Scour Protection Measures for Offshore Wind Turbines: A Systematic Literature Review on Recent Developments

Abstract

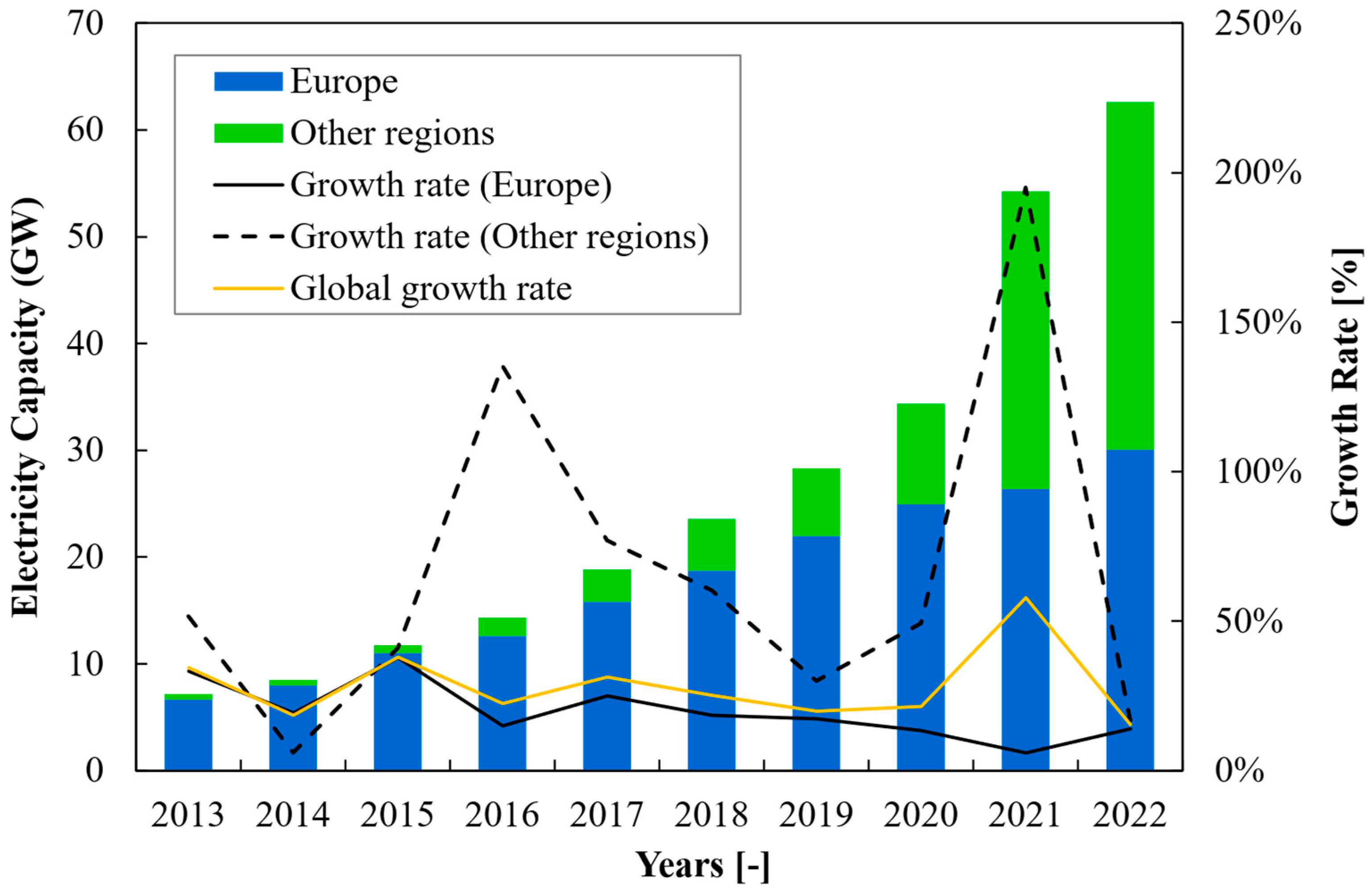

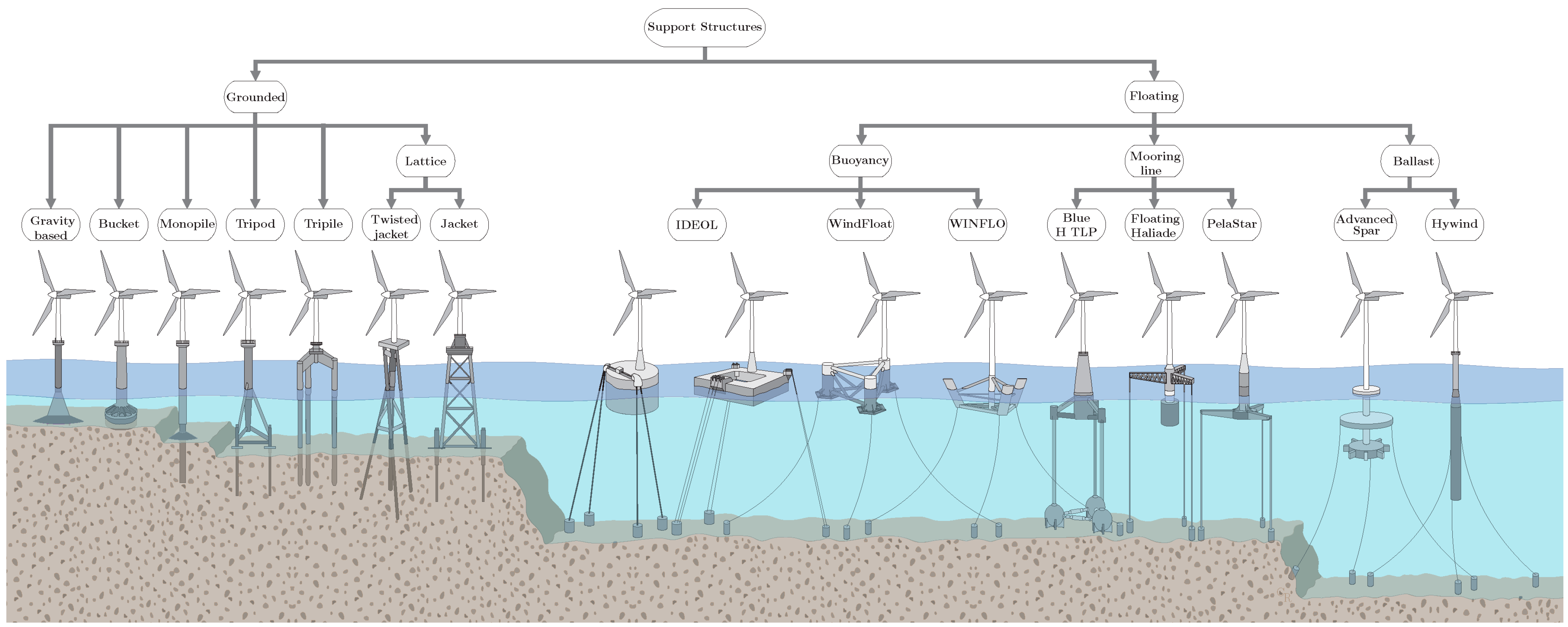

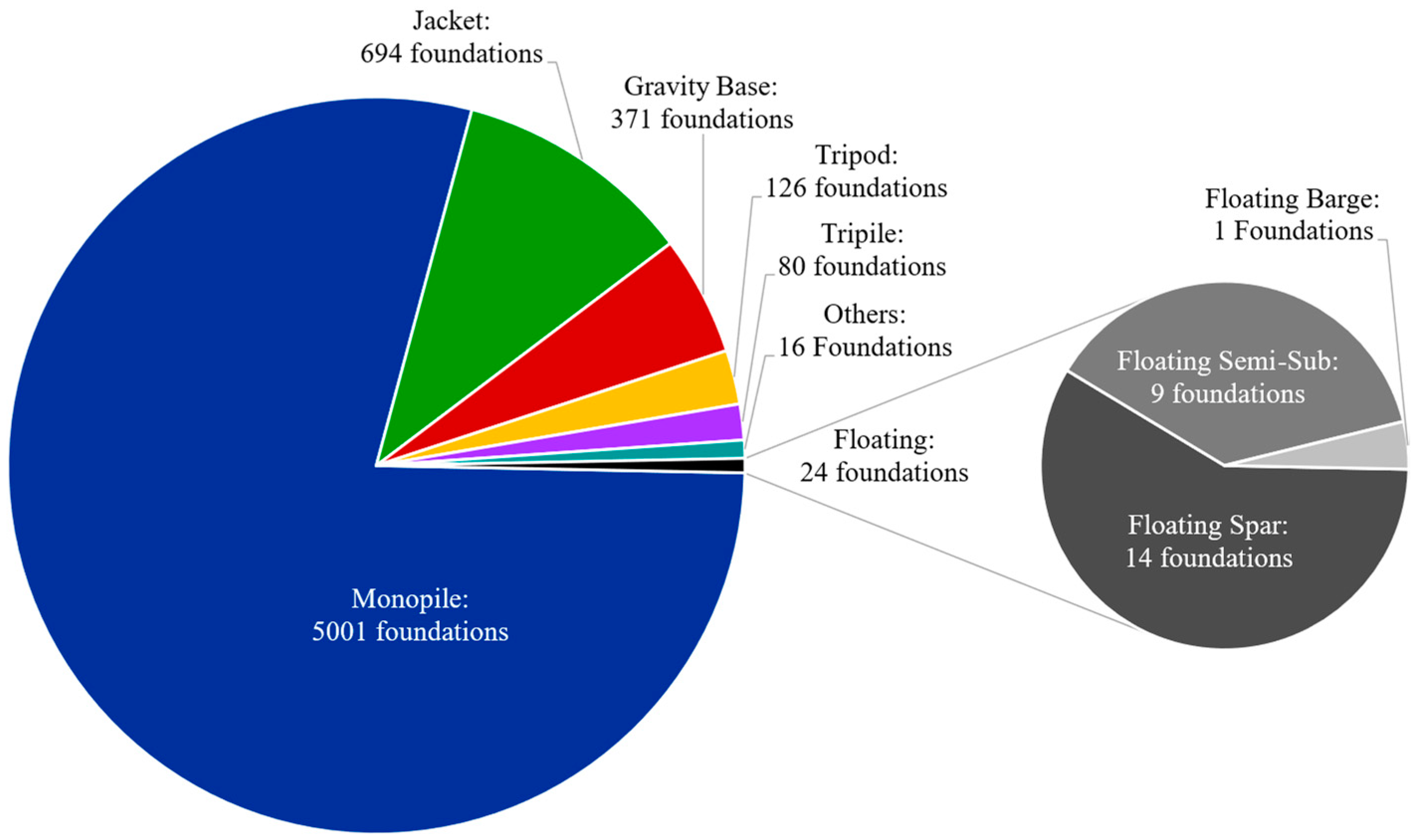

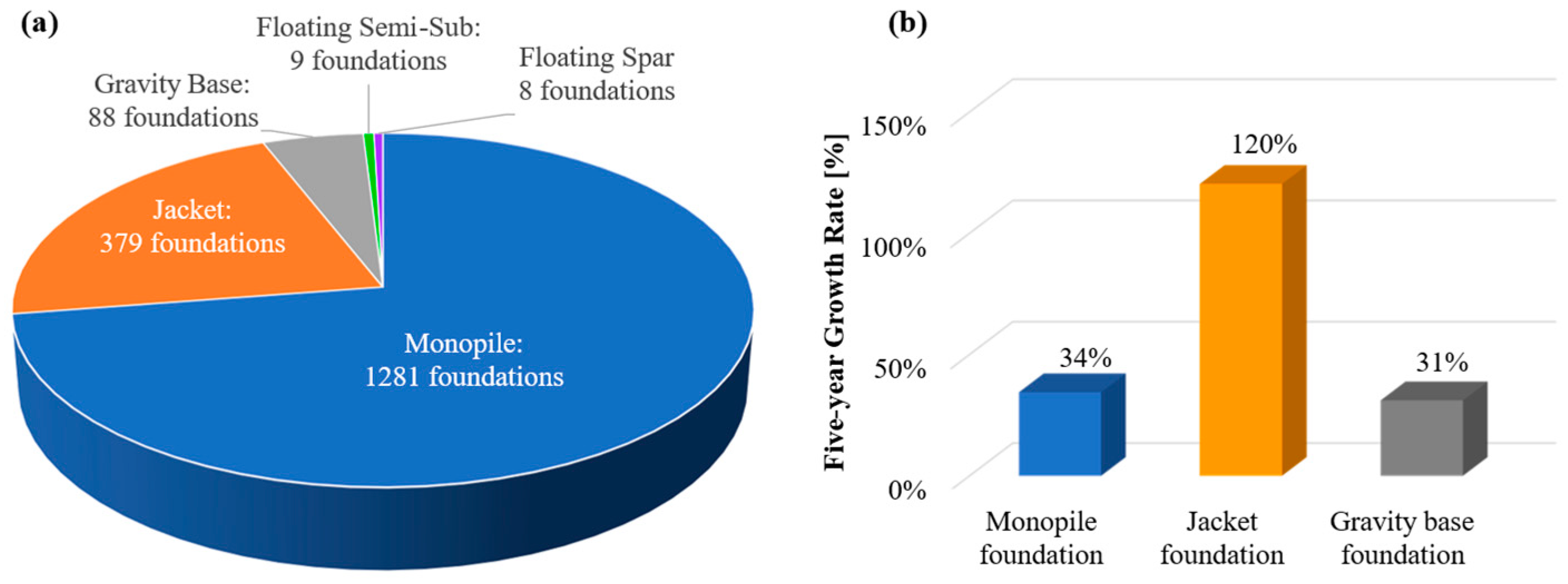

:1. Introduction

2. Systematic Review Method

3. Analysis of Scouring Protection Measures

3.1. Monopile Foundation

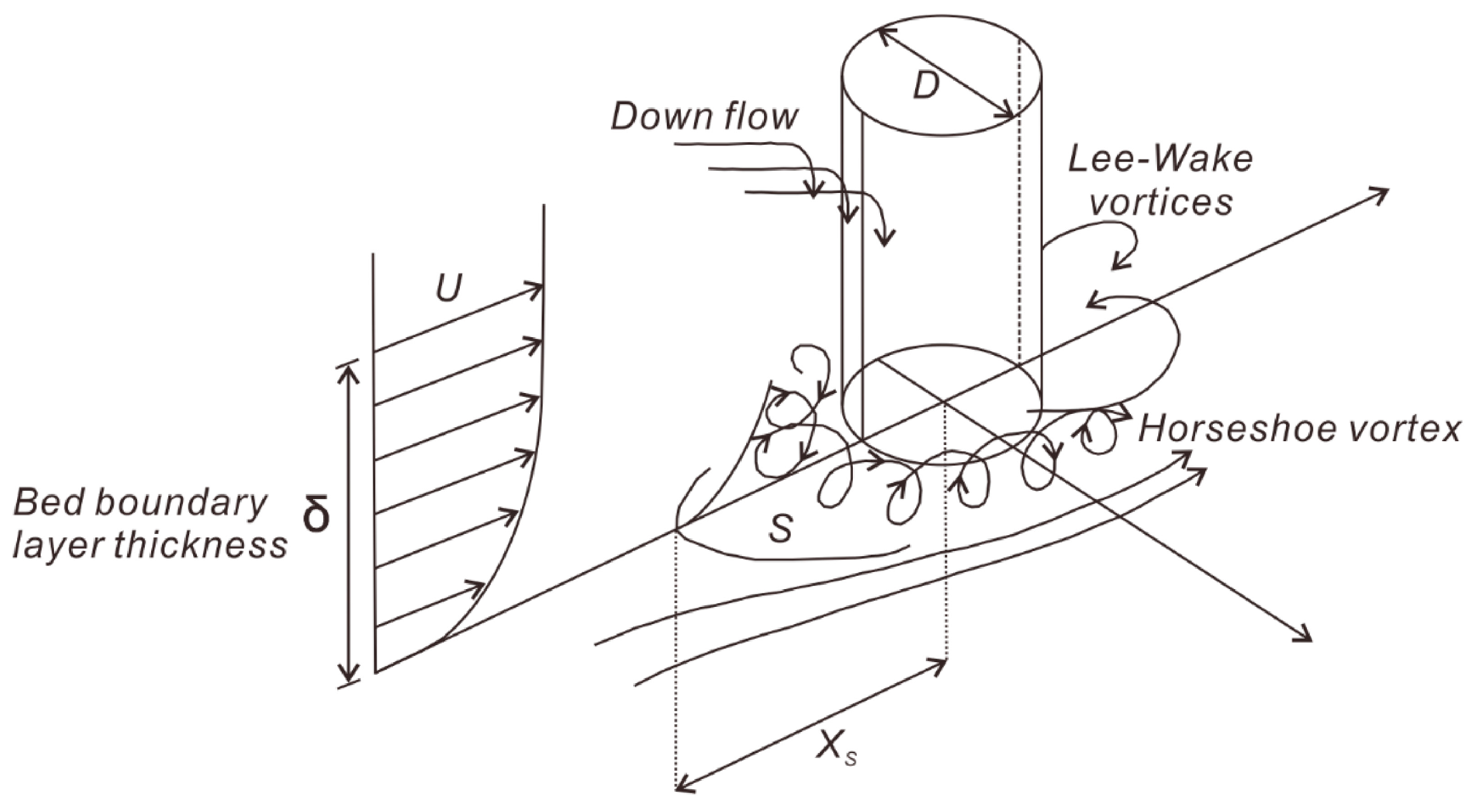

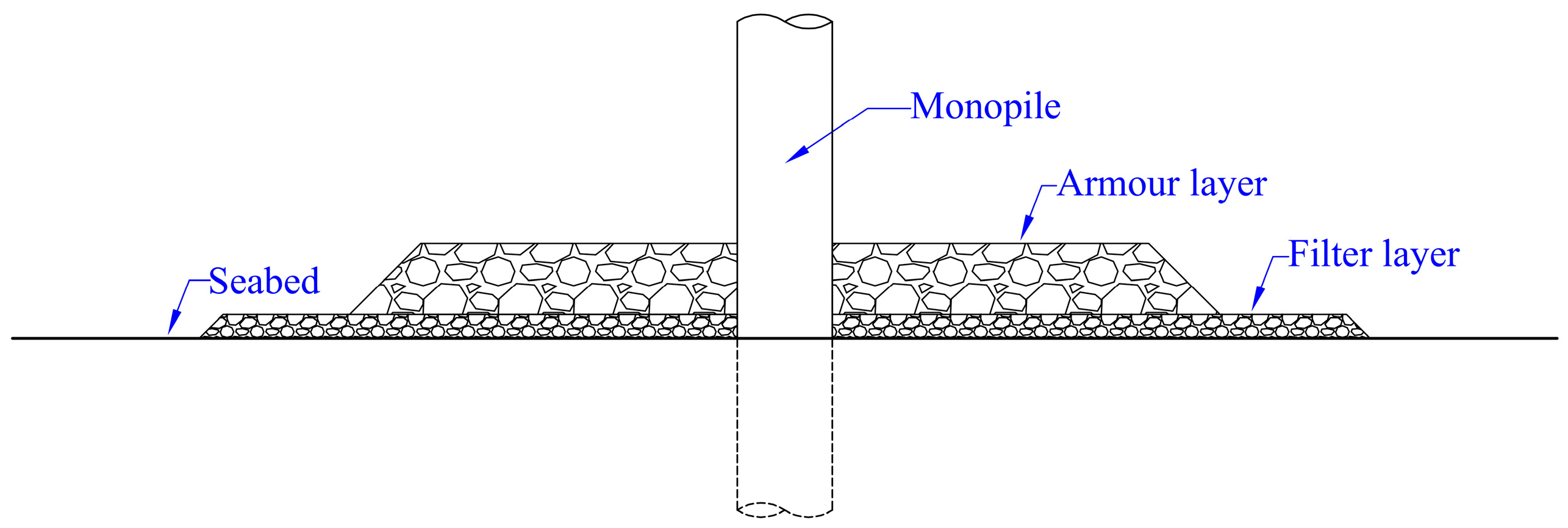

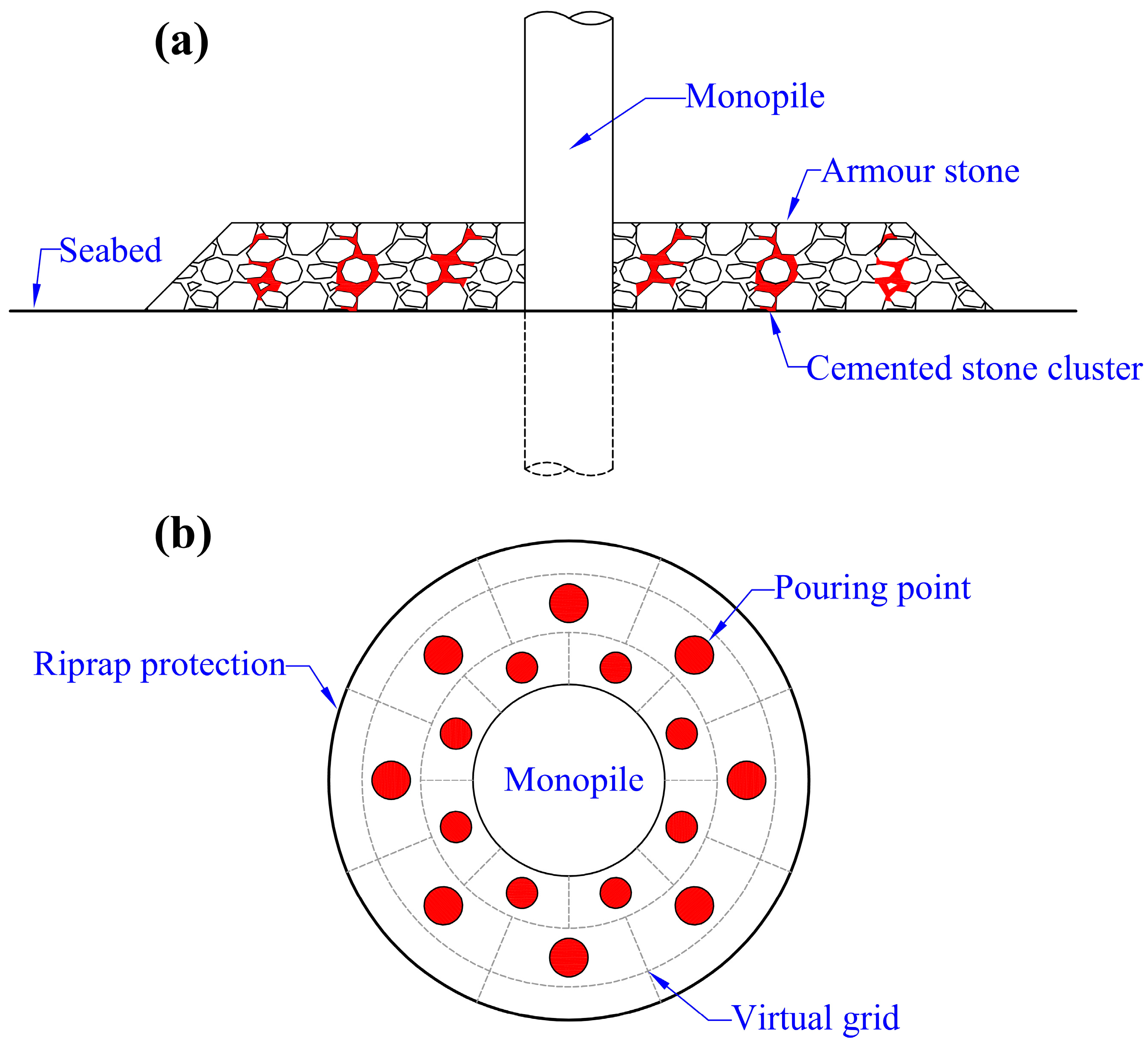

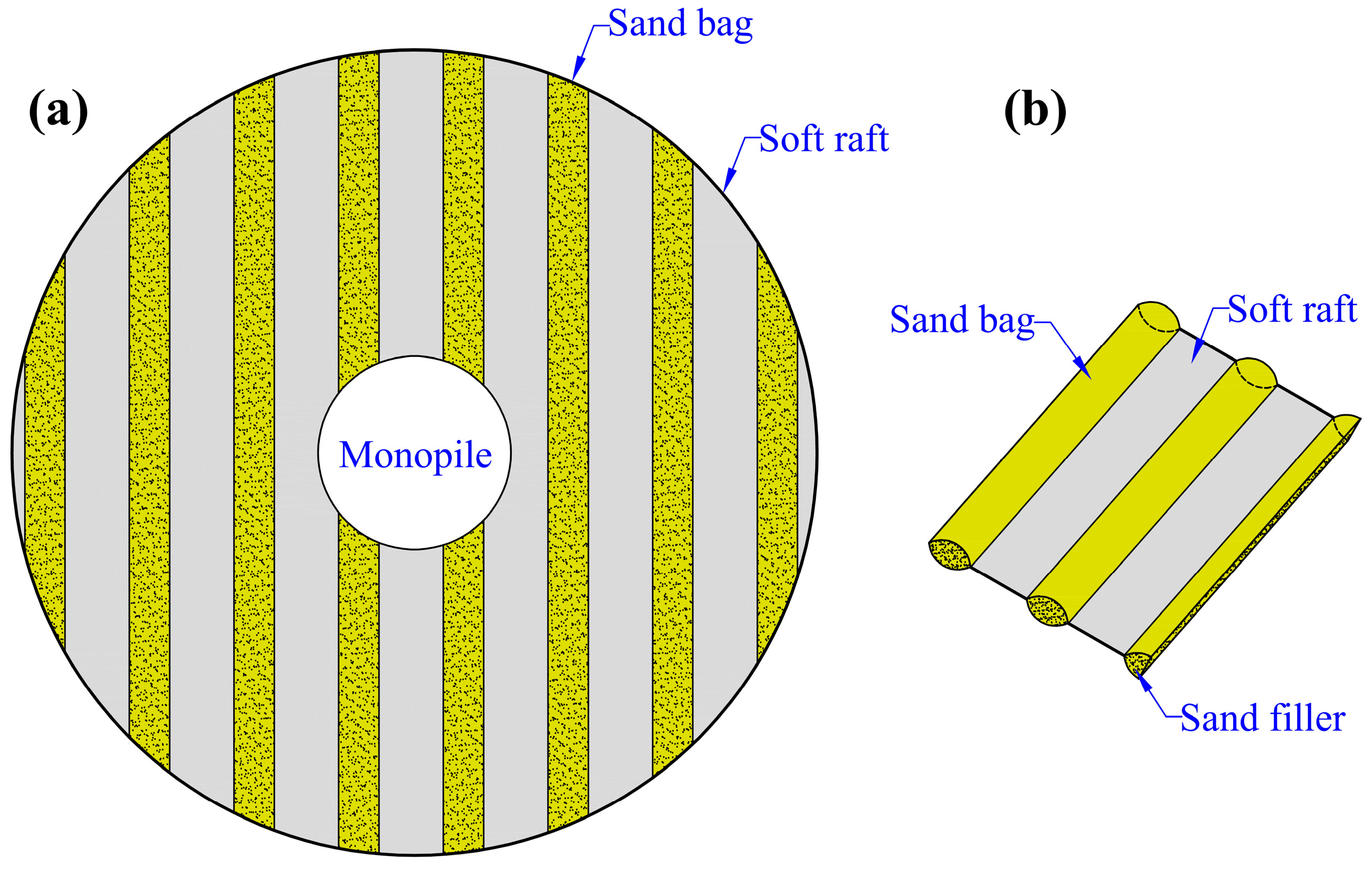

3.1.1. Riprap Scour Protection Measures

3.1.2. Ground Improvement Protection

3.1.3. Flow-Altering Protection

3.2. Jacket Foundation

3.3. Other Foundation Types

3.4. Impacts of Scour Protection Measures on the Environment

4. Key Challenges and Future Research Needs

5. Conclusions

- Scour protection research for monopile foundations is far ahead of research into other foundation types and contributed to more than half of the existing works on scour protections pertaining to riprap protection. When comparing design guidance for different scour protection measures, it is evident that knowledge on riprap measures is advanced and more welcomed by the offshore wind industry.

- Based on our literature review, it can be reported that previously published research works have not investigated scour protection measures for jacket foundations in great depth. Hence, there is a need to explore the suitable scour protection measures for jacket foundations and to generate design guidance for the same.

- Existing scour protection design is mostly based on empirical equations derived from laboratory and field measurements or inputs from designers. It should, however, be noted that results from laboratory experiments (such as small-scale wave-current flume tests) could be influenced by scale and model effects and therefore associated uncertainties. Additionally, more considerations such as geotechnics, statistics, and spatiotemporal changes should be involved in and implemented into the future scour protection design.

- This study also found that there is scope to integrate the design of scour protection measures with different foundation types. When designing such measures, relevant industry should be engaged to maximize their potential. This knowledge from industry is crucial for the sustainable and effective development of scour measures for OWTs, which will help to clarify the needs of stakeholders and provide valuable insights into the design approach.

- Recent works on scour protection measures highlight the potential ecological benefits of scour protection measures. More research on developing multi-functional facilities related to ecological enhancement, aquaculture industry and other marine energy harvesting technologies should be performed to gather information for the development of nature-inclusive scour protection designs for offshore wind farms, thus contributing to improved and sustainable maritime spatial planning.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Leung, D.Y.C.; Yang, Y. Wind Energy Development and Its Environmental Impact: A Review. Renew. Sustain. Energy Rev. 2012, 16, 1031–1039. [Google Scholar] [CrossRef]

- Le Billon, P.; Lujala, P.; Singh, D.; Culbert, V.; Kristoffersen, B. Fossil Fuels, Climate Change, and the COVID-19 Crisis: Pathways for a Just and Green Post-Pandemic Recovery. Clim. Policy 2021, 21, 1347–1356. [Google Scholar] [CrossRef]

- Shukla, J.B.; Arora, M.S.; Verma, M.; Misra, A.K.; Takeuchi, Y. The Impact of Sea Level Rise Due to Global Warming on the Coastal Population Dynamics: A Modeling Study. Earth Syst. Environ. 2021, 5, 909–926. [Google Scholar] [CrossRef]

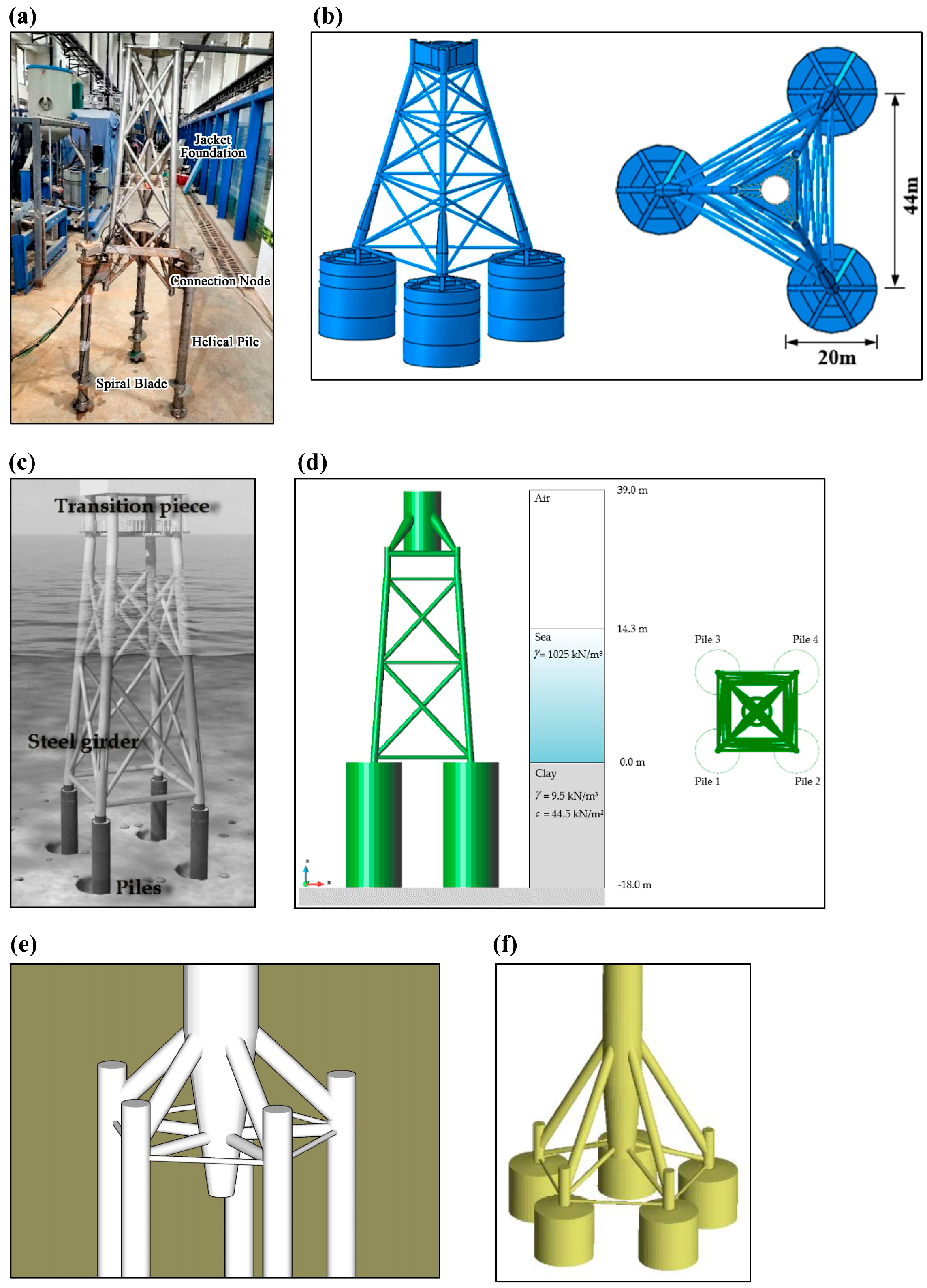

- Lian, J.; Li, J.; Guo, Y.; Wang, H.; Yang, X. Numerical Study on Local Scour Characteristics of Multi-Bucket Jacket Foundation Considering Exposed Height. Appl. Ocean Res. 2022, 121, 103092. [Google Scholar] [CrossRef]

- Li, J.; Wang, G.; Li, Z.; Yang, S.; Chong, W.T.; Xiang, X. A Review on Development of Offshore Wind Energy Conversion System. Int. J. Energy Res. 2020, 44, 9283–9297. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA). Wind Energy. Available online: https://www.irena.org/Energy-Transition/Technology/Wind-energy (accessed on 21 December 2023).

- IRENA; Alliance, G.; Presidency, C. Tripling Renewable Power and Doubling Energy Efficiency by 2030: Crucial Steps towards 1.5 °C; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2023. [Google Scholar]

- Bhattacharya, S. Challenges in Design of Foundations for Offshore Wind Turbines. Inst. Eng. Technol. 2014, 1, 922. [Google Scholar] [CrossRef]

- Sánchez, S.; López-Gutiérrez, J.-S.; Negro, V.; Esteban, M.D. Foundations in Offshore Wind Farms: Evolution, Characteristics and Range of Use. Analysis of Main Dimensional Parameters in Monopile Foundations. J. Mar. Sci. Eng. 2019, 7, 441. [Google Scholar] [CrossRef]

- Sumer, B.M.; Kirca, V.S.O. Scour and Liquefaction Issues for Anchors and Other Subsea Structures in Floating Offshore Wind Farms: A Review. Water Sci. Eng. 2022, 15, 3–14. [Google Scholar] [CrossRef]

- Koh, J.H.; Ng, E.Y.K. Downwind Offshore Wind Turbines: Opportunities, Trends and Technical Challenges. Renew. Sustain. Energy Rev. 2016, 54, 797–808. [Google Scholar] [CrossRef]

- Negro, V.; López-Gutiérrez, J.-S.; Esteban, M.D.; Matutano, C. Uncertainties in the Design of Support Structures and Foundations for Offshore Wind Turbines. Renew. Energy 2014, 63, 125–132. [Google Scholar] [CrossRef]

- Rodrigues, S.; Restrepo, C.; Katsouris, G.; Teixeira Pinto, R.; Soleimanzadeh, M.; Bosman, P.; Bauer, P. A Multi-Objective Optimization Framework for Offshore Wind Farm Layouts and Electric Infrastructures. Energies 2016, 9, 216. [Google Scholar] [CrossRef]

- WineEurope. Offshore Wind in Europe—Key Trends and Statistics 2022. Available online: https://windeurope.org/intelligence-platform/product/offshore-wind-in-europe-key-trends-and-statistics-2022 (accessed on 21 December 2023).

- WindEurope. The European Offshore Wind Industry—Key Trends and Statistics 2017. Available online: https://windeurope.org/intelligence-platform/product/the-european-offshore-wind-industry-key-trends-and-statistics-2017 (accessed on 18 December 2023).

- Sumer, B.M.; Whitehouse, R.J.S.; Tørum, A. Scour around Coastal Structures: A Summary of Recent Research. Coast. Eng. 2001, 44, 153–190. [Google Scholar] [CrossRef]

- Li, J.; Guo, Y.; Lian, J.; Wang, H. Mechanisms, Assessments, Countermeasures, and Prospects for Offshore Wind Turbine Foundation Scour Research. Ocean Eng. 2023, 281, 114893. [Google Scholar] [CrossRef]

- Guan, D.; Xie, Y.; Yao, Z.; Chiew, Y.-M.; Zhang, J.; Zheng, J. Local Scour at Offshore Windfarm Monopile Foundations: A Review. Water Sci. Eng. 2022, 15, 29–39. [Google Scholar] [CrossRef]

- Whitehouse, R.J.S.; Harris, J.M.; Sutherland, J.; Rees, J. The Nature of Scour Development and Scour Protection at Offshore Windfarm Foundations. Mar. Pollut. Bull. 2011, 62, 73–88. [Google Scholar] [CrossRef] [PubMed]

- Petersen, T.U.; Mutlu Sumer, B.; Fredsøe, J.; Raaijmakers, T.C.; Schouten, J.-J. Edge Scour at Scour Protections around Piles in the Marine Environment—Laboratory and Field Investigation. Coast. Eng. 2015, 106, 42–72. [Google Scholar] [CrossRef]

- Tang, Z.; Melville, B.; Singhal, N.; Shamseldin, A.; Zheng, J.; Guan, D.; Cheng, L. Countermeasures for Local Scour at Offshore Wind Turbine Monopile Foundations: A Review. Water Sci. Eng. 2022, 15, 15–28. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, X.; Yan, J.; Gao, X. Countermeasures for Local Scour around Offshore Wind Turbine Monopile Foundations: A Review. Appl. Ocean Res. 2023, 141, 103764. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. Int. J. Surg. 2010, 8, 336–341. [Google Scholar] [CrossRef]

- Roulund, A.; Sumer, B.M.; Fredsøe, J.; Michelsen, J. Numerical and Experimental Investigation of Flow and Scour around a Circular Pile. J. Fluid Mech. 2005, 534, 351–401. [Google Scholar] [CrossRef]

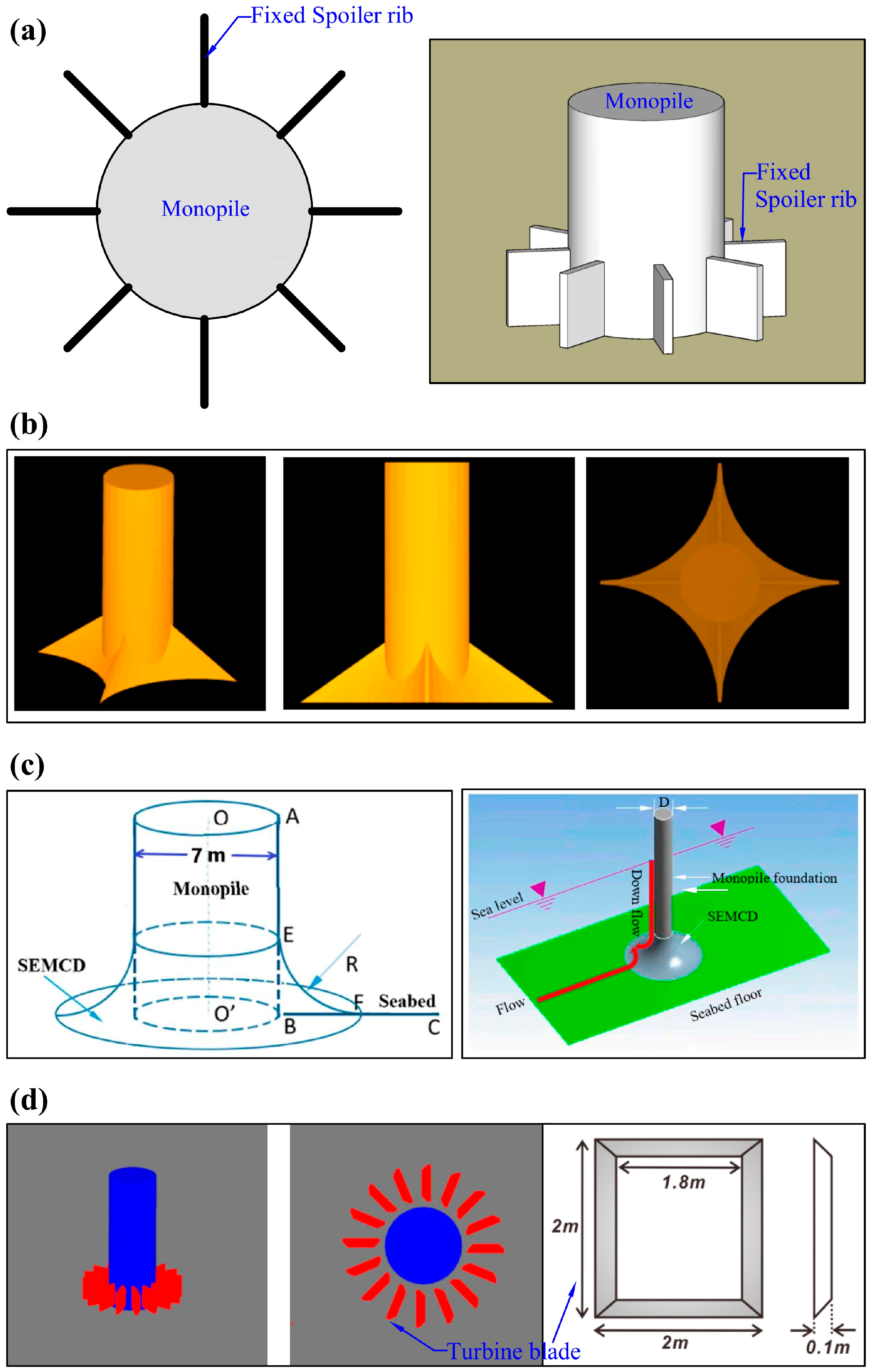

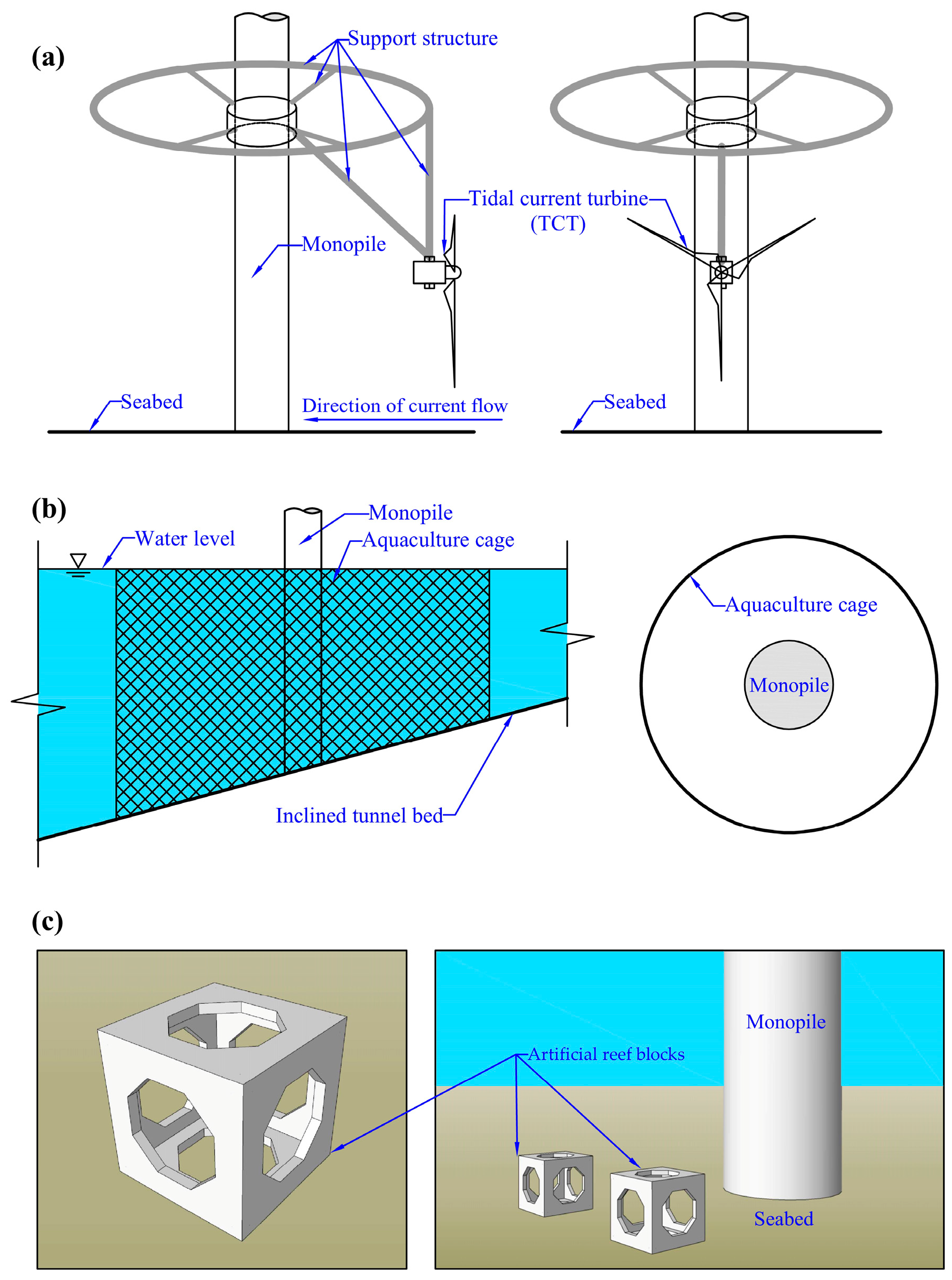

- Yang, B.; Wei, K.; Yang, W.; Li, T.; Qin, B. A Feasibility Study of Reducing Scour around Monopile Foundation Using a Tidal Current Turbine. Ocean Eng. 2021, 220, 108396. [Google Scholar] [CrossRef]

- Cho, Y.-J. Scour Controlling Effect of Hybrid Mono-Pile as a Substructure of Offshore Wind Turbine: A Numerical Study. J. Mar. Sci. Eng. 2020, 8, 637. [Google Scholar] [CrossRef]

- Matutano, C.; Negro, V.; López-Gutiérrez, J.-S.; Dolores Esteban, M. Design of Scour Protection Systems in Offshore Wind Farms. J. Energy Resour. Technol. 2015, 137, 051204. [Google Scholar] [CrossRef]

- Fazeres-Ferradosa, T.; Taveira-Pinto, F.; Reis, M.T.; das Neves, L. Physical Modelling of Dynamic Scour Protections: Analysis of the Damage Number. Proc. Inst. Civ. Eng. Marit. Eng. 2018, 171, 11–24. [Google Scholar] [CrossRef]

- Fazeres-Ferradosa, T.; Taveira-Pinto, F.; Romão, X.; Vanem, E.; Reis, M.T.; das Neves, L. Probabilistic Design and Reliability Analysis of Scour Protections for Offshore Windfarms. Engineering Failure Analysis 2018, 91, 291–305. [Google Scholar] [CrossRef]

- De Vos, L.; De Rouck, J.; Troch, P.; Frigaard, P. Empirical Design of Scour Protections around Monopile Foundations: Part 1: Static Approach. Coast. Eng. 2011, 58, 540–553. [Google Scholar] [CrossRef]

- De Vos, L.; De Rouck, J.; Troch, P.; Frigaard, P. Empirical Design of Scour Protections around Monopile Foundations. Part 2: Dynamic Approach. Coast. Eng. 2012, 60, 286–298. [Google Scholar] [CrossRef]

- Schendel, A.; Goseberg, N.; Schlurmann, T. Experimental Study on the Performance of Coarse Grain Materials as Scour Protection. In Proceedings of the Coastal Engineering Conference (2014), Seoul, Republic of Korea, 15–20 June 2014. [Google Scholar] [CrossRef]

- Wang, W.; Yan, J.; Chen, S.; Liu, J.; Jin, F.; Wang, B. Gridded Cemented Riprap for Scour Protection around Monopile in the Marine Environment. Ocean Eng. 2023, 272, 113876. [Google Scholar] [CrossRef]

- Whitehouse, R.; Audenaert, S.; Baelus, L.; Bolle, A.; Brown, A.; Neves, L.; De Schoesitter, P.; Fazeres Ferradosa, T.; Haerens, P.; Taveira-Pinto, F.; et al. Optimising Scour Protection Stability at Offshore Foundations. In Proceedings of the 7th International Conference on Scour and Erosion, Perth, Australia, 2–4 December 2014; ISBN 978-1-138-02732-9. [Google Scholar]

- Wu, M.; De Vos, L.; Arboleda Chavez, C.E.; Stratigaki, V.; Whitehouse, R.; Baelus, L.; Troch, P. A Study of Scale Effects in Experiments of Monopile Scour Protection Stability. Coast. Eng. 2022, 178, 104217. [Google Scholar] [CrossRef]

- Esteban, M.D.; López-Gutiérrez, J.-S.; Negro, V.; Sanz, L. Riprap Scour Protection for Monopiles in Offshore Wind Farms. J. Mar. Sci. Eng. 2019, 7, 440. [Google Scholar] [CrossRef]

- den Boon, H.; Sutherland, J.; Whitehouse, R.; Soulsby, R.; Stam, C.-J.; Verhoeven, K.; Høgedal, M.; Hald, T. Scour Behaviour and Scour Protection for Monopile Foundations of Offshore Wind Turbines. In Proceedings of the European Wind Energy Conference & Exhibition (EWEC), London, UK, 22–25 November 2004. [Google Scholar]

- Høgedal, M.; Hald, T. Scour Assessment and Design for Scour for Monopile Foundations for Offshore Wind Turbines; Copenhagen Offshore Wind: Copenhagen, Denmark, 2005; pp. 1–10. [Google Scholar]

- Whitehouse, R.; Sutherland, J.; O’Brien, D. Seabed Scour Assessment for Offshore Windfarm. In Proceedings of the International Conference on Scour and Erosion, Gouda, The Netherlands, 3–5 July 2007. [Google Scholar]

- Riezebos, H.; Raaijmakers, T.; Tönnies-Lohmann, A.; Waßmuth, S.; Van Steijn, P. Scour protection design in highly morphodynamic environments. In Proceedings of the 8th International Conference on Scour and Erosion, Oxford, UK, 12–15 September 2016; pp. 301–311. [Google Scholar]

- Matutano, C.; Negro, V.; Lopez-Gutierrez, J.-S.; Esteban, M.D.; del Campo, J.M. Dimensionless Wave Height Parameter for Preliminary Design of Scour Protection in Offshore Wind Farms. J. Coast. Res. 2013, 2, 1633–1638. [Google Scholar] [CrossRef]

- Matutano, C.; Negro, V.; López-Gutiérrez, J.-S.; Esteban, M.D. Scour Prediction and Scour Protections in Offshore Wind Farms. Renew. Energy 2013, 57, 358–365. [Google Scholar] [CrossRef]

- Nielsen, A.W.; Petersen, T.U. Stability of Cover Stones around a Vertical Cylinder under the Influence of Waves and Current. Coast. Eng. 2019, 154, 103563. [Google Scholar] [CrossRef]

- de Schoesitter, P.; Audenaert, S.; Baelus, L.; Bolle, A.; Brown, A.; Das Neves, L.; Ferradosa, T.; Haerens, P.; Pinto, F.T.; Troch, P.; et al. Feasibility of a Dynamically Stable Rock Armour Layer Scour Protection for Offshore Wind Farms. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, San Francisco, CA, USA, 8–14 June 2014. [Google Scholar]

- De Vos, L. Optimisation of Scour Protection Design for Monopiles and Quantification of Waver Run-Up. Ph.D. Thesis, Ghent University, Ghent, Belgium, 2008. [Google Scholar]

- Fazeres-Ferradosa, T.; Chambel, J.; Taveira-Pinto, F.; Rosa-Santos, P.; Taveira-Pinto, F.V.C.; Giannini, G.; Haerens, P. Scour Protections for Offshore Foundations of Marine Energy Harvesting Technologies: A Review. J. Mar. Sci. Eng. 2021, 9, 297. [Google Scholar] [CrossRef]

- Arboleda Chavez, C.E.; Stratigaki, V.; Wu, M.; Troch, P.; Schendel, A.; Welzel, M.; Villanueva, R.; Schlurmann, T.; De Vos, L.; Kisacik, D.; et al. Large-Scale Experiments to Improve Monopile Scour Protection Design Adapted to Climate Change—The PROTEUS Project. Energies 2019, 12, 1709. [Google Scholar] [CrossRef]

- Hansen, E.; Nielsen, A.; Høgedal, M.; Simonsen, H. Scour Protection around Offshore Wind Turbine Foundations, Full-Scale Measurements. In Proceedings of the Scientific Proceedings of the European Wind Energy Conference 2007 (EWEC 2007), Brussels, Belgium, 31 March–3 April 2008. [Google Scholar]

- Raaijmakers, T. Evaluation of Performance of Scour Protection and Edge Scour Development: Offshore Windpark Egmond Aan Zee|Deltares. Available online: https://www.deltares.nl/en/expertise/publicaties/evaluation-of-performance-of-scour-protection-and-edge-scour-development-offshore-windpark-egmond-aan-zee (accessed on 21 December 2023).

- Nielsen, A.W.; Mutlu Sumer, B.; Fredsøe, J.; Christensen, E.D. Sinking of Armour Layer around a Cylinder Exposed to a Current. Proc. Inst. Civ. Eng. Marit. Eng. 2011, 164, 159–172. [Google Scholar] [CrossRef]

- Nielsen, A.W.; Liu, X.; Sumer, B.M.; Fredsøe, J. Flow and Bed Shear Stresses in Scour Protections around a Pile in a Current. Coast. Eng. 2013, 72, 20–38. [Google Scholar] [CrossRef]

- Sumer, B.M.; Nielsen, A.W. Sinking Failure of Scour Protection at Wind Turbine Foundation. Proc. Inst. Civ. Eng. Energy 2013, 166, 170–188. [Google Scholar] [CrossRef]

- Nielsen, A.W.; Petersen, T.U. Onset of Motion of Sediment underneath Scour Protection around a Monopile. J. Mar. Sci. Eng. 2018, 6, 100. [Google Scholar] [CrossRef]

- Nielsen, A.W.; Probst, T.; Petersen, T.U.; Sumer, B.M. Sinking of Armour Layer around a Vertical Cylinder Exposed to Waves and Current. Coast. Eng. 2015, 100, 58–66. [Google Scholar] [CrossRef]

- Tang, Z.; Melville, B.; Shamseldin, A.Y.; Singhal, N.; Guan, D.; Stolte, A. Performance of Riprap Armour at Vibrating Offshore Wind Turbine Monopile Foundations. Coast. Eng. 2023, 186, 104392. [Google Scholar] [CrossRef]

- Ma, H.; Chen, C. Scour Protection Assessment of Monopile Foundation Design for Offshore Wind Turbines. Ocean Eng. 2021, 231, 109083. [Google Scholar] [CrossRef]

- Yin, Q.; Xing, X.; Wang, W.; Zhai, J.; Xu, S. Effect of Scour Erosion and Riprap Protection on Horizontal Bearing Capacity and Reliability of Monopiles Using FEM-BPNN-RSM Coupled Method. Appl. Ocean Res. 2023, 140, 103720. [Google Scholar] [CrossRef]

- Fazeres-Ferradosa, T.; Taveira-Pinto, F.; Rosa-Santos, P.; Chambel, J. Probabilistic Comparison of Static and Dynamic Failure Criteria of Scour Protections. J. Mar. Sci. Eng. 2019, 7, 400. [Google Scholar] [CrossRef]

- Fazeres-Ferradosa, T.; Taveira-Pinto, F.; Romão, X.; Reis, M.; Neves, L. das Reliability Assessment of Offshore Dynamic Scour Protections Using Copulas. Wind. Eng. 2019, 43, 506–538. [Google Scholar] [CrossRef]

- Figueiredo, R.; Fazeres-Ferradosa, T.; Chambel, J.; Rosa Santos, P.; Taveira Pinto, F. How Does the Selection of Wave Hindcast Datasets and Statistical Models Influence the Probabilistic Design of Offshore Scour Protections? Ocean Eng. 2022, 266, 113123. [Google Scholar] [CrossRef]

- Fazeres-Ferradosa, T.; Taveira-Pinto, F.; Rosa-Santos, P.; Chambel, J. A Review of Reliability Analysis of Offshore Scour Protections. Proc. Inst. Civ. Eng. Marit. Eng. 2019, 172, 104–117. [Google Scholar] [CrossRef]

- Wu, M.; De Vos, L.; Arboleda Chavez, C.E.; Stratigaki, V.; Fazeres-Ferradosa, T.; Rosa-Santos, P.; Taveira-Pinto, F.; Troch, P. Large Scale Experimental Study of the Scour Protection Damage Around a Monopile Foundation under Combined Wave and Current Conditions. J. Mar. Sci. Eng. 2020, 8, 417. [Google Scholar] [CrossRef]

- Wu, M.; Arnout, J.; Molina Ruiz, J.; Arboleda Chavez, C.; Stratigaki, V.; Troch, P. Evaluation of Uncertainty of Damage Results in Experimental Modelling of Monopile Foundation Scour Protection. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Glasgow, Scotland, 9–14 June 2019. [Google Scholar]

- Working Group 1 of the Joint Committee for Guides in Metrology (JCGM/WG 1). JCGM 100:2008 Evaluation of Measurement data—Guide to the Expression of Uncertainty in Measurement. Available online: https://www.bipm.org/documents/20126/2071204/JCGM_100_2008_E.pdf/cb0ef43f-baa5-11cf-3f85-4dcd86f77bd6 (accessed on 30 January 2024).

- Mayall, R.O.; McAdam, R.A.; Whitehouse, R.J.S.; Burd, H.J.; Byrne, B.W.; Heald, S.G.; Sheil, B.B.; Slater, P.L. Flume Tank Testing of Offshore Wind Turbine Dynamics with Foundation Scour and Scour Protection. J. Waterw. Port Coast. Ocean. Eng. 2020, 146, 04020033. [Google Scholar] [CrossRef]

- Yao, Z.; Melville, B.W.; Guan, D.; Shamseldin, A.Y.; Li, J.; Tang, Z. The Use of Backfilling to Remediate Sand Motion Issues around Vibrating Monopile Foundations. Ocean Eng. 2022, 256, 111558. [Google Scholar] [CrossRef]

- Wang, J.; Xie, J.; Wu, Y.; Wang, C.; Liang, F. An Investigation of the Effect of Utilizing Solidified Soil as Scour Protection for Offshore Wind Turbine Foundations via a Simplified Scour Resistance Test. J. Mar. Sci. Eng. 2022, 10, 1317. [Google Scholar] [CrossRef]

- OuYang, H.; Dai, G.; Gao, L.; Zhu, W.; Du, S.; Gong, W. Local Scour Characteristics of Monopile Foundation and Scour Protection of Cement-Improved Soil in Marine Environment—Laboratory and Site Investigation. Ocean Eng. 2022, 255, 111443. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, X.; Feng, T.; Wang, Y.; Liu, X.; Liu, X. Experimental Study of Grouting Protection against Local Scouring of Monopile Foundations for Offshore Wind Turbines. Ocean Eng. 2022, 258, 111798. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, X.; Feng, T.; Zhang, Y. Experimental Investigation of the Horizontal Bearing Capacity of Offshore Wind-Turbine Monopiles with Grouting Protection against Scouring. Ocean Eng. 2023, 280, 114848. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, X.; Feng, T.; Zhang, Y.; Guan, J. Method to Determine the Ultimate Horizontal Bearing Capacity of Offshore Wind Turbine Monopiles with Grouting Protection against Scouring. Ocean Eng. 2023, 286, 115638. [Google Scholar] [CrossRef]

- Tao, J.; Li, J.; Wang, X.; Bao, R. Nature-Inspired Bridge Scour Countermeasures: Streamlining and Biocementation. J. Test. Eval. 2018, 46, 20170517. [Google Scholar] [CrossRef]

- Kou, H.; Wu, C.; Ni, P.; Jang, B.-A. Assessment of Erosion Resistance of Biocemented Sandy Slope Subjected to Wave Actions. Appl. Ocean Res. 2020, 105, 102401. [Google Scholar] [CrossRef]

- Lambert, J.W.M.; Novakowski, K.; Blauw, M.; Latil, M.N.; Knight, L.; Bayona, L. Pamper Bacteria, They Will Help Us: Application of Biochemical Mechanisms in Geo-Environmental Engineering. GeoFlorida 2010 Adv. Anal. Model. Des. 2012, 618–627. [Google Scholar] [CrossRef]

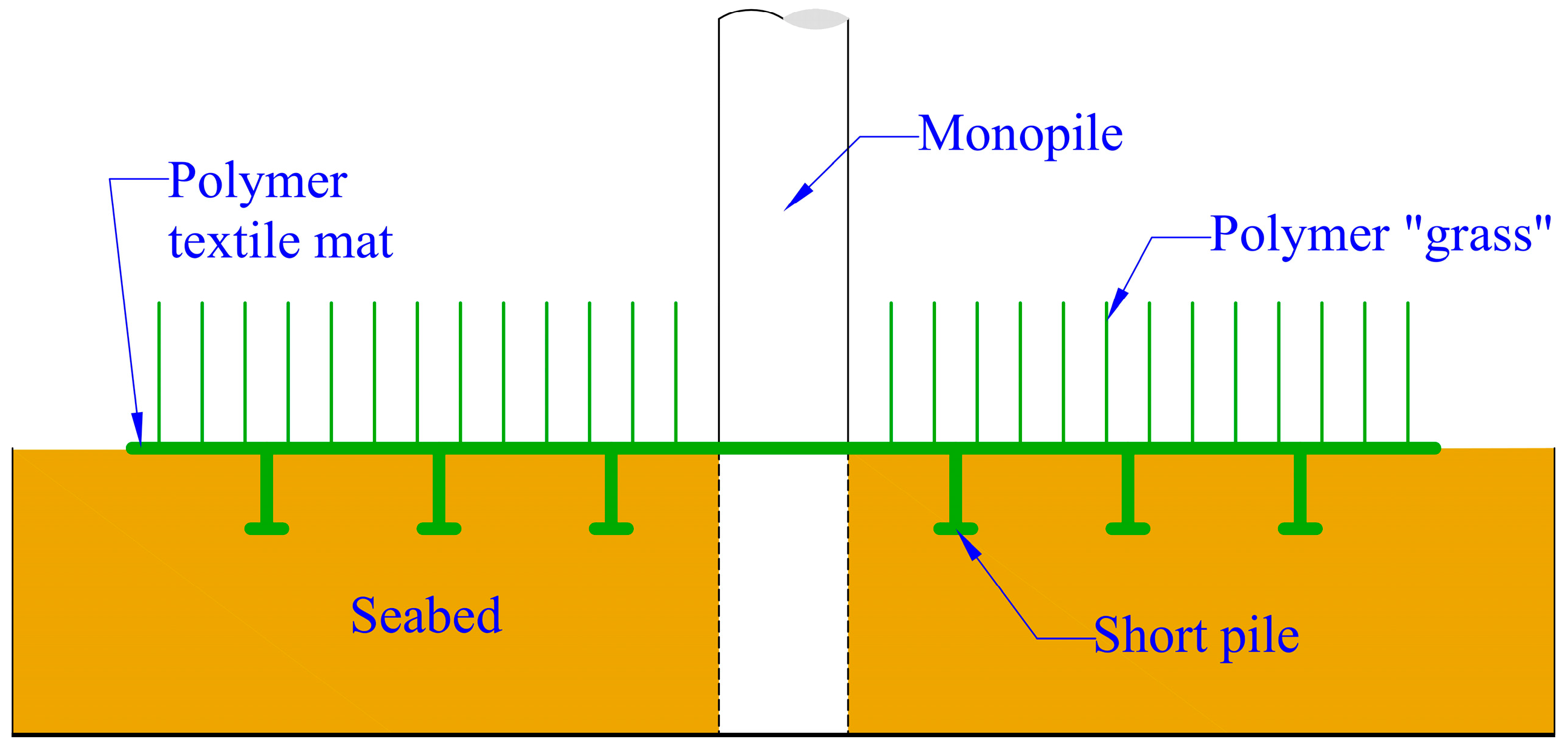

- Li, Y.; Guo, Z.; Wang, L.; Yang, H.; Li, Y.; Zhu, J. An Innovative Eco-Friendly Method for Scour Protection around Monopile Foundation. Appl. Ocean Res. 2022, 123, 103177. [Google Scholar] [CrossRef]

- Hamdan, N.M. Applications of Enzyme Induced Carbonate Precipitation (EICP) for Soil Improvement; Arizona State University: Tempe, AZ, USA, 2015. [Google Scholar]

- Plenker, D.; Heins, E.; Grabe, J. Shape Optimisation of Model Scale Geotextile Sand Containers (GSC) Regarding Sinking Behaviour: First Results of Physical Model Tests. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Busan, Republic of Korea, 19–24 June 2016. [Google Scholar]

- Hoyme, H.; Su, J.H.; Kono, J.; Wallbaum, H. Nonwoven Geotextile Scour Protection at Offshore Wind Parks, Application and Life Cycle Assessment; CRC Press: Boca Raton, FL, USA, 2019; pp. 315–321. [Google Scholar]

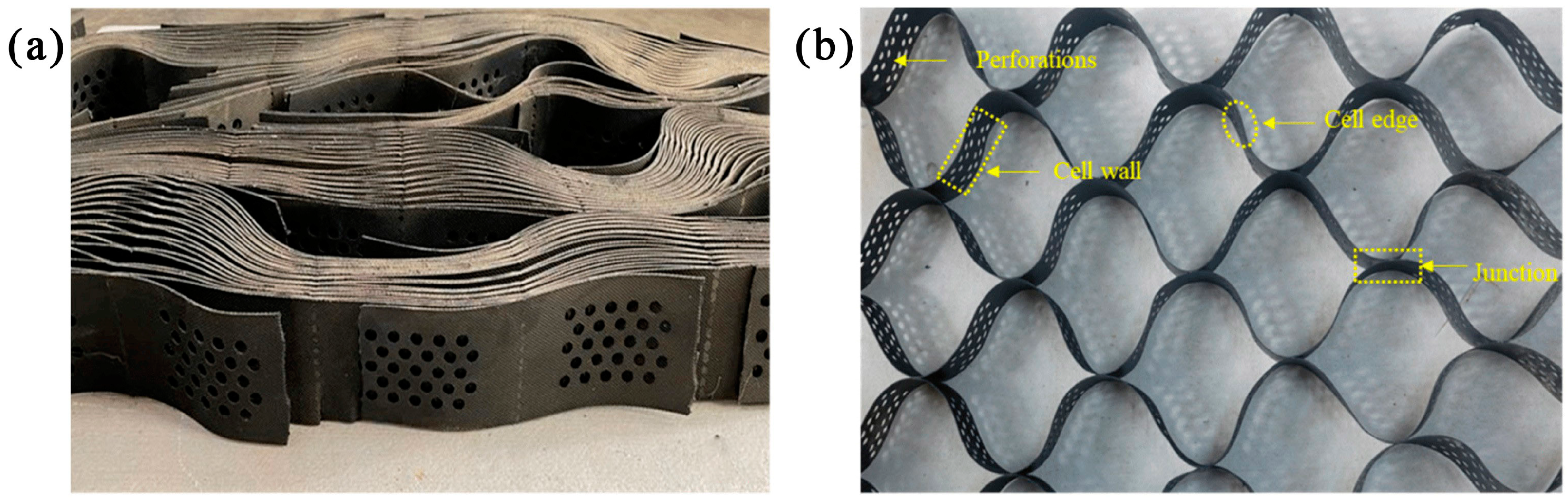

- Wang, G.; Xu, S.; Zhang, Q.; Zhang, J. An Experimental Study of the Local Scour Protection Methods around the Monopile Foundation of Offshore Wind Turbines. Ocean Eng. 2023, 273, 113957. [Google Scholar] [CrossRef]

- Krishna, A.; Latha, G.M. Evolution of Geocells as Sustainable Support to Transportation Infrastructure. Sustainability 2023, 15, 11773. [Google Scholar] [CrossRef]

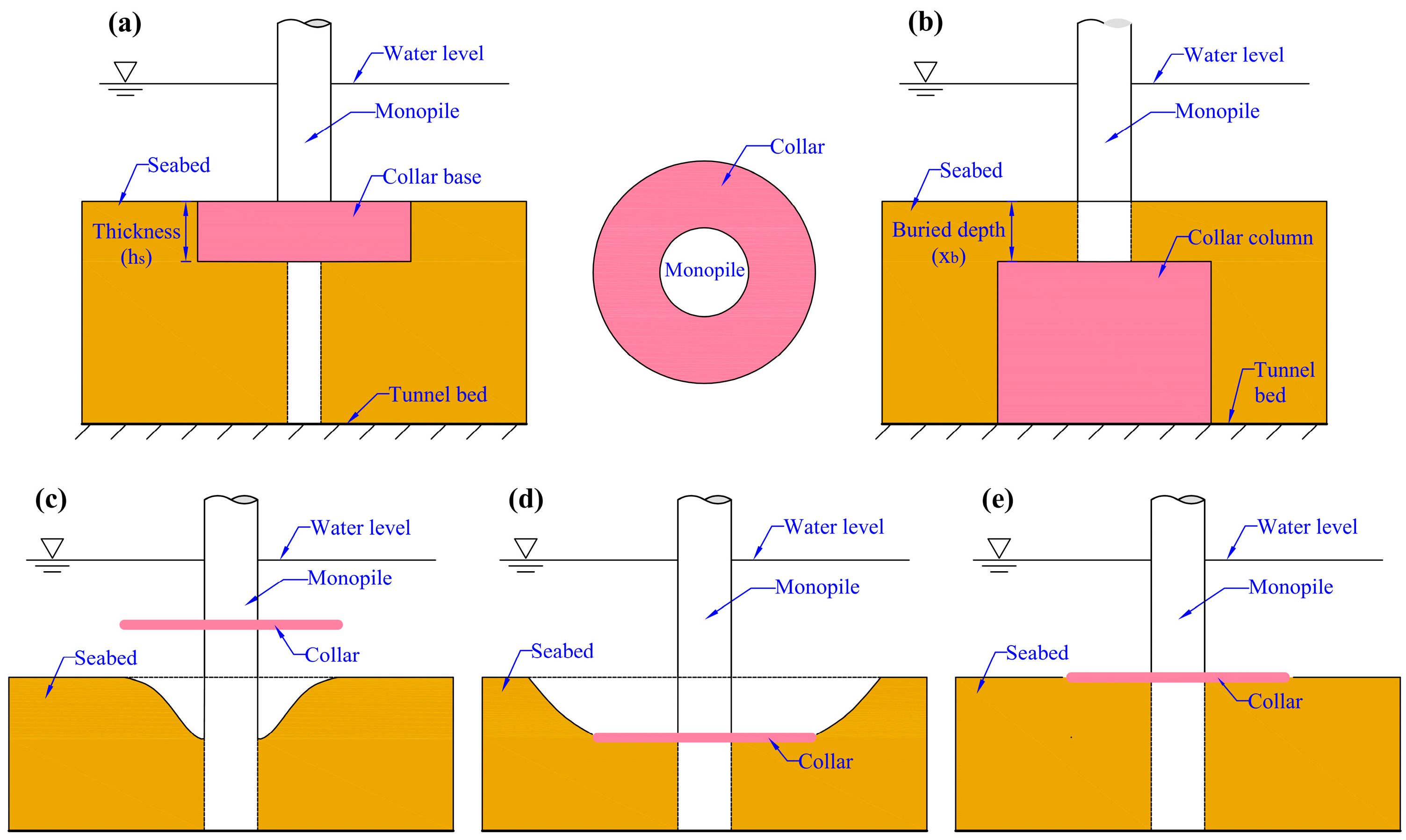

- Zhang, Q.; Tang, G.; Lu, L.; Yang, F. Scour Protections of Collar around a Monopile Foundation in Steady Current. Appl. Ocean Res. 2021, 112, 102718. [Google Scholar] [CrossRef]

- Tang, Z.; Melville, B.; Shamseldin, A.; Guan, D.; Singhal, N.; Yao, Z. Experimental Study of Collar Protection for Local Scour Reduction around Offshore Wind Turbine Monopile Foundations. Coast. Eng. 2023, 183, 104324. [Google Scholar] [CrossRef]

- Li, H.; Qiu, X.; Yan, S.; Zhao, H.; Ma, W. Numerical Investigation on the Influence of a Spoiler Structure for Local Scour Protection. Appl. Ocean Res. 2023, 138, 103675. [Google Scholar] [CrossRef]

- Yang, W.; Tian, W. Concept Research of a Countermeasure Device for Preventing Scour around the Monopile Foundations of Offshore Wind Turbines. Energies 2018, 11, 2593. [Google Scholar] [CrossRef]

- Li, J.; Lian, J.; Guo, Y.; Wang, H.; Yang, X. Numerical Study on Scour Protection Effect of Monopile Foundation Based on Disturbance Structure. Ocean Eng. 2022, 248, 110856. [Google Scholar] [CrossRef]

- Wei, K.; Yang, W.; Yang, B.; Qin, B. Study for Mitigating Scour around the Monopile Foundations of Offshore Wind Turbines. In Proceedings of the 8th Renewable Power Generation Conference (RPG 2019), Shanghai, China, 24–25 October 2019; pp. 1–6. [Google Scholar]

- Yang, B.; Wei, K.; Yang, W.; Li, T.; Qin, B.; Ning, L. A Feasibility Study for Using Fishnet to Protect Offshore Wind Turbine Monopile Foundations from Damage by Scouring. Appl. Sci. 2019, 9, 5023. [Google Scholar] [CrossRef]

- Xie, L.; Zhu, Y. Scour Protection of Underwater Pipelines. J. Civ. Eng. Constr. 2018, 7, 171–177. [Google Scholar] [CrossRef]

- Piano, M.; Neill, S.P.; Lewis, M.J.; Robins, P.E.; Hashemi, M.R.; Davies, A.G.; Ward, S.L.; Roberts, M.J. Tidal Stream Resource Assessment Uncertainty Due to Flow Asymmetry and Turbine Yaw Misalignment. Renew. Energy 2017, 114, 1363–1375. [Google Scholar] [CrossRef]

- Wang, T.-Y.; Xu, T.-J.; Wang, S.; Dong, G.-H.; Yan, L.-H. Hydrodynamic Analysis of the Combined Structure of Offshore Monopile Wind Turbine Foundation and Aquaculture Cage. Ocean Eng. 2023, 287, 115796. [Google Scholar] [CrossRef]

- Yang, M.; Tang, Y.; Zhao, F.; Xu, S. Numerical Simulation of Offshore Wind Power Pile Foundation Scour with Different Arrangements of Artificial Reefs. Front. Mar. Sci. 2023, 10, 1178370. [Google Scholar] [CrossRef]

- Welzel, M.; Schendel, A.; Schlurmann, T.; Hildebrandt, A. Volume-Based Assessment of Erosion Patterns around a Hydrodynamic Transparent Offshore Structure. Energies 2019, 12, 3089. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, J.; Wang, F.; Guo, Y.; Guan, D.; Feng, L. Experimental Investigation of the Current Induced Local Scour around a Jacket Foundation. Ocean Eng. 2023, 285, 115369. [Google Scholar] [CrossRef]

- Welzel, M.; Schendel, A.; Hildebrandt, A.; Schlurmann, T. Scour Development around a Jacket Structure in Combined Waves and Current Conditions Compared to Monopile Foundations. Coast. Eng. 2019, 152, 103515. [Google Scholar] [CrossRef]

- Welzel, M.; Schendel, A.; Goseberg, N.; Hildebrandt, A.; Schlurmann, T. Influence of Structural Elements on the Spatial Sediment Displacement around a Jacket-Type Offshore Foundation. Water 2020, 12, 1651. [Google Scholar] [CrossRef]

- Li, J.; Guo, Y.; Lian, J.; Wang, H. Scour Effects on the Bearing Capacity of Multi-Bucket Jacket Foundation for Offshore Wind Turbines. Ocean Eng. 2022, 259, 111848. [Google Scholar] [CrossRef]

- Cheng, Y.; Ge, X.; He, B.; Zhou, Y. Numerical Analysis of Load Bearing Capacity of Offshore Jacket Platform with Suction Caisson. In Proceedings of the 2022 8th International Conference on Hydraulic and Civil Engineering: Deep Space Intelligent Development and Utilization Forum (ICHCE), Xi’an, China, 25–27 November 2022; pp. 480–484. [Google Scholar]

- Chen, H.-H.; Yang, R.-Y.; Li, J.-W.; Hwung, H.-H.; Lin, T.-H.; Lin, M.-C. Study on Multi-Use of an Integrated Offshore Wind Turbine Foundation and Coastal Cage Net. Int. Conf. Coastal. Eng. 2014, 1, structures.26. [Google Scholar] [CrossRef]

- Ouyang, C.; Luo, J.; Wang, T.; Zhang, P. Research on the Effect of Burial Depth on The Bearing Characteristics of Three Helical Piles Jacket Foundation for Offshore Wind Turbines. J. Mar. Sci. Eng. 2023, 11, 1703. [Google Scholar] [CrossRef]

- Yan, C.; Wang, H.; Guo, Y.; Wang, Z.; Liu, X. Laboratory Study of Integrated Wet-Towing of a Triple-Bucket Jacket Foundation for Far-Offshore Applications. J. Mar. Sci. Eng. 2021, 9, 1152. [Google Scholar] [CrossRef]

- Ku, C.-Y.; Chien, L.-K. Modeling of Load Bearing Characteristics of Jacket Foundation Piles for Offshore Wind Turbines in Taiwan. Energies 2016, 9, 625. [Google Scholar] [CrossRef]

- Plodpradit, P.; Kwon, O.; Dinh, V.N.; Murphy, J.; Kim, K.-D. Suction Bucket Pile–Soil–Structure Interactions of Offshore Wind Turbine Jacket Foundations Using Coupled Dynamic Analysis. J. Mar. Sci. Eng. 2020, 8, 416. [Google Scholar] [CrossRef]

- Tang, D.; Zhao, M. 16—Foundation Monitoring System of Offshore Wind Turbines. In Non-Destructive Testing and Condition Monitoring Techniques in Wind Energy; Garcia Marquez, F.P., Papaelias, M., Junior, V.L.J., Eds.; Wind Energy Engineering; Academic Press: New York, NY, USA, 2023; pp. 399–442. ISBN 978-0-323-99666-2. [Google Scholar]

- Kim, Y.-J.; Ngo, D.-V.; Lee, J.-H.; Kim, D.-H. Ultimate Limit State Scour Risk Assessment of a Pentapod Suction Bucket Support Structure for Offshore Wind Turbine. Energies 2022, 15, 2056. [Google Scholar] [CrossRef]

- Sarmiento, J.; Guanche, R.; Iturrioz, A.; Ojanguren, T.; Ávila, A.; Yanes, C. Experimental Evaluation of Dynamic Rock Scour Protection in Morphodynamic Environments for Offshore Wind Jackets. Energies 2021, 14, 3379. [Google Scholar] [CrossRef]

- Chen, H.-H.; Yang, R.-Y.; Hwung, H.-H. Study of Hard and Soft Countermeasures for Scour Protection of the Jacket-Type Offshore Wind Turbine Foundation. J. Mar. Sci. Eng. 2014, 2, 551–567. [Google Scholar] [CrossRef]

- Yang, R.-Y.; Hwung, H.-H.; Chang, P.-C.; Chen, H.-H.; Li, J.-W.; Lin, T.-H. Feasibility Study on an Integrated Offshore Wind Turbine and Mariculture Cage Facility. In Proceedings of the OCEANS 2014—TAIPEI, Taipei, Taiwan, 19 April 2014; pp. 1–7. [Google Scholar]

- Whitehouse, R.J.S.; Sutherland, J.; Harris, J.M. Evaluating Scour at Marine Gravity Foundations. Proc. Inst. Civ. Eng. Marit. Eng. 2011, 164, 143–157. [Google Scholar] [CrossRef]

- Esteban, M.D.; Couñago, B.; López-Gutiérrez, J.S.; Negro, V.; Vellisco, F. Gravity Based Support Structures for Offshore Wind Turbine Generators: Review of the Installation Process. Ocean Eng. 2015, 110, 281–291. [Google Scholar] [CrossRef]

- Whitehouse, R.J.S.; Dunn, S.L.; Alderson, J.S.; Vun, P.L. Testing of the Interaction of Coastal Windfarm Foundations with the Seabed: Scour and Liquefaction. In Coastal Engineering 2004; World Scientific Publishing Company: Singapore, 2005; pp. 4215–4227. ISBN 978-981-256-298-2. [Google Scholar]

- Causon, P.D.; Gill, A.B. Linking Ecosystem Services with Epibenthic Biodiversity Change Following Installation of Offshore Wind Farms. Environ. Sci. Policy 2018, 89, 340–347. [Google Scholar] [CrossRef]

- Glarou, M.; Zrust, M.; Svendsen, J.C. Using Artificial-Reef Knowledge to Enhance the Ecological Function of Offshore Wind Turbine Foundations: Implications for Fish Abundance and Diversity. J. Mar. Sci. Eng. 2020, 8, 332. [Google Scholar] [CrossRef]

- Krone, R.; Dederer, G.; Kanstinger, P.; Krämer, P.; Schneider, C.; Schmalenbach, I. Mobile Demersal Megafauna at Common Offshore Wind Turbine Foundations in the German Bight (North Sea) Two Years after Deployment—Increased Production Rate of Cancer Pagurus. Mar. Environ. Res. 2017, 123, 53–61. [Google Scholar] [CrossRef]

- Maar, M.; Bolding, K.; Petersen, J.K.; Hansen, J.L.S.; Timmermann, K. Local Effects of Blue Mussels around Turbine Foundations in an Ecosystem Model of Nysted Off-Shore Wind Farm, Denmark. J. Sea Res. 2009, 62, 159–174. [Google Scholar] [CrossRef]

- Horwath, S.; Hassrick, J.; Grismala, R.; Diller, E. Comparison of Environmental Effects from Different Offshore Wind Turbine Foundations; Bureau of Ocean Energy Management (BOEM): Washington, DC, USA, 2020. [Google Scholar]

- Hutchison, Z.; Bartley, M.; Degraer, S.; English, P.; Khan, A.; Livermore, J.; Rumes, B.; King, J. Offshore Wind Energy and Benthic Habitat Changes: Lessons from Block Island Wind Farm. Oceanography 2020, 33, 58–69. [Google Scholar] [CrossRef]

- Spielmann, V.; Dannheim, J.; Brey, T.; Coolen, J.W.P. Decommissioning of Offshore Wind Farms and Its Impact on Benthic Ecology. J. Environ. Manag. 2023, 347, 119022. [Google Scholar] [CrossRef] [PubMed]

- Bull, A.S.; Love, M.S. Worldwide Oil and Gas Platform Decommissioning: A Review of Practices and Reefing Options. Ocean Coast. Manag. 2019, 168, 274–306. [Google Scholar] [CrossRef]

- Geißler, P.; Cuéllar, P.; Hüsken, G.; Kühne, H.-C.; Baeßler, M. Insights Into Compaction Grouting for Offshore Pile Foundations. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Madrid, Spain, 17–22 June 2018. [Google Scholar]

- Habib, M.A.; Abolfathi, S.; O’Sullivan, J.; Salauddin, M. Efficient data-driven machine learning models for scour depth predictions at sloping sea defences. Front. Built Environ. 2024, 10, 1343398. [Google Scholar] [CrossRef]

- Pourzangbar, A.; Losada, M.A.; Saber, A.; Ahari, L.R.; Larroudé, P.; Vaezi, M.; Brocchini, M. Prediction of non-breaking wave induced scour depth at the trunk section of breakwaters using Genetic Programming and Artificial Neural Networks. Coast. Eng. 2017, 121, 107–118. [Google Scholar] [CrossRef]

- Salauddin, M.; Shaffrey, D.; Habib, M.A. Data-driven approaches in predicting scour depths at a vertical seawall on a permeable shingle foreshore. J. Coast. Conserv. 2023, 27, 18. [Google Scholar] [CrossRef]

- WindEurope. Offshore Wind and Biodiversity. Available online: https://windeurope.org/intelligence-platform/product/offshore-wind-and-biodiversity (accessed on 19 December 2023).

| Criteria | Include | Exclude |

|---|---|---|

| Language | Research papers published in English | Papers published in languages other than English |

| Publication Year | Published from January 2003 to November 2023 | Published before January 2003 |

| Publication source | Peer-reviewed articles | Non-peer-reviewed papers |

| Focus/Content | Studies focused on scour protection measures for OWTs | Studies focused on scour protection measures for other structures such as bridge piers, seawalls, etc. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, W.; Malekjafarian, A.; Salauddin, M. Scour Protection Measures for Offshore Wind Turbines: A Systematic Literature Review on Recent Developments. Energies 2024, 17, 1068. https://doi.org/10.3390/en17051068

Wei W, Malekjafarian A, Salauddin M. Scour Protection Measures for Offshore Wind Turbines: A Systematic Literature Review on Recent Developments. Energies. 2024; 17(5):1068. https://doi.org/10.3390/en17051068

Chicago/Turabian StyleWei, Wenhui, Abdollah Malekjafarian, and M. Salauddin. 2024. "Scour Protection Measures for Offshore Wind Turbines: A Systematic Literature Review on Recent Developments" Energies 17, no. 5: 1068. https://doi.org/10.3390/en17051068

APA StyleWei, W., Malekjafarian, A., & Salauddin, M. (2024). Scour Protection Measures for Offshore Wind Turbines: A Systematic Literature Review on Recent Developments. Energies, 17(5), 1068. https://doi.org/10.3390/en17051068