Quantitative Analysis Method of Conversion of Type of Microscopic Remaining Oil Based on CT Technology

Abstract

:1. Introduction

2. Principle of the Conversion of Remaining Oil Types

3. Results and Discussion

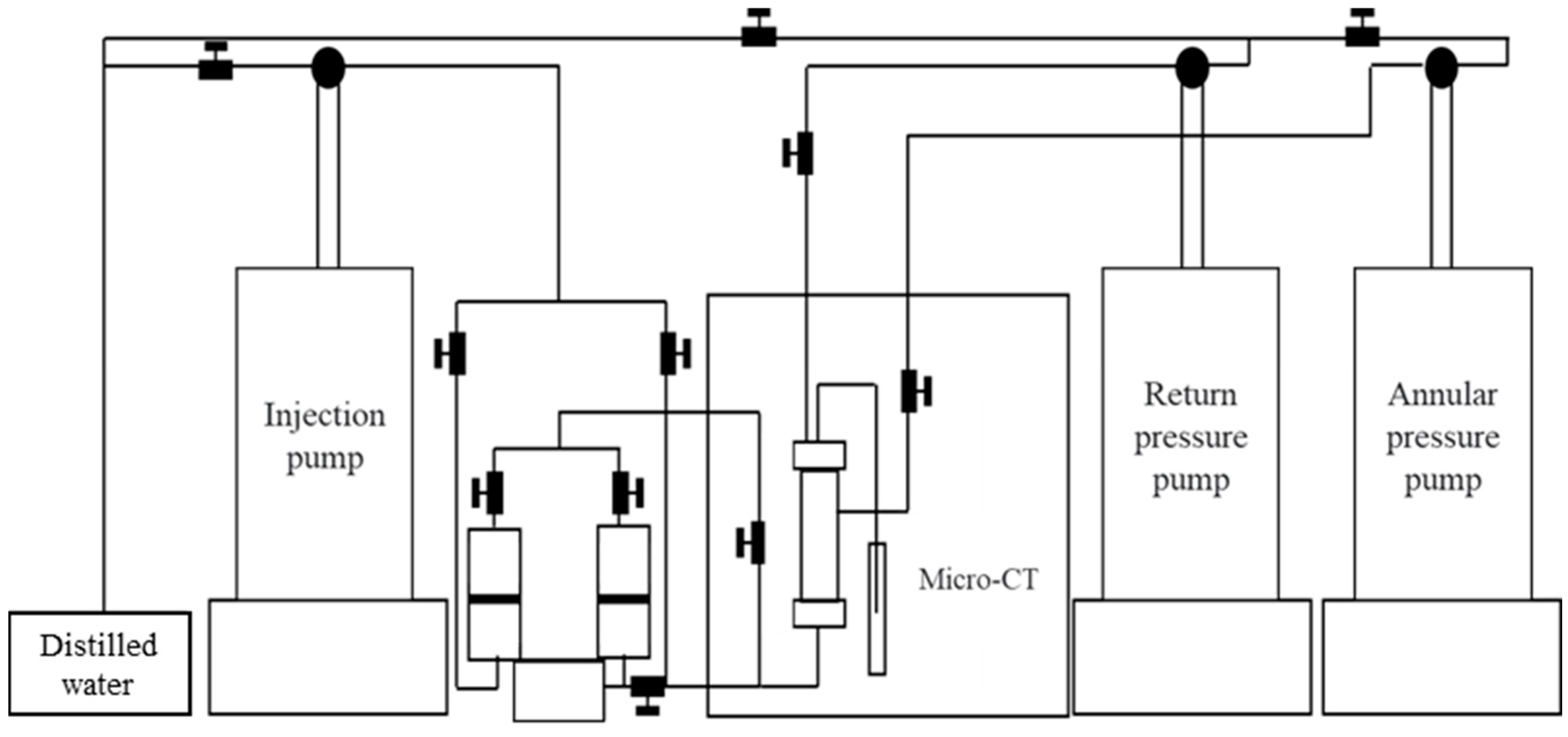

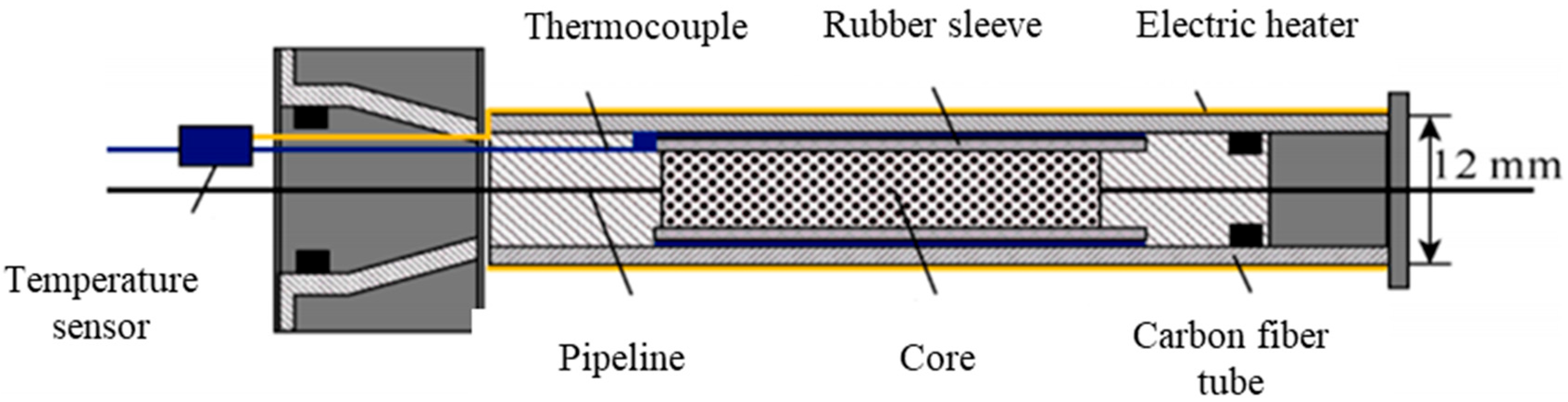

3.1. Experimental Equipment

- Microinjection system: This consists of an ISCO 100DX (TELEDYNE-ISCO, New York, NY, USA) metering pump and an intermediate container (50 mL), which is utilized to control the displacement flow rate, multiple injections, etc., in the oil–water displacement simulation experiment.

- CT scanning imaging system: This is composed of a MicroXCT-200 micron CT scanner (Xradia, New York, NY, USA). The X generated by the X-ray source in the MicroXCT-200 micron CT scanner is transformed into pixels with different resolutions by measuring the number of X-rays transmitted, thereby achieving the acquisition of the microscopic distribution image of the remaining oil inside the piston during the displacement process.

3.2. Experimental Consumables

- A piece of conventional 2.5 cm clastic fine rock sand within the low-permeability zone of the Daqing Saartu oil formation was selected. Subsequently, a small core plunger with a diameter of 8 mm was drilled on this basis. Conventional parameters such as the core permeability and porosity of the two sizes were measured, respectively (Table 1).

- 2.

- The experimental fluid comprises simulated formation water (with a salinity of 6778 mg/L), a petroleum sulfonate solution with a mass percentage of 0.2%, and simulated oil fabricated from crude oil and kerosene from Daqing No. 1 Plant. Li JJ et al. [9] discriminated the contrast of gray values of oil and water in CT scans and added 10% NaI to water. Nevertheless, the influence of brine salinity on the wettability of the plunger is neglected, which is significantly different from the actual formation water salinity in the reservoir. By adding CH2I2, the density disparity and gray value contrast between oil and water are amplified to enhance the accuracy of oil–water segmentation. The density, viscosity, and interfacial tension of the simulated oil and surfactant solution were, respectively, measured at room temperature and pressure (Table 2 and Figure 5).

3.3. Experimental Procedure

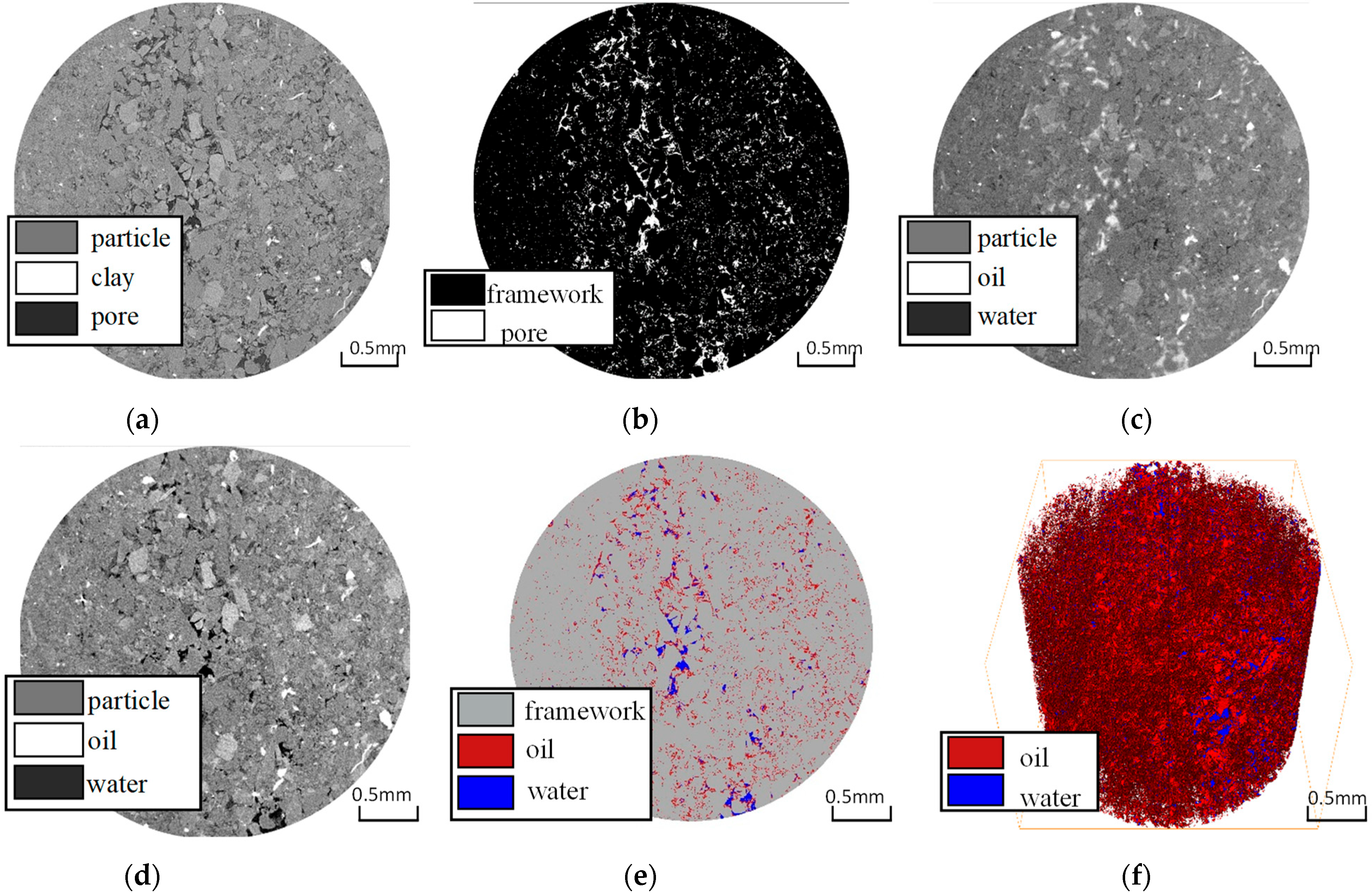

3.4. Manipulation of Images

4. Quantitative Analysis of Microscopic Residual Oil

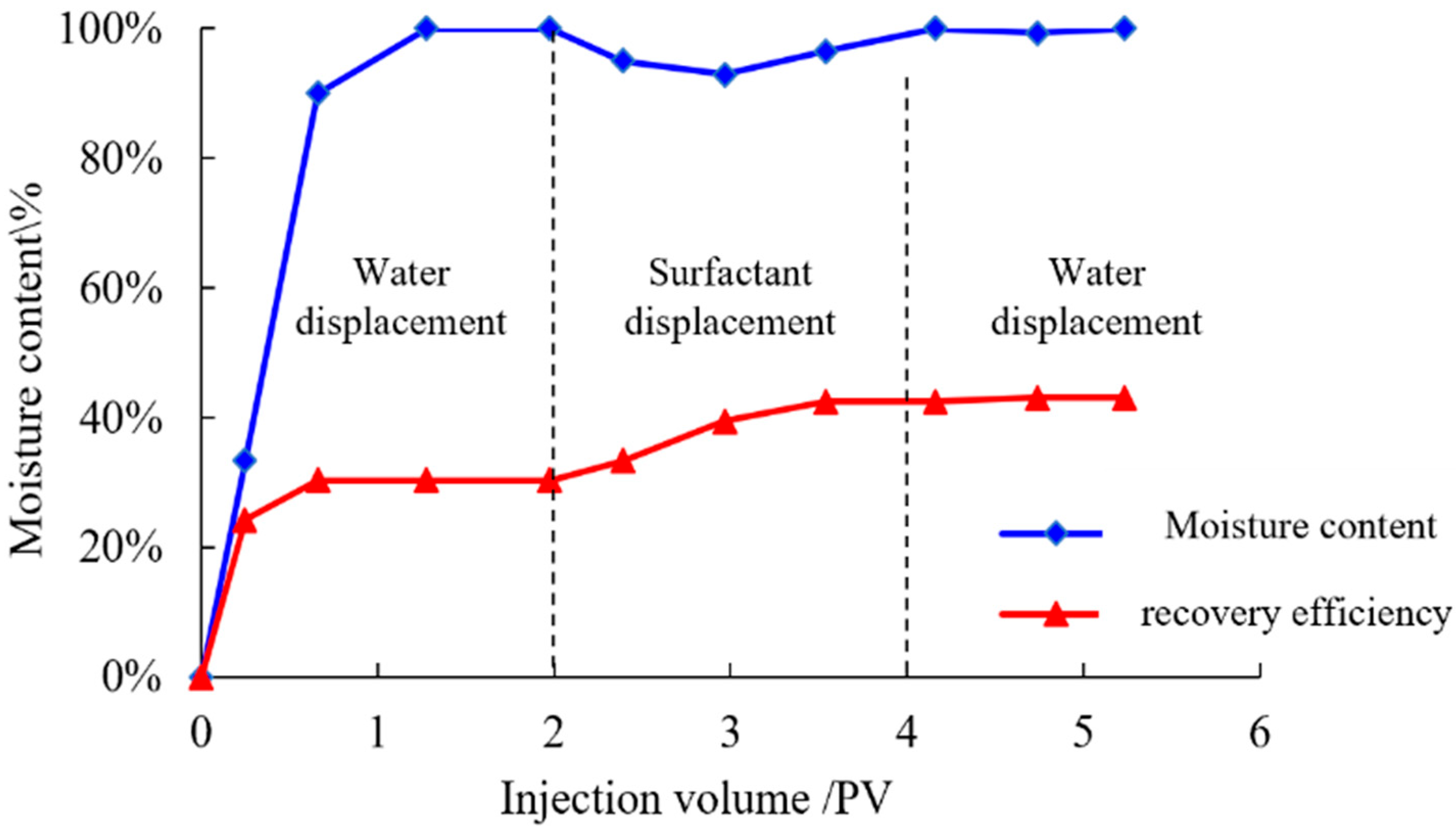

4.1. The Exploitation of Remaining Oil

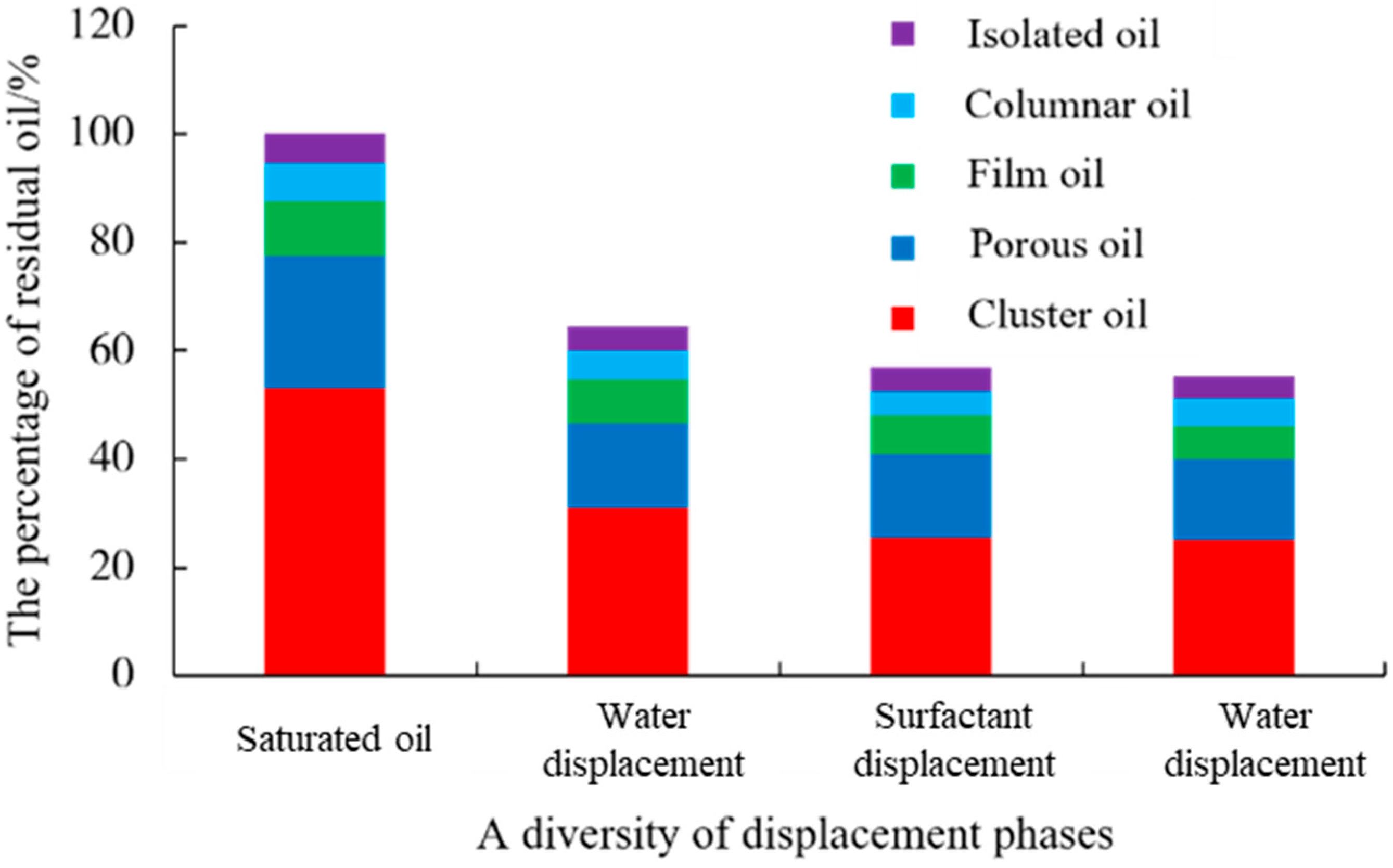

4.2. The Proportion of Remaining Oil at Each Stage

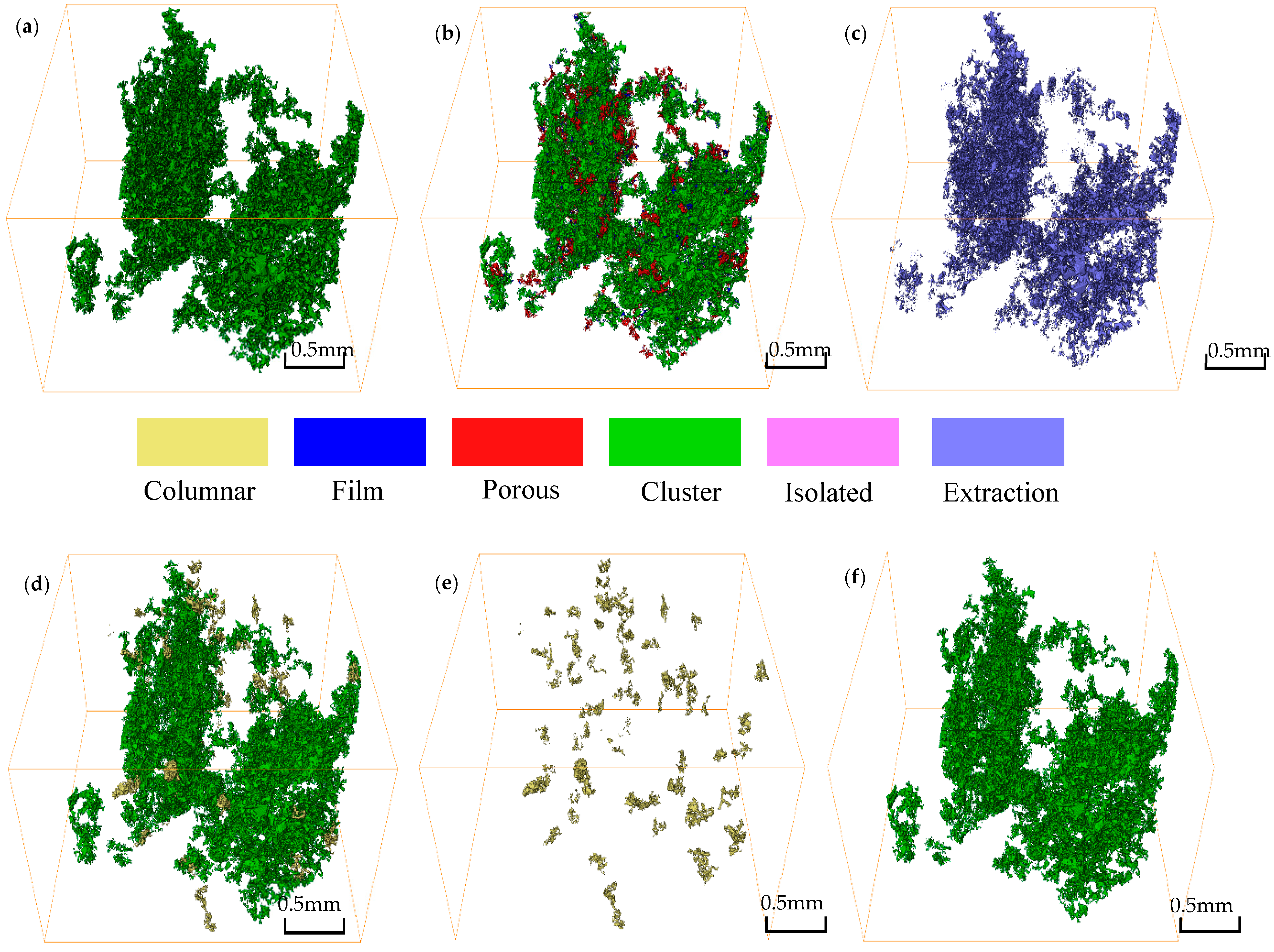

4.3. The Transformation of Micro Residual Oil Types

5. Conclusions

- The analysis approach for residual oil type transformation was established. By tracing back to the composition and direction of various remaining oils, the mutual conversion of various remaining oils at different stages was achieved based on image processing technology, and the oil displacement mechanism of different displacement media was further clarified, offering a new concept for the potential exploitation of remaining oil in the subsequent site.

- When applying the above method to the Saartu sandstone cores in Daqing, significant differences were found in the conversion rules of various remaining oils. After the displacement medium enters the large pores with good connectivity, the continuous oil phase will be gradually separated. Meanwhile, the discontinuous oil phase in the pore tubes with poor connectivity will enter the dominant channel with the displacement medium due to the influence of capillary imbibition, wetting reversal, and emulsification oil carrying performance, and the discontinuous oil phase will undergo a transformation of “coalescence”. Additionally, the surfactant’s unique ability of “micellar solubilization, emulsification, and oil carrying” shows good adaptability to the discontinuous oil phase and can transform the discontinuous-phase remaining oil into the continuous-phase remaining oil, namely columnar–film–cluster–recovery.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hou, Q.J.; He, H.Q.; Li, J.Z.; Yang, T. Recent progress and prospect of oil and gas exploration by PetroChina Company Limited. China Pet. Explor. 2018, 23, 1–13. [Google Scholar]

- Hu, W.R.; Wei, Y.; Bao, J.W. Development of the theory and technology for low permeability reservoirs in China. Pet. Explor. Dev. 2018, 45, 646–656. [Google Scholar] [CrossRef]

- Li, W.C.; Yao, G.Q.; Zhou, F.D.; Huang, Z.; Liang, J.F. Water displacing oil efficiency with cores grouped in parallel of different flow units in low-permeability reservoirs. Acta Pet. Sin. 2011, 32, 658–663. [Google Scholar]

- Hearn, C.L.; Ebanks, W.J.; Tye, R.S.; Ranganathan, V. Geological Factors Influencing Reservoir Performance of the Hartzog Draw Field, Wyoming. J. Pet. Technol. 1984, 36, 1335–1344. [Google Scholar] [CrossRef]

- Hou, J.; Qiu, M.X.; Lu, N.; Qu, Y.T.; Li, F.; Meng, X.H.; Shi, X.L. Characterization of Residual oil Microdistribution at Pore Scale Using Computerized Tomography. Acta Pet. Sin. 2014, 35, 319–325. [Google Scholar]

- Peng, H.L.; Zhou, X.P.; Yao, G.J.; Sun, L.T. Laboratory research on microscopic distribution of residual oil after polymer driving and how to improve recovery factor for reservoirs with big porous channels. Nat. Gas Explor. Dev. 2005, 28, 62–65. [Google Scholar]

- Wang, W.M.; Guo, H.K.; Sun, D.Q.; Zhang, S.Z. A study on polymer flooding by MRI techniques. Acta Pet. Sin. 1997, 18, 54–59. [Google Scholar]

- Bai, Z.Q.; Wu, S.H.; Fu, Z.G. The distribution of microcosmic remaining oils after polymer flooding in Daqing oilfield. Acta Pet. Sin. 2013, 34, 924–931. [Google Scholar]

- Li, J.J.; Liu, Y.; Gao, Y.J.; Cheng, B.Y.; Meng, F.L.; Xu, H.M. Effects of microscopic pore structure heterogeneity on the distribution and morphology of remaining oil. Pet. Explor. Dev. 2018, 45, 1043–1052. [Google Scholar] [CrossRef]

- Wang, X.W.; Yang, Z.M.; Li, H.B.; Guo, H. Microscopic Distribution of Remaining oil of ultra-low permeability reservoir by using NMR technique. J. Basic Sci. Eng. 2013, 21, 702–709. [Google Scholar]

- Song, K.P.; Li, S.J.; Fang, W.; Wu, J.W.; Mu, W.Z. Fluorescence analysis on changeable rules of microscopic remaining oil after polymer flooding. Acta Pet. Sin. 2005, 26, 92–95. [Google Scholar]

- Liu, J.J.; Liu, X.G.; Feng, X.T. Physical simulation of water-oil microcosmic flow through fractured porous media. Chin. J. Rock Mech. Eng. 2003, 22, 1646–1650. [Google Scholar]

- Ling, Z.F.; He, S.L.; Yang, W.X.; Men, C. Physical simulation on experiment of water driving by micro-model and fractal features of residual oil distribution. J. China Univ. Pet. 2006, 30, 68–71. [Google Scholar]

- Zhu, W.Y.; Tian, Y.G.; Weidong, W.; Song, Z.Y.; Han, H.Y.; Song, Y.T.; Li, C.F. Mechanisms of oil displacement by indigenous microorganism producing bio-emulsifier using microscopic modeling. J. Cent. South Univ. (Sci. Technol.) 2016, 47, 3280–3288. [Google Scholar]

- Yan, W.C.; Sun, J.M. Analysis of research present situation of microscopic remaining oil. Prog. Geophys. 2016, 31, 2198–2211. [Google Scholar]

- Zhang, S.K.; Hou, J.; Li, Z.Q.; Chen, Y.M.; Xu, Y.D. Automatic segmentation of polymer-flooding microvadose images by image processing. J. China Univ. Pet. 2005, 29, 75–78. [Google Scholar]

- Mehmain, A.; Tokan, L.A.; Prodanovic, M.; Sheppard, A.P. The Effect of Microporosity on Transport Properties in Tight Reservoirs; SPE: Richardson, TX, USA, 2011; p. 144384. [Google Scholar]

- Blunt, M.J.; Jackson, M.D.; Piri, M.; Valvatne, P.H. Detailed Physics Predictive Capabilities and Macroscopic Consequences for Porenetwork Models of Multiphase Flow. Adv. Water Resour. 2002, 25, 1069–1089. [Google Scholar] [CrossRef]

- Xu, S.Y.; Zhu, L.Z.; Wang, D.J. Dynamic simulation and evolvement model for microscopic remaining oil. Acta Pet. Sin. 2005, 34, 69–72. [Google Scholar]

- Sun, H.Q.; Sun, G.; Cheng, H.M.; Wu, S.Y. The simulation models of remaining oil distribution at super-high water cut stage of Shentuo oil field. Pet. Explor. Dev. 2002, 29, 66–68. [Google Scholar]

- Hu, X.T.; Li, Y. Study of microcosmic distribution of residual oil with stochastic simulation in networks. Acta Pet. Sin. 2000, 21, 46–51. [Google Scholar]

- Li, J.; Jiang, H.; Wang, C.; Zhao, Y.; Gao, Y.; Pei, Y.; Wang, C.; Dong, H. Pore-scale investigation of microscopic remaining oil variation characteristics in water-wet sandstone using CT scanning. J. Nat. Gas Sci. Eng. 2017, 48, 36–45. [Google Scholar] [CrossRef]

- Iglauer, S.; Lebedev, M. High pressure-elevated temperature x-ray micro-computed tomography for subsurface applications. Adv. Colloid Interface Sci. 2018, 256, 393–410. [Google Scholar] [CrossRef]

- Cheng, Z.L.; Sui, W.B.; Ning, Z.F.; Gao, Y.; Hou, Y.; Chang, C.; Li, J. Microstructure characteristics and its effects on mechanical properties of digital core. Chin. J. Rock Mech. Eng. 2018, 37, 449–460. [Google Scholar]

- Li, J.J.; Gao, Y.J.; Zhao, Y.Y.; Liu, Y.; Yu, F.W.; Su, H. One Kind of Core Holder for CT Scanning. Patent CN106706684A, 24 May 2017. [Google Scholar]

- Tong, C.B.; Cheng, S.Q.; Shi, L.H.; Xue, Y.; Shi, B. Micro-residual oil distribution experiment of periodic water injection in tight reservoir based on microfluidic model. Pet. Geol. Dev. Daqing 2024, 1–9. [Google Scholar] [CrossRef]

- Zhang, Y.; Lin, C.; Ren, L. Analysis of Microscopic Remaining Oil Based on the Fluorescence Image and Deep Learning. J. Fluoresc. 2024, 34, 1–18. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Zheng, X.; Wu, J.; Wang, Z.; Wu, J.; Wang, Q.; Gong, W.; Gai, X. Microscopic Remaining Oil Classification Method and Utilization Based on Kinetic Mechanism. Energies 2024, 17, 5467. [Google Scholar] [CrossRef]

- Sun, C.; Wang, X.; Zhao, J.; Zhang, J.; Wu, X.; Wang, W.; Yan, X. Study on the Mobilization Mechanisms of Microscopic Residual Oil in High-Water-Cut Sandstone Reservoirs. Processes 2024, 12, 1608. [Google Scholar] [CrossRef]

| Core Number | Well Number | Horizon | Diameter mm | Length mm | Permeability ×10−3 μm2 | Porosity % |

|---|---|---|---|---|---|---|

| 1 | Z44-JP204 | K2y1 | 25.2 | 108.7 | 2.13 | 21.7% |

| 2 | Z44-JP204 | K2y1 | 7.84 | 50 | 1.26 | 20.3% |

| Type of Fluid | Density g/cm3 | Viscosity mPa·s | Interfacial Tension mN/m |

|---|---|---|---|

| Simulated oil | 0.81 | 9.2 | 0.08 |

| Simulated oil containing diiodomethane | 0.87 | 9.5 | 0.09 |

| surfactant | / | 3.2 | / |

| Water Displacement | Surfactant Displacement | Water Displacement | |||||||

|---|---|---|---|---|---|---|---|---|---|

| The Type of Residual Oil | Before | After | Before | After | Before | After | |||

| Proportion (%) | Type | Proportion (%) | Proportion (%) | Type | Proportion (%) | Proportion (%) | Type | Proportion (%) | |

| Cluster oil | 53.1 | Cluster | 27 | 30.9 | Cluster | 23.97 | 25.65 | Cluster | 24.79 |

| Porous | 2.1 | Porous | 1.38 | Porous | 0.19 | ||||

| Columnar | 0 | Columnar | 0 | Columnar | 0 | ||||

| Film | 0 | Film | 0 | Film | 0 | ||||

| Isolated | 0 | Isolated | 0 | Isolated | 0 | ||||

| extraction | 24 | extraction | 4.61 | extraction | 0.41 | ||||

| Porous oil | 24.4 | Cluster | 2.8 | 15.8 | Cluster | 0.78 | 15.22 | Cluster | 0.12 |

| Porous | 12.6 | Porous | 13.41 | Porous | 14.9 | ||||

| Columnar | 1.2 | Columnar | 0.95 | Columnar | 0.1 | ||||

| Film | 0.4 | Film | 0.28 | Film | 0.04 | ||||

| Isolated | 0 | Isolated | 0 | Isolated | 0 | ||||

| extraction | 7.4 | extraction | 1.92 | extraction | 0.27 | ||||

| Columnar oil | 6.9 | Cluster | 0.4 | 5.5 | Cluster | 0.1 | 4.53 | Cluster | 0.01 |

| Porous | 0.5 | Porous | 0.14 | Porous | 0.03 | ||||

| Columnar | 3 | Columnar | 3.51 | Columnar | 5 | ||||

| Film | 1.3 | Film | 1.34 | Film | 0.14 | ||||

| Isolated | 0.1 | Isolated | 0.16 | Isolated | 0.01 | ||||

| extraction | 1.6 | extraction | 0.56 | extraction | 0.08 | ||||

| Film oil | 10.2 | Cluster | 0.5 | 7.9 | Cluster | 0.78 | 7.16 | Cluster | 0.01 |

| Porous | 0.5 | Porous | 0.09 | Porous | 0.02 | ||||

| Columnar | 1.2 | Columnar | 0.06 | Columnar | 0.07 | ||||

| Film | 5.9 | Film | 5.46 | Film | 5.95 | ||||

| Isolated | 0.4 | Isolated | 0.28 | Isolated | 0.03 | ||||

| extraction | 1.7 | extraction | 0.8 | extraction | 0.06 | ||||

| Isolated oil | 5.4 | Cluster | 0.2 | 4.5 | Cluster | 0.03 | 4.27 | Cluster | 0 |

| Porous | 0.1 | Porous | 0.2 | Porous | 0 | ||||

| Columnar | 0.1 | Columnar | 0.01 | Columnar | 0 | ||||

| Film | 0.3 | Film | 0.08 | Film | 0.01 | ||||

| Isolated | 4 | Isolated | 3.83 | Isolated | 3.89 | ||||

| extraction | 0.7 | extraction | 0.43 | extraction | 0.03 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, C.; Sun, L.; Yang, Z. Quantitative Analysis Method of Conversion of Type of Microscopic Remaining Oil Based on CT Technology. Energies 2025, 18, 563. https://doi.org/10.3390/en18030563

Feng C, Sun L, Yang Z. Quantitative Analysis Method of Conversion of Type of Microscopic Remaining Oil Based on CT Technology. Energies. 2025; 18(3):563. https://doi.org/10.3390/en18030563

Chicago/Turabian StyleFeng, Chun, Linghui Sun, and Zhengming Yang. 2025. "Quantitative Analysis Method of Conversion of Type of Microscopic Remaining Oil Based on CT Technology" Energies 18, no. 3: 563. https://doi.org/10.3390/en18030563

APA StyleFeng, C., Sun, L., & Yang, Z. (2025). Quantitative Analysis Method of Conversion of Type of Microscopic Remaining Oil Based on CT Technology. Energies, 18(3), 563. https://doi.org/10.3390/en18030563