An Ethane-Based CSI Process and Two Types of Flooding Process as a Hybrid Method for Enhancing Heavy Oil Recovery

Abstract

1. Introduction

2. Experimental Methodology

2.1. Materials

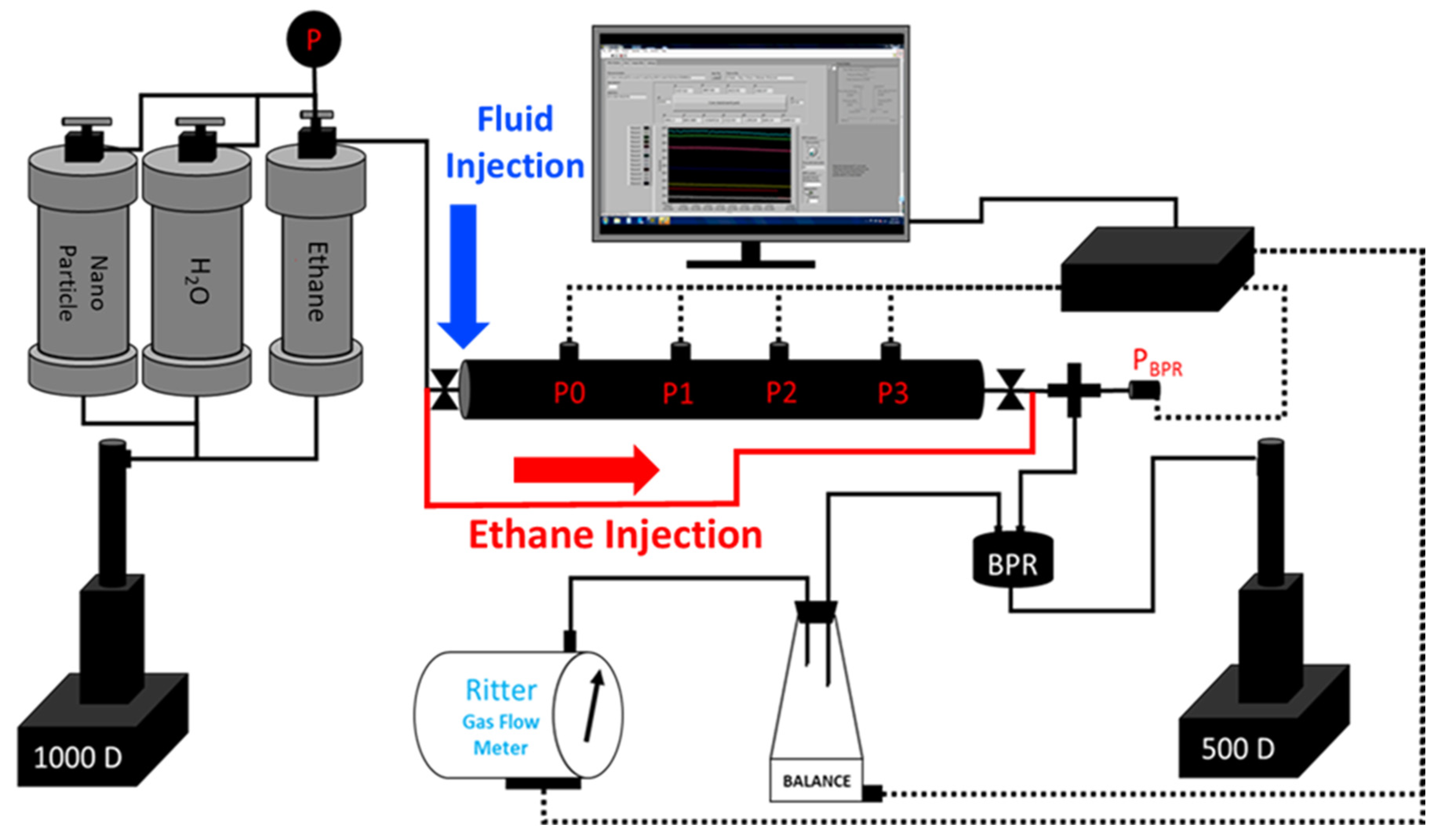

2.2. Experiment Setup

2.3. Experimental Procedure

3. Results and Discussion

3.1. Overview

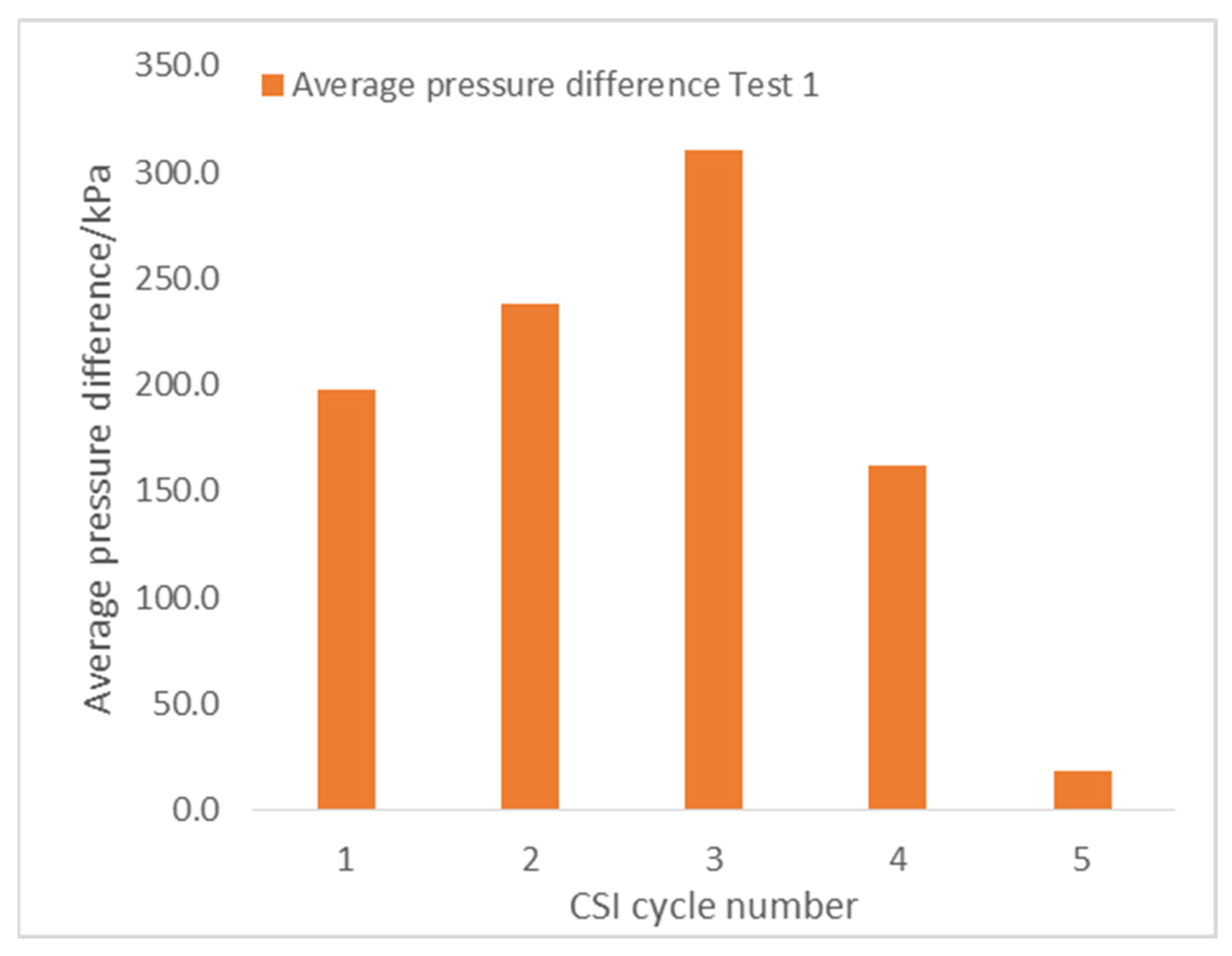

3.2. Experimental Studies of Ethane-Based Cyclic Solvent Injection in Test 1

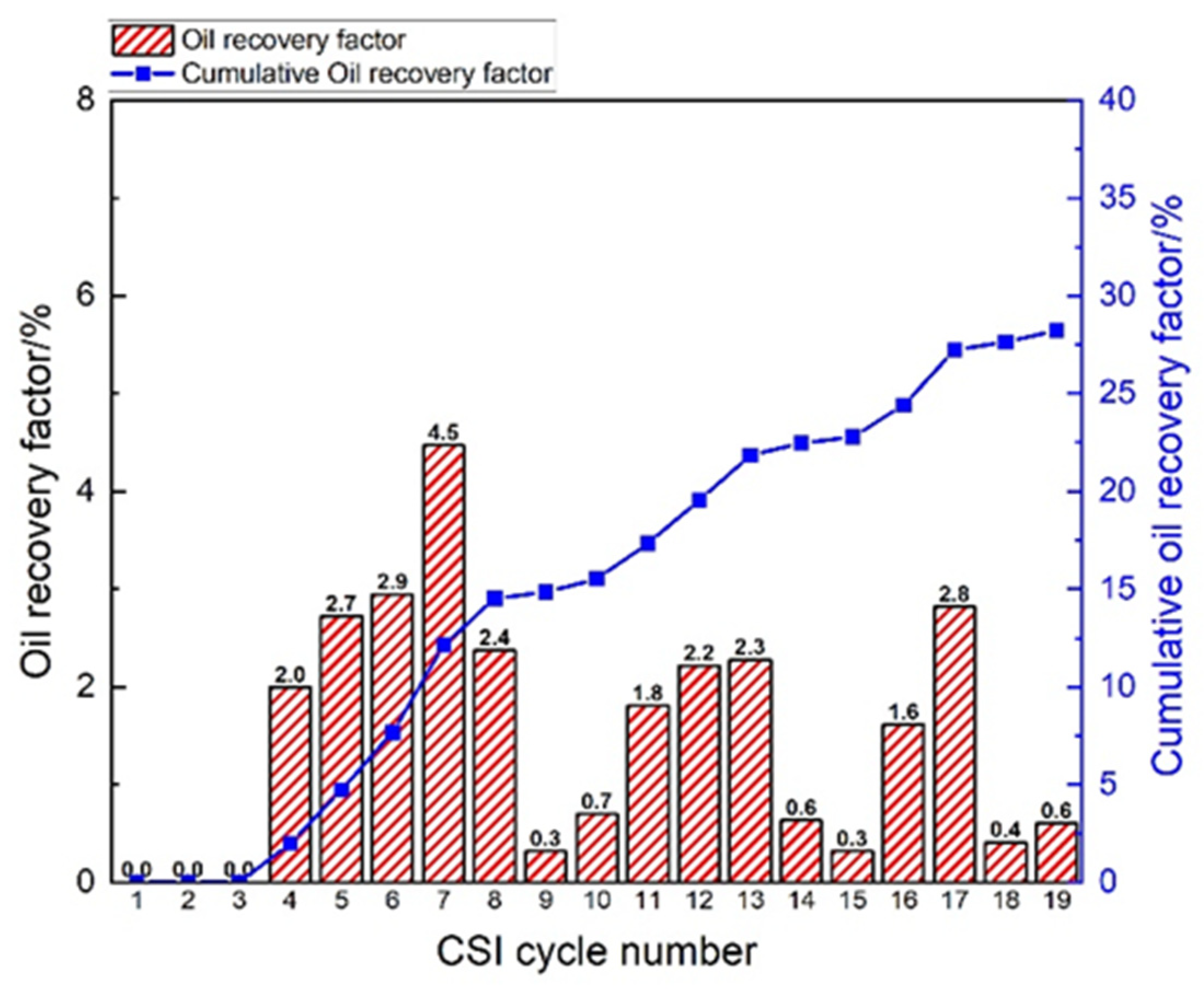

3.3. Experimental Studies of Combined Ethane-Based CSI Process and Water Flooding/Nanoparticle-Solution Flooding Process

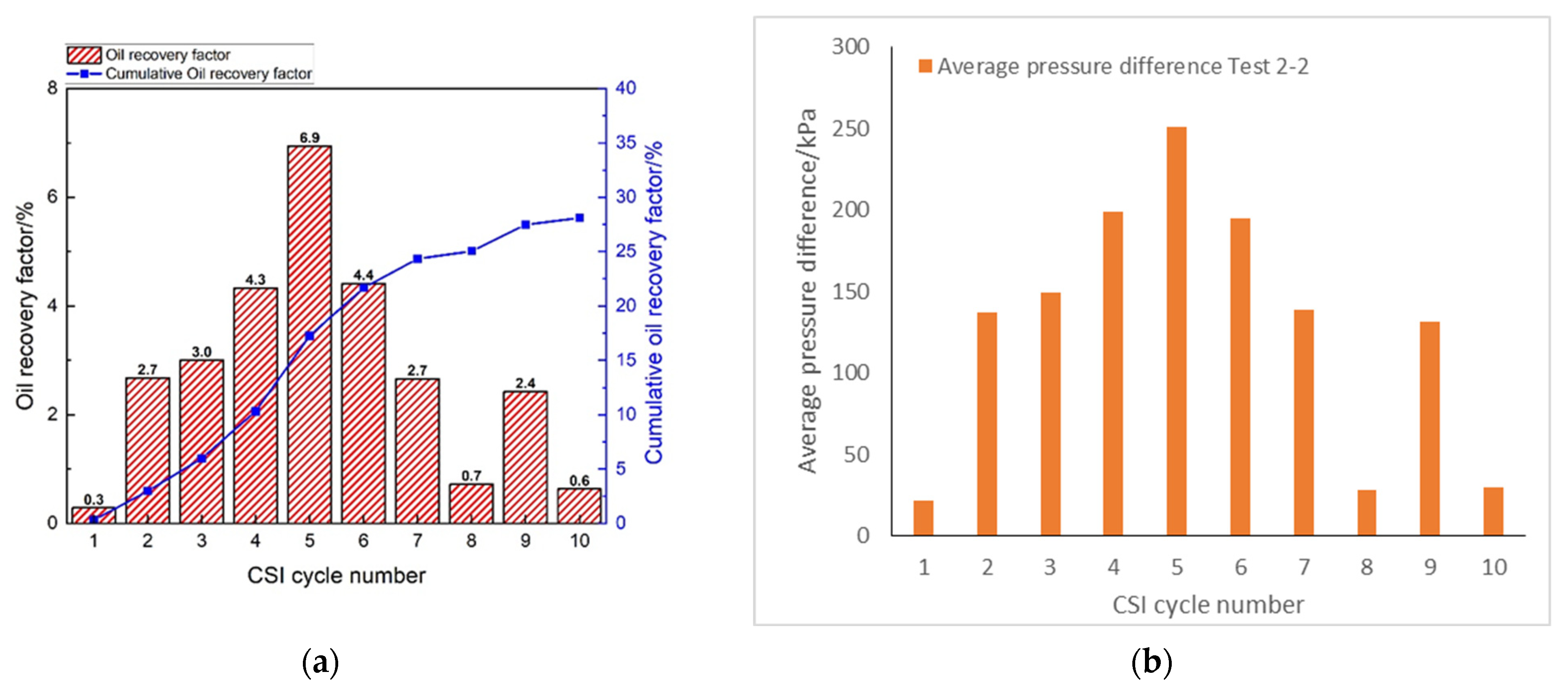

3.3.1. The First Ethane-Based CSI Process

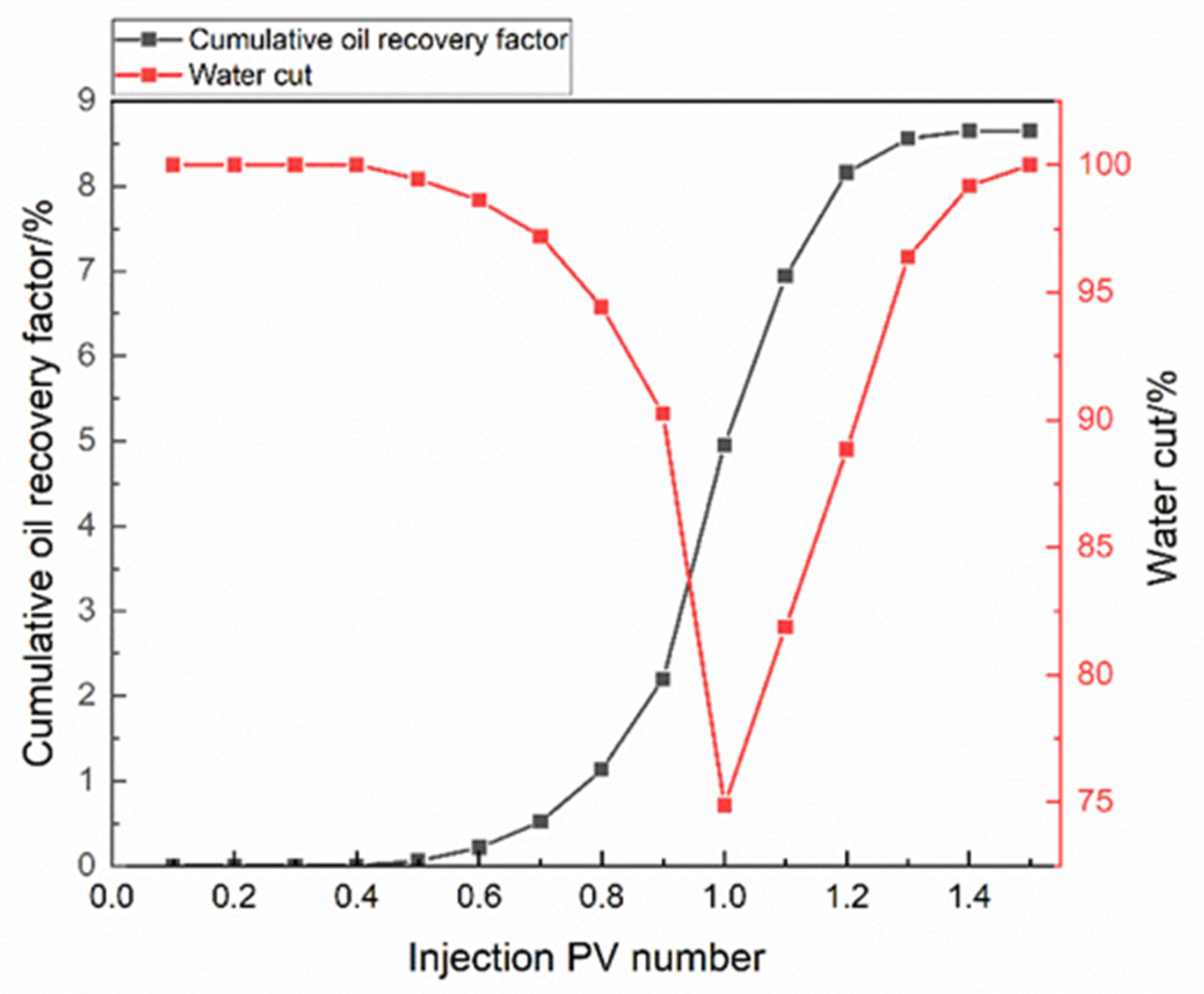

3.3.2. Water Flooding Process

3.3.3. The Second Ethane-Based CSI Process

3.3.4. Nanoparticle-Fluid Flooding Process

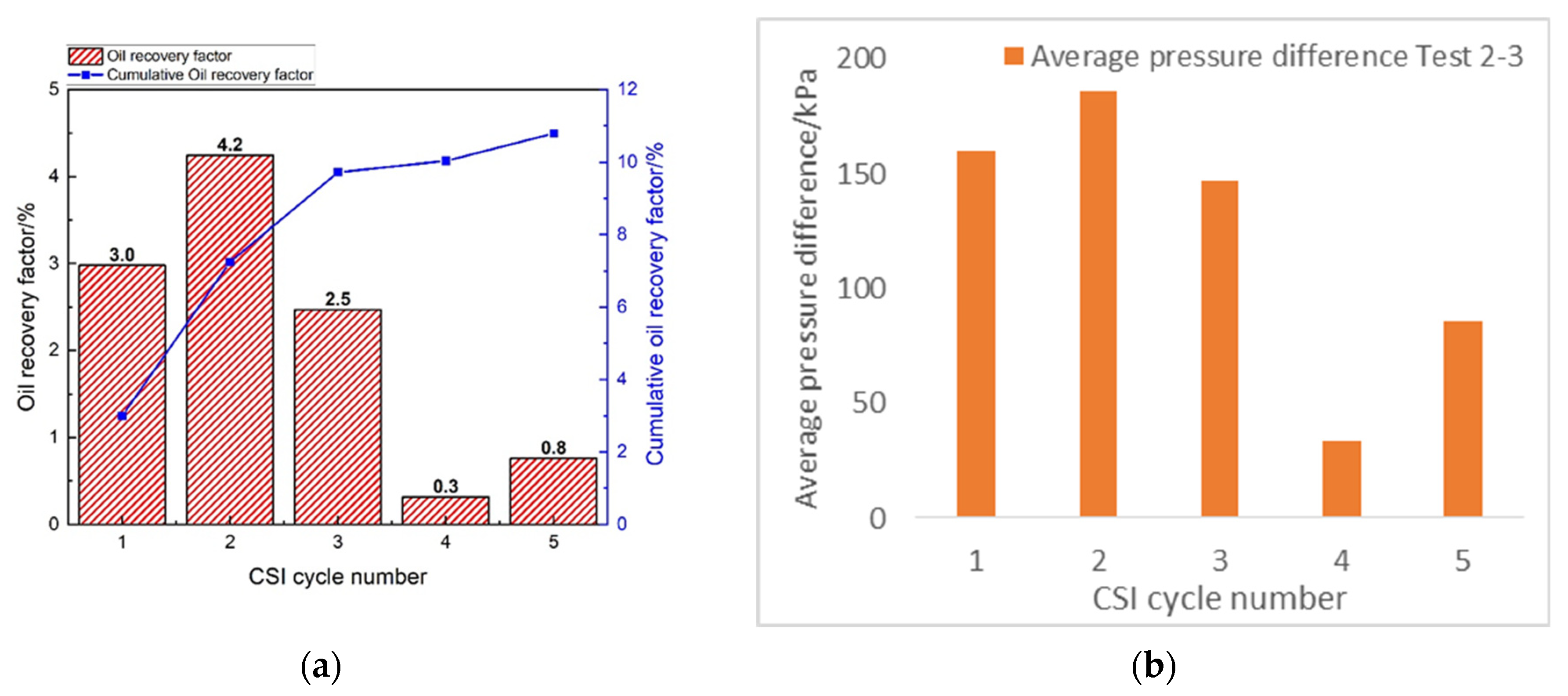

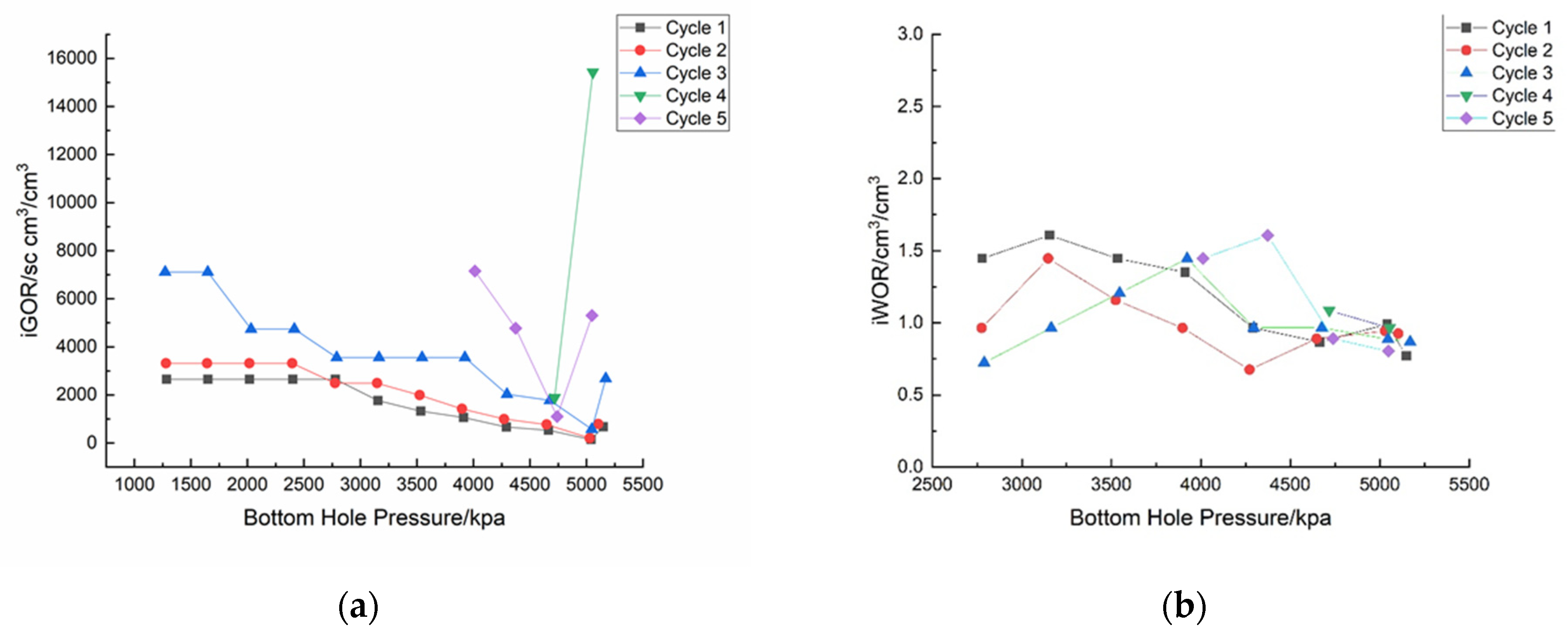

3.3.5. The Third Ethane-Based CSI Process

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alshmakhy, A.S.; Maini, B.B. Heavy oil: A review. J. Pet. Eng. Technol. 2012, 2, 37–56. [Google Scholar]

- Jin, F.-Y.; Gao, H.; Chen, Y.-F.; Wei, B.; Li, Y.-B.; Dong, H.; Pu, W.-F. Low temperature oxidation characteristics analysis of ultra-heavy oil by thermal methods. J. Ind. Eng. Chem. 2017, 48, 249–258. [Google Scholar]

- Ma, H. Optimum Cyclic Solvent Injection (CSI) and Waterflooding/Gasflooding in the Post Cold Heavy Oil Production with Sand (Chops) Reservoirs. Ph.D. Dissertation, Faculty of Graduate Studies and Research, University of Regina, Regina, SK, Canada, 2017. [Google Scholar]

- Bannerjee, D. Oil Sands, Heavy Oil and Bitumen: From Recovery to Refinery; Pennwell Corp.: Tulsa, OK, USA, 2012. [Google Scholar]

- Canadian Association of Petroleum Producers (CAPP). Fast Facts: Canada’s Oil and Natural Gas Industry. 2023. Available online: https://www.capp.ca/wp-content/uploads/2023/11/BMO_Symposium_Brochure_V13.pdf (accessed on 28 February 2024).

- Bowers, B.; Drummond, K.J. Conventional crude oil resources of the western Canada sedimentary basin. J. Can. Pet. Technol. 1997, 36, 56–63. [Google Scholar] [CrossRef]

- Huang, S.S.; Pappas, E.S.; Jha, K.N. The Carbon Dioxide immiscible recovery process and its potential for Saskatchewan reservoirs. In Proceedings of the Technical Meeting/Petroleum Conference of the South Saskatchewan Section, Regina, SK, Canada, 6–8 October 1987. [Google Scholar]

- Srivastava, R.; Huang, S.; Dong, M. Comparative effectiveness of CO2 produced gas, and flue gas for enhanced heavy-oil recovery. SPE Reserv. Eval. Eng. 1999, 2, 238–247. [Google Scholar] [CrossRef]

- Zhao, D.W.; Wang, J.; Gates, I.D. Thermal recovery strategies for thin heavy oil reservoirs. Fuel 2014, 117, 431–441. [Google Scholar] [CrossRef]

- Srivastava, R.K.; Huang, S.S.; Mourits, F.M. A laboratory evaluation of suitable operating strategies for enhanced heavy oil recovery by gas injection. J. Can. Pet. Technol. 1997, 36, 33–41. [Google Scholar] [CrossRef]

- Jiang, T.; Zeng, F.; Jia, X.; Gu, Y. A new solvent-based enhanced heavy oil recovery method: Cyclic production with continuous solvent injection. Fuel 2014, 115, 426–433. [Google Scholar] [CrossRef]

- Lee, J.; Babadagli, T. Mitigating greenhouse gas intensity through new generation techniques during heavy oil recovery. J. Clean. Prod. 2021, 286, 124980. [Google Scholar] [CrossRef]

- James, L.; Rezaei, N.; Chatzis, I. VAPEX, warm VAPEX, and hybrid VAPEX–The state of enhanced oil recovery for in situ heavy oils in Canada. In Proceedings of the 8th Canadian International Petroleum Conference, Calgary, AB, Canada, 12–14 June 2007. [Google Scholar]

- Alvarez, J.; Han, S. Current overview of cyclic steam injection process. J. Pet. Sci. Res. 2013, 2, 116–127. [Google Scholar]

- Song, C.; Ghanizadeh, A.; Younis, A.; Clarkson, C.R. Experimental evaluation of the impact of induced fractures on cyclic solvent injection performance in low-permeability hydrocarbon reservoirs. Fuel 2023, 354, 129327. [Google Scholar] [CrossRef]

- Abedini, A.; Torabi, F. Oil recovery performance of immiscible and miscible CO2 huff-and-puff processes. Energy Fuels 2014, 28, 774–784. [Google Scholar] [CrossRef]

- Murray, M.D.; Frailey, S.M.; Lawal, A.S. New approach to CO2 flood: Soak alternating gas. In Proceedings of the SPE Permian Basin Oil and Gas Recovery Conference, Midland, TX, USA, 15–17 May 2001. [Google Scholar]

- Sayegh, S.G.; Maini, B.B. Laboratory evaluation of the CO2 huff-n-puff process for heavy oil reservoirs. J. Can. Pet. Technol. 1984, 23. [Google Scholar] [CrossRef]

- Shen, C. Experimental Study of Foamy Oil Characteristics and Post-CHOPS CSI Processes Based on CO2-C3H8 Mixture Solvent. Ph.D. Dissertation, The University of Regina, Regina, SK, Canada, 2020. [Google Scholar]

- Simpson, M.R. The CO2 huff “n” puff process in a bottomwater-drive reservoir. J. Pet. Technol. 1988, 40, 887–893. [Google Scholar] [CrossRef]

- Spivak, A.; Chima, C.M. Mechanisms of immiscible CO2 injection in heavy oil reservoirs, Wilmington Field, CA. In Proceedings of the SPE Enhanced Oil Recovery Symposium, Tulsa, OK, USA, 15–18 April 1984. [Google Scholar]

- Zhou, X. Enhanced Heavy Oil Recovery Using CO2 Huff’N’Puff Process. Ph.D. Dissertation, Faculty of Graduate Studies and Research, University of Regina, Regina, SK, Canada, 2019. [Google Scholar]

- Singhal, A.K.; Das, S.K.; Leggitt, S.M.; Kasraie, M.; Ito, Y. Screening of reservoirs for exploitation by application of steam assisted gravity drainage/VAPEX processes. In Proceedings of the International Conference on Horizontal Well Technology, Calgary, AB, Canada, 18–20 November 1996. Paper SPE 37144. [Google Scholar]

- Ma, H.; Yu, G.; She, Y.; Gu, Y. A parabolic solvent chamber model for simulating the solvent vapor extraction (VAPEX) heavy oil recovery process. J. Pet. Sci. Eng. 2017, 149, 465–475. [Google Scholar] [CrossRef]

- Du, Z.; Peng, X.; Zeng, F. Comparison analyses between the linear and non-linear pressure-decline methods in cyclic solvent injection (CSI) process for heavy oil recovery. Fuel 2018, 224, 442–450. [Google Scholar] [CrossRef]

- Lin, L.; Ma, H.; Zeng, F.; Gu, Y. A critical review of the solvent-based heavy oil recovery methods. In Proceedings of the SPE Canada Heavy Oil Conference, Calgary, AB, Canada, 10–12 June 2014; p. D021S006R001. [Google Scholar]

- Dong, X.; Liu, H.; Chen, Z.; Wu, K.; Lu, N.; Zhang, Q. Enhanced oil recovery techniques for heavy oil and oilsands reservoirs after steam injection. Appl. Energy 2019, 239, 1190–1211. [Google Scholar] [CrossRef]

- Ahadi, A.; Torabi, F. Effect of light hydrocarbon solvents on the performance of CO2-based cyclic solvent injection (CSI) in heavy oil systems. J. Pet. Sci. Eng. 2018, 163, 526–537. [Google Scholar] [CrossRef]

- Jamaloei, B.Y.; Dong, M.; Yang, P.; Yang, D.; Mahinpey, N. Impact of solvent type and injection sequence on Enhanced Cyclic Solvent Process (ECSP) for thin heavy oil reservoirs. J. Pet. Sci. Eng. 2013, 110, 169–183. [Google Scholar] [CrossRef]

- Hong, S.Y.; Zeng, F.; Du, Z. Characterization of gas-oil flow in Cyclic Solvent Injection (CSI) for heavy oil recovery. J. Pet. Sci. Eng. 2017, 152, 639–652. [Google Scholar] [CrossRef][Green Version]

- Zhang, M.; Du, Z.; Zeng, F.; Xu, S. Upscaling Study of Cyclic Solvent Injection Process for Post-CHOPS Reservoirs through Numerical Simulation. In Proceedings of the SPE Canada Heavy Oil Conference, Calgary, AB, Canada, 10–12 June 2014; p. D031S022R003. [Google Scholar]

- Lim, G.B.; Kry, R.P.; Harker, B.C.; Jha, C.K. Cyclic stimulation of Cold Lake oil sand with supercritical ethane. In Proceedings of the SPE International Thermal Operations and Heavy Oil Symposium, Calgary, AB, Canada, 19–21 June 1995; p. SPE-30298. [Google Scholar]

- Anderson, M.; Badamchizadeh, A.; Kantzas, A.; Bryan, J. Solvent Screening Study for a Post CHOPS Cyclic Solvent Injection Pilot. In Proceedings of the SPE Annual Technical Conference and Exhibition, Calgary, AB, Canada, 30 September–2 October 2019; p. D031S045R001. [Google Scholar]

- Qazvini Firouz, A.; Torabi, F. Feasibility study of solvent-based huff-n-puff method (cyclic solvent injection) to enhance heavy oil recovery. In Proceedings of the SPE Canada Heavy Oil Conference, Calgary, AB, Canada, 10–12 June 2012; p. SPE-157853. [Google Scholar]

- Ivory, J.; Chang, J.; Coates, R.; Forshner, K. Investigation of cyclic solvent injection process for heavy oil recovery. J. Can. Pet. Technol. 2010, 49, 22–33. [Google Scholar] [CrossRef]

- Ganapathi, R.; Henni, A.; Shirif, E. Solubility of carbon dioxide and ethane in Lloydminster heavy oil: Experimental study and modelling. Can. J. Chem. Eng. 2022, 100, 1235–1243. [Google Scholar] [CrossRef]

- Marufuzzaman, M. Solubility and Diffusivity of Carbon Dioxide, Ethane and Propane in Heavy Oil and Its SARA Fractions; Faculty of Graduate Studies and Research, University of Regina: Regina, SK, Canada, 2011. [Google Scholar]

- Yang, C.; Gu, Y. Diffusion coefficients and oil swelling factors of carbon dioxide, methane, ethane, propane, and their mixtures in heavy oil. Fluid Phase Equilibria 2006, 243, 64–73. [Google Scholar] [CrossRef]

- Wu, M.; Lu, X.; Zhou, X.; Lin, Z.; Zeng, F. Experimental study on the temperature effects of foamy oil flow in porous media. Fuel 2020, 271, 117649. [Google Scholar] [CrossRef]

| Manatokan Heavy Oil Properties | Temperature | Density | Viscosity | Compressibility | Molecular Weight |

| (°C) | kg/m3 | mPa·S | 1/(kPa) | g/mol | |

| 21 | 964.3 | 2200 | 5.5 × 10−7 | 389 | |

| SARA Analysis Results | Saturates | Aromatics | Resins | Asphaltenes | Unrecovered |

| mole% | mole% | mole% | mole% | mole% | |

| 28.4 | 27.0 | 22.5 | 14.8 | 7.3 |

| Test | ρo @ 1 Atm (g/cm3) | Solvent | Porosity, % | Permeability, D | Oil Saturation, % | Water Saturation, % |

|---|---|---|---|---|---|---|

| 1 | 0.9643 | Ethane | 32.95 | 7.56 | 91.55 | 8.45 |

| 2 | 0.9643 | Ethane | 33.28 | 7.48 | 91.29 | 8.71 |

| Test No. | Procedure | Injection Pressure, kPa |

|---|---|---|

| 1 | Ethane CSI (base test) | 5500 |

| 2 | Ethane CSI→Water flooding→2nd Ethane CSI→NP fluid flooding→3rd Ethane CSI | 1st Ethane CSI From 3500 to 5500 2nd Ethane CSI 5500 3rd Ethane CSI 5500 |

| Test No. | Procedure | Oil Recovery Factor, % | Total, % | ||||

|---|---|---|---|---|---|---|---|

| 1 | Ethane CSI | 31.1 | 31.1 | ||||

| 2 | Ethane CSI→Water flooding→Ethane CSI→NP fluid flooding→Ethane CSI | 28.2 | 8.7 | 28.1 | 0.3 | 10.8 | 76.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Du, Z.; Wang, B.; Ding, J.; Zeng, F. An Ethane-Based CSI Process and Two Types of Flooding Process as a Hybrid Method for Enhancing Heavy Oil Recovery. Energies 2024, 17, 1457. https://doi.org/10.3390/en17061457

Li Y, Du Z, Wang B, Ding J, Zeng F. An Ethane-Based CSI Process and Two Types of Flooding Process as a Hybrid Method for Enhancing Heavy Oil Recovery. Energies. 2024; 17(6):1457. https://doi.org/10.3390/en17061457

Chicago/Turabian StyleLi, Yishu, Zhongwei Du, Bo Wang, Jiasheng Ding, and Fanhua Zeng. 2024. "An Ethane-Based CSI Process and Two Types of Flooding Process as a Hybrid Method for Enhancing Heavy Oil Recovery" Energies 17, no. 6: 1457. https://doi.org/10.3390/en17061457

APA StyleLi, Y., Du, Z., Wang, B., Ding, J., & Zeng, F. (2024). An Ethane-Based CSI Process and Two Types of Flooding Process as a Hybrid Method for Enhancing Heavy Oil Recovery. Energies, 17(6), 1457. https://doi.org/10.3390/en17061457