Potential of PN Reduction in Passenger Cars with DPF and GPF

Abstract

:1. Introduction

- -

- GPFs on MPI vehicles;

- -

- Stronger coating of 4WC (4-way catalytic converter);

- -

- GPFs on GDI vehicles;

- -

- PN emissions of CNG cars.

2. Experimental Section

2.1. Tested Vehicles

2.2. Fuels and Lube Oils

2.3. Test Methods and Instrumentation

- Roller dynamometer: AFHB GSA 200;

- Driver conductor system: Tornado, version 3.3.;

- CVS dilution system: Horiba CVS-9500T with Roots blower;

- Air conditioning in the hall is automatic (intake and dilution air).

- Gaseous components:

- Exhaust gas measuring system Horiba MEXA-9400H [44];

- CO, CO2—infrared analyzers (IR), HCIR, HCFID, NO/NOX, CLA.

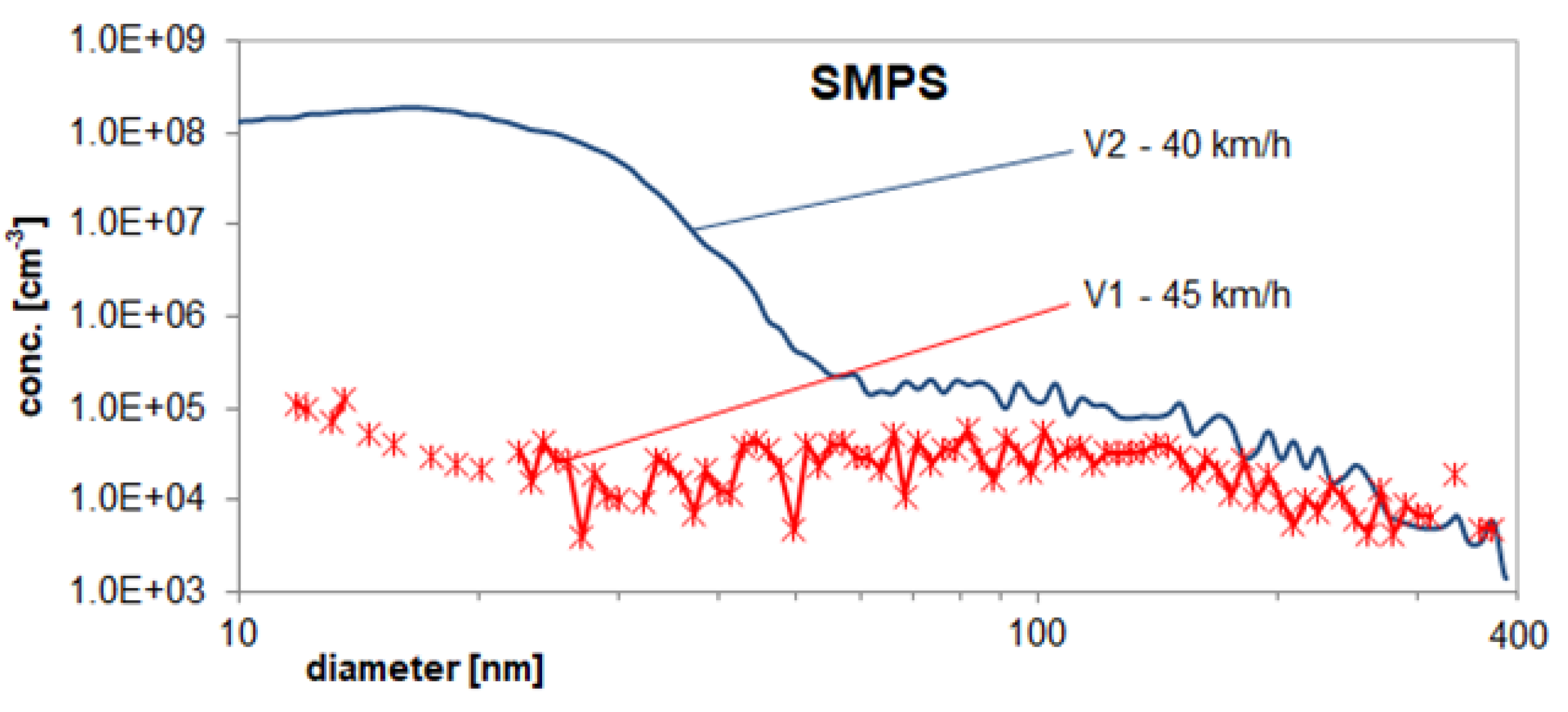

Nanoparticle Analysis

- Primary dilution—MD19 tunable rotating disc minidiluter (Matter Eng. MD19-2E).

- Secondary dilution—dilution of the primary diluted and thermally conditioned sample gas on the outlet of the evaporative tube.

- Thermoconditioner (TC)—sample heating at 300 °C.

2.4. Driving Cycles and Test Routine

3. Results and Discussion

3.1. GPFs on MPI Vehicles

3.2. Stronger Coating of 4WC

- -

- Amplitude scatter of both CPC traces in the calculation interval;

- -

- Scattering of the phase of both signals in the calculation interval;

- -

- Artifact: formation of nanoparticles from substances that pass through the cGPF as volatiles and nucleate after the GPF—an increase in PN after the cGPF.

3.3. GPFs on GDI Vehicles

3.4. PN Emissions of CNG Car

- -

- PN emissions of diesel with DPF are zero or negligible, which sets a quality benchmark;

- -

- The PN emissions of the CNG vehicle (without filtration) are higher or equal to the PN emissions of the high-emitting gasoline vehicle with GPF (V2), with the exception of idling, where the effect of lube oil consumption and aerosol composition of V2 is predominant.

4. Conclusions

- The present work demonstrated that gasoline vehicles with MPI can emit a significant amount of PN emissions.

- With GPFs, it is possible to lower the emissions below the current European limit of 6.0 × 1011#/km.

- The particle count filtration efficiency (PCFE) of the investigated GPFs (and 4WCs) is considerably lower than the PCFE of the DPFs studied. (This drawback has recently been addressed, and new filter substrates for GPFs are available that produce the same high-quality PCFEs as the DPFs [55]).

- The thicker coating of a 4WC has a visible but insignificant effect on PCFE; the more important parameter is the average pore size of the substrate.

- As filtration efficiency increases, particles in the sub-23 nm size range are increasingly eliminated; with high-quality filtration (such as DPF), there are no sub-23 nm particles at all.

- The CNG vehicle (without exhaust filtration) emits average particulate concentrations up to two orders of magnitude higher than diesel with DPF during some phases of the WLTC.

- In the real road tests of two 4WCs, no increase in weight or backpressure could be observed up to 4070 km. (After completion of the paper, operation with a GPF was continued, and positive results were confirmed until the GPF was removed at over 17,000 km).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Muñoz, M.; Haag, R.; Honegger, P.; Zeyer, K.; Mohn, J.; Comte, P.; Czerwinski, J.; Heeb, N.V. Co-formation and co-release of genotoxic PAHs, alkyl-PAHs and soot nanoparticles from gasoline direct injection vehicles. Atmos. Environ. 2018, 178, 242–254. [Google Scholar] [CrossRef]

- Tomašek, I.; Horwell, C.J.; Bisig, C.; Damby, D.E.; Comte, P.; Czerwinski, J.; Petri-Fink, A.; Clift, M.J.D.; Drasler, B.; Rothen-Rutishause, B. Respiratory hazard assessment of combined exposure to complete gasoline exhaust and respirable volcanic ash in a multicellular human lung model at the air-liquid interface. Environ. Pollut. 2018, 238, 977–987. [Google Scholar] [CrossRef] [PubMed]

- Usemann, J.; Roth, M.; Bisig, C.; Comte, P.; Czerwinski, J.; Mayer, A.; Latzin, P.; Müller, L. Gasoline particle filter reduces oxidative DNA damage in bronchial epithelial cells after whole gasoline exhaust exposure in vitro. Sci. Rep. 2018, 8, 2297. [Google Scholar] [CrossRef]

- Suarez-Bertoa, R.; Valverde, V.; Clairotte, M.; Pavlovic, J.; Giechaskiel, B.; Franco, V.; Kregar, Z.; Astorga, C. On-road emissions of passenger cars beyond the boundary conditions of the real-driving emissions test. Environ. Res. 2019, 176, 108572. [Google Scholar] [CrossRef] [PubMed]

- Giechaskiel, B.; Joshi, A.; Ntziachristos, L.; Dilara, P. European Regulatory Framework and Particulate Matter Emissions of Gasoline Light-Duty Vehicle: A Review. Catalysts 2019, 9, 586. [Google Scholar] [CrossRef]

- Health Council of the Netherlands. Diesel Engine Exhaust. Health-based Recommended Occupational Exposure Limit. No. 2019.02, The Hague, March 13, 2019. Available online: https://www.healthcouncil.nl/documents/advisory-reports/2019/03/13/diesel-engine-exhaust (accessed on 28 December 2024).

- Anses (Agence Nationale de Sécurité Sanitaire Alimentation, Environnement, Travail). Particules de L’air Ambiant Extérieur; Edition Scientifique; Anses: Maisons-Alfort, France, 2019; Available online: https://www.anses.fr/fr/system/files/AIR2014SA0156Ra-Emission.pdf (accessed on 28 December 2024).

- Packham, M.S.; Finch, A.; Campbell, B. Study of Particle Number Emissions from a Turbocharged Gasoline Direct Injection (GDI) Engine Including Data from a Fast-Response Particle Size Spectrometer; SAE Technical Paper 2011-01-1224; SAE International: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Farron, C.; Matthias, N.; Andrie, M.; Krieger, R.; Najt, P.; Narayanaswamy, K.; Solomon, A. Particulate Characteristics for Varying Engine Operation in a Gasoline Spark Ignited, Direct Injection Engine; SAE Technical Paper 2011-01-1220; SAE International: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Burtscher, H. Physical characterization of particulate emissions from diesel engines: A review. J. Aerosol Sci. 2005, 36, 896–932. [Google Scholar] [CrossRef]

- Sgro, L.A.; Sementa, P.; Vaglieco, B.M.; Rusciano, G.; D’Anna, A.; Minutolo, P. Investigating the origin of nuclei particles in GDI engine exhausts. Combust. Flame 2012, 159, 1687–1692. [Google Scholar] [CrossRef]

- Ulrich, A.; Wichser, A. Analysis of additive metals in fuel and emission aerosols of diesel vehicles with and without particle traps. Anal. Bioanal. Chem. 2003, 377, 71–81. [Google Scholar] [CrossRef]

- Mayer, A.; Czerwinski, J.; Ulrich, A.; Mooney, J.J. Metal-Oxide Particles in Combustion Engine Exhaust; SAE Technical Paper 2010-01-0792; SAE International: Warrendale, PA, USA, 2010. [Google Scholar] [CrossRef]

- Mayer, A.; Czerwinski, J.; Kasper, M.; Ulrich, A.; Mooney, J.J. Metal Oxide Particle Emissions from Diesel and Petrol Engines; SAE Technical Paper 2012-01-0841; SAE International: Warrendale, PA, USA, 2012. [Google Scholar] [CrossRef]

- Ulrich, A.; Wichser, A.; Heeb, N.; Emmenegger, L.; Comte, P.; Czerwinski, J.; Hess, A.; Kasper, M.; Mooney, J.; Mayer, A. Nano-sized Metal Oxide Emissions from IC-Engines. In Proceedings of the 15th ETH Conference on Combustion Generated Nanoparticles, Zurich, Switzerland, 27–29 June 2011; Available online: https://www.nanoparticles.ch/archive/2011_Ulrich_PO.pdf (accessed on 28 December 2024).

- Lensch-Franzen, C.; Gohl, M.; Scholl, P.; Paoloni, F. Impact of Engine Lubricant Volatility on Oil and Particle Emissions. MTZ Worldw. 2019, 80, 44–53. [Google Scholar] [CrossRef]

- Czerwinski, J.; Comte, P.; Güdel, M.; Kurzwart, M.; Mayer, A. PN-Emissions with Increased Lube Oil Consumption of GDI Car with/without GPF. J. KONES 2017, 24, 101. [Google Scholar] [CrossRef]

- Hadler, J.; Lensch-Franze, C.; Gohl, M.; Mink, T. Emission Reduction A Solution of Lubricant Composition, Calibration and Mechanical Development. MTZ 2015, 9, 30–33. [Google Scholar] [CrossRef]

- Yinhui, W.; Rong, Z.; Yanhong, Q.; Jianfei, P.; Mengren, L.; Jianrong, L.; Yusheng, W.; Min, H.; Shijin, S. The impact of fuel compositions on the particulate emissions of direct injection gasoline engine. Fuel 2016, 166, 543–552. [Google Scholar] [CrossRef]

- Sonntag, D.B.; Bailey, C.R.; Fulper, C.R.; Baldauf, R.W. Contribution of Lubricating Oil to Particulate Matter Emissions from Light-Duty Gasoline Vehicles in Kansas City. Environ. Sci. Technol. 2012, 46, 4191–4199. [Google Scholar] [CrossRef] [PubMed]

- Buchholz, B.A.; Dibble, R.W.; Rich, D.; Cheng, A.S. (Eds.) Quantifying the Contribution of Lubrication Oil Carbon to Particulate Emissions from a Diesel Engine; SAE Technical Paper 2003-01-1987; SAE International: Warrendale, PA, USA, 2003. [Google Scholar] [CrossRef]

- Bielaczyc, P.; Szczotka, A.; Woodburn, J. An overview of particulate matter emissions from modern light duty vehicles. Combust. Engines 2013, 2, 101–108. [Google Scholar] [CrossRef]

- Zahng, S.; McMahon, W. Particulated Emissions for LEV II Light-Duty Gasoline Direct Injection Vehicles; SAE Technical Paper 2012-01-0442; SAE International: Warrendale, PA, USA, 2012. [Google Scholar] [CrossRef]

- Khalek, I.A.; Bougher, T.; Jetter, J.J. Particle Emissions from a 2009 Gasoline Direct Injection Engine Using Different Commercially Available Fuels; SAE Technical Paper 2010-01-2117; SAE International: Warrendale, PA, USA, 2010. [Google Scholar] [CrossRef]

- Boger, T.; Glasson, T.; Rose, D.; Ingram-Ogunwumi, R.; Wu, H. Next Generation Gasoline Particulate Filters for Uncatalyzed Applications and Lowest Particulate Emissions; SAE Technical Paper 2021-01-0584; SAE International: Warrendale, PA, USA, 2021. [Google Scholar] [CrossRef]

- Valverde Morales, V. Exhaust Emissions of In-Use Euro 6d-TEMP and Euro 6d Vehicles in WLTP and RDE Conditions, a Comparison. SAE Int. J. Adv. Curr. Pract. Mobil. 2023, 5, 1230–1242. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Melas, A.; Valverde, V.; Otura, M.; Martini, G. Challenging Conditions for Gasoline Particulate Filters (GPFs). Catalysts 2022, 12, 70. [Google Scholar] [CrossRef]

- Lähde, T.; Giechaskiel, B.; Pavlovic, J.; Suarez-Bertoa, R.; Valverde, V.; Clairotte, M.; Martini, G. Solid particle number emissions of 56 light-duty Euro 5 and Euro 6 vehicles. J. Aerosol Sci. 2022, 159, 105873. [Google Scholar] [CrossRef]

- Kontses, A.; Triantafyllopoulos, G.; Ntziachristos, L.; Samaras, Z. Particle number (PN) emissions from gasoline, diesel, LPG, CNG and hybrid-electric light-duty vehicles under real-world driving conditions. Atmos. Environ. 2020, 222, 117126. [Google Scholar] [CrossRef]

- Available online: https://www.horiba.com/int/automotive/applications/emissions-performance-and-durability/euro-7-1/ (accessed on 28 December 2024).

- Samaras, Z.C.; Kontses, A.; Dimaratos, A.; Kontses, D.; Balazs, A.; Hausberger, S.; Ntziachristos, L.; Andersson, J.; Ligterink, N.; Aakko-Saksa, P.; et al. A European Regulatory Perspective towards a Euro 7 Proposal; SAE Technical Paper 2022-37-0032; SAE International: Warrendale, PA, USA, 2022. [Google Scholar] [CrossRef]

- Czerwinski, J.; Comte, P.; Engelman, D.; Heeb, N.; Muñoz, M.; Bonsack, P.; Hensel, V.; Mayer, A. PN-Emissions of Gasoline Cars MPI and Potentials of GPF; SAE Technical Paper 2018-01-0363; SAE International: Warrendale, PA, USA, 2018. [Google Scholar] [CrossRef]

- Dimou, I.; Kar, K.; Cheng, W. Particulate Matter Emissions from a Direct Injection Spark Ignition Engine under Cold Fast Idle Conditions for Ethanol-Gasoline Blends; SAE Technical Paper 2011-01-1305; SAE International: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Chan, T.W.; Meloche, E.; Kubsh, J.; Brezny, R.; Rosenblatt, D.; Rideout, G. Impact of Ambient Temperature on Gaseous and Particle Emissions from a Direct Injection Gasoline Vehicle and its Implications on Particle Filtration; SAE Technical Paper 2013-01-0527; SAE International: Warrendale, PA, USA, 2013. [Google Scholar] [CrossRef]

- Mathis, U.; Kaegi, R.; Mohr, M.; Zenobi, R. TEM analysis of volatile nanoparticles from particle trap equipped diesel and direct-injection spark-ignition vehicles. Atmos. Environ. 2004, 38, 4347–4355. [Google Scholar] [CrossRef]

- Lee, K.O.; Seong, H.; Sakai, S.; Hageman, M.; Rothamer, D. Detailed Morphological Properties of Nanoparticles from Gasoline Direct Injection Engine Combustion of Ethanol Blends; SAE Technical Paper 2013-24-0185; SAE International: Warrendale, PA, USA, 2013. [Google Scholar] [CrossRef]

- Coulet, B.; Rose, D.; Boger, T.; Glasson, T. Gasoline Engines with Particulate Filters. Experiences with Accumulation of Ash and Impact on Filter Performance. MTZ Worldw. 2019, 80, 42–47. [Google Scholar] [CrossRef]

- Boger, T.; Rose, D.; Nicolin, P.; Coulet, B. Field Experience with Gasoline Particulate Filter Equipped GDI Vehicles. MTZ 2017, 1, 28–35. [Google Scholar] [CrossRef]

- Rose, D.; Coulet, B.; Nicolin, P.; Boger, T.; Kunath, F. Field-Study and Durability Evaluations on GDI Vehicles Equipped with Various Gasoline Particulate Filter (GPF) Concepts. In Proceedings of the 25th Aachen Colloquium Automobile and Engine Technology, Aachen, Germany, 5-7 October 2015; RWTH Publications: Aachen, Germany, 2016; ISBN 978-3-00-052110-2. [Google Scholar]

- Kern, B.; Kunert, S. The Potential of Comprehensive Emission Control for Gasoline DI-Engines—A comparison of Different Exhaust System Options and an Outlook on Future Requirements. In Proceedings of the 24th Aachen Colloquium Automobile and Engine Technology, Aachen, Germany, 5–7 October 2015; RWTH Publications: Aachen, Germany, 2015; Volume 1267, ISBN 978-3-00-049205-1. [Google Scholar]

- Königstein, A.; Fritzsche, J.; Kettenring, K.; Ley, B.; Nolte, R.; Schaffner, P. Alternatives to Meet Future Particule Emission Standards with a Boosted SIDI Engine. In Proceedings of the 24th Aachen Colloquium Automobile and Engine Technology, Aachen, Germany, 5–7 October 2015; RWTH Publications: Aachen, Germany, 2015; Volume 1301, ISBN 978-3-00-049205-1. [Google Scholar]

- SN EN 228+A1:2018-02; Automotive Fuels—Unleaded Petrol—Requirements and Test Methods. Schweizerische Normen-Vereinigung: Zurich, Switzerland, 2018. Available online: https://www.dinmedia.de/en/standard/sn-en-228-a1/290854451 (accessed on 28 December 2024).

- SN EN 590+A1:2018; Automotive Fuels—Diesel—Requirements and Test Methods. Schweizerische Normen-Vereinigung: Zurich, Switzerland, 2018. Available online: https://connect.snv.ch/en/sn-en-590-a1-2018 (accessed on 28 December 2024).

- Available online: https://www.horiba.com/int/automotive/products/detail/action/show/Product/mexa-one-41/ (accessed on 28 December 2024).

- Available online: https://tsi.com/getmedia/46813296-bb91-4fe6-b44e-bce3df9b8a43/5867291247_Particle-Catalog_1931001_RevS_Web.pdf?ext=.pdf (accessed on 28 December 2024).

- Available online: https://tsi.com/getmedia/c2470d2c-7fcc-4a8a-8f6c-a121efab523f/Choosing-the-Right-CPC-App-Note-CPC-002-US?ext=.pdf (accessed on 28 December 2024).

- Kasper, M. The Number Concentration of Non-Volatile Particles—Dessign Study for an Instrument According to the PMP Recommendations; SAE Technical Paper 2004-01-0960; SAE International: Warrendale, PA, USA, 2004. [Google Scholar]

- Available online: https://en.wikipedia.org/wiki/Worldwide_Harmonised_Light_Vehicles_Test_Procedure (accessed on 28 December 2024).

- Available online: https://dieselnet.com/standards/cycles/adac_bab.php (accessed on 28 December 2024).

- Czerwinski, J.; Nauroy, H.; Wichser, A.; Mayer, A. Size-Selective Analysis of Nanoparticles from Diesel Engine with Fuel Traceing. In Proceedings of the TAE, 10th International Colloquium Fuels Conventional and Future Energy for Automobiles, Stuttgart, Germany, 20–22 January 2015. [Google Scholar]

- Czerwinski, J.; Kurzwart, M.; Mayer, A.; Comte, P. Particle Emissions of Modern Handheld Machines; SAE Technical Paper 2014-32-0036; SAE International: Warrendale, PA, USA, 2014. [Google Scholar] [CrossRef]

- VERT Association Filter List. Available online: www.vert-dpf.eu (accessed on 28 December 2024).

- Muñoz, M.; Haag, R.; Zeyer, K.; Mohn, J.; Comte, P.; Czerwinski, J.; Heeb, N.V. Effects of Four Prototype Gasoline Particle Filters (GPFs) on Nanoparticle and Genotoxic PAH Emissions of a Gasoline Direct Injection (GDI) Vehicle. Environ. Sci. Technol. 2018, 52, 10709–10718. [Google Scholar] [CrossRef] [PubMed]

- Stępień, Z.; Czerwinski, J.; Comte, P.; Oleksiak, S. Nanoparticle and Non-legislated Gaseous Emissions from a Gasoline Direct-Injection Car with Ethanol Blend Fuels and Detergent Additives. Enegy Fuels 2016, 30, 7268–7276. [Google Scholar] [CrossRef]

- Boger, T.; Rose, D.; He, S.; Joshi, A. Developments for future EU7 regulations and the path to zero impact emissions—A catalyst substrate and filter supplier’s perspective. Transp. Eng. 2022, 10, 100129. [Google Scholar] [CrossRef]

| V1 Fiat Panda 4 × 4 TwinAir | V2 Renault 18 Break | V3 Renault Mégane Scénic RX4 | V4 Volvo V60 T4F | V5 Opel Insignia 1.6 EcoFlex | V6 Peugeot 4008 1.6 HDi SST | V7 Audi A3 Sportback g-tron | |

|---|---|---|---|---|---|---|---|

| Number and arrangement of cylinders | 2/in line | 4/in line | 4/in line | 4/in line | 4/in line | 4/in line | 4/in line |

| Displacement cm3 | 875 | 2164 | 1998 | 1596 | 1598 | 1560 | 1395 |

| Power kW | 66.2 @ 5500 rpm | 74 @ 5000 rpm | 101.5 @ 5500 rpm | 132 @ 5700 rpm | 125 @ 6000 rpm | 84 @ 3600 rpm | 81 @ 6000 rpm |

| Torque Nm | 145 @ 1900 rpm | 162 @ 2000 rpm | 188 @ 3750 rpm | 240 @ 1600 rpm | 260 @ 1650–3200 rpm | 270 @ 1750 rpm | 200 @ 1500 rpm |

| Injection type | MPI | MPI | MPI | DI | DI | DI | DI/MPI |

| Curb weight kg | 1200 | 1110 | 1495 | 1554 | 1701 | 1462 | 1355 |

| Gross vehicle weight kg | 1585 | 1585 | 1990 | 2110 | 2120 | 2060 | 1820 |

| Drive wheel | AWD | Front-wheel drive | AWD | Front-wheel drive | Front-wheel drive | Front-wheel drive | Front-wheel drive |

| Gearbox | m6 | m5 | m5 | a6 | m6 | m6 | m6 |

| First registration | 2017 | 1985 | 2001 | 2012 | 2014 | 2013 | 2015 |

| Exh. after-treatment | Euro 6b | Euro 0 | Euro 3 | Euro 5a | Euro 5b+ | Euro 5b | Euro 6b |

| Fuel | gasoline | Diesel | CNG | ||||

| Cycle | Duration s | Distance m | Vmax km/h | amax m/s2 | amin m/s2 |

|---|---|---|---|---|---|

| WLTC | 1800 | 23,262 | 131 | 1.58 | −1.49 |

| ADAC130 | 740 | 18,755 | 130 | 6.94 | −5.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stepien, Z.; Comte, P.; Engelmann, D.; Czerwinski, J.; Mayer, A.; Rubino, L. Potential of PN Reduction in Passenger Cars with DPF and GPF. Energies 2025, 18, 494. https://doi.org/10.3390/en18030494

Stepien Z, Comte P, Engelmann D, Czerwinski J, Mayer A, Rubino L. Potential of PN Reduction in Passenger Cars with DPF and GPF. Energies. 2025; 18(3):494. https://doi.org/10.3390/en18030494

Chicago/Turabian StyleStepien, Zbigniew, Pierre Comte, Danilo Engelmann, Jan Czerwinski, Andreas Mayer, and Lauretta Rubino. 2025. "Potential of PN Reduction in Passenger Cars with DPF and GPF" Energies 18, no. 3: 494. https://doi.org/10.3390/en18030494

APA StyleStepien, Z., Comte, P., Engelmann, D., Czerwinski, J., Mayer, A., & Rubino, L. (2025). Potential of PN Reduction in Passenger Cars with DPF and GPF. Energies, 18(3), 494. https://doi.org/10.3390/en18030494