified cottonseed oil biodiesel in diesel engines. Results Eng. 2024, 24, 102873. [Google Scholar] [CrossRef]

- Chembedu, G.; Manu, P.V. Investigation of diesel-watermelon seed biodiesel-isoamyl alcohol blends in CI engine using Response Surface Methodology optimization. Ind. Crops Prod. 2024, 218, 118849. [Google Scholar] [CrossRef]

- Esmi, F.; Borugadda, V.B.; Dalai, A.K. Heteropoly acids as supported solid acid catalysts for sustainable biodiesel production using vegetable oils: A review. Catal. Today 2022, 404, 19–34. [Google Scholar] [CrossRef]

- Khujamberdiev, R.; Cho, H. Impact of Biodiesel Blending on Emission Characteristics of One-Cylinder Engine Using Waste Swine Oil. Energies 2023, 16, 5489. [Google Scholar] [CrossRef]

- Yang, J.; Cong, W.-J.; Zhu, Z.; Miao, Z.-D.; Wang, Y.-T.; Nelles, M.; Fang, Z. Microwave-assisted one-step production of biodiesel from waste cooking oil by magnetic bifunctional SrO–ZnO/MOF catalyst. J. Clean. Prod. 2023, 395, 136182. [Google Scholar] [CrossRef]

- Rozina, M.A.; Zafar, M. Synthesis of green and non-toxic biodiesel from non-edible seed oil of Cichorium intybus using recyclable nanoparticles of MgO. Mater. Today Commun. 2023, 35, 105611. [Google Scholar] [CrossRef]

- Prabakaran, P.; Karthikeyan, S. Algae biofuel: A futuristic, sustainable, renewable and green fuel for I.C. engines. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Khujamberdiev, R.; Cho, H.M. Evaluation of TiO2 Nanoparticle-Enhanced Palm and Soybean Biodiesel Blends for Emission Mitigation and Improved Combustion Efficiency. Nanomaterials 2024, 14, 1570. [Google Scholar] [CrossRef] [PubMed]

- Fu, J.; Li, P.; Lin, Y.; Du, H.; Liu, H.; Zhu, W.; Ren, H. Fight for carbon neutrality with state-of-the-art negative carbon emission technologies. Eco-Environ. Health 2022, 1, 259–279. [Google Scholar] [CrossRef] [PubMed]

- You, X.; Yang, L.; Zhou, X.; Zhang, Y. Sustainability and carbon neutrality trends for microalgae-based wastewater treatment: A review. Environ. Res. 2022, 209, 112860. [Google Scholar] [CrossRef]

- Khujamberdiev, R.; Cho, H.M. Exploring the Environmental and Performance Implications of Utilizing Waste Swine Oil Biodiesel in CI Engines. Energies 2024, 17, 551. [Google Scholar] [CrossRef]

- Pullagura, G.; Vanthala, V.S.P.; Vadapalli, S.; Bikkavolu, J.R.; Barik, D.; Sharma, P.; Bora, B.J. Enhancing performance characteristics of biodiesel-alcohol/diesel blends with hydrogen and graphene nanoplatelets in a diesel engine. Int. J. Hydrogen Energy 2024, 50 Pt B, 1020–1034. [Google Scholar] [CrossRef]

- Shirneshan, A.; Kanberoglu, B.; Gonca, G. Experimental investigation and parametric modeling of the effect of alcohol addition on the performance and emissions characteristics of a diesel engine fueled with biodiesel-diesel-hydrogen fuel mixtures. Fuel 2025, 381 Pt C, 133489. [Google Scholar] [CrossRef]

- Bashir, M.A.; Wu, S.; Zhu, J.; Krosuri, A.; Khan, M.U.; Aka, R.J.N. Recent development of advanced processing technologies for biodiesel production: A critical review. Fuel Process. Technol. 2022, 227, 107120. [Google Scholar] [CrossRef]

- Hoang, A.T. Combustion behavior, performance and emission characteristics of diesel engine fuelled with biodiesel containing cerium oxide nanoparticles: A review. Fuel Process. Technol. 2021, 218, 106840. [Google Scholar] [CrossRef]

- Sia, C.B.; Kansedo, J.; Tan, Y.H.; Lee, K.T. Evaluation on biodiesel cold flow properties, oxidative stability and enhancement strategies: A review. Biocatal. Agric. Biotechnol. 2020, 24, 101514. [Google Scholar] [CrossRef]

- Maleki, B.; Talesh, S.S.A. Cold flow properties and CI engine parameters synchronic improvement of biodiesel/diesel/C3 and C4 alcohol blends: Mixture design approach. Process Saf. Environ. Prot. 2022, 160, 310–326. [Google Scholar] [CrossRef]

- Leiva-Candia, D.E.; García, I.L.; Lopez, I.; Serrano-Herrador, J.A.; Dorado, M.P. Descriptive and inferential statistics as an exhaust emission comparative tool between different engine operating conditions and fuels. Application to highly oxidized biodiesel blended with primary alcohols. Fuel 2022, 324 Pt A, 124453. [Google Scholar] [CrossRef]

- Rathinam, S.; Balan, K.N.; Subbiah, G.; Sajin, J.B.; Devarajan, Y. Emission study of a diesel engine fueled with higher alcohol-biodiesel blended fuels. Int. J. Green Energy 2019, 16, 667–673. [Google Scholar] [CrossRef]

- Ma, Q.; Zhang, Q.; Liang, J.; Yang, C. The performance and emissions characteristics of diesel/biodiesel/alcohol blends in a diesel engine. Energy Rep. 2021, 7, 1016–1024. [Google Scholar] [CrossRef]

- Atmanli, A. Comparative analyses of diesel–waste oil biodiesel and propanol, n-butanol or 1-pentanol blends in a diesel engine. Fuel 2016, 176, 209–215. [Google Scholar] [CrossRef]

- Ma, Q.; Zhang, Q.; Zheng, Z. An experimental assessment on low temperature combustion using diesel/biodiesel/C2, C5 alcohol blends in a diesel engine. Fuel 2021, 288, 119832. [Google Scholar] [CrossRef]

- Musyoka, S.K.; Khalil, A.S.G.; Ookawara, S.; Nada, S.A. Soot morphology and nanostructure of oxygenated fuels: Influence of three- and four-carbon esters and alcohols in a diesel engine. Fuel 2024, 376, 132627. [Google Scholar] [CrossRef]

- Atmanli, A.; Yilmaz, N. An experimental assessment on semi-low temperature combustion using waste oil biodiesel/C3-C5 alcohol blends in a diesel engine. Fuel 2020, 260, 116357. [Google Scholar] [CrossRef]

- Krishnan, M.G.; Rajkumar, S.; Thangaraja, J.; Devarajan, Y. Exploring the synergistic potential of higher alcohols and biodiesel in blended and dual fuel combustion modes in diesel engines: A comprehensive review. Sustain. Chem. Pharm. 2023, 35, 101180. [Google Scholar] [CrossRef]

- Venu, H.; Veza, I.; Selvam, L.; Appavu, P.; Raju, V.D.; Subramani, L.; Nair, J.N. Analysis of particle size diameter (PSD), mass fraction burnt (MFB) and particulate number (PN) emissions in a diesel engine powered by diesel/biodiesel/n-amyl alcohol blends. Energy 2022, 250, 123806. [Google Scholar] [CrossRef]

- Khan, M.M.; Sharma, R.P.; Kadian, A.K.; Hasnain, S.M.M. An assessment of alcohol inclusion in various combinations of biodiesel-diesel on the performance and exhaust emission of modern-day compression ignition engines—A review. Mater. Sci. Energy Technol. 2022, 5, 81–98. [Google Scholar] [CrossRef]

- Algayyim, S.J.M.; Wandel, A.P. Macroscopic and microscopic characteristics of biofuel spray (biodiesel and alcohols) in CI engines: A review. Fuel 2021, 292, 120303. [Google Scholar] [CrossRef]

- Subramani, S.; Govindasamy, R. Application of MRSN ratio and Taguchi parametric design in optimization of parameters of DI CI engine fuelled with diesel-biodiesel-higher alcohol blends. Fuel 2021, 285, 119116. [Google Scholar] [CrossRef]

- Zaharin, M.S.M.; Abdullah, N.R.; Najafi, G.; Sharudin, H.; Yusaf, T. Effects of physicochemical properties of biodiesel fuel blends with alcohol on diesel engine performance and exhaust emissions: A review. Renew. Sustain. Energy Rev. 2017, 79, 475–493. [Google Scholar] [CrossRef]

- Atmanli, A. Effects of a cetane improver on fuel properties and engine characteristics of a diesel engine fueled with the blends of diesel, hazelnut oil and higher carbon alcohol. Fuel 2016, 172, 209–217. [Google Scholar] [CrossRef]

- Zerrakki IŞIK, M. Comparative experimental investigation on the effects of heavy alcohols- safflower biodiesel blends on combustion, performance and emissions in a power generator diesel engine. Appl. Therm. Eng. 2021, 184, 116142. [Google Scholar] [CrossRef]

- Wang, X.; Cheung, C.S.; Di, Y.; Huang, Z. Diesel engine gaseous and particle emissions fueled with diesel–oxygenate blends. Fuel 2012, 94, 317–323. [Google Scholar] [CrossRef]

- Ren, Y.; Huang, Z.; Miao, H.; Di, Y.; Jiang, D.; Zeng, K.; Liu, B.; Wang, X. Combustion and emissions of a DI diesel engine fuelled with diesel-oxygenate blends. Fuel 2008, 87, 2691–2697. [Google Scholar] [CrossRef]

- Yesilyurt, M.K. A detailed investigation on the performance, combustion, and exhaust emission characteristics of a diesel engine running on the blend of diesel fuel, biodiesel and 1-heptanol (C7 alcohol) as a next-generation higher alcohol. Fuel 2020, 275, 117893. [Google Scholar] [CrossRef]

- Liu, X.; Wang, H.; Zheng, Z.; Liu, J.; Reitz, R.D.; Yao, M. Development of a combined reduced primary reference fuel-alcohols (methanol/ethanol/propanols/butanols/n-pentanol) mechanism for engine applications. Energy 2016, 114, 542–558. [Google Scholar] [CrossRef]

- Geng, P.; Cao, E.; Tan, Q.; Wei, L. Effects of alternative fuels on the combustion characteristics and emission products from diesel engines: A review. Renew. Sustain. Energy Rev. 2017, 71, 523–534. [Google Scholar] [CrossRef]

- Mourad, M.; Mahmoud, K.R.M. Performance investigation of passenger vehicle fueled by propanol/gasoline blend according to a city driving cycle. Energy 2018, 149, 741–749. [Google Scholar] [CrossRef]

- Erdiwansyah; Mamat, R.; Sani, M.S.M.; Sudhakar, K.; Kadarohman, A.; Sardjono, R.E. An overview of Higher alcohol and biodiesel as alternative fuels in engines. Energy Rep. 2019, 5, 467–479. [Google Scholar] [CrossRef]

- Emiroğlu, A.O.; Şen, M. Combustion, performance and exhaust emission characterizations of a diesel engine operating with a ternary blend (alcohol-biodiesel-diesel fuel). Appl. Therm. Eng. 2018, 133, 371–380. [Google Scholar] [CrossRef]

- Imdadul, H.K.; Masjuki, H.H.; Kalam, M.A.; Zulkifli, N.W.M.; Alabdulkarem, A.; Rashed, M.M.; Ashraful, A.M. Influences of ignition improver additive on ternary (diesel-biodiesel-higher alcohol) blends thermal stability and diesel engine performance. Energy Convers. Manag. 2016, 123, 252–264. [Google Scholar] [CrossRef]

- Imdadul, H.K.; Masjuki, H.H.; Kalam, M.A.; Zulkifli, N.W.M.; Alabdulkarem, A.; Rashed, M.M.; Teoh, Y.H.; How, H.G. Higher alcohol–biodiesel–diesel blends: An approach for improving the performance, emission, and combustion of a light-duty diesel engine. Energy Convers. Manag. 2016, 111, 174–185. [Google Scholar] [CrossRef]

- Mahalingam, A.; Devarajan, Y.; Radhakrishnan, S.; Vellaiyan, S.; Nagappan, B. Emissions analysis on mahua oil biodiesel and higher alcohol blends in diesel engine. Alex. Eng. J. 2018, 57, 2627–2631. [Google Scholar] [CrossRef]

- Agrawal, T.; Gautam, R.; Agrawal, S.; Singh, V.; Kumar, M.; Kumar, S. Optimization of engine performance parameters and exhaust emissions in compression ignition engine fueled with biodiesel-alcohol blends using taguchi method, multiple regression and artificial neural network. Sustain. Futures 2020, 2, 100039. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, P.; Chen, H.; Wu, H.; Geng, L.; Zhang, W.; Chen, Z.; Qi, D.; Cao, J.; Wang, B. Optical study on the spray and combustion characteristics of diesel-biodiesel-alcohol blend fuels on a constant volume combustion chamber. J. Energy Inst. 2024, 117, 101779. [Google Scholar] [CrossRef]

- Doppalapudi, A.T.; Azad, A.K.; Khan, M.M.K. Exergy, energy, performance, and combustion analysis for biodiesel NOx reduction using new blends with alcohol, nanoparticle, and essential oil. J. Clean. Prod. 2024, 467, 142968. [Google Scholar] [CrossRef]

- Sathish, T.; Ağbulut, Ü.; Ubaidullah, M.; Saravanan, R.; Giri, J.; Shaikh, S.F. Waste to fuel: A detailed combustion, performance, and emission characteristics of a CI engine fuelled with sustainable fish waste management augmentation with alcohols and nanoparticles. Energy 2024, 299, 131412. [Google Scholar] [CrossRef]

- Yesilyurt, M.K.; Eryilmaz, T.; Arslan, M. A comparative analysis of the engine performance, exhaust emissions and combustion behaviors of a compression ignition engine fuelled with biodiesel/diesel/1-butanol (C4 alcohol) and biodiesel/diesel/n-pentanol (C5 alcohol) fuel blends. Energy 2018, 165 Pt B, 1332–1351. [Google Scholar] [CrossRef]

- Musthafa, B.; Saravanan, B.; Asokan, M.A.; Devendiran, S.; Venkatesan, K. Effect of ethanol, propanol and butanol on karanja biodiesel with vegetable oil fuelled in a single cylinder diesel engine. Egypt. J. Pet. 2023, 32, 35–40. [Google Scholar] [CrossRef]

- Selvanathan, A.; Vijayaragavan, M. Effect on minor addition of aromatic (benzyl alcohol) and diethyl ether in Calophyllum inophyllum blended diesel fuel in a CI engine operates by hydrogen energy as a secondary fuel. Energy 2023, 285, 129529. [Google Scholar] [CrossRef]

- Murugan, M.A.; Ganesan, N. An insight into the combustion analysis of low carbon alcohol infused ternary fuel blends operated by varying the compression ratios. Case Stud. Therm. Eng. 2024, 63, 105251. [Google Scholar] [CrossRef]

- Kadian, A.K.; Khan, M.; Sharma, R.P.; Mozammil hasnain, S.M. Performance enhancement and emissions mitigation of DI-CI engine fuelled with ternary blends of jatropha biodiesel-diesel-heptanol. Mater. Sci. Energy Technol. 2022, 5, 145–154. [Google Scholar] [CrossRef]

- Kumar, K.; Nandi, B.K.; Saxena, V.K.; Kumar, R. Experimental studies of thermal behavior, engine performance and emission characteristics of biodiesel/diesel/1 pentanol blend in diesel engine. Alex. Eng. J. 2024, 106, 411–421. [Google Scholar] [CrossRef]

- Mujtaba, M.A.; Cho, H.M.; Masjuki, H.H.; Kalam, M.A.; Farooq, M.; Soudagar, M.E.M.; Gul, M.; Afzal, A.; Ahmed, W.; Raza, A.; et al. Effect of primary and secondary alcohols as oxygenated additives on the performance and emission characteristics of diesel engine. Energy Rep. 2021, 7, 1116–1124. [Google Scholar] [CrossRef]

- Ramesh, A.; Ashok, B.; Nanthagopal, K.; Pathy, M.R.; Tambare, A.; Mali, P.; Phuke, P.; Patil, S.; Subbarao, R. Influence of hexanol as additive with Calophyllum Inophyllum biodiesel for CI engine applications. Fuel 2019, 249, 472–485. [Google Scholar] [CrossRef]

- Upadhyay, N.; Das, R.K.; Ghosh, S.K. Investigating the impact of n-heptane (C7H16) and nanoparticles (TiO2) on diesel–microalgae biodiesel blend in CI diesel engines. Environ. Sci. Pollut. Res. 2024, 31, 8608–8632. [Google Scholar] [CrossRef] [PubMed]

- Ghadikolaei, M.A.; Cheung, C.S.; Yung, K.-F. Study of combustion, performance and emissions of diesel engine fueled with diesel/biodiesel/alcohol blends having the same oxygen concentration. Energy 2018, 157, 258–269. [Google Scholar] [CrossRef]

- Datta, A.; Mandal, B.K. Engine performance, combustion and emission characteristics of a compression ignition engine operating on different biodiesel-alcohol blends. Energy 2017, 125, 470–483. [Google Scholar] [CrossRef]

- Tse, H.; Leung, C.W.; Cheung, C.S. Investigation on the combustion characteristics and particulate emissions from a diesel engine fueled with diesel-biodiesel-ethanol blends. Energy 2015, 83, 343–350. [Google Scholar] [CrossRef]

- Zhu, L.; Xiao, Y.; Cheung, C.S.; Guan, C.; Huang, Z. Combustion, gaseous and particulate emission of a diesel engine fueled with n-pentanol (C5 alcohol) blended with waste cooking oil biodiesel. Appl. Therm. Eng. 2016, 102, 73–79. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K.; Saravanan, B.; Azad, K.; Patel, D.; Sudarshan, B.; Ramasamy, R.A. Study on isobutanol and Calophyllum inophyllum biodiesel as a partial replacement in CI engine applications. Fuel 2019, 235, 984–994. [Google Scholar] [CrossRef]

- Yilmaz, N.; Atmanli, A. Experimental evaluation of a diesel engine running on the blends of diesel and pentanol as a next generation higher alcohol. Fuel 2017, 210, 75–82. [Google Scholar] [CrossRef]

- Candan, F.; Ciniviz, M.; Ors, I. Effect of cetane improver addition into diesel fuel: Methanol mixtures on performance and emissions at different injection pressures. Therm. Sci. 2017, 21 Pt B, 555–566. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, Z.; Chen, H.; Ji, Z.; Ma, Y.; Sun, F. A review on performance, combustion and emission of diesel and alcohols in a dual fuel engine. J. Energy Inst 2024, 116, 101760. [Google Scholar] [CrossRef]

- Subbaiah, G.V.; Gopal, K.R.; Hussain, S.A.; Prasad, B.D.; Reddy, K.T.; Pradesh, A. Rice bran oil biodiesel as an additive in diesel-ethanol blends for diesel engines. Int. J. Res. Rev. Appl. Sci. 2010, 3, 334–342. [Google Scholar]

- Hadi rahimi; Ghobadian, B.; Yusaf, T.; Najafi, G.; Khatamifar, M. Diesterol: An environment-friendly IC engine fuel. Renew. Energy 2009, 34, 335–342. [Google Scholar] [CrossRef]

- Wei, L.; Cheung, C.S.; Huang, Z. Effect of n-pentanol addition on the combustion, performance and emission characteristics of a direct-injection diesel engine. Energy 2014, 70, 172–180. [Google Scholar] [CrossRef]

- Yilmaz, N.; Atmanli, A. Experimental assessment of a diesel engine fueled with diesel-biodiesel-1-pentanol blends. Fuel 2017, 191, 190–197. [Google Scholar] [CrossRef]

- Imdadul, H.K.; Masjuki, H.H.; Kalam, M.A.; Zulkifli, N.W.M.; Alabdulkarem, A.; Kamruzzaman, M.; Rashed, M.M. A comparative study of C4 and C5 alcohol treated diesel–biodiesel blends in terms of diesel engine performance and exhaust emission. Fuel 2016, 179, 281–288. [Google Scholar] [CrossRef]

- Yesilyurt, M.K.; Aydin, M.; Yilbasi, Z.; Arslan, M. Investigation on the structural effects of the addition of alcohols having various chain lengths into the vegetable oil-biodiesel-diesel fuel blends: An attempt for improving the performance, combustion, and exhaust emission characteristics of a compression ignition engine. Fuel 2020, 269, 117455. [Google Scholar]

- Zeleke, D.S.; Tefera, A.K. An experimental investigation of the impacts of titanium dioxide (TiO2) and ethanol on performance and emission characteristics on diesel engines run with castor Biodiesel ethanol blended fuel. Fuel Process. Technol. 2024, 264, 108137. [Google Scholar] [CrossRef]

- Vargün, M.; Özsezen, A.N.; Botsalı, H.; Sayın, C. A study on the impact of fuel injection parameters and boost pressure on combustion characteristics in a diesel engine using alcohol/diesel blends. Process Saf. Environ. Prot. 2023, 177, 29–41. [Google Scholar] [CrossRef]

- Fattah, I.R.; Kalam, M.A.; Masjuki, H.H.; Wakil, M.A. Biodiesel production, characterization, engine performance, and emission characteristics of Malaysian Alexandrian laurel oil. RSC Adv. 2014, 4, 17787–17796. [Google Scholar] [CrossRef]

- Akar, M.A. Performance and emission characteristics of compression ignition engine operating with false flax biodiesel and butanol blends. Adv. Mech. Eng. 2016, 8, 1687814016632677. [Google Scholar] [CrossRef]

- Li, L.; Wang, J.; Wang, Z.; Xiao, J. Combustion and emission characteristics of diesel engine fueled with diesel/biodiesel/pentanol fuel blends. Fuel 2015, 156, 211–218. [Google Scholar] [CrossRef]

- Örs, İ.; Sarıkoç, S.; Atabani, A.E.; Ünalan, S. Experimental investigation of effects on performance, emissions and combustion parameters of biodiesel–diesel–butanol blends in a direct-injection CI engine. Biofuels 2020, 11, 121–134. [Google Scholar] [CrossRef]

- Alptekin, E.; Canakci, M.; Ozsezen, A.N.; Turkcan, A.; Sanli, H. Using waste animal fat based biodiesels–bioethanol–diesel fuel blends in a DI diesel engine. Fuel 2015, 157, 245–254. [Google Scholar] [CrossRef]

- Yasin, M.H.M.; Yusaf, T.; Mamat, R.; Yusop, A.F. Characterization of a diesel engine operating with a small proportion of methanol as a fuel additive in biodiesel blend. Appl. Energy 2014, 114, 865–873. [Google Scholar] [CrossRef]

- EL-Seesy, A.I.; Hassan, H.; Kosaka, H. Improving the Performance of a Diesel Engine Operated with Jojoba Biodiesel-Diesel-n-Butanol Ternary Blends. Energy Procedia 2019, 156, 33–37. [Google Scholar] [CrossRef]

- Yilmaz, N.; Atmanli, A.; Vigil, F.M. Quaternary blends of diesel, biodiesel, higher alcohols and vegetable oil in a compression ignition engine. Fuel 2018, 212, 462–469. [Google Scholar] [CrossRef]

- Yang, P.-M.; Lin, Y.-C.; Lin, K.C.; Jhang, S.-R.; Chen, S.-C.; Wang, C.-C.; Lin, Y.-C. Comparison of carbonyl compound emissions from a diesel engine generator fueled with blends of n-butanol, biodiesel and diesel. Energy 2015, 90 Pt 1, 266–273. [Google Scholar] [CrossRef]

- Huang, J.; Wang, Y.; Li, S.; Roskilly, A.P.; Yu, H.; Li, H. Experimental investigation on the performance and emissions of a diesel engine fuelled with ethanol–diesel blends. Appl. Therm. Eng. 2009, 29, 2484–2490. [Google Scholar] [CrossRef]

- Sayin, C. Engine performance and exhaust gas emissions of methanol and ethanol–diesel blends. Fuel 2010, 89, 3410–3415. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).