Abstract

Linear motor electromagnetic energy regenerative suspension (LMEERS), integrating dual functionalities of energy regeneration and active control, possesses the potential to overcome the performance limitations inherent in existing suspension architectures. Research on key technologies for LMEERS aligns with the contemporary automotive development theme of “enhanced comfort, improved safety, and optimized energy efficiency”. This paper reviews the research progress of the configuration design, performance optimization, functionality switching criterion identification, and top-layer control strategies of LMEERS. Regarding configuration design, a systematic summary is provided for the design schemes of fundamental configuration and the technical features of three composite configurations. In the aspect of performance optimization, the specific approaches and their effectiveness in enhancing LMEERS comprehensive characteristics are analyzed. Concerning functionality switching criterion identification, the operating principles and performance differences among various estimation methods in identifying road surface information are discussed. For top-layer control strategies, the characteristics and applicability of various control methods in exploiting the dual functionalities of LMEERS are summarized. Future developments in LMEERS are anticipated to trend towards integration, lightweighting, standardization, intellectualization, and multi-mode operation. This review provides a theoretical reference for the design optimization and technological innovation of LMEERS, contributing to the advancement of automotive chassis systems in terms of electrification, intellectualization, and energy conservation.

1. Introduction

Automobiles serve as the most frequently utilized mode of daily transportation, offering substantial convenience to the public. However, the continuous growth of the global vehicle population has precipitated numerous societal challenges, including frequent traffic accidents, resource depletion, and environmental pollution, which adversely impacts quality of life. Therefore, extensive attention has been focused on automotive energy-saving technologies. In general, vehicle energy conservation primarily refers to subsystem-level energy efficiency, such as engine energy conservation (for internal combustion engine vehicles) [1,2], motor energy conservation (for electric vehicles) [3,4], braking system energy regeneration [5,6], and suspension system energy regeneration [7,8]. This approach aims to achieve comprehensive vehicle energy efficiency through optimization of individual subsystems. Additionally, advancements in battery chemistry, such as the development of high-energy-density lithium batteries and solid-state batteries, have significantly contributed to the further energy saving of vehicles by reducing weight and improving charge–discharge efficiency [9,10].

The suspension system serves as a critical automotive subsystem and is responsible for transmitting forces and moments between the vehicle body and wheels. It works to mitigate impacts, attenuate vibrations, and regulate vehicle body posture, thereby influencing all key vehicle dynamic performances, including ride comfort, handling stability, and driving safety [11]. Based on control methodologies, suspension systems are categorized as passive suspensions, semi-active suspensions, and active suspensions [12].

Conventionally, passive suspensions employing the traditional “spring-damper” architecture have difficulties in effectively balancing diverse vehicle dynamic performance requirements. Furthermore, the kinetic energy generated from suspension vibration is dissipated as heat into the atmosphere, representing significant energy loss. Although hydraulic active suspension and air active suspension demonstrably enhance vehicle dynamic performance [13,14], they are inherently constrained by the operating principles and intrinsic characteristics of their actuators. These systems commonly exhibit shared limitations, such as high energy consumption, response lag, and limited controllable bandwidth [15], hindering their ability to satisfy the future automotive imperatives. Addressing this technical challenge necessitates, first and foremost, the structural innovation of suspension systems. The design objective is to develop a novel suspension architecture capable of simultaneously fulfilling demanding dynamic performances and energy-saving properties for vehicles. This pursuit represents a major current focus and developmental direction in the automotive industry.

Currently, electromagnetic energy regenerative suspension (EERS) systems have garnered worldwide attention due to their significant advantages, including high power output, simple control implementation, extended service life, superior environmental adaptability, and the capability of seamless switching between vibration suppression and energy harvesting. Fu et al. [16] have laid a valuable foundation for understanding the general advancements in EERSs, particularly in the areas of structural research, optimal design methods, and control methods. These works provide a broad overview of various electromagnetic actuator types and their integration into vehicle suspensions, offering important insights into the field’s developmental trajectory.

However, most existing reviews predominantly tend to analyze and discuss the research progress in structural design and control strategies for all types of EERSs from a generalized perspective. In contrast, this paper focuses specifically on linear motor electromagnetic energy regenerative suspension (LMEERSs), which utilizes the linear motor as its actuator, integrating dual functionalities of energy regeneration and active control. On one hand, it enables the conversion of kinetic energy generated by suspension vibration into electrical energy for recovery and reuse, realizing indirect sub-system energy conservation. On the other hand, it can be actively controlled, significantly reducing the response time and expanding the controllable bandwidth of the control system [17]. Therefore, LMEERS possesses the potential to overcome the performance limitations inherent in existing suspension architectures. Research on its key technologies aligns with the current automotive development imperatives of electrification and energy conservation, holding significant theoretical importance and engineering application value for achieving a leap forward in the comprehensive performances of vehicles.

Unlike broader surveys, this paper delves deeply into the dual-functionality nature of LMEERS, emphasizing four key technologies:

- Principles and schemes of configuration design tailored to linear motors.

- Multidisciplinary performance optimization addressing critical operational characteristics of linear motors.

- Integration of functionality switching criterion identification for trade-off between dual functionalities.

- Selection of top-layer control strategies that fully exploit the dual-functionality capability of LMEERS.

Specifically, configuration design serves as the foundation for satisfying the functionality and reliability requirements of LMEERS. Performance optimization, focusing on structural refinement, parametric optimization, and intelligent control, represents a crucial pathway for further enhancing overall performance. Accurate road surface information identification is a prerequisite for the rational switching between LMEERS’s dual functionalities and the effective implementation of top-layer control strategies. Finally, efficient top-layer control strategies are the key to exploiting the dual functionalities.

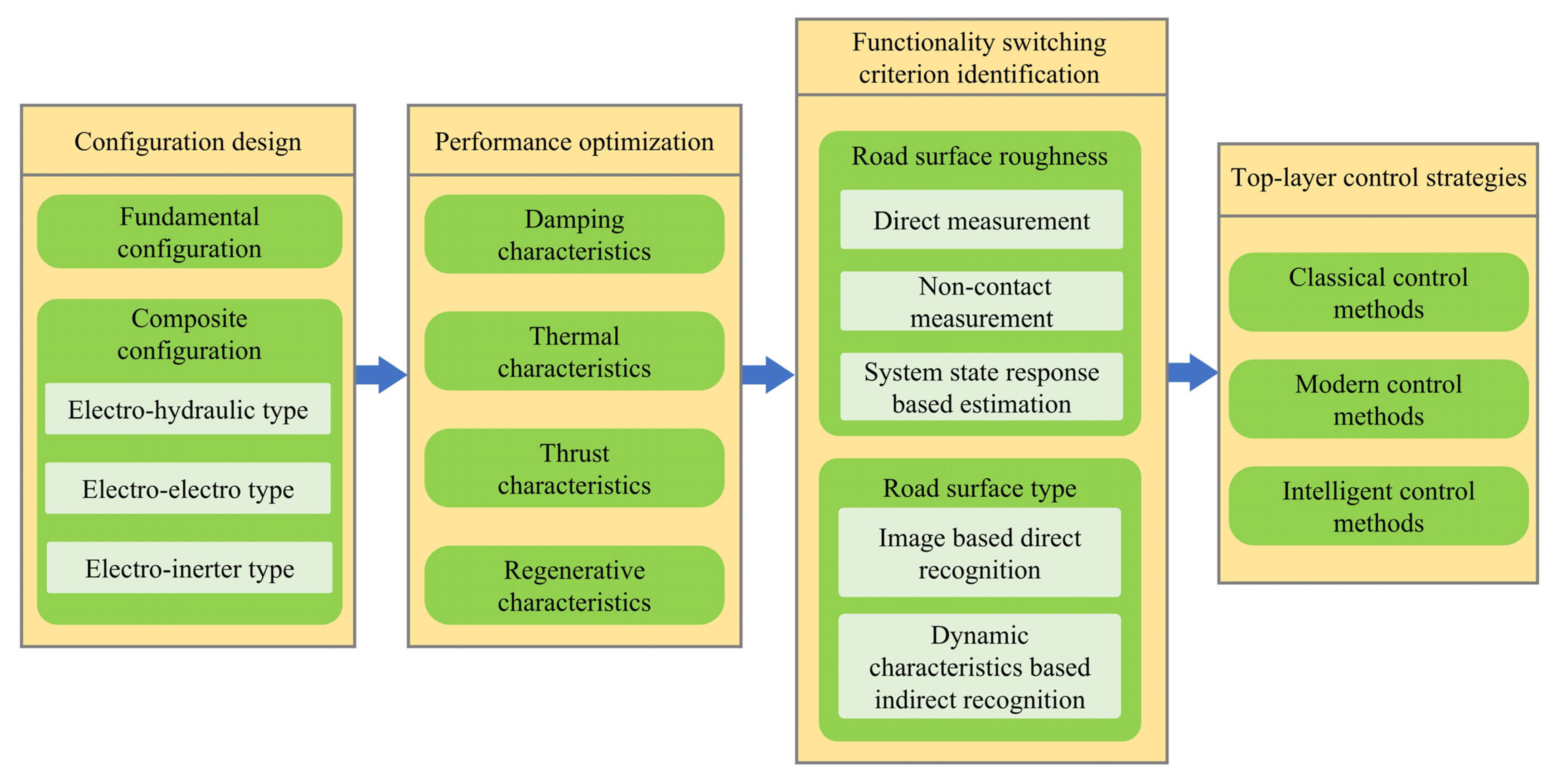

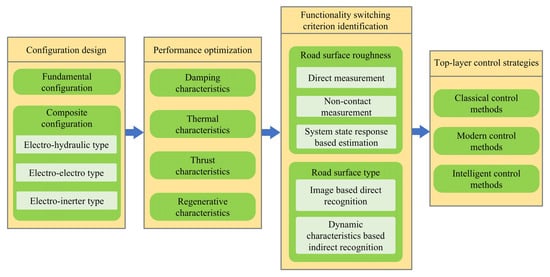

By concentrating on these aspects, this review offers a specialized and in-depth analysis that distinguishes it from more generalized surveys on EERS. It aims to serve as a targeted reference for researchers and engineers working on next-generation high-performance energy regenerative suspension systems centered on linear motor technology. The research framework is illustrated in Figure 1.

Figure 1.

Research framework.

This paper is organized as follows. Section 2 analyzes the structural features of fundamental and composite configurations of LMEERS. In Section 3, optimization pathways for the four primary operational characteristics, namely damping characteristics, thermal characteristics, thrust characteristics, and regenerative characteristics, are systematically summarized. Identification methodologies for two types of road surface information are reviewed in Section 4. A performance comparison of various top-layer control strategies applicable for LMEERS is conducted in Section 5. Section 6 discusses the existing challenges and future development trends in LMEERS. Conclusions are drawn in Section 7.

2. Configuration Design of LMEERS

2.1. Principle and Classification of Vibration Energy Regenerative Systems

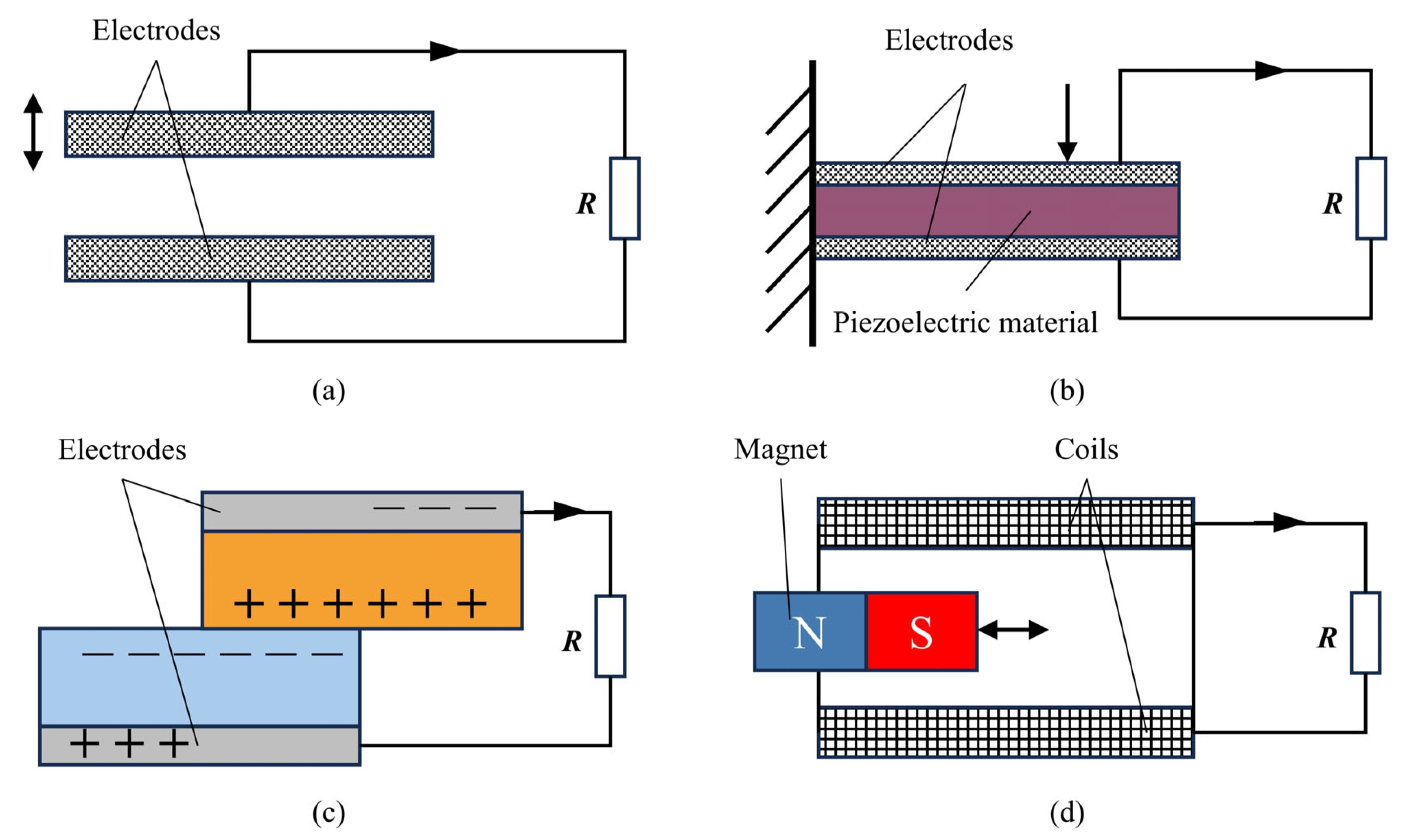

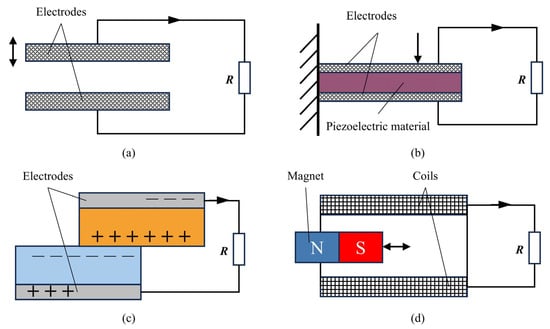

According to the underlying mechanisms for the conversion of vibration energy into electrical energy, energy regenerative approaches are categorized into four types: electrostatic, piezoelectric, triboelectric, and electromagnetic [18]. Their underlying mechanisms are illustrated in Figure 2, with a comparative summary provided in Table 1. Among them, electrostatic systems exhibit a high operating frequency range but suffer from limited load-bearing capacity [19]. Piezoelectric systems are constrained by a narrow operational bandwidth [20]. And triboelectric systems face challenges in reliability and durability [21]. Consequently, these three energy harvesting approaches are not viable for engineering applications in automotive suspension systems. In contrast, electromagnetic systems operate on Faraday’s law of electromagnetic induction, converting suspension vibration energy into electricity through the relative motion between coils and permanent magnets (PMs). This mechanism exhibits high compatibility with suspension systems in terms of structural characteristics and operating principles. Furthermore, electromagnetic systems offer significant advantages, including high power output, simple control implementation, extended service life, superior environmental adaptability, and the capability of seamless switching between vibration suppression and energy harvesting.

Figure 2.

Underlying mechanisms of the four energy harvesting technologies: (a) electrostatic type; (b) piezoelectric type; (c) triboelectric type; (d) electromagnetic type in Ref. [18].

Table 1.

Underlying mechanisms, core characteristics, and application status of vibration energy regenerative systems.

According to Faraday’s law of electromagnetic induction, the power generation capacity of the electromagnetic energy regenerative suspension (EERS) is closely related to the arrangement scheme, motion form, and relative velocity of PMs and coils. Based on the structure and arrangement features of the actuator, EERS can be classified into three primary configurations: rotary motor type [22], linear motor type [23], and composite type [24].

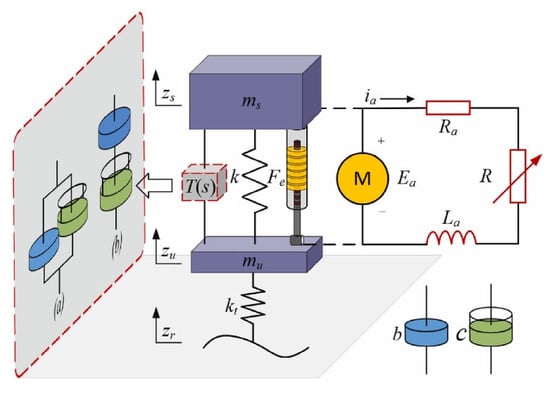

2.2. Fundamental Configuration of LMEERS

Unlike the rotary motor type, the actuator configuration of the linear motor type shares greater structural similarity with conventional hydraulic dampers. It comprises a stator and a mover, in which the mover is functionally analogous to the piston rod of a damper and connects to the vehicle body, and the stator corresponds to the damper cylinder tube and attaches to the wheel. During suspension vibration, relative linear motion occurs between the stator and mover. According to Faraday’s law of electromagnetic induction, the electric current is induced in the coils, thereby converting kinetic energy into electrical energy to achieve energy regeneration. Conversely, when alternating current is supplied to the coils, the mover generates an active force to suppress motion between the vehicle body and wheels, enabling active control functionality. It can be seen that LMEERS possesses dual functionalities of energy regeneration and active control.

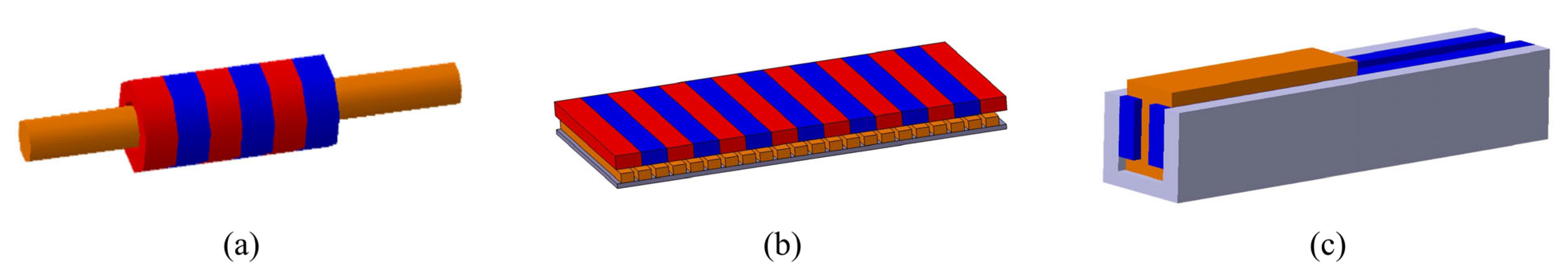

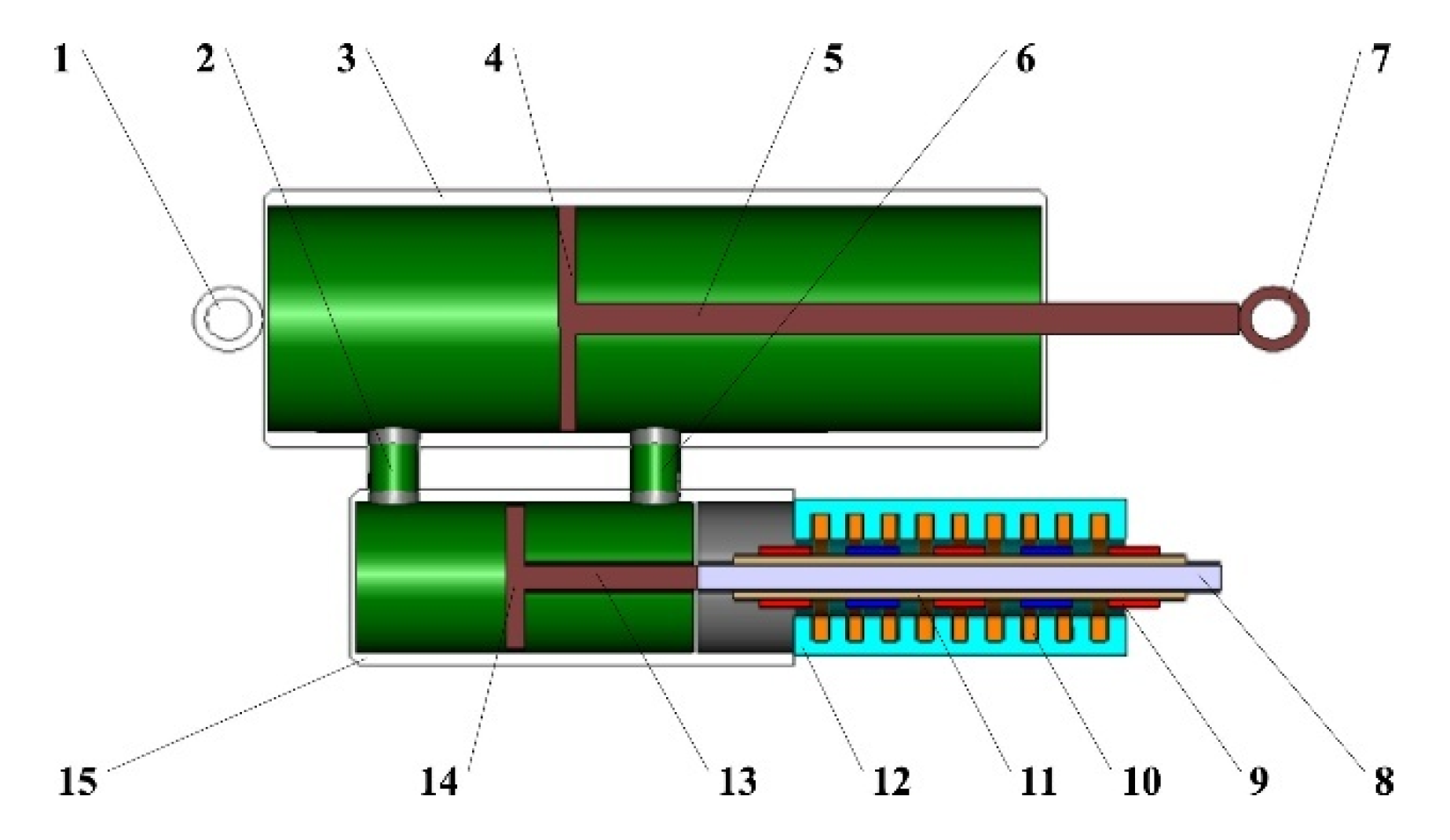

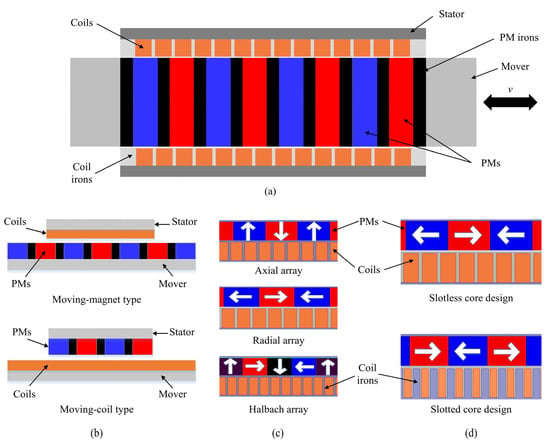

Currently, linear motors exhibit diverse structural forms. Based on their topological configuration, they are classified into the cylindrical, flat-plate, and U-channel types [25,26,27], as illustrated in Figure 3. According to their operating principles, they fall into four categories: permanent magnet synchronous motors (PMSMs), alternating current induction motors (ACIMs), brushless direct current motors (BLDCs), and switched reluctance motors (SRMs) [28,29,30,31,32]. Performance comparisons of two classification schemes are presented in Table 2 and Table 3.

Figure 3.

Classification based on topological configuration: (a) cylindrical type; (b) flat-plate type; (c) U-channel type.

Table 2.

Performance comparison of classification scheme based on topological configuration.

Table 3.

Performance comparison of classification schemes based on operating principles.

Analysis of Table 3 reveals that PMSMs demonstrate superior efficiency, more compact dimensions, and simpler control systems compared to ACIMs. While BLDCs and SRMs exhibit certain advantages in manufacturing cost, control complexity, and reliability, both suffer from inherent drawbacks, including significant thrust ripple and lower efficiency, rendering them unapplicable for high-precision automotive suspension actuators. Furthermore, rapid advancements in motor PM materials and control technologies have substantially improved the manufacturing cost-effectiveness and control performance of PMSMs. Therefore, PMSMs have emerged as the predominant choice for actuators of automotive suspension systems.

Moreover, while cylindrical motors offer high thrust density and superior servo performance, their limited stroke and challenging heat dissipation pose significant design constraints for suspension applications. Flat-plate motors, in contrast, excel in heat dissipation and control precision, making them theoretically better suited for high-performance applications, but their significant thrust ripple and sensitivity to lateral forces could degrade ride comfort and necessitate more complex control algorithms to compensate. The choice of motor topology, therefore, is not a straightforward decision but a critical design compromise based on the prioritization of stroke, force density, thermal management, and cost.

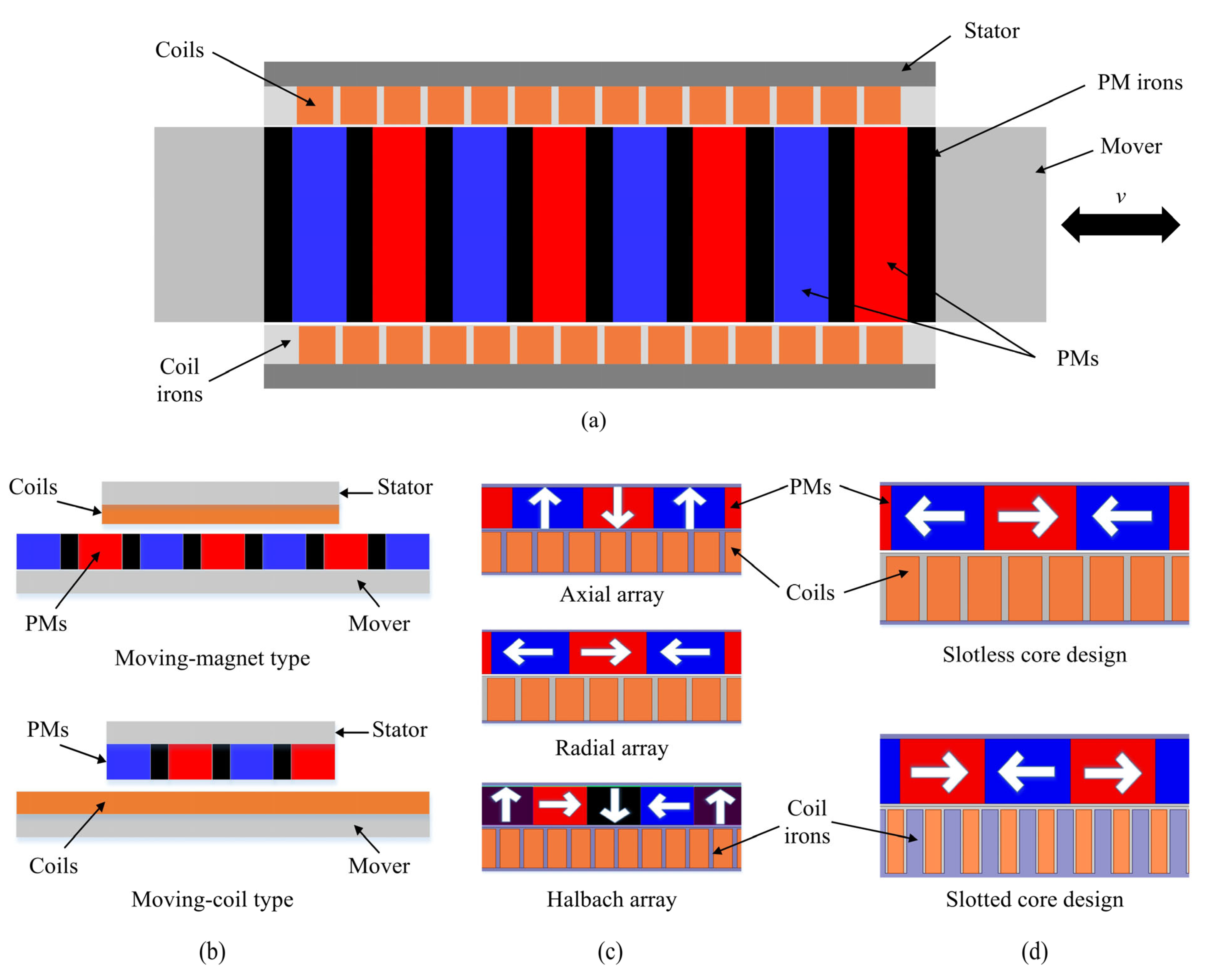

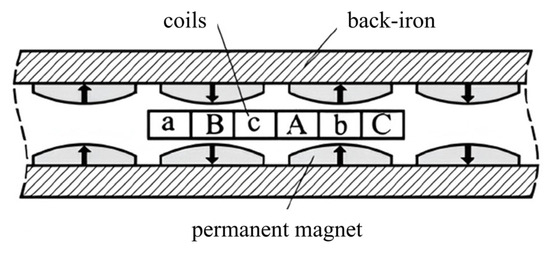

Additionally, the arrangement schemes of two critical components, PMs and coils, exert a profound influence on motor performance [33]. Three primary classification schemes exist: the relative position of PMs and coils categorizes configurations into moving-magnet and moving-coil types, PMs magnetization orientation differentiates axial, radial, and Halbach arrays, while coil core structural form separates into slotless and slotted designs [34,35,36,37]. Schematic illustrations of these three arrangement schemes are provided in Figure 4, with performance comparisons summarized in Table 4.

Figure 4.

Classification based on arrangement scheme of PMs and coils: (a) structural diagram of a PMSM; (b) relative position; (c) PMs magnetization orientation; (d) coil core structural form.

Table 4.

Performance comparison of classification based on arrangement scheme of PMs and coils.

2.3. Composite Configuration of LMEERS

The single-motor configuration of LMEERS cannot simultaneously ensure fundamental dynamic characteristics during energy regeneration and fail-safe properties during active control [38]. To address this limitation, composite configurations integrating complementary advantages of different types of shock absorbers are proposed to enhance the comprehensive performance of LMEERS. They are classified based on their operating principles into electro-hydraulic, electro-electro, and electro-inerter composite systems.

2.3.1. Electro-Hydraulic Composite LMEERS

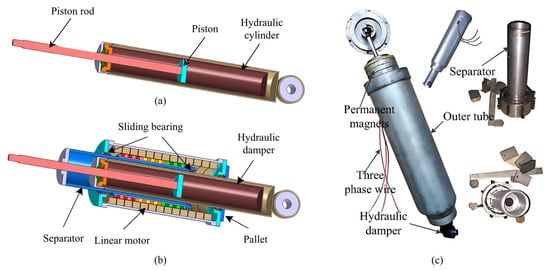

The electro-hydraulic composite (EHC) configuration typically integrates a linear motor with a passive hydraulic damper or a solenoid valve damper. It utilizes the base damping provided by the latter to compensate for the shortcomings of the linear motor in damping characteristics, thereby enhancing the dynamic performance and reliability of the suspension system.

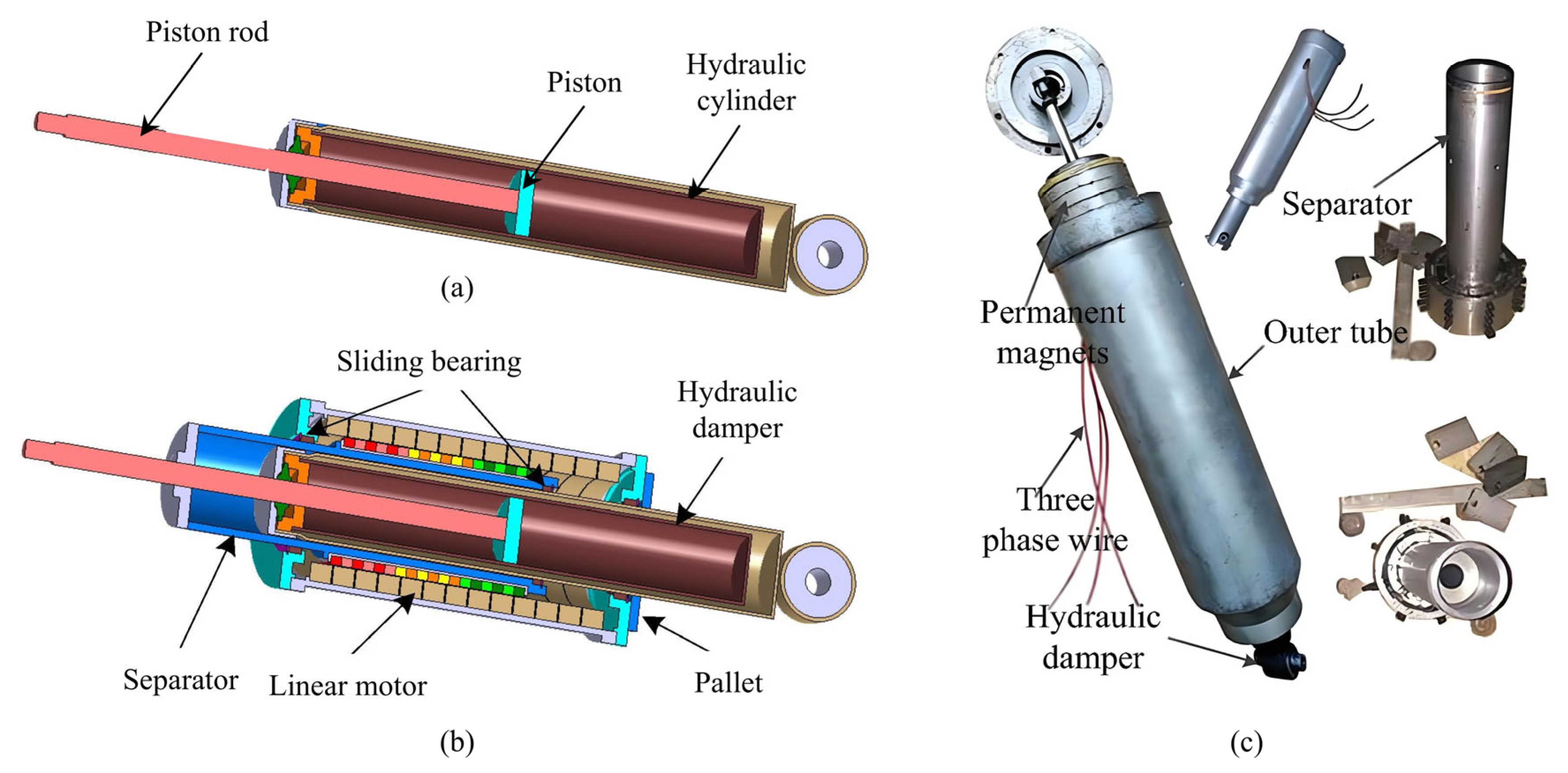

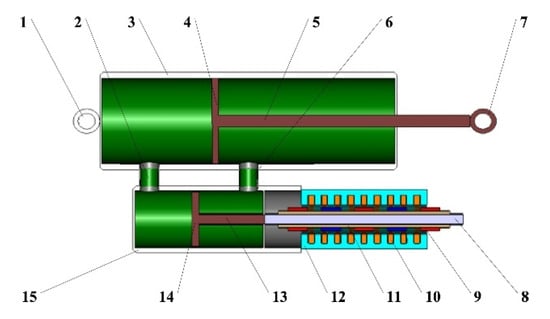

Ding et al. [39,40,41] proposed a hybrid electromagnetic actuator structure where a hydraulic damper was positioned inside a linear motor, as shown in Figure 5. In this configuration, the PM mover of the motor is rigidly connected to the damper piston rod, and the stator coils are rigidly connected to the damper cylinder barrel, thereby achieving a parallel arrangement of the damper and motor. They conducted in-depth research on the working mechanism and control scheme for this EHC configuration, revealing the influence law of damping on energy regeneration and vehicle body vibration isolation. Furthermore, a switching control strategy matching the adjustable damping of the linear motor and the fixed damping of the hydraulic damper was devised. Wei et al. [42] designed an EHC-type LMEERS applicable to MacPherson independent suspensions by employing a coaxially nested arrangement of a linear motor, a hydraulic damper, and a coil spring. The developed configuration ensures the safety and stability of the MacPherson suspension.

Figure 5.

Hybrid electromagnetic actuator designed in Ref. [39]: the passive hydraulic damper is placed inside the linear motor: (a) hydraulic damper; (b) hybrid electromagnetic actuator; (c) prototype of the actuator.

Acknowledging that hydraulic dampers can only provide fixed damping, a hybrid electromagnetic actuator structure integrating a linear motor with a solenoid valve shock absorber was proposed by Kou et al. [43,44]. Here, the former is utilized for active control or energy recovery, while the latter provides variable hydraulic damping by adjusting the solenoid valve opening. A multi-mode switching control strategy was designed for this composite configuration, achieving effective coordination of ride comfort, handling stability, and energy regeneration capability for suspension systems.

In contrast to hydraulic and solenoid valve dampers, which adjust damping by changing the fluid flow, magnetorheological (MR) dampers utilizing smart rheological materials can continuously adjust damping within milliseconds, offering a significantly larger control bandwidth and damping adjustment range. Consequently, MR dampers have become a current research focus in the automotive suspension field. Self-powered electromagnetic damping systems combining an energy-harvesting linear motor with an MR damper represent another common EHC configuration.

Chen et al. [45] positioned a linear motor outside an MR damper for energy regeneration, while the MR damper provided semi-active control. In this setup, the linear motor consistently operates at its maximum energy regeneration power state, and the regenerated electrical energy directly powers the MR damper, thereby achieving self-powered semi-active control. Wang et al. [46] designed a self-powered electromagnetic vibration suppression and absorption system by externally integrating a linear motor and an MR damper in parallel. Within this system, the linear motor functions for vibration absorption and energy regeneration, while the MR damper provides vibration suppression. Simulation results demonstrated that, in comparison with the sole MR suspension, this system achieved superior dynamic performances. Furthermore, the regenerated energy covered the power consumption required for semi-active control.

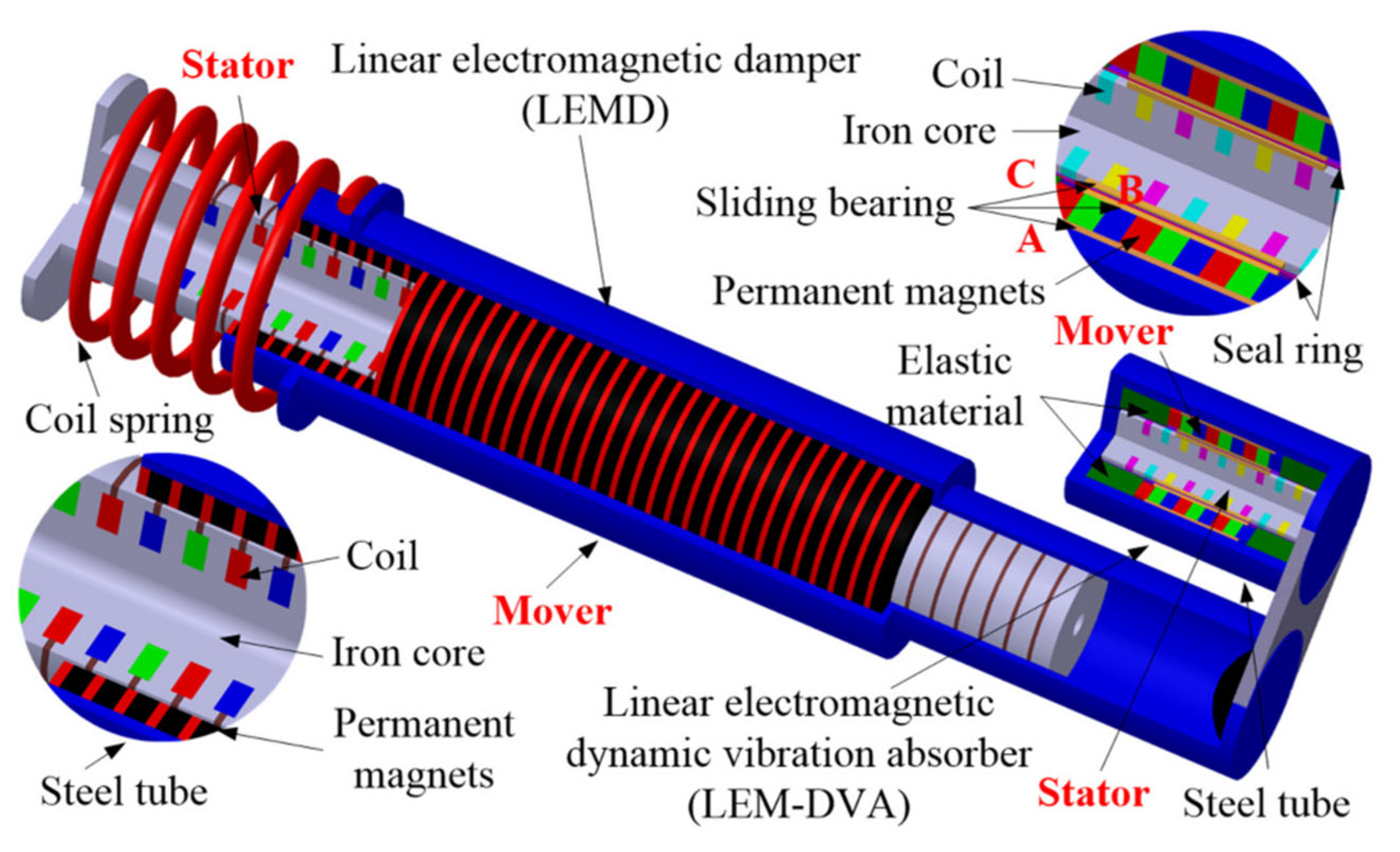

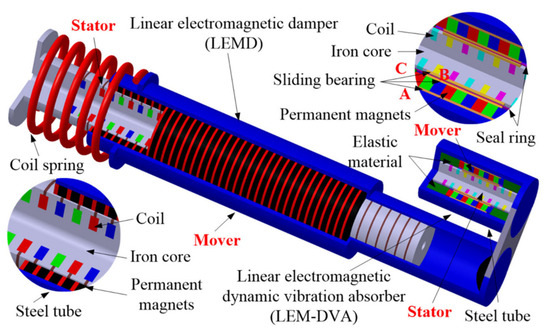

2.3.2. Electro-Electro Composite LMEERS

The electro-electro composite (EEC) configuration typically integrates an eddy current damper or constitutes a dual-motor structure. Ebrahimi et al. [17] proposed a hybrid electromagnetic damper featuring a highly integrated linear motor and eddy current damper. In this structure, an eddy current damper, composed of an outer conductor tube and outer magnet, is placed concentrically outside a cylindrical linear motor. When relative motion occurs in the damper, the varying magnetic field induces the eddy current within the conductor, providing an additional passive damping coefficient of 1570 Ns/m. As a result, system energy consumption was reduced by over 70%. Furthermore, Zhang et al. [47] employed a Halbach PMs array within an EEC structure to enhance the magnetic field variation rate, thereby increasing the magnitude of the induced eddy current damping. They also investigated the influence law of the dislocation ratio between the inner and outer PMs on the motor’s energy regeneration power and the composite damping coefficient.

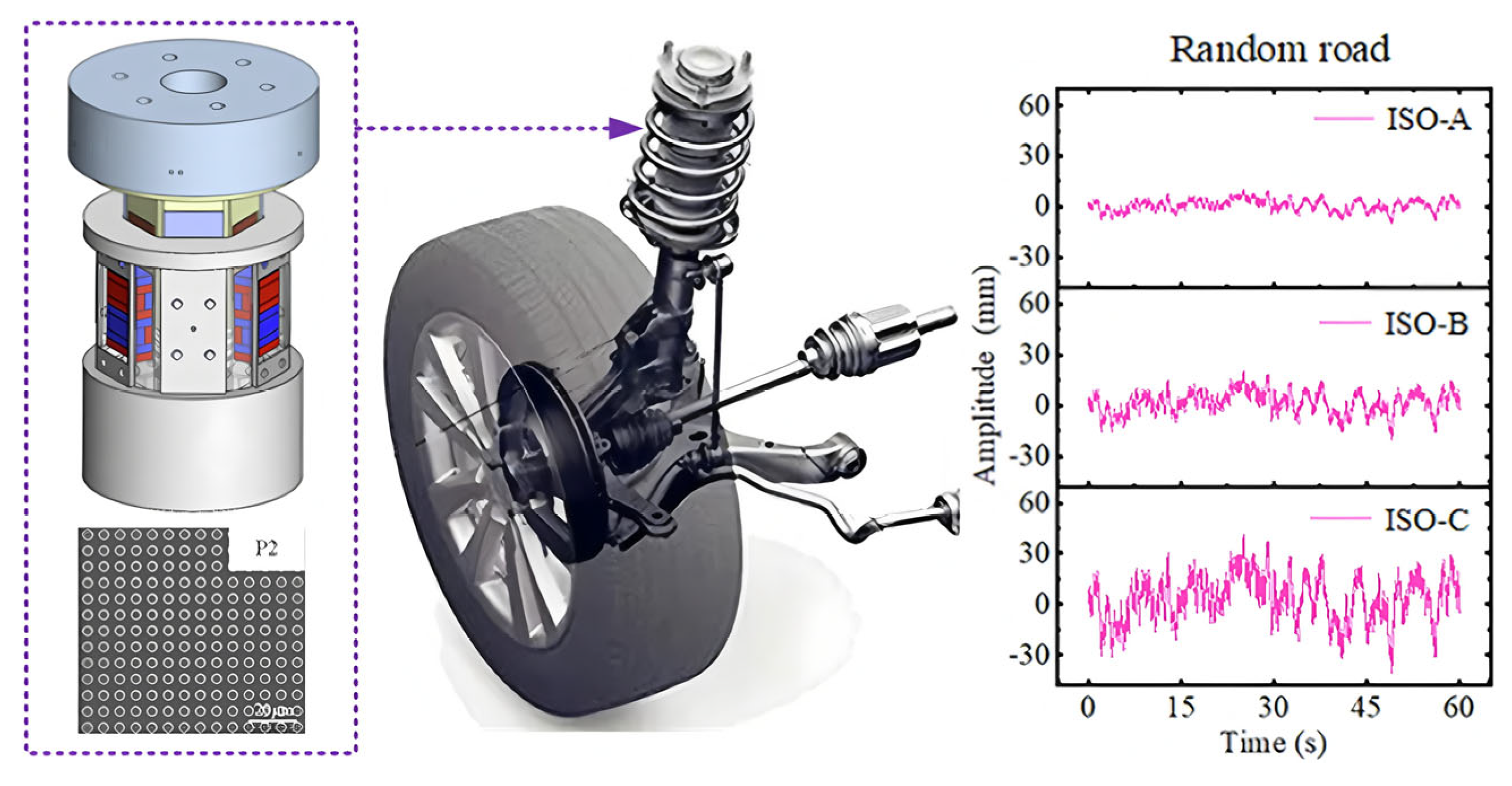

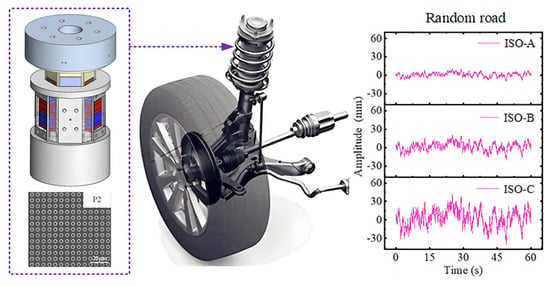

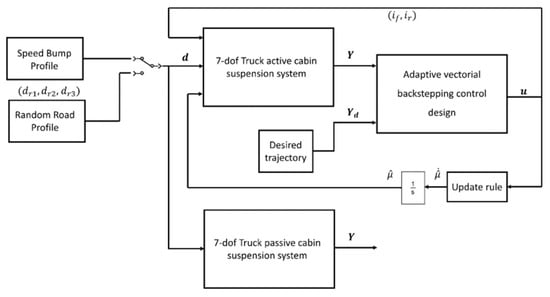

Hu et al. [48] developed a hybrid generator integrating a sliding-mode triboelectric nanogenerator (S−TENG) with a linear motor, as depicted in Figure 6. This dual-motor structure achieved self-powering for onboard sensors without compromising vehicle ride comfort. Suda et al. [49] designed a self-powered electromagnetic active vibration isolation system for heavy-duty truck cabins with the coaxial arrangement of two linear motors. One motor operates in the generator mode to recover energy and simultaneously to provide passive electromagnetic damping. The other utilizes the recovered energy to output active control forces for suspension system. In contrast to Suda’s coaxial arrangement, Li et al. [50] employed the parallel-axis arrangement of dual linear motors, as illustrated in Figure 7. In this configuration, the primary motor functions as the actuator for active vibration suppression and energy recovery, while the secondary motor acts as a vibration absorber to absorb wheel vibration energy. Hardware-in-loop testing results demonstrated that this configuration effectively balanced the vertical dynamic performance and energy-harvesting capability, exhibiting a regeneration potential of 72 W on the B-class random road. The dual-motor structure employing a linear motor and a rotary motor was developed by Wang et al. [51].

Figure 6.

Hybrid generator integrating the S−TENG with a linear motor.

Figure 7.

Diagram of the dual linear motor actuator configuration.

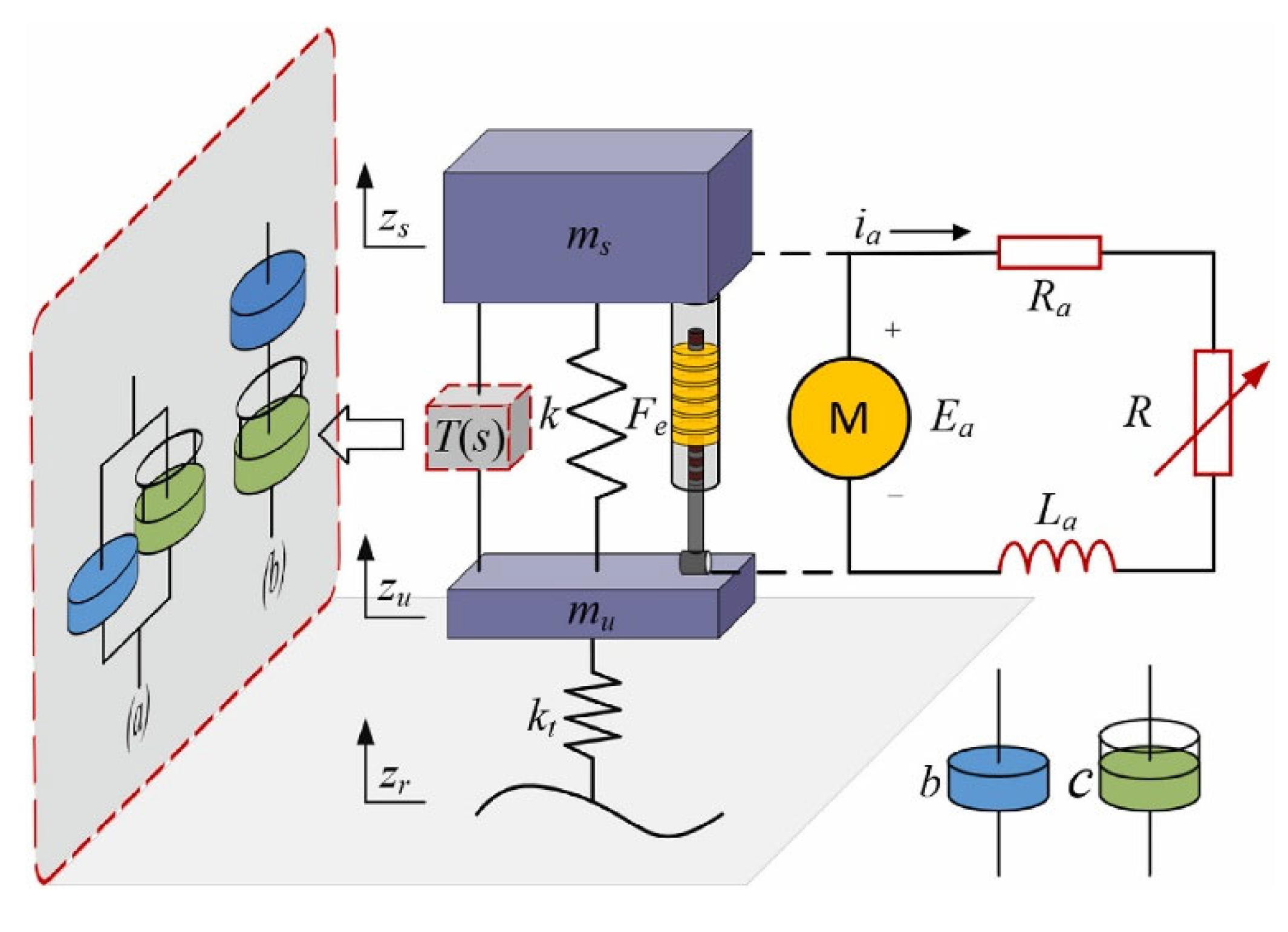

2.3.3. Electro-Inerter Composite LMEERS

The electro-inerter composite (EIC) configuration introduces an inerter element into the electromagnetic system, breaking through the traditional two-element (spring-damper) parallel configuration and broadening the vibration isolation frequency band of suspension systems. Yang et al. [52] investigated the influence of series and parallel arrangements of the linear motor and inerter on the energy regeneration capability and ride comfort of suspensions, as shown in Figure 8. They concluded that the parallel arrangement is more conducive to energy harvesting efficiency, while the series arrangement benefits vehicle ride comfort. Shen et al. [53,54] integrated a linear motor with a hydraulic piston type inerter, designing a split-type EIC actuator, as illustrated in Figure 9. This design features primary and secondary hydraulic cylinders arranged side-by-side and connected via fluid circulation tubes. And the linear motor is integrated with the secondary cylinder. During suspension operation, fluid circulating between the primary and secondary cylinders generates a hydraulic inerter effect. Simultaneously, the motor can recover energy driven by the secondary cylinder piston rod or actively output electromagnetic force to the secondary cylinder. Subsequently, Hu [55] implemented active control for this EIC configuration, exploring its potential for improving vehicle dynamic performance.

Figure 8.

Structure diagram of EIC actuator in series and parallel arrangements.

Figure 9.

Diagram of the split-type EIC actuator designed in Ref. [54].

He et al. [56] compared the performance indexes of EIC actuators with a linear motor and a rotary motor. They concluded that the ball-screw-based rotary motor combined with the inerter achieved a higher inerter–mass ratio, which was more advantageous for reducing actuator volume and mass towards commercialization. Gonzalez-Buelga et al. [57] proposed a novel electrical inerter, formed by connecting a parallel inductor–resistor circuit in series with a capacitor, and then integrated this inerter into the linear motor winding circuit to create an EIC configuration. This structure has minimal impact on the motor’s physical dimensions; however, it exhibits relatively lower energy regeneration power.

The single-motor based LMEERS configuration faces challenges in simultaneously ensuring satisfactory suspension dynamic performance during energy recovery and reliability during active control. To address these limitations, LMEERS is commonly integrated with auxiliary devices, primarily forming three composite configurations: EHC, EEC, and EIC.

- Currently, composite configurations centered around linear motors are predominantly EHC types, which underscores a fundamental engineering trade-off: reliability and “hard damping” versus energy efficiency and integration. The hydraulic component provides a fail-safe property and robust impact resistance, which is a critical advantage for automotive safety. However, this comes at the cost of energy that is intrinsically dissipated within the hydraulic fluid rather than being recovered, thereby reducing the net energy-saving potential of the entire system.

- In contrast, EEC types, exemplified by those integrating eddy current dampers, offer higher integration levels and pure electromagnetic operation but provide only “soft damping”, which may be insufficient for extreme driving conditions or failure modes. Other EEC configurations, such as the dual-motor structure, face challenges related to structural complexity and high cost, hindering commercialization prospects.

- EIC types introduce an inerter element into the electromagnetic system, breaking through the traditional two-element (spring-damper) parallel configuration and broadening the vibration isolation bandwidth. However, they encounter similar issues, including large volume, complex structure, elevated cost, etc.

Therefore, the selection of a composite configuration involves a strategic decision: prioritizing functional safety and robustness (favoring EHC) versus pursuing maximum energy regeneration and integration (favoring EEC/EIC), with the current industry trend leaning towards the former due to safety-critical considerations.

3. Performance Optimization of LMEERS

Commercial validation of LMEERS was demonstrated when Bose Corporation conducted public testing of its in-house developed suspension system in the Lexus LS400 model, revealing its capacity to recover vibration energy during compression strokes. The total energy consumption of LMEERS was reduced to merely one-third of the vehicle’s air conditioning load while excellent vibration attenuation was also achieved [58]. Similarly, BYD Auto has implemented its DiSus-Z, a linear motor electromagnetic suspension system, in the Yangwang U7 model, achieving comprehensive vehicle body control characterized by effective vibration isolation and negligible lateral tilt [59].

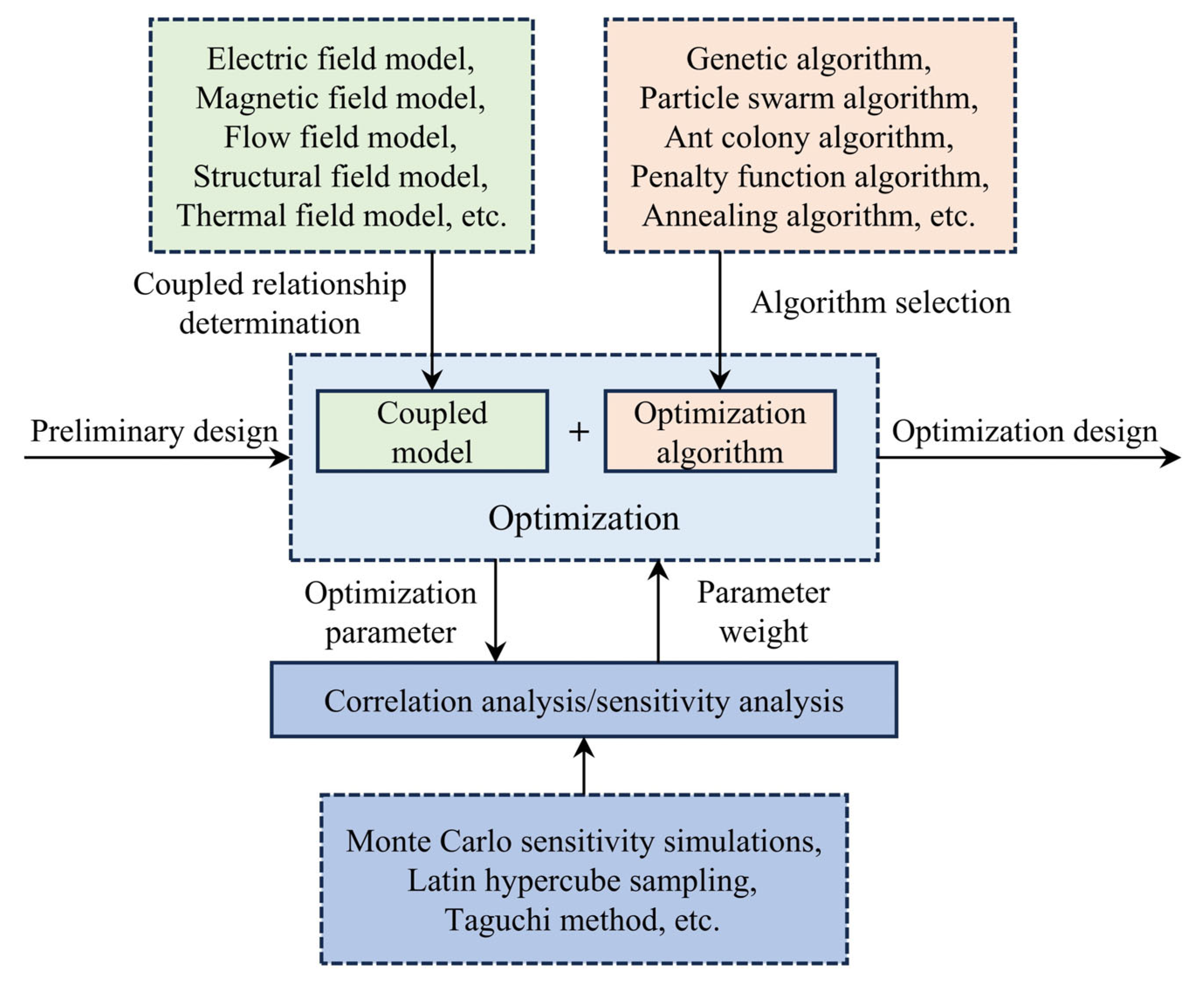

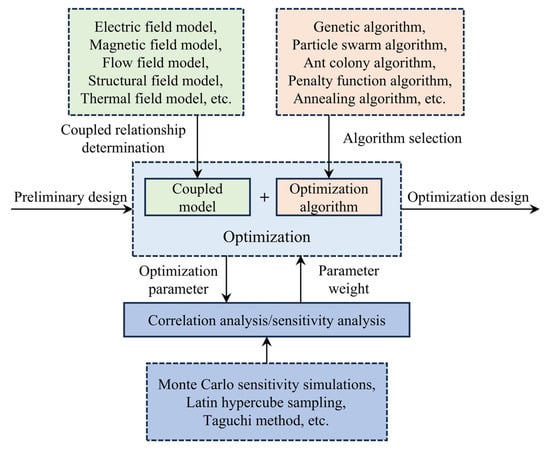

Extensive research substantiates LMEERS’s significant improvements in vehicle dynamic performance and energy conservation capability [60,61]. However, inherent limitations of linear motors constrain LMEERS performance in the aspects of damping, thermal, thrust, and regenerative characteristics. Addressing these deficiencies necessitates the conduction of performance optimization in terms of structural refinement, parametric optimization, and intelligent control. These three approaches all involve optimization processes, where advanced optimization algorithms serve as pivotal enablers for enhancing design efficiency [62,63,64]. Given that performance optimization for LMEERS constitutes a complex multidisciplinary, multi-objective problem, nonlinear programming methods are typically employed for systematic optimization design. The specific optimization workflow is detailed in Figure 10.

Figure 10.

Flow chart of the multidisciplinary and multi-objective optimization problem.

3.1. Optimization in Damping Characteristics

Linear motors are functionally equivalent to passive dampers when operating in energy regeneration mode. Yet, fundamentally distinct from hydraulic damping, the electromagnetic damping generated by motors constitutes “soft damping”, characterized by a significantly lower magnitude than hydraulic systems, thereby failing to rapidly attenuate suspension vibrations. For instance, the linear motor designed by Tang et al. [65] achieved a maximum damping coefficient of merely 940 N·s/m, while conventional passenger vehicles require 1500~2000 N·s/m for adequate vibration suppression. To address this deficiency, Gysen et al. [66,67] proposed embedding aluminum rings within motor stator slots. Relative motion between coils and PMs induces eddy currents in these rings, generating supplemental eddy current damping that reduces energy consumption during active control and enhances damping characteristics.

Building upon this concept, Ebrahimi et al. [17] added an additional layer of PMs concentrically outside the linear motor’s outer conductor tube. Relative stator–mover motion creates varying magnetic fields that induce eddy currents in the outer conductor tube, providing additional passive damping of 1570 N·s/m and reducing total motor mass by 53%. Tang et al. [68] further employed the Finite Element Method (FEM) to optimize motor parameters, aiming to boost power density and damping density. Additionally, they refined the motor structure by introducing a dual-layer laminated configuration and a radial PM array, which further enhanced the power density. Prototype testing results confirmed that the damping coefficient provided by the optimized linear motor met or exceeded the performance standards of conventional hydraulic shock absorbers.

It is noteworthy that the aforementioned solutions primarily focus on optimizing the linear motor structure and parameters to improve its intrinsic damping. Nevertheless, this enhanced damping fundamentally remains “soft damping”, exhibiting potential reliability concerns and failing to meet suspension dynamic demands under extreme operating conditions. Therefore, it is proposed that the reliable “hard damping” provided by hydraulic elements can be directly integrated in parallel with the linear motor to substantially increase the suspension system’s damping coefficient.

Asadi et al. [69,70] placed the linear motor inside a hydraulic damper. In this configuration, the hydraulic damper provides the base damping for the suspension system, while the linear motor recovers vibration energy. The motor’s equivalent damping can be adjusted by varying its load resistance to meet vehicle dynamic requirements under different driving conditions. Xu et al. [71] filled the interior of a linear motor with hydraulic fluid and set solenoid valves onto the piston coaxial with the motor mover. By controlling the solenoid valve opening, the damping coefficient of the hydraulic unit can be modulated. Based on this hybrid structure, the actuator can operate in three modes. In active mode or regeneration mode, the linear motor outputs electromagnetic thrust or recovers energy, while the hydraulic unit provides the base damping, ensuring suspension dynamic performance. In semi-active mode, both the motor and the hydraulic unit can simultaneously provide variable damping.

3.2. Optimization in Thermal Characteristics

Temperature rise directly deteriorates the output thrust and winding losses of linear motors, consequently degrading vibration suppression effectiveness and energy regeneration efficiency of LMEERS. In severe cases, it can even lead to PM demagnetization and winding insulation failure. Common mitigation approaches involve parametric optimization of the motor structure, implementing cooling systems, and developing thermal management control strategies.

3.2.1. Structural Optimization in Thermal Characteristics

In the aspect of parametric optimization, Wang et al. [72] proposed a bidirectional electromagnetic-thermal coupled model, accounting for the influence of variations in material thermal properties on temperature rise. With winding temperature rise and motor detent force as optimization objectives, the Response Surface Methodology (RSM) was employed for multi-objective optimization of sensitive structural parameters. The optimized design reduced winding temperature rise and electromagnetic losses by 11.02% and 17.50%, respectively. Zhu [73] established an electro-magnetic-thermal multiphysics coupled model for the linear motor, the accuracy of which was validated by a constructed temperature rise test platform. Subsequently, a neural network surrogate model was used for co-optimization of motor structural parameters. The results indicated a 6.3% reduction in the optimized coil peak temperature.

BYD Auto has conducted structural refinement of LMEERS by arranging various cooling systems in order to improve its thermal characteristics. Several liquid-cooling schemes have been designed, such as installing external radiators [74] and incorporating internal heat exchange cavities or cooling chambers within motors [75,76,77]. An air-cooling solution featuring a novel rectifier design capable of generating stable, high-speed airflow within the motor housing for stator cooling was also developed [78].

3.2.2. Thermal Management

For the dynamic operating environment of automotive suspensions, precise tracking of the linear motor’s transient temperature response is essential for implementing effective thermal management and improving the utilization efficiency of the motor’s electromagnetic output. Available monitoring methods include sensor-based and model-based approaches. The former involves direct sensor placement within motors but poses significant challenges regarding system cost, reliability, and signal accuracy. Therefore, research should prioritize the latter approach [79,80].

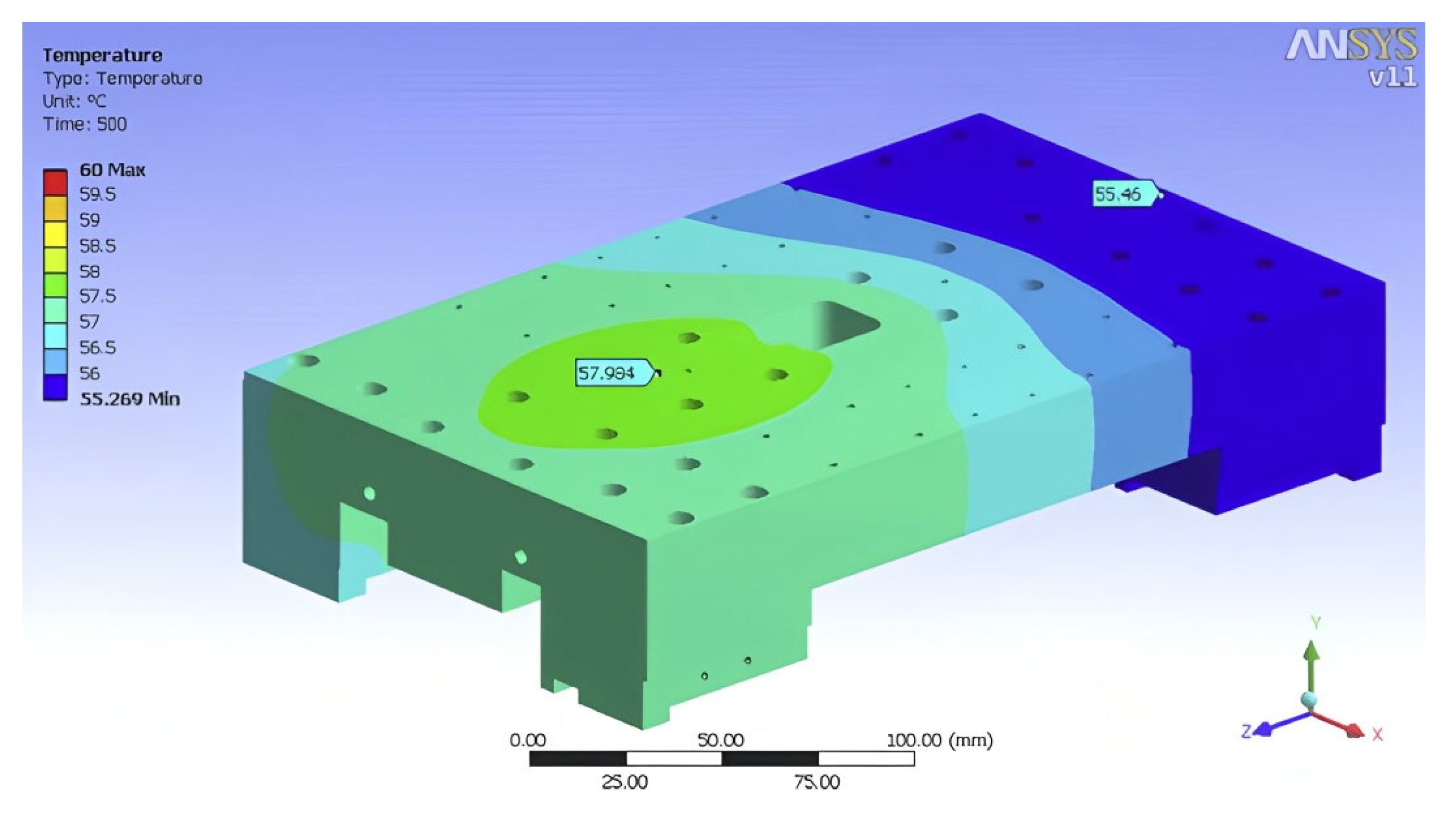

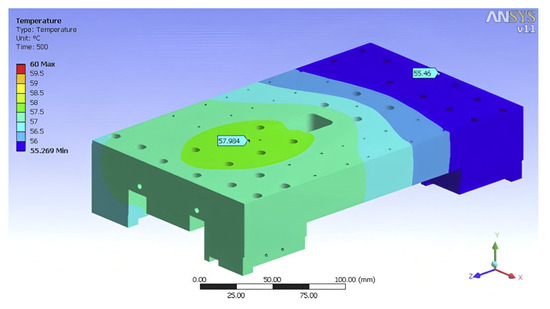

Common thermal monitoring models can be categorized into Lumped Parameter Thermal Networks (LPTNs) or numerical modeling. Both methods can effectively predict motor temperature distribution [81,82]. Lu et al. [83] investigated the thermal distribution of a PM linear motor during operation on the basis of LPTN. This enabled real-time optimization of the coolant flow rate in the liquid-cooling system. Furthermore, the optimal relationship between the short-time large current and working time, as well as the optimal duty cycle for the drive current, were determined. Chow et al. [84,85] modeled the motor with the Finite Difference Method (FDM), as shown in Figure 11, to calculate the internal heat transfer. Experiments confirmed the high accuracy of this method for temperature prediction.

Figure 11.

Temperature profile of the linear motor under steady-state thermal simulation in Ref. [84].

3.3. Optimization in Thrust Characteristics

The thrust output of a linear motor is proportional to its volume, while the compact installation space within a suspension system imposes significant constraints on the dimension design of motors requiring high thrust. Furthermore, several factors such as end effects and cogging effects cause thrust ripple, which deteriorates the positioning accuracy and operational stability of motors [86,87,88]. To optimize the thrust characteristics of linear motors, three approaches are typically employed, namely structural refinement, parametric optimization, and intelligent control.

3.3.1. Structural Optimization in Thrust Characteristics

Regarding refinement and optimization, for the primary unit, Refs [89,90,91] proposed to optimize the primary core length to reduce end forces. Refs [92,93] demonstrated that incorporating an auxiliary pole structure on the primary unit could effectively suppress thrust ripple. Makki et al. [94] investigated the influence of primary core slotting design on the magnetic reluctance force. A tubular linear PMSM featuring a double primary structure was designed by Wu et al. [95,96]. The electromagnetic characteristics of the dual primaries was superimposed, and the end tooth structure was optimized, which effectively suppressed the even harmonics within the detent force, thereby reducing motor thrust ripple. The optimized structure exhibited low thrust ripple and excellent working performance. Zhang et al. [97,98] proposed a modulation method for cogging force and end force based on the destructive interference theory. Accounting for both cogging and end effects, they established an integrated subdomain analytical model to optimize the primary core structural parameters, thereby reducing detent force. The proposed method achieved a thrust ripple below 1.5%.

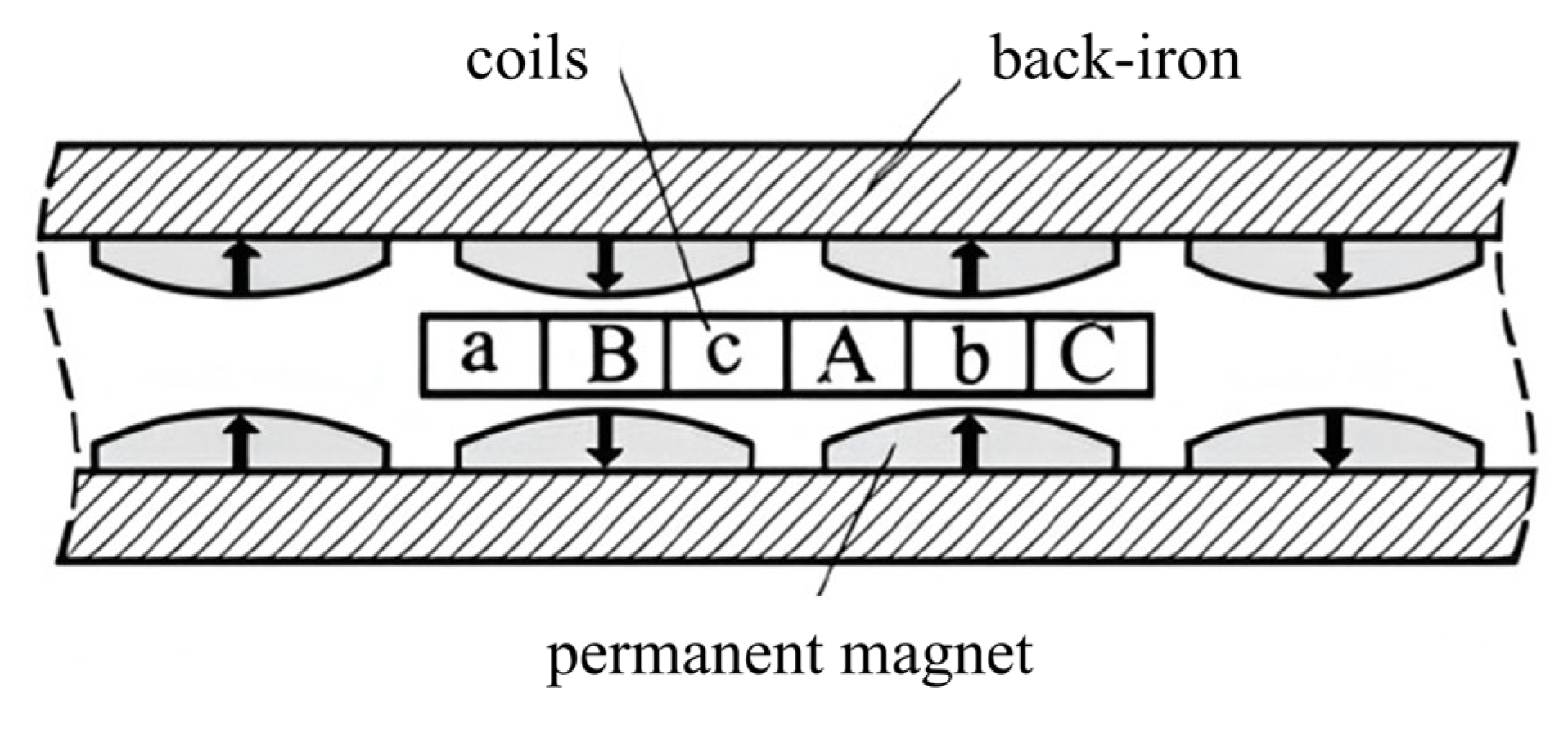

In addition to considering the primary structure, Yan et al. [23] also investigated the influence of secondary PM parameters on thrust ripple. Multi-objective optimization with the Taguchi method and RSM resulted in an 11.9% increase in average thrust and a 76.6% reduction in ripple for the optimized motor. A novel skewing pole structure for PM was proposed by Li et al. [99], which further reduced thrust ripple. Xu et al. [100] suggested employing the Halbach array for PM to suppress thrust ripple. Refs [101,102,103] investigated the impact of PM shape on thrust performance, such as the arc-shaped PMS shown in Figure 12, while complex shapes increased the manufacturing complexity. Cheng [104] discovered that motor detent force would reach its minimum when the number of slots and poles were coprime. Lu et al. [105] further clarified that in single-sided linear motors, thrust characteristics are superior when the slot–pole combination differs by 1 or 2. For double-sided structures, thrust density is higher when the slot–pole combination differs by 1.

Figure 12.

Arc-shaped PMs mentioned in Ref. [101].

3.3.2. Intelligent Control in Thrust Characteristics

Implementing advanced control strategies to compensate for linear motor behavior and improve dynamic response proved to be an effective approach for detent force suppression. Common suppression strategies include active disturbance rejection control [106,107,108], sliding mode control [109,110], predictive control [111,112,113], and iterative learning control [114,115,116].

Kim et al. [117] compensated for thrust ripple with a feedforward controller. Zhang et al. [118] designed a Proportional Resonant Internal Model Extended State Observer (PR-IMESO) specifically targeting detent force. This designed disturbance observer possessed excellent capabilities of observing and compensating for detent forces, and effectively suppressed thrust ripple caused by other unmodeled factors. Model-based feedforward and observers do not change the controller structure and require less computational resources, but their optimization effectiveness is limited in high-frequency, high-speed environments. In contrast, intelligent control strategies, such as neural network and iterative learning, offer superior compensation for thrust ripple. However, they inherently suffer from substantial computational burdens, potentially compromising the real-time performance of the control system.

3.4. Optimization in Regenerative Characteristics

The energy regeneration power in energy recovery mode and the electromagnetic thrust in active control mode are fundamentally determined by the air-gap magnetic flux density between the primary and secondary components. To enhance motor energy regeneration efficiency, optimization efforts are focused on three aspects: structural refinement, parametric optimization, and intelligent control.

3.4.1. Structural Optimization in Regenerative Characteristics

Regarding structural refinement, the layout of PMs and coils is primarily optimized. In the aspect of PM design, Gupta et al. [119] designed an electromagnetic energy regenerative damper featuring a coaxial arrangement of inner and outer dual-layer annular PMs for improving regenerative characteristics. Although increasing the number of PMs could readily enhance the air-gap flux density, it concomitantly increases the actuator’s volume and weight, hindering practical application.

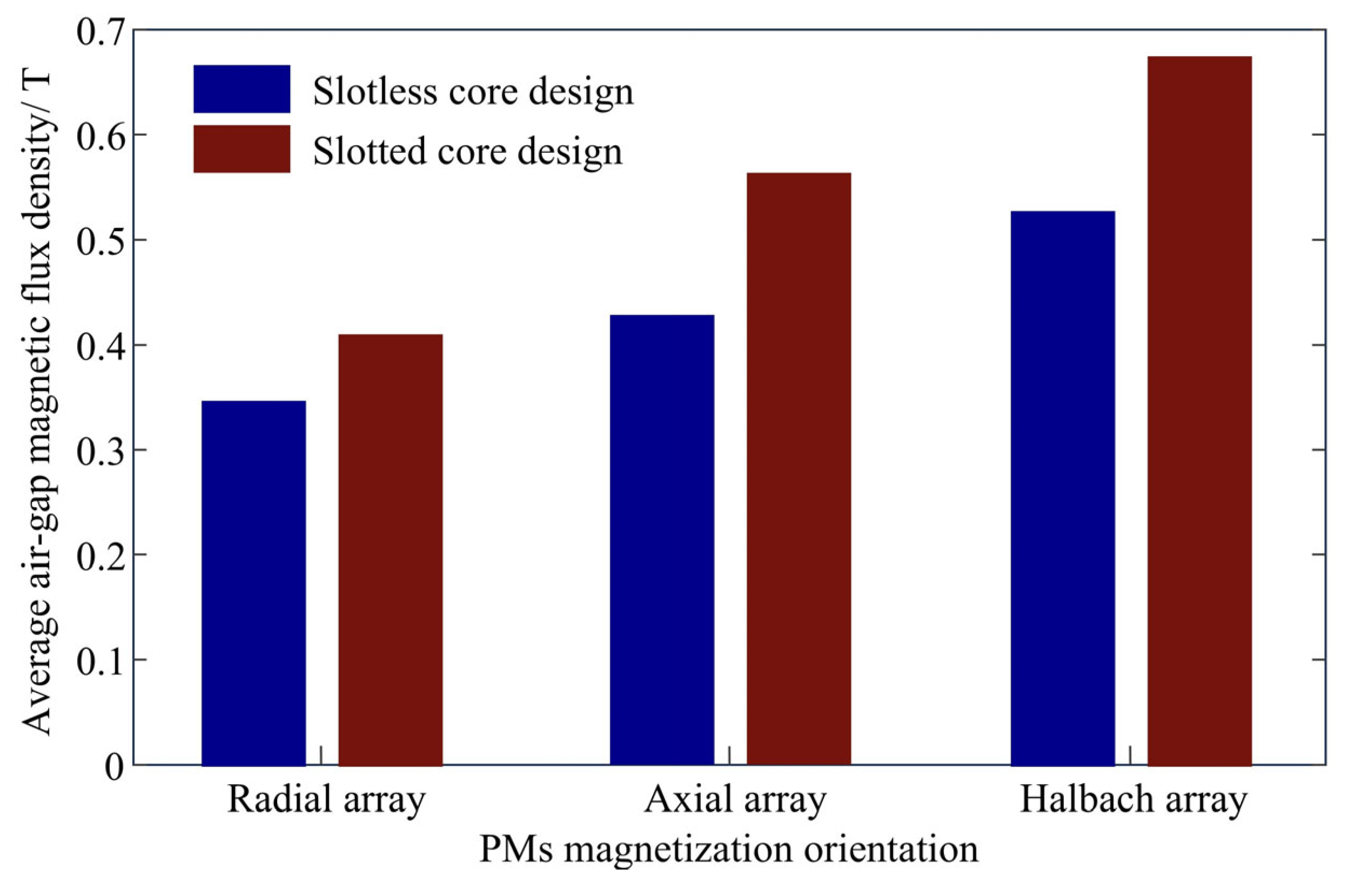

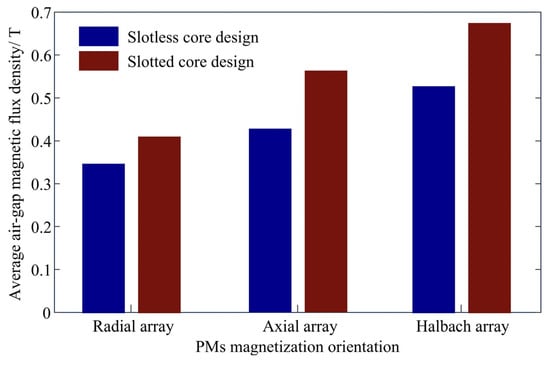

To address this limitation, Halbach [120] innovatively proposed a novel PM array. Unlike conventional arrays, adjacent PMs in this array are magnetized at 90° angles relative to each other. This design significantly strengthens the magnetic field on one side while nearly eliminating it on the opposite side, thereby achieving high field strength within a compact volume. Zhu et al. [121,122] investigated the application potential of Halbach arrays for vibration energy recovery. Simulation results demonstrated that single-layer and double-layer Halbach arrays increased the energy regeneration power of linear motors by 40% and 88%, respectively. Dai [123] compared the air-gap flux density of different arrays on the basis of FEM. As shown in Figure 13, the Halbach array exhibited the highest density. The Halbach-like array was designed by Xiong et al. [124] to increase motor energy regeneration power. Additionally, Kopylov et al. [125] found that implementing a back-iron architecture for PMs yielded higher energy harvesting power.

Figure 13.

Air-gap magnetic flux density of different PM arrays and coil core slots.

Additionally, regarding coil layout, factors such as turn number, layer number, phase number, and the core slotting design also influence energy recovery power. Tang et al. [65] indicated that a larger winding phase number could increase power. Figure 13, above, also illustrates that the slotted core design yields a greater magnetic flux density.

For parametric optimization, Hasani et al. [126] proposed an optimization method based on the electromagnetic damping model to improve motor energy regeneration efficiency. Abdelkareem et al. [127] conducted frequency-based parametrical bandwidth sensitivity analyses on suspension vibration energy recovery potential with Monte Carlo sensitivity simulations. The correlation between energy-harvesting potential and various suspension parameters were revealed, providing the theoretical foundation for subsequent parametric optimization and facilitating the conceptual design of EERS.

3.4.2. Intelligent Control in Regenerative Characteristics

Once the topology and parameters of LMEERS are finalized, efficient and reliable intelligent control strategies are essential to fully exploit its energy regeneration potential. Li et al. [128] proposed a pavement-level-based switching control strategy for LMEERS. Its core logic involves adjusting the control parameters of the top-layer controller according to the road profile to ensure the maximum energy harvesting efficiency under high-frequency excitation. Simulation results showed that this switching strategy improved regenerative efficiency by 30.5%. Azmi et al. [129] designed an optimal control strategy based on a continuous predictive approach. The energy regeneration power increased by 31% due to the suspension control focus steered towards high-efficiency regenerative regions by adjusting weighting coefficients. The time-delay control was employed by Wu et al. [130] to enhance the energy recovery capability. The existing literature demonstrates that the introduction of active control can effectively improve energy harvesting potential. However, it is noteworthy that extracting excessive energy from suspension vibration will degrade other performance indexes, highlighting an inherent trade-off between the dynamic performance and energy regeneration capability of LMEERS.

3.5. Emerging Optimization Methods

While the optimization methods discussed in the preceding sections have significantly enhanced the comprehensive performances of LMEERS, they often face inherent limitations. These include the computational complexity of high-fidelity multi-physics models, challenges in handling system nonlinearities and uncertainties in real-time, and the difficulty in achieving a globally optimal trade-off between dynamic performance and energy regeneration capability. Recent advancements in Artificial Intelligence (AI) and Digital Twin (DT) technologies offer a transformative paradigm to overcome these limitations and unlock new frontiers in LMEERS performance optimization [131,132].

DT technology, characterized by the creation of a high-fidelity virtual replica of the physical suspension system, moves beyond the traditional static modeling. This cyber-physical system synchronizes with its physical counterpart in real-time via sensor data, enabling unprecedented capabilities for optimization [133,134,135,136,137]. The DT framework integrates high-fidelity electromagnetic, thermal, and structural models, facilitating the virtual prototyping and design validation, real-time performance prediction, and closed-loop online calibration. Prusa et al. [138] conducted a comparative analysis of the performance differences between DT technology and the traditional Finite Element Method (FEM) in the development of linear motors, arguing that DT can simultaneously achieve both simulation accuracy and real-time capability. This led to the conclusion that DT is highly important for the motor development process. Luo et al. [139] proposed a data-driven DT method for real-time estimation of the motor operating temperature, with experimental results demonstrating the method’s effectiveness in achieving thermal management for motors. Antonelli et al. [140] developed a DT of a suspension system after performing nonlinear modeling, which was utilized for the development and optimization of the suspension control system. Furthermore, online calibration of the controller was also conducted on the DT.

Meanwhile, AI-driven methodologies are revolutionizing control and optimization strategies [141,142,143,144]. Deep Learning (DL), particularly through deep neural networks, excels at identifying complex, non-linear patterns from operational data [145,146]. DL can be employed to develop data-driven surrogate models that approximate the system’s dynamics with less computational cost than full physical models, or to enhance road information identification algorithms for more precise functionality switching [147,148]. Iwata et al. [149] employed a pre-trained deep learning model to predict the degree of influence of transitions from air to magnetic materials in a PMSM, thereby facilitating the topological optimization of the motor. Both the development efficiency and the motor’s electromagnetic and mechanical performance were significantly improved. Khan et al. [150] introduced a novel method using deep learning to predict the efficiency map of motor drives, which demonstrated higher accuracy and efficiency compared to FEM. In addition, this method is proven to be applicable to the design and optimization processes of motors.

The convergence of DT and AI creates a powerful symbiotic relationship where DT provides the realistic environment necessary for training and validating AI algorithms, while AI provides the intelligent core to analyze data and make decisions within the DT framework. This integrated approach promises a future where LMEERS can autonomously self-optimize its performance in real-time, achieving a truly adaptive and intelligent suspension system. Although these technologies are still immature in their application to LMEERS, they signify a pivotal shift from conventional methodologies towards a more holistic, data-driven, and self-adaptive optimization paradigm, setting a clear direction for future research and development.

In summary, due to performance limitations inherent in the linear motor, LMEERS exhibits shortcomings in damping, thermal, thrust, and regenerative characteristics. Three aspects of structural refinement, parametric optimization, and intelligent control are typically focused on to improve the comprehensive performance of LMEERS.

- Damping characteristics is typically enhanced by integrating the eddy current or hydraulic damping modules.

- Parametric optimization and implementing cooling systems are simple and effective approaches to mitigate motor temperature rise.

- Thrust and regenerative characteristics, being critical to the functional behavior of LMEERS, require a comprehensive set of approaches for improvement.

- Emerging optimization methods, such as DT and AI, demonstrate substantial application potential, representing a promising and critical direction for future research.

4. Functionality Switching Criterion Identification of LMEERS

An inherent trade-off exists between the energy regenerative capability and dynamic performance of LMEERS. Consequently, the working modes of LMEERS must be judiciously switched according to driving conditions to balance its dual functionalities of energy regeneration and active control. Road excitation, as the primary input source generating vibration for suspension systems, also constitutes a critical component of the vehicle’s driving conditions. Therefore, road surface information serves as the most appropriate switching criterion for determining whether LMEERS should prioritize active control or energy recovery [18].

Furthermore, the extraction and identification of road surface information can offer more precise and rational front-end decision-making for subsequent top-layer control. This ensures the organic combination and efficient coordination between energy regeneration and active control, ultimately achieving the control objective of optimal overall performance across all road conditions. With the rapid development of high-level autonomous driving, multi-sensor fusion-based environment recognition technologies are maturing daily. This maturation provides the technical foundation for LMEERS to perform functionality switching based on road surface information. Hence, researchers worldwide have begun to prioritize road surface information as a key criterion for LMEERS mode switching.

For vertical dynamic control of suspension systems, road surface information primarily comprises road surface roughness and road surface type.

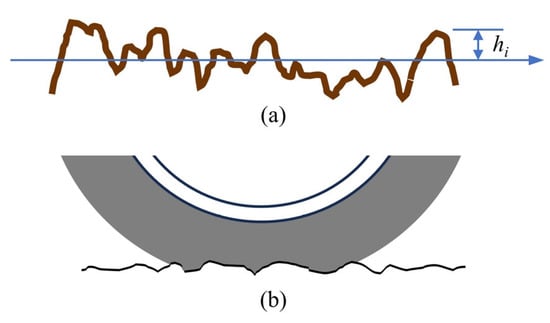

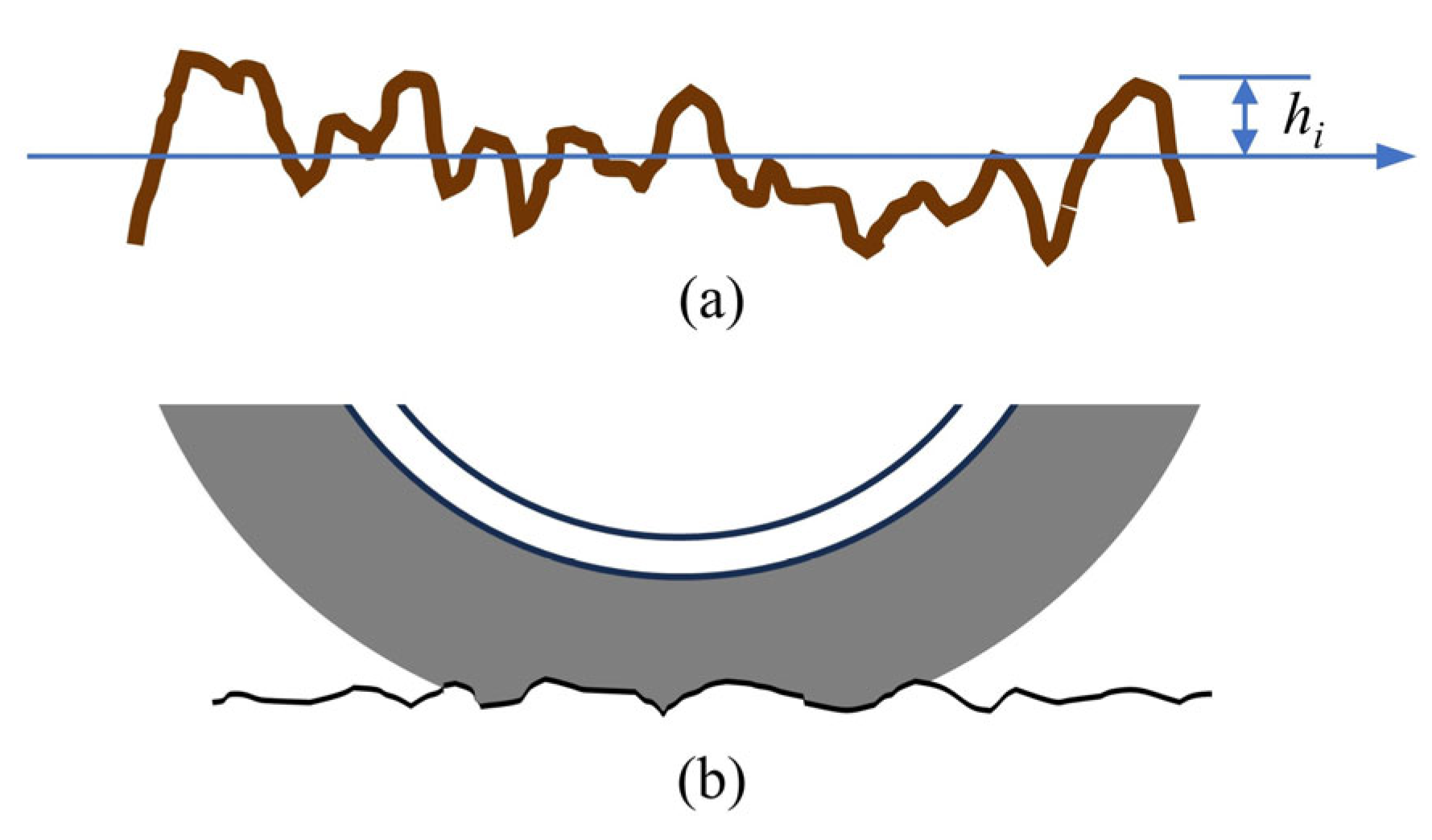

- Road surface roughness, defined as the random variation in road surface profile (as illustrated in Figure 14), is the direct vertical excitation input to the wheels [151]. Through the tire–suspension–body transmission path, it induces vibrations. These vibrations influence the vehicle’s demand for either dynamic performance or energy regeneration capability—essentially determining which functionality mode is the optimal choice at any given moment. Therefore, road surface roughness is the core road information considered during LMEERS functionality switching, particularly in single-wheel suspension application scenarios.

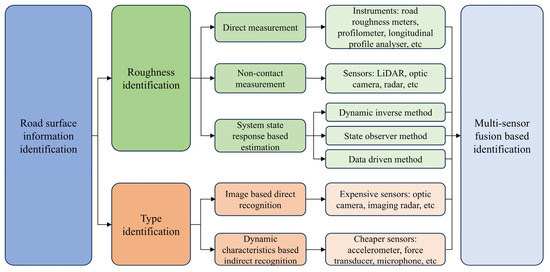

- Regarding the road surface type, it reflects the statistical characteristics of road surface roughness, typically serving as prior knowledge to assist in estimating road surface roughness [152]. The fundamental methods for road surface information identification are summarized in Figure 15. The identification methods of road surface roughness are primarily divided into three categories, namely direct measurement, non-contact measurement, and system state response-based estimation [153,154,155]. And road surface type identification methods are categorized into two main classes, namely image-based direct recognition and vehicle dynamic characteristic-based indirect recognition [156,157].

Figure 14.

Road surface roughness visualization: (a) vertical road surface profile; (b) contact between a rough road surface and tire (the road vertical profile is exaggerated for better visualization).

Figure 14.

Road surface roughness visualization: (a) vertical road surface profile; (b) contact between a rough road surface and tire (the road vertical profile is exaggerated for better visualization).

Figure 15.

Fundamental methods for road surface information identification.

Figure 15.

Fundamental methods for road surface information identification.

4.1. Identification of Road Surface Roughness

4.1.1. Direct Measurement Methods

Direct measurement methods utilize specialized equipment, such as road roughness meters, installed on or connected to vehicles to directly measure the road surface profile in the case of maintaining continuous contact with the ground [158,159]. Guo et al. [160] conducted a comparative analysis of various measurement techniques, concluding that direct measurement methods could yield high-precision road surface roughness data, thereby accurately reflecting road surface profile information.

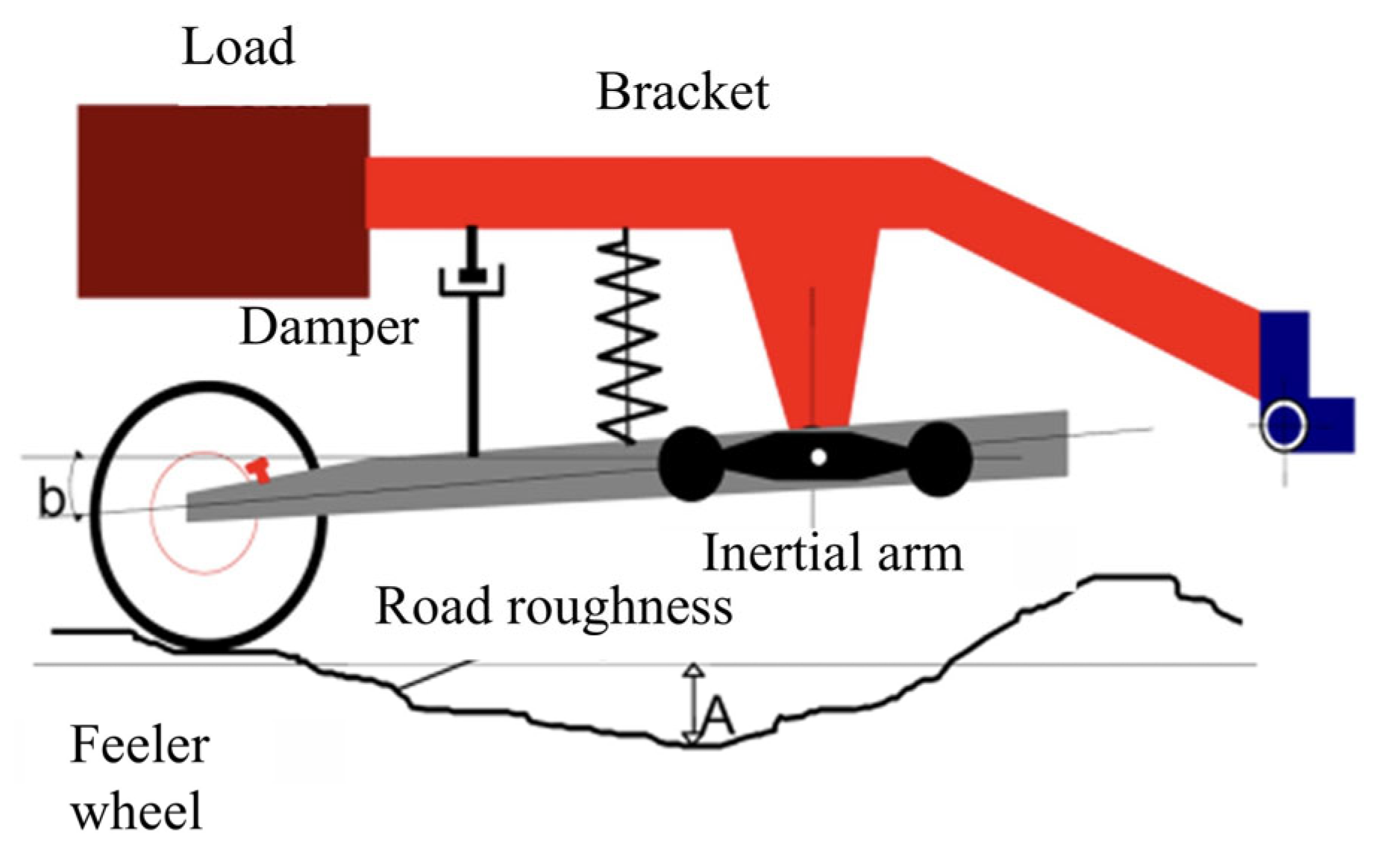

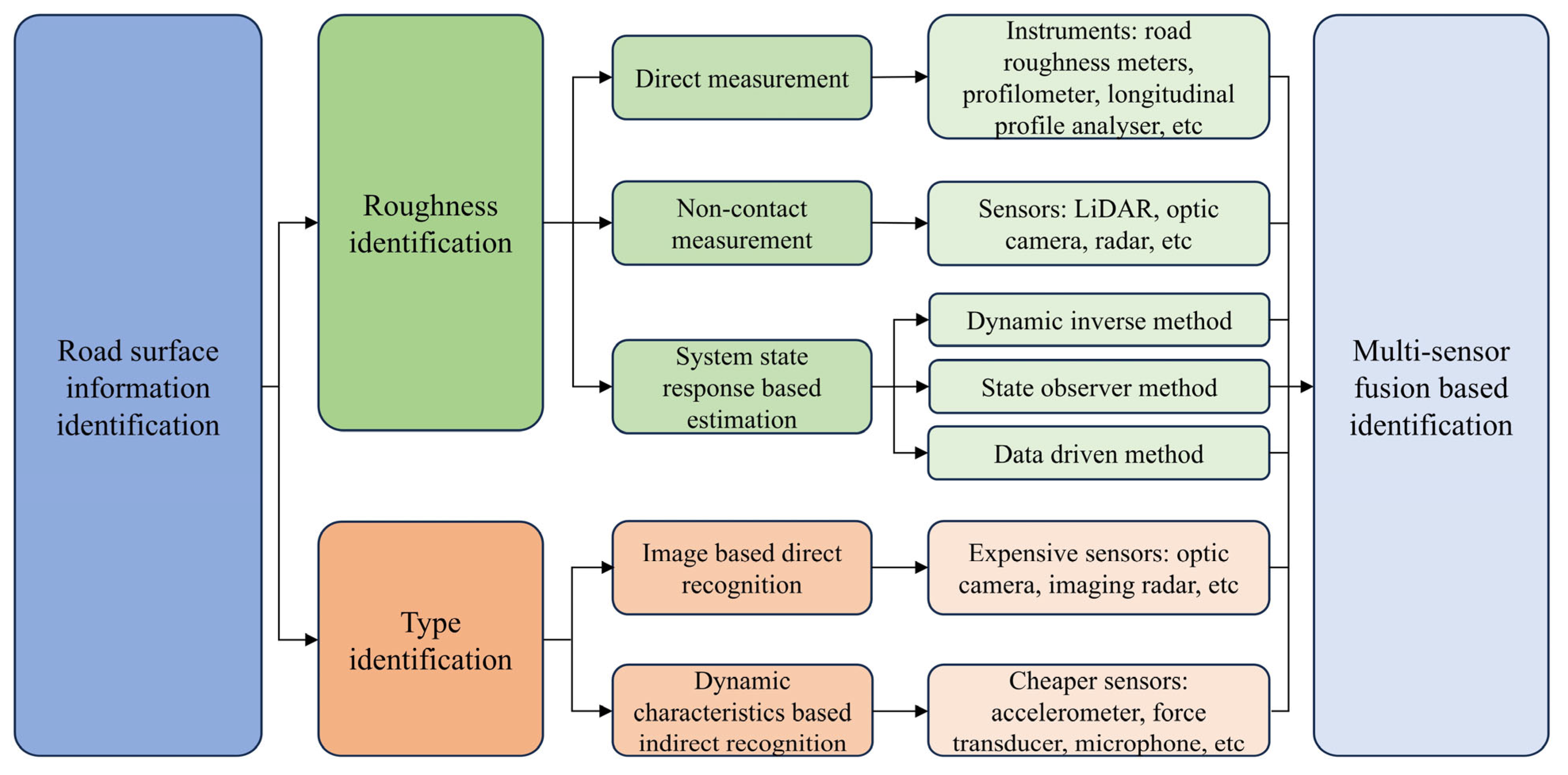

A novel compact pavement profilometer was employed by Abulizi et al. [153] to conveniently collect data for assessing the roughness condition of public roads. Lushnikov et al. [161] compared the operational characteristics and measurement accuracy of several profilometers used for measuring road surface longitudinal roughness. Currently, a widely adopted road roughness meter within the industry is the Longitudinal Profile Analyzer (LPA) developed by the Laboratoire Central des Ponts et Chaussées (LCPC) in Nantes, France. Its structure is shown in Figure 16. This instrument can accurately measure road surface profiles with amplitudes around ±100 mm and wavelengths spanning 0.5–20 m to 1–50 m. Since that the LPA feeler wheel maintains contact with the road surface via a spring and damper system, the spring stiffness and damper damping coefficient influence the amplitude–frequency characteristics of the LPA, thereby affecting the measurement accuracy within its resonance frequency range [162]. Besides the French LPA, other commonly applied road roughness meters include the articulated multi-wheeled profilograph developed by the UK’s Transport Research Laboratory (TRL) [163], and the vibratory cumulative measuring device adopted by the US Federal Highway Administration (FHWA) [164].

Figure 16.

Longitudinal Profile Analzser developed in France.

Limitations inherent in the structure and installation requirements of road roughness meters result in the poor transplant ability of these instruments. Furthermore, the measurement process necessitates that vehicles must travel at relatively low speeds. Therefore, direct measurement methods based on specialized equipment are mainly applied to pavement maintenance and repair and inapplicable for real-time road information acquisition on conventional vehicles.

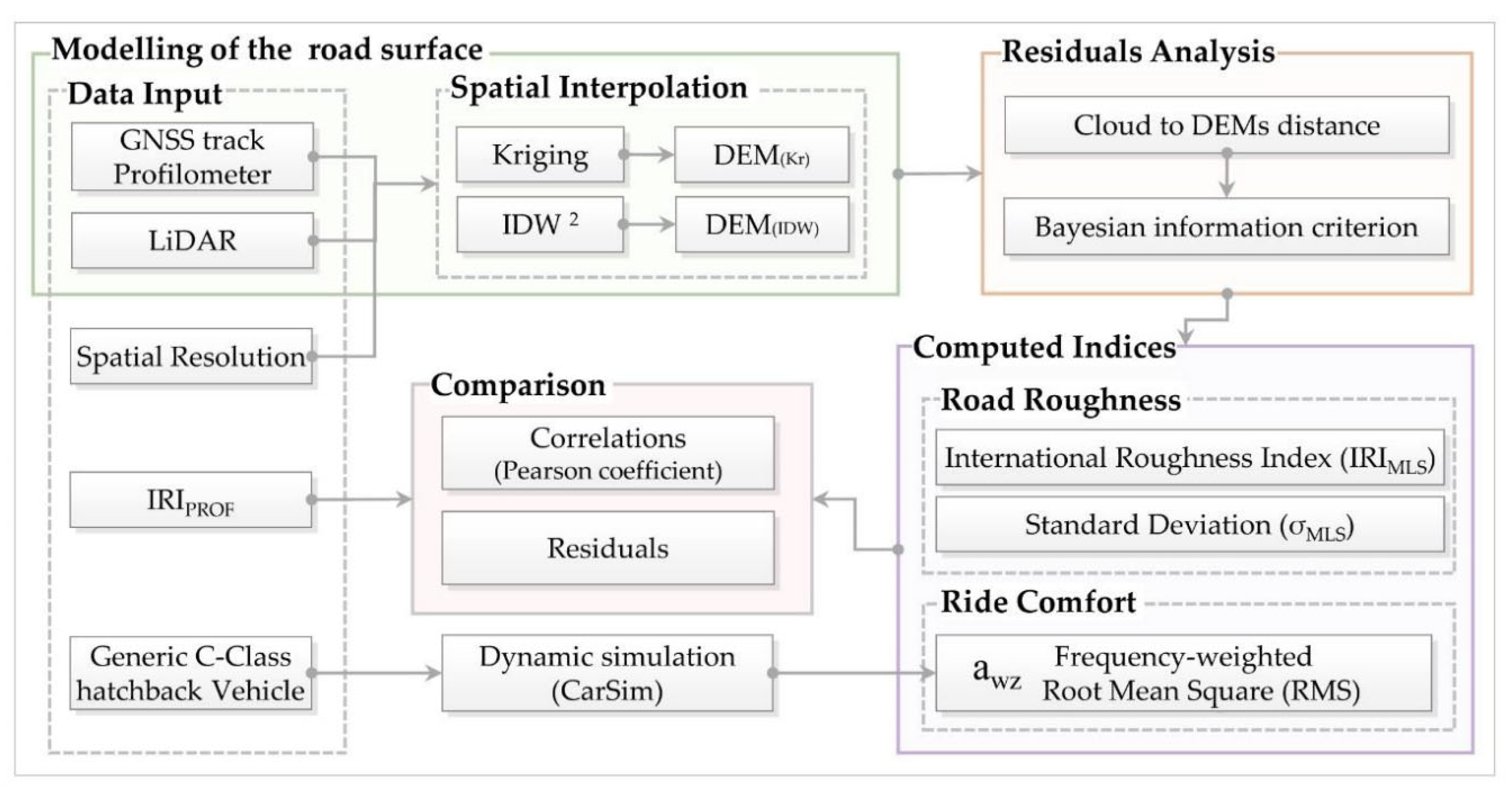

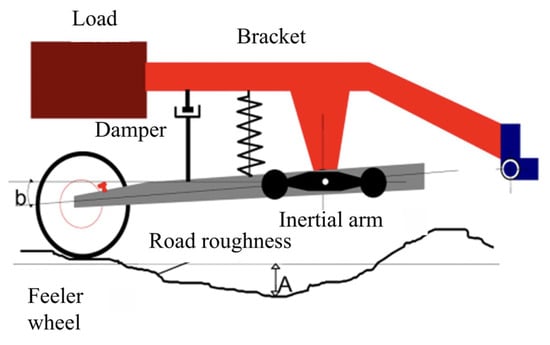

4.1.2. Non-Contact Measurement Methods

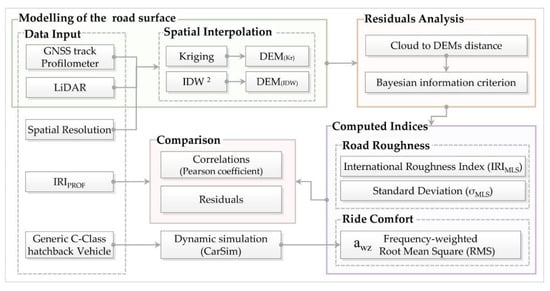

Non-contact measurement methods operate based on the inertial reference principle. Distance sensors (e.g., Light Detection And Ranging (LiDAR), Radar) or vision sensors (e.g., optic camera) installed on vehicles are utilized to directly measure road surface profile [165]. With the advancement of automotive intellectualization, these methods exhibit broad application prospects. Babu et al. [154] proposed a novel semi-empirical model for road surface roughness identification based on the high-resolution airborne Polarimetric Synthetic Aperture Radar (PolSAR). The measurement results demonstrated high agreement with ground truth data. Furthermore, the proposed model is adaptable to lower-performance SAR systems, thereby reducing identification costs. Gao et al. [166] applied high-precision point cloud data from a 3D LiDAR to measure urban pavement roughness. This approach accurately estimated the International Roughness Index (IRI) values of actual roads and the distribution characteristics of their spatial roughness. The LiDAR data-based identification algorithm developed by Kumar et al. [167] estimated pavement roughness by calculating the profile residual values between the LiDAR points and road surface mesh. Their experimental results validated the algorithm’s effectiveness. Blasiis et al. [168] designed the identification workflow illustrated in Figure 17. It demonstrates the minor deviations between road surface profiles calculated from LiDAR data and those directly acquired by a profilometer.

Figure 17.

Identification workflow of a non-contact measurement method based on LiDAR.

Current research indicates that LiDAR-based non-contact measurement methods achieve high accuracy but they impose a significant cost burden on vehicles. Consequently, the relatively lower-cost optic cameras attain expanded concerns. Khalifeh et al. [169] constructed 3D road surface models according to the color and depth images captured by cameras. The road profile under a single wheel track was then extracted to ultimately derive the IRI value. This method offered high measurement accuracy and low equipment costs. Aleadelat et al. [170] employed a low-cost depth camera to estimate IRI values, achieving accuracy of 83%.

Although non-contact measurement methods show high identification accuracy and good transplant ability, enabling on-board measurement on conventional vehicles, they necessitate additional expensive sensors and image processors. Moreover, due to lengthy processing times, measurement effectiveness remains constrained by vehicle speed (typically 20~100 km/h). Additionally, commonly used LiDARs and cameras exhibit poor environmental adaptability, making it difficult to guarantee their measurement accuracy under rainy or snowy weather [171].

4.1.3. System State Response-Based Estimation Methods

To address the limitations of direct measurement methods, such as poor transplant ability, and those of non-contact measurement methods, such as high cost and poor environmental adaptability, estimation methods based on vehicle dynamic responses using low-cost sensors commonly equipped in conventional vehicles have garnered significant attention. The type of suspension signals used obviously impacts the applicability and estimation accuracy of different state response-based estimation methods.

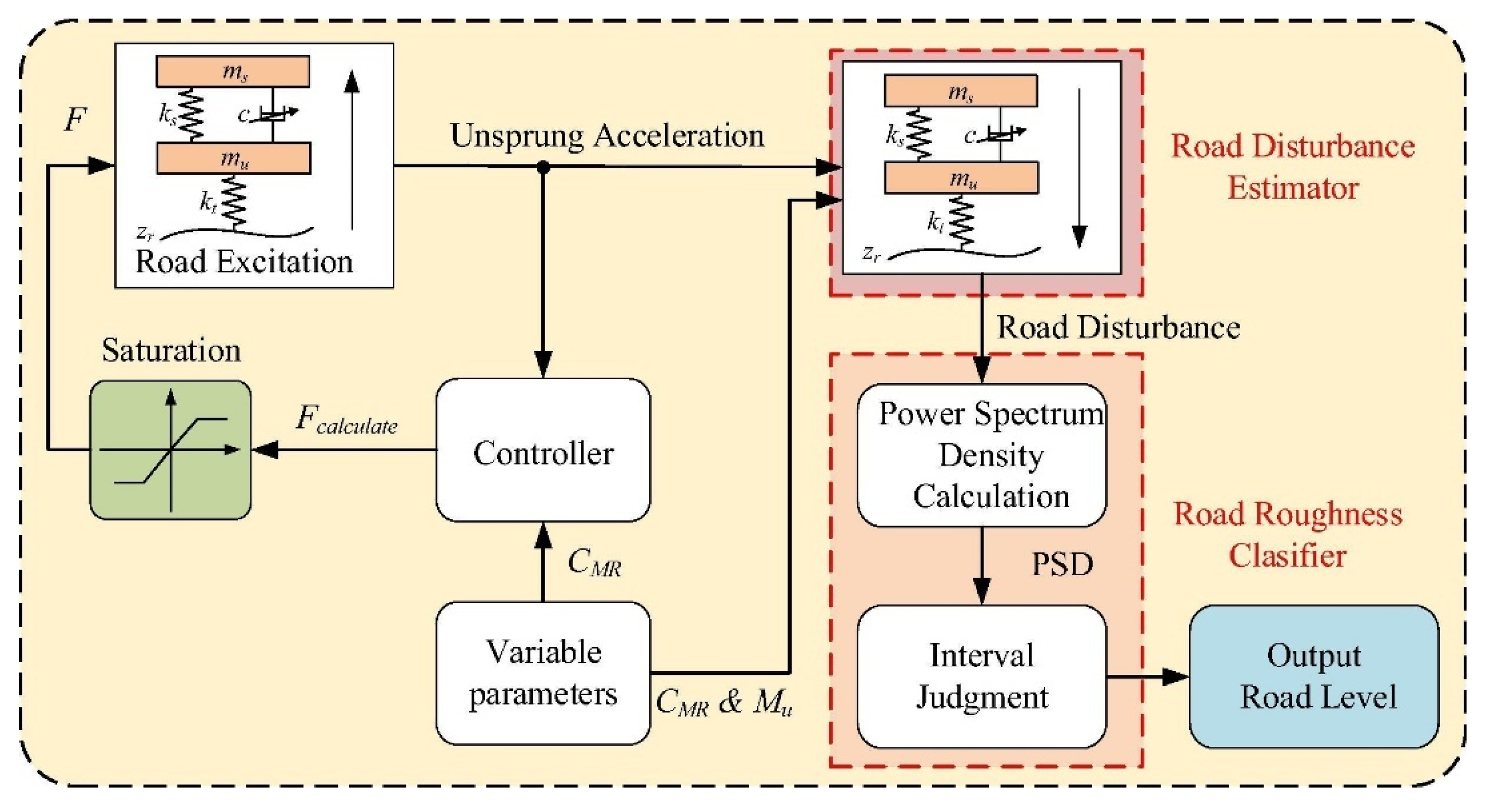

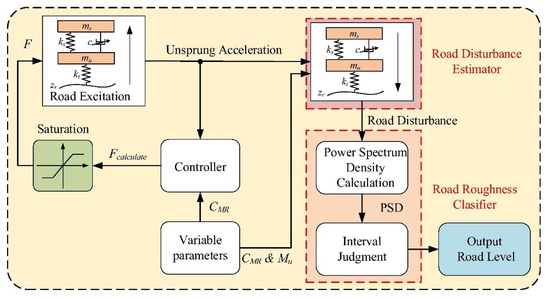

Acceleration is one of the most common signals and boasts the highest sensor equipment rate in suspension systems. It directly reflects vehicle vibration intensity; hence, identification methods based on acceleration signals have been extensively researched. Liu et al. [172] designed an online road level identification algorithm based on vehicle body acceleration signal, with its principle illustrated in Figure 18. First, they constructed an inverse dynamic model of a quarter-car suspension system with the adaptive neural fuzzy network, then the time-domain road surface profile estimator was designed. Finally, the frequency-domain road level estimator was developed based on Power Spectral Density (PSD) estimation. Experimental results demonstrated that this algorithm achieved estimation accuracy exceeding 90% across various random roads and exhibited excellent adaptability to varying vehicle speed. Liu et al. [155] proposed a speed-decoupled road level identification method. Vehicle body and wheel accelerations were selected as input signals, and an improved Least-Squares Method (LSM) was applied to obtain pure spatial-domain pavement roughness parameters independent of vehicle speed, with estimation accuracy exceeding 95%. Axle acceleration was utilized by Ngwangwa et al. [173] to design a road identification method based on an artificial neural network for mining trucks. Notably, this method exhibits high estimation accuracy for discrete road obstacles, such as bumps, depressions, and potholes. Based on the Long Short-Term Memory (LSTM) model, Im et al. [174] designed a deep learning identification system for entire vehicles to estimate the roughness of unknown roads. This method worked with the data from accelerometers and gyroscopes at the vehicle’s center of gravity without a physical suspension system model, rendering it more lightweight and efficient.

Figure 18.

Principle of the online identification algorithm for road level.

In addition to the acceleration signal, suspension working stroke is another readily measurable vibration characteristic parameter. Guo et al. [175] proposed that suspension working stroke has the potential to be employed for pavement roughness identification. For this purpose, a novel road level evaluation index was defined, and its explicit expression in terms of suspension working stroke and vehicle speed was derived. Gong et al. [176] introduced the new Relative Roughness Index (RRI) according to IRI as the basis for identifying complex road roughness encountered by heavy-duty rescue vehicles. Furthermore, with suspension working stroke as the sole input, the road level identification method based on a Takagi–Sugeno (T-S) fuzzy controller was developed. A discrete Kalman observer considering unknown inputs was designed by Kang et al. [177]. Suspension working stroke, vehicle body acceleration, and wheel acceleration were selected as the state variables for online road surface roughness estimation. Due to significant simplifications of suspension system nonlinearities, this method exhibited certain identification errors. To address this limitation, Kim et al. [178] incorporated a vehicle parameter identification module to enhance the Kalman observer’s accuracy. Focusing on a half-car model, Li et al. [179] selected eight suspension signals as inputs, namely suspension working stroke, vehicle body acceleration, wheel acceleration, vehicle body pitch angular velocity, and displacement, and then employed the orthogonal experimental design to analyze the performance of four typical neural networks, namely BackPropagation (BP), Radial Basis Function (RBF), wavelet, and Nonlinear AutoRegressive with eXogenous inputs (NARX). Simulation results verified NARX as the optimal neural network for road roughness identification. Wang et al. [180] investigated the application potential of pavement roughness identification for multi-axle heavy vehicles. Using displacement and oil pressure signals from hydro-pneumatic suspension cylinders as response signals, a Support Vector Machine (SVM) trained by both model and real vehicle data was employed to recognize the road level.

System state response (e.g., acceleration, suspension working stroke)-based road surface roughness identification can be categorized into three core methodologies. The first type is the dynamic model-based inverse method, in which the road profile is directly estimated from sensor data according to the dynamic relationship between vehicle body and wheels. The second type is the state observer method, in which an observer designed based on the vehicle physical model fuses multi-sensor data to simultaneously estimate road information and suspension states. In contrast, the last type bypasses physical modeling and directly establishes end-to-end mapping from sensor data to road roughness, which is referred to as the data-driven method. A comparative analysis of these three methods is presented in Table 5.

Table 5.

Performance comparison of three system state response-based estimation methods.

Road surface roughness identification methods have been primarily classified into three major categories: direct measurement methods, non-contact measurement methods, and system state response-based estimation methods. Each category possesses distinct characteristics and respective strengths. Table 6 summarizes the features and applicable scenarios of these three identification methods.

Table 6.

Performance comparison of three road surface roughness identification methods.

4.2. Identification of Road Surface Type

One fundamental function of suspension systems is to transmit and dynamically distribute the vertical loads acting on the tires. This ensures that tires maintain continuous contact with uneven road surfaces, thereby maximizing effective adhesion utilization between the tires and pavements. Furthermore, this enhances the traction performance, braking performance, and handling stability of vehicles. The same pavement under different environmental conditions, or different types of pavements under the same conditions, exhibit distinct surface characteristics. For instance, road adhesion significantly deteriorates on wet or icy surfaces, while gravel roads present a broadband random excitation. In addition, discrete pavement features, such as potholes, bumps, and cracks, impose more stringent demands on suspension system performance. Therefore, research on road surface type identification, followed by adaptive switching of suspension operating modes, constitutes a critical pathway for ensuring that vehicles maintain superior dynamic performance and energy regeneration capability even under complex road conditions. Additionally, different road types typically exhibit characteristic statistical features of the roughness, which can serve as prior knowledge to assist in estimating road surface roughness. Image-based direct recognition methods and vehicle dynamic characteristic-based indirect recognition methods are typically employed in the estimation of road surface types.

4.2.1. Image-Based Direct Recognition Methods

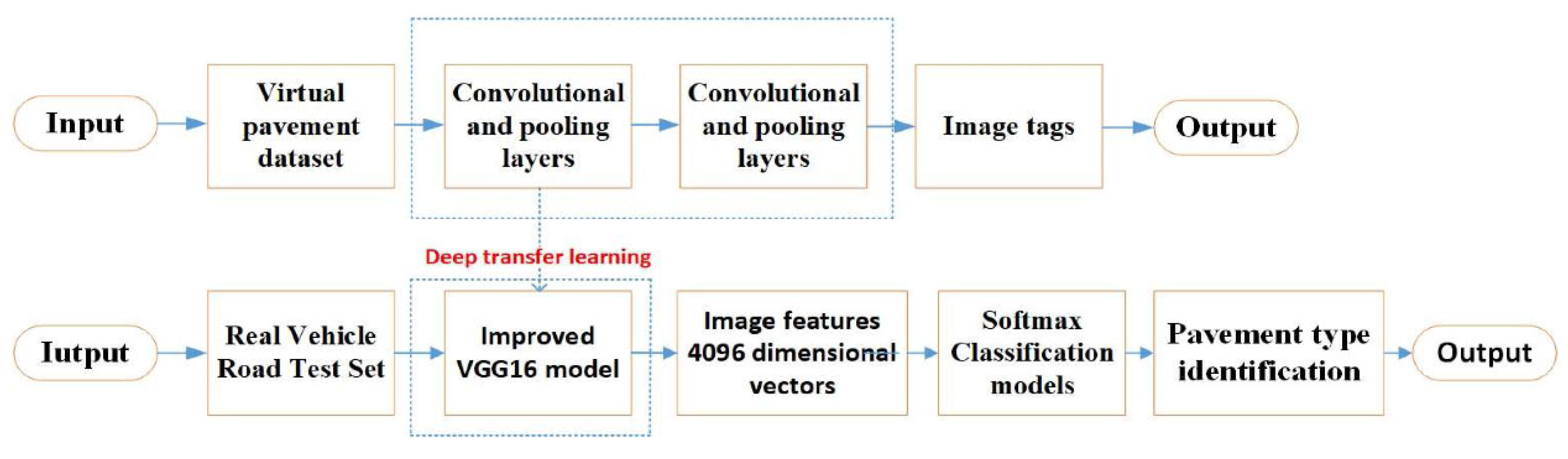

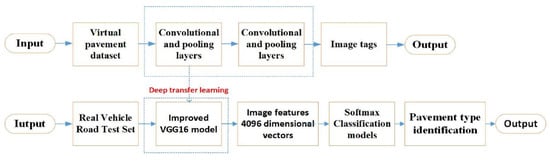

Direct recognition methods comprehensively utilize sensors, such as optic cameras and imaging radar, to acquire road surface images. Target information is then directly identified through image processing [181]. Sabery et al. [156] employed the Convolutional Neural Network (CNN) to classify road surfaces with images captured by an imaging radar. Liu et al. [182] also utilized the CNN to process the collected road surface image data via cameras for type identification. The recognition accuracy exceeded 99.9% for different road surfaces, with a processing time of approximately 9.5 ms per image. Subsequently, the control parameters of a semi-active control strategy were optimized based on the identified road information, enabling the suspension system to achieve superior dynamic performance. Zhao et al. [183] proposed a vision-based road classification method with the recognition accuracy of 94.84%. This method extracted texture features from road surface images captured by a camera, and then a deep learning classification model incorporating specific training strategies was employed to infer the road surface type. Furthermore, advancing this approach, Zou et al. [184] combined transfer learning with the Visual Geometry Group Network (VGGNet) model to design a network architecture specifically tailored for road classification. Its processing workflow is illustrated in Figure 19. Compared to other classical network models, this approach has significantly improved identification accuracy and training speed, making it applicable for preemptive perception of road types. The recognition method combining visual data with a Deep Neural Network (DNN), developed by Šabanovič et al. [185], exhibited high identification efficiency and was capable of monitoring every half-meter of road surface at vehicle speeds of 100 km/h.

Figure 19.

Transfer learning process for pavement classification recognition based on the improved VGGNet-16 model.

For suspension control, discrete road surfaces, such as potholes, bumps, and cracks, significantly impact ride comfort and driving safety. Therefore, with road structural features as classification criterion, vision sensor-based road type identification methods have also been investigated. These methods aim to preemptively adjust suspension control parameters, thereby mitigating the deterioration of vehicle dynamic performance under transient excitations. Wang [186] proposed a semi-global block matching algorithm to construct a road profile model from 2D images captured by binocular cameras, and then extracted the road slope and bump features to train a multi-class SVM. As a result, the SVM could identify four characteristic road types: uphill, downhill, flat roads, and speed bumps.

The effectiveness of image-based direct recognition methods hinges on the efficiency of the image processing techniques. Common techniques are categorized into traditional methods and deep learning methods [187,188]. The former involves two steps: feature extraction and classifier construction. These typically require manual intervention, consuming significant labor and time resources, and exhibit limited performance in complex scenarios [189,190]. In contrast, deep learning methods can directly process raw data. They enable machines to autonomously learn feature representations and abstractions, thereby avoiding tedious manual feature construction and enhancing image recognition accuracy [191,192].

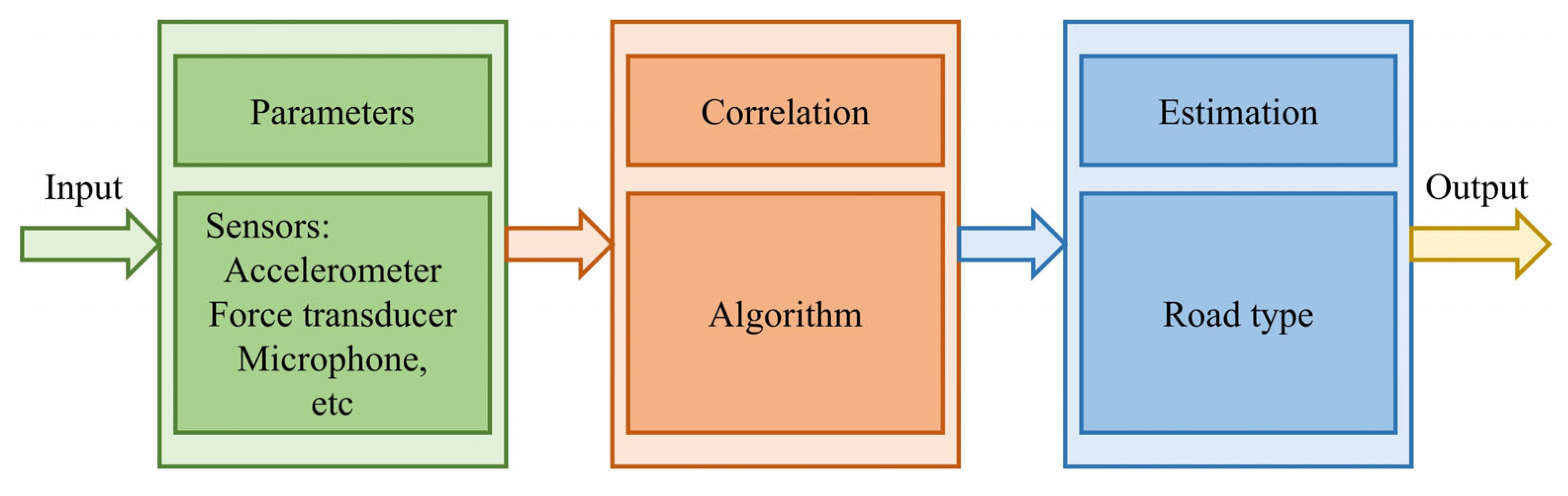

4.2.2. Vehicle Dynamic Characteristic-Based Indirect Recognition Methods

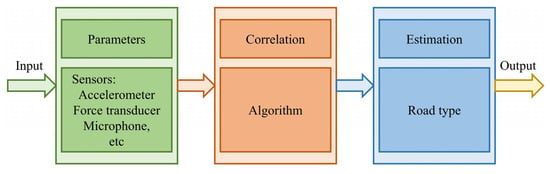

Direct recognition methods are inherently dependent on image quality, and their operational performances under harsh environmental conditions are difficult to guarantee. In addition, when actual driving conditions deviate from the algorithm training conditions, the estimation accuracy for road surface type tends to decrease. In contrast, vehicle dynamic characteristic-based indirect recognition methods exhibit superior environmental adaptability. Their fundamental principle is illustrated in Figure 20. Additionally, dynamic characteristic-based classification models inherently imply the interaction mechanics between the vehicle and the road surface. Therefore, their identification results possess greater applicability value for vehicle control.

Figure 20.

Fundamental principle of vehicle dynamic characteristic-based indirect recognition methods.

Ward et al. [157] posited that the wheel acceleration directly reflected the road profile, thus selecting this signal as the algorithm input and employing an SVM for the identification. Notably, the vehicle speed was decoupled by performing spatial estimation on the road profile. Wang et al. [193] utilized accelerometers to capture triaxial accelerations during tire rolling, and then extracted time-domain and frequency-domain statistical features from the longitudinal and lateral acceleration signals. Following dimensionality reduction via principal component analysis, an SVM was used to classify and train the feature parameters, ultimately achieving road type estimation. With wheel vertical forces selected as the response signals, Yang et al. [194] applied wavelet packet transform for feature extraction, followed by an SVM for unpaved road classification. Zhao [195] selected wheel speed fluctuation, rolling resistance, and vertical acceleration as inputs and adopted the SHapley Additive exPlanations (SHAP) approach to elucidate the correlation between dynamic features and road surface types. A Random Forest (RF)-based road classifier was subsequently designed, and its recognition accuracy and recall rate both exceeded 93%.

The acoustic footprint varies significantly across different road types, and the frequency of tire–road noise on the same surface differs under varying moisture levels. On this basis, Alonso et al. [196] proposed a method to identify the dry/wet state of asphalt pavements by measuring tire–road noise. Paulo et al. [197] investigated the correlation between the acoustic signals generated at the tire–road interface and the road profile based on statistical learning methods. Combining Bayesian analysis with a neural network for road type classification achieved accuracy exceeding 90%. Furthermore, Kalliris et al. [198] evaluated the practical performance of various machine learning algorithms for road type identification using tire noise. Results demonstrated that second-order and third-order SVMs yielded the best performance.

The working principle underlying indirect road type identification is fundamentally identical to the data-driven method for road surface roughness identification introduced in Section 4.1.3. Both bypass system modeling to directly establish a mapping relationship between sensor data and road characteristics (roughness or type). However, the sensors employed for road type identification are not limited to those typically deployed within suspension systems.

To utilize the complementary strengths of both direct and indirect methods, multi-sensor fusion-based road type identification methods have been proposed. Wang et al. [199] introduced an identification method fusing the features of mechanical and visual sensor data. This approach first reconstructed the road profile via a vehicle dynamic model with wheel acceleration and vehicle speed information. Subsequently, feature extraction and classification of road surface images captured by cameras were conducted. Finally, the data features from all sensors were fused for road type identification. Experimental results revealed that identification accuracy based on the sole dynamic characteristics was relatively low, averaging 67%, while sole image-based identification averaged 88% accuracy. Notably, multi-sensor fusion significantly improved the average accuracy to 90%, with enhanced reliability and adaptability. Although multi-sensor fusion offers higher accuracy and reliability, providing a novel direction for road information identification research, vigilance is required regarding the “barrel effect” (where overall performance is limited by the weakest sensor), introduced by multiple sensors.

4.3. Decision-Making Algorithms for Functionality Switching

Accurate identification of road surface information (roughness and type) serves as an essential input for suspension control, but it is the decision-making algorithms that act as the intelligent gateway, determining the functional mode of LMEERS. The core objective of these algorithms is to resolve the inherent conflict between vibration isolation and energy harvesting by the intelligent switching between active control and energy regeneration modes based on real-time driving conditions. The prevailing decision-making algorithms can be categorized as follows.

- Rule-Based Threshold Switching: This is the most straightforward approach, where predefined thresholds on identified road indexes (e.g., IRI [176], root mean square of suspension state variables [177,178,179]) trigger functionality switching. For instance, if the road roughness exceeds a certain threshold, indicating poor road conditions, the algorithm prioritizes active control to ensure ride comfort and driving safety. Conversely, on smooth roads (low roughness), it switches to energy regeneration mode to maximize energy recovery [19,148]. While simple and computationally efficient, this method lacks flexibility and can lead to frequent or oscillatory switching if thresholds are not carefully tuned for complex road scenarios.

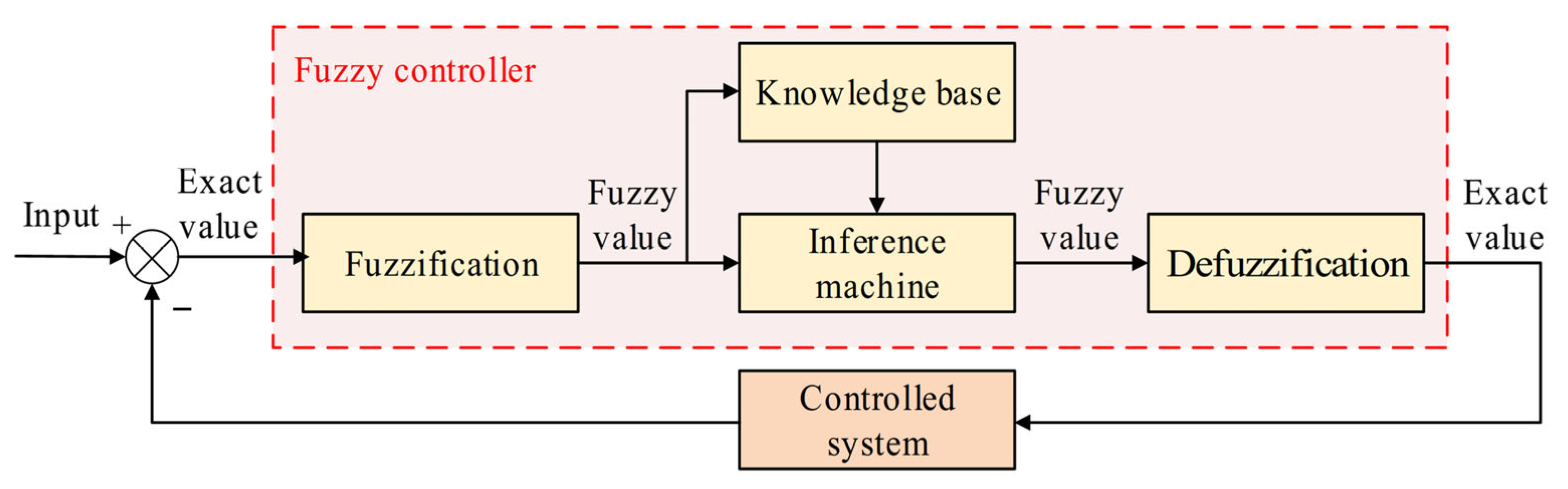

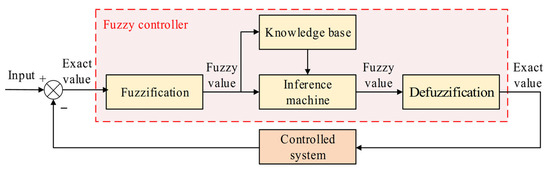

- Fuzzy Logic Inference: Fuzzy Logic Control (FLC) is highly suited for this application due to its ability to handle imprecise inputs with expert knowledge. The identified road information (e.g., “smooth”, “rough”) and vehicle states (e.g., “high speed”, “low speed”) are fuzzified and processed through a set of IF-THEN rules formulated by domain experts to output a decision or a continuous weighting factor between the two functionalities [64,200]. For example, a rule could state: “IF road is very rough AND vehicle speed is high, THEN prioritize active control.” This method offers smoother transitions between modes and better handles the ambiguity in road classification compared to rule-based thresholds.

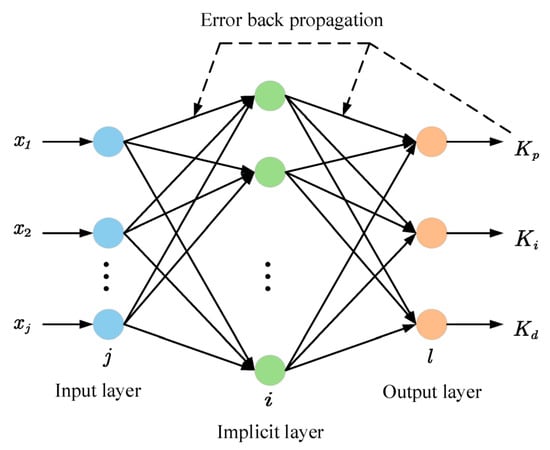

- Learning-Based Adaptive Strategies: With the advancement of onboard processing power, data-driven learning algorithms are emerging for more intelligent and predictive switching. These strategies can adapt the switching policy online based on historical performance or driver preferences. Reinforcement Learning (RL) is a promising framework where an agent learns an optimal policy (switching strategy) by maximizing a reward function that balances ride comfort, driving safety, and energy recovery efficiency [201]. Neural network can also be trained to map identified road features and vehicle states directly to the optimal functionality mode [202,203]. Although these methods promise superior performance and adaptability, they require significant computational resources and extensive training data.

The selection of decision-making algorithms involves a trade-off between computational complexity, performance, and ease of calibration. The ultimate goal is to seamlessly integrate this algorithm with the top-layer control strategies (in Section 5) to form a cohesive hierarchical control architecture that fully exploits the potential of the dual functionality of LMEERS.

In summary, in-depth investigations into road surface information identification have been conducted, establishing it as a crucial switching criterion between the dual functionalities of energy regeneration and active control for LMEERS. Road surface information primarily encompasses road surface roughness and road surface type, typically identified with two on-vehicle approaches, namely image-based methods and dynamic response-based methods.

- The former offers preemptive perception of the road ahead and high identification accuracy but suffers from high equipment costs and poor environmental adaptability.

- The latter provides superior robustness and cost advantages, yet struggles to identify complex road surfaces.

- Multi-sensor fusion-based road information identification methods, capitalizing on the advantages of both methods, represent the future direction for on-vehicle solutions, contingent upon further reductions in sensor costs.

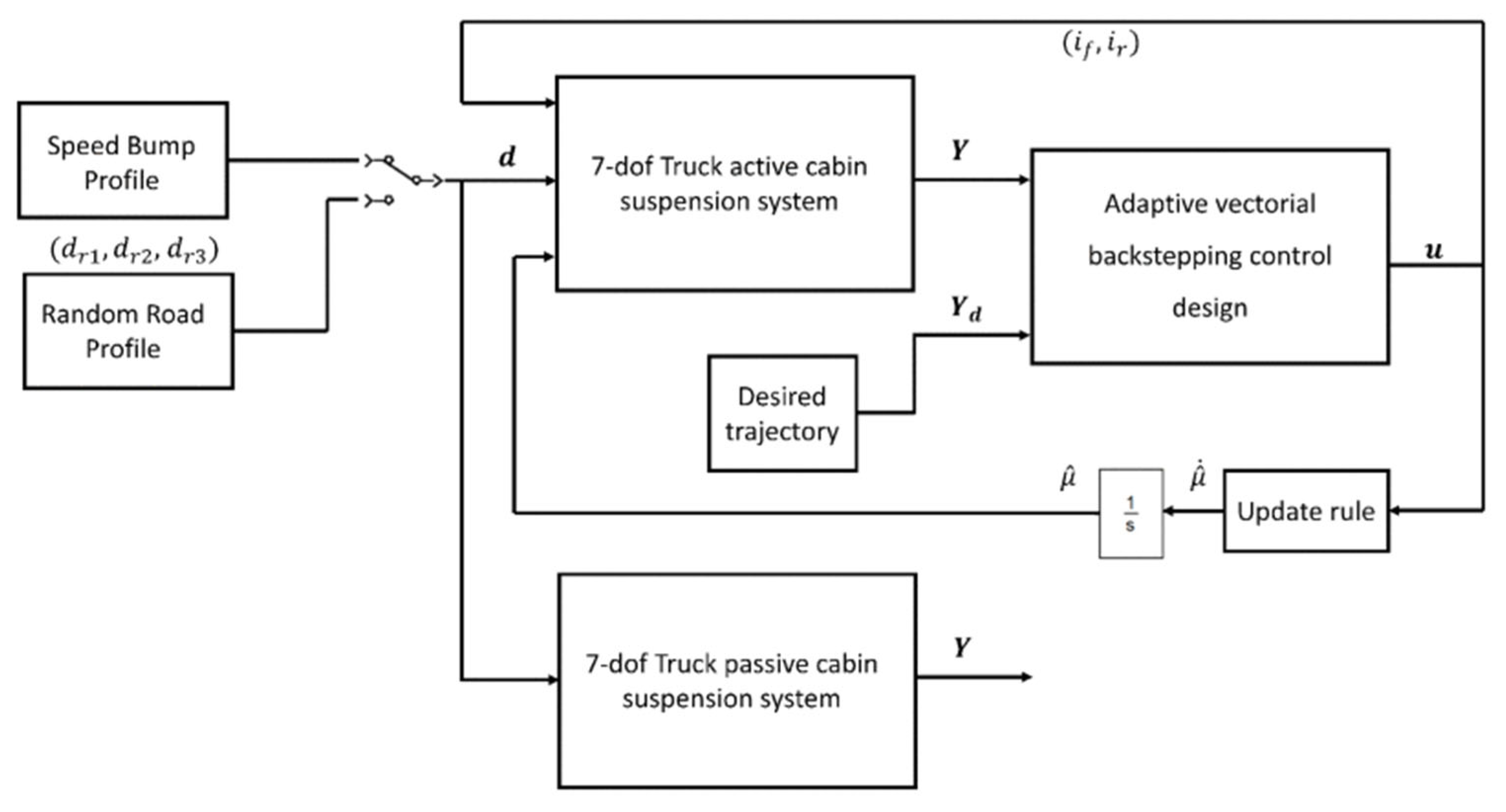

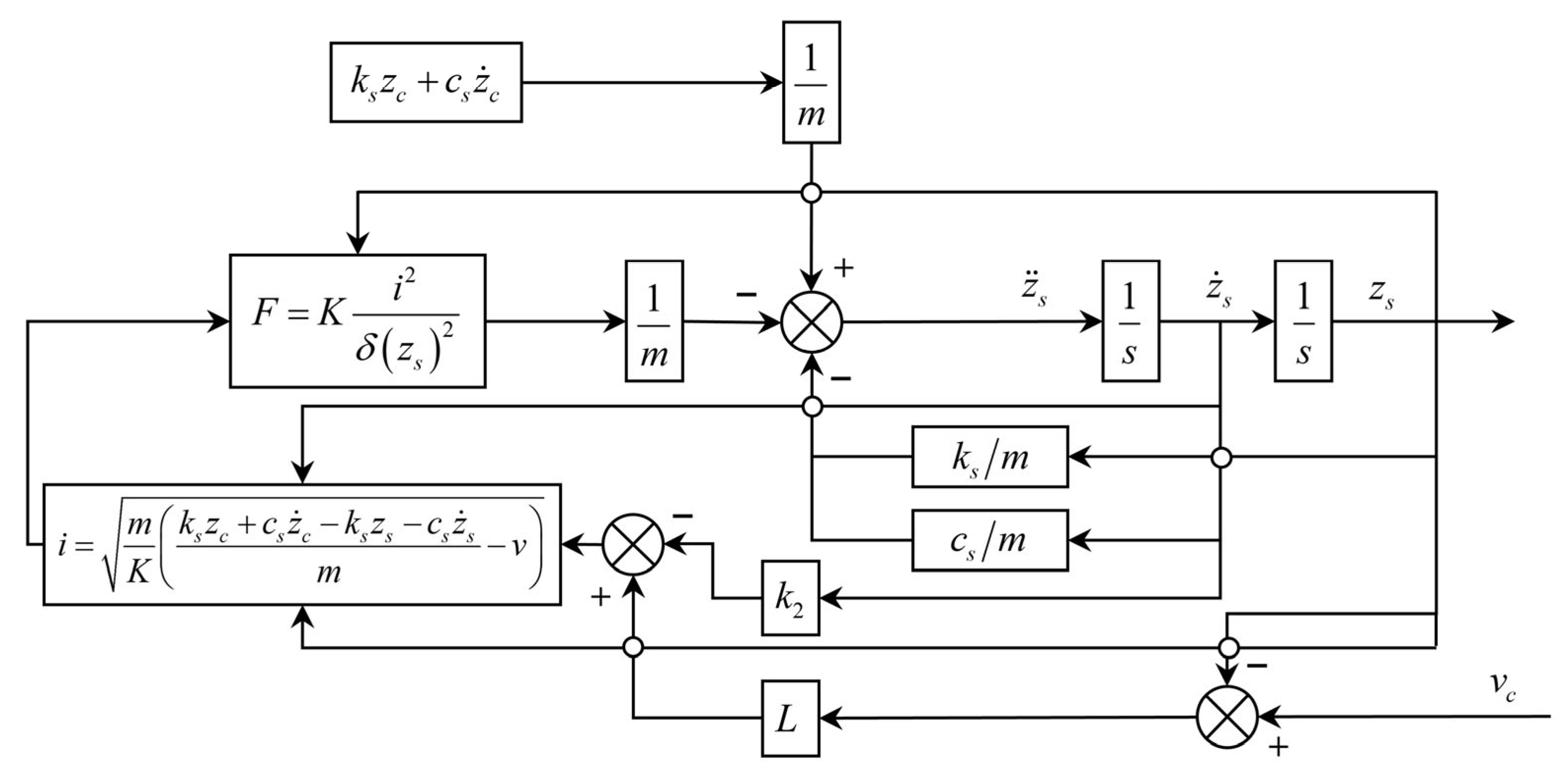

5. Top-Layer Control Strategies of LMEERS

Structural design and top-layer control constitute two pivotal aspects in LMEERS development. The former establishes the physical foundation and defines performance boundaries for the latter, while the latter exploits application potential and compensates for inherent deficiencies of the former. This synergy fundamentally determines the ultimate performance ceiling of LMEERS systems. Currently, extensive and in-depth research has achieved profound advancements in structural design and performance optimization, establishing robust feasibility for active control and energy regeneration within current configurations. Consequently, the imperative now shifts toward developing structure feature-based top-layer control methodologies to maximize operational efficiency across diverse working environments. Top-layer control strategies applicable for LMEERS are typically categorized into three types, namely classical control methods, modern control methods, and intelligent control methods.

5.1. Classical Control Methods

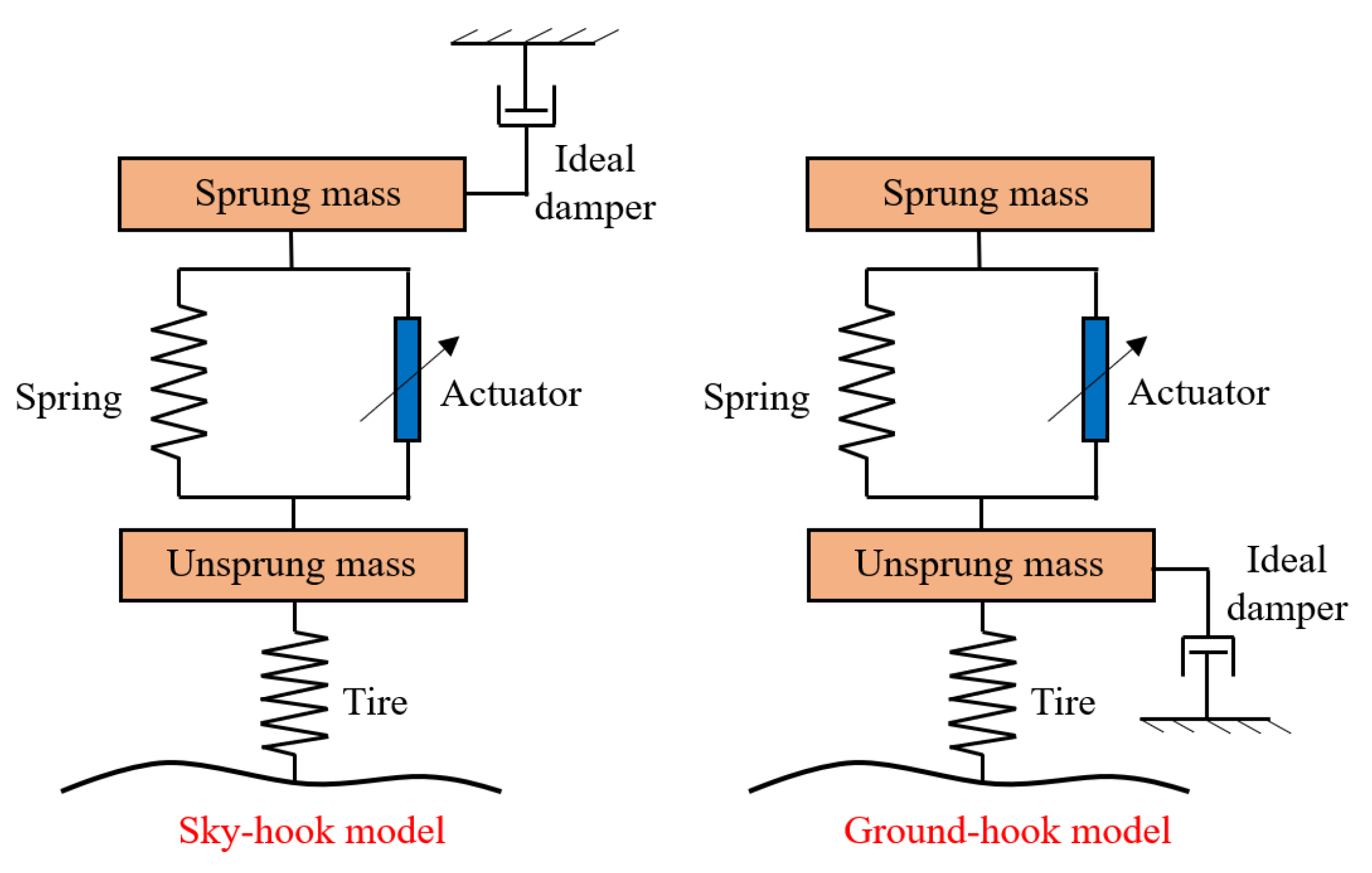

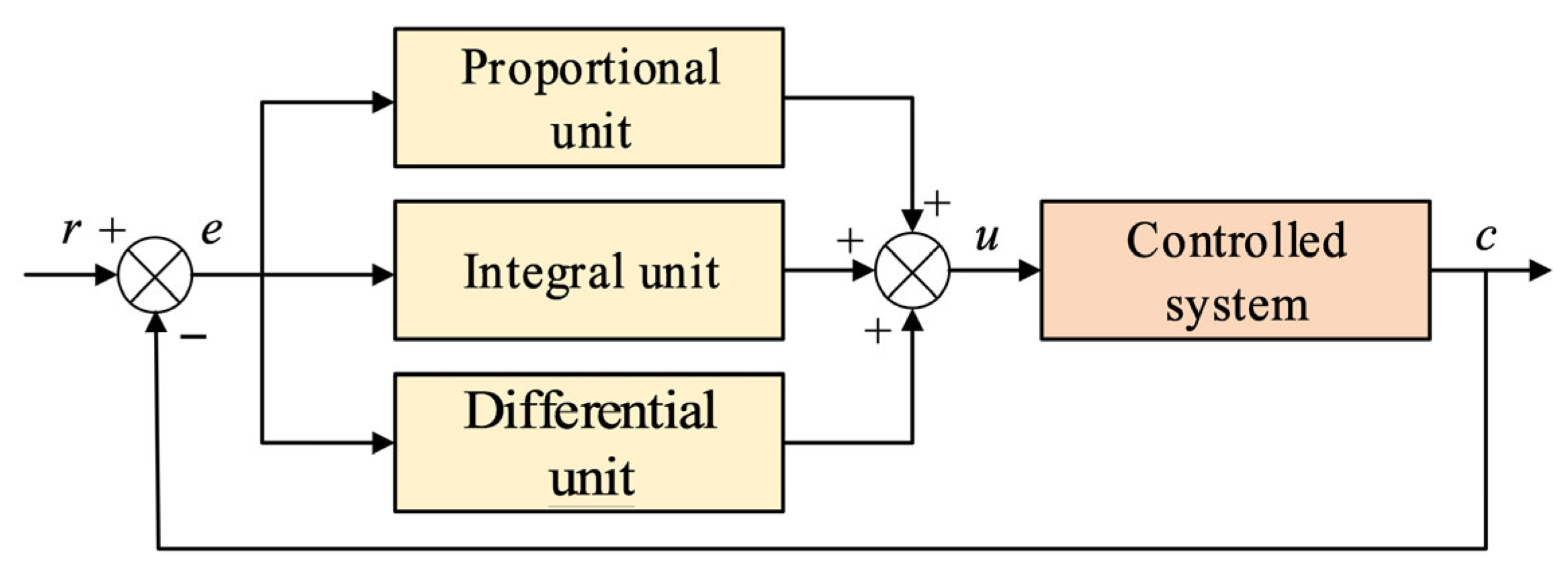

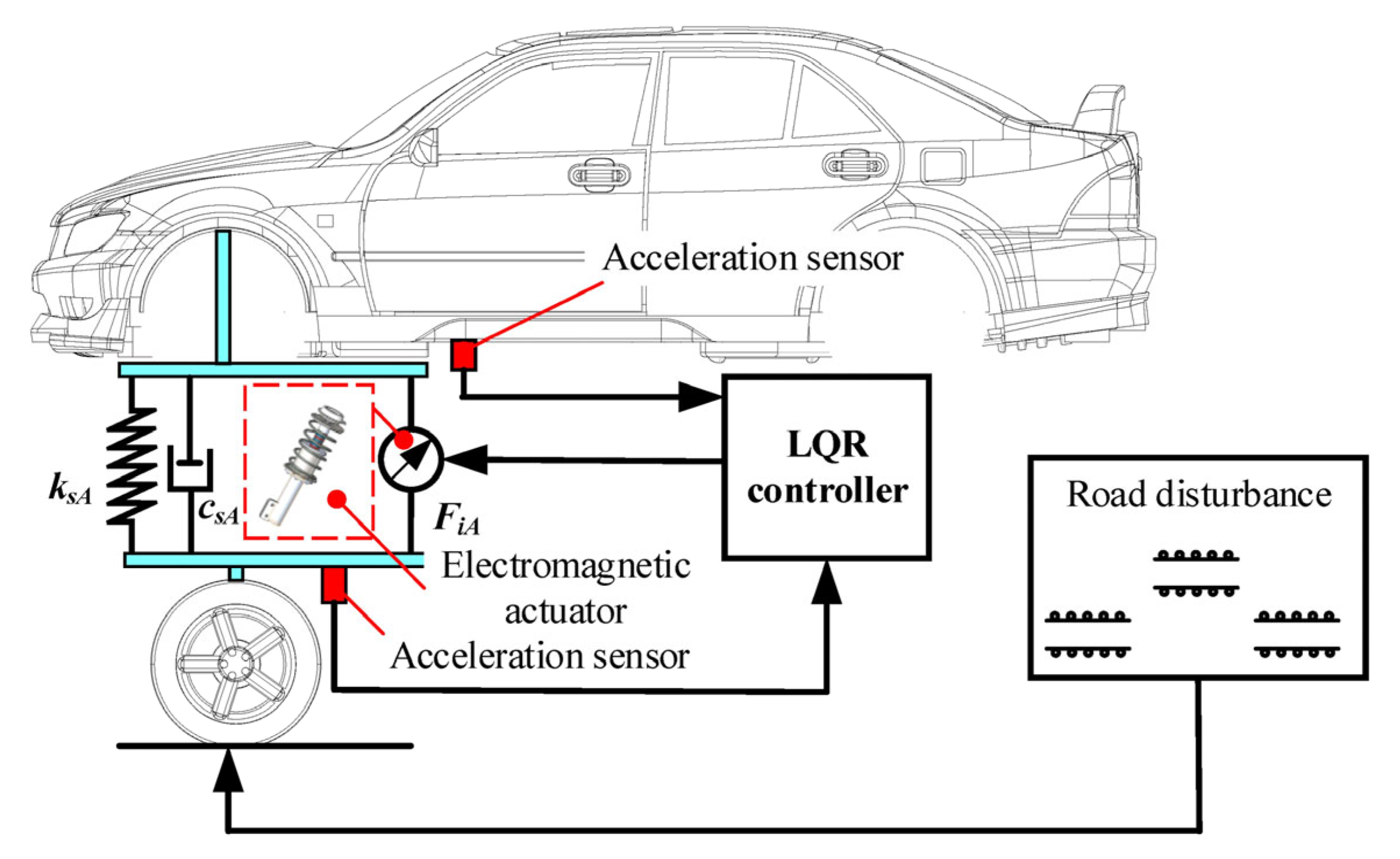

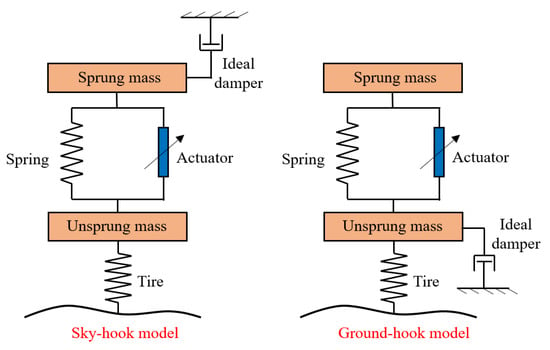

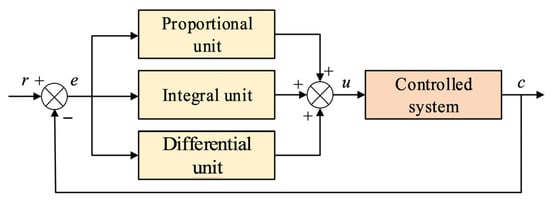

Classical control methods are typically applicable for single-input single-output linear time-invariant systems, the core tools of which are the frequency-domain analysis and transfer function models. These have the advantages of intuitiveness, practicality, and outstanding engineering solution capabilities [204,205]. Presently, the classical control methods commonly applied to LMEERS include skyhook control, groundhook control, and PID control.

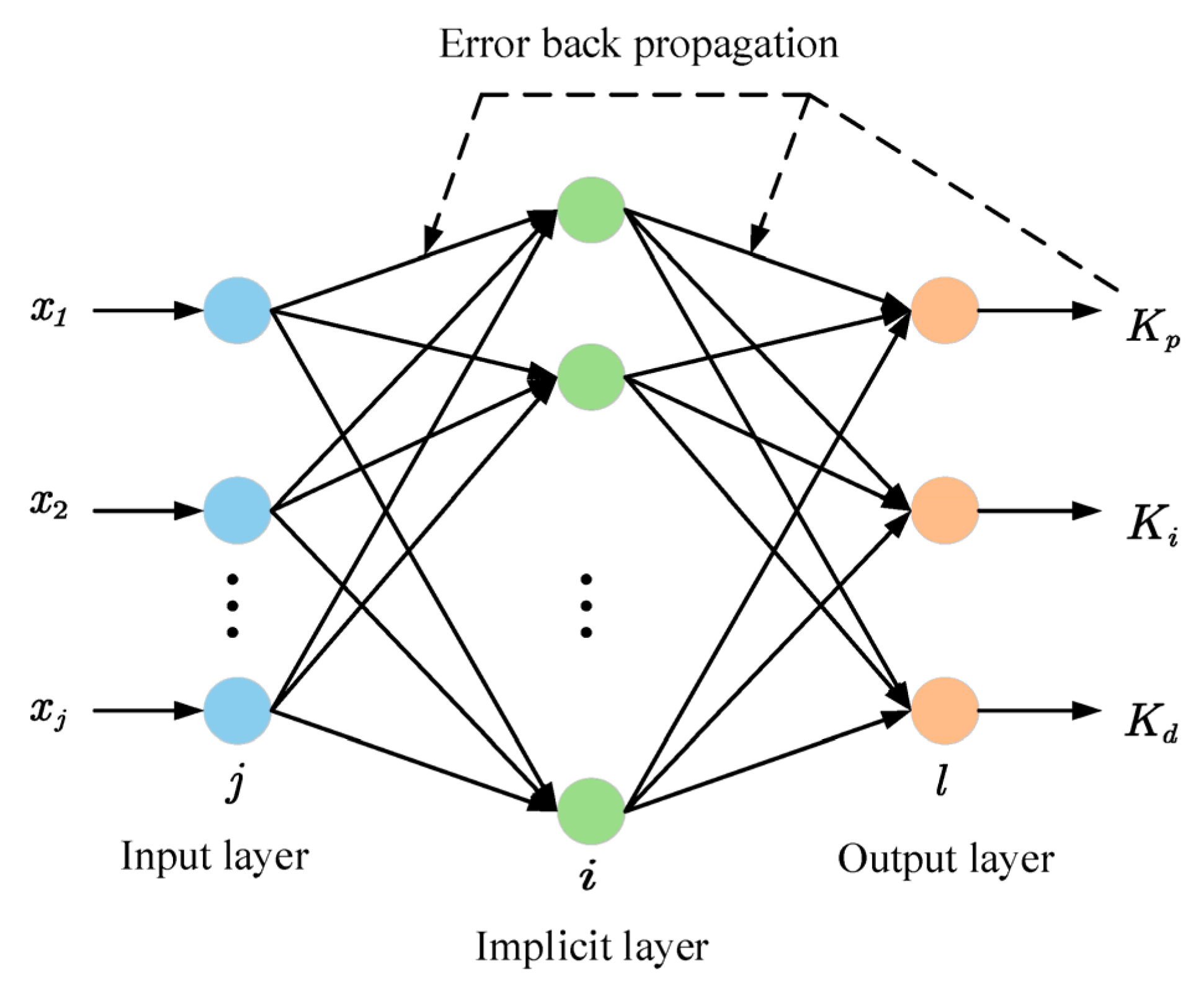

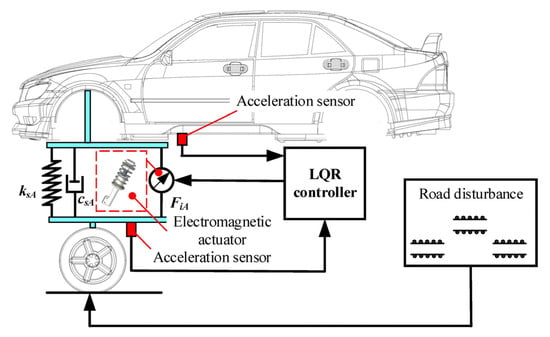

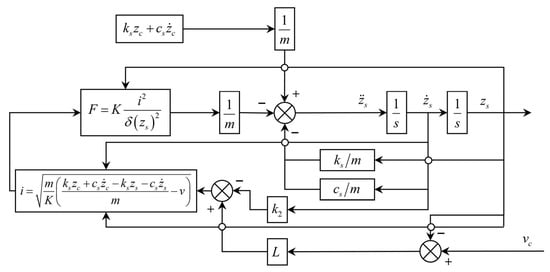

5.1.1. Skyhook and Groundhook Control