Optimization of Well Locations and Trajectories: Comparing Sub-Vertical, Sub-Horizontal and Multi-Lateral Well Concepts for Marginal Geothermal Reservoir in The Netherlands

Abstract

1. Introduction

2. Methodology

2.1. Optimization Approach

- Generate an ensemble of base case (dynamic) simulation models of the geothermal reservoir to represent the inherent uncertainty associated with geological parameters:

- a.

- Construct a 3D static geological model accounting for uncertain reservoir flow properties;

- b.

- Assemble an ensemble of reservoir model realizations following prescribed production constraints.

- Define the well trajectory optimization problem:

- a.

- Specify the optimization variables (here, well trajectories and locations) and their optimization constraints;

- b.

- Set economic parameters of techno-economic objective function.

- Perform well trajectory optimization experiments for different well concepts:

- a.

- Experiment 1: sub-vertical wells;

- b.

- Experiment 2: sub-horizontal wells;

- c.

- Experiment 3: multi-lateral wells (with 3 branches).

- Analyze and compare the results of the optimization experiments performed in (3) to derive case-specific insights and recommendations for well concept selection.

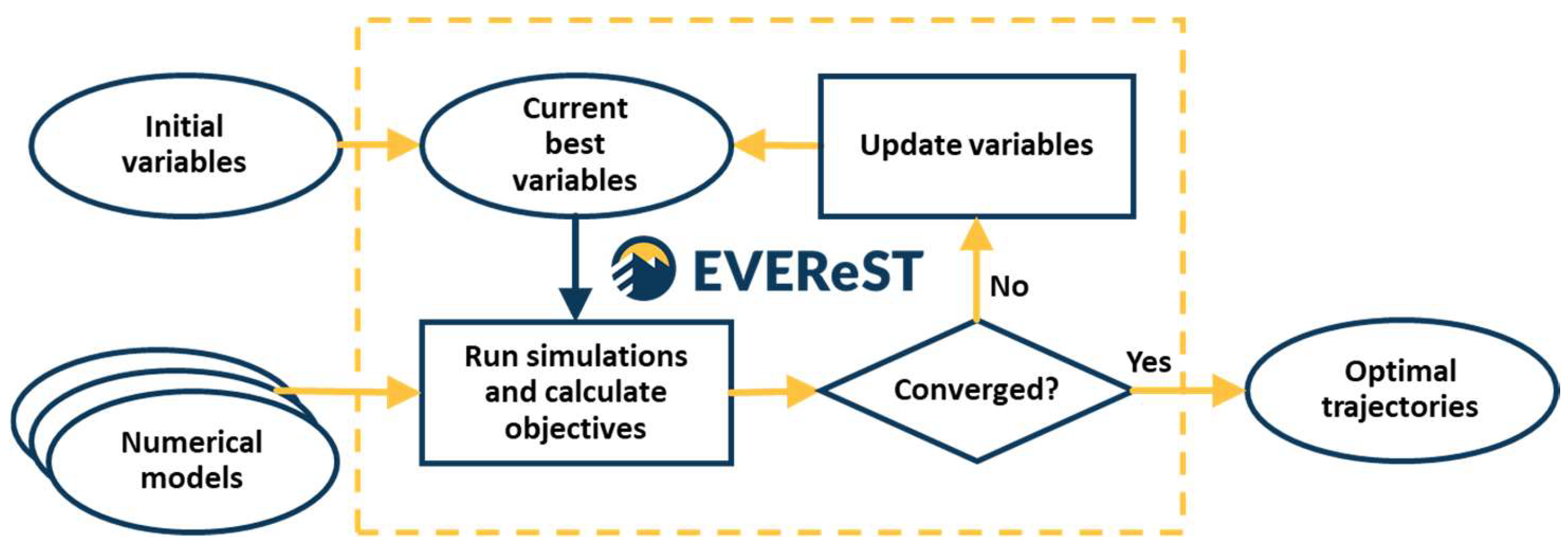

2.2. Numerical Optimization Framework

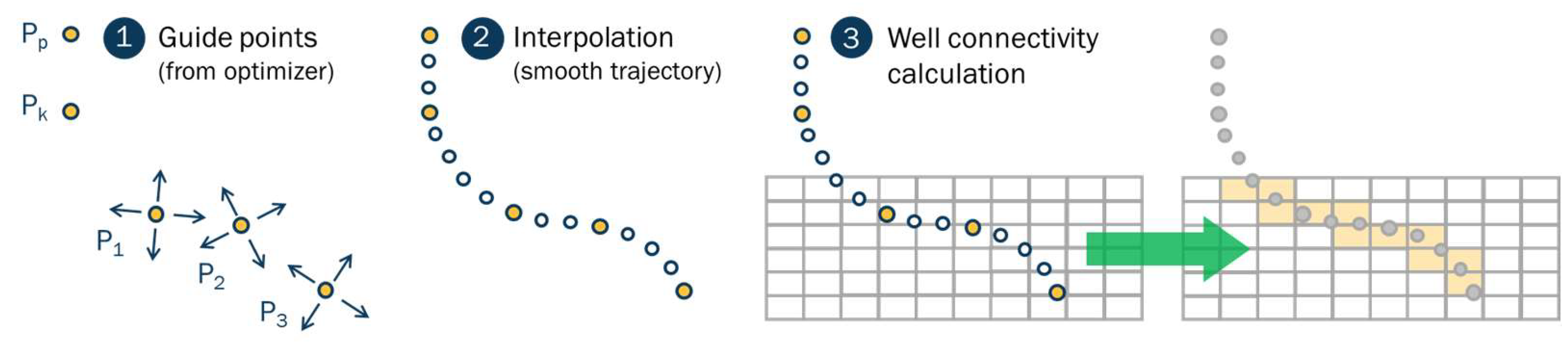

2.3. Parametrization of Well Trajectories

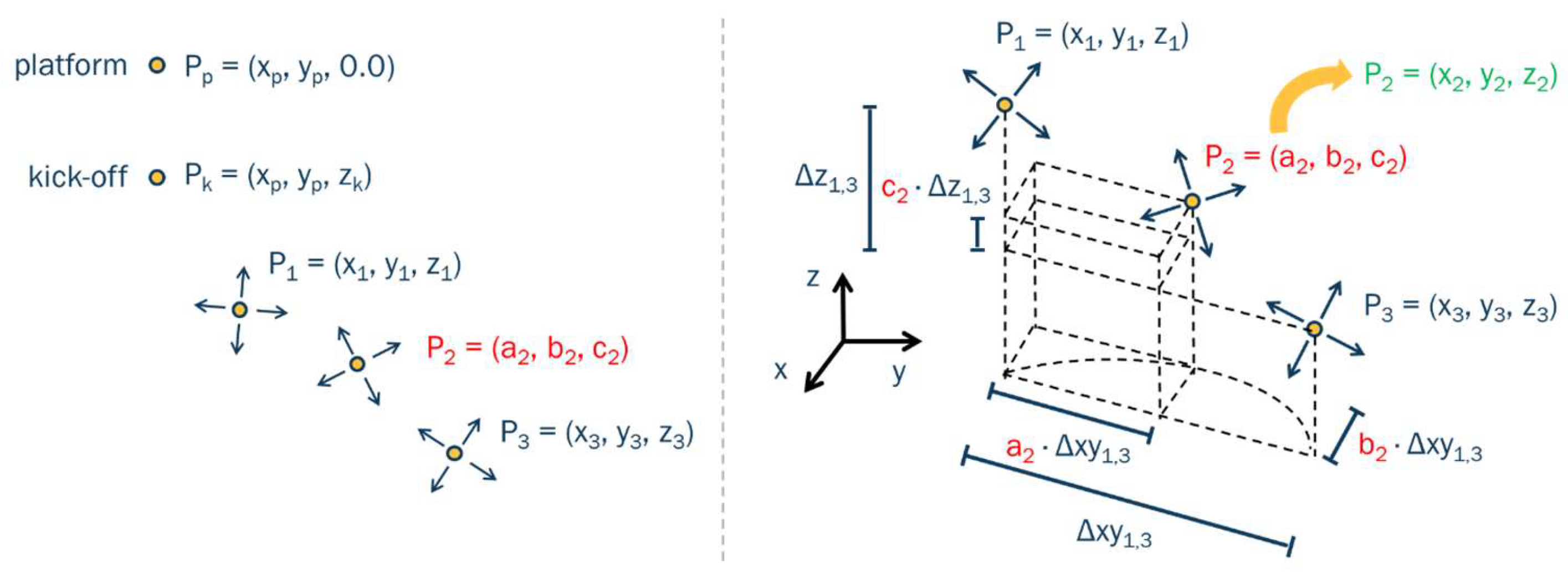

2.3.1. Standard Wells

2.3.2. Multi-Lateral Wells

3. Case Study

3.1. Surface Drilling Location

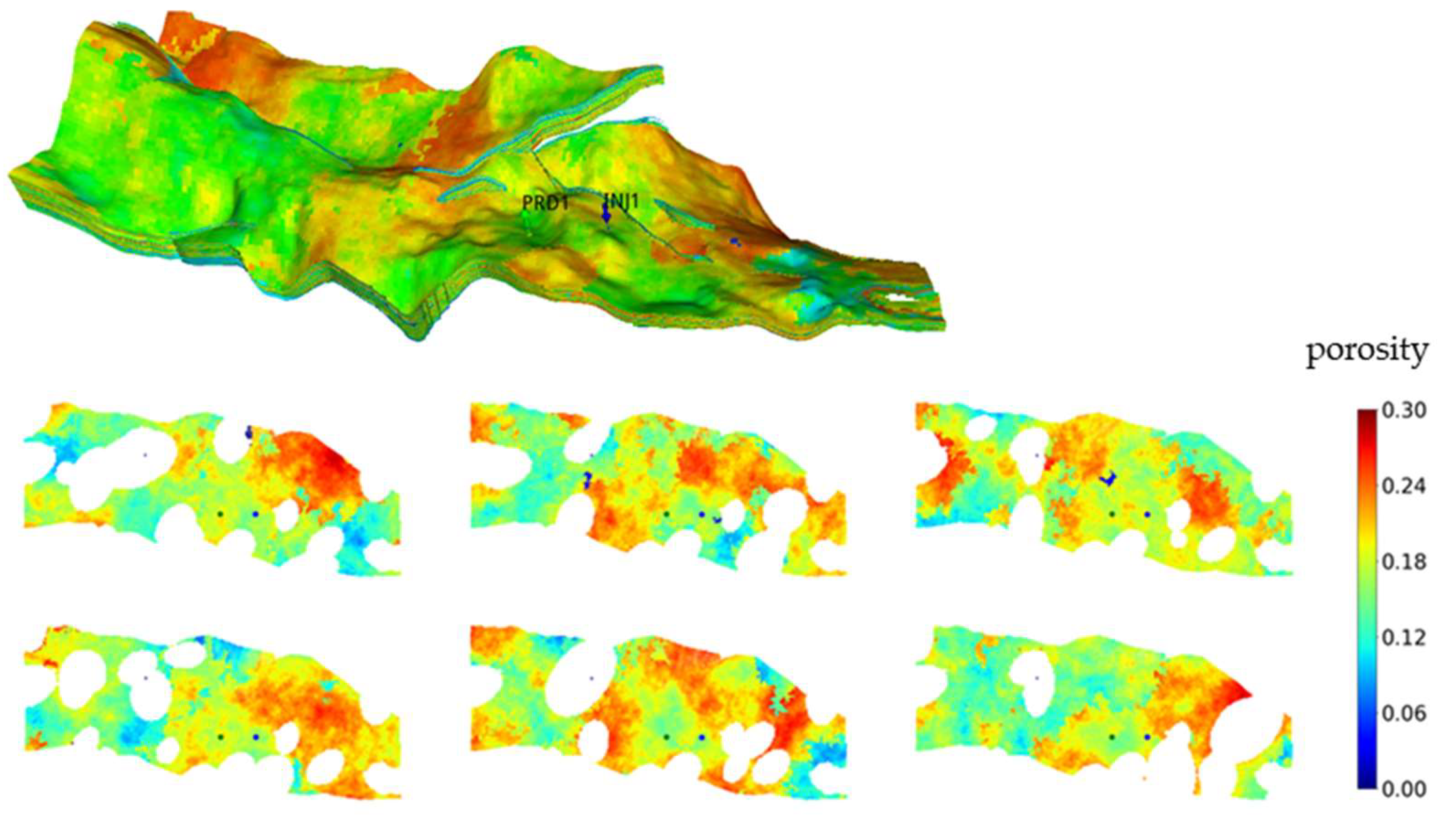

3.2. Geological Characterization

3.3. Reservoir Simulation Model

3.4. Economic Model

4. Results

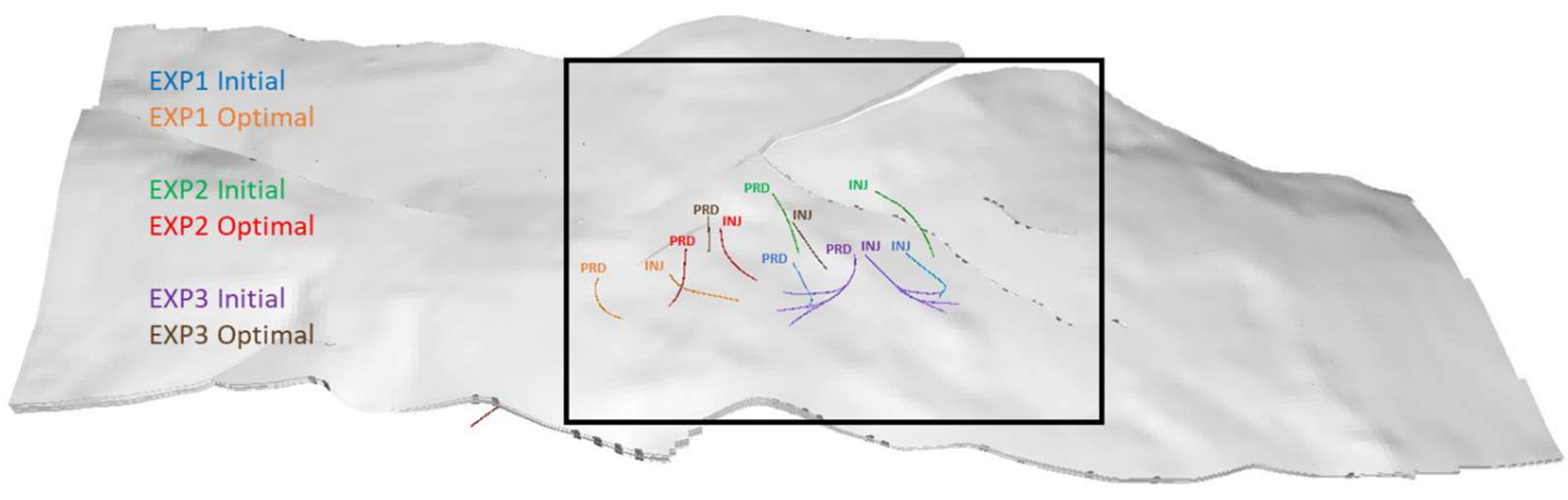

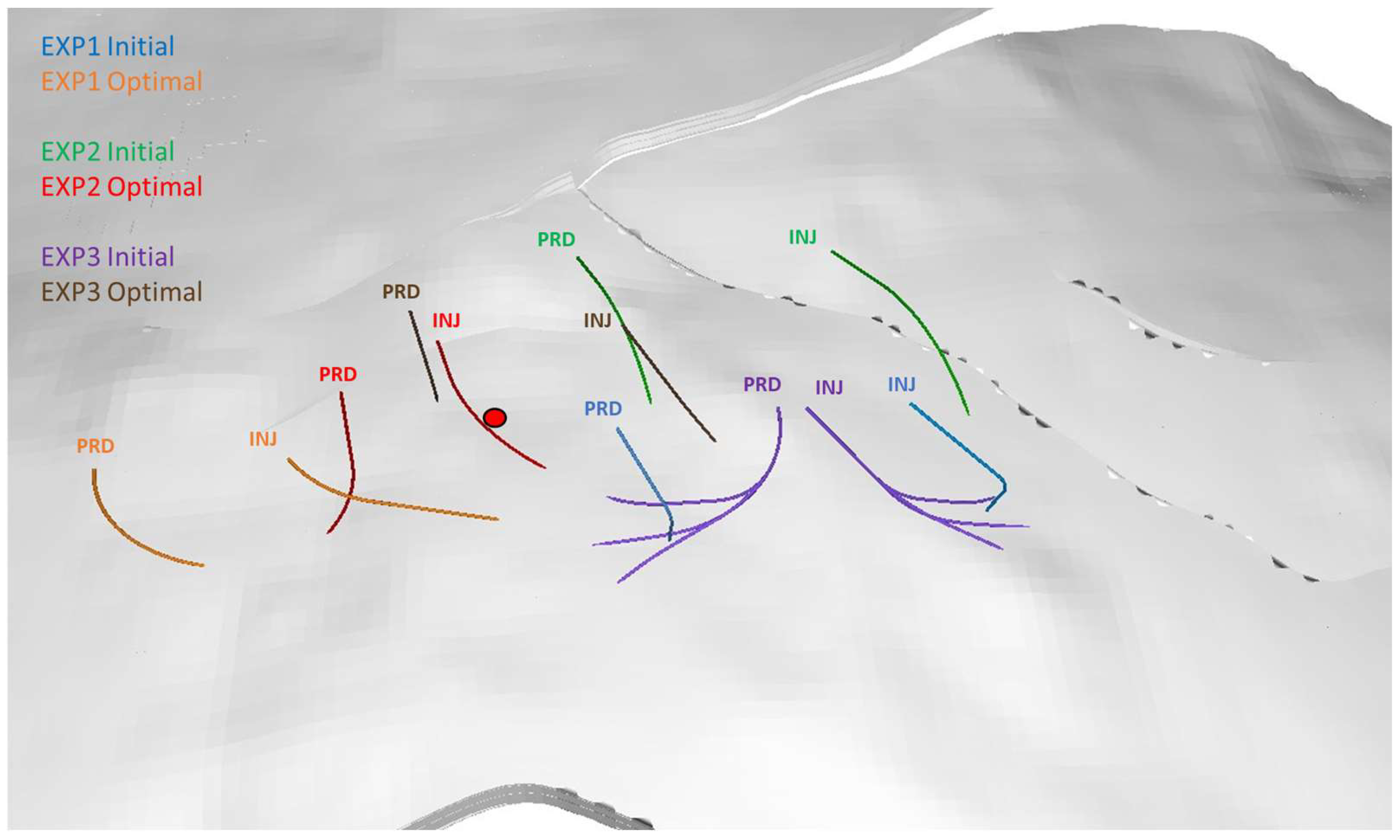

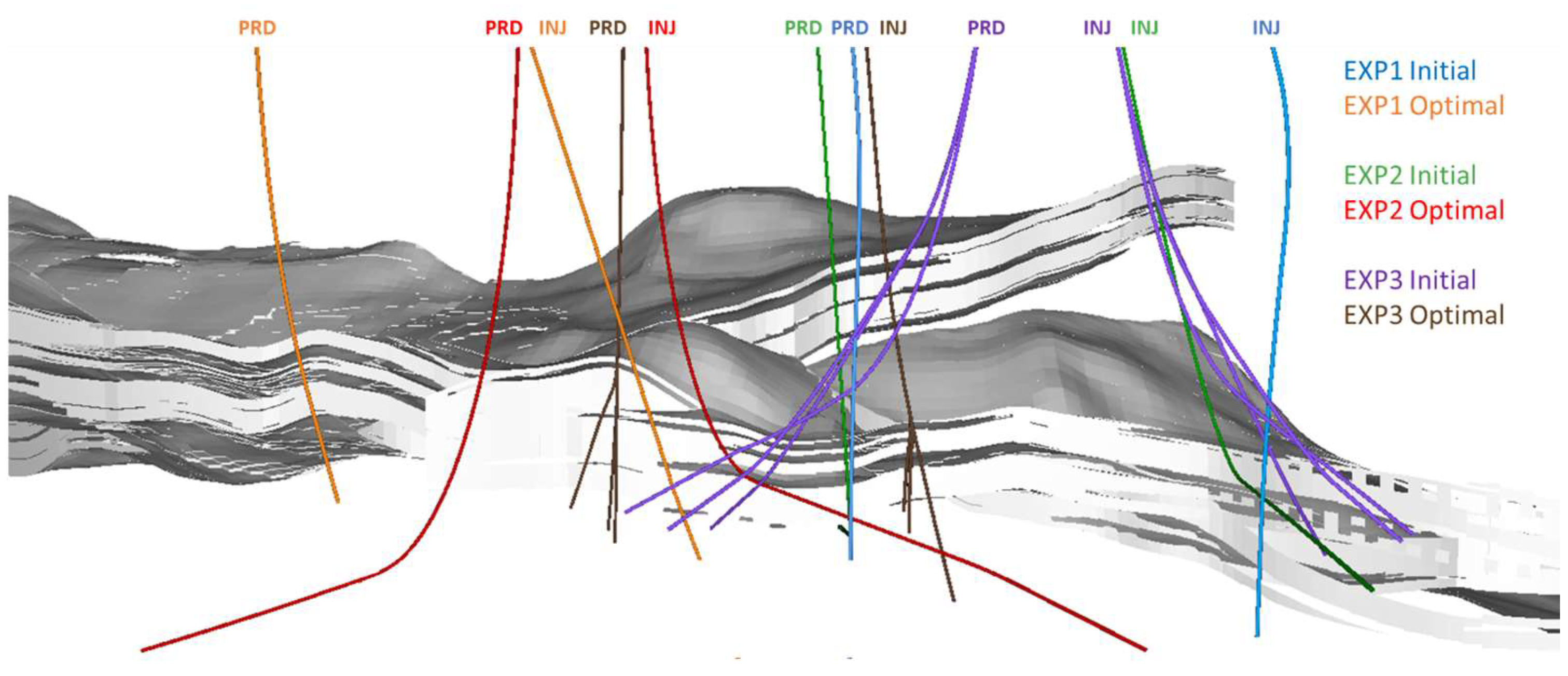

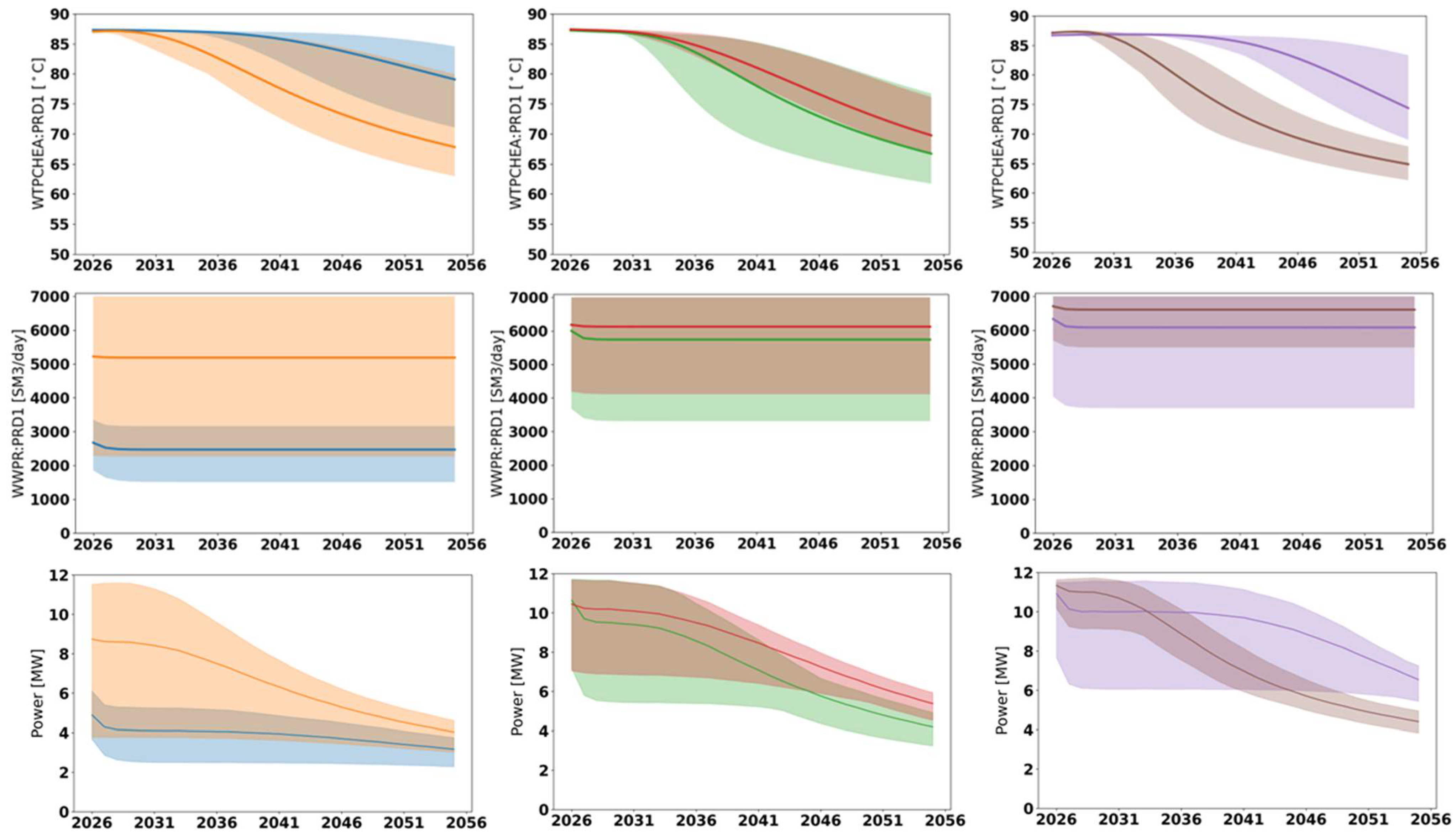

4.1. Optimization Experiments

4.2. Discussion

- The optimization experiments performed in this study assume a certain production rate target for the doublet, which was selected based on realistically achievable volumetric rates for the considered reservoir setting with typical wellbore equipment (e.g., completions and ESPs). The obtained results point to the fact that the defined target limit could be too constraining for the case with multi-lateral wells. Future studies should consider investigating the sensitivity of these results to a broader range of realistically achievable rate targets by multi-lateral wells.

- The pressure drop along the well section within the reservoir has not been taken into consideration in this study. This could be included in future studies by activating the multi-segment well option in the OPM-Flow reservoir simulator used here. Depending on flow rate conditions and wellbore geometrical characteristics (e.g., diameter, roughness), this effect could be important, especially for long sub-horizontal wells and multi-lateral well branches.

- Three cases have been considered where both wells of the doublet followed the same well concept, but in principle it would be possible to have cases where the producer and injector have different concepts (e.g., a sub-horizontal producer with a multi-lateral injector).

- The case with multi-lateral wells has assumed multi-laterals with three branches, but in a more general case, the number of branches is also a choice to be made, and therefore potentially an additional variable to optimize.

- While the techno-economic performance of the various well concepts has taken into account the production response of the reservoir, the wellbore stability risks (potentially different for each well concept and well geometry) have not been quantified. If such risks can be modeled and more detailed drilling constraints can be defined, the optimization framework could then be extended to a more holistic and realistic exercise for searching for well designs that satisfy both production and wellbore stability aspects.

5. Conclusions

- For each well concept, optimization allowed us to significantly improve the techno-economic performance of the doublet system in the Zwolle site by changing the locations and trajectories of both wells (see Table 2).

- Optimized doublet configurations led to a decrease in LCOE from 6.5–9 EURct/kWh to 5–5.5 EURct/kWh, based on the considered economic assumptions.

- The optimized well locations are significantly different to the ones from the engineering-based initial guess and reveal a trend in the location of optimal development areas. This suggests that it is not only the well concept (i.e., the shape or type of wells), but the combination of well concept and well location that determine the techno-economic performance of the doublet.

- The optimized subsurface targets are considered reachable through drilling from the designated surface location.

- Sub-horizontal and multi-lateral well concepts are the most suitable, outperforming the sub-vertical choice in this case.

- The sub-horizontal and multi-lateral concept resulted in similar NPV and LCOE on average across the geological realizations; however, the multi-lateral solution delivers the lowest economic risk (reduced spread in NPV and LCOE).

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Smith, D.P. Fitting geothermal energy into the energy transition. Neth. J. Geosci. 2019, 98, e6. [Google Scholar] [CrossRef]

- Yang, T.; Liu, W.; Kramer, G.J.; Sun, Q. Seasonal thermal energy storage: A techno-economic literature review. Renew. Sustain. Energy Rev. 2021, 139, 110732. [Google Scholar] [CrossRef]

- European Technology and Innovation Platform on Geothermal (ETIP-G). Strategic Research and Innovation Agenda. 2023. Available online: https://etip-geothermal.eu/front/wp-content/uploads/SRIA_2023_Final_ForWeb_compressed.pdf (accessed on 15 September 2024).

- Van Wees, J.D.; Kronimus, A.; van Putten, M.; Pluymaekers, M.P.D.; Mijnlieff, H.; van Hooff, P.; Obdam, A.; Kramers, L. Geothermal aquifer performance assessment for direct heat production—Methodology and application to Rotliegend aquifers. Neth. J. Geosci. 2012, 91, 651–665. [Google Scholar] [CrossRef]

- Van Wees, J.D.; Veldkamp, H.; Brunner, L.; Vrijlandt, M.; de Jong, S.; van Langen, C.; Heijnen, N.; Peijster, J. Accelerating geothermal development with a play-based portfolio approach. Neth. J. Geosci. 2020, 99, e5. [Google Scholar] [CrossRef]

- Vrijlandt, M.; Struijk, E.L.M.; Brunner, L.H.; Veldkamp, J.G.; Witmans, N.; Maljers, D.; van Wees, J.D. ThermoGIS update: A renewed view on geothermal potential in the Netherlands. In Proceedings of the European Geothermal Congress, The Hague, The Netherlands, 11–14 June 2019. [Google Scholar]

- Yeten, B.; Durlofsky, L.J.; Aziz, K. Optimization of Nonconventional Well Type, Location, and Trajectory. SPE J. 2003, 8, 200–210. [Google Scholar] [CrossRef]

- Jesmani, M.; Bellout, M.C.; Hanea, R.G.; Foss, B.A. Well placement optimization subject to realistic field development constraints. Comput. Geosci. 2016, 20, 1185–1209. [Google Scholar] [CrossRef]

- Barros, E.G.D.; Chitu, A.; Leeuwenburgh, O. Ensemble-based well trajectory and drilling schedule optimization—Application to the Olympus benchmark model. Comput. Geosci. 2020, 24, 2095–2109. [Google Scholar] [CrossRef]

- Akın, S.; Kok, M.V.; Uraz, I. Optimization of well placement geothermal reservoirs using artificial intelligence. Comput. Geosci. 2010, 36, 776–785. [Google Scholar] [CrossRef]

- Ansari, E.; Hughes, R.; White, C.D. Well Placement Optimization for Maximum Energy Recovery from Hot Saline Aquifers. In Proceedings of the 39th Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 24–26 February 2014. [Google Scholar]

- Chen, M.; Tompson, A.F.B.; Mellors, R.J.; Abdalla, O. An efficient optimization of well placement and control for a geothermal prospect under geological uncertainty. Appl. Energy 2015, 137, 352–363. [Google Scholar] [CrossRef]

- Zhang, S.; Jiang, Z.; Zhang, S.; Zhang, Q.; Feng, G. Well placement optimization for large-scale geothermal energy exploitation considering nature hydro-thermal processes in the Gonghe Basin, China. J. Clean. Prod. 2021, 317, 128391. [Google Scholar] [CrossRef]

- Schulze-Riegert, R.; Davies, R.; Coronado, J.; Hug, C.; Joonnekindt, J.P.; Mulyani, S.; Pradana, A.; Intani, R.G.; Golla, G.; Gunderson, R.; et al. Well Placement Optimization for Geothermal Reservoir Under Subsurface Uncertainty. In Proceedings of the ECMOR 2022, The Hague, The Netherlands, 5–7 September 2022. [Google Scholar] [CrossRef]

- Hui, G.; Chen, Z.; Schultz, R.; Chen, S.; Song, Z.; Zhang, Z.; Song, Y.; Wang, H.; Wang, M.; Gu, F. Intricate unconventional fracture networks provide fluid diffusion pathways to reactivate pre-existing faults in unconventional reservoirs. Energy 2023, 282, 128803. [Google Scholar] [CrossRef]

- Szklarz, S.P.; Barros, E.G.D.; Khoshnevis Gargar, N.; Peeters, S.H.J.; van Wees, J.D.; van Pul-Verboom, V. Geothermal field development optimization under geomechanical constraints and geological uncertainty: Application to a reservoir with stacked formations. Geothermics 2024, 123, 103094. [Google Scholar] [CrossRef]

- Schulte, D.O.; Arnold, D.; Geiger, S.; Demyanov, V.; Sass, I. Multi-objective optimization under uncertainty of geothermal reservoirs using experimental design-based proxy models. Geothermics 2020, 86, 101792. [Google Scholar] [CrossRef]

- Babaei, M.; Norouzi, A.M.; Nick, H.M.; Gluyas, J. Optimisation of heat recovery from low-enthalpy aquifers with geological uncertainty using surrogate response surfaces and simple search algorithms. Sustain. Energy Technol. Assess. 2022, 49, 101754. [Google Scholar] [CrossRef]

- Fonseca, R.M.; Chen, B.; Jansen, J.D.; Reynolds, A.C. A stochastic simplex approximate gradient (StoSAG) for optimization under uncertainty. Int. J. Numer. Methods Eng. 2017, 109, 1756–1776. [Google Scholar] [CrossRef]

- Lu, R.; Forouzanfar, F.; Reynolds, A.C. Bi-Objective Optimization of Well Placement and Controls Using StoSAG. In Proceedings of the SPE Reservoir Simulation Conference, Montgomery, TX, USA, 20–22 February 2017. [Google Scholar] [CrossRef]

- Chen, B.; Reynolds, A.C. CO2 water-alternating-gas injection for enhanced oil recovery: Optimal well controls and half-cycle lengths. Comput. Chem. Eng. 2018, 113, 44–56. [Google Scholar] [CrossRef]

- Hanea, R.G.; Bjorlykke, O.P.; Hashmi, Y.; Feng, T.; Fonseca, R.M. Robust Multi-Objective Field Development Optimization for the Mariner Asset. In Proceedings of the SPE Reservoir Simulation Conference, Galveston, TX, USA, 10–11 April 2019. [Google Scholar] [CrossRef]

- Barros, E.G.D.; Fonseca, R.M.; de Moraes, R.J. Production optimisation under uncertainty with automated scenario reduction: A real-field case application. In Proceedings of the SPE Reservoir Characterisation and Simulation Conference and Exhibition, Abu Dhabi, United Arab Emirates, 17–19 September 2019. [Google Scholar] [CrossRef]

- Barros, E.G.D.; Ruan, P.; Ishmuratov, R.; Hopman, J.; Fonseca, R.M. Hydraulic fracture stage design optimization of a dry gas field in the North Sea. In Proceedings of the EAGE 2020 Annual Conference & Exhibition Online, 18–20 December 2020. [Google Scholar] [CrossRef]

- Barros, E.G.D.; Szklarz, S.P.; Khoshnevis Gargar, N.; Hopman, J.; Zirotti, G.; Bascialla, G.; Ramsay, T.S.; Fonseca, R.M. Field Development Optimization with Stochastic Gradient Method: Application to a Multi-Reservoir Carbonate Field in the Middle East. In Proceedings of the SPE Reservoir Characterisation and Simulation Conference and Exhibition, Abu Dhabi, United Arab Emirates, 24–26 January 2023. [Google Scholar] [CrossRef]

- Barros, E.G.D.; Szklarz, S.P.; Hopman, J.; Hopstaken, K.; Gonçalves da Silva, J.P.; Bjørlykke, O.P.; Rios, V.; Videla, J.; Oliveira, R.; Hanea, R.G. Well Swapping and Conversion Optimization Under Uncertainty Based on Extended Well Priority Parametrization. In Proceedings of the Offshore Technology Conference Brasil, Rio de Janeiro, Brazil, 24–26 October 2023. [Google Scholar] [CrossRef]

- Chen, Y.; Oliver, D.S.; Zhang, D. Efficient ensemble-based closed-loop production optimization. SPE J. 2009, 14, 634–645. [Google Scholar] [CrossRef]

- Taylor, H.L.; Mason, M.C. A Systematic Approach to Well Surveying Calculations. SPE J. 1972, 12, 474–488. [Google Scholar] [CrossRef]

- Gaupp, R.; Okkerman, J. Reservoir quality of Rotliegend sandstones in the northern Netherlands-A review. In The Permian Rotliegend of the Netherlands; Grötsch, J., Gaupp, R., Eds.; SEPM Society for Sedimentary Geology: Tulsa, OK, USA, 2011; pp. 193–228. [Google Scholar]

- Henares, S.; Bloemsma, M.R.; Donselaar, M.E.; Mijnlieff, H.F.; Redjosentono, A.E.; Veldkamp, H.G.; Weltje, G.J. The role of detrital anhydrite in diagenesis of aeolian sandstones (Upper Rotliegend, The Netherlands): Implications for reservoir-quality prediction. Sediment. Geol. 2014, 314, 60–74. [Google Scholar] [CrossRef]

- Bruijnen, P.; Leewis, M. RESULT-D4.1: 3D Reservoir Characterization Model for Zwolle, 2022.

- Rasmussen, A.F.; Sandve, T.H.; Bao, K.; Lauser, A.; Hove, J.; Skaflestad, B.; Klöfkorn, R.; Blatt, M.; Rustad, A.B.; Sævareid, O.; et al. The Open Porous Media Flow reservoir simulator. Comput. Math. Appl. 2021, 81, 159–185. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Electrical submersible pump (ESP) | 0.5 | million EUR |

| Injection pump | 0.5 | million EUR |

| Pump efficiency | 0.65 | - |

| Well cost base (wb) | 0.25 | million EUR/km |

| Well cost linear (wl) | 1000 | EUR/m |

| Well cost square (ws) | 0.25 | EUR/m2 |

| CAPEX base | 3 | million EUR |

| CAPEX variable | 300 | EUR/kW |

| OPEX base | 10 | kEUR/year |

| OPEX variable | 50 | EUR/kW/year |

| Discount factor | 15 | %/year |

| Heat price | 5 | EUR/GJ |

| Electricity price | 5 | EUR/kWh |

| Economic lifetime | 30 | years |

| Injection temperature | 45 | °C |

| Average NPV (EUR Million) | Min-Max Spread NPV (EUR Million) | ||||

|---|---|---|---|---|---|

| Well Concept | Initial | Optimal | Increase | Initial | Optimal |

| sub-vertical | −5.91 | −1.37 | 4.54 | 2.73 | 5.88 |

| sub-horizontal | −4.73 | −0.78 | 3.95 | 6.11 | 3.53 |

| multi-lateral | −10.8 | −0.55 | 10.25 | 5.21 | 1.91 |

| Average LCOE (EURct/kWh) | Min-Max spread LCOE (EURct/kWh) | ||||

| Well Concept | Initial | Optimal | Increase | Initial | Optimal |

| sub-vertical | 8.88 | 5.59 | 3.29 | 4.86 | 3.92 |

| sub-horizontal | 6.52 | 5.26 | 1.25 | 3.36 | 1.37 |

| multi-lateral | 7.95 | 5.14 | 2.81 | 3.87 | 0.65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barros, E.G.D.; Szklarz, S.P.; Khoshnevis Gargar, N.; Wollenweber, J.; van Wees, J.D. Optimization of Well Locations and Trajectories: Comparing Sub-Vertical, Sub-Horizontal and Multi-Lateral Well Concepts for Marginal Geothermal Reservoir in The Netherlands. Energies 2025, 18, 627. https://doi.org/10.3390/en18030627

Barros EGD, Szklarz SP, Khoshnevis Gargar N, Wollenweber J, van Wees JD. Optimization of Well Locations and Trajectories: Comparing Sub-Vertical, Sub-Horizontal and Multi-Lateral Well Concepts for Marginal Geothermal Reservoir in The Netherlands. Energies. 2025; 18(3):627. https://doi.org/10.3390/en18030627

Chicago/Turabian StyleBarros, Eduardo G. D., Slawomir P. Szklarz, Negar Khoshnevis Gargar, Jens Wollenweber, and Jan Diederik van Wees. 2025. "Optimization of Well Locations and Trajectories: Comparing Sub-Vertical, Sub-Horizontal and Multi-Lateral Well Concepts for Marginal Geothermal Reservoir in The Netherlands" Energies 18, no. 3: 627. https://doi.org/10.3390/en18030627

APA StyleBarros, E. G. D., Szklarz, S. P., Khoshnevis Gargar, N., Wollenweber, J., & van Wees, J. D. (2025). Optimization of Well Locations and Trajectories: Comparing Sub-Vertical, Sub-Horizontal and Multi-Lateral Well Concepts for Marginal Geothermal Reservoir in The Netherlands. Energies, 18(3), 627. https://doi.org/10.3390/en18030627