Characteristics and Changes in the Properties of Cereal and Rapeseed Straw Used as Energy Feedstock

Abstract

1. Introduction

2. Materials and Methods

2.1. Material and Research Factors

2.2. Laboratory Analyses

- LHV—lower heating value (J g−1),

- HHV—higher heating value (J g−1 DM),

- H—hydrogen content (% DM),

- MC—moisture content (%).

2.3. Statistical Analysis

3. Results and Discussion

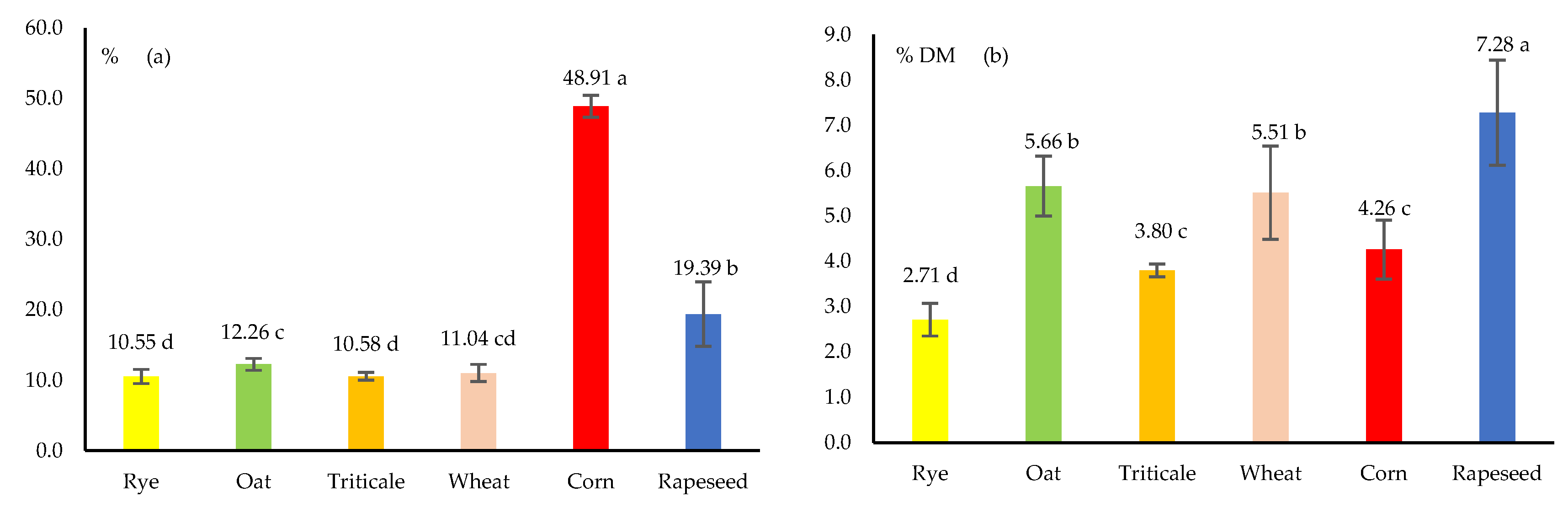

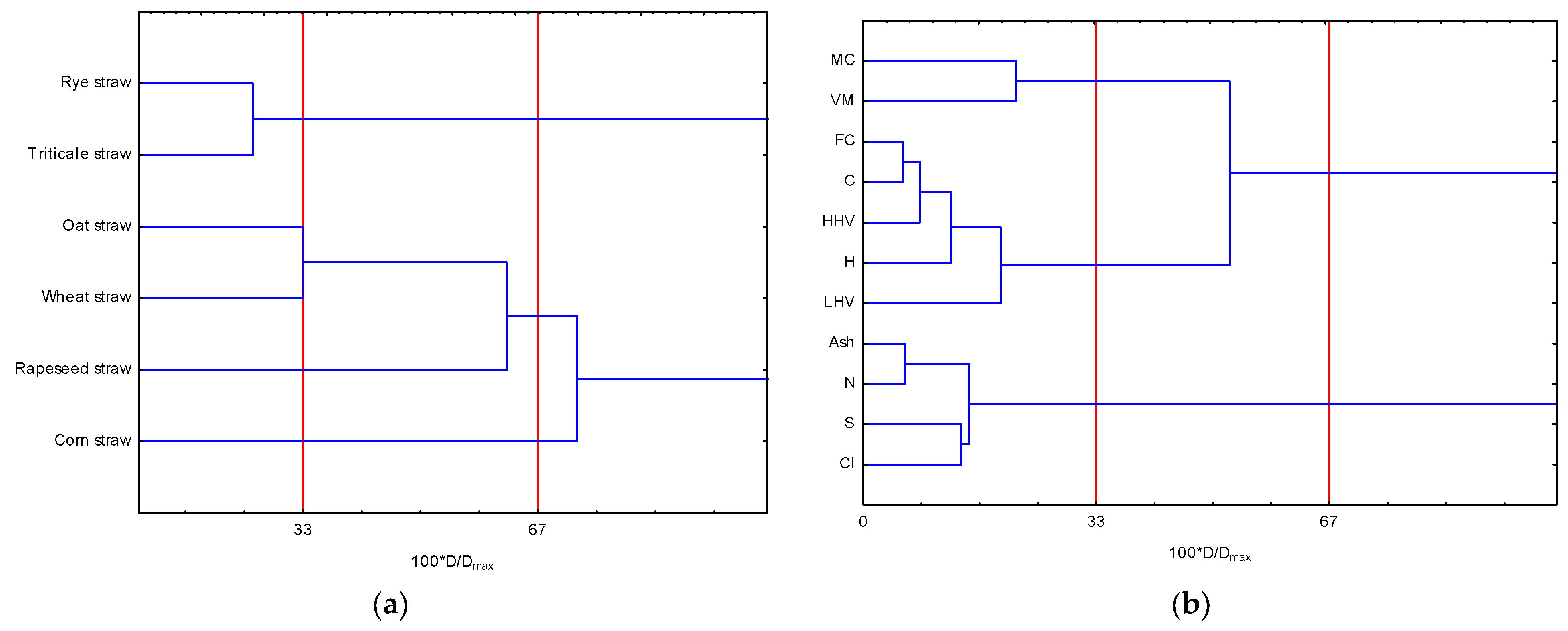

3.1. Thermophysical Characteristics

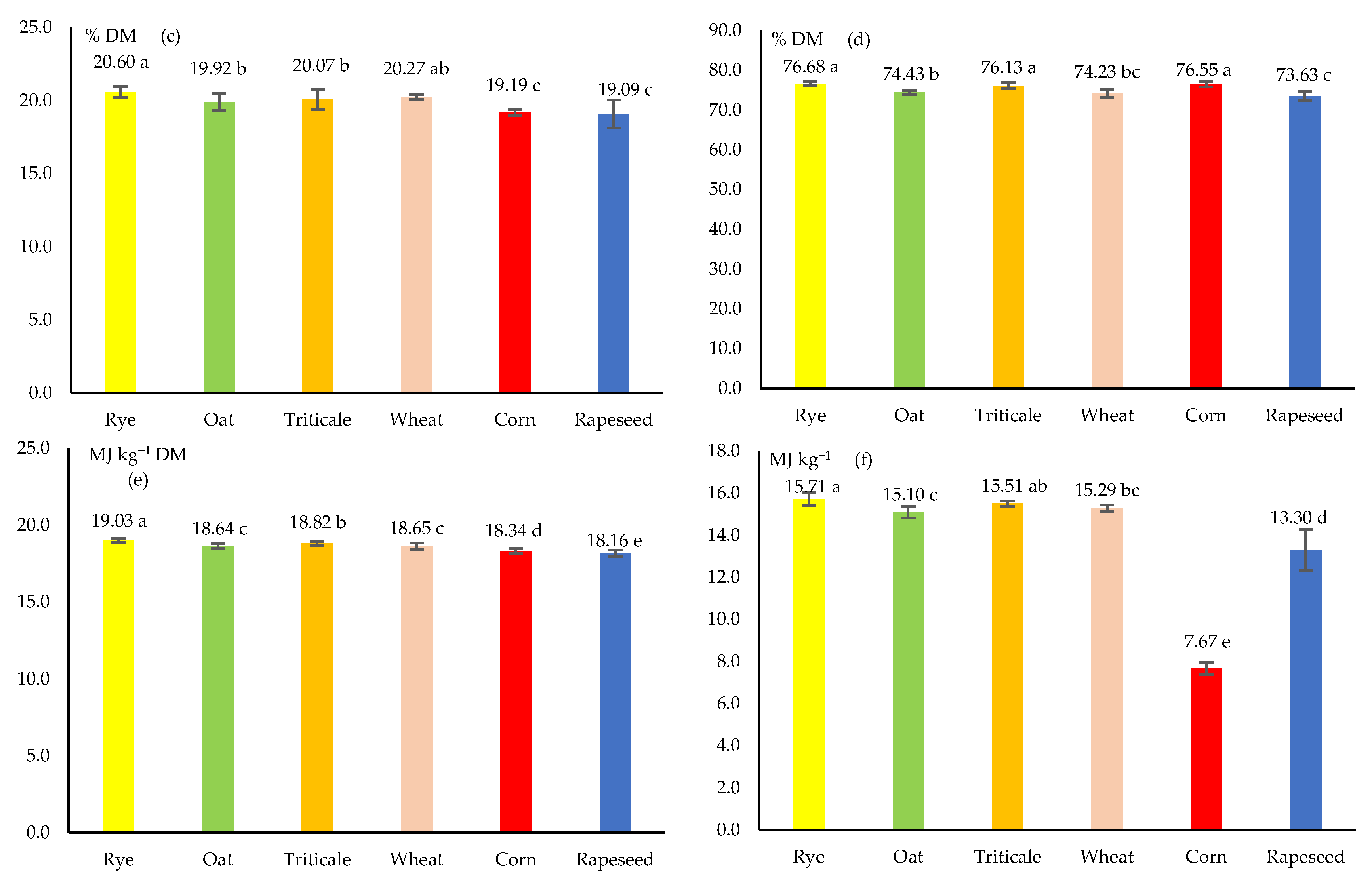

3.2. Elemental Composition

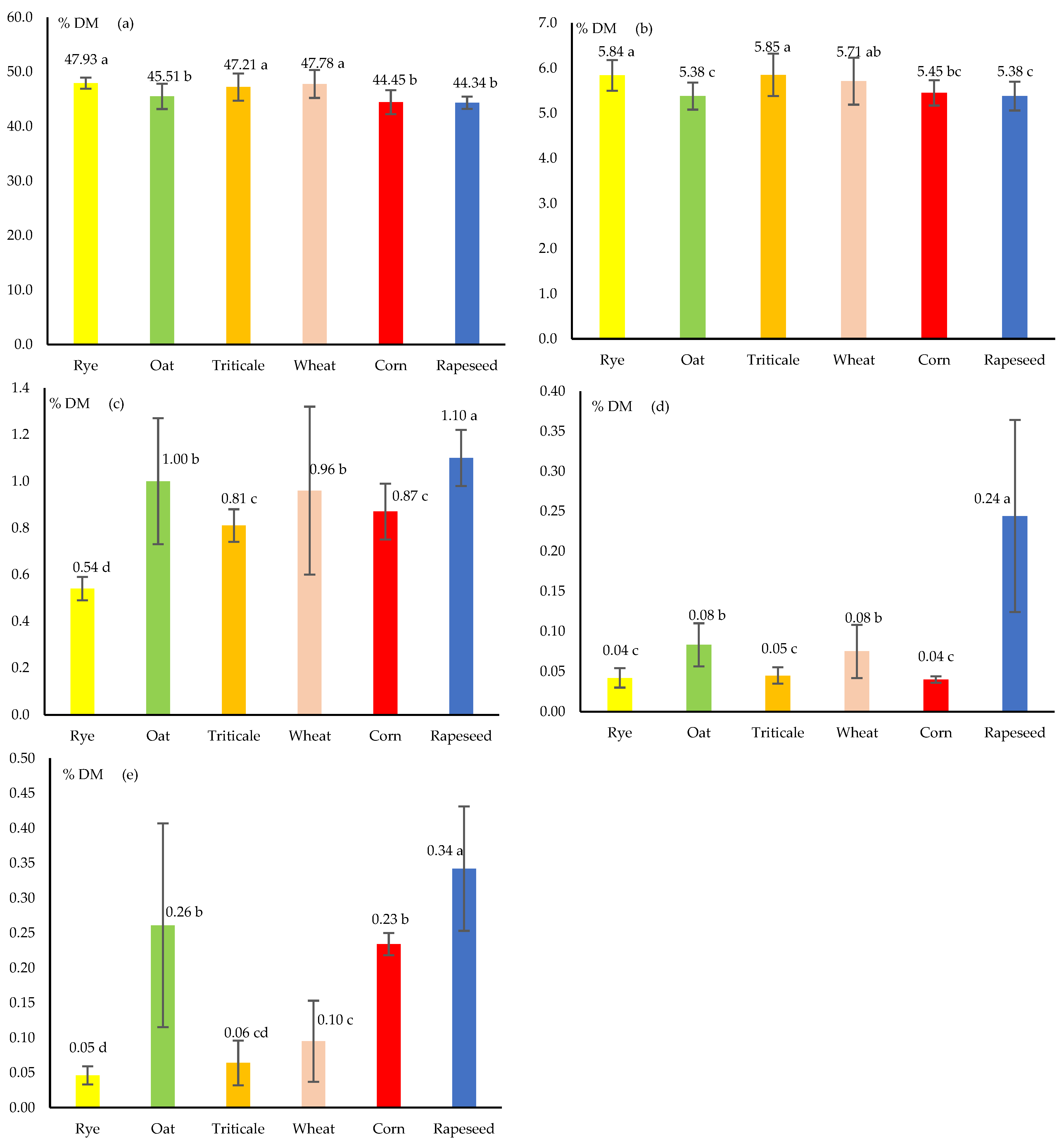

3.3. General Characteristics of Straw as Solid Biofuel

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eurostat 2024 Share of Energy from Renewable Sources. Available online: https://Ec.Europa.Eu/Eurostat/Databrowser/View/Nrg_ind_ren/Default/Table?Lang=en (accessed on 10 January 2024).

- Statistics Poland. Energy from Renewable Sources in 2022; Statistics Poland: Warsaw, Poland, 2023. [Google Scholar]

- Jankowski, K.J.; Dubis, B.; Sokólski, M.M.; Załuski, D.; Bórawski, P.; Szempliński, W. Productivity and Energy Balance of Maize and Sorghum Grown for Biogas in a Large-Area Farm in Poland: An 11-Year Field Experiment. Ind. Crops Prod. 2020, 148, 112326. [Google Scholar] [CrossRef]

- Picchio, R.; Latterini, F.; Venanzi, R.; Stefanoni, W.; Suardi, A.; Tocci, D.; Pari, L. Pellet Production from Woody and Non-Woody Feedstocks: A Review on Biomass Quality Evaluation. Energies 2020, 13, 2937. [Google Scholar] [CrossRef]

- Enström, J.; Eriksson, A.; Eliasson, L.; Larsson, A.; Olsson, L. Wood Chip Supply from Forest to Port of Loading—A Simulation Study. Biomass Bioenergy 2021, 152, 106182. [Google Scholar] [CrossRef]

- Stolarski, J.; Wierzbicki, S.; Nitkiewicz, S.; Stolarski, M.J. Wood Chip Production Efficiency Depending on Chipper Type. Energies 2023, 16, 4894. [Google Scholar] [CrossRef]

- Manzone, M.; Bergante, S.; Facciotto, G. Energy and Economic Evaluation of a Poplar Plantation for Woodchips Production in Italy. Biomass Bioenergy 2014, 60, 164–170. [Google Scholar] [CrossRef]

- Serapiglia, M.J.; Cameron, K.D.; Stipanovic, A.J.; Abrahamson, L.P.; Volk, T.A.; Smart, L.B. Yield and Woody Biomass Traits of Novel Shrub Willow Hybrids at Two Contrasting Sites. Bioenergy Res. 2013, 6, 533–546. [Google Scholar] [CrossRef]

- Scordia, D.; Papazoglou, E.G.; Kotoula, D.; Sanz, M.; Ciria, C.S.; Pérez, J.; Maliarenko, O.; Prysiazhniuk, O.; von Cossel, M.; Greiner, B.E.; et al. Towards Identifying Industrial Crop Types and Associated Agronomies to Improve Biomass Production from Marginal Lands in Europe. GCB Bioenergy 2022, 14, 710–734. [Google Scholar] [CrossRef]

- Matyka, M.; Radzikowski, P. Productivity and Biometric Characteristics of 11 Varieties of Willow Cultivated on Marginal Soil. Agriculture 2020, 10, 616. [Google Scholar] [CrossRef]

- Amaducci, S.; Facciotto, G.; Bergante, S.; Perego, A.; Serra, P.; Ferrarini, A.; Chimento, C. Biomass Production and Energy Balance of Herbaceous and Woody Crops on Marginal Soils in the Po Valley. GCB Bioenergy 2017, 9, 31–45. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Warmiński, K.; Krzyżaniak, M.; Olba–Zięty, E.; Akincza, M. Bioenergy Technologies and Biomass Potential Vary in Northern European Countries. Renew. Sustain. Energy Rev. 2020, 133, 110238. [Google Scholar] [CrossRef]

- Hajj Obeid, M.; Douzane, O.; Freitas Dutra, L.; Promis, G.; Laidoudi, B.; Bordet, F.; Langlet, T. Physical and Mechanical Properties of Rapeseed Straw Concrete. Materials 2022, 15, 8611. [Google Scholar] [CrossRef]

- Fu, Y.; Zhang, J.; Guan, T. High-Value Utilization of Corn Straw: From Waste to Wealth. Sustainability 2023, 15, 14618. [Google Scholar] [CrossRef]

- Li, Z.; Guan, J.; Yan, C.; Chen, N.; Wang, C.; Liu, T.; Cheng, F.; Guo, Q.; Zhang, X.; Ye, X.; et al. Corn Straw Core/Cellulose Nanofibers Composite for Food Packaging: Improved Mechanical, Bacteria Blocking, Ultraviolet and Water Vapor Barrier Properties. Food Hydrocoll. 2023, 143, 108884. [Google Scholar] [CrossRef]

- Shen, T.; Li, M.; Zhang, B.; Zhong, L.; Lin, X.; Yang, P.; Li, M.; Zhuang, W.; Zhu, C.; Ying, H. Enhanced Mechanical Properties of Polyvinyl Chloride-Based Wood–Plastic Composites with Pretreated Corn Stalk. Front. Bioeng. Biotechnol. 2022, 9, 829821. [Google Scholar] [CrossRef] [PubMed]

- Gradziuk, P. The Economic Importance and Possibilities of Using Straw for Energy Purposes in Poland; Institute of Soil Science and Plant Cultivation State Research Institute: Puławy, Poland, 2015. [Google Scholar]

- Scarlat, N.; Martinov, M.; Dallemand, J.-F. Assessment of the Availability of Agricultural Crop Residues in the European Union: Potential and Limitations for Bioenergy Use. Waste Manag. 2010, 30, 1889–1897. [Google Scholar] [CrossRef] [PubMed]

- Neshat, S.A.; Mohammadi, M.; Najafpour, G.D.; Lahijani, P. Anaerobic Co-Digestion of Animal Manures and Lignocellulosic Residues as a Potent Approach for Sustainable Biogas Production. Renew. Sustain. Energy Rev. 2017, 79, 308–322. [Google Scholar] [CrossRef]

- Álvaro, A.G.; Palomar, C.R.; Redondo, D.H.; Torre, R.M.; de Godos Crespo, I. Simultaneous Production of Biogas and Volatile Fatty Acids through Anaerobic Digestion Using Cereal Straw as Substrate. Environ. Technol. Innov. 2023, 31, 103215. [Google Scholar] [CrossRef]

- Kumar, A.; Demirel, Y.; Jones, D.D.; Hanna, M.A. Optimization and Economic Evaluation of Industrial Gas Production and Combined Heat and Power Generation from Gasification of Corn Stover and Distillers Grains. Bioresour. Technol. 2010, 101, 3696–3701. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.; Wyman, C.E. A Novel Mechanism and Kinetic Model to Explain Enhanced Xylose Yields from Dilute Sulfuric Acid Compared to Hydrothermal Pretreatment of Corn Stover. Bioresour. Technol. 2011, 102, 9111–9120. [Google Scholar] [CrossRef]

- Liu, J.; Wang, C.; Zhao, X.; Yin, F.; Yang, H.; Wu, K.; Liang, C.; Yang, B.; Zhang, W. Bioethanol Production from Corn Straw Pretreated with Deep Eutectic Solvents. Electron. J. Biotechnol. 2023, 62, 27–35. [Google Scholar] [CrossRef]

- Poudel, J.; Oh, S.C. Effect of Torrefaction on the Properties of Corn Stalk to Enhance Solid Fuel Qualities. Energies 2014, 7, 5586–5600. [Google Scholar] [CrossRef]

- PN-EN ISO 18134-2; Solid Biofuels–Determination of Moisture Content–Dryer Method–Part 2: Total Moisture–Simplified Method. Polish Standardization Committee: Warsaw, Poland, 2014.

- PN-EN ISO 16948:2015-07; Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen. Polish Standardization Committee: Warsaw, Poland, 2015.

- PN-EN ISO 16994:2016-10; Solid Biofuels—Determination of Total Content of Sulfur and Chlorine. Polish Standardization Committee: Warsaw, Poland, 2016.

- PN-ISO 587:2000; Solid Fuels—Determination of Chlorine Using Eschka Mixture. Polish Standardization Committee: Warsaw, Poland, 2000.

- PN-EN ISO 18122:2016-01; Solid Biofuels—Determination of Ash Content. Polish Standardization Committee: Warsaw, Poland, 2016.

- PN-EN ISO 18123:2016-01; Solid Biofuels—Determination of Volatile Matter Content. Polish Standardization Committee: Warsaw, Poland, 2016.

- PN-EN ISO 18125:2017-07; Solid Biofuels—Determination of Calorific Value. Polish Standardization Committee: Warsaw, Poland, 2017.

- Cordero, T.; Marquez, F.; Rodriguez-Mirasol, J.; Rodriguez, J.J. Predicting Heating Values of Lignocellulosics and Carbonaceous Materials from Proximate Analysis. Fuel 2001, 80, 1567–1571. [Google Scholar] [CrossRef]

- Qian, X.; Lee, S.; Soto, A.; Chen, G. Regression Model to Predict the Higher Heating Value of Poultry Waste from Proximate Analysis. Resources 2018, 7, 39. [Google Scholar] [CrossRef]

- Obidziński, S.; Cwalina, P.; Kowczyk-Sadowy, M.; Krasowska, M.; Sienkiewicz, A.; Faszczewski, D.; Szyszlak-Bargłowicz, J. The Use of Bread Bakery Waste as a Binder Additive in the Production of Fuel Pellets from Straw. Energies 2023, 16, 7313. [Google Scholar] [CrossRef]

- Karcz, H.; Kantorek, M.; Grabowicz, M.; Wierzbicki, K. The Feasibility of Straw as a Fuel Source for Power Generating Boilers. Environ. Eng. 2013, XI–XII, 8–15. [Google Scholar]

- Kachel-Jakubowska, M.; Kraszkiewicz, A.; Szpryngiel, M.; Niedziółka, I. Analysis of the Characteristics of Raw Materials Used in Production of Solid Biofuels. Agric. Eng. 2013, 2, 103–111. [Google Scholar]

- Stolarski, M.; Krzyżaniak, M.; Rybczyńska, B.; Peni, D.; Bordiean, A.; Lajszner, W.; Graban, Ł. Thermophysical Properties and Elemental Composition of Agricultural and Forest Solid Biofuels versus Fossil Fuels. J. Elem. 2019, 24, 1215–1228. [Google Scholar] [CrossRef]

- Krzyżaniak, M.; Stolarski, M.J.; Graban, Ł.; Lajszner, W.; Kuriata, T. Camelina and Crambe Oil Crops for Bioeconomy—Straw Utilisation for Energy. Energies 2020, 13, 1503. [Google Scholar] [CrossRef]

- Tobiasz-Salach, R.; Stadnik, B.; Bajcar, M. Oat as a Potential Source of Energy. Energies 2023, 16, 6019. [Google Scholar] [CrossRef]

- Szufa, S.; Wielgosiński, G.; Piersa, P.; Czerwińska, J.; Dzikuć, M.; Adrian, Ł.; Lewandowska, W.; Marczak, M. Torrefaction of Straw from Oats and Maize for Use as a Fuel and Additive to Organic Fertilizers—TGA Analysis, Kinetics as Products for Agricultural Purposes. Energies 2020, 13, 2064. [Google Scholar] [CrossRef]

- Torres Ramos, R.; Valdez Salas, B.; Montero Alpírez, G.; Coronado Ortega, M.A.; Curiel Álvarez, M.A.; Tzintzun Camacho, O.; Beleño Cabarcas, M.T. Torrefaction under Different Reaction Atmospheres to Improve the Fuel Properties of Wheat Straw. Processes 2023, 11, 1971. [Google Scholar] [CrossRef]

- Owczuk, M.; Kołodziejczyk, K. Assessment of the Possibility of Using Straw and Pomace of Camelina Sativa as an Alternative Energy Source. Chemik 2011, 65, 537–542. [Google Scholar]

- Kacorzyk, P.; Szkutnik, J.; Kasperczyk, M. Energy Value of Selected Plant Species. Interdiscip. Issues Eng. Environ. Prot. 2013, 3, 239–244. [Google Scholar]

- Cui, L.; Zhao, W.; Mostafa, E.; Zhang, Y. Heating Performances of Corn Straw Particle with/without SiC Particle in a Microwave Chamber. Environ. Sci. Pollut. Res. 2023. Online ahead of print. [Google Scholar] [CrossRef] [PubMed]

- Król, K.; Nowak-Woźny, D. Application of the Mechanical and Pressure Drop Tests to Determine the Sintering Temperature of Coal and Biomass Ash. Energies 2021, 14, 1126. [Google Scholar] [CrossRef]

| Crop Species | Nitrogen (kg ha−1) | Phosphorus (kg ha−1) | Potassium (kg ha−1) | Sulfur (kg ha−1) | Cattle Manure (kg ha−1) |

| Rye | 90.0 | 50.0 | 80.0 | - | - |

| Oat | 100.0 | 50.0 | 80.0 | - | - |

| Triticale | 150.0 | 50.0 | 80.0 | - | - |

| Wheat | 200.0 | 60.0 | 110.0 | - | - |

| Corn | 165.0 | 70.0 | 105.0 | - | 30,000 |

| Rapeseed | 220.0 | 80.0 | 160.0 | 48.0 | - |

| Source of Variation | MC | Ash | FC | VM | HHV | LHV | C a |

|---|---|---|---|---|---|---|---|

| Straw type (A) | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * |

| Harvest year (B) | <0.001 * | 0.023 | <0.001 * | 0.143 | 0.166 | <0.001 * | <0.001 * |

| A × B | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * |

| Straw Type and Harvest Year | MC (%) | Ash (% DM) | FC (% DM) | VM (% DM) | HHV (GJ Mg−1 DM) | LHV (GJ Mg−1) |

|---|---|---|---|---|---|---|

| Rye 2020 | 10.38 ± 0.23 d | 2.68 ± 0.04 d | 20.21 ± 0.31 ab | 77.11 ± 0.26 a | 19.06 ± 0.17 a | 15.79 ± 0.09 a |

| Rye 2021 | 11.55 ± 0.59 d | 3.15 ± 0.07 d | 20.72 ± 0.26 ab | 76.14 ± 0.31 ab | 18.93 ± 0.15 ab | 15.34 ± 0.03 ab |

| Rye 2022 | 9.72 ± 1.07 d | 2.32 ± 0.01 d | 20.88 ± 0.18 a | 76.80 ± 0.18 a | 19.11 ± 0.03 a | 16.00 ± 0.19 a |

| Oat 2020 | 12.27 ± 1.18 cd | 5.60 ± 0.46 b | 19.44 ± 0.27 b | 74.96 ± 0.72 b | 18.52 ± 0.07 bc | 14.98 ± 0.39 b |

| Oat 2021 | 11.68 ± 0.57 d | 6.40 ± 0.14 b | 19.65 ± 0.11 b | 73.96 ± 0.24 bc | 18.63 ± 0.23 bc | 15.20 ± 0.33 ab |

| Oat 2022 | 12.85 ± 0.05 cd | 4.97 ± 0.01 bc | 20.66 ± 0.17 ab | 74.37 ± 0.17 bc | 18.77 ± 0.05 b | 15.13 ± 0.06 b |

| Triticale 2020 | 10.38 ± 0.16 d | 3.65 ± 0.14 c | 19.64 ± 0.52 b | 76.72 ± 0.65 a | 18.83 ± 0.16 ab | 15.47 ± 0.13 a |

| Triticale 2021 | 10.90 ± 0.80 d | 3.83 ± 0.07 c | 19.69 ± 0.37 b | 76.48 ± 0.33 ab | 18.94 ± 0.11 ab | 15.54 ± 0.18 a |

| Triticale 2022 | 10.47 ± 0.56 d | 3.91 ± 0.01 c | 20.88 ± 0.05 a | 75.21 ± 0.04 b | 18.71 ± 0.04 b | 15.52 ± 0.07 a |

| Wheat 2020 | 12.43 ± 0.10 cd | 5.18 ± 0.02 bc | 20.07 ± 0.07 ab | 74.75 ± 0.07 b | 18.84 ± 0.10 ab | 15.18 ± 0.07 ab |

| Wheat 2021 | 10.59 ± 1.10 d | 4.52 ± 0.20 bc | 20.39 ± 0.05 ab | 75.09 ± 0.22 b | 18.73 ± 0.06 b | 15.34 ± 0.22 ab |

| Wheat 2022 | 10.11 ± 0.57 d | 6.82 ± 0.04 b | 20.34 ± 0.02 ab | 72.83 ± 0.02 c | 18.40 ± 0.01 bc | 15.36 ± 0.10 a |

| Corn 2020 | 49.07 ± 0.81 a | 4.35 ± 1.29 bc | 19.30 ± 0.19 bc | 76.35 ± 1.33 ab | 18.20 ± 0.05 c | 7.53 ± 0.17 f |

| Corn 2021 | 49.36 ± 0.94 a | 4.27 ± 0.13 c | 18.99 ± 0.23 c | 76.74 ± 0.25 a | 18.30 ± 0.08 c | 7.59 ± 0.15 f |

| Corn 2022 | 48.32 ± 2.69 a | 4.16 ± 0.02 c | 19.27 ± 0.07 bc | 76.57 ± 0.06 a | 18.51 ± 0.20 bc | 7.88 ± 0.43 f |

| Rapeseed 2020 | 17.82 ± 0.24 c | 7.56 ± 0.14 a | 19.95 ± 0.70 b | 72.48 ± 0.58 c | 17.97 ± 0.01 c | 13.41 ± 0.07 d |

| Rapeseed 2021 | 25.09 ± 1.06 b | 8.32 ± 1.01 a | 17.97 ± 0.29 d | 73.71 ± 1.04 bc | 18.09 ± 0.22 c | 12.14 ± 0.13 e |

| Rapeseed 2022 | 15.25 ± 1.84 cd | 5.95 ± 0.07 b | 19.35 ± 0.07 bc | 74.69 ± 0.14 b | 18.41 ± 0.03 bc | 14.35 ± 0.37 c |

| Mean 2020 | 18.72 ± 14.21 B | 4.84 ± 1.66 AB | 19.77 ± 0.48 B | 75.40 ± 1.72 | 18.57 ± 0.40 | 13.73 ± 2.96 B |

| Mean 2021 | 19.86 ± 14.57 A | 5.08 ± 1.84 A | 19.57 ± 0.95 B | 75.35 ± 1.29 | 18.60 ± 0.35 | 13.53 ± 2.99 C |

| Mean 2022 | 17.78 ± 14.24 C | 4.69 ± 1.50 B | 20.23 ± 0.70 A | 75.08 ± 1.39 | 18.65 ± 0.27 | 14.04 ± 2.89 A |

| Feature | MC | FC | VM | Ash | HHV | LHV | C | H | N | S | Cl |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MC (%) | 1.00 | ||||||||||

| FC (% DM) | −0.54 * | 1.00 | |||||||||

| VM (% DM) | 0.26 | 0.00 | 1.00 | ||||||||

| Ash (% DM) | 0.03 | −0.47 * | −0.88 * | 1.00 | |||||||

| HHV (MJ kg−1 DM) | −0.52 * | 0.59 * | 0.51 * | −0.72 * | 1.00 | ||||||

| LHV (MJ kg−1) | −1.00 * | 0.57 * | −0.20 | −0.09 | 0.58 * | 1.00 | |||||

| C (% DM) | −0.41 * | 0.37 * | 0.28 * | −0.42 * | 0.49 * | 0.42 * | 1.00 | ||||

| H (% DM) | −0.22 | 0.19 | 0.33 * | −0.38 * | 0.35 * | 0.22 | 0.78 * | 1.00 | |||

| N (% DM) | 0.08 | −0.44 * | −0.45 * | 0.60 * | −0.50 * | −0.13 | −0.20 | −0.01 | 1.00 | ||

| S (% DM) | −0.02 | −0.60 * | −0.51 * | 0.73 * | −0.53 * | −0.03 | −0.37 * | −0.31 * | 0.39 * | 1.00 | |

| Cl (% DM) | 0.38 * | −0.54 * | −0.37 * | 0.58 * | −0.62 * | −0.41 * | −0.45 * | −0.51 * | 0.24 | 0.62 * | 1.00 |

| Straw Type and Harvest Year | C (% DM) | H (% DM) | N (% DM) | S (% DM) | Cl (% DM) |

|---|---|---|---|---|---|

| Rye 2020 | 48.65 ± 0.47 a | 5.72 ± 0.09 ab | 0.53 ± 0.03 d | 0.057 ± 0.001 e | 0.056 ± 0.005 cd |

| Rye 2021 | 48.40 ± 0.85 a | 6.26 ± 0.13 a | 0.60 ± 0.01 d | 0.037 ± 0.003 e | 0.034 ± 0.005 d |

| Rye 2022 | 46.76 ± 0.04 b | 5.53 ± 0.02 bc | 0.50 ± 0,01 d | 0.030 ± 0.001 e | 0.050 ± 0.017 d |

| Oat 2020 | 48.51 ± 0.29 a | 5.47 ± 0.55 bc | 0.96 ± 0.06 b | 0.111 ± 0.022 cd | 0.376 ± 0.105 a |

| Oat 2021 | 43.43 ± 0.55 c | 5.44 ± 0.09 bc | 1.32 ± 0.07 a | 0.081 ± 0.007 d | 0.082 ± 0.003 c |

| Oat 2022 | 44.57 ± 0.05 bc | 5.22 ± 0.06 bc | 0.71 ± 0.10 cd | 0.056 ± 0.004 e | 0.326 ± 0.020 ab |

| Triticale 2020 | 49.70 ± 0.83 a | 6.32 ± 0.12 a | 0.85 ± 0.04 bc | 0.037 ± 0.010 e | 0.024 ± 0.013 d |

| Triticale 2021 | 46.73 ± 2.92 b | 5.87 ± 0.41 ab | 0.85 ± 0.03 bc | 0.043 ± 0.006 e | 0.022 ± 0.007 d |

| Triticale 2022 | 45.20 ± 0.22 bc | 5.36 ± 0.02 bc | 0.72 ± 0.01 cd | 0.056 ± 0.001 e | 0.145 ± 0.007 bc |

| Wheat 2020 | 49.21 ± 0.39 a | 5.72 ± 0.02 ab | 0.60 ± 0.02 d | 0.073 ± 0.003 de | 0.163 ± 0.010 bc |

| Wheat 2021 | 49.67 ± 0.97 a | 6.29 ± 0.20 a | 1.42 ± 0.02 a | 0.039 ± 0.004 e | 0.029 ± 0.003 d |

| Wheat 2022 | 44.45 ± 0.25 bc | 5.11 ± 0.03 c | 0.87 ± 0.01 bc | 0.114 ± 0.007 cd | 0.092 ± 0.006 c |

| Corn 2020 | 47.30 ± 0.93 ab | 5.80 ± 0.16 ab | 0.99 ± 0.06 b | 0.037 ± 0.002 e | 0.243 ± 0.025 b |

| Corn 2021 | 42.95 ± 0.24 d | 5.22 ± 0.09 bc | 0.88 ± 0.07 bc | 0.040 ± 0.004 e | 0.227 ± 0.012 b |

| Corn 2022 | 43.09 ± 0.37 c | 5.33 ± 0.01 bc | 0.74 ± 0.01 cd | 0.043 ± 0.004 e | 0.233 ± 0.007 b |

| Rapeseed 2020 | 45.70 ± 0.31 bc | 5.61 ± 0.18 bc | 0.97 ± 0.02 b | 0.133 ± 0.019 c | 0.233 ± 0.023 b |

| Rapeseed 2021 | 43.41 ± 0.51 c | 5.40 ± 0.44 bc | 1.18 ± 0.15 ab | 0.394 ± 0.052 a | 0.425 ± 0.045 a |

| Rapeseed 2022 | 43.91 ± 0.45 c | 5.12 ± 0.01 c | 1.14 ± 0.01 ab | 0.205 ± 0.004 b | 0.367 ± 0.012 a |

| Mean 2020 | 48.18 ± 1.46 A | 5.77 ± 0.35 A | 0.82 ± 0.19 B | 0.075 ± 0.039 B | 0.182 ± 0.128 A |

| Mean 2021 | 45.77 ± 2.95 B | 5.75 ± 0.49 A | 1.04 ± 0.30 A | 0.106 ± 0.135 A | 0.136 ± 0.152 B |

| Mean 2022 | 44.66 ± 1.19 C | 5.28 ± 0.15 B | 0.78 ± 0.20 B | 0.084 ± 0.062 B | 0.202 ± 0.121 A |

| Feature | Mean | Minimum Value | Maximum Value | Lower Quartile | Upper Quartile | Standard Deviation | Coefficient of Variation (%) |

|---|---|---|---|---|---|---|---|

| MC (%) | 18.79 | 9.06 | 51.42 | 10.53 | 17.87 | 14.09 | 75.00 |

| FC (% DM) | 19.86 | 17.66 | 21.07 | 19.34 | 20.43 | 0.78 | 3.91 |

| VM (% DM) | 75.28 | 71.82 | 77.74 | 74.37 | 76.57 | 1.46 | 1.94 |

| Ash (% DM) | 4.87 | 2.31 | 9.47 | 3.81 | 5.95 | 1.65 | 33.91 |

| HHV (MJ kg−1 DM) | 18.61 | 17.85 | 19.17 | 18.38 | 18.83 | 0.34 | 1.82 |

| LHV (MJ kg−1) | 13.76 | 7.39 | 16.13 | 13.40 | 15.45 | 2.90 | 21.06 |

| C (% DM) | 46.20 | 42.68 | 50.67 | 43.99 | 48.74 | 2.47 | 5.36 |

| H (% DM) | 5.60 | 4.84 | 6.42 | 5.30 | 5.79 | 0.42 | 7.48 |

| N (% DM) | 0.88 | 0.49 | 1.44 | 0.71 | 1.02 | 0.26 | 29.70 |

| S (% DM) | 0.088 | 0.029 | 0.438 | 0.038 | 0.103 | 0.088 | 99.721 |

| Cl (% DM) | 0.174 | 0.009 | 0.476 | 0.050 | 0.255 | 0.135 | 77.611 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stolarski, M.J.; Welenc, M.; Krzyżaniak, M.; Olba-Zięty, E.; Stolarski, J.; Wierzbicki, S. Characteristics and Changes in the Properties of Cereal and Rapeseed Straw Used as Energy Feedstock. Energies 2024, 17, 1243. https://doi.org/10.3390/en17051243

Stolarski MJ, Welenc M, Krzyżaniak M, Olba-Zięty E, Stolarski J, Wierzbicki S. Characteristics and Changes in the Properties of Cereal and Rapeseed Straw Used as Energy Feedstock. Energies. 2024; 17(5):1243. https://doi.org/10.3390/en17051243

Chicago/Turabian StyleStolarski, Mariusz Jerzy, Michał Welenc, Michał Krzyżaniak, Ewelina Olba-Zięty, Jakub Stolarski, and Sławomir Wierzbicki. 2024. "Characteristics and Changes in the Properties of Cereal and Rapeseed Straw Used as Energy Feedstock" Energies 17, no. 5: 1243. https://doi.org/10.3390/en17051243

APA StyleStolarski, M. J., Welenc, M., Krzyżaniak, M., Olba-Zięty, E., Stolarski, J., & Wierzbicki, S. (2024). Characteristics and Changes in the Properties of Cereal and Rapeseed Straw Used as Energy Feedstock. Energies, 17(5), 1243. https://doi.org/10.3390/en17051243