Prospective Life Cycle Assessment of Biological Methanation in a Trickle-Bed Pilot Plant and a Potential Scale-Up

Abstract

1. Introduction

2. Materials and Methods

2.1. Power-to-Gas Systems Investigated

2.2. Life Cycle Analysis

2.3. Scale-Up

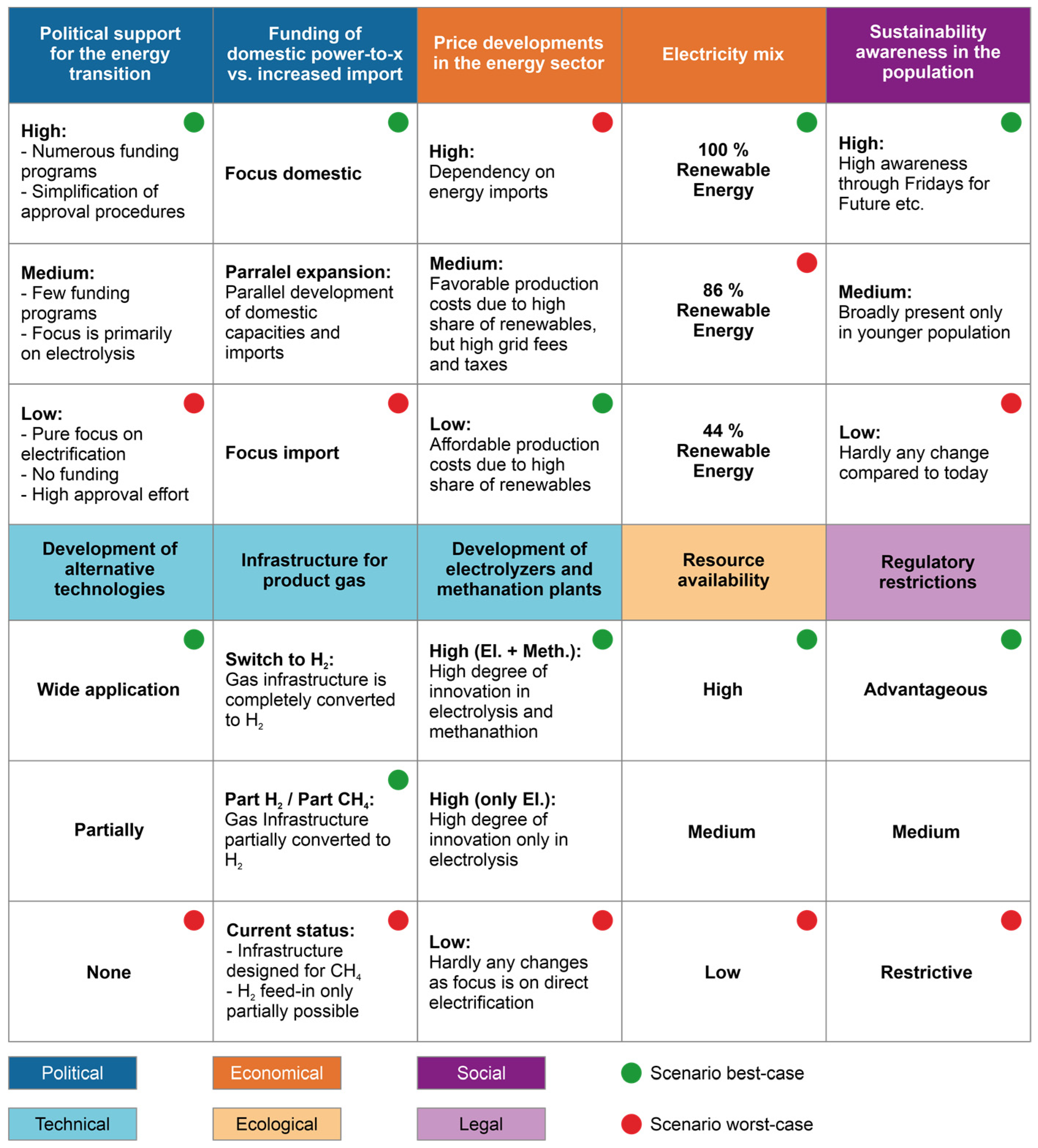

2.4. Scenario Development

3. Results and Discussion

3.1. Resulting Scenarios

3.1.1. Scenario Best-Case

3.1.2. Scenario Worst-Case

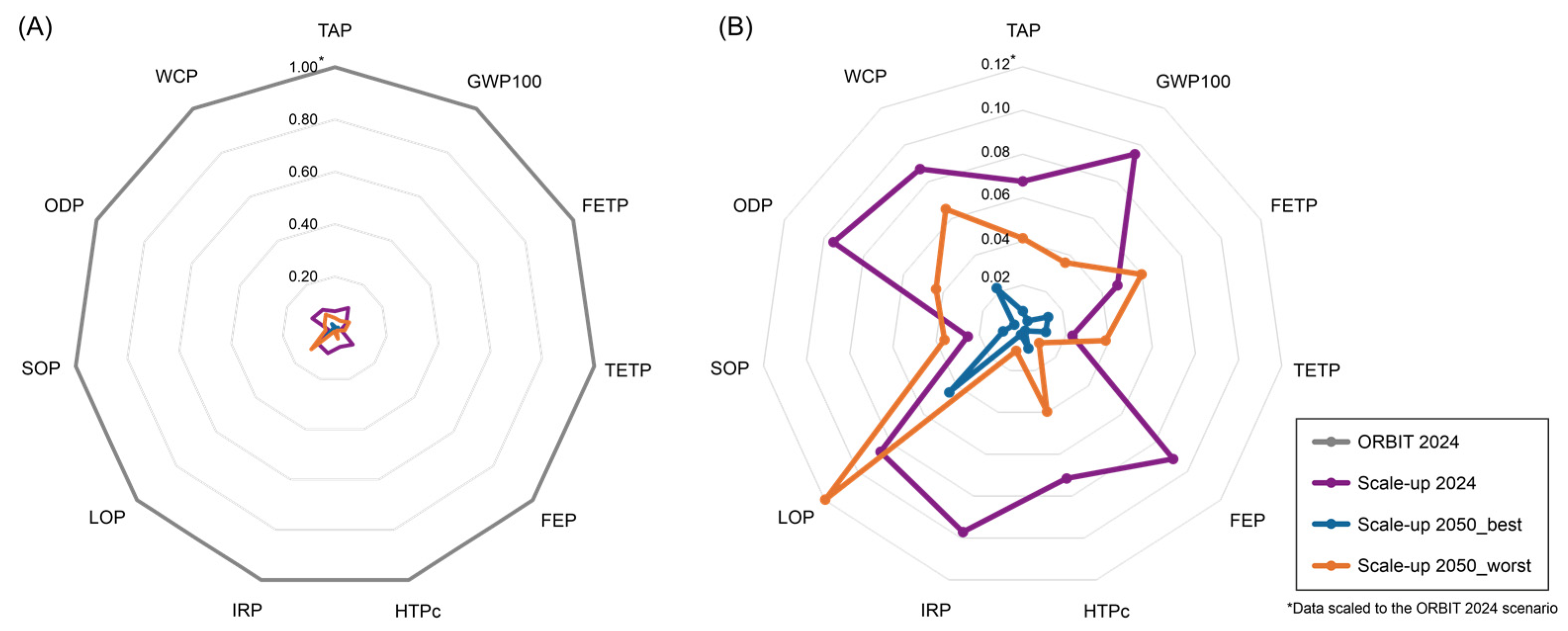

3.2. Comparison of the LCA Results

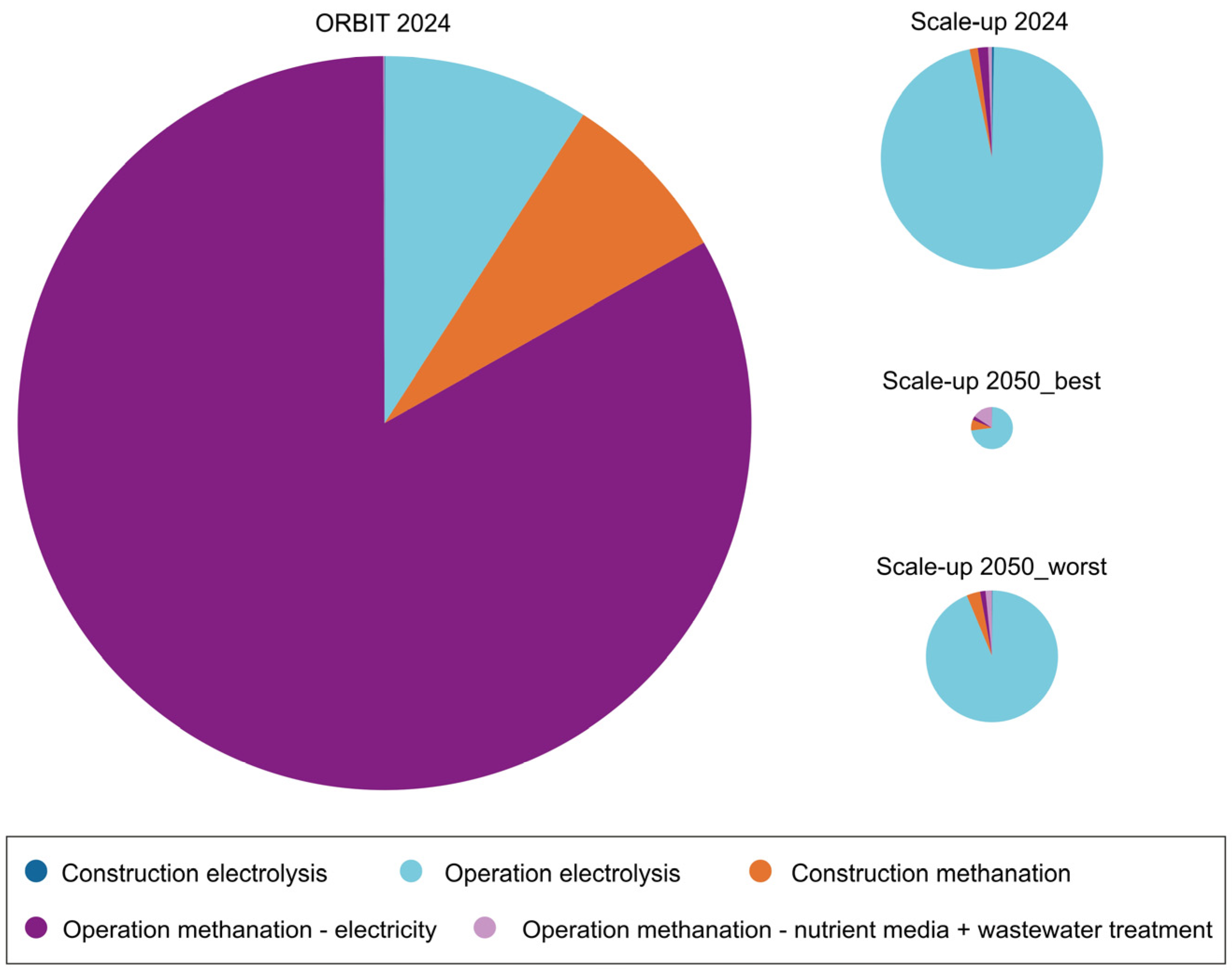

3.3. Hot Spot Analysis

3.4. Monte Carlo Analysis

4. Conclusions

- Plant scale-up has a positive impact on the sustainability of the resulting methane production;

- Emissions can be reduced by a factor of 23–780 if an industrial-scale plant and renewable electricity are used;

- The Monte Carlo analysis shows that there is a very high probability that the GWP of the plant will reach a value of 106.4 kg CO2-eq/MWh CH4, which is significantly lower than the emissions of fossil natural gas;

- The LCA results of laboratory and pilot-scale plants do not allow any direct conclusions about the environmental impact of industrial-scale plants;

- Electrolysis operation has the largest impact on industrial scale, even when using renewable electricity;

- When using renewable electricity, the efficient and sustainable use of the necessary nutrient media and the treatment of wastewater becomes relevant, as this accounts for 15.7% of the CO2-eq emissions.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- European Comission. The European Green Deal; European Comission: Brussels, Belgium, 2019. [Google Scholar]

- Reiter, G.; Lindorfer, J. Global Warming Potential of Hydrogen and Methane Production from Renewable Electricity via Power-to-Gas Technology. Int. J. Life Cycle Assess. 2015, 20, 477–489. [Google Scholar] [CrossRef]

- Sterner, M. Bioenergy and Renewable Power Methane in Integrated 100% Renewable Energy Systems; Limiting Global Warming by Transforming Energy Systems; Universität Kassel: Kassel, Germany, 2009; Volume 14. [Google Scholar]

- Sterner, M.; Specht, M. Power-to-Gas and Power-to-X—The History and Results of Developing a New Storage Concept. Energies 2021, 14, 6594. [Google Scholar] [CrossRef]

- Götz, M.; Lefebvre, J.; Mörs, F.; McDaniel Koch, A.; Graf, F.; Bajohr, S.; Reimert, R.; Kolb, T. Renewable Power-to-Gas: A Technological and Economic Review. Renew. Energy 2016, 85, 1371–1390. [Google Scholar] [CrossRef]

- Thapa, A.; Jo, H.; Han, U.; Cho, S.K. Ex-Situ Biomethanation for CO2 Valorization: State of the Art, Recent Advances, Challenges, and Future Prospective. Biotechnol. Adv. 2023, 68, 108218. [Google Scholar] [CrossRef] [PubMed]

- Parra, D.; Zhang, X.; Bauer, C.; Patel, M.K. An Integrated Techno-Economic and Life Cycle Environmental Assessment of Power-to-Gas Systems. Appl. Energy 2017, 193, 440–454. [Google Scholar] [CrossRef]

- Collet, P.; Flottes, E.; Favre, A.; Raynal, L.; Pierre, H.; Capela, S.; Peregrina, C. Techno-Economic and Life Cycle Assessment of Methane Production via Biogas Upgrading and Power to Gas Technology. Appl. Energy 2017, 192, 282–295. [Google Scholar] [CrossRef]

- Burkhardt, M.; Busch, G. Methanation of Hydrogen and Carbon Dioxide. Appl. Energy 2013, 111, 74–79. [Google Scholar] [CrossRef]

- Kaul, A.; Böllmann, A.; Thema, M.; Kalb, L.; Stöckl, R.; Huber, H.; Sterner, M.; Bellack, A. Combining a Robust Thermophilic Methanogen and Packing Material with High Liquid Hold-up to Optimize Biological Methanation in Trickle-Bed Reactors. Bioresour. Technol. 2021, 345, 126524. [Google Scholar] [CrossRef] [PubMed]

- Thema, M. Process Optimization for Microbial Biosynthesis of Methane in a Trickle-Bed Reactor for Power-to-Gas Applications: The ORBIT-Process; FAU Erlangen-Nürnberg: Erlangen, Germany, 2020. [Google Scholar]

- Fenske, C.F.; Strübing, D.; Koch, K. Biological Methanation in Trickle Bed Reactors—A Critical Review. Bioresour. Technol. 2023, 385, 129383. [Google Scholar]

- Strübing, D.; Moeller, A.B.; Mößnang, B.; Lebuhn, M.; Drewes, J.E.; Koch, K. Load Change Capability of an Anaerobic Thermophilic Trickle Bed Reactor for Dynamic H2/CO2 Biomethanation. Bioresour. Technol. 2019, 289, 121735. [Google Scholar] [CrossRef]

- Fenske, C.F.; Strübing, D.; Koch, K. Preliminary Gas Flow Experiments Identify Improved Gas Flow Conditions in a Pilot-Scale Trickle Bed Reactor for H 2 and CO 2 Biological Methanation. Bioresour. Technol. 2023, 371, 128648. [Google Scholar]

- Fenske, C.F.; Kirzeder, F.; Strübing, D.; Koch, K. Biogas Upgrading in a Pilot-Scale Trickle Bed Reactor—Long-Term Biological Methanation under Real Application Conditions. Bioresour. Technol. 2023, 376, 128868. [Google Scholar]

- Moni, S.M.; Mahmud, R.; High, K.; Carbajales-Dale, M. Life Cycle Assessment of Emerging Technologies: A Review. J. Ind. Ecol. 2020, 24, 52–63. [Google Scholar] [CrossRef]

- Schropp, E.; Naumann, G.; Gaderer, M. Prospective Life Cycle Assessment: A Case Study of Hydrogen Production with Water Electrolysis. Procedia CIRP 2022, 105, 92–97. [Google Scholar] [CrossRef]

- van der Giesen, C.; Cucurachi, S.; Guinée, J.; Kramer, G.J.; Tukker, A. A Critical View on the Current Application of LCA for New Technologies and Recommendations for Improved Practice. J. Clean. Prod. 2020, 259, 120904. [Google Scholar] [CrossRef]

- Bareiß, K.; de la Rua, C.; Möckl, M.; Hamacher, T. Life Cycle Assessment of Hydrogen from Proton Exchange Membrane Water Electrolysis in Future Energy Systems. Appl. Energy 2019, 237, 862–872. [Google Scholar] [CrossRef]

- Bhandari, R.; Trudewind, C.A.; Zapp, P. Life Cycle Assessment of Hydrogen Production via Electrolysis—A Review. J. Clean. Prod. 2014, 85, 151–163. [Google Scholar] [CrossRef]

- Delpierre, M.; Quist, J.; Mertens, J.; Prieur-Vernat, A.; Cucurachi, S. Assessing the Environmental Impacts of Wind-Based Hydrogen Production in the Netherlands Using Ex-Ante LCA and Scenarios Analysis. J. Clean. Prod. 2021, 299, 126866. [Google Scholar] [CrossRef]

- Mehmeti, A.; Angelis-Dimakis, A.; Muñoz, C.B.; Graziadio, M.; McPhail, S.J. Eco-Thermodynamics of Hydrogen Production by High-Temperature Electrolysis Using Solid Oxide Cells. J. Clean. Prod. 2018, 199, 723–736. [Google Scholar] [CrossRef]

- Melideo, D.; Ortiz Cebolla, R.; Weidner, E. Workshop on Lifecycle Analysis of Fuel Cell and H2 Technologies; Publications Office of the European Union: Luxembourg, 2020; ISBN 9789276125839. [Google Scholar]

- Olindo, R.; Schmitt, N.; Vogtländer, J. Life Cycle Assessments on Battery Electric Vehicles and Electrolytic Hydrogen: The Need for Calculation Rules and Better Databases on Electricity. Sustainability 2021, 13, 5250. [Google Scholar] [CrossRef]

- Palmer, G.; Roberts, A.; Hoadley, A.; Dargaville, R.; Honnery, D. Life-Cycle Greenhouse Gas Emissions and Net Energy Assessment of Large-Scale Hydrogen Production via Electrolysis and Solar PV. Energy Environ. Sci. 2021, 14, 5113–5131. [Google Scholar] [CrossRef]

- Zhao, G.; Kraglund, M.R.; Frandsen, H.L.; Wulff, A.C.; Jensen, S.H.; Chen, M.; Graves, C.R. Life Cycle Assessment of H2O Electrolysis Technologies. Int. J. Hydrogen Energy 2020, 45, 23765–23781. [Google Scholar] [CrossRef]

- Schropp, E.; Campos-Carriedo, F.; Iribarren, D.; Naumann, G.; Bernäcker, C.I.; Gaderer, M.; Dufour, J. Environmental and Material Criticality Assessment of Hydrogen Production Via Anion Exchange Membrane Electrolysis. Appl. Energy 2024, 356, 122247. [Google Scholar] [CrossRef]

- Yury, I.; Martirosyan, A. The Development of the Soderberg Electrolyzer Electromagnetic Field’s State Monitoring System. Sci. Rep. 2024, 14, 3501. [Google Scholar] [CrossRef] [PubMed]

- Goffart De Roeck, F.; Buchmayr, A.; Gripekoven, J.; Mertens, J.; Dewulf, J. Comparative Life Cycle Assessment of Power-to-Methane Pathways: Process Simulation of Biological and Catalytic Biogas Methanation. J. Clean. Prod. 2022, 380, 135033. [Google Scholar] [CrossRef]

- P2G-BioCat. ANNEX 1 ForskEL 2014-1-12164—Life Cycle Analysis. 2017. Available online: https://energiforskning.dk/files/slutrapporter/12164_annex_1_p2g_biocat_lca_final_report.pdf (accessed on 22 April 2024).

- Wettstein, S.; Itten, R.; Stucki, M. Life Cycle Assessment of Renewable Methane for Transport and Mobility; Zurich University of Applied Sciences: Zurich, Switzerland, 2018. [Google Scholar]

- Vinardell, S.; Feickert, C.; Heimann, A.; Luis, J.; Koch, K. Exploring the Potential of Biological Methanation for Future Defossilization Scenarios: Techno-Economic and Environmental Evaluation. Energy Convers. Manag. 2024, 307, 118339. [Google Scholar] [CrossRef]

- Thema, M.; Weidlich, T.; Kaul, A.; Böllmann, A.; Huber, H.; Bellack, A.; Karl, J.; Sterner, M. Optimized Biological CO2-Methanation with a Pure Culture of Thermophilic Methanogenic Archaea in a Trickle-Bed Reactor. Bioresour. Technol. 2021, 333, 125135. [Google Scholar] [CrossRef] [PubMed]

- Heberl, M.; Kaul, A.; Rank, D.; Sterner, M. ORBIT Project Homepage. Available online: https://orbit-projekt.de/en/home-english/ (accessed on 22 April 2024).

- Elhaus, N.; Kolb, S.; Müller, J.; Goldbrunner, M.; Karl, J.; Herkendell, K. Environmental Assessment of Anaerobic Digestion and Biological Methanation in Power-to-Methane Systems. J. Clean. Prod. 2023, 429, 139509. [Google Scholar] [CrossRef]

- Yu, S.; He, J.; Zhang, Z.; Sun, Z.; Xie, M.; Xu, Y.; Bie, X.; Li, Q.; Zhang, Y.; Sevilla, M.; et al. Towards Negative Emissions: Hydrothermal Carbonization of Biomass for Sustainable Carbon Materials. Adv. Mater. 2024, 2307412, 1–44. [Google Scholar] [CrossRef] [PubMed]

- Ritchey, T. Wicked Problems/Social Messes: Decision Support Modelling with Morphological Analysis; Springer: Berlin/Heidelberg, Germany, 2011; ISBN 9783642196522. [Google Scholar]

- DIN EN ISO 14040:2021-02; Environmental Management—Life Cycle Assessment—Principles and Framework (ISO 14040:2006 + Amd 1:2020). German Version EN ISO 14040:2006 + A1:2020. DIN e. V.: Berlin, Germany, 2021.

- DIN EN ISO 14044:2018-05; EN: Environmental Management—Life Cycle Assessment—Requirements and Guidelines (ISO 14044:2006 + Amd 1:2017 + Amd 2:2020). German Version EN ISO 14044:2006 + A1:2018 + A2:2020. DIN e. V.: Berlin, Germany, 2018.

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Yu, S.; Dong, X.; Zhao, P.; Luo, Z.; Sun, Z.; Yang, X.; Li, Q.; Wang, L.; Zhang, Y.; Zhou, H. Decoupled Temperature and Pressure Hydrothermal Synthesis of Carbon Sub-Micron Spheres from Cellulose. Nat. Commun. 2022, 13, 3616. [Google Scholar] [CrossRef] [PubMed]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The Ecoinvent Database Version 3 (Part I): Overview and Methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Federici, F.; Puna, J.; Mata, T.M.; Martins, A.A. Life Cycle Analysis of a Combined Electrolysis and Methanation Reactor for Methane Production. Energy Rep. 2022, 8, 554–560. [Google Scholar] [CrossRef]

- Kurada, S.D.; Ali, M.I.; Gokulachandran, J. Ali, M.I.; Gokulachandran, J. A Comparative Life Cycle Assessment of an Electric, a Hybrid and an Internal Combustion Engine Vehicle Using Monte Carlo Simulation. In Recent Advances in Energy Technologies: Select Proceedings of ICEMT 2021; Springer: Singapore, 2022; pp. 357–373. [Google Scholar] [CrossRef]

- Sun, S.; Ertz, M. Life Cycle Assessment and Monte Carlo Simulation to Evaluate the Environmental Impact of Promoting LNG Vehicles. MethodsX 2020, 7, 101046. [Google Scholar] [CrossRef] [PubMed]

- Elginoz, N.; Owusu-Agyeman, I.; Finnveden, G.; Hischier, R.; Rydberg, T.; Cetecioglu, Z. Application and Adaptation of a Scale-up Framework for Life Cycle Assessment to Resource Recovery from Waste Systems. J. Clean. Prod. 2022, 355, 131720. [Google Scholar] [CrossRef]

- Piccinno, F.; Hischier, R.; Seeger, S.; Som, C. From Laboratory to Industrial Scale: A Scale-up Framework for Chemical Processes in Life Cycle Assessment Studies. J. Clean. Prod. 2016, 135, 1085–1097. [Google Scholar] [CrossRef]

- Simon, B.; Bachtin, K.; Kiliç, A.; Amor, B.; Weil, M. Proposal of a Framework for Scale-up Life Cycle Inventory: A Case of Nanofibers for Lithium Iron Phosphate Cathode Applications. Integr. Environ. Assess. Manag. 2016, 12, 465–477. [Google Scholar] [CrossRef] [PubMed]

- Ritchey, T. Principles of Cross-Consistency Assessment in General Morphological Modelling. Acta Morphol. Gen. 2015, 4, 2001–2241. [Google Scholar]

- Bauer, F.; Erdmann, M.C.; Geyer, F. The Market Ramp-Up of Renewable Hydrogen and Its Derivatives—The Role of H2 Global; H2Global Foundation: Hamburg, Germany, 2023. [Google Scholar]

- European Commission. European Hydrogen Bank. Available online: https://energy.ec.europa.eu/topics/energy-systems-integration/hydrogen/european-hydrogen-bank_en (accessed on 22 April 2024).

- Ausfelder, F.; Tran, D.D. 4th Roadmap—Options for a Sustainable Energy System with Power-to-X Technologies (Translated from German); DECHEMA Gesellschaft für Chemische Technik und Biotechnologie e.V.: Frankfurt, Germany, 2022. [Google Scholar]

- Statistisches Bundesamt Gross Electricity Production in Germany. Available online: https://www.destatis.de/EN/Themes/Economic-Sectors-Enterprises/Energy/Production/Tables/gross-electricity-production.html (accessed on 22 April 2024).

- Wulf, C.; Kaltschmitt, M. Hydrogen Supply Chains for Mobility—Environmental and Economic Assessment. Sustainability 2018, 10, 1699. [Google Scholar] [CrossRef]

- Burkhardt, M.; Horn, O.; Uellendahl, H.; Viertmann, O.; Vith, W.; Fischer, D.; Busch, G. Schlussbericht Zum Verbundvorhaben WeMetBio; Fachagentur Nachwachsende Rohstoffe e. V. (FNR): Gülzow, Germany, 2021. [Google Scholar]

- Cheng, G.; Gabler, F.; Pizzul, L.; Olsson, H.; Nordberg, Å.; Schnürer, A. Microbial Community Development during Syngas Methanation in a Trickle Bed Reactor with Various Nutrient Sources. Appl. Microbiol. Biotechnol. 2022, 106, 5317–5333. [Google Scholar] [CrossRef]

- Graf, F. Store & Go—Innovative Large-Scale Energy Storage Technologies and Power-to-Gas Concepts after Optimisation. Impact 2018, 2018, 81–83. [Google Scholar] [CrossRef]

| Group | Parameter | Unit | Methanation | |

|---|---|---|---|---|

| 2024 | 2050 | |||

| Lifespan | Full load hours | h/year | 3000 | 3000–8000 |

| Lifespan | year | 20 | 20–30 | |

| Operation | Product gas yield | kg/h | 68.7 | 66.6–68.7 |

| Methane content in product gas | % | 95% | 95–98 | |

| Amount of methane in the product gas | kg/h | 65.3 | 65.3 | |

| Electrical energy demand | kWh/h | 24.5 | 17.2–24.5 | |

| Input H2 | kg/h | 31.6 | 31.6 | |

| Input CO2 | kg/h | 174.2 | 174.2 | |

| Wastewater | kg/h | 277.8 | 277.8 | |

| Nutrient solution demand | Nutrient medium | L/h | 140.8 | 140.8 |

| Ammonium | L/h | 4.3 | 4.3 | |

| Sodium sulfide | L/h | 1.7 | 1.7 | |

| Construction reactor | Chromium steel | t | 45.0 | 45.0 |

| Packing material | t | 170.0 | 170.0 | |

| Construction BOP | Piping | t | 11.0 | 11.0 |

| Fittings | t | 24.0 | 24.0 | |

| Adapter pieces | t | 2.0 | 2.0 | |

| Distributed control system | kg | 133.0 | 133.0 | |

| Pumps | Pieces | 21.0 | 21.0 | |

| Filter | t | 1.5 | 1.5 | |

| Filter—silica gel | kg | 560.0 | 560.0 | |

| Filter—activated carbon | kg | 1670.0 | 1670.0 | |

| Cable | m | 3200.0 | 3200.0 | |

| Container—steel | t | 7.5 | 7.5 | |

| Container—insulation wool | kg | 800.0 | 800.0 | |

| Foundation | t | 60.0 | 60.0 | |

| Abbreviation | Impact Categories |

|---|---|

| TAP | acidification: terrestrial—terrestrial acidification potential |

| GWP100 | climate change—global warming potential |

| FETP | ecotoxicity: freshwater—freshwater ecotoxicity potential |

| TETP | ecotoxicity: terrestrial—terrestrial ecotoxicity potential |

| FEP | eutrophication: freshwater—freshwater eutrophication potential |

| HTPc | human toxicity: carcinogenic—human toxicity potential |

| IRP | ionizing radiation—ionizing radiation potential |

| LOP | land use—agricultural land occupation |

| SOP | material resources: metals/minerals—surplus ore potential |

| ODP | ozone depletion—ozone depletion potential |

| WCP | water use—water consumption potential |

| Group | Parameters | Unit | PEM | |

|---|---|---|---|---|

| 2019 | 2050 | |||

| Lifespan | of the electrolysis plant | years | 20 | 30 |

| of the stack | h | 60,000–80,000 | 130,000 | |

| Capacity | Plant capacity | MW | a few | 100–1000 |

| Stack capacity | MW | 1 | 20 | |

| Operation | Electrical consumption | kWhe/kg H2 | 50 | 50–55 |

| Water consumption | kg/kg H2 | 10 | 9–10 | |

| Construction | Steel consumption | kg/kW | 8.5 | 7–10 |

| Iridium load | g/kW | 0.7 | 0.001–0.05 | |

| Platinum load | g/kW | 0.1–0.3 | 0.01–0.03 | |

| Titanium Load | g/kW | 450–500 | 35 | |

| Nafion consumption | kg/kW | 0.016 | 0.002 | |

| Indicator | Unit | ORBIT Reactor 2024 | Scale-Up 2024 | Scale-Up 2050_Best | Scale-Up 2050_Worst |

|---|---|---|---|---|---|

| TAP | kg SO2-Eq | 23.4 | 1.5 | 0.2 | 0.9 |

| GWP100 | kg CO2-Eq | 10,508.0 | 965.3 | 34.7 | 341.7 |

| FETP | kg 1,4-DCB-Eq | 1299.2 | 59.8 | 16.1 | 75.6 |

| TETP | kg 1,4-DCB-Eq | 82,168.9 | 1710.4 | 834.3 | 2978.3 |

| FEP | kg P-Eq | 13.5 | 1.2 | 0.0 | 0.1 |

| HTPc | kg 1,4-DCB-Eq | 1278.3 | 86.5 | 10.7 | 45.6 |

| IRP | kBq Co-60-Eq | 790.9 | 74.7 | 1.7 | 6.1 |

| LOP | m2*a crop-Eq | 151.5 | 12.1 | 6.5 | 17.3 |

| SOP | kg Cu-Eq | 251.1 | 6.4 | 2.3 | 9.1 |

| ODP | kg CFC-11-Eq | 0.0 | 0.0 | 0.0 | 0.0 |

| WCP | m3 | 35.6 | 2.9 | 0.7 | 2.2 |

| Indicator | ORBIT Reactor to Scale-Up 2024 | ORBIT Reactor to Scale-Up 2050_Best | Scale-Up 2024 to Scale-Up 2050_Best |

|---|---|---|---|

| TAP | 15.7 | 142.1 | 9.0 |

| GWP100 | 10.9 | 303.0 | 27.8 |

| FETP | 21.7 | 80.8 | 3.7 |

| TETP | 48.0 | 98.5 | 2.1 |

| FEP | 11.1 | 781.5 | 70.7 |

| HTPc | 14.8 | 119.4 | 8.1 |

| IRP | 10.6 | 456.9 | 43.2 |

| LOP | 12.5 | 23.2 | 1.9 |

| SOP | 39.3 | 110.6 | 2.8 |

| ODP | 10.7 | 269.5 | 25.2 |

| WCP | 12.1 | 47.5 | 3.9 |

| Main Component | ORBIT Reactor 2024 | Scale-Up 2024 | Scale-Up 2050_Best | Scale-Up 2050_Worst |

|---|---|---|---|---|

| Operation methanation (nutrient media + wastewater treatment) | 0.1% | 0.6% | 15.7% | 1.6% |

| Operation methanation (electricity) | 83.1% | 1.5% | 3.2% | 1.3% |

| Construction methanation | 7.7% | 1.2% | 8.3% | 3.4% |

| Operation electrolysis | 9.1% | 96.5% | 72.7% | 93.6% |

| Construction electrolysis | 0.0% | 0.3% | 0.2% | 0.1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heberl, M.; Withelm, C.; Kaul, A.; Rank, D.; Sterner, M. Prospective Life Cycle Assessment of Biological Methanation in a Trickle-Bed Pilot Plant and a Potential Scale-Up. Energies 2024, 17, 2206. https://doi.org/10.3390/en17092206

Heberl M, Withelm C, Kaul A, Rank D, Sterner M. Prospective Life Cycle Assessment of Biological Methanation in a Trickle-Bed Pilot Plant and a Potential Scale-Up. Energies. 2024; 17(9):2206. https://doi.org/10.3390/en17092206

Chicago/Turabian StyleHeberl, Michael, Christian Withelm, Anja Kaul, Daniel Rank, and Michael Sterner. 2024. "Prospective Life Cycle Assessment of Biological Methanation in a Trickle-Bed Pilot Plant and a Potential Scale-Up" Energies 17, no. 9: 2206. https://doi.org/10.3390/en17092206

APA StyleHeberl, M., Withelm, C., Kaul, A., Rank, D., & Sterner, M. (2024). Prospective Life Cycle Assessment of Biological Methanation in a Trickle-Bed Pilot Plant and a Potential Scale-Up. Energies, 17(9), 2206. https://doi.org/10.3390/en17092206