Experimental Study on Improving Oil Recovery Mechanism of Injection–Production Coupling in Complex Fault-Block Reservoirs

Abstract

:1. Introduction

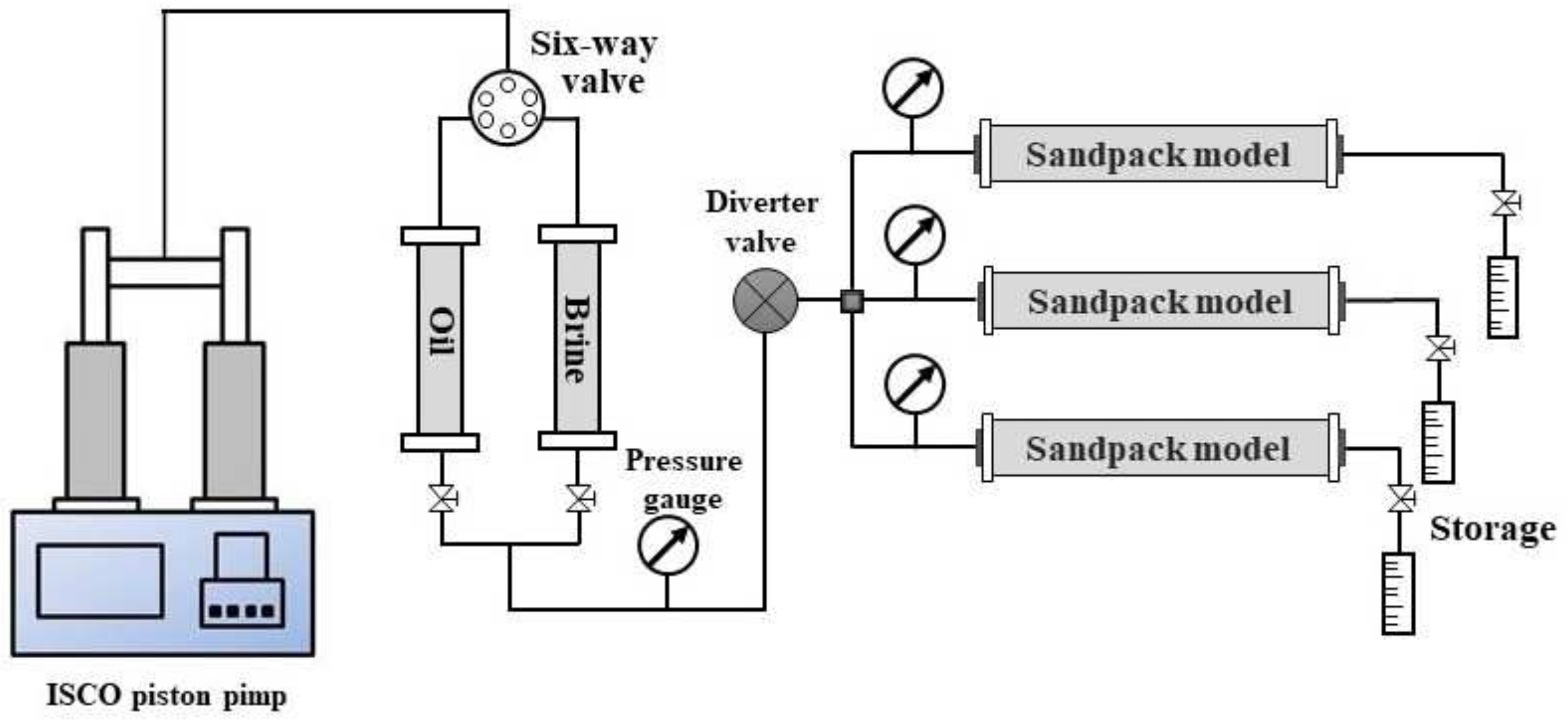

2. Physical Simulation Experiment

2.1. Experimental Apparatus

2.2. Experimental Material

2.3. Experimental Process

- (1)

- The sandpack model was numbered, and the displacement device of the sandpack model was connected according to the experimental design requirements.

- (2)

- When the formation water was saturated at a rate of 0.10 mL/min and the liquid output was approximately 3–4 PV, the internal pores of the sandpack model were considered to be completely saturated. The porosity and permeability were calculated according to the mass difference before and after the formation water saturated the model (Figure 3).

- (3)

- When the simulated crude oil was saturated at a displacement rate of 0.10 mL/min, the core was considered to be completely saturated when the simulated crude oil was completely discharged from the outlet, and the original oil–water distribution of the reservoir was established.

- (4)

- The displacement device was connected to the sandpack model, and the formation water was injected into the model at a rate of 0.10 mL/min to displace the simulated crude oil. When there was no more simulated crude oil flowing out of the outlet and the liquid output was approximately 3–4 PV, it was considered that the water-cut limit had been reached, and the water-driven volume limit was recorded with the measuring cylinder (Figure 4).

- (5)

- The outlet end was closed, the injection–production coupling test pressure was set, and the overall pressure of the sandpack model was raised to the experimental set value at a flow rate of 0.10 mL/min. After stabilizing for 30 min, the inlet end was closed, and the simulated well was standing for 24 h. The outlet was opened until there was no more liquid flowing out of each sandpack model, and the amount of liquid flowing out was recorded. The above experiments were repeated to carry out several cycles of injection–production coupling simulation experiments under different pressure conditions.

- (6)

- The experimental instruments were cleaned, and the experiment was ended.

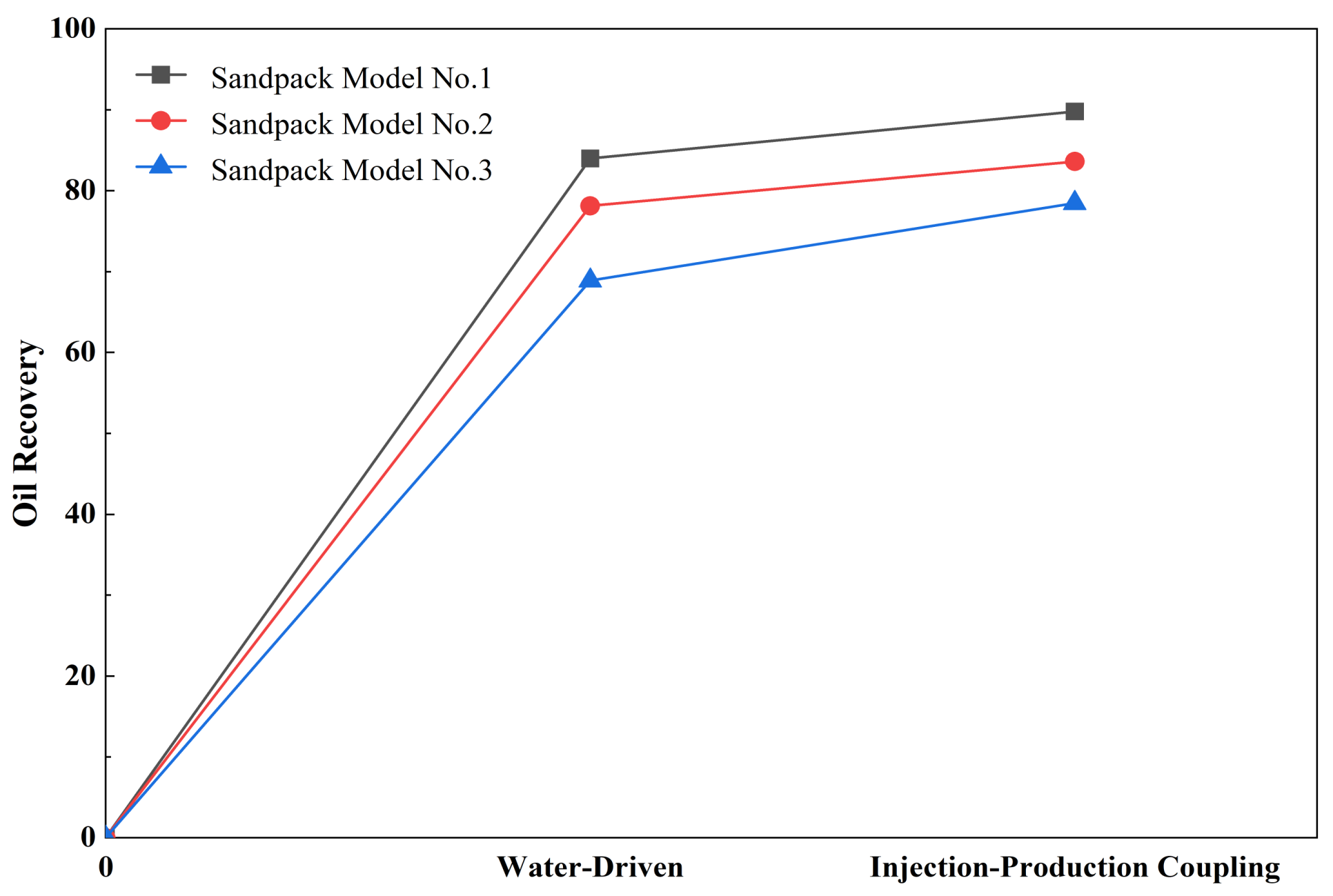

2.4. Results

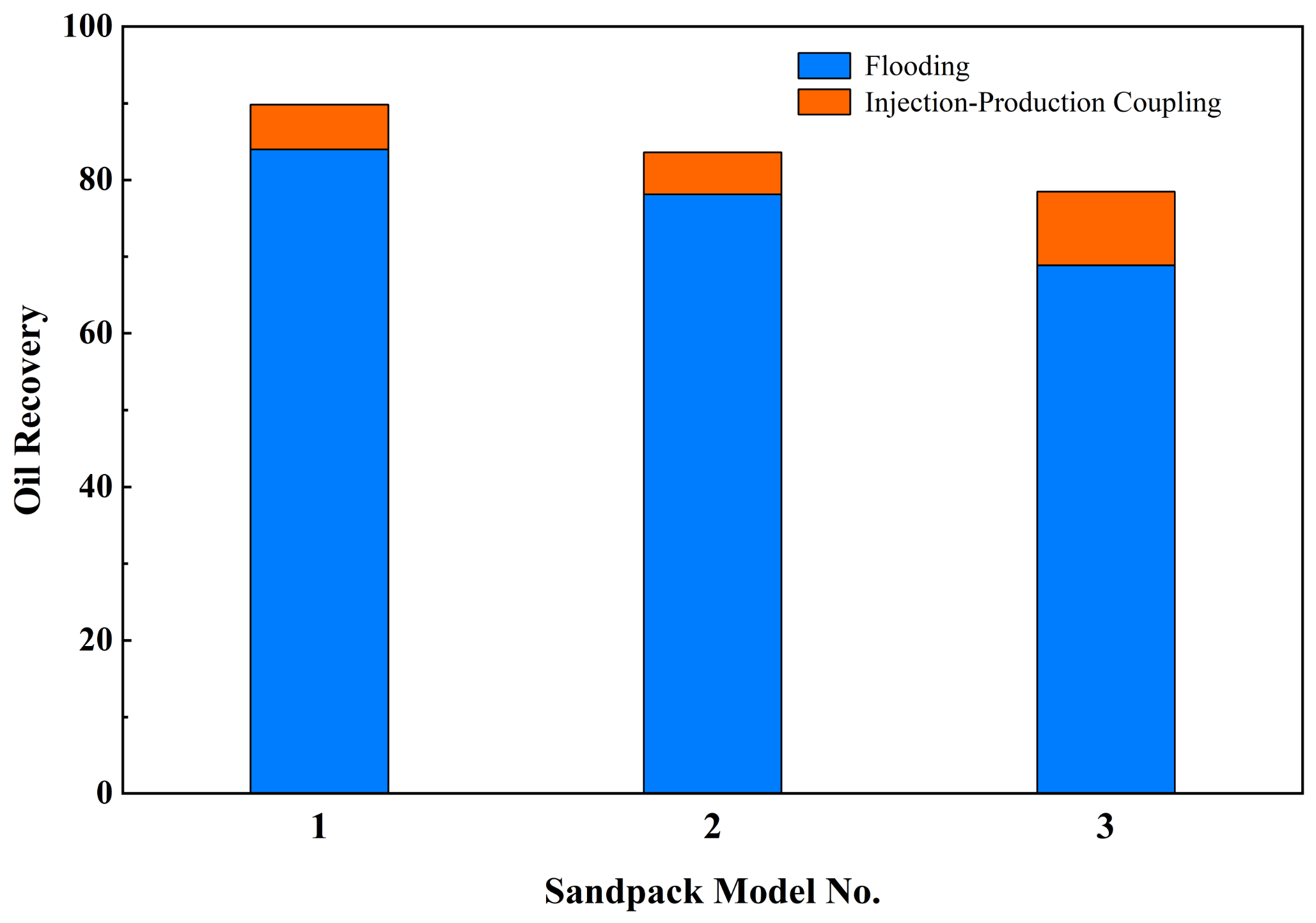

2.4.1. Single-Layer Injection–Production Coupling Experiment

2.4.2. Multilayer Injection–Production Coupling Model Experiment

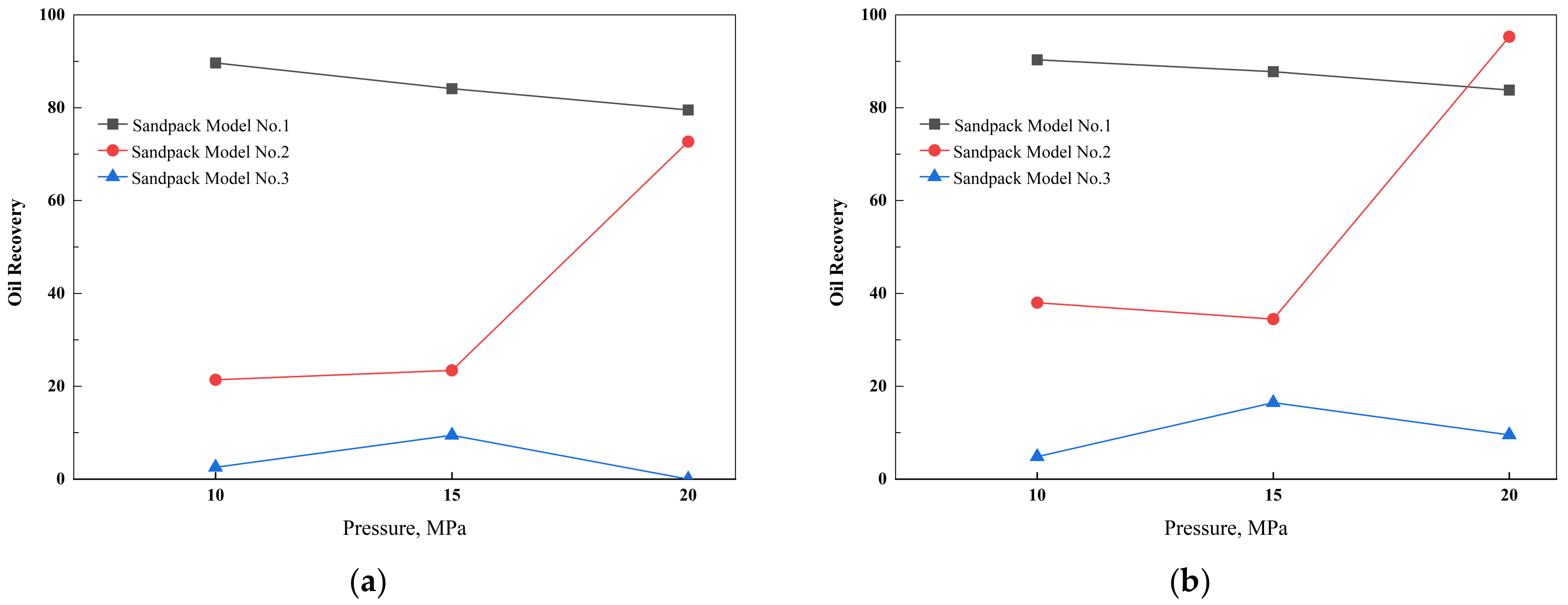

Impact of Injection Pressure

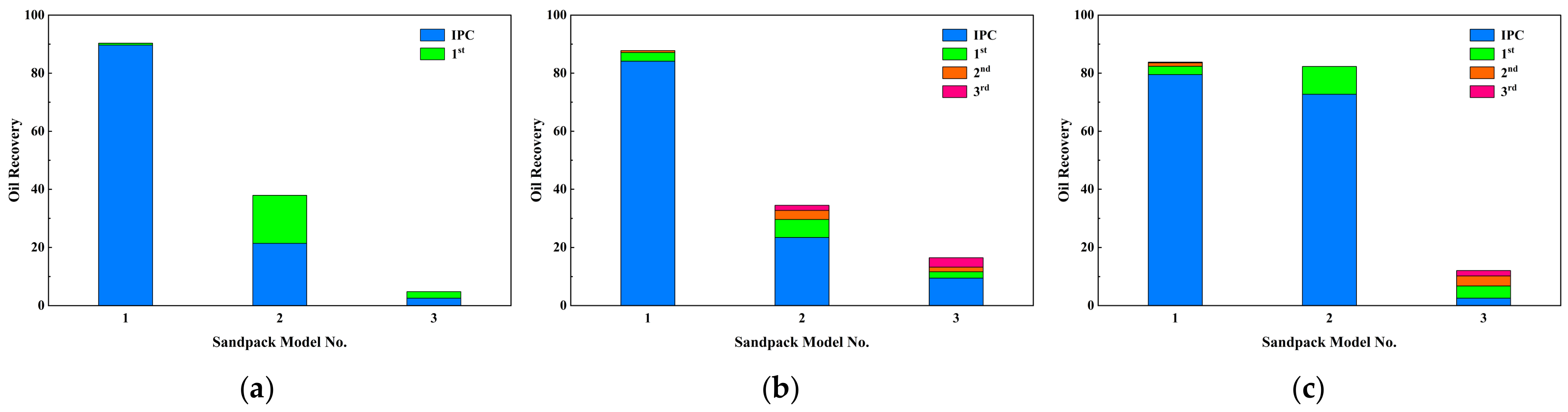

Impact of Coupling Cycles

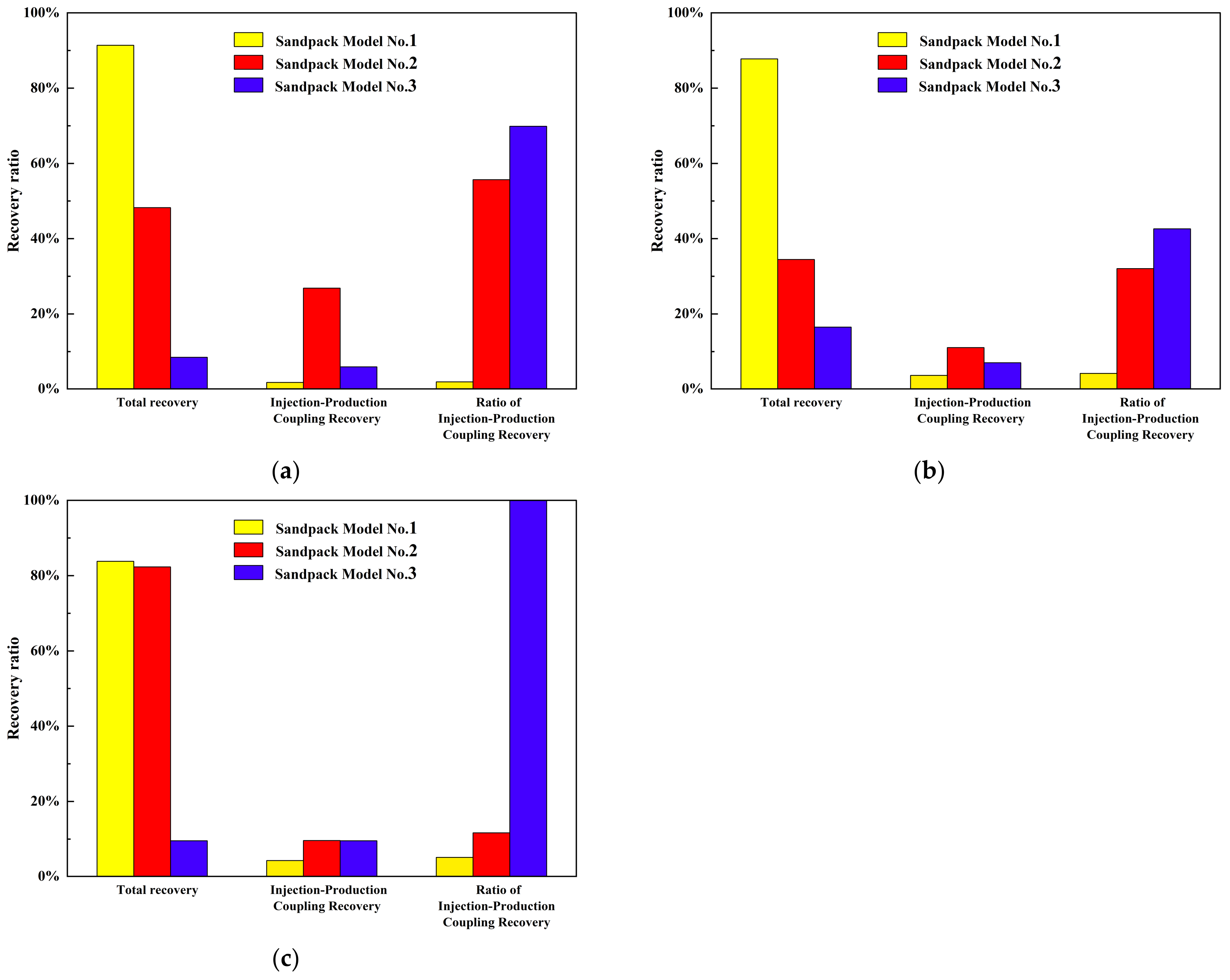

2.4.3. Law of Injection–Production Coupling to Enhance Oil Recovery

3. Injection–Production Coupling Numerical Simulation

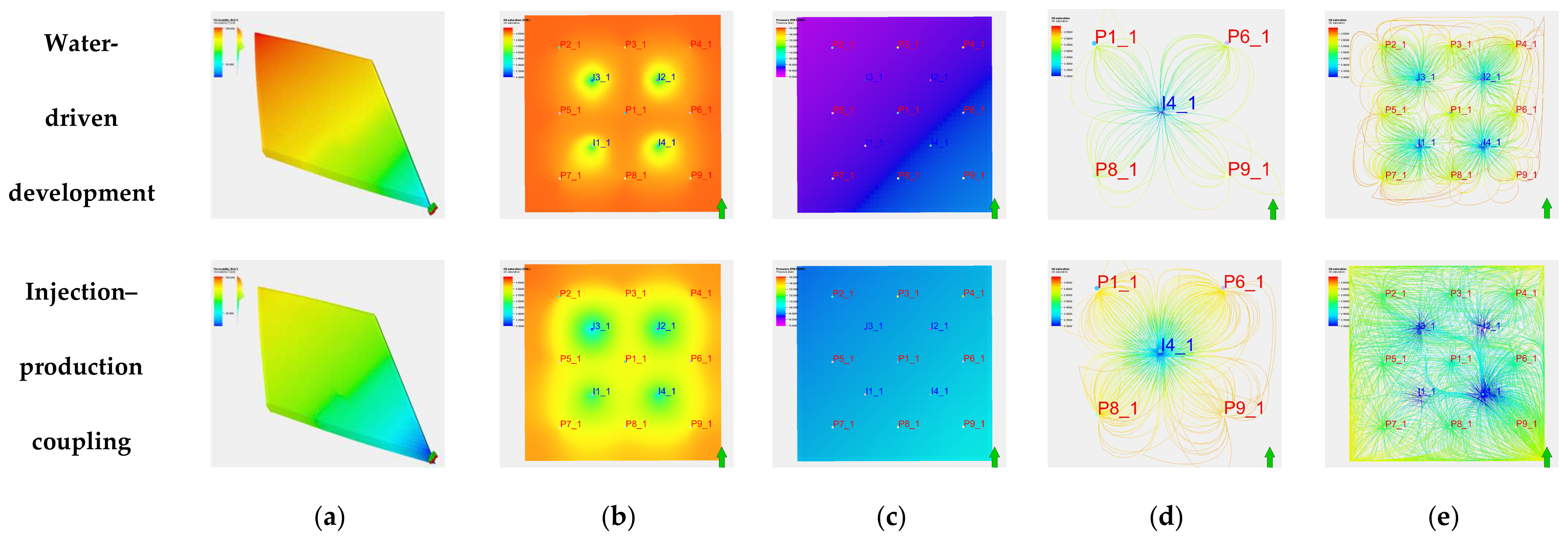

3.1. Study of Streamline Field and Remaining Oil Distribution Characteristics

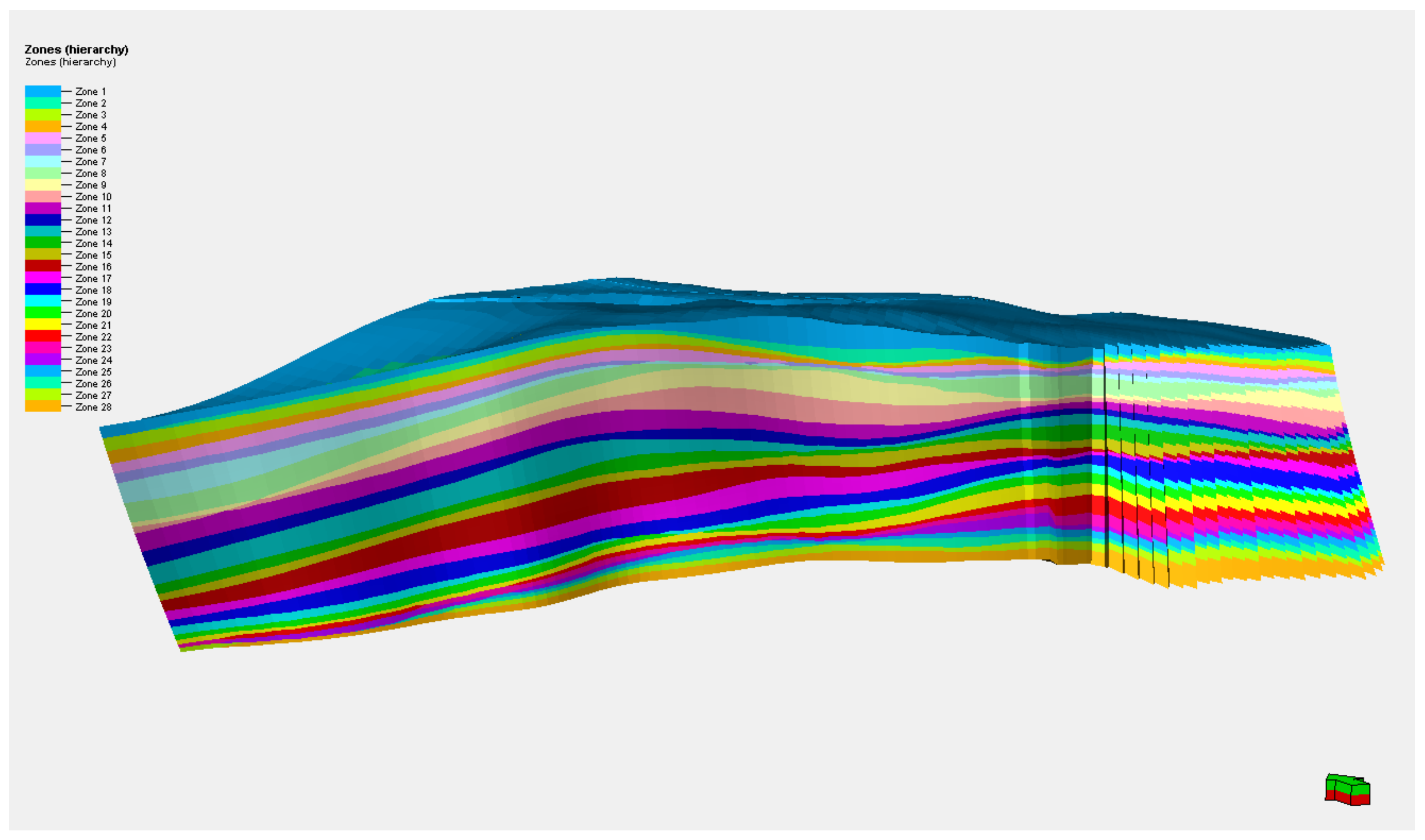

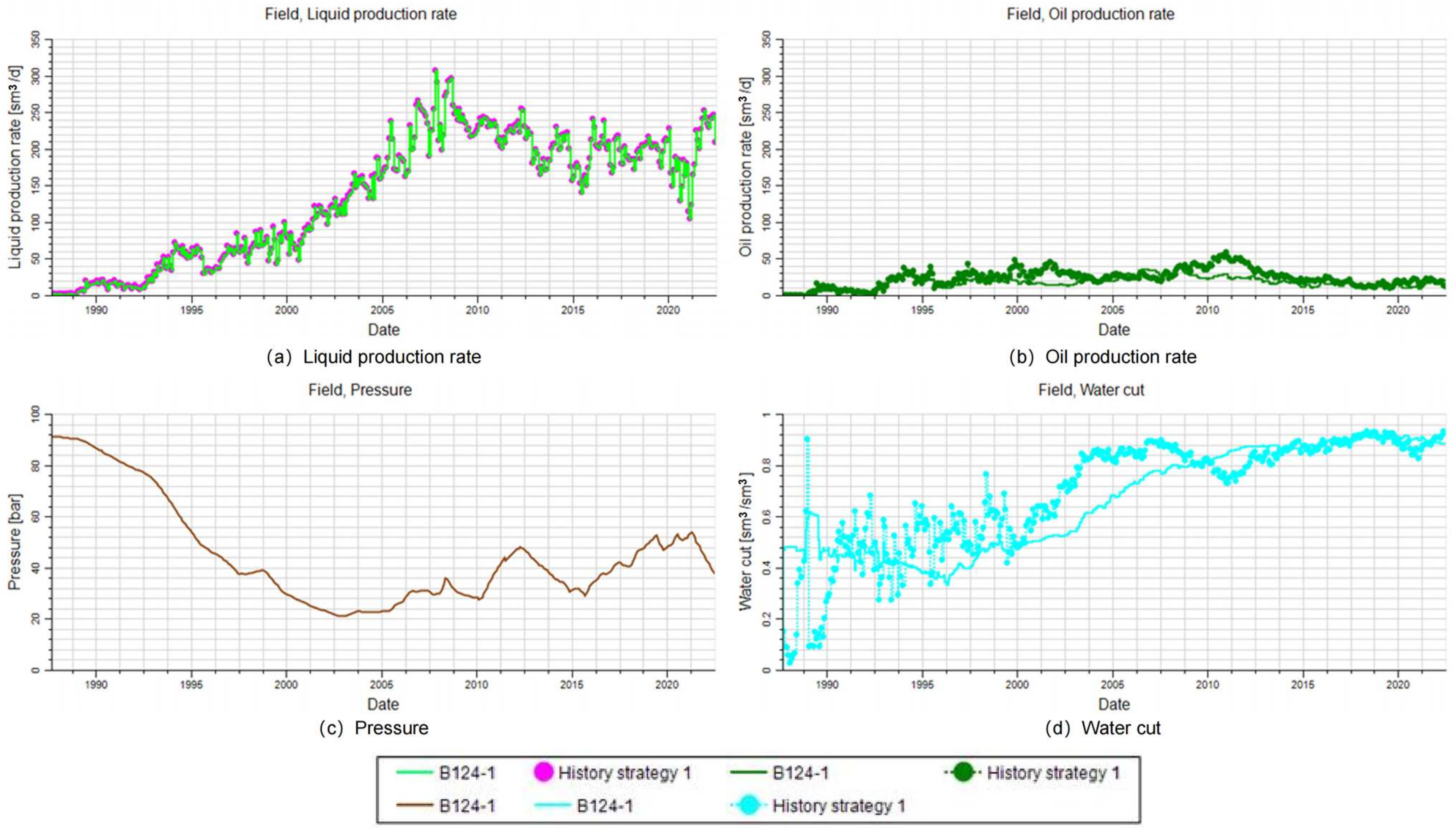

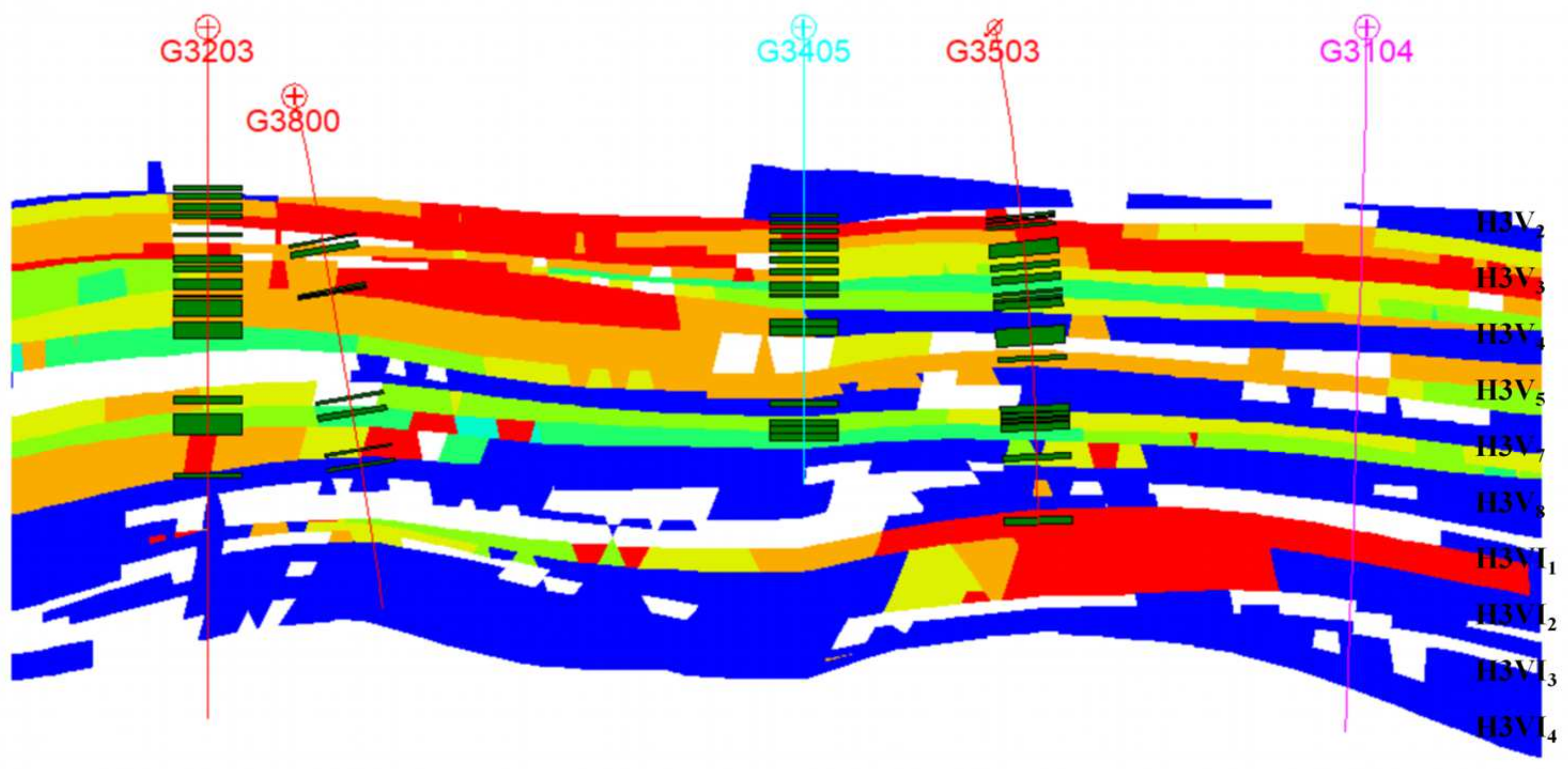

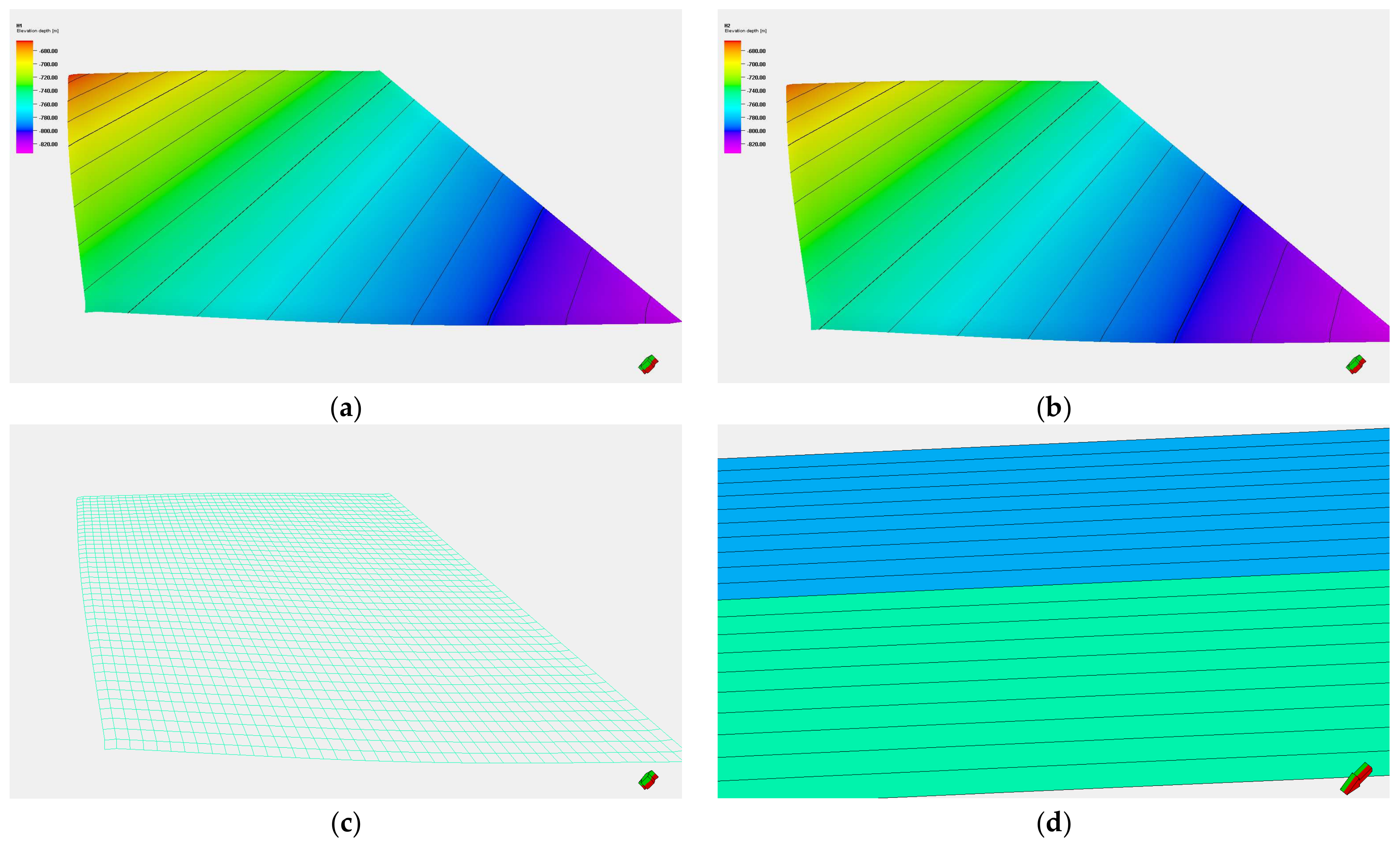

3.1.1. Modeling and History Fitting

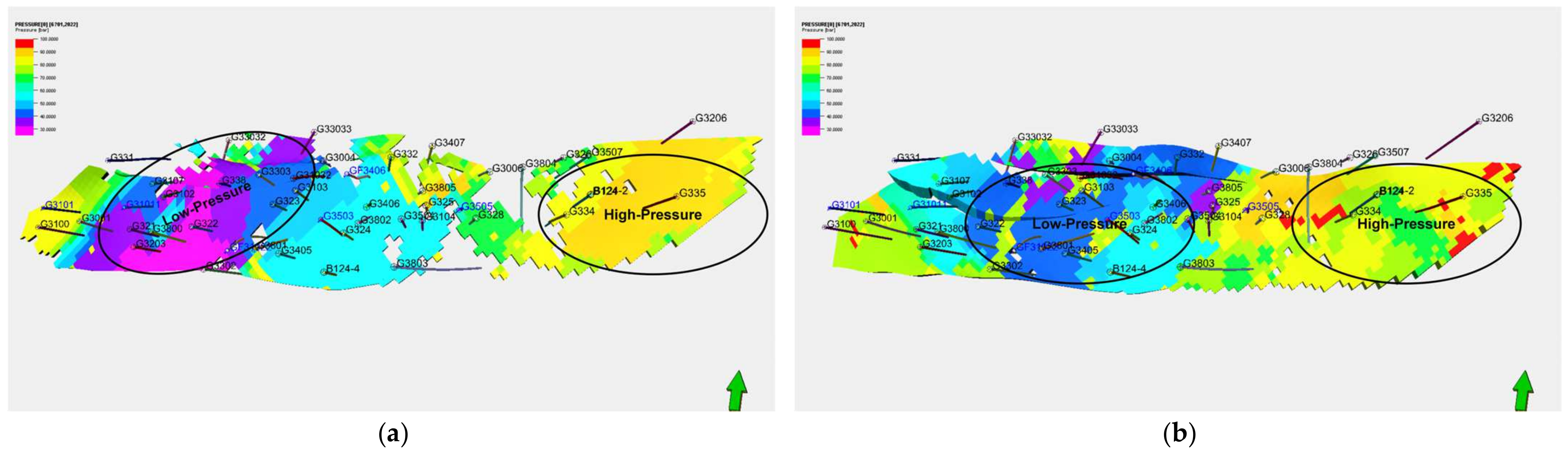

3.1.2. Numerical Simulation of Formation Pressure Characteristics and Streamline Field

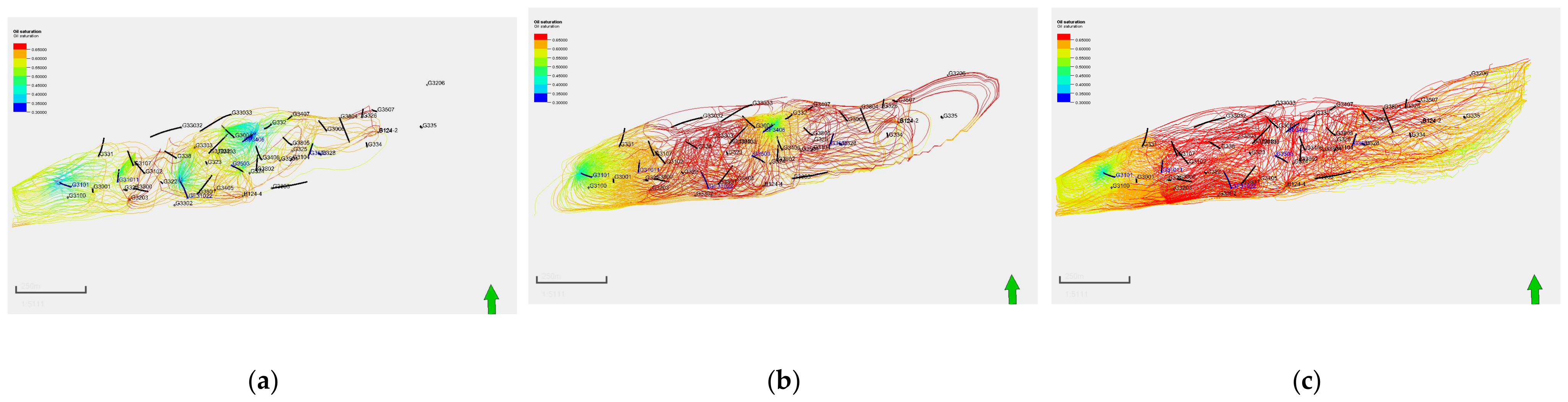

3.1.3. Distribution of Residual Oil

- (1)

- Enrichment in interwell

- (2)

- Enrichment in low-permeability areas

- (3)

- Imperfect well pattern

- (4)

- Mismatch between injection and production

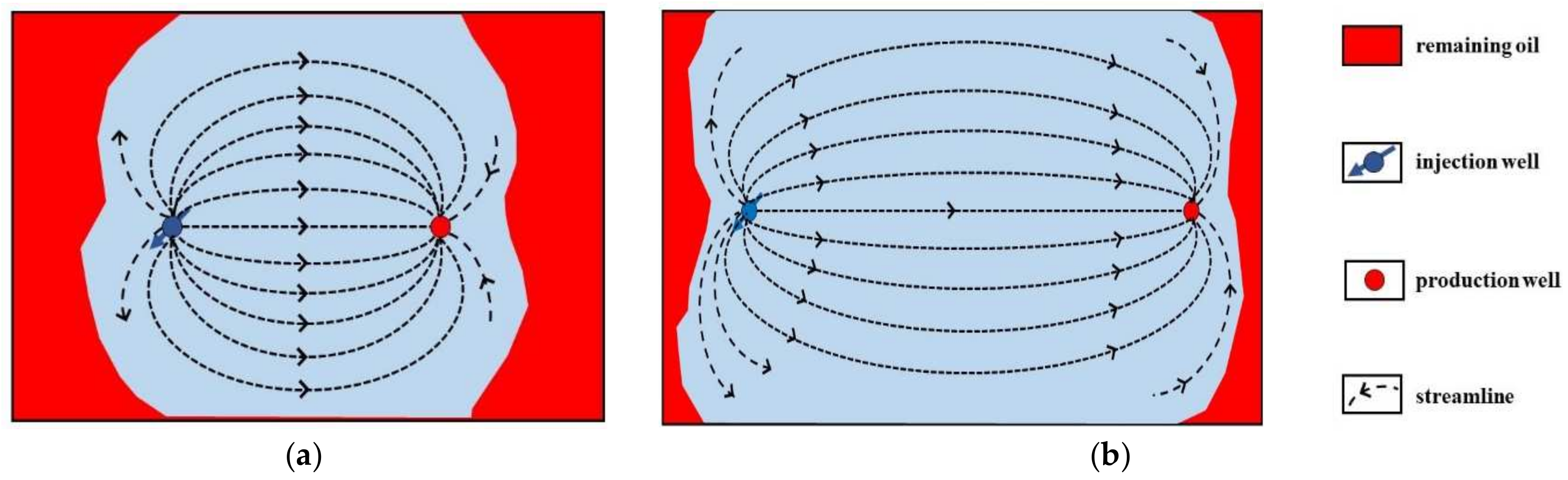

3.2. Research on the Mechanism by which Injection–Production Coupling Improves the Recovery Rate

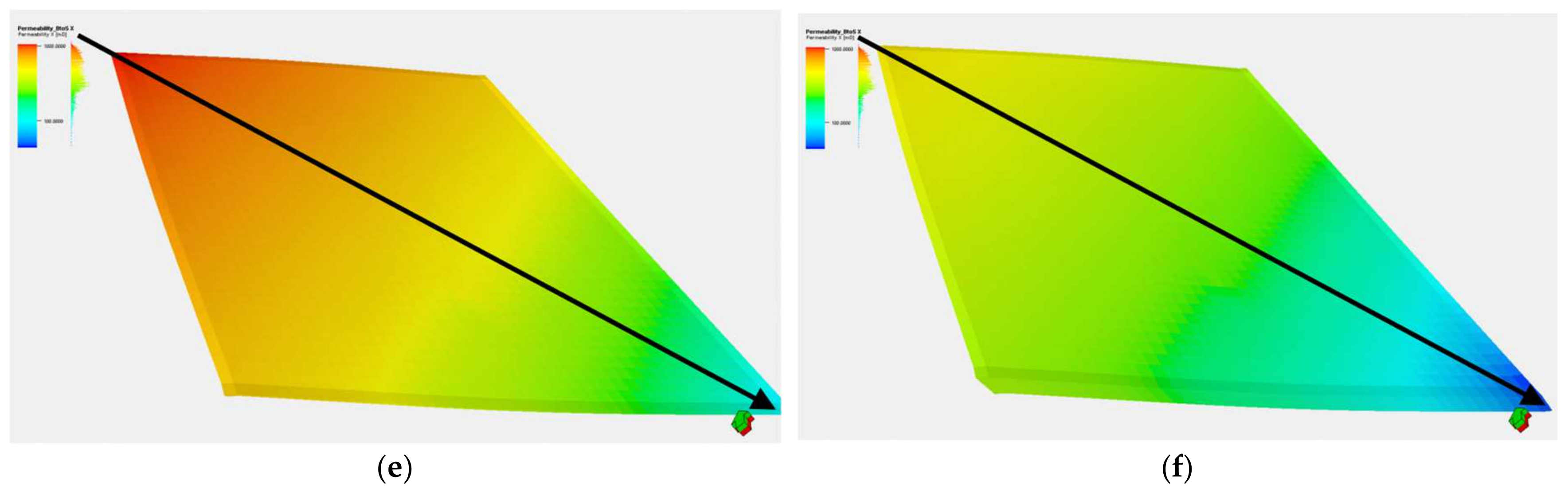

3.2.1. Setting Parameters

3.2.2. Mechanisms of Enhanced Oil Recovery (EOR)

- (1)

- The permeability showed the change rule of gradually becoming smaller from northwest to southeast, the high value point of the permeability of the lower matrix decreased significantly after the development of injection–production coupling, and the fluctuation in the permeability of the reservoir slowed down.

- (2)

- The oil saturation around the production wells was significantly reduced, and effective digging of residual oil was realized around the wells.

- (3)

- Compared with conventional water-driven development, the injection–production coupling development method disrupted the uniform regional distribution of formation pressure and changed the internal pressure distribution of the reservoir while increasing the formation energy.

- (4)

- In the simulation of the single-well streamline field, the seepage field under the conventional water-driven flow formed a solid streamline pattern, and the main streamline pattern was very obvious. Even in the simulation of the well group state, there was still a large area of unaffected streamline between different well groups. However, under injection–production coupling development, the pressure propagation range was wider, the water-driven wave range was obviously increased, the dominant channel formed by the main streamline field no longer existed, the stage of injection–production coupling exhibited a relatively continuous flow, and the injection and production were more homogeneous.

4. Conclusions

- (1)

- The main contribution to the recovery rate of the higher-permeability sandpack model came from the conventional water-driven injection method, and the average water-driven recovery rate of a single layer reached 77%. The injection pressure and the number of coupling cycles had a significant impact on the effect of multilayer injection–production coupling, improving the recovery rate of the middle- and low-permeability sandpack models, and with an increase in the injection pressure, the crude oil in the lower-permeability model was effectively utilized after the development of multiple cycles of injection–production coupling.

- (2)

- For the four main types of residual oil (enrichment in interwell, enrichment in low-permeability areas, imperfect well pattern, and mismatch between injection and production), interwell enrichment residual oil, due to the restriction of the control radius of a single well and the unstable nature of extraction, accounted for 48.52% of the total residual geologic reserves, followed by enrichment in low-permeability areas, which accounted for 22.95%. Residual oil from an imperfect well pattern and mismatch between injection and production accounted for only 14.95% and 13.55%, respectively.

- (3)

- Compared with conventional water-driven coupling, the development of injection–production coupling had a good effect on the reservoir water cut, oil saturation, formation pressure, injection water circulation, etc. The streamline was more continuous and uniform, and the scope of the water-driven wave was wider.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiao, F.Z. Re-recognition of “unconventional” in unconventional oil and gas. Pet. Explor. Dev. 2019, 46, 803–810. [Google Scholar] [CrossRef]

- Zou, C.N.; Pan, S.Q.; Jing, Z.H.; Gao, Z.L.; Yang, Z.; Wu, S.T.; Zhao, Q. Shale oil and gas revolution and its impact. Acta Pet. Sin. 2020, 41, 1. [Google Scholar]

- Li, J.Z.; Zheng, M.; Chen, X.M.; Li, D.H.; Wang, S.Y.; Song, T. Connotation analysis, source-reservoir assemblage types and development potential of unconventional hydrocarbon in China. Acta Pet. Sin. 2015, 36, 521–532. [Google Scholar] [CrossRef]

- Jia, C.Z.; Pang, X.Q.; Song, Y. The mechanism of unconventional hydrocarbon formation: Hydrocarbon self-containment and intermolecular forces. Pet. Explor. Dev. 2021, 48, 437–452. [Google Scholar] [CrossRef]

- Zou, C.N.; Zhu, R.K.; Wu, S.T.; Yang, Z.; Tao, S.Z. Types, characteristics, genesis and prospects of conventional and unconventional hydrocarbon accumulations: Taking tight oil and tight gas in China as an instance. Acta Pet. Sin. 2012, 33, 173–187. [Google Scholar]

- Jia, C.Z.; Zheng, M.; Zhang, Y.F. Unconventional hydrocarbon resources in China and the prospect of exploration and development. Pet. Explor. Dev. 2012, 39, 129–136. [Google Scholar] [CrossRef]

- Zhu, W.Y.; Yue, M.; Liu, Y.F.; Liu, K.; Song, Z.Y. Research progress on tight oil exploration in China. Chin. J. Eng. 2019, 41, 1103–1114. [Google Scholar]

- Gao, H.; Li, H. Determination of movable fluid percentage and movable fluid porosity in ultra-low permeability sandstone using nuclear magnetic resonance (NMR) technique. J. Pet. Sci. Eng. 2015, 133, 258–267. [Google Scholar] [CrossRef]

- Wang, L.; Tian, Y.; Yu, X.Y.; Wang, G.; Yao, B.W.; Wang, S.H. Advances in improved/enhanced oil recovery technologies for tight and shale reservoirs. Fuel 2017, 210, 425–445. [Google Scholar] [CrossRef]

- Chen, H.; Wang, T.; Liu, R.M.; Tian, M.; Meng, Q.C. Study on optimization of injection and production for improving development effect of heterogeneous reservoirs at high water cut stage. Complex Hydrocarb. Reserv. 2023, 02, 215–219. [Google Scholar]

- Yuan, S.Y.; Wang, Q.; Li, J.S.; Hang, H.S. Technology progress and prospects of enhanced oil recovery by gas injection. Acta Pet. Sin. 2020, 41, 1623–1632. [Google Scholar]

- Zhu, W.; Zheng, X.; Li, G. Micro-bubbles size, rheological and filtration characteristics of Colloidal Gas Aphron (CGA) drilling fluids for high temperature well: Role of attapulgite. J. Pet. Sci. Eng. 2020, 186, 106683. [Google Scholar] [CrossRef]

- Wang, R. Mechanical mechanism of the injection-production coupling technique for complex fault-block oil reservoirs. China Sci. 2020, 15, 60–66. [Google Scholar]

- Li, S.O. Study on mechanism of enhanced oil recoveryby injection-production coupling technology. Petrochem. Ind. Technol. 2019, 26, 91–92. [Google Scholar]

- Liu, R.J.; Lu, W.M. Mechanism and field practice of injection-production coupling enhanced oil recovery in fault block reservoirs. Lithol. Reserv. 2023, 1–9. [Google Scholar]

- Wang, R. Study on both characteristics and applicabilities of dynamic injection-production coupling development and technical policy boundaries. Pet. Geol. Recovery Effic. 2022, 29, 100–108. [Google Scholar]

- Sun, Z.G.; Yang, H.B.; Zhang, H.X.; Wang, J.; Wang, R.; Zhang, B. Physical simulation experiment of injection-production coupling. Pet. Geol. Eng. 2021, 43, 144–153. [Google Scholar]

- Wang, J. Research on unstable injection-production to improve oil recovery in complicated fault block of Shengli oilfield-case study of fault block oil reservoirs in Linpan oilfield. Pet. Geol. Recovery Effic. 2013, 20, 89–91. [Google Scholar]

- Li, Z.Y.; Tan, H.Q.; Li, L.X.; Cao, X.L.; Cui, W.F.; Chen, X.Z.; Wang, Y.F.; Li, W.H. Research and application of injection-production coupling technology for enhancing oil recovery in reservoirs at later stage of polymer water-driven. Pet. Geol. Recovery Effic. 2019, 26, 115–121. [Google Scholar]

- Gao, H.; Liu, Y.L.; Zhang, Z.; Niu, B.L.; Li, H.Z. Impact of secondary and tertiary floods on microscopic residual oil distribution in medium-to-high permeability cores with NMR technique. Energy Fuels 2015, 29, 4721–4729. [Google Scholar] [CrossRef]

- Chen, Z.H.; Wu, G.Y.; Qian, W.M.; Wang, J.; Ma, T.; Wang, H.M.; Zheng, Y.W.; Xiong, X.Y. EOR technology and application of CO2 injection for small complex fault block reservoirs in Subei Basin. Pet. Geol. Recovery Effic. 2020, 48, 437–452. [Google Scholar]

- Zhang, H.Y.; Wang, Y.J.; Lei, Y.; Yang, M.; Liu, W.Z. Evaluation method of water water-driven sweep in fault block reservoirs with infill adjustment based on stream—Tube method. Fault-Block Oil Gas Field 2022, 29, 687–691. [Google Scholar]

- Zhao, B.; Han, W.; Ma, T.J.; Gao, G.; Ji, L. Reservoir Quality and Its Control Factors of Complex Fault Block Reservoir in Continental Faulted Basin, Case Study in the Wang Guantun Area, Bohai Bay Basin, China. Energies 2022, 15, 5895. [Google Scholar] [CrossRef]

- Liu, S.Y.; Song, Y.C.; Zhao, C.Z.; Zhang, Y.; Lv, P.F.; Jiang, L.L.; Liu, Y.; Zhao, Y.C. The horizontal dispersion properties of CO2 -CH4 in sand packs with CO2 displacing the simulated natural gas. J. Nat. Gas Sci. Eng. 2018, 50, 293–300. [Google Scholar] [CrossRef]

- Lv, P.F.; Liu, Y.; Liu, F.; Yang, W.Z.; Liu, H.T.; Zhang, B.; Song, Y.C. Pore-based architecture and representative element volume evaluation in artificial sand packs and natural rock cores. Pet. Sci. 2022, 19, 1473–1482. [Google Scholar] [CrossRef]

| No. | Inlet Pressure, MPa | Outlet Pressure, MPa | Porosity, % | Permeability, 10−3 μm2 | Oil Saturation,% |

|---|---|---|---|---|---|

| T1 | 0.084 | 0 | 22.84 | 0.964 | 59.32 |

| T2 | 0.081 | 0 | 22.44 | 0.523 | 86.04 |

| T3 | 0.075 | 0 | 23.17 | 0.286 | 77.36 |

| Horizon | Grid Number | Horizon | Grid Number |

|---|---|---|---|

| H3V11 | 4 | H3V8 | 11 |

| H3V12 | 8 | H3VI11 | 5 |

| H3V21 | 7 | H3VI12 | 5 |

| H3V22 | 5 | H3VI13 | 5 |

| H3V23 | 4 | H3VI21 | 6 |

| H3V31 | 5 | H3VI22 | 8 |

| H3V32 | 7 | H3VI3 | 10 |

| H3V33 | 8 | H3VI41 | 6 |

| H3V41 | 6 | H3VI42 | 7 |

| H3V42 | 9 | H3VI5 | 5 |

| H3V51 | 7 | H3VI61 | 5 |

| H3V52 | 6 | H3VI62 | 5 |

| H3V6 | 9 | H3VI7 | 7 |

| H3V7 | 9 | H3VI8 | 14 |

| Parameters | Value |

|---|---|

| Porosity | 25.37% |

| Permeability | 0.475 D |

| Saturation pressure | 4.15 MPa |

| GOR | 12.3 m3/t |

| API | 30.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Gan, H.; Zhang, C.; Jia, S.; Yu, X.; Zhang, K.; Zhong, X.; Zheng, X.; Shen, T.; Qu, L.; et al. Experimental Study on Improving Oil Recovery Mechanism of Injection–Production Coupling in Complex Fault-Block Reservoirs. Energies 2024, 17, 1505. https://doi.org/10.3390/en17061505

Zhang Z, Gan H, Zhang C, Jia S, Yu X, Zhang K, Zhong X, Zheng X, Shen T, Qu L, et al. Experimental Study on Improving Oil Recovery Mechanism of Injection–Production Coupling in Complex Fault-Block Reservoirs. Energies. 2024; 17(6):1505. https://doi.org/10.3390/en17061505

Chicago/Turabian StyleZhang, Zhe, Hongjun Gan, Chao Zhang, Shengbin Jia, Xianzheng Yu, Kejian Zhang, Xinyu Zhong, Xiaolei Zheng, Tao Shen, Le Qu, and et al. 2024. "Experimental Study on Improving Oil Recovery Mechanism of Injection–Production Coupling in Complex Fault-Block Reservoirs" Energies 17, no. 6: 1505. https://doi.org/10.3390/en17061505

APA StyleZhang, Z., Gan, H., Zhang, C., Jia, S., Yu, X., Zhang, K., Zhong, X., Zheng, X., Shen, T., Qu, L., & Zhang, R. (2024). Experimental Study on Improving Oil Recovery Mechanism of Injection–Production Coupling in Complex Fault-Block Reservoirs. Energies, 17(6), 1505. https://doi.org/10.3390/en17061505