Microalga-Based Electricity Production: A Comprehensive Review

Abstract

1. Introduction

1.1. The Imperative for Sustainable Energy Sources

1.2. Economic and Social Benefits of Renewable Energy

1.3. Microalgae as a Promising Renewable Energy Source

1.4. Novelty and Future Directions

2. Microalgae as a Sustainable Energy Source

3. Methods of Microalga-Based Electricity Production

4. Efficiency and Environmental Impact

4.1. Microalgal Cultivation Efficiency

4.2. Electricity Generation Efficiency

4.3. Biomass Conversion Efficiency

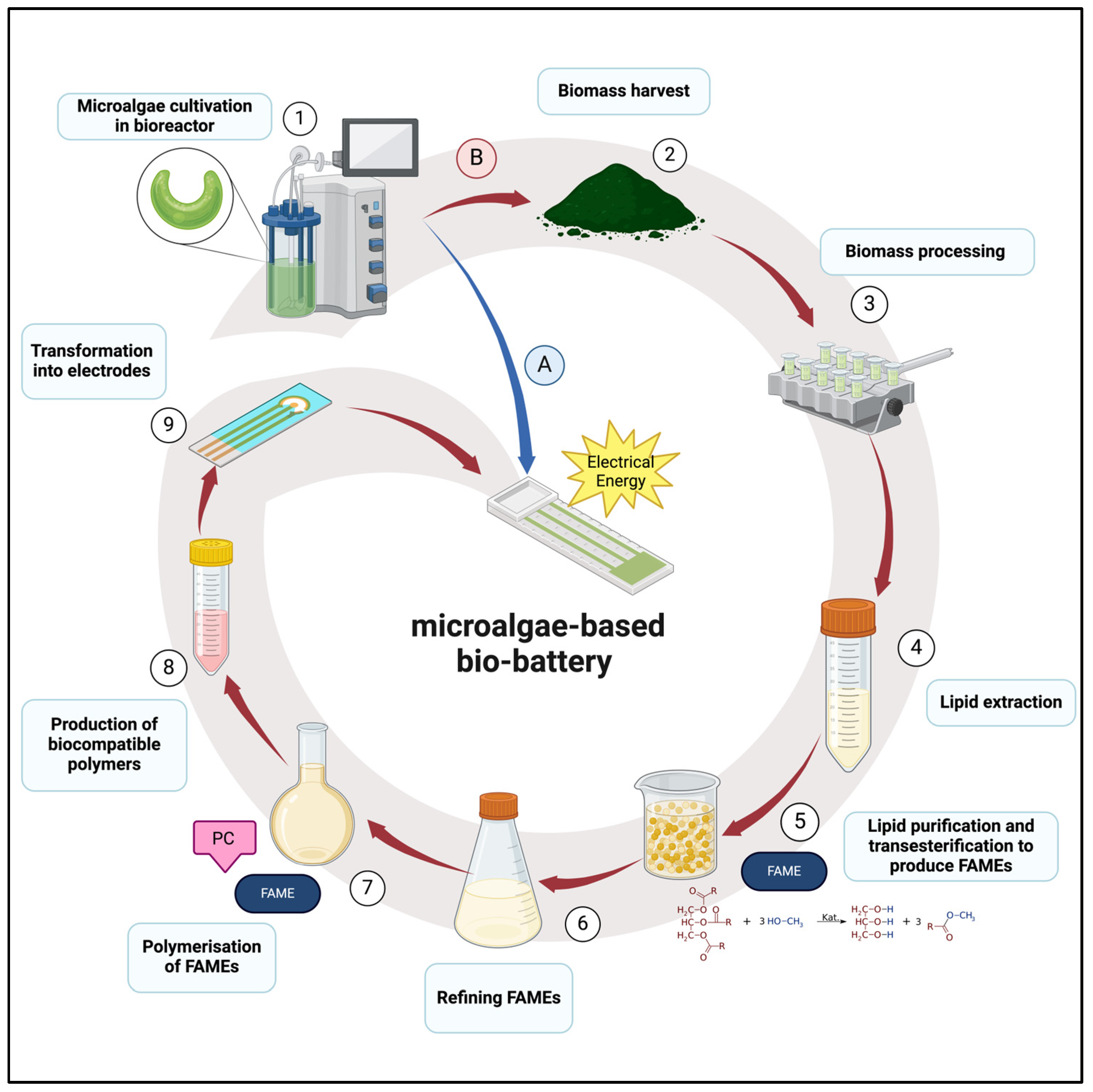

4.4. Microalga Biobattery Integration Efficiency

4.5. Electrolyte Selection

4.6. System Integration and Energy Management

4.7. Overall System Efficiency and Scalability

4.8. Environmental Impact Considerations

5. Current Research and Innovations

6. Case Studies and Applications

6.1. Bioelectricity Investments: Global Examples

6.2. Local Approaches for Bioelectricity Production: Saudi Arabia

7. Challenges and Limitations

8. Future Perspectives and Recommendations

8.1. Emerging Trends in Microalga-Based Biobatteries

8.2. Nanotechnology and AI Applications

8.3. Future Directions and Challenges

9. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Secretariat, R. Why is Renewable Energy Important? 2023. Available online: https://www.ren21.net/why-is-renewable-energy-important/ (accessed on 28 April 2024).

- ACCIONA. The Importance of Renewable Energies. Business as Unusual. 2021. Available online: https://www.acciona.com/renewable-energy/ (accessed on 28 April 2024).

- IEA. Renewables 2023. 2024. Available online: https://www.iea.org/reports/renewables-2023 (accessed on 1 June 2024).

- Jacobson, M.Z.; Delucchi, M.A.; Bauer, Z.A.; Goodman, S.C.; Chapman, W.E.; Cameron, M.A.; Bozonnat, C.; Chobadi, L.; Clonts, H.A.; Enevoldsen, P.; et al. 100% clean and renewable wind, water, and sunlight all-sector energy roadmaps for 139 countries of the world. Joule 2017, 1, 108–121. [Google Scholar] [CrossRef]

- Resch, G.; Liebmann, L.; Geipel, J.; Hasengst, F.; Hendricks, D.; Vollmer, J.; Fouquet, D. Study on 2030 Renewable Energy and Energy Efficiency Targets in the European Union; European Renewable Energies Federation: Brussels, Belgium, 2023. [Google Scholar]

- Paumann, M.; Regelsberger, G.; Obinger, C.; Peschek, G.A. The bioenergetic role of dioxygen and the terminal oxidase (s) in cyanobacteria. Biochim. Biophys. Acta (BBA)-Bioenerg. 2005, 1707, 231–253. [Google Scholar] [CrossRef] [PubMed]

- Sivaramakrishnan, R.; Suresh, S.; Kanwal, S.; Ramadoss, G.; Ramprakash, B.; Incharoensakdi, A. Microalgal Biorefinery Concepts’ Developments for Biofuel and Bioproducts: Current Perspective and Bottlenecks. Int. J. Mol. Sci. 2022, 23, 2623. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.I.; Shin, J.H.; Kim, J.D. The promising future of microalgae: Current status, challenges, and optimization of a sustainable and renewable industry for biofuels, feed, and other products. Microb. Cell Factories 2018, 17, 36. [Google Scholar] [CrossRef]

- Wang, M.; Ye, X.; Bi, H.; Shen, Z. Microalgae biofuels: Illuminating the path to a sustainable future amidst challenges and opportunities. Biotechnol. Biofuels Bioprod. 2024, 17, 10. [Google Scholar] [CrossRef]

- Medipally, S.R.; Yusoff, F.M.; Banerjee, S.; Shariff, M. Microalgae as sustainable renewable energy feedstock for biofuel production. BioMed Res. Int. 2015, 2015, 519513. [Google Scholar] [CrossRef]

- Eze, C.N.; Onyejiaka, C.K.; Ihim, S.A.; Ayoka, T.O.; Aduba, C.C.; Ndukwe, J.K.; Nwaiwu, O.; Onyeaka, H. Bioactive compounds by microalgae and potentials for the management of some human disease conditions. AIMS Microbiol 2023, 9, 55–74. [Google Scholar] [CrossRef]

- Sundaram, T.; Rajendran, S.; Gnanasekaran, L.; Rachmadona, N.; Jiang, J.-J.; Khoo, K.S.; Show, P.L. Bioengineering strategies of microalgae biomass for biofuel production: Recent advancement and insight. Bioengineered 2023, 14, 2252228. [Google Scholar] [CrossRef]

- Harun, R.; Danquah, M.K.; Forde, G.M. Microalgal biomass as a fermentation feedstock for bioethanol production. J. Chem. Technol. Biotechnol. 2010, 85, 199–203. [Google Scholar] [CrossRef]

- Gendy, T.S.; El-Temtamy, S.A. Commercialization potential aspects of microalgae for biofuel production: An overview. Egypt. J. Pet. 2013, 22, 43–51. [Google Scholar] [CrossRef]

- Benedetti, M.; Vecchi, V.; Barera, S.; Dall’osto, L. Biomass from microalgae: The potential of domestication towards sustainable biofactories. Microb. Cell Factories 2018, 17, 173. [Google Scholar] [CrossRef] [PubMed]

- Pandey, A. Microalgae biomass production for CO2 mitigation and biodiesel production. J. Microbiol. Exp. 2017, 4, 00117. [Google Scholar] [CrossRef]

- Lin, B.; Li, Q.; Liu, B.; Zhang, S.; Deng, C. Biochemistry-directed hollow porous microspheres: Bottom-up self-assembled polyanion-based cathodes for sodium ion batteries. Nanoscale 2016, 8, 8178–8188. [Google Scholar] [CrossRef]

- Çakmak, E.K.; Ugurlu, A. Enhanced biogas production of red microalgae via enzymatic pretreatment and preliminary economic assessment. Algal Res. 2020, 50, 101979. [Google Scholar] [CrossRef]

- Shokrkar, H.; Ebrahimi, S.; Zamani, M. Enzymatic hydrolysis of microalgal cellulose for bioethanol production, modeling and sensitivity analysis. Fuel 2018, 228, 30–38. [Google Scholar] [CrossRef]

- Morales, M.; Hélias, A.; Bernard, O. Optimal integration of microalgae production with photovoltaic panels: Environmental impacts and energy balance. Biotechnol. Biofuels 2019, 12, 239. [Google Scholar] [CrossRef]

- Alsarayreh, M.; Almomani, F.; Khraisheh, M.; Nasser, M.S.; Soliman, Y. Biological-Based Produced Water Treatment Using Microalgae: Challenges and Efficiency. Sustainability 2022, 14, 499. [Google Scholar] [CrossRef]

- Chisti, Y. Biodiesel from microalgae. Biotechnol. Adv. 2007, 25, 294–306. [Google Scholar] [CrossRef]

- Tan, J.S.; Lee, S.Y.; Chew, K.W.; Lam, M.K.; Lim, J.W.; Ho, S.-H.; Show, P.L. A review on microalgae cultivation and harvesting, and their biomass extraction processing using ionic liquids. Bioengineered 2020, 11, 116–129. [Google Scholar] [CrossRef]

- de Cassia Soares Brandão, B.; Oliveira, C.Y.B.; dos Santos, E.P.; de Abreu, J.L.; Oliveira, D.W.S.; da Silva, S.M.B.C.; Gálvez, A.O. Microalgae-based domestic wastewater treatment: A review of biological aspects, bioremediation potential, and biomass production with biotechnological high-value. Env. Monit Assess 2023, 195, 1384. [Google Scholar] [CrossRef]

- Gao, X.; Wu, Q.; Tang, C.; Li, S.; Li, Z.; Chen, C.; Zhu, L. Microalgae cultivation with recycled harvesting water achieved economic and sustainable production of biomass and lipid: Feasibility assessment and inhibitory factors analysis. Bioresour. Technol. 2024, 394, 130276. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Marzorati, S.; Schievano, A.; Pant, D.; Elias, S.A.; Abraham, M. Microbial Fuel Cells. In Encyclopedia of Sustainable Technologies; Abraham, M.A., Ed.; Elsevier: Oxford, UK, 2017; pp. 245–259. [Google Scholar]

- Alif, A.; Baari, M.J.; Febryanti, A. Performance of Sediment Microbial Fuel Cells in Generating Electricity using Fish Wastewater and Shrimp Wastewater as a Nutrient and Their Effect on Waste Quality. Int. J. Sci. Technol. Manag. 2023, 4, 7–13. [Google Scholar] [CrossRef]

- Rabaey, K.; Verstraete, W. Microbial fuel cells: Novel biotechnology for energy generation. Trends Biotechnol. 2005, 23, 291–298. [Google Scholar] [CrossRef] [PubMed]

- Saratale, R.G.; Kuppam, C.; Mudhoo, A.; Saratale, G.D.; Periyasamy, S.; Zhen, G.; Koók, L.; Bakonyi, P.; Nemestóthy, N.; Kumar, G. Bioelectrochemical systems using microalgae—A concise research update. Chemosphere 2017, 177, 35–43. [Google Scholar] [CrossRef] [PubMed]

- Singh, K.P.; Wareppam, B.; Raghavendra, K.G.; Singh, N.J.; de Oliveira, A.C.; Garg, V.K.; Ghosh, S.; Singh, L.H. Heterophase Grain Boundary-Rich Superparamagnetic Iron Oxides/Carbon Composite for Cationic Crystal Violet and Anionic Congo Red Dye Removal. Adv. Eng. Mater. 2023, 25, 2300354. [Google Scholar] [CrossRef]

- Cai, G.; Yang, Z.; Chen, Y.-C.; Huang, Y.; Liang, L.; Feng, S.; Zhao, J. Magnetic Bead Manipulation in Microfluidic Chips for Biological Application. Cyborg Bionic Syst. 2023, 4, 0023. [Google Scholar] [CrossRef]

- Cao, K.; Zhi, R.; Zhang, G. Photosynthetic bacteria wastewater treatment with the production of value-added products: A review. Bioresour. Technol. 2020, 299, 122648. [Google Scholar] [CrossRef]

- Sun, J.; Konda, N.V.S.N.M.; Parthasarathi, R.; Dutta, T.; Valiev, M.; Xu, F.; Simmons, B.A.; Singh, S. One-pot integrated biofuel production using low-cost biocompatible protic ionic liquids. Green Chem. 2017, 19, 3152–3163. [Google Scholar] [CrossRef]

- Ma, J.; Xu, L.; Shen, C.; Hu, C.; Liu, W.; Wen, Y. Fe-N-graphene wrapped Al2O3/pentlandite from microalgae: High Fenton catalytic efficiency from enhanced Fe3+ reduction. Environ. Sci. Technol. 2018, 52, 3608–3614. [Google Scholar] [CrossRef]

- Pan, X.; Yang, M.-Q.; Tang, Z.-R.; Xu, Y.-J. Noncovalently functionalized graphene-directed synthesis of ultralarge graphene-based TiO2 nanosheet composites: Tunable morphology and photocatalytic applications. J. Phys. Chem. C 2014, 118, 27325–27335. [Google Scholar] [CrossRef]

- Zhu, D.; Kong, H.; Sun, Z.; Xu, Y.; Han, P.; Xi, Y.; Wei, G. Recent advance in tailoring the structure and functions of self-assembled peptide nanomaterials for biomedical applications. Coord. Chem. Rev. 2023, 494, 215374. [Google Scholar] [CrossRef]

- Chen, C.Y.; Yeh, K.-L.; Aisyah, R.; Lee, D.-J.; Chang, J.-S. Cultivation, photobioreactor design and harvesting of microalgae for biodiesel production: A critical review. Bioresour Technol 2011, 102, 71–81. [Google Scholar] [CrossRef] [PubMed]

- Joshi, J.S.; Langwald, S.V.; Ehrmann, A.; Sabantina, L. Algae-Based Biopolymers for Batteries and Biofuel Applications in Comparison with Bacterial Biopolymers—A Review. Polymers 2024, 16, 610. [Google Scholar] [CrossRef] [PubMed]

- Liedel, C. Sustainable battery materials from biomass. ChemSusChem 2020, 13, 2110–2141. [Google Scholar] [CrossRef] [PubMed]

- Perumal, P.; Selvin, P.C. Red algae-derived k-carrageenan-based proton-conducting electrolytes for the wearable electrical devices. J. Solid State Electrochem. 2020, 24, 2249–2260. [Google Scholar] [CrossRef]

- Tay, Z.H.-Y.; Ng, F.-L.; Ling, T.-C.; Iwamoto, M.; Phang, S.-M. The use of marine microalgae in microbial fuel cells, photosynthetic microbial fuel cells and biophotovoltaic platforms for bioelectricity generation. 3 Biotech 2022, 12, 148. [Google Scholar] [CrossRef]

- Roxby, D.N.; Yuan, Z.; Krishnamoorthy, S.; Wu, P.; Tu, W.; Chang, G.; Lau, R.; Chen, Y. Enhanced biophotocurrent generation in living photosynthetic optical resonator. Adv. Sci. 2020, 7, 1903707. [Google Scholar] [CrossRef]

- Dasan, Y.K.; Lam, M.K.; Chai, Y.H.; Lim, J.W.; Ho, Y.C.; Tan, I.S.; Lau, S.Y.; Show, P.L.; Lee, K.T. Unlocking the potential of microalgae bio-factories for carbon dioxide mitigation: A comprehensive exploration of recent advances, key challenges, and energy-economic insights. Bioresour. Technol. 2023, 380, 129094. [Google Scholar]

- Survase, S.A.; Zebroski, R.; Bayuadri, C.; Wang, Z.; Adamos, G.; Nagy, G.; Pylkkanen, V. Membrane assisted continuous production of solvents with integrated solvent removal using liquid-liquid extraction. Bioresour. Technol. 2019, 280, 378–386. [Google Scholar] [CrossRef]

- Don, C.D.Y.A.; Babel, S. Effects of organic loading on bioelectricity and micro-algal biomass production in microbial fuel cells using synthetic wastewater. J. Water Process Eng. 2021, 39, 101699. [Google Scholar]

- Vijayan, D.; Arumugam, M. Valued products from algae grown in wastewater. In Phycology-Based Approaches for Wastewater Treatment and Resource Recovery; CRC Press: Boca Raton, FL, USA, 2021; pp. 209–246. [Google Scholar]

- Al-Gheethi, A.A.S.; Noman, E.A.; Talip, B.A.; Radin Mohamed, R.M.S. Microbial Fuel Cells: A Green and Alternative Source for Bioenergy Production. In Prospects of Fresh Market Wastes Management in Developing Countries; Springer: Berlin/Heidelberg, Germany, 2020; pp. 89–99. [Google Scholar]

- Sánchez-Zurano, A.; Rodríguez-Miranda, E.; Guzmán, J.L.; Acién-Fernández, F.G.; Fernández-Sevilla, J.M.; Grima, E.M. ABACO: A New Model of Microalgae-Bacteria Consortia for Biological Treatment of Wastewaters. Appl. Sci. 2021, 11, 998. [Google Scholar] [CrossRef]

- Fallahi, A.; Rezvani, F.; Asgharnejad, H.; Nazloo, E.K.; Hajinajaf, N.; Higgins, B. Interactions of microalgae-bacteria consortia for nutrient removal from wastewater: A review. Chemosphere 2021, 272, 129878. [Google Scholar] [CrossRef] [PubMed]

- Khoo, C.G.; Dasan, Y.K.; Lam, M.K.; Lee, K.T. Algae biorefinery: Review on a broad spectrum of downstream processes and products. Bioresour. Technol. 2019, 292, 121964. [Google Scholar] [CrossRef]

- Pandey, A.; Singh, M.P.; Kumar, S.; Srivastava, S. Phycoremediation of persistent organic pollutants from wastewater: Retrospect and prospects. In Application of Microalgae in Wastewater Treatment: Volume 1: Domestic and Industrial Wastewater Treatment; Springer: Berlin/Heidelberg, Germany, 2019; pp. 207–235. [Google Scholar]

- Chakraborty, S.; Mohanty, D.; Ghosh, S.; Das, D. Improvement of lipid content of Chlorella minutissima MCC 5 for biodiesel production. J. Biosci. Bioeng. 2016, 122, 294–300. [Google Scholar] [CrossRef]

- Gao, Y.; Mohammadifar, M.; Choi, S. Biobatteries: From Microbial Fuel Cells to Biobatteries: Moving toward On-Demand Micropower Generation for Small-Scale Single-Use Applications (Adv. Mater. Technol. 7/2019). Adv. Mater. Technol. 2019, 4, 1970039. [Google Scholar] [CrossRef]

- Chamkalani, A.; Zendehboudi, S.; Rezaei, N.; Hawboldt, K. A critical review on life cycle analysis of algae biodiesel: Current challenges and future prospects. Renew. Sustain. Energy Rev. 2020, 134, 110143. [Google Scholar] [CrossRef]

- Algae Biomass Organization. Renewable and Sustainable Commodities Derived from Algae. 2024. Available online: https://algaebiomass.org/ (accessed on 8 June 2024).

- Rusu, V.D.; Mocanu, M.; Bibiri, A.D. Determining factors of participation and success rates in research funding competitions: Case study. PLoS ONE 2022, 17, e0272292. [Google Scholar] [CrossRef]

- Kumar, A.; Hsu, L.H.-H.; Kavanagh, P.; Barrière, F.; Lens, P.N.L.; Lapinsonnière, L.; V, J.H.L.; Schröder, U.; Jiang, X.; Leech, D. The ins and outs of microorganism–electrode electron transfer reactions. Nat. Rev. Chem. 2017, 1, 24. [Google Scholar] [CrossRef]

- Ebrahimi, M. Using Soft Systems Methodology for the Analysis of Sustainable Energy Initiatives. In Applications of Soft Systems Methodology for Organizational Change; IGI Global: Hershey, PA, USA, 2021; pp. 211–232. [Google Scholar]

- Romagnoli, F.; Thedy, A.; Ievina, B.; Feofilovs, M. Life Cycle Assessment of an Innovative Microalgae Cultivation System in the Baltic Region: Results from SMORP Project. Environ. Clim. Technol. 2023, 27, 117–136. [Google Scholar] [CrossRef]

- Vitale, R. Novel Chemometric Proposals for Advanced Multivariate Data Analysis, Processing and Interpretation. Doctoral Dissertation, Universitat Politècnica de València, Valencia, Spain, 2017. [Google Scholar]

- Condorelli, G.; Favre, W.; Sciuto, M.; Ragonesi, A.; Rotoli, P.; Di Matteo, A.; Nicotra, D.; Rametta, F.; Iuvara, D.; Foti, M.; et al. Initial Results of Enel Green Power Silicon Heterojunction Factory and Strategies for Improvements. In Proceedings of the 2020 47th IEEE Photovoltaic Specialists Conference (PVSC), Calgary, ON, Canada, 15 June–21 August 2020. [Google Scholar]

- Jeong, E.; Mah, J.S. The Role of the Government in the Development of the Rechargeable Battery Industry in Korea. Perspect. Glob. Dev. Technol. 2022, 21, 202–220. [Google Scholar] [CrossRef]

- Karkar, Z.; Houache, M.S.E.; Yim, C.-H.; Abu-Lebdeh, Y. An Industrial Perspective and Intellectual Property Landscape on Solid-State Battery Technology with a Focus on Solid-State Electrolyte Chemistries. Batteries 2024, 10, 24. [Google Scholar] [CrossRef]

- Wei, J.; Yi, X.; Yang, X.; Liu, Y. Blockchain-Based Design of a Government Incentive Mechanism for Manufacturing Supply Chain Data Governance. Sustainability 2023, 15, 6968. [Google Scholar] [CrossRef]

- Kumar, S.P.; Raut, R.D.; Aktas, E.; Narkhede, B.E.; Gedam, V.V. Barriers to adoption of industry 4.0 and sustainability: A case study with SMEs. Int. J. Comput. Integr. Manuf. 2022, 36, 657–677. [Google Scholar] [CrossRef]

- Anjali Mahendra, R.K.; Du, J.; Dasgupta, A.; Beard, V.A.; Kallergis, A.; Schalch, K. Seven Transformations for More Equitable and Sustainable Cities. 2021. Available online: https://www.wri.org/research/7-transformations-more-equitable-sustainable-cities (accessed on 26 September 2024).

- Nazarov, A.; Sulimin, V.; Shvedov, V. Renewable energy sources: Global implementation experience. In Proceedings of the E3S Web of Conferences, International Annual Conference “Industrial Technologies and Engineering” (ICITE 2023), Shymkent, Kazakhstan, 9–10 November 2023; EDP Sciences: Les Ulis, France, 2023. [Google Scholar]

- Balabel, A.; Alzaed, A.N. A proposed design of eco-tourism camps for sustainable development in Taif, Saudi Arabia. In Proceedings of the 2020 Industrial & Systems Engineering Conference (ISEC), Makkah, Saudi Arabia; 9–12 April 2020; pp. 1–5. [Google Scholar]

- Al-Ismail, F.S.; Alam, S.; Shafiullah, M.; Hossain, I.; Rahman, S.M. Impacts of renewable energy generation on greenhouse gas emissions in Saudi Arabia: A comprehensive review. Sustainability 2023, 15, 5069. [Google Scholar] [CrossRef]

- Almutairi, K.; Almutairi, M.S.; Harb, K.M.; Marey, O. A thorough investigation of renewable energy development strategies through integrated approach: A case study. Energy Sources Part A Recovery Util. Environ. Eff. 2023, 45, 708–726. [Google Scholar] [CrossRef]

- Matar, W. Making Distributed Photovoltaic Generation Attractive for Households; Social Science Research Network; USAEE: Cleveland, OH, USA, 2016. [Google Scholar]

- Alnaieli, H.A.; Jadallah, A.A.; Numan, A.H. Design, Fabrication, and Experimental Analysis of a PV Panel for a Smart Sunflower System. Tikrit J. Eng. Sci. 2024, 31, 113–126. [Google Scholar] [CrossRef]

- Nizam, A.-S.; Rehan, M.; Shahzad, K.; Ismail, I.M. Development of algae biorefinery in Saudi Arabia: A source of bioenergy and bioproducts. In Proceedings of the 1st Renewable Energy Sources—Research and Business (RESRB-2016), Wrocław, Poland, 22–24 June 2016. [Google Scholar]

- Abusaq, M.J.; Zohdy, M.A. Optimizing Renewable Energy Integration through Innovative Hybrid Microgrid Design: A Case Study of Najran Secondary Industrial Institute in Saudi Arabia. Clean Technol. 2024, 6, 397–417. [Google Scholar] [CrossRef]

- Xiong, W.; Peng, Y.; Ma, W.; Xu, X.; Zhao, Y.; Wu, J.; Tang, R. Microalgae–material hybrid for enhanced photosynthetic energy conversion: A promising path towards carbon neutrality. Natl. Sci. Rev. 2023, 10, nwad200. [Google Scholar] [CrossRef]

- Sicard, C.; Perullini, M.; Spedalieri, C.; Coradin, T.; Brayner, R.; Livage, J.; Jobbágy, M.; Bilmes, S.A. CeO2 nanoparticles for the protection of photosynthetic organisms immobilized in silica gels. Chem. Mater. 2011, 23, 1374–1378. [Google Scholar] [CrossRef]

- Duan, P.; Huang, T.; Xiong, W.; Shu, L.; Yang, Y.; Shao, C.; Xu, X.; Ma, W.; Tang, R. Protection of photosynthetic algae against ultraviolet radiation by one-step CeO2 shellization. Langmuir 2017, 33, 2454–2459. [Google Scholar] [CrossRef]

- Ko, E.H.; Yoon, Y.; Park, J.H.; Yang, S.H.; Hong, D.; Lee, K.B.; Shon, H.K.; Lee, T.G.; Choi, I.S. Bioinspired, cytocompatible mineralization of silica-titania composites: Thermoprotective nanoshell formation for individual chlorella cells. Angew. Chem. Int. Ed. 2013, 52. [Google Scholar]

- Ranjbar, S.; Malcata, F.X. Is Genetic Engineering a Route to Enhance Microalgae-Mediated Bioremediation of Heavy Metal-Containing Effluents? Molecules 2022, 27, 1473. [Google Scholar] [CrossRef]

- Gupta, A.; Kang, K.; Pathania, R.; Saxton, L.; Saucedo, B.; Malik, A.; Torres-Tiji, Y.; Diaz, C.J.; Molino, J.V.D.; Mayfield, S.P. Harnessing genetic engineering to drive economic bioproduct production in algae. Front. Bioeng. Biotechnol. 2024, 12, 1350722. [Google Scholar] [CrossRef] [PubMed]

- Verma, M.L.; Dhanya, B.S.; Wang, B.; Thakur, M.; Rani, V.; Kushwaha, R. Bio-Nanoparticles Mediated Transesterification of Algal Biomass for Biodiesel Production. Sustainability 2024, 16, 295. [Google Scholar] [CrossRef]

- Iberdrola. APPLICATIONS OF NANOTECHNOLOGY. 2021. Available online: https://www.iberdrola.com/innovation/nanotechnology-applications (accessed on 22 May 2024).

- Magotra, V.K.; Kang, T.; Ahmed, A.T.A.; Inamdar, A.I.; Im, H.; Ghodake, G.; Choubey, R.K.; Kumar, V.; Kumar, S. Effect of gold nanoparticles laced anode on the bio-electro-catalytic activity and power generation ability of compost based microbial fuel cell as a coin cell sized device. Biomass Bioenergy 2021, 152, 106200. [Google Scholar] [CrossRef]

- Choi, S. Biofuel Cells and Biobatteries: Misconceptions, Opportunities, and Challenges. Batteries 2023, 9, 119. [Google Scholar] [CrossRef]

- Malik, S.; Muhammad, K.; Waheed, Y. Nanotechnology: A Revolution in Modern Industry. Molecules 2023, 28, 661. [Google Scholar] [CrossRef]

- IGB. Machine Learning for Algae Cultivation. 2024. Available online: https://www.igb.fraunhofer.de/en/about-us/spotlight/machine-learning-for-algae-cultivation.html (accessed on 22 May 2024).

- Jiang, M.; Cao, X.; Wang, Z.; Xing, M.; Sun, Z.; Wang, J.; Hu, J. A kinetic-assisted growth curve prediction method for Chlamydomonas reinhardtii incorporating transfer learning. Bioresour. Technol. 2024, 394, 130246. [Google Scholar] [CrossRef]

- Janjua, M.Y.; Azfar, A.; Asghar, Z.; Quraishi, K.S. Modeling and optimization of biomass productivity of Chlorella vulgaris using response surface methodology, analysis of variance and machine learning for carbon dioxide capture. Bioresour. Technol. 2024, 400, 130687. [Google Scholar] [CrossRef]

- Auch, M.; Kuthada, T.; Giese, S.; Wagner, A. Influence of Lithium-Ion-Battery Equivalent Circuit Model Parameter Dependencies and Architectures on the Predicted Heat Generation in Real-Life Drive Cycles. Batteries 2023, 9, 274. [Google Scholar] [CrossRef]

- Oudot, E.; Gholmane, K.; Fakra, D.A.H.; Benelmir, R. Energetic Valorization of the Innovative Building Envelope: An Overview of Electric Production System Optimization. Sustainability 2024, 16, 2305. [Google Scholar] [CrossRef]

- Mais, L.; Rodriguez, J.; Melis, N.; Vacca, A.; Mascia, M. Computational modelling as a design tool for bioelectrochemical systems. Curr. Opin. Electrochem. 2024, 44, 101460. [Google Scholar] [CrossRef]

- Sravan, J.S.; Matsakas, L.; Sarkar, O. Advances in Biological Wastewater Treatment Processes: Focus on Low-Carbon Energy and Resource Recovery in Biorefinery Context. Bioengineering 2024, 11, 281. [Google Scholar] [CrossRef] [PubMed]

- Malik, S.; Kishore, S.; Dhasmana, A.; Kumari, P.; Mitra, T.; Chaudhary, V.; Kumari, R.; Bora, J.; Ranjan, A.; Minkina, T.; et al. A Perspective Review on Microbial Fuel Cells in Treatment and Product Recovery from Wastewater. Water 2023, 15, 316. [Google Scholar] [CrossRef]

- Greenman, J.; Thorn, R.; Willey, N.; Ieropoulos, I. Energy harvesting from plants using hybrid microbial fuel cells; potential applications and future exploitation. Front. Bioeng. Biotechnol. 2024, 12, 1276176. [Google Scholar] [CrossRef]

- Koehle, A.P.; Brumwell, S.L.; Seto, E.P.; Lynch, A.M.; Urbaniak, C. Microbial applications for sustainable space exploration beyond low Earth orbit. Npj Microgravity 2023, 9, 47. [Google Scholar] [CrossRef]

| Investment Focus | Description | Example Companies/Institutions | Citations |

|---|---|---|---|

| Early-Stage Research and Development | Funding research into the optimization of microalgal strains for electricity generation, improving bioreactor design for efficient growth, and developing novel electrode materials from microalgal extracts. | Universities (e.g., Wageningen University, Arizona State University) and government research grants (e.g., US Department of Energy, European Union Horizon 2020 program). | [56,57] |

| Pilot Project Development | Supporting pilot projects testing the feasibility and scalability of microalga-powered biobatteries in real-world settings. | Cleantech startups (e.g., JouleBug(Raleigh, US), PhycoBloom (London, UK)) and venture capital firms (e.g., SOSV Chinaccelerator (Shanghai, China)). | [58,59] |

| Strategic Partnerships | Collaboration between energy companies, biotechnology firms, and research institutions to accelerate technology development and commercialization. | Established energy companies (e.g., Shell (Coventry, UK), Enel Green Power (Rome, Italy)), biorefinery companies (e.g., Green Plains Inc. (Omaha, NE, USA), Neste (Espoo, Finland)), and national laboratories (e.g., National Renewable Energy Laboratory (Denver, CO, USA), Forschungszentrum Jülich (Jülich, Germany)). | [60,61] |

| Technology Acquisition and Integration | Investments in companies developing microalga processing technologies or biobattery components that can be integrated with microalga-derived materials. | Material science companies (e.g., Covion (Newcastle, UK), BASF (Ludwigshafen, Germany)) and battery technology companies (e.g., Samsung SDI (Yongin-si, South Korea), LG Chem (Seoul, South Korea)). | [62,63] |

| Manufacturing and Supply Chain Development | Investments in building infrastructure and establishing robust supply chains for the large-scale production of microalga-based biobatteries. | Engineering firms specializing in biorefinery design, logistics companies, and government incentives for sustainable manufacturing. | [64,65] |

| Market Development and Consumer Awareness | Funding initiatives to raise awareness of microalga biobatteries and promote consumer adoption. | Sustainability advocacy groups, clean energy marketing agencies, and government subsidies for renewable-energy solutions. | [66,67] |

| Year | Investment | Description | Citation |

|---|---|---|---|

| 2020 | Eco-tourism camps with solar energy systems | A proposed design for an eco-tourism camp in Taif, Saudi Arabia, with solar energy systems used for lighting and power generation. | [68] |

| 2023 | Wind resource assessment | A wind resources assessment of Jubail Industrial City, Saudi Arabia, for industrial and commercial applications. | [69] |

| 2023 | Renewable energy development strategies | A study on selecting appropriate renewable-energy development strategies for Saudi Arabia, including solar, wind, biomass, hydroelectric, and geothermal energy. | [70] |

| 2016 | Distributed photovoltaic generation | A study on making distributed photovoltaic generation attractive for households in Saudi Arabia, including grid-connected PV systems. | [71] |

| 2023 | Optimizing residential solar PV systems | A study on optimizing residential solar PV systems via net-metering approaches, including energy storage and microgrid applications. | [72] |

| 2016 | Alga biorefinery | The development of an alga biorefinery in Saudi Arabia to produce bioenergy and bioproducts via wastewater treatment. | [73] |

| 2024 | Renewable energy integration | Optimizing renewable energy integration through innovative hybrid microgrid design, including solar photovoltaic (PV) panels, a battery storage system (BSS), and a diesel generator (DG). | [74] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alrashidi, W.; Alhazmi, S.; Sayegh, F.; Edris, S. Microalga-Based Electricity Production: A Comprehensive Review. Energies 2025, 18, 536. https://doi.org/10.3390/en18030536

Alrashidi W, Alhazmi S, Sayegh F, Edris S. Microalga-Based Electricity Production: A Comprehensive Review. Energies. 2025; 18(3):536. https://doi.org/10.3390/en18030536

Chicago/Turabian StyleAlrashidi, Wid, Safiah Alhazmi, Fotoon Sayegh, and Sherif Edris. 2025. "Microalga-Based Electricity Production: A Comprehensive Review" Energies 18, no. 3: 536. https://doi.org/10.3390/en18030536

APA StyleAlrashidi, W., Alhazmi, S., Sayegh, F., & Edris, S. (2025). Microalga-Based Electricity Production: A Comprehensive Review. Energies, 18(3), 536. https://doi.org/10.3390/en18030536