Abstract

The study deals with the possibilities of using alternative types of fuels to produce electricity. Power Plant Vojany (PPV) is a thermal power plant (TPP) in eastern Slovakia, which is part of the company Slovenské elektrárne, a. s. (SE). PPV primarily used black coal to produce electricity, which had to be imported from abroad (the Russian Federation). This activity has become inefficient both economically and environmentally, due to the high price of CO2 permits and the high emission factor of this type of fuel. PPV decided to co-combust biomass and refuse-derived fuel (RDF), which resulted in much better economic conditions due to their price, economic efficiency, and partly closed CO2 cycle. The aim of the paper is to explore the possibilities related to the production of energy in the cleanest possible way and with the least possible damage to the environment in coal thermal power plants using the example of operating Power Plant Vojany located in eastern part of Slovakia and to inspire each other for the modern transformation. For the purposes of hypothesis verification, analytical methods focused on overview studies of average fuel prices, comparisons, and the balance of fuels in connection with eliminated CO2 emissions, as well as municipal waste (MW) management in the EU and V4 countries, were used. The authors also focused on the energy recovery and combustion of MW and tracking the achieved CO2 savings in connection with the development of fuel sources in PPV. The results point to the fact that PPV is one of the power plants that could use biomass and RDF as fuel, which confirms the economic advantages of this procedure. The results confirm that the potential of RDF production in Slovakia is sufficient to ensure the operation of PPV at planned, even higher volumes of electricity production. The transformation to cleaner operation of coal thermal power plants represents a significant contribution of this study.

1. Introduction

The EU has set an ambitious goal of achieving net zero CO2 emissions in the near future [1]. This requires a rapid increase in RES share in the energy mix, as stated in all 2050 EU energy mix decarbonisation scenarios of the European Commission [2,3].

Hand in hand with this requirement, a solution for retiring coal power plants, traditional centralised power sources in many EU countries, is sought [4,5]. In line with the zero energy from black coal target of the EU and given the simple fact that power production from black coal becomes non-economic, these power plants face various options [6]: gradual shut down, replacement by more efficient power sources based on cleaner fuels, or reconstruction and repowering aimed at increasing their energy efficiency as well as prolonging their operation before shutdown [7,8]. A viable alternative for the carbon footprint reduction of power production is represented by large power plants refit to co-firing of various biomass and waste materials or even to full fuel switch from black coal to other, more environmentally friendly, fuels [9].

Biomass fired and co-fired in TPPs can originate from several sources, such as the residues from silviculture and agriculture, or can be grown for this purpose [10,11]. Among other calorific materials suitable for this purpose [12], SRF is a promising candidate [13] as a highly heterogeneous mixture of waste fractions produced according to the EU specifications. The spatial and seasonal variability of both potential fuels together with extensive fuel requirement (2 to 3 million tons per annum per a single fully fuel-switched 600 MWe power plant) can limit their contributions to energy sector decarbonisation [14]. In addition, the supply chain of potential fuels was identified as another key factor in achieving net greenhouse gas (GHG) emissions reduction [15].

The Central European region has traditionally relied on power production from black coal in TPPs built in the former Soviet era; for Poland and the Czech Republic especially, black coal is still an important item in their national energy mix [16]. At the same time, it is a region known for its agricultural, silvicultural, and industrial production coupled with the availability of residual biomass and various calorific by-products and wastes from biomass-processing facilities [17].

The aim of the paper is to explore options to produce energy in the most environmentally friendly way, minimising CO2 emissions in coal thermal power plants, based on the real operational data of the Power Plant Vojany located in eastern Slovakia.

The authors of the paper consider hypotheses related to energy production in the cleanest possible way and with the least possible damage to the environment, thus becoming an inspiration for similar power plant transformations in other regions. This study and its results contribute to the discussion on the use of alternative sources and fuels for power plants in the V4 region.

For the purpose of the study, this paper is divided into the following six parts: Section 1 presents introduction; Section 2 shows theoretical background, including relevant information on the topic of the paper, e.g., biomass and RDF-to-energy routes or power production from black coal; Section 3 describes methodological approach used in this paper; the major findings are presented in the Section 4; presented results are discussed in the Section 5; and in the last Section 6 concluding remarks are presented.

2. Theoretical Background

2.1. Biomass and RDF-to-Energy Routes, Combustion, and Co-Combustion in TPP Boilers

A variety of technological routes can be employed to convert biomass and waste fractions to electrical energy (EE). The most straightforward and technologically mature method is combustion and co-combustion in TPP boilers [18]. To overcome the technical and thermodynamic limitations of the water steam cycle and exploit the potential of a combined cycle plant, the thermochemical conversion of solid fuels into clean combustible gas or liquid is necessary [19]. Moreover, plans for the construction of such poorly reputed plants [20] are often hindered by low public acceptance. The inhabitants of neighbouring settlements and non-governmental bodies voice fears of increased pollution, noise, and traffic caused by the operation of such plants [21] with several cases of halted plant projects reported in Slovakia in recent years [22,23].

RDF is produced in waste management plants as a fraction rich in paper and plastic wastes [24] with a minor share of biomass, textile, and other components [25,26]. Its combustion and co-combustion in TPPs in Western and Northern Europe are well established, as well as its application as alternative fuel in clinker and cement production [27] or in the iron and steel industry [28].

The terms RDF and SRF are often confused [29,30], but SRF differs from RDF by complying with the European Standard EN ISO 21637:2021 [31]. SRF production potential in Europe is estimated to be over 60 MT per year [32], but its current production is much lower [29], which opens possibilities of its production increase and subsequent conversion to EE and heat, following the principles of a circular economy (CE). Biomass and RDF combustion and co-combustion in TPPs have a range of benefits [33,34], including lower greenhouse gas emissions than those generated in black coal combustion, especially in the cases of CO2 and SOx.

Lifecycle analyses performed by Al-Qayim et al. [35] and Glushkov et al. [36,37] revealed that GHG emissions can be cut down by up to 76% compared to the black coal use baseline. Both biomass and RDF generate less ash than black coal and lower the associated disposal costs; ash produced from co-combustion has interesting properties, making it useful in construction, thus further reducing waste generation and contributing to CE [38].

Zhang et al. [39] developed a combined cooling, heating, and power (CCHP) system that integrates plasma gasification, a solid oxide fuel cell (SOFC), a gas turbine, a supercritical carbon dioxide (S-CO2) cycle, and a double-effect absorption refrigeration cycle (ARC) to solve the environmental problems associated with municipal sludge incineration and landfilling. In this context, another study by Zhang et al. [40] is focused on the processing of food waste, where the authors propose a new combined cooling, heating, supply, and dehumidification system based on the plasma gasification of food waste (PG).

2.2. Power Production Structure in V4 Countries

The V4 countries, including Poland, the Czech Republic, Slovakia, and Hungary, are an example of enhanced international cooperation in Central Europe. In line with the recommendations of the European Commission as one of the means to reach the goals of the Paris Agreement, the agenda of V4 cooperation includes meeting EU goals on green energy production using alternative fuels. This is an extraordinary actual cooperation topic, as the industry, together with EE and heat production, is responsible for the major share of total CO2 emissions in all V4 countries [41]. The V4 countries took different paths to accomplish this task. Slovakia has significantly increased its climatic goals regarding greenhouse gas emission reduction lately [42], while the other V4 countries have increased their contributions to the EU renewable energy production goal. Nevertheless, the share of Polish power sources in total EU energy sector emissions has increased as, unlike other EU countries, Poland still heavily relies on power from black coal [43]. Six out of ten of the largest GHG sources in the EU in the power production sector are Polish power plants [44].

This trend is documented in Table 1, elucidating the net power production structure in V4 countries in 2019, stating that, in 2019, almost 75% of net power produced in Poland and almost 45% in the Czech Republic originated from black coal combustion. Both countries declared the intent to continue with power production from black coal even with the supposed coal phase-out being dated to 2030 in the Czech Republic [45] and to 2049 in Poland [46]. Slovakia and Hungary announced an earlier black coal phase-out [47], with Slovakia already having accomplished this at the end of 2023 [46].

The share of black coal in power production sources in the remaining two V4 countries was much lower, especially in Slovakia and Hungary, while other sources, especially nuclear power, had an eminent share in it. Both natural gas, as a transition fuel, and renewable sources played only a minor role in all V4 countries [48]. Recently, discussions on the future installations of small modular nuclear reactors intensified in Slovakia, highlighting their potential in providing heat and power for the industrial sites and for municipalities [49].

Poland was the only one of V4 countries that did not meet the 2020 greenhouse gas emission goals, even though it was, like other V4 countries, allowed to increase its emission levels compared to those in 2005. In 2018, GHG emissions in Hungary and Slovakia were below the 2020 limit, at 82% and 84.5%, respectively, while the Czech Republic reached 95.4% of the limit [50].

Table 1.

Net power production structure in Visegrád countries in 2019 expressed in % of feedstock consumed.

Table 1.

Net power production structure in Visegrád countries in 2019 expressed in % of feedstock consumed.

| Feedstock | Czech Republic | Slovakia | Poland | Hungary |

|---|---|---|---|---|

| Black coal | 44.2 | 8.5 | 73.9 | 11.6 |

| Natural gas | 6.8 | 10.2 | 9.3 | 25.1 |

| Other sources except RES | 34.6 | 54 | 0 | 48.2 |

| RES total, out of which: | 12.7 | 23.3 | 15.6 | 13.9 |

| Biofuels | 5.8 | 3 | 4.2 | 6.1 |

| Hydropower | 2.7 | 17.6 | 1.4 | 0.7 |

| Solar energy | 3.4 | 2.6 | 0.5 | 4.9 |

| Wind energy | 0.8 | 0 | 9.4 | 2.2 |

Source: Own elaboration, adapting data from [51,52,53]; note: RES—renewable energy sources.

2.3. Power Production from Black Coal in Slovakia

Two large coal power plants were operated for decades in Slovakia, PPN and PPV, both are a part of SE—the primary power producer in Slovakia. PPN was located in the Upper Nitra region and combusted local brown coal. Its installed power output of 266 MWe was cut down to 46 MWe in 2015 and was completely shut down in 2023.

Unlike PPN, PPV relied on black coal imports from Ukraine and the Russian Federation at its founding, as it is situated in Eastern Slovakia, close to the Slovakia–Ukraine state border. Its actual installed power output is 2 × 110 MWe (two identical units of 110 MWe), and it operates with subcritical steam parameters [54]. Its operation capability in the range of 2× (40 to 110) MWe enables the provision of both base load power and ancillary services for the National Transmission Operator. Besides coal, heavy fuel oil and natural gas were co-combusted in the plant’s boilers in the past; biomass co-combustion was introduced in 2009. The fuel mix was extended by including RDF in 2020 after a successful test run.

Currently, in the case of PPV, high-quality RDF (class A), in compliance with all requirements according to decree no. 228/2014 [55] and its amendments pursuant to decree no. 365/2015 [56], is used. This high-quality RDF has currently reached an end of waste state according to national legislation and the fulfilment of strict criteria for producers and suppliers. So, it is no longer waste but fuel that can be (co-)burned in standard incinerators and not only in waste incinerators or waste co-incineration plants.

SE’s continuous aim is to lower its environmental footprint, and the company was awarded the Europe’s Climate Leader 2021 award by the Financial Times [57], and, additionally, in 2022 [58], ranked among the top 300 climate leaders in Europe—the only enterprise from the V4 countries to achieve this. The aim of this award is to highlight companies that managed to lower their emission intensity (ratio of emitted greenhouse gases to incomes) substantially between 2014 and 2019 [57]. The company also achieved this in 2022. In the rankings of the prestigious Financial Times newspaper, SE have been ranked among the top thirty energy companies in Europe that pay strict attention to the climate and emissions for two years in a row [58].

A major part of the emission intensity cut achieved by SE can be attributed to both PPN and PPV plants: PPN cut down its installed power output in 2015 and power production in PPV stagnated for several years. The economics of power production in PPV was negatively affected by black coal prices, its transportation costs, and, in the last few years, by continuously increasing CO2 prices. As documented in Table 2, power production decrease in PPV escalated in 2020, accompanied by the lowest annual hours in service by far. Only successful test drives with RDF in August 2020 and subsequently obtained integrated permission for trial operation from SIE allowed PPV to resume its operations [59].

Table 2.

Power production structure in PPV in 2016–2022.

Since then, PPV has gradually adjusted and diversified its fuel mix, has lowered the its black coal share, and is on the way to becoming a multi-fuel plant, relying mostly on alternative fuels. Thus, it contributes to the environmental protection of the Eastern Slovakia region and produces power without receiving any subsidy. In 2021, the fuel energy mix consisted of 50% black coal and 50% RDF and biomass mix, at a ratio of 2:1.

2.4. Summary

Theoretical overview presented above indicates following key findings:

- Ageing fossil power plants offer possibilities for conversion to multi-fuel power plants or their infrastructure can be reused for establishing modern cleaner power sources;

- Production capacities of alternative solid fuels in Europe are not fully exploited and there is potential for their extension, especially in countries that still landfill a significant share of produced waste;

- A major share of such fuels is currently used in cement and clinker plants, replacing fossil fuels;

- A gap exists between the use of such fuels for power production and existing production capacities;

- The development of an alternative feedstock supply chain could contribute to regional CE;

- Black coal still plays an important role in power generation in the V4 region, and the approaching black coal phase-out poses a challenge for socio-economic transformation of the entire region.

Out of Slovakia’s two coal power plants, one (PPN) will be irrevocably phased-out in 2023 and the other one (PPV) has gradually optimised its fuel mix to avoid permanent shutdown due to unfavourable power production economics.

3. Materials and Methods

The present study, (1) quantifying the available alternative fuels for power production in the broader region of Slovakia (V4 region) and (2) exploring the economics of a model coal power plant transformation, can inspire similar transformations in other power plants in the region in order to achieve improved waste management, including landfilled waste share decrease with a significant contribution to cleaner and sustainable power production. The following operational hypotheses were defined for the purpose of this study:

- H1—Regional biomass and RDF sources are sufficient to ensure future coal-free operation of PPV.

- H2—Power production from alternative feedstock in transformed power plants is cost competitive.

Solving the established hypotheses based on the identification of the scientific problem and the transformation to a cleaner operation of coal-fired power plants (especially in the broader area of Slovakia, as part of the V4 region) represents a significant contribution to the investigated issue, based on the expected results of this study.

The research method has been assembled to ensure the usability of results not only at the corporate level (PPV) but also on a European scale, to be used in other power plants. The use of statistical models required a survey of contemporary literature sources, followed by the classification and specification of suitable variables for economic calculations for 2022 conditions. Subsequently, the necessary variables were specified for their economic expression in the analysed year 2022.

In this study, input data from the Power Plant Vojany (PPV) operated in eastern Slovakia were used.

The calculations were based on data on waste production in 2020 obtained from EUROSTAT for the EU and V4, and EU targets for municipal waste, where, by 2035, at least 65% of municipal waste (MW) should be materially recovered and less than 10% of MW should be landfilled (65 + 10 = 75; the difference (25%) remains for other uses, e.g., for energy purposes. In the case of a landfill rate less than 10%, the percentage of energy use could be even higher). Recycling includes both material recycling and composting.

The input data (as summarised in Table 3) allowed us to calculate the energy recovery and combustion of MW in V4 countries expressed by following results:

Table 3.

Data and parameters of fuels combusted in 2022.

- Total energy recovery and its percentage;

- Energetically usable potential of up to 25% of produced municipal waste;

- Usable energy potential, with the calorific value of municipal waste at the level of 13 GJ/t (13 in the case of less calorific fuel, such as RDF as the calorific value of the RDF fuel supplied to PPV was at the level of 22.45 in 2021 and 19.5 GJ/t in 2022);

- According to operational data, energy from waste required to produce electricity in MWh was calculated based on the heat rate 12.37 GJ/t:13 = 0.951 t (So, to produce 1 MWh of EE, 0.951 tons of waste with calorific value of 13 GJ/t are required);

- Black coal savings (taking into account calorific value of coal at a level of 26 GJ·t−1);

- Reduced production of CO2, resulting from the reduced combustion of black coal. (A value of 2.12 for the emission factor of CO2 production by burning 1 t of black coal was used).

4. Results

PPV operates two units with rated power output of 110 MWe each, employing a subcritical (13.5 MPa, 521 °C) steam cycle. Fluid boilers were set into operation 20 years ago and were designed to combust low-sulphur semi-anthracite black coal, with limestone dosing in the combustion chamber for sulphur entrapment in ash. As a moderate-size subcritical plant with a net thermal efficiency of 29% (a heat rate of 12.4 GJ.MWh−1), its purpose was to act as a flexible power source, providing peak power and balancing the national power transmission network rather than to provide base load only. Power production in PPV has become economically less attractive in the last few years compared to in the past. This is documented in Table 4, showing the values of normalised working times of both power plant units (units no. 5 and 6). The year 2020 was critical, with unit no. 5 operated only for a fraction of year and unit no. 6 being shut down all year long.

Table 4.

Normalised working time of Power Plant Vojany blocks: 0 = not in service; 1 = uninterrupted operation all year long.

As a result of the unstable electricity market situation, PPV sought optimal fuel mix to avoid being shut down. The amounts of fuels combusted in 2016–2022 along with avoided CO2 emissions are provided in Table 5. Black coal prevailed over all other fuels consumed in the whole evaluated period of 2016 to 2022. Biomass consumption peaked in 2017 to 2019, but its share in fuel consumption was the highest in 2020, accompanied by the lowest PPV time in service (Table 5) and the lowest amount of power produced (Table 2). The largest amount of biomass was consumed in 2021. Natural gas was consumed during steam boilers startups (unit no. 5), which were very frequent in 2020 and 2021. The PPV plant was granted a permit for RDF co-combustion in 2020, and since 2021, RDF has become part of its fuel mix. Reduced CO2 emissions follow the biomass consumption trend with small variations due to unstable biomass composition and calorific value.

Table 5.

Fuel balance and avoided CO2 emissions in PPV.

Reasons for the declining power production and the fuel mix shift from black coal are apparent from average fuel and CO2 prices presented in Table 6. Both black coal and biomass chips experienced price increases in the period of 2016 to 2022; the increasing CO2 price made the power production from black coal unfeasible. Natural gas, despite its gradual price decrease, was still too expensive to use for power production. The CO2 price is expected to increase further. An association of large French enterprises predicted its rise to 230 EUR·t−1 by 2050 [60]. Operations in 2022 were influenced primarily by the increase in energy prices, fuels used for energy production, and the conflict in Ukraine. Production and other management-secured processes were carried out in agreement with the IPPC permits with acceptable technological problems.

Table 6.

Average prices of fuels and CO2.

Test runs performed in 2019 and the subsequent biomass, black coal, and RDF co-firing mode in 2021 and 2022 confirmed the technical feasibility of multi-fuel mix co-firing at PPV. Steam boilers proved capable of full range operation without any impact on produced steam quality and all emission limits were kept. The higher dosing of calcium-based sulphur- and chlorine-entrapment additives proved necessary to compensate for higher chlorine content in the RDF compared to black coal or biomass. A secondary sorbent (Ca(OH)2) was introduced for the same purpose. Ash formed during biomass and RDF combustion is finer than black coal ash, and a larger amount is formed in the combustion chamber as fly ash, which resulted in the need for external fluidising agent dosing. Ash from a black coal settling tank can also serve this purpose. In cases of an insufficient ash bed, sand or a slag-ash mixture can be used.

Steam boilers are capable of biomass–RDF fuel mix combustion; however, to achieve complete black coal phase-out, additional equipment needs to be installed and a metering system upgrade is necessary.

Municipal Waste Management in V4 Countries

The production of MW and other waste in 2020 and methods of MW management in the countries of the Visegrád Group (V4)—the Slovak Republic, the Czech Republic, Hungary, and Poland are presented in Table 7. Table 8 contains data on the methods of MW management in the EU and V4 countries.

Table 7.

Municipal and other waste in V4 countries.

Table 8.

MW management in the EU and V4 countries in 2020 in t.

The proportions of material recovered waste in V4 countries are as follows: the Slovak Republic (28.58%), Poland (26.68%), Hungary (22.68%), and the Czech Republic (30.63%). The performance of all V4 countries was worse in comparison with the average of the EU (30.68%). In terms of energy recovery, it was achieved to the largest extent in Poland and to the smallest extent in the Slovak Republic. The share of energy recovery in Slovakia is significantly lower than in other countries. This is because Slovakia does not have an adequate number of waste-to-energy facilities. Out of the V4 countries, composting and digestion are most used in Slovakia, namely 13.69%.

Combustion without energy use is the least frequently used method in all V4 countries. Poland combusts the most MW (1.27%), while Slovakia combusts none. Landfilling and other methods of MW management are the most used methods. Hungary landfills the most waste at 55.15%, the Slovak Republic landfills 49.75%, the Czech Republic landfills 45.12%, and Poland landfills the least at 39.78%. Collected waste, which is waiting for its further disposal, is listed separately in Table 8.

According to the current WMP SR, Slovakia should recycle 55% of MW by 2025, 60% by 2030, and 65% by 2035. It is difficult for the Slovak Republic to meet these goals due to the lack of facilities to process such a quantity of waste [62].

In 2020, up to 50% of the total amount of MW was landfilled in Slovakia, which is an alarming amount as by 2035 only a max. 10% of MW should be landfilled [63]. Based on clearly defined EU goals, possibilities for the remaining part of MW for energy recovery of up to 25%, or even more of the total MW production, are created on the condition that at least 65% of material recovery and recycling and less than 10% of MW is landfilled. Calculations in Table 9 consider the average calorific value of MW of 13 GJ/t for the determination of the usable amount of MW energy, its calorific potential in GJ, the potential amount of electricity produced in MWh, the reduced extraction and consumption of black coal, and reduced CO2 production by avoiding black coal combustion.

Table 9.

Energy recovery and combustion of MW in V4 countries.

Table 8 and Table 9 consider only the production and disposal of MW in the V4 countries. Data presented here do not consider the total production of waste, as waste is considerably heterogeneous and specific in individual countries, even though part of this waste, which cannot be used for material recovery, can be used energetically.

5. Discussion

In this study, the feasibility of burning a fuel mix consisting of black coal, wood chips, and RDF is demonstrated based on real results from PPV. Also, the use of fuel mix is an advantage from an environmental point of view due to the closed cycle of CO2 when burning biomass. Several authors draw attention to the positive or negative aspects of the use of fuel mixes and fuel produced from waste or the use of waste for energy production. Due to the typically high share of organic components in waste (>50%), MSW has high moisture content, which reduces the recovery of materials and increases the operating costs of combustion [64]. To overcome these problems and improve material and energy recovery from the waste stream, several processes can be applied. Composting and other biostabilisation processes lead to the degradation of easily degradable organic matter, while the biological drying of MSW increases its calorific value by reducing its moisture content. However, RDF is an alternative fuel made from energy-rich MSW materials that are converted in landfills [65], and it can be used as an alternative to conventional fossil fuels in industrial sectors [66].

The analysis of the current state of the art shows that the burning of composite fuels containing 10–20% of MSW enables the decrease in MSW by 20–30%. The above approach is economically efficient because free combustible waste replaces expensive fossil fuels to produce EE and heat energy [67]. The design, development, and implementation of promising technologies require an in-depth study of the technical, environmental, and economic aspects of this new approach to waste disposal [37]. The combustion mechanisms and properties of solid fossil fuels and fuel mix (a mixture of industrial waste, MSW, and waste oil) are similar, and therefore it is possible to burn them using operational black coal boilers. Substantial modernisation is necessary, especially in case of raw material storage systems, fuel preparation, and fuel handling systems [68].

Within the study prepared for EC [69], which assessed the implementation by the EU Member States of certain provisions of Directive 1999/31/EC on the landfilling of waste (regulations on landfill waste in EU member states), it was found that 15 member states did not fully fulfil the obligations set out in the directive, namely, to treat waste before landfilling [70]. The Slovak Republic is one of the countries that does not process waste before disposing it in landfill. It should be emphasised that as early as 2019, in the Slovak legislation, a legislative amendment to the Waste Act (§ 13 paragraph 9 Act No. 79/2015 Coll. Act on Waste and on Amendments and Supplements to Certain Acts in the Commercial Code) [71] was adopted, which stipulates that from 1 January 2023, it is prohibited to dispose of untreated waste by landfilling. There is an assumption, according to European Commission [72], that after the introduction of this regulation, waste that cannot be used for materials recovery will be used to produce energy. However, it is questionable as to how the Slovak waste management system will fulfil this obligation since several “infringements” in this area have already been issued by the European Commission against Slovakia for serious deficiencies regarding the introduction of new European directives into Slovak waste legislation. These infringements were related, for example, to compliance with the hierarchy of waste management and waste processing; in this context, Slovakia faces high fines [73].

Strategic documents from this environmental area also draw attention to the need to solve the problem of proper waste management. WPM SR for 2016–2020 in Measure 20 already emphasised the goal “To support the production of alternative fuels made from mixed MW within the framework of supporting the use of renewable energy sources if their material recovery is not environmentally suitable”. According to the WMP SR for 2021–2025, the main goal of waste management in the Slovak Republic by 2025 is to divert waste from disposal by landfilling, especially for MW [74]. As one of the tools for diverting waste from landfills, the Slovak Republic must also focus on the use of existing waste-to-energy facilities, especially in relation to non-recyclable MW, which is also an example of PPV. When using the fuel mix in business practice, Agenda 2030 has to be considered. Specifically, point 7.2: “By 2030, substantially increase the share of renewable energy in the global energy mix” (SDG 7: Ensure access to affordable, reliable, and sustainable modern energy sources for all) [75].

As part of solving the problem in this study, three working hypotheses were established with the aim to methodically verifying theoretical assumptions by real results in the energy industry.

Hypothesis H1 was formulated as follows: “There is an assumption that regional biomass and RDF sources are sufficient to ensure future coal-free operation of PPV.” The verification of the established working hypothesis is based on our own analyses and calculations during our study of currently used and potential sources of waste biomass in PPV. The use of the fuel mix described is closely related to concepts such as CE and SD. One of the principles of CE is renewability, i.e., if we produce something, we should consider the materials that are used so that they can be restored or retrieved without the depletion of fossil fuels [76]. By replacing black coal with the calorific value of 26 GJ/t with RDF with the calorific value of 13 GJ/t, a reduction in black coal consumption as well as a positive impact on Slovakia’s trade balance can be achieved.

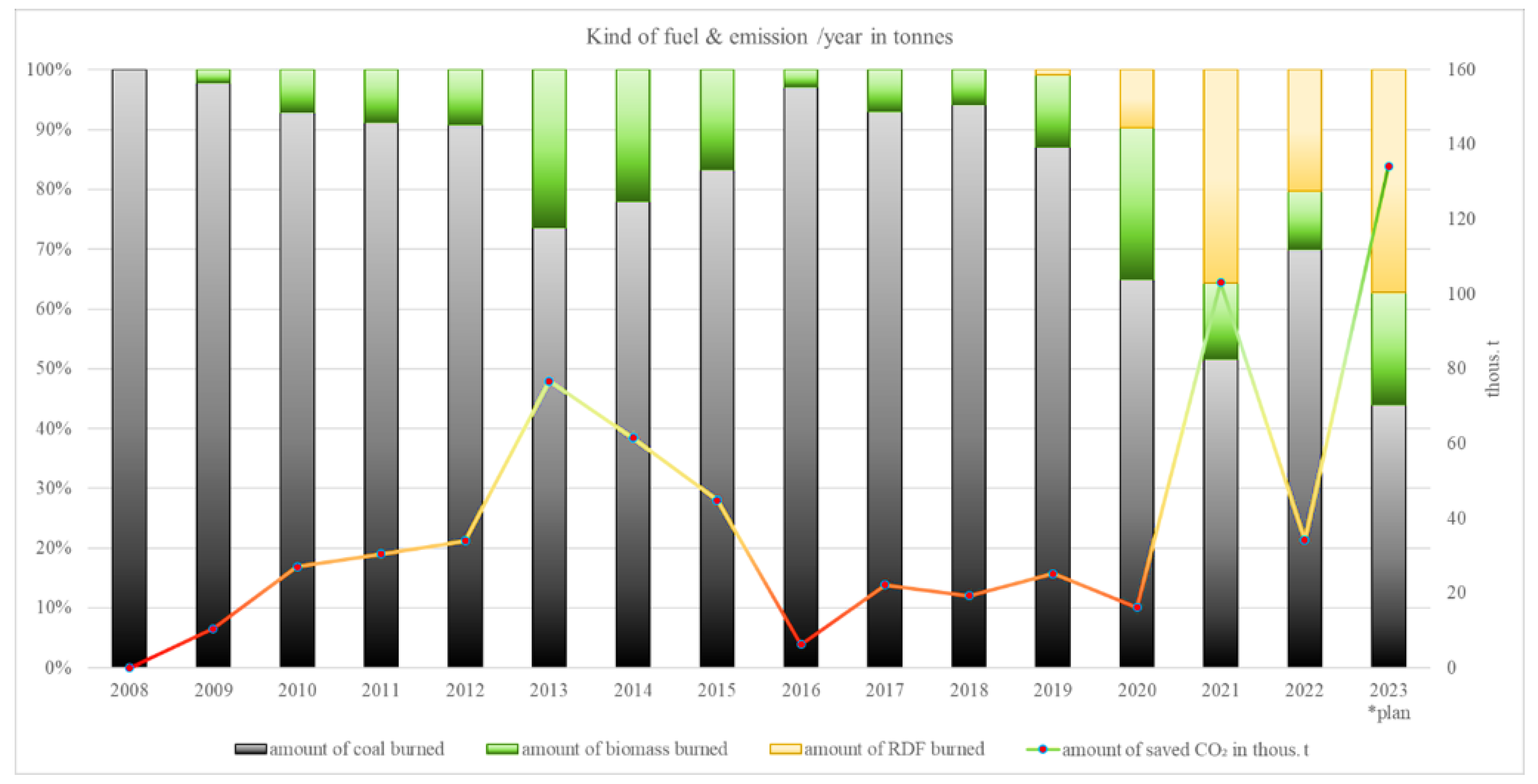

Figure 1 shows the real and planned development of the fuel base in PPV, where 100% of the fuel was black coal in 2008, and from 2009 to 2018, it was a combination of black coal and biomass. Since 2019, PPV has used a combination of three fuels, including black coal, biomass, and RDF. In the future, the gradual reduction in black coal and the transition to a larger share of RDF and waste biomass should be considered.

Figure 1.

Development of fuel sources in PPV and achieved CO2 savings (source: own elaboration based on unpublished data from PPV), note: with the increasing amount of saved CO2 the color of line changes from red (0 to 15%) to orange (15 to 25%), yellow (25 to 50%) and green (more than 50%).

The use of fuel produced from waste for energy production can have a positive impact on greenhouse gas reduction in the future. In 2018, 50% of the total CO2 produced, i.e., 21.570,6 gigatons, was from energy production [77].

Considering fuel sources, we can state that there is enough waste in Slovakia that can be used for energy production. Based on the results presented in Table 9, 7.95% of MW is recovered for energy production in Slovakia, which represented 188,000 tons in 2020. As the gradual decrease in landfilling to below 10% and the increase in waste and material recovery of at least 65% of MW are expected by 2035, there is significant potential for the further production of fuels from waste and its recovery. In this way, we will approach the EU average in MW utilisation, which was 26.42% in 2020. When reaching a level of 25% of MW energy recovery, at the current level of waste production and energy recovery of 188,000 tons of MW, another 403,000 tons of waste will still be available. With the planned annual production of EE for the needs of PPV, 78 kilotons of RDF produced from waste will be needed, which applies to the planned annual production of EE (58 MW for 6400 h annually; in the past, 2 × 110 MW for over 8000 h annually). If PPV was to produce as much EE as it did in 2009 (799 MWh), then, compared to 78 kilotons of RDF planned for 2023, an additional 392 kilotons will be needed. This value is close to the calculated potential for the Slovak Republic.

The Slovak Republic does not have sufficient sorting line capacity for the increased sorting of MW components and the production of SRF and RDF. Production capacities in Slovakia are at a level of approximately 100 to 120 thousand tons of RDF and SRF. As WMP SR foresees the use of this fuel at a level of 200,000 tons by 2025, Slovakia is significantly behind and only has half of the production capacity to produce the SRF needed [74]. Also, based on the aforementioned facts, PPV ensures RDF supply through imports from other EU countries.

Regarding the available sources of waste biomass, for the confirmation or rejection of hypothesis H1, it was necessary to collect facts concerning the current use of waste biomass resources in PPV for the observed period and to predict future development and capacities.

For the fuel mix consisting of RDF and wood chips, 39 kilotons of wood chips are needed for the planned production of EE in 2023, which represents 3.1% of the total Slovak consumption. PPV has secured suppliers based on electronic tenders [78].

The total annual consumption of solid fuelwood biomass (firewood, wood chips) reached 1.26 million tons in Slovakia in 2021 [79]. According to the available data, approximately 48% of the usable potential of fuel wood biomass on forest land was not exploited in 2021. This is wood unsuitable for mechanical and chemical processing, the occurrence of which is related to the high extent and frequency of catastrophic situations and subsequent accidental logging, mainly in coniferous (spruce) stands. This increases the potential of hardwood (by saving on harvesting) and the assortment structure, which includes higher proportion of fuel dendromass. This situation is not in accordance with the Integrated National Energy and Climate Plan for 2021–2030, which set the goal of increasing the share of renewable energy sources (RES) to 19.2% in 2030 compared to 16.9% in 2019 [51].

Conclusion H1: Based on the available sources and data, the hypothesis can be confirmed. The coal-free operation of PPV can be ensured partly through the supply of wood chips and partly through the supply of RDF within Slovakia (and thus the entire region). Despite the sufficient resources of MW in Slovakia, it is currently necessary to use RDF supplies from abroad.

Table 8 shows that, within the V4 countries, there is the potential to increase RDF production compared to the current state by approximately 2 million tons, from which it is possible to produce approximately 2000 GWh of EE in power plants at the same heat rate as PPV. In the cases of power plants with a 10–15% lower heat rate compared to PPV, this can be up to 2400 GWh of EE per year or approximately 300 MW with a working time of 8000 h. The installed electrical power of typical coal-fired power plants ranges from several hundred to several thousand MW (e.g., the largest Polish coal-fired power plant Belchatow has an installed power of over 5000 MW), according to ClientEarth [80]. The share of EE that can be produced from additionally obtainable RDF from the entire V4 region compared to the current state thus represents only a fraction of the output of the largest coal-fired power plants in the region.

Conclusion H2: Within the achieved results, this hypothesis was confirmed. However, the risk arising from the volatility of EE prices and the uncertain prices of emission allowances in the future and the availability of alternative fuels are not considered; this could result in the process not being economical, and in which case, the hypothesis could not be confirmed.

Taking into consideration previously published papers, e.g., Nunes et al. [81], the results and findings presented in this study are not theoretically based but reflect real power plant (PPV) operations. Therefore, the presented results may be considered of much more practical value, especially in Slovakia and the V4 countries region.

6. Conclusions

Energy efficiency is a major global issue that plays a fundamental role in achieving SDG, as defined in Agenda 2030 [75]. Although the use of clean energy is gradually increasing, about 80% of global energy consumption still comes from fossil fuels (oil and natural gas), and about 50% of energy production depends on black coal. The present study analysed the potential role and economic importance of biomass and fuels produced from waste in the energy mix of PPV in Slovakia, which is part of SE. Based on the Financial Times evaluation, this company was ranked among Europe’s Climate Leaders in 2021 and 2022, which also confirms our findings and results. PPV gradually switched from burning black coal in the production of EE to a combined fuel mix, a combination of black coal and biomass, between 2009 and 2018.

However, the hypothesis that a potential increase in RDF production in V4 countries is sufficient to provide fuel for several coal-fired power plants in the region was not confirmed. The identified potential is sufficient to replace coal with RDF for one medium-sized power plant unit or for one smaller (300 MW) coal-fired power plant. Moreover, the co-combustion of RDF will face competitive use in existing and planned projects of waste-to-energy facilities.

Given its recent operation history and the ongoing search for optimal fuel mix, PPV constitutes a model power plant which was transformed into an environmentally more friendly power source. As such, it can be an example for multiple other coal power plants in V4 countries that face the same challenge—to undergo transformation or to be phased out. However, in the particular case of the Power Plant Vojany, only low-cost solutions are acceptable to the plant’s management. Obviously, more costly solutions, including carbon capture and storage (CCS), repowering with advanced combined cycle technologies or fuel cells, or a significant reconstruction to a supercritical unit might be considered for a coal-fired power plant in general. However, for a power plant with a modest installed output of hundreds of MWs, none of these options are both cost-effective and contribute to decarbonization at the same time, unlike the implementation of biomass and alternative fuel.

Considering SDGs 2030, the future direction of research should be focused on exploring the possibilities of integrating CE principles for the sustainable production of fuel obtained from waste (RDF) [82,83]. This may provide insight into the creation of a closed waste recovery system that is consistent with the goals of sustainability and environmental impact reduction.

Author Contributions

Conceptualization, M.S., L.K. and P.Sz.; methodology, M.S., L.K., M.V., P.Sz., B.K. and Ľ.Š.; investigation, M.S., L.K., M.V., P.Sz., B.K. and Ľ.Š.; resources, M.S., L.K., M.V., P.Sz. and Ľ.Š.; data curation, M.S., L.K., M.V., P.Sz., B.K. and Ľ.Š.; writing—original draft preparation, M.S., L.K., M.V., P.Sz., B.K. and Ľ.Š.; visualization, Ľ.Š.; supervision, M.S., B.K. and Ľ.Š.; project administration, M.S.; funding acquisition, M.S. and B.K. All authors have read and agreed to the published version of the manuscript.

Funding

This study was financially supported by the project KEGA 035EU-4/2022, Achieving the goals of the 2030 Agenda for Sustainable Development under the influence of the global pandemic COVID-19, and by the Slovak Research and Development Agency under the contracts no. APVV-18-0134 and APVV-19-0170.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mac Kinnon, M.A.; Brouwer, J.; Samuelsen, S. The role of natural gas and its infrastructure in mitigating greenhouse gas emissions, improving regional air quality, and renewable resource integration. Prog. Energy Combust. Sci. 2018, 64, 62–92. [Google Scholar] [CrossRef]

- Elavarsan, R.M.; Pugazhedhi, R.; Irfan, M.; Mihet-Popa, L.; Khan, I.A.; Compana, P.E. State-of-the-art sustainable approaches for deeper decarbonization in Europe—An endowment to climate neutral vision. Renew. Sustain. Energy Rev. 2022, 159, 112204. [Google Scholar] [CrossRef]

- Paardekooper, S.; Lund, H.; Thellfsen, J.Z.; Bertelsen, N.; Mathiesen, B.V. Heat Roadmap Europe: Strategic heating transition typology as a basis for policy recommendations. Energy Effic. 2022, 15, 32. [Google Scholar] [CrossRef]

- Portillo, E.; Gallego Fernández, L.M.; Vega, F.; Alonso-Fariñas, B.; Navarrete, B. Oxygen transport membrane unit applied to oxy-combustion coal power plants: A thermodynamic assessment. J. Environ. Chem. Eng. 2021, 9, 105266. [Google Scholar] [CrossRef]

- Qvist, S.; Gładysz, P.; Bartela, L.; Sowiżdżał, A. Retrofit Decarbonization of Coal Power Plants—A Case Study for Poland. Energies 2020, 14, 120. [Google Scholar] [CrossRef]

- Kefford, B.M.; Ballinger, B.; Schmeda-Lopez, D.R.; Greig, C.; Smart, S. The early retirement challenge for fossil fuel power plants in deep decarbonisation scenarios. Energy Policy 2018, 119, 294–306. [Google Scholar] [CrossRef]

- del Rio, M.S.; Gibbins, J.; Lucquiaud, M. On the retrofitting and repowering of coal power plants with post-combustion carbon capture: An advanced integration option with a gas turbine windbox. Int. J. Greenh. Gas Control. 2017, 58, 299–311. [Google Scholar] [CrossRef]

- Tańczuk, M.; Skorek, J.; Bargiel, P. Energy and economic optimization of the repowering of coal-fired municipal district heating source by a gas turbine. Energy Convers. Manag. 2017, 149, 885–895. [Google Scholar] [CrossRef]

- Milićević, A.; Belošević, S.; Crnomarković, N.; Tomanović, I.; Tucaković, D. Mathematical modelling and optimisation of lignite and wheat straw co-combustion in 350 Mwe boiler furnace. Appl. Energy 2019, 260, 114206. [Google Scholar] [CrossRef]

- Cuong, T.T.; Le, H.A.; Khai, N.M.; Hung, P.A.; Linh, L.T.; Thanh, N.V.; Tri, N.D.; Huan, N.X. Renewable energy from biomass surplus resource: Potential of power generation from rice straw in Vietnam. Sci. Rep. 2021, 11, 792. [Google Scholar] [CrossRef] [PubMed]

- Merzic, A.; Turkovic, N.; Ikanovic, N.; Lapandic, E.; Kazagic, A.; Music, M. Towards just transition of coal regions—Cultivation of short rotation copies and dedicated energy crops for biomass co-firing vs photo voltaic power plants. Energy Convers. Manag. X 2022, 15, 100267. [Google Scholar] [CrossRef]

- Vamvuka, D.; Alexandrakis, S.; Papagiannis, I. Evaluation of municipal wastes as secondary fuels through co-combustion with woody biomass in a fluidized bed reactor. J. Energy Inst. 2020, 93, 272–280. [Google Scholar] [CrossRef]

- Skopec, P.; Hrdlička, F.; Jeníková, J. Co-firing of coal with a solid recovered fuel as a route of reduction of sulphur dioxide emissions. Waste Forum 2018, 1, 26–34. [Google Scholar]

- Hansen, K. Decision-making based on energy costs: Comparing levelized cost of energy and energy system costs. Energy Strategy Rev. 2019, 24, 68–82. [Google Scholar] [CrossRef]

- Miedema, J.H.; Benders, R.M.; Moll, H.C.; Pierie, F. Renew, reduce or become more efficient? The climate contribution of biomass co-combustion in a coal-fired power plant. Appl. Energy 2017, 187, 873–885. [Google Scholar] [CrossRef]

- Brożyna, J.; Strielkowski, W.; Fomina, A.; Nikitina, N. Renewable Energy and EU 2020 Target for Energy Efficiency in the Czech Republic and Slovakia. Energies 2020, 13, 965. [Google Scholar] [CrossRef]

- Piwowar, A.; Dzikuć, M. Outline of the economic and technical problems associated with the co-combustion of biomass in Poland. Renew. Sustain. Energy Rev. 2016, 54, 415–420. [Google Scholar] [CrossRef]

- Karampinis, E.; Grammelis, P.; Agraniotis, M.; Violidakis, I.; Kakaras, E. Co-firing of biomass with coal in thermal power plants: Technology schemes, impacts, and future perspectives. WIREs Energy Environ. 2014, 3, 384–399. [Google Scholar] [CrossRef]

- Poskart, A.; Skrzyniarz, M.; Sajdak, M.; Zajemska, M.; Skibiński, A. Management of Lignocellulosic Waste towards Energy Recovery by Pyrolysis in the Framework of Circular Economy Strategy. Energies 2021, 14, 5864. [Google Scholar] [CrossRef]

- AGT. Advanced Gasification Technologies—Review and Benchmarking. 2021; p. 41. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/1022926/agt-benchmarking-task-4-report.pdf (accessed on 15 November 2021).

- Upham, P.; Shackley, S. Local public opinion of a proposed 21.5 MW(e) biomass gasifier in Devon: Questionnaire survey results. Biomass Bioenergy 2007, 31, 433–441. [Google Scholar] [CrossRef]

- Ministry of Interior of the Slovak Republic. Rozhodnutie. 2017. Available online: https://www.minv.sk/swift_data/source/miestna_statna_sprava/ou_trnava/vystavba/Rozhodnutie_20171221.pdf (accessed on 23 June 2022).

- Priatelia Zeme. Pomoc Občanom Piatich Miest/Obcí Proti Zámerom Depolymerizácie Plastov. 2021. Available online: http://www.priateliazeme.sk/spz/z-nasej-prace/pomoc-obcanom-piatich-miestobci-proti-zamerom-depolymerizacie-plastov (accessed on 7 March 2022).

- Zajemska, M.; Magdziarz, A.; Iwaszko, J.; Skrzyniarz, M.; Poskart, A. Numerical and experimental analysis of pyrolysis process of RDF containing a high percentage of plastic waste. Fuel 2022, 320, 123981. [Google Scholar] [CrossRef] [PubMed]

- Januszewski, J.; Brzezińska, D. RDF Fire and Explosion Hazards at Power Plants. Sustainability 2021, 13, 12718. [Google Scholar] [CrossRef]

- Šuhaj, P.; Haydary, J.; Husár, J.; Steltenpohl, P.; Šupa, I. Catalytic gasification of refuse-derived fuel in a two-stage laboratory scale pyrolysis/gasification unit with catalyst based on clay minerals. Waste Manag. 2019, 85, 1–10. [Google Scholar] [CrossRef]

- Abu-Elyazeed, O.S.M.; Nofal, M.; Ibrahim, K.; Yang, J. Co-combustion of RDF and biomass mixture with bituminous coal: A case study of clinker production plant in Egypt. Waste Dispos. Sustain. Energy 2021, 3, 257–266. [Google Scholar] [CrossRef]

- Han, J.; Huang, Z.; Qin, L.; Chen, W.; Zhao, B.; Xing, F. Refused derived fuel from municipal solid waste used as an alternative fuel during the iron ore sinter process. J. Clean. Prod. 2021, 278, 123594. [Google Scholar] [CrossRef]

- Chavando, J.A.M.; Silva, V.B.; Tarelho, L.A.; Cardoso, J.S.; Eusébio, D. Snapshot review of refuse-derived fuels. Util. Policy 2022, 74, 101316. [Google Scholar] [CrossRef]

- Iacovidou, E.; Hahladakis, J.; Deans, I.; Velis, C.; Purnell, P. Technical properties of biomass and solid recovered fuel (SRF) co-fired with coal: Impact on multi-dimensional resource recovery value. Waste Manag. 2018, 73, 535–545. [Google Scholar] [CrossRef]

- EN ISO 21637:2021; Solid Recovered Fuels—Vocabulary. Úrad Pre Normalizáciu, Metrológiu a Skúšobníctvo Slovenskej Republiky: Bratislava, Slovakia, 2021.

- Cuperus, G. SRF—The Missing Link in the Circlar Economy; European Recovered Fuel Organisation (ERFO): Bruxelles, Belgium, 2017. [Google Scholar]

- Rimar, M.; Kulikova, O.; Kulikov, A.; Fedak, M. Energy Treatment of Solid Municipal Waste in Combination with Biomass by Decentralized Method with the Respect to the Negative Effects on the Environment. Sustainability 2021, 13, 4405. [Google Scholar] [CrossRef]

- Sajdak, M.; Kmieć, M.; Micek, B.; Hrabak, J. Determination of the optimal ratio of coal to biomass in the co-firing process: Feed mixture properties. Int. J. Environ. Sci. Technol. 2019, 16, 2989–3000. [Google Scholar] [CrossRef]

- Al-Qayim, K.; Nimmo, W.; Pourkashanian, M. Comparative techno-economic assessment of biomass and coal with CCS technologies in a pulverized combustion power plant in the United Kingdom. Int. J. Greenh. Gas Control. 2015, 43, 82–92. [Google Scholar] [CrossRef]

- Glushkov, D.; Kuznetsov, G.; Paushkina, K. Switching Coal-Fired Thermal Power Plant to Composite Fuel for Recovering Industrial and Municipal Waste: Combustion Characteristics, Emissions, and Economic Effect. Energies 2020, 13, 259. [Google Scholar] [CrossRef]

- Glushkov, D.O.; Paushkina, K.K.; Shabardin, D.P. Co-combustion of coal processing waste, oil refining waste and municipal solid waste: Mechanism, characteristics, emissions. Chemosphere 2019, 240, 124892. [Google Scholar] [CrossRef]

- Kalembkiewicz, J.; Chmielarz, U. Ashes from co-combustion of coal and biomass: New industrial wastes. Resour. Conserv. Recycl. 2012, 69, 109–121. [Google Scholar] [CrossRef]

- Zhang, J.; Cui, P.; Yang, S.; Zhou, Y.; Du, W.; Wang, Y.; Deng, C.; Wang, S. Thermodynamic analysis of SOFC–CCHP system based on municipal sludge plasma gasification with carbon capture. Appl. Energy 2023, 336, 120822. [Google Scholar] [CrossRef]

- Zhang, J.; Cheng, H.; Xu, Z.; Zhou, Y.; Yin, K.; Wang, X.; Gao, Y.; Sun, C.; Wang, Y.; Cui, P. Thermodynamic analysis of a food waste plasma gasification-based multigeneration system with dehumidification and carbon capture. J. Clean. Prod. 2023, 402, 136844. [Google Scholar] [CrossRef]

- Kochanek, E. The Energy Transition in the Visegrad Group Countries. Energies 2021, 14, 2212. [Google Scholar] [CrossRef]

- The Slovak Energy Transition-Decarbonization and Energy Security. Available online: https://energytransition.org (accessed on 15 October 2020).

- Rokicki, T.; Perkowska, A. Changes in Energy Supplies in the Countries of the Visegrad Group. Sustainability 2020, 12, 7916. [Google Scholar] [CrossRef]

- Ciesielska-Maciągowska, D.; Klimczak, D.; Skrzek-Lubasińska, M. Central and Eastern European CO2 Market—Challenges of Emissions Trading for Energy Companies. Energies 2021, 14, 1051. [Google Scholar] [CrossRef]

- Beyond Fossil Fuels. Czech Republic Joins the Powering Past Coal Alliance, Accelerating the End of Coal in Europe. 2023. Available online: https://beyondfossilfuels.org/2023/12/02/czech-republic-joins-the-powering-past-coal-alliance-accelerating-the-end-of-coal-in-europe/ (accessed on 10 January 2024).

- EURACTIV. Slovakia Announces Regional Coal Phase-Out, Set to Save Big. 2023. Available online: https://www.euractiv.com/section/politics/news/slovakia-announces-regional-coal-phase-out-set-to-save-big/ (accessed on 10 January 2024).

- Tucki, K.; Krzywonos, M.; Orynycz, O.; Kupczyk, A.; Bączyk, A.; Wielewska, I. Analysis of the Possibility of Fulfilling the Paris Agreement by the Visegrad Group Countries. Sustainability 2021, 13, 8826. [Google Scholar] [CrossRef]

- Sulich, A.; Sołoducho-Pelc, L. Renewable Energy Producers’ Strategies in the Visegrád Group Countries. Energies 2021, 14, 3048. [Google Scholar] [CrossRef]

- Vrban, B.; Nečas, V.; Čerba, Š.; Luley, J.; Filová, V. Perspectives on the future of nuclear energy in Slovakia. Energy Syst. 2023, 1–22. [Google Scholar] [CrossRef]

- Wach, K.; Głodowska, A.; Maciejewski, M.; Sieja, M. Europeanization Processes of the EU Energy Policy in Visegrad Countries in the Years 2005–2018. Energies 2021, 14, 1802. [Google Scholar] [CrossRef]

- Integrovaný Národný Energetický a Klimatický Plán na Roky 2021–2030. Ministerstvo Hospodárstva Slovenskej Republiky: Bratislava, Slovakia, 2019; p. 41. Available online: https://www.mhsr.sk/energetika/integrovany-narodny-energeticky-a-klimaticky-plan-na-roky-2021-2030 (accessed on 12 May 2022).

- Ogrodnik, Ł. Czechia’s Climate Policy and Energy Transformation. PISM Bulletin, 7 September 2020; p. 1613. [Google Scholar]

- van der Burg, L.; Trilling, M.; Gençsü, I. Fossil Fuel Subsidies in Draft EU National Energy and Climate Plans; ODI: London, UK, 2019; Volume 562, p. 15. Available online: https://cdn.odi.org/media/documents/12895.pdf (accessed on 23 December 2022).

- Slovenské elektrárne. 2022. Available online: https://www.seas.sk/elektraren/elektrarne-vojany/ (accessed on 20 January 2022).

- Decree of the Ministry of the Environment of the Slovak Republic No. 228/2014 Coll. Available online: https://www.slov-lex.sk/pravne-predpisy/SK/ZZ/2014/228/ (accessed on 26 April 2022).

- Decree of the Ministry of the Environment of the Slovak Republic No. 365/2015 Coll. Available online: https://www.slov-lex.sk/pravne-predpisy/SK/ZZ/2015/365/ (accessed on 26 April 2022).

- Financial Times: Interactive Listing. Europe’s Climate Leaders 2021. 2021. Available online: https://www.ft.com/climate-leaders-europe-2021 (accessed on 11 September 2021).

- Financial Times: Interactive Listing. Europe’s Climate Leaders 2022. 2022. Available online: https://www.ft.com/climate-leaders-europe-2022 (accessed on 8 September 2022).

- Enviroportal. 2023. Available online: https://www.enviroportal.sk/ipkz/prevadzka?id=291 (accessed on 10 January 2023).

- AFEP. AFEP (French Association of Large Companies) Study on Trade & Climate Change/Final Report. [online] Paris. 2020. 113p. Available online: https://afep.com/wp-content/uploads/2021/01/Trade-and-Climate-Change-Quantitative-Assessment-of-the-Best-Policy-Tools.pdf (accessed on 15 February 2021).

- EUROSTAT: Municipal Waste Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Municipal_waste_statistics (accessed on 10 January 2023).

- Implementing Agency of the Ministry of Labour, Social Affairs and Family of the Slovak Republic. Analýza Odpadového Hospodárstva. 2021. Available online: https://www.zmos.sk/analyza-odpadoveho-hospodarstva-oznam/mid/419520/.html (accessed on 17 April 2022).

- Ministry of Environment of the Slovak Republic. Európska Zelená Dohoda. 2021. Available online: https://www.minzp.sk/klima/europska-zelena-dohoda/ (accessed on 18 March 2022).

- Bezama, A.; Aguayo, P.; Konrad, O.; Navia, R.; Lorber, K.E. Investigations on mechanical biological treatment of waste in South America: Towards more sustainable MSW management strategies. Waste Manag. 2007, 27, 228–237. [Google Scholar] [CrossRef] [PubMed]

- Rada, E.C.; Istrate, I.A.; Ragazzi, M. Trends in the management of residual municipal solid waste. Env. Technol. 2009, 30, 651–661. [Google Scholar] [CrossRef] [PubMed]

- Hemidat, S.; Saidan, M.; Al-Zu’bi, S.; Irshidat, M.; Nassour, A.; Nelles, M. Potential utilization of RDF as an alternative fuel to be used in cement industry in Jordan. Sustainability 2019, 11, 5819. [Google Scholar] [CrossRef]

- Halkos, G.; Petrou, K.N. Analysing the Energy Efficiency of EU Member States: The Potential of Energy Recovery from Waste in the Circular Economy. Energies 2019, 12, 3718. [Google Scholar] [CrossRef]

- Dmitrienko, M.A.; Strizhak, P.A. Coal-water slurries containing petrochemicals to solve problems of air pollution by coal thermal power stations and boiler plants: An introductory review. Sci. Total. Environ. 2018, 613-614, 1117–1129. [Google Scholar] [CrossRef]

- Milieu. Study to Assess the Implementation by the EU Member States of Certain Provisions of Directive 1999/31/EC on the Landfill of Waste. 2017. Available online: https://op.europa.eu/en/publication-detail/-/publication/cd1748fb-0884-11e7-8a35-01aa75ed71a1 (accessed on 3 March 2022).

- EK. Správa Komisie Európskemu Parlamentu, Rade, Európskemu Hospodárskemu a Sociálnemu Výboru a Výboru Regiónov. 2018. Available online: https://eur-lex.europa.eu/legal-content/SK/TXT/HTML/?uri=CELEX:52018DC0656&from=EN (accessed on 15 March 2021).

- Slovak Government. Act No. 79/2015 Col. On Waste and on the Amendment of Certain Acts. Order of the Government of the Slovak Republic: Bratislava, Slovakia, 2015. Available online: https://www.slov-lex.sk/pravne-predpisy/SK/ZZ/2015/79/20211201 (accessed on 24 June 2022).

- European Commission. Infringement Decisions. 2023. Available online: https://ec.europa.eu/atwork/applying-eu-law/infringements-proceedings/infringement_decisions/?typeOfSearch=true&active_only=1&noncom=0&r_dossier=&decision_date_from=&decision_date_to=&EM=SK&DG=ENV&title=&submit=Search&lang_code=en (accessed on 22 January 2023).

- Odpady. 2021. Available online: https://www.odpady-portal.sk/Dokument/106410/slovensko-celi-dalsiemu-infringementu-pre-nedostatky-v-odpadovom-hospodarstve.aspx (accessed on 13 June 2022).

- Ministry of Environment of the Slovak Republic. Program Odpadového Hospodárstva Slovenskej Republiky na Roky 2021–2025. 2021. Available online: https://www.enviroportal.sk/sk/eia/detail/program-odpadoveho-hospodarstva-slovenskej-republiky-na-roky-2021-2025 (accessed on 12 November 2022).

- United Nations. A/RES/70/1—Transforming Our World: The 2030 Agenda for Sustainable Development. 2015. Available online: https://sdgs.un.org/2030agenda (accessed on 4 February 2023).

- Ellen Macarthur Foundation. Growth within: A Circular Economy Vision for a Competitive Europe. 2015. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/publications/EllenMacArthurFoundation_Growth-Within_July15.pdf (accessed on 15 May 2021).

- Ministry of Environment of the Slovak Republic. Správa o Stave Životného Prostredia Slovenskej Republiky v Roku 2019; Ministry of Environment of the Slovak Republic: Bratislava, Slovakia, 2020; p. 182. ISBN 978-80-8213-028-0. [Google Scholar]

- Slovenské elektrárne. 2023. Available online: https://www.seas.sk/pre-dodavatelov/obstaravanie/tendre/ (accessed on 13 January 2023).

- Ministry of Agriculture and Rural Development of the Slovak Republic. Správa o Lesnom Hospodárstve v Slovenskej Republike za rok 2021. ZELENÁ SPRÁVA. 2022, pp. 64–65. Available online: https://www.mpsr.sk/zelena-sprava-2022/123---18463/ (accessed on 22 January 2023).

- ClientEarth. 2023. Available online: https://www.clientearth.org/media/hqqbceot/enervis-belchatow-lignite-power-plant-full-documentation-ext-en1.pdf (accessed on 12 January 2023).

- Nunes, L.J.R.; Casau, M.; Matias, J.C.O.; Dias, M.F. Coal to Biomass Transition as the Path to Sustainable Energy Production: A Hypothetical Case Scenario with the Conversion of Pego Power Plant (Portugal). Appl. Sci. 2023, 13, 4349. [Google Scholar] [CrossRef]

- Shehata, N.; Obaideen, K.; Sayed, E.T.; Abdelkareem, M.A.; Mahmoud, M.S.; El-Salamony, A.-H.R.; Mahmoud, H.M.; Olabi, A.G. Role of refuse-derived fuel in circular economy and sustainable development goals. Process Saf. Environ. Prot. 2022, 163, 558–573. [Google Scholar] [CrossRef]

- Mateus, M.M.; Cecílio, D.; Fernandes, M.C.; Correia, M.J.N. Refuse derived fuels as an immediate strategy for the energy transition, circular economy, and sustainability. Bus. Strat. Environ. 2023, 32, 3915–3926. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).