Abstract

Bubbling Inception Temperature (BIT) is a critical metric that indicates the temperature at which gas bubbles form due to cellulose decomposition in a paper–oil insulation system. It serves as a key indicator of the thermal stability of transformer insulation, offering valuable insights into its performance under elevated temperatures. Building on findings from a companion study that examined the BIT of Kraft paper (KP), thermally upgraded Kraft paper (TUK), and aramid paper in mineral oil, this research expands the analysis to assess the impact of moisture, aging, and alternative dielectric fluids. Using the same customized experimental setup featuring precise dynamic load control, real-time bubble detection, and continuous monitoring of moisture and temperature, this study evaluates BIT across four distinct oil–paper aging stages: new (0 h) and 2 weeks, 4 weeks, and 6 weeks of accelerated thermal aging. This approach enables a comparative analysis of BIT in various paper–oil systems, focusing on both mineral oil and synthetic esters, as well as the influence of different moisture levels in the paper insulation. The results show that BIT decreases with aging, indicating reduced thermal stability. Furthermore, KP impregnated with synthetic ester exhibits a higher BIT than when impregnated with mineral oil, suggesting that synthetic esters may offer better resistance to bubble formation under thermal stress. Based on these results, empirical BIT models were developed as a function of degree of polymerization (DP) and water content in paper (WCP). This study further demonstrates how these models can be applied to quantify safety margins under emergency overloading conditions, providing a practical tool for operational decision-making in transformer thermal risk management.

1. Introduction

Power transformers are indispensable for the efficient transmission and distribution of electrical energy, acting as the cornerstone of any electrical system [1]. The insulating materials within these transformers, particularly cellulose-based paper immersed in transformer oil, are crucial for maintaining optimal performance [2]. These materials endure various stressors over time, including electrical, thermal, oxidative, and hydrolytic forces, which lead to aging phenomena. This aging can significantly affect the thermal and dielectric properties of the insulation, potentially undermining the transformer’s reliability and efficiency [3].

Transformers operating at rated loads present a low risk of bubble formation in oil–paper insulating systems. However, during overloads, the risk increases significantly due to the associated temperature rise. Bubble formation is critical because it can trigger partial discharges, lower dielectric strength, and accelerate local insulation degradation [4].

Bubbling Inception Temperature (BIT) represents the point at which gas bubbles begin to form, and it is a key parameter for evaluating the thermal stability of insulating materials [3]. It is influenced by factors such as moisture content, the aging state of the insulation, operating temperature, and the properties of both the insulating oil and paper. Higher moisture content reduces BIT by increasing internal vapor pressure, while insulation aging generally lowers BIT by reducing the energy required for bubble formation [3]. The chemical and physical properties of the insulating fluid, as well as the thermal and sorption behavior of the paper type, also play a role. For example, esters—being more hygroscopic than mineral oils—can dissolve more water and better resist bubble formation, and paper types, such as aramid and thermally upgraded Kraft (TUK), have different BIT characteristics compared to conventional Kraft paper (KP) [5,6].

Several studies have investigated BIT. Gao et al. [7] and Wilhelm et al. [4] examined the impact of water content, showing that higher moisture levels significantly lower BIT; Wilhelm observed bubbles forming at 130 °C with 2.5% water content [4]. The effect of aging on BIT was studied by Przybylek et al. [8,9,10] and Koch et al. [11], with Przybylek reporting a decrease in BIT and Koch noting an increase due to hornification [11]. Research by Perkasa et al. [12] indicated that esters have higher BITs than mineral oils due to their hygroscopic nature and thermal stability. Previous work has also compared BIT among KP, TUK, and aramid papers impregnated with mineral oil, showing that TUK exhibited the highest BIT, followed by KP and aramid.

Despite these insights, gaps remain in the literature. The influence of aging on BIT shows inconsistent trends, highlighting the need to better understand mechanisms such as hornification. The long-term performance of esters under varied operational conditions remains insufficiently studied. Comparative research on different paper types (e.g., aramid, TUK) under varying moisture and thermal conditions is limited, and existing BIT formulas are available only for mineral oils; none are tailored for esters, despite their different chemical and physical properties.

Building on previous findings, the present study investigates how BIT is influenced by both insulation aging and moisture levels, considering two dielectric fluids (mineral oil and synthetic ester) and various paper conditions. BIT measurements were carried out for initial (new) insulation and after accelerated thermal aging for 2, 4, and 6 weeks. Based on experimental data, empirical BIT formulas were developed for both fluids, and modeling analyses were performed to understand the mechanisms of bubble formation. The originality of this work lies in analyzing the combined effects of moisture content and insulation aging—often studied separately—and in developing a dedicated BIT formula for synthetic esters.

To bridge the gap between laboratory results and field application, simulation studies were conducted to demonstrate how the proposed BIT model can be used to determine safe loading thresholds under real transformer operating conditions. This integrated approach advances our knowledge of thermal risk management in transformer insulation systems and provides a practical tool for condition assessment.

Overall, this work contributes to improving the thermal design and lifetime management of transformer insulation systems, supporting a more resilient and efficient power grid.

2. Methodology

2.1. Experimental Setup

This study evaluates the BIT of KP impregnated with mineral oil and synthetic esters under varying conditions of moisture and aging. A custom setup, initially presented in the research presented in reference [5,6], was employed to measure the BIT accurately. Bubble initiation is influenced by specific moisture levels within the paper and the extent of aging, making it essential to understand the water content in paper (WCP) at the point of bubbling inception. To address this, a calibration curve was developed to show capacitance as a function of WCP. Each measurement was performed at least twice to ensure repeatability. The variability of BIT values between repetitions ranged from 1 °C to 3 °C, and the reported results correspond to the average of the repeated measurements.

Initially, the insulating liquid underwent degassing and vacuum drying, and the paper samples were dried before impregnation. After impregnation, these samples, with a paper/oil ratio of (1/10), were subjected to accelerated aging at 120 °C with copper (3 g/L) in a closed beaker for periods of 2, 4, and 6 weeks. While the ASTM D-1934 suggests adjusting the oven temperature to 115 ± 1 °C, 120 °C was chosen to effectively accelerate cellulose degradation, thereby simulating long-term thermal aging within the available experimental timeframe. This elevated temperature enabled the observation of measurable changes in the degree of polymerization (DP) and by-product formation over a shorter duration. Although this acceleration may lead to faster DP degradation rates and higher by-product concentrations compared to in-service conditions, the fundamental degradation mechanisms remain consistent with those occurring in real transformers.

The process resulted in four sample groups: unaged (new) paper and paper aged in mineral oil for 2, 4, and 6 weeks.

To determine the relationship between capacitance and WCP, paper samples with varying moisture levels were prepared, as described in [5], and capacitance measurements were taken at four distinct WCP values. The calibration curve was generated twice to improve repeatability, with both results combined to create a unified curve. This process was repeated for each batch of samples, ensuring accurate BIT measurements and precise determinations of the WCP at the point of bubble formation.

This methodology facilitated accurate BIT assessment for oil–paper insulation samples. WCP was capacitively assessed by sandwiching layers of impregnated KP between two custom made electrodes for precise capacitance measurement.

Various measurements have been conducted on both paper and oil to monitor insulation degradation or quantify specific variables. Interfacial Tension (IFT), acidity, and moisture content in oil were measured, while for paper insulation, DP, moisture content, and capacitance measurement were performed. IFT assessments followed ASTM D971 [13], acidity testing was conducted according to ASTM D974-22 [14], and DP tests adhered to ASTM D4243-99 [15].

2.2. Materials

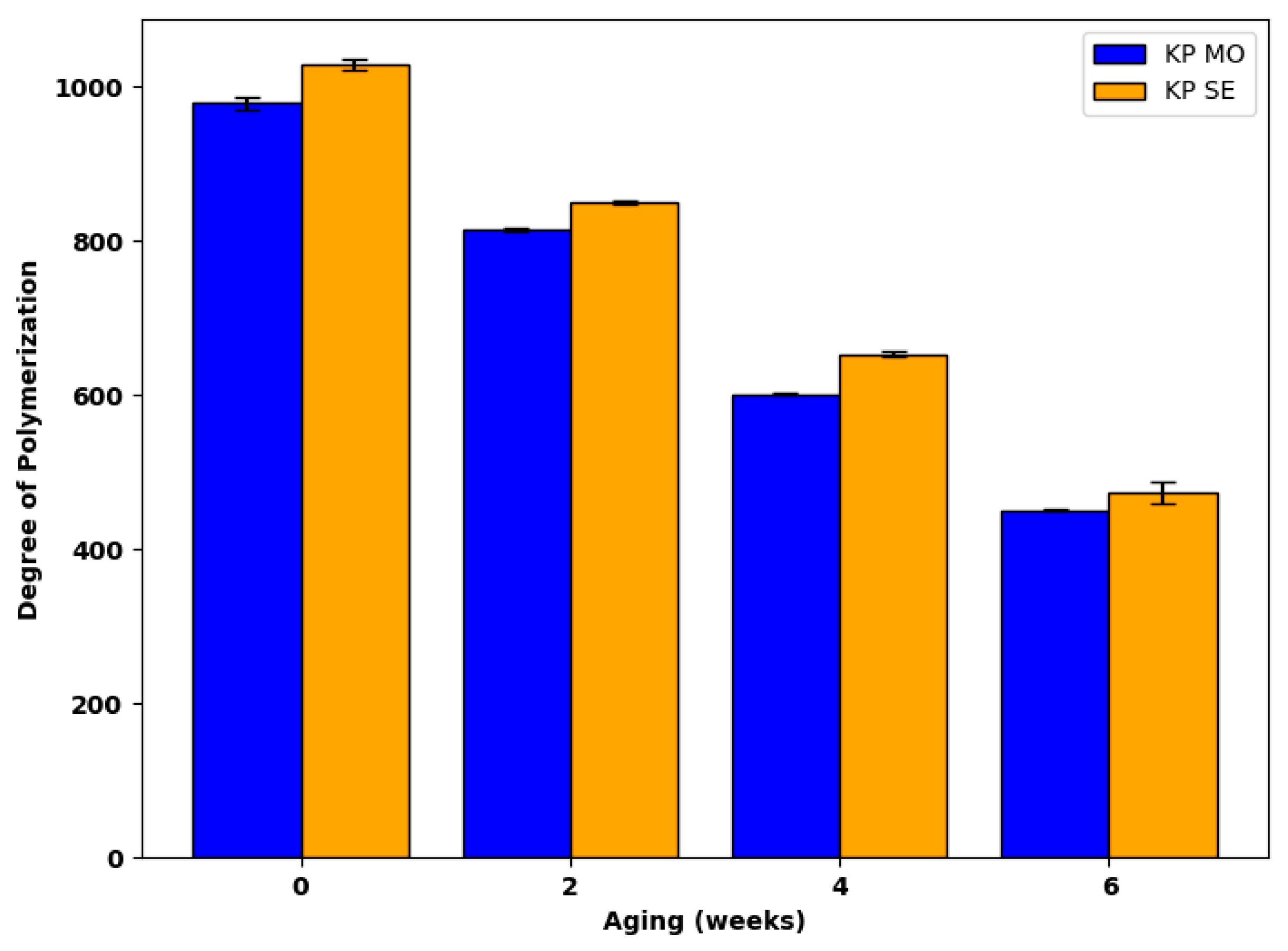

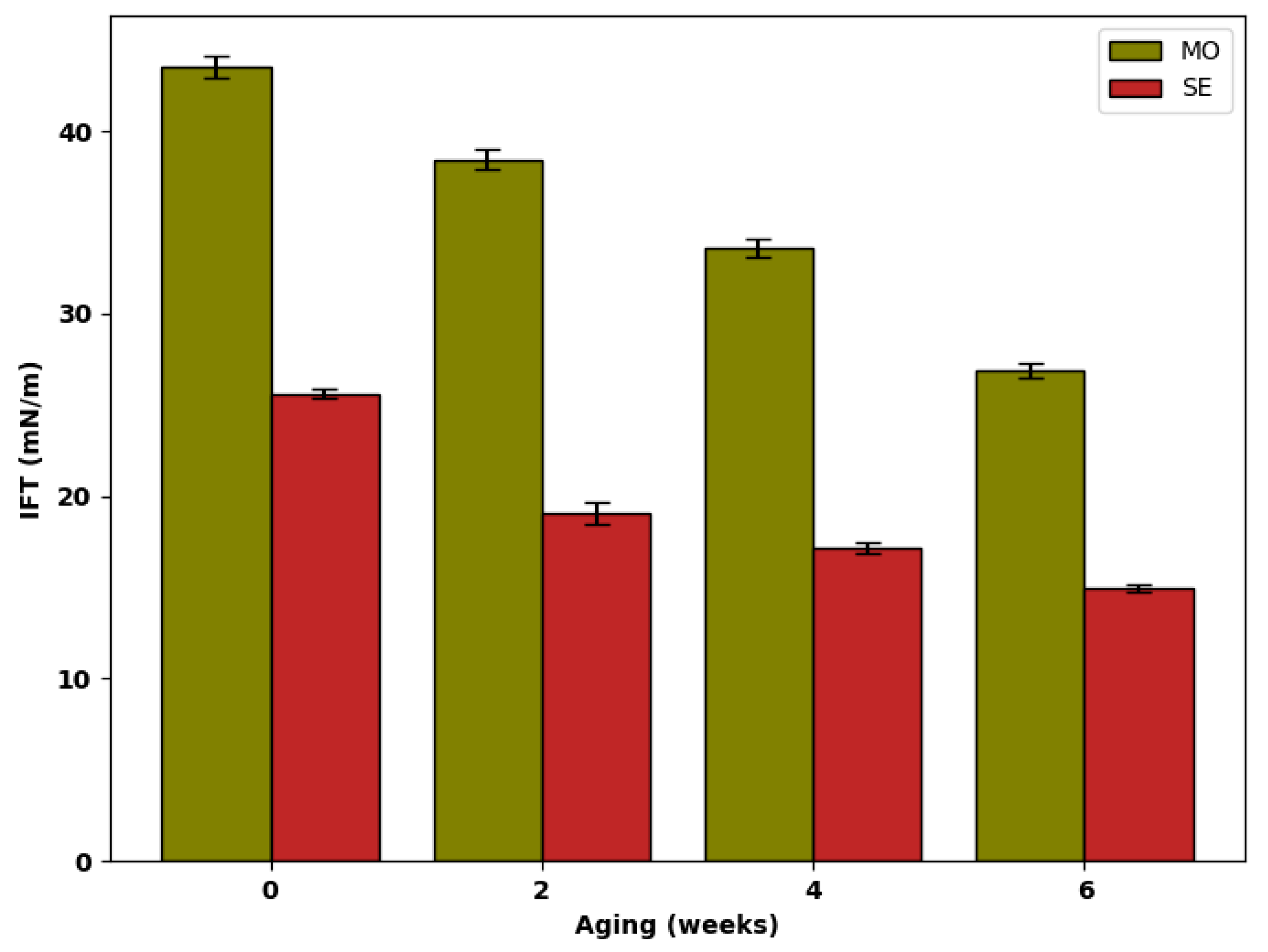

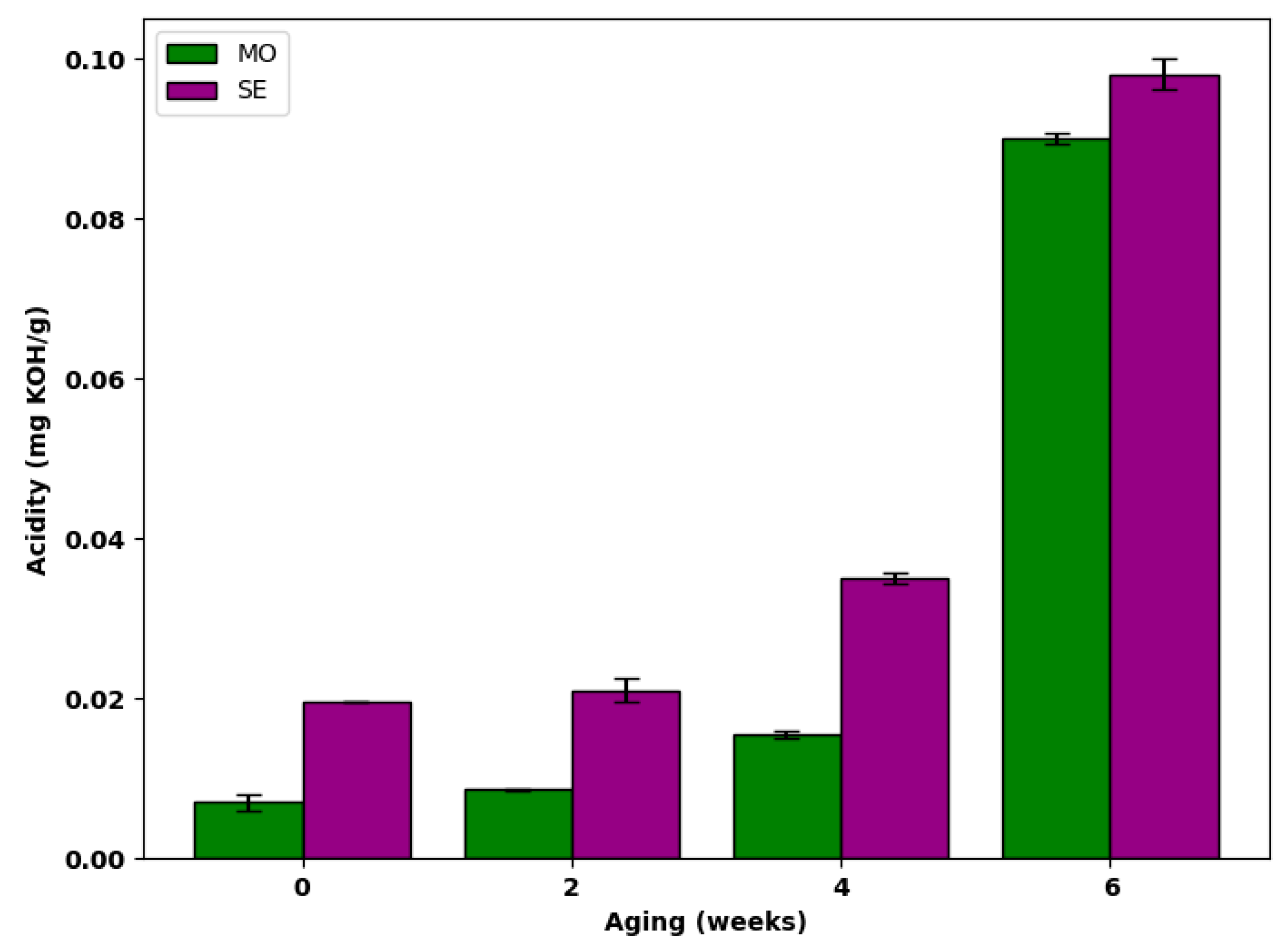

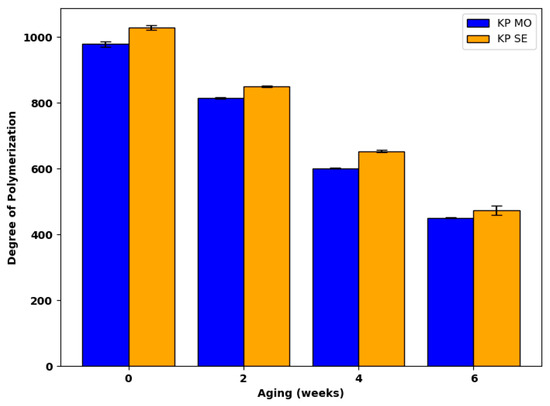

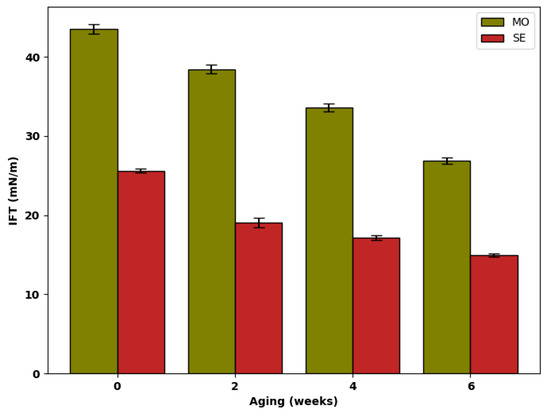

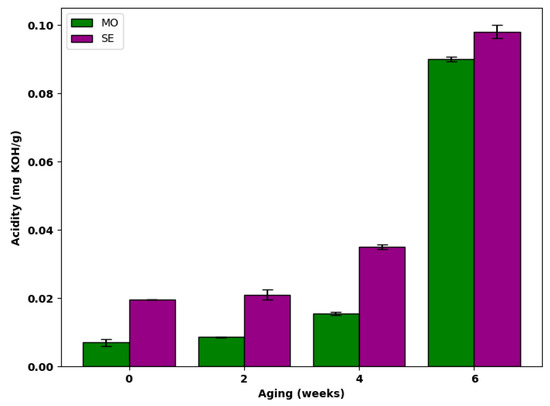

The experimental materials used in this study consisted of Kraft paper with a thickness of 0.25 mm, mineral oil (Nynas Nytro Polaris GX), Nynas AB, Stockholm, Sweden) and synthetic ester (Midel 7131, MIDEL & MIVOLT Fluids Ltd., Manchester, United Kingdom). The Kraft paper conformed to IEC 60554 [16], which specifies requirements for cellulosic papers for electrical purposes. The mineral oil is a high-grade inhibited transformer oil in compliance with IEC 60296 [17], while the synthetic ester is a biodegradable insulating fluid conforming to IEC 61099 [18]. Several conditions were tested: Fresh insulation and insulation degraded over 2, 4, and 6 weeks. The DP of the KP impregnated in both mineral oil (MO) and synthetic ester (SE) is shown in Figure 1. Figure 2 and Figure 3 present the IFT and acidity of the investigated liquids, respectively. Mineral oil has higher IFT than synthetic ester oil. This is because, in essence, mineral oil resists mixing with water more strongly, which creates a sharper interface and a higher IFT. Synthetic ester oils, being more polar and water-absorbing, blend more with water at the molecular level, softening that interface and reducing the IFT. As shown in Figure 3, a significant increase in acidity is observed after 6 weeks of aging. This rise could be attributed to intensified oxidation and hydrolysis reactions at this stage, especially in the presence of copper and residual moisture, leading to the formation and accumulation of acidic by-products such as carboxylic acids.

Figure 1.

DP of MO- and SE-impregnated KP as a function of aging duration.

Figure 2.

IFT of MO and SE as a function of aging duration.

Figure 3.

Acidity of MO and SE as a function of aging duration.

3. Results

This section presents the findings of this study on BIT with WCP, considering aging acting as a parameter for both MO and SE. Understanding these relationships is important for optimizing the performance and longevity of power transformers.

3.1. Bubbling Inception Temperature

The BIT was measured across different water content levels in paper samples immersed in MO and SE for each insulating quality (unaged or aged). The methodology involved controlled hydration of paper samples and subsequent BIT testing, as described in the Methodology section. WCP have been varied to reach several samples with different moistures inside. To this end, new and 2, 4, and 6 week aged mineral oil-impregnated paper with varying WCP were investigated. In addition to moisture in paper, aging is a significant factor influencing bubble formation, for that the effects of paper and oil degradation on BIT for both MO and SE are investigated. BIT is determined for four aging conditions.

3.1.1. Mineral Oil

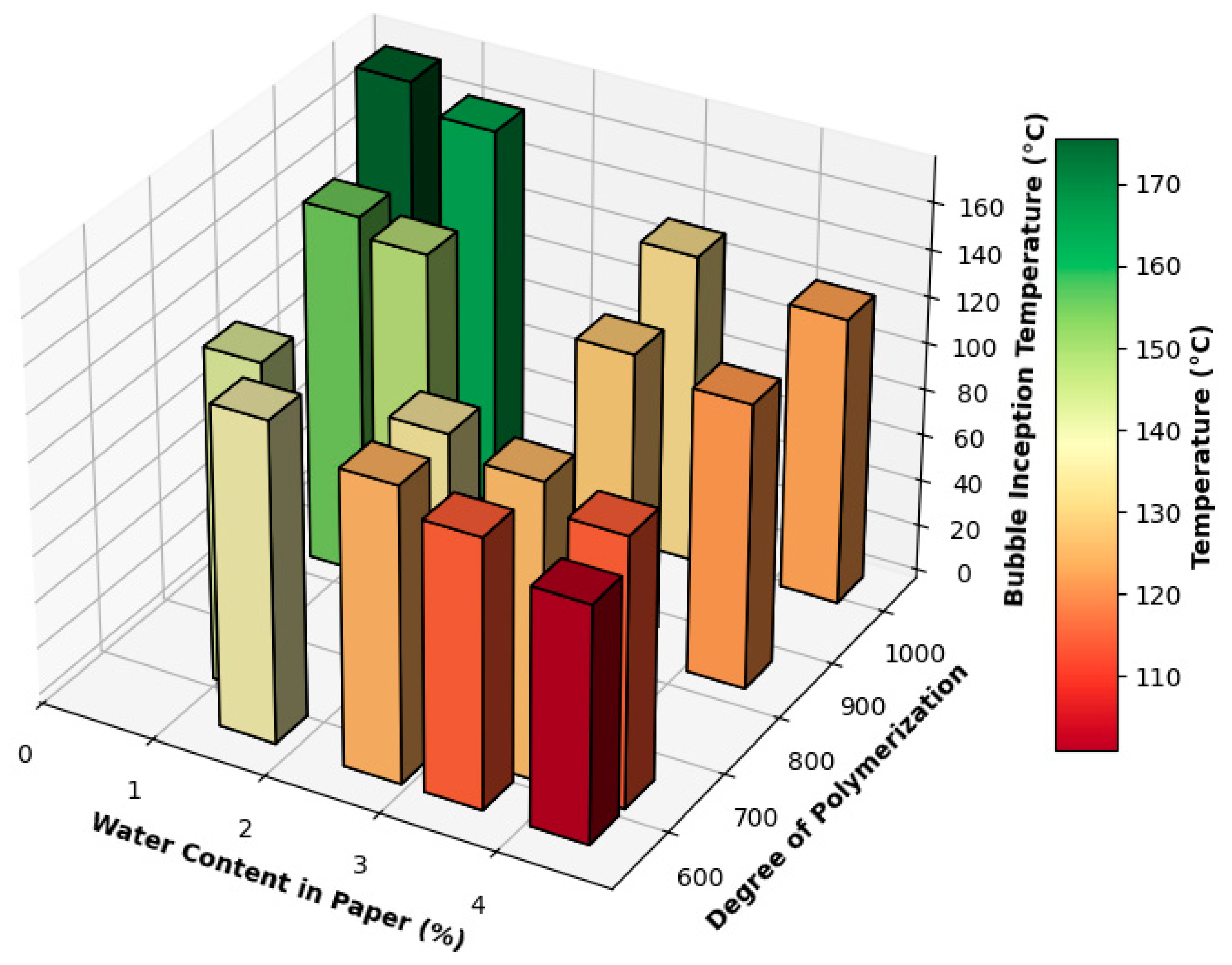

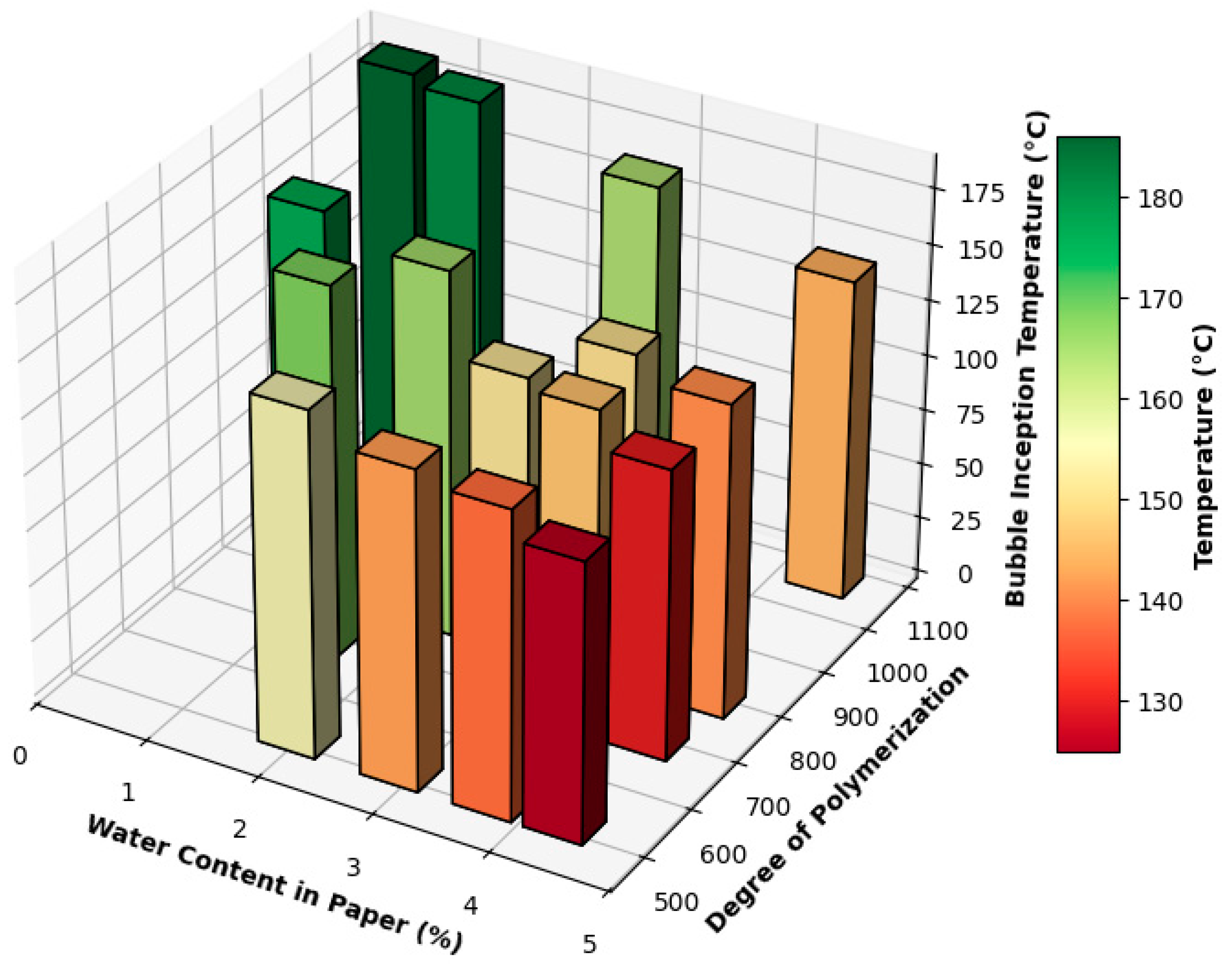

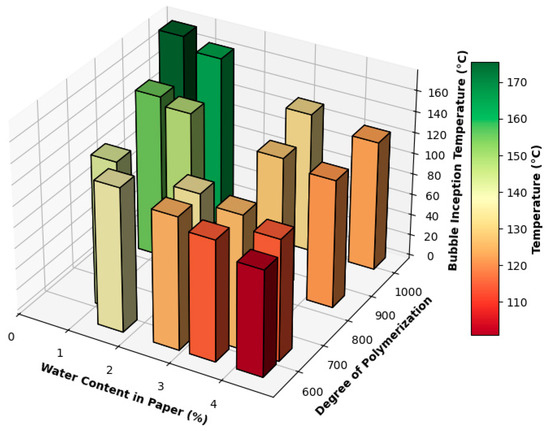

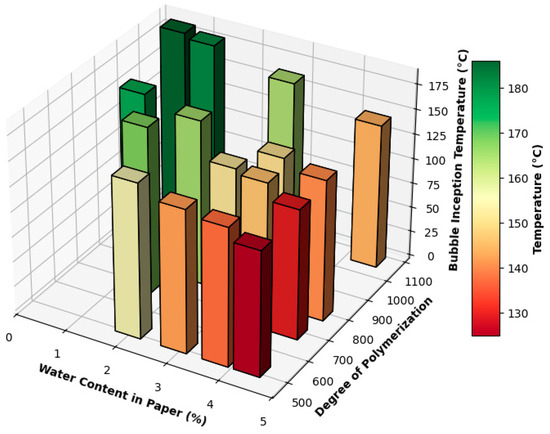

The BIT of MO-impregnated KP was evaluated for unaged KP (DP = 980) and after aging periods of 2 weeks (DP = 815), 4 weeks (DP = 601), and 6 weeks (DP = 540). For each insulation condition, the BIT was measured across various WCP levels. Figure 4 presents a comprehensive three-dimensional representation of the relationship between BIT, DP, and WCP for MO-impregnated KP. A color gradient is used to illustrate temperature variations, with green indicating higher BIT values and red indicating lower ones.

Figure 4.

Three-dimensional representation of BIT of MO-impregnated KP function of DP and WCP.

The data reveal a consistent trend: BIT decreases as WCP increases, emphasizing the detrimental impact of moisture on the thermal stability of the insulation material. High moisture content weakens the cellulose structure and elevates the internal vapor pressure during heating, thereby making the material more susceptible to bubble formation.

Furthermore, higher DP values (e.g., DP = 980) correspond to higher BITs, reflecting better insulation quality, while lower DP values (e.g., DP = 540) are associated with significantly lower BITs due to material degradation.

3.1.2. Synthetic Ester

Similarly to mineral oil-impregnated KP, the BIT of synthetic ester-impregnated KP is evaluated across various aging conditions and WCP levels. A 3D bar chart, shown in Figure 5, illustrates the relationship between DP, WCP, and BIT for SE-impregnated KP. The relationship between DP, WCP, and BIT is rooted in the thermal stability and mechanical integrity of the insulation paper. The combined effects of reduced DP and increased WCP make the insulation system more vulnerable to bubble formation and potential electrical breakdown, emphasizing the need for the careful management of both factors to ensure the reliability of power transformers. The results for synthetic esters, however, show that even aged SE maintain a relatively higher BIT compared to aged MO.

Figure 5.

Three-dimensional representation of BIT of SE-impregnated KP as a function of DP and WCP.

3.2. Comparison

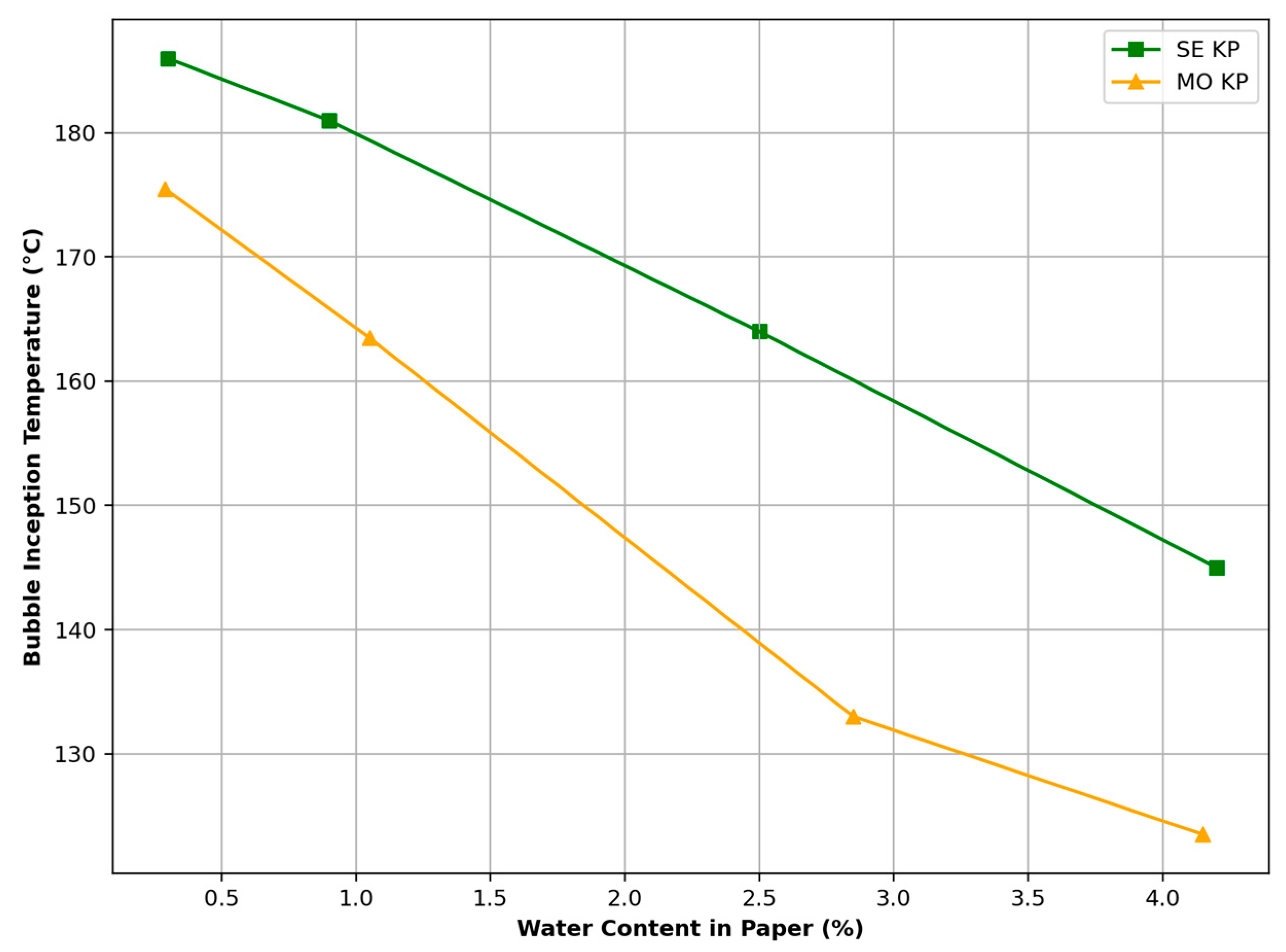

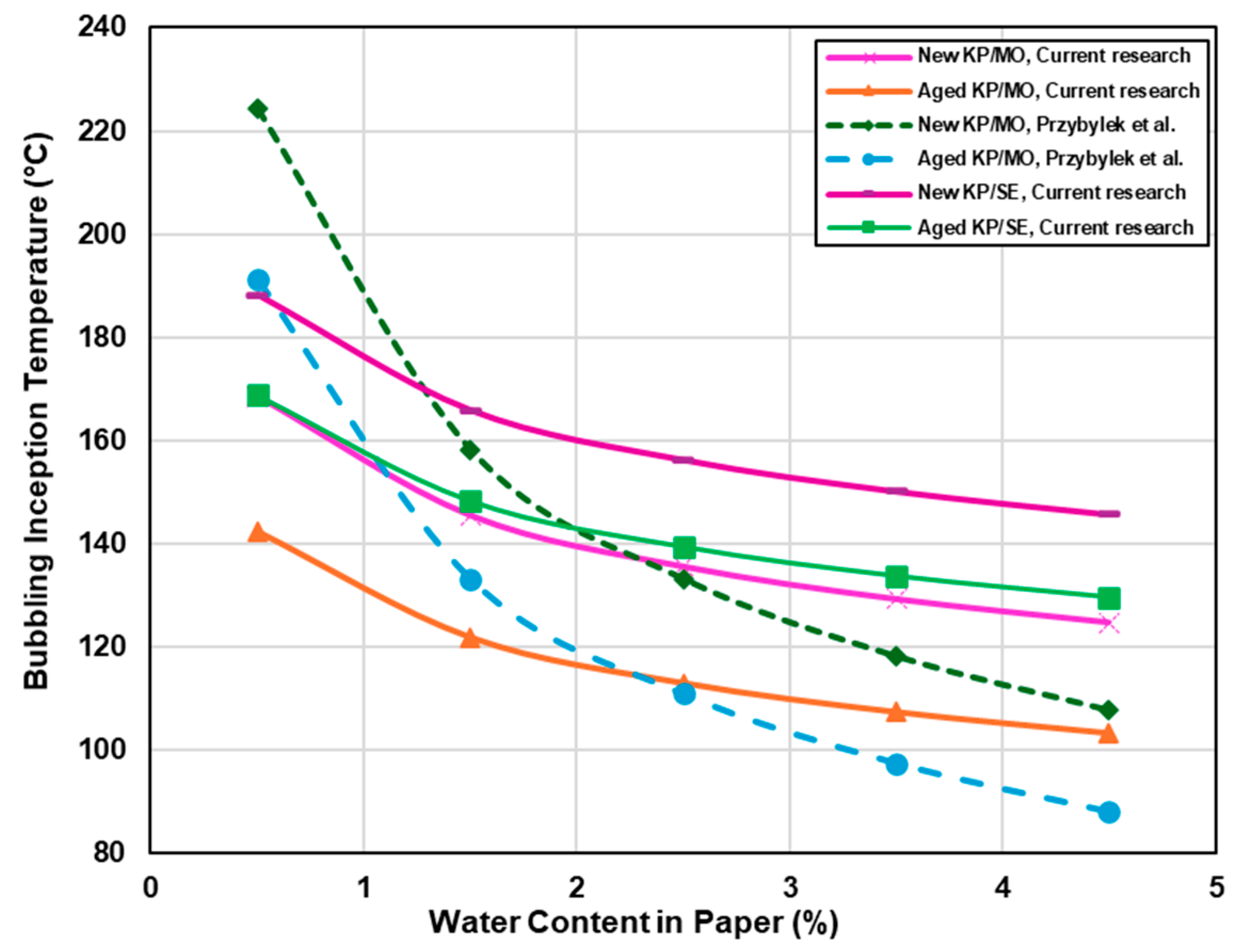

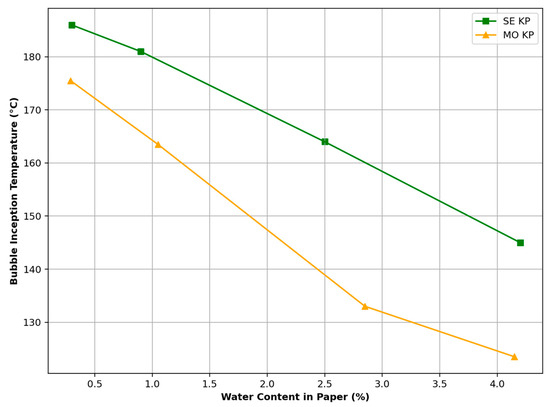

Both liquids were also tested under different moisture levels in this paper to assess their performance and impact on insulation integrity. Figure 6 illustrates the differences in BIT for fresh MO-impregnated KP and SE-impregnated KP as a function of WCP, which ranges from approximately 0.5% to 4.5%. The data clearly shows that synthetic ester-impregnated KP consistently exhibits higher BIT values compared to mineral oil-impregnated KP at similar WCP levels.

Figure 6.

Comparison of BIT for MO- and SE-impregnated KP with different water content levels.

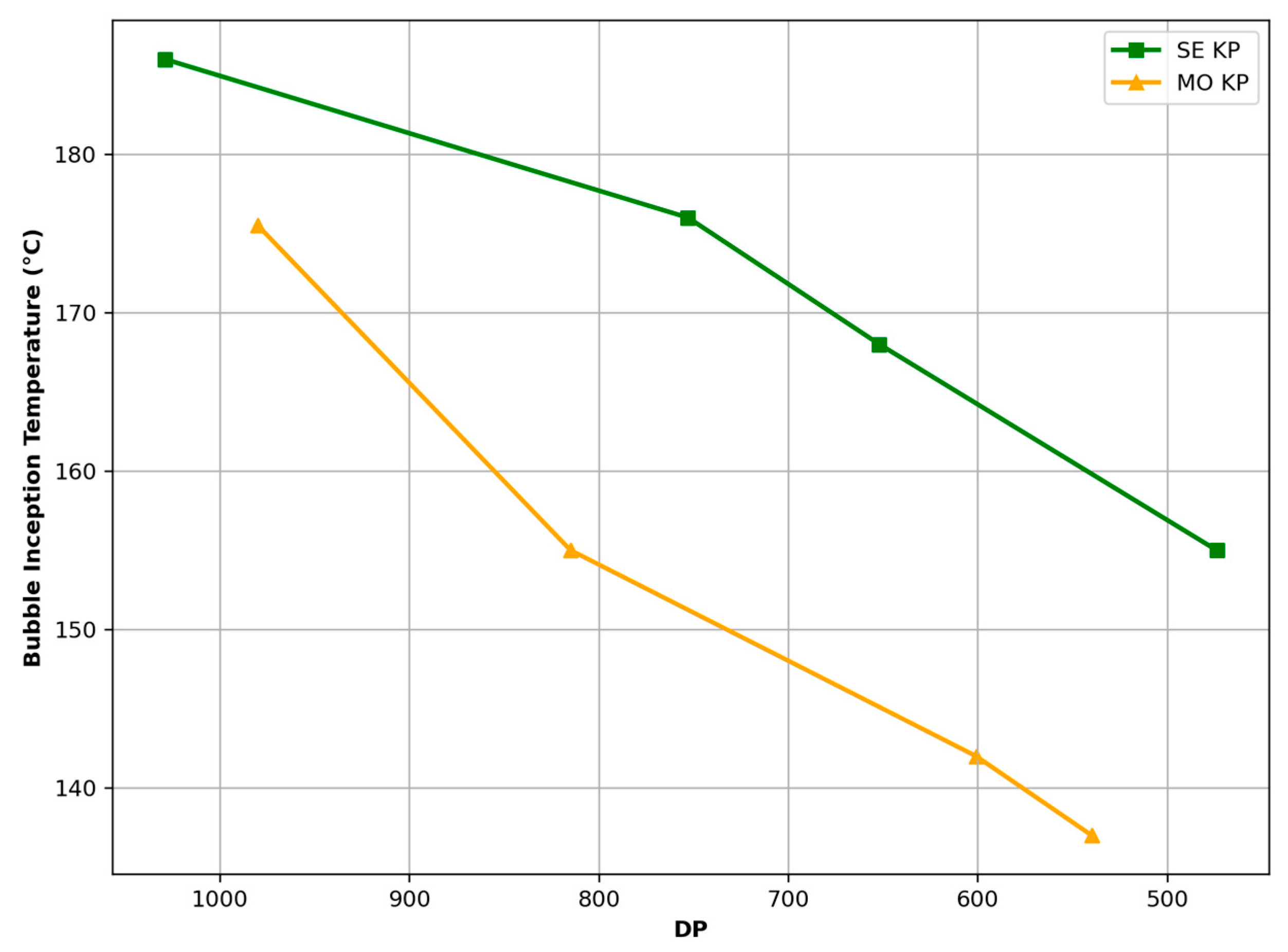

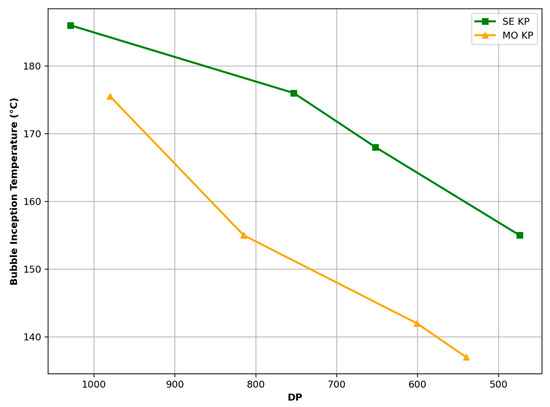

Figure 7 highlights the relationship between the BIT and the DP for MO-impregnated KP and SE-impregnated KP. The papers used for this comparison were fresh and aged for 2, 4, and 6 weeks, without undergoing hydration.

Figure 7.

Comparison of BIT for MO and SE impregnated KP at different aging conditions.

The data shows a clear trend where BIT decreases as the DP decreases for both materials. However, SE-impregnated KP consistently demonstrates higher BIT values compared to MO-impregnated KP at equivalent DP levels. The reason why esters have a higher BIT value compared to mineral oil, even when the paper has the same WCP, lies in the differences in fluid properties.

Although both cases have the same amount of water and similar conditions for bubble formation, esters have a significantly higher water saturation limit (≈2700 ppm at 20 °C, compared to 50 ppm for mineral oil) and are polar in nature. This polarity creates stronger interactions between the ester molecules and water, enabling the esters to absorb water vapor more effectively. As a result, bubble formation is less likely or delayed in esters compared to mineral oil, which is less polar and less effective at absorbing water vapor.

As the paper ages, its cellulose chains break down due to chemical reactions like acid hydrolysis and oxidation, leading to shorter chains. This reduction in chain length makes the paper more fragile and brittle, weakening its strength and flexibility. Consequently, the paper becomes more prone to cracking or breaking under mechanical stress or thermal expansion. This brittleness diminishes its ability to withstand mechanical stress. As the paper loses its integrity, it becomes more susceptible to bubble formation at lower temperatures, lowering the BIT.

3.3. BIT Formula

Several studies, including those by Przybylek et al. [9,10], Koch and Tenbohlen [11], Oommen and Lindgren [19], and Hill et al. [20], have developed formulas for BIT as a function of WCP. Notably, all of these formulas, except Hill’s, are dependent on just WCP. However, this research indicates that BIT also depends on the degree of aging. Additionally, existing formulas are specific to mineral oil-impregnated KP or TUK, with no BIT equations available for ester-impregnated paper. Therefore, it is crucial to update the BIT formula to include both WCP and DP for mineral oil-impregnated KP and to develop a new formula for esters. The BIT formula could be represented as (1), as a function of WCP and P.

where a, b, and c are empirical constants. WCP is water content in paper and P is the total pressure in Torr, which includes atmospheric pressure and the pressure of the oil column.

However, according to the research by Hill et al. [19], the BIT equation could be adjusted taking into consideration the paper quality. For that, the coefficient b could be written as depicted in (2):

where n, α, and β are constants and DP is the degree of polymerization of paper.

Finally, the BIT equation is formulated as shown in (3):

Equation (3) provides a physically grounded approach to bubble formation by relating the BIT to fundamental parameters such as WCP (%), DP, and P (Torr), thereby capturing the key mechanisms involved in bubble inception within insulation systems. The BIT values in Table 1 are given in kelvin (K).

Table 1.

Formulas for BIT of MO-impregnated KP and SE-impregnated KP.

Data from Figure 4 and Figure 5 could be used to find the fitting formula of BIT for MO- and SE-impregnated KP. The fitting formulas are shown in Table 1. The pressure P in this study is 766 Torr. The proposed BIT equation is applicable for DP values in the range 1000–400 and WCP values in the range 0.5–5%.

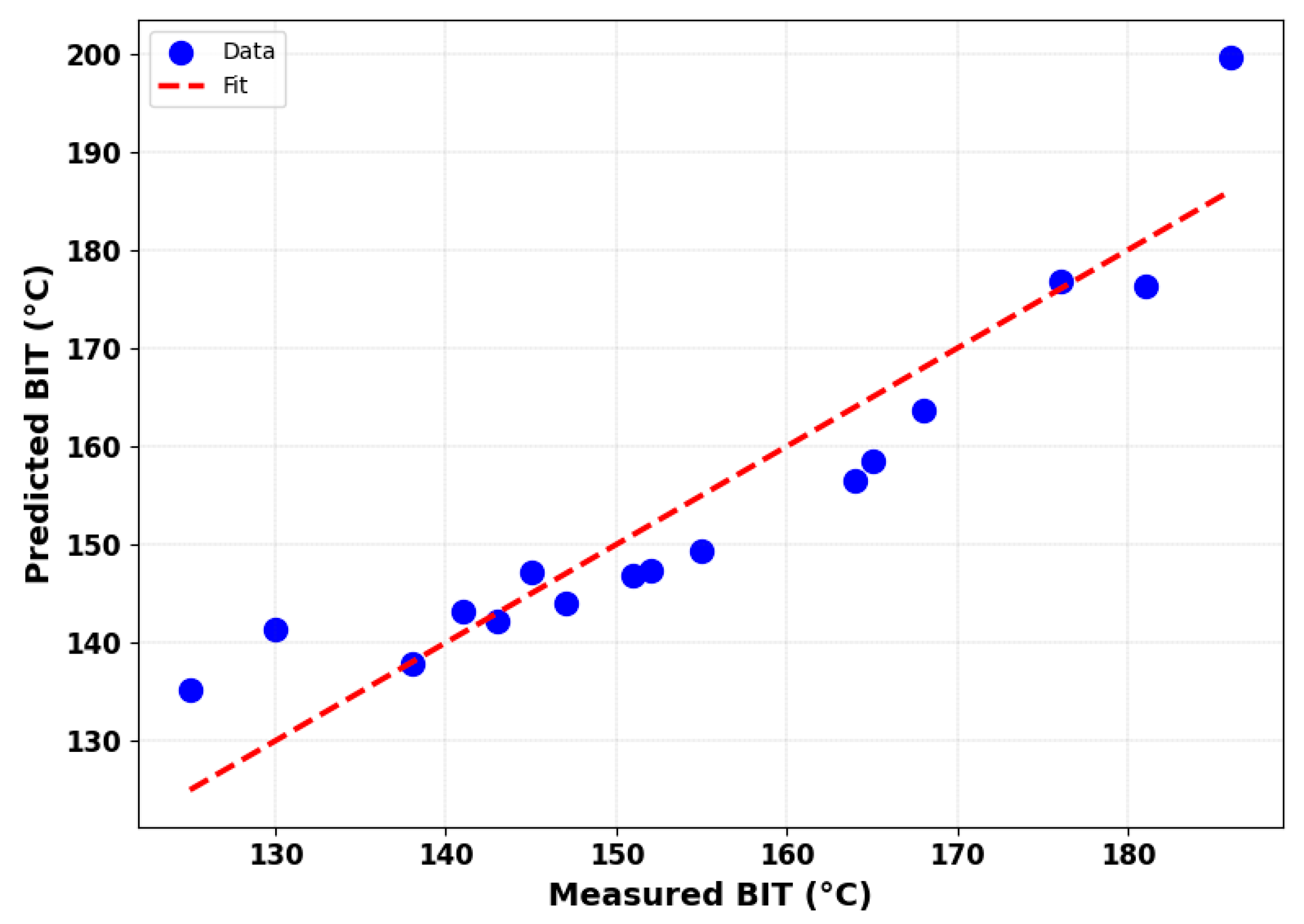

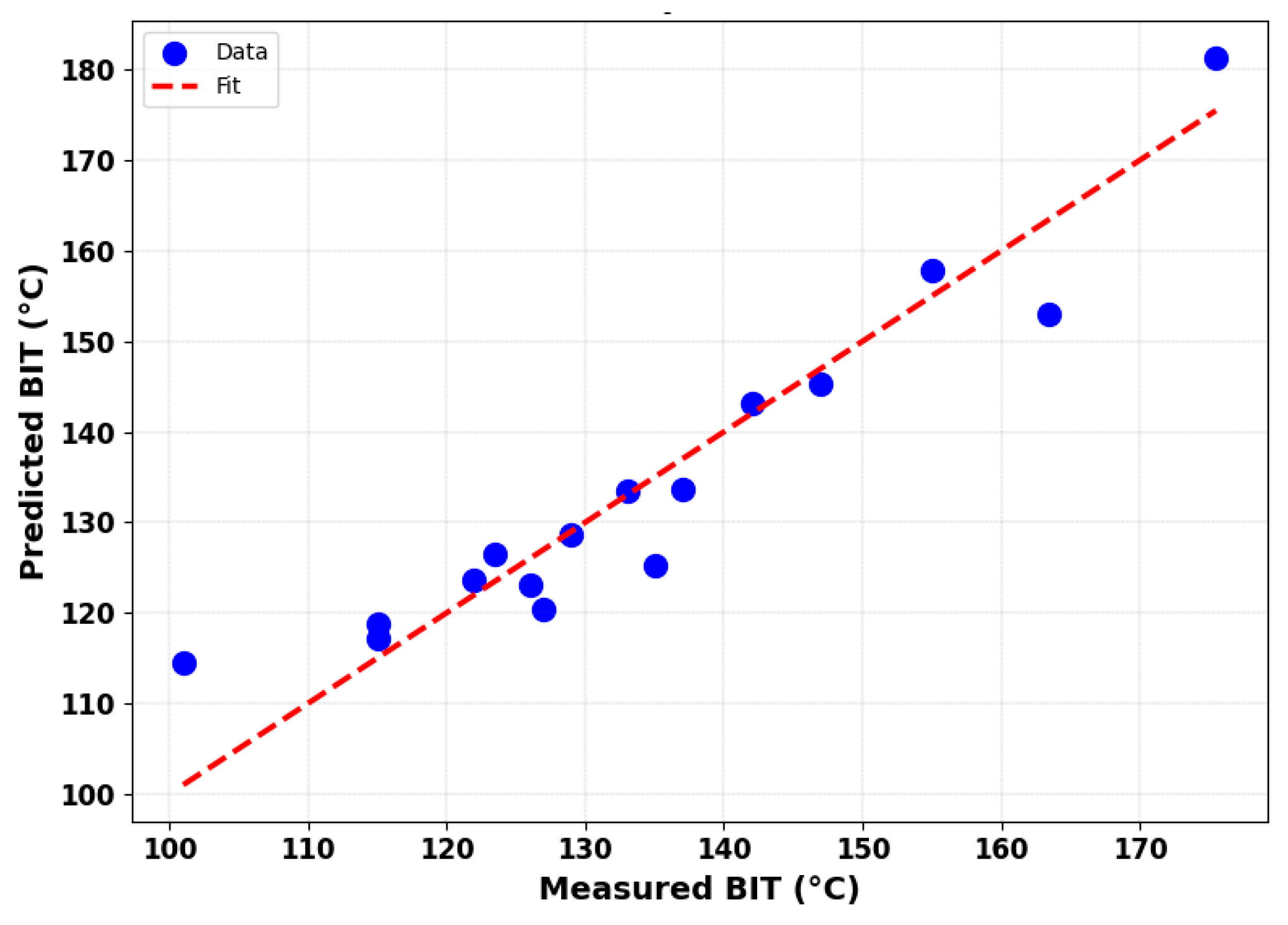

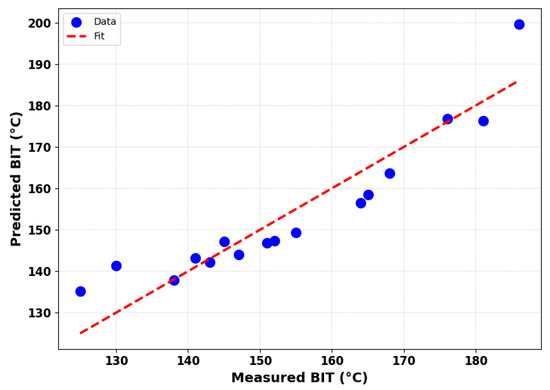

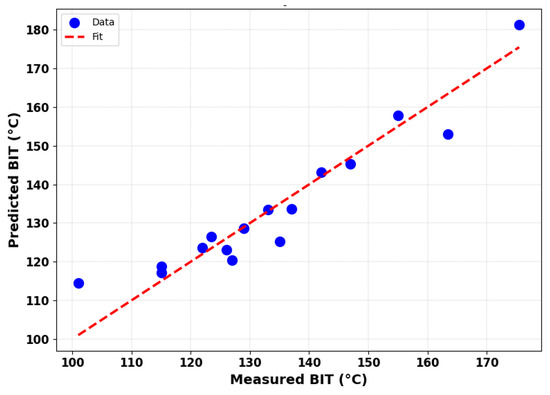

The fitted curves are compared with the experimental data, as shown in Figure 8 and Figure 9. These figures show a strong correlation between the measured and predicted BIT values, and this is especially true for MO-impregnated KP. The correlation coefficient (R2) for MO-impregnated KP is 0.904, which indicates a high degree of correlation and supports the robustness of the model for MO-insulated transformers. Although minor deviations are observed, most points closely align with the trend line, confirming the model’s predictive accuracy. For SE-impregnated KP, the R2 value is slightly lower at 0.864, suggesting a good but less strong correlation compared to MO.

Figure 8.

Comparison of measured and predicted BIT values for SE-impregnated KP.

Figure 9.

Comparison of measured and predicted BIT values for MO-impregnated KP.

3.4. Maximum Loading

In this study, the maximum load capacity () that can be safely applied to a transformer is determined using a mathematical model. This model integrates the thermal model outlined in the IEC standard 60076-7 [21] and the BIT formulas derived in this paper. The thermal model allows for the determination of the top-oil and hot-spot temperatures, as described by Equations (4)–(8). This model takes as inputs the load , ambient temperature , and includes constants such as the oil exponent x, the load to no-load losses ratio R, the oil time constant , the winding time constant , and the coefficients , , and . Additionally, is the hot-spot-to-top-oil gradient at rated current and is the top-oil temperature rise in steady state at rated losses. To avoid errors, the hot-spot temperature rise over the top-oil temperature is calculated as the difference between two hot-spot gradients, . The outputs of the thermal model are oil temperature and hot-spot temperature . The thermal parameters used in this study are shown in Table 2.

Table 2.

Thermal parameters.

The differential equation for determining the top-oil temperature is given by (4):

The differential equation for the hot-spot temperature rise can be solved by expressing it as the sum of two differential equations, as per (5):

where and can be calculated as (6) and (7):

The solutions for these differential equations are combined according to (5). The final equation for the hot-spot temperature is given by (8):

After calculating , the moisture diffusion model described in [5] is applied to compute the evolution of WCP, which subsequently enables the determination of BIT.

The initial load is assumed to be in a steady state, and is adjusted to achieve a hot-spot temperature of 110 °C before a step-load increase to .

The calculation of under short-term emergency conditions is performed with the margin of safety against bubbling (MSB) set to zero (MSB = 0) within 30 min, indicating the onset of bubble formation. The is directly linked to the hot-spot temperature () and the through a specific relationship, as shown in (9):

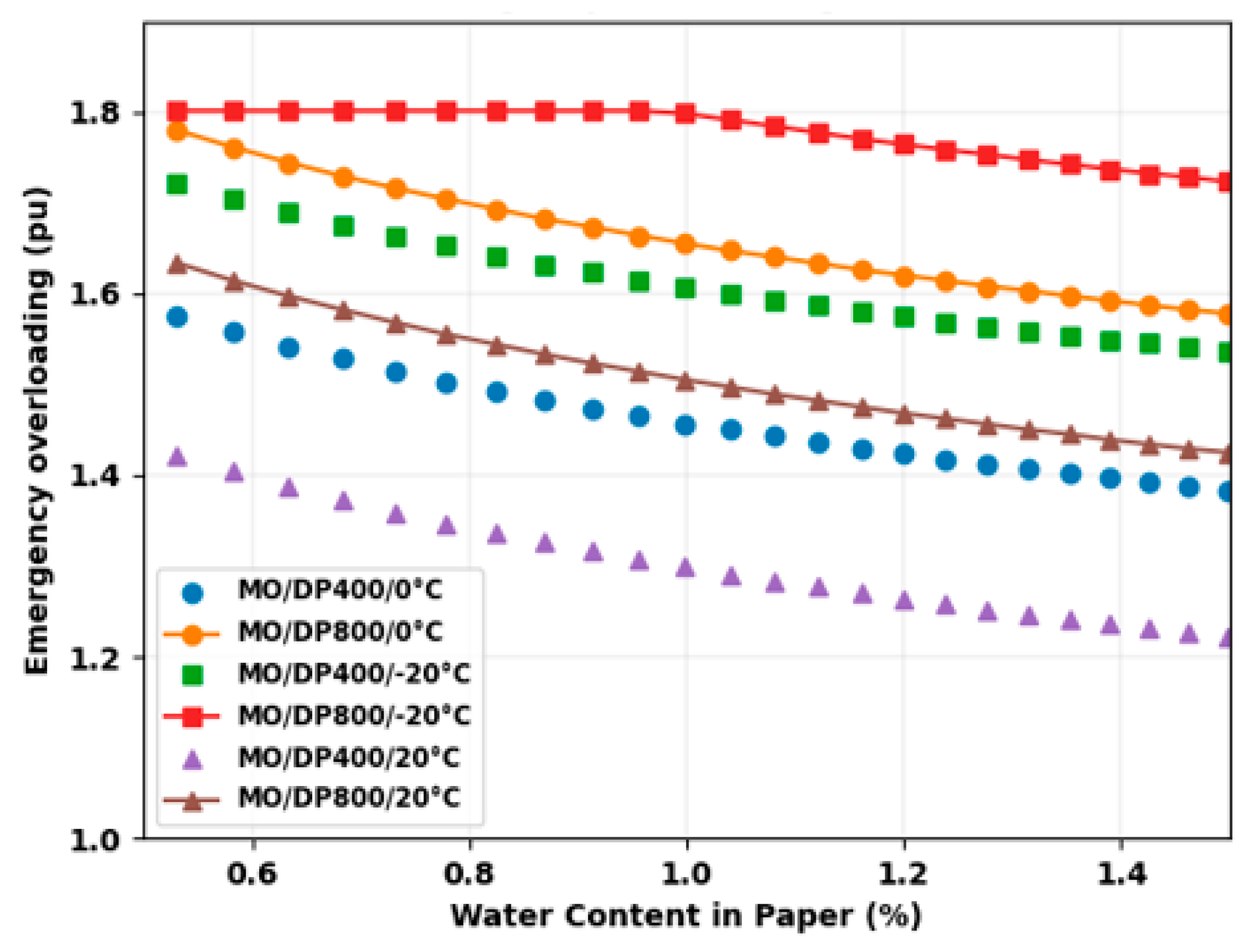

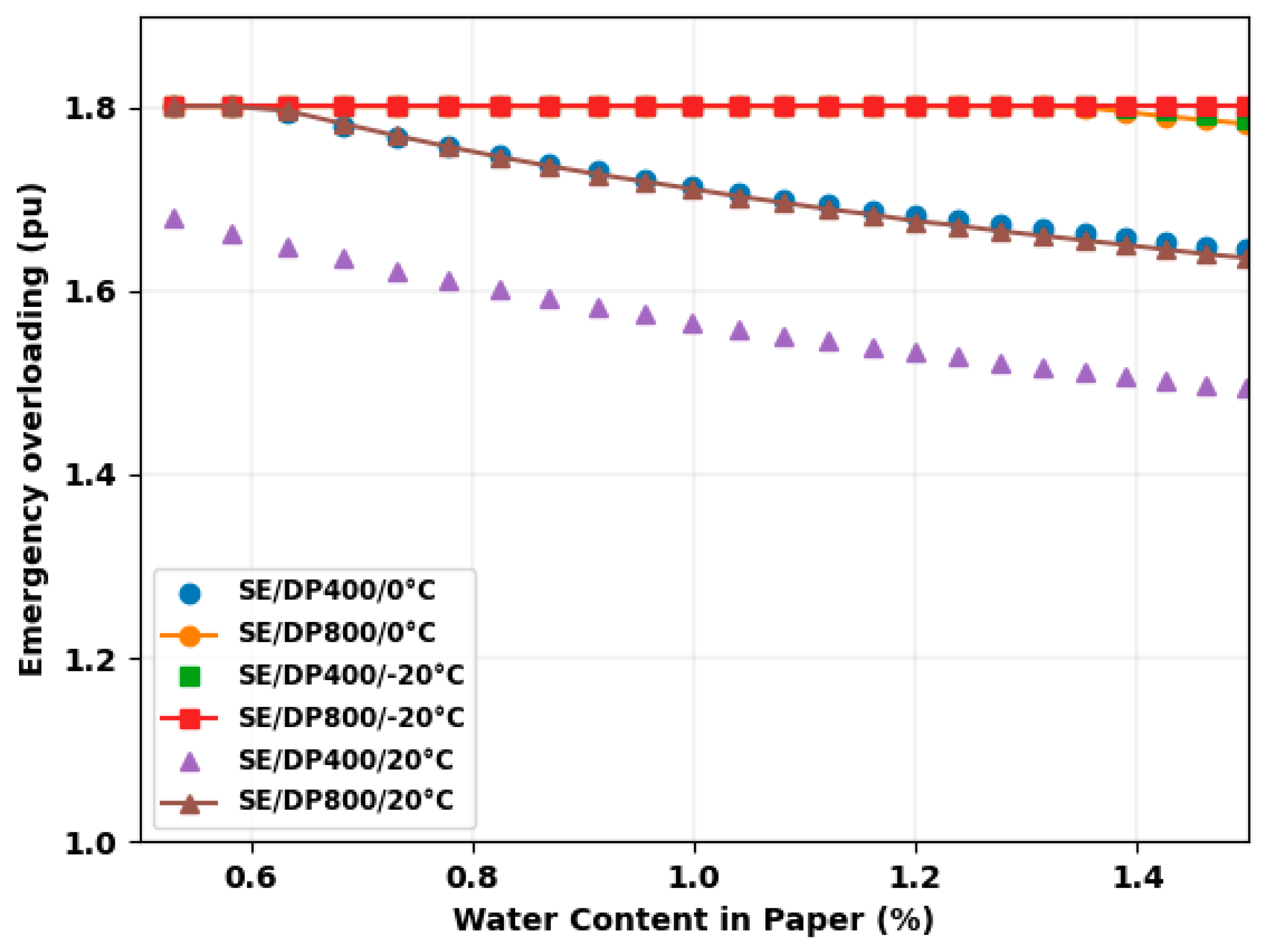

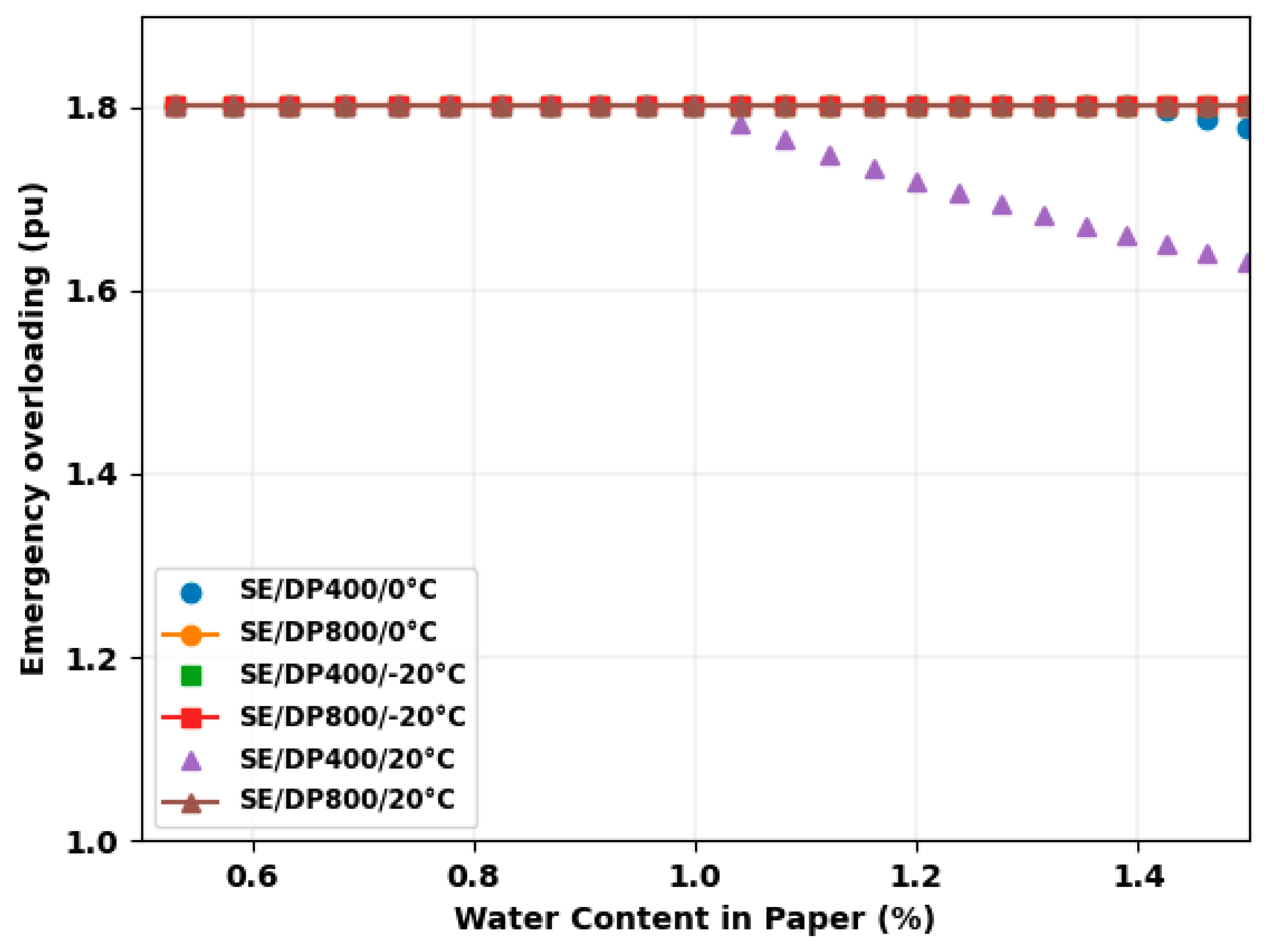

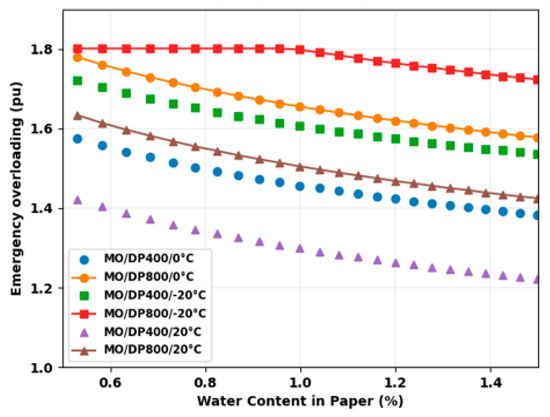

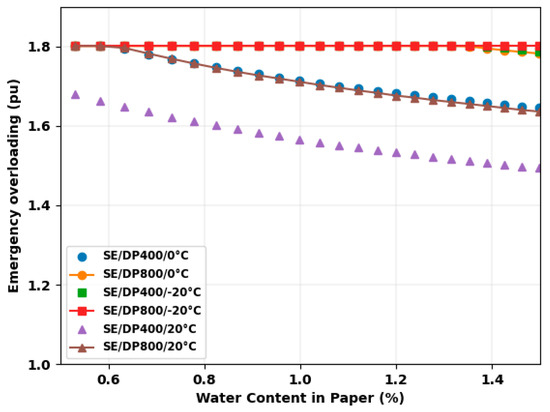

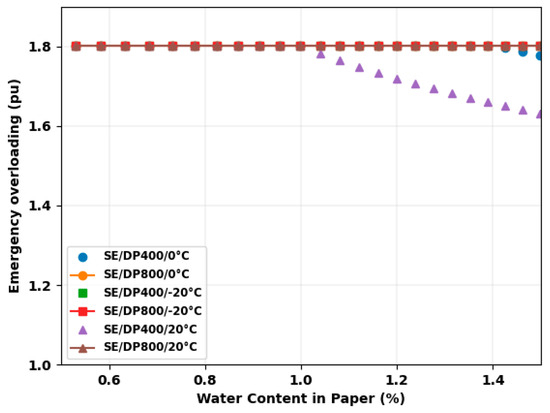

Figure 10 and Figure 11 present the values for MO and SE, respectively, across various combinations of WCP and ambient temperatures. The simulation considers two DP values (800 and 400) and three ambient temperatures (−20 °C, 0 °C, 20 °C), with the maximum load set at 1.8 p.u.

Figure 10.

Emergency overloading as a function of water content in paper (constant WCP) for different degrees of polymerization and ambient temperatures for MO.

Figure 11.

Emergency overloading as a function of water content in paper (constant WCP) for different degrees of polymerization and ambient temperatures for SE.

Figure 10 and Figure 11 highlight the differences in values between mineral oil and SE-impregnated solid insulation, emphasizing the superior performance of SE. Note, however, that the thermal parameters were set identically for MO- and SE-impregnated transformers. Synthetic ester consistently exhibits higher or equal values compared to mineral oil under the same conditions, demonstrating its better moisture management properties. This indicates that SE is more reliable for maintaining transformer performance, particularly in scenarios involving higher moisture levels or more degraded insulation. Additionally, is significantly higher for solid insulation in less aged material, as indicated by a higher DP (DP = 800). This reflects the ability of less-degraded insulation to withstand higher loads without risking the onset of bubble formation. Furthermore, as expected, decreases as the water content in the paper insulation (WCP) increases. This trend underscores the importance of maintaining low WCP levels to ensure that the transformer can operate safely at higher loads. The 1.8 p.u. represents the maximum emergency overloading limit considered in this study. This limit is reached in cases of high-DP insulation combined with low ambient temperature, conditions under which the system can sustain the maximum permissible overloading before the onset of bubbling.

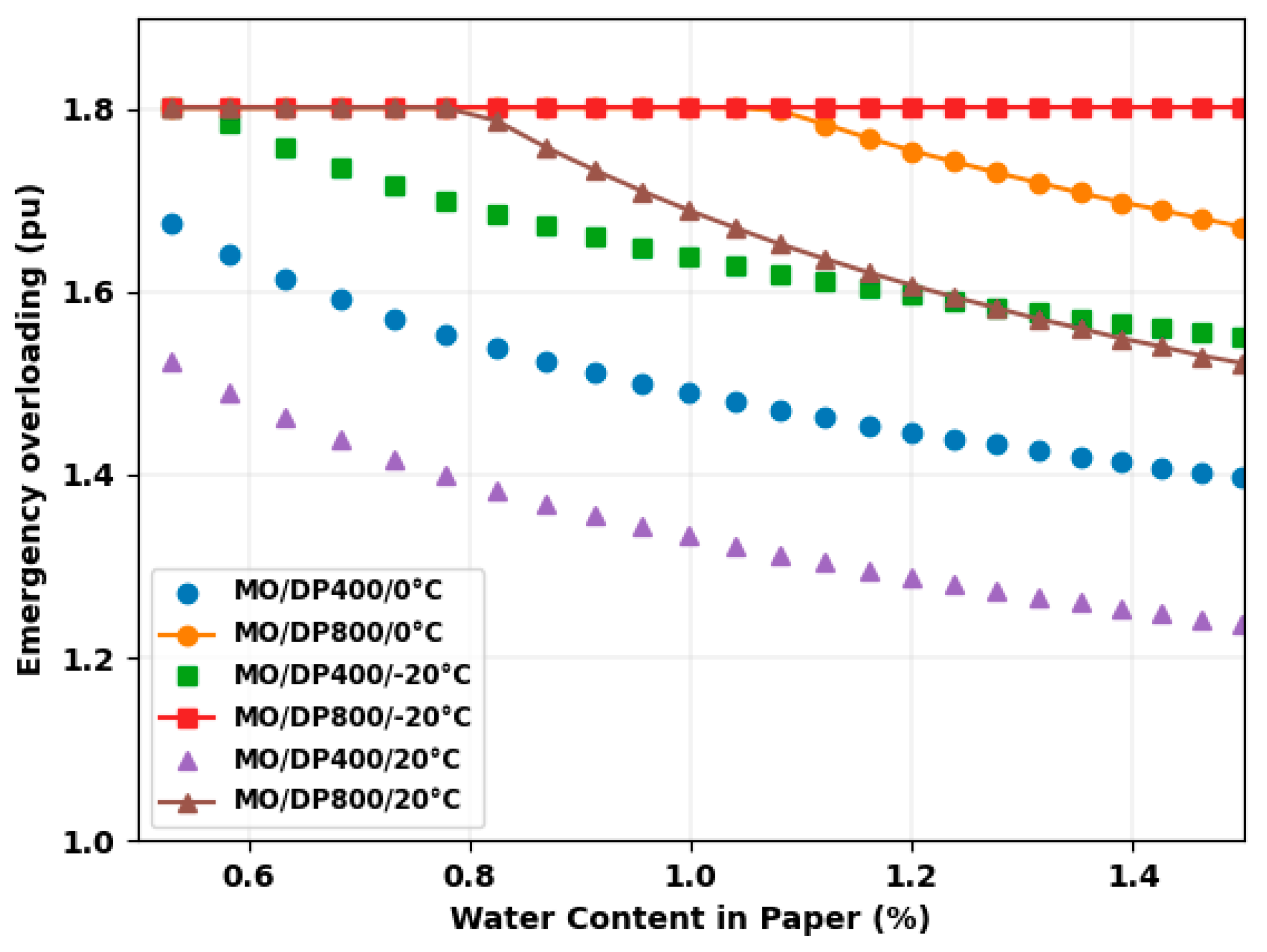

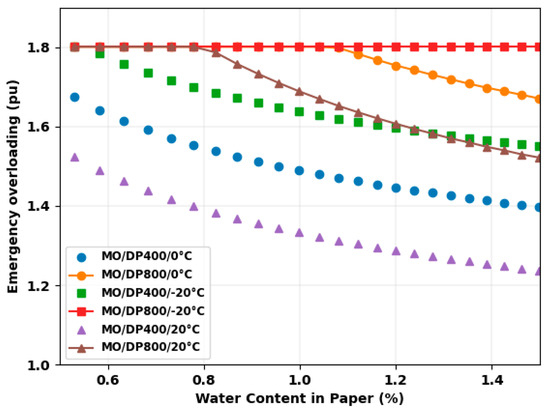

Figure 10 and Figure 11 show the maximum emergency overloading as a function of WCP, assuming that the WCP remains constant after the step-load increase. In contrast, Figure 12 and Figure 13 illustrate the maximum emergency overloading, assuming a constant water content in oil, meaning that the WCP at the hot-spot location varies according to the diffusion coefficient.

Figure 12.

Emergency overloading as a function of water content in paper (variable WCP) for different degrees of polymerization and ambient temperatures for MO.

Figure 13.

Emergency overloading as a function of water content in paper (variable WCP) for different degrees of polymerization and ambient temperatures for SE.

A constant WCP scenario is deemed to be more conservative because it overestimates the actual WCP during sudden load increases by ignoring the water transfer to the oil. This approach offers a greater margin of safety by considering the worst-case conditions that may not fully occur in real-life scenarios, thereby ensuring that the system remains robust across a wide range of operating situations.

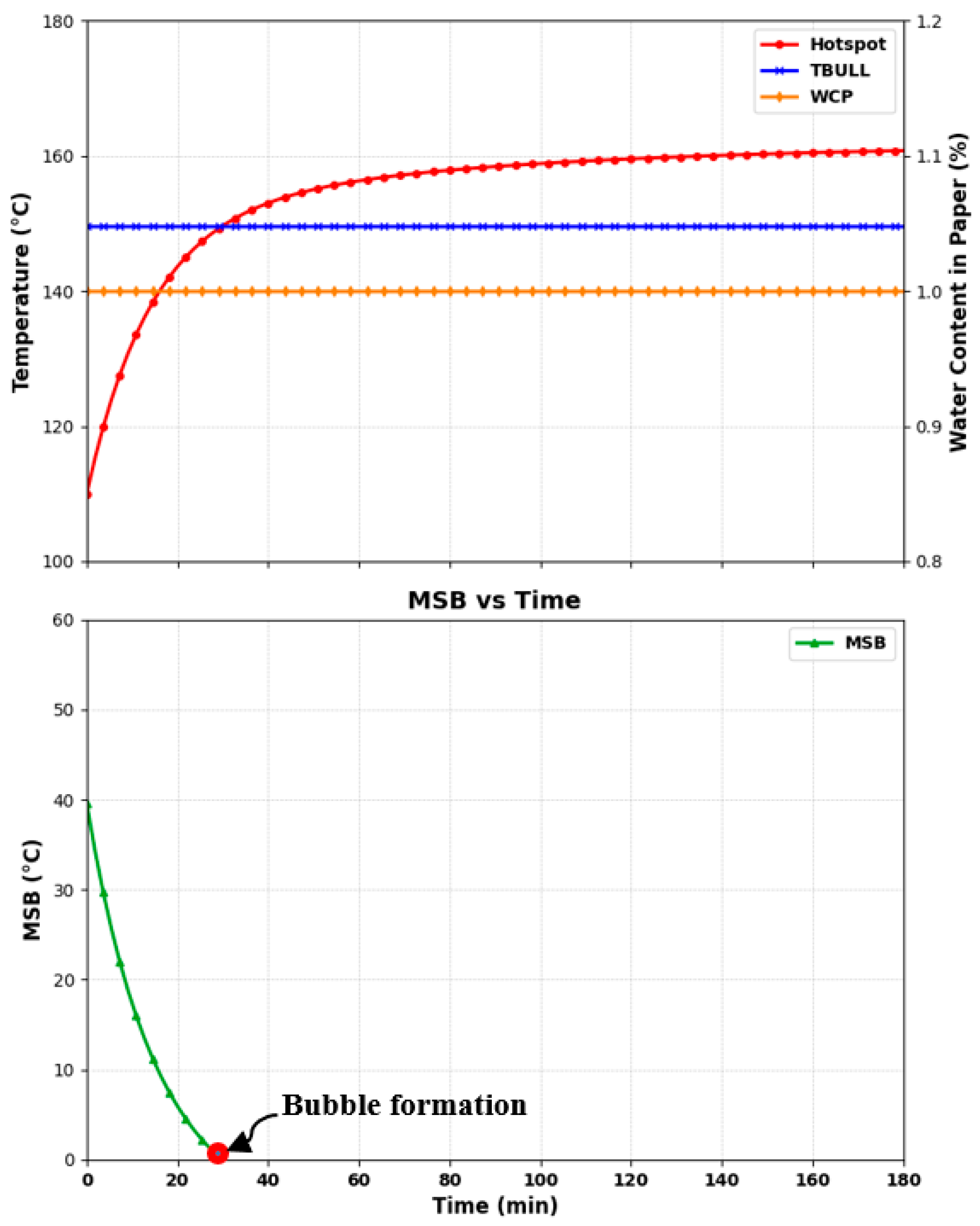

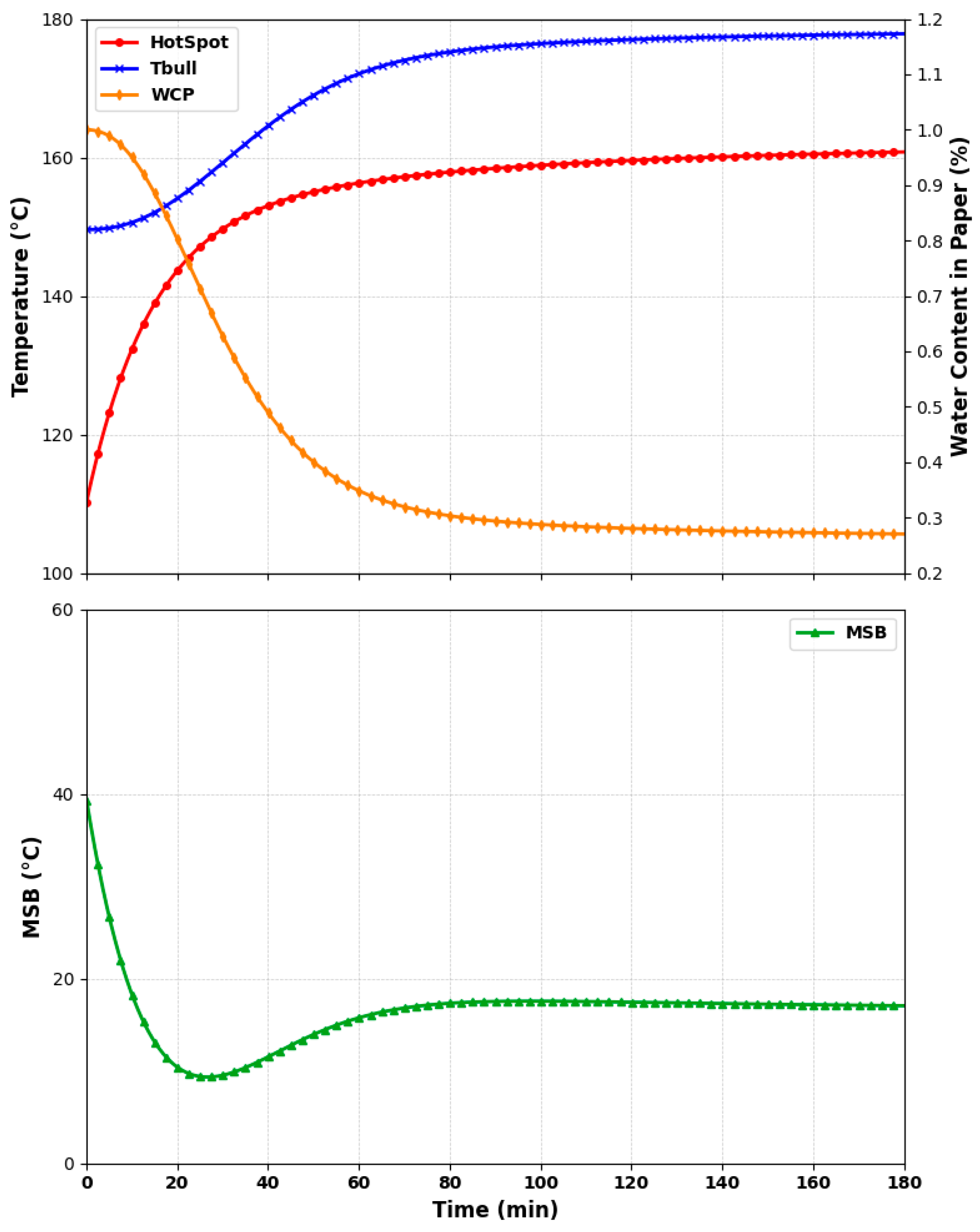

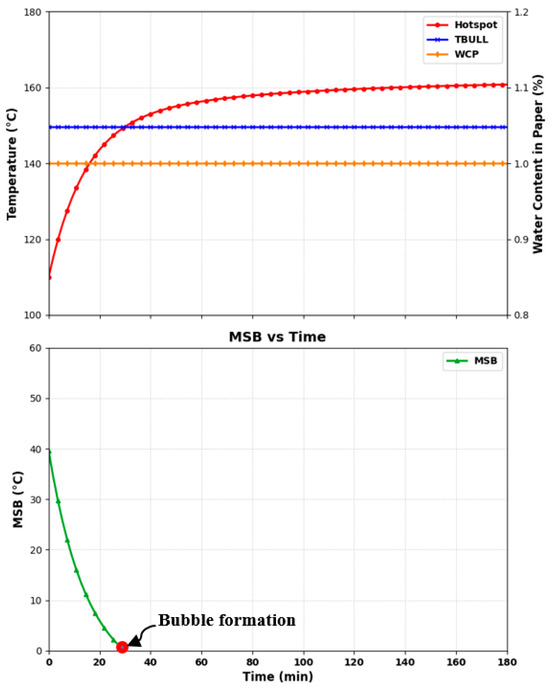

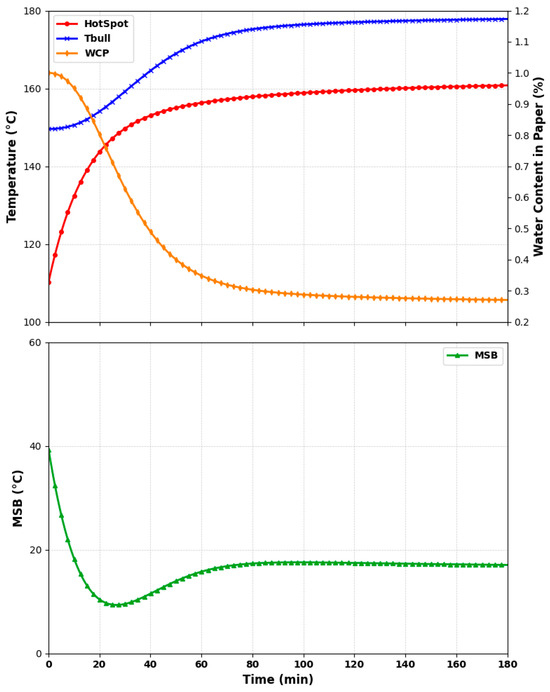

Figure 14 and Figure 15 analyze the hot-spot temperature, BIT, MSB, and WCP, using MO as the insulating fluid. In both figures, the DP is set to 800, and the ambient temperature is maintained at 20 °C. The initial load is set at 1.089 p.u, and the final load is 1.505 p.u.

Figure 14.

Modeling of hot-spot temperature, BIT, WCP, and MSB over time under constant WCP conditions.

Figure 15.

Modeling of hot-spot temperature, BIT, WCP, and MSB over time under variable WCP conditions.

Figure 14 focuses on scenarios with a constant WCP. In contrast, Figure 15 examines scenarios with variable WCP, highlighting the dynamic impact of fluctuating moisture levels on bubble formation in the transformer insulation system. Both figures start with a load of 1.089 p.u, corresponding to an initial hot-spot temperature of 110 °C, which progressively rises due to the step-load increase. The critical moment of bubbling is indicated by MSB = 0.

The results presented in Figure 14 and Figure 15 confirm the more conservative nature of the calculation under a fixed WCP. The actual maximum emergency overload should be within the range of values obtained from the two simulated scenarios. To achieve more accurate simulation results, a significantly more complex model would be required, incorporating details such as winding construction, the mass of cellulosic material, the quantity of oil, and the temperature distribution within the transformer’s active part. This level of simulation is beyond the scope of this research.

4. Discussion

This study provides a comprehensive analysis of the BIT in KP immersed in MO and SE, emphasizing the critical role of water content and aging in the risk of bubbling within insulation systems in power transformers. The results demonstrate that both moisture and aging significantly decrease the BIT. This phenomenon is particularly concerning in aged transformers, where the degradation of the paper’s DP exacerbates the risk of bubbling.

When comparing these findings with the existing literature, our study aligns with prior research that underscores the influence of moisture on reducing BIT. For instance, the work by Wilhelm et al. [4] and Gao et al. [7] also observed a significant drop in BIT with increased water content. However, this study goes further by incorporating the effects of aging, highlighting that the combined impact of moisture and degradation is more pronounced than previously reported. Unlike the studies by Przybylek et al. [8,9,10] and Koch et al. [11], which presented somewhat contradictory results regarding the effect of aging on BIT, this research provides a more nuanced understanding. It shows that while aging generally decreases BIT, the extent of this reduction depends on the specific interaction between moisture content and DP.

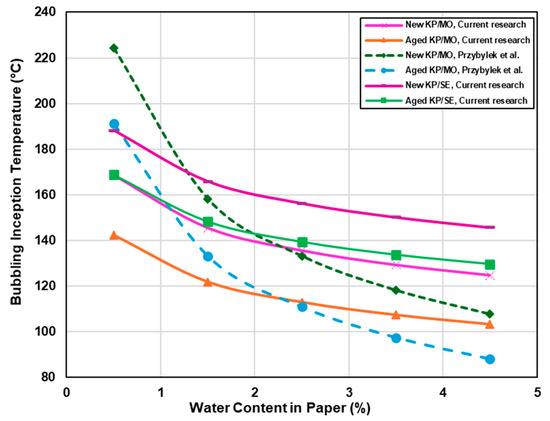

As aforementioned, Hill’s model is used in this study. Table 3 compares the empirical coefficients used to model the behavior of mineral oil (MO)-impregnated Kraft paper (KP) between the current research and Hill’s model [20]. In fact, the coefficients reported by Hill, shown in Table 3, were obtained based on the experimental setup and results presented in [9,10].

Table 3.

Comparison of empirical coefficients between current research and Hill [20] for MO-impregnated KP.

Figure 16 compares the predicted bubble inception temperatures (BIT) for two insulation conditions, new paper (DP = 1000) and aged paper (DP = 400), based on the current research model and Hill’s formulation [20] based on Przybylek’s research [10,11]. A significant difference is observed between the two datasets. These discrepancies may be attributed to differences in experimental setups, laboratory conditions, material types, or pre-treatment procedures used in the respective studies.

Figure 16.

Comparison of predicted and experimental Bubble Inception Temperatures for new (DP = 1000) and aged (DP = 400) cellulosic insulation [8,9].

The proposed model demonstrates enhanced relevance compared to existing formulations, including the well-established model by Hill [20]. While Hill’s approach provides a valuable foundation, it is based on coefficients derived from previous studies conducted under varying conditions. In contrast, the present model relies on parameters obtained directly from the current experimental campaign, ensuring consistency in applied conditions, sample preparation, and material origin.

The comparative analysis between mineral oil and synthetic esters also offers new insights. While previous research, such as that by Perkasa et al. [12], indicates that esters have higher BITs due to their hygroscopic nature, our study not only confirms this, but also demonstrates that esters maintain higher BITs even under varied aging conditions, further establishing their superiority in managing moisture.

By gaining a deeper understanding of the factors influencing BIT, engineers can devise more effective strategies for managing moisture content and monitoring the aging process in insulation systems, potentially leading to the development of more resilient transformers that can safely operate under higher thermal loads.

In future work, the authors aim to include accompanying microscopic comparative images to better illustrate the bubble formation associated with insulation paper degradation. Such visual evidence would further support the observed relationship between aging, moisture content, and bubble initiation. Furthermore, a comparative investigation involving TUK under similar conditions is planned to broaden the scope and practical relevance of the findings. The proposed BIT modeling framework can be extended to other insulation papers (e.g., TUK) by recalibrating the empirical coefficients to reflect material-specific properties. Furthermore, regression could also be reformulated in a different mathematical form and, if necessary, with a reduced number of coefficients to simplify the fitting process and minimize potential difficulties in parameter estimation.

In addition, the influence of varying Kraft paper dimensions and thicknesses on BIT will be explored to assess the model’s applicability across a wider range of insulation geometries. Moreover, complementary characterizations, such as oil viscosity, dissolved gas content, and paper composition (e.g., fiber structure and additives), are also planned to further clarify the physicochemical mechanisms underlying the observed BIT variations. Finally, given that the proposed BIT models are empirical and based on specific materials and controlled laboratory conditions, future research will aim to validate, refine, and adapt these models across diverse insulation systems and real-world operating environments, thereby improving their robustness and enhancing their general applicability. In this study, validation was carried out using laboratory measurements under simulated transformer conditions, showing satisfactory agreement with model predictions. However, additional validation using real-world transformer measurements and independent datasets is recommended to enhance their robustness and ensure applicability to in-service equipment.

A practical software tool enabling engineers to input key parameters and estimate BIT under specific conditions for operational decision-making would be of considerable interest. Additional data collection from diverse insulation systems and service conditions will be essential to support and optimize such an application.

5. Conclusions

This study provides a comprehensive analysis of the BIT in KP impregnated with mineral oil and synthetic ester under various conditions, using a robust and well-designed methodology. The BIT is examined as a function of WCP and DP, uncovering significant influences of both moisture content and aging on the thermal stability of transformer insulation systems. The findings confirm that the BIT decreases with increasing WCP and insulation aging, highlighting the critical role of these factors in determining the performance and reliability of transformer insulation.

Predictive empirical formulas for BIT as a function of WCP and DP were developed for both mineral oil (MO)- and synthetic ester (SE)-impregnated insulation papers. These mathematical models provide valuable tools for assessing insulation performance and identifying operational thresholds. Additionally, this study quantifies the maximum load that transformers can safely support under various operating conditions. The results demonstrate that SE-filled transformers have a significantly higher loading capacity impregnated compared to MO-filled transformers. This enhanced performance of synthetic esters is attributed to their superior ability to manage moisture, thereby reducing the risk of bubble formation under elevated thermal and moisture stresses. Identifying the BIT based on different insulation systems (Kraft/TUK/Aramid paper and the type of impregnant) and conditions (temperature, moisture content, IFT, acidity, and DP, which can be estimated from furan or methanol analyses) may enable engineers to define safe operating thresholds, thereby minimizing the likelihood of bubble generation.

Author Contributions

Conceptualization and methodology, G.G., I.F., P.P. and O.H.A.-F.; formal analysis, G.G., P.P., I.F. and O.H.A.-F.; data curation, G.G., Y.B. and K.M.L.Y.; writing—original draft preparation, G.G.; writing—review and editing, P.P., I.F., O.H.A.-F., D.R., F.M., Y.B. and K.M.L.Y.; supervision, I.F., P.P. and D.R.; funding acquisition, I.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Sciences and Engineering Research Council of Canada (NSERC), Hydro-Québec (Grant No. RDCPJ513264-17), InnovÉÉ (Grant No. R11-1707), and the IEEE DEIS Graduate Fellowship 2023.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Fofana, I.; Hadjadj, Y. Power Transformer Diagnostics, Monitoring and Design Features. Energies 2018, 11, 3248. [Google Scholar] [CrossRef]

- Wei, W.; Chen, H.; Zha, J.; Zhang, Y. Research Progress on Low Dielectric Constant Modification of Cellulose Insulating Paper for Power Transformers. Front. Chem. Sci. Eng. 2023, 17, 991–1009. [Google Scholar] [CrossRef]

- Gmati, G.; Rao, U.M.; Fofana, I.; Picher, P.; Arroyo-Fernàndez, O.; Rebaine, D. Bubbling Phenomena in Liquid-Filled Transformers: Background and Assessment. Energies 2023, 16, 3829. [Google Scholar] [CrossRef]

- Wilhelm, H.M.; Ferraz, L.A.; Ferreira, J.L.B.P.; Affeldt, J.M. Study of Bubbles Evolution in Mineral Oil-Paper Insulating System under Sudden Changes in Temperature. In Proceedings of the 2021 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Vancouver, BC, Canada, 17–20 October 2021; pp. 547–550. [Google Scholar] [CrossRef]

- Gmati, G.; Fofana, I.; Picher, P.; Meghnefi, F.; Arroyo-Fernández, O.A.; Rebaine, D.; Brahami, Y.; Kouba, Y.M.L. Bubbling Inception Temperature in Power Transformers—Part 1: Comparative Study of Kraft Paper, Thermally Upgraded Kraft Paper, and Aramid Paper with Mineral Oil. IEEE Access 2025, 13, 51287–51299. [Google Scholar] [CrossRef]

- Gmati, G. Modélisation et Etude Expérimentale de la Température de Formation des Bulles dans les Systèmes D’isolation des Transformateurs. Ph.D. Thesis, Université du Québec à Chicoutimi, Saguenay, QC, Canada, 2025. Available online: https://constellation.uqac.ca/id/eprint/10177/ (accessed on 19 August 2025).

- Gao, M.; Zhang, Q.; Ding, Y.; Wang, T.; Ni, H.; Yuan, W. Investigation on Bubbling Phenomenon in Oil-Paper Insulation. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2362–2370. [Google Scholar] [CrossRef]

- Przybylek, P. The Influence of Temperature and Aging of Cellulose on Water Distribution in Oil-Paper Insulation. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 552–556. [Google Scholar] [CrossRef]

- Przybylek, P. The influence of cellulose insulation aging degree on its water sorption properties and bubble evolution. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 906–912. [Google Scholar] [CrossRef]

- Przybylek, P. A comparison of bubble evolution temperature in aramid and cellulose paper. In Proceedings of the 2013 IEEE International Conference on Solid Dielectrics (ICSD), Bologna, Italy, 7 October 2013; pp. 983–986. [Google Scholar] [CrossRef]

- Koch, M.; Tenbohlen, S. Evolution of Bubbles in Oil-Paper Insulation Influenced by Material Quality and Ageing. IET Electr. Power Appl. 2011, 5, 168–174. [Google Scholar] [CrossRef]

- Perkasa, C.Y.; Lelekakis, N.; Wijaya, J.; Martin, D. Investigating Bubble Formation in Vegetable and Mineral Oil Impregnated Transformer Paper Insulation Systems. In Proceedings of the 2012 22nd Australasian Universities Power Engineering Conference (AUPEC), Bali, Indonesia, 26–29 September 2012; pp. 1–5. [Google Scholar]

- ASTM D971-20; Standard Test Method for Interfacial Tension of Insulating Liquids Against Water by the Ring Method. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM D974-22; Standard Test Method for Acid and Base Number by Color-Indicator Titration. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- ASTM D4243-99; Standard Test Method for Measurement of Average Viscometric Degree of Polymerization of New and Aged Electrical Papers and Boards. ASTM International: West Conshohocken, PA, USA, 1999.

- IEC 60554-2:2001; Cellulosic Papers for Electrical Purposes—Part 2: Methods of Test. International Electrotechnical Commission: Geneva, Switzerland, 2001.

- IEC 60296:2020; Fluids for Electrotechnical Applications—Mineral Insulating Oils for Electrical Equipment. International Electrotechnical Commission: Geneva, Switzerland, 2020.

- IEC 61099:2010; Insulating Liquids—Specifications for Unused Synthetic Organic Esters for Electrical Purposes. International Electrotechnical Commission: Geneva, Switzerland, 2010.

- Oommen, T.V.; Lindgren, S.R. Bubble Evolution from Transformer Overload. In Proceedings of the 2001 IEEE/PES Transmission and Distribution Conference and Exposition. Developing New Perspectives (Cat. No. 01CH37294), Atlanta, GA, USA, 28 October–2 November 2001; Volume 1, pp. 283–289. [Google Scholar] [CrossRef]

- Hill, J.P.; Wang, Z.; Liu, Q.; Matharage, S.; Hilker, A.; Walker, D. Improvements to the Construction of Bubble Inception Formulae for Use with Transformer Insulation. IEEE Access 2019, 7, 171673–171683. [Google Scholar] [CrossRef]

- IEC 60076-7; Power Transformers—Part 7: Loading Guide for Oil-Immersed Power Transformers. International Electrotechnical Commission: Geneva, Switzerland, 2018.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).