A Lifecycle Analysis of a Floating Power Plant Using Biomethane as a Drop-In Fuel for Cold Ironing of Vessels at Anchorage

Abstract

:1. Introduction

- Acquisition and extraction of raw materials;

- Inputs and outputs in the main process;

- Transportation and distribution;

- Production and consumption of energy (fuels, electricity, or heat);

- Product use and maintenance;

- Waste disposal;

- Recycling and recovery of used products.

2. Literature Review

2.1. Biomethane Technology and Transportation (WtT) Compared to Existing LCAs of Biogas-Upgrading Technologies

2.2. Cold Ironing and Utilization of Biomethane as a Pragmatic Solution (PtW)

3. Methodology

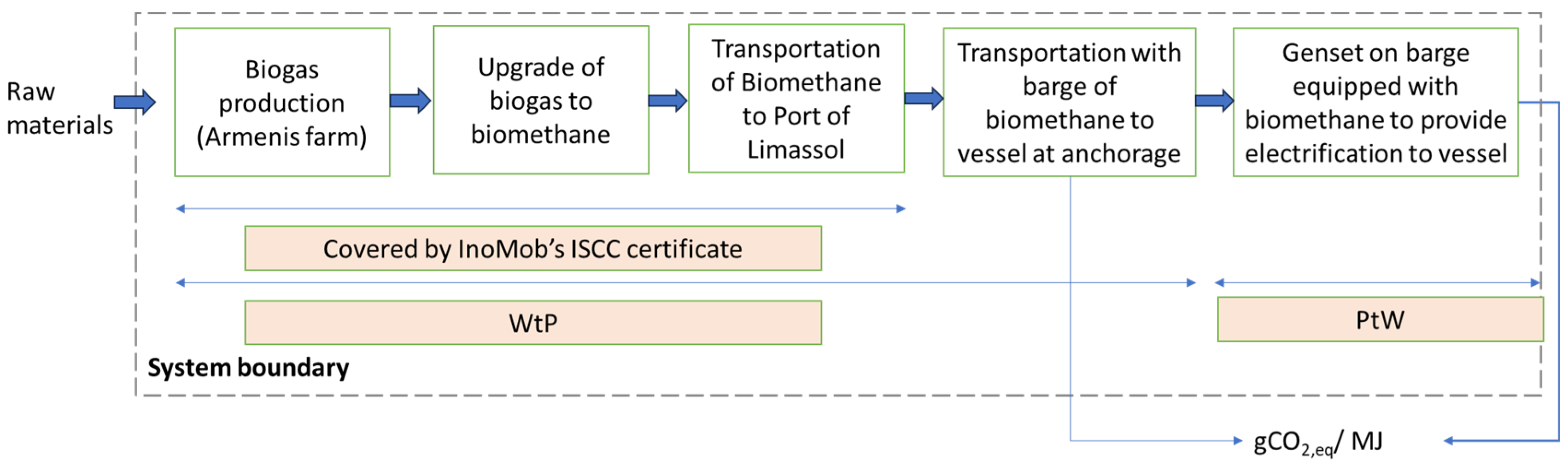

3.1. Scope and Goal Definition of the Current Study

3.2. Inventory Analysis

3.2.1. WtT Calculations and the International Sustainability & Carbon Certification (ISCC)

3.2.2. Emission Factors Used in This Study

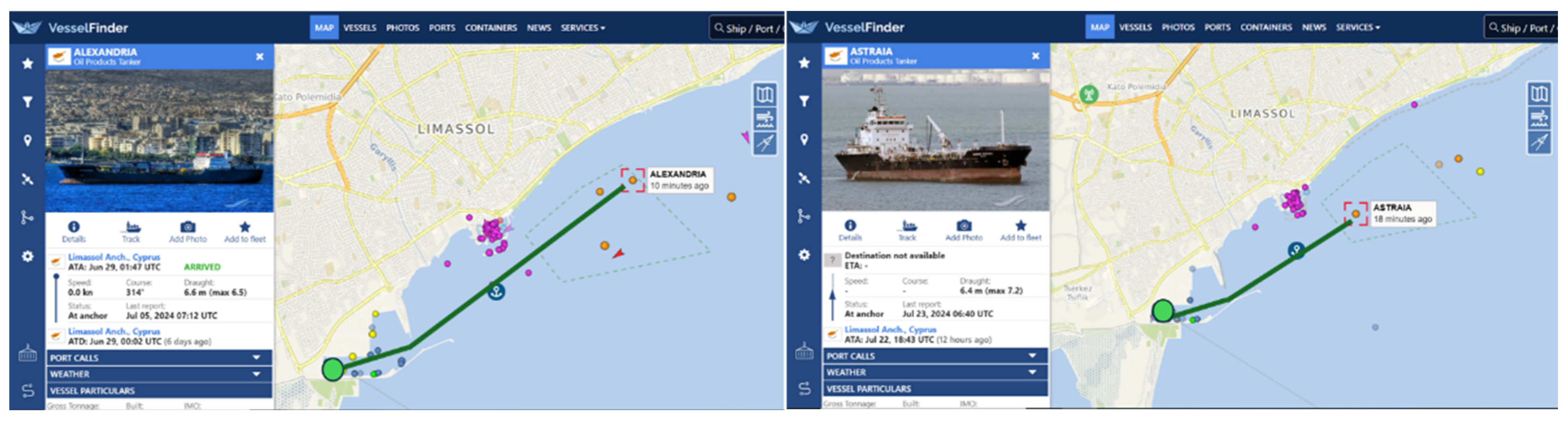

3.2.3. Althaia Barge Propulsion Engines to Transport the Genset to M/T Alexandria and M/T Astraia While at Anchorage

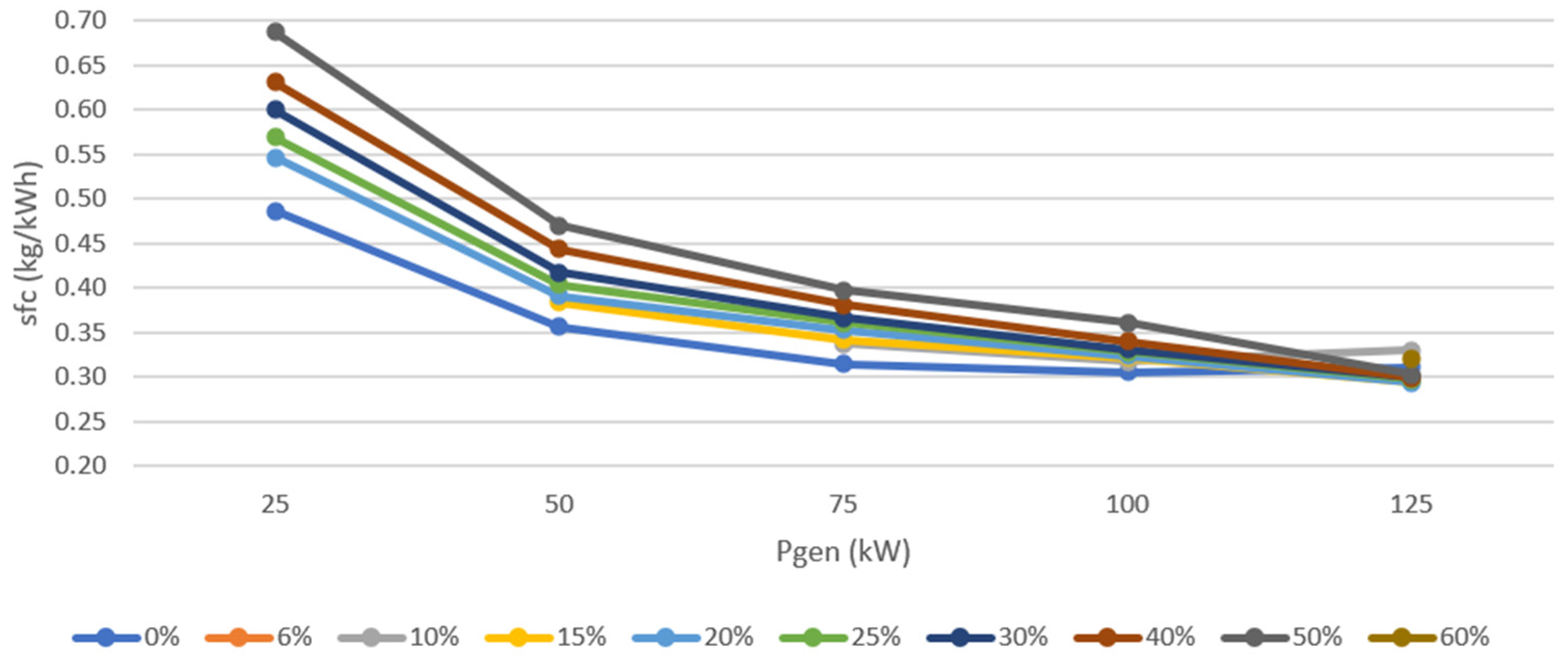

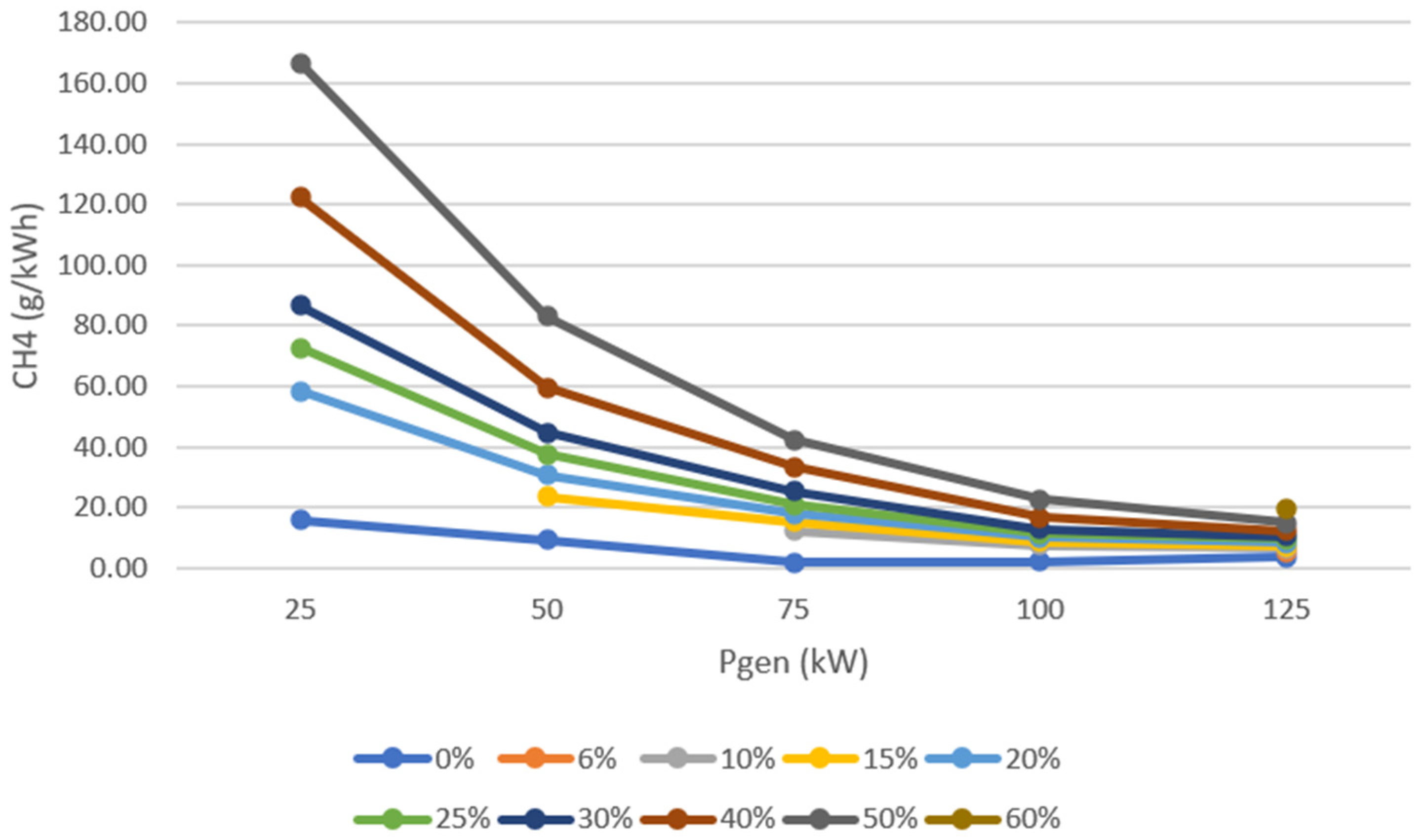

3.2.4. Marine Genset Installed on Barge

4. Results and Discussion

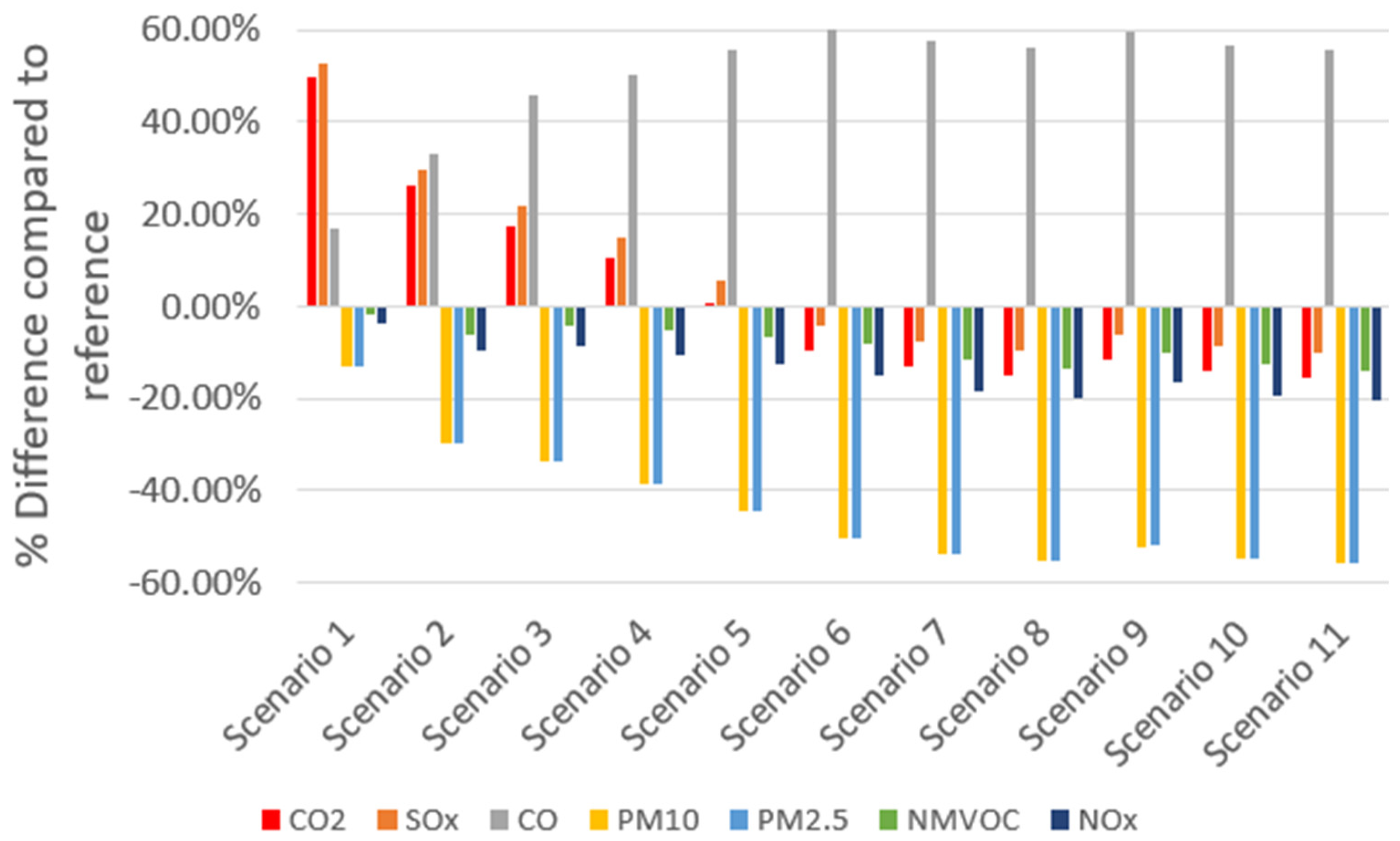

4.1. Impact Assessment and Interpretation of Scenarios on Biomethane Supplementation on M/T Alexandria

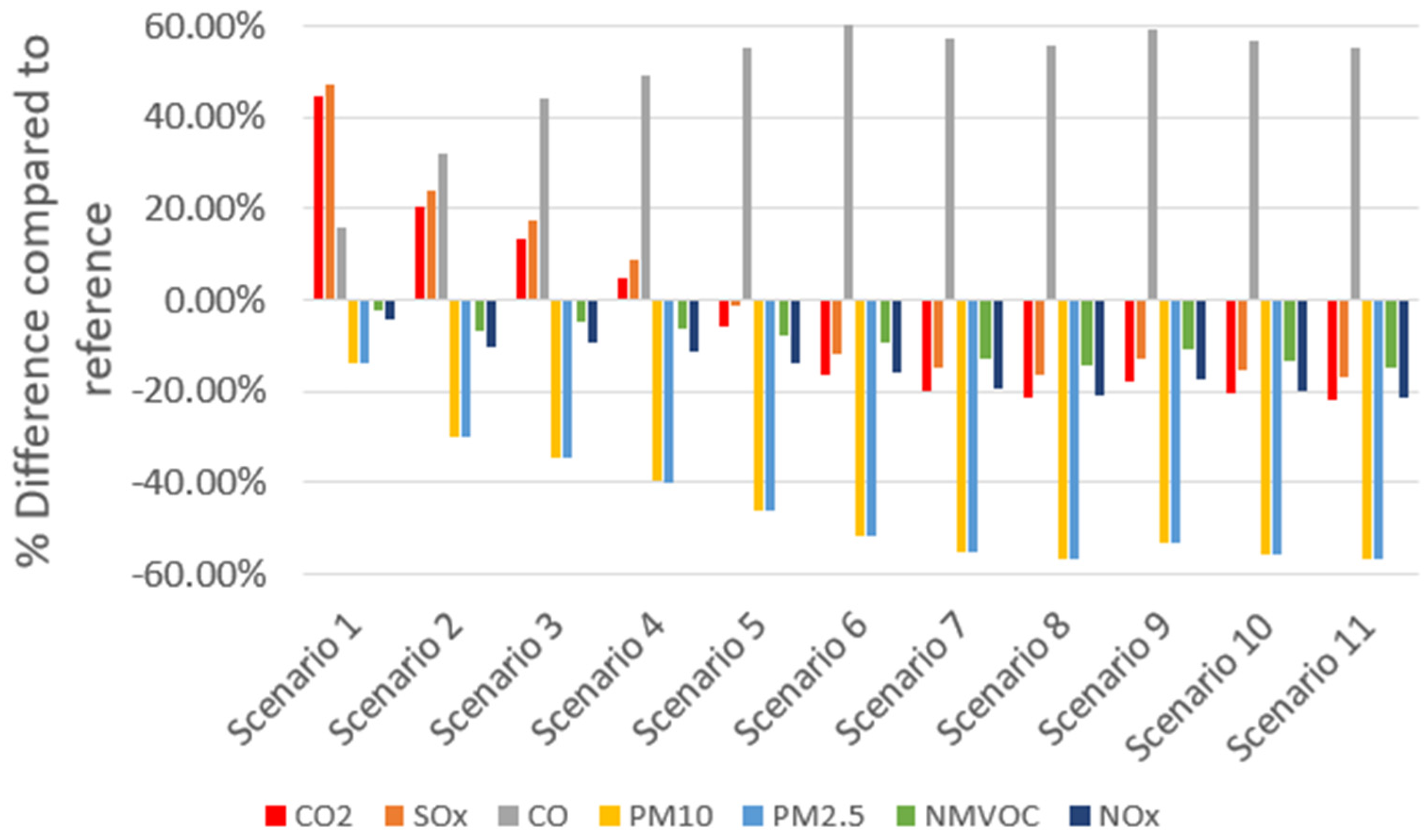

4.2. Impact Assessment and Interpretation of Scenarios on Biomethane Supplementation on M/T Astraia

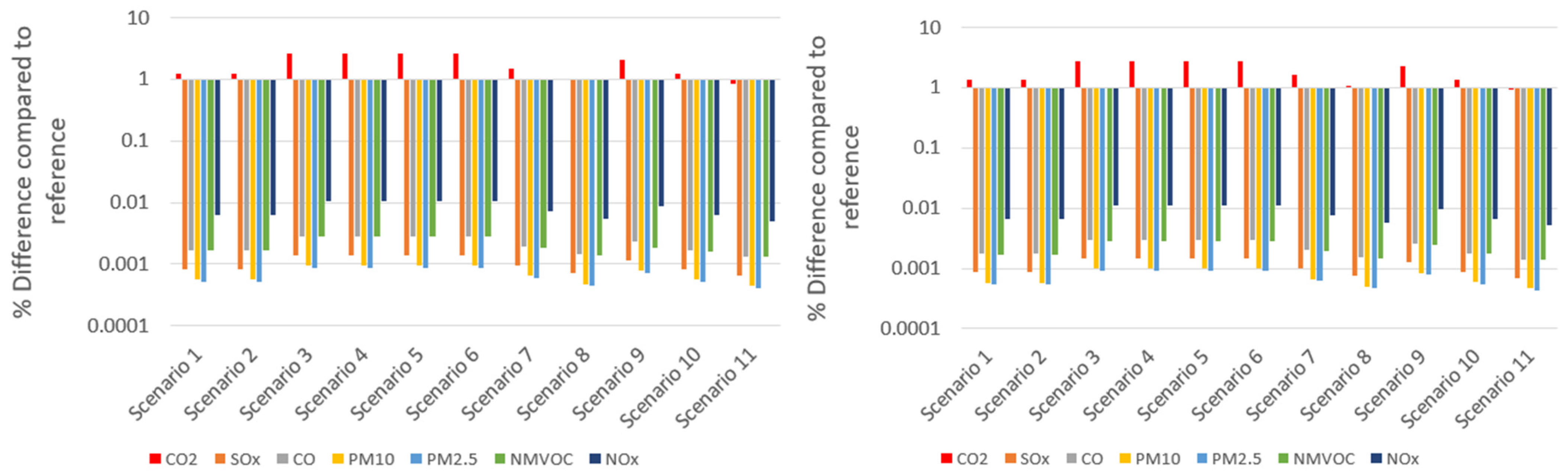

4.3. WtP Impact Assessment and Interpretation of Scenarios for Both Vessels

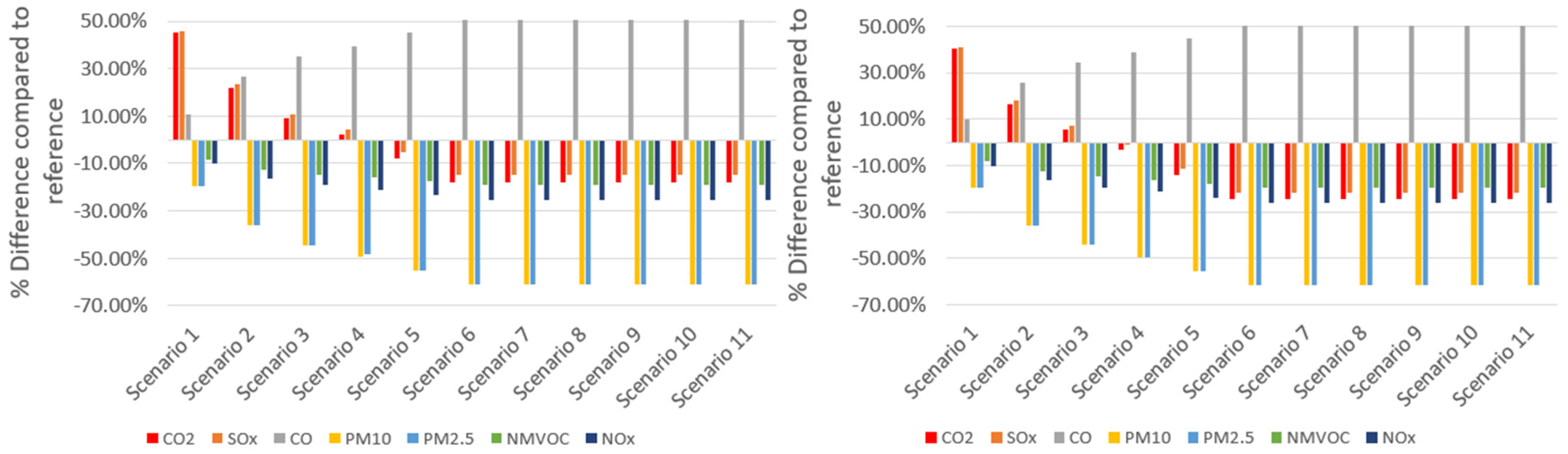

4.4. PtW Impact Assessment and Interpretation of Scenarios for Both Vessels

- The results for scenarios 6–11 are identical because they have no influence on a PtW basis. The scenarios only examine the impact of barge speed and distance to vessels, which is part of WtP.

- Scenarios 6–11 utilize 80% biomethane substitution on an energy basis and compared to the reference lead to up to 18.2% and 24.4% CO2 reduction for M/T Alexandria and M/T Astraia, respectively.

- CO2 emissions increase for scenarios 1–4 and scenarios 1–3 for M/T Alexandria and M/T Astraia, respectively, because for the vessels a 190 g/kWh specific fuel consumption (sfc) is assumed [7], p. 70, however, for the genset real fuel consumption rates are used. In Mallouppas et al. [30] the derating of the genset is clearly illustrated (with an sfc well above 190 g/kWh).

- CO emissions increase and NOx emissions decrease as expected with dual fuel combustion engines utilizing biomethane. The relevant explanation has been provided in the previous section. Note that, on a PtW basis, the propulsion engines of the barge are switched off, hence only the genset combusting biomethane in dual fuel mode is operating. For the scenarios examining barge service speed and overall distance, the biomethane energy substitution is assumed to be 80%, thus there is no impact on a PtW basis. However, on a WtP basis the impact on CO is small but with a decreasing trend since the overall fuel consumption of the barge decreases (due to the benefits of lower service speed; i.e., slow steaming and smaller overall distances traveled).

- SOx decrease by up to 20% since the sulfur content in MDO is higher compared to biomethane (refer to emission factors proposed by the IMO on Table 5).

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mallouppas, G.; Yfantis, E. Decarbonization in Shipping Industry: A Review of Research, Technology Development, and Innovation Proposals. J. Mar. Sci. Eng. 2021, 9, 415. [Google Scholar] [CrossRef]

- European Commission. Directive 2003/30/EC of the European Parliament and of the Council of 8 May 2003 on the Promotion of the Use of Biofuels or Other Renewable Fuels for Transport; European Commission: Brussels, Belgium, 2003. [Google Scholar]

- Oh, Y.-K.; Hwang, K.-R.; Kim, C.; Kim, J.R.; Lee, J.-S. Recent developments and key barriers to advanced biofuels: A short review. Bioresour. Technol. 2018, 257, 320–333. [Google Scholar] [CrossRef]

- Panoutsou, C.; Germer, S.; Karka, P.; Papadokostantakis, S.; Kroyan, Y.; Wojcieszyk, M.; Maniatis, K.; Marchand, P.; Landalv, I. Advanced biofuels to decarbonise European transport by 2030: Markets, challenges, and policies that impact their successful market uptake. Energy Strategy Rev. 2021, 34, 100633. [Google Scholar] [CrossRef]

- IEA. Biofuels for Transport, An International Perspective; International Energy Agency: Paris, France, 2004. [Google Scholar]

- Mallouppas, G.; Yfantis, E.; Ioannou, C.; Paradeisiotis, A.; Ktoris, A. Application of Biogas and Biomethane as Maritime Fuels: A Review of Research, Technology Development, Innovation Proposals, and Market Potentials. Energies 2023, 16, 2066. [Google Scholar] [CrossRef]

- IMO. Fourth Greenhouse Gas Study 2020; International Maritime Organization: London, UK, 2020. [Google Scholar]

- Carvalho, F.; O’Malley, J.; Osipova, L.; Pavlenko, N. Key Issues in LCA Methodology for Marine Fuels; International Council on Clean Transportation: Washington, DC, USA, 2023. [Google Scholar]

- CMMI. bioCNG-to-Cold Ironing. Cyprus Marine and Maritime Institute. 2023. Available online: https://www.cmmi.blue/biocng-to-cold-ironing/ (accessed on 12 December 2024).

- Obaideen, K.; Abdelkareem, M.A.; Wilberforce, T.; Elsaid, K.; Sayed, E.T.; Maghrabie, H.M.; Olab, A. Biogas role in achievement of the sustainable development goals: Evaluation, Challenges, and Guidelines. J. Taiwan Inst. Chem. Eng. 2022, 131, 104207. [Google Scholar] [CrossRef]

- World Biogas Association. How to Achieve the Sustainable Development Goals Through Biogas: Factsheet 3. 2018. Available online: https://www.worldbiogasassociation.org/wp-content/uploads/2018/07/WBA-SDGs-Biogas-factsheet-3.pdf (accessed on 3 January 2025).

- Catalano, G.; D’Adamo, I.; Gastaldi, M.; Nizami, A.-S.; Ribichini, M. Incentive policies in biomethane production toward circular economy. Renew. Sustain. Energy Rev. 2024, 202, 114710. [Google Scholar] [CrossRef]

- Lubańska, A.; Kazak, J.K. The Role of Biogas Production in Circular Economy Approach from the Perspective of Locality. Energies 2023, 16, 3801. [Google Scholar] [CrossRef]

- Szarka, N.; Laverde, L.G.; Thrän, D.; Kiyko, O.; Ilkiv, M.; Moravčíková, D.; Cudlínová, E.; Lapka, M.; Hatvani, N.; Koós, Á.; et al. Stakeholder Engagement in the Co-Design of Regional Bioeconomy Strategies. Sustainability 2023, 15, 6967. [Google Scholar] [CrossRef]

- Shogole, M.P. 18—Stakeholder engagement and governance issues in applying green principles to the biogas sector. In Innovations in the Global Biogas Industry; Applications of Green Principles; Woodhead Publishing: Cambridge, UK, 2025; pp. 495–509. [Google Scholar]

- InoMob Ltd. Renewable Natural Gas (RNG) Supply. InoMob Ltd. Available online: https://www.inomob.eu/renewable-natural-gas-supply/ (accessed on 12 December 2024).

- Future Fuels Nordic. Fuel Life-Cycle Assessment Resources. Nordic Roadmap—Future Fuels for Shipping. 2024. Available online: https://futurefuelsnordic.com/fuel-life-cycle-assessment-resources/ (accessed on 8 November 2024).

- Hiloidhari, M.; Kumari, S. Chapter 15—Biogas upgrading and life cycle assessment of different biogas upgrading technologies. In Emerging Technologies and Biological Systems for Biogas Upgrading; Academic Press; Elsevier: London, UK, 2021; pp. 413–445. [Google Scholar]

- Sun, Q.; Li, H.; Yan, J.; Liu, L.; Yu, Z.; Yu, X. Selection of appropriate biogas upgrading technology-a review of biogas cleaning, upgrading and utilisation. Renew. Sustain. Energy Rev. 2015, 51, 521–532. [Google Scholar] [CrossRef]

- Florio, C.; Fiorentino, G.; Corcelli, F.; Ulgiati, S.; Dumontet, S.; Güsewell, J.; Eltrop, L. A life cycle assessment of biomethane production from waste feedstock through different upgrading technologies. Energies 2019, 12, 718. [Google Scholar] [CrossRef]

- Ardolino, F.; Cardamone, G.; Parrillo, F.; Arena, U. Biogas-to-biomethane upgrading: A comparative review and assessment in a life cycle perspective. Renew. Sustain. Energy Rev. 2021, 139, 110588. [Google Scholar] [CrossRef]

- Suhartini, S.; Nugroho, W.; Putranto, A.; Pangestuti, M.; Rohma, N.; Melville, L. Life cycle assessment of biomethane technology. In Biogas to Biomethane; Woodhead Publishing: Sawston, UK, 2024; pp. 243–275. [Google Scholar]

- Buivydas, E.; Navickas, K.; Venslauskas, K. A Life Cycle Assessment of Methane Slip in Biogas Upgrading Based on Permeable Membrane Technology with Variable Methane Concentration in Raw Biogas. Sustainability 2024, 16, 3323. [Google Scholar] [CrossRef]

- Kapoor, R.; Ghosh, P.; Kumar, M.; Vijay, V. Evaluation of biogas upgrading technologies and future perspectives: A review. Environ. Sci. Pollut. Res. 2019, 26, 11631–11661. [Google Scholar] [CrossRef]

- Bureau Veritas, Marine & Offshore. Alternative Fuels Outlook for Shipping—An Overview of Alternative Fuels from a Well-To-Wake Perspective; Bureau Veritas, Marine & Offshore: Trignac, France, 2022. [Google Scholar]

- Zhou, Y.; Swidler, D.; Searle, S.; Baldino, C. Life-Cycle Greenhouse Gas Emissions of Biomethane and Hydrogen Pathways in the European Union; The International Council of Clean Transportation: Washington, DC, USA, 2021. [Google Scholar]

- Repele, M.; Paturska, A.; Valters, K.; Bazbauers, G. Life cycle assessment of bio-methane supply system based on natural gas infrastructure. Agron. Res. 2014, 12, 999–1006. [Google Scholar]

- Lorenzi, G.; Gorgoroni, M.; Silva, C.; Santarelli, M. Life Cycle Assessment of biogas upgrading routes. Energy Procedia 2019, 158, 2012–2018. [Google Scholar] [CrossRef]

- European Union. Cyprus Energy Snapshot. 2021. Available online: https://energy.ec.europa.eu/document/download/24db0005-9efe-4564-bb34-b9db28a3d217_en?filename=CY%202022%20Energy%20Snapshot_rev.pdf (accessed on 12 December 2024).

- Mallouppas, G.; Ktoris, A.; Ioannou, C.; Damianou, S. D4.2 Report on the Experimental Results and the Overall Assessment of the Biomethane as a Marine Biofuel Supplement. BioCH4-to-Market, Grant Agreement Number: ENTERPRISES/0521/0162; Cyprus Research Innovation Foundation: Larnaca, Cyprus, 2023. [Google Scholar]

- European Standard EN 16723-2; Natural Gas and Biomethane for Use in Transport and Biomethane for Injection in the Natural Gas Network—Part 2: Automotive Fuels Specification. European Commission: Brussels, Belgium, 2017.

- Winkel, R.; Weddige, U.; Johnsen, D.; Hoen, V.; Papaefthimiou, S. Shore Side Electricity in Europe: Potential and environmental benefits. Energy Policy 2016, 88, 584–593. [Google Scholar] [CrossRef]

- Martínez-López, A.; Romero-Filgueira, A.; Chica, M. Specific environmental charges to boost Cold Ironing use in the European Short Sea Shipping. Transp. Res. Part D 2021, 94, 102775. [Google Scholar] [CrossRef]

- Stolz, B.; Held, M.; Georges, G.; Boulouchos, K. The CO2 reduction potential of shore-side electricity in Europe. Appl. Energy 2021, 285, 116425. [Google Scholar] [CrossRef]

- Yfantis, E.A.; Mallouppas, G.; Ktoris, A.; Ioannou, C. Fit for 55—Impact on Cypriot Shipping Industry. Preliminary Report—Assessement of the New Measures and Their Effect on the Shipping Industry and the Relevant Cyprus Economy Sectors; Submitted to MECI; Cyprus Marine and Maritime Institute: Larnaca, Cyprus, 2022. [Google Scholar]

- Sornn-Friese, H.; Poulsen, R.T.; Nowinska, A.U.; de Langen, P. What drives ports around the world to adopt air emissions abatement measures? Transp. Res. Part D Transp. Environ. 2021, 90, 102644. [Google Scholar] [CrossRef]

- Zis, T.; North, R.J.; Angeloudis, P.; Ochieng, W.Y.; Bell, M.G.H. Evaluation of cold ironing and speed reduction policies to reduce ship emissions near and at ports. Marit. Econ. Logist. 2014, 16, 371–398. [Google Scholar] [CrossRef]

- Ballini, F.; Bozzo, R. Air pollution from ships in ports: The socio-economic benefit of cold-ironing technology. Res. Transp. Bus. Manag. 2015, 17, 92–98. [Google Scholar] [CrossRef]

- Innes, A.; Monios, J. Identifying the unique challenges of installing cold ironing at small and medium ports—The case of aberdeen. Transp. Res. Part D Transp. Environ. 2018, 62, 298–313. [Google Scholar] [CrossRef]

- Mallouppas, G.; Pieri, T. D4.2 “Report on Performance Monitoring and Predictive Maintenance Software Tools”—Under Review. BioCNG-to-CI, Grant Agreement Number: CODEVELOP-GT/0322/0014; Cyprus Research Innovation Foundation: Larnaka, Cyprus, 2024. [Google Scholar]

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- ISCC EU 205; GreenHouse Gas Emissions. International Sustainability & Carbon Certification (ISCC): Rutherford, NJ, USA, 2021.

- European Commission. Red II—Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources; European Commision: Brussels, Belgium, 2018. [Google Scholar]

- ISCC. All ISCC Certificates—InoMob Ltd. Certificate. Available online: https://hub.iscc-system.org//FileHandler/download/certificateFile/NTE5ODNfRVUtSVNDQy1DZXJ0LUlUMjA2LTAwMDAyNjA5 (accessed on 8 November 2024).

- ISCC. ISCC Certficate—InoMob LTD ISCC Summary Audit Report. Available online: https://hub.iscc-system.org//FileHandler/download/summaryAuditReportFile/NTE5ODNfRVUtSVNDQy1DZXJ0LUlUMjA2LTAwMDAyNjA5 (accessed on 8 November 2024).

- Jalkanen, J.-P.; Johansson, L.; Kukkonen, J.; Brink, A.; Kalli, J.; Stipa, T. Extension of an assessment model of ship traffic exhaust emissions for particulate matter and carbon monoxide. Atmos. Chem. Phys. 2012, 12, 2641–2659. [Google Scholar] [CrossRef]

- VesselFinder. VesselFinder—M/T Alexandria. VesselFinder. 5 July 2024. Available online: https://www.vesselfinder.com/?imo=9448889 (accessed on 5 July 2024).

- Vessel Finder. VesselFinder—M/T Astraia. Vessel Finder. Available online: https://www.vesselfinder.com/?imo=9550589 (accessed on 5 July 2024).

- Net-Zero-Emissions-CI: Towards bioCNG as a Carbon Negative Maritime Power Source. The Project CODEVELOP-REPowerEU/1223/0096 Is Funded by the European Union—NextGenerationEU, Through the Research and Innovation Foundation. 2024. Available online: https://www.cmmi.blue/net-zero-emissions-ci/ (accessed on 12 December 2024).

- Papagiannakis, R.G.; Zannis, T.C.; Kotsiopoulos, P.N.; Yfantis, E.A.; Hountalas, D.T.; Rakopoulos, C.D. Theoretical Study of the Effects of Engine Parameters on Performance and Emissions of a Pilot Ignited Natural Gas Diesel Engine. Energy 2010, 35, 1129–1138. [Google Scholar] [CrossRef]

- Misra, A.; Yadav, M.S.A.; Singh, G. Proceedings of International Conference in Mechanical and Energy Technology, Smart Innovation, Systems and Technologies 174. In Chapter 30: Methane–Diesel Dual Fuel Engine: A Comprehensive Review; Springer Nature Singapore Pte Ltd.: Singapore, 2020; pp. 327–337. [Google Scholar]

- Bouguessa, R.; Tarabet, L.; Loubar, K.; Belmrabet, T.; Tazerout, M. Experimental investigation on biogas enrichment with hydrogen for improving the combustion in diesel engine operating under dual fuel mode. Int. J. Hydrogen Energy 2020, 45, 9052–9063. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw Hill International Editions: New York, NY, USA, 1988. [Google Scholar]

- Papagiannakis, R.G.; Hountalas, D.T.; Rakopoulos, C.D.; Rakopoulos, D.C. Combustion and Performance Characteristics of a DI Diesel Engine Operating from Low to High Natural Gas Supplement Ratios at Various Operating Conditions; SAE International: Washington, DC, USA, 2008; Volume 2008-01-1392, pp. 1–22. [Google Scholar]

- Di Iorio, S.; Magno, A.; Mancaruso, E.; Vaglieco, B.M. Analysis of the effects of diesel/methane dual fuel combustion on nitrogen oxides and particle formation through optical investigation in a real engine. Fuel Process. Technol. 2017, 159, 200–210. [Google Scholar] [CrossRef]

- Di Iorio, S.; Magno, A.; Mancaruso, E.; Vaglieco, B.M. Performance, Gaseous and Particle Emissions of a Small Compression Ignition Engine Operating in Diesel/Methane Dual Fuel Mode 2016-01-0771; SAE Technical Paper; SAE International: Washington, DC, USA, 2016; Volume 2016-01-0771. [Google Scholar]

- Mustafi, N.N.; Raine, R.R.; Verhelst, S. Combustion and emissions characteristics of a dual fuel engine operated. Fuel 2013, 109, 669–678. [Google Scholar] [CrossRef]

- Lounici, M.S.; Loubar, K.; Tarabet, L.; Balistrou, M.; Niculescu, D.-C.; Tazerout, M. Towards improvement of natural gas-diesel dual fuel mode: An experimental investigation on performance and exhaust emissions. Energy 2014, 64, 200–211. [Google Scholar] [CrossRef]

| Ship Category | Percentage of Total Estimated 19 GWh (%) | Auxiliary Energy (GWh) |

|---|---|---|

| Passenger and cruise ships | 5.04 | 0.9576 |

| Container ships | 24.42 | 4.6398 |

| Bulk carriers | 9.69 | 1.8411 |

| Oil tankers | 23.64 | 4.4916 |

| Chemical tankers | 23.26 | 4.4194 |

| Other ship types | 5.81 | 1.1039 |

| Ro-Ro ships | 4.65 | 0.8835 |

| Vehicle carriers | 0.78 | 0.1482 |

| Gas carriers | 2.71 | 0.5249 |

| Scenario | % Biomethane Substitution | Total Distance Traveled by Barge Including Return Leg (km) | Barge Service Speed (knots) |

|---|---|---|---|

| Reference | M/T Alexandria and M/T Astraia using their auxiliary engines (MDO) | ||

| Scenario 1 | 20.0 | 10.0 | 5.0 |

| Scenario 2 | 40.0 | 10.0 | 5.0 |

| Scenario 3 | 50.0 | 10.0 | 5.0 |

| Scenario 4 | 60.0 | 10.0 | 5.0 |

| Scenario 5 | 70.0 | 10.0 | 5.0 |

| Scenario 6 | 80.0 | 10.0 | 5.0 |

| Scenario 7 | 80.0 | 5.0 | 5.0 |

| Scenario 8 | 80.0 | 2.5 | 5.0 |

| Scenario 9 | 80.0 | 10.0 | 2.5 |

| Scenario 10 | 80.0 | 5.0 | 2.5 |

| Scenario 11 | 80.0 | 2.5 | 2.5 |

| Type | Description | Value |

|---|---|---|

| Sn | Share of feedstock n, in fraction of input to the digester | n = 1 |

| ecn,n | GHG emissions from the extraction or cultivation of raw materials of feedstock n | 0.0 gCO2,eq/MJ |

| etd,feedstock,n | Emissions from the transport of feedstock n to the digester | Set to 0.0 gCO2,eq/MJ due to onsite farming—no transport of feedstock |

| el,n | Annualized (over 20 years) GHG emissions from carbon stock change due to land use change of feedstock n | Set to 0.0 gCO2,eq/MJ |

| esca,n | GHG emissions savings from soil carbon accumulation via improved agricultural management of feedstock, n | Set to 124.4 gCO2,eq/MJ as per manure credits |

| ep | Emissions from processing | 117.9 + 6.3 = 124.2 gCO2,eq/MJ as per RED II directive Annex C [43] for “Disaggregated default values for biomethane” for wet manure—open digestate (no off-gas combustion) |

| etd,product | Emissions from the transport and distribution of biogas and/or biomethane | 0.144 gCO2,eq/MJ, see later for calculation |

| eu | Emissions from the fuel in use, which is GHG emitted during combustion | 0.0 gCO2,eq/MJ |

| eccs | GHG emissions savings from carbon capture and storage | 0.0 gCO2,eq/MJ |

| eccr | GHG emissions savings from carbon capture and replacement | 0.0 gCO2,eq/MJ |

| E | Total emissions of fuel | −0.056 gCO2,eq/MJ For simplicity total emissions rounded to 0.0 gCO2,eq/MJ |

| Type | Value | Comments |

|---|---|---|

| On road delivery radius from production site to Port of Limassol | 60 km |  |

| Amount of upgraded biomethane per delivery | 5390 Nm3 | Equivalent to 194,040 MJ |

| Diesel truck consumption for 60 km delivery radius | 60 × 0.49 + 60 × 0.25 = 44.4 L | 0.49 L/km (fully loaded); 0.25 L/km (empty); as per ISCC EU Annex I [42]. |

| Corresponding CO2 emissions from diesel truck | 44.4 × 3.14 = 139.4 kgCO2,eq/L | Emission factor for diesel 3.14 as per ISCC EU Annex I [42]. |

| Emissions in gCO2,eq/MJ | 139.4 kgCO2,eq/L × 1000/194,040 = 0.72 gCO2,eq/MJ | |

| InoMob’s current biomethane GHG footprint (0.0 gCO2,eq/MJ) as per InoMob’s ISCC. | ||

| Dual fuel track uses 80% biomethane and 20% diesel | etd,product = 0.72 × 20% = 0.144 gCO2,eq/MJ | The engine of the truck has been retrofitted to combustion biomethane in dual fuel mode |

| Fuel Type | Fuel-Based Emission Factors | Energy-Based Emission Factors | |||||

|---|---|---|---|---|---|---|---|

| CO2 [gCO2/g Fuel] | SOx [gSOx/g Fuel] | CO [gCO/kWh] | PM10 [gPM10/kWh] | PM2.5 [gPM2.5/kWh] | NMVOC [gNMVOC/kWh] | NOx [gNOx/kWh] | |

| HFO | 3.114 | 0.0508 | 0.540 | 1.39 * | 92% of PM10 | 0.527 | 2.0 * |

| MDO | 3.206 | 0.0014 | 0.540 | 0.19 * | 0.527 | 2.0 * | |

| LNG | 2.750 | 3.17 × 10−5 | 1.04 | 0.01 * | 0.400 | 1.3 * | |

| % Biomethane Substitution | sfcbase [kg/kWh] at Pgen = 80 kW | sfcbase [kg/kWh] at Pgen = 90 kW |

|---|---|---|

| 0.0 | 0.313 | 0.309 |

| 20.0 | 0.347 | 0.335 |

| 40.0 | 0.373 | 0.357 |

| 50.0 | 0.390 | 0.375 |

| 60.0 | 0.405 | 0.385 |

| 70.0 | 0.420 | 0.397 |

| 80.0 | 0.434 | 0.409 |

| Althaia Characteristics | |

|---|---|

| Length | 16.75 m |

| Beam | 5.02 m |

| Depth | 1.75 m |

| Draft | 0.95 |

| Displacement | 70 t |

| Design/reference speed | 6 knots |

| Service speed | 5 knots |

| Built Year ≤ 1983 | 1983 < Built Year ≤ 2000 | Built Year > 2000 | |

|---|---|---|---|

| sfcbase (g/kWh) | Residual fuel (HFO) | ||

| 205.0 | 185.0 | 175.0 | |

| Distillate fuel (MDO) | |||

| 190.0 | 175.0 | 165.0 | |

| Pgen (kW) | Energy Substitution (%) | Diesel Fuel Consumption (kg/h) | Biomethane Consumption (kg/h) |

|---|---|---|---|

| 75 | 0.0 | 22.64 | 0.0 |

| 20.0 | 21.13 | 4.30 | |

| 30.0 | 19.59 | 6.83 | |

| 40.0 | 17.80 | 9.66 | |

| 50.0 | 15.82 | 12.80 | |

| 100 | 0.0 | 29.40 | 0.00 |

| 20.0 | 25.98 | 5.10 | |

| 30.0 | 23.71 | 8.10 | |

| 40.0 | 21.41 | 11.29 | |

| 50.0 | 19.51 | 15.13 | |

| Linearly interpolated | |||

| 80 (M/T Alexandria) | 0.0 | 23.99 | 0.00 |

| 20.0 | 22.10 | 4.46 | |

| 30.0 | 20.41 | 7.08 | |

| 40.0 | 18.52 | 9.99 | |

| 50.0 | 16.56 | 13.27 | |

| 60.0 | 15.53 | 15.37 | |

| 70.0 | 13.99 | 18.03 | |

| 80.0 | 12.44 | 20.69 | |

| 90 (M/T Astraia) | 0.0 | 26.69 | 0.00 |

| 20.0 | 24.04 | 4.78 | |

| 30.0 | 22.06 | 7.59 | |

| 40.0 | 19.96 | 10.64 | |

| 50.0 | 18.04 | 14.20 | |

| 60.0 | 16.53 | 16.42 | |

| 70.0 | 14.73 | 19.26 | |

| 80.0 | 12.92 | 22.09 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mallouppas, G.; Ktoris, A.; Yfantis, E.A.; Petrakides, S.; Drousiotis, M. A Lifecycle Analysis of a Floating Power Plant Using Biomethane as a Drop-In Fuel for Cold Ironing of Vessels at Anchorage. Energies 2025, 18, 253. https://doi.org/10.3390/en18020253

Mallouppas G, Ktoris A, Yfantis EA, Petrakides S, Drousiotis M. A Lifecycle Analysis of a Floating Power Plant Using Biomethane as a Drop-In Fuel for Cold Ironing of Vessels at Anchorage. Energies. 2025; 18(2):253. https://doi.org/10.3390/en18020253

Chicago/Turabian StyleMallouppas, George, Angelos Ktoris, Elias Ar. Yfantis, Sotiris Petrakides, and Marios Drousiotis. 2025. "A Lifecycle Analysis of a Floating Power Plant Using Biomethane as a Drop-In Fuel for Cold Ironing of Vessels at Anchorage" Energies 18, no. 2: 253. https://doi.org/10.3390/en18020253

APA StyleMallouppas, G., Ktoris, A., Yfantis, E. A., Petrakides, S., & Drousiotis, M. (2025). A Lifecycle Analysis of a Floating Power Plant Using Biomethane as a Drop-In Fuel for Cold Ironing of Vessels at Anchorage. Energies, 18(2), 253. https://doi.org/10.3390/en18020253