Abstract

This review presents a comprehensive analysis of battery thermal management systems (BTMSs) for prismatic lithium-ion cells, focusing on air and liquid cooling, heat pipes, phase change materials (PCMs), and hybrid solutions. Prismatic cells are increasingly favored in electric vehicles and energy storage applications due to their high energy content, efficient space utilization, and improved thermal management capabilities. We evaluate the effectiveness, advantages, and challenges of each thermal management technique, emphasizing their impact on performance, safety, and the lifespan of prismatic Li-ion batteries. The analysis reveals that while traditional air and liquid cooling methods remain widely used, 80% of the 21 real-world BTMS samples mentioned in this review employ liquid cooling. However, emerging technologies such as PCM and hybrid systems offer superior thermal regulation, particularly in high-power applications. However, both PCM and hybrid systems come with significant challenges; PCM systems are limited by their low thermal conductivity and material melting points. While hybrid systems face complexity, cost, and potential reliability concerns due to their multiple components nature. This review underscores the need for continued research into advanced BTMSs to optimize energy efficiency, safety, and longevity for prismatic cells in electric vehicle applications and beyond.

1. Introduction

The realities of fossil fuel reserve scarcity coupled with growing energy demands, together with the concerns over energy security and affordable access to energy and climate change, drive the transition to a more sustainable energy economy [1,2]. A more sustainable energy economy needs a higher share of renewable energy sources (RESs) [3]. The intermittent nature of RES necessitates suitable storage solutions as RES penetration go up [4]. Chemical energy storage systems are the most direct form of electrical energy storage. These systems enable technologies suitable for high energy applications. Additionally, they serve low energy needs such as those of portable electronic devices [5,6].

The development of efficient, cost-effective, and environmentally sustainable electrochemical storage systems is crucial for the advancement of the renewable energy economy. Various types of electrochemical energy storage systems exist, including rechargeable batteries [7], electrochemical capacitors [8], and fuel and electrolysis cells [9]. Among these, lithium-ion (Li-ion) batteries have gained significant global attention due to their high energy density, excellent capacity, superior efficiency, and long operational lifespan [10,11].

Research has shown that temperature is a key factor influencing battery aging, negatively affecting both capacity and internal resistance [12]. Understanding heat generation inside batteries during operation is critical for minimizing the adverse effects of high temperatures [13]. If the heat generated by the battery is not properly managed, it may lead to increased temperatures and a reduction in the temperature uniformity of the battery pack. Therefore, robust battery thermal management systems (BTMSs) that prevent thermal runaway (TR) by regulating battery temperature, ensuring uniform heat distribution, dissipating excess heat, and preventing overheating are crucial for maintaining optimal battery performance and safety.

Recent advancements in thermal management systems have benefited from data-driven approaches, particularly machine learning (ML), which provides a fast and cost-effective way to predict TR behavior in lithium-ion batteries. By using minimal data like ejected mass and cell metadata, ML models can accurately estimate heat output variability, reducing the need for extensive calorimetry measurements and accelerating battery safety assessments [14,15].

BTMSs are classified into two categories: active systems and passive systems [16]. The active BTMS dissipates heat from the battery using a heat exchange medium, such as air or liquid, to effectively cool the battery. Passive BTMSs, including heat pipe (HP) and PCM, do not require extensive or complex auxiliary equipment and operate without consuming extra energy.

Battery thermal management systems (BTMSs) can be categorized into active and passive types [16]. Active BTMSs utilize a heat exchange medium, such as air or liquid, to dissipate heat generated by the battery, thereby ensuring effective cooling. In contrast, passive BTMSs, including heat pipe (HP) and phase change material (PCM) systems, are simpler in design, do not rely on extensive auxiliary equipment, and operate without consuming additional energy.

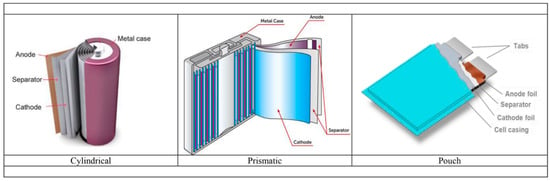

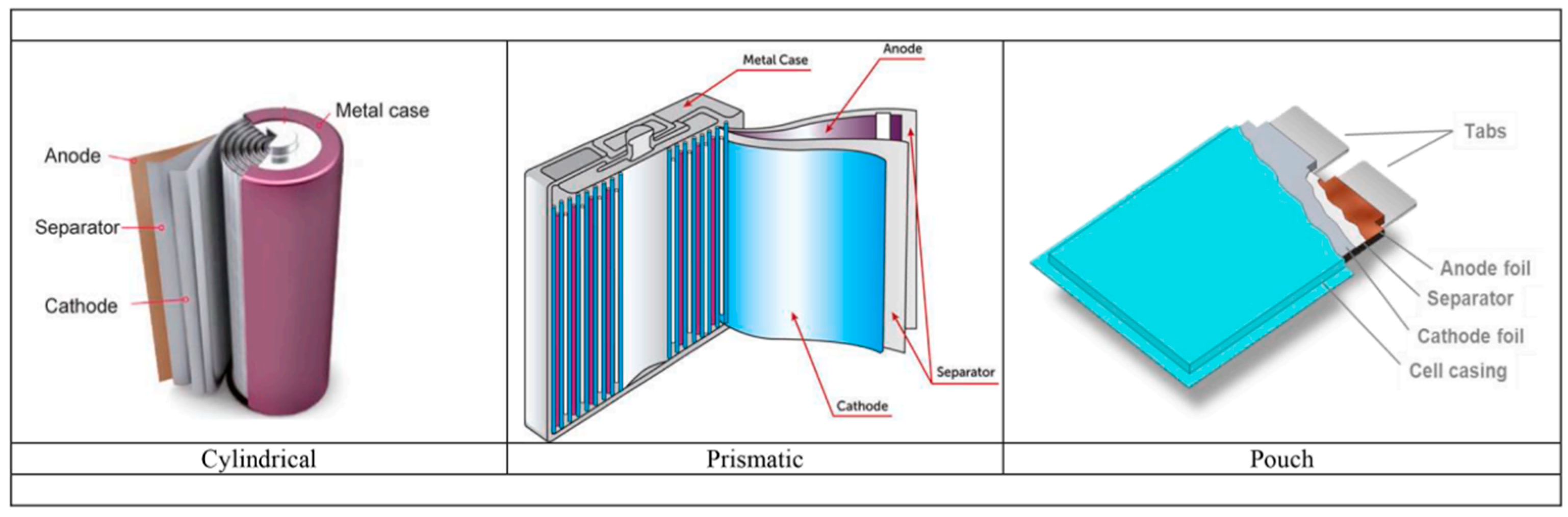

The geometry of the battery, including the arrangement of its material layers and packaging structure, influences its heat generation behavior [17]. Therefore, understanding this aspect is important for the design of a BTMS. There are three types of Li-ion cells: cylindrical, prismatic, and pouch [18]. These are illustrated in Figure 1. Cylindrical and prismatic cells are housed in hard cases, while pouch cells use multilayer aluminum composite foils. Cylindrical cells feature electrode webs that are wound into a jelly roll configuration, while prismatic cells utilize either flat jelly rolls or stacked electrodes. In contrast, pouch cells are designed with a purely stacked electrode arrangement [19,20,21]. Prismatic cells provide better energy capacity and effective use of space, which make them ideal for electric vehicles. Cylindrical cells improve heat transfer because they have a more uniform temperature distribution and a greater surface area to volume ratio. However, they are less efficient in terms of space utilization [22,23,24].

Prismatic cells are constructed by flattening rolled stacks of cathode, separator, and anode layers; although they have a slightly lower energy density compared to cylindrical cells, they shine when it comes to maximizing space usage [25]. The increased size of cells enables effective heat control and dissipation [26,27]. Modern electric vehicles favor these cells due to their packing efficiency and adaptability [28].

Despite the growing use of prismatic Li-ion cells in electric vehicles and stationary energy storage systems, the existing literature has primarily focused on cylindrical and pouch cells, leaving a noticeable gap in the comprehensive evaluation of thermal management techniques tailored specifically to prismatic cell designs.

Our review aims to address this gap by providing a comprehensive evaluation of thermal management techniques specifically for prismatic Li-ion cells, which are increasingly prominent in high-performance electric vehicles and stationary energy storage systems. While traditional air and liquid cooling methods have been extensively studied, there is a growing interest in innovative solutions such as PCMs and hybrid systems, particularly for prismatic cells. This paper systematically analyzes the strengths, limitations, and potential of these emerging techniques, offering insights into their effectiveness in enhancing temperature control, safety, and overall battery lifespan. By focusing on prismatic cells, we aim to contribute to the development of more efficient and reliable BTMSs, supporting the advancement of electric vehicle technology and stationary electric storage applications.

The structure of the paper is as follows: Initially, it examines and compares various battery cell geometries. This is followed by a detailed review of key thermal management techniques, including air-based, liquid-based, heat pipe, PCM, and hybrid systems, incorporating insights from previous research. Finally, the paper synthesizes the findings, offering a comparative analysis and concluding observations.

Figure 1.

Types of Li-ion battery cells [29].

Figure 1.

Types of Li-ion battery cells [29].

2. Comparison of Different Li-Ion Battery Cell Geometries

Cylindrical, prismatic, and pouch cells each offer distinct advantages and challenges based on their geometry. Table 1 includes aspects such as construction, energy density, packing efficiency, thermal management, and ease of manufacturing.

Table 1.

Advantages and challenges of various cell geometries.

Pouch cells are rectangular batteries made by stacking cathode, separator, and anode layers in a pouch, adding electrolytes, sealing it, and attaching terminals outside. A pouch Li-ion battery cell has a flexible, flat, pouch-like design, with a laminated aluminum or polymer material used as its casing. This flexible design lowers the cost, weight, and thickness of the cell compared to rigid metal cases. However, it can cause swelling, which affects the cell’s safety, lifespan, and capacity [30]. The flexible structure also allows the cell to fit easily into available spaces and reduces the overall weight of the battery system. These features improve packaging efficiency and increase energy density [31]. The flat and soft design provides high packing efficiency, typically between 90% and 95% [32].

The pouch-type battery has become more popular recently because it offers higher capacity, flexibility, cost-effectiveness, and is lightweight and compact. It can also deliver high-load currents. Additionally, they have designs that allow better thermal management due to their good heat transfer surfaces. However, pouch cells have a lower energy storage capacity compared to prismatic batteries [28].

Cylindrical cells are manufactured by winding the layers of cathode, separator, and anode into a spiral structure, which is then enclosed within a rigid aluminum or stainless steel shell. These cells offer higher energy density when compared to both prismatic and pouch designs. However, their lower packing efficiency leads to a reduced overall energy density in battery packs [25]. Cylindrical Li-ion cells are valued for their compact size, high energy density, cost-effectiveness, and flexibility in system integration [30].

The thermal management of cylindrical battery packs is more challenging than that of other cell types [28]. The thermal conductivity of cylindrical cells is higher along the axis than in the radial direction. This makes heat dissipation easier through axial heat transfer. Another issue is the shape of cylindrical packs. The arrangement of cylindrical cells in the modules creates gaps between them, which reduces the energy density at the pack level and adds challenges to designing effective heat removal and cooling systems [33].

Air-based thermal management of cylindrical battery packs is challenging because of the limited contact area for heat dissipation and the low thermal conductivity of the jellyroll structure. Additionally, the geometry and spacing of cylindrical cells complicate efficient cooling. However, air cooling can be more effective when applied to the top and bottom of the battery pack, though higher airflow rates are required to achieve significant temperature reduction [28,34].

Heat pipe-based BTMSs are difficult to attach to cylindrical cells, as they offer limited contact areas, requiring careful attention to surface contact for effective cooling [35,36,37]. In contrast, liquid cooling is the preferred method in the electric vehicle (EV) industry, though it requires specialized structures, such as discrete tubes or jackets, to improve contact between the cell surface and coolant. This increases the system’s complexity and mass [28,35].

PCMs present an alternative to traditional liquid and air-cooling systems, particularly for cylindrical batteries. PCMs can fill unused spaces between cells and provide passive cooling by addressing the gaps and block-like behavior of cylindrical battery packs [28].

Prismatic Li-ion cells provide high energy content and are similar to cylindrical cells in construction. They make better use of space but are more expensive to produce. Prismatic cells are made by rolling layers of cathode, separator, and anode into stacks and flattening them into a rectangular shape. Although they have slightly lower energy density than cylindrical cells, they offer higher packing efficiency [25].

Some studies [26,27] suggest that prismatic pouches provide better thermal management because of their larger surface area, which helps with heat dissipation, and they are also more cost-effective. However, cylindrical batteries are still preferred by some due to their easier mass production.

High-capacity prismatic cells are commonly used for high-power electric vehicles. Although prismatic batteries are usually thicker than pouch batteries, some electric vehicle specifications still refer to pouch cells as prismatic. One drawback of prismatic batteries is that they have less surface area for heat transfer compared to pouch cells of the same capacity. Because of this, high-capacity pouch cells are likely to be the main choice for future electric vehicle battery packs [28].

Heat pipe-based BTMSs demonstrate excellent heat dissipation performance. They are mainly studied for prismatic cells because their shape allows for easy adaptation and larger contact areas [35,36,38]. Flat heat pipes are useful for both pouch and prismatic cells. Their flat surface allows for direct attachment to the battery, enhancing thermal management efficiency [39,40]. Most studies on BTMS with flat single-channel heat pipes focus on prismatic or pouch batteries [41].

Prismatic and pouch cells are studied more than cylindrical cells with liquid cooling because they allow for a simpler and more compact design of cooling plates [42,43]. Since prismatic and pouch batteries are commonly used in commercial vehicles, liquid cooling plates are one of the most widely used cooling systems in electric vehicles, thanks to their good heat capacity and compact design [35].

In summary, each Li-ion battery cell geometry—cylindrical, prismatic, and pouch—offers distinct advantages and challenges, making them suitable for different applications. Cylindrical cells excel in energy density and manufacturing efficiency but face limitations in space utilization and thermal management. Prismatic cells provide better packing efficiency and enhanced thermal management due to their larger surface area, making them ideal for high-power applications like electric vehicles. Pouch cells, with their flexible design, offer the highest packing efficiency and are gaining attention for applications requiring lightweight and compact energy storage. Understanding these differences is essential, as the choice of cell geometry significantly influences the design and effectiveness of BTMSs, which play a critical role in maintaining optimal battery performance and safety.

3. Battery Thermal Management Systems (BTMSs)

There are three main heat transfer methods: conduction, convection, and radiation. These methods can work alone or together. Additionally, the complexity of battery structures makes it challenging to create a universal heat dissipation model suitable for all types of batteries. Therefore, choosing the right cooling strategy and heat dissipation method based on the battery’s design is essential for optimizing BTMSs [39].

Different types of BTMSs and their advantages or disadvantages (as indicated by color) are summarized in Table 2. Air-cooled BTM is suitable for various types of batteries. They are typically categorized into two types: free convection cooling and forced convection cooling [44]. Desirable properties of air-based batteries include simple design, light weight, absence of leakage risk, electrical safety, ability to heat the battery in winter, and most significantly, low manufacturing cost. These factors are behind increasing interest in industrial applications of air-cooled BTMSs, particularly for prismatic battery packages [25,41,43].

Table 2.

System characteristics of basic BTMS. (Green: advantage; red: disadvantage; yellow: moderate) *.

Natural cooling is often insufficient to manage the needs of high temperature operating conditions, large battery packs, and frequent charge–discharge cycles. To address these challenges, a forced air cooling method is used. However, air cooling systems have limitations, including high noise levels, poor temperature uniformity, and low thermal conductivity.

In contrast, liquid-cooled BTM offers higher heat dissipation capacity and better thermal performance because liquids have higher thermal conductivity than air [36]. It can be used in immersion cooling, or indirectly through contact between the battery surface and the coolant [51]. However, having external components increases structural complexity and production costs [36], maintenance, overall weight, and risk of leaking coolant.

In recent years, passive BTMSs based on HP have been extensively used for temperature regulation in battery packs. Heat pipes offer several advantages, such as extremely high thermal conductivity [48], flexibility, lightweight design, cost-effectiveness [46,47], easier maintenance, and reliability. The use of heat pipes as a method for BTM is relatively novel and has the capability of combining heat pipes with air or liquid coolers, necessitating further investigation. Due to the underdevelopment of pipes, production standards, and manufacturing equipment, the application of these technologies in the thermal management of power batteries remains largely in the research phase and has not yet been widely adopted or implemented.

Phase change materials (PCMs) have also been proposed as a method for passive battery cooling; it utilizes PCM as a heat transfer medium which can absorb and release energy during phase transitions to provide low temperature heating and high temperature cooling for the battery [52]. It offers a relatively simple design and cost-effectiveness [35]. However, its disadvantages include low thermal conductivity [49], which reduces heat dissipation efficiency. Additionally, the system may lose effectiveness over time due to complete melting.

Hybrid systems integrate components from two or more BTMSs types to enhance the cooling efficiency compared to standalone systems. By combining them into a hybrid BTMS, the drawbacks of basic BTMSs are minimized.

BTMSs that include active systems like air and liquid cooling and passive systems like HP and PCMs are the brain of a battery pack. Each system has its strengths and limitations, and the effectiveness of them can be evaluated by considering these criteria: thermal performance, energy efficiency, temperature uniformity, and cost and complexity. As discussed, we are reviewing various BTMS solutions for prismatic cells, with detailed discussions on different BTMS types in the following sections.

3.1. Air-Based BTMSs

Air cooling has gained significant attention in recent years for its industrial applications, particularly in prismatic battery packages [53]. It remains one of the most widely studied techniques in both theoretical and numerical investigations of prismatic battery cells and packs [28].

The studies on air-based BTMSs for prismatic batteries have been categorized based on their primary research focus as follows. Early studies prioritized duct design and airflow configuration, exploring the identified double "U" type as the most effective duct design [54], uneven gap spacing improves airflow and thermal performance in prismatic battery packs [55], and smaller gaps and increased airflow improve temperature uniformity [56]. As research evolved, structural optimizations focused on improving cooling effectiveness through air flow patterns [57], design adjustments in ventilation [58], and cell spacing [59,60]. Later, advanced techniques like pin-fins [61] and active cooling controls with an on-off cooling control strategy [62], demonstrating significant improvements in thermal management and energy efficiency. Most recently, multi-objective optimization studies aimed to balance cooling efficiency, size reduction [63], and temperature control, advancing the potential of air-based BTMSs for practical applications. Table 3 compiles the previous research that works on air cooled. This table categorizes previous studies according to their methodology, battery type, number of cells, arrangement of the battery pack, and main point of each study.

Table 3.

Overview of studies on air-cooled BTMS for prismatic batteries (N.A.—not available).

Battery life is compromised when continually subjected to ambient temperatures above 25° C. Increased ambient heat reduces heat dissipation, accelerates internal chemical reactions, and raises float charging current, further elevating the battery’s temperature and exacerbating degradation [66]. Among the reviewed studies, those that focus on ambient temperatures above 27 °C are particularly significant for our review. Below, we delve into the methodologies proposed by them.

The gap spacing between battery cells affects airflow and temperature distribution. Fan et al. [56] focused on the impact of gap spacing and airflow rate in an air-cooled lithium-ion battery module. They investigated various configurations, including even and uneven gap spacings as well as single-side versus dual-side cooling. The finding showed that decreasing gap spacing and increasing air flow rate notably reduced the peak temperature increase, while moderate gap spacing improved temperature uniformity within the module. Similarly, Bakar et al. [65] studied the effect of airflow distribution across the batteries. Unlike previous studies relying on standard z-type and u-type air ducts, which struggled with temperature control for high-capacity batteries, this study innovatively optimized the size, location, and number of air intake holes. They designed and tested five module cases having different intake hole lengths, numbers, and same air intake areas. Through CFD simulations and experimental validation, they identified Design 5 as the best-performing design. Design 5 stood out due to its precise optimization of air intake holes, where each hole was sized and positioned according to the cooling needs of individual batteries. By ensuring batteries farther from the fan received more airflow, the design effectively eliminated temperature imbalances. This resulted in a 62% improvement in cooling efficiency, maintaining a minimal temperature difference of just 0.25°C between the batteries with the highest and lowest temperatures.

Pin-fins enhance heat transfer by increasing the surface area in contact with airflow. Shahabeddin et al. [61] aimed to optimize an air-based BTMS by employing an innovative pin-fin heat sink design. The study used 3D transient thermal simulation to evaluate how pin-fin configurations, inlet air flow velocities, discharge rates, and inlet air temperatures affected the thermal performance of a prismatic Li-ion battery module. The results demonstrated that the proposed pin-fin heat sinks significantly reduced both the bulk temperature and the temperature field’s standard deviation within the battery, thereby enhancing thermal uniformity and overall cooling efficiency.

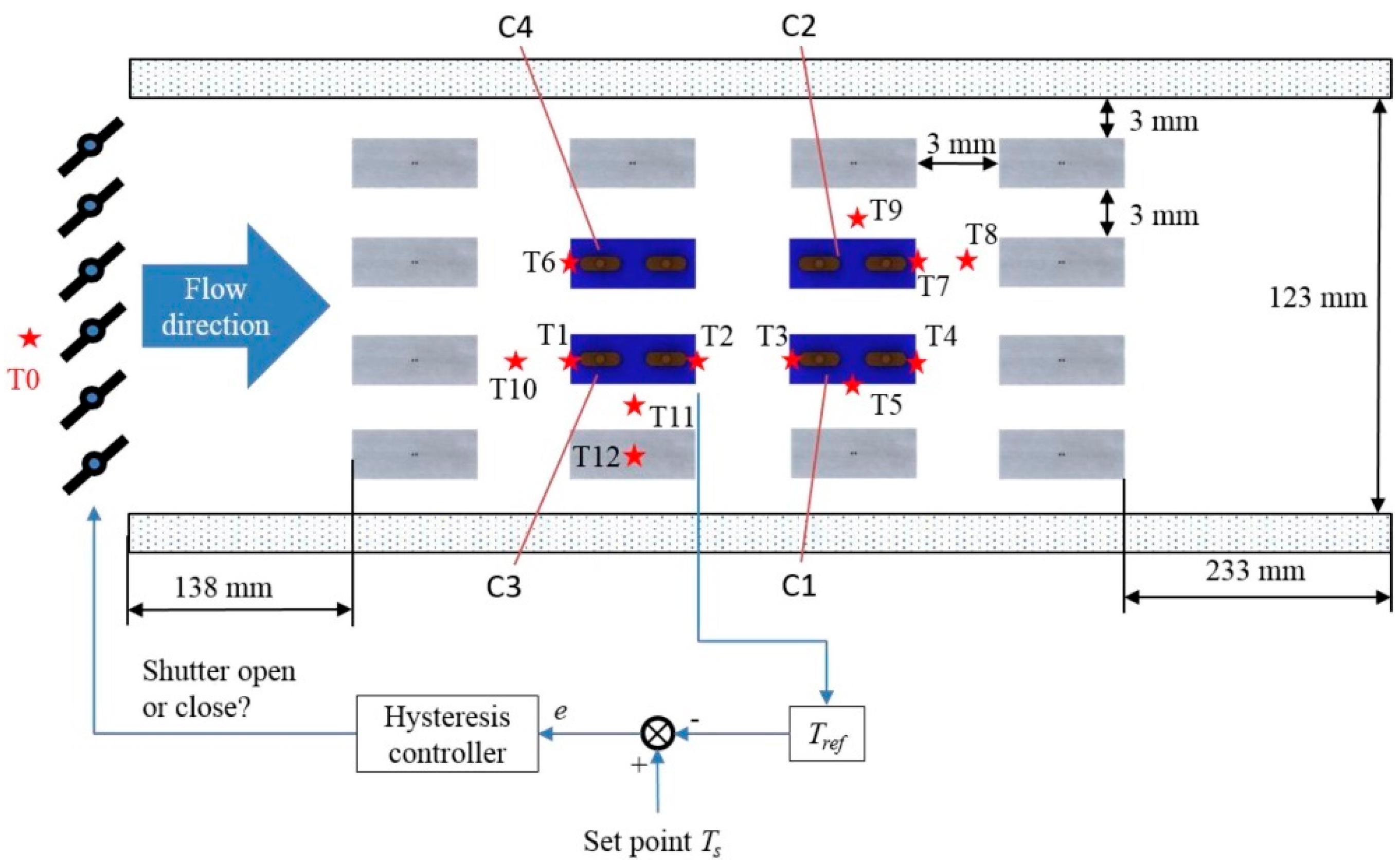

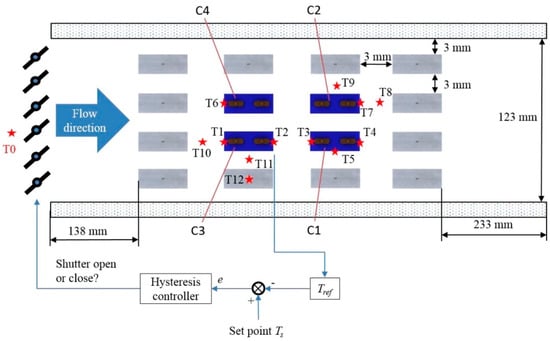

Smart BTMSs minimize parasitic losses. Wang et al. [62] studied the active thermal management of prismatic cells in high-temperature conditions to reduce parasitic energy consumption while maintaining optimal battery performance. The researchers employed combining real prismatic cells with dummy cells to reduce experimental study cost. The research focused on evaluating the effectiveness of an on-off cooling control strategy under both steady and dynamic loads with well-controlled airflow in a wind tunnel. Results indicated that the active control system reduced parasitic energy consumption by 83–92% while maintaining battery temperatures within a safe operating range. The authors recommended the on-off active cooling system for its energy efficiency in managing thermal loads under elevated conditions (Figure 2).

Figure 2.

A block diagram of the control scheme and battery module configuration with dummy cells for energy-efficient on-off cooling in prismatic Li-ion BTMSs [62].

Air-cooled BTMSs have gained considerable interest due to their simple design, low cost, and no leakage. However, they face significant limitations, including the lower heat transfer efficiency due to the lower thermal conductivity and specific heat capacity of air than other fluids, as well as increased energy consumption for forced convection, which highlights the need for alternative methods.

3.2. Liquid-Cooling BTMSs

A liquid-based BTMS works well with prismatic batteries because their regular shape allows for a compact arrangement of the system [35].

Studies on liquid-based BTMSs for prismatic batteries have been categorized according to their research focus. Early research began by comparing internal and external cooling methods, internal cooling with microchannels embedded in electrodes significantly enhances temperature uniformity [67]. As research evolved, cold plate configurations focused on improving cooling effectiveness through the location of cold plates and the contact area between the cooling structure and the battery, including using dual cold plates on top and bottom [68], side ice plates and bottom plates [69], dual-purpose cooling plates with staggered pins [70], dual-cooling plate systems with plates on the bottom and busbars [71], and cold plates with airfoil fins [72]. A common solution for prismatic batteries is using cooling plates [35]. Further advancements centered on cold plates with innovative channel designs: designing cold plates positioned between batteries and bifurcation channels manufactured in the cover plates on top and bottom [73,74], cold plates based on butterfly-shaped channels [75], bionic fishbone channel liquid cooling plates [76], and cooling plates with the topological cooling channels [77] were developed to improve coolant distribution and reduce maximum temperatures. Subsequently, mini-channel designs showed an increase in heat transfer area and conductivity and lower pressure drops. Studies on mini-channel designs include configurations such as mini-channel configurations in aluminum tubes [78] and streamline-shaped mini channels [79], mini-channel cold plates designed for water cooling in large prismatic lithium-ion batteries [42], and mini-channel cooling systems using aluminum multi-port extrusions [80]. Liquid immersion cooling was another key area; the authors of [81] studied a fluorinated liquid immersion cooling system using SF33 for prismatic lithium-ion batteries. Additionally, nanofluid-based cooling has garnered attention. A liquid mini-channel cooling system for high-power prismatic lithium-ion batteries compared base fluids and nanofluids. The findings showed significant thermal performance improvements, with water and alumina nanofluids offering the best results [82]. Morali et al. [83] introduced an innovative cooling system using Fe2O3 nanofluid, which significantly improves heat dissipation.

Among the reviewed studies, those examining ambient temperatures exceeding 27 °C hold particular relevance to our analysis. The following section explores the methodologies they have proposed.

The arrangement of cold plates and the contact area between the cooling structure and the battery are crucial for effective cooling. Darcovich et al. [69] compared two liquid cooling configurations with plates positioned on the side and bottom of the prismatic battery. Using a numerical simulation, they evaluated thermal behavior under different drive cycles and cooling regimes. Their findings revealed that ice plates, positioned between cells, outperformed cold plates, reducing temperature rises by 5–8 K. With higher heat transfer coefficients (h = 340 W/m2K), ice plates kept temperature increases below 2 K, ensuring better temperature uniformity. The study also showed that battery lifetimes ranged from 3.5 to over 8.1 years, with ice plates offering superior performance and longevity compared to cold plates. Side cooling offers a larger surface area in contact with the battery, resulting in a lower maximum temperature and improved thermal uniformity.

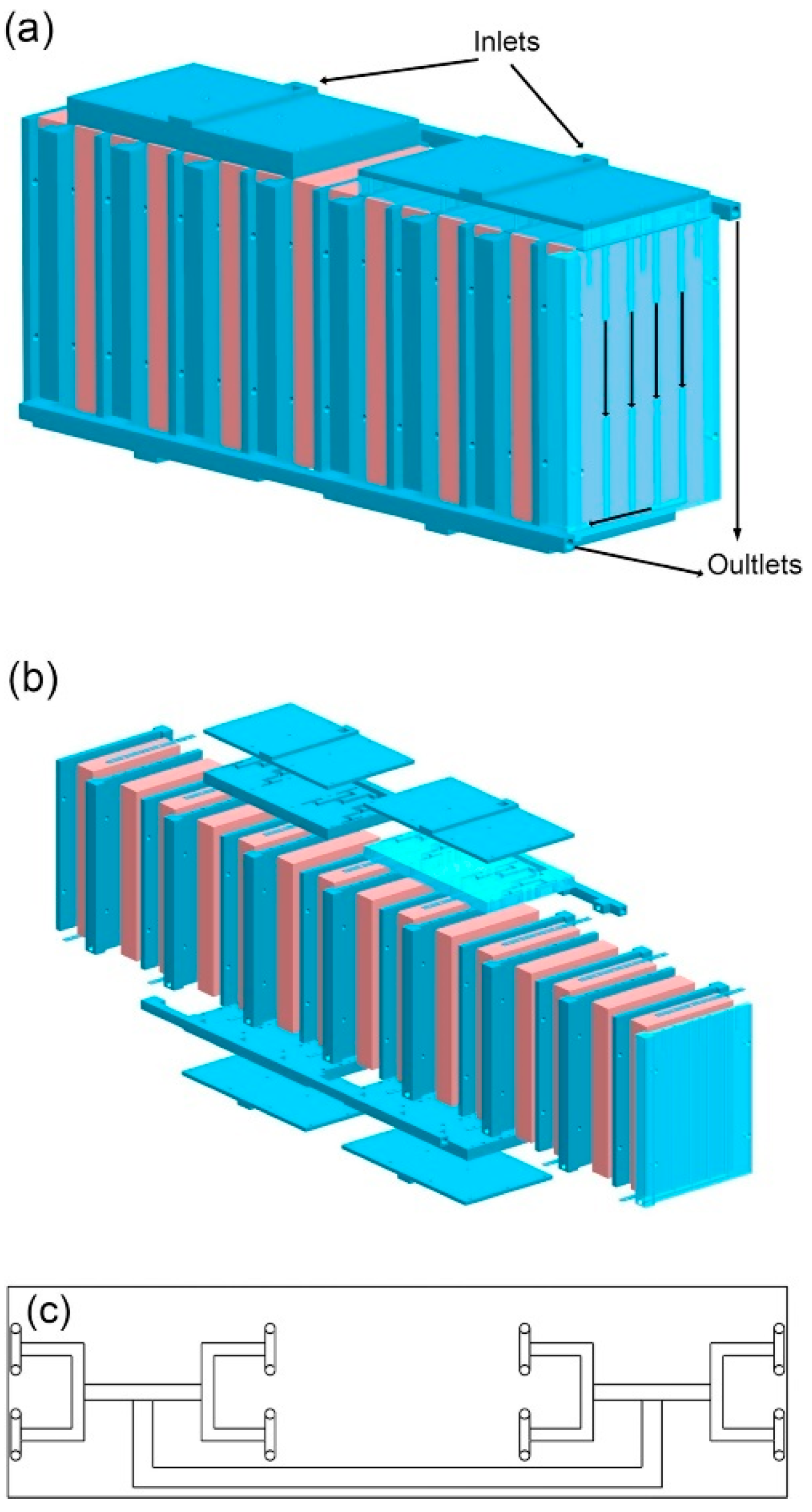

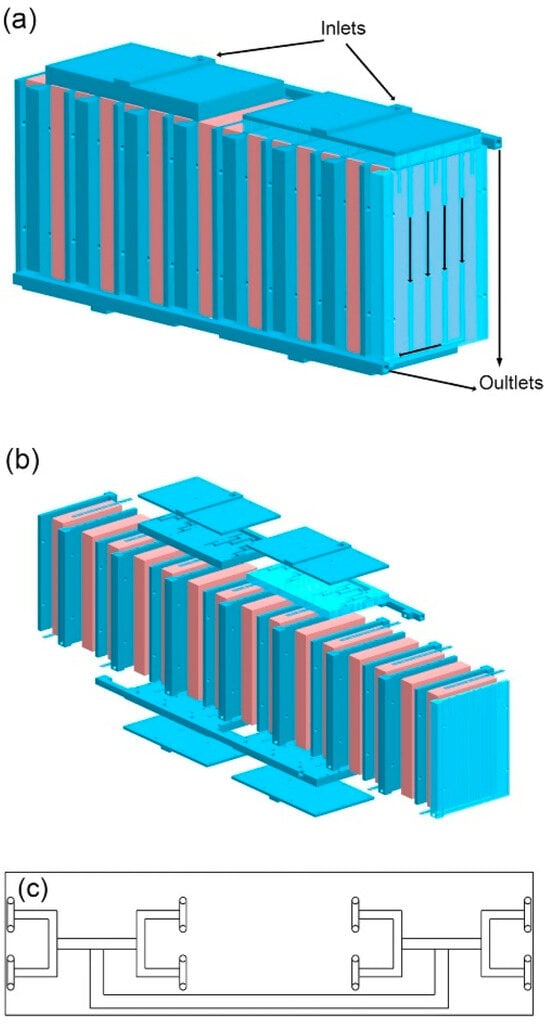

Enhancing flow distribution and minimizing thermal resistance positively impacts the performance of BTMSs. The study by Xu et al. [73,74] aimed to develop a new liquid cooling system for a prismatic LiFePO4 battery module in high ambient temperatures. This innovative cooling device consisted of and high-conductivity aluminum plates for efficient heat transfer placed between adjacent cells in the battery module, with bifurcation channels manufactured in the cover plates to ensure uniform water distribution across sixteen mini channels. The system comprised two sets of cold plates with counterflow water circulation to reduce temperature differences. Their experiments measured temperatures across the module during different discharge rates and ambient temperatures. The results indicated that passive cooling was insufficient at 40 °C, while the novel liquid cooling system effectively maintained the maximum temperature under 35 °C, ensuring uniform temperature distribution (Figure 3).

Figure 3.

(a) Schematic of an innovative liquid cooling system with enhanced flow distribution, (b) exploded view, and (c) top view of cover plate with bifurcation channels for uniform coolant distribution [73].

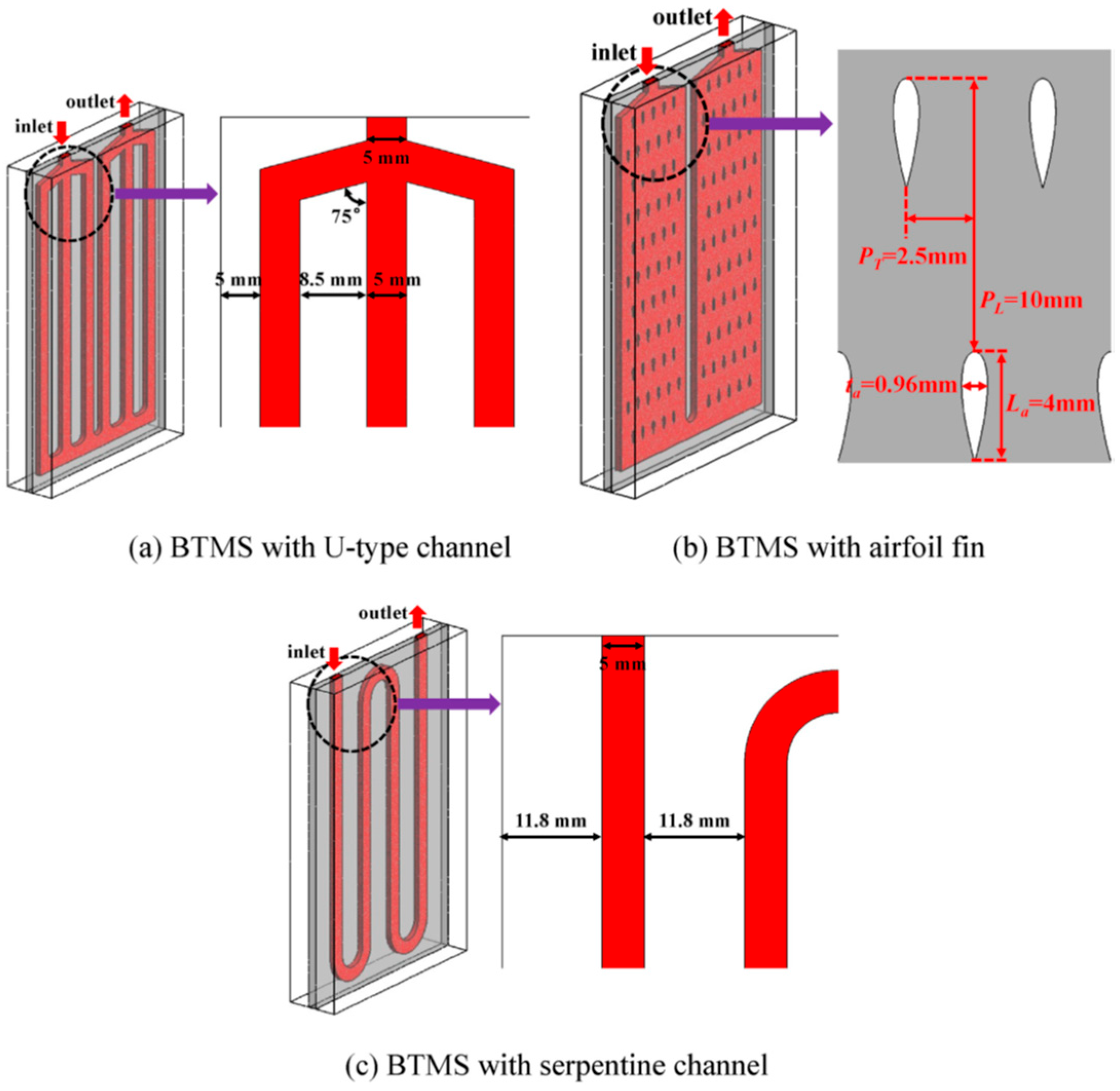

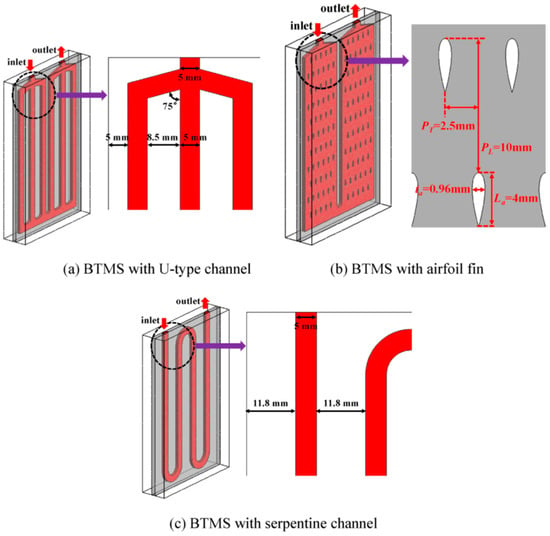

Increasing heat transfer area and turbulence, leading to better heat dissipation performance. Wang et al. [72] introduced a cold plate with airfoil fins to enhance the thermal management of prismatic LiFePO4 batteries. This novel design improved heat dissipation by 3.47% and 4.64% over to u-type and serpentine channels, respectively, by increasing turbulence in the coolant flow while reducing pressure loss. Unlike previous designs, which struggled with high pressure drops and less efficient thermal performance, the airfoil fins optimized heat transfer and minimized energy consumption. This system achieved better temperature control, temperature uniformity, and energy efficiency, making it a highly effective solution for battery cooling (Figure 4).

Figure 4.

Schematic of cold plate with airfoil fins for improved heat transfer and turbulence enhancement [72].

Using nanofluids have gained significant attention because of their excellent electrical and thermal transport characteristics. Morali et al. [83] introduced an innovative cooling system using Fe2O3 nanofluid for prismatic lithium-ion batteries, which significantly improves heat dissipation. The system enhances thermal conductivity by incorporating nanoparticles into the cooling fluid, achieving better temperature control compared to conventional air, water, and PCM cooling methods. By optimizing factors such as ambient temperature, C-rate, nanoparticle concentration, and inlet velocity through the Taguchi method, the system reduced maximum battery temperature by 23.1% and improved temperature uniformity by 70.35%. This precise optimization marks a major advancement in BTMSs.

Table 4 compiles the previous studies that work on liquid-cooled BTMSs. This table categorizes previous studies according to their methodology, battery type, number of cells, and arrangement of the battery pack. In summary, liquid-cooled BTMSs for prismatic lithium-ion cells have made significant progress over the years. Research focused on high ambient temperatures has shown the effectiveness of solutions such as airfoil fin cold plates and bifurcation channel designs using dual cold plates on top and bottom and nanofluids, such as Fe2O3 and alumina, to enhance the thermal management of batteries.

Table 4.

Overview of studies on liquid-cooled BTMSs for prismatic batteries (N.A.—not available).

3.3. Heat Pipe BTMSs

Over the years and advancements in BTMS, the evolution has shifted from basic optimization techniques and active cooling approaches to incorporate intricate microstructures and passive cooling methods. This transition showcases a move towards effective thermal management solutions that are also simpler in design.

Studies on heat pipe BTMSs for prismatic batteries have been categorized according to their research focus over the years, reflecting the evolution of this technology.

Early studies primarily focused on design optimization and material advancements.

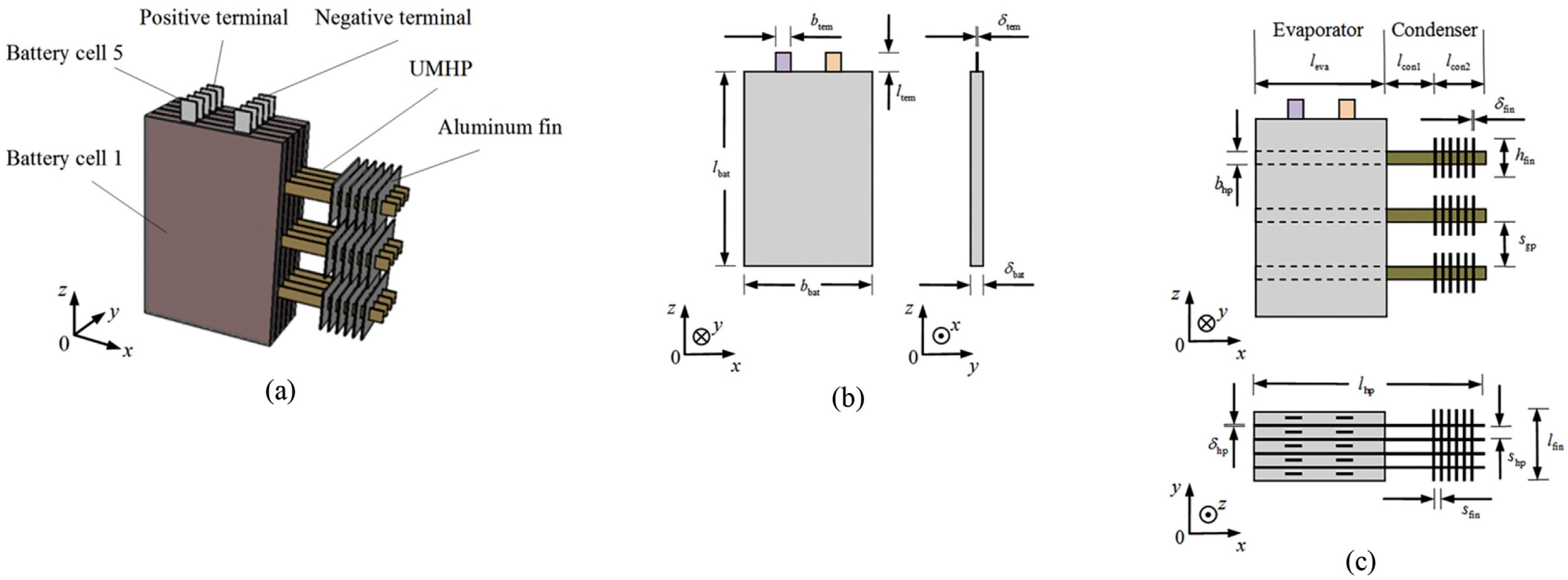

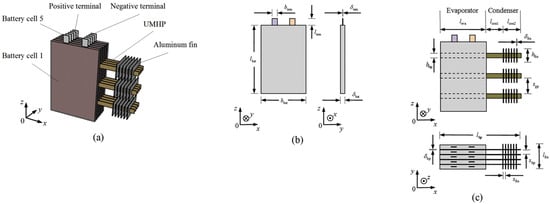

Yonghuang et al. [87] investigated the influence of working fluids, including water and methanol, and incorporated cooling fins to enhance dissipation efficiency during fast charging. Liu et al. [88] improved BTMS with ultra-thin micro heat pipes (UMHPs) with segmented thermal resistance models, showing that forced convection with UMHPs kept temperatures below 40 °C, enhancing cooling efficiency with aluminum fins and minimizing temperature differences (Figure 5).

Figure 5.

Improved cooling efficiency with UMHP and forced convection: (a) the UMHP cooling system demonstration; (b) the shape of the battery cell; and (c) the UMHP group geometry [88].

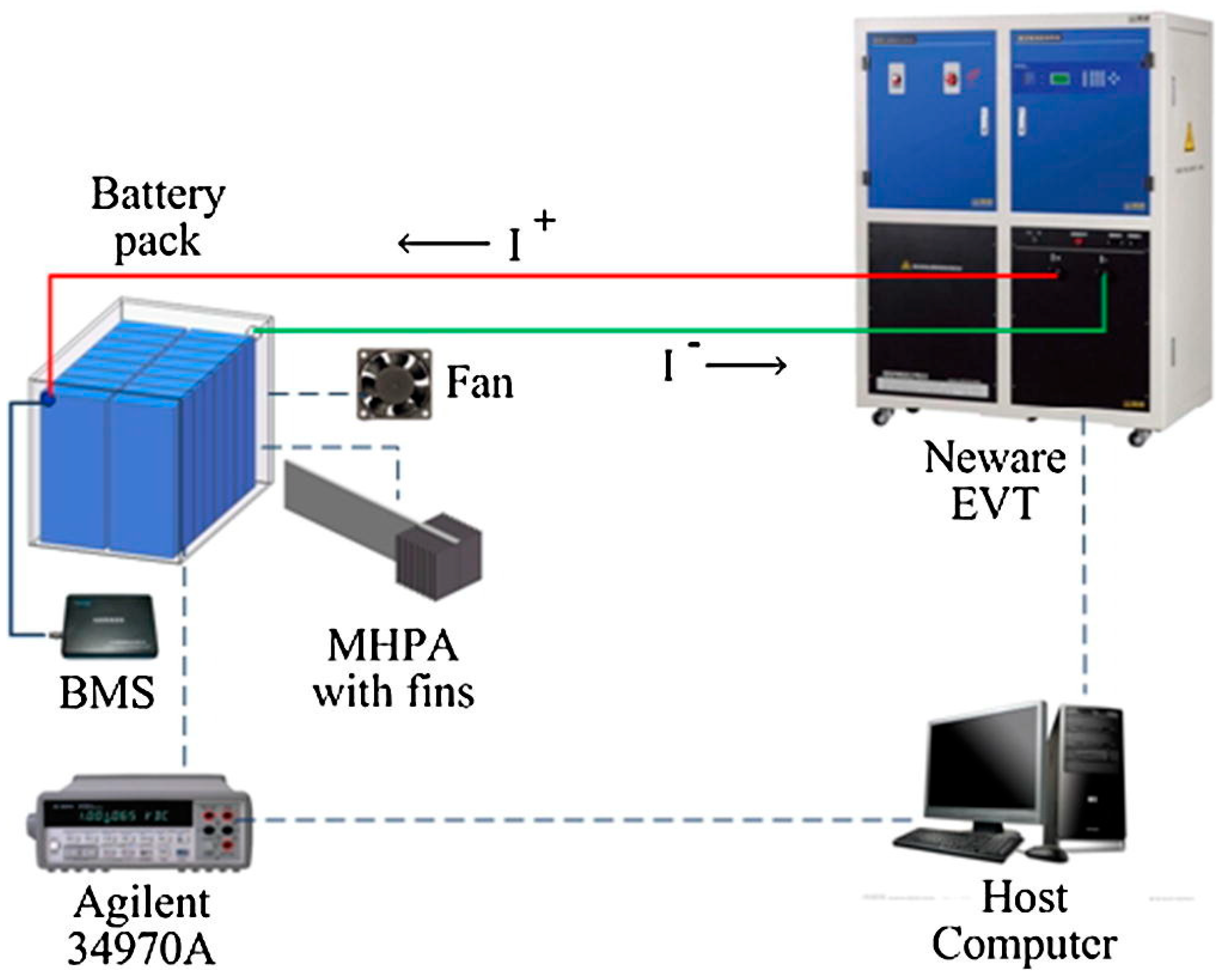

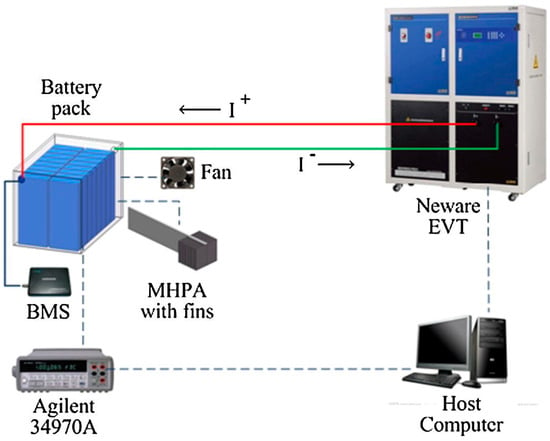

Subsequent studies aimed at improving surface contact with the battery by using flat heat pipes. Ye et al. [89] implemented flat micro heat pipe arrays (MHPAs) for improved surface contact during high-discharge conditions. Results showed forced convection with MHPAs and fins maintained temperatures within 33–34 °C, preventing TR and ensuring stability (Figure 6). Zhang and Wei [90] combined flat heat pipes with finned structures, achieving significant reductions in surface temperature and improving battery safety. Table 5 summarizes the previous studies that work on heat pipe BTMSs.

Figure 6.

Configuration of the battery test bench with flat micro heat pipe arrays (MHPAs) for enhanced surface contact and thermal management under high-discharge conditions [89].

Table 5.

Overview of studies on heat pipe BTMS for prismatic batteries (N.A.—not available).

In summary, traditional BTMSs such as air and liquid cooling have been widely adopted due to their straightforward design and effectiveness in maintaining battery temperatures within safe operating ranges. While air cooling is lightweight and cost-effective, its limited thermal conductivity makes it less suitable for high-power applications. Liquid cooling, on the other hand, offers superior heat dissipation but increases system complexity and weight. Heat pipe-based systems provide efficient thermal regulation, particularly for prismatic cells, due to their adaptability and large contact areas. Flat heat pipes are advantageous for integrating with prismatic cells. The heat pipe’s flat surface allows for a direct connection to the battery, ensuring efficient thermal management. As advancements continue in battery technology, integrating these conventional methods with innovative solutions like PCMs and hybrid systems offers promising potential for more effective and efficient thermal management.

3.4. PCM and Hybrid Cooling System

The drawback of active methods lies in their complexity and reliance on an external energy source. Consequently, passive techniques utilizing PCMs have increasingly gained attention but are limited by the low thermal conductivity and melting of the PCM. Low thermal conductivity limits efficient heat transfer, leading to incomplete phase changes and reduced energy absorption. Melting points influence operational temperature ranges, and frequent phase changes can cause material degradation, leakage, and reduced reliability. Once fully melted, passive systems lose their ability to regulate battery temperature [25]. Incorporating highly conductive nanoparticles [92] or carbon-based materials, utilizing metal foams, employing carbon nanomaterials, encapsulating PCMs within conductive shells, and enhancing PCM surfaces with nanostructures or specialized coatings effectively addresses the challenge of low thermal conductivity in PCMs [93].

Active methods, though continuously usable, depend on energy. Hybrid systems that combine both approaches offer a balanced solution, using passive cooling when no energy is needed and switching to active cooling to solidify the PCM and maintain control, allowing for alternating between the two methods for sustained effectiveness [94,95,96].

Heat insulation and heat dissipation are considered as two common methods to reduce risk of TR [80,97,98]. A balance between these two approaches can effectively reduce TR risks. While heat insulation is crucial for suppressing TR, it can conflict with heat dissipation strategies that enhance heat transfer. Improving dissipation, however, helps delay TR propagation and lower peak temperatures. Hybrid BTMSs, combining passive and active cooling techniques, are more efficient in managing TR risks than standalone methods. Active cooling systems, such as liquid or air cooling, dissipate heat effectively [99], while passive methods like heat insulation and PCMs provide thermal resistance and prevent TR from spreading to neighboring cells [100].

Ambient temperature indirectly affects Li-ion battery surface temperature. Effective thermal management is crucial to minimizing the risk of TR, especially during rapid discharge in elevated ambient conditions. For instance, road temperatures can exceed 40 °C in summer, subjecting battery packs to rapid discharge in scenarios like uphill driving or heavy loads in electric vehicles (EVs). Such conditions heighten the likelihood of thermal hazards, emphasizing the need for a robust BTMS capable of managing rapid discharge in high-temperature environments [101]. So, the reviewed studies focus on high ambient temperature scenarios, proposing solutions to enhance thermal management in environments exceeding 30 °C. These conditions are typical in real-world high-power applications, such as electric vehicles operating under heavy loads or during summer.

To highlight the key parameters examined in recent research and the focus of each study, a comparison of the most relevant and recent investigations on BTMSs is presented in Table 6. The reviewed papers examine various cooling system combinations, including PCMs with liquid cooling, PCMs with heat pipes, PCMs with air cooling, PCMs with fins, PCMs with heat pipes and air cooling, heat pipes with air and liquid cooling, PCMs with liquid and fins, and heats pipe with liquid cooling.

Table 6.

Comparison of recent research on hybrid BTMSs: key parameters and study focus.

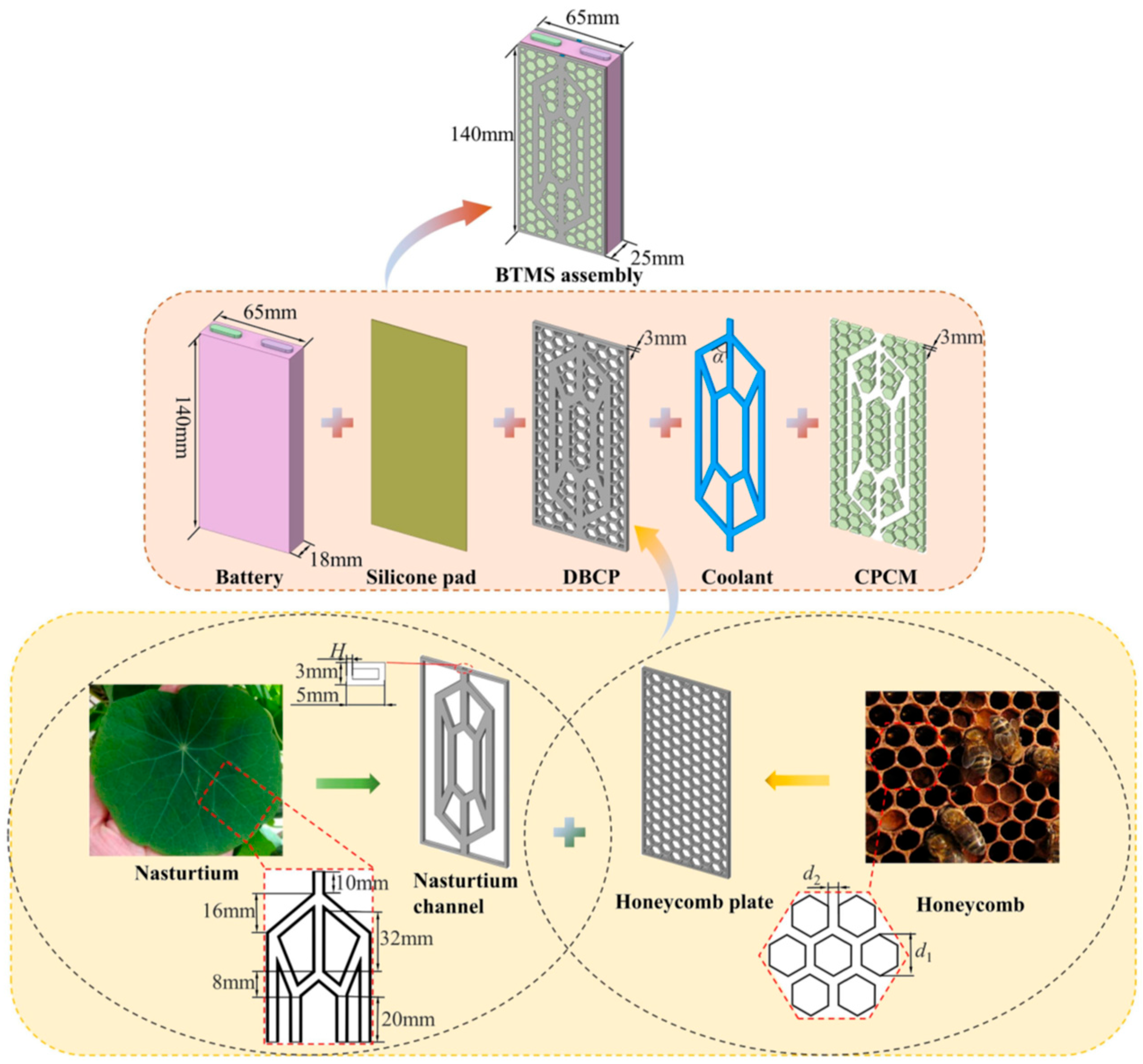

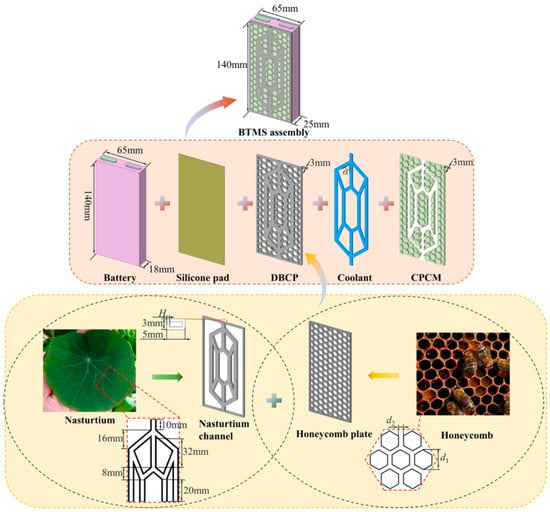

The innovative cooling system developed by Zhiguo An et al. [107] integrated dual bionic cold plates inspired by nasturtium veins and honeycomb patterns, which enhanced heat dissipation and reduced weight compared to traditional systems. Multi-objective optimization of parameters such as porosity, channel angle, wall thickness, and mass flow rate resulted in a 1.46% reduction in maximum temperature and a 13.92% improvement in temperature uniformity. The hybrid system, which combined liquid cooling and PCMs, offered superior thermal regulation and efficiency, surpassing previous designs like serpentine channels in both energy efficiency and cooling performance (Figure 7).

Figure 7.

Dual bionic cold plate cooling system with nasturtium vein and honeycomb patterns: enhanced heat dissipation and reduced weight compared to traditional systems [107].

Mohammed et al. [108] designed a BTMS utilizing multiple PCMs and liquid cooling. The system features heatsinks with nine fluid passages and is divided into three portions, each containing distinct PCMs with different melting points and heat of fusion. The results show that increasing the PCM thickness lowers the temperature rise by over 2.85 K and improves temperature uniformity. This is more effective than increasing the width of fluid channel. Water was identified as the most effective coolant, offering superior thermal regulation compared to air or single PCM setups, making it ideal for electric vehicle applications.

Chen et al. [110] investigated a BTMS combining PCM and heat pipes. They found that increasing convective heat transfer, latent heat, and PCM thickness significantly improved the system’s performance. The optimization of PCM thickness distribution led to a 30% reduction in maximum temperature differences without increasing system size or cost.

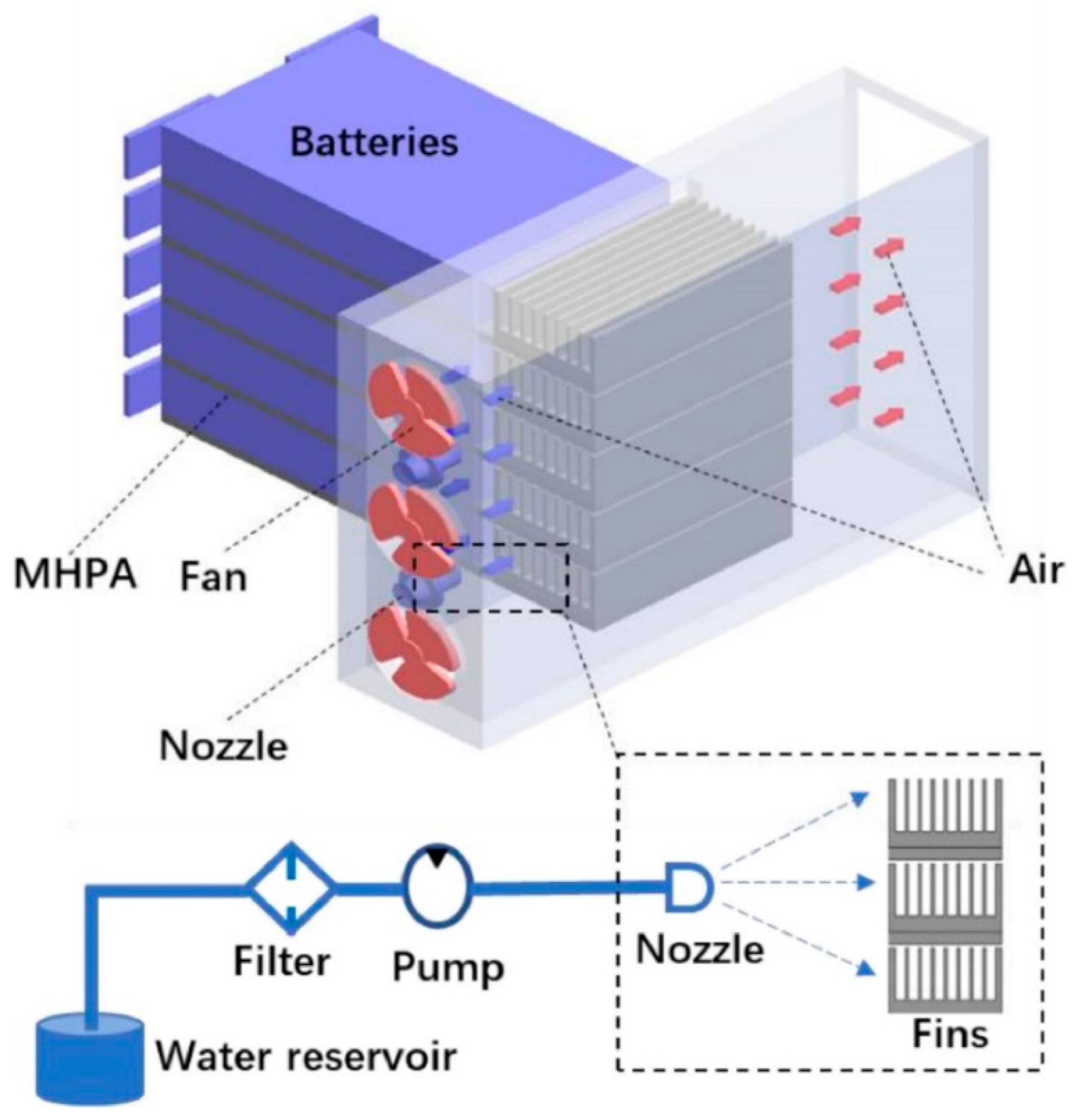

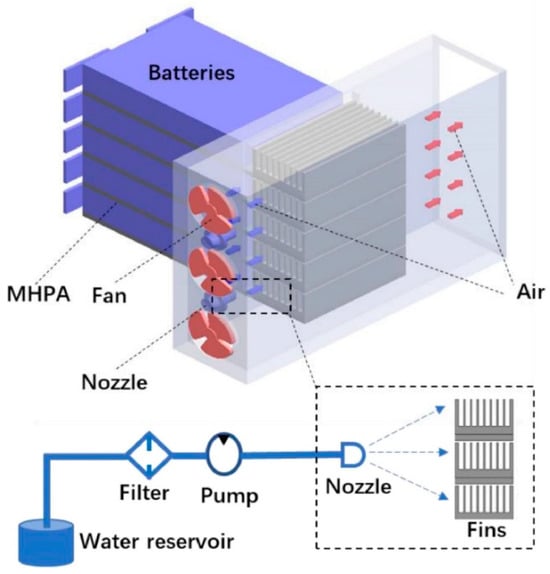

To further enhance the performance of air cooling, some researchers suggested combining it with additional cooling techniques. For instance, Yue et al. [112] aimed to develop an advanced hybrid BTMS for electric vehicles under dynamic operating conditions. The research method involved the integration of micro heat pipe arrays, air cooling, and intermittent water spraying. Heat pipes transfer heat from the interior of the battery pack to its exterior, where convective airflow disperses it during regular EV operation. Additional cooling is provided through periodic water spraying during high-power activities. The study demonstrated that this hybrid cooling system significantly reduced the maximum battery temperature to 29.6 °C and maintained a temperature non-uniformity of 1.6 °C, achieving a 21% and 57% improvement, respectively, compared to air-based systems (Figure 8).

Figure 8.

Hybrid BTMS with micro heat pipes, air cooling, and intermittent water spraying for enhanced thermal management [112].

Ping et al. [111] proposed a novel PCM-fin structure. The proposed PCM-fin structure optimized parameters like PCM type (lower melting temperature), fin thickness (0.5–1 mm), fin spacing (2.5 mm), and PCM thickness (10 mm). The results demonstrated that the optimized PCM-fin structure maintained the maximum battery surface temperature below 51 °C at a discharge rate of 3 °C.

The integration of PCMs and hybrid cooling systems has emerged as a highly effective approach for enhancing thermal management in Li-ion batteries, particularly for prismatic cells. PCM-based systems excel in absorbing and dissipating heat during phase transitions, offering passive thermal regulation with minimal energy consumption. However, their effectiveness can be limited once the PCM reaches its melting point. Hybrid systems, which combine PCMs with active cooling methods such as liquid cooling, heat pipes, or air cooling, overcome these limitations by providing continuous and adaptive thermal management. This combination offers improved temperature control, enhanced safety, and increased efficiency, making hybrid solutions a promising direction for future BTMSs in high-power applications, such as electric vehicles and stationary energy storage systems. However, hybrid and PCM cooling systems face distinct challenges and limitations that can affect their effectiveness in battery thermal management. Hybrid systems struggle with complexity, cost, and reliability. Increased complexity introduces additional components, leading to more potential failure points and require frequent maintenance, thereby reducing system reliability. On the cost side, initial costs increase due to complex designs and extra components, followed by higher operational costs.

Understanding these challenges is crucial for selecting the appropriate cooling solution for specific battery applications, particularly as the demand for high-performance and efficient battery systems continues to grow. There are several factors that have to be balanced: (1) system simplification: use modular components and combine passive and minimal active cooling; (2) cost management: use low-cost materials and optimize cooling with localized focus and dynamic, energy-efficient operation to maximize efficiency without increasing costs; (3) material selection: select efficient PCMs, lightweight materials, and cost-effective, recyclable coolants; and (4) smart integration: use AI, sensors, and energy harvesting for efficient thermal management. Table 7 summarizes the previous studies that work on hybrid BTMSs.

Table 7.

Overview of studies on hybrid BTMSs for prismatic batteries (N.A.—not available).

4. Comparative Synthesis of Thermal Management Techniques

This review represents different types of BTMSs with advantages and limitations depending on the application requirements. Key aspects of them are summarized below.

Table 8 provides a consolidated view of how these systems adapt to real-world automotive applications. The use of liquid cooling systems predominates in high-performance models, while air-based systems are more common in economy or smaller vehicles. However, under extreme conditions, these methods have some challenges in ensuring both temperature and uniformity. Therefore, exploring hybrid solutions could be beneficial for overcoming these limitations.

Table 8.

Real-world BTMSs for electric vehicle applications.

Similarly, Table 9 highlights practical examples from battery energy storage systems (BESSs). Air-cooled systems are extensively utilized in residential and small-scale commercial applications, while liquid-cooled systems are primarily employed in large-scale energy storage setups, such as utility grids and industrial facilities.

Table 9.

Real-world automotive applications.

4.1. Air Cooling BTMS

- Advantages: simplicity, lightweight design, cost-effectiveness, and ease of maintenance.

- Limitations: limited thermal conductivity and poor temperature uniformity restrict its performance, especially in high-power or fast-charging scenarios; limited cooling capacity, particularly in high-performance applications; dependency on ambient conditions reducing effectiveness in extreme environments; and contaminants cause short circuits, corrosion, performance decline.

- Applications: Suitable for EVs used for short distance driving and low thermal load needs and smaller battery energy storage systems (BESSs). Real-world examples include the Tesla Powerwall [134], VW Jetta [123], Nissan Leaf [121], Toyota Prius [119], Hyundai IONIQ, Honda Fit EV, Nissan e-NV 200, Honda Insight, Hyundai IONIQ, Renault Zoe, SAIC GM Wuling Hongguang, and the Lexus UX300e [141].

4.2. Liquid Cooling BTMS

- Advantages: higher specific heat capacities, higher thermal conductivity, efficient heat dissipation, uniformed cooling distributions, and large cooling surface area.

- Limitations: complexity and cost (due to components like pumps and heat exchangers), risk of leakage and short circuit, more components, and it requires more maintenance.

- Applications: Suitable for EVs designed for long distance driving and high thermal load needs. Real-world examples include the McLaren Speedtail, Audi e-tron GT quattro, BMW i4 eDrive40, Porsche Taycan, Mercedes EQ, Tesla Model Y, Nissan Ariya, Toyota bZ4X, Volkswagen ID.4 [116], Chevrolet Volt [123], Tesla Model S [127], BMW i3 [127], Hornsdale power reserve (HPR), Tesla Megapack, Mira Loma BESS, Noor power station, and the Microsoft data center [134].

4.3. Heat Pipes Cooling BTMS

- Advantages: high effective heat transfer, high specific heat capacity, large cooling surface area, adaptable for various spaces, and less maintenance.

- Limitations: complex design, high cost, large space requirements, the condenser section needs to be cooled, and risk of leaks and corrosion.

- Applications: Commonly used for compact electronics enclosures, aerospace, medical [142], power electronics cooling, and air conditioning systems. Implementing them in EV applications is still challenging due to the large space requirements, lack of temperature control, and the need for extra cooling at the condenser part [141].

4.4. PCMs BTMS

- Advantages: provides a stable thermal environment with minimal energy input, low energy consumption, and low cost.

- Limitations: limited by PCM melting points, low thermal conductivity causing overheating, structural instability, flammability, deformation, leakage, and challenges in TR suppression [143].

- Applications: it could be used for EVs that produce constant thermal loads and operate in environments with relatively stable ambient temperatures [141].

4.5. Hybrid BTMS

- Advantages: combines the strengths of two or more BTMS types.

- Limitations: High system complexity, cost, and increased maintenance requirements, Increased weight and size due to additional components, and large energy consumption.

- Applications: Their complexity and cost are a limiting factor for implementation in electric vehicles.

5. Conclusions

This paper has reviewed nearly 50 studies, of which 45% focus on high temperatures exceeding 27 °C, which are particularly significant for our review. Effective thermal management is pivotal for maximizing the performance, safety, and lifespan of prismatic Li-ion batteries, particularly as they become increasingly vital in electric vehicles and stationary energy storage applications. This review has underscored the evolution of BTMSs, from traditional air and liquid cooling methods to more advanced solutions like PCM and hybrid systems, which offer significant improvements in heat regulation and energy efficiency. Several proposed methods in the reviewed studies demonstrated promising results under specific conditions. An optimized airflow distribution system achieved a 62% improvement in cooling efficiency [65]. Another proposed method utilizing active thermal management reduced parasitic energy consumption by 83–92% while maintaining safe temperatures [62]. A nanofluid-based cooling system was found to reduce battery temperatures by 23.1% and improve uniformity by 70.35% [83]. A hybrid BTMS with liquid cooling and PCMs resulted in a 30% reduction in temperature differences and a 13.92% improvement in temperature uniformity [107]. Similarly, a system combining PCM and heat pipes reduced temperature differences by 30% without increasing system size or cost [110]. In dynamic EV conditions, a hybrid BTMS incorporating micro heat pipe arrays, air cooling, and intermittent water spraying demonstrated a 21% improvement in performance and a 57% reduction in temperature non-uniformity compared to air-based systems [112].

Despite significant progress in BTMS technologies, some challenges persist in their real-world commercialization.

- Extreme environments, fast charging, and high discharge rates often exceed what current systems can handle. Future research should focus on validating BTMS performance under diverse operational conditions to bridge the gap between academia and the industrial sector.

- Most of the research highlight technical aspects but does not provide a detailed economic analysis on the cost-effectiveness of different BTMSs. Although cost is a major challenge for hybrid solutions, only 3 out of the 12 studies reviewed in this paper considered cost as a factor in improving performance for hybrid systems. None of these studies provided comprehensive economic evaluations, including manufacturing and maintenance costs. A comprehensive cost–performance analysis, considering manufacturing, operational, and maintenance expenses, is crucial for guiding future development and market implementation.

- Safety studies on BTMSs are limited, and addressing safety concerns must become a priority in future research to improve system reliability.

- The sustainability of BTMSs is as crucial as their technical performance. Many current systems face environmental challenges related to recyclability and disposal. Research into eco-friendly alternatives and life-cycle assessments of BTMS materials is critical for ensuring their long-term viability. Our review does not cover bio-based PCMs or low-impact liquid coolants; future research could review and analyze these materials. Additionally, advancements in BTMSs could incorporate sustainable practices, like using ultra-low-power design and energy harvesting [144]. These approaches can reduce auxiliary power demands, enhance energy efficiency, and promote environmentally friendly solutions, paving the way for greener and more efficient thermal management systems.

- This review focused on heat dissipation in BTMSs but highlights the need for customized solutions to manage low-temperature conditions in extreme environments. Effective heating methods include BTMS-integrated external systems (air-cooled, liquid-cooled, PCMs, heat pipes), electric heating elements, and internal approaches (self-heating, DC, AC, pulse heating) [145].

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| BTMSs | battery thermal management systems |

| PCMs | phase change materials |

| RESs | renewable energy sources |

| ML | machine learning |

| TR | thermal runaway |

| HP | heat pipe |

| EV | electric vehicle |

| Li-ion | lithium-ion |

| UMHP | ultra-thin micro heat pipes |

| MHPA | micro heat pipe arrays |

| BESS | battery energy storage systems |

| HPR | Hornsdale power reserve |

References

- Snyder, N. A Sustainable Energy Economy: The Next Challenge for Systems Engineers. In Proceedings of the INCOSE International Symposium, Utrecht, The Netherlands, 15–19 June 2008. [Google Scholar]

- Huan, N.Q.; Hong, T.T.T. Role of Corporate Social Responsibility in Sustainable Energy Development in Emerging Economy. Int. J. Energy Econ. Policy 2020, 11, 172–186. [Google Scholar]

- EC Energy Roadmap 2050; Publications Office of the European Union: Luxembourg, 2012.

- Gür, T. Review of electrical energy storage technologies, materials and systems: Challenges and prospects for large-scale grid storage. Energy Environ. Sci. 2018, 11, 2696–2767. [Google Scholar] [CrossRef]

- Bindra, S.R.H. Storage and Hybridization of Nuclear Energy: Techno-Economic Integration of Renewable and Nuclear Energy; Academic Press: Cambridge, MA, USA, 2018. [Google Scholar]

- Garche, J. Energy Storage, Encyclopedia of Electrochemical Power Sources; Elsevier: Amsterdam, The Netherlands, 2009; pp. 215–231. [Google Scholar]

- Chombo, P.; Laoonual, Y. A Review of Safety Strategies of a Li-Ion Battery. J. Power Sources 2020, 478, 228649. [Google Scholar] [CrossRef]

- Simon, P.; Gogotsi, Y. Perspectives for Electrochemical Capacitors and Related Devices. Nat. Mater. 2020, 19, 1151–1163. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Nik-Ghazali, N.; Ali, M.; Chong, W.; Yang, Z.; Liu, H. A Review on Thermal Management in Proton Exchange Membrane Fuel Cells: Temperature Distribution and Control. Renew. Sustain. Energy Rev. 2023, 187, 113737. [Google Scholar] [CrossRef]

- Divakaran, A.M.; Hamilton, D.; Manjunatha, K.N.; Minakshi, M. Design, Development and Thermal Analysis of Reusable Li-Ion Battery Module for Future Mobile and Stationary Applications. Energies 2020, 13, 1477. [Google Scholar] [CrossRef]

- Zhou, Y. Transition towards carbon-neutral districts based on storage techniques and spatiotemporal energy sharing with electrification and hydrogenation. Renew. Sustain. Energy Rev. 2022, 162, 112444. [Google Scholar] [CrossRef]

- Bae, H.; Kim, Y. Technologies of lithium recycling from waste lithium ion batteries: A review. Mater. Adv. 2021, 2, 3234–3250. [Google Scholar] [CrossRef]

- Shen, J.; Li, X.; Shi, X.; Wang, W.; Zhou, H.; Wu, J.; Wang, L.; Li, J. The toxicity of lithium to human cardiomyocytes. Environ. Sci. Eur. 2020, 32, 59. [Google Scholar] [CrossRef]

- Shi, C.; Zhu, D.; Zhang, L.; Song, S.; Sheldon, B.W. Transfer learning prediction on lithium-ion battery heat release under thermal runaway condition. Nano Res. Energy 2024, 3, e9120147. [Google Scholar] [CrossRef]

- Masalkovaitė, K.; Gasper, P.; Finegan, D.P. Predicting the heat release variability of Li-ion cells under thermal runaway with few or no calorimetry data. Nat. Commun. 2024, 15, 8399. [Google Scholar] [CrossRef] [PubMed]

- He, L.; Gu, Z.; Zhang, Y.; Jing, H.; Li, P. Review on Thermal Management of Lithium-Ion Batteries for Electric Vehicles: Advances, Challenges, and Outlook. Energy Fuels 2023, 37, 4835–4857. [Google Scholar] [CrossRef]

- Trinuruk, P.; Onnuam, W.; Senanuch, N.; Sawatdeejui, C.; Jenyongsak, P.; Wongwises, S. Piyatida Trinuruk. Experimental and Numerical Studies on the Effect of Lithium-Ion Batteries’ Shape and Chemistry on Heat Generation. Energies 2023, 16, 264. [Google Scholar] [CrossRef]

- Baazouzi, S.; Feistel, N.; Wanner, J.; Landwehr, I.; Fill, A.; Birke, K.P. Design, Properties, and Manufacturing of Cylindrical Li-Ion Battery Cells—A Generic Overview. Batteries 2023, 9, 309. [Google Scholar] [CrossRef]

- Heimes, H.; Kampker, A.; Lienemann, C.; Locke, M.; Offermanns, C.; Michaelis, S.; Rahimzei, E. Lithium-Ion Battery Cell Production Process; PEM der RWTH Aachen University: Aachen, Germany; VDMA: Frankfurt, Germany, 2018; ISBN 978-3-947920-03-7. [Google Scholar]

- Waldmann, T.; Scurtu, R.-G.; Richter, K.; Wohlfahrt-Mehrens, M. 18650 vs. 21700 Li-ion cells—A direct comparison of electrochemical, thermal, and geometrical properties. J. Power Sources 2020, 472, 228614. [Google Scholar] [CrossRef]

- Miao, Y.; Hynan, P.; Jouanne, A.; Yokochi, A. Current Li-Ion Battery Technologies in Electric Vehicles and Opportunities for Advancements. Energies 2019, 12, 1074. [Google Scholar] [CrossRef]

- Hosseinzadeh, E.; Genieser, R.; Worwood, D.; Barai, A.; Marco, J.; Jennings, P. A systematic approach for electrochemical-thermal modelling of a large format lithium-ion battery for electric vehicle application. Power Sources 2018, 382, 77–94. [Google Scholar] [CrossRef]

- Murray, V.; Hall, D.S.; Dahn, J.R. A Guide to Full Coin Cell Making for Academic Researchers. Electrochem. Soc. 2019, 166, A329–A333. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Z.; Luo, L.; Fan, Y.; Du, Z. Theory and Practices of Li-Ion Battery Thermal Management for Electric and Hybrid Electric Vehicles. Energies 2022, 45, 121652. [Google Scholar]

- Sanker, S.B.; Baby, R. Phase change material based thermal management of lithium ion batteries: A review on thermal performance of various thermal conductivity enhancers. J. Energy Storage 2022, 50, 104606. [Google Scholar] [CrossRef]

- Ciez, R.E.; Whitacre, J.F. Comparison between cylindrical and prismatic lithium-ion cell costs using a process based cost model. J. Power Sources 2017, 340, 273–281. [Google Scholar] [CrossRef]

- Rodriguez-Martinez, L.; Villarreal, I.; Swierczynski, M.J.; Rodriguez, P.; Gosso, M.; Marckx, E.; Jutz, G.; Warnecke, A.; Rauscher, F.; Timmermans, J. A Joint European Effort towards European Competitive Automotive Batteries. In Proceedings of the 28th International Electric Vehicle Symposium and Exhibition, Goyang, Republic of Korea, 3–6 May 2015. [Google Scholar]

- Gungor, S.; Gocmen, S.; Cetkın, E. A review on battery thermal management strategies in lithium-ion and post-lithium batteries for electric vehicles. J. Therm. Eng. 2023, 9, 1078–1099. [Google Scholar] [CrossRef]

- Zubi, G.; Adhikari, R.S.; Sánchez, N.E.; Acuña-Bravo, W. Lithium-ion battery-packs for solar home systems: Layout, cost and implementation perspectives. J. Energy Storage 2020, 32, 101985. [Google Scholar] [CrossRef]

- Hamed, M.M.; El-Tayeb, A.; Moukhtar, I.; El Dein, A.Z.; Abdelhameed, E.H. A review on recent key technologies of lithium-ion battery thermal management: External cooling systems. Results Eng. 2023, 16, 100703. [Google Scholar] [CrossRef]

- Larrañaga-Ezeiza, M.; Vertiz, G.; Arroiabe, P.F.; Martinez-Agirre, M.; Berasategi, J. A novel direct liquid cooling strategy for electric vehicles focused on pouch type battery cells. Therm. Eng. 2022, 216, 118869. [Google Scholar] [CrossRef]

- Amer, M.M.; Shouman, M.A.; Salem, M.S.; Kannan, A.M.; Hamed, A.M. Advances in thermal management systems for Li-Ion batteries: A review. Therm. Sci. Eng. Prog. 2024, 53, 102714. [Google Scholar] [CrossRef]

- Ahmadian-Elmi, M.; Zhao, P. Review of Thermal Management Strategies for Cylindrical Lithium-Ion Battery Packs. Batteries 2024, 10, 50. [Google Scholar] [CrossRef]

- Moosavi, A.; Ljung, A.L.; Lundström, T.S. A study on the effect of cell spacing in large-scale air-cooled battery thermal management systems using a novel modeling approach. J. Energy Storage 2023, 72, 108418. [Google Scholar] [CrossRef]

- Buidin, T.I.C.; Mariasiu, F. Battery Thermal Management Systems: Current Status and Design Approach of Cooling Technologies. Energies 2021, 14, 4879. [Google Scholar] [CrossRef]

- Tete, P.R.; Gupta, M.M.; Joshi, S.S. Developments in battery thermal management systems for electric vehicles: A technical review. J. Energy Storage 2021, 35, 102255. [Google Scholar] [CrossRef]

- Shinde, P.S.; Naik, P. Heat-Pipe-Assisted Air Cooling of Lithium-Titanate Prismatic Battery. J. Therm. Sci. Eng. Appl. 2022, 15, 021012. [Google Scholar] [CrossRef]

- Greco, A.; Cao, D.; Jiang, X.; Yang, H. A theoretical and computational study of lithium-ion battery thermal management for electric vehicles using heat pipes. J. Power Sources 2014, 257, 344–355. [Google Scholar] [CrossRef]

- Weragoda, D.M.; Tian, G.; Burkitbayev, A.; Lo, K.H.; Zhang, T. A comprehensive review on heat pipe based battery thermal management systems. Appl. Therm. Eng. 2023, 224, 120070. [Google Scholar] [CrossRef]

- Zhao, R.; Gu, J.; Liu, J. An experimental study of heat pipe thermal management system with wet cooling method for lithium ion batteries. J. Power Sources 2015, 273, 1089–1097. [Google Scholar] [CrossRef]

- Ren, D.; Smith, K.; Guo, D.; Han, X.; Feng, X.; Lu, L.; Ouyangm, M.; Li, J. Investigation of lithium plating-stripping process in Li-ion batteries at low temperature using an electrochemical model. Electrochem. Soc. 2018, 165, 2167–2178. [Google Scholar] [CrossRef]

- Panchal, S.; Khasow, R.; Dincer, I.; Agelin-Chaab, M.; Fraser, R.; Fowler, M. Thermal design and simulation of mini-channel cold plate for water cooled large sized prismatic lithium-ion battery. Appl. Therm. Eng. 2017, 122, 80–90. [Google Scholar] [CrossRef]

- Panchal, S.; Mathewson, S.; Fraser, R.; Culham, R.; Fowler, M. Thermal management of lithium-ion pouch cell with indirect liquid cooling using dual cold plates approach. SAE Int. J. Altern. Powertrains 2015, 4, 293–307. [Google Scholar] [CrossRef]

- Wu, W.; Wang, S.; Wu, W.; Chen, K.; Hong, S.; Lai, Y. A critical review of battery thermal performance and liquid based battery thermal management. Energy Convers. Manag. 2019, 182, 262–281. [Google Scholar] [CrossRef]

- Deng, Y.; Feng, C.; Jiaqiang, E.; Zhu, H.; Chen, J.; Wen, M.; Yin, H. Effects of different coolants and cooling strategies on the cooling performance of the power lithium ion battery system: A review. Therm. Eng. 2018, 142, 10–29. [Google Scholar] [CrossRef]

- Jiang, Z.; Qu, Z. Lithium–ion battery thermal management using heat pipe and phase change material during discharge–charge cycle: A comprehensive numerical study. Appl. Energy 2019, 242, 378–392. [Google Scholar] [CrossRef]

- Wei, A.; Qu, J.; Qiu, H.; Wang, C.; Cao, G. Heat transfer characteristics of plug-in oscillating heat pipe with binary-fluid mixtures for electric vehicle battery thermal management. Int. J. Heat Mass Transf. 2019, 135, 746–760. [Google Scholar] [CrossRef]

- Wang, J.; Gan, Y.; Liang, J.; Tan, M.; Li, Y. Sensitivity analysis of factors influencing a heat pipe-based thermal management system for a battery module with cylindrical cells. Appl. Therm. Eng. 2019, 151, 475–485. [Google Scholar] [CrossRef]

- Farid, M.M.; Khudhair, A.M.; Razack, S.A.K.; Al-Hallaj, S. A review on phase change energy storage: Materials and applications. Energy Convers. Manag. 2004, 45, 1597–1615. [Google Scholar] [CrossRef]

- Kim, J.; Oh, J.; Lee, H. Review on battery thermal management system for electric vehicles. J. Appl. Therm. Eng. 2019, 149, 192–212. [Google Scholar] [CrossRef]

- E, J.; Xu, S.; Deng, Y.; Zhu, H.; Zuo, W.; Wang, H.; Chen, J.; Peng, Q.; Zhang, Z. Investigation on thermal performance and pressure loss of the fluid cold-plate used in thermal management system of the battery pack. Appl. Therm. Eng. 2018, 145, 552–568. [Google Scholar] [CrossRef]

- Wang, X.; Liu, S.; Zhang, Y.; Lv, S.; Ni, H.; Deng, Y.; Yuan, Y. A Review of the Power Battery Thermal Management System with Different Cooling, Heating and Coupling System. Energies 2022, 15, 1963. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M.; Zhang, H. A review of air-cooling battery thermal management systems for electric and hybrid electric vehicles. J. Power Sources 2021, 501, 230001. [Google Scholar] [CrossRef]

- Xu, X.M.; He, R. Research on the heat dissipation performance of battery pack based on forced air cooling. J. Power Sources 2013, 240, 33–41. [Google Scholar] [CrossRef]

- Peng, X.; Ma, C.; Garg, A.; Bao, N.; Liao, X. Thermal performance investigation of an air-cooled lithium-ion battery pack Thermal performance investigation of an air-cooled lithium-ion battery pack. Appl. Therm. Eng. 2019, 153, 596–603. [Google Scholar] [CrossRef]

- Fan, L.; Khodadadi, J.M.; Pesaran, A.A. A parametric study on thermal management of an air-cooled lithium-ion battery module for plug-in hybrid electric vehicles. J. Power Sources 2013, 238, 301–312. [Google Scholar] [CrossRef]

- Chen, K.; Song, M.; Wei, W.; Wang, S. Structure optimization of parallel air-cooled battery thermal management system. Int. J. Heat Mass Transf. 2017, 111, 943–952. [Google Scholar] [CrossRef]

- Ye, M.; Xu, Y.; Huangfu, Y. The Structure Optimization of Lithium-ion Battery Pack Based on Fluid-solid Conjugate Thermodynamic Analysis. Energy Procedia 2018, 152, 643–648. [Google Scholar] [CrossRef]

- Chen, K.; Wang, S.; Song, M.; Chen, L. Configuration optimization of battery pack in parallel air-cooled battery thermal management system using an optimization strategy. Appl. Therm. Eng. 2017, 123, 177–186. [Google Scholar] [CrossRef]

- Chen, K.; Chen, Y.; Li, Z.; Yuan, F.; Wang, S. Design of the cell spacing of battery pack in parallel air-cooled battery thermal management system. Int. J. Heat Mass Transf. 2018, 127, 393–401. [Google Scholar] [CrossRef]

- Mohammadian, S.K.; Zhang, Y. Thermal management optimization of an air-cooled Li-ion battery module using pin-fin heat sinks for hybrid electric vehicles. J. Power Sources 2015, 273, 431–439. [Google Scholar] [CrossRef]

- Wang, H.; Xu, W.; Ma, L. Actively controlled thermal management of prismatic Li-ion cells under elevated temperatures. Int. J. Heat Mass Transf. 2016, 102, 315–322. [Google Scholar] [CrossRef]

- Li, W.; Xiao, M.; Peng, X.; Garg, A.; Gao, L. A surrogate thermal modeling and parametric optimization of battery pack with air cooling for EVs. Appl. Therm. Eng. 2019, 147, 90–100. [Google Scholar] [CrossRef]

- Jiang, G.; Zhuang, L.; Hu, Q.; Liu, Z.; Huang, J. An investigation of heat transfer and capacity fade in a prismatic Li-ion battery based on an electrochemical-thermal coupling model. Appl. Therm. Eng. 2020, 171, 115080. [Google Scholar] [CrossRef]

- Bakar, O.; Uysal, M.; Feyzioğlu, A. Optimization and experimental validation of the air intake holes of the lithium-ion battery pack. Eng. Therm. Sci. 2024, 4. [Google Scholar] [CrossRef]

- Available online: https://www.mitsubishicritical.com/resources/blog/thermal-runaway/ (accessed on 20 November 2024).

- Mohammadian, S.K.; He, Y.-L.; Zhang, Y. Internal cooling of a lithium-ion battery using electrolyte as coolant through microchannels embedded inside the electrodes. J. Power Sources 2015, 293, 458–466. [Google Scholar] [CrossRef]

- Panchal, S.; Dincer, I.; Agelin-Chaab, M.; Fraser, R.; Fowler, M. Experimental temperature distributions in a prismatic lithium-ion battery at varying conditions. Int. Commun. Heat Mass Transf. 2016, 71, 35–43. [Google Scholar] [CrossRef]

- Darcovich, K.; MacNeil, D.D.; Recoskie, S.; Cadic, Q.; Ilinca, F. Comparison of cooling plate configurations for automotive battery pack thermal management. Appl. Therm. Eng. 2019, 155, 185–195. [Google Scholar] [CrossRef]

- Mohammed, A.H.; Esmaeeli, R.; Aliniagerdroudbari, H.; Alhadri, M.; Hashemi, S.R.; Nadkarni, G.; Farhad, S. Dual-purpose cooling plate for thermal management of prismatic lithium-ion batteries during normal operation and thermal runaway. Appl. Therm. Eng. 2019, 160, 114106. [Google Scholar] [CrossRef]

- Madaoui, S.; Guzowski, B.; Gozdur, R.; Dimitrova, Z.; Audiot, N.; Sabatier, J.; Vinassa, J.-M.; Guillemard, F. Evaluation of dual side cooling system for prismatic batteries for vehicle application. In Proceedings of the 36th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems (ECOS 2023), Grande Canarie, Spain, 25–30 June 2023; pp. 2218–2228. [Google Scholar]

- Wang, L.; Zuo, H.; Zhang, B.; Jia, G. Effects of the cold plate with airfoil fins on the cooling performance enhancement of the prismatic LiFePO4 battery pack. Energy 2024, 296, 131210. [Google Scholar] [CrossRef]

- Xu, X.; Li, W.; Xu, B.; Qin, J. Numerical study on a water cooling system for prismatic LiFePO4 batteries at abused operating conditions. Appl. Energy 2019, 250, 404–412. [Google Scholar] [CrossRef]

- Xu, J.; Zhou, T.; Xu, X. Experimental investigation on a novel liquid cooling device for a prismatic Li-ion battery module operating at high ambient temperature. Technol. Sci. 2020, 63, 2147–2153. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, X.; Liu, Z.; Kong, J.; Zhai, Q.; Zakaria, H.; Wang, Q.; Zhou, F.; Wei, H. Optimization of liquid cooling for prismatic battery with novel cold plate based on butterfly-shaped channel. J. Energy Storage 2023, 73, 109161. [Google Scholar] [CrossRef]

- Fan, X.; Meng, C.; Yang, Y.; Lin, J.; Li, W.; Zhao, Y.; Xie, S.; Jiang, C. Numerical optimization of the cooling effect of a bionic fishbone channel liquid cooling plate for a large prismatic lithium-ion battery pack with highdischarge rate. J. Energy Storage 2023, 72, 108239. [Google Scholar] [CrossRef]

- Sun, Y.; Bai, R.; Ma, J. Design and thermal analysis of a new topological cooling plate for prismatic lithium battery thermal management. Appl. Therm. Eng. 2023, 219, 119547. [Google Scholar] [CrossRef]

- Lan, C.; Xu, J.; Qiao, Y.; Ma, Y. Thermal management for high power lithium-ion battery by minichannel aluminum tubes. Appl. Therm. Eng. 2016, 101, 284–292. [Google Scholar] [CrossRef]

- Huang, Y.; Mei, P.; Lu, Y.; Huang, R.; Yu, X.; Chen, Z.; Roskilly, A.P. A novel approach for Lithium-ion battery thermal management with streamline shape mini channel cooling plates. Appl. Therm. Eng. 2019, 157, 113623. [Google Scholar] [CrossRef]

- Xu, J.; Lan, C.; Qiao, Y.; Ma, Y. Prevent thermal runaway of lithium-ion batteries with minichannel cooling. Appl. Therm. Eng. 2017, 110, 883–890. [Google Scholar] [CrossRef]

- Li, Y.; Bai, M.; Gao, L.; Yang, Y.; Li, Y.; Li, Y.; Song, Y. Effective Heat Dissipation for Prismatic Lithium-ion Battery by Fluorinated Liquid Immersion Cooling Approach. Int. J. Green Energy 2023, 21, 244–255. [Google Scholar] [CrossRef]

- Liu, H.; Chika, E.; Zhao, J. Investigation into the effectiveness of nanofluids on the mini-channel thermal management for highpower lithium ion battery. Appl. Therm. Eng. 2018, 142, 511–523. [Google Scholar] [CrossRef]

- Morali, U.; Yetik, O.; Karakoc, T.H. Nanofluid-based cooling of prismatic lithium-ion battery packs: An integrated numerical and statistical approach. Therm. Anal. Calorim. 2024, 149, 799–811. [Google Scholar] [CrossRef]

- Tang, Z.; Ji, Y.; Yu, P.; Cheng, J. Investigation on the thermal management performance of a non-contact flow boiling cooling system for prismatic batteries. J. Energy Storage 2023, 66, 107499. [Google Scholar] [CrossRef]

- Han, J.; Ko, W.; Lim, M.S.; Lee, T.; Yoo, J. A numerical study of enhanced lithium-ion battery cooling using a module insert. Case Stud. Therm. Eng. 2023, 42, 102751. [Google Scholar] [CrossRef]

- Han, S.Y.; Kim, Y.T. Cooling channel designs of a prismatic battery pack for electric vehicle using the deep Q-network algorithm. Appl. Therm. Eng. 2023, 219, 119610. [Google Scholar]

- Ye, Y.; Shi, Y.; Saw, L.H.; Tay, A.A. Performance assessment and optimization of a heat pipe thermal management system for fast charging lithium ion battery packs. Int. J. Heat Mass Transf. 2023, 92, 893–903. [Google Scholar] [CrossRef]

- Liu, F.; Lan, F.; Chen, J. Dynamic thermal characteristics of heat pipe via segmented thermal resistance model for electric vehicle battery cooling. J. Power Sources 2016, 321, 57–70. [Google Scholar] [CrossRef]

- Ye, X.; Zhao, Y.; Quan, Z. Experimental study on heat dissipation for lithium-ion battery based on micro heat pipe array (MHPA). Appl. Therm. Eng. 2018, 130, 74–82. [Google Scholar] [CrossRef]

- Zhang, Z.; Wei, K. Experimental and numerical study of a passive thermal management system using flat heat pipes for lithium-ion batteries. Appl. Therm. Eng. 2020, 166, 114660. [Google Scholar] [CrossRef]

- Atieh Alihosseini, M.S. Experimental study and numerical simulation of a Lithium-ion battery thermal management system using a heat pipe. J. Energy Storage 2021, 39, 102616. [Google Scholar] [CrossRef]

- Faraji, H.; Faraji, M.; El Alami, M.; Hariti, Y.; Arshad, A.; Hader, A.; Benkaddour, A. Cooling of recent microprocessors by the fusion of nano-enhanced phase change materials. Mater. Today Proc. 2020, 30, 865–869. [Google Scholar] [CrossRef]

- Said, Z.; Pandey, A.; Tiwari, A.K.; Kalidasan, B.; Jamil, F.; Thakur, A.K.; Tyagi, V.; Sarı, A.; Ali, H.M. Nano-enhanced phase change materials: Fundamentals and applications. Prog. Energy Combust. Sci. 2024, 104, 101162. [Google Scholar] [CrossRef]

- Qin, P.; Liao, M.; Zhang, D.; Liu, Y.; Sun, J.; Wang, Q. Experimental and numerical study on a novel hybrid battery thermal management system integrated forced-air convection and phase change material. Energy Convers. Manag. 2019, 195, 1371–1381. [Google Scholar] [CrossRef]

- Deng, T.; Ran, Y.; Zhang, G.; Yin, Y. Novel leaf-like channels for cooling rectangular lithium ion batteries. Appl. Therm. Eng. 2019, 150, 1186–1196. [Google Scholar] [CrossRef]

- Samimi, F.; Babapoor, A.; Azizi, M.; Karimi, G. Thermal management analysis of a Li-ion battery cell using phase change material loaded with carbon fibers. Energy 2016, 96, 355–371. [Google Scholar] [CrossRef]

- Coello Coello, C.A.; Toscano Pulido, G.; Salazar Lechuga, M. Handling multiple objectives with particle swarm optimization. IEEE Trans. Evol. Comput. 2004, 8, 256–279. [Google Scholar] [CrossRef]

- Hu, Y.; Lan, F.; Chen, J.; Xian, J. Effectiveness of Heat Insulation and Heat Dissipation for Mitigating Thermal Runaway Propagation in Lithium-Ion Battery Module. In Proceedings of the 5th International Conference on Energy, Electrical and Power Engineering, Chongqing, China, 22–24 April 2022. [Google Scholar]

- Olabi, A.G.; Maghrabie, H.M.; Adhari, O.H.K.; Sayed, E.T.; Yousef, B.A.; Salameh, T.; Kamil, M.; Abdelkareem, M.A. Battery thermal management systems: Recent progress and challenges. Int. J. Thermofluids 2022, 15, 100171. [Google Scholar] [CrossRef]

- Sun, X.; Dong, Y.; Sun, P.; Zheng, B. Effects of thermal insulation layer material on thermal runaway of energy storage lithium battery pack. J. Energy Storage 2024, 76, 109812. [Google Scholar] [CrossRef]

- Zheng, J.; Chang, L.; Mu, M.; Li, J.; Li, C.; Ma, C.; Du, H. A novel thermal management system combining phase change material with wavy cold plate for lithium-ion battery pack under high ambient temperature and rapid discharging. Appl. Therm. Eng. 2024, 245, 122803. [Google Scholar] [CrossRef]

- Al-Zareer, M.; Dincer, I.; Rosen, M.A. A novel phase change based cooling system for prismatic lithium ion batteries. Int. J. Refrig. 2018, 86, 203–217. [Google Scholar] [CrossRef]

- Wu, W.; Wu, W.; Wang, S. Thermal management optimization of a prismatic battery with shape-stabilized phase change material. Int. J. Heat Mass Transf. 2018, 121, 967–977. [Google Scholar] [CrossRef]

- Rao, Z.; Wang, Q.; Huang, C. Investigation of the thermal performance of phase change material/mini-channel coupled battery thermal management system. Appl. Energy 2016, 164, 659–669. [Google Scholar] [CrossRef]

- Mousavi, S.; Zadehkabir, A.; Siavashi, M.; Yang, X. An improved hybrid thermal management system for prismatic Li-ion batteries integrated with mini-channel and phase change materials. Appl. Energy 2023, 334, 120643. [Google Scholar] [CrossRef]

- Hekmat, S.; Tavana, P.; Molaeimanesh, G.R. A novel compact battery thermal management system comprising phase change material, mini-channels, and fins suitable for EV battery packs. J. Energy Storage 2024, 82, 110392. [Google Scholar] [CrossRef]

- An, Z.; Gao, W.; Zhang, J.; Liu, H.; Gao, Z. Enhancing heat dissipation of thermal management system utilizing modular dual bionic cold plates for prismatic lithium batteries. J. Energy Storage 2024, 87, 111541. [Google Scholar] [CrossRef]

- Mohammed, A.G.; Wang, Q.; Elfeky, K.E. Rapid cooling effectiveness of Li-ion battery module with multiple phase change materials for plug-in hybrid electric vehicle. Int. J. Therm. Sci. 2023, 185, 108040. [Google Scholar] [CrossRef]

- Wu, W.; Yang, X.; Zhang, G.; Chen, K.; Wang, S. Experimental investigation on the thermal performance of heat pipe-assisted phase change material based battery thermal management system. Energy Convers. Manag. 2017, 138, 486–492. [Google Scholar] [CrossRef]

- Chen, K.; Hou, J.; Song, M.; Wang, S.; Wu, W.; Zhang, Y. Design of battery thermal management system based on phase change material and heat pipe. Appl. Therm. Eng. 2021, 188, 116665. [Google Scholar] [CrossRef]

- Ping, P.; Peng, R.; Kong, D.; Chen, G.; Wen, J. Investigation on thermal management performance of PCM-fin structure for Li-ion battery module in high-temperature environment. Energy Convers. Manag. 2018, 176, 131–146. [Google Scholar] [CrossRef]

- Yue, Q.L.; He, C.X.; Jiang, H.R.; Wu, M.C.; Zhao, T.S. A hybrid battery thermal management system for electric vehicles under dynamic working conditions. Int. J. Heat Mass Transf. 2021, 164, 120528. [Google Scholar] [CrossRef]

- Alqaed, S.; Mustafa, J.; Almehmadi, F.A.; Sharifpur, M. Thermal management of a prismatic lithium battery pack with organic phase change material. Taiwan Inst. Chem. Eng. 2023, 148, 104886. [Google Scholar] [CrossRef]

- Suo, Y.; Tang, C.; Jia, Q.; Zhao, W. Influence of PCM configuration and optimization of PCM proportion on the thermal management of a prismatic battery with a combined PCM and air cooling structure. J. Energy Storage 2024, 80, 110340. [Google Scholar] [CrossRef]

- Yang, T.; Li, J.; Xin, Q.; Zhang, H.; Zeng, J.; Agbossou, K.; Du, C.; Xiao, J. Thermal Performance Analysis of a Prismatic Lithium-Ion Battery Module under Overheating Conditions. Batteries 2024, 10, 86. [Google Scholar] [CrossRef]