Offshore Wind Power—Seawater Electrolysis—Salt Cavern Hydrogen Storage Coupling System: Potential and Challenges

Abstract

1. Introduction

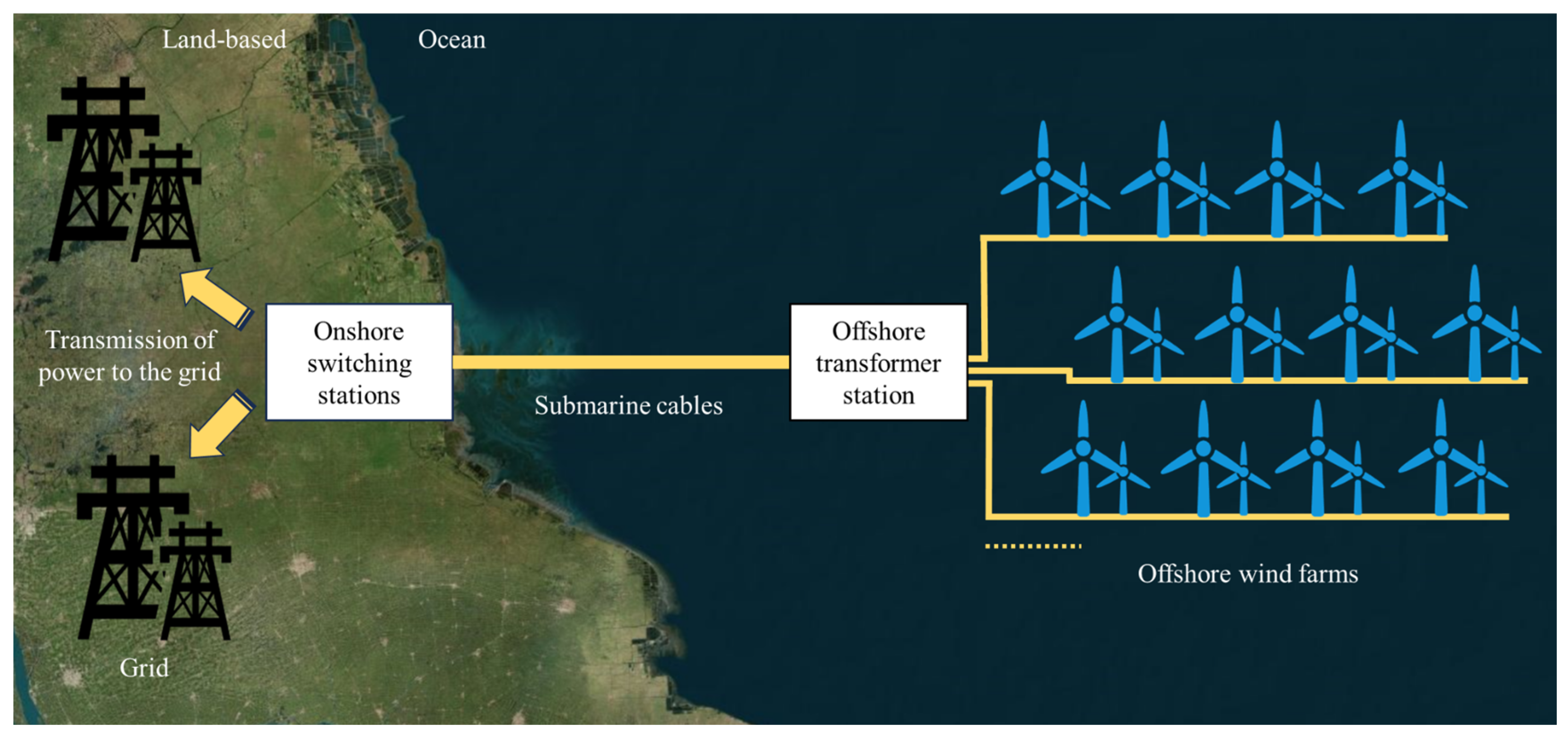

2. Analysis of Offshore Wind Power Technology

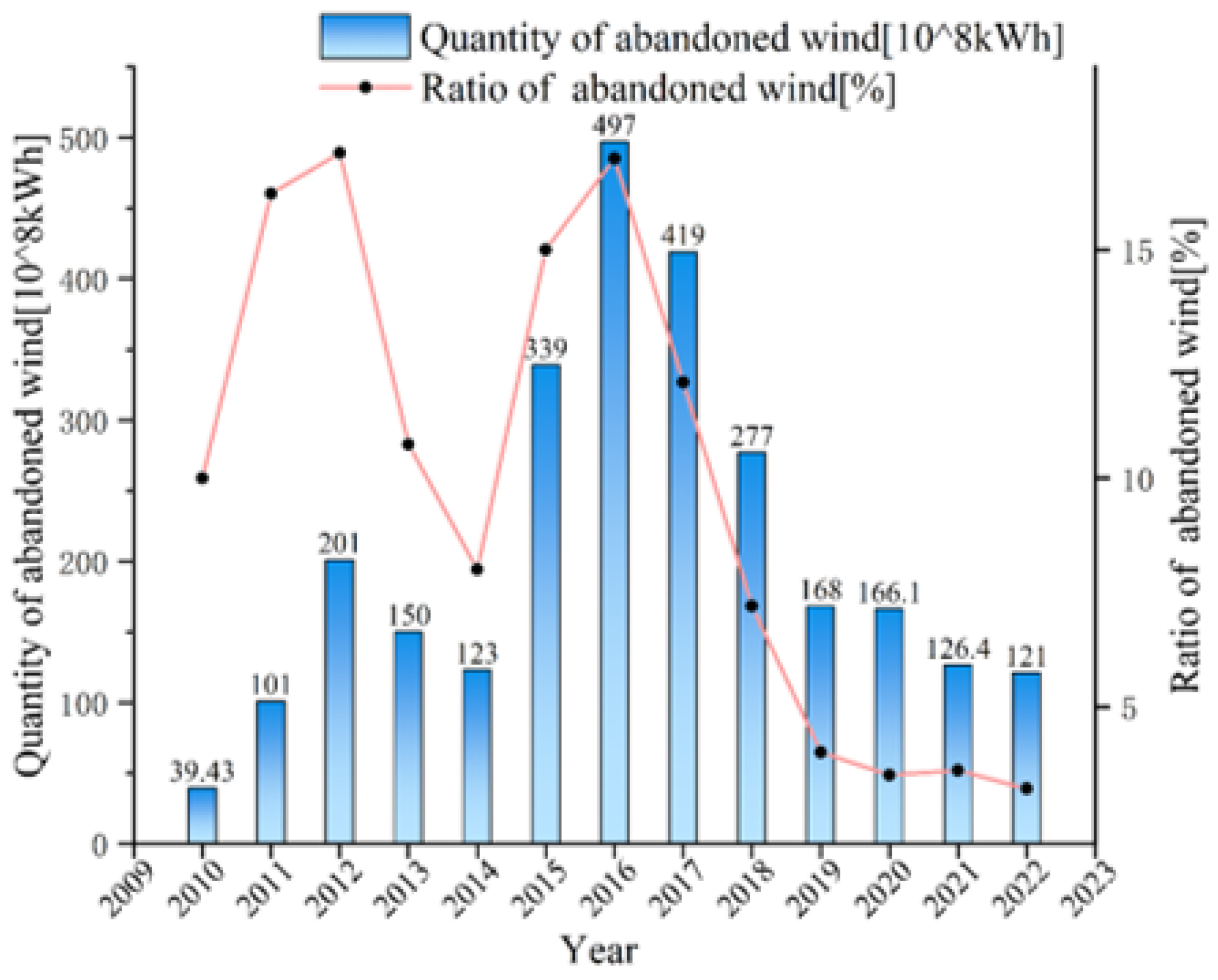

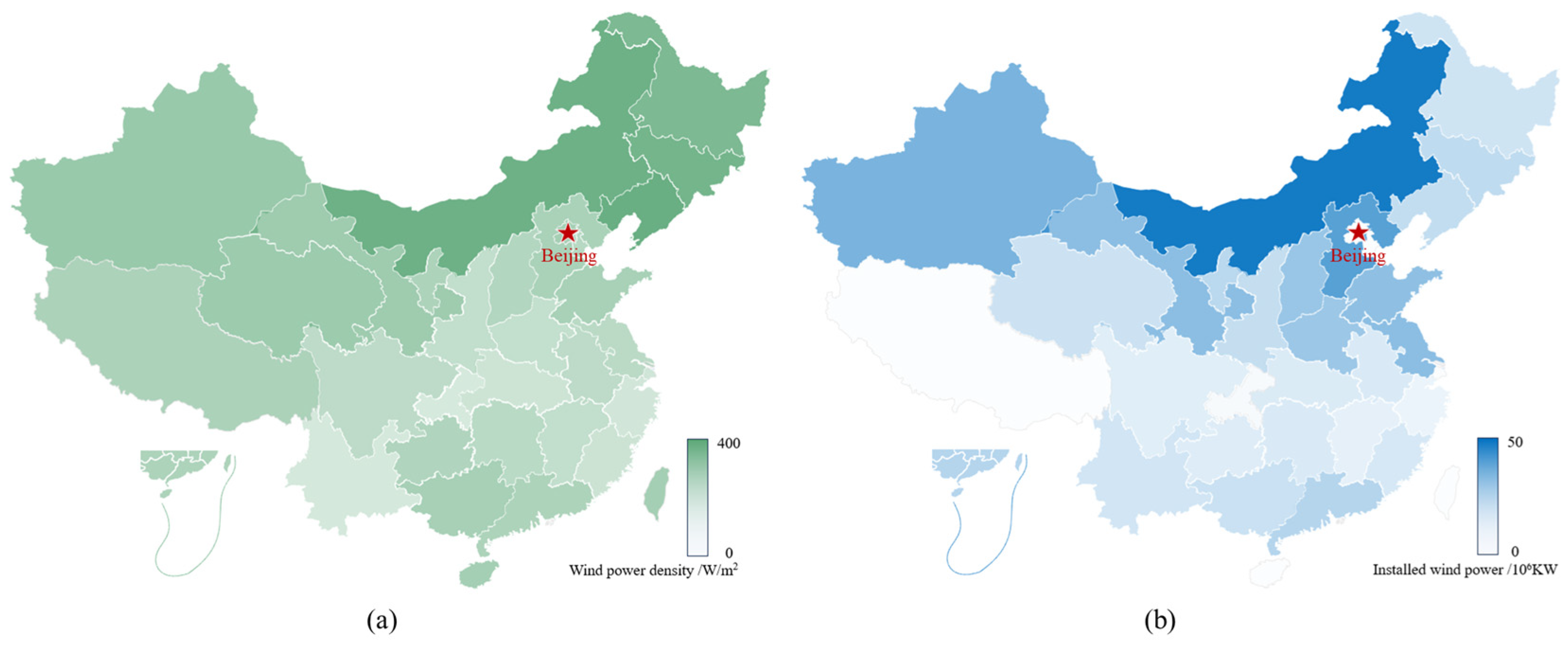

2.1. Status of Offshore Wind Power in China

2.2. Challenges of Offshore Wind Power Grid Integration

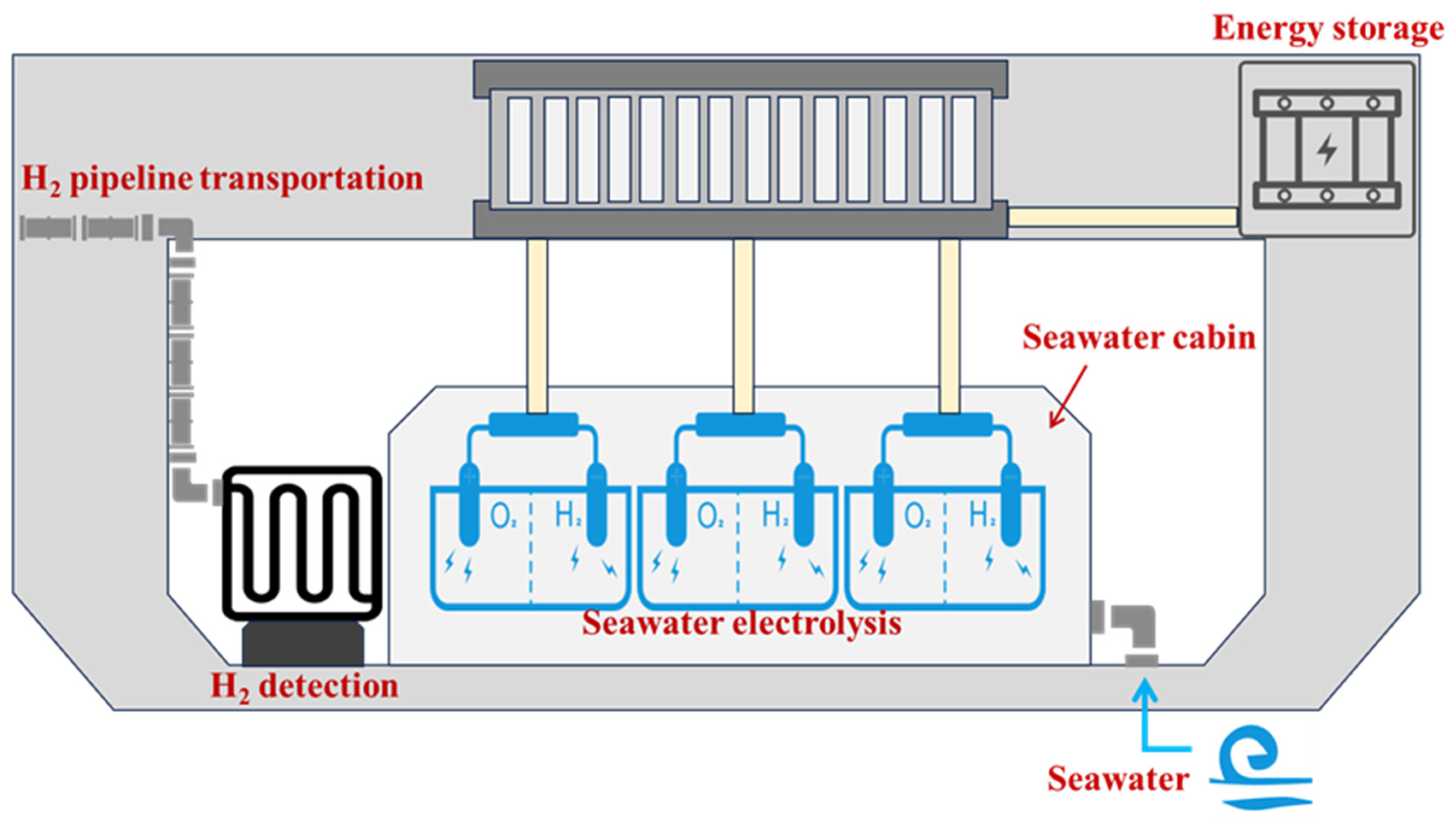

3. Hydrogen Production from Seawater

3.1. Status of Water Electrolysis Technology for Hydrogen Production

3.2. Electrolytic Hydrogen Production from Seawater

4. Hydrogen Storage in Caverns

4.1. Status of Hydrogen Storage Technology

4.2. Hydrogen Storage in Salt Caverns

- (1)

- (2)

- Salt caverns offer more favorable engineering conditions compared to other storage reservoirs. For example, the space of salt caverns typically ranges from 10 to 10 × 10⁵ m3, with depths ranging from 600 to 2000 m, making them highly suitable and economically efficient for the storage of high-pressure hydrogen gas. Salt cavern hydrogen storage has the ability to rapidly inject and extract hydrogen, allowing it to quickly respond to changes in market demand [60]. This characteristic gives it a significant advantage in energy peak shaving and emergency supply;

- (3)

- The costs of salt cavern UHS are lower than those of depleted gas reservoirs or aquifers [38,39], as salt caverns require only one-third of the total gas volume as buffer gas, compared to 50–80% [40] for depleted gas reservoirs or aquifers [61]. From the viewpoint of foreign practice, developed countries such as the UK and the USA have taken an early lead in salt cavern hydrogen storage projects, and the technology for salt cavern hydrogen storage is now well established. Table 2 presents basic information on salt cavern hydrogen storage facilities currently in operation worldwide [62,63,64]. Currently, there are four hydrogen storage facilities in operation worldwide, all of which are salt cavern storage types. These facilities have demonstrated excellent hydrogen storage performance and safety. The earliest salt cavern hydrogen storage facility in the UK has been operating safely for nearly 50 years. These successful practical cases not only prove the technical feasibility of salt cavern hydrogen storage but also provide valuable experience and reference for the development of salt cavern hydrogen storage technology in China. Meanwhile, in recent years, many countries around the world have formulated and implemented their own hydrogen energy development strategies. In this context, the site selection research and experimental validation activities for salt caverns as hydrogen storage facilities are accelerating. This proves that salt caverns have good hydrogen storage capacity, both theoretically and practically.

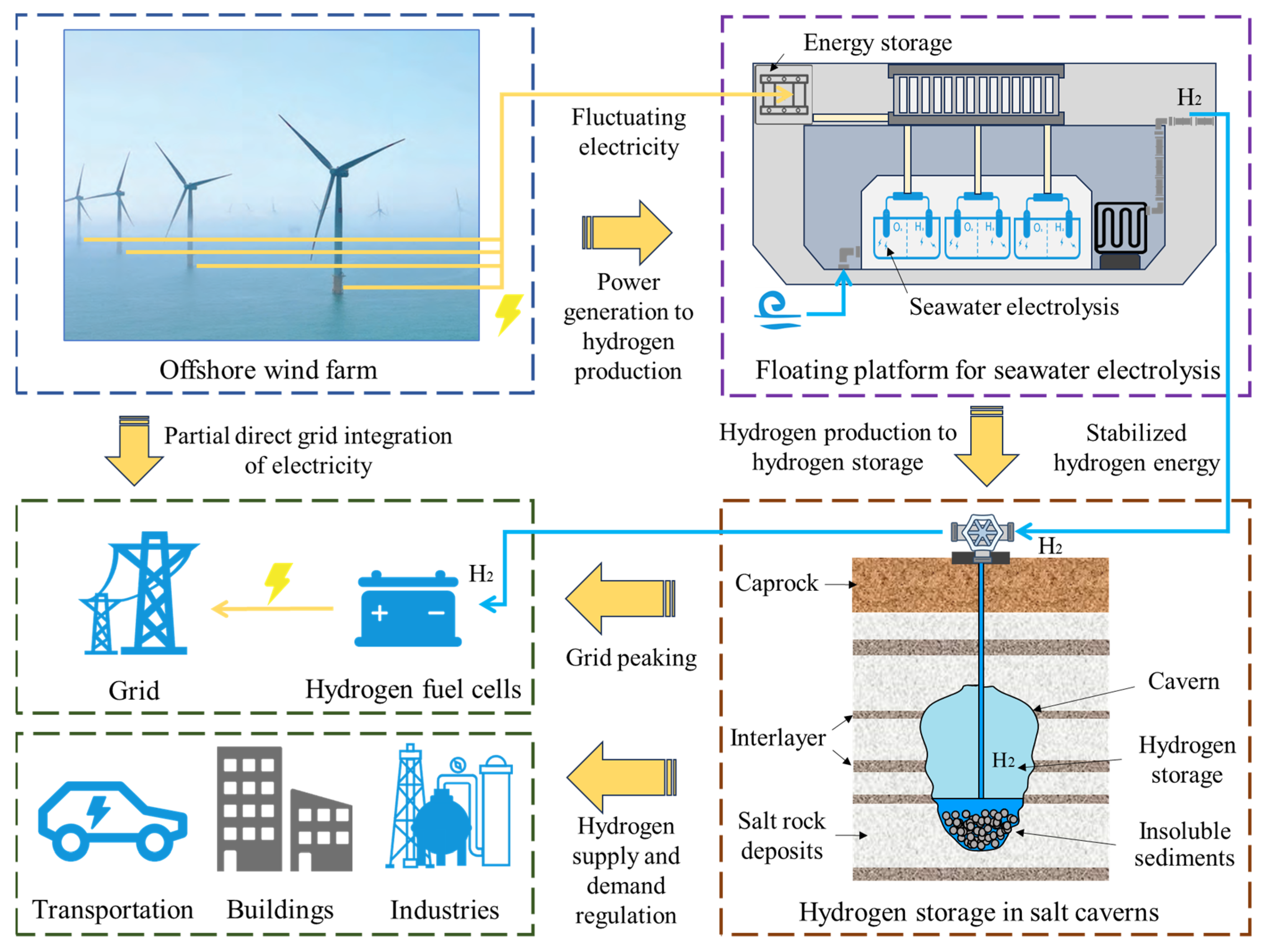

5. OWP—SWE—SCHS Coupling System

5.1. System Description

- (1)

- It achieves efficient utilization of offshore renewable energy, overcomes the challenges of integrating offshore wind power into the grid, and significantly enhances the utilization rate of offshore wind power;

- (2)

- By utilizing offshore wind power for in situ hydrogen production, it reduces freshwater resource consumption, avoids occupying land resources, and contributes to seawater desalination while utilizing hydrogen energy;

- (3)

- Transitioning from onshore to offshore hydrogen production, it converts electricity transmission into hydrogen transportation, saving costs associated with submarine cables and offshore substations, thereby offering greater economic benefits;

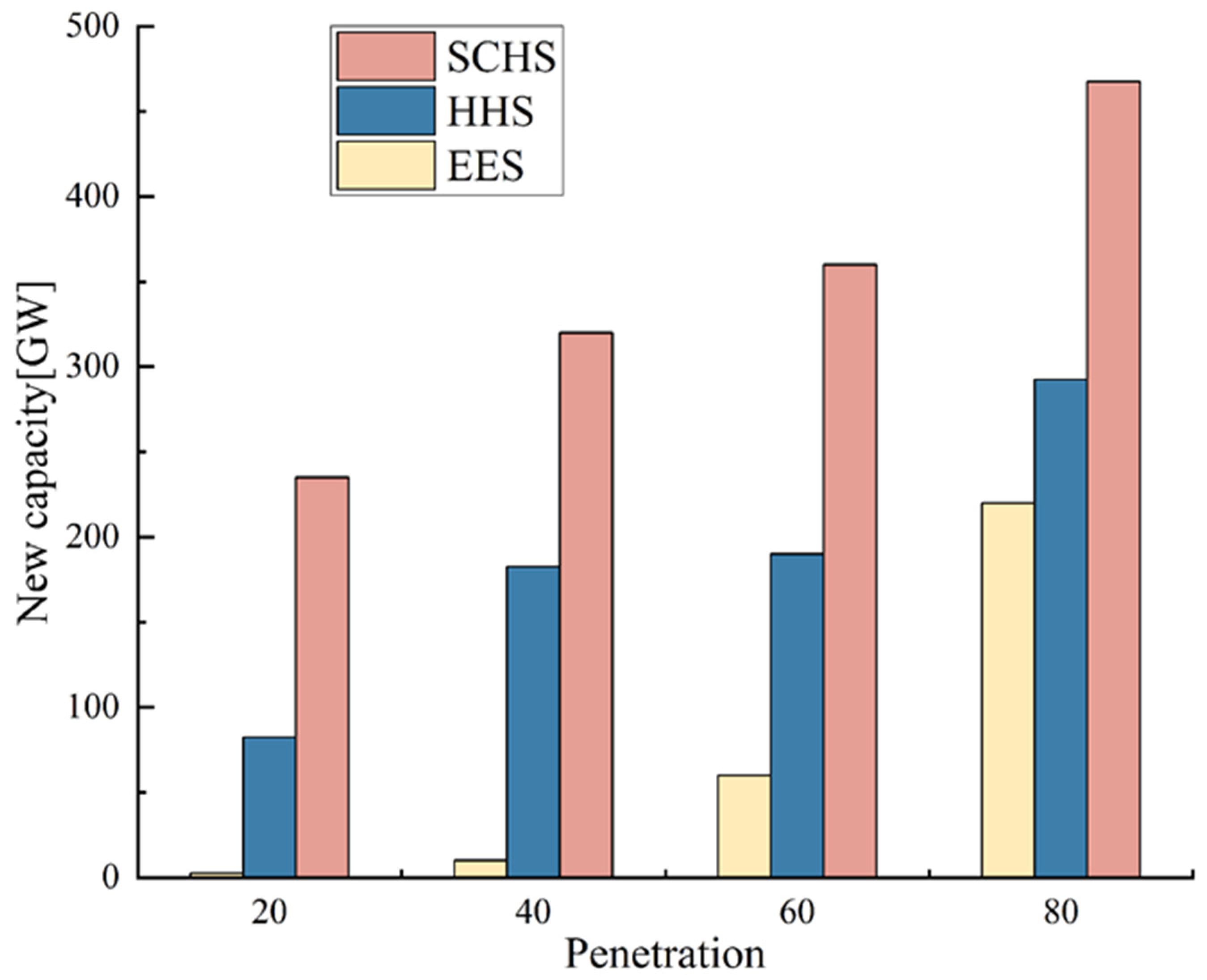

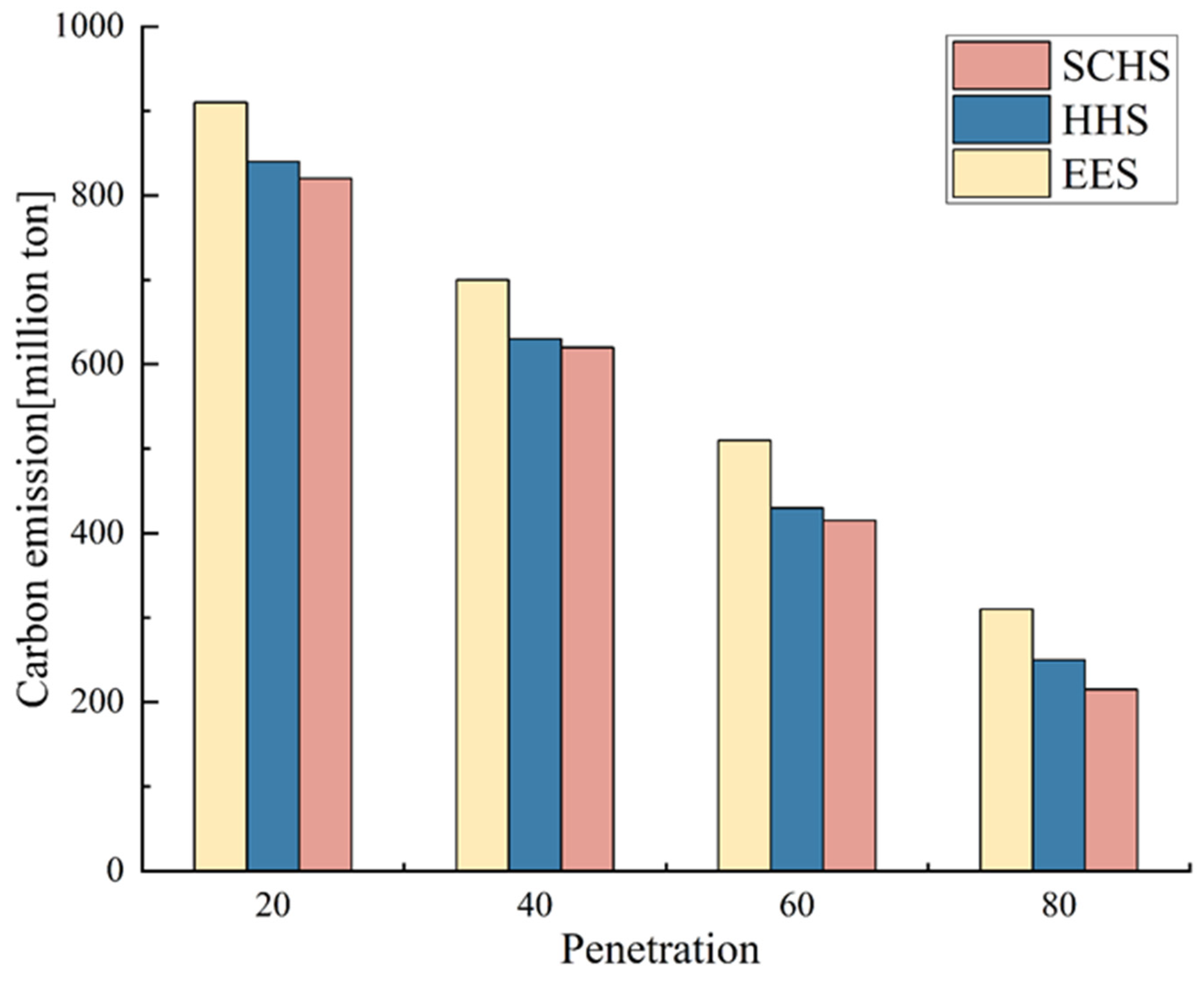

5.2. Application Potential in China

- (1)

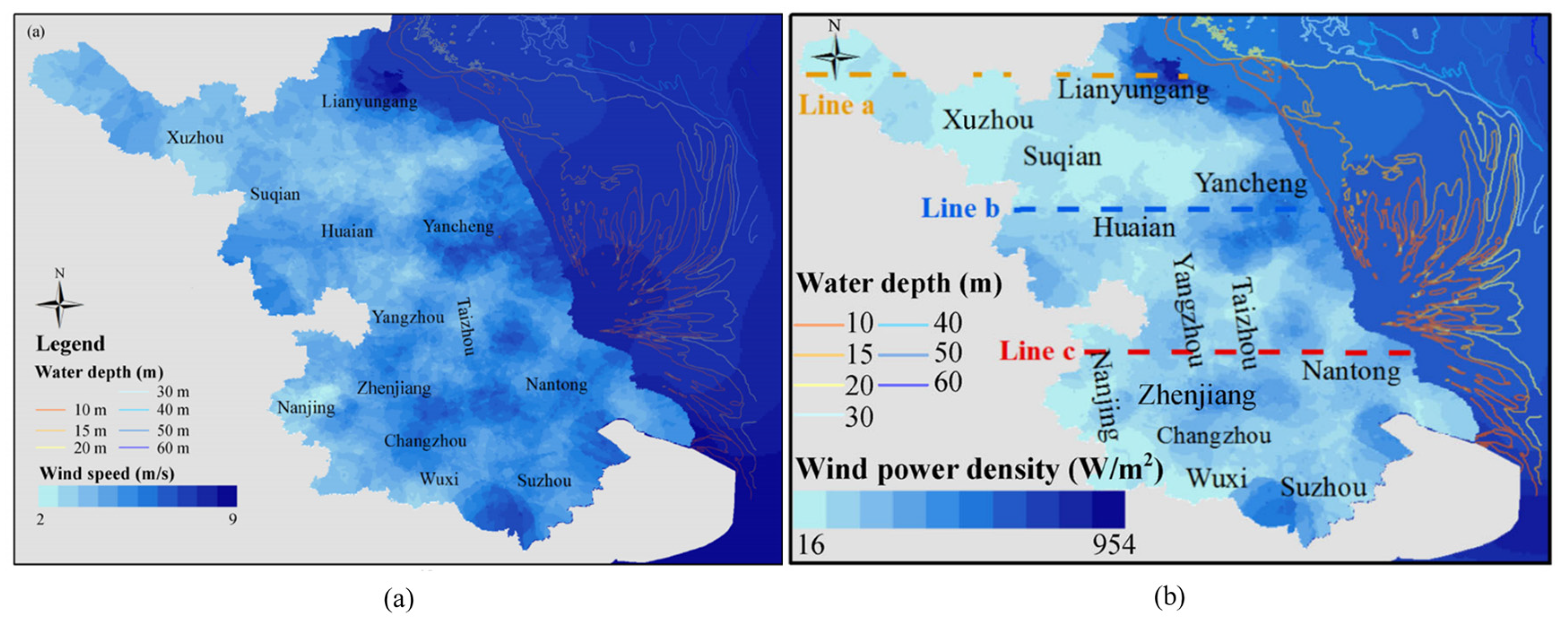

- Advantages of Offshore Wind Power in Jiangsu

- (2)

- Advantages of hydrogen storage in salt caverns in Jiangsu

- (3)

- System Implementation Analysis

6. Challenges and Solutions

- (1)

- Specific Feasibility

- (2)

- Applicability in other regions

- (3)

- Overall Economics

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bilgili, M.; Alphan, H. Global growth in offshore wind turbine technology. Clean Technol. Environ. Policy 2022, 24, 2215–2227. [Google Scholar] [CrossRef]

- He, Y.; Guo, S.; Zhou, J.; Wang, J.; Ji, W.; Song, T. Province-level techno-economic feasibility analysis of baseload supply from hybrid renewable energy systems in China. Energy Convers. Manag. 2022, 268, 116037. [Google Scholar] [CrossRef]

- Dansoh, C. The viability of hydrogen storage to supplement renewable energy when used to power municipal scale reverse osmosis plant. Int. J. Hydrogen Energy 2014, 39, 12676–12689. [Google Scholar] [CrossRef]

- Uyar, T.S.; Beşikci, D. Integration of hydrogen energy systems into renewable energy systems for better design of 100% renewable energy communities. Int. J. Hydrogen Energy 2017, 42, 2453–2456. [Google Scholar] [CrossRef]

- Ishaq, H.; Dincer, I. Comparative assessment of renewable energy-based hydrogen production methods. Renew. Sustain. Energy Rev. 2021, 135, 110192. [Google Scholar] [CrossRef]

- Chi, J.; Yu, H. Water Electrolysis Based on Renewable Energy for Hydrogen Production. Chin. J. Catal. 2018, 39, 390–394. [Google Scholar] [CrossRef]

- Marocco, P.; Novo, R.; Lanzini, A.; Mattiazzo, G.; Santarelli, M. Towards 100% renewable energy systems: The role of hydrogen and batteries. J. Energy Storage 2023, 57, 106306. [Google Scholar] [CrossRef]

- Wu, F.; Gao, R.; Li, C.; Liu, J. A comprehensive evaluation of wind-PV-salt cavern-hydrogen energy storage and utilization system: A case study in Qianjiang salt cavern, China. Energy Convers. Manag. 2023, 277, 116633. [Google Scholar] [CrossRef]

- Song, Y.; Song, R.; Liu, J. Hydrogen tightness evaluation in bedded salt rock cavern: A case study of Jintan, China. Int. J. Hydrogen Energy 2023, 48, 30489–30506. [Google Scholar] [CrossRef]

- Ruban, N.; Rudnik, V.; Askarov, A.; Maliuta, B. Frequency control by the PV station in electric power systems with hydrogen energy storage. Int. J. Hydrogen Energy 2023, 48, 28262–28276. [Google Scholar] [CrossRef]

- Vavilov, O.A.; Yurkevich, V.D.; Korobkov, D.V. Synthesis of an automatic control system for a voltage inverter as part of an autonomous power supply system with a hydrogen module. Int. J. Hydrogen Energy 2024, 86, 742–750. [Google Scholar] [CrossRef]

- Krishna, D.R.H. Review of Research on Production Methods of Hydrogen: Future Fuel. Eur. J. Biotechnol. Biosci. Null 2013, 1, 84–93. [Google Scholar]

- Amikam, G.; Nativ, P.; Gendel, Y. Chlorine-free alkaline seawater electrolysis for hydrogen production. Int. J. Hydrogen Energy 2018, 43, 6504–6514. [Google Scholar] [CrossRef]

- Zheng, X.; Liu, P. An Economic Analysis of Mid- to Long-Term Prospects for Deep-Sea Offshore Wind-Power-to-Ammonia: A Case Study of Fujian Province. Energies 2024, 17, 6301. [Google Scholar] [CrossRef]

- Sharma, S.; Ghoshal, S.K. Hydrogen the future transportation fuel: From production to applications. Renew. Sustain. Energy Rev. 2015, 43, 1151–1158. [Google Scholar] [CrossRef]

- Masoudi, M.; Hassanpouryouzband, A.; Hellevang, H.; Haszeldine, R.S. Lined rock caverns: A hydrogen storage solution. J. Energy Storage 2024, 84, 110927. [Google Scholar] [CrossRef]

- Zeng, L.; Sander, R.; Chen, Y.; Xie, Q. Hydrogen Storage Performance During Underground Hydrogen Storage in Depleted Gas Reservoirs: A Review. Engineering 2024, 40, 211–225. [Google Scholar] [CrossRef]

- Zhu, S.; Shi, X.; Yang, C.; Li, Y.; Li, H.; Yang, K.; Wei, X.; Bai, W.; Liu, X. Hydrogen loss of salt cavern hydrogen storage. Renew. Energy 2023, 218, 119267. [Google Scholar] [CrossRef]

- Tackie-Otoo, B.N.; Haq, M.B. A comprehensive review on geo-storage of H2 in salt caverns: Prospect and research advances. Fuel 2024, 356, 129609. [Google Scholar] [CrossRef]

- Cai, B.; Li, Y.; Lu, X.; Guo, J.; Wang, R.; Zhang, L.; Liu, C.; Lv, C.; Zhang, Z.; Li, Z.; et al. Assessment of China’s Wind and Solar Power Potential. Available online: https://www.caep.org.cn/sy/tdftzhyjzx/zxdt/202406/t20240614_1075803.shtml (accessed on 14 June 2024).

- Lin, H.; Guo, Y.; Sun, B.; Jiang, Y.; Huang, Y.; Zhang, J.; Lu, X. Overview of offshore wind power key technologies. J. Southeast Univ. Nat. Sci. Ed. 2011, 41, 882–888. [Google Scholar]

- Erlich, I.; Shewarega, F.; Feltes, C.; Koch, F.W.; Fortmann, J. Offshore Wind Power Generation Technologies. Proc. IEEE 2013, 101, 891–905. [Google Scholar] [CrossRef]

- Wang, X.; Wei, X.; Ning, L.; Wang, X. Integration Techniques and Transmission Schemes for Off-shore Wind Farms. Proc. CSEE 2014, 34, 5459–5466. [Google Scholar] [CrossRef]

- Wu, L. Overview of offshore wind power technology development. Machinery 2024, 62, 1–15. [Google Scholar]

- Cai, X.; Yang, R.; Zhou, J.; Fang, Z.; Yang, M.; Shi, X.; Chen, Q. Review on Offshore Wind Power Integration via DC Transmission. Autom. Electr. Power Syst. 2021, 45, 2–22. [Google Scholar]

- International Renewable Energy Agency. Renewable Energy Statistics. Available online: https://www.irena.org/Publications/2024/Jul/Renewable-energy-statistics-2024 (accessed on 11 July 2024).

- Kumar, D.; Shireen, W.; Ram, N. Grid Integration of Offshore Wind Energy: A Review on Fault Ride Through Techniques for MMC-HVDC Systems. Energies 2024, 17, 5308. [Google Scholar] [CrossRef]

- Du, J.; Li, M.; Fu, X.; Li, B. Construction Cost Trend Analysis of Offshore Wind Power and Investment Suggestions of Petrochemical Industry. Eng. Cost Manag. 2022, 06, 85–91. [Google Scholar] [CrossRef]

- Kojima, H.; Nagasawa, K.; Todoroki, N.; Ito, Y.; Matsui, T.; Nakajima, R. Influence of renewable energy power fluctuations on water electrolysis for green hydrogen production. Int. J. Hydrogen Energy 2023, 48, 4572–4593. [Google Scholar] [CrossRef]

- dos Santos, K.G.; Eckert, C.T.; De Rossi, E.; Bariccatti, R.A.; Frigo, E.P.; Lindino, C.A.; Alves, H.J. Hydrogen production in the electrolysis of water in Brazil, a review. Renew. Sustain. Energy Rev. 2017, 68, 563–571. [Google Scholar] [CrossRef]

- Dawood, F.; Anda, M.; Shafiullah, G.M. Hydrogen production for energy: An overview. Int. J. Hydrogen Energy 2020, 45, 3847–3869. [Google Scholar] [CrossRef]

- Anwar, S.; Khan, F.; Zhang, Y.; Djire, A. Recent development in electrocatalysts for hydrogen production through water electrolysis. Int. J. Hydrogen Energy 2021, 46, 32284–32317. [Google Scholar] [CrossRef]

- Shiva Kumar, S.; Himabindu, V. Hydrogen production by PEM water electrolysis—A review. Mater. Sci. Energy Technol. 2019, 2, 442–454. [Google Scholar] [CrossRef]

- Grigoriev, S.A.; Fateev, V.N.; Bessarabov, D.G.; Millet, P. Current status, research trends, and challenges in water electrolysis science and technology. Int. J. Hydrogen Energy 2020, 45, 26036–26058. [Google Scholar] [CrossRef]

- Zvonareva, I.; Fu, X.-Z.; Medvedev, D.; Shao, Z. Electrochemistry and energy conversion features of protonic ceramic cells with mixed ionic-electronic electrolytes. Energy Environ. Sci. 2022, 15, 439–465. [Google Scholar] [CrossRef]

- Barbir, F. PEM electrolysis for production of hydrogen from renewable energy sources. Sol. Energy 2005, 78, 661–669. [Google Scholar] [CrossRef]

- Gandía, L.M.; Oroz, R.; Ursúa, A.; Sanchis, P.; Diéguez, P.M. Renewable Hydrogen Production: Performance of an Alkaline Water Electrolyzer Working under Emulated Wind Conditions. Energy Fuels 2007, 21, 1699–1706. [Google Scholar] [CrossRef]

- Yu, Z.; Liu, L. Recent Advances in Hybrid Seawater Electrolysis for Hydrogen Production. Adv. Mater. 2024, 36, 2308647. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Wang, G.; Shi, X.; Zhu, S.; Zheng, Z.; Liu, W.; Fan, J.Y. Demands and challenges of large-scale salt cavern hydrogen storage in China. Rock Soil Mech. 2024, 45, 1–19. [Google Scholar] [CrossRef]

- Zhang, W.; Wei, Y.; Li, J.; Xiao, H. Harvesting energy from marine: Seawater electrolysis for hydrogen production. Fuel 2024, 377, 132782. [Google Scholar] [CrossRef]

- Mika, Ł.; Sztekler, K.; Bujok, T.; Boruta, P.; Radomska, E. Seawater Treatment Technologies for Hydrogen Production by Electrolysis—A Review. Energies 2024, 17, 6255. [Google Scholar] [CrossRef]

- Dresp, S.; Dionigi, F.; Klingenhof, M.; Strasser, P. Direct Electrolytic Splitting of Seawater: Opportunities and Challenges. ACS Energy Lett. 2019, 4, 933–942. [Google Scholar] [CrossRef]

- Gao, F.-Y.; Yu, P.-C.; Gao, M.-R. Seawater electrolysis technologies for green hydrogen production: Challenges and opportunities. Curr. Opin. Chem. Eng. 2022, 36, 100827. [Google Scholar] [CrossRef]

- Materials Design and System Innovation for Direct and Indirect Seawater Electrolysis|ACS Nano n.d. Available online: https://pubs.acs.org/doi/abs/10.1021/acsnano.3c08450 (accessed on 22 December 2024).

- Song, Y.; Sun, M.; Zhang, S.; Zhang, X.; Yi, P.; Liu, J.; Huang, B.; Huang, M.; Zhang, L. Alleviating the Work Function of Vein-Like CoXP by Cr Doping for Enhanced Seawater Electrolysis. Adv. Funct. Mater. 2023, 33, 2214081. [Google Scholar] [CrossRef]

- Chang, J.; Wang, G.; Yang, Z.; Li, B.; Wang, Q.; Kuliiev, R.; Orlovskaya, N.; Gu, M.; Du, Y.; Wang, G.; et al. Dual-Doping and Synergism toward High-Performance Seawater Electrolysis. Adv. Mater. 2021, 33, 2101425. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Wu, L.; McElhenny, B.; Song, S.; Luo, D.; Zhang, F.; Yu, Y.; Chen, S.; Ren, Z. Ultrafast room-temperature synthesis of porous S-doped Ni/Fe (oxy)hydroxide electrodes for oxygen evolution catalysis in seawater splitting. Energy Environ. Sci 2020, 13, 3439–3446. [Google Scholar] [CrossRef]

- Groenemans, H.; Saur, G.; Mittelsteadt, C.; Lattimer, J.; Xu, H. Techno-economic analysis of offshore wind PEM water electrolysis for H2 production. Curr. Opin. Chem. Eng. 2022, 37, 100828. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, X.; Wen, H.; Pei, A. Hydrogen production from offshore wind power in South China. Int. J. Hydrogen Energy 2022, 47, 24558–24568. [Google Scholar] [CrossRef]

- Hill, S.J.P.; Bamisile, O.; Hatton, L.; Staffell, I.; Jansen, M. The cost of clean hydrogen from offshore wind and electrolysis. J. Clean. Prod. 2024, 445, 141162. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.; He, Y.; Li, M.; Wang, X.; Wang, B.; Zhu, Y.; Cen, K. Comparison of onshore/offshore wind power hydrogen production through water electrolysis by life cycle assessment. Sustain. Energy Technol. Assess. 2023, 60, 103515. [Google Scholar] [CrossRef]

- Liu, T.; Zhao, Z.; Tang, W.; Chen, Y.; Lan, C.; Zhu, L.; Jiang, W.; Wu, Y.; Wang, Y.; Yang, Z. In-situ direct seawater electrolysis using floating platform in ocean with uncontrollable wave motion. Nat. Commun. 2024, 15, 5305. [Google Scholar] [CrossRef] [PubMed]

- Chandra Muduli, R.; Kale, P. Silicon nanostructures for solid-state hydrogen storage: A review. Int. J. Hydrogen Energy 2023, 48, 1401–1439. [Google Scholar] [CrossRef]

- Yang, N.; Deng, J.; Wang, C.; Bai, Z.; Qu, J. High pressure hydrogen leakage diffusion: Research progress. Int. J. Hydrogen Energy 2024, 50, 1029–1046. [Google Scholar] [CrossRef]

- Yin, L.; Yang, H.; Ju, Y. Review on the key technologies and future development of insulation structure for liquid hydrogen storage tanks. Int. J. Hydrogen Energy 2024, 57, 1302–1315. [Google Scholar] [CrossRef]

- Lin, A.; Bagnato, G. Revolutionising energy storage: The Latest Breakthrough in liquid organic hydrogen carriers. Int. J. Hydrogen Energy 2024, 63, 315–329. [Google Scholar] [CrossRef]

- He, X.; Lu, T.; Li, J.; Sheng, W.; Li, R. Power System Capacity Planning Considering Seasonal Hydrogen Storage by Salt Caverns. arXiv 2023, arXiv:2311.12525. [Google Scholar] [CrossRef]

- Huang, S.; Li, Y.; Shi, X.; Liu, Y.; Ma, H.; Li, P.; Liu, Y.; Liu, X.; Xu, M.; Yang, C. Key Issues of Salt Cavern Flow Battery. Energies 2024, 17, 5190. [Google Scholar] [CrossRef]

- Wei, X.; Shi, X.; Li, Y.; Li, P.; Ban, S.; Zhao, K.; Ma, H.; Liu, H.; Yang, C. A comprehensive feasibility evaluation of salt cavern oil energy storage system in China. Appl. Energy 2023, 351, 121807. [Google Scholar] [CrossRef]

- Dong, Z.; Li, Y.; Li, H.; Wang, Z.; Shi, X.; Chen, X.; Lu, Q. Experimental Study on the Influence of Temperature on Rock Salt Creep. Rock Mech. Rock Eng. 2023, 56, 3499–3518. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, Z.; Chen, J.; Jiang, D.; Wu, F.; Fan, J.; Li, Y. Feasibility evaluation of large-scale underground hydrogen storage in bedded salt rocks of China: A case study in Jiangsu province. Energy 2020, 198, 117348. [Google Scholar] [CrossRef]

- Tarkowski, R. Underground hydrogen storage: Characteristics and prospects. Renew. Sustain. Energy Rev. 2019, 105, 86–94. [Google Scholar] [CrossRef]

- Ho, A.; Mohammadi, K.; Memmott, M.; Hedengren, J.; Powell, K.M. Dynamic simulation of a novel nuclear hybrid energy system with large-scale hydrogen storage in an underground salt cavern. Int. J. Hydrogen Energy 2021, 46, 31143–31157. [Google Scholar] [CrossRef]

- Peng, T.; Wan, J.; Liu, W.; Li, J.; Xia, Y.; Yuan, G.; Jurado, M.J.; Fu, P.; He, Y.; Liu, H. Choice of hydrogen energy storage in salt caverns and horizontal cavern construction technology. J. Energy Storage 2023, 60, 106489. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, W.; Guo, Q.; Duan, X.; Li, Y.; Wang, T. Tightness evaluation and countermeasures for hydrogen storage salt cavern contains various lithological interlayers. J. Energy Storage 2022, 50, 104454. [Google Scholar] [CrossRef]

- Bai, W.; Shi, X.; Yang, C.; Zhu, S.; Wei, X.; Li, Y.; Liu, X. Assessment of the potential of salt mines for renewable energy peaking in China. Energy 2024, 300, 131577. [Google Scholar] [CrossRef]

- Wei, X.; Duan, Y.; Liu, Y.; Jin, S.; Sun, C. Onshore-offshore wind energy resource evaluation based on synergetic use of multiple satellite data and meteorological stations in Jiangsu Province, China. Front. Earth Sci. 2019, 13, 132–150. [Google Scholar] [CrossRef]

- National Energy Administration. 13th Five-Year Plan for Wind Power Development. Available online: https://www.nea.gov.cn/2016-11/29/c_135867633.htm (accessed on 29 November 2016).

- Jiangsu Province Development and Reform Commission. Jiangsu Province “14th Five-Year” Renewable Energy Development Plan. Available online: https://fzggw.jiangsu.gov.cn/art/2022/7/11/art_83783_10531644.html (accessed on 30 June 2022).

- Zhu, S.; Shi, X.; Yang, C.; Bai, W.; Wei, X.; Yang, K.; Li, P.; Li, H.; Li, Y.; Wang, G. Site selection evaluation for salt cavern hydrogen storage in China. Renew. Energy 2024, 224, 120143. [Google Scholar] [CrossRef]

- Shi, X.; Ma, H.; Zhang, Y. Advances of large-scale gas storage technology in existing salt caverns in high-insoluble salt formations. J. Shandong Univ. Sci. Technol. (Nat. Sci.) 2020, 39, 55–65. [Google Scholar] [CrossRef]

- Özgür, T.; Yakaryılmaz, A.C. A review: Exergy analysis of PEM and PEM fuel cell based CHP systems. Int. J. Hydrogen Energy 2018, 43, 17993–178000. [Google Scholar] [CrossRef]

- Yousefi, S.H.; Groenenberg, R.; Koornneef, J.; Juez-Larré, J.; Shahi, M. Techno-economic analysis of developing an underground hydrogen storage facility in depleted gas field: A Dutch case study. Int. J. Hydrogen Energy 2023, 48, 28824–28842. [Google Scholar] [CrossRef]

| Technology | AWE | PEMWE | AEMWE | SOE |

|---|---|---|---|---|

| H2 production rate (Nm3 H2/h) | 0.97 | 0.5 or 1.0 | — | — |

| Current density/(A·cm–2) | <0.8 | 1~4 | 1~2 | 0.2~0.4 |

| Power consumption (kWh/Nm3 H2) | 4.5~5.5 | 4.0~5.0 | 4.2~4.6 | >3 |

| Efficiency | 60~70% | 60~80% | 60~75% | 85~100% |

| Operating temperature/°C | ≤90 | ≤80 | ≤60 | ≥800 |

| Service life/kh | 60~90 | 30~90 | 10~30 | 10~30 |

| Hydrogen purity (%) | ≥99.8 | ≥99.99 | ≥99.99% | — |

| Technology maturity | Fully commercialized | Initial commercialization | Initial commercialization | Early demonstration |

| Advantages | Significant economies of scale; low hydrogen production material costs | High hydrogen production efficiency; large current; quick start-stop capability; strong adaptability to renewable energy fluctuations | Relatively low cost; quick response; no pollution | High electrolytic efficiency |

| Disadvantages | Poor compatibility with renewable energy; corrosive strong alkali; product requires maintenance; low working current | High cost due to use of precious metals | Material technology requires further breakthroughs; still in the research and development stage | High operating temperature; high energy consumption; still under development and validation |

| Country | Hydrogen Storage Facility | Commissioning Year/Year | Hydrogen Purity/% | Salt Cavern Volume/(105 m3) | Stored Energy/(GW·h) | ||

|---|---|---|---|---|---|---|---|

| UK | Teesside | 1972 | 95% | 365 | 4.5 | 3 × 0.70 | 25 |

| USA | Clemens | 1983 | 95% | 1000 | 7.0~13.5 | 5.80 | 92 |

| USA | Moss Bluff | 2007 | 95% | 1200 | 5.5~15.2 | 5.66 | 120 |

| USA | Spindletop | 2014 | 95% | 1340 | 6.8~20.2 | >5.80 | >120 |

| Gas Storage Facility | Location | Design Capacity/(108 Nm3) | Working Gas Volume/(108 Nm3) | Operating Entity |

|---|---|---|---|---|

| Jintan Gas Storage | Jintan, Jiangsu | 26.40 | 17.10 | PipeChina |

| Jintan Gas Storage | Jintan, Jiangsu | 11.80 | 7.20 | Sinopec |

| Jintan Gas Storage | Jintan, Jiangsu | 10.00 | 6.00 | Towngas |

| Zhangxing Gas Storage | Huaian, Jiangsu | 31.26 | 18.47 | Jiangsu Guoneng |

| Jianghan Gas Storage | Qianjiang, Hubei | 48.09 | 28.04 | Sinopec |

| Category | Value |

|---|---|

| System efficiency | 20.8% (when the final product is electricity) 37.8% (when the final product is hydrogen) |

| Hydrogen produced from curtailment/t | 3.56 × 104 |

| Electricity produced from curtailment/GWh | 4.16 × 105 |

| Category | Challenge | Solution |

|---|---|---|

| Specific feasibility | The fluctuation of offshore wind power generation and hydrogen demand cycles has not been thoroughly studied. | Investigate the cyclical fluctuations of offshore wind power and grid connection capacity in Jiangsu Province, estimate excess electricity, and determine the scale of the hydrogen production platform; investigate the demand for hydrogen in grid peak shaving and industrial sectors, and develop the scale and injection/extraction strategy for salt cavern hydrogen storage. |

| Lack of domestic cases for salt cavern hydrogen storage engineering, making risk assessment difficult. | Accelerate the development of a salt cavern hydrogen storage demonstration project, focusing on salt cavern sealing properties, hydrogen material selection, risk assessment, and post-disaster measures to ensure safety. | |

| Applicability to other regions | The system has high geographical, geological, and economic development requirements, limiting its applicability. | Conduct feasibility studies in other coastal regions (such as Shandong, Hebei, and Guangdong) and develop site-specific construction plans. |

| Overall economic viability | High system construction costs, making commercial promotion difficult. | Prioritize pilot projects in economically developed areas to accumulate experience and promote technological standardization and scaling, reducing construction and operational costs; make full use of existing gas storage facilities for renovation, reducing overall system construction costs |

| Harsh marine environment leads to increased installation and operational challenges and costs. | Improve equipment durability and corrosion resistance; optimize offshore installation, remote operation, and maintenance technologies; and reduce operational costs. | |

| Technology is still in the demonstration phase, and the potential for large-scale development has not been fully realized. | Increase investment in technology research and development and policy support to enhance the maturity of relevant technologies and accelerate the transition from demonstration projects to commercial ventures. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Huang, Y.; Shi, X.; Bai, W.; Huang, S.; Li, P.; Xu, M.; Li, Y. Offshore Wind Power—Seawater Electrolysis—Salt Cavern Hydrogen Storage Coupling System: Potential and Challenges. Energies 2025, 18, 169. https://doi.org/10.3390/en18010169

Liu X, Huang Y, Shi X, Bai W, Huang S, Li P, Xu M, Li Y. Offshore Wind Power—Seawater Electrolysis—Salt Cavern Hydrogen Storage Coupling System: Potential and Challenges. Energies. 2025; 18(1):169. https://doi.org/10.3390/en18010169

Chicago/Turabian StyleLiu, Xiaoyi, Yashuai Huang, Xilin Shi, Weizheng Bai, Si Huang, Peng Li, Mingnan Xu, and Yinping Li. 2025. "Offshore Wind Power—Seawater Electrolysis—Salt Cavern Hydrogen Storage Coupling System: Potential and Challenges" Energies 18, no. 1: 169. https://doi.org/10.3390/en18010169

APA StyleLiu, X., Huang, Y., Shi, X., Bai, W., Huang, S., Li, P., Xu, M., & Li, Y. (2025). Offshore Wind Power—Seawater Electrolysis—Salt Cavern Hydrogen Storage Coupling System: Potential and Challenges. Energies, 18(1), 169. https://doi.org/10.3390/en18010169