A Brief Review of Recent Research on Reversible Francis Pump Turbines in Pumped Storage Plants

Abstract

:1. Introduction

2. Design and Optimization of Pump Turbine

2.1. Traditional Design Methods for Flow Domains

2.2. Inverse Design Method (IDM)

2.3. Multi-Objective Optimization Method (MOM)

2.4. Pump Turbine with Variable Speed

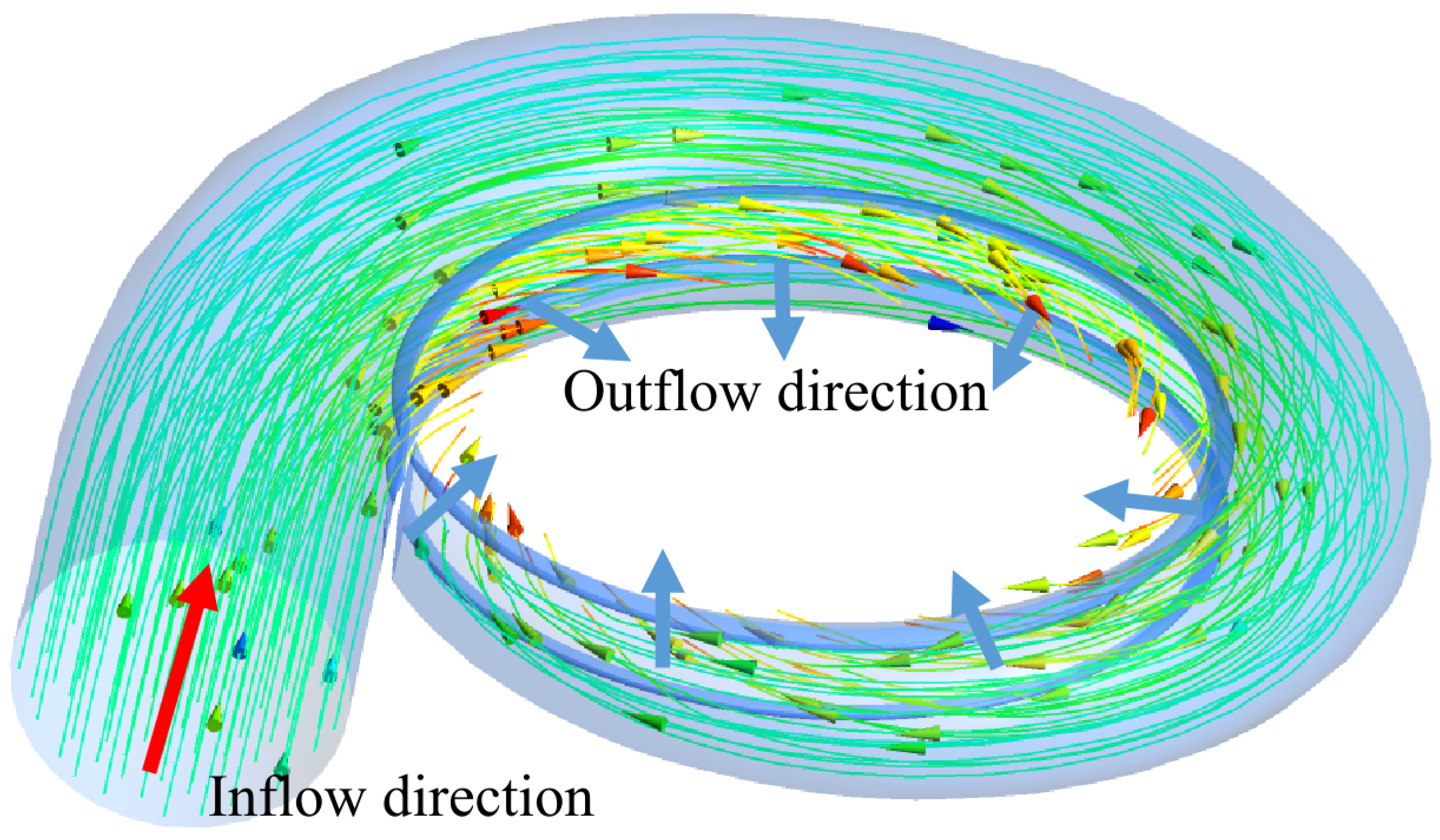

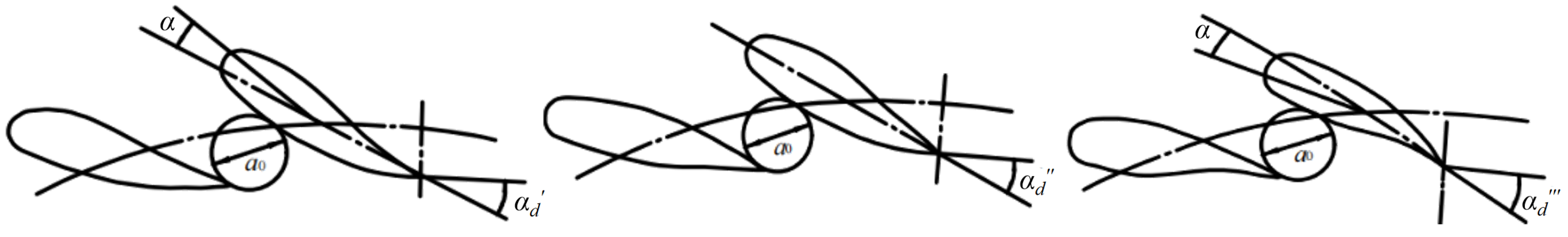

2.5. Newer Structure of Flow Domains

3. Operational Performance of PTs

3.1. Hydraulic Performance

3.2. Cavitation and Sediment Abrasion

3.3. Operational Stability

4. Advanced Research Methods for Flow Domains

4.1. Dynamic Mesh Technology (DMT)

4.2. Improved Turbulence Models (ITMs)

4.3. Liutex Vortex Identification Method (LVIM)

4.4. Advanced Experimental Techniques

5. Conclusions

Funding

Conflicts of Interest

Nomenclature

| Velocity (m/s) | |

| r | Radius (m) |

| Guide-vane opening (°) | |

| Inlet angle (°) | |

| Outlet angles (°) | |

| Q | Mass flow rate (/s) |

| H | Water head (m) |

| Angle between incoming flow velocity and circumferential direction (°) | |

| k | Slope (-) |

| Angle of inclination (°) | |

| PSP | Pumped storage plant |

| PT | Pump turbine |

| BEP | Best efficient point |

| PAT | Pump as turbine |

| IDM | Inverse problem design method |

| CFD | Computational fluid dynamics |

| MOM | Multi-objective optimization method |

| OTM | Orthogonal test method |

| LE | Load on leading edge of blade |

| NC | Start point of streamline |

| ND | End point of streamline |

| DMT | Dynamic mesh technology |

| UDF | User-defined function |

| MPANS | Modified partial averaged Navier–Stokes |

| RANS | Reynolds-Averaged Navier–Stokes |

| LES | Large Eddy Simulation |

| ITM | Improvedturbulence model |

| MZGB | Modified Zwart–Gerber–Belamri |

| LVIM | Liutex vortex identification method |

| PID | Proportional-integral derivative |

| LDA | Laser Doppler velocimeter |

| PIV | Particle image velocimetry |

| MGV | Misaligned guide vane |

References

- National Energy Administration. Medium and Long-Term Development Plan for Pumped Storage (2021–2035). Available online: https://zfxxgk.nea.gov.cn/2021-09/17/c_1310193456.htm (accessed on 18 December 2024).

- National Energy Administration. National Development and Reform Commission and the National Energy Administration Deployed to Accelerate the Development and Construction of Pumped Storage Projects During the ‘14th Five-Year Plan’ Period. Available online: https://www.nea.gov.cn/2022-04/02/c_1310541305.htm (accessed on 18 December 2024).

- Wikipediaps. Pumped-Storage Hydroelectricity. Available online: https://en.wikipedia.org/wiki/Pumped-storage_hydroelectricity (accessed on 26 June 2023).

- Zheng, Y.; Wu, F.; Zhou, D. Modern Pumped Storage Technology; China Water & Power Presss: Beijing, China, 2020. [Google Scholar]

- Power China, Beijing Engineering Corporation. Pumped Storage Power Plant Engineering Technology; China Electric Power Press: Beijing, China, 2023. [Google Scholar]

- Yang, J. Transient Processes of Unit in Pumped Storage Plant; China Science Publishing & Media Ltd.: Beijing, China, 2017. [Google Scholar]

- Lv, C.; Xu, Y.; Wu, X.; Zhang, Q. Characteristic analysis and optimal regulation of primary frequency regulation condition in low water head area based on hydraulic-mechanical-electrical coupling model of pumped storage unit. Complexity 2020, 2020, 6161784. [Google Scholar] [CrossRef]

- Wang, Z.; Fang, G.; Wen, X.; Tan, Q.; Zhang, P.; Liu, Z. Coordinated operation of conventional hydropower plants as hybrid pumped storage hydropower with wind and photovoltaic plants. Energy Convers. Manag. 2023, 277, 116654. [Google Scholar] [CrossRef]

- Hoffstaedt, J.P.; Truijen, D.; Fahlbeck, J.; Gans, L.H.A.; Qudaih, M.; Laguna, A.J.; De Kooning, J.; Stockman, K.; Nilsson, H.; Storli, P.T.; et al. Low-head pumped hydro storage: A review of applicable technologies for design, grid integration, control and modelling. Renew. Sustain. Energy Rev. 2022, 158, 112119. [Google Scholar] [CrossRef]

- Panda, D.K.; Das, S. Smart grid architecture model for control, optimization and data analytics of future power networks with more renewable energy. J. Clean. Prod. 2021, 301, 126877. [Google Scholar] [CrossRef]

- Alotaibi, I.; Abido, M.A.; Khalid, M.; Savkin, A.V. A comprehensive review of recent advances in smart grids: A sustainable future with renewable energy resources. Energies 2020, 13, 6269. [Google Scholar] [CrossRef]

- Wang, X.; Zhu, B.; Cao, S.; Tan, L. Optimal design of reversible pump-turbine runner. Trans. Chin. Soc. Agric. Eng. 2014, 30, 78–85. (In Chinese) [Google Scholar]

- Schleicher, W.; Oztekin, A. Hydraulic design and optimization of a modular pump-turbine runner. Energy Convers. Manag. 2015, 93, 388–398. [Google Scholar] [CrossRef]

- Huang, Q. Hydeaulic Design and Internal Fluid Analysis of Reversible Pump Turbine. Master’s Thesis, Lanzhou University of Science and Technology, Lanzhou, China, 2012. [Google Scholar]

- Yan, J. Design and Performance Study on Small-Scale Pumped Storage Plant. Master’s Thesis, University of Chinese Academy of Sciences, Beijing, China, 2019. [Google Scholar]

- Zheng, Y. Hydraulic Turbine; China Water & Power Press: Beijing, China, 2011. [Google Scholar]

- Guan, X. Modern Pump Theory and Design; China Astronautic Publishing House: Beijing, China, 2023. [Google Scholar]

- Gülich, J. Centrifugal Pumps; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar]

- Yu, C. Research on Design Method and Numerical Analysis of Pump Turbine Spiral Case. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2019. [Google Scholar]

- Wang, S. Research on the Development and Application of Pumped Storage Technology; China Science Publishing & Media Ltd.: Beijing, China, 2016. [Google Scholar]

- Chen, X. Research on the Influence of Pump-Turbine Guide Airfoil on “S” Characteristics. Master’s Thesis, Lanzhou University of Science and Technology, Lanzhou, China, 2020. [Google Scholar]

- Li, C. Modern Design Methods for Water Pumps; Shanghai Scientific & Technical Publishers: Shanghai, China, 2010. [Google Scholar]

- Thapa, B.S.; Trivedi, C.; Dahlhaug, O.G. Design and development of guide vane cascade for a low speed number Francis turbine. J. Hydrodyn. Ser. B 2016, 28, 676–689. [Google Scholar] [CrossRef]

- Joy, J.; Raisee, M.; Cervantes, M.J. Experimental investigation of an adjustable guide vane system in a Francis turbine draft tube at part load operation. Renew. Energy 2023, 210, 737–750. [Google Scholar] [CrossRef]

- Desai, J.; Roghelia, A.; Soni, V.A.; Chauhan, V. Validation of hydraulic design of spiral casing and stay vanes of Francis turbine using CFD. In Proceedings of the 37th International and 4th National Conference on Fluid Mechanics and Fluid Power, Chennai, India, 16–18 December 2010; pp. 1–9. [Google Scholar]

- Shrestha, U.; Park, J.; Choi, Y.D. Optimal design of reaction hydro turbine model stay vane by vane Angle and thickness distribution. In Proceedings of the Fluids Engineering Division Summer Meeting, San Francisco, CA, USA, 28 July–1 August 2019; American Society of Mechanical Engineers: New York, NY, USA, 2019; Volume 59049, p. V03AT03A013. [Google Scholar]

- Abbas, A.; Kumar, A. Development of draft tube in hydro-turbine: A review. Int. J. Ambient. Energy 2015, 38, 323–330. [Google Scholar] [CrossRef]

- Jiri, S.; Nowak, P. Optimization of elbow draft tubes for variable speed propeller turbine. Water 2024, 16, 1457. [Google Scholar] [CrossRef]

- Kim, S.; Kim, Y.I.; Kim, J.H.; Choi, Y.S. Three-objective optimization of a mixed-flow pump impeller for improved suction performance and efficiency. Adv. Mech. Eng. 2019, 11, 1687814019898969. [Google Scholar] [CrossRef]

- Fang, Y.; Xiao, Y.; Liu, D.; Wang, G.; Zhang, J. Effect of different draft tube designs on the phase resonance in a pump-turbine based on compressible CFD simulation. J. Phys. Conf. Ser. 2024, 2707, 012073. [Google Scholar] [CrossRef]

- Favrel, A.; Lee, N.j.; Irie, T.; Miyagawa, K. Design of experiments applied to francis turbine draft tube to minimize pressure pulsations and energy losses in off-design conditions. Energies 2021, 14, 3894. [Google Scholar] [CrossRef]

- Semenova, A.; Chirkov, D.; Skorospelov, V.; Ustimenko, A.; Turuk, P.; Rigin, V.; Germanova, I. Optimization design of the elbow draft tube of the hydraulic turbine. IOP Conf. Ser. Earth Environ. Sci. 2022, 1079, 012028. [Google Scholar] [CrossRef]

- Tani, K.; Okumura, E.H. Performance improvement of pump-turbine for large capacity pumped storage power plant in USA. Hitachi Rev. 2009, 58, 199. [Google Scholar]

- Kong, Y.; Kong, Z.; Liu, Z.; Wei, C.; Zhang, J.; An, G. Pumped storage power stations in China: The past, the present, and the future. Renew. Sustain. Energy Rev. 2017, 71, 720–731. [Google Scholar] [CrossRef]

- Yang, L.; Chen, N.; Fan, H. Full three-dimensional reverse design method for pump turbine runner. J. Tsinghua Univ. (Sci. Technol.) 2005, 45, 1118–1121. [Google Scholar]

- Li, Q.; Zhang, Z.; Quan, H.; Wang, R. Flow mechanism and research progress of pump-turbine in the S-shaped Region. J. Eng. Therm. Energy Power 2017, 32, 1–6+119. [Google Scholar]

- Zheng, Y.; Zhang, J. Pumped Storage Technology; Hohai University Press: Nanjing, China, 2011. [Google Scholar]

- Zhu, B.; Wang, X.; Tan, L.; Zhou, D.; Zhao, Y.; Cao, S. Optimization design of a reversible pump-turbine runner with high efficiency and stability. Renew. Energy 2015, 81, 366–376. [Google Scholar] [CrossRef]

- Yang, G.; Feng, C. Pump turbine unner design and flow simulation based on inverse design method. J. Drain. Irrig. Mach. Eng. 2013, 31, 1674–8530. [Google Scholar]

- State Grid Xin Yuan Company Limited. General Equipment for Pumped Storage Power Stations-Hydraulic Machinery Fascicle; China Electric Power Press: Beijing, China, 2019. [Google Scholar]

- Yang, W.; Liu, B.; Xiao, R. Three-dimensional inverse design method for hydraulic machinery. Energies 2019, 12, 3210. [Google Scholar] [CrossRef]

- Yin, J.; Wang, D. Review on applications of 3D inverse design method for pump. Chin. J. Mech. Eng. 2014, 27, 520–527. [Google Scholar] [CrossRef]

- Yang, S.; Lee, S.; Yee, K. Inverse design optimization framework via a two-step deep learning approach: Application to a wind turbine airfoil. Eng. Comput. 2023, 39, 2239–2255. [Google Scholar] [CrossRef]

- Ghosh, S.; Anantha Padmanabha, G.; Peng, C.; Andreoli, V.; Atkinson, S.; Pandita, P.; Vandeputte, T.; Zabaras, N.; Wang, L. Inverse aerodynamic design of gas turbine blades using probabilistic machine learning. J. Mech. Des. 2022, 144, 021706. [Google Scholar] [CrossRef]

- Zanetti, G.; Siviero, M.; Cavazzini, G.; Santolin, A. Application of the 3D inverse design method in reversible pump turbines and Francis turbines. Water 2023, 15, 2271. [Google Scholar] [CrossRef]

- Zuo, Z.; Fan, H.; Liu, S.; Wu, Y. S-shaped characteristics on the performance curves of pump-turbines in turbine mode-A review. Renew. Sustain. Energy Rev. 2016, 60, 836–851. [Google Scholar] [CrossRef]

- Li, D.; Zuo, Z.; Wang, H.; Liu, S.; Wei, X.; Qin, D. Review of positive slopes on pump performance characteristics of pump-turbines. Renew. Sustain. Energy Rev. 2019, 112, 901–916. [Google Scholar] [CrossRef]

- Mao, X.; Gou, W.; Qu, B.; Zhang, Z.; Mou, T.; Liu, Q. Design and numerical validation of a pump turbine considering hydraulic and abrasion performance. Trans. Chin. Soc. Agric. Eng. 2025, 41, 1–12. (In Chinese) [Google Scholar]

- Wang, L.; Qiu, F. Complex Multi-Objective Optimization and It’s Applications; China Science Publishing & Media Ltd.: Beijing, China, 2018. [Google Scholar]

- Gunantara, N. A review of multi-objective optimization: Methods and its applications. Cogent Eng. 2018, 5, 1502242. [Google Scholar] [CrossRef]

- Lai, X.; Li, C.; Zhou, J.; Zhang, N. Multi-objective optimization of the closure law of guide vanes for pumped storage units. Renew. Energy 2019, 139, 302–312. [Google Scholar] [CrossRef]

- Rezghi, A.; Riasi, A.; Tazraei, P. Multi-objective optimization of hydraulic transient condition in a pump-turbine hydropower considering the wicket-gates closing law and the surge tank position. Renew. Energy 2020, 148, 478–491. [Google Scholar] [CrossRef]

- Qin, Y.; Li, D.; Wang, H.; Liu, Z.; Wei, X.; Wang, X. Multi-objective optimization design on high pressure side of a pump-turbine runner with high efficiency. Renew. Energy 2022, 190, 103–120. [Google Scholar] [CrossRef]

- An, C. Hydrodynamic Chafracteristics and Load Ration Control of Bidirectional Contra-Rotating Axial Flow Pump Turbine. Ph.D. Thesis, Jiangsu University, Zhenjiang, China, 2023. [Google Scholar]

- Hou, J.; Li, C.; Tian, Z.; Xu, Y.; Lai, X.; Zhang, N.; Zheng, T.; Wu, W. Multi-objective optimization of start-up strategy for pumped storage units. Energies 2018, 11, 1141. [Google Scholar] [CrossRef]

- Ji, Y.; Yang, Z.; Ran, J.; Li, H. Multi-objective parameter optimization of turbine impeller based on RBF neural network and NSGA-II genetic algorithm. Energy Rep. 2021, 7, 584–593. [Google Scholar] [CrossRef]

- Shang, L.; Cao, J.; Jia, X.; Yang, S.; Li, S.; Wang, L.; Wang, Z.; Liu, X. Effect of rotational speed on pressure pulsation characteristics of variable-speed pump turbine unit in turbine mode. Water 2023, 15, 609. [Google Scholar] [CrossRef]

- Wang, H.; Ma, Z. Regulation characteristics and load optimization of pump-turbine in variable-speed operation. Energies 2021, 14, 8484. [Google Scholar] [CrossRef]

- People’s Daily Overseas Edition. China’s Large-Scale Variable-Speed Pumped Storage Unit Development Enters Engineering Application Stage. Available online: http://paper.people.com.cn/rmrbhwb/html/2023-06/26/content_26000565.htm (accessed on 26 June 2023).

- Shang, L.; Cao, J.; Wang, Z.; Liu, X. Hydraulic characterization of variable-speed pump turbine under typical pumping modes. Processes 2023, 11, 2903. [Google Scholar] [CrossRef]

- Hu, W.; Wang, Z.; Fan, H. Grid synchronization of variable speed pump-turbine units in turbine mode. Renew. Energy 2021, 173, 625–638. [Google Scholar]

- Li, J. Contercurrent Phenomenon of Pump Condition in Variale Pumped Storage Unit and Its Suppression Strategy. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2023. [Google Scholar]

- Hunt, J.D.; Zakeri, B.; Lopes, R.; Barbosa, P.S.F.; Nascimento, A.; de Castro, N.J.; Brandao, R.; Schneider, P.S.; Wada, Y. Existing and new arrangements of pumped-hydro storage plants. Renew. Sustain. Energy Rev. 2020, 129, 109914. [Google Scholar] [CrossRef]

- Miao, S.-C.; Zhang, H.-B.; Wang, T.-T.; Wang, X.-H.; Shi, F.-X. Optimal design of blade in pump as turbine based on multidisciplinary feasible method. Sci. Prog. 2020, 103, 0036850420982105. [Google Scholar]

- Hu, J.; Zhao, Z.; He, X.; Zeng, W.; Yang, J.; Yang, J. Design techniques for improving energy performance and S-shaped characteristics of a pump-turbine with splitter blades. Renew. Energy 2023, 212, 333–349. [Google Scholar] [CrossRef]

- Song, H.; Zhang, J.; Huang, P.; Cai, H.; Cao, P.; Hu, B. Analysis of rotor-stator interaction of a pump-turbine with splitter blades in a pump mode. Mathematics 2020, 8, 1465. [Google Scholar] [CrossRef]

- Gui, Z.; Xu, Z.; Li, D.; Zhang, F.; Zhao, Y.; Xu, L.; Zheng, Y.; Kan, K. Analysis of the Energy Loss Mechanism of Pump-Turbines with Splitter Blades under Different Characteristic Heads. Water 2023, 15, 2776. [Google Scholar] [CrossRef]

- Shi, F.; Yang, J.; Wang, X. Analysis on the effect of variable guide vane numbers on the performance of pump as turbine. Adv. Mech. Eng. 2018, 10, 1687814018780796. [Google Scholar] [CrossRef]

- Lu, Z.; Tao, R.; Yao, Z.; Liu, W.; Xiao, R. Effects of guide vane shape on the performances of pump-turbine: A comparative study in energy storage and power generation. Renew. Energy 2022, 197, 268–287. [Google Scholar] [CrossRef]

- Zhang, F.; Fang, M.; Pan, J.; Tao, R.; Zhu, D.; Liu, W.; Xiao, R. Guide vane profile optimization of pump-turbine for grid connection performance improvement. Energy 2023, 274, 127369. [Google Scholar] [CrossRef]

- Miao, S.; Zhang, H.; Tian, W.; Li, Y. A study on the unsteady flow characteristics and energy conversion in the volute of a pump-as-turbine device. Fluid Dyn. Mater. Process. 2021, 17, 1021–1036. [Google Scholar] [CrossRef]

- Huang, T. Research on the Influence of the Arrangement of the Modified Guide Vanes on the “S” Characteristic of the Pump-Turbine. Master’s Thesis, Lanzhou University of Technology, Lanzhou, China, 2022. [Google Scholar]

- Ante, S.; Ivana, L.; Marta, A.; Ladoca, K.; Zoran, C. Computationally Efficient Optimisation of Elbow-type Draft Tube Using Neural Network Surrogates. Alex Eng. J. 2024, 90, 129–152. [Google Scholar]

- Zhou, X.; Hu, X.; Huang, Q.; Wu, H.; Tang, X.; Cervantes, M.J. Optimization design of an innovative francis draft tube: Insight into improving operational flexibility. Energy 2024, 299, 131489. [Google Scholar] [CrossRef]

- Binama, M.; Su, W.; Li, X.; Li, F.; Wei, X.; An, S. Investigation on pump as turbine (PAT) technical aspects for micro hydropower schemes: A state-of-the-art review. Renew. Sustain. Energy Rev. 2017, 79, 148–179. [Google Scholar] [CrossRef]

- Liu, M.; Tan, L.; Cao, S. Performance prediction and geometry optimization for application of pump as turbine: A review. Front. Energy Res. 2022, 9, 818118. [Google Scholar] [CrossRef]

- Souza, D.E.S.E.; Mesquita, A.L.A.; Blanco, C.J.C. Pump-as-turbine for energy recovery in municipal water supply networks. A review. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 489. [Google Scholar] [CrossRef]

- Kan, K.; Binama, M.; Chen, H.; Zheng, Y.; Zhou, D.; Su, W.; Muhirwa, A. Pump as turbine cavitation performance for both conventional and reverse operating modes: A review. Renew. Sustain. Energy Rev. 2022, 168, 112786. [Google Scholar] [CrossRef]

- Zheng, X.; Zhang, S.; Zhang, Y.; Li, J.; Zhang, Y. Investigation on operational stability of main shaft of a prototype reversible pump turbine in generating mode based on ensemble empirical mode decomposition and permutation entropy. J. Mech. Sci. Technol. 2022, 36, 6093–6105. [Google Scholar] [CrossRef]

- Zhou, L.; Hang, J.; Bai, L.; Krzemianowski, Z.; El-Emam, M.A.; Yasser, E.; Agarwal, R. Application of entropy production theory for energy losses and other investigation in pumps and turbines: A review. Appl. Energy 2022, 318, 119211. [Google Scholar] [CrossRef]

- Mao, X.; Zheng, Y.; Pavesi, G.; Xie, Z. A new method of dynamic mesh used in continuous guide vane closure of a reversible pump-turbine in generating mode. J. Hydrodyn. 2019, 31, 976–985. [Google Scholar] [CrossRef]

- Yang, H.; He, Q.; Huang, X.; Yang, M.; Bi, H.; Wang, Z. Experimental and numerical investigation of rotor-stator interaction in a large prototype pump-turbine in turbine mode. Energies 2022, 15, 5523. [Google Scholar] [CrossRef]

- Hu, J.; Yang, J.; He, X.; Zeng, W.; Zhao, Z.; Yang, J. Transition of amplitude-frequency characteristic in rotor-stator interaction of a pump-turbine with splitter blades. Renew. Energy 2023, 205, 663–677. [Google Scholar] [CrossRef]

- He, Q.; Huang, X.; Yang, M.; Yang, H.; Bi, H.; Wang, Z. Fluid-Structure coupling analysis of the stationary structures of a prototype pump turbine during load rejection. Energies 2022, 15, 3764. [Google Scholar] [CrossRef]

- Yang, J.; Pavesi, G.; Liu, X.; Xie, T.; Liu, J. Unsteady flow characteristics regarding hump instability in the first stage of a multistage pump-turbine in pump mode. Renew. Energy 2018, 127, 377–385. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, Q.; Ma, Z.; Wang, X. Transient vibration analysis of unit-plant structure for hydropower station in sudden load increasing process. Mech. Syst. Signal Process. 2019, 120, 486–504. [Google Scholar] [CrossRef]

- Guo, C.; Gao, M.; He, S. A review of the flow-induced noise study for centrifugal pumps. Appl. Sci. 2020, 10, 1022. [Google Scholar] [CrossRef]

- Si, Q.; Ali, A.; Yuan, J.; Fall, I.; Muhammad Yasin, F. Flow-induced noises in a centrifugal pump: A review. Sci. Adv. Mater. 2019, 11, 909–924. [Google Scholar] [CrossRef]

- Pires, F.; Sangiuliano, L.; Denayer, H.; Deckers, E.; Desmet, W.; Claeys, C. The use of locally resonant metamaterials to reduce flow-induced noise and vibration. J. Sound Vib. 2022, 535, 117106. [Google Scholar] [CrossRef]

- Gangipamula, R.; Ranjan, P.; Patil, R.S. Flow-induced noise sources and reduction methods in centrifugal pumps: A literature review. Phys. Fluids 2022, 34, 081302. [Google Scholar] [CrossRef]

- Kim, K.H.; Chahine, G.; Franc, J.P.; Karimi, A. Advanced Experimental and Numerical Techniques for Cavitation Erosion Prediction; Springer: Dordrecht, The Netherlands, 2014; Volume 106. [Google Scholar]

- Ayli, E. Cavitation in Hydraulic Turbines. Int. J. Heat Technol. 2019, 37, 334–344. [Google Scholar] [CrossRef]

- Tao, R.; Xiao, R.; Wang, F.; Liu, W. Cavitation behavior study in the pump mode of a reversible pump-turbine. Renew. Energy 2018, 125, 655–667. [Google Scholar] [CrossRef]

- Yuan, Z.; Zhang, Y.; Zhang, J.; Zhu, J. Experimental studies of unsteady cavitation at the tongue of a pump-turbine in pump mode. Renew. Energy 2021, 177, 1265–1281. [Google Scholar] [CrossRef]

- Sangal, S.; Singhal, M.K.; Saini, R. Hydro-abrasive erosion in hydro turbines: A review. Int. J. Green Energy 2018, 15, 232–253. [Google Scholar] [CrossRef]

- Singh, J.; Chohan, J.S.; Hlail, S.H.; Saxena, K.K. Future perspective on the flow disturbances in Francis turbine caused by sediment particles and implementation of protection technique. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Pan, J.; Ma, J.; Han, J.; Zhou, Y.; Wu, L.; Zhang, W. Prediction of sediment wear of francis turbine with high head and high sediment content. Front. Energy Res. 2023, 10, 1117606. [Google Scholar] [CrossRef]

- Zhao, X.; Peng, Y.; Yang, J.; Ren, M.; Liu, X. Experimental analysis of the effect of wear factors on guide vane of hydraulic turbine. Machines 2022, 10, 264. [Google Scholar] [CrossRef]

- Suh, J.W.; Kim, J.W.; Choi, Y.S.; Kim, J.H.; Joo, W.G.; Lee, K.Y. Development of numerical Eulerian-Eulerian models for simulating multiphase pumps. J. Pet. Sci. Eng. 2018, 162, 588–601. [Google Scholar] [CrossRef]

- Liu, S.; Dong, H.; Li, S.; Song, X. Study on the influence of working characteristics of centripetal pump based on VOF/Mixture model. Processes 2024, 12, 1376. [Google Scholar] [CrossRef]

- Zhao, J.; Pei, J.; Yuan, J.; Wang, W. Structural optimization of multistage centrifugal pump via computational fluid dynamics and machine learning method. J. Comput. Des. Eng. 2023, 10, 1204–1218. [Google Scholar] [CrossRef]

- Rossi, M.; Renzi, M. A general methodology for performance prediction of pumps-as-turbines using artificial neural networks. Renew. Energy 2018, 128, 265–274. [Google Scholar] [CrossRef]

- Sun, J.; Ge, X.; Zhou, Y.; Liu, D.; Liu, J.; Li, G.; Zheng, Y. Research on synergistic erosion by cavitation and sediment: A review. Ultrason. Sonochem. 2023, 95, 106399. [Google Scholar] [CrossRef]

- Kumar, P.; Singal, S.; Gohil, P.P. A technical review on combined effect of cavitation and silt erosion on Francis turbine. Renew. Sustain. Energy Rev. 2024, 190, 114096. [Google Scholar] [CrossRef]

- Peters, A.; Lantermann, U.; el Moctar, O. Numerical prediction of cavitation erosion on a ship propeller in model-and full-scale. Wear 2018, 408, 1–12. [Google Scholar] [CrossRef]

- Zhang, S.; Qian, Z.; Ji, B. Estimation of cavitation erosion area in unsteady cavitating flows using a modified approach. Ocean Eng. 2022, 262, 112229. [Google Scholar] [CrossRef]

- Yadav, Y.K.; Sehgal, R. Prediction of erosive wear—A novel mathematical model. Tribol. Int. 2024, 191, 109133. [Google Scholar] [CrossRef]

- Sun, G.; Zhang, Y.; Zhang, R.; Wang, Y.; Mao, X. Numerical prediction and analysis of abrasion in a Francis turbine with high sediment concentration. J. Drain. Irrig. Mach. Eng. 2022, 40, 1197–1203. [Google Scholar]

- Rode, B.R.; Kumar, A. Unstable pressure fluctuations in the vaneless space of high-head reversible pump-turbines—A systematic review. J. Energy Storage 2023, 72, 108397. [Google Scholar] [CrossRef]

- Jin, F.; Luo, Y.; Wang, Z. Research on the starting-up process of a prototype reversible pump turbine with misaligned guide vanes: An energy loss analysis. Energy 2024, 304, 132219. [Google Scholar] [CrossRef]

- Mao, X.; Chen, D.; Wang, Y.; Mao, G.; Zheng, Y. Investigation on optimization of self-adaptive closure law for load rejection to a reversible pump turbine based on CFD. J. Clean. Prod. 2021, 283, 124739. [Google Scholar] [CrossRef]

- Mao, X.; Chen, X.; Lu, J.; Liu, P.; Zhang, Z. Improving internal fluid stability of pump turbine in load rejection process by co-adjusting inlet valve and guide vane. J. Energy Storage 2022, 50, 104623. [Google Scholar] [CrossRef]

- Liu, H.; Lin, Y.; Cheng, Y.; Xue, S.; Tang, M.; Zhang, J.; Fan, J. Optimization of the co-closing law of guide vanes and blades for bulb turbines based on CFD. J. Hydrodyn. 2024, 36, 363–377. [Google Scholar] [CrossRef]

- Muntean, S.; Susan-Resiga, R.F.; Campian, V.C.; Dumbrava, C.; Cuzmos, A. In situ unsteady pressure measurements on the draft tube cone of the Francis turbine with air injection over an extended operating range. UPB Sci. Bull. Ser. D 2014, 76, 173–180. [Google Scholar]

- Shahzer, M.A.; Kim, J. Investigation of role of fins in a Francis turbine model’s cavitation-induced instabilities under design and off-design conditions. Energy 2024, 292, 130514. [Google Scholar] [CrossRef]

- Li, W.; Feng, J.; Wu, H.; Lu, J.; Liao, W.; Luo, X. Numerical investigation of pressure fluctuation reducing in draft tube of Francis turbines. Int. J. Fluid Mach. Syst. 2015, 8, 202–208. [Google Scholar] [CrossRef]

- Li, Y.; Yang, W.; Huang, Y.; Zhao, Z.; Yang, J.; Cheng, Y.; Qian, Z.; Yang, J. Reduction of pressure pulsation for pump-turbine by variable speed operation. J. Energy Resour. Technol. 2023, 145, 081301. [Google Scholar] [CrossRef]

- Quaranta, E.; Davies, P. Emerging and innovative materials for hydropower engineering applications: Turbines, bearings, sealing, dams and waterways, and ocean power. Engineering 2022, 8, 148–158. [Google Scholar] [CrossRef]

- Isametova, M.; Nussipali, R.; Karaivanov, D.; Abilkhair, Z.; Isametov, A. Computational and experimental study of the composite material for the centrifugal pump impellers manufacturing. J. Appl. Comput. Mech. 2022, 8, 1407–1421. [Google Scholar]

- Li, H.; Zhou, D.; Martinez, J.J.; Deng, Z.D.; Johnson, K.I.; Westman, M.P. Design and performance of composite runner blades for ultra low head turbines. Renew. Energy 2019, 132, 1280–1289. [Google Scholar] [CrossRef]

- Singh, J. A review on mechanisms and testing of wear in slurry pumps, pipeline circuits, and hydraulic turbines. J. Tribol. 2021, 143, 090801. [Google Scholar] [CrossRef]

- Jandaghian, M. Enhancement of Mesh-Free Particle Methods for Highly Dynamic Free-Surface and Granular Flows. Ph.D. Thesis, University of Montreal, Montreal, QC, Canada, 2022. [Google Scholar]

- Tang, T.; Li, R.; Zhang, Z. Moving Grid Methods for Partial Differential Equations; China Science Publishing & Media Ltd.: Beijing, China, 2023. [Google Scholar]

- Gammon, M. A review of common geometry issues affecting mesh generation. In Proceedings of the 2018 AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 8–12 January 2018; p. 1402. [Google Scholar]

- Duarte, C.A.R.; de Souza, F.J. Dynamic mesh approaches for eroded shape predictions. Wear 2021, 484, 203438. [Google Scholar] [CrossRef]

- Balan, A.; Park, M.A.; Wood, S.L.; Anderson, W.K.; Rangarajan, A.; Sanjaya, D.P.; May, G. A review and comparison of error estimators for anisotropic mesh adaptation for flow simulations. Comput. Fluids 2022, 234, 105259. [Google Scholar] [CrossRef]

- Neural Concept. Innovations in Turbulence Modeling: Enhancing Simulation. Available online: https://www.neuralconcept.com/post/innovations-in-turbulence-modeling-enhancing-simulation (accessed on 18 December 2024).

- Zeng, Y.; Wang, H.; Sun, M.; Wang, C.; Liu, X. SST turbulence model improvements: Review. Acta Aeronaut. Astronaut. Sinca 2023, 44, 027411. [Google Scholar]

- Rodi, W. Turbulence modeling and simulation in hydraulics: A historical review. J. Hydraul. Eng. 2017, 143, 03117001. [Google Scholar] [CrossRef]

- Han, Y.; Liu, M.; Tan, L. A review on the application of hybrid RANS-LES methods in hydraulic machinery. Ocean Eng. 2024, 305, 117943. [Google Scholar] [CrossRef]

- Folden, T.S.; Aschmoneit, F.J. A classification and review of cavitation models with an emphasis on physical aspects of cavitation. Phys. Fluids 2023, 35, 081301. [Google Scholar] [CrossRef]

- Zhao, Y.; Akolekar, H.D.; Weatheritt, J.; Michelassi, V.; Sandberg, R.D. RANS turbulence model development using CFD-driven machine learning. J. Comput. Phys. 2020, 411, 109413. [Google Scholar] [CrossRef]

- Yusuf, S.N.A.; Asako, Y.; Sidik, N.A.C.; Mohamed, S.B.; Japar, W.M.A.A. A short review on rans turbulence models. CFD Lett. 2020, 12, 83–96. [Google Scholar]

- Zhang, Y.; Zhang, D.; Jiang, H. Review of challenges and opportunities in turbulence modeling: A comparative analysis of data-driven machine learning approaches. J. Mar. Sci. Eng. 2023, 11, 1440. [Google Scholar] [CrossRef]

- Mao, X.; Liu, Z.; Li, T.; Mao, G.; Chen, D. A brief review of numerical solving methods for internal fluid of pumped storage unit. Int. J. Energy Res. 2020, 44, 7886–7902. [Google Scholar] [CrossRef]

- Liu, C.; Yu, Y. Mathematical foundation of Liutex theory. J. Hydrodyn. 2022, 34, 981–993. [Google Scholar] [CrossRef]

- Dong, X.; Hao, C.; Liu, C. Correlation between vorticity, Liutex and shear in boundary layer transition. Comput. Fluids 2022, 238, 105371. [Google Scholar] [CrossRef]

- Tran, C.T.; Long, X.P.; Ji, B.; Liu, C. Prediction of the precessing vortex core in the Francis-99 draft tube under off-design conditions by using Liutex/Rortex method. J. Hydrodyn. 2020, 32, 623–628. [Google Scholar] [CrossRef]

- Xiao, Y.; Xiao, W.; Ren, S.; Chen, L.; Liu, Z. Analysis of vortex characteristics in S region of a pump turbine based on Liutex method. J. Hydroelectr. Eng. 2024, 1–7. Available online: http://kns.cnki.net/kcms/detail/11.2241.tv.20240806.0927.002.html (accessed on 18 December 2024). (In Chinese).

- Qin, Y.; Li, D.; Wang, H.; Liu, Z.; Wei, X.; Wang, X. Investigation on the relationship between hydraulic loss and vortex evolution in pump mode of a pump-turbine. J. Hydrodyn. 2022, 34, 555–569. [Google Scholar] [CrossRef]

- Su, D.; Rao, H.; Wang, S.; Pan, Y.; Xu, Y.; Hou, L. Study of error flow for hydraulic system simulation models for construction machinery based on the state-space approach. Actuators 2023, 13, 14. [Google Scholar] [CrossRef]

- Qin, Y.; Li, D.; Wang, H.; Liu, Z.; Wei, X.; Wang, X. Investigation on hydraulic loss component and distribution in hydraulic machinery: A case study of pump-turbine in pump mode. J. Energy Storage 2022, 52, 104932. [Google Scholar] [CrossRef]

- Hu, Y.; Xiong, Z.; Chen, Y.; Tian, F.; Gao, C.; Xun, H. Pump turbine model test and analysis of Meizhou pumped storage station. Mech. Electr. Tech. Hydropower Stn. 2022, 45, 22–25. [Google Scholar]

- IEC 60193; Hydraulic Turbines, Storage Pumps and Pump-Turbines—Model Acceptance Tests. International Electrotechnical Commission: Geneva, Switzerland, 2019.

- Trivedi, C.; Agnalt, E.; Dahlhaug, O.G. Experimental study of a Francis turbine under variable-speed and discharge conditions. Renew. Energy 2018, 119, 447–458. [Google Scholar] [CrossRef]

- Iliev, I.; Trivedi, C.; Agnalt, E.; Dahlhaug, O.G. Variable-speed operation and pressure pulsations in a Francis turbine and a pump-turbine. IOP Conf. Ser. Earth Environ. Sci. 2019, 240, 072034. [Google Scholar] [CrossRef]

- Vinod, J.; Sarkar, B.K.; Sanyal, D. Flow control in a small Francis turbine by system identification and fuzzy adaptation of PID and deadband controllers. Renew. Energy 2022, 201, 87–99. [Google Scholar] [CrossRef]

- Li, Q.; Xin, L.; Li, R. Application of digital twin technology in monitoring system of pump turbine. Discov. Mech. Eng. 2024, 3, 30. [Google Scholar] [CrossRef]

- Dai, H.; Wan, L.; Zeng, Q.; Lu, Z.; Sun, Z.; Liu, W. Method and test bench for hydro-mechanical continuously variable transmission based on multi-level test and verification. Machines 2021, 9, 358. [Google Scholar] [CrossRef]

- Li, Y.; Ma, Z.; Sun, B. Experimental study on pressure fluctuation of a pump-turbine in a variable-speed pumped-storage unit under power generation condition. Water Power 2023, 49, 94–102. [Google Scholar]

- Lai, X.; Liang, Q.; Ye, D.; Chen, X.; Xia, M. Experimental investigation of flows inside draft tube of a high-head pump-turbine. Renew. Energy 2019, 133, 731–742. [Google Scholar] [CrossRef]

- Xue, P.; Liu, Z.; Lu, L.; Gao, Z.; Meng, X. Experimental research on the rotating stall of a pump turbine in pump mode. Water 2019, 11, 2426. [Google Scholar] [CrossRef]

| No. | Name | Capacity | Project Progress |

|---|---|---|---|

| 1 | Zhenan | 1200 MW | Fully operation at the end of 2024 |

| 2 | Shanyang | 1200 MW | Approved in 2023 |

| 3 | Foping | 1400 MW | Full-scale construction begins in 2024 |

| 4 | Caoping | 1400 MW | Approved in 2022 |

| 5 | Mianxian | 1400 MW | Full-scale construction beganin 2024 |

| 6 | Dazhuangli | 2100 MW | Approval expected in 2024 |

| 7 | Danfeng | 1400 MW | Confirmed qualifications of the investment subject |

| 8 | Ningshanbei | 1800 MW | Confirmed qualifications of the investment subject |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, X.; Hu, J.; Pan, Z.; Zhong, P.; Zhang, N. A Brief Review of Recent Research on Reversible Francis Pump Turbines in Pumped Storage Plants. Energies 2025, 18, 394. https://doi.org/10.3390/en18020394

Mao X, Hu J, Pan Z, Zhong P, Zhang N. A Brief Review of Recent Research on Reversible Francis Pump Turbines in Pumped Storage Plants. Energies. 2025; 18(2):394. https://doi.org/10.3390/en18020394

Chicago/Turabian StyleMao, Xiuli, Jiaren Hu, Zhongyong Pan, Pengju Zhong, and Ning Zhang. 2025. "A Brief Review of Recent Research on Reversible Francis Pump Turbines in Pumped Storage Plants" Energies 18, no. 2: 394. https://doi.org/10.3390/en18020394

APA StyleMao, X., Hu, J., Pan, Z., Zhong, P., & Zhang, N. (2025). A Brief Review of Recent Research on Reversible Francis Pump Turbines in Pumped Storage Plants. Energies, 18(2), 394. https://doi.org/10.3390/en18020394