Abstract

The fluctuating nature of renewable energies results in the need for sustainable storage technologies to defossilize the energy system without other negative consequences for humans and the environment. In this study, a pilot-scale trickle-bed reactor for biological methanation and various scale-up scenarios for 2024 and 2050 were investigated using life cycle assessment. A best- and worst-case scenario for technology development until 2050 was evolved using cross-consistency analysis and a morphological field, based on which the data for the ecological models were determined. The results show that the plant scale-up has a very positive effect on the ecological consequences of methanation. In the best-case scenario, the values are a factor of 23–780 lower than those of the actual plant today. A hot-spot analysis showed that electrolysis operation has an especially large impact on total emissions. The final Monte Carlo simulation shows that the technology is likely to achieve a low global warming potential with a median of 104.0 kg CO2-eq/MWh CH4 and thus can contribute to decarbonization.

1. Introduction

The Paris Climate Agreement and the European Green Deal have made the transition of the energy system to renewable technologies a fixed goal [1]. The fluctuating nature of renewable energy, especially photovoltaics and wind power, causes major challenges. In addition to grid expansion, various storage technologies are necessary in order to be able to compensate for these fluctuations both locally and in terms of time [2,3,4].

Power-to-gas (PtG) is an innovative technology in which renewable electricity is converted into gaseous energy carriers such as hydrogen or methane using electrolysis and methanation. PtG has the potential to store renewable electricity in the form of CO2-neutral energy carriers and thus contribute comprehensively to the defossilization of the energy system. Compared to the direct use of hydrogen, the use of biological or chemical methanation involves efficiency losses but has the advantage that existing infrastructure can be used without restriction.

Methanation technologies entail various advantages and disadvantages, which have already been discussed extensively in the respective literature [5,6,7,8]. An intriguing approach to biological methanation is offered by trickle-bed reactors, which have several benefits over conventional stirred-tank reactors [9,10,11,12]. In particular, the low energy input make methanation using a trickle-bed reactor appear advantageous from an ecological point of view. In the technical field, there is a great range of publications on the improvement, optimization, and long-term stability of trickle-bed reactors, with a focus on systems in the laboratory to pilot the plant scale [13,14,15].

Before new technologies are deployed on a broad scale, the ecological consequences of these need to be investigated as comprehensively as possible. This can prevent the use of technologies at an early stage that at first glance may have ecological advantages, e.g., in the area of greenhouse gas emissions but have major disadvantages in other areas. Life cycle analysis (LCA), in particular prospective LCA, is a suitable method for investigating the environmental impact of technologies [16,17,18].

The ecological consequences of various electrolysis technologies have already been studied from a wide range of perspectives [19,20,21,22,23,24,25,26,27,28]. The general focus of previous studies in the field of methanation was mostly on the chemical option, the impact indicator Global Warming Potential, and the operation of plants. The construction effort of the technologies and other environmental indicators have usually been examined only superficially or even neglected. Collet et al. as well as Parra et al. have investigated the impact of the operation of different concepts with chemical methanation [7,8]. Biological methanation plants with stirred tanks were investigated within the P2G-BioCat project and by Goffart De Roeck et al. [29,30]. To date, there are only two publications that have examined the ecological consequences of a trickle-bed bioreactor, whereby no future scenarios were analyzed [31,32]. Since such plants will primarily play a role in the future, it is important to analyze the ecological consequences of the plants today.

The aim of this work is to close this gap. The basis for the investigation is the ecological investigation of a real PtG plant consisting of 5 kW Proton Exchange Membrane (PEM) electrolysis and biological methanation with a trickle-bed reactor. The plant was built and investigated within the ORBIT projects [33]. In addition, since it does not have a relevant output for industrial use, a scale-up of the system designed for life cycle analysis is investigated. This scale-up is projected to the year 2050, which allows the ecological impact of the plant in the future energy system to be estimated today. For this purpose, scenarios are developed using technological field, configuration field, and cross-consistency analysis. As the projection of plant data into the future is subject to certain uncertainties, best- and worst-case scenarios are derived. A final Monte Carlo simulation reveals the environmental impact of biological methanation using a trickle-bed reactor for the most likely case.

The purpose of this investigation is to identify the ecological advantages and disadvantages of power-to-gas systems using biological methanation in trickle-bed reactors at an early stage. For the first time, the focus is placed on analyzing the environmental impact of using the technology in a future energy system built on renewable energies based on which further technological development can be controlled and suitable areas of application for the technology can be derived.

2. Materials and Methods

2.1. Power-to-Gas Systems Investigated

The basic PtG system “ORBIT-Demo” was set up as part of the ORBIT II project. The system consists primarily of a 5 kW PEM electrolysis from Ostermeier H2ydrogen Solutions GmbH and the ORBIT trickle-bed bioreactor shown in Figure 1 [34].

Figure 1.

ORBIT PtG system at the Regensburg site and picture of the inside of the plant. Photo: Michael Heberl | OTH Regensburg.

The components were integrated into an insulated and custom-built container (6.0 × 3.0 × 2.7 m) to ensure that the plant is transportable. Electricity, tap water, and CO2 are supplied externally during plant operation. The water is purified in the electrolysis and split into hydrogen and oxygen. The CO2 source can have a major influence on the LCA results, as shown by Elhaus et al., but was not considered further due to the focus on the methanation concept [35]. The study assumes that the CO2 comes from a sustainable source (for example biomass) and can therefore be regarded as burden-free and carbon-neutral in this system [36]. The oxygen can be used for various purposes (e.g., combustion processes and sewage treatment plants) but will not be considered further in this work. H2 is fed into the methanation process in a 4:1 ratio with CO2. The trickle-bed reactor is filled with ceramic packing (DuraTop®,Vereinigte Füllkörper-Fabriken GmbH & Co. KG Füllkörpertechnik Rheinstraße 176, 56235 Ransbach-Baumbach, Germany) [10]. The packing materials represent the base surface for the growth of the archaea, which convert the reactants into methane and water (Equation (1)):

The product gas is finally dried via cryostat and a silica gel filter and afterwards separated from by-products via an activated carbon filter. The gas can then be analyzed, stored, or fed into the gas grid. A detailed list of the components and data considered can be found in Table 1.

Table 1.

Technological field of methanation with a trickle-bed bioreactor on the industrial scale according to the ORBIT process.

As a second system, an ecological scale-up of ORBIT-Demo was investigated. The system basically consists of the same components as shown in the graphical abstract. The individual components were designed for a methanation capacity of 1 MW methane based on the higher heating value (HHV). More detailed information on the scale-up is presented in Section 2.3.

Based on a general morphological analysis (GMA), the scale-up was then projected to the year 2050 [37]. The values assumed for this purpose are based on own calculations, scientific sources, and expert statements. Due to uncertainties in forecasting the necessary data, there are ranges of values for most of the points. A best and worst-case scenario was derived from these. The two scenarios contain the best and worst values considered from an ecological and technological point of view. The corresponding ranges are listed in Table 1 and the exact methodology is described in 2.4. Finally, the uncertainties for the system in 2050 were addressed using Monte Carlo analysis.

2.2. Life Cycle Analysis

Life cycle analysis is a method to analyze the environmental impact of a product system or service. The basis for the work carried out is the standards ISO 14040 and ISO 14044 [38,39]. The widely used ReCiPe method (ReCiPe Midpoint (H) V1.13) was selected as the life cycle impact assessment method [8,18,19,22,29,40,41]. To provide a comprehensive overview of the ecological impacts of the systems studied, all midpoint impact indicators were considered, with this paper addressing the 11 presented in Table 2.

Table 2.

Within this paper, ReCiPe Midpoint (H) V1.13 impact indicators are addressed.

The cut-off by classification method was used to allocate the emissions [42]. As is common for comparable work, a cradle-to-gate approach was used to define the system boundaries [19,21,43]. For the inputs and outputs to the system boundaries, cut-off processes of the life-cycle inventory (LCI) database ecoinvent were used accordingly. Since the plant was built and is operated in Germany, German processes were considered as far as possible. The production of 1 MWh of product gas was used as a functional unit in all models, with its energy content referenced to the HHV of methane. This approach also allows the representation of different product gas quality of the systems. The investigations were carried out with the software openLCA 2.0.0 and the database ecoinvent 3.9.1. Ecoinvent is a widely used database that provides a very good basis for carrying out work in the field of life cycle assessment and thus for this work [26,44,45,46].

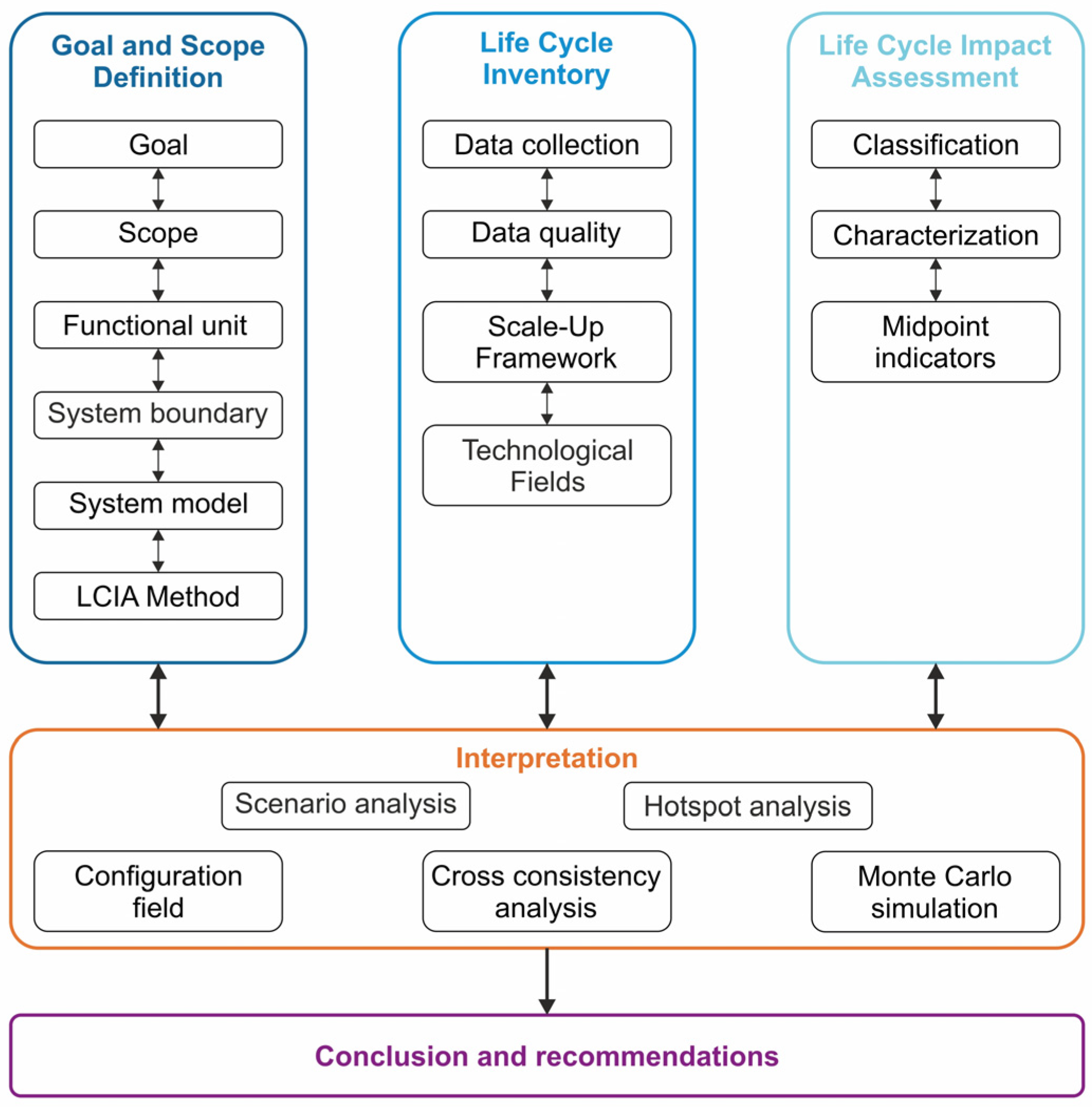

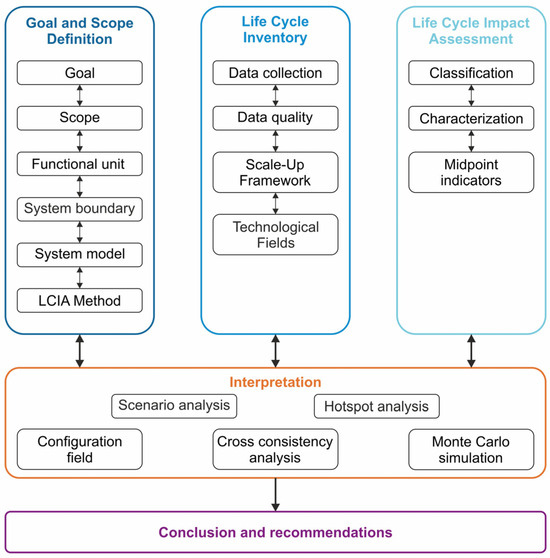

To determine the influence of individual process components, a hot spot analysis was carried out. An overview of the methodology used in this paper is shown in Figure 2.

Figure 2.

Schematic representation of the methodology used in this paper.

The data for the PtG system in 2050 are associated with strong uncertainties due to their forward-looking nature. Here, various authors recommend carrying out a Monte Carlo simulation [17,18]. In addition to the best- and worst-case scenarios, this also allows a likely scenario to be mapped. For this purpose, standard distributions were deposited for the power demand and the lifetime. The middle between best- and worst-case was selected as the mean value and a third of the difference between the mean and maximum value was selected as the standard deviation. This approach results in 99.7% of all considered values being within the minimum and maximum values. For the electrolysis, the best-case variant according to Delpierre et al. for the year 2050 was assumed in order to be able to represent the greatest possible influence of the variation in methanation values [21]. For the Monte Carlo simulation, 10,000 runs were carried out as is common in the literature [44].

2.3. Scale-Up

Since the existing pilot-scale facility does not allow valid conclusions for larger industrial operations, a scale-up is being investigated. Upscaling plants for ecological investigation in LCAs faces many challenges. Since innovative technologies are often studied where appropriate comparative data for industrial-scale plants do not yet exist, as is the case with trickle bed reactors for biological methanation, it is important to apply a suitable and replicable methodology. Piccinno et al. and Simon et al. have described an appropriate framework that can be applied to the scale-up of the trickle-bed bioreactor [47,48]. The application of this methodology has been successfully demonstrated, for example, in the treatment of sewage sludge [46].

The core of the methodology follows two approaches. All process components for which a scale-up has no or only irrelevant effects are extrapolated linearly to the target size. All other process components are first considered individually and scaled up to the desired plant size based on technologies that have the same or a comparable application purpose but exist on a larger scale [47]. As an example, pumps responsible for the supply of nutrient media can be compared with pumps on an industrial scale based on the required delivery volume resulting in well-suited data for the scale-up. In the final step, individual observations are compared with the literature values and combined again to form a product system in the LCA.

The result of the methanation scale-up is shown in the technological field in Table 1. For the data of the scale-up in 2050, bandwidths are given due to high uncertainties. For the PEM electrolysis used in this study, a technological field has already been published by Delpierre et al. based on current data and expert surveys, which can be seen in Table 3. The data used in the modeling are listed in Tables S2–S4.

Table 3.

Technological field of PEM electrolysis according to [21].

It is important to note that this is not a technical scale-up and only serves the purpose of the ecological investigation. Since certain contexts, such as the practical implementation of thermal management, do not play a role in the LCA, they are neglected. [47]

Despite the application of this methodology, it should be noted that the resulting data are subject to uncertainties, which are reflected in value ranges for 2050. To counteract these uncertainties, scenarios for the year 2050 are developed using a cross-consistency analysis, on the basis of which final values for the LCA were selected.

2.4. Scenario Development

The prediction of future characteristics and framework conditions of biological methanation is highly complex and burdened with uncertainties due to various multi-dimensional interrelationships, non-quantifiable factors, and questions that cannot be answered today. One possibility for a scientific approach to the topic is offered by GMA [37].

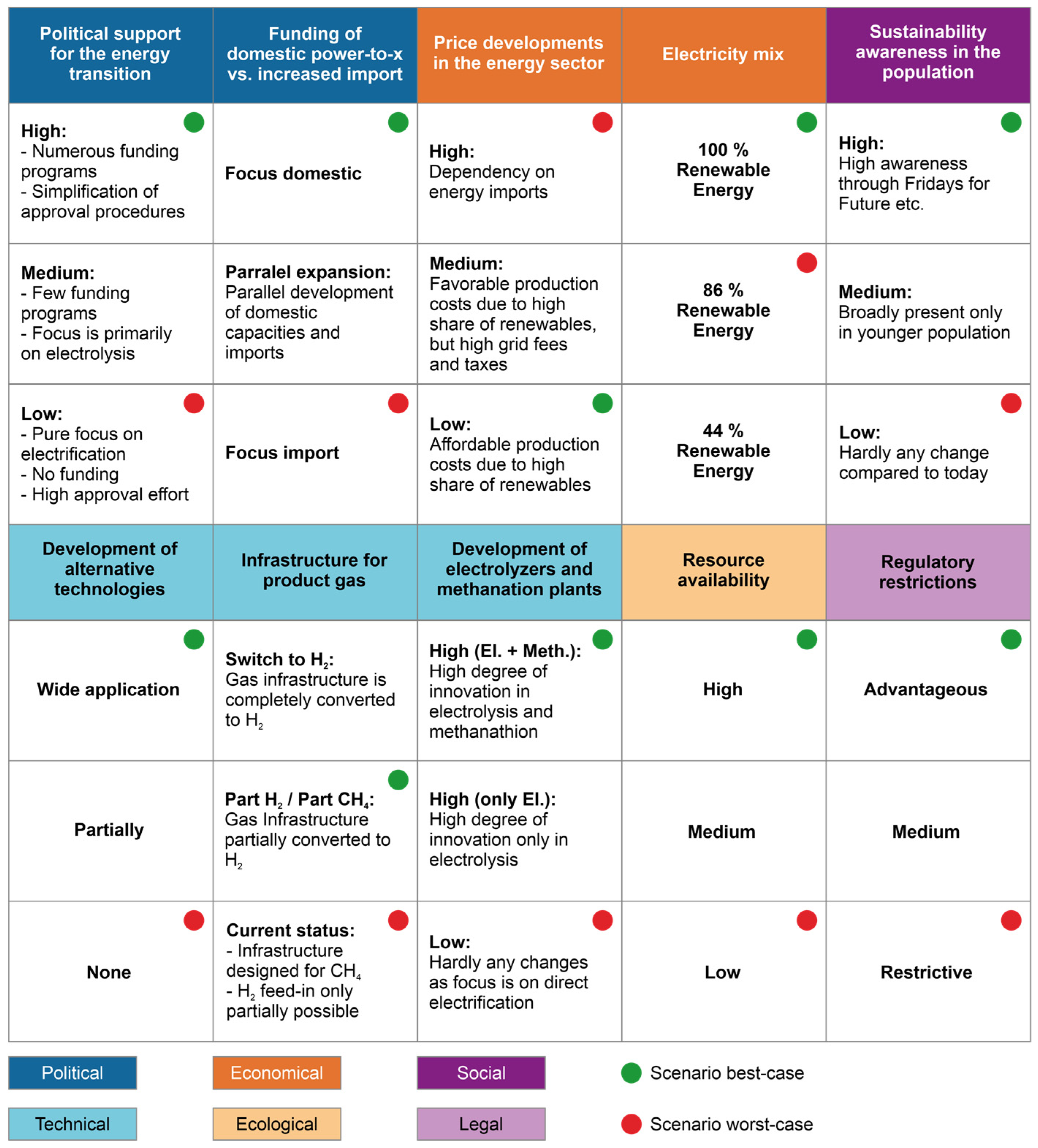

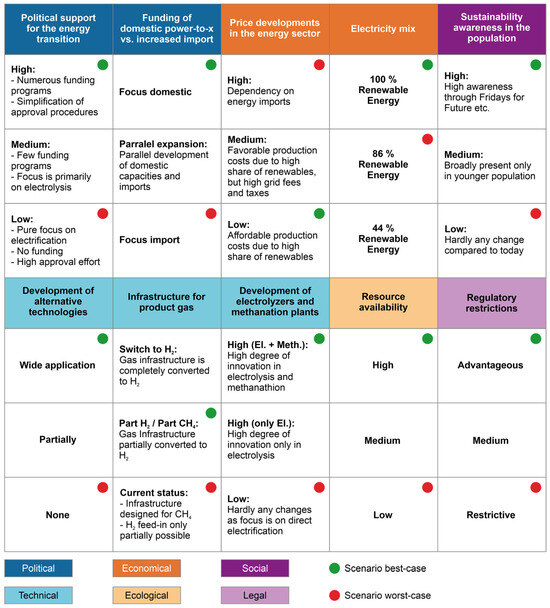

Using GMA, different scenarios can be developed thanks to a systematic and comprehensible approach [21]. In the first step, the dimensions and aspects to be addressed are defined [37]. The focus is on possible factors influencing biological methanation. Social, political, economic, technical, environmental, and legal aspects have been considered in this paper. In the second step, possible options for the selected parameters are identified. With this information, a morphological field can be created. The morphological field serves as the basis for the cross-consistency analysis, in which all options are compared in pairs and checked for consistency (see Table S1) [49]. As an example, in an optimal scenario for the development and expansion of power-to-gas systems, it is assumed that there are numerous funding programs for the development of the technology and that approval procedures have been greatly simplified (green marking for parameter “High” under dimension “Political support for the energy transition”). Assuming this high level of political support, it is likely that the focus in the country (“Funding of domestic power-to-x vs. increased import”) will be on domestic production or a parallel expansion of imports and domestic production. This allows all dimensions to be compared with each other and a consistent scenario can be developed.

The results can be transferred to the morphological field, resulting in the configuration field, shown in Figure 3.

Figure 3.

Configuration field for the year 2050. The color-coded fields represent the dimensions and aspects examined and the fields below them are the corresponding parameters. From cross-consistency analysis, the resulting best-case scenario is marked in green and the worst-case scenario in red.

Scenarios can be derived from this analysis in the final step. Two exemplary scenarios were developed for the best- and worst-case for the development of PtG.

The identification of options and the cross-consistency analysis were carried out against the background of current European energy policy and, if a more precise classification was necessary, German energy policy. For example, the latest funding instruments such as H2Global [50] and the European Hydrogen Bank [51] can be considered in the aspect “Funding of domestic power-to-X vs. increased import from other countries” and social influences, e. g., caused by climate movements, in the aspect “Sustainability awareness in the population”.

The aspect “electricity mix” represents a special feature. Here, it was assumed that a switch to a larger share of renewable energy in the electricity mix is inevitable for society, regardless of the framework conditions. As a result, the “electricity mix 2022” option is not included even in the worst-case scenario. The basis of the German electricity mix composition in 2030 and 2050 are calculations of the Kopernikus project P2X-2 [52].

To transfer qualitative scenarios into LCA, the parameters were linked to quantitative figures and presented in the technological field in Table 1. For electrolysis, the results of Delpierre et al. were used (see Table 3), who applied a comparable methodology for projecting PEM electrolysis until 2050 [21].

3. Results and Discussion

3.1. Resulting Scenarios

3.1.1. Scenario Best-Case

The first scenario represents the best case for biological methanation in Germany. It describes a complete switch to renewable technologies with partial continued use of the current gas infrastructure. The political as well as legal framework is favorable for renewable technologies, which can be seen in the form of various funding programs for their development, a focus on domestic production of energy carriers, and a high CO2 tax. These aspects promote the ramp-up of methanation and enhance its economic viability compared to fossil alternatives. In addition, this results in a high degree of innovation in the further development of electrolysis and methanation, for example, through a national hydrogen strategy and a generally high level of interest from the political side.

In this scenario, Germany has a pure renewable-based electricity mix, with the resulting electricity price being very low due to their favorable electricity generation costs. On the social side, there is a high awareness of the need for energy transition in broad sections of the population, partly due to current climate movements. This also has an impact on technical aspects: due to the open-mindedness and approval of sustainable approaches, various technologies and thus methanation are gaining widespread acceptance. The natural gas grid in Germany is partly operated with mixed gases of H2 and CH4 and otherwise permanently operated with green CH4 from methanation. This also applies to further gas infrastructure, where direct electrification is not possible or only feasible with enormous effort. In the best-case scenario, necessary resources for the transformation of the energy system are provided by a high recycling rate and resource partnerships between Germany and other countries.

3.1.2. Scenario Worst-Case

The second scenario represents the opposite of the best-case scenario with the worst-case for biological methanation. Obstacles to the expansion of methanation dominate in the political and legal fields. There are no suitable funding programs or instruments, the permitting burden for new plants is high, there is no or only a very low CO2 tax, and policymakers focus purely on direct electrification of processes and the import of energy carriers. Additionally, further raw material partnerships have been neglected, resulting in low availability of resources for new technologies, such as precious metals for catalysts in electrolysis.

In this scenario, Germany will not achieve its climate targets. Characteristic of this is the fact that the electricity mix in 2050 has only an 86% share of renewable energy. In combination with the dependence on imported energy carriers, this leads to a high electricity price. There is hardly any awareness of sustainability among the population, which means that new technological approaches have no acceptance and are therefore not widespread. As there have been no major changes to the energy system apart from the increase in renewable energy in the power grid, the infrastructure is at the level of 2024. The gas grid is primarily used for fossil natural gas imports; H2 feed-in is only possible to a limited extent and H2 applications are hardly available. Due to the lack of a regulatory framework and the non-existent expansion of electrolysis and methanation, there is no innovation-promoting environment in Germany in this scenario. This leads to the fact that technologies have hardly improved compared to the status of today.

3.2. Comparison of the LCA Results

The LCA results of the impact indicators investigated are listed in Table 4. When comparing all scenarios, it becomes clear that enormous amounts of emissions can be saved by scaling up the plant. The ORBIT Reactor 2024 has by far the largest impact on humans and the environment with the highest values in all impact categories.

Table 4.

LCA results of the systems studied, divided by the impact indicators.

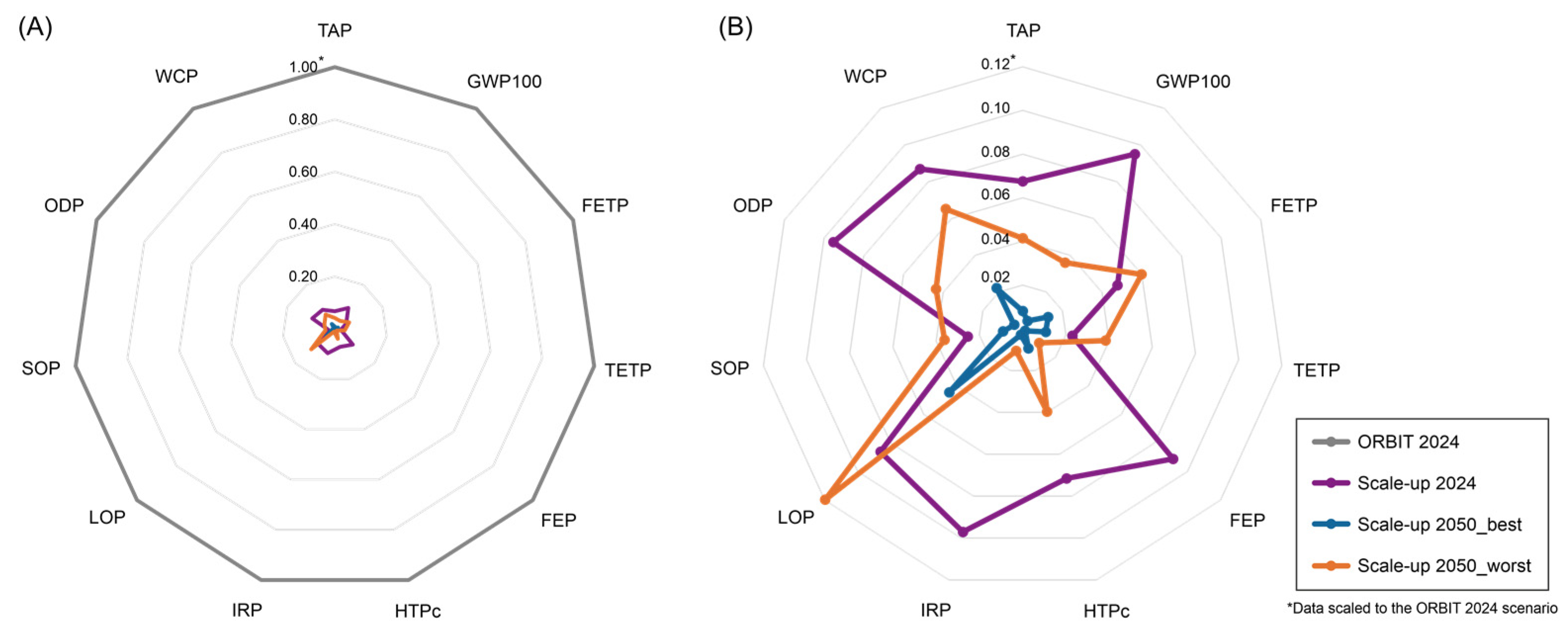

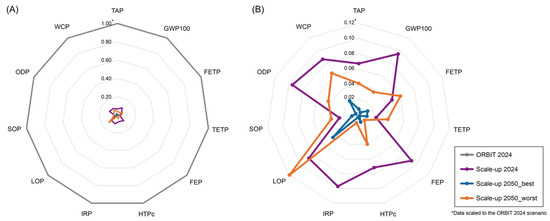

These huge differences between pilot scale and scale-up can also be seen in Figure 4a. In Figure 4b, only scenarios with scale-up reactors are shown, with the values scaled to the ORBIT reactor 2024. This allows their differences to be addressed in more detail. Scenario 2050_worst is closest to the ORBIT reactor in the LOP impact indicator, with 12% of its emissions. The other indicators in the scale-up variant are all below 10% of the ORBIT reactor’s emissions. This shows that LCA studies in a laboratory to demonstrate scale plants are not reliable for industrial-scale plants and that scaling effects have a very positive impact on the sustainability of new technologies.

Figure 4.

Comparison of the investigated impact indicators of the different reactors. Figure 4 (A) shows all analyzed scenarios while (B) shows only the scale-up scenarios for better visualization. The results were scaled to the ORBIT 2024 scenario.

Scenario Scale-Up 2050_best shows the lowest values in all categories. With a maximum of 5% of the plant’s emissions today, it has a very low ecological impact. The Scale-Up 2024 scenario has the highest values apart from the LOP, SOP, TETP, and FETP indicators, with scenario 2050_worst leading in these four categories. Reasons for this are the combination of still relatively high electricity consumption per methane produced compared to the best-case and the already high share of renewables in the electricity mix. For example, 90% of the LOP is due to the electricity mix used to run the PEM, with 70% coming from PV electricity. A more detailed investigation of influences on the GWP indicator caused by individual system components follows via hot-spot analysis.

Table 5 shows the calculated emission reductions between the ORBIT reactor, its scale-up in 2024, and the Scale-Up 2050_best scenario. The values of the 2024 reactor are up to 780 times higher than the 2050_best-case scenario (FEP indicator). The scale-up alone can reduce emissions by up to 48 times compared to the pilot-scale plant. A reduction by a factor of 10 to 15 is achieved for most indicators, with SOP and TETP standing out at 39 and 48, respectively. The GWP, FEP, IRP, and ODP indicators stand out in the comparison between the Scale-Up 2024 and the optimized reactor operated with 100% renewable energy in the Scale-Up 2050_best scenario. A further reduction in emissions of 25 to 70 can be achieved for these. Renewable electricity plays a major role here. As the Scale-Up for 2024 is operated with the current electricity mix, emissions from coal and nuclear power are particularly noticeable and are reflected in reductions in the GWP and IRP indicators, among others.

Table 5.

Emission reductions between the scenarios allocated to impact indicators.

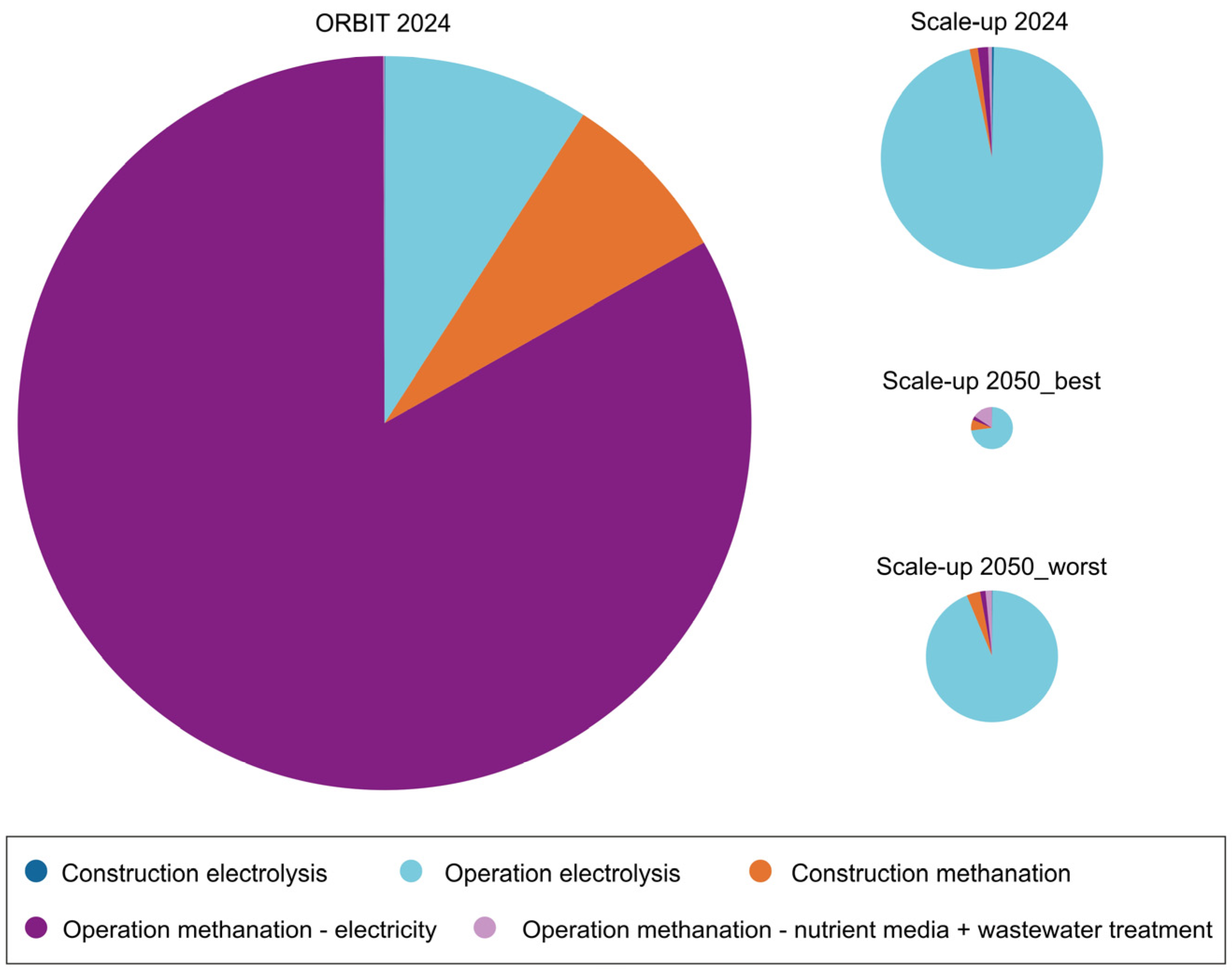

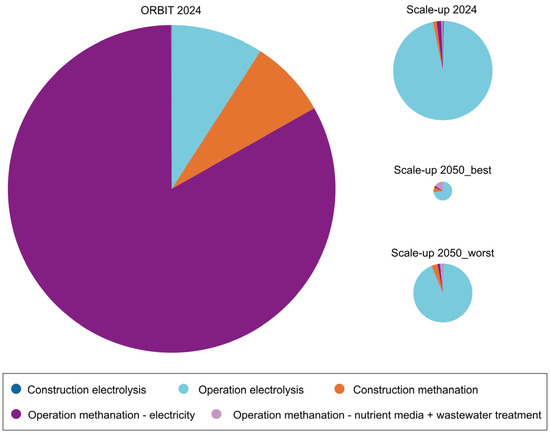

3.3. Hot Spot Analysis

The hot-spot analysis for the GWP indicator, presented in Figure 5, clearly shows the large difference between the ORBIT Reactor 2024 and the Scale-Up variants. The course of the emissions is as expected so that the best-case scenario has the lowest CO2-eq, followed by the worst-case and the scale-up in 2024. The ORBIT Reactor 2024 is clearly dominated by the electricity demand of the methanation; in addition, the construction effort of the methanation and the operation of the electrolysis are relevant here. The main reason for the large proportion of methanation is the low methane production volume. As a result, the electricity consumption of measurement technology, PC, and gas analysis, among other things, is very significant. Energy consumption in these areas only increases to a limited extent in the upscale, as one PC is still sufficient to control a bigger plant, for example.

Figure 5.

Hot-spot analysis of the Global Warming Potential of the four reactors studied. The area of the circles corresponds to the value of the GWP.

An exact analysis can be seen in the percentage breakdown in Table 6. In the scale-up scenarios, the operation of electrolysis dominates, accounting for 72.7–96.5 % of total emissions, whereas the operation of methanation is not very relevant (<4 %). The construction efforts (methanation and electrolysis) are very low; only in 2050_best is the construction effort of the methanation more noticeable, at 8.3 %. The breakdown of emissions is nearly identical in the Scale-Up 2024 and Scale-up 2050_worst scenarios, underscoring the poor progress of the technology in the worst-case scenario.

Table 6.

Percentage distribution of the GWP100 to the main components of the power-to-gas system.

The influence of methanation operation in the wastewater treatment and nutrient media areas is considerable in the scenario Scale-Up 2050_best with a large share of 15.7 % in the total process emissions. This shows the relevance of the effective use of material flows in methanation, especially if the electricity mix has already been decarbonized. One approach to reduce these emissions may be to treat the wastewater, returning the nutrient media and archaea to the reactor and the purified water to electrolysis, resulting in a closed loop.

It should be noted when assessing results for the systems in 2050 that the underlying data in ecoinvent are at today’s level. Accordingly, the calculated values are likely to be rather too high, as effects such as improvements in the production of PV cells or possibilities for sustainable production of chemicals are not represented in this way.

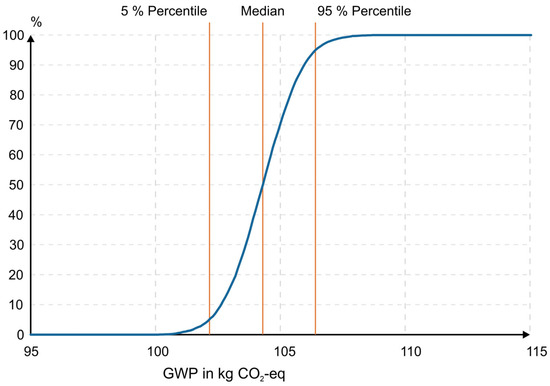

3.4. Monte Carlo Analysis

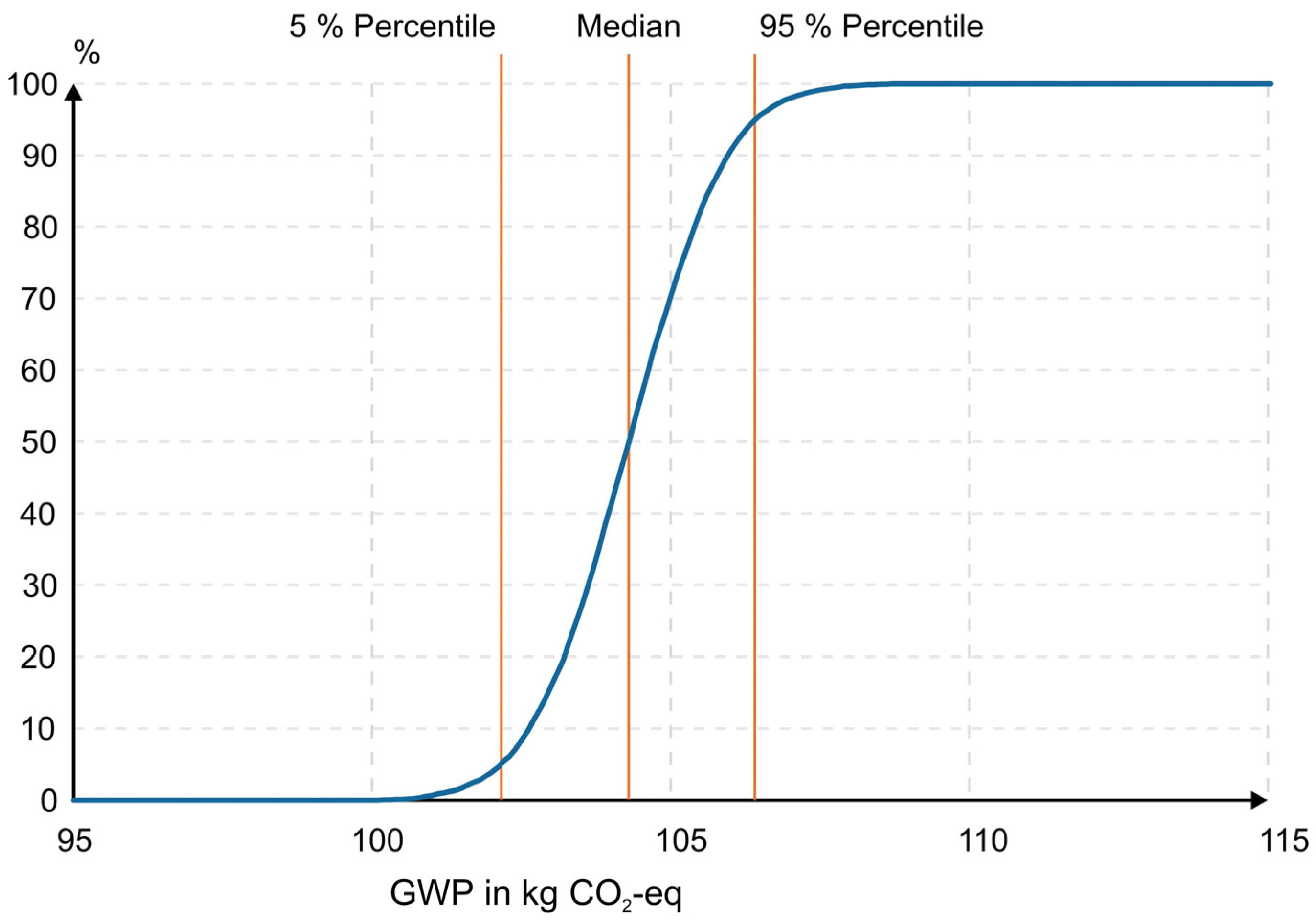

The worst-case and best-case scenario results presented in 3.2 and 3.3 represent scientific estimates of the ecological limits of a PtG system with biological methanation by trickle-bed using the ORBIT process for 2050. Monte Carlo simulation of the system is intended to help identify the most likely outcome.

Figure 6 shows the cumulative occurrence probability above the expected GWP of the methanation plant. The results of the Monte Carlo analysis of all impact indicators investigated can be found in Table S5. Due to the use of best-case electrolysis in the Monte Carlo analysis, the range of results is 99.3 to 109.3 kg CO2-eq/MWh CH4, well below the values of the worst-case scenario. With a median of 104.0 kg CO2-eq/MWh CH4, a low value in the GWP range is achieved with high probability. Looking at the 95 % percentile, which is the value that is at least reached in 95 % of the simulation runs, methanation with 106.4 kg CO2-eq/MWh CH4 is far below the emission factor of fossil natural gas (approx. 200 kg CO2-eq/MWh CH4). This shows that biological methanation based on the ORBIT process can make a significant contribution to the decarbonization of the energy system with a high probability.

Figure 6.

Representation of the cumulative occurrence probability of the resulting GWP as a result of the Monte Carlo simulation.

4. Conclusions

A trickle-bed reactor for biological methanation as the main part of a power-to-gas system and scale-up scenarios for 2050 were investigated using prospective LCA and Monte Carlo analysis. The plant data required for the LCA up to 2050 were derived from an existing plant based on specially developed scenarios. For this purpose, technical, economic, ecological, social, political, and legal factors were compared using cross-consistency analysis and transferred into a morphological field.

The results of LCA and Monte Carlo analysis show

- Plant scale-up has a positive impact on the sustainability of the resulting methane production;

- Emissions can be reduced by a factor of 23–780 if an industrial-scale plant and renewable electricity are used;

- The Monte Carlo analysis shows that there is a very high probability that the GWP of the plant will reach a value of 106.4 kg CO2-eq/MWh CH4, which is significantly lower than the emissions of fossil natural gas;

- The LCA results of laboratory and pilot-scale plants do not allow any direct conclusions about the environmental impact of industrial-scale plants;

- Electrolysis operation has the largest impact on industrial scale, even when using renewable electricity;

- When using renewable electricity, the efficient and sustainable use of the necessary nutrient media and the treatment of wastewater becomes relevant, as this accounts for 15.7% of the CO2-eq emissions.

Efforts to further increase efficiency in electrolysis are therefore essential to achieve sustainability within the power-to-gas system and the energy system overall. In addition, future work should consider topics such as the use of alternative nutrient media, for example, treated sewage sludge, or the reprocessing of wastewater containing nutrient media. Power-to-gas systems, especially when using biological methanation, have enormous potential to become part of a sustainable and efficient circular economy if all material and energy flows are utilized efficiently.

In conclusion, biological methanation is a good alternative to conventional gas production and can contribute to the decarbonization of our energy system.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/en17092206/s1. Table S1: Cross-Consistency Analysis; Table S2: LCI Electricity Mix; Table S3: LCI Electrolysis; Table S4: LCI Methanation; Table S5: Results of Monte Carlo Analysis [53,54,55,56,57].

Author Contributions

Conceptualization, M.H. and C.W.; Funding acquisition, M.S.; Investigation, M.H. and C.W.; Methodology, M.H. and C.W.; Project administration, M.H. and M.S.; Supervision, M.S.; Validation, M.H., A.K. and D.R.; Visualization, M.H., C.W. and M.S.; Writing—original draft, M.H.; Writing—review and editing, M.H., C.W., A.K., D.R. and M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the German Federal Ministry for Economic Affairs and Climate Action [BMWK, grant numbers 03EI3050A]; and the Bavarian Ministry of Economic Affairs, Regional Development and Energy [StWMi, grant numbers 2-LSB-2011-0005].

Data Availability Statement

The original contributions presented in the study are included in the article/Supplementary Material; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- European Comission. The European Green Deal; European Comission: Brussels, Belgium, 2019. [Google Scholar]

- Reiter, G.; Lindorfer, J. Global Warming Potential of Hydrogen and Methane Production from Renewable Electricity via Power-to-Gas Technology. Int. J. Life Cycle Assess. 2015, 20, 477–489. [Google Scholar] [CrossRef]

- Sterner, M. Bioenergy and Renewable Power Methane in Integrated 100% Renewable Energy Systems; Limiting Global Warming by Transforming Energy Systems; Universität Kassel: Kassel, Germany, 2009; Volume 14. [Google Scholar]

- Sterner, M.; Specht, M. Power-to-Gas and Power-to-X—The History and Results of Developing a New Storage Concept. Energies 2021, 14, 6594. [Google Scholar] [CrossRef]

- Götz, M.; Lefebvre, J.; Mörs, F.; McDaniel Koch, A.; Graf, F.; Bajohr, S.; Reimert, R.; Kolb, T. Renewable Power-to-Gas: A Technological and Economic Review. Renew. Energy 2016, 85, 1371–1390. [Google Scholar] [CrossRef]

- Thapa, A.; Jo, H.; Han, U.; Cho, S.K. Ex-Situ Biomethanation for CO2 Valorization: State of the Art, Recent Advances, Challenges, and Future Prospective. Biotechnol. Adv. 2023, 68, 108218. [Google Scholar] [CrossRef] [PubMed]

- Parra, D.; Zhang, X.; Bauer, C.; Patel, M.K. An Integrated Techno-Economic and Life Cycle Environmental Assessment of Power-to-Gas Systems. Appl. Energy 2017, 193, 440–454. [Google Scholar] [CrossRef]

- Collet, P.; Flottes, E.; Favre, A.; Raynal, L.; Pierre, H.; Capela, S.; Peregrina, C. Techno-Economic and Life Cycle Assessment of Methane Production via Biogas Upgrading and Power to Gas Technology. Appl. Energy 2017, 192, 282–295. [Google Scholar] [CrossRef]

- Burkhardt, M.; Busch, G. Methanation of Hydrogen and Carbon Dioxide. Appl. Energy 2013, 111, 74–79. [Google Scholar] [CrossRef]

- Kaul, A.; Böllmann, A.; Thema, M.; Kalb, L.; Stöckl, R.; Huber, H.; Sterner, M.; Bellack, A. Combining a Robust Thermophilic Methanogen and Packing Material with High Liquid Hold-up to Optimize Biological Methanation in Trickle-Bed Reactors. Bioresour. Technol. 2021, 345, 126524. [Google Scholar] [CrossRef] [PubMed]

- Thema, M. Process Optimization for Microbial Biosynthesis of Methane in a Trickle-Bed Reactor for Power-to-Gas Applications: The ORBIT-Process; FAU Erlangen-Nürnberg: Erlangen, Germany, 2020. [Google Scholar]

- Fenske, C.F.; Strübing, D.; Koch, K. Biological Methanation in Trickle Bed Reactors—A Critical Review. Bioresour. Technol. 2023, 385, 129383. [Google Scholar]

- Strübing, D.; Moeller, A.B.; Mößnang, B.; Lebuhn, M.; Drewes, J.E.; Koch, K. Load Change Capability of an Anaerobic Thermophilic Trickle Bed Reactor for Dynamic H2/CO2 Biomethanation. Bioresour. Technol. 2019, 289, 121735. [Google Scholar] [CrossRef]

- Fenske, C.F.; Strübing, D.; Koch, K. Preliminary Gas Flow Experiments Identify Improved Gas Flow Conditions in a Pilot-Scale Trickle Bed Reactor for H 2 and CO 2 Biological Methanation. Bioresour. Technol. 2023, 371, 128648. [Google Scholar]

- Fenske, C.F.; Kirzeder, F.; Strübing, D.; Koch, K. Biogas Upgrading in a Pilot-Scale Trickle Bed Reactor—Long-Term Biological Methanation under Real Application Conditions. Bioresour. Technol. 2023, 376, 128868. [Google Scholar]

- Moni, S.M.; Mahmud, R.; High, K.; Carbajales-Dale, M. Life Cycle Assessment of Emerging Technologies: A Review. J. Ind. Ecol. 2020, 24, 52–63. [Google Scholar] [CrossRef]

- Schropp, E.; Naumann, G.; Gaderer, M. Prospective Life Cycle Assessment: A Case Study of Hydrogen Production with Water Electrolysis. Procedia CIRP 2022, 105, 92–97. [Google Scholar] [CrossRef]

- van der Giesen, C.; Cucurachi, S.; Guinée, J.; Kramer, G.J.; Tukker, A. A Critical View on the Current Application of LCA for New Technologies and Recommendations for Improved Practice. J. Clean. Prod. 2020, 259, 120904. [Google Scholar] [CrossRef]

- Bareiß, K.; de la Rua, C.; Möckl, M.; Hamacher, T. Life Cycle Assessment of Hydrogen from Proton Exchange Membrane Water Electrolysis in Future Energy Systems. Appl. Energy 2019, 237, 862–872. [Google Scholar] [CrossRef]

- Bhandari, R.; Trudewind, C.A.; Zapp, P. Life Cycle Assessment of Hydrogen Production via Electrolysis—A Review. J. Clean. Prod. 2014, 85, 151–163. [Google Scholar] [CrossRef]

- Delpierre, M.; Quist, J.; Mertens, J.; Prieur-Vernat, A.; Cucurachi, S. Assessing the Environmental Impacts of Wind-Based Hydrogen Production in the Netherlands Using Ex-Ante LCA and Scenarios Analysis. J. Clean. Prod. 2021, 299, 126866. [Google Scholar] [CrossRef]

- Mehmeti, A.; Angelis-Dimakis, A.; Muñoz, C.B.; Graziadio, M.; McPhail, S.J. Eco-Thermodynamics of Hydrogen Production by High-Temperature Electrolysis Using Solid Oxide Cells. J. Clean. Prod. 2018, 199, 723–736. [Google Scholar] [CrossRef]

- Melideo, D.; Ortiz Cebolla, R.; Weidner, E. Workshop on Lifecycle Analysis of Fuel Cell and H2 Technologies; Publications Office of the European Union: Luxembourg, 2020; ISBN 9789276125839. [Google Scholar]

- Olindo, R.; Schmitt, N.; Vogtländer, J. Life Cycle Assessments on Battery Electric Vehicles and Electrolytic Hydrogen: The Need for Calculation Rules and Better Databases on Electricity. Sustainability 2021, 13, 5250. [Google Scholar] [CrossRef]

- Palmer, G.; Roberts, A.; Hoadley, A.; Dargaville, R.; Honnery, D. Life-Cycle Greenhouse Gas Emissions and Net Energy Assessment of Large-Scale Hydrogen Production via Electrolysis and Solar PV. Energy Environ. Sci. 2021, 14, 5113–5131. [Google Scholar] [CrossRef]

- Zhao, G.; Kraglund, M.R.; Frandsen, H.L.; Wulff, A.C.; Jensen, S.H.; Chen, M.; Graves, C.R. Life Cycle Assessment of H2O Electrolysis Technologies. Int. J. Hydrogen Energy 2020, 45, 23765–23781. [Google Scholar] [CrossRef]

- Schropp, E.; Campos-Carriedo, F.; Iribarren, D.; Naumann, G.; Bernäcker, C.I.; Gaderer, M.; Dufour, J. Environmental and Material Criticality Assessment of Hydrogen Production Via Anion Exchange Membrane Electrolysis. Appl. Energy 2024, 356, 122247. [Google Scholar] [CrossRef]

- Yury, I.; Martirosyan, A. The Development of the Soderberg Electrolyzer Electromagnetic Field’s State Monitoring System. Sci. Rep. 2024, 14, 3501. [Google Scholar] [CrossRef] [PubMed]

- Goffart De Roeck, F.; Buchmayr, A.; Gripekoven, J.; Mertens, J.; Dewulf, J. Comparative Life Cycle Assessment of Power-to-Methane Pathways: Process Simulation of Biological and Catalytic Biogas Methanation. J. Clean. Prod. 2022, 380, 135033. [Google Scholar] [CrossRef]

- P2G-BioCat. ANNEX 1 ForskEL 2014-1-12164—Life Cycle Analysis. 2017. Available online: https://energiforskning.dk/files/slutrapporter/12164_annex_1_p2g_biocat_lca_final_report.pdf (accessed on 22 April 2024).

- Wettstein, S.; Itten, R.; Stucki, M. Life Cycle Assessment of Renewable Methane for Transport and Mobility; Zurich University of Applied Sciences: Zurich, Switzerland, 2018. [Google Scholar]

- Vinardell, S.; Feickert, C.; Heimann, A.; Luis, J.; Koch, K. Exploring the Potential of Biological Methanation for Future Defossilization Scenarios: Techno-Economic and Environmental Evaluation. Energy Convers. Manag. 2024, 307, 118339. [Google Scholar] [CrossRef]

- Thema, M.; Weidlich, T.; Kaul, A.; Böllmann, A.; Huber, H.; Bellack, A.; Karl, J.; Sterner, M. Optimized Biological CO2-Methanation with a Pure Culture of Thermophilic Methanogenic Archaea in a Trickle-Bed Reactor. Bioresour. Technol. 2021, 333, 125135. [Google Scholar] [CrossRef] [PubMed]

- Heberl, M.; Kaul, A.; Rank, D.; Sterner, M. ORBIT Project Homepage. Available online: https://orbit-projekt.de/en/home-english/ (accessed on 22 April 2024).

- Elhaus, N.; Kolb, S.; Müller, J.; Goldbrunner, M.; Karl, J.; Herkendell, K. Environmental Assessment of Anaerobic Digestion and Biological Methanation in Power-to-Methane Systems. J. Clean. Prod. 2023, 429, 139509. [Google Scholar] [CrossRef]

- Yu, S.; He, J.; Zhang, Z.; Sun, Z.; Xie, M.; Xu, Y.; Bie, X.; Li, Q.; Zhang, Y.; Sevilla, M.; et al. Towards Negative Emissions: Hydrothermal Carbonization of Biomass for Sustainable Carbon Materials. Adv. Mater. 2024, 2307412, 1–44. [Google Scholar] [CrossRef] [PubMed]

- Ritchey, T. Wicked Problems/Social Messes: Decision Support Modelling with Morphological Analysis; Springer: Berlin/Heidelberg, Germany, 2011; ISBN 9783642196522. [Google Scholar]

- DIN EN ISO 14040:2021-02; Environmental Management—Life Cycle Assessment—Principles and Framework (ISO 14040:2006 + Amd 1:2020). German Version EN ISO 14040:2006 + A1:2020. DIN e. V.: Berlin, Germany, 2021.

- DIN EN ISO 14044:2018-05; EN: Environmental Management—Life Cycle Assessment—Requirements and Guidelines (ISO 14044:2006 + Amd 1:2017 + Amd 2:2020). German Version EN ISO 14044:2006 + A1:2018 + A2:2020. DIN e. V.: Berlin, Germany, 2018.

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Yu, S.; Dong, X.; Zhao, P.; Luo, Z.; Sun, Z.; Yang, X.; Li, Q.; Wang, L.; Zhang, Y.; Zhou, H. Decoupled Temperature and Pressure Hydrothermal Synthesis of Carbon Sub-Micron Spheres from Cellulose. Nat. Commun. 2022, 13, 3616. [Google Scholar] [CrossRef] [PubMed]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The Ecoinvent Database Version 3 (Part I): Overview and Methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Federici, F.; Puna, J.; Mata, T.M.; Martins, A.A. Life Cycle Analysis of a Combined Electrolysis and Methanation Reactor for Methane Production. Energy Rep. 2022, 8, 554–560. [Google Scholar] [CrossRef]

- Kurada, S.D.; Ali, M.I.; Gokulachandran, J. Ali, M.I.; Gokulachandran, J. A Comparative Life Cycle Assessment of an Electric, a Hybrid and an Internal Combustion Engine Vehicle Using Monte Carlo Simulation. In Recent Advances in Energy Technologies: Select Proceedings of ICEMT 2021; Springer: Singapore, 2022; pp. 357–373. [Google Scholar] [CrossRef]

- Sun, S.; Ertz, M. Life Cycle Assessment and Monte Carlo Simulation to Evaluate the Environmental Impact of Promoting LNG Vehicles. MethodsX 2020, 7, 101046. [Google Scholar] [CrossRef] [PubMed]

- Elginoz, N.; Owusu-Agyeman, I.; Finnveden, G.; Hischier, R.; Rydberg, T.; Cetecioglu, Z. Application and Adaptation of a Scale-up Framework for Life Cycle Assessment to Resource Recovery from Waste Systems. J. Clean. Prod. 2022, 355, 131720. [Google Scholar] [CrossRef]

- Piccinno, F.; Hischier, R.; Seeger, S.; Som, C. From Laboratory to Industrial Scale: A Scale-up Framework for Chemical Processes in Life Cycle Assessment Studies. J. Clean. Prod. 2016, 135, 1085–1097. [Google Scholar] [CrossRef]

- Simon, B.; Bachtin, K.; Kiliç, A.; Amor, B.; Weil, M. Proposal of a Framework for Scale-up Life Cycle Inventory: A Case of Nanofibers for Lithium Iron Phosphate Cathode Applications. Integr. Environ. Assess. Manag. 2016, 12, 465–477. [Google Scholar] [CrossRef] [PubMed]

- Ritchey, T. Principles of Cross-Consistency Assessment in General Morphological Modelling. Acta Morphol. Gen. 2015, 4, 2001–2241. [Google Scholar]

- Bauer, F.; Erdmann, M.C.; Geyer, F. The Market Ramp-Up of Renewable Hydrogen and Its Derivatives—The Role of H2 Global; H2Global Foundation: Hamburg, Germany, 2023. [Google Scholar]

- European Commission. European Hydrogen Bank. Available online: https://energy.ec.europa.eu/topics/energy-systems-integration/hydrogen/european-hydrogen-bank_en (accessed on 22 April 2024).

- Ausfelder, F.; Tran, D.D. 4th Roadmap—Options for a Sustainable Energy System with Power-to-X Technologies (Translated from German); DECHEMA Gesellschaft für Chemische Technik und Biotechnologie e.V.: Frankfurt, Germany, 2022. [Google Scholar]

- Statistisches Bundesamt Gross Electricity Production in Germany. Available online: https://www.destatis.de/EN/Themes/Economic-Sectors-Enterprises/Energy/Production/Tables/gross-electricity-production.html (accessed on 22 April 2024).

- Wulf, C.; Kaltschmitt, M. Hydrogen Supply Chains for Mobility—Environmental and Economic Assessment. Sustainability 2018, 10, 1699. [Google Scholar] [CrossRef]

- Burkhardt, M.; Horn, O.; Uellendahl, H.; Viertmann, O.; Vith, W.; Fischer, D.; Busch, G. Schlussbericht Zum Verbundvorhaben WeMetBio; Fachagentur Nachwachsende Rohstoffe e. V. (FNR): Gülzow, Germany, 2021. [Google Scholar]

- Cheng, G.; Gabler, F.; Pizzul, L.; Olsson, H.; Nordberg, Å.; Schnürer, A. Microbial Community Development during Syngas Methanation in a Trickle Bed Reactor with Various Nutrient Sources. Appl. Microbiol. Biotechnol. 2022, 106, 5317–5333. [Google Scholar] [CrossRef]

- Graf, F. Store & Go—Innovative Large-Scale Energy Storage Technologies and Power-to-Gas Concepts after Optimisation. Impact 2018, 2018, 81–83. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).