Sealing Effects on Organic Pore Development in Marine Shale Gas: New Insights from Macro- to Micro-Scale Analyses

Abstract

1. Introduction

2. Formation Characteristics

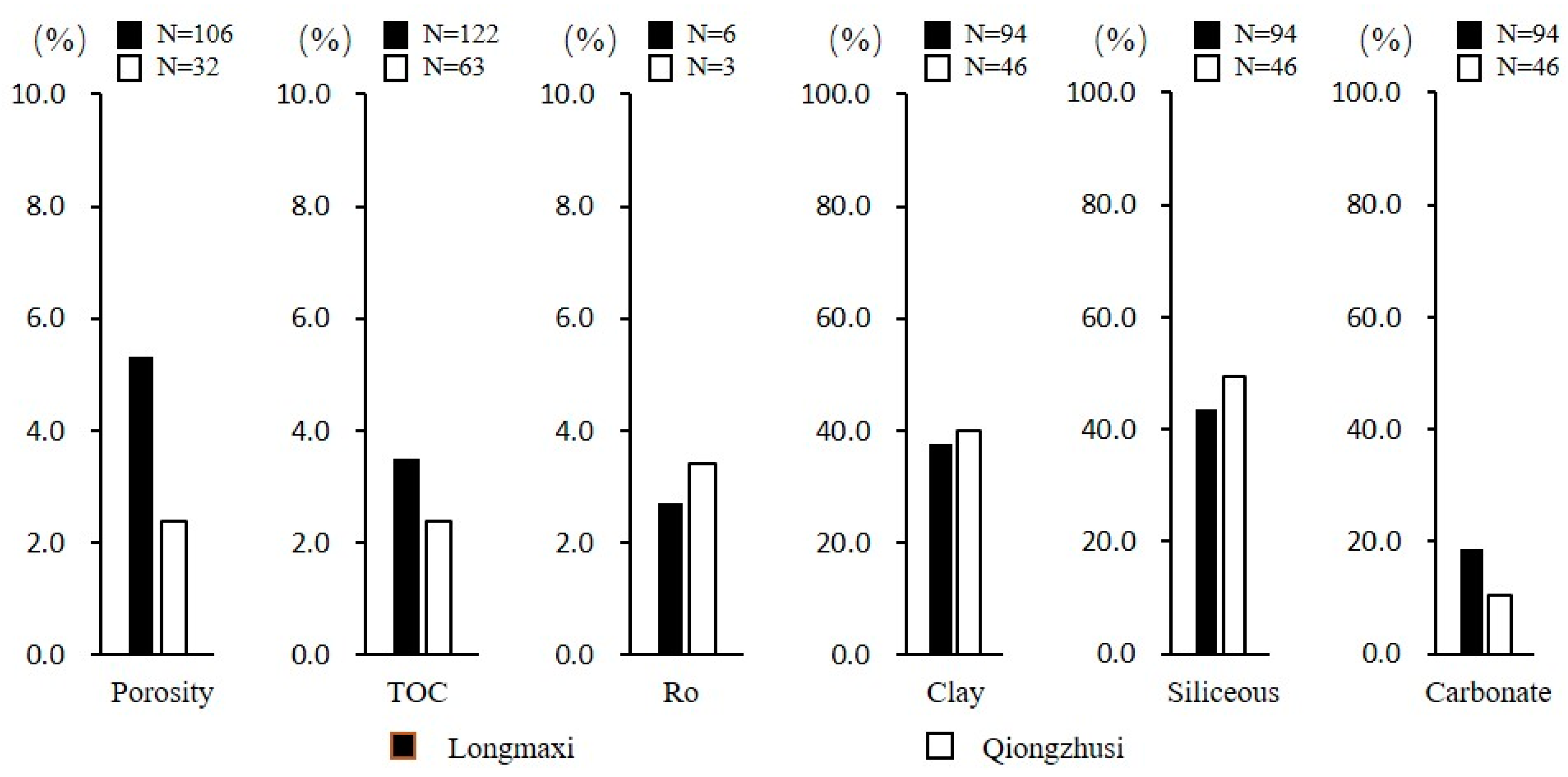

2.1. Wufeng–Longmaxi and Qiongzhusi Formations

2.2. Dalong Formation in Northwestern Part of the Sichuan Basin

3. Experimental Methods

3.1. Pyrolysis Simulation

- (1)

- Six column samples were selected as a single set (total of two sets, one set for the semi-closed system and one set for the open system, total of 12 column samples).

- (2)

- The sample was placed in the thermal simulation instrument for hydrocarbon generation and expulsion (the surrounding void was filled with fragments).

- (3)

- The temperature was increased to 350 °C at a rate of 20 °C/h, and this temperature was maintained for 48 h. The fluid pressure was then measured, and the fluid was cooled to room temperature.

- (4)

- The column samples were removed after the thermal simulation experiment and sectioned into slices for field emission scanning electron microscopy (FE-SEM) observations.

- (5)

- The fragment samples were removed from the thermal simulation instrument and used for geochemical, low-pressure N2 and CO2 adsorption and desorption, high-pressure mercury injection, and alcohol porosity tests.

- (6)

- Steps 3 to 5 were repeated using target temperatures of 400 °C, 450 °C, 500 °C, 550 °C, and 600 °C.

3.2. FE-SEM

3.3. Other Analyses

4. Results and Discussion

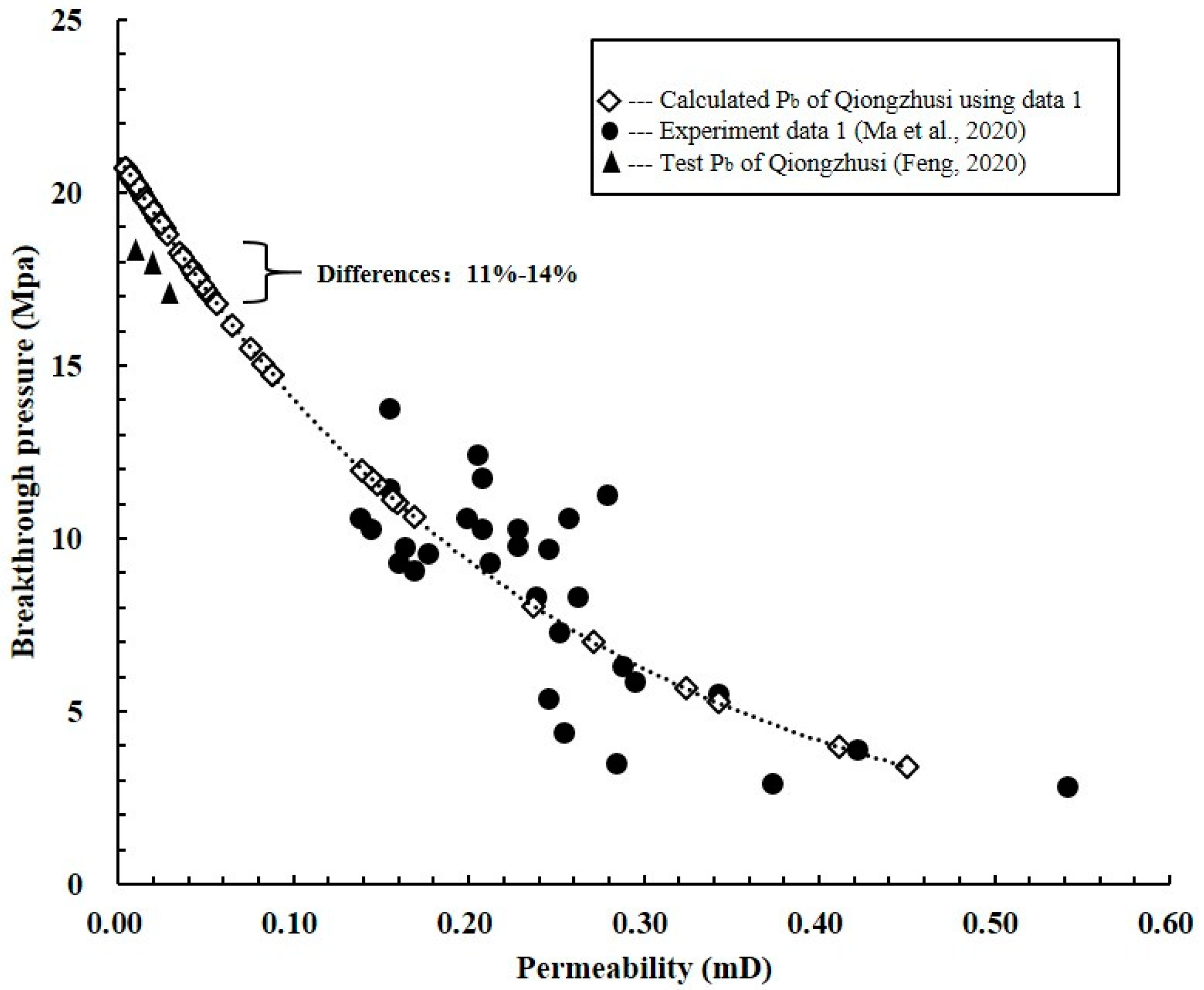

4.1. Effect of Roof–Floor Sealing Capacity on Organic Pore Development

4.2. Effect of Micro-Sealing Capacity on Organic Pore Development

4.3. Discussion and Comparison of Pyrolysis Simulation Experiment Results

4.3.1. TOC, Ro, and Mineral Contents in the Semi-Closed and Open Systems

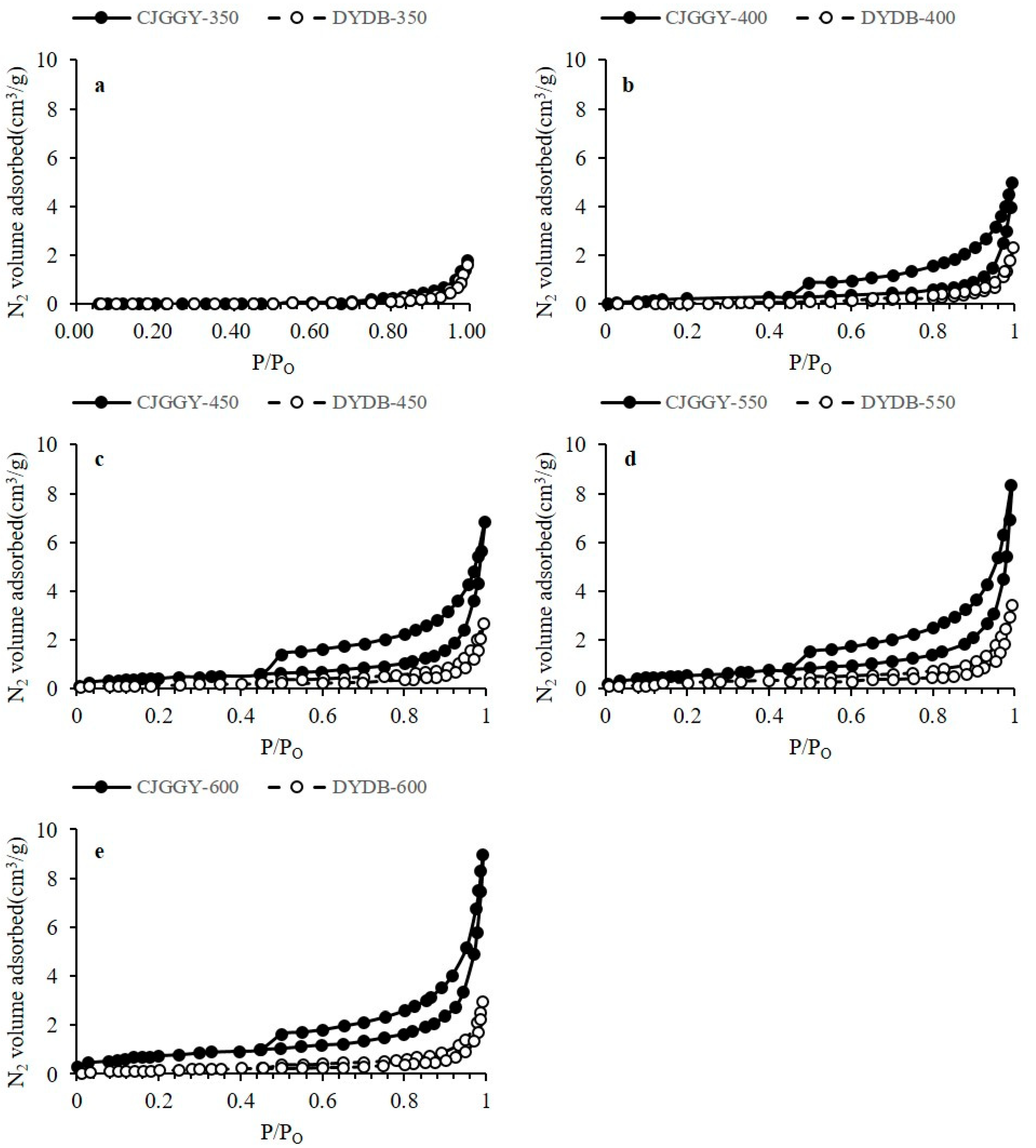

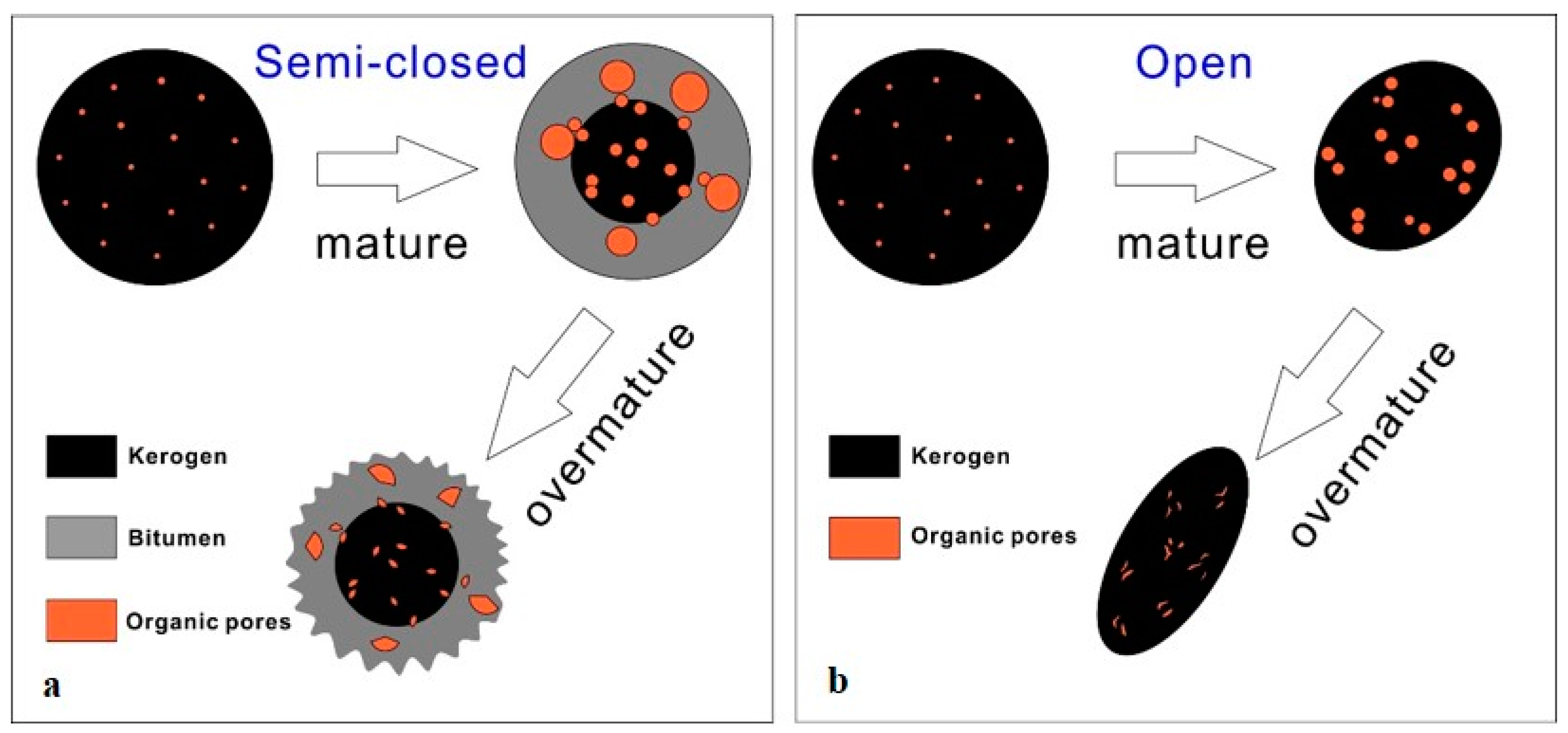

4.3.2. Pore Morphology in the Semi-Closed and Open Systems

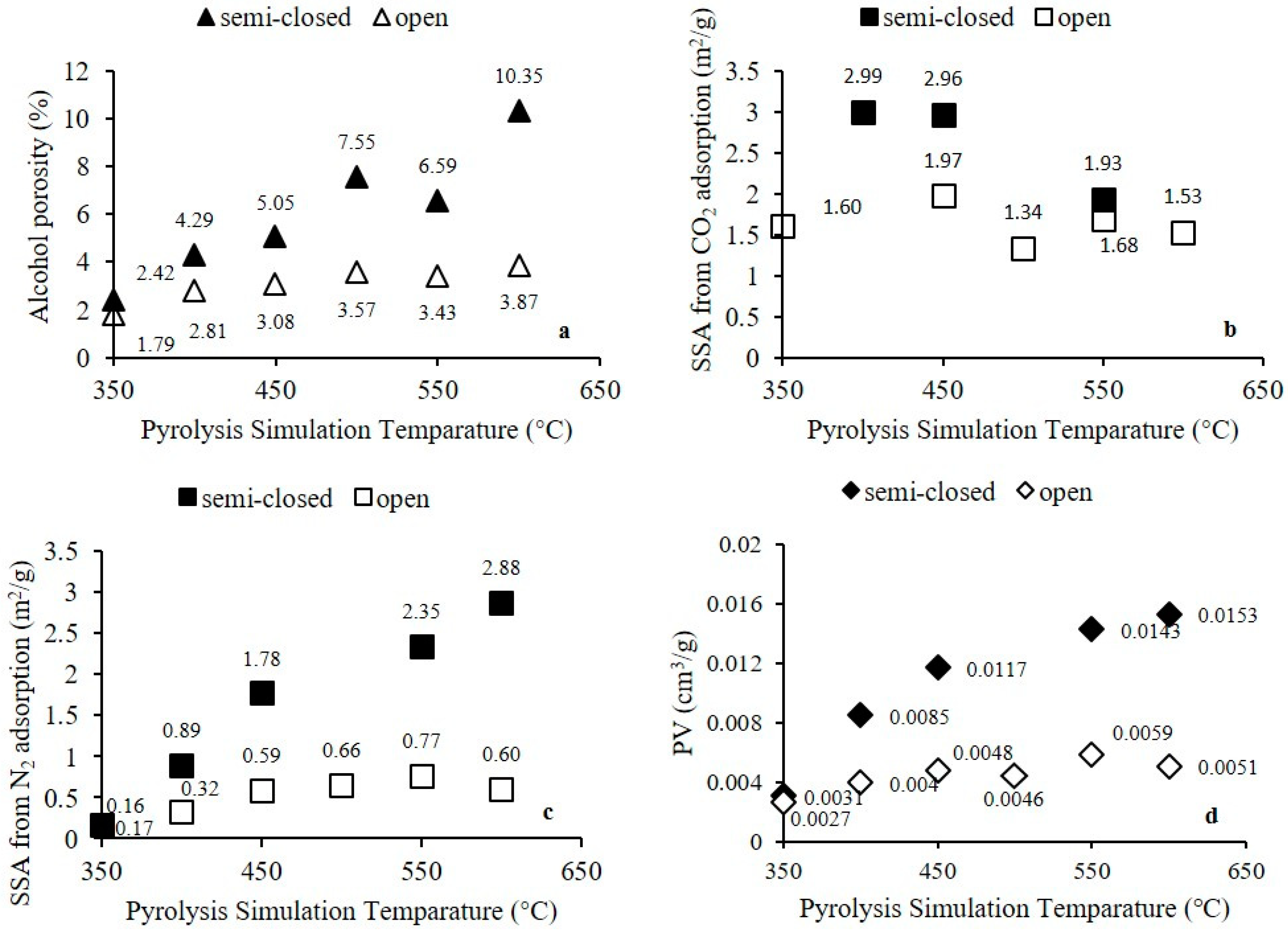

4.3.3. Pore Structure in the Semi-Closed and Open Systems

4.3.4. Pore Diameter Distribution in the Semi-Closed and Open Systems

4.4. Effect of Sealing Capacity on Macro-, Meso-, and Micropore Development

4.5. Similarity Analyses of Pyrolysis Results and Shale Pore Evolution

4.6. Organic Pore Development Patterns in the Longmaxi and Qiongzhusi Formations

5. Conclusions

- (1)

- The trend in the mineral contents, TOC, and Ro changes with temperature in the semi-closed and open systems indicated that the pressure difference caused by the sealing capacity had limited impacts on the thermal maturity and mineral contents, but it could control the organic carbon content.

- (2)

- The porosity, SSA, PV, and PD were higher in the semi-closed system than in the open system. These differences mainly occurred in the overmature stage. Moreover, based on the comparison of the PV changes in different pores at different thermal stages, the results showed that the macropores and mesopores were easily affected by the sealing conditions, but the micropores were not.

- (3)

- On the macro-scale, the sealing capacity of the Longmaxi floor layer was higher than the sealing capacity of the Qiongzhusi floor layer (quantified using breakthrough calculations). On the micro-scale, the SEM results revealed that organic pores developed in the semi-closed system, and the organic pores on the edge were larger than the organic pores inside the kerogen.

- (4)

- Finally, the pyrolysis simulation results were validated with the Longmaxi shale and Qiongzhusi Formations properties. The Longmaxi shale is similar to the semi-closed system, and the Qiongzhusi shale is similar to the open system.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Delle Piane, C.; Ansari, H.; Li, Z.S.; Mata, J.; Rickard, W.; Pini, R.; Dewhust, D.N.; Sherwood, N. Influence of organic matter type on porosity development in the Wufeng-Longamxi Shale: A combined microscopy, neutron scattering and physisorption approach. Int. J. Coal Geol. 2022, 249, 103880. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, C.; Gao, G.; Luo, C.; Hu, X. Controlling factors and evolution laws of shale porosity in Longmaxi Formation, Sichuan Basin. Acta Pet. Sin. 2017, 38, 175–184. [Google Scholar]

- Hu, G.; Pang, Q.; Jiao, K.; Hu, C.; Liao, Z. Development of organic pores in the Longmaxi Formation overmature shales: Combined effects of thermal maturity and organic matter composition. Mar. Pet. Geol. 2020, 116, 104314. [Google Scholar] [CrossRef]

- Milliken, K.; Rudnicki, M.; Awwiller, D.N.; Zhang, T. Organic matter-hosted pore system, Marcellus Formation (Devonian), Pennsylvania. AAPG Bull. 2013, 97, 177–200. [Google Scholar] [CrossRef]

- Pan, B.; Li, Y.; Zhang, M.; Iglauer, S. Effect of total organic carbon (TOC) content on shale wettability at high pressure and high temperature conditions. J. Pet. Sci. Eng. 2020, 193, 107374. [Google Scholar] [CrossRef]

- Curtis, M.; Cardott, B.J.; Sondergeld, C.H.; Rai, C.S. Development of organic porosity in the Woodford Shale with increasing thermal maturity. Int. J. Coal Geol. 2012, 103, 26–31. [Google Scholar] [CrossRef]

- Chen, L.; Jiang, Z.; Liu, K.; Tan, J.; Gao, F.; Wang, P. Pore structure characterization for organic-rich Lower Silurian shale in the Upper Yangtze Platform, South China: A possible mechanism for pore development. J. Nat. Gas Sci. Eng. 2017, 46, 1–15. [Google Scholar] [CrossRef]

- Walters, C.C.; Kliewer, C.E.; Awwiller, D.N.; Rudnicki, M.D.; Passey, Q.R.; Lin, M.W. Influence of turbostratic carbon nanostructures on electrical conductivity in shales. Int. J. Coal Geol. 2014, 122, 105–109. [Google Scholar] [CrossRef]

- Kenneth, C.; Emese, M.; Angelique, C. Evolution of porosity and pore geometry in the Permian Whitehill Formation of South Africa—A FE-SEM image analysis study. Mar. Pet. Geol. 2018, 91, 262–278. [Google Scholar]

- Jin, Z.; Nie, H.; Liu, Q.; Zhao, J.; Jiang, T. Source and seal coupling mechanism for shale gas enrichment in upper Ordovician Wufeng Formation—Lower Silurian Longmaxi Formation in Sichuan Basin and its periphery. Mar. Pet. Geol. 2018, 97, 78–93. [Google Scholar] [CrossRef]

- Li, X.; Jiang, Z.; Song, Y.; Zhai, G.; Bao, S.; Li, Z.; Tang, X.; Wang, P.; Li, T.; Wang, G.; et al. Porosity evolution mechanisms of marine shales at overmaturity stage: Insight from comparable analysis between Lower Cambrian and Lower Silurian inside and at the margin of the Sichuan Basin, South China. Interpretation 2018, 6, T739–T757. [Google Scholar] [CrossRef]

- Zhao, J.; Jin, Z.; Hu, Q.; Wang, R. Mineral composition and seal condition implicated in pore structure development of organic-rich Longmaxi shales, Sichuan Basin, China. Mar. Pet. Geol. 2018, 98, 507–522. [Google Scholar] [CrossRef]

- Tang, L.; Song, Y.; Jiang, S.; Li, L.; Li, Z.; Li, Q.; Yang, Y. Sealing Mechanism of the Roof and Floor for the Wufeng-Longmaxi Shale Gas in the Southern Sichuan Basin. Energy Fuels 2020, 34, 6999–7018. [Google Scholar] [CrossRef]

- Zhang, K.; Song, Y.; Jia, C.; Jiang, Z.; Han, F.; Wang, P.; Yuan, X.; Yang, Y.; Zeng, Y.; Li, Y.; et al. Formation mechanism of the sealing capacity of the roof and floor strata of marine organic-rich shale and shale itself, and its influence on the characteristics of shale gas and organic matter pore development. Mar. Pet. Geol. 2022, 140, 105647. [Google Scholar] [CrossRef]

- Jiang, S.; Li, C.; Chen, G. Occurrence of normally-pressured shale gas in China and the United States and their effects on mobility and production: A case study of southeast Sichuan Basin and Appalachia Basin. Pet. Reserv. Eval. Dev. 2022, 12, 399–406. [Google Scholar]

- Zhou, W. Interview with Dr. Wen Zhou, Chengdu University of Technology. AAPG Learn Blog. 2020. Available online: https://www.aapg.org/publications/blogs/learn/article/articleid/56649/interview-with-dr-wen-zhou-chengdu-university-of-technology?utm_medium=website&utm_source=See_Also_Sidebar_Text&srsltid=AfmBOooBiyj_By9-cpZ6EwrFE961g9XpXYugu4qMy3t51MQxQFd5B87w (accessed on 18 November 2024).

- Wang, P. The Correlation Between Shale Sealing Capacity and the Gas Generation Characteristics of Shale Organic Matter, Minerals Compositions and Pore Structure. Ph.D. Dissertation, University of Chinese Academy of Sciences, Guangzhou Institute of Geochemistry, Guangzhou, China, 2017. [Google Scholar]

- Mastalerz, M.; Drobniak, A.; Stankiewicz, A.B. Origin, properties, and implications of solid bitumen in source-rock reservoirs: A review. Int. J. Coal Geol. 2018, 195, 14–36. [Google Scholar] [CrossRef]

- Wang, R.; Nie, H.; Hu, Z.; Liu, G.; Liu, W. Controlling effect of pressure evolution on shale gas reservoirs: A case study of the Wufeng-Longmaxi Formation in the Sichuan Basin. Tianranqi Gongye/Nat. Gas Ind. 2020, 40, 1–11. [Google Scholar]

- He, C.; Li, T. Studying advances in effects of pressure on organic matter maturation. Acta Sedimentol. Sin. 2018, 36, 1041–1047. [Google Scholar]

- Shi, M.; Yu, B.; Zhang, J.; Huang, H.; Yuan, Y.; Li, B. Evolution of organic pores in marine shales undergoing thermocompression: A simulation experiment using hydrocarbon generation and expulsion. J. Nat. Gas Sci. Eng. 2018, 59, 406–413. [Google Scholar] [CrossRef]

- Shao, D.; Zhang, T.; Zhang, L.; Li, Y.; Meng, K. Effects of pressure on gas generation and pore evolution in thermally matured calcareous mudrock: Insights from gold-tube pyrolysis of the Eagle Ford Shale using miniature core plugs. Int. J. Coal Geol. 2022, 252, 103936. [Google Scholar] [CrossRef]

- Song, D.; Tuo, J.; Dai, S.; Wu, C.; Sun, L.; Zhang, M.; Su, L. New insights into the role of system sealing capacity in shale evolution under conditions analogous to geology: Implications for nanopore evolution. Mar. Pet. Geol. 2022, 143, 105831. [Google Scholar] [CrossRef]

- Zhao, W.; Li JYang TWang, S.; Huang, J. Geological difference and its significance of marine shale gases in South China. Pet. Explor. Dev. Online 2016, 43, 547–559. [Google Scholar] [CrossRef]

- Liu, R.; Zhou, W.; Xu, H.; Zhou, Q.; Jiang, K.; Shang, F.; Gao, W.; Song, W.; Liu, D.; Zhao, H.; et al. Impact of mineral and sealing systems on the pore characteristics of the Qiongzhusi Formation Shale in the southern sichuan basin. ACS Omega 2021, 7, 15821–15840. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Xu, H.; Yu, Q.; Xie, R.; Deng, K. Shale gas-bearing property differences and their genesis between Wufeng-Longmaxi Formation and Qiongzhusi Formation in Sichuan Basin and surrounding areas. Lithol. Reserv. 2016, 28, 18–25. [Google Scholar]

- Jiang, P.; Wu, J.; Zhu, Y.; Zhang, D.; Wu, W.; Zhang, R.; Wu, Z.; Wang, Q.; Yang, Y.; Yang, X.; et al. Enrichment conditions and favorable areas for exploration and development of marine shale gas in Sichuan Basin. Acta Sedimentol. Sin. 2023, 44, 92–109. [Google Scholar]

- Shi, J.; Jin, Z.; Liu, Q.; Zhang, R.; Huang, Z. Cyclostratigraphy and astronomical tuning of the middle Eocene terrestrial successions in the Bohai Bay Basin, Eastern China. Glob. Planet. Change 2019, 174, 115–126. [Google Scholar] [CrossRef]

- Li, X.; Pan, I.; Wu, W.; Yan, J.; Lu, Y. Shale gas comparision and evaluation of Longmaxi Formation and Qiongzhusi Formation of lower Palaeozoic in the area of southern Sichuan. Petrochem. Ind. Appl. 2016, 1, 101–108. [Google Scholar]

- Shi, J.; Jin, Z.; Liu, Q.; Huang, Z. Depositional process and astronomical forcing model of lacustrine fine-grained sedimentary rocks: A case study of the early Paleogene in the Dongying Sag, Bohai Bay Basin. Mar. Pet. Geol. 2020, 113, 103995. [Google Scholar] [CrossRef]

- Fu, X.; Qin, J.; Teng, G.; Wang, X. Evaluation on Dalong Formation source rock in the north Sichuan Basin. Pet. Geol. Exp. 2010, 32, 567–577. [Google Scholar]

- Dai, H.; Shen, B.; Li, K.; Zhang, X.; Xu, X.; Xu, Z.; Zhou, J. Characteristics and hydrocarbon generation process of the organic-rich shale of Permian Dalong Formation in North Sichuan: Pyrolysis experiments with geological constraint. J. Nanjing Univ. (Nat. Sci.) 2020, 56, 383–392. [Google Scholar]

- Guo, J.; Hu, G.; He, K.; Mi, J.; Tian, L.; He, F.; Guo, C.; Lu, M. Geochemical characteristics and sedimentary environment of source rocks of Permian Dalong Formation in Northern Sichuan Basin. Lithol. Reserv. 2023, 35, 139–152. [Google Scholar]

- Teng, G.; Qin, J.; Fu, X.; Li, W.; Rao, D.; Zhang, M. Basin conditions of marine hydrocarbon accumulation in northwest Sichuan Basin. Pet. Geol. Exp. 2008, 30, 479–483. [Google Scholar]

- Wei, S.; He, S.; Pan, Z.; Guo, X.; Yang, R.; Dong, T.; Yang, W. Models of shale gas storage capacity during burial and uplift: Application to Wufeng-Longmaxi shales in the Fuling shale gas field. Mar. Pet. Geol. 2019, 109, 233–244. [Google Scholar] [CrossRef]

- Song, Y.; Liu, C.; Gao, H.; Li, S.; Zhang, P.; Wang, Z.; Han, Y. Chemical characteristics of flowback water and production characteristics of Zhaotong shale gas wells. Nat. Gas Explor. Dev. 2020, 43, 102–109. [Google Scholar]

- Zhang, G.; Nie, H.; Tang, X. Evaluation of shale gas preservation conditions based on formation water index: A case study of Wufeng-Longmaxi Formation in Southeastern Chongqing. Reserv. Eval. Dev. 2021, 11, 47–55. [Google Scholar]

- Wu, T.; Pan, Z.; Connell, L.D.; Liu, B.; Fu, X.; Xue, Z. Gas breakthrough pressure of tight rocks: A review of experimental methods and data. J. Nat. Gas Sci. Eng. 2020, 81, 103408. [Google Scholar] [CrossRef]

- Xu, L.; Ye, W.; Chen, B. A new approach for determination of gas breakthrough in saturated materials with low permecapacity. Engingering Geol. 2018, 241, 121–131. [Google Scholar] [CrossRef]

- Ma, C.; Lin, C.; Dong, C.; Elsworth, D.; Wu, S.; Wang, X.; Sun, X. Determination of the critical flow pore diameter of shale caprock. Mar. Pet. Geol. 2020, 112, 104042. [Google Scholar] [CrossRef]

- Feng, G. High-Temperature High-Pressure Methane Adsorption and Shale Gas Occurrence in Lower Cambrian Shale, Upper Yangtze Area. Ph.D. Dissertation, China University of Mining and Technology, Xuzhou, China, 2020. [Google Scholar]

- Hartkopf-Froder, C.; Konigshof, P.; Littke, R.; Schwarzbauer, J. Optical thermal maturity parameters and organic geochemical alteration at low grade diagenesis to anchimetamorphism A review. Int. J. Coal Geol. 2015, 150–151, 74–119. [Google Scholar] [CrossRef]

- Milkov, A.; Faiz, M.; Etiope, G. Geochemistry of shale gases from around the world: Composition, origins, isotope reversals and rollovers, and implications for the exploration of shale plays. Org. Geochem. 2020, 143, 103997. [Google Scholar] [CrossRef]

| Sample | Mineral Contents (%) | Ro (%) | TOC (%) | OM Type | |||||

|---|---|---|---|---|---|---|---|---|---|

| Quartz | Plagioclase | Calcite | Dolomite | Pyrite | Clay | ||||

| CJG-1 | 39 | 5 | 30 | 0 | 2 | 24 | 0.57 | 6.46 | I |

| CJG-2 | 34 | 4 | 24 | 4 | 4 | 30 | 0.5 | 9.14 | I |

| CJG-3 | 18 | 1 | 42 | 35 | 4 | 0 | \ | 1.57 | \ |

| CJG-4 | 5 | 3 | 43 | 41 | 0 | 8 | 0.65 | 2.17 | I |

| CJG-5 | 22 | 0 | 15 | 49 | 2 | 12 | 0.76 | 1.76 | I |

| CJG-6 | 21 | 0 | 22 | 44 | 5 | 8 | \ | 1.83 | \ |

| CJG-8 | 16 | 2 | 23 | 49 | 2 | 8 | \ | 1.97 | \ |

| CJG-9 | 13 | 0 | 63 | 12 | 0 | 12 | \ | 1.04 | I |

| CJG-10 | 24 | 4 | 49 | 0 | 6 | 17 | \ | 5.43 | I |

| Median | 21.0 | 2.0 | 30.0 | 35.0 | 2.0 | 12.0 | 0.6 | 1.97 | I |

| Sample | Sapropelite (%) | Vitrinite (%) | Exinite (%) | Inertinite (%) | OM Type | ||

|---|---|---|---|---|---|---|---|

| Phytoplankton | Amorphous OM | Hydrogen-Rich | Normal | Fusinite | |||

| CJG-1 | 9 | 86 | 0 | 5 | 0 | 0 | I |

| CJG-2 | 8 | 87 | 0 | 5 | 0 | 0 | I |

| CJG-3 | \ | \ | \ | \ | \ | \ | \ |

| CJG-4 | 5 | 87 | 0 | 8 | 0 | 0 | I |

| CJG-5 | 8 | 85 | 0 | 7 | 0 | 0 | I |

| CJG-6 | \ | \ | \ | \ | \ | \ | \ |

| CJG-8 | \ | \ | \ | \ | \ | \ | \ |

| CJG-9 | 7 | 88 | 0 | 5 | 0 | 0 | I |

| CJG-10 | 4 | 90 | 0 | 6 | 0 | 0 | I |

| System | Sample Number | Simulation Temperature (°C) | Simulation Time (h) | Fluid Type | Formation Pressure (MPa) | Lithostatic Pressure (MPa) |

|---|---|---|---|---|---|---|

| Semi-closed | CJGGY-350 | 350 | 48 | Brine | 37 | 89 |

| CJGGY-400 | 400 | 48 | Brine | 50 | 125 | |

| CJGGY-450 | 450 | 48 | Brine | 59 | 148 | |

| CJGGY-500 | 500 | 48 | Brine | 61 | 153 | |

| CJGGY-550 | 550 | 48 | Brine | 71 | 176 | |

| CJGGY-600 | 600 | 48 | Brine | 79 | 196 | |

| Open | DYDB-350 | 350 | 48 | Brine | \ | 89 |

| DYDB-400 | 400 | 48 | Brine | \ | 125 | |

| DYDB-450 | 450 | 48 | Brine | \ | 148 | |

| DYDB-500 | 500 | 48 | Brine | \ | 153 | |

| DYDB-550 | 550 | 48 | Brine | \ | 176 | |

| DYDB-600 | 600 | 48 | Brine | \ | 196 |

| Layer | Stratigraphy | Lithology | Depth (m) | Breakthrough Pressure (MPa) |

|---|---|---|---|---|

| Roof | S1l2 | Argillaceous shale | 2262 | 38 |

| Shale | S1l1, O3w | Siliceous shale | 2309–2322 | 27–34 |

| Floor | O2b | Limestone | 2332 | 40 |

| Layer | Stratigraphy | Lithology | Depth (m) | Breakthrough Pressure (MPa) |

|---|---|---|---|---|

| Roof | Ꞓ1z2 | Argillaceous shale | 3080–3141 | 19.9 |

| Shale | Ꞓ1z1 | Siliceous shale | 3141–3245 | 20.1 |

| Floor | Z2dn4 | Dolomite | 3245–3310 | 3.4 |

| System | Sample | TOC (%) | Ro (%) | Mineral Contents (%) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Quartz | Plagioclase | Calcite | Dolomite | Pyrite | Clay | ||||

| ORIGIN | 1.97 | 0.60 | 21.00 | 2.00 | 30.00 | 35.00 | 2.00 | 12.00 | |

| Semi-Closed | CJGGY-350 | 1.41 | 1.18 | 10.00 | 0.00 | 35.00 | 38.00 | 1.00 | 16.00 |

| CJGGY-400 | 1.40 | 1.47 | 9.00 | 1.00 | 44.00 | 34.00 | 0.00 | 12.00 | |

| CJGGY-450 | 1.24 | 1.85 | 4.00 | 5.00 | 47.00 | 23.00 | 0.00 | 21.00 | |

| CJGGY-500 | 1.11 | 2.16 | 10.00 | 1.00 | 34.00 | 38.00 | 1.00 | 16.00 | |

| CJGGY-550 | 1.15 | 2.50 | 6.00 | 1.00 | 42.00 | 40.00 | 1.00 | 10.00 | |

| CJGGY-600 | 1.08 | 2.63 | 4.00 | 3.00 | 41.00 | 40.00 | 1.00 | 11.00 | |

| Open | ORIGIN | 1.97 | 0.60 | 21.00 | 2.00 | 30.00 | 35.00 | 2.00 | 12.00 |

| DYDB-350 | 0.99 | 1.29 | 16.00 | 1.00 | 35.00 | 40.00 | 2.00 | 6.00 | |

| DYDB-400 | 0.95 | 1.39 | 12.00 | 1.00 | 21.00 | 58.00 | 1.00 | 7.00 | |

| DYDB-450 | 0.94 | 1.81 | 14.00 | 1.00 | 23.00 | 54.00 | 1.00 | 7.00 | |

| DYDB-500 | 1.01 | 2.12 | 15.00 | 1.00 | 24.00 | 53.00 | 2.00 | 5.00 | |

| DYDB-550 | 0.98 | 2.35 | 15.00 | 1.00 | 26.00 | 50.00 | 2.00 | 6.00 | |

| DYDB-600 | 1.01 | 2.43 | 14.00 | 1.00 | 25.00 | 53.00 | 2.00 | 5.00 | |

| Temperature (°C) | System | Porosity (%) | CO2 SSA (m2/g) | N2 SSA (m2/g) | PV (cm3/g) |

|---|---|---|---|---|---|

| Origin | Semi-closed | 0.44 | 1.71 | 0.27 | 0.0012 |

| 350 | 2.42 | \ | 0.16 | 0.0031 | |

| 400 | 4.29 | 2.99 | 0.89 | 0.0085 | |

| 450 | 5.05 | 2.96 | 1.78 | 0.0117 | |

| 500 | 7.55 | \ | \ | \ | |

| 550 | 6.59 | 1.93 | 2.35 | 0.0143 | |

| 600 | 10.35 | \ | 2.88 | 0.0153 | |

| Origin | Open | 0.44 | 1.71 | 0.27 | 0.0012 |

| 350 | 1.79 | 1.60 | 0.17 | 0.0027 | |

| 400 | 2.81 | \ | 0.32 | 0.0040 | |

| 450 | 3.08 | 1.97 | 0.59 | 0.0048 | |

| 500 | 3.57 | 1.34 | 0.66 | 0.0046 | |

| 550 | 3.43 | 1.68 | 0.77 | 0.0059 | |

| 600 | 3.87 | 1.53 | 0.60 | 0.0051 |

| Sealing Capacity | δ13C1(CH4) (‰) | δ13C2(C2H6) (‰) | δ13C1(CH4) − δ13C2(C2H6) (‰) |

|---|---|---|---|

| Good | −29.5 to −31.0 | −34.7 to −35.9 | 4.9 to 6.0 |

| Poor | −29.6 to −41.4 | −29.0 to −39.4 | −10 to 1.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Q.; Xu, H.; Zhou, W.; Zhao, X.; Liu, R.; Jiang, K. Sealing Effects on Organic Pore Development in Marine Shale Gas: New Insights from Macro- to Micro-Scale Analyses. Energies 2025, 18, 193. https://doi.org/10.3390/en18010193

Zhou Q, Xu H, Zhou W, Zhao X, Liu R, Jiang K. Sealing Effects on Organic Pore Development in Marine Shale Gas: New Insights from Macro- to Micro-Scale Analyses. Energies. 2025; 18(1):193. https://doi.org/10.3390/en18010193

Chicago/Turabian StyleZhou, Qiumei, Hao Xu, Wen Zhou, Xin Zhao, Ruiyin Liu, and Ke Jiang. 2025. "Sealing Effects on Organic Pore Development in Marine Shale Gas: New Insights from Macro- to Micro-Scale Analyses" Energies 18, no. 1: 193. https://doi.org/10.3390/en18010193

APA StyleZhou, Q., Xu, H., Zhou, W., Zhao, X., Liu, R., & Jiang, K. (2025). Sealing Effects on Organic Pore Development in Marine Shale Gas: New Insights from Macro- to Micro-Scale Analyses. Energies, 18(1), 193. https://doi.org/10.3390/en18010193