A Comprehensive Review on the Power Supply System of Hydrogen Production Electrolyzers for Future Integrated Energy Systems

Abstract

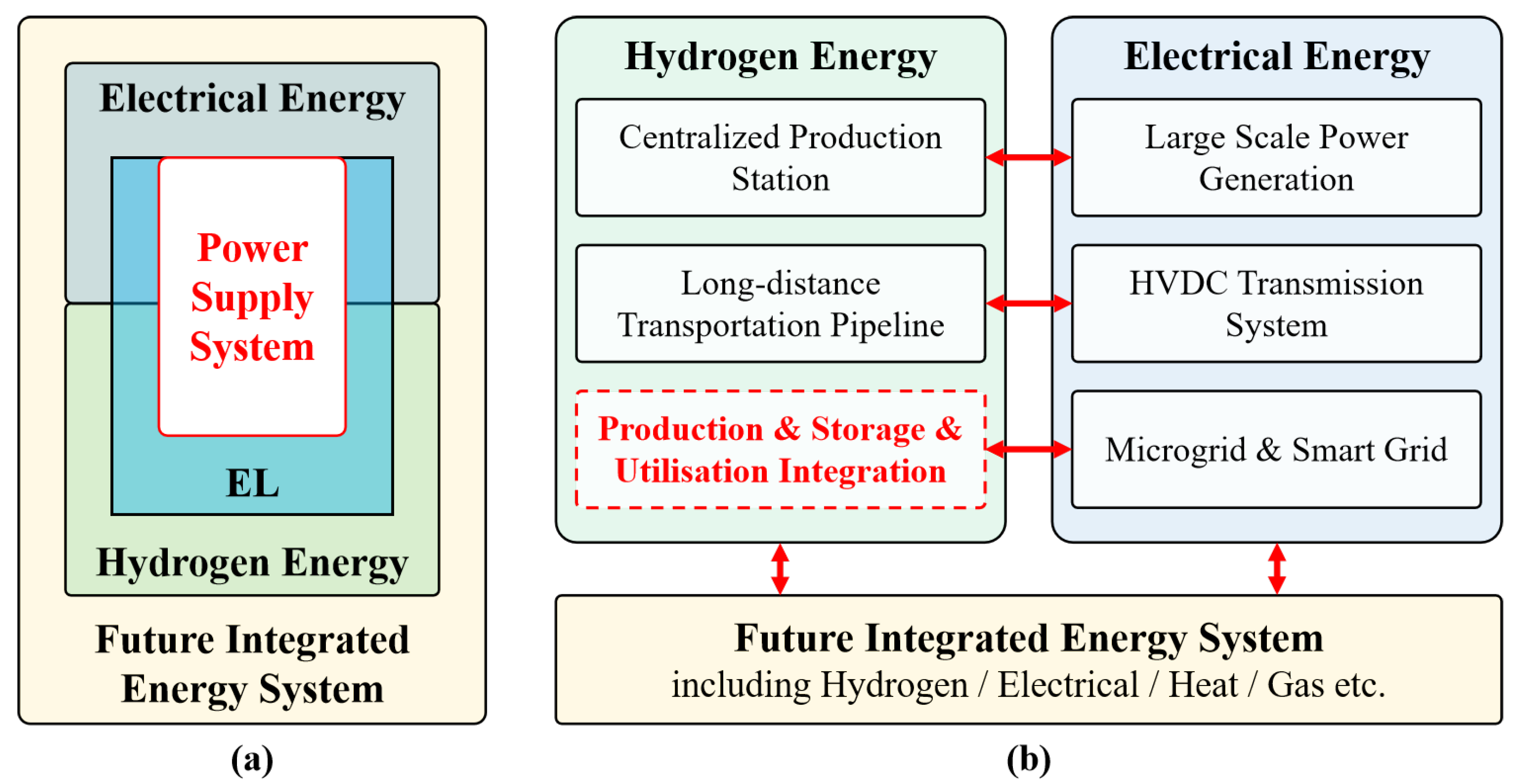

1. Introduction

2. Hydrogen Electrolyzer

2.1. Water Electrolysis Methods

2.2. EL Market

3. Electrical Interface Modelling of EL

3.1. Thermodynamics and Electrochemical Models

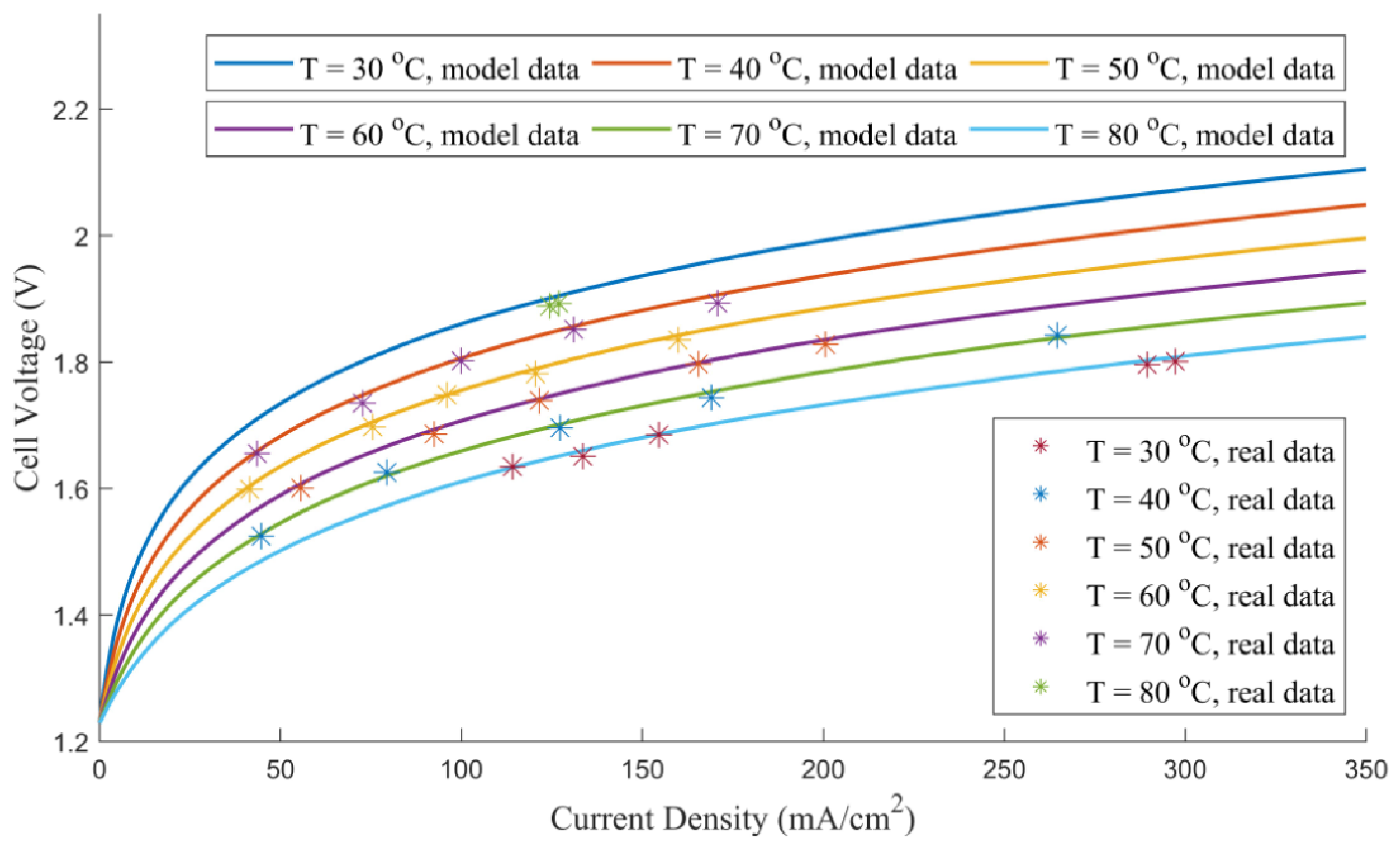

3.2. Empirical Model

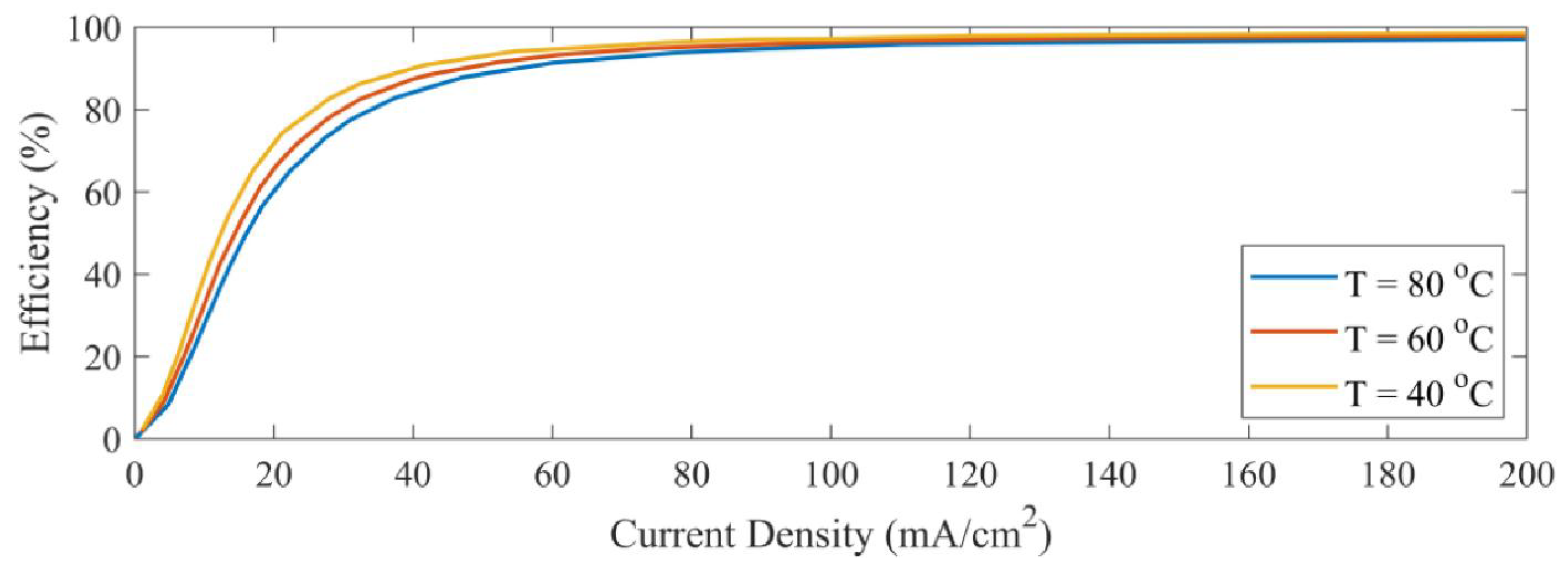

3.3. Hydrogen Production Efficiency Model

- Improving operating conditions, including the application of forced electrolyte flow and increasing reaction temperature and pressure;

- Improve the structure of ELs, such as zero gap ELs, membrane free ELs, etc.;

- Optimise diaphragm materials;

- Improve catalyst effectiveness;

- Change the physical field of operation.

3.4. Characteristic Requirements of EL Power Supply

4. Topologies of the EL Power Supply

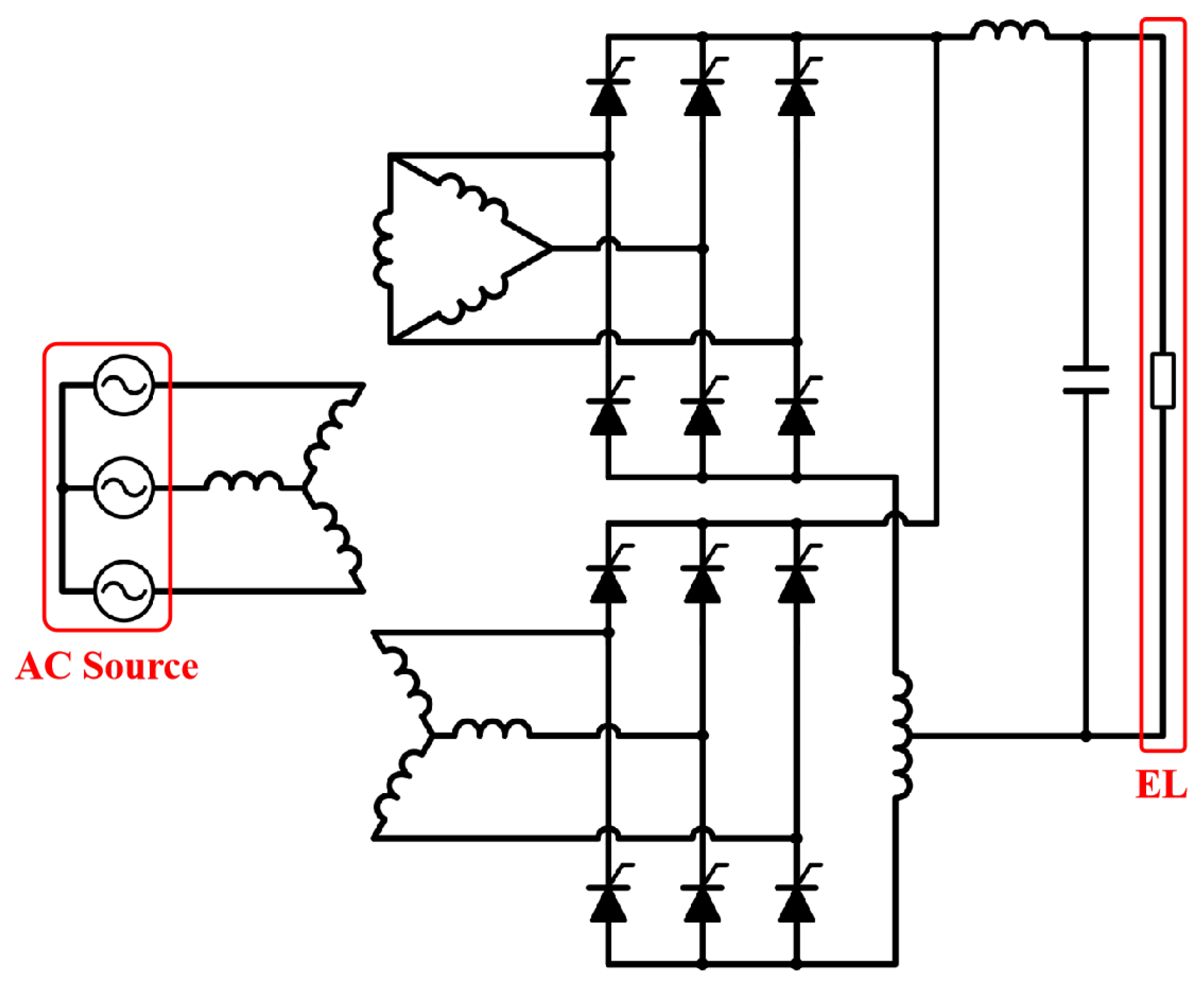

4.1. Single-Stage AC Source-Based Topologies

4.2. Single-Stage DC Source-Based Topology

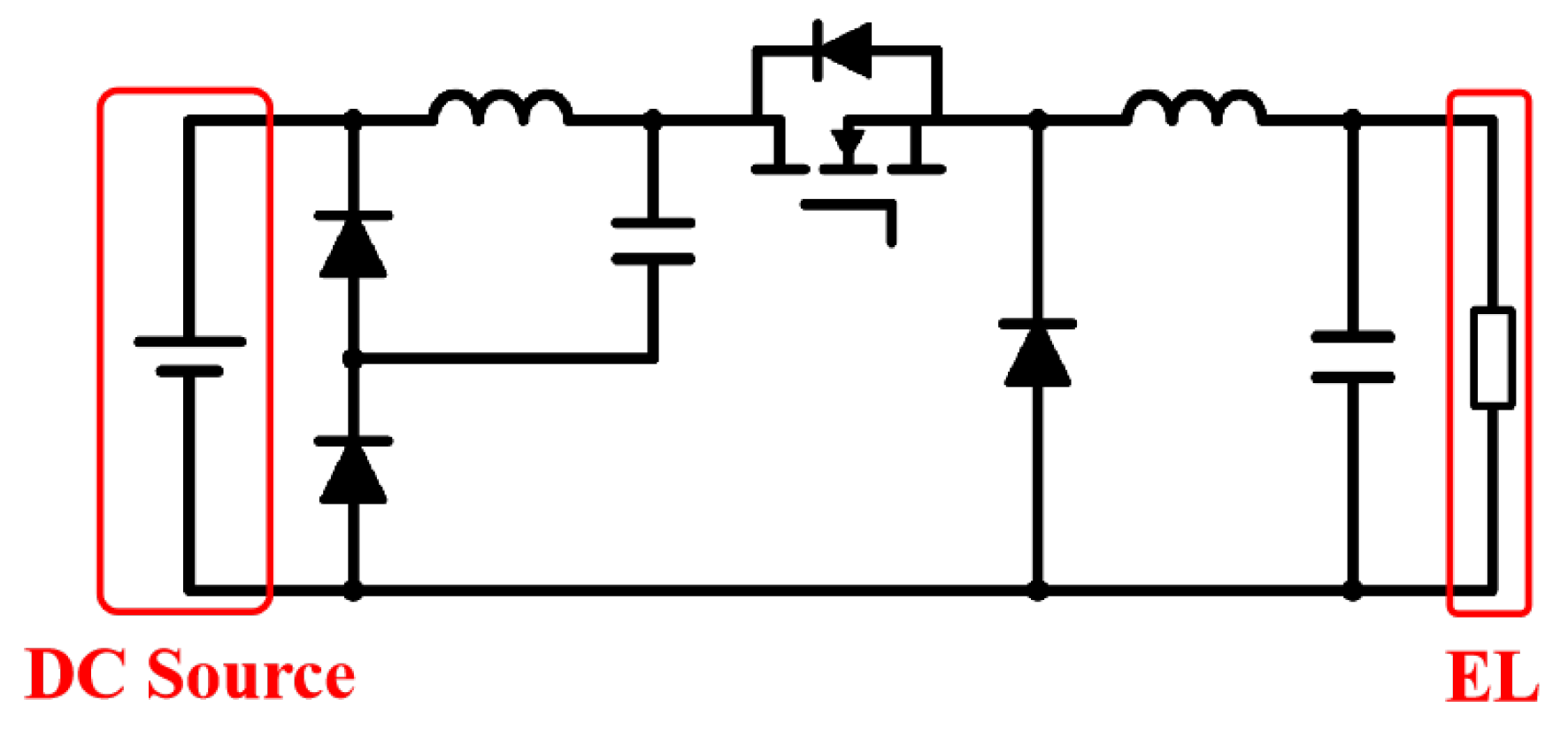

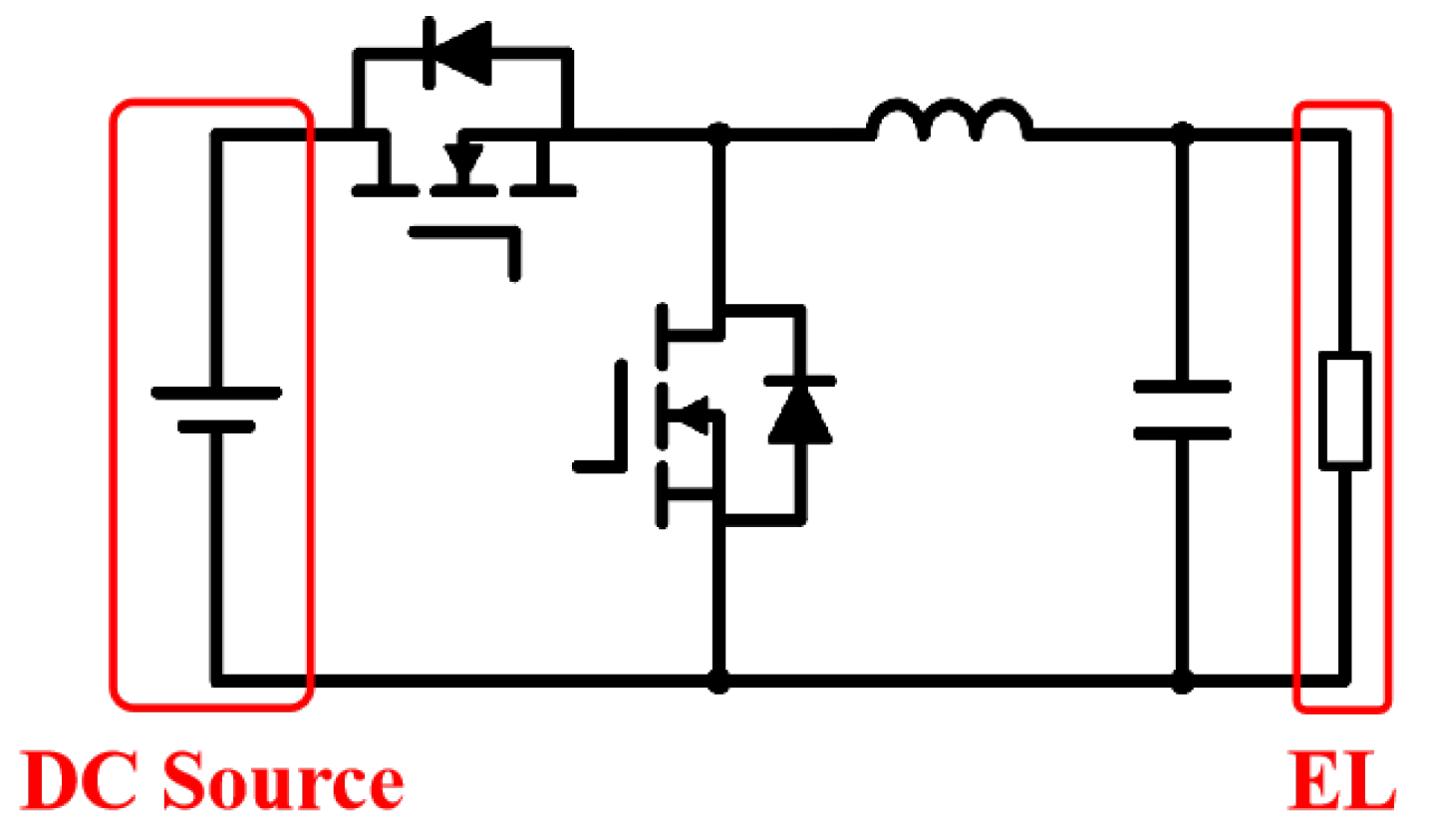

4.2.1. Non-Isolated DC/DC

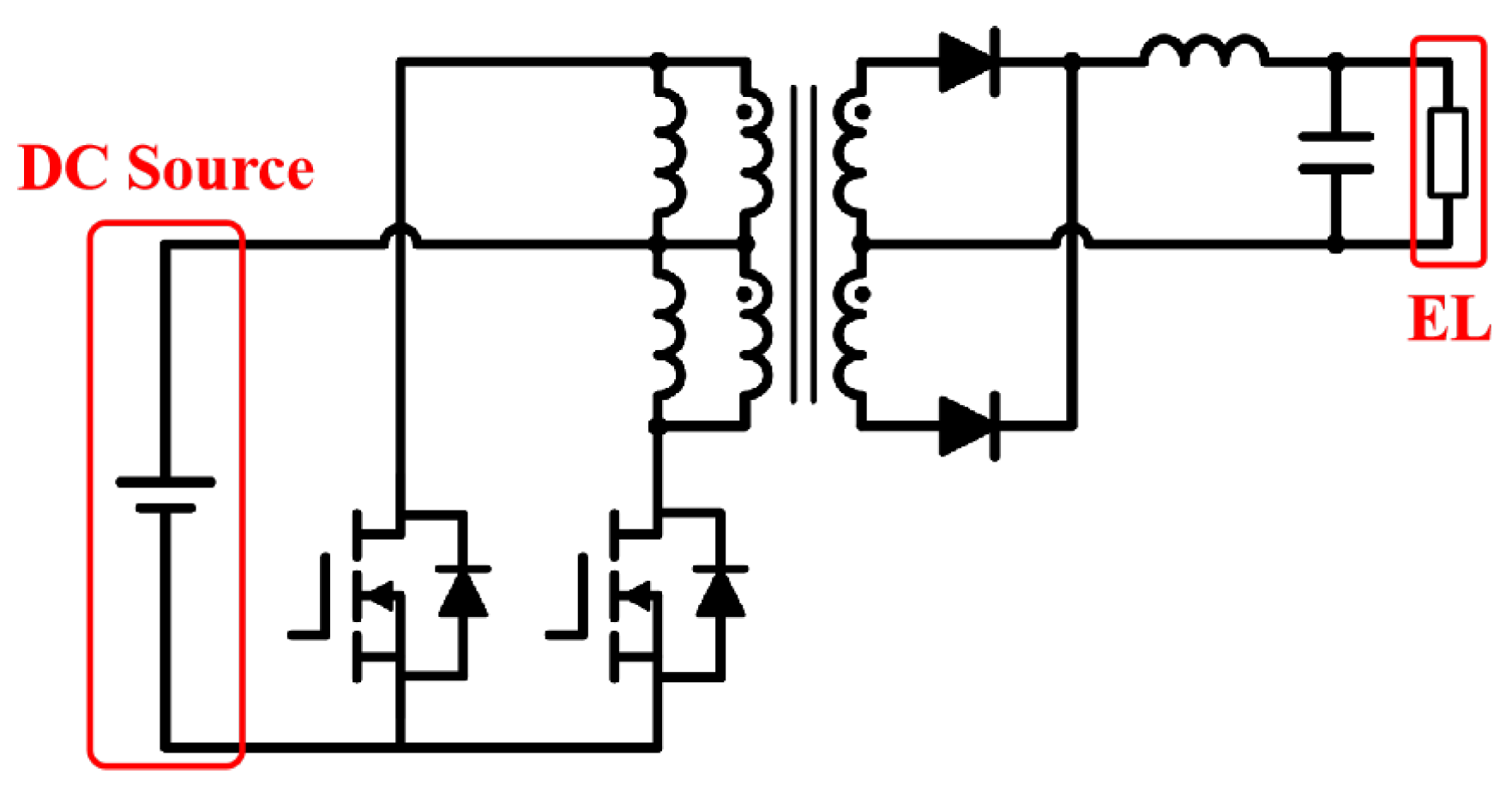

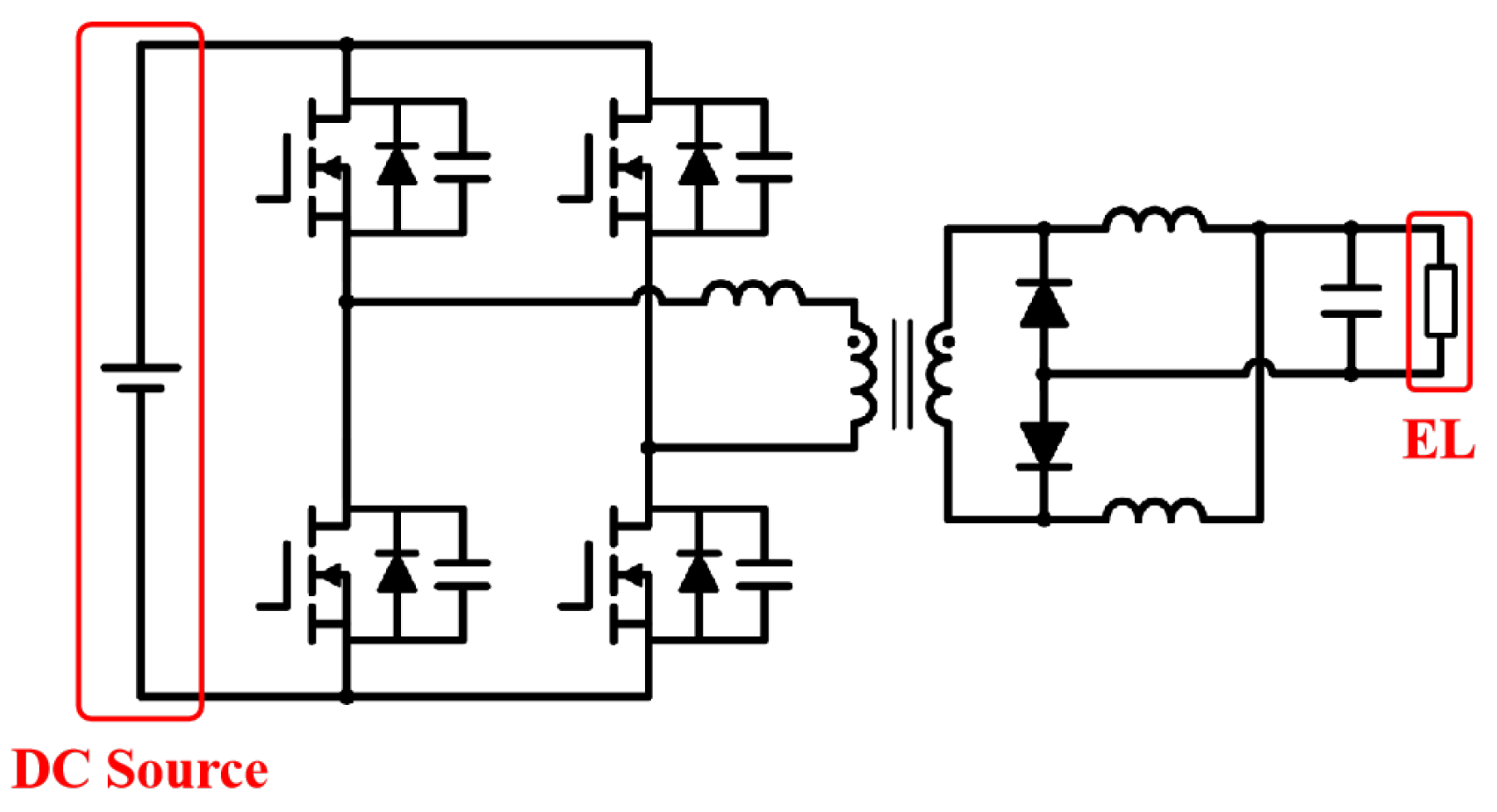

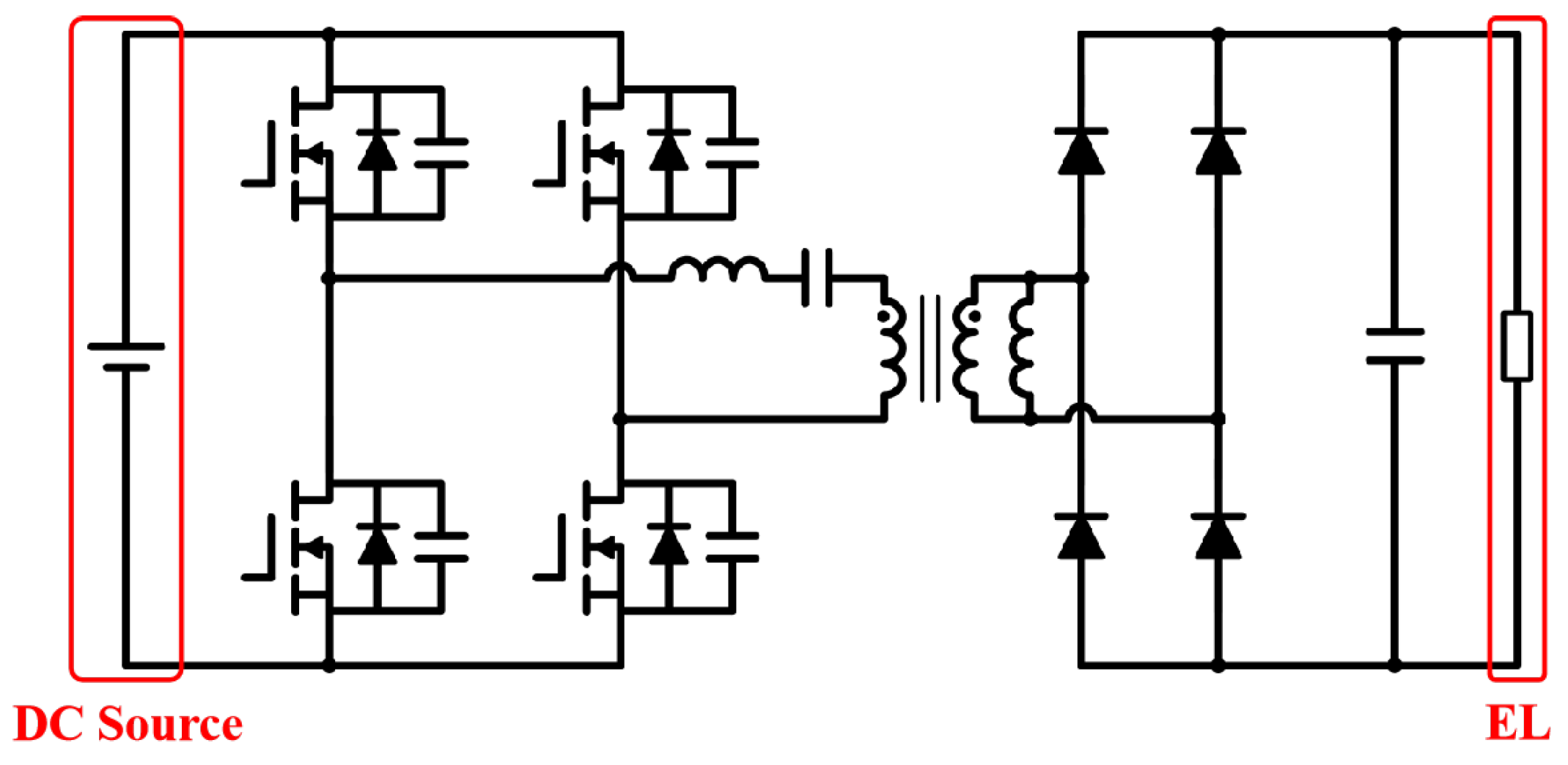

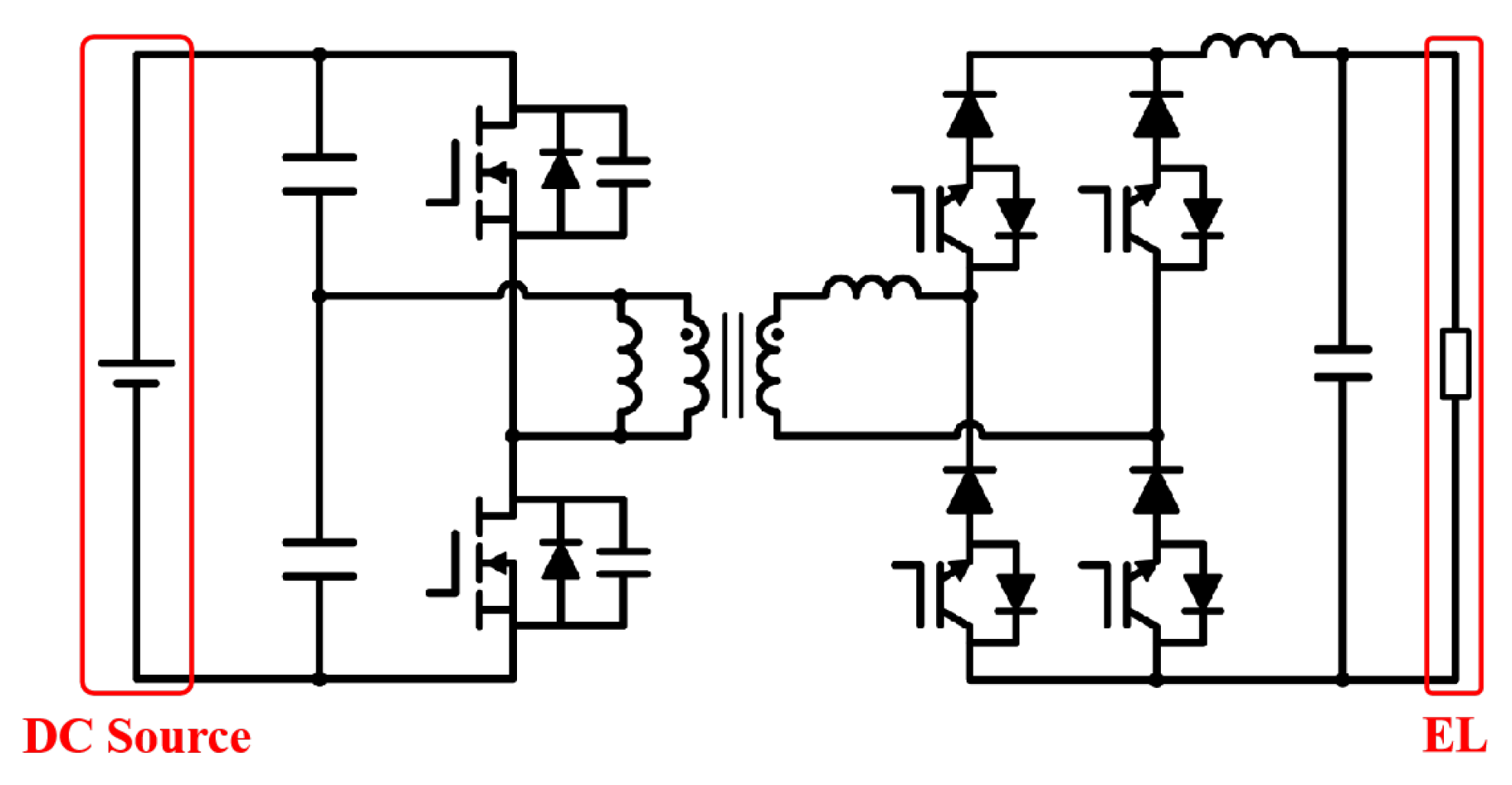

4.2.2. Isolated DC/DC

4.3. Hybrid Topology

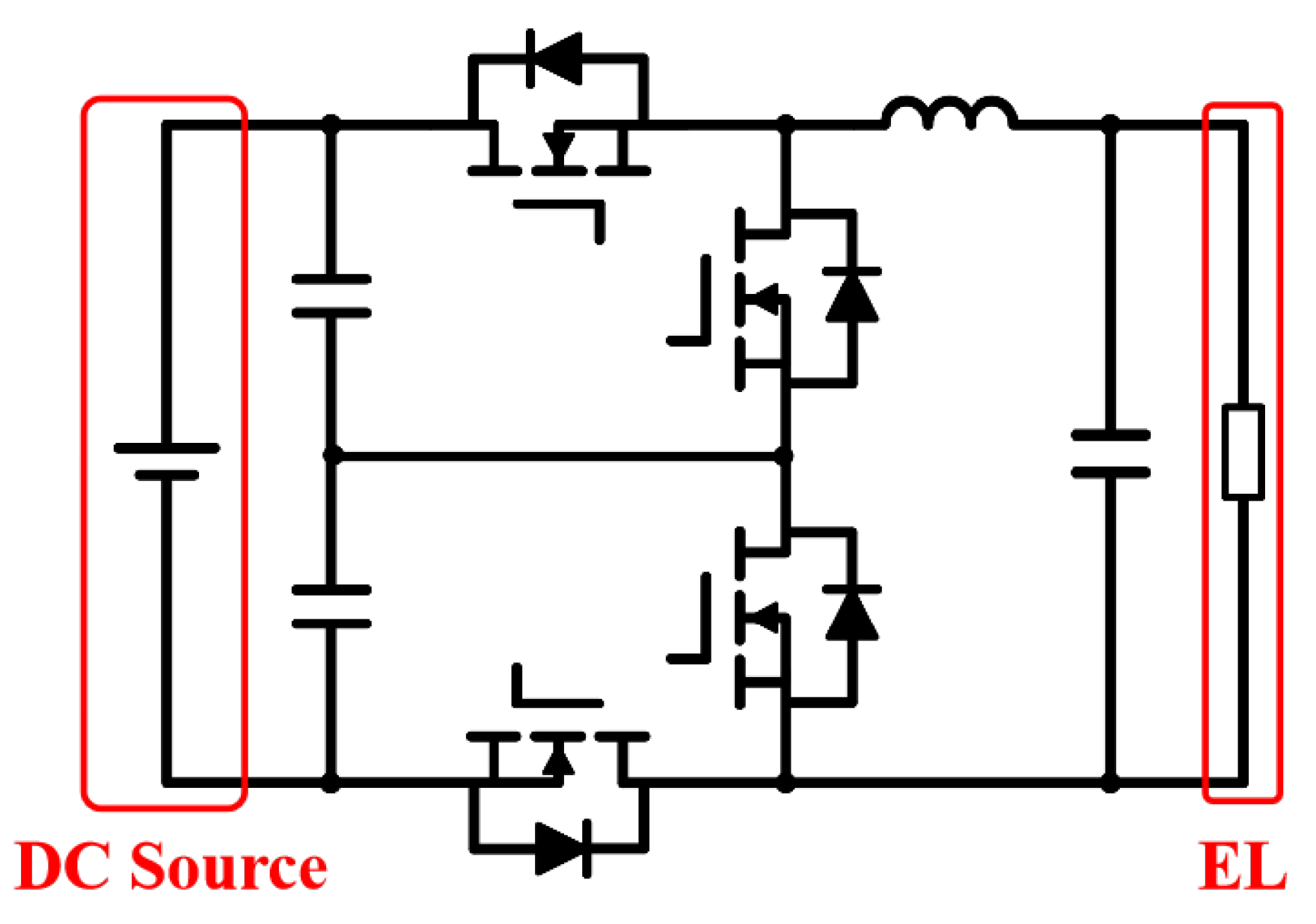

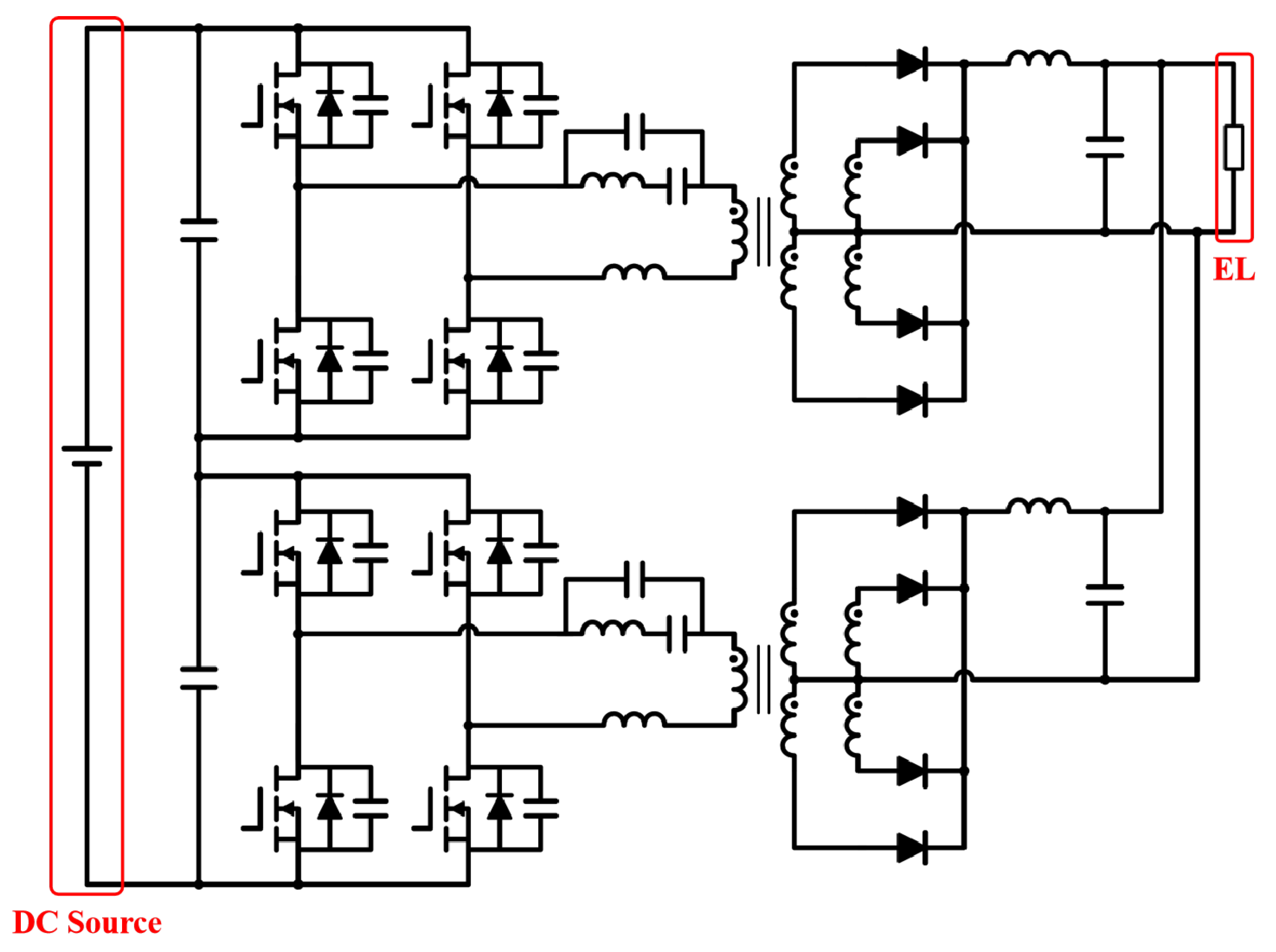

4.3.1. Interleaved Parallel Connection

4.3.2. Multi-Stage Serial Connection

4.3.3. Other Hybrid Topologies

4.4. Comparison and Analysis

- Designing redundant parallel branches is a commonly used method to improve the fault tolerance and converter reliability [117].

- The efficiency of parallel topologies is close to that of its single-stage counter part, while the efficiency of serial topologies is the product of each stage’s efficiency [118].

- The ripples of the output current can be reduced by increasing the inductance and capacitance of the filter, increasing the switching frequency, and applying an interleaved parallel configuration [119,120,121]. However, increasing inductance and capacitance will inevitably increase the size of these magnetic components, and consequently, the power density drops. Additionally, increasing the switching frequency brings great challenges to the thermal design and suppression of switching loss in semiconductors. The interleaved parallel configuration becomes the most suitable solution for reducing current ripples.

5. Control Framework of the EL Power Supply in Future Integrated Energy Systems

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CCUS | carbon capture and carbon sequestration |

| FC | fuel cell |

| WE | water electrolysis |

| EL | electrolyzer |

| ALK | alkaline |

| PEM | proton exchange membrane |

| AEM | anion exchange membrane |

| SOE | solid oxide electrolyzer |

| IGBT | insulated gate bipolar transistor |

| MOSFET | metal oxide semiconductor field effect transistor |

| SiC | silicon carbide |

| GaN | gallium nitride |

| PSFB | phase-shift full-bridge |

| IBC | interleaved buck converter |

| CIBC | classic interleaved buck converter |

| SIBC | stacked interleaved buck converter |

| TLIBC | three level interleaved buck converter |

| ISOP | input-serial–output-parallel |

| PWM | pulse width modulation |

| ZVS | zero-voltage switching |

| MPPT | maximum power point tracking |

References

- Hua, H.; Shi, J.; Chen, X.; Qin, Y.; Wang, B.; Yu, K.; Naidoo, P. Carbon Emission Flow Based Energy Routing Strategy in Energy Internet. IEEE Trans. Ind. Inform. 2023, 1–12. [Google Scholar] [CrossRef]

- Liang, H.; Hua, H.; Qin, Y.; Ye, M.; Zhang, S.; Cao, J. Stochastic Optimal Energy Storage Management for Energy Routers Via Compressive Sensing. IEEE Trans. Ind. Inform. 2022, 18, 2192–2202. [Google Scholar] [CrossRef]

- Hua, H.; Qin, Z.; Dong, N.; Qin, Y.; Ye, M.; Wang, Z.; Chen, X.; Cao, J. Data-Driven Dynamical Control for Bottom-up Energy Internet System. IEEE Trans. Sustain. Energy 2022, 13, 315–327. [Google Scholar] [CrossRef]

- Hao, C.; Qin, Y.; Hua, H. Energy “Routers”, “Computers” and “Protocols”; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Pan, G.; Gu, Z.; Luo, E.; Gu, W. Analysis and Prospect of Electrolytic Hydrogen Technology Under Background of New Power Systems. Autom. Electr. Power Syst. 2023, 47, 1–13. [Google Scholar] [CrossRef]

- Xu, S. Current Development and Prospect of Hydrogen Energy Technology in China. J. Beijing Inst. Technol. (Soc. Sci. Ed.) 2021, 23, 1–12. [Google Scholar] [CrossRef]

- Yu, H.; Shao, Z.; Hou, M.; Yi, B.; Duan, F.; Yang, Y. Hydrogen Production by Water Electrolysis: Progress and Suggestions. Chin. J. Eng. Sci. 2021, 23, 146–152. [Google Scholar] [CrossRef]

- Medium and Long-Term Plan for the Development of Hydrogen Energy Industry (2021–2035). Available online: http://zfxxgk.nea.gov.cn/2022-03/23/c_1310525630.htm (accessed on 9 October 2023).

- The U.S. National Clean Hydrogen Strategy and Roadmap. Available online: https://www.hydrogen.energy.gov/library/roadmaps-vision/clean-hydrogen-strategy-roadmap (accessed on 9 October 2023).

- Strategic Research and Innovation Agenda 2021–2027. Available online: https://www.clean-hydrogen.europa.eu/about-us/key-documents/strategic-research-and-innovation-agenda (accessed on 9 October 2023).

- UK Hydrogen Strategy. Available online: https://www.gov.uk/government/publications/uk-hydrogen-strategy (accessed on 9 October 2023).

- The National Hydrogen Strategy. Available online: https://www.bmbf.de/files/bmwi-Nationale (accessed on 9 October 2023).

- National Strategy for Carbon-Free Hydrogen Energy Development. Available online: https://www.economie.gouv.fr/plan-de-relance/mesures/strategie-nationale-developpement-hydrogene-decarbone (accessed on 9 October 2023).

- The 6th Strategic Energy Plan. Available online: https://www.enecho.meti.go.jp/en/category/others/basic_plan/ (accessed on 9 October 2023).

- Clean Hydrogen Ecosystem Construction Plan. Available online: https://doc.msit.go.kr/SynapDocViewServer (accessed on 9 October 2023).

- Action Plan for the Development of Hydrogen Energy in the Russian Federation by 2024. Available online: http://government.ru/docs/40703/ (accessed on 9 October 2023).

- National Hydrogen Roadmap. Available online: https://www.csiro.au/en/news/All/News/2018/August/Roadmap-finds-Hydrogen-Industry-set-for-scale-up (accessed on 9 October 2023).

- Zhang, Z.; Zhao, Y.; Cai, N. Technological development status and prospect of hydrogen energy industry in China. Nat. Gas Ind. 2022, 42, 156–165. [Google Scholar] [CrossRef]

- David, M.; Ocampo-Martínez, C.; Sánchez-Peña, R. Advances in alkaline water electrolyzers: A review. J. Energy Storag. 2019, 23, 392–403. [Google Scholar] [CrossRef]

- Carmo, M.; Fritz, D.L.; Mergel, J.; Stolten, D. A comprehensive review on PEM water electrolysis. Int. J. Hydrogen Energy 2013, 38, 4901–4934. [Google Scholar] [CrossRef]

- Shiva Kumar, S.; Himabindu, V. Hydrogen production by PEM water electrolysis—A review. Mater. Sci. Energy Technol. 2019, 2, 442–454. [Google Scholar] [CrossRef]

- Ursua, A.; Gandia, L.M.; Sanchis, P. Hydrogen Production From Water Electrolysis: Current Status and Future Trends. Proc. IEEE 2012, 100, 410–426. [Google Scholar] [CrossRef]

- Hu, S.; Guo, B.; Ding, S.; Yang, F.; Dang, J.; Liu, B.; Gu, J.; Ma, J.; Ouyang, M. A comprehensive review of alkaline water electrolysis mathematical modeling. Appl. Energy 2022, 327, 120099. [Google Scholar] [CrossRef]

- Majumdar, A.; Haas, M.; Elliot, I.; Nazari, S. Control and control-oriented modeling of PEM water electrolyzers: A review. Int. J. Hydrogen Energy 2023, 48, 30621–30641. [Google Scholar] [CrossRef]

- Guilbert, D.; Collura, s.; Scipioni, A. DC/DC converter topologies for electrolyzers: State-of-the-art and remaining key issues. Int. J. Hydrogen Energy 2017, 42. [Google Scholar] [CrossRef]

- Guo, X.; Wei, Y.; Wan, Y.; Zhou, Y.; Kong, L.; Zhang, Z.; Lu, Z.; Hua, C.; Malinowski, M. Review on Power Electronic Converters for Producing Hydrogen from Renewable Energy Sources. Autom. Electr. Power Syst. 2021, 45, 185–199. [Google Scholar] [CrossRef]

- Li, D.; Park, E.; Zhu, W.; Shi, Q.; Zhou, Y.; Tian, H.; Lin, Y.; Serov, A.; Zulevi, B.; Baca, E.; et al. Highly quaternized polystyrene ionomers for high performance anion exchange membrane water electrolysers. Nat. Energy 2020, 5, 1–8. [Google Scholar] [CrossRef]

- Vasudevan, S. Electrolysis—Inevitable energy transformer in a world of sustainable energy. In Proceedings of the 2013 International Conference on Energy Efficient Technologies for Sustainability, Nagercoil, India, 10–12 April 2013; pp. 306–311. [Google Scholar] [CrossRef]

- Guilbert, D.; Vitale, G. Variable Parameters Model of a PEM Electrolyzer Based Model Reference Adaptive System Approach. In Proceedings of the 2020 IEEE International Conference on Environment and Electrical Engineering and 2020 IEEE Industrial and Commercial Power Systems Europe (EEEIC/ICPS Europe), Madrid, Spain, 9–12 June 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Terlouw, T.; Bauer, C.; Mckenna, R.; Mazzotti, M. Large-scale hydrogen production via water electrolysis: A techno-economic and environmental assessment. Energy Environ. Sci. 2022. [Google Scholar] [CrossRef]

- Falcão, D.; Pinto, A. A review on PEM electrolyzer modelling: Guidelines for beginners. J. Clean. Prod. 2020, 261, 121184. [Google Scholar] [CrossRef]

- Song, X.; Liang, D.; Song, J.; Xu, G.; Deng, Z.; Niu, M. Problems and Technology Development Trends of Hydrogen Production from Renewable Energy Power Electrolysis—A Review. In Proceedings of the 2021 IEEE 5th Conference on Energy Internet and Energy System Integration (EI2), Taiyuan, China, 22–24 October 2021; pp. 3879–3882. [Google Scholar] [CrossRef]

- Zhang, K.; Liang, X.; Wang, L.; Sun, K.; Wang, Y.; Xie, Z.; Wu, Q.; Bai, X.; Hamdy, M.; Chen, H.; et al. Status and perspectives of key materials for PEM electrolyzer. Nano Res. Energy 2022, 1, 9120032. [Google Scholar] [CrossRef]

- Pirom, W.; Srisiriwat, A. Experimental Study of Hybrid Photovoltaic-PEM Electrolyzer-PEM Fuel Cell System. In Proceedings of the 2022 International Electrical Engineering Congress (iEECON), Khon Kaen, Thailand, 9–11 March 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Ni, M.; Leung, M.K.; Leung, D.Y. Technological development of hydrogen production by solid oxide electrolyzer cell (SOEC). Int. J. Hydrogen Energy 2008, 33, 2337–2354. [Google Scholar] [CrossRef]

- Wappler, M.; Unguder, D.; Lu, X.; Ohlmeyer, H.; Teschke, H.; Lueke, W. Building the green hydrogen market—Current state and outlook on green hydrogen demand and electrolyzer manufacturing. Int. J. Hydrogen Energy 2022, 47, 33551–33570. [Google Scholar] [CrossRef]

- A Breakneck Growth Pivot Nears for Green Hydrogen. Available online: https://about.bnef.com/blog/a-breakneck-growth-pivot-nears-for-green-hydrogen/ (accessed on 9 October 2023).

- Varela, C.; Mostafa, M.; Zondervan, E. Modeling alkaline water electrolysis for power-to-x applications: A scheduling approach. Int. J. Hydrogen Energy 2021, 46, 9303–9313. [Google Scholar] [CrossRef]

- Iribarren, A.; Elizondo, D.; Barrios, E.L.; Ibaiondo, H.; Sanchez-Ruiz, A.; Arza, J.; Sanchis, P.; Ursúa, A. Dynamic Modeling of a Pressurized Alkaline Water Electrolyzer: A Multiphysics Approach. IEEE Trans. Ind. Appl. 2023, 59, 3741–3753. [Google Scholar] [CrossRef]

- Rahim, A.H.A.; Tijani, A.S.; Shukri, F.H.; Hanapi, S.; Sainan, K.I. Mathematical modelling and simulation analysis of PEM electrolyzer system for hydrogen production. In Proceedings of the 3rd IET International Conference on Clean Energy and Technology (CEAT) 2014, Kuching, Malaysia, 24–26 November 2014; pp. 1–7. [Google Scholar] [CrossRef]

- Abomazid, A.M.; El-Taweel, N.A.; Hany E. Z., F. Electrochemical Optimization Model for Parameters Identification of PEM Electrolyzer. In Proceedings of the 2020 IEEE Electric Power and Energy Conference (EPEC), Edmonton, AB, Canada, 9–10 November 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Omez, A.; Ramírez, V.; Guilbert, D. Investigation of PEM electrolyzer modeling: Electrical domain, efficiency, and specific energy consumption ScienceDirect. Int. J. Hydrogen Energy 2020, 45, 14625–14639. [Google Scholar] [CrossRef]

- Rizwan, M.; Alstad, V.; Jäschke, J. Design considerations for industrial water electrolyzer plants. Int. J. Hydrogen Energy 2021, 46, 37120–37136. [Google Scholar] [CrossRef]

- Guilbert, D.; Zasadzinski, M.; Rafaralahy, H.; Boutat-Baddas, L. Modeling of the dynamic behavior of a PEM electrolyzer. In Proceedings of the 2022 10th International Conference on Systems and Control (ICSC), Marseille, France, 23–25 November 2022; pp. 78–84. [Google Scholar] [CrossRef]

- Sakas, G.; Ibáñez-Rioja, A.; Ruuskanen, V.; Kosonen, A.; Ahola, J.; Bergmann, O. Dynamic energy and mass balance model for an industrial alkaline water electrolyzer plant process. Int. J. Hydrogen Energy 2022, 47, 4328–4345. [Google Scholar] [CrossRef]

- Ren, Z.; Wang, J.; Yu, Z.; Zhang, C.; Gao, S.; Wang, P. Experimental studies and modeling of a 250-kW alkaline water electrolyzer for hydrogen production. J. Power Source 2022, 544, 231886. [Google Scholar] [CrossRef]

- Ulleberg, Ø. Modeling of advanced alkaline electrolyzers: A system simulation approach. Int. J. Hydrogen Energy 2003, 28, 21–33. [Google Scholar] [CrossRef]

- Atlam, O.; Kolhe, M. Equivalent electrical model for a proton exchange membrane (PEM) electrolyser. Energy Convers. Manag. 2011, 52, 2952–2957. [Google Scholar] [CrossRef]

- Ojong, E.T.; Kwan, J.T.H.; Nouri-Khorasani, A.; Bonakdarpour, A.; Wilkinson, D.P.; Smolinka, T. Development of an experimentally validated semi-empirical fully-coupled performance model of a PEM electrolysis cell with a 3-D structured porous transport layer. Int. J. Hydrogen Energy 2017, 42, 25831–25847. [Google Scholar] [CrossRef]

- Zhou, J.; Meng, X.; Chen, Y.; Zhang, G. Research on DC Power Supply for Hydrogen Production from Electrolytic ater Based on New Energy Generation. Acta Energiae Solaris Sin. 2022, 43, 389–397. (In Chinese) [Google Scholar] [CrossRef]

- Guilbert, D.; Vitale, G. Dynamic Emulation of a PEM Electrolyzer by Time Constant Based Exponential Model. Energies 2019, 12, 750. [Google Scholar] [CrossRef]

- Keddar, M.; Da Conceicao, M.; Doumbia, M.L.; Zhang, Z. Electrolyzer Degradation influence on power electronics performance for 6-pulse thyristor rectifier in a large-scale water electrolyzer. In Proceedings of the 2022 13th International Renewable Energy Congress (IREC), Hammamet, Tunisia, 13–15 December 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Iribarren, A.; Barrios, E.L.; Ibaiondo, H.; Sanchez-Ruiz, A.; Arza, J.; Sanchis, P.; Ursúa, A. Modelling and Operation of 6-Pulse Thyristor Rectifiers for supplying High Power Electrolyzers. In Proceedings of the 2022 IEEE 23rd Workshop on Control and Modeling for Power Electronics (COMPEL), Tel Aviv, Israel, 20–23 June 2022; pp. 1–8. [Google Scholar] [CrossRef]

- Keddar, M.; Zhang, Z.; Periasamy, C.; Doumbia, M.L. Comparative analysis of thyristor-based and transistor-based rectifiers for PEM water electrolysis. In Proceedings of the 2021 12th International Renewable Energy Congress (IREC), Hammamet, Tunisia, 26–28 October 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Ruuskanen, V.; Koponen, J.; Kosonen, A.; Niemelä, M.; Ahola, J.; Hämäläinen, A. Power quality and reactive power of water electrolyzers supplied with thyristor converters. J. Power Source 2020, 459, 228075. [Google Scholar] [CrossRef]

- Rautela, P.; Kulkarni, R.D.; Deep Srivastava, G. Design Consideration of High Power High Current Twelve Pulse Thyristor Controlled Rectifiers. In Proceedings of the 2018 2nd International Conference on Power, Energy and Environment: Towards Smart Technology (ICEPE), Shillong, India, 1–2 June 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Solanki, J.; Fröhleke, N.; Böcker, J. Implementation of Hybrid Filter for 12-Pulse Thyristor Rectifier Supplying High-Current Variable-Voltage DC Load. IEEE Trans. Ind. Electron. 2015, 62, 4691–4701. [Google Scholar] [CrossRef]

- Rodriguez, J.; Pontt, J.; Silva, C.; Wiechmann, E.; Hammond, P.; Santucci, F.; Alvarez, R.; Musalem, R.; Kouro, S.; Lezana, P. Large current rectifiers: State of the art and future trends. IEEE Trans. Ind. Electron. 2005, 52, 738–746. [Google Scholar] [CrossRef]

- Li, Y.; Lou, Z.; Zhang, Z. Novel control scheme for 3-phase PWM current-source converters under unbalanced source voltage conditions. J. Zhejiang Univ.-Sci. A Appl. Phys. Eng. 2006, 7, 263–268. [Google Scholar] [CrossRef]

- Solanki, J.; Fröhleke, N.; Böcker, J.; Averberg, A.; Wallmeier, P. High-current variable-voltage rectifiers: State of the art topologies. IET Power Electron. 2015, 8, 1068–1080. [Google Scholar] [CrossRef]

- Guo, Q.; Liu, H.; Peng, D.; Liu, Q.; Zhang, Y. A multi-loop control strategy and parameter design for current-source PWM rectifiers. Zhongguo Dianji Gongcheng Xuebao/Proc. Chin. Soc. Electr. Eng. 2015, 35, 1193–1202. [Google Scholar] [CrossRef]

- Koponen, J.; Ruuskanen, V.; Kosonen, A.; Niemelä, M.; Ahola, J. Effect of Converter Topology on the Specific Energy Consumption of Alkaline Water Electrolyzers. IEEE Trans. Power Electron. 2019, 34, 6171–6182. [Google Scholar] [CrossRef]

- Albarghot, M.; Rolland, L. MATLAB/Simulink modelling and experimental results of a PEM electrolyzer powered by a solar panel. In Proceedings of the 2016 IEEE Electrical Power and Energy Conference (EPEC), Ottawa, ON, Canada, 12–14 October 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Guilbert, D.; Yodwong, B.; Kaewmanee, W.; Phattanasak, M.; Hinaje, M. Hydrogen Flow Rate Control of a Proton Exchange Membrane Electrolyzer. In Proceedings of the 2019 Research, Invention, and Innovation Congress (RI2C), Bangkok, Thailand, 11–13 December 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Gorji, S.A. Reconfigurable Quadratic Converters for Electrolyzers Utilized in DC Microgrids. IEEE Access 2022, 10, 109677–109687. [Google Scholar] [CrossRef]

- Şahin, M.; Okumuş, H.; Aydemir, M. Implementation of an electrolysis system with DC/DC synchronous buck converter. Int. J. Hydrogen Energy 2014, 39, 6802–6812. [Google Scholar] [CrossRef]

- Fan, L.; Luo, S.; Lai, Y.; Liu, H. Development of three level DC power supply for hydrogen production from electrolytic water. Power Electron. Technol. 2023, 57, 31–34. [Google Scholar]

- de Sá, F.L.; Eiterer, C.V.B.; Ruiz-Caballero, D.; Mussa, S.A. Double Quadratic Buck Converter. In Proceedings of the 2013 Brazilian Power Electronics Conference, Gramado, Brazil, 27–31 October 2013; pp. 36–43. [Google Scholar] [CrossRef]

- Birca-Galateanu, S. Triple step-down DC-DC converters. In Proceedings of the PESC Record, 27th Annual IEEE Power Electronics Specialists Conference, Baveno, Italy, 23–27 June 1996; Volume 1, pp. 408–413. [Google Scholar] [CrossRef]

- Kondrath, N.; Kazimierczuk, M. Analysis and design of common-diode tapped-inductor PWM buck converter in CCM. In Proceedings of the Electrical Manufacturing Technical Conference 2009: Electrical Manufacturing and Coil Winding Expo, Nashville, TE, USA, 29 September–1 October 2009. [Google Scholar]

- Yao, K.; Ye, M.; Xu, M.; Lee, F. Tapped-inductor buck converter for high-step-down DC-DC conversion. IEEE Trans. Power Electron. 2005, 20, 775–780. [Google Scholar] [CrossRef]

- Xiong, S.; Wong, S.C.; Tan, S.C.; Tse, C.K. A Family of Exponential Step-Down Switched-Capacitor Converters and Their Applications in Two-Stage Converters. IEEE Trans. Power Electron. 2014, 29, 1870–1880. [Google Scholar] [CrossRef]

- Garrigós, A.; Blanes, J.; Carrasco, J.; Lizán, J.; Beneito, R.; Molina, J. 5kW DC/DC converter for hydrogen generation from photovoltaic sources. Int. J. Hydrogen Energy 2010, 35, 6123–6130. [Google Scholar] [CrossRef]

- Cavallaro, C.; Chimento, F.; Musumeci, S.; Sapuppo, C.; Santonocito, C. Electrolyser in H2 Self-Producing Systems Connected to DC Link with Dedicated Phase Shift Converter. In Proceedings of the 2007 International Conference on Clean Electrical Power, Capri, Italy, 21–23 May 2007; pp. 632–638. [Google Scholar] [CrossRef]

- Diabate, M.; Vriend, T.; Krishnamoorthy, H.S.; Shi, J. Hydrogen and Battery–Based Energy Storage System (ESS) for Future DC Microgrids. In Proceedings of the 2022 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Jaipur, India, 14–17 December 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Gautam, D.S.; Bhat, A.K.S. A Comparison of Soft-Switched DC-to-DC Converters for Electrolyzer Application. IEEE Trans. Power Electron. 2013, 28, 54–63. [Google Scholar] [CrossRef]

- Vinnikov, D.; Hoimoja, H.; Andrijanovits, A.; Roasto, I.; Lehtla, T.; Klytta, M. An improved interface converter for a medium-power wind-hydrogen system. In Proceedings of the 2009 International Conference on Clean Electrical Power, Capri, Italy, 9–11 June 2009; pp. 426–432. [Google Scholar] [CrossRef]

- Blinov, A.; Andrijanovits, A. New DC/DC Converter for Electrolyser Interfacing with Stand-Alone Renewable Energy System. Electr. Control. Commun. Eng. 2012, 1, 24–29. [Google Scholar] [CrossRef]

- Agbossou, K.; Doumbia, M.; Anouar, A. Optimal hydrogen production in a stand-alone renewable energy system. In Proceedings of the Fourtieth IAS Annual Meeting, Conference Record of the 2005 Industry Applications Conference, Hong Kong, China, 2–6 October 2005; Volume 4, pp. 2932–2936. [Google Scholar] [CrossRef]

- Koundi, M.; El Fadil, H. Mathematical modeling of PEM electrolyzer and design of a voltage controller by the SMPWM approach. In Proceedings of the 2019 International Conference on Power Generation Systems and Renewable Energy Technologies (PGSRET), Istanbul, Turkey, 26–27 August 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Lee, I.O.; Cho, S.Y.; Moon, G.W. Interleaved buck converter having low switching losses and improved step-down conversion ratio. In Proceedings of the 8th International Conference on Power Electronics—ECCE Asia, Jeju, Republis of Korea, 30 May–3 June 2011; pp. 2136–2143. [Google Scholar] [CrossRef]

- Pan, C.T.; Chuang, C.F.; Chu, C.C. A Novel Transformerless Interleaved High Step-Down Conversion Ratio DC–DC Converter with Low Switch Voltage Stress. IEEE Trans. Ind. Electron. 2014, 61, 5290–5299. [Google Scholar] [CrossRef]

- Yao, K.; Qiu, Y.; Xu, M.; Lee, F. A novel winding-coupled buck converter for high-frequency, high-step-down DC-DC conversion. IEEE Trans. Power Electron. 2005, 20, 1017–1024. [Google Scholar] [CrossRef]

- Ilic, M.; Maksimovic, D. Interleaved zero current transition buck converter. In Proceedings of the Twentieth Annual IEEE Applied Power Electronics Conference and Exposition, 2005, APEC 2005, Austin, TX, USA, 6–10 March; 2005; Volume 2, pp. 1265–1271. [Google Scholar] [CrossRef]

- Li, W.; He, X. A Family of Interleaved DC–DC Converters DeducedFrom a Basic Cell with Winding-Cross-CoupledInductors (WCCIs) for High Step-Upor Step-Down Conversions. IEEE Trans. Power Electron. 2008, 23, 1791–1801. [Google Scholar] [CrossRef]

- Tsai, C.T.; Shen, C.L. Interleaved soft-switching coupled-buck converter with active-clamp circuits. In Proceedings of the 2009 International Conference on Power Electronics and Drive Systems (PEDS), Taipei, Taiwan, 2–5 November 2009; pp. 1113–1118. [Google Scholar] [CrossRef]

- Guida, V.; Guilbert, D.; Douine, B. Candidate Interleaved DC-DC Buck Converters for Electrolyzers: State-of-the-Art and Perspectives. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/ICPS Europe), Palermo, Italy, 12–15 June 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Guilbert, D.; Sorbera, D.; Vitale, G. A stacked interleaved DC-DC buck converter for proton exchange membrane electrolyzer applications: Design and experimental validation. Int. J. Hydrogen Energy 2020, 45, 64–79. [Google Scholar] [CrossRef]

- Guilbert, D.; Vitale, G. Optimal Hydrogen Production from Direct Coupled Variable Speed Wind Generator with a Stacked Interleaved Buck converter. In Proceedings of the 2019 IEEE International Conference on Environment and Electrical Engineering and 2019 IEEE Industrial and Commercial Power Systems Europe (EEEIC/ICPS Europe), Genova, Italy, 11–14 June 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Makineni, R.R.; Sutanto, D.; Muttaqi, K.M.; Islam, M.R.; Agalgaonkar, A.P. Dual Loop Cascade Control of a Stacked Interleaved Buck Converter for Electrolyzer Application. In Proceedings of the 2022 IEEE IAS Global Conference on Emerging Technologies (GlobConET), Arad, Romania, 20–22 May 2022; pp. 1029–1035. [Google Scholar] [CrossRef]

- Yodwong, B.; Sikkabut, S.; Guilbert, D.; Kaewmanee, W.; Phattanasak, M.; Hinaje, M.; Vitale, G. Reliable Control Strategy and Power Switch Failure Analysis of a Three-level Interleaved Buck Converter for Electrolyzer Applications. In Proceedings of the 2022 25th International Conference on Electrical Machines and Systems (ICEMS), Chiang Mai, Thailand, 29 November–2 December 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Yodwong, B.; Guilbert, D.; Kaewmanee, W.; Phattanasak, M.; Hinaje, M.; Vitale, G. Modified Sliding Mode-Based Control of a Three-Level Interleaved DC-DC Buck Converter for Proton Exchange Membrane Water Electrolysis. In Proceedings of the 2021 Research, Invention, and Innovation Congress: Innovation Electricals and Electronics (RI2C), Bangkok, Thailand, 1–3 September 2021; pp. 221–226. [Google Scholar] [CrossRef]

- Yodwong, B.; Guilbert, D.; Kaewmanee, W.; Phattanasak, M. Energy Efficiency Based Control Strategy of a Three-Level Interleaved DC-DC Buck Converter Supplying a Proton Exchange Membrane Electrolyzer. Electronics 2019, 8, 933. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, J.; Pan, Y.; Diao, Y.; Li, D. A DC/DC Converter for Electrolytic Hydrogen Production Based on DC Microgrid. In Proceedings of the 2022 IEEE International Power Electronics and Application Conference and Exposition (PEAC), Guangzhou, China, 4–7 November 2022; pp. 1348–1353. [Google Scholar] [CrossRef]

- Muyeen, S.; Takahashi, R.; Tamura, J. Electrolyzer switching strategy for hydrogen generation from variable speed wind generator. Electr. Power Syst. Res. 2011, 81, 1171–1179. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, S.; Cirrincione, G.; Cirrincione, M.; Guilbert, D.; Ram, K.; Mohammadi, A. Power Switch Open-Circuit Fault-Diagnosis Based on a Shallow Long-Short Term Memory Neural Network: Investigation of an Interleaved Buck Converter for Electrolyzer applications. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Vancouver, BC, Canada, 10–14 October 2021; pp. 483–488. [Google Scholar] [CrossRef]

- Zhang, H.; Lu, Y.; Zhang, J.; Benigni, A. Real-Time Simulation of an Electrolyzer with a Diode Rectifier and a Three-Phase Interleaved Buck Converter. In Proceedings of the 2022 IEEE 13th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Kiel, Germany, 26–29 June 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Török, L.; Mathe, L. Stability analysis of a three-phase grid-connected DC power supply with small DC-link capacitor and voltage feed-forward compensation. In Proceedings of the 2017 IEEE 26th International Symposium on Industrial Electronics (ISIE), Edinburgh, UK, 19–21 June 2017; pp. 867–872. [Google Scholar] [CrossRef]

- Török, L.; Mathe, L.; Munk-Nielsen, S. Voltage ripple compensation for grid connected electrolyser power supply using small DC link capacitor. In Proceedings of the 2014 International Conference on Optimization of Electrical and Electronic Equipment (OPTIM), Bran, Romania, 22–24 May 2014; pp. 607–611. [Google Scholar] [CrossRef]

- Török, L.; Mathe, L.; Nielsen, C.K.; Munk-Nielsen, S. Modeling and Control of Three-Phase Grid-Connected Power Supply with a Small DC-Link Capacitor for Electrolyzers. IEEE Trans. Ind. Appl. 2017, 53, 4634–4643. [Google Scholar] [CrossRef]

- Török, L.; Nielsen, C.K.; Munk-Nielsen, S.; Rømer, C.; Flindt, P. High efficiency electrolyser power supply for household hydrogen production and storage systems. In Proceedings of the 2015 17th European Conference on Power Electronics and Applications (EPE’15 ECCE-Europe), Geneva, Switzerland, 8–10 September 2015; pp. 1–9. [Google Scholar] [CrossRef]

- Ayivor, P.K. Feasibility of Demand Side Response from Electrolyzers to Support Power System Stability; Delft University of Technology: Delft, The Netherlands, 2018. [Google Scholar]

- Monroy-Morales, J.L.; Hernández-Ángeles, M.; Campos-Gaona, D.; Peña-Alzola, R.; Ordonez, M.; Mérida, W. Modeling and control design of a Vienna rectifier based electrolyzer. In Proceedings of the 2016 IEEE 7th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Vancouver, BC, Canada, 27–30 June 2016; pp. 1–8. [Google Scholar] [CrossRef]

- Meng, X.; Chen, M.; He, M.; Wang, X.; Liu, J. A Novel High Power Hybrid Rectifier with Low Cost and High Grid Current Quality for Improved Efficiency of Electrolytic Hydrogen Production. IEEE Trans. Power Electron. 2022, 37, 3763–3768. [Google Scholar] [CrossRef]

- Meng, X.; Jiang, L.; He, M.; Wang, X.; Liu, J. A Novel Multi-Scale Frequency Regulation Method of Hybrid Rectifier and Its Specific Application in Electrolytic Hydrogen Production. IEEE Trans. Power Electron. 2023, 38, 123–129. [Google Scholar] [CrossRef]

- Vinnikov, D.; Andrijanovitš, A.; Roasto, I.; Jalakas, T. Experimental study of new integrated DC/DC converter for hydrogen-based energy storage. In Proceedings of the 2011 10th International Conference on Environment and Electrical Engineering, Rome, Italy, 8–11 May 2011; pp. 1–4. [Google Scholar] [CrossRef]

- Andrijanovitš, A.; Blinov, A.; Husev, O.; Vinnikov, D. Multiport converter with integrated energy storage for hydrogen buffer interfacing with renewable energy systems. In Proceedings of the 2012 IEEE International Conference on Industrial Technology, Athens, Greece, 19–21 March 2012; pp. 230–235. [Google Scholar] [CrossRef]

- Kaufmann, M.; Lueders, M.; Kaya, C.; Wicht, B. 18.2 A Monolithic E-Mode GaN 15W 400V Offline Self-Supplied Hysteretic Buck Converter with 95.6% Efficiency. In Proceedings of the 2020 IEEE International Solid-State Circuits Conference—(ISSCC), San Francisco, CA, USA, 16–20 February 2020; pp. 288–290. [Google Scholar] [CrossRef]

- Zhang, J.; Lai, J.S.; Kim, R.Y.; Yu, W. High-Power Density Design of a Soft-Switching High-Power Bidirectional dc–dc Converter. IEEE Trans. Power Electron. 2007, 22, 1145–1153. [Google Scholar] [CrossRef]

- Tarzamni, H.; Babaei, E.; Esmaeelnia, F.P.; Dehghanian, P.; Tohidi, S.; Sharifian, M.B.B. Analysis and Reliability Evaluation of a High Step-Up Soft Switching Push–Pull DC–DC Converter. IEEE Trans. Reliab. 2020, 69, 1376–1386. [Google Scholar] [CrossRef]

- Zhao, L.; Li, H.; Wu, X.; Zhang, J. An Improved Phase-Shifted Full-Bridge Converter with Wide-Range ZVS and Reduced Filter Requirement. IEEE Trans. Ind. Electron. 2018, 65, 2167–2176. [Google Scholar] [CrossRef]

- Qin, Z.; Shen, Y.; Loh, P.C.; Wang, H.; Blaabjerg, F. A Dual Active Bridge Converter with an Extended High-Efficiency Range by DC Blocking Capacitor Voltage Control. IEEE Trans. Power Electron. 2018, 33, 5949–5966. [Google Scholar] [CrossRef]

- Ta, L.A.D.; Dao, N.D.; Lee, D.C. High-Efficiency Hybrid LLC Resonant Converter for On-Board Chargers of Plug-In Electric Vehicles. IEEE Trans. Power Electron. 2020, 35, 8324–8334. [Google Scholar] [CrossRef]

- Lee, J.S.; Lee, K.B. Performance Analysis of Carrier-Based Discontinuous PWM Method for Vienna Rectifiers with Neutral-Point Voltage Balance. IEEE Trans. Power Electron. 2016, 31, 4075–4084. [Google Scholar] [CrossRef]

- Xue, Y.; Lu, J.; Wang, Z.; Tolbert, L.M.; Blalock, B.J.; Wang, F. Active current balancing for parallel-connected silicon carbide MOSFETs. In Proceedings of the 2013 IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013; pp. 1563–1569. [Google Scholar] [CrossRef]

- Hao, C.; Judge, P.; Finney, S.; Merlin, M. Enabling the use of lower current-rated SiC MOSFET devices in large-current power converters by paralleling multiple H-bridges in the sub-modules. In Proceedings of the 19th International Conference on AC and DC Power Transmission (ACDC 2023), Glasgow, UK, 1–3 March 2023; Volume 2023, pp. 142–147. [Google Scholar] [CrossRef]

- Wang, B.; Wang, X.; Bie, Z.; Judge, P.D.; Wang, X.; Green, T.C. Reliability model of MMC considering periodic preventive maintenance. IEEE Trans. Power Deliv. 2016, 32, 1535–1544. [Google Scholar] [CrossRef]

- Fang, J.; Blaabjerg, F.; Liu, S.; Goetz, S.M. A Review of Multilevel Converters with Parallel Connectivity. IEEE Trans. Power Electron. 2021, 36, 12468–12489. [Google Scholar] [CrossRef]

- Liu, G.; Wang, B.; Liu, F.; Wang, X.; Guan, Y.; Wang, W.; Wang, Y.; Xu, D. An Improved Zero-Voltage and Zero-Current- Switching Phase-Shift Full-Bridge PWM Converter with Low Output Current Ripple. IEEE Trans. Power Electron. 2023, 38, 3419–3432. [Google Scholar] [CrossRef]

- Bagawade, S.; Pahlevani, M.; Jain, P. Novel Soft-Switched Three-Phase Inverter with Output Current Ripple Cancellation. IEEE Trans. Power Electron. 2023, 38, 1232–1248. [Google Scholar] [CrossRef]

- Joshi, K.; Yang, Z.; Fu, C.; Mandal, D.; Waterfall, G.; Bakkaloglu, B. A Mixed-Signal Adaptive Ripple Canceler for Switching Regulators Providing 18 dB–24 dB of Ripple Rejection up to 1 MHz. IEEE Trans. Power Electron. 2020, 35, 10249–10259. [Google Scholar] [CrossRef]

- Hao, C.; Cao, J.; Xia, P.; Finney, S.J.; Merlin, M.M.C. Meet the Micro-MMC. IEEE Power Electron. Mag. 2023, 10, 47–52. [Google Scholar] [CrossRef]

- Heath, T.; Barnes, M.; Judge, P.D.; Chaffey, G.; Clemow, P.; Green, T.C.; Green, P.R.; Wylie, J.; Konstantinou, G.; Ceballos, S.; et al. Cascaded- and Modular-Multilevel Converter Laboratory Test System Options: A Review. IEEE Access 2021, 9, 44718–44737. [Google Scholar] [CrossRef]

- Islam, M.T.; Ayon, S.I. Performance Analysis of Three-Phase Inverter for Minimizing Total Harmonic Distortion Using Space Vector Pulse Width Modulation Technique. In Proceedings of the 2020 23rd International Conference on Computer and Information Technology (ICCIT), Dhaka, Bangladesh, 19–21 December 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Hao, C.; Merlin, M. Automatic Derivation of State-Space Model from Linear Electrical Circuits with Dependent Variables using Modified Nodal Analysis. In Proceedings of the 2020 IEEE 21st Workshop on Control and Modeling for Power Electronics (COMPEL), Aalborg, Denmark, 9–12 November 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Li, N.; Macavilca, M.B.; Wu, C.; Finney, S.; Judge, P.D. Converter Topology for Megawatt Scale Applications with Reduced Filtering Requirements, Formed of IGBT Bridge Operating in the 1000 Hz Region with Parallel Part-Rated High-Frequency SiC MOSFET Bridge. IEEE Trans. Power Electron. 2024, 39, 799–813. [Google Scholar] [CrossRef]

- Shan, Y.; Pei, X.; Sun, T.; Zhou, P.; Zhang, M.; Zhou, L. Space Spread-Spectrum-Based PSC-PWM for MMC to Reduce Conducted CM EMI. In Proceedings of the 2021 IEEE 12th Energy Conversion Congress and Exposition—Asia (ECCE-Asia), Singapore, 24–27 May 2021; pp. 1916–1921. [Google Scholar] [CrossRef]

- Huang, Q.; Yu, R.; Ma, Q.; Huang, A.Q. Predictive ZVS Control with Improved ZVS Time Margin and Limited Variable Frequency Range for a 99% Efficient, 130-W/in3 MHz GaN Totem-Pole PFC Rectifier. IEEE Trans. Power Electron. 2019, 34, 7079–7091. [Google Scholar] [CrossRef]

| Countries | Issued Date | Title of the Policy Document |

|---|---|---|

| China | 2022 | Medium and long-term plan for the development of hydrogen energy industry (2021–2035) [8] |

| USA | 2022 | The U.S. National Clean Hydrogen Strategy and Roadmap [9] |

| European Union | 2022 | Strategic Research and Innovation Agenda 2021–2027 [10] |

| Japan | 2022 | The 6th Strategic Energy Plan [14] |

| Russia | 2021 | Action Plan for the Development of Hydrogen Energy in the Russian Federation by 2024 [16] |

| UK | 2021 | UK Hydrogen Strategy [11] |

| Germany | 2020 | The National Hydrogen Strategy [12] |

| France | 2020 | The National Strategy for the Development of Carbon-Free Hydrogen Energy [13] |

| Australia | 2018 | National Hydrogen Roadmap [17] |

| References | Characteristics |

|---|---|

| [19,20,21,22,23,24] |

|

| [25,26] |

|

| ALK WE | PEM WE | SOE WE | |

|---|---|---|---|

| Anode Reaction | |||

| Cathnode Reaction | |||

| Device Capacity | 0.5∼1000 N·m3/h | 0.01∼500 N·m3/h | / |

| Current Density | 0.2∼0.4 A/cm2 | 1.0∼2.0 A/cm2 | 1.0∼10.0 A/cm2 |

| Power Consumption | 4.5∼5.5 kW·h/(N·m3) | 3.8∼5.0 kW·h/(N·m3) | 2.6∼3.6 kW·h/(N·m3) |

| Hydrogen Purity | ≥99.8% | ≥99.99% | / |

| Operation Temperature | 70∼90 °C | 70∼80 °C | 600∼1000 °C |

| Dynamic Response | In several minutes | In several seconds | Very slow |

| Development Status | Product | Product | Prototype |

| Device Cost | 0.08 $/(N·m3), 30% | 0.57 $/(N·m3), 77% | / |

| Power Cost | 0.19 $/(N·m3), 70% | 0.17 $/(N·m3), 23% | / |

| Total Cost | 0.28 $/(N·m3) | 0.74 $/(N·m3) | / |

| Manufacturer | EL Type | Capacity (2022) | Proportion (2022) | Capacity (2023) | Proportion (2023) | Capacity Growth Rate |

|---|---|---|---|---|---|---|

| Longi (Xi’an, China) | ALK | 1.5 GW | 9.7% | 2.5 GW | 8.0% | 66.7% |

| John Cockerill (Seraing, Belgium) | ALK | 1.0 GW | 6.5% | 2.5 GW | 8.0% | 150.0% |

| ThyssenKrupp (Essen, Germany) | ALK | 1.0 GW | 6.5% | 1.5 GW | 4.8% | 50.0% |

| PERIC (Beijing, China) | ALK | 1.4 GW | 9.1% | 1.4 GW | 4.5% | 0% |

| HydrogenPro (Telemark, Norway) | ALK | 0.3 GW | 1.9% | 1.3 GW | 4.2% | 333.3% |

| Auyan (Qingdao, China) | ALK | 1.0 GW | 6.5% | 1.0 GW | 3.2% | 0% |

| Sungrow (Hefei, China) | ALK | 1.0 GW | 6.5% | 1.0 GW | 3.2% | 0% |

| GuofuHee (Zhangjiagang, China) | ALK | 0.5 GW | 3.2% | 1.0 GW | 3.2% | 100.0% |

| NEL (Oslo, Norway) | ALK | 0.5 GW | 3.2% | 0.5 GW | 1.6% | 0% |

| SinoHy Energy (Beijing, China) | ALK | 0.5 GW | 3.2% | 0.5 GW | 1.6% | 0% |

| Sunfire (Dresden, Germany) | ALK | 0.2 GW | 1.3% | 0.5 GW | 1.6% | 150.0% |

| Kohodo (Shenzhen, China) | ALK | 0.2 GW | 1.3% | 0.5 GW | 1.6% | 150.0% |

| Green Hydrogen System (Kolding, Denmark) | ALK | 0.1 GW | 0.6% | 0.4 GW | 1.3% | 300.0% |

| Kylin Tech (Shenzhen, China) | ALK | 0.3 GW | 1.9% | 0.3 GW | 1.0% | 0% |

| McPhy (Grenoble, France) | ALK | 0.1 GW | 0.6% | 0.3 GW | 1.0% | 200.0% |

| Others (ALK) | ALK | 1.5 GW | 9.7% | 5.0 GW | 16.1% | 233.3% |

| Plug Power (Latham, NY, USA) | PEM | 1.0 GW | 6.5% | 3.0 GW | 9.6% | 200.0% |

| ITM Power (Sheffield, UK) | PEM | 1.0 GW | 6.5% | 2.5 GW | 8.0% | 150.0% |

| Ohmium (Fremont, CA, USA) | PEM | 1.0 GW | 6.5% | 2.0 GW | 6.4% | 100.0% |

| Cummins (Columbus, IN, USA) | PEM | 0.6 GW | 3.9% | 1.6 GW | 5.1% | 166.7% |

| Siemens Energy (Munich, Germany) | PEM | 0.3 GW | 1.9% | 1.3 GW | 4.2% | 333.3% |

| PERIC (Beijing, China) | PEM | 0.1 GW | 0.6% | 0.1 GW | 1.9% | 0% |

| Sungrow (Hefei, China) | PEM | 0.1 GW | 0.6% | 0.1 GW | 1.9% | 0% |

| NEL (Oslo, Norway) | PEM | 0.1 GW | 0.6% | 0.1 GW | 1.9% | 0% |

| Others (PEM) | PEM | 0.1 GW | 0.6% | 0.4 GW | 1.9% | 300.0% |

| Total | / | 15.4 GW | 100% | 31.1 GW | 100% | 101.9% |

| Total (ALK) | ALK | 11.1 GW | 72.1% | 20.0 GW | 64.3% | 80.2% |

| Total (PEM) | PEM | 4.3 GW | 27.9% | 11.1 GW | 35.7% | 158.1% |

| Parameters | Value | Parameters | Value | Parameters | Value |

|---|---|---|---|---|---|

| −1.002 A−1m2 | 8.424 A−1m2°C | 247.3 A−1m2°C2 | |||

| 8.05 m2 | −2.5 m2°C−1 | s | 0.185 V | ||

| k | 0.226 A−1cm2V | b | 1.416 V |

| Parameters | Set-Point 1 | Set-Point 2 | Set-Point 3 | Unit |

|---|---|---|---|---|

| T | 40 | 60 | 80 | °C |

| 150 | 200 | 250 | mA2cm−4 | |

| 0.990 | 0.985 | 0.980 | / |

| Topology | Source | Status | EL Type | Category | Rated Power | Efficiency | Semiconductor Quantity | Control Type |

|---|---|---|---|---|---|---|---|---|

| Figure 8, [53] | AC | Product | ALK | Single-Stage | 5.5 MW | ≈97% | 6 SCRs | Semi- |

| Figure 9, [58] | AC | Product | ALK | Single-Stage | 19.5 MW | ≈97.5% | 12 SCRs | Semi- |

| Figure 10, [59] | AC | Product | ALK/PEM | Single-Stage | 5.7 MW | ≈98% | 6 IGBTs 6 Diodes | PWM |

| Figure 11, [63] | DC | Prototype | PEM | Single-Stage | 2 W | ≈94.3% | 1 MOSFET 1 Diode | PWM/ZVS |

| Figure 12, [64] | DC | Prototype | PEM | Single-Stage | 120 W | N/A | 1 MOSFET 3 Diodes | PWM |

| Figure 13, [66] | DC | Prototype | PEM | Single-Stage | 50 W | ≈95% | 2 MOSFETs | PWM/ZVS |

| Figure 14, [67] | DC | Concept | N/A | Single-Stage | 1.5 MW | N/A | 4 MOSFETs | PWM |

| Figure 15, [73] | DC | Prototype | ALK | Isolated | 5 kW | ≈90% | 2 MOSFETs 2 Diodes | ZVS |

| Figure 16, [74] | DC | Concept | ALK | Isolated | 1 kW | N/A | 4 MOSFETs 2 Diodes | ZVS |

| Figure 17, [75] | DC | Concept | PEM | Isolated | 10 kW | ≈96.7% | 4 MOSFETs 2 Diodes | ZVS |

| Figure 18, [76] | DC | Prototype | N/A | Isolated | 7.2 kW | ≈90.87% | 4 MOSFETs 4 Diodes | ZVS |

| Figure 19, [76] | DC | Prototype | N/A | Isolated | 7.2 kW | ≈90.0% | 4 MOSFETs 4 Diodes | ZVS |

| Figure 20, [76] | DC | Prototype | N/A | Isolated | 7.2 kW | ≈89.92% | 4 MOSFETs 4 Diodes | ZVS |

| Figure 21, [78] | DC | Prototype | N/A | Isolated | 1 kW | N/A | 6 MOSFETs 4 Diodes | ZVS |

| Figure 22, [79] | DC | Concept | N/A | Interleaved Parallel | 2.5 kW | ≈96% | 2 MOSFETs 2 Diodes | PWM/ZVS |

| Figure 23, [88] | DC | Prototype | PEM | Interleaved Parallel | 400 W | N/A | 4 MOSFETs | PWM/ZVS |

| Figure 24, [91] | DC | Concept | PEM | Interleaved Parallel | 80 W | N/A | 4 MOSFETs 4 Diodes | PWM |

| Figure 25, [50] | DC | Prototype | PEM | Interleaved Parallel | 6 kW | ≈93.1% | 6 MOSFETs 12 Diodes | ZVS |

| Figure 26, [94] | DC | Concept | N/A | Interleaved Parallel | 26 kW | N/A | 8 MOSFETs 8 Diodes | ZVS |

| Figure 27, [95] | AC | Concept | N/A | Multi-stage Serial | 5 MW | N/A | n MOSFETs (6 + n) Diodes | PWM/ZVS |

| Figure 28, [103] | AC | Concept | N/A | Multi-stage Serial | N/A | N/A | (3 + 2n) MOSFETs 18 Diodes | PWM/ZVS |

| Figure 29, [104] | DC | Prototype | N/A | Master-slave Parallel | 270 W | N/A | 16 MOSFETs 2 Diodes | PWM/ZVS |

| Figure 30, [106] | DC | Prototype | N/A | Three-ports | 2.4 kW | N/A | 6 MOSFETs 3 Diodes | ZVS |

| Figure 31, [107] | DC | Prototype | N/A | Three-ports | 1.2 kW | N/A | 8 MOSFETs 5 Diodes | ZVS |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, J.; Ma, H.; Qin, G.; Guo, Z.; Xia, P.; Hao, C. A Comprehensive Review on the Power Supply System of Hydrogen Production Electrolyzers for Future Integrated Energy Systems. Energies 2024, 17, 935. https://doi.org/10.3390/en17040935

Lei J, Ma H, Qin G, Guo Z, Xia P, Hao C. A Comprehensive Review on the Power Supply System of Hydrogen Production Electrolyzers for Future Integrated Energy Systems. Energies. 2024; 17(4):935. https://doi.org/10.3390/en17040935

Chicago/Turabian StyleLei, Jianhua, Hui Ma, Geng Qin, Zhihua Guo, Peizhou Xia, and Chuantong Hao. 2024. "A Comprehensive Review on the Power Supply System of Hydrogen Production Electrolyzers for Future Integrated Energy Systems" Energies 17, no. 4: 935. https://doi.org/10.3390/en17040935

APA StyleLei, J., Ma, H., Qin, G., Guo, Z., Xia, P., & Hao, C. (2024). A Comprehensive Review on the Power Supply System of Hydrogen Production Electrolyzers for Future Integrated Energy Systems. Energies, 17(4), 935. https://doi.org/10.3390/en17040935