Techno-Economic and Environmental Analysis of a Sewage Sludge Alternative Treatment Combining Chemical Looping Combustion and a Power-to-Methane System

Abstract

:1. Introduction

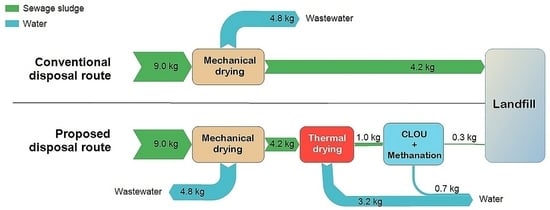

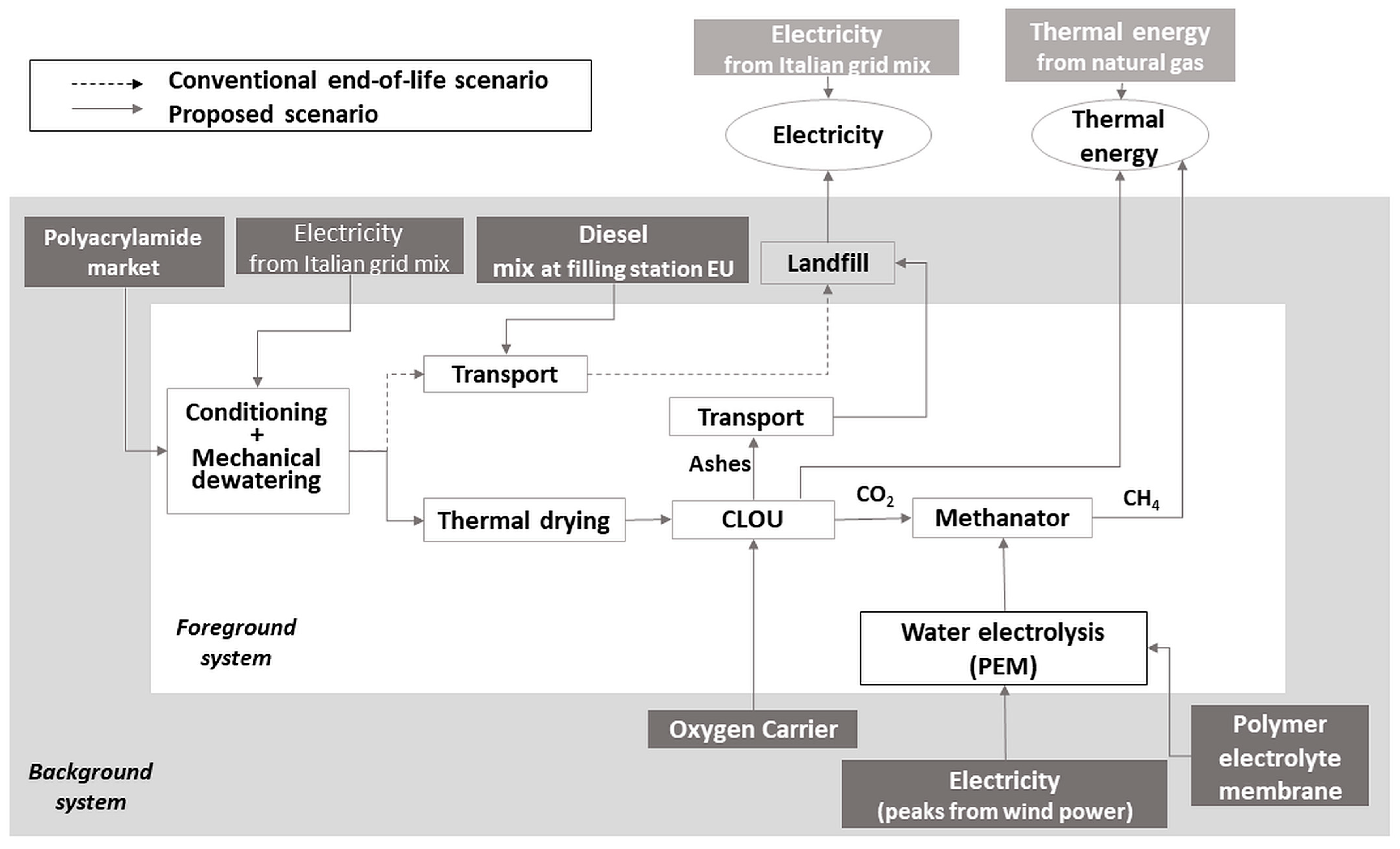

2. Materials and Methods

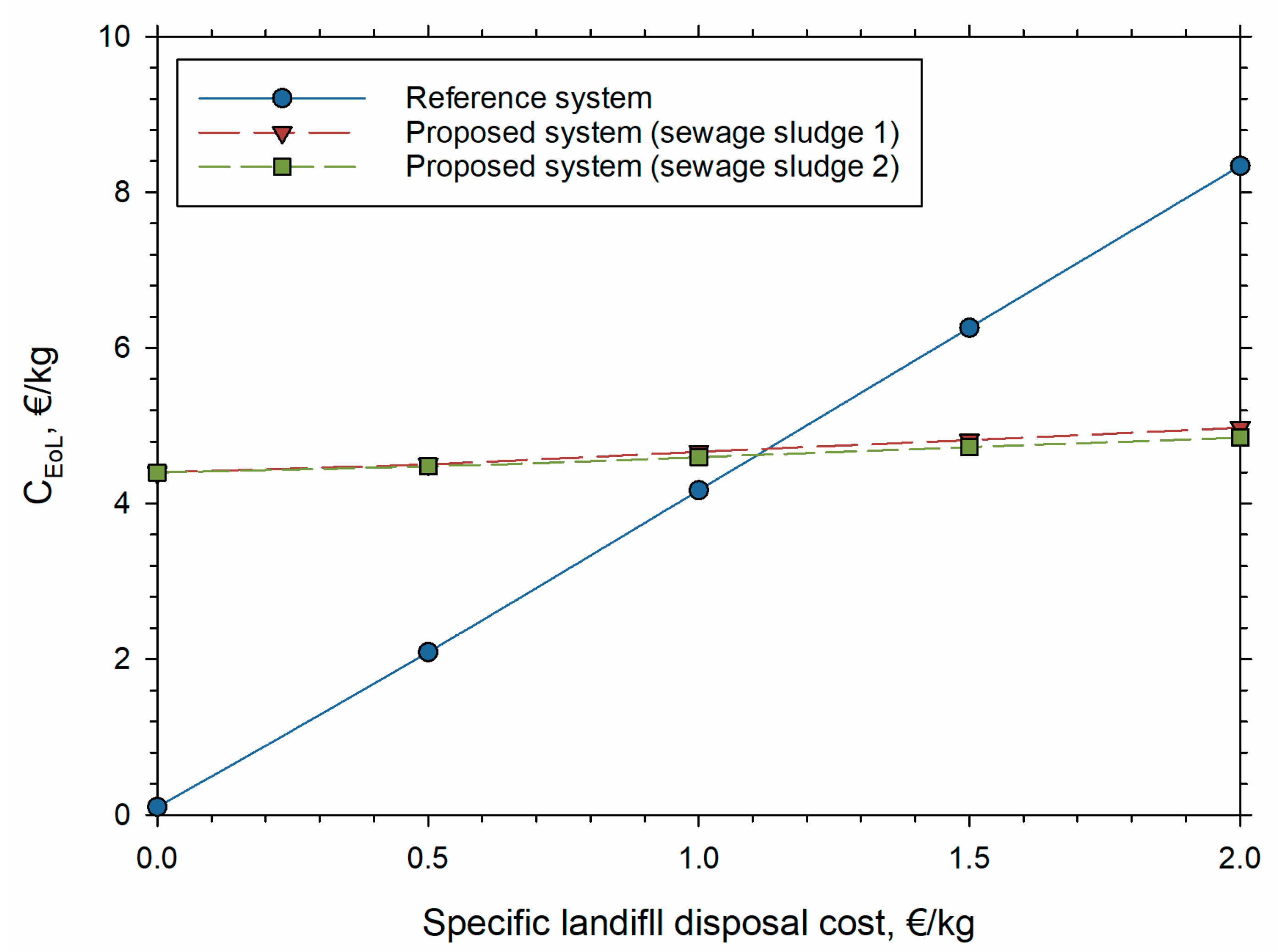

2.1. Economic Analysis

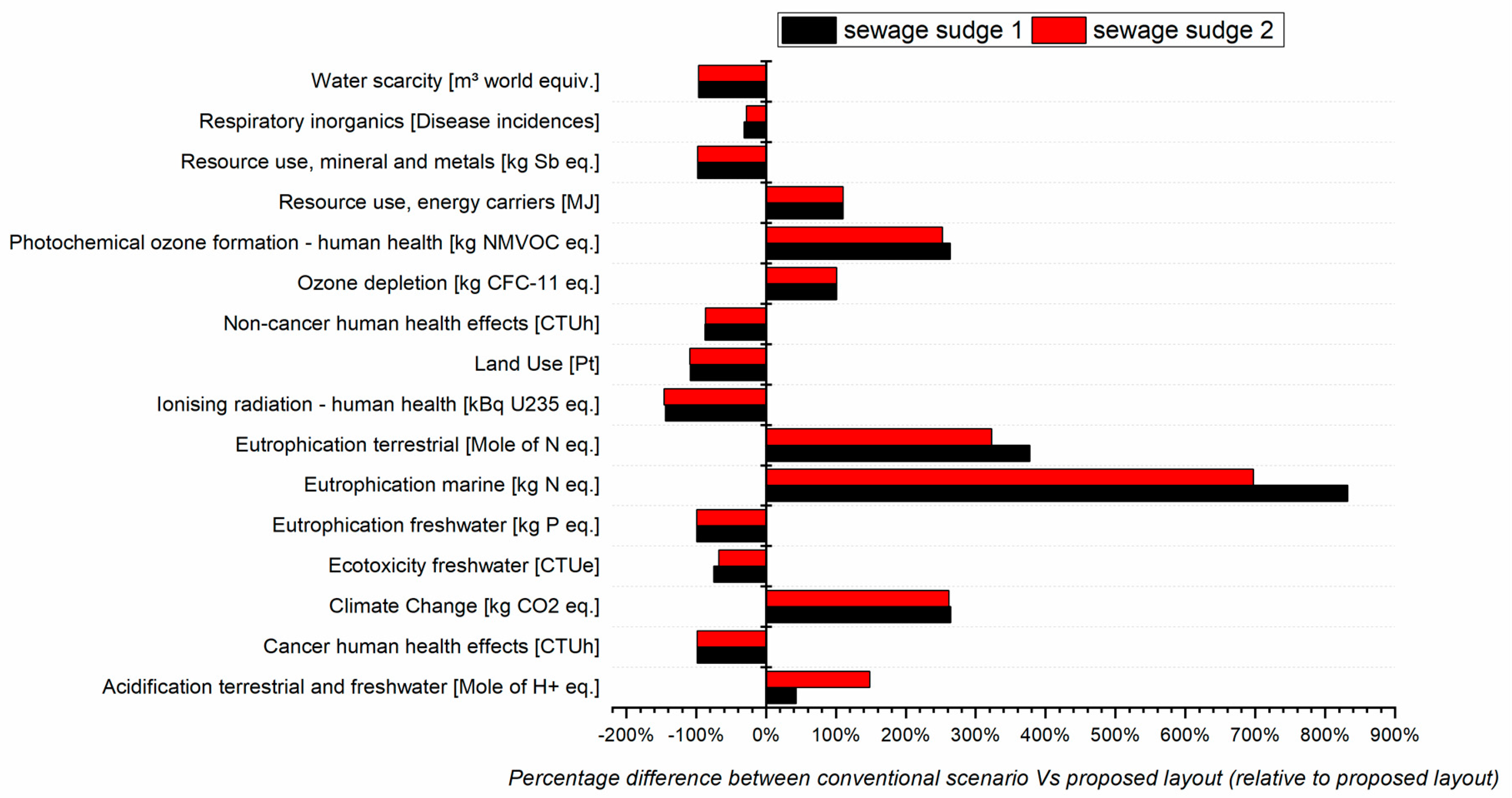

2.2. Life Cycle Assessment

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- FAO. Information System on Water and Agriculture; FAO: Rome, Italy.

- Bagheri, M.; Bauer, T.; Burgman, L.E.; Wetterlund, E. Fifty years of sewage sludge management research: Mapping researchers’ motivations and concerns. J. Environ. Manag. 2023, 325, 116412. [Google Scholar] [CrossRef]

- Eurostat. Eurostat—European Statistics, Database; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- ISPRA. Rapporto Rifiuti Speciali, 2nd ed.; ISPRA: Rome, Italy, 2018. [Google Scholar]

- Mininni, G.; Mauro, E.; Piccioli, B.; Colarullo, G.; Brandolini, F.; Giacomelli, P. Production and characteristics of sewage sludge in Italy. Water Sci. Technol. 2019, 79, 619–626. [Google Scholar] [CrossRef]

- Buonocore, E.; Mellino, S.; De Angelis, G.; Liu, G.; Ulgiati, S. Life cycle assessment indicators of urban wastewater and sewage sludge treatment. Ecol. Indic. 2018, 94, 13–23. [Google Scholar] [CrossRef]

- Kacprzak, M.; Neczaj, E.; Fijałkowski, K.; Grobelak, A.; Grosser, A.; Worwag, M.; Rorat, A.; Brattebo, H.; Almås, Å.; Singh, B.R. Sewage sludge disposal strategies for sustainable development. Environ. Res. 2017, 156, 39–46. [Google Scholar] [CrossRef]

- Zhang, H.; Rigamonti, L.; Visigalli, S.; Turolla, A.; Gronchi, P.; Canziani, R. Environmental and economic assessment of electro-dewatering application to sewage sludge: A case study of an Italian wastewater treatment plant. J. Clean. Prod. 2019, 210, 1180–1192. [Google Scholar] [CrossRef]

- Migliaccio, R.; Brachi, P.; Montagnaro, F.; Papa, S.; Tavano, A.; Montesarchio, P.; Ruoppolo, G.; Urciuolo, M. Sewage Sludge Gasification in a Fluidized Bed: Experimental Investigation and Modeling. Ind. Eng. Chem. Res. 2021, 60, 5034–5047. [Google Scholar] [CrossRef]

- Niu, X.; Shen, L.; Jiang, S.; Gu, H.; Xiao, J. Combustion performance of sewage sludge in chemical looping combustion with bimetallic Cu-Fe oxygen carrier. Chem. Eng. J. 2016, 294, 185–192. [Google Scholar] [CrossRef]

- Bareschino, P.; Mancusi, E.; Urciuolo, M.; Paulillo, A.; Chirone, R.; Pepe, F. LCA and Feasibility Analysis of a Combined Chemical Looping Combustion and Power-to-Methane System for CO2 Capture and Utilization. Renew. Sustain. Energy Rev. 2020, 130, 109962. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- Bareschino, P.; Mancusi, E.; Urciuolo, M.; Coppola, A.; Solimene, R.; Pepe, F.; Chirone, R.; Salatino, P. Modelling of a combined biomass CLC combustion and renewable-energy-based methane production system for CO2 utilization. Powder Technol. 2020, 373, 421–432. [Google Scholar] [CrossRef]

- Rönsch, S.; Schneider, J.; Matthischke, S.; Schlüter, M.; Götz, M.; Lefebvre, J.; Prabhakaran, P.; Bajohr, S. Review on methanation—From fundamentals to current projects. Fuel 2016, 166, 276–296. [Google Scholar] [CrossRef]

- Soleimani, S.; Lehner, M. Tri-Reforming of Methane: Thermodynamics, Operating Conditions, Reactor Technology and Efficiency Evaluation—A Review. Energies 2022, 15, 7159. [Google Scholar] [CrossRef]

- Brachi, P.; Bareschino, P.; Tregambi, C.; Pepe, F.; Urciuolo, M.; Ruoppolo, G.; Mancusi, E. Assessing the feasibility of an integrated CLC-methanation system using solar dried and torrefied biomasses as a feedstock. Fuel 2023, 331, 125951. [Google Scholar] [CrossRef]

- Gómez, L.; Martínez, I.; Navarro, M.V.; García, T.; Murillo, R. Sorption-enhanced CO and CO2 methanation (SEM) for the production of high purity methane. Chem. Eng. J. 2022, 440, 135842. [Google Scholar] [CrossRef]

- Ferrero, D.; Lanzini, A.; Santarelli, M.; Leone, P. A comparative assessment on hydrogen production from low- and high-temperature electrolysis. Int. J. Hydrogen Energy 2013, 38, 3523–3536. [Google Scholar] [CrossRef]

- Peters, M.S.; Timmerhaus, K.D.; West, R.E.; Timmerhaus, K.; West, R. Plant Design and Economics for Chemical Engineers; McGraw-Hill: New York, NY, USA, 2003. [Google Scholar]

- Lyngfelt, A.; Leckner, B. A 1000MWth boiler for chemical-looping combustion of solid fuels—Discussion of design and costs. Appl. Energy 2015, 157, 475–487. [Google Scholar] [CrossRef]

- Diglio, G.; Hanak, D.P.; Bareschino, P.; Mancusi, E.; Pepe, F.; Montagnaro, F.; Manovic, V. Techno-economic analysis of sorption-enhanced steam methane reforming in a fixed bed reactor network integrated with fuel cell. J. Power Sources 2017, 364, 41–51. [Google Scholar] [CrossRef]

- M.I.T., Pubblicazione del 9.luglio.2015 concernente i valori indicativi di riferimento dei costi di esercizio dell’impresa di autotrasporto per conto di terzi. 2015, 3.

- ISO 14044:2006/Amd 2:2020; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland; Amendment 2: London, UK, 2020.

- Deloitte Consulting. Energy Market Reform in Europe European Energy and Climate Policies: Achievements and Challenges to 2020 and Beyond; International Atomic Energy Agency: Vienna, Austria, 2020. [Google Scholar]

- Clift, R.; Doig, A.; Finnveden, G. The application of Life Cycle Assessment to Integrated Solid Waste Management. Part 1—Methodology. Process Saf. Environ. Prot. 2000, 78, 279–287. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (Part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Zhang, X.; Bauer, C.; Mutel, C.L.; Volkart, K. Life Cycle Assessment of Power-to-Gas: Approaches, system variations and their environmental implications. Appl. Energy 2017, 190, 326–338. [Google Scholar] [CrossRef]

- Mistry, M.; Gediga, J.; Boonzaier, S. Life cycle assessment of nickel products. Int. J. Life Cycle Assess. 2016, 21, 1559–1572. [Google Scholar] [CrossRef]

- Thorne, R.J.; Bouman, E.A.; Sundseth, K.; Aranda, A.; Czakiert, T.; Pacyna, J.M.; Pacyna, E.G.; Krauz, M.; Celińska, A. Environmental impacts of a chemical looping combustion power plant. Int. J. Greenh. Gas Control. 2019, 86, 101–111. [Google Scholar] [CrossRef]

- Fazio, S.; Castellani, V.; Sala, S.; Schau, E.; Secchi, M.; Zampori, L.; Diaconu, E. Supporting Information to the Characterisation Factors of Recommended EF Life Cycle Impact Assessment Method; JRC Technical Reports; New Models and Differences with ILCD Contents; European Commission: Brussels, Belgium, 2018. [Google Scholar] [CrossRef]

- Joint Research Centre. Product Environmental Footprint Category Rules Guidance, Version 6.3; Joint Research Centre: Brussels, Belgium, 2018. [Google Scholar]

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S.I. Life Cycle Assessment: Theory and Practice; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Tenhumberg, N.; Büker, K. Ecological and Economic Evaluation of Hydrogen Production by Different Water Electrolysis Technologies. Chem. Ing. Tech. 2020, 92, 1586–1595. [Google Scholar] [CrossRef]

| Sewage Sludge 1 | Sewage Sludge 2 | ConventionalEnd of Life | |||

|---|---|---|---|---|---|

| 1 kg–10%wt water content into CLOU system | |||||

| Conditioning and mechanical drying | |||||

| Sewage sludge | kg | 9.00 | 9.00 | 9.00 | |

| Polyacrylamide | kg | 1.06 × 10−2 | 1.06 × 10−2 | 1.06 × 10−2 | |

| Electricity | kWh | 7.44 × 10−2 | 7.44 × 10−2 | 7.44 × 10−2 | |

| Thermal drying | |||||

| Energy | kWh | 2.36 | 2.36 | - | |

| CLOU | |||||

| OC | kg | 8.62 × 10−3 | 6.67 × 10−3 | - | |

| Air | kg | 3.86 | 3.86 | - | |

| Produced thermal energy | kWh | 2.59 | 2.68 | - | |

| PEM | |||||

| H2O | kg | 6.91 | 6.91 | - | |

| Renewable electricity | kWh | 1.79 | 1.79 | - | |

| MU | |||||

| CO2 produced in CLOU | kg | 2.11 | 2.11 | - | |

| H2 produced in PEM | kg | 3.84 × 10−1 | 3.84 × 10−1 | - | |

| Methane | kg | 7.37 × 10−1 | 7.37 × 10−1 | - | |

| Ni catalyst | kg | 1.47 × 10−5 | 1.47 × 10−5 | - | |

| Transport | |||||

| Cargo | kg | 3.15 × 10−1 | 2.50 × 10−1 | 4.17 | |

| Diesel | kg | 1.80 × 10−3 | 1.43 × 10−3 | 2.44 × 10−2 | |

| Single way | km | 3.00 × 102 | 3.00 × 102 | 3.00 × 102 | |

| Landfill | |||||

| Ash | kg | 3.06 × 10−1 | 2.43 × 10−1 | - | |

| OC spent | kg | 8.62 × 10−3 | 6.67 × 10−3 | - | |

| Catalyst | kg | 1.47 × 10−5 | 1.47 × 10−5 | - | |

| Sewage | kg | - | - | 4.17 | |

| Electricity | kWh | - | - | 9.66 × 10−1 | |

| Sewage Sludge 1 | Sewage Sludge 2 | Reference | |

|---|---|---|---|

| EUR/kg | EUR/kg | EUR/kg | |

| Conditioning and drying | |||

| Polyacrylamide | 1.48 × 10−2 | 1.48 × 10−2 | 1.48 × 10−2 |

| Mechanical drying | 5.36 × 10−3 | 5.36 × 10−3 | 5.36 × 10−3 |

| Thermal drying | 1.68 × 10−2 | 1.68 × 10−2 | - |

| CLOU system | |||

| Reactors | 2.77 × 10−2 | 2.77 × 10−2 | - |

| Cyclone | 6.49 × 10−3 | 6.49 × 10−3 | - |

| Compressors | 8.46 × 10−3 | 8.46 × 10−3 | - |

| OC (inventory) | 8.74 × 10−4 | 8.74 × 10−4 | - |

| Heat exchanger | 2.37 × 10−2 | 2.37 × 10−2 | - |

| OC (replacement) | 1.51 × 10−3 | 1.17 × 10−3 | - |

| Produced thermal energy | 1.21 × 10−1 | 1.21 × 10−1 | - |

| Electric energy | 2.46 × 10−3 | 2.46 × 10−3 | - |

| Hydrogen production system | |||

| PEM | 2.67 × 10−1 | 2.67 × 10−1 | - |

| Water | 1.34 × 10−2 | 1.34 × 10−2 | - |

| Electric energy | 4.83 | 4.83 | - |

| Methanation unit | |||

| Reactors | 4.36 × 10−2 | 4.36 × 10−2 | - |

| Compressors | 3.55 × 10−2 | 3.55 × 10−2 | - |

| Catalyst (inventory) | 1.40 × 10−2 | 1.40 × 10−2 | - |

| Methane | 4.00 × 10−1 | 4.00 × 10−1 | - |

| Catalyst (replacement) | 6.62 × 10−4 | 6.62 × 10−4 | - |

| Electric energy | 9.58 × 10−3 | 9.58 × 10−3 | - |

| Produced thermal energy | 2.20 × 10−2 | 2.20 × 10−2 | - |

| Transport | |||

| Diesel | 3.28 × 10−3 | 2.60 × 10−3 | 4.44 × 10−2 |

| Single way | 5.24 × 10−3 | 5.24 × 10−3 | 5.24 × 10−3 |

| Landfilling | |||

| Ash | 1.53 × 10−1 | 1.22 × 10−1 | - |

| OC spent | 4.31 × 10−3 | 3.34 × 10−3 | - |

| Ni catalyst | 7.35 × 10−6 | 7.35 × 10−6 | - |

| Sewage | - | - | 2.09 |

| Produced electric energy | - | - | 6.52 × 10−2 |

| Total | |||

| TCRs + TCLs | 5.03 | 5.00 | 2.15 |

| Rs | 5.21 × 10−1 | 5.21 × 10−1 | 6.52 × 10−2 |

| CEoL | 4.51 | 4.48 | 2.09 |

| Sludge Transportation Scenario | Oxygen Carrier Replacement Ratio Scenario | Energy Consumption PEM Scenario | |||||||

|---|---|---|---|---|---|---|---|---|---|

| +5% | +10% | +25% | +5% | +10% | +25% | +5% | +10% | +25% | |

| variation (from baseline) | |||||||||

| Acidification terrestrial and freshwater | 0% | 0% | 0% | 10% | 21% | 52% | 8% | 16% | 40% |

| Cancer human health effects | 0% | 0% | 0% | 0% | 0% | 1% | 5% | 10% | 24% |

| Climate change | 0% | 0% | 0% | 0% | 1% | 2% | 1% | 2% | 6% |

| Ecotoxicity freshwater | 0% | 0% | 0% | 5% | 11% | 26% | 1% | 1% | 3% |

| Eutrophication freshwater | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| Eutrophication marine | 0% | 0% | 1% | 5% | 10% | 26% | 15% | 29% | 74% |

| Eutrophication terrestrial | 0% | 0% | 1% | 6% | 11% | 28% | 13% | 26% | 65% |

| Ionising radiation–human health | 0% | 0% | 0% | 1% | 2% | 5% | 4% | 9% | 21% |

| Land use | 0% | 0% | 1% | 1% | 2% | 4% | 6% | 11% | 28% |

| Non-cancer human health effects | 0% | 0% | 0% | 1% | 1% | 3% | 3% | 7% | 17% |

| Ozone depletion | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| Photochemical ozone formation–human health | 0% | 0% | 0% | 2% | 4% | 9% | 4% | 8% | 20% |

| Resource use, energy carriers | 0% | 0% | 0% | 0% | 1% | 2% | 1% | 2% | 4% |

| Resource use, mineral and metals | 0% | 0% | 0% | 2% | 5% | 12% | 3% | 5% | 14% |

| Respiratory inorganics | 0% | 0% | 0% | 1% | 2% | 6% | 4% | 8% | 20% |

| Water scarcity | 0% | 0% | 0% | 1% | 1% | 4% | 1% | 2% | 4% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bareschino, P.; Chirone, R.; Paulillo, A.; Tregambi, C.; Urciuolo, M.; Pepe, F.; Mancusi, E. Techno-Economic and Environmental Analysis of a Sewage Sludge Alternative Treatment Combining Chemical Looping Combustion and a Power-to-Methane System. Energies 2024, 17, 901. https://doi.org/10.3390/en17040901

Bareschino P, Chirone R, Paulillo A, Tregambi C, Urciuolo M, Pepe F, Mancusi E. Techno-Economic and Environmental Analysis of a Sewage Sludge Alternative Treatment Combining Chemical Looping Combustion and a Power-to-Methane System. Energies. 2024; 17(4):901. https://doi.org/10.3390/en17040901

Chicago/Turabian StyleBareschino, Piero, Roberto Chirone, Andrea Paulillo, Claudio Tregambi, Massimo Urciuolo, Francesco Pepe, and Erasmo Mancusi. 2024. "Techno-Economic and Environmental Analysis of a Sewage Sludge Alternative Treatment Combining Chemical Looping Combustion and a Power-to-Methane System" Energies 17, no. 4: 901. https://doi.org/10.3390/en17040901