A Review of AI Applications in Unconventional Oil and Gas Exploration and Development

Abstract

:1. Introduction

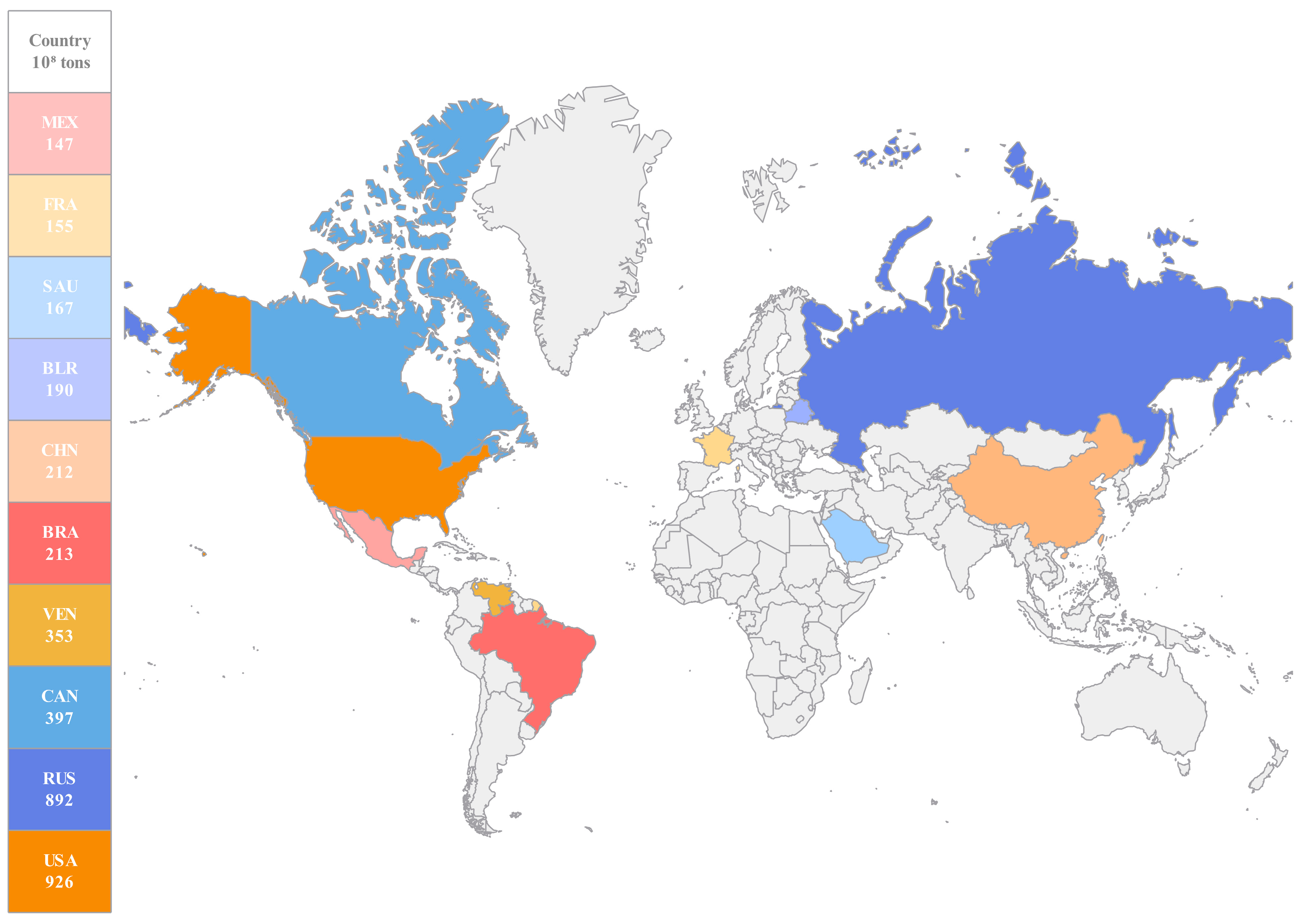

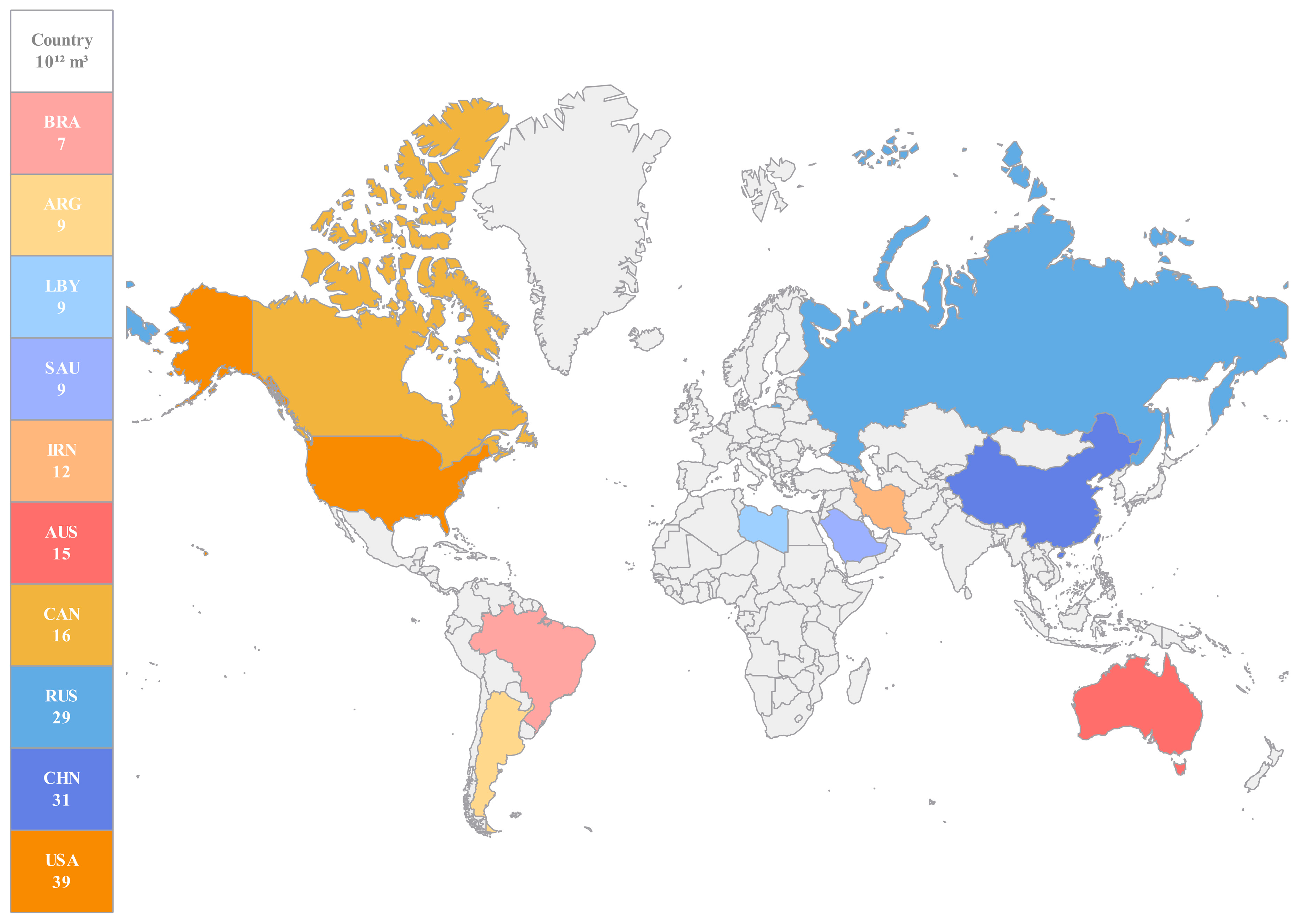

2. From Conventional to Unconventional Oil and Gas Resources

2.1. Background to the Rise of Unconventional Oil and Gas

2.2. Challenges in the Development of Unconventional Oil and Gas

2.3. The Technological Transition from Conventional to Unconventional: The Necessity of Introducing AI Technologies

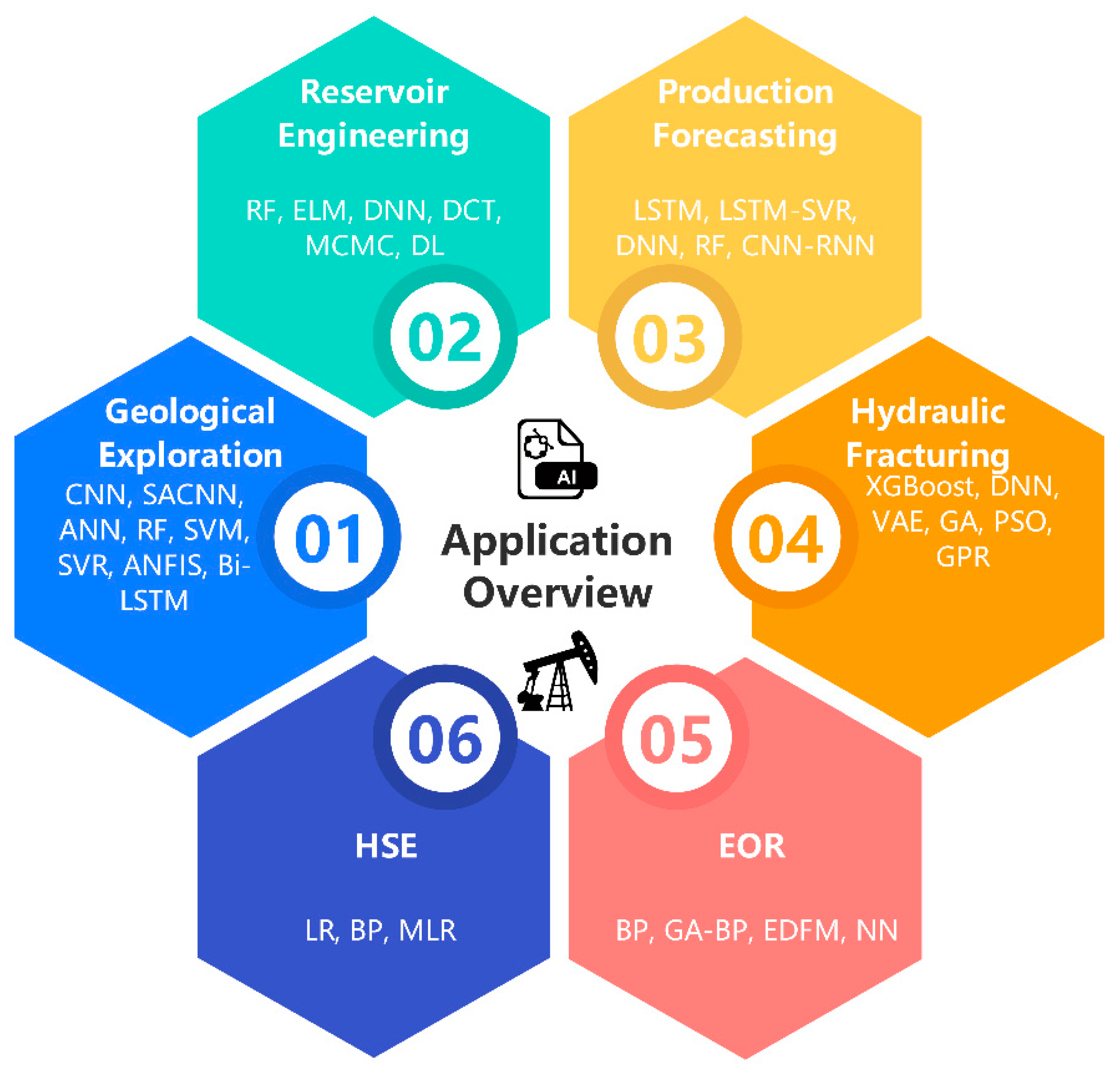

3. The Applications for AI Algorithms in Unconventional Oil and Gas Exploration and Development

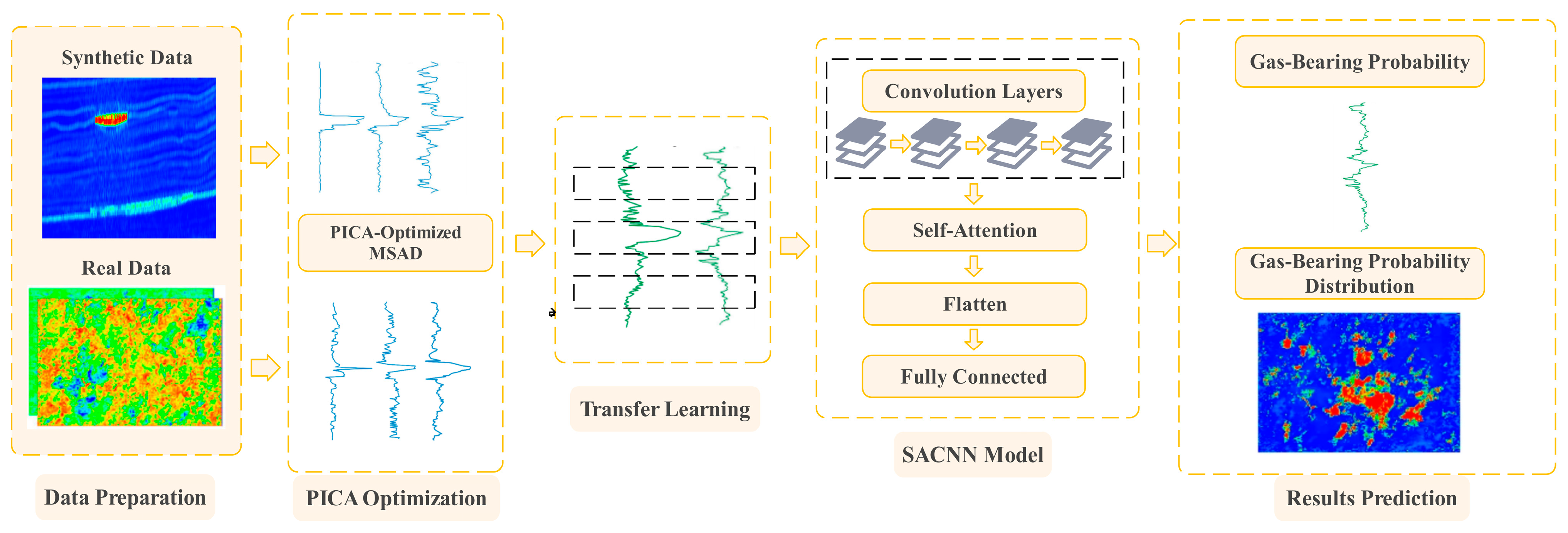

3.1. The Applications for AI in Geological Exploration

3.1.1. Prediction of Gas Probability in Reservoirs

3.1.2. Lithology Classification

3.1.3. Brittleness Index Estimation

3.1.4. Prediction of Total Organic Carbon Content

3.1.5. Prediction of Geomechanical Parameters

3.2. AI Drives Reservoir Engineering

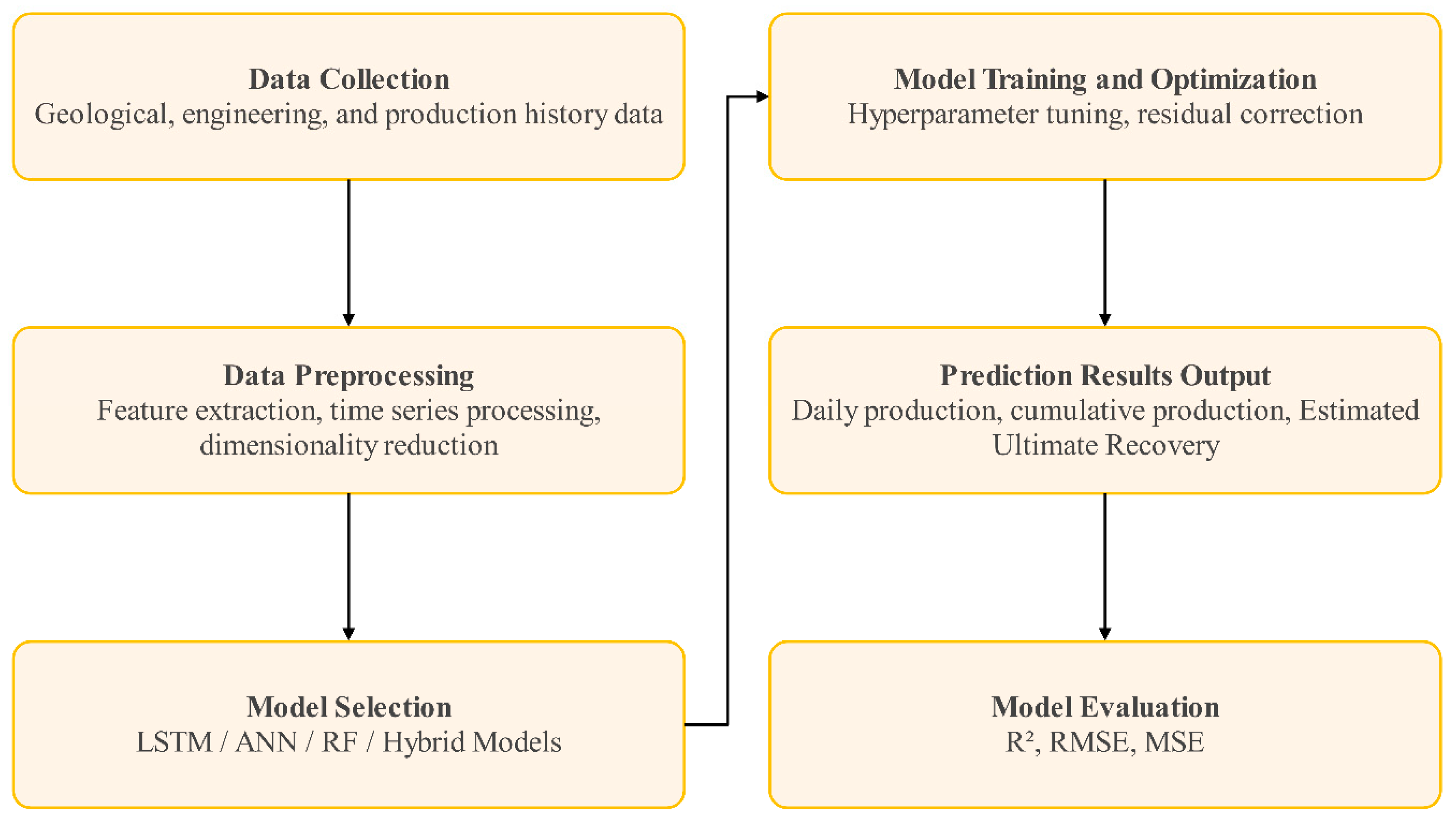

3.3. Applications of AI in Production Forecasting for Unconventional Oil and Gas

3.3.1. The LSTM Model

3.3.2. The ANN/DNN Models

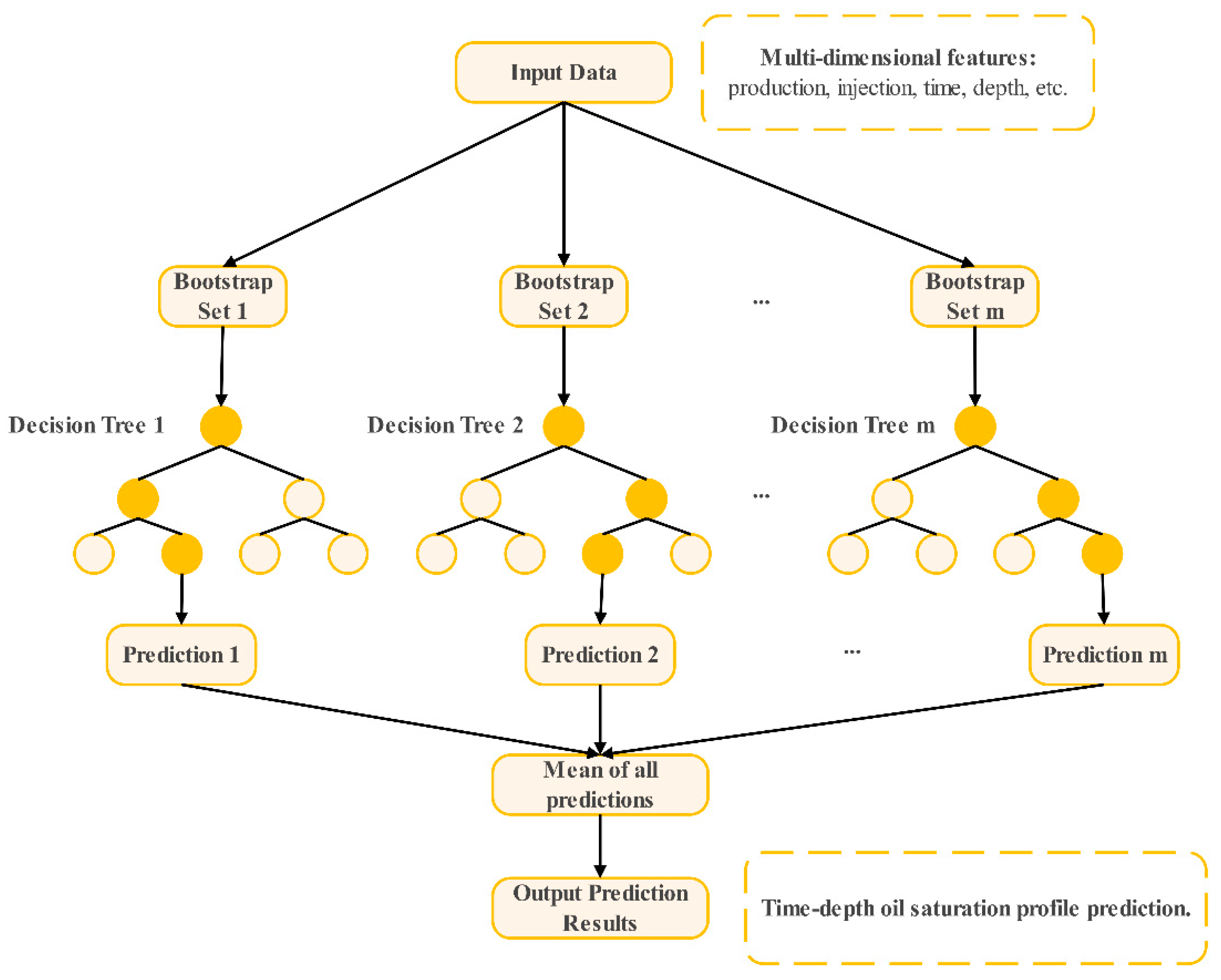

3.3.3. The Random Forest Model

3.3.4. The Hybrid CNN–RNN Model

3.3.5. Other AI Models

| Reference | Method | Input Parameters | Output Parameters | Resource |

|---|---|---|---|---|

| [119] | RF | Geological data, seismic attributes, engineering data | Principal Component scores of production curves | Eagle Ford shale oil |

| [121] | CNN, BiGRU, AM | Wellhead pressure, tubing pressure, output pressure, daily fluid balance volume | Daily shale oil production rate | Shale oil |

| [123] | ARIMA, LSTM, PRO | Monthly production history | Future production forecast | DJ Basin shale oil |

| [124] | ANN, DNN, SVM, RF, XGBoost, LSTM | Geological, production, and engineering parameters | Production forecast curves | Shale oil/gas |

| [125] | RNN | Rock mechanical properties, completion variables, well spacing | Cumulative production over five years | Montney shale gas |

| [115] | ANN | Production history, completion parameters, decline curve analysis ultimate recovery | Estimated ultimate recovery | - |

| [117] | DNN | Well location, formation thickness, fracture parameters, proppant parameters | Cumulative production over six and eighteen months | Bakken shale oil |

| [120] | RF | Initial production rate, proppant amount, fracture fluid volume, completion length | Decline model parameters and estimated ultimate recovery | Bakken shale oil |

| [126] | ANN | Completion parameters, geological attributes | Cumulative production over the first six months | Shale oil |

| [118] | DNN | Geological attributes, completion parameters, production parameters | Estimated ultimate recovery | Tight oil |

| [127] | LSTM, SVR | Wellhead pressure, nozzle size, daily water production | Daily oil and gas production | Bakken shale oil |

| [128] | LSTM | Production data series | Future production forecast | Sichuan Basin shale gas |

| [116] | Opt-LSTM | Wellhead pressure, reservoir temperature, water production, gas production rate | Daily gas production | Ordos Basin tight gas |

| [129] | TL, LSTM | Completion parameters, formation properties, fluid properties, early production data | Long-term oil, gas, and water production curves | Bakken shale oil |

| [122] | XGBoost, LR | Geological, drilling, completion, production, and economic factors | Cumulative production over the first twelve months | Duvernay shale oil |

| [130] | MLP, CAE | Geological parameters, fracture parameters | Cumulative gas production and daily gas production rate | Shale gas |

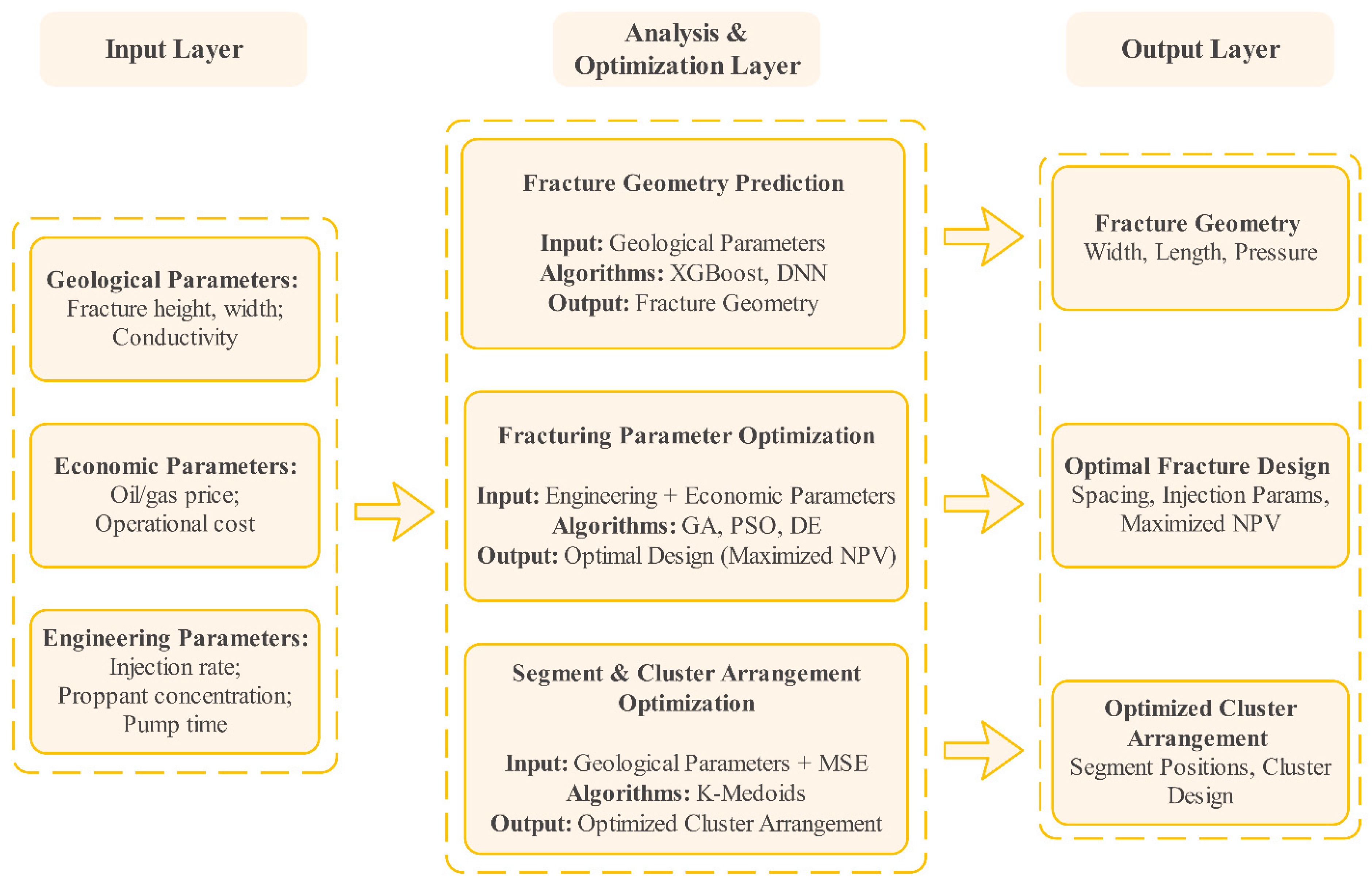

3.4. Applications of AI in Hydraulic Fracturing for Unconventional Oil and Gas

| Reference | Method | Input Parameters | Output Parameters | Resource |

|---|---|---|---|---|

| [131] | XGBoost + BO | Fracture height, fracture length, injection rate | Fracture width, fracture pressure | Shale oil and gas |

| [141] | ANN + BP | Source-reservoir combination parameters | Shale oil production | Shale oil |

| [134] | GPR + GA | Horizontal well length, fracture half-length | Optimized fracturing parameters and well placement | Shale gas |

| [135] | GA, PSO, DE | Number of fracturing stages, fracture half-length | Optimal fracturing configuration | Shale gas |

| [138] | MLP + PSO | Fracture parameters, well location | Net Present Value (NPV), Cumulative Gas Production (CGP) | Shale gas |

| [140,142] | K-Medoids Clustering | Mechanical Specific Energy (MSE) data | Optimized fracture cluster arrangement | - |

| [132] | DNN + PSO | Fracturing parameters, sweet spot distribution | Cumulative production, NPV | Shale oil |

| [136] | MLP + DE | Fracture parameters | NPV | Shale gas |

| [139] | Improved NN | Fracturing parameters, physical features | NPV | Shale gas |

| [133] | VAE + RNN | Production data | Fracture distribution map | - |

3.5. Applications of AI in EOR Methods for Unconventional Oil and Gas

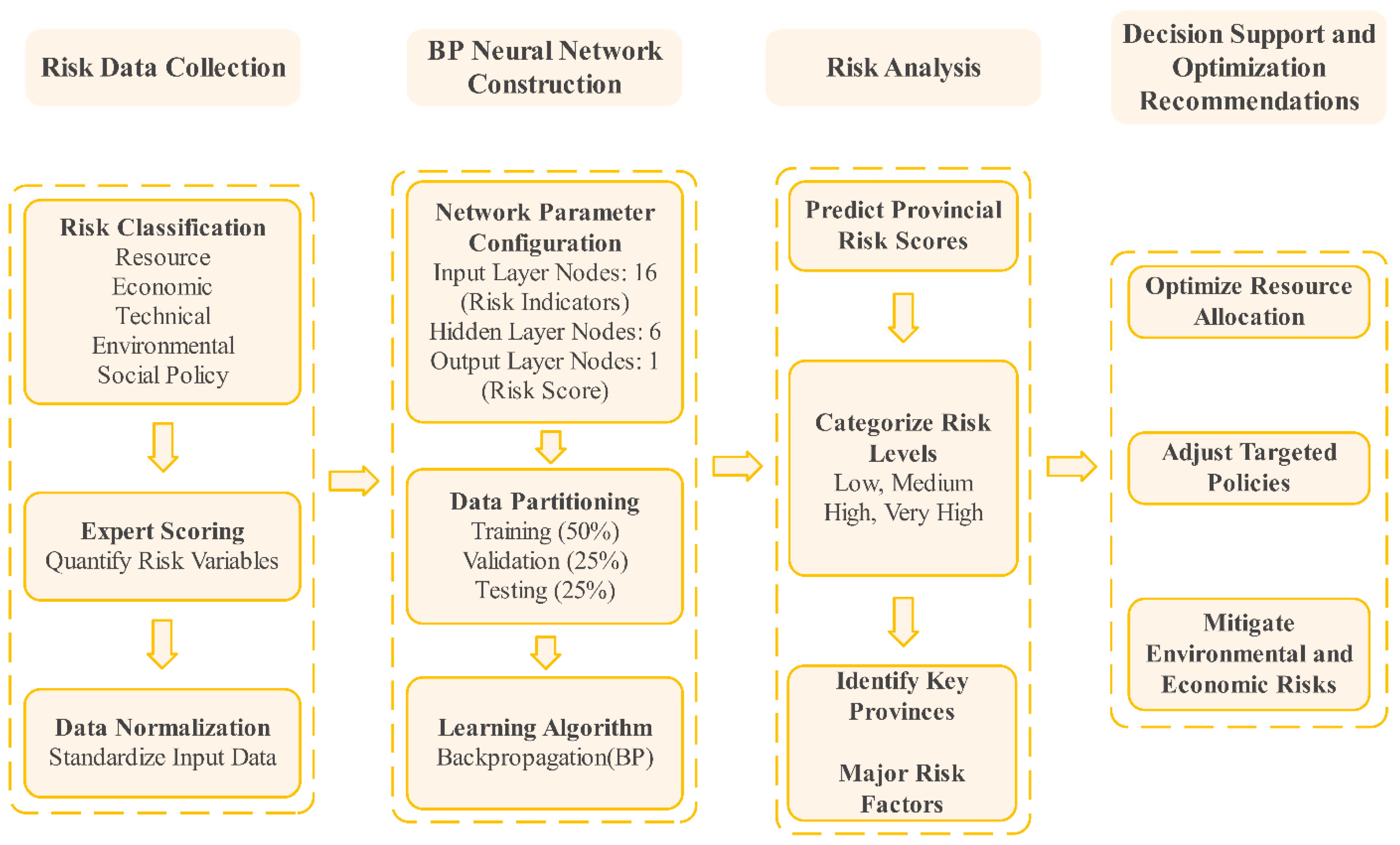

3.6. Applications of AI in HSE Management for Unconventional Oil and Gas Projects

3.7. Industrial Applications of AI in Unconventional Oil and Gas

4. Limitations

- (1)

- Data Quality and Availability Constraints

- (2)

- Limited Generalization Capability of Models

- (3)

- Poor Model Interpretability and Lack of Physical Significance

- (4)

- Insufficient Integration of Domain Knowledge and Physical Constraints

- (5)

- Conflict Between Computational Costs and Real-Time Requirements

- (6)

- Practical Barriers to Technology Integration and Application

5. Prospects

- (1)

- Establishing High-Quality Data Sharing and Standardization Systems

- (2)

- Integrating Domain Knowledge and Physical Constraints to Develop Physics-Driven AI Models

- (3)

- Enhancing Model Generalization and Adaptability

- (4)

- Improving Model Interpretability and Transparency

- (5)

- Optimizing Computational Resources and Model Efficiency

- (6)

- Building Integrated Intelligent Management Systems for Oil and Gas Fields

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CNN | Convolutional Neural Network |

| ANN | Artificial Neural Network |

| MLP | Multi-Layer Perceptron |

| RBF | Radial Basis Function |

| FCDN | Fully Connected Deep Network |

| DNN | Deep Neural Network |

| RNN | Recurrent Neural Network |

| LSTM | Long Short-Term Memory |

| Bi-LSTM | Bidirectional Long Short-Term Memory |

| BiGRU | Bidirectional Gated Recurrent Unit |

| SVM | Support Vector Machine |

| SVR | Support Vector Regression |

| RF | Random Forest |

| XGBoost | Extreme Gradient Boosting |

| GB | Gradient Boosting |

| VAE | Variational Autoencoder |

| TL | Transfer Learning |

| ARIMA | AutoRegressive Integrated Moving Average |

| PRO | Prophet |

| AM | Attention Mechanism |

| CAE | Convolutional Autoencoder |

| LR | Linear Regression |

| GA | Genetic Algorithm |

| PSO | Particle Swarm Optimization |

| GWO | Grey Wolf Optimizer |

| ACO | Ant Colony Optimization |

| MPSO | Mutation Particle Swarm Optimization |

| MCMC | Markov Chain Monte Carlo |

| DE | Differential Evolution |

| STNet | Spatiotemporal Network |

| SSGCN | Spatial-Sequential Graph Convolution Network |

| FL | Fuzzy Logic |

| ANFIS | Adaptive Neuro-Fuzzy Inference System |

| BP | Backpropagation |

| ELM | Extreme Learning Machine |

| DCT | Discrete Cosine Transform |

| Improved NN | Improved Neural Network |

| EUR | Estimated Ultimate Recovery |

| NPV | Net Present Value |

| HSE | Health, Safety, and Environment |

| BI | Brittleness Index |

| Input Parameters in the table | |

| Seismic Attributes | Amplitude, frequency, phase, dip, curvature, and similarity. |

| Well Logging Data | Gamma ray (GR), resistivity (RT), density, acoustic impedance (AI), velocity (Vp, Vs), porosity, Poisson’s ratio, and more. |

| Reservoir Properties | Porosity, permeability, saturation, thickness, fracture properties, compliance coefficients, and total organic carbon (TOC). |

| Fracture Parameters | Fracture height, length, width, pressure, efficiency, conductivity, and compressibility. |

| Fluid Properties | Oil viscosity, oil density, gas composition, water saturation, and CO2 diffusion coefficient. |

| Production Data | Production rates (oil, gas, water), cumulative production, production time, and initial production rates. |

| Operational Conditions | Pressure, temperature, injection volume, injection rate, and soaking time. |

| Geological Data | Brittleness index, TOC, and water saturation. |

| Elastic Attribute Data | Young’s modulus, Poisson’s ratio, P-wave and S-wave velocities. |

| Completion Parameters | Proppant amount, fracture fluid volume, and completion length. |

| NMR Features | Porosity, T2 relaxation time, and pore size distribution. |

| Mechanical Specific Energy (MSE) | Work required to break the rock during drilling. |

| Rock Image Features | Features extracted from digital rock images (e.g., using DCT). |

| Sweet Spot Distribution | Areas with high production potential. |

| Source-Reservoir Combination Parameters | Geological and reservoir characteristics. |

| Production and Operational Data | Production rates, injection volumes, market prices, and water depth. |

| Output Parameters in the table | |

| Production Metrics | Daily production, cumulative production, recovery prediction, gas breakthrough time, and estimated ultimate recovery (EUR). |

| Fracture Metrics | Fracture index, optimized fracture parameters, and fracture distribution maps. |

| Reservoir Properties | Porosity, permeability, saturation, lithofacies, and mineral composition (e.g., quartz, clay). |

| Economic Metrics | Net Present Value (NPV) and production error (e.g., RMSE). |

| Geological Metrics | Brittleness index, TOC, and sweet spot distribution. |

| Phase and Component Metrics | Phase state, component concentrations, and CO2 diffusion coefficients. |

| Adsorption Capacity | CH4 and CO2 adsorption under specific conditions. |

| Forecasting Metrics | Production curves, future production forecasts, and principal component scores. |

| Efficiency Metrics | CO2 displacement efficiency and oil recovery efficiency. |

| Gas Probability Distribution | Probability map of gas presence. |

References

- Wachtmeister, H.; Höök, M. Investment and Production Dynamics of Conventional Oil and Unconventional Tight Oil: Implications for Oil Markets and Climate Strategies. Energy Clim. Change 2020, 1, 12. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, J.F.; Gao, Z.H.; Chen, S.Y.; Liu, B.Y. Review on the Challenges and Strategies in Oil and Gas Industry’s Transition Towards Carbon Neutrality in China. Pet. Sci. 2023, 20, 3931–3944. [Google Scholar] [CrossRef]

- Ciarreta, A.; Nasirov, S. Development Trends in the Azerbaijan Oil and Gas Sector: Achievements and Challenges. Energy Policy 2012, 40, 282–292. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, Q.M.; Lyu, Q.; Xu, Z.J.; Cao, X.P.; Liu, Z.P. Evaluation Technology and Practice of Continental Shale Oil Development in China. Pet. Explor. Dev. 2022, 49, 1098–1109. [Google Scholar] [CrossRef]

- Sun, L.D.; Fang, C.L.; Li, F.; Zhu, R.K.; Zhang, Y.H.; Yuan, X.J.; Jia, A.L.; Gao, X.J.; Su, L. Innovations and Challenges of Sedimentology in Oil and Gas Exploration and Development. Pet. Explor. Dev. 2015, 42, 143–151. [Google Scholar] [CrossRef]

- Zou, C.N.; Yang, Z.; Zhu, R.K.; Zhang, G.S.; Hou, L.H.; Wu, S.T.; Tao, S.Z.; Yuan, X.J.; Dong, D.Z.; Wang, Y.M.; et al. Progress in China’s Unconventional Oil & Gas Exploration and Development and Theoretical Technologies. Acta Geol. Sin.-Engl. Ed. 2015, 89, 938–971. [Google Scholar] [CrossRef]

- Mu, L.X.; Ji, Z.F. Technologcial Progress and Development Directions of PetroChina Overseas Oil and Gas Exploration. Pet. Explor. Dev. 2019, 46, 1088–1099. [Google Scholar] [CrossRef]

- Guo, X.S.; Hu, D.F.; Li, Y.P.; Duan, J.B.; Zhang, X.F.; Fan, X.J.; Duan, H.; Li, W.C. Theoretical Progress and Key Technologies of Onshore Ultra-Deep Oil/Gas Exploration. Engineering 2019, 5, 458–470. [Google Scholar] [CrossRef]

- Liu, S.Y. Review of the Development Status and Technology of Tight Oil: Advances and Outlook. Energy Fuels 2023, 37, 14645–14665. [Google Scholar] [CrossRef]

- Soeder, D.J. The Successful Development of Gas and Oil Resources from Shales in North America. J. Pet. Sci. Eng. 2018, 163, 399–420. [Google Scholar] [CrossRef]

- Kuang, L.C.; Liu, H.; Ren, Y.L.; Luo, K.; Shi, M.Y.; Su, J.; Li, X. Application and Development Trend of Artificial Intelligence in Petroleum Exploration and Development. Pet. Explor. Dev. 2021, 48, 1–14. [Google Scholar] [CrossRef]

- Liu, H.; Ren, Y.L.; Li, X.; Deng, Y.; Wang, Y.T.; Cao, Q.W.; Du, J.Y.; Lin, Z.W.; Wang, W.J. Research Status and Application of Artificial Intelligence Large Models in the Oil and Gas Industry. Pet. Explor. Dev. 2024, 51, 1049–1065. [Google Scholar] [CrossRef]

- Choubey, S.; Karmakar, G.P. Artificial Intelligence Techniques and Their Application in Oil and Gas Industry. Artif. Intell. Rev. 2021, 54, 3665–3683. [Google Scholar] [CrossRef]

- Koroteev, D.; Tekic, Z. Artificial Intelligence in Oil and Gas Upstream: Trends, Challenges, and Scenarios for the Future. Energy AI 2021, 3, 100041. [Google Scholar] [CrossRef]

- Waqar, A.; Othman, I.; Shafiq, N.; Mansoor, M.S. Applications of AI in Oil and Gas Projects Towards Sustainable Development: A Systematic Literature Review. Artif. Intell. Rev. 2023, 56, 12771–12798. [Google Scholar] [CrossRef]

- Li, H.; Yu, H.Y.; Cao, N.I.; Tian, H.; Cheng, S.Q. Applications of Artificial Intelligence in Oil and Gas Development. Arch. Comput. Method Eng. 2021, 28, 937–949. [Google Scholar] [CrossRef]

- Zhong, R.Z.; Salehi, C.; Johnson, R. Machine Learning for Drilling Applications: A Review. J. Nat. Gas Sci. Eng. 2022, 108, 17. [Google Scholar] [CrossRef]

- Lawal, A.; Yang, Y.J.; He, H.M.; Baisa, N.L. Machine Learning in Oil and Gas Exploration: A Review. IEEE Access 2024, 12, 19035–19058. [Google Scholar] [CrossRef]

- Ochieng, E.G.; Ominde, D.; Zuofa, T. Potential Application of Generative Artificial Intelligence and Machine Learning Algorithm in Oil and Gas Sector: Benefits and Future Prospects. Technol. Soc. 2024, 79, 14. [Google Scholar] [CrossRef]

- Syed, F.I.; Alshamsi, M.; Dahaghi, A.K.; Neghabhan, S. Artificial Lift System Optimization Using Machine Learning Applications. Petroleum 2022, 8, 219–226. [Google Scholar] [CrossRef]

- Agwu, O.E.; Akpabio, J.U.; Alabi, S.B.; Dosunmu, A. Artificial Intelligence Techniques and Their Applications in Drilling Fluid Engineering: A Review. J. Pet. Sci. Eng. 2018, 167, 300–315. [Google Scholar] [CrossRef]

- Gu, X.; Lu, W.; Ao, Y.; Li, Y.; Song, C. Seismic Stratigraphic Interpretation Based on Deep Active Learning. IEEE Trans. Geosci. Remote Sens. 2023, 61, 5912511. [Google Scholar] [CrossRef]

- Wu, Y.; Jiang, F.; Hu, T.; Xu, Y.; Guo, J.; Xu, T.; Xing, H.; Chen, D.; Pang, H.; Chen, J.; et al. Shale Oil Content Evaluation and Sweet Spot Prediction Based on Convolutional Neural Network. Mar. Pet. Geol. 2024, 167, 106997. [Google Scholar] [CrossRef]

- Cheng, B.J.; Xu, T.J.; Luo, S.Y.; Chen, T.J.; Li, Y.S.; Tang, J.M. Method and Practice of Deep Favorable Shale Reservoirs Prediction Based on Machine Learning. Pet. Explor. Dev. 2022, 49, 1056–1068. [Google Scholar] [CrossRef]

- Zhou, W.; Li, X.C.Z.; Qi, Z.L.; Zhao, H.H.; Yi, J. A Shale Gas Production Prediction Model Based on Masked Convolutional Neural Network. Appl. Energy 2024, 353, 14. [Google Scholar] [CrossRef]

- Li, C.; Zou, C.C.; Peng, C.; Lan, X.X.; Zhang, Y.Y. Intelligent Identification and Segmentation of Fractures in Images of Ultrasonic Image Logging Based on Transfer Learning. Fuel 2024, 369, 13. [Google Scholar] [CrossRef]

- Wang, J.; Cao, J.X.; Fu, J.C.; Xu, H.Q. Missing Well Logs Prediction Using Deep Learning Integrated Neural Network with the Self-Attention Mechanism. Energy 2022, 261, 9. [Google Scholar] [CrossRef]

- Liu, J.J.; Liu, J.C. Integrating Deep Learning and Logging Data Analytics for Lithofacies Classification and 3D Modeling of Tight Sandstone Reservoirs. Geosci. Front. 2022, 13, 14. [Google Scholar] [CrossRef]

- Li, G.; Song, X.; Tian, S.; Zhu, Z. Intelligent Drilling and Completion: A Review. Engineering 2022, 18, 33–48. [Google Scholar] [CrossRef]

- Davoodi, S.; Mehrad, M.; Wood, D.A.; Rukavishnikov, V.S.; Bajolvand, M. Predicting Uniaxial Compressive Strength from Drilling Variables Aided by Hybrid Machine Learning. Int. J. Rock Mech. Min. Sci. 2023, 170, 24. [Google Scholar] [CrossRef]

- Salehian, M.; Sefat, M.H.; Muradov, K. Multi-Solution Well Placement Optimization Using Ensemble Learning of Surrogate Models. J. Pet. Sci. Eng. 2022, 210, 15. [Google Scholar] [CrossRef]

- Abdelaal, A.; Elkatatny, S.; Abdulraheem, A. Real-Time Prediction of Formation Pressure Gradient While Drilling. Sci. Rep. 2022, 12, 14. [Google Scholar] [CrossRef]

- Bizhani, M.; Kuru, E. Towards Drilling Rate of Penetration Prediction: Bayesian Neural Networks for Uncertainty Quantification. J. Pet. Sci. Eng. 2022, 219, 13. [Google Scholar] [CrossRef]

- Ahmed, O.S.; Adeniran, A.A.; Samsuri, A. Computational Intelligence Based Prediction of Drilling Rate of Penetration: A Comparative Study. J. Pet. Sci. Eng. 2019, 172, 1–12. [Google Scholar] [CrossRef]

- Barbosa, L.; Nascimento, A.; Mathias, M.H.; de Carvalho, J.A. Machine Learning Methods Applied to Drilling Rate of Penetration Prediction and Optimization—A Review. J. Pet. Sci. Eng. 2019, 183, 20. [Google Scholar] [CrossRef]

- Ashrafi, S.B.; Anemangely, M.; Sabah, M.; Ameri, M.J. Application of Hybrid Artificial Neural Networks for Predicting Rate of Penetration (ROP): A Case Study from MARUN Oil Field. J. Pet. Sci. Eng. 2019, 175, 604–623. [Google Scholar] [CrossRef]

- Yang, X.; Wu, M.; Lu, C.D.; Li, W.N.; Chen, L.F.; Du, S. Prediction of Rate of Penetration Based on Drilling Conditions Identification for Drilling Process. Neurocomputing 2024, 579, 127439. [Google Scholar] [CrossRef]

- Elkatatny, S. Real-Time Prediction of Rate of Penetration While Drilling Complex Lithologies Using Artificial Intelligence Techniques. Ain Shams Eng. J. 2021, 12, 917–926. [Google Scholar] [CrossRef]

- Hegde, C.; Daigle, H.; Millwater, H.; Gray, K. Analysis of Rate of Penetration (ROP) Prediction in Drilling Using Physics-Based and Data-Driven Models. J. Pet. Sci. Eng. 2017, 159, 295–306. [Google Scholar] [CrossRef]

- Ertekin, T.; Sun, Q. Artificial Intelligence Applications in Reservoir Engineering: A Status Check. Energies 2019, 12, 2897. [Google Scholar] [CrossRef]

- Zhu, B.R.; Liu, J.; Lin, J.Q.; Liu, Y.; Zhang, D.; Ren, Y.F.; Peng, Q.D.; Yang, J.; He, H.J.; Feng, Q. Cascade Reservoirs Adaptive Refined Simulation Model Based on the Mechanism-AI Coupling Modeling Paradigm. J. Hydrol. 2022, 612, 128229. [Google Scholar] [CrossRef]

- Vukelic, M.A.; Miranda, E.N. Neural Networks in Petroleum Engineering: A Case Study. Int. J. Neural Syst. 1996, 7, 187–194. [Google Scholar] [CrossRef]

- Zhuang, X.Y.; Wang, W.D.; Su, Y.L.; Yan, B.C.; Li, Y.; Li, L.; Hao, Y.M. Multi-Objective Optimization of Reservoir Development Strategy with Hybrid Artificial Intelligence Method. Expert Syst. Appl. 2024, 241, 122707. [Google Scholar] [CrossRef]

- Hou, J.; Zhou, K.; Zhang, X.S.; Kang, X.D.; Xie, H. A Review of Closed-Loop Reservoir Management. Pet. Sci. 2015, 12, 114–128. [Google Scholar] [CrossRef]

- Cavalcante, C.C.B.; Maschio, C.; Santos, A.A.S.; Schiozer, D.; Rocha, A. A Continuous Learning Algorithm for History Matching. Eng. Appl. Artif. Intell. 2019, 85, 543–568. [Google Scholar] [CrossRef]

- Kim, S.; Lee, K.; Lim, J.; Jeong, H.; Min, B. Development of Ensemble Smoother-Neural Network and Its Application to History Matching of Channelized Reservoirs. J. Pet. Sci. Eng. 2020, 191, 107159. [Google Scholar] [CrossRef]

- Li, H.; Misra, S. Reinforcement Learning Based Automated History Matching for Improved Hydrocarbon Production Forecast. Appl. Energy 2021, 284, 116311. [Google Scholar] [CrossRef]

- Liang, B.; Liu, J.; You, J.Y.; Jia, J.; Pan, Y.; Jeong, H. Hydrocarbon Production Dynamics Forecasting Using Machine Learning: A State-of-the-Art Review. Fuel 2023, 337, 127067. [Google Scholar] [CrossRef]

- Qikang, Z.; Botao, L.; Guang, Y.; Lijia, W.; Man, C. Intelligent Production Optimization Method for a Low Pressure and Low Productivity Shale Gas Well. Pet. Explor. Dev. 2022, 49, 886–894. [Google Scholar] [CrossRef]

- Duan, Y.G.; Wang, H.; Wei, M.Q.; Tan, L.J.; Yue, T. Application of ARIMA-RTS Optimal Smoothing Algorithm in Gas Well Production Prediction. Petroleum 2022, 8, 270–277. [Google Scholar] [CrossRef]

- Du, S.Y.; Wang, J.L.; Wang, M.Z.; Yang, J.S.; Zhang, C.; Zhao, Y.; Song, H.Q. A systematic Data-Driven Approach for Production Forecasting of Coalbed Methane Incorporating Deep Learning and Ensemble Learning Adapted to Complex Production Patterns. Energy 2023, 263, 126121. [Google Scholar] [CrossRef]

- Yang, R.Y.; Qin, X.Z.; Liu, W.; Huang, Z.W.; Shi, Y.; Pang, Z.Y.; Zhang, Y.Q.; Li, J.B.; Wang, T.Y. A Physics-Constrained Data-Driven Workflow for Predicting Coalbed Methane Well Production Using Artificial Neural Network. SPE J. 2022, 27, 1531–1552. [Google Scholar] [CrossRef]

- Kim, S.; Kim, T.W.; Hong, Y.; Kim, J.; Jeong, H. Enhancing Pressure Gradient Prediction in Multi-Phase Flow Through Diverse Well Geometries of North American Shale Gas Fields Using Deep Learning. Energy 2024, 290, 130291. [Google Scholar] [CrossRef]

- Zhong, Z.; Sun, A.Y.; Wang, Y.Y.; Ren, B. Predicting Field Production Rates for Waterflooding Using a Machine Learning-Based Proxy Model. J. Pet. Sci. Eng. 2020, 194, 107574. [Google Scholar] [CrossRef]

- Mohr, S.H.; Evans, G.M. Long Term Prediction of Unconventional Oil Production. Energy Policy 2010, 38, 265–276. [Google Scholar] [CrossRef]

- Lin, W. A Review on Shale Reservoirs as an Unconventional Play—The History, Technology Revolution, Importance to Oil and Gas Industry, and the Development Future. Acta Geol. Sin.-Engl. Ed. 2016, 90, 1887–1902. [Google Scholar] [CrossRef]

- Wang, H.J.; Ma, F.; Tong, X.G.; Liu, Z.D.; Zhang, X.S.; Wu, Z.Z.; Li, D.H.; Wang, B.; Xie, Y.F.; Yang, L.Y. Assessment of Global Unconventional Oil and Gas Resources. Pet. Explor. Dev. 2016, 43, 925–940. [Google Scholar] [CrossRef]

- Chew, K.J. The Future of Oil: Unconventional Fossil Fuels. Philos. Trans. R. Soc. A-Math. Phys. Eng. Sci. 2014, 372, 20120324. [Google Scholar] [CrossRef] [PubMed]

- Tong, X.G.; Zhang, G.Y.; Wang, Z.M.; Wen, Z.X.; Tian, Z.J.; Wang, H.J.; Ma, F.; Wu, Y.P. Distribution and Potential of Global Oil and Gas Resources. Pet. Explor. Dev. 2018, 45, 779–789. [Google Scholar] [CrossRef]

- Hein, F.J.; Ambrose, W.A.; Hackley, P.; Mead, J.S.; American Association of Petroleum Geologists, Energy Minerals Division. Unconventional Energy Resources: 2017 Review. Nat. Resour. Res. 2019, 28, 1661–1751. [Google Scholar] [CrossRef]

- Demirbas, A.; Bafail, A.; Zytoon, M.A.M.; Al Sayed, N. Unconventional Energy Sources: Safety Impacts, Opportunities, and Economic Challenges. Energy Sources Part B 2017, 12, 387–393. [Google Scholar] [CrossRef]

- Song, Y.; Li, Z.; Jiang, Z.X.; Luo, Q.; Liu, D.D.; Gao, Z.Y. Progress and Development Trend of Unconventional Oil and Gas Geological Research. Pet. Explor. Dev. 2017, 44, 675–685. [Google Scholar] [CrossRef]

- Bera, A.; Shah, S. A Review on Modern Imaging Techniques for Characterization of Nanoporous Unconventional Reservoirs: Challenges and Prospects. Mar. Pet. Geol. 2021, 133, 105287. [Google Scholar] [CrossRef]

- Liu, G. Challenges and Countermeasures of Log Evaluation in Unconventional Petroleum Exploration and Development. Pet. Explor. Dev. 2021, 48, 1033–1047. [Google Scholar] [CrossRef]

- Yang, Z.; Zou, C. “Exploring Petroleum Inside Source Kitchen”: Connotation and Prospects of Source Rock Oil and gas. Pet. Explor. Dev. 2019, 46, 181–193. [Google Scholar] [CrossRef]

- Li, G.; Xian, C.; Liu, H. A ?One Engine with Six Gears? System Engineering Methodology for the Economic Development of Unconventional Oil and Gas in China. Engineering 2022, 18, 105–115. [Google Scholar] [CrossRef]

- Li, J.; Yang, Z.; Wu, S.; Pan, S. Key Issues and Development Direction of Petroleum Geology Research on Source Rock Strata in China. Adv. Geo-Energy Res. 2021, 5, 121–126. [Google Scholar] [CrossRef]

- Burrows, L.C.; Haeri, F.; Cvetic, P.; Sanguinito, S.; Shi, F.; Tapriyal, D.; Goodman, A.; Enick, R.M. A Literature Review of CO2, Natural Gas, and Water-Based Fluids for Enhanced Oil Recovery in Unconventional Reservoirs. Energy Fuels 2020, 34, 5331–5380. [Google Scholar] [CrossRef]

- De Silva, P.N.K.; Simons, S.J.R.; Stevens, P. Economic Impact Analysis of Natural Gas Development and the Policy Implications. Energy Policy 2016, 88, 639–651. [Google Scholar] [CrossRef]

- Espig, M.; de Rijke, K. Unconventional Gas Developments and the Politics of Risk and Knowledge in Australia. Energy Res. Soc. Sci. 2016, 20, 82–90. [Google Scholar] [CrossRef]

- Centner, T.J. Observations on Risks, the Social Sciences, and Unconventional Hydrocarbons. Energy Res. Soc. Sci. 2016, 20, 1–7. [Google Scholar] [CrossRef]

- Evans, N.; Jones, C.; Munday, M.; Song, M. Economic Effects in the UK Periphery from Unconventional Gas Development: Evidence from Wales. Energy 2019, 166, 1037–1046. [Google Scholar] [CrossRef]

- Kondash, A.J.; Albright, E.; Vengosh, A. Quantity of Flowback and Produced Waters from Unconventional Oil and Gas Exploration. Sci. Total Environ. 2017, 574, 314–321. [Google Scholar] [CrossRef]

- Qin, L.; Zhang, X.; Zhai, C.; Lin, H.; Lin, S.; Wang, P.; Li, S. Advances in Liquid Nitrogen Fracturing for Unconventional Oil and Gas Development: A Review. Energy Fuels 2022, 36, 2971–2992. [Google Scholar] [CrossRef]

- Waterworth, A.; Bradshaw, M.J. Unconventional Trade-Offs? National Oil Companies, Foreign Investment and Oil and Gas Development in Argentina and Brazil. Energy Policy 2018, 122, 7–16. [Google Scholar] [CrossRef]

- Farfour, M.; Yoon, W.J. A Review on Multicomponent Seismology: A Potential Seismic Application for Reservoir Characterization. J. Adv. Res. 2016, 7, 515–524. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Haghshenas, B.; Ghanizadeh, A.; Qanbari, F.; Williams-Kovacs, J.D.; Riazi, N.; Debuhr, C.; Deglint, H.J. Nanopores to Megafractures: Current Challenges and Methods for Shale Gas Reservoir and Hydraulic Fracture Characterization. J. Nat. Gas Sci. Eng. 2016, 31, 612–657. [Google Scholar] [CrossRef]

- Osiptsov, A.A. Fluid Mechanics of Hydraulic Fracturing: A Review. J. Pet. Sci. Eng. 2017, 156, 513–535. [Google Scholar] [CrossRef]

- Mahmoud, H.; Hamza, A.; Nasser, M.S.; Hussein, I.A.; Ahmed, R.; Karami, H. Hole Cleaning and Drilling Fluid Sweeps in Horizontal and Deviated Wells: Comprehensive Review. J. Pet. Sci. Eng. 2020, 186, 106748. [Google Scholar] [CrossRef]

- Cai, J.C.; Jiao, X.H.; Wang, H.; He, W.; Xia, Y.X. Multiphase Fluid-Rock Interactions and Flow Behaviors in Shale Nanopores: A Comprehensive Review. Earth-Sci. Rev. 2024, 257, 104884. [Google Scholar] [CrossRef]

- Zhao, J.L.; Wang, J.J.; Zhang, G.Q.; Zhou, D.W.; Chen, L.; Viswanathan, H.; Kang, Q.J. Minireview on Lattice Boltzmann Modeling of Gas Flow and Adsorption in Shale Porous Media: Progress and Future Direction. Energy Fuels 2023, 37, 1511–1524. [Google Scholar] [CrossRef]

- Wang, H.; Chen, L.; Qu, Z.G.; Yin, Y.; Kang, Q.J.; Yu, B.; Tao, W.Q. Modeling of Multi-Scale Transport Phenomena in Shale Gas Production—A Critical Review. Appl. Energy 2020, 262, 114575. [Google Scholar] [CrossRef]

- Yang, J.Q.; Lin, N.T.; Zhang, K.; Jia, L.Y.; Fu, C. A Framework for Predicting the Gas-Bearing Distribution of Unconventional Reservoirs by Deep Learning. Nat. Resour. Res. 2024, 33, 1625–1655. [Google Scholar] [CrossRef]

- Yang, J.Q.; Lin, N.T.; Zhang, K.; Jia, L.Y.; Zhang, D.; Li, G.H.; Zhang, J.W. A Parametric Study of MPSO-ANN Techniques in Gas-Bearing Distribution Prediction Using Multicomponent Seismic Data. Remote Sens. 2023, 15, 3987. [Google Scholar] [CrossRef]

- Zhu, K.; Du, Y.H.; Wang, Q.; Ji, N.I.; Zhang, L. A Comparative Study of Five Networks for Reservoir Classification Based on Geophysical Logging Signals. IEEE Access 2020, 8, 197776–197786. [Google Scholar] [CrossRef]

- Pang, Q.W.; Chen, C.L.Z.; Sun, Y.Z.; Pang, S.C. STNet: Advancing Lithology Identification with a Spatiotemporal Deep Learning Framework for Well Logging Data. Nat. Resour. Res. 2024, 34, 327–350. [Google Scholar] [CrossRef]

- Kivi, I.R.; Zare-Reisabadi, M.; Saemi, M.; Zamani, Z. An Intelligent Approach to Brittleness Index Estimation in Gas Shale Reservoirs: A Case Study from a Western Iranian Basin. J. Nat. Gas Sci. Eng. 2017, 44, 177–190. [Google Scholar] [CrossRef]

- Ore, T.; Gao, D.L. Prediction of Reservoir Brittleness from Geophysical Logs Using Machine Learning Algorithms. Comput. Geosci. 2023, 171, 105266. [Google Scholar] [CrossRef]

- Zheng, D.Y.; Wu, S.X.; Hou, M.C. Fully Connected Deep Network: An Improved Method to Predict TOC of Shale Reservoirs from Well Logs. Mar. Pet. Geol. 2021, 132, 105205. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Wu, W.S.; Wu, H. TOC Prediction Using a Gradient Boosting Decision Tree Method: A Case Study of Shale Reservoirs in Qinshui Basin. Geoenergy Sci. Eng. 2023, 221, 111271. [Google Scholar] [CrossRef]

- Nath, F.; Asish, S.M.; Ganta, D.; Debi, H.R.; Aguirre, G.; Aguirre, E. Artificial Intelligence Model in Predicting Geomechanical Properties for Shale Formation: A Field Case in Permian Basin. Energies 2022, 15, 8752. [Google Scholar] [CrossRef]

- Ashraf, U.; Zhang, H.C.; Anees, A.; Mangi, H.N.; Ali, M.; Ullah, Z.; Zhang, X.N. Application of Unconventional Seismic Attributes and Unsupervised Machine Learning for the Identification of Fault and Fracture Network. Appl. Sci. 2020, 10, 3864. [Google Scholar] [CrossRef]

- Mustafa, A.; Tariq, Z.; Mahmoud, M.; Radwan, A.E.; Abdulraheem, A.; Abouelresh, M.O. Data-Driven Machine Learning Approach to Predict Mineralogy of Organic-Rich Shales: An example from Qusaiba Shale, Rub’ al Khali Basin, Saudi Arabia. Mar. Pet. Geol. 2022, 137, 105495. [Google Scholar] [CrossRef]

- Qian, K.R.; He, Z.L.; Liu, X.W.; Chen, Y.Q. Intelligent Prediction and Integral Analysis of Shale Oil and Gas Sweet Spots. Pet. Sci. 2018, 15, 744–755. [Google Scholar] [CrossRef]

- Zhu, W.Y.; Song, T.R.; Wang, M.C.; Jin, W.J.; Song, H.Q.; Yue, M. Stratigraphic Subdivision-Based Logging Curves Generation Using Neural Random Forests. J. Pet. Sci. Eng. 2022, 219, 111086. [Google Scholar] [CrossRef]

- Yang, J.Q.; Lin, N.T.; Zhang, K.; Zhang, C.; Ding, R.W.; Tian, G.P.; Jin, Z.W. ANN-Based Multicomponent Seismic Data-Driven Prediction of Gas-Bearing Distribution. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 84. [Google Scholar] [CrossRef]

- Parapuram, G.; Mokhtari, M.; Ben Hmida, J. An Artificially Intelligent Technique to Generate Synthetic Geomechanical Well Logs for the Bakken Formation. Energies 2018, 11, 680. [Google Scholar] [CrossRef]

- Zhao, W.J.; Liu, T.Y.; Yang, J.; Zhang, Z.; Feng, C.; Tang, J.Z. Approaches of Combining Machine Learning with NMR-Based Pore Structure Characterization for Reservoir Evaluation. Sustainability 2024, 16, 2774. [Google Scholar] [CrossRef]

- He, M.; Gu, H.M.; Wan, H. Log Interpretation for Lithology and Fluid Identification Using Deep Neural Network Combined with MAHAKIL in a Tight Sandstone Reservoir. J. Pet. Sci. Eng. 2020, 194, 107498. [Google Scholar] [CrossRef]

- Hou, M.Q.; Xiao, Y.X.; Lei, Z.D.; Yang, Z.; Lou, Y.H.; Liu, Y.M. Machine Learning Algorithms for Lithofacies Classification of the Gulong Shale from the Songliao Basin, China. Energies 2023, 16, 2581. [Google Scholar] [CrossRef]

- Tahmasebi, P.; Javadpour, F.; Sahimi, M. Data Mining and Machine Learning for Identifying Sweet Spots in Shale Reservoirs. Expert Syst. Appl. 2017, 88, 435–447. [Google Scholar] [CrossRef]

- Mahmouda, A.A.A.; Elkatatny, S.; Mahmoud, M.; Abouelresh, M.; Abdulraheem, A.; Ali, A. Determination of the Total Organic Carbon (TOC) Based on Conventional Well Logs Using Artificial Neural Network. Int. J. Coal Geol. 2017, 179, 72–80. [Google Scholar] [CrossRef]

- Saporetti, C.M.; Fonseca, D.L.; Oliveira, L.C.; Pereira, E.; Goliatt, L. Hybrid Machine Learning Models for Estimating Total Organic Carbon from Mineral Constituents in Core Samples of Shale Gas Fields. Mar. Pet. Geol. 2022, 143, 105783. [Google Scholar] [CrossRef]

- Goliatt, L.; Saporetti, C.M.; Oliveira, L.C.; Pereira, E. Performance of Evolutionary Optimized Machine Learning for Modeling Total Organic Carbon in Core Samples of Shale Gas Fields. Petroleum 2024, 10, 150–164. [Google Scholar] [CrossRef]

- Shan, X.C.; Chen, Z.X.; Fu, B.Y.; Zhang, W.; Li, J.; Wu, K.L. Predicting Total Organic Carbon from Well Logs Based on Deep Spatial-Sequential Graph Convolutional Network. Geophysics 2023, 88, D193–D206. [Google Scholar] [CrossRef]

- Tan, M.J.; Song, X.D.; Yang, X.; Wu, Q.Z. Support-Vector-Regression Machine Technology for Total Organic Carbon Content Prediction from Wireline Logs in Organic Shale: A Comparative Study. J. Nat. Gas Sci. Eng. 2015, 26, 792–802. [Google Scholar] [CrossRef]

- Singh, A.; Zoback, M.D. Predicting Variations of the Least Principal Stress with Depth: Application to Unconventional Oil and Gas Reservoirs Using a Log-Based Viscoelastic Stress Relaxation Model. Geophysics 2022, 87, MR105–MR116. [Google Scholar] [CrossRef]

- Wang, B.Z.; Sharma, J.; Chen, J.H.; Persaud, P. Ensemble Machine Learning Assisted Reservoir Characterization Using Field Production Data-An Offshore Field Case Study. Energies 2021, 14, 1052. [Google Scholar] [CrossRef]

- Liu, X.Y.; Ge, Q.; Chen, X.H.; Li, J.Y.; Chen, Y.K. Extreme Learning Machine for Multivariate Reservoir Characterization. J. Pet. Sci. Eng. 2021, 205, 108869. [Google Scholar] [CrossRef]

- Li, D.S.; You, S.H.; Liao, Q.Z.; Lei, G.; Liu, X.; Chen, W.Q.; Li, H.J.; Liu, B.; Guo, X.X. Permeability Prediction of Nanoscale Porous Materials Using Discrete Cosine Transform-Based Artificial Neural Networks. Materials 2023, 16, 4668. [Google Scholar] [CrossRef]

- Fang, Z.J.; Ba, J.; Carcione, J.M.; Xiong, F.S.; Gao, L. Permeability Prediction Using Logging Data from Tight Reservoirs Based on Deep Neural Networks. J. Appl. Geophys. 2024, 229, 105501. [Google Scholar] [CrossRef]

- Wang, S.H.; Sobecki, N.; Ding, D.; Zhu, L.C.; Wu, Y.S. Accelerating and Stabilizing the Vapor-Liquid Equilibrium (VLE) Calculation in Compositional Simulation of Unconventional Reservoirs Using Deep Learning Based Flash Calculation. Fuel 2019, 253, 209–219. [Google Scholar] [CrossRef]

- Dachanuwattana, S.; Yu, W.; Zuloaga-Molero, P.; Sepehrnoori, K. Application of Assisted-History-Matching Workflow Using Proxy-Based MCMC on a Shale Oil Field Case. J. Pet. Sci. Eng. 2018, 167, 316–328. [Google Scholar] [CrossRef]

- Yao, C.; Yan, R.; Zhou, F.; Zhang, Q.; Niu, G.; Chen, F.; Cao, W.; Wang, J. A Novel Method to Calculate Water Influx Parameters and Geologic Reserves for Fractured-Vuggy Reservoirs with Bottom/Edge Water. Energies 2024, 17, 2822. [Google Scholar] [CrossRef]

- Alarifi, S.A.; Miskimins, J. A New Approach To Estimating Ultimate Recovery for Multistage Hydraulically Fractured Horizontal Wells by Utilizing Completion Parameters Using Machine Learning. SPE Prod. Oper. 2021, 36, 468–483. [Google Scholar] [CrossRef]

- Qiu, K.X.; Li, J.; Chen, D. Optimized Long Short-Term Memory (LSTM) Network for Performance Prediction in Unconventional Reservoirs. Energy Rep. 2022, 8, 15436–15445. [Google Scholar] [CrossRef]

- Wang, S.H.; Chen, Z.; Chen, S.N. Applicability of Deep Neural Networks on Production Forecasting in Bakken Shale Reservoirs. J. Pet. Sci. Eng. 2019, 179, 112–125. [Google Scholar] [CrossRef]

- Luo, S.G.; Ding, C.; Cheng, H.F.; Zhang, B.N.; Zhao, Y.L.; Liu, L.F. Estimated Ultimate Recovery Prediction of Fractured Horizontal Wells in Tight Oil Reservoirs Based on Deep Neural Networks. Adv. Geo-Energy Res. 2022, 6, 111–122. [Google Scholar] [CrossRef]

- Smith, R.; Mukerji, T.; Lupo, T. Correlating Geologic and Seismic Data with Unconventional Resource Production Curves Using Machine Learning. Geophysics 2019, 84, O39–O47. [Google Scholar] [CrossRef]

- Bhattacharyya, S.; Vyas, A. Application of Machine Learning in Predicting Oil Rate Decline for Bakken Shale Oil Wells. Sci. Rep. 2022, 12, 16154. [Google Scholar] [CrossRef]

- Zhou, G.Z.; Guo, Z.Q.; Sun, S.M.; Jin, Q.S. A CNN-BiGRU-AM Neural Network for AI Applications in Shale Oil Production Prediction. Appl. Energy 2023, 344, 121249. [Google Scholar] [CrossRef]

- Kong, B.; Chen, Z.H.; Chen, S.N.; Qin, T.J. Machine Learning-Assisted Production Data Analysis in Liquid-Rich Duvernay Formation. J. Pet. Sci. Eng. 2021, 200, 108377. [Google Scholar] [CrossRef]

- Ning, Y.R.; Kazemi, H.; Tahmasebi, P. A Comparative Machine Learning Study for Time Series Oil Production Forecasting: ARIMA, LSTM, and Prophet. Comput. Geosci. 2022, 164, 105126. [Google Scholar] [CrossRef]

- Rahmanifard, H.; Gates, I. A Comprehensive Review of Data-Driven Approaches for Forecasting Production from Unconventional Reservoirs: Best Practices and Future Directions. Artif. Intell. Rev. 2024, 57, 213. [Google Scholar] [CrossRef] [PubMed]

- Chaikine, I.A.; Gates, I.D. A Machine Learning Model for Predicting Multi-Stage Horizontal Well Production. J. Pet. Sci. Eng. 2021, 198, 108133. [Google Scholar] [CrossRef]

- Tatsipie, N.R.K.; Sheng, J.J. Deep Learning-Based Sensitivity Analysis of the Effect of Completion Parameters on Oil Production. J. Pet. Sci. Eng. 2022, 209, 109906. [Google Scholar] [CrossRef]

- Wen, S.Q.; Wei, B.; You, J.Y.; He, Y.J.; Xin, J.; Varfolomeev, M.A. Forecasting Oil Production in Unconventional Reservoirs Using Long Short Term Memory Network Coupled Support Vector Regression Method: A Case Study. Petroleum 2023, 9, 647–657. [Google Scholar] [CrossRef]

- Yang, R.; Liu, X.G.; Yu, R.Z.; Hu, Z.M.; Duan, X.G. Long Short-Term Memory Suggests a Model for Predicting Shale Gas Production. Appl. Energy 2022, 322, 119415. [Google Scholar] [CrossRef]

- Razak, S.M.; Cornelio, J.; Cho, Y.; Liu, H.H.; Vaidya, R.; Jafarpour, B. Transfer Learning with Recurrent Neural Networks for Long -Term Production Forecasting in Unconventional Reservoirs. SPE J. 2022, 27, 2425–2442. [Google Scholar] [CrossRef]

- Xiao, C.; Wang, G.D.; Zhang, Y.Y.; Deng, Y. Machine-Learning-Based Well Production Prediction Under Geological and Hydraulic Fracture Parameters Uncertainty for Unconventional Shale Gas Reservoirs. J. Nat. Gas Sci. Eng. 2022, 106, 104762. [Google Scholar] [CrossRef]

- Rezaei, A.; Aminzadeh, F. A Data-Driven Reduced-Order Model for Estimating the Stimulated Reservoir Volume (SRV). Energies 2022, 15, 5582. [Google Scholar] [CrossRef]

- Lu, C.H.; Jiang, H.Q.; Yang, J.L.; Wang, Z.Q.; Zhang, M.; Li, J.J. Shale Oil Production Prediction and Fracturing Optimization Based on Machine Learning. J. Pet. Sci. Eng. 2022, 217, 110900. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, R.X. A Machine Learning-based Hybrid Model for Fracture Parameterization and Distribution Prediction in Unconventional Reservoirs. Comput. Geotech. 2024, 168, 106146. [Google Scholar] [CrossRef]

- Wang, H.J.; Qiao, L.; Zhang, J.; Lu, S.F.; Chen, F.W.; Liu, Y.; Fu, Z. An Effective Integration Optimization Algorithm for Regional Fracturing Design and Drilling Placement. J. Nat. Gas Sci. Eng. 2022, 101, 104505. [Google Scholar] [CrossRef]

- Rahmanifard, H.; Plaksina, T. Application of fast analytical approach and AI Optimization Techniques to Hydraulic Fracture Stage Placement in Shale Gas Reservoirs. J. Nat. Gas Sci. Eng. 2018, 52, 367–378. [Google Scholar] [CrossRef]

- Xiao, C.; Zhang, S.C.; Ma, X.F.; Zhou, T.; Li, X.C. Surrogate-Assisted Hydraulic Fracture Optimization Workflow with Applications for Shale Gas Reservoir Development: A Comparative Study of Machine Learning Models. Nat. Gas Ind. B 2022, 9, 219–231. [Google Scholar] [CrossRef]

- Wang, S.; Qin, C.X.; Feng, Q.H.; Javadpour, F.; Rui, Z.H. A Framework for Predicting the Production Performance of Unconventional Resources Using Deep Learning. Appl. Energy 2021, 295, 117016. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, H.T.; Xiao, C.; Zhang, S.C. Hierarchical Surrogate-Assisted Evolutionary Algorithm for Integrated Multi-Objective Optimization of Well Placement and Hydraulic Fracture Parameters in Unconventional Shale Gas Reservoir. Energies 2023, 16, 303. [Google Scholar] [CrossRef]

- Li, L.Z.; Zhou, F.J.; Zhou, Y.; Cai, Z.L.; Wang, B.; Zhao, Y.Y.; Lu, Y.T. The Prediction and Optimization of Hydraulic Fracturing by Integrating the Numerical Simulation and the Machine Learning Methods. Energy Rep. 2022, 8, 15338–15349. [Google Scholar] [CrossRef]

- Hu, S.M.; Sheng, M.; Shi, S.Z.; Li, J.C.; Tian, S.C.; Li, G.S. Optimization of Fracturing Stages/Clusters in Horizontal Well Based on Unsupervised Clustering of Bottomhole Mechanical Specific Energy on the Bit. Nat. Gas Ind. B 2023, 10, 583–590. [Google Scholar] [CrossRef]

- Liu, Z.; Lei, Q.; Weng, D.W.; Yang, L.F.; Wang, X.; Wang, Z.; Fan, M.; Wang, J.L. A Powerful Prediction Framework of Fracture Parameters for Hydraulic Fracturing Incorporating eXtreme Gradient Boosting and Bayesian Optimization. Energies 2023, 16, 7890. [Google Scholar] [CrossRef]

- Duan, C.L.; Huang, L.J.; Gross, M.; Fehler, M.; Lumley, D.; Glubokovskikh, S. Monitoring Subsurface Fracture Flow Using Unsupervised Deep Learning of Borehole Microseismic Waveform Data. IEEE Trans. Geosci. Remote Sens. 2024, 62, 3369577. [Google Scholar] [CrossRef]

- Chen, H.; Wang, Y.; Zuo, M.S.; Zhang, C.; Jia, N.H.; Liu, X.L.; Yang, S.L. A New Prediction Model of CO2 Diffusion Coefficient in Crude Oil Under Reservoir Conditions Based on BP Neural Network. Energy 2022, 239, 122286. [Google Scholar] [CrossRef]

- Qin, S.L.; Li, J.H.; Chen, J.Y.; Bi, X.L.; Xiang, H. Research on Displacement Efficiency by Injecting CO2 in Shale Reservoirs Based on a Genetic Neural Network Model. Energies 2023, 16, 4812. [Google Scholar] [CrossRef]

- Wan, X.C.; Jin, L.; Azzolina, N.A.; Butler, S.K.; Yu, X.; Zhao, J. Applying Reservoir Simulation and Artificial Intelligence Algorithms to Optimize Fracture Characterization and CO2 Enhanced Oil Recovery in Unconventional Reservoirs: A Case Study in the Wolfcamp Formation. Energies 2022, 15, 8266. [Google Scholar] [CrossRef]

- Zhao, J.; Jin, L.; Yu, X.; Azzolina, N.A.; Wan, X.C.; Smith, S.A.; Bosshart, N.W.; Sorensen, J.A.; Ling, K.G. Progress of Gas Injection EOR Surveillance in the Bakken Unconventional Play-Technical Review and Machine Learning Study. Energies 2024, 17, 4200. [Google Scholar] [CrossRef]

- Tavakolian, M.; Najafi-Silab, R.; Chen, N.Y.; Kantzas, A. Modeling of Methane and Carbon Dioxide Sorption Capacity in Tight Reservoirs Using Machine Learning Techniques. Fuel 2024, 360, 130578. [Google Scholar] [CrossRef]

- Syed, F.I.; Muther, T.; Dahaghi, A.K.; Neghabhan, S. CO2 EOR Performance Evaluation in an Unconventional Reservoir Through Mechanistic Constrained Proxy Modeling. Fuel 2022, 310, 122390. [Google Scholar] [CrossRef]

- Wen, T.; Liu, M.Q.; Woda, J.; Zheng, G.J.; Brantley, S.L. Detecting Anomalous Methane in Groundwater Within Hydrocarbon Production Areas Across the United States. Water Res. 2021, 200, 117236. [Google Scholar] [CrossRef] [PubMed]

- Dong, C.; Dong, X.C.; Gehman, J.; Lefsrud, L. Using BP Neural Networks to Prioritize Risk Management Approaches for China’s Unconventional Shale Gas Industry. Sustainability 2017, 9, 979. [Google Scholar] [CrossRef]

- Singh, H. Machine Learning for Surveillance of Fluid Leakage from Reservoir Using Only Injection Rates and Bottomhole Pressures. J. Nat. Gas Sci. Eng. 2019, 69, 102933. [Google Scholar] [CrossRef]

- Botao, L.; Jiancheng, G. Discussion on Current Application of Artificial Intelligence in Petroleum Industry. Pet. Sci. Bull. 2019, 4, 403–413. [Google Scholar] [CrossRef]

- Favour, D.A. Petroleum Industry Value Chain Optimization: The Inevitability of Artificial Intelligence and Data Science in Midstream and Downstream Development. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 5–7 August 2024. [Google Scholar]

- Jia, D.; Zhang, J.; Li, Y.; Wu, L.; Qiao, M. Recent Development of Smart Field Deployment for Mature Waterflood Reservoirs. Sustainability 2023, 15, 784. [Google Scholar] [CrossRef]

- Gan, T.; Kumar, A.; Ehiwario, M.; Zhang, B.; Sembroski, C.; de Jesus, O.; Hoffmann, O.; Metwally, Y. Artificial Intelligent Logs for Formation Evaluation Using Case Studies in Gulf of Mexico and Trinidad & Tobago. In Proceedings of the SPE Annual Technical Conference and Exhibition, Calgary, AB, Canada, 30 September–2 October 2019. [Google Scholar]

- Jacobs, T. Shell Picks a Digital Platform To Build Its AI Future Upon. J. Pet. Technol. 2018, 70, 43–44. [Google Scholar] [CrossRef]

- Pallanich, J. Unsung Hero: Artificial Lift Boosts Production Without Breaking the Bank. J. Pet. Technol. 2024, 76, 30–40. [Google Scholar] [CrossRef]

- Di, S.; Cheng, S.; Cao, N.; Gao, C.; Miao, L. AI-Based Geo-Engineering Integration in Unconventional Oil and Gas. J. King Saud Univ.—Sci. 2021, 33, 101542. [Google Scholar] [CrossRef]

| Reservoir Property Prediction and Gas Probability Prediction | |||

|---|---|---|---|

| Reference | Method | Input Parameters | Output Parameters |

| [83] | CNN, TL | Seismic attributes | Gas probability distribution |

| [84] | ANN, MPSO | Seismic attributes | Gas probability distribution |

| [96] | MLP, RBF | Seismic attributes | Gas probability distribution |

| Lithology and Facies Classification | |||

| Reference | Method | Input Parameters | Output Parameters |

| [97] | CNN | Well logging data | Reservoir classification |

| [98] | RF, SVM, XGB | NMR pore structure features, reservoir physical data | Reservoir classification |

| [99] | DNN, MAHAKIL | Well logging data | Lithology and fluid classification |

| [100] | RF, SVM, XGB | Well logging data | Lithofacies classification |

| [86] | STNet | Well logging data | Lithology classification |

| Brittleness Index Estimation | |||

| Reference | Method | Input Parameters | Output Parameters |

| [88] | GB, SVR, ANN | Well logging data | Brittleness index |

| [87] | ANFIS | Well logging data | Brittleness index |

| [101] | FL, ANN, GA | Well logging data, mineral composition, rock mechanics | Brittleness index, TOC, Fracture index |

| TOC Content Prediction | |||

| Reference | Method | Input Parameters | Output Parameters |

| [102] | ANN | Well logging data | TOC |

| [89] | FCDN | Well logging data | TOC |

| [103] | GWO, EN, ELM, SVR, MARS | Mineral composition | TOC |

| [104] | Metaheuristic, ELM, EN, SVR, MARS | Mineral composition | TOC |

| [105] | SSGCN | Well logging data | TOC |

| [106] | SVR | Well logging data | TOC |

| [90] | GBDT | Well logging data | TOC |

| Geomechanical Parameter Prediction | |||

| Reference | Method | Input Parameters | Output Parameters |

| [97] | ANN | Well logging data | Vs, geomechanical parameters |

| [91] | Bi-LSTM, RF | Well logging data | DTS, geomechanical parameters |

| [107] | Bagging | Well logging data | Minimum horizontal stress (Shmin) |

| Others | |||

| Reference | Method | Input Parameters | Output Parameters |

| [92] | UVQ, ACO | Seismic attributes | Fracture parameters |

| [93] | ANN, ANFIS | Well logging data | Quartz content, clay content |

| [94] | SVM, FL | Geological and seismic attributes | Sweet spot property prediction |

| [95] | NRF | Well logging data | Generation of missing logging curves |

| Reference | Method | Input Parameters | Output Parameters | Resource |

|---|---|---|---|---|

| [112] | FCNN | Reservoir Conditions, Composition Data | Phase State, Component Concentration, Pc | Shale Gas |

| [113] | Proxy-based MCMC | Reservoir Properties | BHP, Production Error, Recovery Prediction | Shale Oil |

| [108] | RF | Production and Operational Data | Oil Saturation Profile (So) | Tight Oil |

| [109] | ELM | Elastic Attribute Data | Lithofacies, Reservoir Properties | Tight Sandstone Gas |

| [110] | DCT, ANN | Rock Image Features | Permeability | Shale Gas |

| [111] | DNN | Well Logging Data | Permeability | Ordos Basin Tight Oil |

| Reference | Method | Input Parameters | Output Parameters | Resource |

|---|---|---|---|---|

| [143] | BP | Temperature, pressure, oil density, oil viscosity, permeability, porosity, surface area, volume | CO2 diffusion coefficient | Tight oil and shale oil |

| [145] | NN + MCMC | Fracture efficiency, fracture half-length, fracture height, fracture width, conductivity, water saturation, fracture compressibility, reservoir compressibility | Production history matching solution | - |

| [148] | DNN | Reservoir pressure, porosity, fracture permeability, fracture width, conductivity, permeability contrast | Recovery prediction | - |

| [147] | RF, DT, SVR, XGBoost, ANN | CO2 ratio, rock type, total organic carbon, moisture content, temperature, pressure | CH4 and CO2 adsorption amount | Shale gas and coalbed methane gas |

| [146] | DNN + Numerical Simulation | Pressure, temperature, injection volume, composition, fracture permeability, injection rate | Production prediction, gas breakthrough time | Bakken tight oil |

| [144] | GA + BP | Porosity, total compressibility, oil saturation, total organic carbon, median pore size, permeability, soaking time, injection pressure | CO2 displacement efficiency | Shale oil |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, F.; Sun, L.; Jiang, B.; Huo, X.; Pan, X.; Feng, C.; Zhang, Z. A Review of AI Applications in Unconventional Oil and Gas Exploration and Development. Energies 2025, 18, 391. https://doi.org/10.3390/en18020391

Chen F, Sun L, Jiang B, Huo X, Pan X, Feng C, Zhang Z. A Review of AI Applications in Unconventional Oil and Gas Exploration and Development. Energies. 2025; 18(2):391. https://doi.org/10.3390/en18020391

Chicago/Turabian StyleChen, Feiyu, Linghui Sun, Boyu Jiang, Xu Huo, Xiuxiu Pan, Chun Feng, and Zhirong Zhang. 2025. "A Review of AI Applications in Unconventional Oil and Gas Exploration and Development" Energies 18, no. 2: 391. https://doi.org/10.3390/en18020391

APA StyleChen, F., Sun, L., Jiang, B., Huo, X., Pan, X., Feng, C., & Zhang, Z. (2025). A Review of AI Applications in Unconventional Oil and Gas Exploration and Development. Energies, 18(2), 391. https://doi.org/10.3390/en18020391